Page 1

User guide

F-9921-0201-04-B

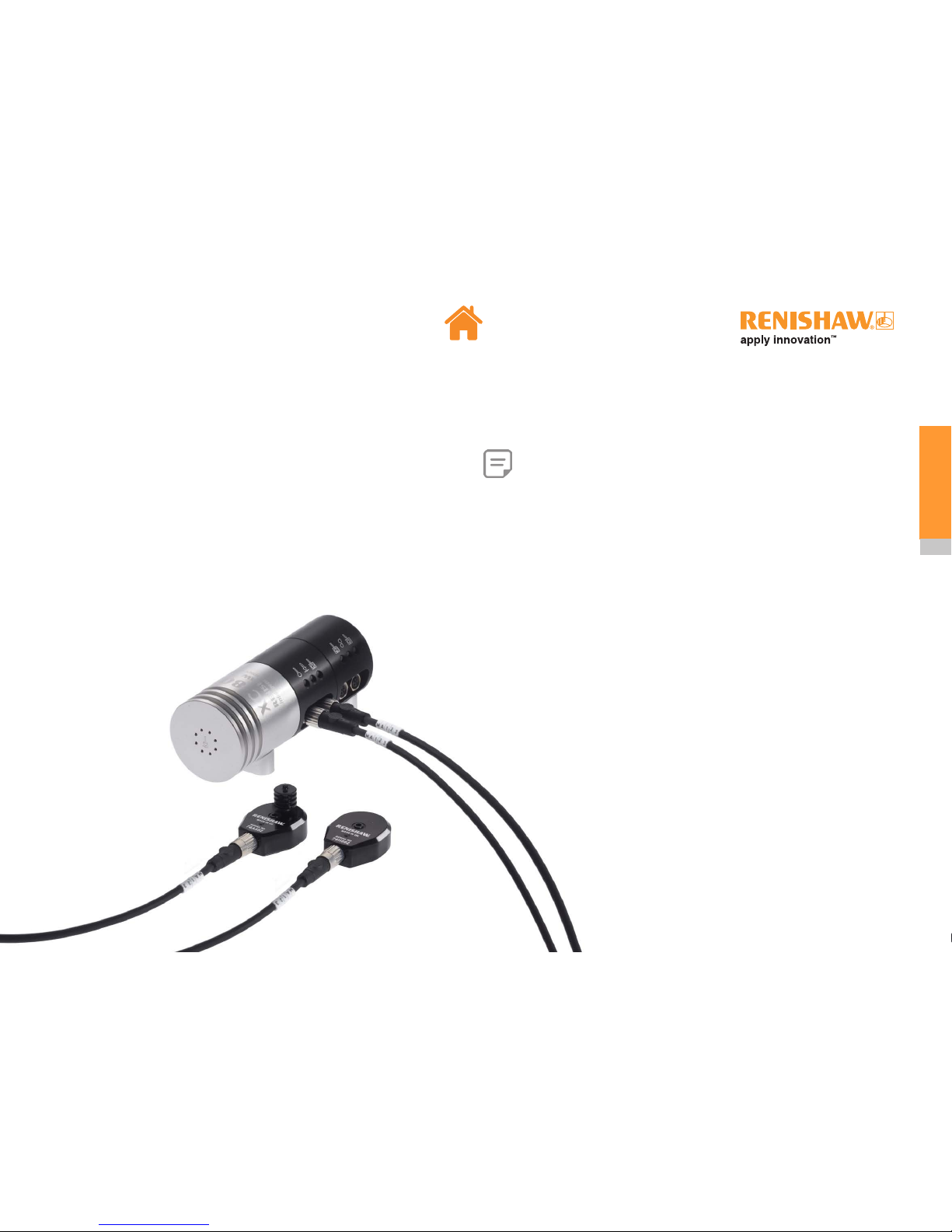

XM multi-axis calibrator

Page 2

XM multi-axis calibrator

Patents

Features of the XM multi-axis calibrator, and other similar Renishaw products, are

subject of one or more of the following patents and/or patent applications:

CN 101715540 US 2016/0169710

CN 105637326 US 5975744

EP 3028011 US 6473250

GB 2337339 US 6597505

IN WO2015/015213 US 7304815

JP 2015/015213 US 8368887

JP 4499924

Renishaw part no: F-9921-0201-04-B

Issued: 09.2018

Legal information

Disclaimer and warranty information

Renishaw reserves the right to make changes to this document and to the product

described herein without obligation to notify any person of such changes.

Disclaimer

Renishaw has made considerable efforts to ensure the content of this document

is correct at the date of publication but makes no warranties or representations

regarding the content. Renishaw excludes liability, howsoever arising, for any

inaccuracies in this document.

Warranty

Equipment requiring attention under warranty must be returned to your equipment

supplier.

Unless otherwise specifically agreed in writing between you and Renishaw, if you

purchased the equipment from a Renishaw company, the warranty provisions

contained in Renishaw’s CONDITIONS OF SALE apply. You should consult these

conditions in order to find out the details of your warranty but, in summary, the

main exclusions from the warranty are if the equipment has been:

• neglected, mishandled or inappropriately used; or

• modified or altered in any way except with the prior written agreement of

Renishaw.

If you purchased the equipment from any other supplier, you should contact them

to find out what repairs are covered by their warranty.

Trade marks

RENISHAW and the probe symbol used in the RENISHAW logo are registered

trade marks of Renishaw plc in the United Kingdom and other countries. apply

innovation and names and designations of other Renishaw products and

technologies are trade marks of Renishaw plc or its subsidiaries.

All other brand names and product names used in this document are trade

names, trade marks, or registered trade marks of their respective owners.

Copyright

© 2016-2018 Renishaw. All rights reserved.

This document may not be copied or reproduced in whole or in part, or transferred

to any other media or language, by any means without the prior written

permission of Renishaw. The publication of material within this document does not

imply freedom from the patent rights of Renishaw plc.

Page 3

XM multi-axis calibrator

Legal information

International regulations and conformance

EC compliance

Renishaw plc declares that the XM system complies with the applicable directives,

standard and regulations. A copy of the full EC Declaration of Conformity is

available upon request.

In compliance with BS EN 61010-1:2010 the product is safe to use in the following

environmental conditions:

• Indoor use only

• Altitude up to 2000 m

• Maximum relative humidity (non-condensing) of 80% for

temperatures up to 31 °C decreasing linearly to

50% relative humidity at 40 °C

• Pollution Degree 2

RoHS compliance

Compliant with EC directive 2011/65/EU (RoHS)

Packaging component Material ISO 11469 Recycling

guidance

Outer box Cardboard N/A Recyclable

Inserts Cardboard N/A Recyclable

Bags Low density polyethylene LDPE Recyclable

WEEE

The use of this symbol on Renishaw products and/or accompanying

documentation indicates that the product should not be mixed

with general household waste upon disposal. Due to fibre optic

handling requirements the unit must be returned to Renishaw for

disposal. Please contact your local Renishaw office to arrange

collection. Correct disposal of this product will help to save valuable

resources and prevent potential negative effects on the environment.

For more information, please contact your local Renishaw office.

Page 4

XM multi-axis calibrator

Radio communication

The wireless communication module used within the XM system is pre-approved

in a number of regions including EU, EFTA countries, USA and Canada.

Module manufacturer: Laird plc

Part number: TRBLU23-00200

FCC ID: FCC ID PI401B

Module ID No: 1931 B-BISMII

For details of national radio approvals for this device, see the Compliance

with radio device regulations document on the Calibration product quality and

conformance web pages.

Further radio approval country specific statements can be found below:

Singapore

Reg. No. N1116-17

Complies with

IDA Standards

DA104642

Mexico

La operación de este equipo está sujeta a las siguientes dos condiciones:

(1) es posible que este equipo o dispositivo no cause interferencia perjudicial y

(2) este equipo o dispositivo debe aceptar cualquier interferencia, incluyendo la

que pueda causar su operación no deseada.

Taiwan

低功率電波輻性電機管理辦法

第十二條經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不

得擅自變更頻率、加大功率或變更原設計之特性及功能。

第十四條低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾

現象時,應立即停用,並改善至無干擾時方得繼續使用。前項合法通信,指依電信

規定作業之無線電信。低功率射頻電機須忍受合法通信或工業、科學及醫療用電波

輻射性電機設備之干擾 。

Page 5

XM multi-axis calibrator

Legal information

USA and Canadian regulations

FCC

Information to the user (47CFR:2001 part 15.19)

This device complies with Part 15 of the FCC rules. Operation is subject to the

following conditions:

This device may not cause harmful interference.

This device must accept any interference received, including interference that may

cause undesired operation.

Information to the user (47CFR:2001 part 15.105)

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses and

can radiate radio frequency energy and, if not used in accordance with this user

guide, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which

case you will be required to correct the interference at your own expense.

Information to the user (47CFR:2001 part 15.21)

The user is cautioned that any changes or modifications, not expressly approved

by Renishaw plc or authorised representative, could void the user’s authority to

operate the equipment.

Special accessories (47CFR:2001 part 15.27)

The user is also cautioned that any peripheral device installed with this

equipment, such as a computer, must be connected with a high-quality shielded

cable to ensure compliance with FCC limits.

Canada – Industry Canada (IC)

This device complies with RSS 210 of Industry Canada. Operation is subject to

the following two conditions: (1) this device may not cause interference, and (2)

this device must accept any interference, including interference that may cause

undesired operation of this device.

L’utilisation de ce dispositif est autorisée seulement aux conditions suivantes :

(1) il ne doit pas produire d’interference et (2) l’utilisateur du dispositif doit étre

prêt à accepter toute interference radioélectrique reçu, même si celle-ci est

susceptible de compromettre le fonctionnement du dispositif.

Page 6

XM multi-axis calibrator

Contents

Legal information ........................ 2

Safety information........................ 7

Safety labelling ........................... 8

Mechanical safety ......................... 9

Laser optical safety ........................ 9

Electrical and power safety ................. 10

Battery safety ........................... 10

Fibre optic safety......................... 11

Principles of measurement...............12

XM multi-axis calibrator.................... 12

System components..................... 14

XM-60 system kit ........................ 14

System components..................... 15

XM-600 system kit ....................... 15

Laser / Launch ........................ 16

Receiver ............................. 17

Calibration software kit .................. 18

XC-80 environmental compensator .......... 19

Fixturing kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Other accessories for use on CMMs.......... 21

Setting up a test......................... 22

Testing precautions....................... 22

Quick start system set-up using CARTO software 24

Test overview ........................... 25

XM system set-up ........................ 26

XC-80 set-up............................ 28

Basic rules of alignment ................... 29

Alignment overview....................... 30

Visual axis alignment ................... 31

Fine axis alignment .................... 34

Receiver alignment..................... 36

Data capture ............................ 37

Data analysis ........................... 39

Diagnostics and troubleshooting .........40

Laser LED .............................. 40

Receiver LED ........................... 41

Battery charger LED ...................... 42

System troubleshooting ................... 43

Measurement troubleshooting .............. 44

Care and handling .......................45

System ................................ 45

Conduit ................................ 45

Optics ................................. 45

System specifications ...................46

Performance specifications................. 47

Operating and storage environment . . . . . . . . . . 48

Radio communication ..................... 49

PICS connector (XM-600 only) .............. 49

Receiver battery and charger ............... 50

Power supply unit ........................ 51

Weights ................................ 52

Dimensions (laser unit) .................... 52

Dimensions (launch unit) .................. 53

Dimensions (receiver unit) ................. 54

Appendix A .............................55

Replacing the receiver battery .............. 55

Appendix B .............................56

Using the 90 degree bracket................ 56

Appendix C .............................57

Sign detection ........................... 57

Appendix D .............................58

Machine tool fixturing kit good practice guide ... 58

Appendix E .............................63

Example XM system set-ups on CMM ........ 63

Appendix F .............................64

Straightness measurement ................. 64

Angular errors ........................... 65

XM set-up best practice ................... 66

Page 7

7

XM multi-axis calibrator

Safety information

Use of controls or adjustments or performance of

procedures other than those specified herein may result

in hazardous radiation exposure.

Ensure that you read and understand the XM system

user guide before using any XM system.

The XM system can be used in a variety of environments and applications. To

ensure the safety of the user and other personnel in the vicinity it is therefore

paramount that a comprehensive risk assessment is carried out for the machine

under test before using the XM system.

This should be carried out by qualified users (requiring machine competency,

applicable technical knowledge and a trained risk assessor) with consideration for

the safety of all personnel. The risks identified must be mitigated prior to using the

product. The risk assessment should pay particular attention to machine, manual

handling, mechanical, laser, electrical, power and fibre optic safety.

Based on current research, the wireless devices used in this product would not

seem to pose a significant health problem for the vast majority of pacemaker

wearers. However, people with pacemakers may want to ensure a minimum

distance of 3 cm between the XM system and the pacemaker.

Page 8

8

XM multi-axis calibrator

Safety labelling

There are no user-serviceable parts inside the XM system. Do not

remove any part of the housing; to do so could expose the user to

high voltages and/or Class 3R laser radiation.

Ensure that you read and understand the XM system user guide

before using any XM system.

COMPLIES WITH FDA PERFORMANCE STANDARDS FOR

LASER PRODUCTS EXCEPT FOR DEVIATIONS PURSUANT

TO LASER NOTICE NO.50, DATED JUNE 24, 2007

Page 9

9

XM multi-axis calibrator

Mechanical safety

• When setting up and mounting Renishaw XM and XC-80 systems beware

of pinch and/or crush hazards that may be created e.g. due to magnetic

mounting bases.

• Beware of trip hazards that may be created when using the XM and XC-80

systems, e.g. due to trailing cables.

• Exercise caution if components are to be mounted to moving or rotating

machinery. Beware of cables becoming entangled.

• Exercise extreme caution if XM and XC-80 system components are to be

mounted to machinery that may accelerate rapidly or move at high speed,

which could lead to items colliding or being ejected.

• If it is necessary to operate the machine with the guards or any safety

feature removed or disabled, it is the responsibility of the operator to

ensure that alternative safety measures are taken in line with the machine

manufacturer’s operating instructions or relevant codes of practice.

• If you are using a part program or error correction parameters generated by

the Renishaw software, it is the responsibility of the user to validate these

at low feedrate and be prepared to operate the emergency stop button if

necessary.

• The XM system weighs approximately 24 kg in the case (31 kg with the

machine tool fixturing kit attached). Users should exercise caution and follow

local manual handling guidelines.

Laser optical safety

• In accordance with (IEC) EN60825-1, XM systems are Class 2M lasers and

safety goggles are not required (under normal circumstances the eye will

blink and look away before damage can occur).

• Do not stare directly into the laser beams or view them with optical

equipment such as telescopes, convergent mirrors or binoculars as

permanent retinal damage could occur. Do not direct the beam at other

people or into areas where people unconnected with laser work might be

present. It is safe to view a diffuse-reflected beam during system alignment.

• FDA compliance (USA) – complies with 21CFR1040.10 and 1040.11 except

for deviations pursuant to laser notice no. 50, dated 24 June, 2007.

Rotating the shutter to the closed position (the right hand position on the picture)

ensures no beam is emitted.

Page 10

10

XM multi-axis calibrator

Power connector On/off switch

Electrical and power safety

• The power supply unit must not come into contact with

fluids e.g. coolant on the floor.

• The power supply unit must not be positioned inside the

machine volume.

• The XM system has been qualified for use with the power

supply unit supplied with the system. A specification for this power supply

unit can be found here.

• In the event of damage to the single phase mains cabling section of the

power supply (power lead), all power must be isolated from the equipment

before any other action is taken.

• Never connect the system to devices not intended to be used with the

XM system.

Battery safety

The XM multi-axis calibrator is supplied with rechargeable batteries.

• Once depleted, recharge the battery in the charger provided: do not attempt

to charge the battery by other means.

• For specific battery operating, safety and disposal guidelines, please refer to

the battery manufacturers’ literature.

• Replace the batteries only with the specified type.

• Ensure that all batteries are inserted with the correct polarity.

• Do not store batteries in direct sunlight.

• Do not heat or dispose of batteries in a fire.

• Do not short-circuit or force discharge the batteries.

• Do not disassemble, pierce, deform or apply excessive pressure

to the batteries.

• Do not swallow the batteries.

• Keep the batteries out of the reach of children.

• Do not get batteries wet.

• If a battery is damaged, exercise caution when handling it.

Page 11

11

XM multi-axis calibrator

Battery safety

Transportation

Please ensure that you comply with international and national battery transport

regulations when transporting batteries or XM system kits.

The XM system uses a lithium ion battery. Lithium batteries are classified as

dangerous goods and strict controls apply on their shipment by air. To reduce the

risk of shipment delays, should you need to return the XM system to Renishaw for

any reason, do not return any batteries.

The operation of wireless appliances on aircraft is forbidden by many airlines

to prevent interference with communications systems. Remove the battery from

the receiver unit when boarding an aircraft to ensure it cannot be switched on

inadvertently.

EU REACH SVHC compliance

Please see the relevant battery manufacturer’s website for further information:

Varta: http://www.varta-microbattery.com/en/news-downloads/downloads.html

Fibre optic safety

The XM system contains fibre optics. In the unlikely event that the flexible steel

conduit is cut or severed, fibre optic splinters may be produced.

Fibre optic splinters can be very small and extremely sharp. Should any fibre

optic splinter become embedded in the skin, medical attention should be sought

immediately.

Should the fibre optic become damaged, the following procedure should be

followed (be aware that the affected area might contain splinters of unattached

fibre optic which can present a hazard):

• immediately power down the XM system,

• wear eye protection and protective gloves when handling damaged or

exposed fibre optics,

• carefully remove the XM system from the machine and package in a suitable

thick-walled cardboard box, clearly marked ‘Caution: exposed fibre optics,

handle with care’ on the outside of the box,

• return the unit to the nearest Renishaw office.

No attempt should be made to repair or dismantle the fibres from the laser unit.

Note: Fibre optic splinters do not show up on X-rays.

The use of this symbol on the batteries, packaging or accompanying documents

indicates that used batteries should not be mixed with general

household waste. Please dispose of the used batteries at a

designated collection point. This will prevent potential negative effects

on the environment and human health which could otherwise arise

from inappropriate waste handling. Please contact your local authority

or waste disposal service concerning the separate collection and

disposal of batteries. All lithium and rechargeable batteries must be

fully discharged or protected from short circuiting prior to disposal.

Page 12

12

XM multi-axis calibrator

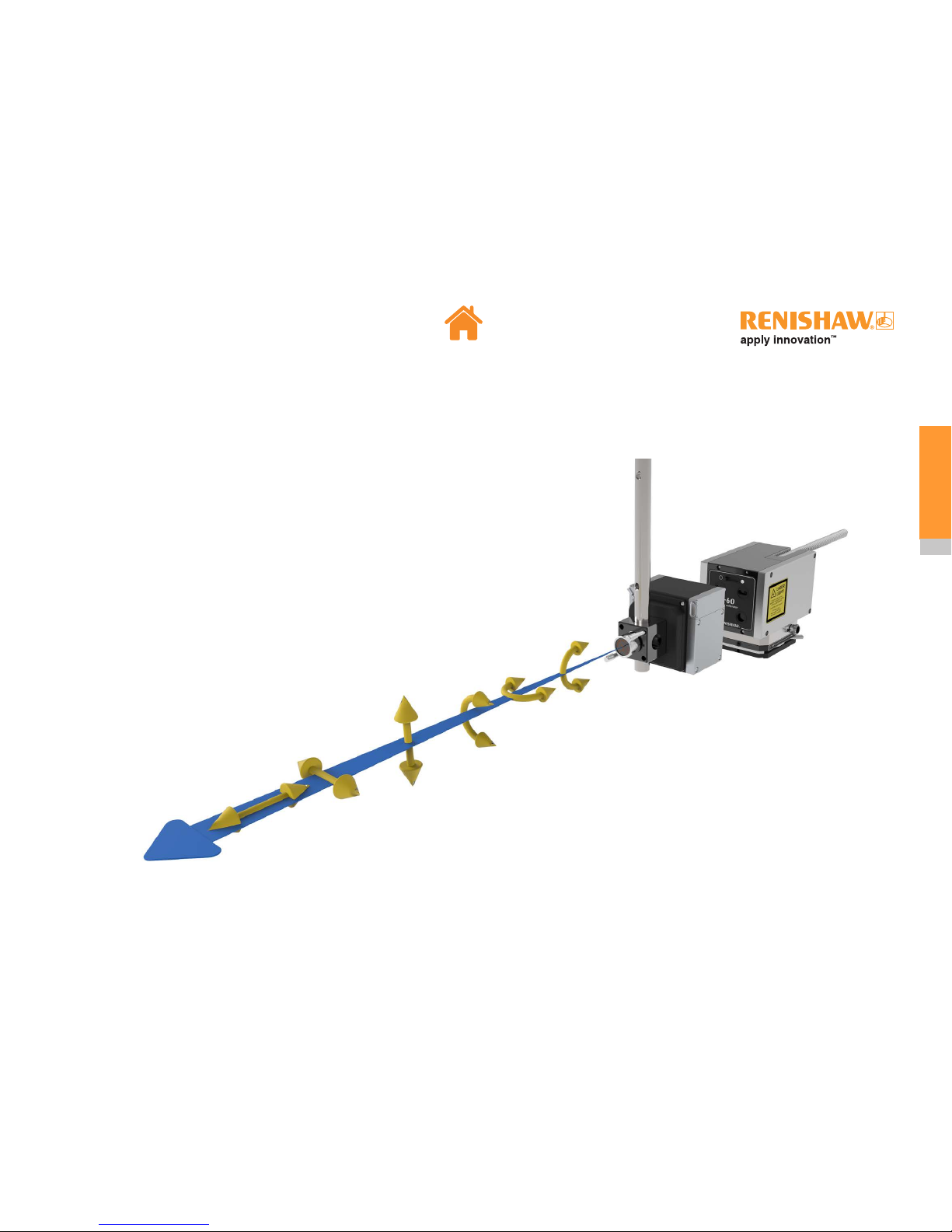

XM multi-axis calibrator is a laser measurement system capable of measuring six degrees of freedom:

• along a linear axis

• in any orientation

• from a single set-up

The measured errors are:

• Linear positioning of the axis

• Angular rotation in the vertical plane (pitch)

• Angular rotation in the horizontal plane (yaw)

• Straightness deviation in the vertical plane

• Straightness deviation in the horizontal plane

• Roll about the linear axis of travel

Principles of measurement

XM multi-axis calibrator

Page 13

13

XM multi-axis calibrator

The XM system uses three laser beams (1,2 and 3) to measure the linear, pitch

and yaw errors using interferometry. The light emitting diode (LED) beam (4) is

used for straightness and roll measurements.

The basic measurement concept is:

Angular

The three interferometric beams provide a linear measurement

of the separation between launch and receiver. Because the

distance between these beams is known, angular errors of pitch

and yaw can be determined by the system.

Linear

Using the pitch and yaw measurements, the linear error is

determined based on the combination of beams 1, 2 and 3 to

calculate the linear error at the position of beam 4.

The 4th (diode source) beam is used to measure straightness and roll.

Straightness

The vertical and horizontal straightness error is measured using

a position sensor within the receiver and transmitted back to the

laser via wireless communication.

Roll

Roll measurement is performed optically using a roll detector

inside the receiver. Roll measurements are absolute between

the launch and the receiver.

1

2

3

4

Page 14

14

XM multi-axis calibrator

1

Laser / Launch

2

Receiver

3

Calibration software kit

4

Beam shroud

5

90 degree bracket

6

Battery Li-Polymer 3.7 V × 3

7

Battery charger

8

Magnetic base

9

Clamp blocks × 2

10

M8 pillars × 4

11

Spirit level

12

Cable clamps × 3

13

Beam blocker (for rotary

applications, see XR20-W rotary

axis calibrator manual for details)

3

4

9

8

2

5

10

11

6

12

7

1

System components

XM-60 system kit

13

Page 15

15

XM multi-axis calibrator

1

Laser / Launch

2

Receiver

3

Calibration software kit

4

Beam shroud

5

90 degree bracket

6

Battery Li-Polymer 3.7 V × 3

7

Battery charger

8

Magnetic base

9

Clamp blocks × 2

10

M8 pillars × 4

11

Spirit level

12

Cable clamps × 3

13

PICS cable

14

Beam blocker (for rotary applications,

see XR20-W rotary axis calibrator

manual for details)

3

4

9

8

2

5

13

10

11

6

12

7

1

System components

XM-600 system kit

14

Page 16

16

XM multi-axis calibrator

Laser / Launch

The laser contains a Helium-Neon (HeNe) laser tube providing laser beams

to the launch via fibre optics. In addition, the laser contains signal processing

electronics.

The laser beam is split into three in the launch for linear and angular

measurements. It also houses a diode beam source for roll and straightness

measurements.

1

Wireless communication module

2

USB connection port

3

PICS connector (XM-600 only)

4

System status LED

5

Power connector

6

Power on/off switch

7

Laser safety shutter

8

Magnetic mount safety pin

(prevents accidental magnet operation)

9

Magnetic clamp on/off lever

10

Pitch adjuster

11

Yaw adjuster

8

9

10

7

11

1

2

6

4 53

Page 17

17

XM multi-axis calibrator

Receiver

The receiver contains three retro-reflectors for the interferometric laser beams.

It also contains a straightness and roll sensor for the diode beam, data from this

sensor is transmitted to the laser via wireless communication.

The beam shroud is attached by a ‘push-fit’ on to the receiver roll aperture.

1

Beam shroud

2

Roll adjuster

3

Shutter

4

Battery release buttons

5

Power button

6

Receiver/battery status LED

5

2

6

3

1

4

Page 18

18

XM multi-axis calibrator

Calibration software kit

The XM system is supplied with the “Calibration software kit” which comprises:

• CARTO suite

• User guides and documentation for XM, XL-80, XC-80 and XR20-W

The CARTO suite features two applications:

Note: XM-600 supports additional functionality when

used on a CMM which is equipped with Renishaw’s

UCC system. This functionality is accessed using UCC

Assist, which is part of UCC Suite - a software package for the

CMM controller. XM-600 is supported from UCC Suite V5.4.

UCC Assist enables additional features which are unique to

XM-600, and contains support information on how to use XM600 to calibrate a UCC-equipped CMM.

Page 19

19

XM multi-axis calibrator

XC-80 environmental compensator

The XM specified accuracy for interferometric measurements is only valid when

used with a calibrated XC-80 environmental compensator.

Changes in air temperature, pressure and relative humidity affect the wavelength

of the laser light and, therefore, the measurement readings taken.

The XC-80 environmental compensator and its sensors very accurately measure

the environmental conditions and compensate the wavelength of the laser beam

for variations in air temperature, air pressure and relative humidity.

Note: For full details on XC-80 operation and specification please refer to

XC-80 user guide.

Page 20

20

XM multi-axis calibrator

Fixturing kit

An optional fixturing kit is available. It provides the user with more flexible mounting options, particularly when a magnetic surface is available.

Typical applications of the fixturing kit include:

• Overhang the XM launch unit to enable the full travel of an axis to be measured

• Secure the launch unit in the chuck of a lathe or mill-turn machine tool (See Appendix D)

1

450 mm extrusion

350 mm extrusion

250 mm extrusion

200 mm extrusion

150 mm extrusion

2

Extrusion connectors × 8

3

Magnets × 5

4

Extrusion alignment aids × 2

5

Lathe adaptor

6

Steel mounting plate

7

Hex drivers × 3

7

1

2

3

4

5

6

Page 21

21

XM multi-axis calibrator

Other accessories for use on CMMs

Additional accessories are available to allow flexible use of the XM system (see Appendix E). These can be used to:

Pan / Tilt Adaptor

• Elevate the launch unit. This may be

useful when the machine has otherwise

insufficient axis travel to move receiver

to required position.

• Use the XM system when there are no

convenient mounting surfaces that are

parallel or perpendicular to the direction

of machine travel.

• Rapidly change launch unit orientation

between horizontal and vertical.

CMM table plate adaptor

• Provide a base on which to support the launch unit when a convenient

magnetic surface is not available on the machine (compatible with threaded

hardware up to M12).

• Overhang the XM launch unit to enable the full travel of an axis to be

measured.

Steel mounting plate

• Provide a repeatable, magnetic

mounting point for the XM launch unit

and the 90° bracket, such as on the

length bar plate, pan/tilt adaptor or

customer-designed fixturing.

Machine optics mounting kit

• Use the XM system where a

magnetic mounting location for

the receiver is not convenient.

• Assemble lightweight mounting

solutions for the XM receiver.

• Quickly and conveniently mount

the XM receiver onto the quill of

a CMM in place of a Renishaw

head.

Page 22

22

XM multi-axis calibrator

Setting up a test

Testing precautions

Light interference

External light can cause errors in roll measurement performance.

To minimise the effect of light interference the user should:

• Always use the beam shroud

• Switch off the machine lighting

• Minimise external lighting

Sources of lighting that can affect the performance are:

• Sunlight

• Flashing beacons

• Welding

• LED and fluorescent room lighting

Performance can be affected by abnormal changes in any of the above. It is

important to consider light effect and reflections over the full range of the axis

under test.

CARTO allows the user to perform an ambient light check. See Capture user

guide for details.

Page 23

23

XM multi-axis calibrator

Testing precautions

Thermal stabilisation

• To meet the quoted specifications the XM system must be thermally stable.

• Thermal stability is achieved 45 minutes after the laser/launch and receiver

are powered on. Therefore it is recommended to turn the laser/launch and

receiver on at the earliest opportunity.

• The receiver and the launch must be removed from the case during the

thermal stabilisation period and should be placed at least 200 mm away from

each other.

• To avoid the need for further thermal stabilisation, once discharged the

receiver battery should be changed within 30 seconds:

Mechanical set-up

• In order to take relative measurements between the tool and the workpiece,

the launch must always be attached to the structure that holds the

workpiece, i.e. the machine bed or the chuck on a lathe. See Appendix F for

XM set-up best practice.

• When the XM system is used on a

machine where the workpiece moves,

the conduit should be fixed to the

machine bed to stop it dragging,

misaligning, or causing the launch

to move during machine motion.

Magnetic cable clamps are included

in the kit for this purpose.

• There may be situations when sufficient magnetic force is not available to

securely mount the launch unit. This could occur when there is a requirement

for overhanging the launch unit, or the machine bed is not magnetic. In this

case, additional fixturing components (such as the Machine Tool Fixturing Kit

or other mounting accessories) may be required.

• In general, metrology performance is improved when the system is

used with fewer accessories. Use only the minimum amount of fixturing

components required to align the system to the axis under test.

Note: An uninterruptible power supply can be used when moving

XM from one machine to the next.

30

seconds

Page 24

24

XM multi-axis calibrator

Quick start system set-up using CARTO software

Application XM-60 XM-600

CNC machine tool / lathe CARTO software CARTO software

UCC-equipped CMM CARTO software UCC Assist software

Non-UCC-equipped CMM CARTO software Contact your local Renishaw office

Together with Renishaw’s CARTO software suite,

the XM systems can be used to calibrate most

CNC machines.

With XM-600, additional features are available

on some machines (such as a CMM with a UCC

controller), and other software may offer greater

functionality.

Page 25

25

XM multi-axis calibrator

Receiver alignment

Test overview

The steps to perform a test using the XM system are as follows (click on links to jump to relevant section):

Set-upAlignmentCapture

XC-80 set-up

Fine axis alignment

XM set-up

Visual axis alignment

Data analysis

Data capture

Page 26

26

XM multi-axis calibrator

XM system set-up

The recommended set-up sequence for the XM system is as follows:

Attach the beam shroud to the receiver roll aperture

Fit the battery in the receiver

Switch the laser on

Connect the power supply to the laser

Ensure the launch shutter is closed

Take the removable tray out of the case before removing launch

Page 27

27

XM multi-axis calibrator

XM system set-up

Connect the XM laser to the PC

Mount the receiver to the part of the machine where

the tool would be attached

Where appropriate, level the launch using the spirit level

Attach the launch to the bed of the machine,

parallel to the axis under test

Turn the receiver on

0.5

seconds

Page 28

28

XM multi-axis calibrator

XC-80 set-up

The recommended set-up sequence for the XC-80 is as follows:

Connect the XC-80 to the PC

Position the air temperature sensor on the machine

Attach the XC-80 environmental compensator to the

machine

Connect the air and material sensors to the XC-80

Note: For more information on sensor positioning refer to XC-80 user guide

Page 29

29

XM multi-axis calibrator

Basic rules of alignment

1. Launch and receiver are close to each other = translation adjustment

2. Launch and receiver are far from each other = rotation adjustment

Page 30

30

XM multi-axis calibrator

Alignment overview

The recommended alignment sequence is as follows (click on links to jump to relevant section):

Receiver alignment

Fine axis alignment

Visual axis alignment

Page 31

31

XM multi-axis calibrator

Visual axis alignment

Visual axis alignment is performed using the target on the front of the receiver.

Translate the machine so that one of the beams is on the

receiver target

Open the shutter on the launch and the receiver

Visually check the launch and the receiver are parallel to

each other

Move the launch and the receiver as close to each other

as possible

Set the pitch and yaw adjusters to the middle of their travel

Pitch

Yaw

Page 32

32

XM multi-axis calibrator

Visual axis alignment

Continue the process below until the beam stays on the target during the full machine movement. Use the machine to perform translations and pitch/yaw adjusters for

rotational alignment.

Page 33

33

XM multi-axis calibrator

Translate

Move the machine to align the laser beams into the

receiver apertures. Adjust position until the straightness

beam appears in CARTO

Select Align

Select New or Open

Run Capture

Page 34

34

XM multi-axis calibrator

Fine axis alignment

Continue the process below until the beam stays on the target in CARTO software during the machine movement.

Page 35

35

XM multi-axis calibrator

Fine axis alignment

Roll alignment

Adjust the roll lever to the centre of the roll display.

Page 36

36

XM multi-axis calibrator

Receiver alignment

• To maintain the system accuracy the launch and the receiver must be

parallel to each other.

• The software will check the parallelism on the completion of the fine axis

alignment.

• If the parallelism tolerance is not met when selecting Capture, the software

will prompt the user to physically adjust the mounting of the receiver. Rotate

the receiver until the red border disappears. Do not adjust the pitch and yaw

adjustment of the launch unit.

Note: It maybe necessary to perform minor translation of the

machine after this step is complete.

Note: Once set-up is complete and before capturing data, it is

recommended to perform an ambient light check. See Capture user

guide for details.

Page 37

37

XM multi-axis calibrator

Note: For full details on Capture please refer to the Capture user guide.

1

Define

2

Bring close

3

Capture

4

Datum

5

Move to start position

6

Start

300.00mm

Data capture

Page 38

38

XM multi-axis calibrator

Data capture

Roll tuning

When Start is selected the system will perform a calibration cycle on the roll

detection scheme to compensate for the set-up conditions.

Sign detection

To ensure the errors of the machine are measured with the correct sign (+/-) it

is important that the coordinate system of the XM (X,Y,Z and their directions) is

labelled according to that of the machine. Further details on sign detection can be

found here.

There are two methods of sign detection:

• Automatic

Part programs produced with CARTO will perform machine moves to detect

the sign.

• Manual

The user can manually jog the machine ±150 µm in each axis when

prompted by the software to perform sign detection.

Note: Users can skip an axis if they don’t have three perpendicular

axes. Further details can be found in the Capture user guide.

On completion of these steps the system will start capturing data.

Page 39

39

XM multi-axis calibrator

Data analysis

On completion of the test select Analyse to launch Explore.

Note: For further details on Explore please refer to the Explore user guide.

Page 40

40

XM multi-axis calibrator

This LED demonstrates the laser status and the wireless communication with the receiver.

LED status Description Actions

Flashing amber Pre-heat cycle No action required

Solid green

• Laser is stabilised

• Receiver is not switched on or the wireless

communication is not yet established

Check the receiver is powered on

Solid blue

• Wireless communication is established

• Software is not running (not synced)

Open Capture in XM mode

Flashing blue

• System operational

• The software is running and the data is being

transmitted from the receiver

No action required

Solid amber Laser unstable

• Check launch/receiver alignment

• If issue persists, power cycle

• If issue persists, contact local Renishaw office

Flashing or solid red Error encountered

• Check all four beams are present

• Power cycle the laser

• If issue persists, contact local Renishaw office

Diagnostics and troubleshooting

Laser LED

Page 41

41

XM multi-axis calibrator

Receiver LED

After the receiver power button has been pressed, the receiver LED will go through a start-up sequence

and after a few seconds will settle on one of the following options:

LED status Description Actions

Flashing amber No roll beam detected

• Open launch/receiver shutters

• Check launch/receiver alignment

• If issue persists, contact local Renishaw office

Flashing purple

Launch/receiver not synchronised

and/or no roll beam detected

Run Capture while making sure launch/receiver shutters are open

Flashing blue System is operational No action required

Periodic one second amber

followed by usual operational

sequence

Low battery Replace the battery (See Appendix A)

None

• Battery charge too low

• Battery contacts dirty/damaged

• Battery inserted incorrectly

• Receiver not operational

• Insert a fully charged battery

• If issue persists, contact local Renishaw office

Flashing green

Wireless communication device is

not operational

• Power cycle the receiver

• If issue persists, contact local Renishaw office

Flashing or solid red Receiver not operational

• Power cycle the receiver

• If issue persists, contact local Renishaw office

Page 42

42

XM multi-axis calibrator

Battery charger LED

LED status Description

Solid amber Fast charge in progress

Flashing amber Pre-charge in progress

Solid green Power on and no battery connected, or battery full

Flashing red Failure

Page 43

43

XM multi-axis calibrator

System troubleshooting

Problem Action

Software is not installed in my language • Check PC system locale is set correctly

XM is not recognised by CARTO

• Ensure Capture is running in the XM system mode

• Check the XM is connected to the PC USB port

• Try a different USB port on the PC (the port could be damaged)

• Disconnect USBs, power cycle XM/PC, reconnect USBs

• If issue persists, contact local Renishaw office

Cannot align my XM

• Ensure shutters on launch/receiver are open

• Check four beams are present from launch using a card as a target.

If not present, power cycle XM.

• Restart XM alignment

• If issue persists, contact local Renishaw office

CARTO diagnostic messages • Please refer to Capture user guide

Page 44

44

XM multi-axis calibrator

Measurement troubleshooting

Problem Possible causes Action

Beam strength fluctuating Environment is outside operating temperature range Ensure XM environment is between 10 °C - 40 °C

Beam strength fluctuating during

machine movement

• Normal behaviour at increased speed between

targets

• Receiver clamp block is not tight

• No action required (this has no effect on metrology)

• Tighten the receiver clamp block

All data looks noisy XM fixed loosely Improve the rigidity of the system mounting

All data (except for roll) looks

noisy

The unit is positioned in turbulent air environment Reposition the unit to avoid the turbulent air or stir the air with a fan

Noisy straightness measurement None or short term averaging is used Select long term averaging in Capture

Drift (most significant for linear

measurements)

The system and/or the set-up is not thermally

stabilised

• Perform a number of runs before capturing data for the machine axis

to thermally stabilise

• Ensure the laser/receiver are warmed up as per recommendations

before testing. Specifications - warm up time.

• If the receiver battery has been replaced, follow the thermal

stabilisation recommendations.

• Avoid excessive handling of the launch/receiver to avoid body heat

exchange

• If using custom mounting parts, ensure they are suitable to avoid

thermal growth

Page 45

45

XM multi-axis calibrator

Care and handling

System

• It is recommended to store the XM in the system case when not in use.

• Do not attempt to clean the system with water or other fluids.

• Avoid exposure to oil and coolant.

• Do not direct the air lines at the XM.

• Do not expose the system to impact.

Conduit

• Ensure the conduit is not pinched, crushed or stretched. If damaged, consult

the Fibre optic safety section.

• When storing in the case, twist the launch whilst vertical to allow the conduit

to coil.

• If the laser is left in the case during measurement, do not close the lid of the

case to avoid damage to the conduit.

• Fix the conduit using the magnetic cable clamps to ensure the conduit does

not drag, misaligning the launch.

− Manually check the movement of the axis over the full range of the test,

before running a test.

• Never hold the laser or launch by the conduit.

Optics

Cleaning of the optics should be a last resort

To maintain system performance, the XM optics must be kept clean by

following good handling practice:

• Close the receiver and launch shutters when not in use.

• Do not touch the optical surfaces.

• Minimise use in contaminated atmospheres.

Cleaning recommendations

• Only use approved solvents for cleaning the optics: Methylated spirit and

optical grade IPA only (methylated spirit is preferred to IPA).

• Wipe only with non-abrasive lens tissue or lint-free cloth wrapped around a

cotton bud (do not use a cotton bud directly on the optic as this may increase

debris).

• Clean the optics using a gentle action. Never use a scrubbing action as this

might damage the coatings.

Failure to follow these recommendations may lead to damage to the coatings and

glass elements of the optics.

Page 46

46

XM multi-axis calibrator

System specifications

XM system

Beam source HeNe laser and light emitting diode (LED) (Class 2M)

Beam power (maximum output) < 1 mW (sum of four beams)

Mode of operation

Continuous-wave (HeNe)

Pulsed (LED)

Nominal laser beam diameter 3 mm

Source wavelengths 633 nm and 655 nm nominal

Recommended recalibration period 2 years under typical use

Warm up time (measured from receiver and laser power on)

45 minutes

• 15 minutes laser tube pre-heat

• 30 minutes thermal drift reduction

Input power connector

Inner core = 24 V

Outer core = 0 V

Maximum velocity 1 m/s

Page 47

47

XM multi-axis calibrator

Performance specifications

Linear

Accuracy ±0.5 ppm (with environmental compensation)

Resolution 1 nm

Range 0 m to 4 m

Angular (pitch/yaw)

Accuracy

±0.006A ±(0.5 µrad +0.1M µrad)

(M = measured distance in metres) (A = displayed angular reading)

Resolution 0.03 µrad

Range ±500 µrad

Straightness

Accuracy ±0.01A ±2 µm (A = displayed straightness reading)

Resolution 0.25 µm

Range 250 µm radius

Roll

Accuracy ±0.01A ±9.1 µrad (A = displayed angular reading)

Resolution 0.5 µrad

Range ±500 µrad

Accuracy values are reported to a statistical confidence of 95% (k=2), they do not include the errors associated with the normalisation of the readings to a

material temperature of 20 °C.

Page 48

48

XM multi-axis calibrator

Operating and storage environment

Operating environment

Pressure 600 mbar – 1150 mbar Normal atmospheric

Humidity 0% to 95% RH Non-condensing

Temperature 10 °C to 40 °C

Storage environment

Pressure 550 mbar – 1200 mbar Normal atmospheric

Humidity 0% to 95% RH Non-condensing

Temperature -20 °C to 70 °C

Page 49

49

XM multi-axis calibrator

Radio communication

Class 1 wireless communication device

Output power 0 dBm nominal; +6 dBm maximum

Frequency band 2.402 GHz – 2.480 GHz

Communication distance 12 m typical operation

PICS connector (XM-600 only)

The XM-600 includes a synchronisation output which is designed to be compatible with the PICS interface of Renishaw’s UCC range of CMM controllers. The PICS

signal from the XM-600 is a protected, isolated, open – collector output. The connector on the launch unit is a male 9-way D-Subminiature plug.

The connections on this plug are as follows:

PIN number Function

5 Collector

9 Emitter

All others No Connection

9-way male D-Subminiature plug, viewed from connector side Illustration of internal connection of PICS output

Page 50

50

XM multi-axis calibrator

Receiver battery and charger

Technical data

Battery type Varta EasyPack XL Part # 56456 702 099 (rechargeable Li-Polymer), 3.7 V 2400 mAh 8.9 Wh

Max current 3.7V DC

Battery life 3 hours typical operation (for new batteries)

Technical data

Input voltage 100 V to 240 V AC, 50 Hz / 60 Hz Output Voltage 4.2 V nominal

Input current Max. 0.2 A (100 V AC)

Output current 0 A – 1.0 A

Output power rating Max. 6 W

Safety standard EN(IEC)60950

PC minimum requirements

For details on PC minimum requirements please refer to renishaw.com/lasercalsoftware

Page 51

51

XM multi-axis calibrator

Power supply unit

Technical data

Input voltage 100 V – 240 V

Input frequency 50 Hz – 60 Hz

Maximum input current 1.5 A

Output voltage 24 V

Maximum output current 3 A

Safety standard EN(IEC)60950

Page 52

52

XM multi-axis calibrator

Weights

Weights (approximately)

XM system 6.2 kg (complete system in the case excluding optional XC-80 compensator: 23 kg)

Laser 3.7 kg

Launch 1.9 kg

Receiver 0.6 kg

320

193

Conduit length nominal 3 m

185

122

78

Dimensions (laser unit)

Page 53

53

XM multi-axis calibrator

Dimensions (launch unit)

125.5

123

86

79

114.4

Conduit length

nominal 3 m

124.1

45.1

26.2

25.2

97.5

86

155.2

Page 54

54

XM multi-axis calibrator

16.5

65

82

57.9

8.2

85.15

55

28.1

17.5

11.862.5

86

76

Dimensions (receiver unit)

Page 55

55

XM multi-axis calibrator

Appendix A

Replacing the receiver battery

To replace the battery, follow the procedure below:

2

4

1

3

Page 56

56

XM multi-axis calibrator

Appendix B

Using the 90 degree bracket

The 90 degree bracket can be used in two orientations (standard and reverse).

Reverse orientation allows the launch to be mounted from the side of the machine

tool bed to maximise the length of the axis that can be measured.

When using the 90 degree bracket the user must clock the side face of the

bracket to ensure it is parallel to the axis of travel (e.g. if measuring Z on a vertical

machining centre, clock one of the faces of the 90 degree bracket to the X or Y

axis of the machine).

Standard orientation Reverse orientation Clocking the side face of the bracket

Page 57

57

XM multi-axis calibrator

Appendix C

Sign detection

XM system has 6 measurement channels:

• 3 channels (T1,T2 and T3) correspond to translations (linear and

straightness)

• 3 channels (R1, R2 and R3) correspond to rotations around T1,T2 and T3

Sign detection process performs the following:

• Links the T1,T2 and T3 axes of the XM to the machine linear axes

• Sets the sign (+/-) of the T1,T2 and T3 measurements

• Sets the sign (+/-) of the R1,R2 and R3 measurements

Yaw

Roll

Pitch

Page 58

58

XM multi-axis calibrator

× 2

× 1

A

min

=

B

-----------

5

(if used

with XM)

A

min

=

B

-----------

2

(if used

with XL-80)

A B

Appendix D

Machine tool fixturing kit good practice guide

Page 59

59

XM multi-axis calibrator

3

2

4

1

Page 60

60

XM multi-axis calibrator

5

6

Page 61

61

XM multi-axis calibrator

Page 62

62

XM multi-axis calibrator

Page 63

63

XM multi-axis calibrator

Appendix E

Example XM system set-ups on CMM

Page 64

64

XM multi-axis calibrator

Appendix F

Straightness measurement

Consider a tool machining a component on a machine bed. As the bed moves

from right-left, errors in the machine cause the height of the tool to vary above

the bed.

To measure this effect we measure the height between the tool and the bed

at ‘intervals’ along the movement of the axis. The error is the variation from a

straight line.

Error

Placing the launch unit on the bed of a machine the laser beam becomes the

reference. Variations in height are detected by the receiver as the machine moves

left-right.

Page 65

65

XM multi-axis calibrator

Angular errors

Angular errors (rotations while moving) will cause a variation in

the height difference between the tool and machine bed. This

height variation is also seen on the XM system measurement.

The measurement is not influenced by the exact position of the launch unit ... … but it is affected by the position of the receiver.

The receiver should be positioned as close as possible to the

centre line of the spindle.

Page 66

66

XM multi-axis calibrator

For relative measurements between the tool and the bed/component, the launch

unit must always be mounted on the bed of the machine.

The receiver must always be mounted on centreline of the spindle.

Measurement comparisons

Measurements taken with the launch unit on the bed of

the machine are equivalent to running a dial indicator

along a ‘straight edge’ mounted to the surface of the bed.

XM set-up best practice

If the launch unit is mounted

in the spindle, angular errors

can cause errors in the

straightness measurement.

At the point measured

below there is zero height

variation between tool and

bed, but the XM system

would show a deviation

because of the rotation of

the bed.

Page 67

Renishaw plc

New Mills, Wotton-under-Edge

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details, visit

www.renishaw.com/contact

F-9921-0201-04

© 2016-2018 Renishaw plc

Issued: 09.2018

Part no. F-9921-0201-04-B

Loading...

Loading...