Page 1

UCC T5 PH20 CMM controller installation guide

Documentation part number: H-1000-7573-04-B

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

1

Page 2

General information

©20132018Renishawplc.Allrightsreserved.

This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any means, without

the prior written permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE

DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW

EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and other

countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are trade names, service marks, trademarks, or registered trademarks of their

respective owners.

Windows XP, Windows 2000, Vista, Windows 7 and Windows 10 are registered trade names of the Microsoft Corporation.

All trademarks and trade names are acknowledged.

WEEE

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product should not be mixed with the

general household waste upon disposal. It is the responsibility of the end user to dispose of this product at a designated collection point for

waste electrical and electronic equipment (WEEE) to enable reuse or recycling. Correct disposal of this product will help save valuable

resources and prevent potential negative effects on the environment. For more information, please contact your local waste disposal

service or Renishaw distributor.

Warranty

Renishaw plc warrants its equipment for a limited period (as set out in our Standard Terms and Conditions of Sale) provided that it is

installed exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or cabling) is to be used or substituted.

Failure to comply with this will invalidate the Renishaw warranty.

Claims under warranty must be made from authorised service centres only, which may be advised by the supplier or distributor.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

2

Page 3

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise measurements and must therefore be treated

with care.

Changes to Renishaw products

Renishaw reserves the right to improve, change or modify its hardware or software without incurring any obligations to make changes to

Renishaw equipment previously sold.

Packaging

To aid end user recycling and disposal the materials used in the different components of the packaging are stated here:

Packaging component Material 94/62/EC code 94/62/EC number

Outer box Cardboard - 70% recycled content PAP 20

Packing foam Polypropylene PP 5

Packing foam Cross-linked polyethylene LDPE 4

Plastic bags Low density polyethylene bag LDPE 4

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

3

Page 4

EU declaration of conformity

Contact Renishaw plc or visit www.renishaw.com/productcompliance for the full EU declaration.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

4

Page 5

FCC (USA only)

Information to user (47CFR section 15.105)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case you will be required to correct the interference at your own expense.

Information to user (47CFR section 15.21)

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or authorised representative could void

the user's authority to operate the equipment.

Equipment label (47CFR section 15.19)

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference

2. This device must accept any interference received, including interference that may cause undesired operation.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

5

Page 6

Safety

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

There are no user serviceable parts inside the equipment.

The UCC T5 controller is only warranted and approved for use with the provided PSU - Cincon TRG70A240-02E02

PSU electrical ratings

Supply voltage 100 V to 240 Vac +10%,-10%

Frequency range 50 Hz to 60 Hz

Output current 3 A

Output voltage 24 V

Transient voltages Installation category II

The UCC T5 is isolated from ac power by disconnection of the IEC mains connector from the supplied PSU. If any additional means of

isolation is required, it must be specified and fitted by the machine manufacturer or installer of the product. The isolator / disconnection

device must be sited within easy reach of the operator and comply with any applicable national wiring regulations for the country of

installation.

The UCC T5 is provided with an equipotential bonding point which must be used to connect it to the rest of the installations ground

structures.

WARNING: Switching off or isolating the UCC T5 may NOT prevent unexpected machine movement. The user is advised to isolate

the machine from the electricity supply, compressed air or other energy sources in accordance with the machine manufacturer's

instructions before entering the danger zone or performing any maintenance operations.

WARNING: The system can accelerate quickly during operation. It is recommended that eye protection is worn if the user enters the

working volume of the CMM.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

6

Page 7

Enviromental conditions

Indoor use IP30* (BS EN60529:1992)

Altitude Up to 2000 m

Operating temperature +5°Cto+50°C

Storage temperature 25°Cto+70°C

Relative humidity 80%maximum(noncondensing)fortemperaturesupto+31°C

Lineardecreaseto50%at+50°C

Transient voltages Installation category II

Pollution degree 2

* NOTE: It may be necessary to house UCC T5 in a suitable enclosure according to the installation's environmental conditions to

obtain a higher IP rating.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

7

Page 8

References and associated documents

It is recommended that the following documentation is referenced when installing the UCC T5:

Renishaw documents

Title Document number

Installation guide: PH20 H-1000-5209

Installation guide: SPA3 H-1000-7566

Installation and user's guide: MCU H-1000-5182

UCCassist-2 help Found within UCCassist-2

External documents

National and international standards including the following may be applicable to the finished machine or installation:EN (IEC) 60204-1:2006 (Safety of machinery - Electrical equipment of machines - Part 1: General requirements).

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

8

Page 9

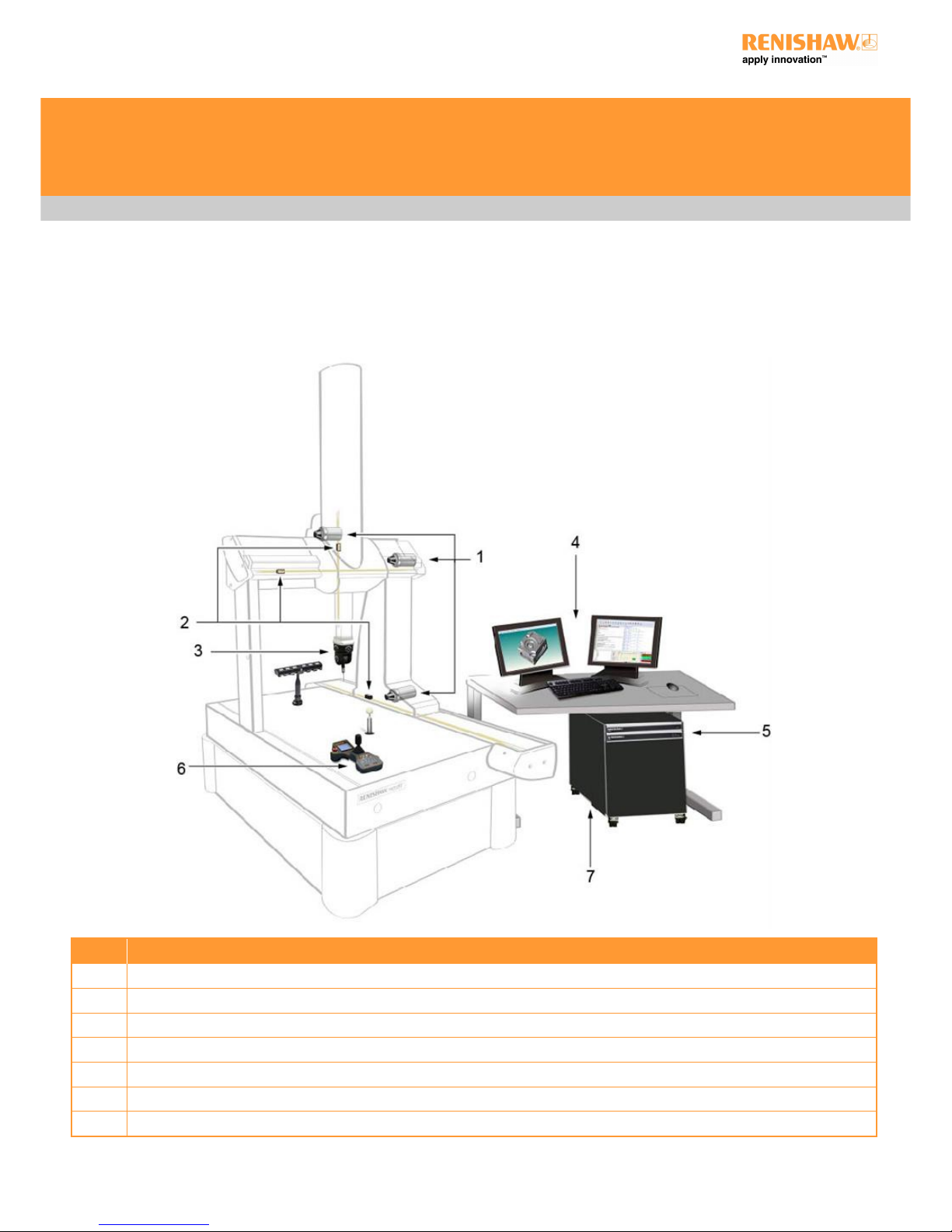

Introduction

The UCC T5 is the latest addition to the Renishaw CMM controller product range. It replaces the UCC2 and 5-axis card in PH20

applications.

Key Description

1 Machine motors

2 Machine scales and readheads

3 Probe head - PH20 connects to UCC T5 via the orange machine cabling

4 UCCassist-2 commissioning software and application software

5 UCC T5 and power amplifier SPA3 - these connect to the machine cabling

6 MCU joystick - MCUlite-2, MCU5 or MCU W - connects to SPA3

7 PC - connects to UCC T5 via an Ethernet cable

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

9

Page 10

The UCC T5 comprises of a controller in a 19 inch rack-mountable enclosure. It is coupled to the CMM host computer by an Ethernet link

and to the CMM via external cable interface connectors.

The UCC T5 controller has the capability to:

control three axes of a CMM (accepting digital readhead signals and generating three axes drive motor control signals)

accept input signals from emergency stop, air pressure, crash detector, digital SPA, amplifier faults and all axis inner and outer travel

limit switches

accept two uncommitted general purpose input signals and generate one uncommitted general purpose output signal

interface PH20

directly support the Renishaw SPA3 servo power amplifier

directly support the Renishaw TEC (16 channels) and RS232 (Mitutoyo) TEC systems

provide a +24 V supply for use by the CMM switches

The UCC T5 supports the MCUlite-2, MCU5 and MCU W joysticks through the SPA3.

This guide gives information on physical installation, system connections and communications, as well as assistance in fault finding during

the installation of the UCC T5.

WARNING: UCC T5 is not compatible with PH9, PHS, PH10 and REVO systems. No attempt should be made to connect these

system components to the UCC T5 as this will result in damage to the product or attached equipment.

Please use this guide in conjunction with the PH20 user's guide in order to fully understand the system's features, capabilities and

operation.

The UCC T5 must be used in conjunction with a Renishaw SPA3. Setup and commissioning should be completed through Renishaw's

UCCassist-2 software.

The UCC T5 has replaced the UCC2-2 and 5-axis daughtercard. It also replaces the TEC card and provides support for 16 channels of

temperature compensation.

The UCC T5 uses an external power supply and manages full control of the PH20 head, CMM and probe signals and communicates with

the CMM's computer.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

10

Page 11

Front panel

UCC T5

Rear panel layout

Key Description Key Description

1 37 way D-type plug for temperature compensation 7 Reserved

2 Ethernet communications connector to CMM computer 8 Reserved

3 Reset button 9 15 way D-type socket for PH20 connection

4 Reserved - (USB type B socket) 10 Equipment bond point

5 RJ45 connector to SPA3 11 DC power jack

6 RJ45 connector to second SPA3 (not implemented at this time)

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

11

Page 12

Installation

Dimensions

Width: 440 mm (17.3 in) Depth: 180 mm (7.1 in) Height: 44 mm (1.7 in) Weight: 2.1 kg (4 lb 10 oz)

UCC T5 can either be free standing or used in a 19 inch rack system.

CAUTION: Ensure the controller is disconnected from the mains supply during installation.

Stand-alone installation

The UCC T5 unit draws air from the right hand side when viewed from the front and expels air out of the left hand side. A minimum

clearance gap of 10 mm is necessary between the sides of the unit and any potential obstruction.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

12

Page 13

Mounting in a 19 inch rack (optional)

Therackmountingkit(partnumberA10180189)containstwobracketsandfourM5×6mmscrews.Assemblethebracketstothe

UCC T5 as shown below:

Cable lengths

UCC T5 to SPA3 connection

The units are linked via a CAT 5 or STP/ FTP cable. 300 mm cables are supplied with the UCC T5 kits. It is not recommended to use a

cable over 400 mm.

Ethernet cable link to PC

This is a standard ethernet CAT 5 cross-over cable and a 5 m cable is supplied as part of the UCC T5 kit. Lengths up to a maximum of

20 metres can be used.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

13

Page 14

General wiring standards

To achieve reliable operation of the UCC T5 and the CMM's host computer, the following points should be observed:

All signal cables MUST be screened and all cable screens must be connected electrically to the metal shells of the cable connectors

It is recommended that cable screens should only be connected to the protective earth (via the connector shell) of the UCC T5 and

SPA3

To avoid earth loops, cable screens should not be directly attached to the CMM's protective earth

The protective grounding must be continuous between the controller and all other equipment in the installation

All cable connectors should be secured to the UCC T5 and SPA3 by the connector jack screws

NOTE: The UCC T5 and SPA3 electronic zero volt rails are connected to their respective ground planes at star points within the

UCC T5, the SPA3 and also to the protective ground of the ac supply.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

14

Page 15

Reset button

The rear panel reset button has two different functions. The function depends on the operational state of the controller.

1. Pressing and releasing the reset button within fifteen seconds of switching on the unit will force the controller into IP configuration state.

2. Pressing and releasing the reset button after fifteen seconds of switching on the unit will cause the unit to restart.

To enter IP configuration state when the unit is already running the control software, press and release the reset button twice.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

15

Page 16

System connection

Earth bonding scheme

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

16

Page 17

PH20 interconnection diagram

Key Description Key Description

1 PH20 orange head cable 4 MCU connection

2 CAT 5 300 mm cable (supplied) 5 CAT 5 ethernet cable (5 m cross-over cable supplied)

3 16 / 0.2 mm earth connection 6 Power supply (supplied)

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

17

Page 18

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

18

Page 19

Cable connections

The cable connection to the head uses a standard 15-way high-density D connector. The cable should be connected and terminated as

detailed below. It is mandatory that the Renishaw universal machine cable is used.

Various lengths of cable are available and include pre-crimped options for ease of installation.

The following image shows the pin numbers for each connector end view of the Renishaw universal machine cable.

15-way HDD socket pin number (quill) Function Core colour 15-way D plug pin number (controller)

11 Comms D+ Green 1

2 0 V Black 2

1 Comms U+ Orange 3

7 0 V White 4

13 Motor B0 Blue 5

3 +20 V Red 6

4 Motor A2 Grey 7

10 Motor A0 Pink 8

9 0 V Inner screen * 9

12 Comms D- Green / black 10

6 Comms U- Orange / black 11

8 +20 V Clear 12

14 Motor B1 Violet 13

15 Motor B2 Yellow 14

5 Motor A1 Brown 15

Shell Outer screen Shell

* NOTE: In pre-crimped cables this will be yellow / green.

Ensure that the inner screen is not shorted to the outer screen at either end of the cable. A short can be prevented by using a small

piece of heatshrink or other suitable method.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

19

Page 20

Preparation of Renishaw universal machine cable for quill mounted systems

Preparation of Renishaw universal machine cable for shank mounted systems

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

20

Page 21

Temperature compensation connector

Pin number Channel Pin number Channel

1 Channel 1 input 20 Channel 1 return

2 Channel 2 input 21 Channel 2 return

3 Channel 3 input 22 Channel 3 return

4 Channel 4 input 23 Channel 4 return

5 Channel 5 input 24 Channel 5 return

6 Channel 6 input 25 Channel 6 return

7 Channel 7 input 26 Channel 7 return

8 Channel 8 input 27 Channel 8 return

9 Channel 9 input 28 Channel 9 return

10 Channel 10 input 29 Channel 10 return

11 Channel 11 input 30 Channel 11 return

12 Channel 12 input 31 Channel 12 return

13 Channel 13 input 32 Channel 13 return

14 Channel 14 input 33 Channel 14 return

15 Channel 15 input 34 Channel 15 return

16 Channel 16 input 35 Channel 16 return

17 Reserved 36 Reserved

18 Reserved 37 Reserved

19 Reserved Shell GND

The thermistors for each channel connects between the CH input and CH return numbers. The return signals are NOT zero volts and MUST

NOT be connected to any zero volt signal, GND or screen.

NOTE: For more information regarding the set up and usage of axis and work piece sensors, please read the temperature

compensation page of this installation guide.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

21

Page 22

Connecting the UCC T5 to the host PC

Hardware connection

The host PC must have a dedicated ethernet connection to the UCC T5. It is recommended that this is not a USB plug-in adapter

because of the reduction in speed these devices normally produce.

If the host PC is connected to a network, it is necessary to install additional hardware to allow a dedicated connection for UCC T5

communication. For details on how to install additional hardware on the host PC, please refer to the manufacturer user's guide.

The UCC T5 is capable of using 1 Gbps ethernet (with appropriate cable). .

A 5 m ethernet cable is provided for this link as part of the UCC T5 kit. The cable included is a Cat 5E, cross-over type. Other lengths may

be used, but the maximum length is determined by the generic specification for ethernet connections which are sufficient for any CMM

installation.

It is recommended that a shielded cross-over cable is used if there is a likelihood of EMC disruption due to the environment or location of

the routed cable.

It is recommended that the cross-over cable is labelled to avoid being mistaken for a non cross-over cable.

Software installation

UCCsuite 4.7 or newer software must be installed on the host PC prior to connection of the UCC T5. The UCC software suite can be

downloaded from the Renishaw website. After the software has been installed, run UCCassist-2 to set up and configure the CMM

controller.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

22

Page 23

Temperature compensation

NOTE: Thermal compensation is activated and setup through UCCassist-2.

Axis sensors

Axis sensors are required to monitor and compensate for any temperature changes within the CMM's scale. The axis sensor is housed in

apottedringterminalwithaØ3.7mmholewhichcanbescrewedorgluedinpositionusingathermallyconductiveglue.Theaxis

sensors are supplied with a 200 mm cable (attached) with a male JST connector fitted to the end. The mating part of the connector is

supplied as part of the axis sensor kit.

Workpiece sensors

Workpiece sensors are required to monitor and compensate for any temperature changes of the workpiece material. They can be

magneticallymountedorclampedtotheworkpiece.ThesensorsarehousedinaØ20mmaluminiumbodywithapolyacetalsleeve.The

sensors should always be handled by the polyacetal sleeve in order to reduce any thermal effects. The sensors are supplied with a cable

length of 2000 mm and have a LEMO connector fitted. The mating part of the connector is supplied as part of the workpiece sensor kit in

either panel mount or in-line form.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

23

Page 24

Pin allocation

With the red dot on the LEMO pointing upwards:

‘PairA'Topleftpinandbottomleftpin

‘PairB'Toprightandbottomright

NOTE: Ensurethesensorisconnectedtothecontrollerwithonepinfrom‘pairA'andonepinfrom‘pairB'.

Sensor resistance checks

A resistance check test is recommended:

During system installation once all sensor cabling has been completed

After every hardware change to the system (e.g. sensor, cable or switch change)

Every six months, after the system has been commissioned, to check for any sensor failure or cabling issues

Resistance check procedure

RegulatethetemperatureoftheCMMroomtoaconstanttemperaturebetween16°Cand28°C

Allow the CMM to stabilise thermally for a minimum of one hour

Measure the sensor resistance from the 37-way D-type socket that the sensors are wired into. This is the resistance that the UCC

measures (cable plus sensor resistance).

Allworkpieceandaxissensorresistancemeasurementsshouldbewithinthisrange;8.4kΩ<R<15.7kΩ

Best practise for using the thermal compensation system

Ensure the CMM is not subjected to unnecessary changes in temperature (fans blowing, close to radiator, in direct sunlight or any other

powerful radiant sources)

Excessive humidity should be avoided

Use the system as close as possible to the calibrated temperature

Renishaw recommends that workpiece and axis sensors are verified at six month intervals

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

24

Page 25

Workpiece sensor

Ensure the workpiece sensor is in full contact with the workpiece

Aim to position the workpiece sensor in the middle of the workpiece or near where the measurement is taking place

Electrically ground workpiece prior to using the thermal effect compensation system to avoid electrostatic discharge (ESD) through the

workpiece sensor

Use multiple sensors for large workpieces

Handle the workpiece sensor by the white sleeve if possible or wait for five minutes once the sensor is in position before proceeding to

take a measurement

Keep the workpiece sensor cabling away from moving sections of the CMM

NOTE: It is not recommended to run axis thermal compensation without workpiece compensation (where axes and workpiece are at

the same temperature) as it is unlikely that reliable results will be obtained.

Axis sensors

Ensure the sensors are mounted as close as possible to the axis scales

It is recommended to have at least two sensors per axis to account for temperature gradient effects

On large or high specification CMMs, use more than three sensors per axis

Thermally conductive glue should be used when gluing axis sensors to an axis

All axis sensor cabling must be tightly secured to the axis body to prevent it getting trapped during moves

System accuracy and calibration

TheTECsystemcanbeusedwithoutcalibration.Thesystemaccuracyis±0.2°C.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

25

Page 26

Testing and verification

The machine manufacturer or the installer of the UCC T5 is responsible for ensuring that the following testing and verification is performed

to the appropriate standard:

Verification that the electrical equipment is in compliance with the technical documentation

Continuity testing of the protective bonding circuit

Insulation resistance tests

Functional tests, particularly those related to safety and safeguarding

NOTE: Itisstronglyrecommendedthatanymeasuringequipmentisregularlycheckedforaccuracy.Aninitial‘passoff'testshould

be performed prior to normal use.

System performance

Advisory

It is recommended that periodic metrology tests are performed in order to identify any faults in subsystems e.g. air bearings, structure,

cables software etc.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

26

Page 27

Troubleshooting

UCC T5 visual diagnostics

A visual indication of the system status is provided by a multicoloured LED on the front panel. The LED provides assistance in diagnosing

system faults.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

27

Page 28

LED Description

No LED No power to unit.

Continuous blue Unit has overheated.

Continuous red Issue with comms link. Reboot unit and configure IP.

Continuous green Normal operation.

Slow green flash Unit waiting for download.

Slow blue flash Unit waiting for download.

Slow red and blue flash Reboot the unit.

Slow blue and green

flash

An excess of 48 V is being supplied. Use correct power supply and reboot.

Slow green and red

flashes

Scale issue, reboot unit.

Fast blue flash Contact your nearest Renshaw support office.

Fast red flash IP configuration mode.

Fast green flash Comms lost to PC. Resync unit.

One grouped red flash Contact you nearest Renishaw support office.

One grouped blue flash Power supply has begun supplying excess power. Replace power supply

and reboot.

Two grouped red flash Reboot the unit.

Two grouped blue flash An excess of 48 V is being supplied. Use correct power supply and reboot.

Three grouped red

flashes

Contact you nearest Renishaw support office.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

28

Page 29

Fatal faults

Situations can occur that make it inadvisable or dangerous to continue using the CMM servo system. These are known in this document

and UCCassist-2 as fatal faults. A list of fatal faults are shown below and will be indicated through the user's software (for example

UCCserver);

A report of the emergency stop switch being active

Air pressure is too low

Crash switch operated, if fitted

A scale reading failure

An indicated overspeed (calculated from the rate of change of position)

Outer limit switch active

NOTE: Other faults not classed as fatal can prevent the CMM's operation.

Motors will not engage / re-engage

Symptoms

Eithertheservodriveswillnotengagewhenthecontrollerhasbeensentthe‘engage'command,orthedriveshavedisengaged

automatically and will not re-engage.

Possible causes (or reported causes)

After the unit is switched on and before the system is allowed to engage, it must be configured for motion (i.e. the machine, servo and

move parameters must be sent to the controller).

Any of the 'fatal faults' will prevent the system from engaging. In addition, the following will disengage the servo motors;

A reported failure from a servo power amplifier (amplifier feedback signal)

The absence of the feedback signal from the motor contactor

The following list can also inhibit drive engagement or re-engagement

The probe being deflected

Any outer limit switch being operated or a soft limit exceeded

Tests / cures

UCCassist-2 can be used for further help with this by displaying the system status, the status bytes and signals.

Theamplifierandmotorcontactorfeedbacksignalscanalsobeexaminedusingthe‘inputsignals'windowinUCCassist2.

NOTE: A scale error will cause the UCC T5 to enter an error state which is not recoverable within a metrology application

environment. If a scale error occurs it will be necessary to reinitialise the installation due to the possibility of lost scale counts

and metrology being affected.

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

29

Page 30

Maintenance

WARNING: Maintenance should only be carried out after the machine has been isolated from the electrical supply, compressed air

supply or other energy sources in accordance with the machine manufacturer's instructions.

Periodically check that all mounting screws and electrical connectors are securely tightened. Electrical safety checks should include

inspecting the mains cable for damage and the safety of the connections. Periodical safety checks should also include the function of the

emergency stop system, including operation of all switches integrated into the system. After operating the emergency stop system, the

servo amplifier system should be checked to ensure servo power can be engaged.

Remove dust from the external surfaces with a clean dry cloth as the unit is not sealed against liquid.

Filter replacement

UCC T5 has a positive, internal air flow for cooling purposes. This system has a replaceable filter to protect it from the ingress of dust. The

machine operator should check the condition of this filter on a regular basis. It is recommended that this filter is removed and checked /

replaced as necessary during the machine installer or retrofitter's regular maintenance routine.

The following procedure is recommended when replacing the air filter:

Remove power from the controller

Remove the 19 inch rack mounting brackets (if fitted) by removing the two fixing screws (not shown)

Pull the head of both the filter retaining clips away from the unit so they disengage (1)

Pull away the external filter cover (2)

Remove the filter material from the filter recess (3)

Replace the filter using the reverse of the method given above (the replacement filter part number is A-5518-0011)

UCC T5 PH20 CMM controller installation guide

www.renishaw.com

Issued 01 2018

30

Page 31

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

www.renishaw.com/cmmsupport

Issued 01 2018

Loading...

Loading...