Page 1

UCC2 universal CMM controller

Installation guide

H-1000-5223-04-B

EXTENDED WARRANTY

Now available for this product.

Contact your vendor.

www.renishaw.com/ew

Page 2

© 2004 - 2008 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means, without the prior

written permission of Renishaw.

The publication of material within this document does not imply freedom from

the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE

THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are

registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are trade names,

service marks, trademarks, or registered trademarks of their respective owners.

Renishaw part no: H-1000-5223-04-B

Issued: 06 2008

Page 3

UCC2

Installation guide

Page 4

2 FCC

FCC

Information to user (FCC section 15.105)

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

installation manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case you will be required to correct the

interference at your expense.

Information to user (FCC section 15.21)

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or

authorised representative could void the user’s authority to operate the equipment.

EC declaration of conformity

The UCC2 has been manufactured in conformity with the following standards:

BS EN 61326:1998 Electrical equipment for measurement, control and laboratory use – EMC

requirements.

Immunity to Annex A - industrial locations.

Emissions to class A (non-domestic) limits.

BS EN 61010-1:2001 Safety requirements or electrical equipment for measurement, control and

laboratory use.

Part 1: General requirements.

and that it complies with the requirements of the following EC Directives (as amended):

89/336/EEC - Electromagnetic compatibility (EMC)

73/23/EEC - Low voltage

Page 5

Care of equipment 3

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise measurements

and must therefore be treated with care.

Changes to Renishaw products

Renishaw reserves the right to improve, change or modify its hardware or software without incurring any

obligations to make changes to Renishaw equipment previously sold.

Warranty

Renishaw plc warrants its equipment for a limited period (as set out in our Standard Terms and Conditions

of Sale) provided that it is installed exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or cabling)

is to be used or substituted. Failure to comply with this will invalidate the Renishaw warranty.

Claims under warranty must be made from authorised service centres only, which may be advised by the

supplier or distributor.

Machine safety

WARNING: Switching off or isolating the UCC2 may NOT prevent unexpected machine

!

movement. The user is advised to Isolate the machine from the electricity supply, compressed air

or other energy sources in accordance with the machine manufacturer's instructions before

entering the danger zone or performing any maintenance operations.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

Trademarks

Windows 98, Windows XP, Windows 2000 and Windows NT are registered tradenames of the Microsoft

Corporation.

All trademarks and tradenames are acknowledged.

Page 6

4 References and associated documents

References and associated documents

It is recommended that the following documentation is referenced when installing the UCC2.

Renishaw documents

A full set of documents are supplied on Renishaw UCC software CD. Reference to the following

documents may be needed when installing a UCC2 system:

Document number Title

H-1000-5057 UCC controller programmer’s guide

H-1000-5058 UCC Renicis user’s guide

H-1000-5067 MCU1 installation guide

H-1000-5068 SPA1 installation guide

H-1000-5220 UCC daughtercard installation guide

H-1000-5222 UCC command set

H-1000-5227 SPA1 tuning guide

H-1000-5234 SPA2 installation guide

H-1000-5107 SPAlite user’s guide

External documents

National and international standards including the following may be applicable to the finished machine or

installation: -

EN 292-2:1991 (Safety of machinery - Basic concepts, general principles for design - Part 2: Technical

principles and specifications.

EN (IEC) 60204-1:1997 (Safety of machinery - Electrical equipment of machines - Part 1: General

requirements).

Page 7

Safety 5

Safety

Electrical requirements

The UCC1 is powered from the a.c. mains supply via an IEC 320 connector. The operating voltages of the

unit are as follows:

100 - 120 V ac and 220 - 240 V ac –15%, +10% 50/60 Hz ±5% 120 W maximum

This equipment must be connected to a protective earth conductor via a three core mains (line) cable. The

mains plug shall be inserted only into a socket outlet provided with a protective earth contact. Do not use

an extension cable without a protective conductor.

An earth stud is provided to allow bonding of the CMM’s metal parts to the protective earth.

CAUTION: Any interruption of the protective conductor may make the equipment dangerous.

!

Make sure that the grounding requirements are strictly observed.

Environmental requirements

The following environmental conditions comply with (or exceed) BS EN 61010-1:1993

Indoor use

Altitude

Operating temperature

Storage temperature

Relative humidity

Transient overvoltages

Pollution degree

NOTE: If a higher IP rating is required, an additional external enclosure will be required to house the

UCC2. This enclosure must facilitate an airflow to allow the internal temperature to maintain the ambient

within the operating temperature range.

IP30 (no protection against water)*

up to 2000 m

0 °C to +50 °C

-10 °C to +70 °C

80% maximum (non-condensing) for temperatures

up to +31 °C

Linear decrease to 50% at +40 °C

Installation category II

2

Page 8

6

This page intentionally left blank

Page 9

Contents 7

Contents

1 Introduction.......................................................................................................................................12

1.1 Overview ................................................................................................................................12

1.2 Literature ................................................................................................................................13

1.3 CMM host computer...............................................................................................................13

1.4 Installation software ...............................................................................................................14

1.4.1 Renicis ....................................................................................................................14

1.4.2 UCCassist™ ...........................................................................................................14

1.4.3 IP configurer ...........................................................................................................14

1.4.4 Licence manager ....................................................................................................14

1.5 Items supplied ........................................................................................................................15

1.5.1 UCC2 kits................................................................................................................15

1.5.2 UCC2 upgrade........................................................................................................15

1.5.3 UCC2 system accessories......................................................................................15

2 Description of the UCC2...................................................................................................................17

2.1 Motherboard...........................................................................................................................17

2.2 TP200 interface......................................................................................................................18

2.2.1 Differences between the PI 200 and the UCC2 interface .......................................18

2.2.2 Connectors .............................................................................................................18

2.3 SP25M and SP600 interface..................................................................................................18

2.3.1 Connectors .............................................................................................................18

2.4 Power supply unit...................................................................................................................19

2.4.1 Input........................................................................................................................19

2.4.2 Output .....................................................................................................................19

3 Connecting the UCC2 to the host PC...............................................................................................20

3.1 Hardware connection .............................................................................................................20

3.2 Software installation ...............................................................................................................20

3.3 Configuration of IP addresses................................................................................................21

3.3.1 IP addressing..........................................................................................................21

3.3.2 Setting the IP address of the PC ............................................................................22

3.3.3 Setting the IP address of the UCC2........................................................................24

3.3.4 Changing the IP address of the UCC2 ...................................................................27

3.3.5 Establishing a new UCC2-PC pairing .....................................................................27

3.4 Downloading ..........................................................................................................................27

Page 10

8 Contents

4 Connecting the UCC2 to a CMM..................................................................................................... 28

4.1 The controller’s 24 V supply .................................................................................................. 30

4.2 Motor engagement via SPA connector.................................................................................. 30

4.2.1 Amplifier enabling .................................................................................................. 31

4.2.2 Contactor energising.............................................................................................. 31

4.3 Motor command signals ........................................................................................................ 32

4.4 Motor command polarity........................................................................................................ 32

4.5 Brakes ................................................................................................................................... 32

4.6 Air solenoid............................................................................................................................ 33

4.7 Switched outputs ................................................................................................................... 33

4.8 Switched inputs ..................................................................................................................... 33

4.8.1 Limit switches......................................................................................................... 33

4.8.2 Amplifier OK and contactor feedback .................................................................... 33

4.8.3 Fatal fault ............................................................................................................... 34

4.8.4 Declutched mode ................................................................................................... 34

4.8.5 Uncommitted inputs ............................................................................................... 34

5 Connectors and signals................................................................................................................... 35

5.1 Overview ............................................................................................................................... 35

5.2 Ethernet connection .............................................................................................................. 35

5.3 CMM readhead input connections......................................................................................... 35

5.3.1 CMM readhead interface circuit ............................................................................. 37

5.3.2 Adjusting readhead supply voltage ........................................................................ 38

5.4 SPA2 connector A and B....................................................................................................... 38

5.5 Aux comms............................................................................................................................ 38

5.6 MCU connector ..................................................................................................................... 39

5.7 SCR200 connector ................................................................................................................39

5.8 PICS connector ..................................................................................................................... 40

5.9 Scanning probe connector .................................................................................................... 40

5.10 Servo power amplifier connector........................................................................................... 41

Page 11

Contents 9

5.10.1 +24 V dc..................................................................................................................42

5.10.2 Contactor ................................................................................................................42

5.10.3 ESTOP_C ...............................................................................................................42

5.10.4 Enable amps ...........................................................................................................42

5.10.5 ESTOP_A and ESTOP_B.......................................................................................42

5.10.6 Axis command signals ............................................................................................42

5.10.7 Command common ................................................................................................42

5.10.8 Reserved ................................................................................................................42

5.10.9 Contactor feedback.................................................................................................43

5.10.10 AMPs OK ................................................................................................................43

5.10.11 ESTOP tripped........................................................................................................43

5.10.12 0 V (24 V return) .....................................................................................................43

5.11 Machine I/O connector ...........................................................................................................44

5.11.1 +24 V DC ................................................................................................................45

5.11.2 UCC2 general purpose outputs ..............................................................................46

5.11.3 UCC2 general purpose inputs ................................................................................46

5.11.4 Amplifier OK input ...................................................................................................47

5.11.5 CMM declutch .........................................................................................................47

5.11.6 ESTOP tripped........................................................................................................47

5.11.7 Air pressure switch .................................................................................................47

5.11.8 Crash switch ...........................................................................................................47

5.11.9 Contactor feedback.................................................................................................48

5.11.10 Limit switches .........................................................................................................48

5.11.11 24 V return ..............................................................................................................48

5.12 Reset button...........................................................................................................................48

5.13 Daughtercard slots .................................................................................................................49

5.14 PCI interface slot....................................................................................................................49

6 Installation of the UCC2 components...............................................................................................50

6.1 General wiring standards .......................................................................................................50

6.1.1 Preparations ...........................................................................................................51

6.2 Installation of daughtercards ..................................................................................................51

6.3 Connecting UCC2 cables to and from CMM ..........................................................................51

6.4 Connecting the UCC2 mains supply ......................................................................................52

7 Mounting the UCC2..........................................................................................................................53

7.1 Stand alone mounting ............................................................................................................53

7.2 Mounting in a 19” rack............................................................................................................53

Page 12

10 Contents

8 Renishaw license key manager system .......................................................................................... 54

8.1 Using the Renishaw license key manager ............................................................................ 54

8.2 Ordering extra functionality/upgrading .................................................................................. 55

8.3 Obtaining the key .................................................................................................................. 55

8.4 Applying the key .................................................................................................................... 55

8.5 Demonstration mode ............................................................................................................. 55

8.6 Repairing upgraded systems................................................................................................. 56

8.7 Available functionality............................................................................................................ 56

8.7.1 Triggering............................................................................................................... 56

8.7.2 Scan 3.................................................................................................................... 56

8.7.3 I++DME.................................................................................................................. 57

8.7.4 Error reporting........................................................................................................ 57

9 UCC2 troubleshooting ..................................................................................................................... 58

9.1 Front panel LED displays ...................................................................................................... 58

9.1.1 UCC2 power not switched ON ............................................................................... 58

9.1.2 UCC2 power switched ON ..................................................................................... 58

9.1.3 Initialisation/test ..................................................................................................... 59

9.1.4 System file downloading ........................................................................................ 59

9.1.5 Servo active LED ................................................................................................... 59

9.1.6 Probe seated LED.................................................................................................. 59

9.2 Probe head LED configuration .............................................................................................. 60

9.3 Fault finding........................................................................................................................... 60

9.3.1 Fatal faults ............................................................................................................. 60

9.3.2 Motors will not engage/re-engage.......................................................................... 61

9.3.3 Poor positioning accuracy...................................................................................... 62

9.3.4 Controller will not respond to host PC.................................................................... 63

9.3.5 Motor stalling.......................................................................................................... 66

9.3.6 Machine overspeed report ..................................................................................... 66

9.3.7 Scale reading (‘grating’) failures ............................................................................ 67

9.3.8 Timing out during moves or scans ......................................................................... 69

9.3.9 Cannot start a move............................................................................................... 69

9.3.10 Cannot start a scan ................................................................................................ 70

Page 13

Contents 11

10 Specifications ...................................................................................................................................71

10.1 Physical specification .............................................................................................................71

10.2 Cable lengths .........................................................................................................................71

10.2.1 UCC2 to CMM measuring scale readhead .............................................................71

10.2.2 UCC2 to CMM servo power amplifier input ............................................................71

10.2.3 Ethernet cable link to PC ........................................................................................71

10.3 Scale readhead signal speed.................................................................................................72

10.4 Electrical power requirements................................................................................................72

10.4.1 Controller output supplies .......................................................................................72

11 System interconnections ..................................................................................................................73

11.1 Probing system interconnection .............................................................................................73

11.1.1 2 wire touch-trigger probe system ..........................................................................73

11.1.2 PH10 probe head and 2 wire touch-trigger probe system ......................................73

11.1.3 PH10 probe head and ‘multiwire’ probe system .....................................................74

11.1.4 PH10 probe head, ‘multiwire’ probe system and ACR1..........................................74

11.1.5 PH10 probe head and ‘multiwire’ probe system using external PHC10-2 ..............75

11.2 Servo amplifier interconnection..............................................................................................75

11.2.1 UCC2 and SPA1 .....................................................................................................75

11.2.2 UCC2 and SPAlite ..................................................................................................76

11.2.3 UCC2 and SPA2.....................................................................................................77

12 Fitting a UCC2 into a UCC1 installation ...........................................................................................78

12.1 Machine I/O connection .........................................................................................................78

12.2 Servo power amplifier connection ..........................................................................................78

12.3 Software compatibility ............................................................................................................79

12.3.1 UCC software release.............................................................................................79

12.4 Machine ini file .......................................................................................................................79

12.5 Installed PC............................................................................................................................79

13 Maintenance.....................................................................................................................................80

14 Testing and verification.....................................................................................................................81

15 Revision history ................................................................................................................................82

Page 14

12 Introduction

1 Introduction

The purpose of this chapter is to describe the UCC2 (universal CMM controller) and the available options.

1.1 Overview

The UCC2 is a further development in Renishaw’s CMM controller product range. Building on the UCC1

platform introduced over five years ago, the UCC2 offers additional capability and system performance.

The UCC2 further optimises measurement performance through closer probe integration and is suitable

for original equipment and retrofit installations.

With ever tighter tolerances, more complex components and increasing pressures on lead times, the

ability to acquire large volumes of measurement data, both accurately and rapidly, is key to manufacturing

competitiveness. The new UCC2 controller offers advanced adaptive scanning, allowing accurate known

part scanning at velocities limited only by the dynamic performance of the CMM. Speeds of over

500 mm/sec (20 in/sec) can be achieved.

UCC2 offers true multi-sensor integration, giving benefits for original equipment manufacturers (OEMs),

retrofit/re-builders and end-users requiring system upgrades. The controller is supplied configured for

touch-trigger operation and UCCserver™(I++DME) as standard. It can be upgraded to conventional 3axes scanning, Renscan3™, or 5-axis scanning, Renscan5™, by keying in a 16 digit code.

The complete range of Renishaw probe systems is supported; conventional contact, strain-gauge and

analogue scanning sensors, manual and motorised probe heads, probe and stylus changers, and the

latest developments in servo positioning systems. Other optical and video sensors can also be supported.

A key benefit of UCC2 is the simple integration of complex probe systems, for existing systems and future

developments, and is central to Renishaw’s future plans for sensor innovation. Future products will be

easily integrated via plug-in daughtercards, and because the UCC control software is downloaded from

the PC each time the system is switched on, software upgrades for new products are easily integrated.

The UCC2 comprises of a mains-powered controller in a rack-mountable enclosure with a micro-processor

based computer system. It is coupled to the CMM’s host computer by a network link, and to the CMM by

external cable interface connectors.

Page 15

Introduction 13

The UCC2 CMM controller has the capability of:

• Controlling four axes of a CMM (accepting digital readhead signals and generating four axes drive

motor control signals)

• Accepting input signals from emergency stop, air pressure, crash detector, contactor feedback,

amplifier faults and all axis inner and outer travel limit switches

• Generating seven uncommitted general purpose output signals

• Accepting six uncommitted general purpose input signals

• Providing a +24 V supply for use by the CMM switches

• Directly supporting the TP2, TP6, TP20, TP200 touch-trigger probes, also the SP25M and SP600

analogue scanning probes

• Other Renishaw probes can be integrated into the UCC2 system using plug-in daughtercards

• Directly supporting the Renishaw MCU1 joystick

• Directly supporting the Renishaw SPA2, SPAlite or SPA1 servo power amplifiers

1.2 Literature

A number of other manuals are available to assist with the installation of the UCC2 system and are

included on the UCC software CD ROM. Some of the more relevant ones are listed below:

Part number Title Description

H-1000-5068 SPA1 installation guide System connection details

H-1000-5234 SPA2 installation guide System connection details

H-1000-5058 Renicis installation guide System set-up and testing

H-1000-5057 UCC1 programmers guide Programming

H-1000-5222 Command set Programming

H-1000-5107 SPAlite user’s guide Operation

1.3 CMM host computer

For the installation of a UCC2 controller, the CMM’s host computer must use Windows NT (service pack 6

or later), Windows 2000 or Windows XP Pro as an operating system; a CD-ROM drive, and a hard disc

drive. The storage requirements of the UCC system are less than 500 Mbytes. The processor speed and

RAM requirements are not excessive, if the PC is supporting the operating system and application

software, it will almost certainly support the UCC controller operation.

The PC must have one free dedicated network (Ethernet) connection port available for the UCC2

communication. It is recommended that this NOT a USB plug-in adapter because of the reduction in

speed of operation these devices normally produce.

Page 16

14 Introduction

1.4 Installation software

1.4.1 Renicis

The Renishaw Renicis program is a utility to assist the engineer to install, commission and maintain a

CMM system based on the UCC2 controller.

It also has features which assist in the development of a software interface between any existing CMM

application program and the UCC2.

Please refer to the Renicis user’s guide (Renishaw part number H-1000-5058) for more information on this

product.

1.4.2 UCCassist™

The UCCassist software suite complements the Renicis software package offering the following additional

capabilities of:

• Basic machine system diagnostics

• Compatibility with Renishaw’s machine checking gauge, enabling the user to complete frequent

volumetric accuracy tests to ensure the CMM is running within the specified operational tolerances

• Automated CMM error mapping routines, when used in conjunction with the Renishaw ML10 laser

system

1.4.3 IP configurer

The IP configurer software utility is a stand-alone tool for checking and setting the IP address compatibility

of the UCC2 controller and application PC.

1.4.4 Licence manager

This is a stand-alone software utility which is used to check and update the licence for controller

functionality.

Page 17

Introduction 15

1.5 Items supplied

The part numbers of the UCC2 kits and upgrades are:

1.5.1 UCC2 kits

A-5121-0001 UCC2 (touch-trigger enabled)

Comprising:

• UCC2 controller

• 5 metre Ethernet (cross-over) cable

• CD ROM containing:-

• System literature

• UCC operating software

• COM dlls

• Renicis installation and diagnostic program

• IP configurer software

• Link logger

1.5.2 UCC2 upgrade

A-5121-0005 Renscan3™ scanning functionality upgrade

A-5121-0007 Renscan5™ scanning functionality upgrade

1.5.3 UCC2 system accessories

1.5.3.1 SPA2

The SPA2 servo power amplifier is designed specifically for use with the UCC2 product and offers a

comprehensive solution for most CMM installations.

1.5.3.2 SPAlite

The SPAlite servo power amplifier is designed specifically for use with the UCC2 product and offers a

solution for CMMs typically <1 m³.

1.5.3.3 MCU1

The MCU1 is a comprehensive joystick solution designed for use with the UCC range of controllers.

Page 18

16 Introduction

1.5.3.4 Daughtercards

Various daughtercards are available for integration with the UCC2 as listed below. The daughtercards,

which plug into sockets on the motherboard, are available as required by the CMM application.

The UCC daughtercard installation guide (Renishaw part number H-1000-5220) details all of these cards,

please refer to it for installation details.

• Joystick interface daughtercard; for use with OEM’s own analogue joysticks

• PH10 probe head (PHC1050) daughtercard

• PHS1 probe head daughtercard

• Additional axis daughtercard; configurable for use as, a rotary table interface, an additional (twin)

scale input, or a dual axis drive interface

• PICS/RS232 daughtercard; required to interface older (not integrated) product interfaces

• Temperature sensor daughtercard

• SP80 daughtercard

Page 19

Description of the UCC2 17

2 Description of the UCC2

2.1 Motherboard

The motherboard comprises:

• Central processor unit (CPU)

• System memory, I/O and interconnection logic

• On-board connectors for optional plug-in daughter-boards

• Rear panel connectors for the external interface cables to and from the CMM

• Rear panel network connection for the two-way communication link to the CMM host computer

• Readhead circuitry for CMM digital measuring scales

• Axis servo control circuits

• Status indicating LEDs

• Control electronics for probes and peripheral devices attached to the CMM

LEDs visible through the front panel of the UCC2 enclosure indicate the operational status of the UCC2.

Sub-circuits on the motherboard control the following interfaces through connectors on the rear panel of

the enclosure:

• Ethernet data link to the CMM host computer

• X, Y, Z and additional axis data input from the CMM readheads

• A communication loop (SPA-A and SPA-B) to the SPA2 servo power amplifier

• A communications port (CH1), reserved for use on future products

• An MCU1 joystick interface

• Supplies and control signals for an SCR200 stylus changer rack

• Connections for the TP200 and TP20 range of touch-trigger probes

• Power to and input signals from the Renishaw SP25M or SP600 analogue probes

• Signal outputs to the axis drive motors servo amplifiers of the CMM

• I/O connections to limit switches, air pressure and other digital inputs and outputs

• A reset switch

Page 20

18 Description of the UCC2

2.2 TP200 interface

The UCC2 motherboard incorporates the circuitry and software necessary to interface with a Renishaw

TP200 probe, and operate the associated SCR200 stylus changer rack. The UCC2 implementation of the

TP200 interface has the same automatic recognition of, and support for, conventional touch-trigger probes

such as TP20, TP1, TP2 and TP6.

2.2.1 Differences between the PI 200 and the UCC2 interface

• Most of the PI 200 configuration options (dil switches) have been replaced by UCC command

number 426, PIB200 configure interface

• Internal connections have been implemented to permit connection of the required PICS signals to

the PHC1050 daughtercard or an external probe head controller (via a PICs/RS232 daughtercard)

• The probe reset function is now activated by command number 427, PIB200 reset probe

• The interface status LEDs on the front of the PI 200, are replaced by the command number 428,

PIB200 read status. This provides interface status information from the UCC2

• No audio ‘beep’ signal is generated within the UCC2. If fitted, the joystick unit beeper can be used

for this function

2.2.2 Connectors

The 9-pin D-socket labelled ‘trigger probe‘ will accept TP200 or conventional probe signals and direct

them to the PI 200 interface on the UCC2 motherboard.

A 6-pin miniature DIN socket labelled ‘SCR200‘ is used for connection of a SCR200 rack.

2.3 SP25M and SP600 interface

The UCC2 motherboard incorporates the circuitry necessary to interface with the Renishaw SP25M and

SP600 probes.

The UCC2s implementation of the SP25M and SP600 interface has automatic recognition of, and support

for, Renishaw touch-trigger probes TP200 and TP20.

2.3.1 Connectors

The 15-pin D-socket labelled ‘analogue probe‘ will accept probe signals from Renishaw’s SP25, SP600,

TP200 and standard Renishaw touch-trigger probes, and direct them to the appropriate interface on the

UCC2 motherboard.

Page 21

Description of the UCC2 19

2.4 Power supply unit

The UCC2 controller has a shielded switched-mode power supply unit (PSU) which is mounted inside the

UCC2 enclosure.

The PSU supplies the UCC2 controller and can also supply power to the specified probes and readheads,

and the status switches of the CMM.

2.4.1 Input

The power supply has a universal a.c. input circuit. See safety statement at the start of this document.

2.4.2 Output

The UCC2 PSU provides protected low voltage d.c. supplies of +15 V, +5 V and –15 V for external

devices such as scale readheads, the SP600 probe etc.

These supplies share a common 0 V return which is connected at a star point within the UCC2 to the

protective ground of the AC supply and the UCC2 case.

The UCC2 also provides a +24 Vdc supply available for use by the CMM to power the status switches etc.

The return line of this 24 Vdc supply (which should be wired separately from the returns of the +15 V, +5 V

and –15 V supplies) is also connected to the a.c. supply protective ground at a star point within the UCC2.

Page 22

20 Connecting the UCC2 to a CMM

3 Connecting the UCC2 to the host PC

The following sections detail how to connect and configure the communication link between the UCC2 and

the host PC that is running either the UCC utilities or metrology application software.

3.1 Hardware connection

The host PC must have a dedicated Ethernet connection to the UCC2. It is recommended that this NOT a

USB plug-in adapter because of the reduction in speed of operation these devices normally produce.

If the host PC is also to be connected to a network, it is necessary to install additional hardware within the

host PC to permit a dedicated connection to be available for UCC2 communication. For details on how to

install additional hardware into the host PC, please refer to the PC’s installation / users guide.

The UCC2 is capable of using both 10 and 100 Mbps Ethernet, the selection being determined by the

capability of the network adapter to which it is connected. We recommend that you use a 100 Mbps

network adaptor.

A 5 m Ethernet cable is provided for this link as part of the UCC2 kit and is a Cat 5e, cross-over type.

Other lengths may be used, the maximum being is governed by the generic specification for Ethernet

connections (i.e. a hundred metres), which is sufficient for any CMM installation. It must be a cross-over

type for a single installation.

If you are concerned about EMC disruption due to your environment, or the routing of the cable, then the

use a shielded cross-over cable is recommended.

We suggest that you label your cross-over cable as a cross-over cable as it looks identical to a normal,

not-crossed-over, cable.

3.2 Software installation

The UCC software must be installed on the host PC, prior to connection of the UCC2.

The UCC software disc (A-1333-0080), version 6.0 and later, supports UCC2 installations.

After the software has been installed, one of the utility programs available is “IP Configurer”; which is used

to give the UCC2 an IP address, and establishes the pairing of the PC and the UCC2.

Another software utility that is installed is “Renicis”. It is important that for UCC2 installations you use

Renicis version 6.0, provided on the UCC software version 6.0 CD-ROM, or later versions.

Page 23

Connecting the UCC2 to a CMM 21

3.3 Configuration of IP addresses

This section describes the steps needed to connect your UCC2 to the host PC and configure the Ethernet

communication link.

NOTE: The examples used in this section are for Windows XP Professional and will vary for other

operating systems.

3.3.1 IP addressing

You have to decide what IP address to give to the UCC2. The key to this is to choose an IP address for

the UCC2 and an IP address for the PC’s network adaptor that are of the same network. What does this

mean? Well, firstly we must introduce sets of networks called network classes which are defined by their

IP address ranges:

class A 1.0.0.1 – 126.255.255.254

class B 128.0.0.1 – 191.255.255.254

class C 192.0.0.1 – 223.255.255.254

For class A networks, a network is defined by the first number.

For class B networks, a network is defined by the first two numbers.

For class C networks, a network is defined by the first three numbers.

If you choose to use IP addresses that belong to the class A network class, then you must be sure that the

first numbers are identical, e.g. 10.0.0.1 and 10.123.4.17. If you choose to use IP addresses that belong to

the class B network class, then you must be sure that the first two numbers are identical, e.g. 155.23.0.1

and 155.23.86.207. If you choose to use IP addresses that belong to the class C network class, then you

must be sure that the first three numbers are identical, e.g. 192.168.32.1 and 192.168.32.2.

A rule that always works is to choose ‘adjacent’ IP addresses from the ranges given above (by adjacent

we mean that the last numbers differ only by 1, e.g. 172.16.40.1 and 172.16.40.2).

NOTE: The last number must not be 0 or 255.

Page 24

22 Connecting the UCC2 to a CMM

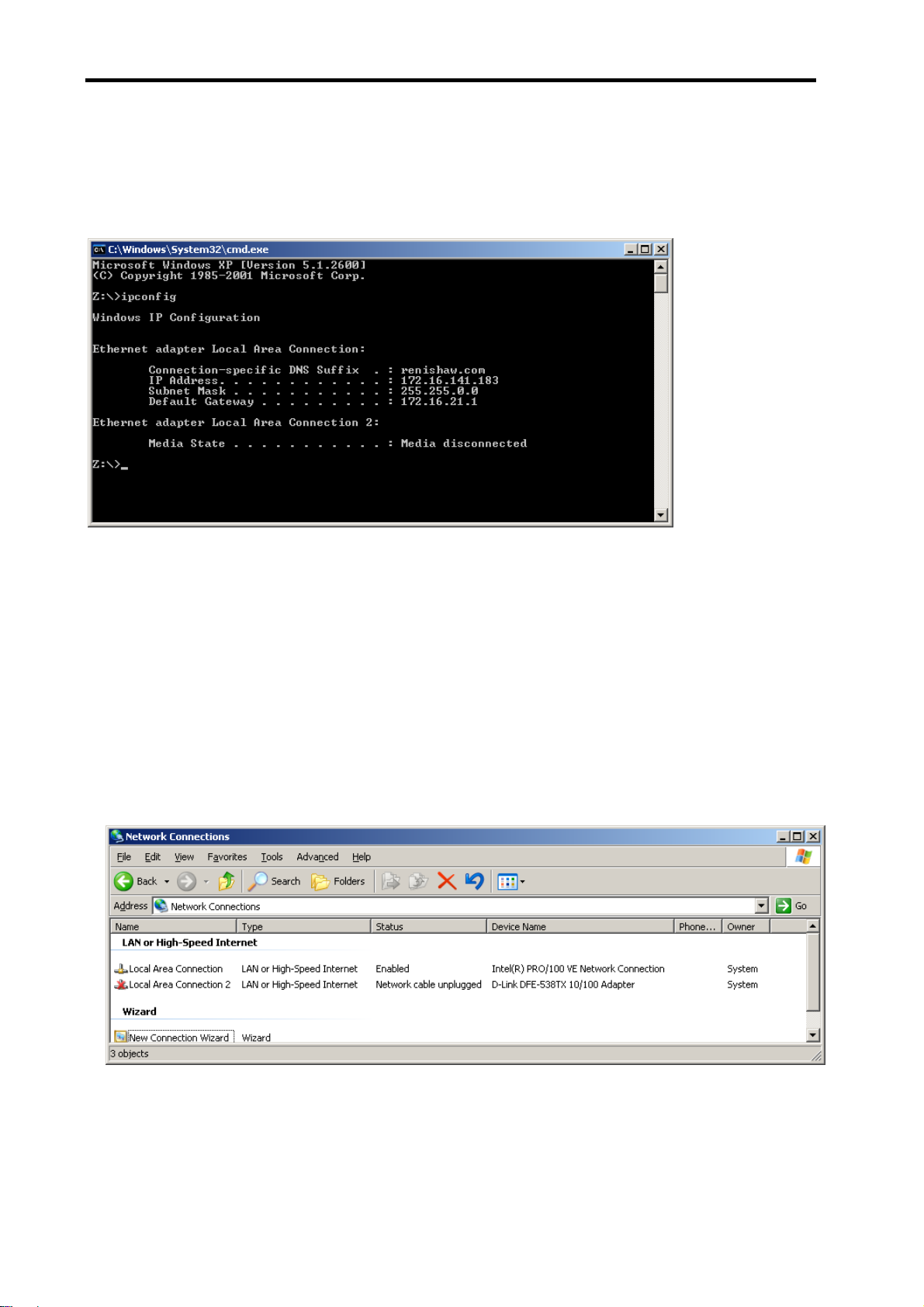

If there is more than one network connection in your PC, choose a network class for the UCC2-PC

connection that is not currently in use to keep the connections clearly separate. To find out which IP

address, and hence which network class your other network interfaces use, type “ipconfig” at a command

prompt. Its output will look similar to this:

Here the UCC2-PC network interface had its cable removed, so shows up as “Media disconnected”. The

other connection was the corporate one, and is seen to be a class B network. Hence the UCC2-PC

network is best chosen to be a class A or a class C one.

3.3.2 Setting the IP address of the PC

The network adapter in the PC to which the UCC2 is connected needs an IP address. See section 3.3.1,

“IP addressing” for a discussion of the choice. How to set the address in the PC varies with each version

of Windows, but the basic idea is the same. Here is the process using Windows XP Professional. You

need administrator rights in order to perform this operation.

a) Select Start → Settings → Control Panel → Network Connections to give:

Page 25

Connecting the UCC2 to a CMM 23

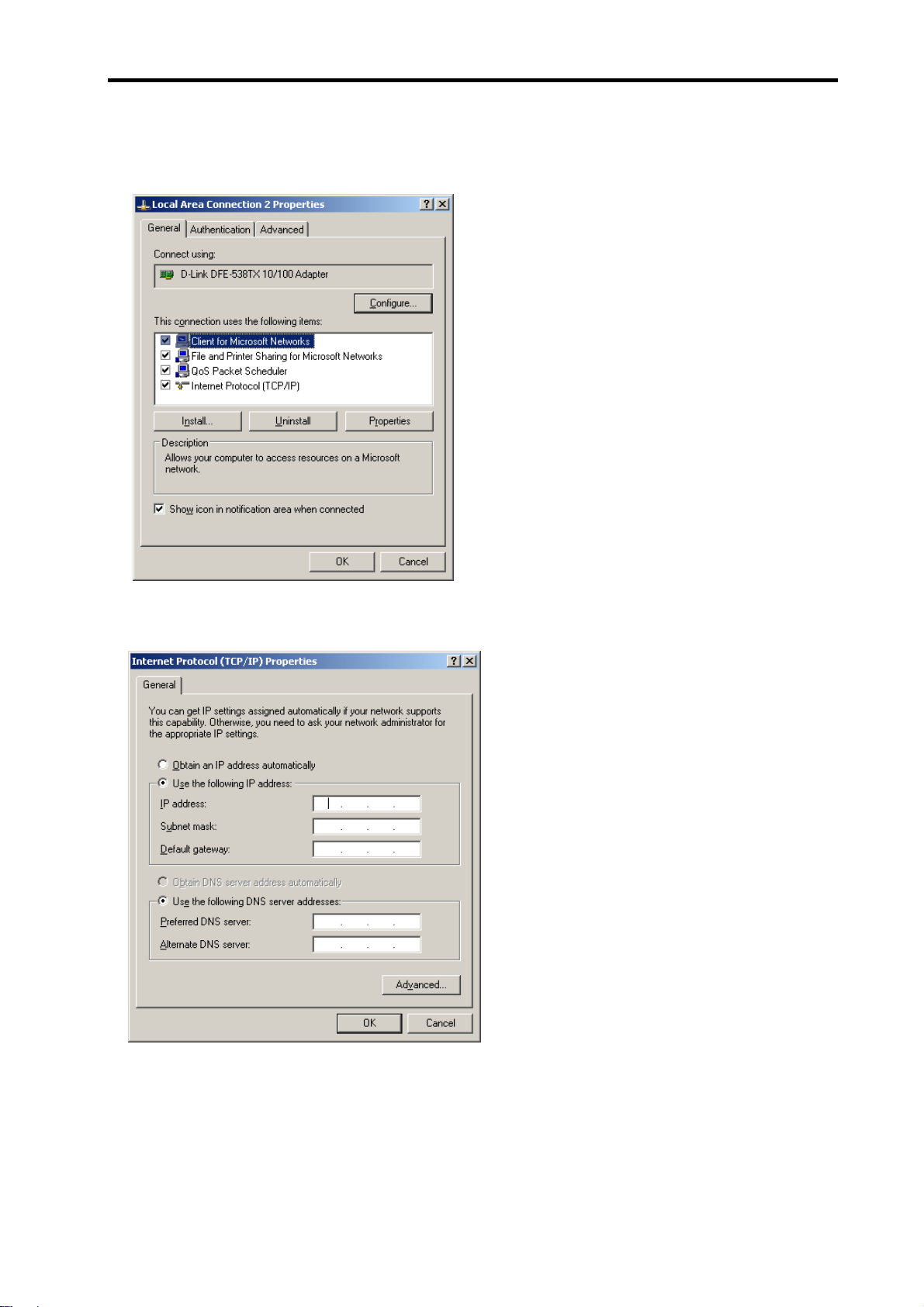

b) Right-click the appropriate Local Area Connection and select Properties from the resultant popup menu

box to give:

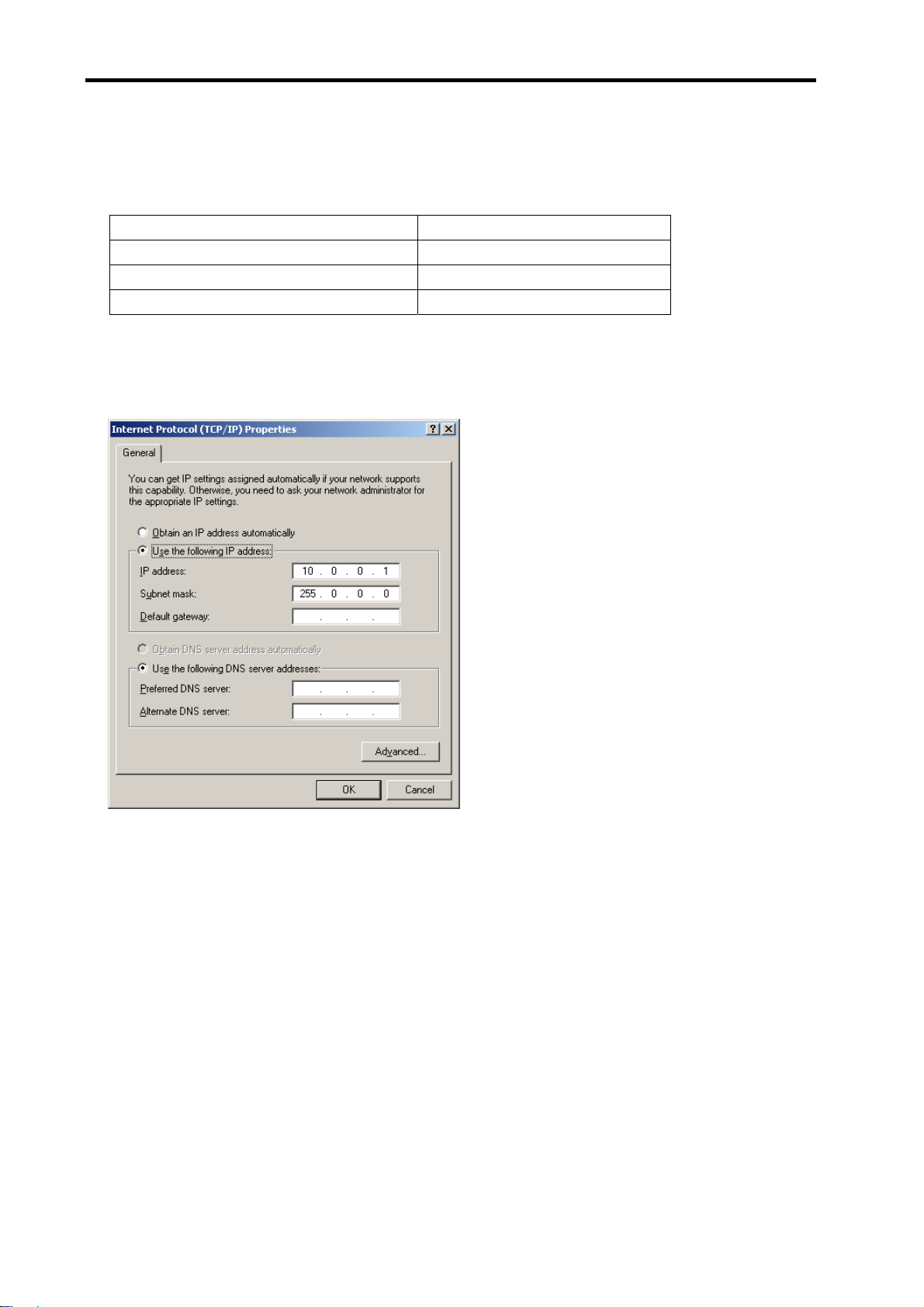

c) Select ‘Internet Protocol (TCP/IP)’ and click Properties to give:

Page 26

24 Connecting the UCC2 to a CMM

d) If not already selected select ‘Use the following IP address’ and type in the IP address that you want to

use for the PC end of the comms link. Now click in the Subnet mask field. On Windows XP the Subnet

mask will be filled in for you. If you have to fill it in for yourself, here are the values:

Class of network IP address belongs to Subnet mask to use

A 255.0.0.0

B 255.255.0.0

C 255.255.255.0

Leave the Default gateway field blank.

Example:

e) Click OK and then OK again. Whether or not this setting has taken effect depends on the version of

Windows that you are running. On earlier versions you will need to reboot the PC. To be absolutely

sure, reboot your PC anyway.

3.3.3 Setting the IP address of the UCC2

The UCC2 is not intended to be used on a corporate network. It is extremely important that this setting of

the IP address of the UCC2 is on a dedicated connection. It is also important that the connection is not

“firewalled” at the PC end. You need administrator rights in order to perform this operation.

When it is first installed the UCC2 does not have any IP address. Turn the UCC2 on and wait for it to boot

up. It will enter its IP configuration state, shown by the Error LED flashing rapidly. (Please be patient; this

will take about 15 seconds.)

Now start the UCC IP configuration software on the PC.

Page 27

Connecting the UCC2 to a CMM 25

a) Start → UCC Software → IP Configurer

b) Click on the drop-down icon and select the IP address of the network adapter into which the UCC2 is

plugged. (This should be the one on which you set the IP address of in section 3.3.2.)

Page 28

26 Connecting the UCC2 to a CMM

c) You are now told that the UCC2 does not have an IP address:

d) Fill in the desired IP address – the IP Configuration software has given you a head start by filling in the

network part of the address appropriate for the network adapter you have selected. (See section 3.3.1,

“IP addressing” for a discussion of the choice and of IP addresses in general.)

e) Click on ‘Configure PC and UCC pair’. If all is well this will result in a confirmatory dialogue box:

Page 29

Connecting the UCC2 to a CMM 27

The UCC2 will now have moved into its ‘waiting for download’ state – shown by the error LED flashing

slowly.

You have established the UCC2-PC system using the IP addresses of section 3.3.2 and this section.

NOTE: Whenever you change one of the items in this pairing, e.g. by connecting a different UCC2 to the

PC, you must re-run the UCC2 IP configuration software to establish the new UCC2-PC system.

3.3.4 Changing the IP address of the UCC2

If the UCC2 has an IP address, after booting up it skips its IP configuration state and proceeds into waiting

for a download, shown by the error LED flashing slowly. There are two ways to force the UCC2 into its IP

configuration state:-

a) During the 15 second power up phase, before the error LED comes on, press and release the Reset

button on the rear of the UCC2. At the end of the power up phase the error LED will flash rapidly

indicating it is in the IP configuration state.

b) If the UCC2 has already powered up with the error light flashing slowly, i.e. about once per second, or

even if the control software has been downloaded, the reset switch will need to be pressed twice. The

first time to reset the controller then a second time, within 15 seconds, to force the IP configuration

state.

The UCC2 is now in its IP configuration state, and the UCC2 IP configuration software can be run on the

PC, selecting the appropriate network adapter required. The current IP address of the UCC2 will be

displayed. Type in the new one and click on ‘Configure PC and UCC pair’.

3.3.5 Establishing a new UCC2-PC pairing

If you connect a different UCC2 to your PC, or a different PC to your UCC2, or even if you modify the

network settings on the PC, you must ensure that they are a matched pair. To do this, go through the

procedure in section 3.3.2, even if you do not wish to change the IP address of the UCC2. (If the IP

address is already suitable, then you do not need to re-type it.) Clicking on ‘Configure PC and UCC pair’

will establish the new pairing.

3.4 Downloading

The name of the downloadable file is contrler.uca. UCC1 and other controller downloadables will not work

on a UCC2. Remember to change the name in any configuration settings appropriate for your front-end.

Your UCC2 system is now established.

Page 30

28 Connecting the UCC2 to a CMM

4 Connecting the UCC2 to a CMM

The purpose of this chapter is to describe the various connections available within the UCC2 design to

enable connection to a CMM.

This section reviews each UCC2 connection and gives comments on the preferred methods and available

alternatives.

Figure 1 - Suggested wiring to the servo power amplifier connection

Page 31

Connecting the UCC2 to a CMM 29

Figure 2 - Suggested wiring to the servo power amplifier connection

Page 32

30 Connecting the UCC2 to a CMM

4.1 The controller’s 24 V supply

This supply is available at both the servo power amplifier connector and the machine’s I/O connector for

use by the CMM signalling circuits. It has a relatively low current rating, see section 5.11, and is thus not

suitable for heavy loads.

Please use semiconductors or relays to interface with high power loads or to those which need electrical

isolation.

All inputs and outputs (excepting the optically isolated amp control signals) are referenced to this supply.

It is not a floating supply, the 24 V return line is connected to the controller’s chassis and to the mains

supply protective ground at a star point within the controller.

If there are any interconnections between this supply and any of the CMM’s supplies, there is a possibility

that an additional path to ground may be created.

A separate supply of similar voltage may be used for signalling purposes in place of the controller’s 24 V

supply but its negative rail must be connected to the controller’s 24 V return line.

4.2 Motor engagement via SPA connector

The controller will begin to engage the servo motors when instructed to do so by the host computer, if all

the operating functions are in a safe or acceptable condition.

Listed below are possible causes for the motor engagement to fail:

• The system has not yet been configured for motion (i.e. the machine, servo and move parameters

have not been sent to the controller)

• A fatal fault has been detected (refer to Renicis users guide, Renishaw part number H-1000-5058)

• The emergency stop system has been activated

• A PICS ‘stop’ signal is detected within the system

• The amplifier OK signal not asserted

• An open limit switch

• A present or previously present scale reading fault

The process is in two stages, amplifier enabling and contactor energising, with protective delays between

each stage.

Page 33

Connecting the UCC2 to a CMM 31

4.2.1 Amplifier enabling

The ‘amps OK’ signal produced by the amplifier control circuits is an indication to the UCC2 controller that

the servo power amplifiers are not faulty.

The controller will first ensure that all its motor demand signals are zero and will then try to enable the

power amplifiers by asserting the ‘enable amps‘ signal (servo power amplifier connector pin 4 or 5, figure

1). See chapter 6 for its electrical ratings.

This “enable amps”, signal will be held on for 0.1 second to allow the ‘amps OK’ signal, from the servo

power amplifier, to become valid. If this signal does not become valid (i.e. pin 19 of the machine I/O

connector is not pulled low) the controller will abandon the engagement process. If no error is detected

then the controller will wait for a further period of 1 second before beginning the next stage, to allow the

amplifiers to settle after any initial transients.

Figure 1 (section 4) is an example of the recommended circuits that can be used to drive the power

amplifier enable inputs and to generate the amps OK signal shown. The circuits that are used in the

installation will vary depending on the amplifiers’ requirements but must pull the ‘amps OK’ input (pin 19)

down if all amplifiers are operating correctly.

If the user wishes to signal amplifier failures individually to the main computer, it is recommended that the

uncommitted user inputs (machine I/O connector, figure 2) are used for this purpose.

If the installer of the CMM makes the decision that the amplifier enabling function is not needed, the

‘Enable amps (active low)’ signal could be connected directly to the ‘amps OK’ input signal. This will

provide immediate feedback to the controller during the amplifier enabling process and permit the next

stage to begin.

NOTE: This method is not recommended.

4.2.2 Contactor energising

After establishing that the amplifiers are working correctly, the controller will take the “contactor” signal (pin

2 of the servo power amplifier connector) low, this should be used to signal the servo power amplifier to

apply power to the motors. The controller will keep this output signal low for 0.2 of a second during which

it expects the ‘contactor feedback’ input (machine I/O connector pin 24) to be pulled low to indicate that

the motors are now powered.

If the ‘contactor feedback’ signal is not received in time, the contactor (pin 2 ) and the amp control signals

(pins 4+5) are turned off and the motor engagement process is stopped.

If the ‘contactor feedback’ signal is received within this 0.2 second window, the controller keeps all motor

commands at zero for another 1.0 second before allowing the servo system to begin operating. This is

intended to give further protection against sudden machine movements when engaging the motors.

Page 34

32 Connecting the UCC2 to a CMM

If the installer of the CMM makes the decision that the contactor energising function is not needed, the

‘contactor’ signal (pin 2) can be joined to the ‘contactor feedback’ input signal (pin 22). This will provide

immediate feedback to the controller during the contactor energising process and permit the next stage to

begin.

NOTE: This method is not recommended.

4.3 Motor command signals

The UCC2 controller generates complementary motor velocity command signals for each axis (X axis =

pins 8+9, Y axis = pins 10+11, Z axis = pins 12+13, 4th axis = pins 14+15).

Each motor velocity signal is capable of a swing of +/-10 Vs centred on a zero velocity command of 0 Vs.

A motor “command common” connection is provided to define this 0 V level (servo power amplifier

connector, pin 16, figure 1).

The motor command common signal is also connected to the 24 V supply return, the controller chassis

and the mains supply protective ground at a star point within the controller. Care may be required in its

application.

The controller’s setting up process (detailed in the Renicis users guide H-1000-5058) will help the user to

set his power amplifier gains such that the maximum command signal (+/- 10 V) will produce 125% of the

required maximum machine speed.

If complementary signals are not required, either of the motor command signals may be used as a single

ended input, referred to the motor “command common” line.

Each motor command signal has a series resistor of 1k ohm to protect the controller from inadvertent

damage and this will reduce the drive signal to the power amplifiers if their inputs are of low impedance.

The ‘RENICIS‘ setting up program provided with the controller will compensate for this automatically.

4.4 Motor command polarity

For each axis, the motor command +ve pin will go negative with respect to the command common line to

produce a positive change of position.

The motor command -ve pin will go positive at the same time.

4.5 Brakes

These outputs have not yet been activated. Do not make connections to these outputs.

Page 35

Connecting the UCC2 to a CMM 33

4.6 Air solenoid

This output has not yet been activated. Do not make connections to this output.

4.7 Switched outputs

The UCC2 has the following uncommitted switched outputs, please refer to section 5.11.2 for details :

There are 7 uncommitted outputs available on the UCC2 I/O connector, pins 6 to 12 are allocated to be

outputs 0 to 6 consecutively. The UCC does not directly control these outputs, it merely acts as a postbox. These outputs are controlled from the application software package via command 318 “Write to

controller port”.

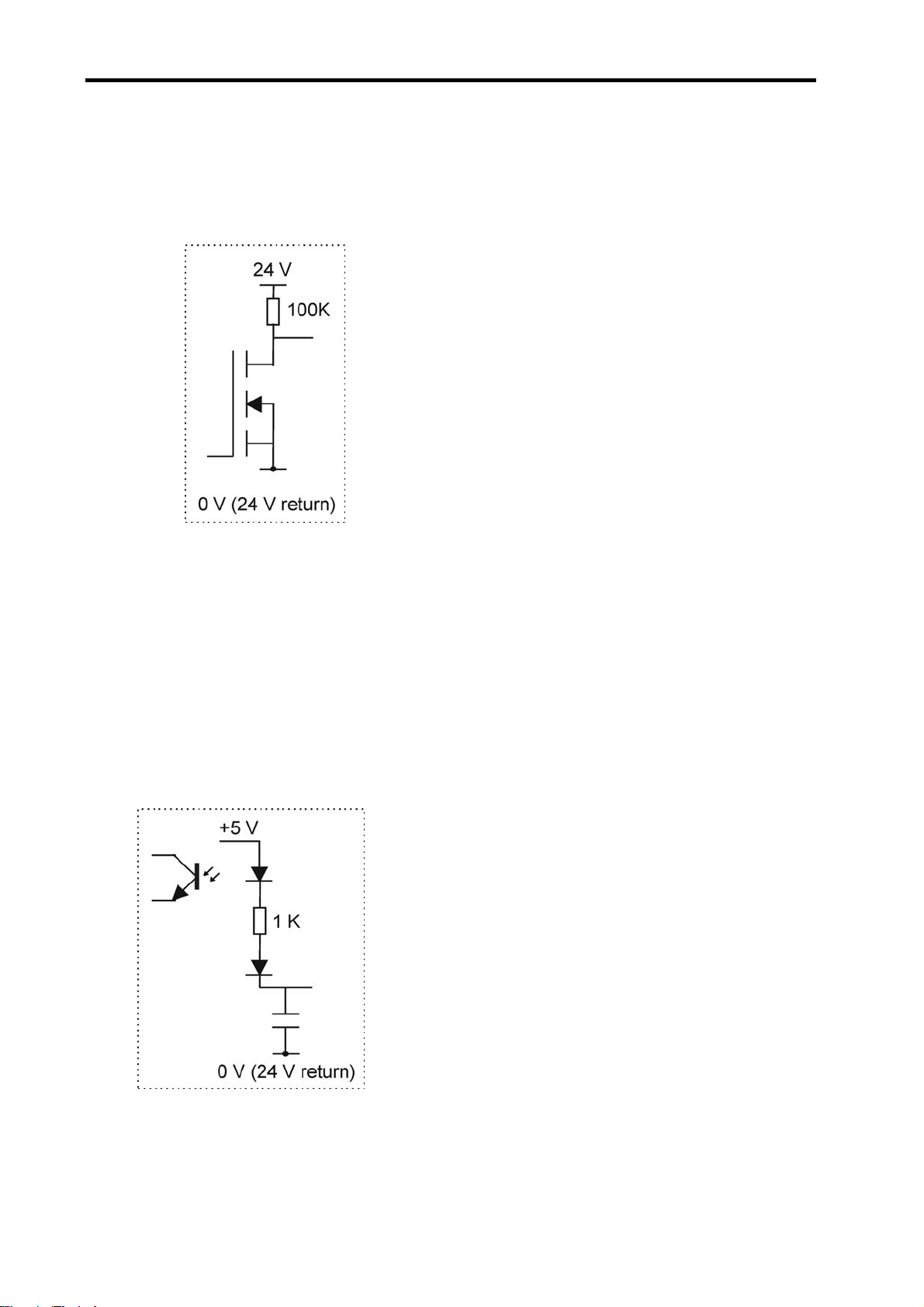

These switched outputs are pulled up to the 24 V rail by a 20 k ohm resistor when inactive, and will be

pulled down to the 24 V return line via an NPN transistor when activated. There is an excess voltage

protective diode fitted internally to the controller.

The outputs can be activated by a command from the main computer to the controller. If not being used

they should be left open circuit.

4.8 Switched inputs

The UCC2 has the following controller switch inputs, please refer to section 5.11.3 for details:

There are 6 uncommitted inputs available on the UCC2 I/O connector, pins 13 to 18 are allocated to be

inputs 0 to 5 consecutively. The UCC does not directly read these inputs, it merely acts as a post-box.

These inputs are read by the application software package via command 279 “Read from controller ports”.

The controller provides 29 inputs of this type. See chapter 5 for their electrical ratings.

Each input is connected to an LED fed from the +24 V rail, and is activated by being pulled down to the

24 V return line. The LED is part of an opto-coupler which is used to give the controller some isolation

from unwanted electrical signals on the input wiring.

4.8.1 Limit switches

Sixteen inputs are allocated to limit switch signals, 8 inner and 8 outer. When a limit switch is not activated

(i.e. the machine is within its working range) these inputs should be connected to the 24 V return line by

the limit switch contacts. If the machine installation does not require the connection of the limit switches

the signals must be connected to the 24 V return line.

NOTE: Limit switches should be installed such that they will not be damaged in the event of overtravel.

Where necessary for safety related functions, they should be of the direct (or positive) operating type to

IEC 60947-5-1).

4.8.2 Amplifier OK and contactor feedback

The ‘amplifier OK’ and the ‘contactor feedback’ inputs have been discussed in sections 4.2.1 and 4.2.2.

Page 36

34 Connecting the UCC2 to a CMM

4.8.3 Fatal fault

Three ‘Fatal Fault’ inputs are provided: emergency stop, machine air pressure low and a ‘Crash Switch’

input. This last is intended for use with a sensing mechanism which detects an unintended contact

between the machine’s moving and fixed components. The controller monitors these inputs and will stop

the motors if one or more input goes open circuit or high. If not required these inputs should be connected

to the 24 V return line.

NOTE: The ‘emergency stop’ input is not a primary safety device, although the controller will stop the

motors as far as it can. Its main use is to allow the controller to inform the main computer, and hence the

operator, of the ‘emergency stop’ switch actuation. In addition it will prevent motor re-engagement if the

‘emergency stop’ switch is still activated. Where an electromechanical controlled emergency stop is

required, to IEC/ EN60204-1 category 0, it must be separately provided and external to the UCC2.

4.8.4 Declutched mode

The ‘CMM in declutched mode’ input is intended to tell the controller that the driving motors are

mechanically disconnected from the machine, and that the machine may be moved by some other means,

e.g. by hand. In this state, the motor commands will be kept at zero velocity until the machine clutches are

re-engaged, at which time the controller will resume servo control at the new machine position. For normal

servo operation, this input should be pulled down to the 24 V return line. If this function is not required, the

input should be connected to the 24 V return line.

4.8.5 Uncommitted inputs

The remaining six inputs are uncommitted and may be used as required. These signals are not used by

the controller and are simply passed to the main computer, on request. If not required these inputs should

be connected to the 24 V return line.

Page 37

Connectors and signals 35

5 Connectors and signals

The purpose of this chapter is to describe in detail the pin-outs of the connectors mounted at the rear of

the UCC2 controller and to show examples of relevant circuit diagrams for the input and output circuits.

5.1 Overview

The connectors on the rear panel of the UCC2 controller enclosure are shown below:

The pin-out of each connector, and its purpose, is described in the following sections.

5.2 Ethernet connection

This is a standard RJ45 connector providing the Ethernet connection between the UCC2 and the PC

hosting the application software. Connection between these two units must be made using a standard,

Cat 5e, cross-over type Ethernet cable.

5.3 CMM readhead input connections

The X, Y, Z and “4th Axis” measuring scale readhead input connectors are high density 15-way ‘D’

sockets.

The X, Y and Z axis scale readheads of the CMM must be connected to the relevant socket on the rear

panel of the UCC2 enclosure.

Similarly the 4th axis scale readhead (dual axis or rotary table capability), if required, must be connected

to the socket (marked 4

Suggestion: Label all readhead connectors to avoid cross connection, if removed and replaced in the

future.

th

axis) on the rear panel of the UCC2 enclosure.

The four CMM readhead sockets are wired to the same pin-out, suitable for direct connection to Renishaw

RGH22 and RGH24 scale readhead wiring.

NOTE: Other manufacturers’ readheads and interpolators may require an external adapter to enable

them to use the Renishaw standard readhead connector wiring. They may also not produce an error signal

to the RS-422 specification.

Page 38

36 Connectors and signals

The UCC2 supplies a servoed 5 V dc power supply for the readheads. See chapters 5.3 and 10.4 for

details.

If standard Renishaw cables are used, the recommended cable sizes are 3 m of head cable and 15 m of

extension cable, or an equivalent combination. That the head cable is 5 times the resistance of the

extension cable, e.g. 4 m of head cable and 10 m of extension cable.

Even with the servoed 5 V supply it is still important that the cable resistance is kept to less than 2 ohms.

CAUTION: The connection of the cabling should be such that the CMM’s movements, as reported

!

by the UCC2, are of the correct polarity i.e. machine movement in a positive direction along any

axis should give positive change of position as reported to the host computer by the UCC2

controller. Adjust this, if required, by reversing the inputs of the scale readhead signal (change

over +A with +B and –A with -B).

15

Figure 3 - Readhead connector, view on face of sockets (rear of plugs)

Pin number Function

1 External set up

2 0 V supply from UCC2

3 - Error

4 - Reference mark

5 - B signal

6 - A signal

7 +5 V supply from UCC2

8 +5 V sensing

9 0 V sensing

10 Limit switch P

11 + Error / limit switch Q*

12 + Reference mark

13 + B signal

14 + A signal

15 Inner screen

Shell Screen

10

15

6

11

* The UCC2 is capable of supporting both

single and dual limit-switch RG22

readheads. The electronic circuits can

interface either type without any

intervention but the correct type must be

set in the machine “ini” file. If dual limit

types are fitted pin 11 functions as the

second limit switch. If single types are fitted

then pin 11 becomes the +Error signal.

NOTE: The 0 V supply and the 0 V sensing leads are connected together at the readhead. The +5 V

supply and +5 V sensing leads are similarly connected at the readhead. It is important that all the cable

cores are connected to ensure the voltage drop is compensated for.

Page 39

Connectors and signals 37

5.3.1 CMM readhead interface circuit

The signals from a readhead or interpolator should be to EIA specification RS-422.

Figure 4 - UCC2 input circuit for CMM readhead – scale and reference mark inputs

NOTE: If error inputs are not used or the readhead type is RGH24, tie the +error input to 0 V and the –

error input to +5 V.

Figure 5 - UCC2 input circuit for CMM readhead – limit switch inputs

Figure 6 - UCC2 input circuit for CMM readhead – error input

Page 40

38 Connectors and signals

5.3.2 Adjusting readhead supply voltage

It is strongly recommended that the sense lines are connected to the readhead so that the adjustment of

the supply voltage, to compensate for cable drop, is automatic. However, there are some circumstances

where this is not practical and we have provided a manual method of boosting the supply voltage.

In the .ini file there is a section called ReadHeadPSU which contains three parameters per axis. These

parameters are termination type, enable and voltage.

Termination type – controls the controller readhead circuits to provide either AC termination (0) or DC

termination (1) [recommended].

Enable – This is set to 0 as a default which allows the normal automatic voltage servo to operate. If it is

set to 1, then the readhead supply voltage can be manually set.

Voltage – This is the manual readhead voltage setting. It is only read when the enable is set to 1 and the

allowable range is 5.0 V to 7.5 V.

NOTE: You must ensure that the voltage at the readhead is within the range 5 V ± 5% (i.e. must not

exceed 5.25 V).

5.4 SPA2 connector A and B

This a pair of standard RJ45 connectors that support the high speed communication links to and from the

SPA2 servo power amplifier. See SPA2 installation guide (Renishaw part number H-1000-5234) for

details.

5.5 Aux comms

This connector is reserved for future use, no connections should be made to it.

Page 41

Connectors and signals 39

5.6 MCU connector

This is a 9 pin D plug suitable for direct connection to the MCU1 joystick unit.

Pin number Function

1 Ground

2 RX_B

3 RX_A

2.0H X

5

9

1

6

4 TX_A

5 Reserved

6 +15 V

7 TX_B

8 ESTOP_B

9 ESTOP_A

Shell Screen

Figure 8 – MCU connector. View on face of

socket (rear of plug)

5.7 SCR200 connector

This is a 6 pin miniature DIN socket suitable for direct connection to the SCR200 stylus change rack.

Pin number Function

1 Remote reset

2 Error

3 Inhibit

4 Rack power

5 0 V

6 Not connected

Shell Screen

Figure 9 - SCR connector. View on face of

socket (rear of plug)

Page 42

40 Connectors and signals

5.8 PICS connector

This socket is intended for use with any of the range of Renishaw touch-trigger probes, including the

TP200. The connector is a 9 pin miniature D socket, pinout as follows:

Pin number Function

1 PICS STOP

2.0H X

5

1

2 PICS probe power off (PPOFF)

3 0 V

4 PICS LED anode

5 Probe signal

6 Reserved

7 PICS probe damping (PDAMP)

8 PICS LED off (LEDOFF)

9 Probe common

Shell Screen

9

Figure 10 - PICS connector. View on face of

socket (rear of plug)

6

5.9 Scanning probe connector

The plug on the cable from the analogue probe connects to the 15-way high-density ‘D’ socket on the rear

panel of the UCC2.

This socket is intended for use with the Renishaw TP2, TP6, TP20 and TP200 touch-trigger probes and

the SP25 and SP600 series of analogue scanning probes.

The pin-out of the socket is as follows:

Pin number Function

1 +5 V supply

2 Not connected

3 Probe common

4 B signal

5 C signal

6 +12 V supply

7 -12 V supply

8 Probe identification

9 Not connected

10 Overtravel

11 A signal

12 0 V reference

13 Touch-trigger probe signal

14 Fixed probe head LED cathode

15 Fixed probe head LED anode

Shell Screen

15

10

15

Figure 11 - Scanning probe connector. View on

face of socket (rear of plug)

6

11

Page 43

Connectors and signals 41

5.10 Servo power amplifier connector

The UCC2 has the ability to connect to either a SPA1 or 3

this 25-way D-type socket on its rear panel. A 24 V dc supply is also provided by the UCC2 through this

connector to energise the CMM status switch.

13 1

2.0H X 8.6W

25

Figure 12 - Servo power amplifier connector. View on face of socket (rear of plug)

Pin

number

1 +24 V dc Supply provided for use with CMM status switches 5.10.1

2

3 ESTOP_C ESTOP system - reset signal 5.10.3

4

5

6 ESTOP_A ESTOP signal from MCU1 / Joystick 5.10.5

7 ESTOP_B ESTOP signal from MCU1 / Joystick 5.10.5

8 -X command Differential output to CMM X drive motor 5.10.6

9 X command Differential output to CMM X drive motor 5.10.6

10 -Y command Differential output to CMM Y drive motor 5.10.6

11 Y command Differential output to CMM Y drive motor 5.10.6

12 -Z command Differential output to CMM Z drive motor 5.10.6

13 Z command Differential output to CMM Z drive motor 5.10.6

14 -4th axis command Differential output to CMM 4th axis drive motor 5.10.6

15 4th axis command Differential output to CMM 4th axis drive motor 5.10.6

16 Command common Reference line for power amplifiers 5.10.7

17 Reserved 5.10.8

18 Reserved 5.10.8

19 Reserved 5.10.8

20 Reserved 5.10.8

21

22 Contactor feedback Confirmation of contactor operation 5.10.9

23 Amps OK Confirmation from the servo amplifiers that they are ready 5.10.10

24 ESTOP tripped Indication from the SPA that the ESTOP signal is asserted 5.10.11

25 24 V return Common reference line for supply and contactor signals 5.10.12

Shell Screen

Function Description

Contactor

(active low)

Enable Amps

(active low)

Contactor

(active high)

Enable Amps

(active high)

Output signal to control motor contactor (active low) 5.10.2

Command to SPA to enable amplifiers (active low) 5.10.4

Output signal to control motor contactor (active high) 5.10.2

Command to SPA to enable amplifiers (active high) 5.10.4

rd

party servo power amplifier system through

14

Refer to

section

Page 44

42 Connectors and signals

5.10.1 +24 V dc

+24 V dc supply provided for the use of contactors, relays and other motor control circuits. Current limit

1.0 Amps

5.10.2 Contactor

This command is issued by the UCC2, to the SPA, to engage the motor contactor. This output signal can

drive the contactor directly providing its current consumption is within the output specification. This output

signal is available in both an active low on pin 2 and an active high on pin 5.

5.10.3 ESTOP_C

This is the ESTOP reset line from the servo power amplifier. It is made available to the UCC2 plug in

daughter-card slots for incorporation by products that need to be aware or pass on this signal’s status. It is

part of the “category 2” ESTOP system supported by the UCC2 and SPA2 controller system.

5.10.4 Enable amps

This is a command from the UCC2 to the SPA requesting it to enable its amplifiers. This output signal is

provided as both an active low signal on pin 4 and as an active high signal on pin 21.

5.10.5 ESTOP_A and ESTOP_B

These are the connections from the SPA ESTOP system to the joystick / MCU mounted emergency stop

switch. ESTOP_A is the high end and ESTOP_B is the return. The ESTOP_B signal is also made

available to the UCC2 plug in daughter-card slots for incorporation by products that need to be aware or

pass on this signal’s status. A rotary table is a good example of where it needs to be incorporated as part

of the ESTOP system.

5.10.6 Axis command signals

These outputs (pins 8 to 15) are the velocity demand signals for each axis from the UCC2 to the servo

power amplifiers. They vary over the range +10 V to –10 V.

5.10.7 Command common

An analogue reference zero is available to the servo power amplifiers but this signal is not used by our

SPA1 and SPA2 amplifiers although some third party units do require this reference. It is important that

this is not used as a 0 V return for digital signals because this will inject noise into the velocity demands.

This pin (16) should be left open circuit if not required.

5.10.8 Reserved

These pins (17 to 20) have high-speed serial communication driver / receivers connected to them, they

are intended for future development. It is important that these pins should be left open circuit.

Page 45

Connectors and signals 43

5.10.9 Contactor feedback

This is a confirmation signal from the motor contactor to the UCC2 that is has successfully operated and

the motors are now engaged. This signal was on the I/O connector (pin 24) for the UCC1 and is still

available on that connector on the UCC2 for backwards compatibility reasons.

5.10.10 AMPs OK