Page 1

User guide

F-9950-0400-01 B

XR20-W rotary axis calibrator

Page 2

Legal information

Disclaimer

Renishaw has made considerable efforts to ensure the content of this document

is correct at the date of publication but makes no warranties or representations

regarding the content. Renishaw excludes liability, howsoever arising, for any

inaccuracies in this document.

Trade marks

RENISHAW and the probe symbol used in the RENISHAW logo are registered

trade marks of Renishaw plc in the United Kingdom and other countries.

apply innovation and names and designations of other Renishaw products

and technologies are trade marks of Renishaw plc or its subsidiaries.

All other brand names and product names used in this document are trade

names, trade marks, or registered trade marks of their respective owners.

Copyright

© 2018 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or transferred

to any other media or language, by any means without the written prior

permission of Renishaw plc.

The publication of material within this document does not imply freedom from the

patent rights of Renishaw plc.

Warranty

Equipment requiring attention under warranty must be returned to your equipment

supplier.

Unless otherwise specifically agreed in writing between you and Renishaw, if you

purchased the equipment from a Renishaw company, the warranty provisions

contained in Renishaw’s CONDITIONS OF SALE apply. You should consult these

conditions in order to find out the details of your warranty but, in summary, the

main exclusions from the warranty are if the equipment has been:

• neglected, mishandled or inappropriately used; or

• modified or altered in any way except with the prior written agreement of

Renishaw.

If you purchased the equipment from any other supplier, you should contact them

to find out what repairs are covered by their warranty.

XR20-W rotary axis calibrator

Renishaw part no: F-9950-0400-01

Issued: 07.2018

Renishaw reserves the right to make changes to this document and to the product

described herein without obligation to notify any person of such changes.

Page 3

WEEE

The use of this symbol on Renishaw products and/or accompanying

documentation indicates that the product should not be mixed with

general household waste upon disposal. It is the responsibility of

the end user to dispose of this product at a designated collection

point for waste electrical and electronic equipment (WEEE) to

enable reuse or recycling.

Correct disposal of this product will help to save valuable

resources and prevent potential negative effects on the

environment. For more information, please contact your local

waste disposal service or Renishaw distributor.

“La operación de este equipo está sujeta a las siguientes dos condiciones:

(1) es posible que este equipo o dispositivo no cause interferencia perjudicial y

(2) este equipo o dispositivo debe aceptar cualquier interferencia, incluyendo la

que pueda causar su operación no deseada.”

XR20-W rotary axis calibrator

Legal information

International regulations and conformance

EC compliance

Renishaw plc declares that the XR20-W system complies with the applicable

directives, standard and regulations. A copy of the full EC Declaration of

Conformity is available upon request.

In compliance with BS EN 61010-1:2001 the product is safe to use in the following

environmental conditions:

• Indoor use only

• Altitude up to 2000 m

• Maximum relative humidity (non-condensing) of 80% for

temperatures up to 31 °C decreasing linearly to

50% relative humidity at 40 °C

• Pollution Degree 2

Complies with

IDA Standards

DA104642

Radio communications

Class 2 Bluetooth® device

Output power: 0 dBm maximum

Frequency band: 2.402 - 2.480 GHz

Communication distance: 10 m typical operation

For details of national radio approvals for this device, see the Compliance

with radio device regulations document on the Calibration product quality and

conformance web pages.

Further radio approval country specific statements can be found below:

Singapore

Reg. No. N2095-11

Mexico

Page 4

低功率電波輻性電機管理辦法

第十二條經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不

得擅自變更頻率、加大功率或變更原設計之特性及功能。

第十四條低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾

現象時,應立即停用,並改善至無干擾時方得繼續使用。前項合法通信,指依電信

規定作業之無線電信。低功率射頻電機須忍受合法通信或工業、科學及醫療用電波

輻射性電機設備之干擾

Este equipamento opera em caráter secundário, isto é, não tem direito a proteção

contra interferência prejudicial, mesmo de estações do mesmo tipo, e não pode

causar interferência a sistemas operando em caráter primário.

XR20-W rotary axis calibrator

RoHS compliance

Packaging

components

Material ISO 11469 Recycling

guidance

Internal box Cardboard Not applicable Recyclable

Outer box Cardboard Not applicable Recyclable

Insert Cardboard Not applicable Recyclable

Bag Low density polyethylene LDPE Recyclable

Taiwan

Brazil

Frequency bandwidth (MHz) 2400 to 2483 MHz

Modulation GFSK

Output power (W) 0.0676 W

Page 5

USA and Canadian regulations

FCC

Information to the user (47CFR:2001 part 15. 19)

This device complies with Part 15 of the FCC rules. Operation is subject to the

following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that

may cause undesired operation.

Information to the user (47CFR:2001 part 15.21)

The user is cautioned that any changes or modifications, not expressly approved

by Renishaw plc or authorised representitive, could void the user’s authority to

operate the equipment.

Canada - Industry Canada (IC)

This device complies with RSS 210 of Industry Canada. Operation is subject to

the following two conditions: (1) this device may not cause interference, and (2)

this device must accept any interference, including interference that may cause

undesired operation of this device.

L’utilisation de ce dispositif est autorisée seulement aux conditions suivantes :

(1) il ne doit pas produire d’interference et (2) l’utilisateur du dispositif doit étre

prêt à accepter toute interference radioélectrique reçu, même si celle-ci est

susceptible de compromettre le fonctionnement du dispositif.

XR20-W rotary axis calibrator

Page 6

Contents

Safety information ...............................................7

Safety warnings ................................................7

Battery safety .................................................. 8

Mechanical safety ............................................... 8

Laser optical safety .............................................. 8

Transportation .................................................. 9

EU REACH SVHC communication .................................. 9

System overview ...............................................10

System components ............................................ 11

Calibration software kit ..........................................12

Setting up a test ................................................ 14

Setting up the hardware ......................................... 14

Setup XM system .............................................. 16

Setup XL system............................................... 18

Bluetooth® setup ...............................................21

Feedrate .....................................................22

Different mounting configurations .................................. 23

Setup errors .................................................. 28

Diagnostics and troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

XR20-W fault finding ............................................ 32

Status LEDs .................................................. 33

Care and handling .............................................. 34

Recalibration .................................................. 34

Calibration certificate ........................................... 35

Care and maintenance .......................................... 35

Storage and environmental specification ............................35

Cleanliness of optics ............................................ 36

System specification ............................................ 37

USB power supply .............................................39

Power supply: rechargeable battery ................................ 40

Weights and dimensions......................................... 42

XR20-W rotary axis calibrator

Page 7

7

XR20-W rotary axis calibrator

Safety information

Use of controls or adjustments or performance of

procedures other than those specified herein may result

in hazardous radiation exposure.

Ensure that you read and understand the XR20-W user

guide before using any XR20-W system.

The XR20-W rotary axis calibrator can be used in a variety of environments and

applications. To ensure the safety of the user and other personnel in the vicinity

it is therefore paramount that a comprehensive risk assessment is carried out for

the machine under test before using the XR20-W rotary axis calibrator.

This should be carried out by qualified users (requiring machine competency,

applicable technical knowledge and a trained risk assessor) with consideration for

the safety of all personnel. The risks identified must be mitigated prior to using the

product. The risk assessment should pay particular attention to machine, manual

handling, mechanical, laser, electrical, power and fibre optic safety.

Based on current research, the wireless devices used in this product would not

seem to pose a significant health problem for the vast majority of pacemaker

wearers. However, people with pacemakers may want to ensure a minimum

distance of 3 cm between the product and pacemaker.

Safety warnings

The XR20-W rotary axis calibrator system is designed to be used to test machine

tools. As such, the user will need to prepare and run a part program which moves

the machine as required. Do not spin the optics. It is assumed therefore that the

user is thoroughly familiar with the operation of the machine tool and its controller

and knows the location of all emergency stop switches. Also, if it is necessary to

operate the machine with the guards or any safety feature removed or disabled, it

is the responsibility of the operator to ensure that alternative safety measures are

taken in line with the machine manufacturer’s operating instructions or relevant

codes of practice. Safety procedures should be in accordance with the user’s risk

assessment.

The XR20-W device works in conjunction with a Renishaw laser system. Before

using the laser system, please read the safety section of the relevant Laser user

guide.

The XR20-W can reflect the laser beam from the laser around the room as it

rotates. Consideration should be given to other users working in the area.

If this equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Page 8

8

XR20-W rotary axis calibrator

Battery safety

The XR20-W rotary axis calibrator is supplied with rechargeable batteries.

• Once depleted, recharge the battery in the charger provided: do not attempt

to charge the battery by other means.

• For specific battery operating, safety and disposal guidelines, please refer to

the battery manufacturers’ literature.

• Replace the batteries only with the specified type.

• Ensure that all batteries are inserted with the correct polarity.

• Do not store batteries in direct sunlight.

• Do not heat or dispose of batteries in a fire.

• Do not short-circuit or force discharge the batteries.

• Do not disassemble, pierce, deform or apply excessive pressure to the

batteries.

• Do not swallow the batteries.

• Keep the batteries out of the reach of children.

• Do not get batteries wet.

• If a battery is damaged, exercise caution when handling it.

Mechanical safety

• When setting up and mounting Renishaw laser calibration equipment,

beware of pinch and/or crush hazards that may be created e.g. due to

magnetic mounting bases.

• Beware of trip hazards that may be created when using Renishaw

equipment, e.g. due to trailing cables.

• Exercise caution if components are to be mounted to moving or rotating

machinery. Beware of cables becoming entangled.

• Exercise extreme caution if Renishaw equipment is to be mounted to

machinery that may accelerate rapidly or move at high speed, which could

lead to items colliding or being ejected.

• If it is necessary to operate the machine with the guards or any safety

feature removed or disabled, it is the responsibility of the operator to

ensure that alternative safety measures are taken in line with the machine

manufacturer’s operating instructions or relevant codes of practice.

• If you are using a part program or error correction parameters generated by

Renishaw software, it is the responsibility of the user to validate these at low

feedrate and be prepared to operate the emergency stop button if necessary.

Laser optical safety

• In accordance with (IEC) EN60825-1, Renishaw XL-80 and XM systems

used to provide a laser source for XR20-W are class 2M lasers and safety

goggles are not required (under normal circumstances the eye will blink and

look away before damage can occur).

• Do not stare directly into the laser beams or view them with optical

equipment such as telescopes, convergent mirrors or binoculars as

permanent retinal damage could occur.

• Do not direct the beam at other people or into areas where people

unconnected with the laser might be present. It is safe to view a diffusereflected beam during system alignment.

Page 9

9

XR20-W rotary axis calibrator

Transportation

Please ensure that you comply with international and national battery transport

regulations when transporting batteries or XM system kits.

The XR20-W uses a lithium ion battery. Lithium batteries are classified as

dangerous goods and strict controls apply on their shipment by air. To reduce the

risk of shipment delays, should you need to return your XR20-W to Renishaw for

any reason, do not return any batteries.

The operation of wireless appliances on aircraft is forbidden by many airlines

to prevent interference with communication systems. Remove the battery from

the receiver unit when boarding an aircraft to ensure it cannot be switched on

inadvertently.

EU REACH SVHC communication

Please see the relevant battery manufacturers’ website for further

information:

Varta:

https://www.varta-storage.com/wp-content/uploads/2017/08/

VARTA_Design_Library_56456_701_099.zip

The use of this symbol on the batteries, packaging or accompanying documents

indicates that used batteries should not be mixed with general household waste.

Please dispose of the used batteries at a designated collection point. This will

prevent potential negative effects on the environment and human health which

could otherwise arise from inappropriate waste handling. Please contact your

local authority or waste disposal service concerning the separate collection

and disposal of batteries. All lithium and rechargeable batteries must be fully

discharged or protected from short circuiting prior to disposal.

Page 10

10

XR20-W rotary axis calibrator

System overview

XR20-W is a rotary axis calibrator designed for measuring rotary axes, key

features include:

• Compatible with Renishaw’s XL-80 or XM systems

• Compact and lightweight

• Quick and simple mounting system

• Easy alignment with built-in alignment aid

• Wireless operation by utilising Bluetooth communication

• Battery powered (can be powered by external USB if required)

• Typical system configurations are shown in figure 1 and 2 for use with XL-80

and XM-60.

Figure 1 - typical set-up for calibrating a rotary axis using XL-80 as the laser

reference.

Figure 2 - typical set-up for calibrating a rotary axis using XM as the laser

reference.

The CARTO data capture software uses both the measured angle and the

position from the XR20-W’s internal encoder scale to very accurately measure

the positioning performance of the table under test. The rotation of an axis is

calibrated by rotating it sequentially through a number of angular targets, pausing

at each defined target to capture a reading. As the axis rotates, the software

counter-rotates the XR20-W to ensure that the laser beam is returned back to the

laser, maintaining signal strength.

Page 11

11

XR20-W rotary axis calibrator

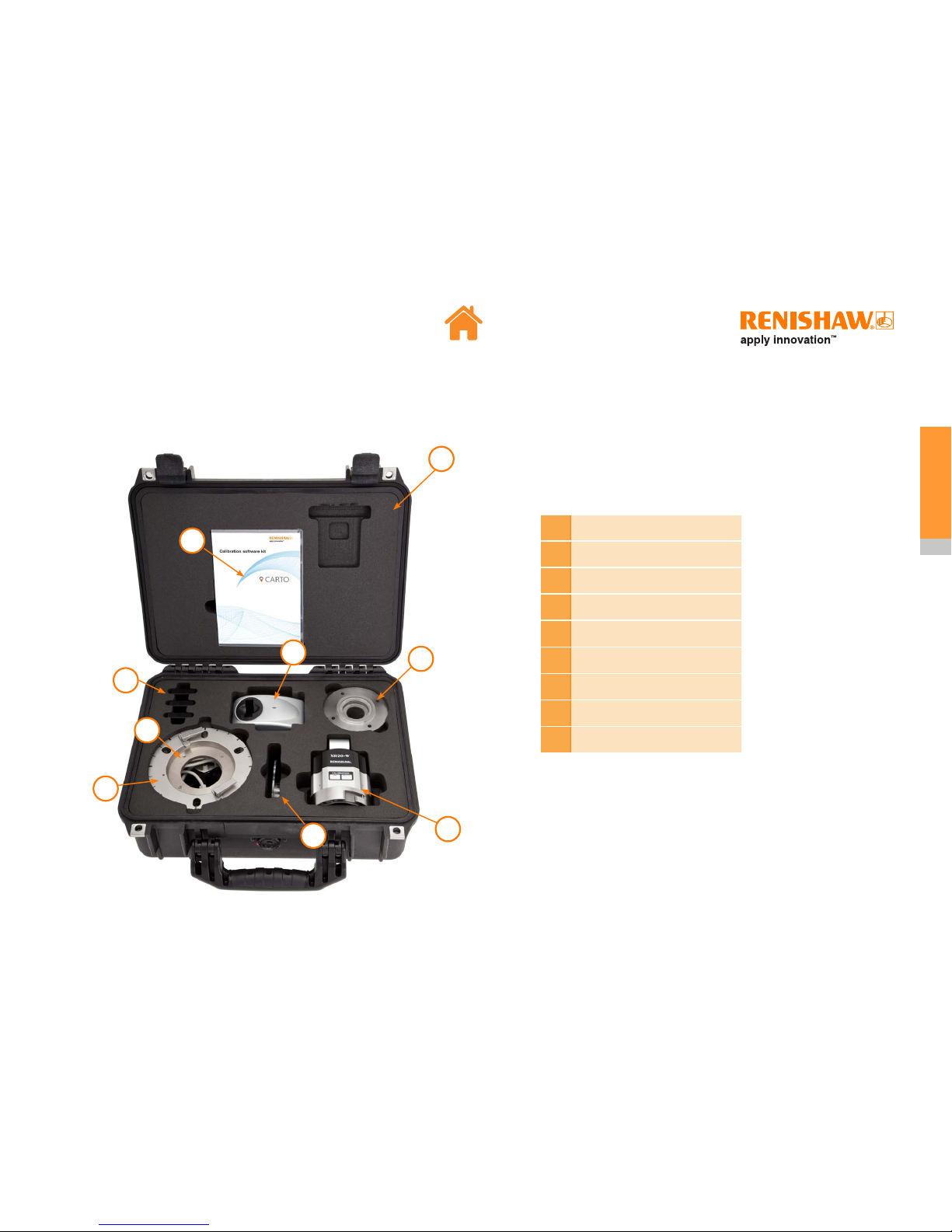

System components

1

XR20-W

2

Centration aid

3

Mounting ring

4

Mounting ring adaptor

5

Battery Li-Polymer

6

Calibration software kit

7

Battery charger & cables

8

XR20-W case

9

Chuck adaptor

6

8

7

5

2

9

3

4

1

Page 12

12

XR20-W rotary axis calibrator

Calibration software kit

The XR20-W rotary axis calibrator is supplied with the “Calibration software kit”

which comprises:

• CARTO suite

• User guides and documentation for XM, XL-80 and XC-80.

The CARTO suite features two applications:

Page 13

13

XR20-W rotary axis calibrator

Mounting ring

The mounting ring bolts or clamps directly to the surface of machine and locks the

XR20-W in position.

Mounting ring adaptor

The mounting ring adaptor plate enables the XR20-W to be fitted to rotary tables

with unsuitable centre recesses. It can also be used to secure the XR20-W rotary

axis calibrator to the chuck adaptor and custom mounts.

Chuck adaptor

The chuck (lathe) adaptor has a 40 mm diameter to fit most popular chuck sizes. It

can also be used to secure the XR20-W to custom mounts.

Centration aid

The centration aid allows the mounting ring to be easily centred to the axis of

rotation of the machine under test before the XR20-W rotary axis calibrator is

mounted to the machine.

Page 14

14

XR20-W rotary axis calibrator

Setting up a test

Setting up the hardware

Before proceeding please read the safety section.

1. Prepare the machine for calibration. Remove all tools from the spindle of the

machine and retract them into the tool holder. Ensure surfaces are clean and

free of swarf, debris and burrs. Ensure that the laser beam can reach the rotary

table without obstruction.

2. The XR20-W will require a defined test method to be entered into the machine

tool control via a part program. The test method and part program can be

generated from the CARTO software. For further information, see the CARTO

Capture manual.

3. Ensure that your PC is Bluetooth enabled and that the CARTO software is

installed. See the Bluetooth setup section for more information.

4a. For XL-80 use mount the laser head on the stage and tripod. Turn on the laser

and it will begin stabilisation. For safety, the shutter of the laser should initially

be rotated to its closed position.

4b. For XM system use, suspend the XM launch unit within the machine

environment, switch on the laser unit to begin stabilisation. For safety, the

shutter of the XM launch unit should be in the closed position.

Page 15

15

XR20-W rotary axis calibrator

Both XL-80 and XM laser systems are classified as Class 2 and

safety goggles are not required (under normal circumstances

the eye will blink and look away before damage can occur).

Please refer to the relevant laser system manual.

5.

Connect the laser to the PC. If you want to monitor the environment during

calibration, then plug the environmental compensator to the PC. Place the

temperature sensors in suitable positions on or around the machine and connect

them to the environmental compensator. For more information on setting up the

laser and environmental compensator, refer to the relevant laser user guide.

6. Before mounting the XR20-W to the rotary axis ensure the mounting ring and

XR20-W facing ring are clean and free of swarf, debris and burrs. See the Care

and handling section for more information.

7. Alignment of the rotary table can be carried out visually with the centration aid

from the XR20-W kit or by using a dial test indicator (DTI). The centration of the

mounting ring should be aligned to the following specification:

XL-80 use <± 1 mm:

XM-60 use <± 0.25 mm:

8. Once aligned, the mounting ring should be fixed to the axis using bolts

mounted through the mounting holes into the machine’s T-Slots. When the

T-Slots do not pass under the mounting holes then toe clamps may need to be

used. Remove the centration aid.

Page 16

16

XR20-W rotary axis calibrator

9. Switch on the XR20-W briefly to check the battery power by confirming that

the LED goes green, then switch off again to conserve battery power. If the

LED is amber then change the battery. See the power supply: rechargeable

battery section for more details and the Diagnostics and trouble shooting

section for a full list of LED states.

10. Attach the XR20-W to the mounting ring. Ensure the clamp levers are

released (in the up position). Align the red spot on the facing ring with the

red spot on the mounting ring so that the slots in the facing ring are aligned

with the clamps. Lower the facing ring on to the table surface, then rotate the

XR20-W clockwise until the clamps are aligned above the clamping surfaces.

11. Lock the clamp levers down to secure the XR20-W.

For XL-80, proceed to page 18.

Setup XM system

1. Attach the beam blocker to the front of the XM launch unit.

1

Beam blocker

1

2. Translate the laser launch horizontally and vertically so that the laser beam hits

the target on the alignment aid as shown:

Page 17

17

XR20-W rotary axis calibrator

3. Observe the reflected beam on the launch beam blocker. Adjust the pitch of the

launch so that the reflected beam is on the centreline.

1

Beam aperture

2

Reflected beam

2

1

4. Translate vertically to align the beam again as per image in step 2.

5. Turn the XR20-W optics back around so that the retroreflectors are pointing

back towards the laser within ±2°.

Note: if it is difficult to access the optics, use the 180° rotation feature in

the software. Refer to the jog function section in CARTO software for more

details.

Now XM system setup is complete, go to page 22.

Page 18

18

XR20-W rotary axis calibrator

Setup XL system

1. For XL-80 use, assemble the magnetic base, optics mounting kit and the

angular interferometer optic and attach to the machine spindle as shown. In this

example the input aperture of the angular interferometer is on the right hand

side. See Optical setup section for alternative mounting schemes. Refer to the

XL laser system user guide for more information on the optics mounting kit and

angular interferometer.

1

Mounting pillar

2

Magnetic mount

3

Clamp block

4

Angular interferometer

1

3

2

4

2. Move the machine using the hand wheel in X, Y and Z to provisionally position

the angular interferometer between the laser and the XR20-W. The angular

interferometer should be relatively close to the XR20-W angular reflector to

optimise measurement performance but ensure that it cannot collide during the

test. Ensure that the angular interferometers input aperture is aligned with the

right hand retro reflector in the angular reflector.

3. Using the machine’s handwheel raise the interferometer, attached to the

spindle, out of the way in Z only. Do not move X or Y so that the alignment

between the XR20-W and the angular interferometer is maintained.

4. Rotate the alignment aid on the back of the angular reflector so that it faces the

laser.

Note: if it is difficult to access the angular reflector, it can be moved using

the jog functions in CARTO Capture.

5. Position the laser and tripod in front of the machine. To simplify setup, use

a level on the top of the laser to ensure that the laser is level and hence

nominally perpendicular to the machine’s axis of rotation.

6. Rotate the laser shutter to the 6 mm beam alignment position.

1

Beam aperture

2

Target

1

2

Page 19

19

XR20-W rotary axis calibrator

7. Adjust the laser so that the beam hits the alignment aid. For more information

on laser alignment controls, refer to the relevant laser user guide.

8. Transate the XL-80 horizontally and vertically so that the laser beam hits the

target on the alignment aid as shown:

9. To minimise measurement errors the laser beam should be aligned

perpendicular to the machine’s axis of rotation. Refer to the setup errors

section for more information. Adjust the pitch of the laser so that the beam

reflects onto an imaginary horizontal line which passes through the centre of

the shutter’s output aperture as shown.

1

Beam aperture

2

Reflected beam

1

2

Note: do not be concerned if the laser is destabilised.

Page 20

20

XR20-W rotary axis calibrator

10. Turn the laser shutter so that the 3 mm aperture is set. Check that the beam

returning from the retroreflectors is concentric inside the white target. Make

translation adjustments to the laser and tripod, if required.

1

Reduced beam aperture

2

Target

2

1

11. Fix a target into the input aperture of the angular interferometer and lower the

interferometer back into position by using the Z control on the handwheel. The

beam from the laser should now be concentric with the white target.

1

Angular interferometer

2

Reduced laser beam

3

Target

3

1

2

12. Remove the target from the angular interferometer. The beams should now

pass through the angular interferometer and both beams returned from the

XR20-W’s angular reflector should now overlap on the middle of the laser

shutter’s target.

1

Reduced beam aperture

2

Target

2

1

13. Turn the shutter to 6 mm aperture and check that good signal strength is

obtained.

1

Beam aperture

2

Detector aperture

1

2

14. Switch on the XR20-W and check the status LEDs go green.

Page 21

21

XR20-W rotary axis calibrator

Bluetooth® setup

The XR20-W rotary axis calibrator communicates with the PC using Bluetooth

wireless technology.

Before you can connect the XR20-W you must provide Bluetooth capability on

your PC. This can be done either by enabling the PC’s internal Bluetooth device

(if available) or by using a proprietary USB Bluetooth dongle recommended by

Renishaw.

The CARTO software will only work with Bluetooth devices which use the

Microsoft stack (a stack is software which enables communication between a PC

and a Bluetooth device).

Setup for a PC with a built in Bluetooth device

Windows 10:

1. Right click on the start menu

2. Select the “device manager” button

Proceed to point 5

Windows 7:

1. Click on the start menu

2. Right click on Computer

3. Manage

4. Select the “device manager” button

5. If the device list shows “Generic Bluetooth Radio” and “Microsoft Bluetooth

Enumerator”, then your PC is both Bluetooth capable and has the Microsoft

stack installed

6. Ensure that Bluetooth functionality is switched on (see PC user instructions)

7. Run the CARTO software and connect the XR20-W to establish communication

If your PC does not have the Microsoft stack installed, please refer to the

Calibration service, support and training web pages for further instructions.

Page 22

22

XR20-W rotary axis calibrator

Setup for a PC without a built in Bluetooth device

If you do not have on-board Bluetooth capacity on your PC then you will need to

obtain a USB Bluetooth dongle.

When you first use the USB Bluetooth dongle, DO NOT INSTALL the software

provided with the device, simply plug the dongle into a spare USB port and then

run CARTO and connect the XR20-W to establish communication.

Note: Some USB Bluetooth dongle software provide Bluetooth stacks

(other than the Microsoft version) which are not compatible with CARTO

software.

Feedrate

If the target interval is greater than 10 degrees then the XR20-W rotary axis

calibrator will automatically track the movement of the machine under test so that

the XR20-W’s angular reflector continues to face the laser as the machine moves

so the laser’s beam does not break.

The feedrate of the test can be determined automatically or entered into the

software manually via the test menu.

The XR20-W system can determine the velocity of the machine under test

automatically, during the machine overrun move, at the beginning of the test. To

allow the feedrate to be automatically determined, an overrun move of 5° should

be programmed. If during this move the software can not determine the velocity of

the machine, it will display a warning message. If a warning message is displayed,

try the following:

• Decrease the programmed machine feedrate by modifying the part program.

Refer to the part program section for more details.

• Increase the angle of the overrun move to allow it to get up to its

programmed feedrate.

• Manually enter the feedrate into the software.

Enter the feedrate set in the machines part program. Alternatively, for optimum

performance, enter the reported feedrate displayed by the machine controller

during a move.

Page 23

23

XR20-W rotary axis calibrator

Different mounting configurations

The XR20-W rotary axis calibrator can be mounted to many different types of

rotary axis. Setup 1-3 show typical setups using the fittings supplied with the

standard XR20-W kit. Always ensure the mounting surface of the table under test

and the XR20-W facing ring are clean and free of swarf, debris and burrs.

Mounting setup 1 (default configuration)

In most applications the facing ring of the XR20-W can be mounted directly to the

surface of the axis under test (as shown) using the mounting ring.

1

1

2

1

Mounting bolt

2

Mounting ring

The mounting ring should be fixed to the table using bolts secured through the

mounting holes into the machines T-slots.

Page 24

24

XR20-W rotary axis calibrator

Mounting setup 2 (machine with large centre bore)

The adaptor plate should be used if the axis under test has a centre bore or

recess that prevents the XR20-W mounting ring being mounted securely and

parallel to the rotary axis. Mount the XR20-W to the axis under test as shown.

Ensure the correct screws are used to mount the adaptor plate to the mounting

ring.

The mounting screws required are as follows:

• The screws to fix the adapter plate to the mounting ring are 3 off M5 x 12

long countersunk screws.

1

1

1

Mounting bolt

2

Mounting ring

3

Adaptor plate

4

Countersunk

screws M5 x 12

2

4

3

Page 25

25

XR20-W rotary axis calibrator

Mounting setup 3 (lathes)

When calibrating lathes, the chuck adaptor should be used.

The mounting screws required are as follows:

• The screws to fix the chuck adapter to the adapter plate are 4 off M4 x 12

long cap head screws.

Note: when mounted to the chuck adaptor, each of the components must

be screwed in the locations indicated in the image using the correct

screws. Refer to the specification section for more information. To ensure

optimum measurement performance, it is recommended that the TIR of the

top surface of the adaptor plate is checked using a digital gauge. Refer to

the setup errors section for more information.

Machine setup 4

A variation of the chuck adaptor can be used for mounting to small or partially

concealed axes (e.g. behind access corners). This uses a through bolthole to

secure to the test axis. Note, however, that the orthogonality of the adaptor to the

test axis is crucial to capturing ‘clean’ data.

1

Mounting ring

2

Adaptor plate

3

Chuck adaptor

4

Cap head screws

M4 x 12

1

2

3

4

Page 26

26

XR20-W rotary axis calibrator

Optical setups using XL-80

Optical setup 1

This optical setup is used when the axis under test has a vertical axis of rotation.

An example of how to set this up is described in the getting started section; see

setting up the hardware section for more details.

1

Laser

2

Angular interferometer

4

XR20-W

5

Mounting ring

5

4

3

2

1

3

Angular retroreflector

Optical setup 2

This scheme may be required if it is not possible to mount the laser directly in front

of the XR20-W rotary axis calibrator due to machining guarding. In this example

the beam enters the angular interferometer through the side aperture rather than

the front aperture

1

Angular interferometer

1

Page 27

27

XR20-W rotary axis calibrator

Optical setup 3

If the beam emerging from the laser is parallel to the machine axis of rotation then

an additional turning mirror will be needed. The turning mirror turns the beam

through 90° into the angular interferometers input aperture as shown. Refer to the

XL Laser system user guide for more information about the turning mirror.

1

Angular interferometer

2

Turning mirror

2

1

Optical setup using XM-60

If using XM system laser source, use custom fixturing to suspend launch unit from

spindle.

Note: To avoid measurement error, the XM launch unit should not be

mounted to a tripod.

Page 28

28

XR20-W rotary axis calibrator

Setup errors

When mounting the XR20-W rotary axis calibrator and setting up the optics, it

is important to get them aligned as accurately as possible. Small misalignments

are expected to exist so this section indicates how tolerant the software is at

minimising or eliminating them, or the effect they have on captured data.

Axes of rotation parallel but not coincident

E

• Optics translate during rotation

• To avoid signal strength loss, ensure:

• For XL-80, E = <± 1 mm

• For XM system, E = <± 0.25 mm

Axes of rotation coincident but not parallel

Induced error

E

Sinusoidal component measurement error induced into the captured data over

360° rotation. Size of error dependent on E and shows one cycle in 360°.*

• For induced error to be less than ±1 arcsecond, ensure E<0.025° or the TIR

is <0.04 mm at a radius of 50 mm from the centre of rotation of the machine

under test.*

• For induced error to be less than ±10 arcseconds, ensure E<0.23°, or the

TIR is <0.4 mm at a radius of 50 mm from the centre of rotation of the

machine under test.*

*Note: it is relatively easy to achieve the alignment tolerances quoted

when calibrating a rotary table where there is a mounting surface which is

perpendicular to the axis of rotation. Care should be taken to ensure the

rotary tables and XR20-W mounting surface are clean and free from

debris, swarf and burrs.

Page 29

29

XR20-W rotary axis calibrator

However, special care must be taken when calibrating rotating axes without such

mounting surfaces. In this case it is recommended that the TIR (Total Indication

Run out) of the surface the XR20-W is to be mounted to is checked (whilst rotating

the axis under test) using a dial gauge. This allows alignment to be verified before

the test starts.

Laser beam not perpendicular to reflector, axes of rotation coincident

• Use the XR20-W alignment aid to align the laser beam to be perpendicular to

the shutter. Refer to the getting started section for more information.

• E is the angle between the normal of the XR20-W alignment aid and the

beam from the XL-80/XM system.

• For XM system/XL-80 E < 2 mrad

E

E

Page 30

30

XR20-W rotary axis calibrator

The angle of E can be calculated within the setup by measuring the vertical

position of beam 2 relative to 1 and then using the comparison table below.

1

Beam aperture

2

Reflected beam

2

1

1

2

Distance between XL80/

XM and the XR20-W (m)

Maximum vertical offset

(mm)

0.1 0.4

0.2 0.8

0.5 2

1 4

2 8

3 12

4 16

Page 31

31

XR20-W rotary axis calibrator

Reflector not perpendicular to laser beam when laser is datumed at start of

optical set up calibration cycle

E

• Limited danger of beam obstruct (only if E > 10°). To avoid signal strength

loss, ensure E<2°.

• Use alignment aid to align optics perpendicular to laser beam

• Error eliminated by optical set up calibration cycle

Reflector separation not exactly 30 mm

30 mm

E

• Caused by thermal expansion and manufacturing tolerances

• Error eliminated by optical set up calibration cycle

• No danger of beam obstruct

Page 32

32

XR20-W rotary axis calibrator

Diagnostics and troubleshooting

XR20-W fault finding

The following table should be used for fault finding. If you experience further difficulties, please see the Calibration service, support and training web pages, or contact

your local Renishaw office.

Problem Possible cause Action

Bluetooth communication cannot be established

(XR20-W status stays green)

PC Bluetooth is not activated or PC is out of range

• Check Bluetooth is enabled on PC (or presence of

USB Bluetooth dongle)

• Ensure the Bluetooth is setup correctly on PC

• Move PC closer to XR20-W

Intermittent Bluetooth communication Machine enclosure preventing communication

• Attach Bluetooth dongle to USB extension lead and

position inside of machine enclosure

XR20-W status LED off

• XR20-W switched off

• No battery fitted

• Battery flat

• Battery fault

• Environment is outside XR20-W operational

temperature range

• Ensure XR20-W is switched on

• Switch the XR20-W off and then on

• Replace the battery

• Ensure the USB cable is disconnected and reinsert

battery

• Connect USB power supply

Red XR20-W status LED XR20-W fault

• Switch the XR20-W off then on

• Replace the battery

• If problems persist, contact your local Renishaw

office

XR20-W status LED is slow flashing blue and

CARTO software DRO (Digital Read Out) is dim

XR20-W and software in power saving mode • Click on DRO to resume live reading

Software has not installed in the required language

of operation

The PC’s regional settings are not set to the users

preference

• Change the ‘regional settings’ in the PC’s control

panel to the required language

Battery life is too short

Dirt/contamination on battery contact in the battery

cap

• Clean the battery contact

• The inside of the cap should be cleaned with a soft

cloth and appropriate solvent, e.g. IPA.

Page 33

33

XR20-W rotary axis calibrator

Status LEDs

LED status Description

OFF Off, no power or power down mode

Solid green On, communication has not been established

Solid blue Communication established and drive disabled

Flashing blue Communication established and drive enabled

Slow flashing blue Power saving, see below

Solid amber Battery low and drive disabled. Charge battery

Flashing amber Battery low and drive enabled. Change battery

Red Fault, see fault finding section

Power saving

If the system is idle for 2 minutes, then the DRO in the CARTO software will go

dim and the XR20-W status LEDs will slowly flash blue as the system goes into

power saving mode. To exit power saving mode, click on the DRO. The XR20-W

will need to be re-referenced before testing can continue.

If the XR20-W is idle for 5 minutes it will switch itself off and the status LED will go

off. The unit will need to be switched off, then on again, and re-referenced before

testing can continue.

Page 34

34

XR20-W rotary axis calibrator

Care and handling

Recalibration

Why recalibrate?

As with any recalibration equipment, it is recommended that the Renishaw

XR20-W rotary axis calibrator is periodically recalibrated to give confidence that

the system:

• is currently still within original specified (or required) performance

• is likely to remain within its specified (or required) performance until its next

recalibration

This is the reason that recalibration of calibration test equipment is a mandatory

requirement of most quality management/assurance systems.

An added benefit of periodic calibration is that the inspection Renishaw carries

out when recalibrating your XR20-W can also show up accidental damage that

you might have not been aware of. Renishaw’s recalibration procedure includes

general cleaning.

Compared to your investment in the measurement system, staff and procedures,

periodic recalibration is a modest additional cost and could prevent far more

expensive and bigger problems arising later.

Recalibration periods

The Renishaw recommended recalibration period for an XR20-W is 3 years.

Note: This is 3 years from sale by Renishaw rather than from factory

calibration date as stated on the calibration certificates supplied with the

new equipment, since the units are stored under controlled conditions by

Renishaw prior to sale.

Renishaw recommended recalibration periods are only a recommendation and

are based on typical use of the equipment in a typical environment. Under such

conditions your XR20-W system should still be performing within Renishaw’s

specification at the end of this period.

However, there are several factors that may generate the need for more or less

frequent calibrations including:

• Environmental conditions

• Frequency and duration of use

• Harsh treatment of the equipment during storage, transportation or use

• Level of accuracy required by the user

• The requirements of company QA procedures and/or local regulations

Ultimately it is for you to determine the appropriate calibration period after taking

into account your own operational environment and performance requirements.

Recalibration reminders

Because evidence of calibration is important for users and their customers, there

are several reminders built into both the main system hardware and system

software.

Hardware reminder

The XR20-W has the calibration date indicated on a label on the side of the unit.

Software reminders

Further reminders are built into the CARTO software. If an XR20-W is out of

calibration, you will see displayed on the screen the last recalibration date and

recommended date for recalibration.

Recalibration facilities

Recalibration of the XR20-W requires specialist test rigs and software to give

results comparable to the original factory calibration. Renishaw therefore

recommends that items are returned to our specialist facilities via your local

Renishaw office.

Periodic recalibrations and recalibrations following repairs (if required) are carried

out in accordance with the same procedures used for new systems and an

identical format certificate will be issued.

Page 35

35

XR20-W rotary axis calibrator

Calibration certificate

Each Renishaw XR20-W rotary axis calibrator is delivered with a calibration

certificate. This demonstrates that the system has been calibrated at the Renishaw

factory against reference systems with traceability to National Standards. It is

proof of the equipment’s performance as tested before delivery.

The certificate is a valuable document. You should keep it safe as it may be

required to satisfy your own or your customers quality assurance requirements.

Duplicate documents can be supplied but there will be a charge for this service.

Certificate content

Each certificate is unique and is identified by a certificate number. All XR20-W

certificates provide the following key information:

• Serial number of calibrated XR20-W

• Specific test results and graph

• Statement of accuracy

• Traceability data (calibration details, see below)

• Test conditions and methodology

The first page gives graphical representation of test results and specification

limits as well as tabulated details of the specific test results and uncertainty of

measurement. This enables you to see clearly whether or not the unit meets

published specifications and/or your own requirements. To enable “traceability”,

details of the test equipment used are given. The date of testing and the date

of printing the certificate are separately noted and the results are signed by a

Renishaw authorised person.

The second page gives generic details of the test procedure, test environment,

and applicable standards, all in accordance with requirements of ISO 17025.

Care and maintenance

The Renishaw XR20-W rotary axis calibrator system is precision-engineered to

ensure very high levels of measurement accuracy and repeatability. Correctly used

and handled, it will give you excellent service.

• To ensure optimum measurement performance ensure the XR20-W facing

ring, mounting ring and adaptor plate are clean and free from debris, swarf

and burrs before use.

• Place the XR20-W mounting ring and adaptor plate into the case when not in

use.

• Switch off the unit before transporting it.

Care should be taken to avoid extremes of environment (heat, humidity etc.)

and to avoid any sharp blows or violent vibration. Do not attempt to clean using

water or any other fluids. The system should not be exposed to dusty or misty

environments as particles could enter housings and cause damage, preventing

correct operation and affecting accuracy. Renishaw system cases provide secure

storage for the equipment when not in use.

Storage and environmental specification

The equipment should always be inspected before use to check for any signs of

damage on all system components (including optics and tripods) such as cracks,

dents or other evidence of physical damage, loose joints, cracked or pinched

cables etc.

This is important as the equipment may still function but the accuracy of the

reading may have been affected.

If you are in any doubt, contact your local Renishaw office for advice and

guidance. Defective products should be returned to Renishaw for repair.

There are no user-serviceable parts inside the main calibration system equipment.

Never remove housings as doing so may invalidate the warranty and cause

additional damage. If in any doubt, contact your local Renishaw office for advice

and guidance.

Page 36

36

XR20-W rotary axis calibrator

Cleanliness of optics

The optics must be kept as clean as possible. Dirty optical surfaces are likely to

result in a loss of signal strength making calibration more difficult.

Clean the optics only when necessary. The emphasis should be on handling and

storing the optical components so that they don’t become dirty or smeared, rather

than frequent cleaning.

• Do not touch the optical surfaces

• Do not use in contaminated atmospheres

• Store securely when not in use

Cleaning recommendations

• Wipe only with non-abrasive lens tissue or cloth, for example spectacle

cleaning cloths.

• Use cleaning fluid suitable for spectacles or similar (do not use acetone).

• Clean the optics using a gentle wiping action. Never use a scrubbing action.

Failure to follow these recommendations may lead to damage to the coatings

and glass elements of the optics.

Page 37

37

XR20-W rotary axis calibrator

System specification

XR20-W system

Recommended recalibration period 3 years or under typical use

Max feed rate 10 rpm

Performance specifications

Rotary (with XL-80)

Accuracy ±1 arcsec (at 20°C)

Resolution 0.1 arcsecs

Range 0° to 360°

Rotary (with XM system)

Accuracy ±1.2 arcsec (at 20°C)

Resolution 0.1 arcsecs

Range 0° to 360°

Operating and storage environment

Operating environment

Pressure 600 mbar - 1150 mbar Normal atmospheric

Humidity 0% to 95% RH Non-condensing

Temperature 0°C to 40°C

Storage environment

Pressure 550 mbar - 1200 mbar Normal atmospheric

Humidity 0% to 95% RH Non-condensing

Temperature -20°C to 60°C

Note: to protect against battery damage the XR20-W rotary axis calibrator

will not power up when operated below 0°C and above 40°C

Radio communication

Class 1 wireless communication device

Output power 0 dBm nominal

Frequency band 2.402 GHz - 2.480 GHz

Communication distance 10 m typical operation

Page 38

38

XR20-W rotary axis calibrator

Battery and charger

Technical data: part # 56446 702 099 (rechargeable Li-Polymer)

Battery type Varta EasyPack XL part # 56446 702 099

(rechargeable Li-Polymer), 3.7 V 2260 mAh 8.4 Wh

Max current 3.7V DC

Battery life 3 hours typical operation (for new batteries)

Technical data: part # 56456 702 099 (rechargeable Li-Polymer)

Battery type Varta EasyPack XL part # 56456 702 099

(rechargeable Li-Polymer), 3.7 V 2400 mAh 8.9 Wh

Max current 3.7V DC

Battery life 3 hours typical operation (for new batteries)

Spec for charger

Technical data

Input voltage 100 V to 240 V

AC, 50 Hz / 60 Hz

Output Voltage 4.2 V nominal

Input current Max. 0.2 A (100 V

AC)

Output current 0 A - 1.0 A

Output power rating Max. 6 W

Safety standard EN(IEC)60950

Power supply

USB power supply

Minimum current 1A

Shielded USB2 Full or high speed

For cable length less than 3 m 28AWG/2C (for signals), +24 AWG/2C

(for power)

For cable length greater than 3 m 28AWG/2C (for signals), +20AWG/2C

(for power)

Page 39

39

XR20-W rotary axis calibrator

USB power supply

The USB power supply can be used to power the XR20-W rotary axis calibrator.

The USB power supply should be used if no charged batteries are available or the

user is performing a long test.

Ensure the plug adaptor that is compatible with your country or region is attached

to the USB power supply. Push the plug adaptor firmly until it is securely held in

place. Connect the USB power supply to the XR20-W USB port via the supplied

USB cable. Finally connect the USB power supply to the electrical outlet.

Do not connect the USB power supply to the XR20-W during a test, or

measurement errors may result.

Note: There is no need to remove the battery when using the USB power

supply.

Important: to ensure correct operation only use the USB power supply supplied

and USB cables with the correct power rating.

Replacement USB power supplies and USB cables and are available from

Renishaw.

The XR20-W should not be connected to a standard PC’s USB port. If connected

the XR20-W will not recognise the PC as a suitable power supply and therefore

will not turn on.

Care must be taken that the USB cable does not snag inside the machine as the

rotary axis rotates. Snagging of the cable may cause damage to the XR20-W.

Page 40

40

XR20-W rotary axis calibrator

Power supply: rechargeable battery

The XR20-W rotary axis calibrator kit contains Li-Polymer Varta Easypack

batteries and associated charger. These batteries are the only type which should

be used with the XR20-W unit.

Before charging or using the battery it is recommended that you read the battery

safety section of this manual.

To remove a battery, turn the battery cover on the bottom of the XR20-W

anticlockwise, and remove to reveal the battery compartment.

Page 41

41

XR20-W rotary axis calibrator

When fitting a battery, ensure the terminals of the battery sit over the terminals

inside the battery compartment.

Battery life

Battery life in use will depend on many variables including age and condition of

battery; initial charge and test cycle and duration. The published specification is for

a new battery and with the XR20-W used in a typical configuration.

For optimum battery performance only fit fully charged batteries.

A battery should be continued to be used until battery low is indicated by the

XR20-W status LEDs. Once battery low is indicated, replace the battery with a fully

charged one as soon as possible.

The battery contact inside the battery cap must be kept clean. Dirt build up on

the contact can cause a high resistance circuit which can give false battery flat

indication. The inside of the cap should be cleaned with a soft cloth and appropriate

solvent, e.g. IPA.

Note: batteries should be removed during transportation.

Battery charger

The XR20-W will indicate that the battery charge is getting low via the status LEDs

on the side of the unit. To recharge the battery, remove it from the unit and place it

into the slot in the battery charger. Ensure that the terminals of the battery line up

with the terminals inside the charger. The colour status for the LED on the charger

are shown below:

LED status Description

Solid green If there is a battery in the charger,

the green LED indicates that is fully

charged and ready to be used. If there

isn’t a battery in the charger, the green

LED indicates the charger is plugged

in and ready to charge a battery.

Solid amber This means that the battery in the

charger is in the process of being

charged.

Flashing amber This indicates that the charger is going

through its pre-charge cycle.

Off The charger is not plugged in.

Red This indicates a fault with the charger.

See the battery charger booklet

provided in the XR20-W kit for more

information.

To maintain optimum battery performance, batteries should be recharged every 6

months irrespective of use.

Page 42

42

XR20-W rotary axis calibrator

Weights and dimensions

Description Weight

XR20-W weight 1.2 kg

XR20-W system weight in case 6.5 kg

XR20-W

83

96

59

130

96

22

Chuck adaptor

Ø 101

Ø 60

Ø 40

4 x 80 PCD, C’BORE

Ø 9.2 x 7 DP &

Ø5.5 THRO’

Ø 28

58

18

4

Page 43

43

XR20-W rotary axis calibrator

Mounting ring

Ø 60

Ø 120 PCD

Ø 128 PCD

4 SLOTS Ø 10.6

Ø 150

Ø 96

60°

60°

11

17

Mounting adaptor

Ø 60

Ø 150

Ø 80 PCD

4 POSN’S M5

THRO’

6

6

Page 44

Renishaw plc

New Mills, Wotton-under-Edge

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details, visit

www.renishaw.com/contact

*F-9950-0400-01*

© 2018 Renishaw plc

Issued: 07. 2018

Part no. F-9950-0400-01-B

Loading...

Loading...