Page 1

Installation guide

H-1000-5220-02-B

UCC daughtercards

Page 2

© 2003 - 2006 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in

part, or transferred to any other media or language, by any means,

without the prior written permission of Renishaw.

The publication of material within this document does not imply

freedom from the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of

this document are free from inaccuracies and omissions. However,

Renishaw makes no warranties with respect to the contents of

this document and specifi cally disclaims any implied warranties.

Renishaw reserves the right to make changes to this document

and to the product described herein without obligation to notify any

person of such changes.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo

are registered trademarks of Renishaw plc in the UK and other

countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are

trade names, service marks, trademarks, or registered trademarks

of their respective owners.

Renishaw part no: H-1000-5220-02-B

Issued: 05 2006

Page 3

UCC daughtercard

installation guide

Page 4

2 Care of equipment

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise

measurements and must therefore be treated with care.

Changes to Renishaw products

Renishaw reserves the right to improve, change or modify its hardware or software without

incurring any obligations to make changes to Renishaw equipment previously sold.

Warranty

Renishaw plc warrants its equipment for a limited period (as set out in our Standard Terms and

Conditions of Sale) provided that it is installed exactly as defined in associated Renishaw

documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or

cabling) is to be used or substituted. Failure to comply with this will invalidate the Renishaw

warranty.

Claims under warranty must be made from authorised service centres only, which may be advised

by the supplier or distributor.

Trade marks

Windows 98, Windows XP, Windows 2000 and Windows NT are registered tradenames of the

Microsoft Corporation.

All trademarks and tradenames are acknowledged

References and associated documents

It is recommended that the following documentation is referenced to when installing the UCC.

Renishaw documents

Relevant documentation supplied on Renishaw UCC software CD.

Document number Title

H-1000-5056 UCC1 installation guide

H-1000-5057 UCC controller programmer’s guide

H-1000-5058 UCC Renicis user’s guide

H-1000-5227 UCC servo tuning user’s guide

H-1000-5223 UCC2 installation guide

Page 5

Contents 3

Contents

1 Introduction.............................................................................................................................................. 6

2 Daughtercards ......................................................................................................................................... 7

2.1 Installation in the UCC................................................................................................................... 8

2.2 Removal of a daughtercard ........................................................................................................... 9

3 PHC1050 daughtercard......................................................................................................................... 10

3.1 Introduction.................................................................................................................................. 10

3.2 Connector and pin outs ............................................................................................................... 11

3.2.1 Head connector.............................................................................................................11

3.2.2 HCU connector .............................................................................................................11

3.3 Configuration options .................................................................................................................. 12

3.3.1 Two wire probe configuration........................................................................................12

3.3.2 Multiwire probe configuration ........................................................................................13

3.4 Operating overview ..................................................................................................................... 14

3.4.1 Communication with the PHC1050...............................................................................14

3.4.2 Configuring the PHC1050 board...................................................................................14

3.4.3 Power-up sequence ......................................................................................................15

3.4.4 Probe head operation ...................................................................................................15

4 PICS/RS232 daughtercard .................................................................................................................... 16

4.1 Introduction.................................................................................................................................. 16

4.2 Connector and pin outs ............................................................................................................... 16

4.2.1 PICS A connector .........................................................................................................16

4.2.2 RS232 connectors (9-way D-type plug) ........................................................................17

4.3 Configuration options .................................................................................................................. 18

4.3.1 Connecting an external PHC10 to the UCC..................................................................18

4.3.2 Connecting an ACC2-2 to the UCC ..............................................................................19

4.3.3 RS232 communication cable ........................................................................................20

4.4 Operating overview ..................................................................................................................... 20

4.4.1 PICS A port ...................................................................................................................20

4.4.2 RS232 channel 2 ..........................................................................................................20

4.4.3 RS232 channel 3 ..........................................................................................................21

5 Joystick interface daughtercard (JI card)............................................................................................... 22

5.1 Introduction.................................................................................................................................. 22

5.2 Connector and pin outs ............................................................................................................... 22

5.2.1 Joystick connector ........................................................................................................23

5.2.2 Emergency stop connector ...........................................................................................24

5.3 Configuration options .................................................................................................................. 25

5.3.1 Minimum recommended installation wiring ...................................................................25

5.3.2 Emergency stop signal..................................................................................................26

5.3.3 Analogue input signal....................................................................................................27

5.3.4 input circuit...................................................................................................................27

5.3.5 Binary output circuit ......................................................................................................28

Page 6

4 Contents

5.4 Operating overview...................................................................................................................... 28

5.4.1 Method of operation ..................................................................................................... 28

5.4.2 Initialising the JI card.................................................................................................... 29

5.4.3 Joystick modes.............................................................................................................29

5.4.4 Joystick type selection ................................................................................................. 30

5.4.5 Enable joystick ............................................................................................................. 30

5.4.6 Functionality in DCC mode .......................................................................................... 31

5.4.7 Functionality in joystick mode ...................................................................................... 32

5.4.8 Changing modes.......................................................................................................... 32

5.4.9 Moving and touching.................................................................................................... 32

5.4.10 Recording points ..........................................................................................................33

5.4.11 Probe damping.............................................................................................................33

5.4.12 Joystick orientation....................................................................................................... 34

6 MCU1 daughtercard .............................................................................................................................. 36

6.1 Introduction.................................................................................................................................. 36

6.2 Connector and pin outs ............................................................................................................... 36

6.2.1 MCU connector ............................................................................................................ 37

6.2.2 Emergency stop connector .......................................................................................... 37

6.3 Configuration options................................................................................................................... 38

6.3.1 Emergency stop signal................................................................................................. 38

6.4 Operating overview...................................................................................................................... 38

6.4.1 Method of operation ..................................................................................................... 38

7 SP25M daughtercard............................................................................................................................. 39

7.1 Introduction.................................................................................................................................. 39

7.2 Connectors and pin outs.............................................................................................................. 39

7.2.1 Analogue probe connector........................................................................................... 39

7.3 Operating overview...................................................................................................................... 40

7.3.1 Method of operation ..................................................................................................... 40

8 SP80 daughtercard................................................................................................................................ 41

8.1 Introduction.................................................................................................................................. 41

8.2 Connector and pin outs ............................................................................................................... 41

8.2.1 SP80 connector............................................................................................................ 41

8.3 Operating overview...................................................................................................................... 42

9 Additional I/O daughtercard ................................................................................................................... 43

9.1 Introduction.................................................................................................................................. 43

9.2 Connector and pin outs ............................................................................................................... 43

9.2.1 Additional I/O connector............................................................................................... 43

9.3 Operating overview...................................................................................................................... 44

9.3.1 Software integration ..................................................................................................... 44

9.3.2 Electrical integration.....................................................................................................45

10 Temperature sensor daughtercard ........................................................................................................ 46

10.1 Introduction.................................................................................................................................. 46

10.2 Connector and pin outs ............................................................................................................... 46

Page 7

Contents 5

10.2.1 44-way connector..........................................................................................................47

10.3 Operating overview ..................................................................................................................... 47

10.3.1 Software integration ......................................................................................................48

10.3.2 Electrical integration......................................................................................................49

11 Additional axis daughtercard ................................................................................................................. 50

11.1 Introduction.................................................................................................................................. 50

11.2 Connector and pin outs ............................................................................................................... 50

11.2.1 Scale connector ............................................................................................................51

11.2.2 Table / axis connector...................................................................................................52

11.2.3 Emergency stop connector ...........................................................................................54

11.3 Configuration options .................................................................................................................. 55

11.3.1 Daughtercard channel setting .......................................................................................55

11.3.2 Emergency stop signal..................................................................................................56

12 PHS daughtercard ................................................................................................................................. 57

12.1 Introduction.................................................................................................................................. 57

12.2 Connector and pin outs ............................................................................................................... 57

12.2.1 PHS connector..............................................................................................................57

12.3 Configuration options .................................................................................................................. 58

12.3.1 PHS power PCB settings ..............................................................................................58

12.4 PHS card installation ................................................................................................................... 58

12.4.1 Power connection .........................................................................................................58

12.4.2 PHS control PCB settings .............................................................................................60

13 Revision history ..................................................................................................................................... 61

13.1 What’s new in release 01-A......................................................................................................... 61

13.2 What’s new in release 02-A......................................................................................................... 61

13.3 What’s new in release 02-B......................................................................................................... 61

Page 8

6 Introduction

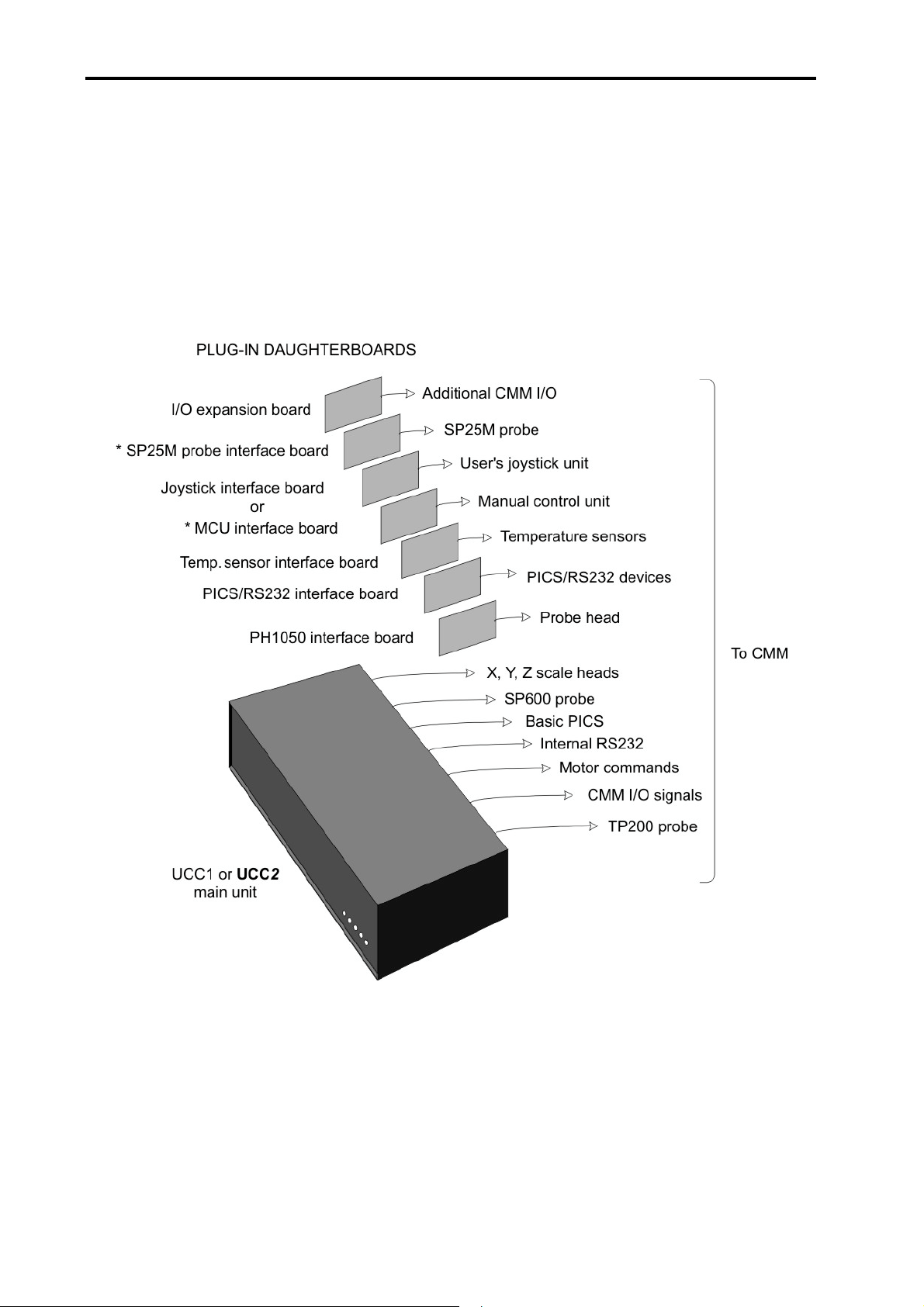

1 Introduction

The purpose of this chapter is to outline the capabilities of the various UCC daughtercards and the

generic installation instructions to fit these cards into the UCC1 or UCC2 units.

There are a range of UCC daughtercards available, each offering additional capabilities to the

standard UCC1 or UCC2 product. For specific details on each card please refer to the respective

section within this installation guide.

* Not compatible with UCC2 system as these cards have been integrated into the UCC2 design

Page 9

Daughtercards 7

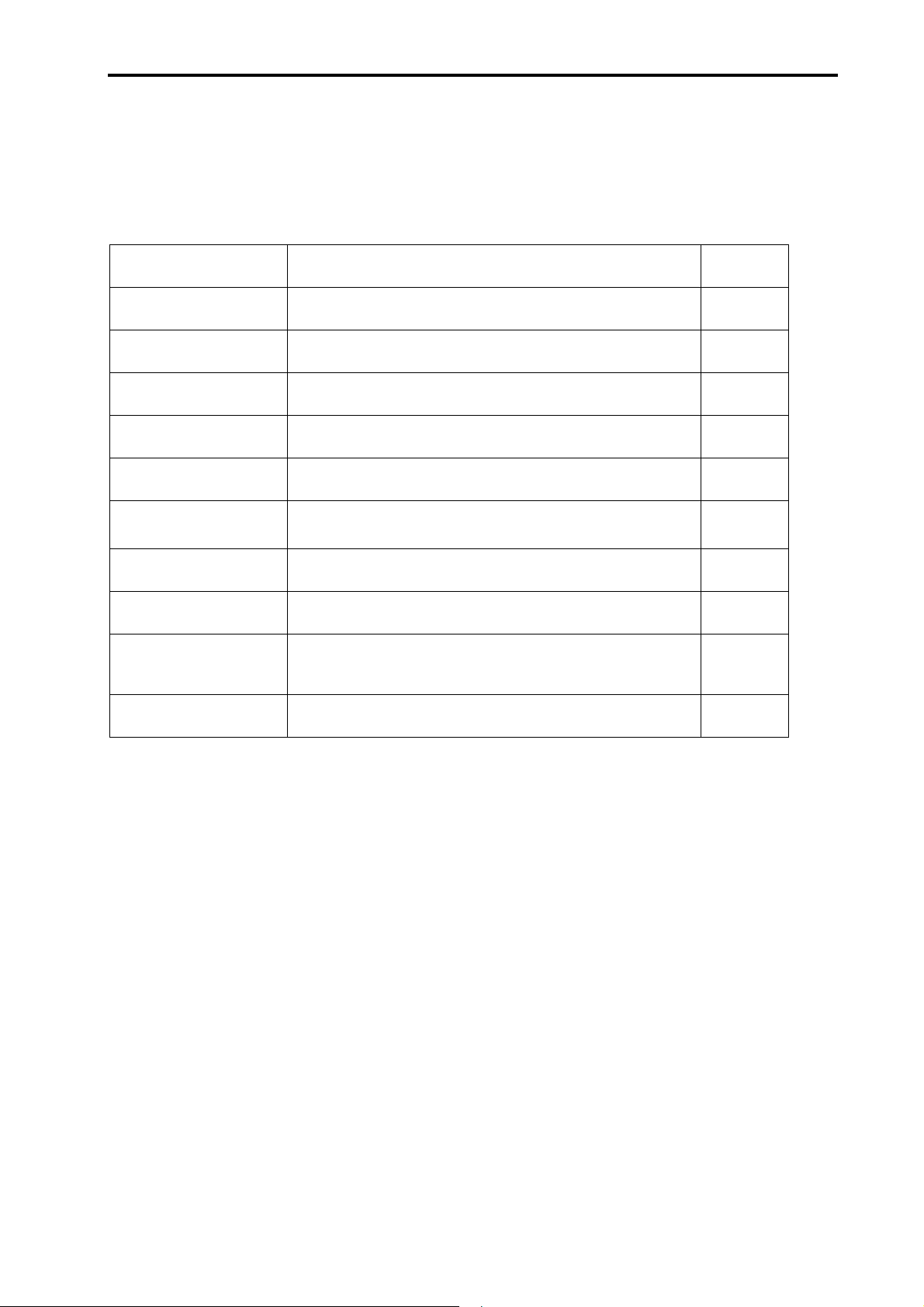

2 Daughtercards

Listed below are the range of UCC1 daughtercards available with a brief explanation of their

capabilities:

Daughtercard Description

PHC1050 Permits connection of a PH10 motorised probe head to

the UCC controller.

PICS/RS232 Adds two RS232 communication ports to the UCC, and

includes a PICS compliant connector.

JI Permits the connection of a third party analogue joystick

to the UCC controller.

MCU1 Permits the connection of the Renishaw MCU1 joystick to

the UCC controller.

SP25M Permits the UCC controller to accept the SP25M probe

signals.

SP80 Permits the UCC controller to accept the SP80 probe

signals.

Additional input/output Increases the number of uncommitted input and output

signals available to the UCC controller.

Temperature sensor Permits the UCC to accept and interface up to 24

temperature sensors.

Additional axis Permits the UCC to control an additional machine axis or

a rotary table. Multiple cards can be installed within a

UCC system.

PHS Permits the PHS probe head to be integrated into the

UCC2 controller.

Refer to

section

3

4

5

6

7

8

9

10

11

12

Page 10

8 Daughtercards

2.1 Installation in the UCC

CAUTION: It is essential that full anti-static precautions are taken before working within

!

the UCC1 or UCC2 controllers enclosure or handling individual boards.

CAUTION: Removing the top panel of the UCC enclosure will give access to the mains

!

driver power supply (PSU). The PSU is further protected by a metal cover. This

protective cover MUST NOT BE REMOVED as it would expose hazardous voltages.

The following procedure is recommended for installing a daughtercard:

1. Remove the ac power supply from the UCC1 or UCC2 and move the unit so you have clear

access to the top and rear of the enclosure, it may be necessary to disconnect some of the

other cables to achieve this.

2. Remove the top panel of the UCC1 or UCC2 enclosure by removing the screws at the top

of the rear panel and the screw located at the top of each side panel, near the front. Retain

the fixing screws.

3. Select a socket on the motherboard to house the daughtercard (all sockets are compatible).

NOTE: Install long daughtercards and daughtercards with appreciable heat dissipation towards

the power supply end of the UCC1 or UCC2.

If the PHS daughtercard is to be installed into the UCC2 it must be fitted into the fourth socket

from the power supply.

4. Remove (and store for possible re-use) the appropriate blanking plate from the rear panel of

the enclosure.

5. Carefully position the daughtercard so that the rear connectors pass through the hole in the

controller rear panel, but without engaging the motherboard connector.

6. Align the daughtercard plug with the socket on the motherboard.

7. Check that the rear panel hook of the daughtercard is located above the slot in the rear

panel.

8. Press the daughtercard firmly into the socket on the motherboard until it is seen to be fully

engaged.

9. Confirm that the top hook is engaged in the rear panel, if it is not then repeat steps 7 and 8.

Page 11

Daughtercards 9

10. If a PHS daughtercard is being installed please refer to section 12.4 at this stage of the

process.

11. Refit the top panel of the enclosure and secure using the fixing screws.

12. Reconnect all disconnected cables between the UCC1 or UCC2 and the CMM and then the

mains cable. Switch on the ac supply.

2.2 Removal of a daughtercard

The following procedure is recommended for removal of a daughtercard from the UCC1 or UCC2.

CAUTION: It is essential that full anti-static precautions are taken before working within

!

the UCC1 or UCC2 controller enclosure or handling individual boards.

1. Remove the ac power supply from the UCC1 or UCC2 and move the unit so you have clear

access to the top and rear of the enclosure, it may be necessary to disconnect some of the

other cables to achieve this.

2. Remove the top panel of the enclosure by removing the five screws at the top of the rear

panel and the screw located at the top of each side panel, near the front. Retain the fixing

screws.

3. Carefully remove the daughtercard from the socket on the motherboard, taking care to

disengage the top hook from the rear panel.

4. Refit the blanking plate in the rear panel of the enclosure

5. Refit the top panel of the enclosure and secure using the fixing screws.

6. Reconnect all disconnected cables between the UCC1 or UCC2 and the CMM and then the

mains cable. Switch on the ac supply.

Page 12

10 PHC1050 daughtercard

3 PHC1050 daughtercard

NOTE: This daughtercard is suitable for use in both UCC1 and UCC2 controllers.

3.1 Introduction

The PHC1050 interface board is one of a range of plug-in daughtercards for Renishaw CMM

controllers. It provides a simple interface between the PH10 probe head and the metrology frontend software using no external hardware and with minimal cabling and connectors.

Provision is made for a probe head hand controller (HCU1), although this is not necessary if an

MCU1 joystick is fitted to the system.

The PHC1050 is an internal option which enables the UCC1 or UCC2 to offer all the functions of

the Renishaw PHC10-2 probe head controller.

The PHC1050 supports the basic and extended command set from the front-end software in their

original format, ensuring interchangeability and an easy upgrade path. The commands are

transmitted via the link from the host PC to the UCC controller. Probe signals are handled directly

by the UCC1 or UCC2.

Page 13

PHC1050 daughtercard 11

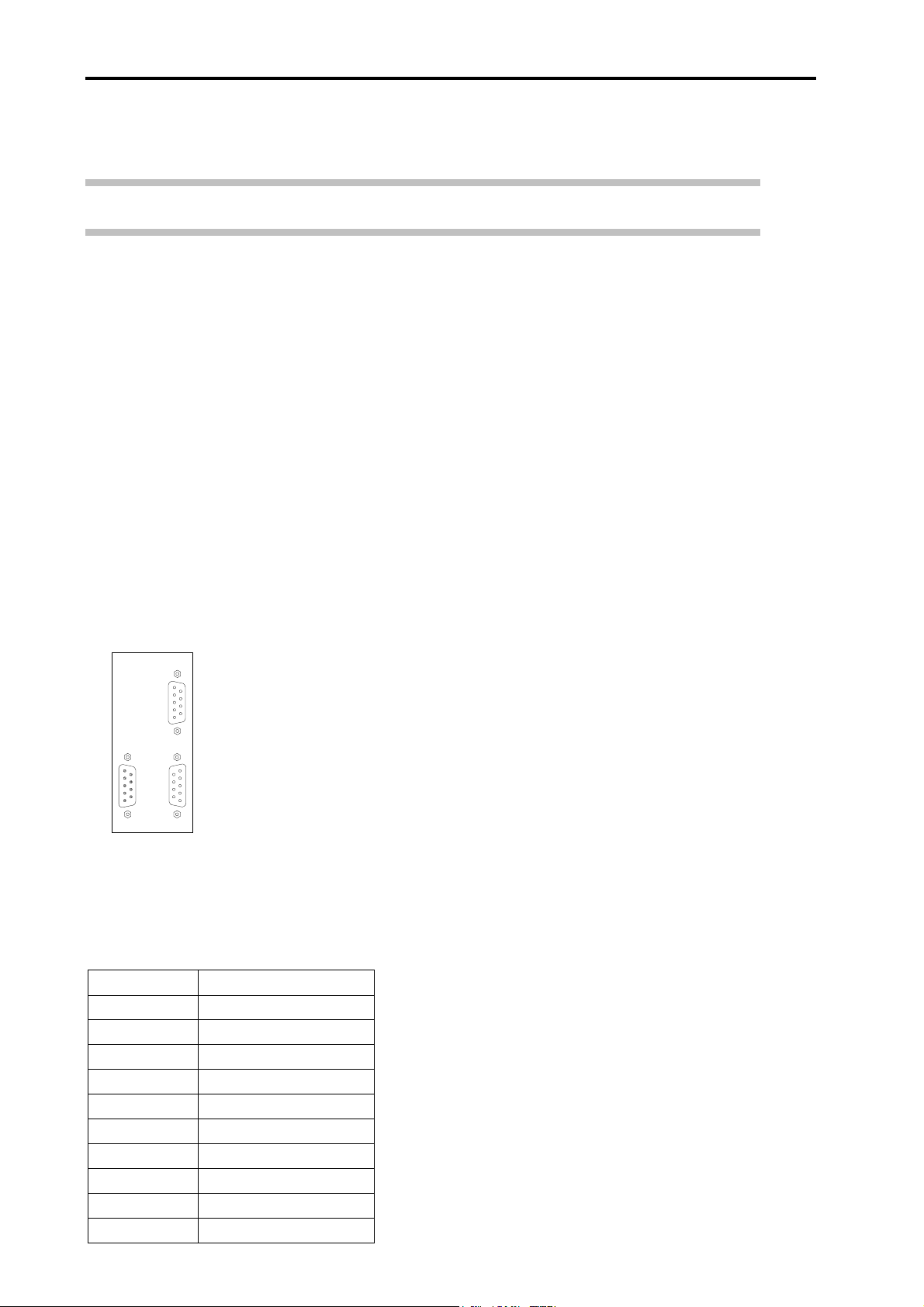

3.2 Connector and pin outs

On the rear panel of the PHC1050 are two connectors:

• The connection to the PH10 head, via the 15-way D-type plug labelled HEAD

• The optional connection to the HCU1, via the 9-way D-type socket labelled HCU

PHC1050

HCU

HEAD

efg

3.2.1 Head connector

The head connector is a 15-way D-type socket with the signals as detailed in the table below, for

further details on these signals please refer to the PH10 installation guide (Renishaw part number

H-1000-5071).

Pin number Function

1 Ground sense

2 Head present

3 A axis feedback

40 V

5 Motor probe switch

6 12 V reference

7 B axis motor / probe contact

8 LED and datum

9 Not connected

10 Locking motor drive

11 A axis motor

12 A axis motor

13 Not connected

14 B axis feedback

15 B axis motor / probe contact

Shell Screen

3.2.2 HCU connector

The HCU connector is a 9-way D-type socket with the necessary signals to connect directly to the

HCU1 handbox, for further information please refer to the HCU1 user’s guide (Renishaw part

number H-1000-5016).

Page 14

12 PHC1050 daughtercard

3.3 Configuration options

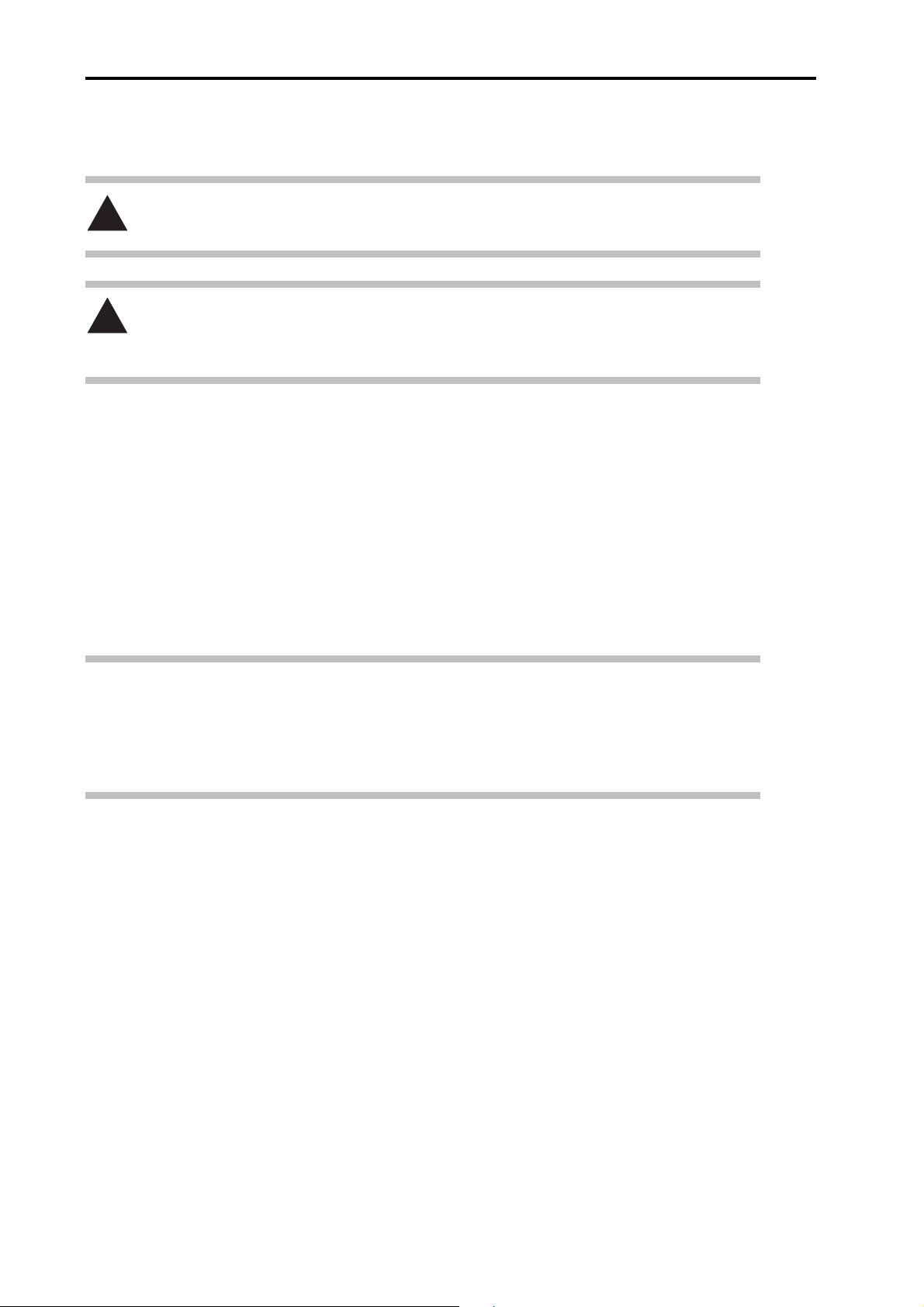

3.3.1 Two wire probe configuration

The diagram below shows a typical wiring arrangement for a two-wire touch trigger probe system

incorporating a PH10 motorised probe head.

The PHC1050 daughtercard may be fitted into any of the available slots in the UCC.

• The cable from the probe head should be connected to the 15-way D-type plug marked 'HEAD'

on the PHC1050 rear panel. The probe signals within this cable are connected automatically to

the UCC motherboard for interfacing.

• The cable from the hand control unit (if fitted) should be connected to the 9-way D-type socket.

NOTE: Ensure that the configuration switches on the PHC1050 card are both set to ‘ON’ UP

position as shown in diagram below (factory default). This routes the probe signal through the card

to the internal interface.

PHC1050

card

Page 15

PHC1050 daughtercard 13

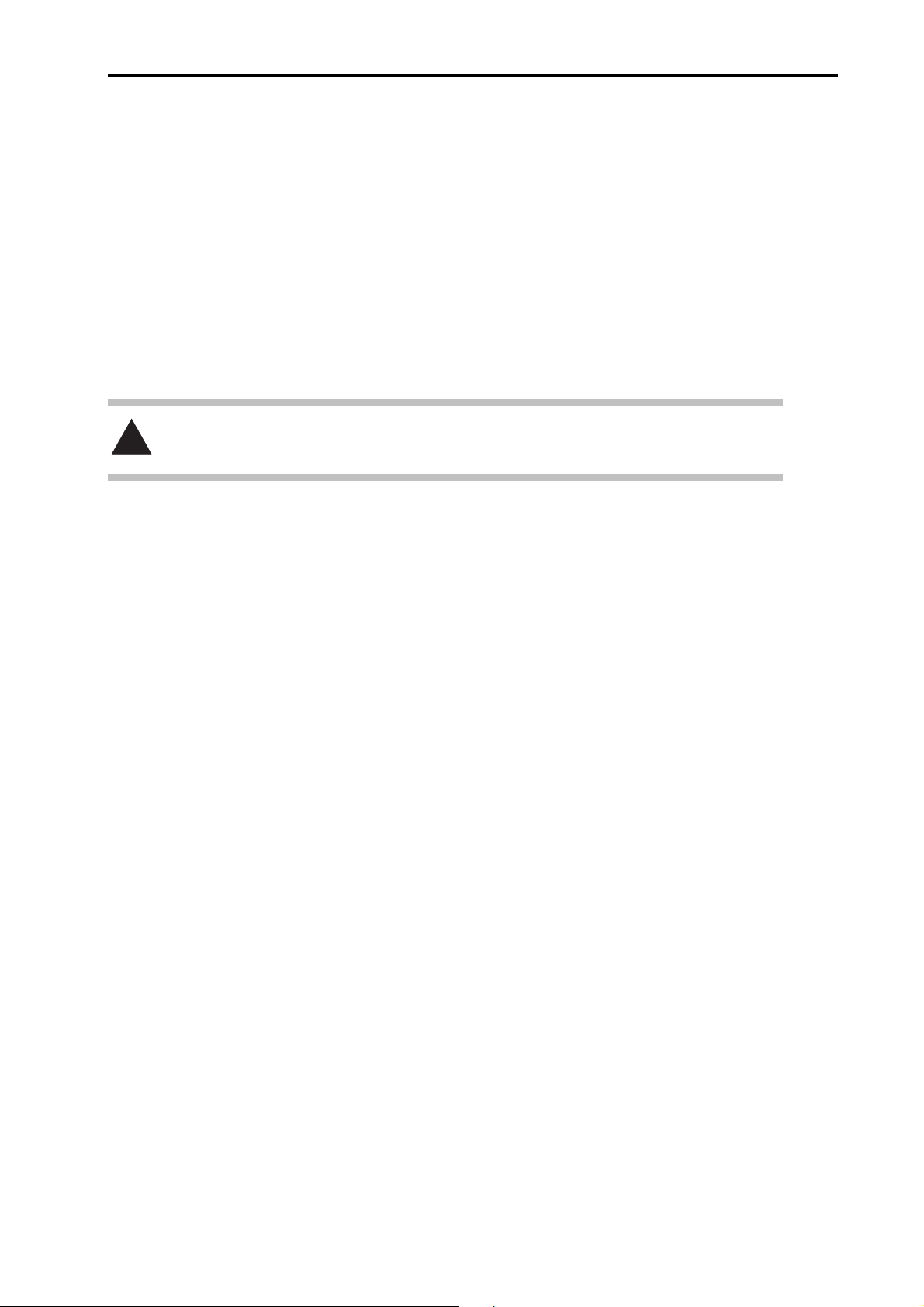

3.3.2 Multiwire probe configuration

The diagram below shows a typical wiring arrangement for a system incorporating an analogue

scanning probe (SP600) and two-wire touch trigger probe incorporating a PH10 motorised probe

head.

The head cable links the probe head to the PH1050 daughtercard and the multiwire cable

connects directly to the analogue probe socket on the rear panel of the controller, to permit

interfacing of TP2/6/20, TP200 and SP600 probes (and SP25 on UCC2).

The PHC1050 daughtercard may be fitted into any of the available slots in the UCC.

• The cable from the probe head should be connected to the 15-way D-type plug marked 'HEAD'

on the PHC1050 rear panel. The probe signals within this cable are connected automatically to

the UCC motherboard for interfacing.

• The cable from the hand control unit (if fitted) should be connected to the 9-way D-type socket

marked 'HCU' on the PHC1050 rear panel.

NOTE: Ensure that the configuration switches on the PHC1050 Card are both set to ‘OFF’

DOWN position as shown in diagram below. This routes only the head signals through the

PHC1050 card.

Failure to configure the switches as detailed can result in illegal triggers when using the system.

PHC1050

card

Page 16

14 PHC1050 daughtercard

3.4 Operating overview

The PHC1050 must be installed within the UCC and connected to the PH10 motorised probe head

before the controller is powered up.

When the UCC software is downloaded, it searches the internal bus for daughtercards and will

detect the presence of the PHC1050 daughtercard.

NOTE: If no PHC1050 card is found and a PICS/RS232 daughtercard is identified on the UCC

internal bus, all PHC commands will be routed to the PICS/RS232 daughtercard for use by an

external motorised head controller.

However, if no PHC1050 or PICS/RS232 daughtercards are found then the system will return an

error if any motorised probe head commands are sent to the UCC1 controller.

The metrology front-end software may then configure the PHC1050 using UCC command 340

(PHC1050 initialise), refer to following section and the UCC command set (Renishaw part number

H-1000-5222) for more information.

3.4.1 Communication with the PHC1050

The CMM metrology front-end program can communicate with the probe head in a similar manner

to that used in the RS232C link with an external PHC system.

• The application selects commands from either the basic command set or the RECS (Renishaw

extended command set).

• The command is sent to the controller using UCC command number 336 (Write to PHC10), to

transfer the data.

• The UCC will automatically direct the command to the PHC1050 daughtercard. (If this is not

fitted refer to note above)

• Any reply is read by using the UCC command number 337 (Read from PHC10), referring to the

status flags as described in the UCC command set document.

3.4.2 Configuring the PHC1050 board

The only hardware configuration on the PHC1050 board is that for probe type selection, please

refer to section 3.3 for details.

Other configuration options for the PHC1050 daughtercard are software configurable using UCC1

command 340 (PHC1050 initialise). Refer to the UCC command set (Renishaw part number

H-1000-5222) for further details.

Following receipt of command 340 (PHC1050 initialise) the UCC system will enable/disable the

applicable options.

Page 17

PHC1050 daughtercard 15

NOTE: As part of this process the servo motors, if engaged, will be disengaged and the

PHC1050 will be reset to its default manual or automatic mode.

The default configuration mode of the PHC1050 depends on whether a hand control unit is fitted

(manual mode) or not fitted (automatic mode). This mode can be changed by the use of command

336 (Write to PHC10).

3.4.3 Power-up sequence

The PHC1050 (or PICS/RS232) daughtercard is powered from the internal UCC power supply,

provided that all components are connected before power-up, they will initialise correctly.

Plugging or unplugging a motorised probe head with the system live is described in the basic

command set programming manual (H-1000-5075). The same process should be used with a

PHC1050.

3.4.4 Probe head operation

For programming probe head operation, refer to the basic command set programming manual

(Renishaw part number H-1000-5075), the same flow charts and programming techniques apply.

Any references in the basic command set programming manual with regards to RS232

communications should be replaced by the UCC commands 336 (Write to PHC10) and 337 (Read

from PHC10) to send data over the link to the PHC1050 or PICS/RS232 daughtercard via the

UCC controller.

NOTE: None of the IEEE488 communications protocols are supported by the UCC system.

Page 18

16 PICS/RS232 daughtercard

4 PICS/RS232 daughtercard

NOTE: This daughtercard is suitable for use in both UCC1 and UCC2 controllers.

4.1 Introduction

The UCC supports a PICS B (IN) and an RS232 port (channel 1) for use by Renishaw probes and

peripherals. By including this option card into the UCC system two additional RS232 ports and a

PICS A (OUT) port are incorporated, allowing the basic measuring system to be enhanced with

alternative probes and/or added peripherals.

4.2 Connector and pin outs

On the rear panel of the PICS/RS232 daughtercard there are three connectors these are:

• PICS A

• RS232 channel 2

• RS232 channel 3

PICS / RS232

RS232 CH 2

efg

PICS A

RS232 CH 3

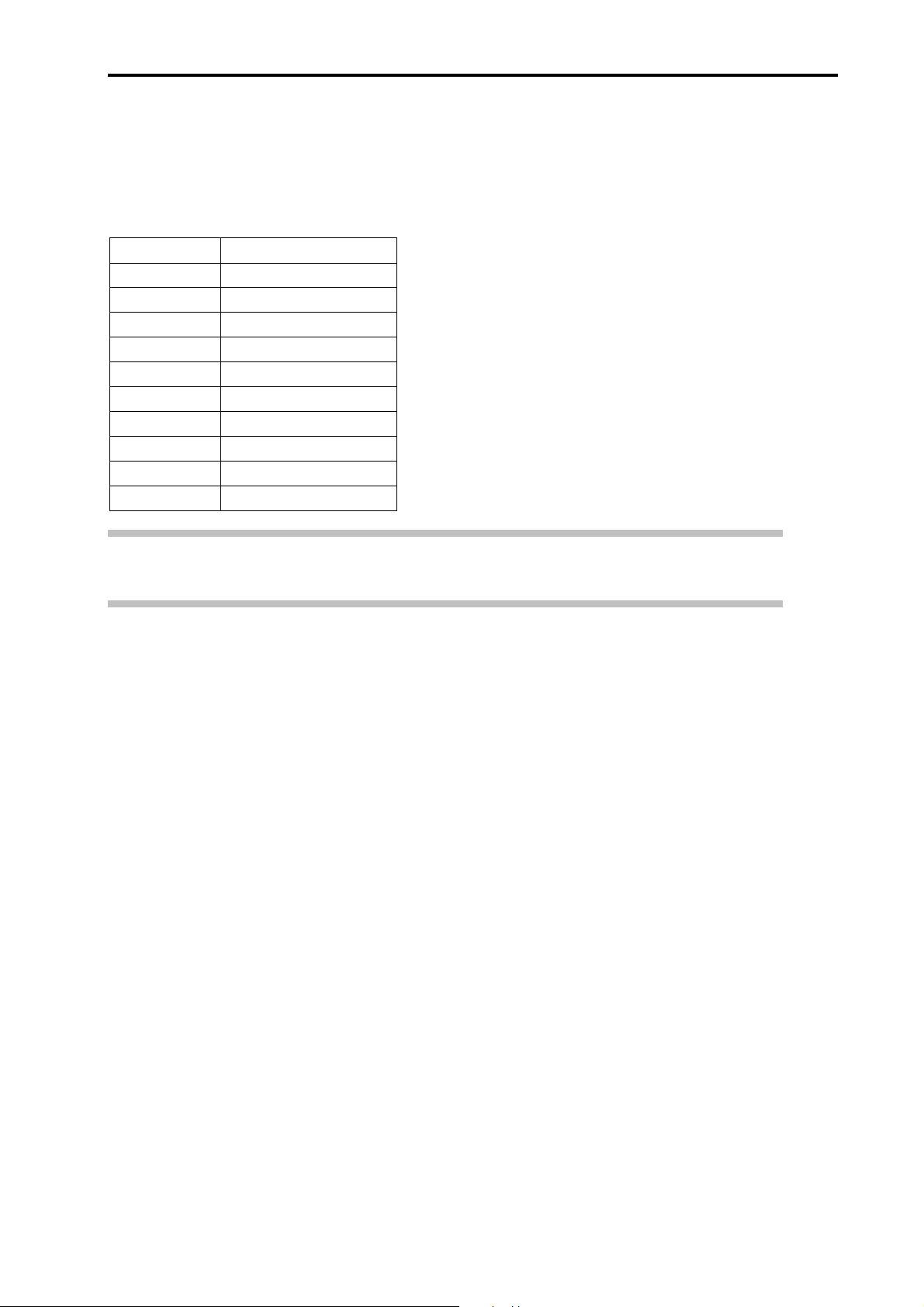

4.2.1 PICS A connector

The PICS A connector is a 9-way D-type socket with the signals as detailed in the table below.

This connection conforms to the Renishaw PICS standard and all signals are active low. Refer to

PICS installation guide (Renishaw part number H-1000-5000) for further information.

Pin number Function

1STOP

2 PPOFF

30V

4 Reserved

5 SYNC

6HALT

7PDAMP

8 LED OFF (out)

9

Shell Screen

Page 19

PICS/RS232 daughtercard 17

4.2.2 RS232 connectors (9-way D-type plug)

RS232 CH2 (RS232 channel 2) and RS232 CH3 (RS232 channel 3) connectors have the same

pin-outs as detailed in the table below.

Pin number Function

1 Not connected

2 RX data

3 TX data

4DTR

5 Signal ground

6 Not connected

7RTS

8CTS

9 Not connected

Shell Screen

NOTE: The communication protocols for these connectors are fixed and can not be changed.

Refer to section 4.4.2 and 4.4.3 for details.

Page 20

18 PICS/RS232 daughtercard

4.3 Configuration options

4.3.1 Connecting an external PHC10 to the UCC

The figure below shows a UCC system fitted with the PICS/RS22 daughtercard, an external

PHC10-2 and an external Renishaw interface (OPI6).

In this case it is necessary to use both the PICS A and the RS232 channel 3 connectors on the

PICS/RS232 daughtercard.

PICS / RS232

RS232 CH 2

efg

PICS A

RS232 CH 3

The recommended dip switch settings for the PHC10-2 unit shown in this configuration are given

in the table below

NOTE: If the RECS command set is being used then dip switch should be in the up position.

123456789101112131415161718

UP X X XXXX

DOWN X XXXXXXXXXXX

The RS232 communication cable between the PICS RS232 daughtercard and the PHC10-2

shown in this configuration is not available from Renishaw, the connections details for this cable

are as detailed in section 0.

Page 21

PICS/RS232 daughtercard 19

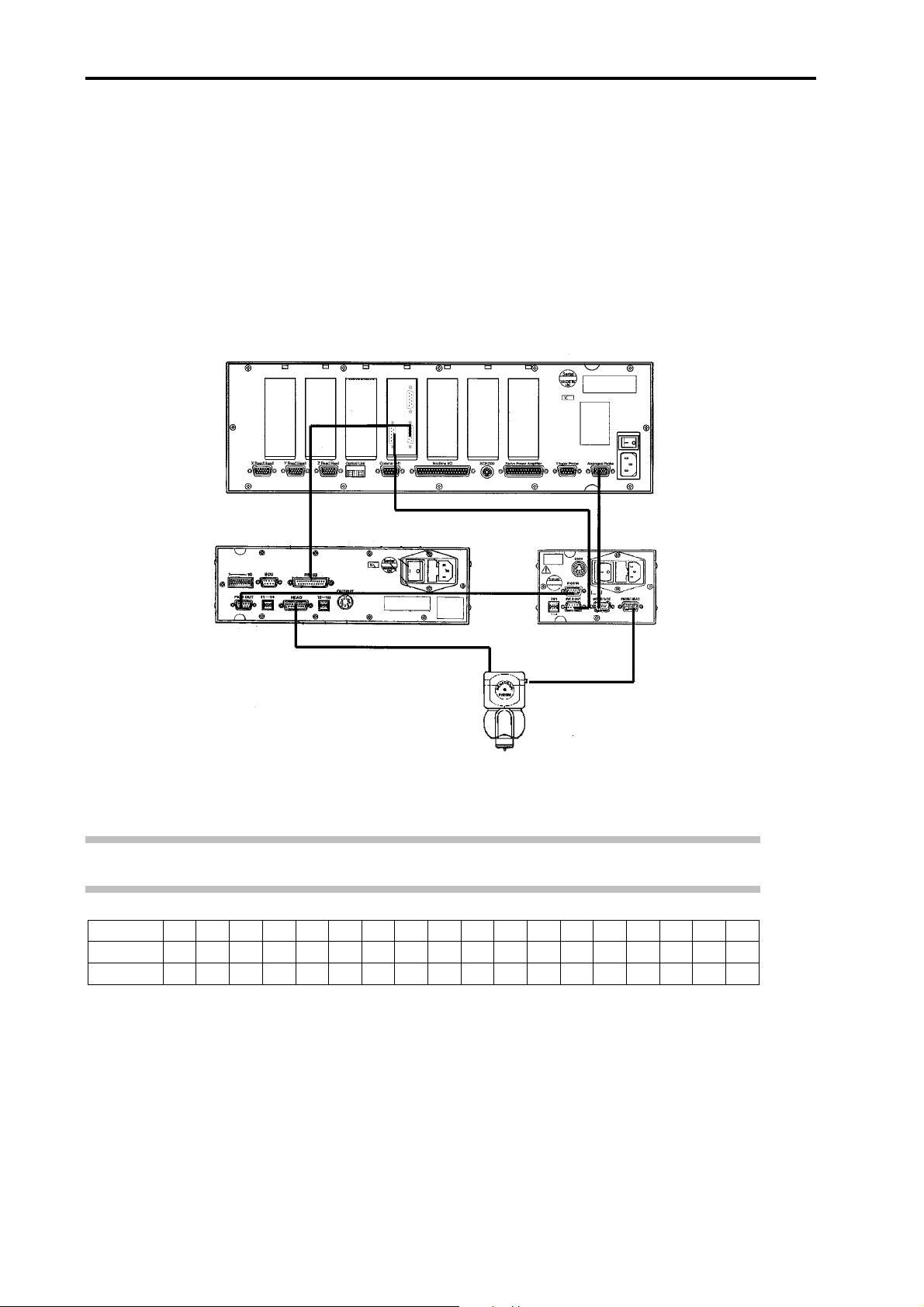

4.3.2 Connecting an ACC2-2 to the UCC

The figure below shows a UCC system fitted with the PICS/RS22 daughtercard, an external

PHC10-2, an ACC2-2 and an external Renishaw interface (OPI6).

In this case it is necessary to use all three of the connectors on the PICS/RS232 daughtercard.

PICS / RS232

RS232 CH 2

efg

PICS A

RS232 CH 3

In this connection scheme it is necessary to configure the PHC10-2 as detailed in section 4.3.1, it

is also necessary to manufacture two RS232 cables as detailed in section 4.3.3 to connect the

ACC2-2 and the PHC10-2 to the PICS/RS232 daughtercard.

NOTE: If only an external ACC2-2 is to be used without the external interface and PHC10-2

controller then it is necessary to terminate the PICs signals used by the ACC2-2 controller. This is

done by placing a 100K resistor between pins 1 & 6 and 1 & 5 on the PIC IN connector of the

ACC2-2 unit.

The recommended dip switch settings for the ACC2-2 unit shown in this configuration are given in

the table below:

1 2 3 4 5 6 7 8 9 10 11 12 A B

UP X X X X

DOWN X XXXXX XX XX

Page 22

20 PICS/RS232 daughtercard

4.3.3 RS232 communication cable

The RS232 communication cable between the PICS/RS232 daughtercard and either the ACC2-2

or the PHC10-2 product is a standard null modem cable, the connection details are shown below:

PICS/RS232 CH3

9-way D-socket

1

2

3

4

5

6

7

84

4.4 Operating overview

4.4.1 PICS A port

PHC10-2

25-way D-socket

20

2

3

6

7

8

5

This port will be used for the control of external Renishaw interface products (e.g. PI 7-2, OPI6,

etc.) as described in the appropriate UCC installation manual (Renishaw part number

H-1000-5056 for UCC1, H-1000-5223 for UCC2) and the installation guide for the peripherals

concerned.

The signals produced by the PICS interface circuits in the board are used internally by the UCC

controller but may be examined or modified by using the appropriate UCC commands 280 (Read

from PICS port) and command 325 (Write to PICS port).

NOTE: Installing the PICS/RS232 daughtercard will disable the PICS “B” (IN) port on the UCC.

This is no longer required, since the interface board connects internally to the controller.

4.4.2 RS232 channel 2

This connector handles the serial data link to such Renishaw products as the ACC2-2 or any other

compatible external equipment connected to this communication port.

More detailed information about the ACC2-2 software routines is available in the installation and

programmers guide (Renishaw part number H-1000-6010).

To read or write to this communication port command 338 (write to ACC), and command 339

(read from ACC), please refer to the UCC command set document (Renishaw part number

H-1000-5222) for further information.

Page 23

PICS/RS232 daughtercard 21

The serial communications parameters used by this port are not configurable and set as detailed

below:

Baud rate 9600

Data 7 bits

Parity even

Stop 1 bit

The user should ensure that the device connected to this port uses the same settings.

4.4.3 RS232 channel 3

This connector handles the serial data link to Renishaw products such as the PHC10-2 or any

other compatible external equipment connected to the communication port.

More detailed information about the PHC10-2 software routines is available in the programmers

guide (H-1000-5075).

To read or write to this communication port command 336 (Write to PHC), and command 337

(read from PHC), please refer to the UCC command set document (Renishaw part number

H-1000-5222) for further information.

The serial communications parameters used by this port are not configurable and set as detailed

below:

Baud rate 9600

Data 8 bits

Parity none

Stop 2 bit

The user should ensure that the device connected to this port uses the same settings.

Page 24

22 Joystick interface daughtercard

5 Joystick interface daughtercard (JI card)

NOTE: This daughtercard is suitable for use in both UCC1 and UCC2 controllers.

5.1 Introduction

The joystick interface daughtercard (referred to in this document as the ‘JI card’) is one in a range

of plug-in daughtercards for the Renishaw UCC universal CMM controllers.

For the UCC1 kit (A-1333-0003) a JI card is provided as part of the kit. UCC1 kit (A-1333-0006)

provides an MCU1 (Renishaw joystick) interface.

The UCC2 controller has the MCU1 interface integrated into the motherboard and no other

interfaces are fitted. If a JI card is required then it must be ordered as a separate item

(A-1333-0020).

The JI card provides a flexible interface between the UCC controller and many different types of

OEM joystick control units. It has provision for analogue signals from the joystick unit. Multiple

switch and indicator signals can be accepted or provided.

The JI card is configured by commands from the metrology front-end software, via the UCC

controller, to select the required functions from the available range.

Physically, the device consists of a single printed circuit board with a connector to suit the

controller's internal bus sockets. The board has a metal end plate for fixing to the rear panel of a

UCC1 or UCC2 controller. Attached to the metal panel is a 37-way D-type plug, to connect to the

user's joystick unit, and a 2-way socket dedicated to the wiring from any emergency stop switch

on the joystick unit.

Electrically, the interface board carries an embedded processor and the required circuits to

process analogue joystick signals and to handle the two-way communications with the controller.

The JI board is powered by the UCC controller and will provide d.c. power to the joystick unit if

required.

5.2 Connector and pin outs

On the rear panel of the JI daughtercard are two connectors:

• the connection to the joystick unit, via a 37-way D-type connector, labelled joystick

• the connection to the CMMs emergency stop system, via a dedicated 2-way connector,

labelled EMERGENCY STOP

Page 25

Joystick interface daughtercard 23

5.2.1 Joystick connector

The joystick connector is a 37-way D-type plug with the signals as detailed in the table below:

Pin

number

1 +5 V supply from JI - 2 Digital ground - - 3 +12 Vdc supply from JI - 4 -12 Vdc supply from JI - 5 Analogue ground - - 6 +24 Vdc supply from JI - 7 24V return to JI - 8 Emergency stop A to JI - 5.3.2

9 Emergency stop B to JI - 5.3.2

10 Analogue axis, X to JI + signal gives + move* 5.3.3

11 Analogue axis, Y to JI + signal gives + move* 5.3.3

12 Analogue axis, Z to JI + signal gives + move* 5.3.3

13 Analogue axis, W to JI - 5.3.3

14

15 Dead man's handle to JI <1V = JI operational 5.3.4

16 X axis lock to JI <1V = axis locked 5.3.4

17 Y axis lock to JI <1V = axis locked 5.3.4

18 Z axis lock to JI <1V = axis locked 5.3.4

19** W axis lock to JI - 5.3.4

20 Probe enable to JI <1V = probe disabled 5.3.4

21 Fast/slow to JI <1V = Fast 5.3.4

22 Record point to JI <1V = record point 5.3.4

23 Cancel last point to JI <1V = cancel last point 5.3.4

24 Reset TP200 probe to JI <1V = reset TP200 5.3.4

25 Reserved 26 Reserved 27 Axis swap to JI 28 Axis swap to JI 29 Joystick/DCC to JI <1V = DCC mode 5.3.4

30 X axis lock indicator from JI <1V = axis not locked 5.3.5

31 Y axis lock indicator from JI <1V = axis not locked 5.3.5

32 Z axis lock indicator from JI <1V = axis not locked 5.3.5

33** W axis lock indicator from JI - 5.3.5

34 Probe enabled indicator from JI <1V = probe is enabled 5.3.5

35 Beep control from JI <1V = beep sounding 5.3.5

36 Near max. speed from JI <1V = near max speed 5.3.5

37

Shell Shell and screen - - -

Function (primary)

Analogue speed

override

Servo engaged

indicator

Signal

direction

to JI +12V = FS, -12v = stop 5.3.3

from JI <1V = servo disengaged 5.3.5

Signal

effect

Schematic

* Assuming an ISO 841 right-handed co-ordinate system

** See also secondary built-in functions

Page 26

24 Joystick interface daughtercard

5.2.2 Emergency stop connector

The emergency stop connector is a two pin Lemo connector that is connected directly to pins 8

and 9 of the 37-way D-type plug. These pins should be connected into the CMM’s emergency

stop system if an emergency stop button is mounted on the joystick.

Pin number Function

1 ESTOP A

2 ESTOP B

Shell Screen

Page 27

Joystick interface daughtercard 25

5.3 Configuration options

5.3.1 Minimum recommended installation wiring

The figure below shows the recommended minimum installation wiring scheme for connecting a

joystick to the JI card.

Page 28

26 Joystick interface daughtercard

5.3.2 Emergency stop signal

The figure below shows the EMERGENCY STOP signal routing through the JI card.

NOTE: The emergency stop signal is not connected to any internal circuits within the UCC1 or

UCC2, the emergency stop signal is routed directly from the 37-way D-type connector to the

emergency stop connector on the rear of the card.

For recommended installation wiring please refer to the UCC1 or UCC2 installation guides

(Renishaw part numbers H-1000-5056 or H-1000-5223 respectively).

Page 29

Joystick interface daughtercard 27

5.3.3 Analogue input signal

The figure below gives the analogue input circuit that is incorporated into the JI card. These are

all transient-protected and standardised.

There are connections for four analogue axis signals and one analogue speed signal from the

joystick unit to the UCC JI card.

The input voltage range is ±12 V nominal, ±15 V maximum. Positive inputs should produce

machine movements in a positive direction.

5.3.4 Binary input circuit

The figure below gives the binary input circuit that is incorporated into the JI card, which are all

transient-protected and standardised.

The input voltage range is ±12 V nominal, ±15 V maximum. The active state for this connection is

with the input connected to pin 2.

Page 30

28 Joystick interface daughtercard

5.3.5 Binary output circuit

The figure below gives the binary output circuit that is incorporated into the JI card. These are all

standardised.

The active state for this connection is with the transistor conducting and the limits for this

connection are listed below.

Maximum output current = 100 mA

Output voltage @ 100 mA = 1.1 volts max.

5.4 Operating overview

5.4.1 Method of operation

The JI board CPU scans all inputs from the joystick unit, the analogue signals are processed to

give suitable velocity commands for the servo system and when information is requested by the

controller, these velocity commands and other input signals are returned to it.

The controller can also send instructions to the JI board to change the states of the outputs going

to the joystick unit, e.g. to turn indicators on or off.

There is provision for up to 19 user inputs or outputs from the joystick unit which can be

configured as simple I/O to and from the user’s PC, or as controls for many built-in functions.

Page 31

Joystick interface daughtercard 29

5.4.2 Initialising the JI card

After powering up the UCC1 or UCC2 controller, the JI card must be brought into operation by the

following three actions:

• The JI card must be selected by setting Joystick type = 1 in the command 256 (Machine

configuration).

NOTE: This action will prevent the PC command 320 (Enter velocity demand) from working, since

the joystick will now provide this function.

• The JI card should also be configured to provide the characteristics required for the front-end

software application. Like most other parts of the UCC1 or UCC2 system, the JI board can be

used with all its parameters as their default settings, in which case no configuration is required.

Otherwise command 396 (Joystick configuration) should be sent to the controller. The board

can be configured before or after it has been selected.

• Finally, the JI card should be enabled using the command 397 (Joystick enable) command.

5.4.3 Joystick modes

When a CMM system is fitted with a joystick unit and a joystick daughtercard, these must be

suitably commissioned as described above. This will then permit the system to operate in one of

two modes: DCC mode or joystick mode.

In DCC mode the majority of the functions offered by the JI card are not active, moves can only be

initiated and controlled by commands from the front-end software.

NOTE: The emergency stop will always be available, if integrated, and the speed override

functions will be available if configured

In joystick mode the joystick(s) can be used to move the machine and all other JI card functions

are available, but no metrology front-end software controlled moves can be made.

The required mode can be selected either by a metrology front-end software command or by a

switch on the joystick unit.

Page 32

30 Joystick interface daughtercard

NOTE: The default JI card characteristics can be changed using command 396.

This command may be used to remove the need for the dead man’s handle and joystick/DCC

switch signals. In this state the joystick must be enabled as required by command 397 and

disabled again by the same command when a computer controlled move is required.

5.4.4 Joystick type selection

Command 256 (Machine configuration) sets a parameter called joystick type to 0 or 1.

If joystick type is set to 0:

• No joystick functions will be available (even beeps or uncommitted I/O)

• Command 320 (Enter velocity demand) from the PC will operate to give mouse-like

movements controlled by the PC

If Joystick type is set to 1:

• JI functions may be available, depending on the other factors (see below)

• A command 320 (Enter velocity demand) from the PC will be ignored

5.4.5 Enable joystick

To move the machine under joystick control requires the following conditions to have been met:

• The JI must be selected using command 256 as type 1, see Joystick type selection section

below

• The JI must be enabled using command 397 with enable set to 1

• The dead man’s handle switch signal to the JI from the joystick unit must be active (contacts

closed)

• The joystick/DCC switch signal to the JI from the joystick unit must be active (contacts open or

pulled high)

Even when the JI is selected and enabled, the signal from the joystick/DCC switch on the JI

affects the joystick availability.

Page 33

Joystick interface daughtercard 31

Since both the joystick/DCC switch and command 397 (Joystick enable) command from the PC

control the same things and both may be present, the truth table governing the system mode is:

Joystick/DCC switch set to

DCC

Joystick disabled by front

end software

Joystick enabled by front end

software

NOTE: If the joystick/DCC switch is not fitted to the JI card, the default state of the signal must be

wired to the joystick, on the JI connector, to allow the PC to control the mode.

Alternatively, the switch signal pin may be reconfigured (by command 396) for a secondary built-in

pin or as an uncommitted I/O pin: the PC command alone will then select the mode.

DCC mode DCC mode

DCC mode joystick mode

Joystick/DCC switch set to

joystick

5.4.6 Functionality in DCC mode

Active CMM functions when the system is in DCC mode:

Machine state

Function

JI commands

Speed override Yes - Yes No

Joystick controlled movements No - No No

Built-in JI functions Beep only - Beep only None

Probe enabled or disabled

Probe enable/disable indicator (on JI)

JI uncommitted I/O Yes - Yes None

Disengaged

or hold

All JI

commands

PC

controlled

PC

controlled

Joystick

move

Unavailable None None

-

-

Point-to-point

move

PC

controlled

PC

controlled

Scanning or

pencil*

PC

controlled

PC

controlled

Page 34

32 Joystick interface daughtercard

5.4.7 Functionality in joystick mode

Active CMM functions when the system is in joystick mode:

Machine state

Function

JI commands

Speed override No No - -

Joystick-controlled movements

Built-in JI functions All functions All functions -

Probe enabled or disabled

Probe enable/disable indicator (on JI) JI controlled JI controlled - -

JI uncommitted I/O Yes Yes - -

Disengaged

or hold

All JI

commands

Can be

started if in

hold state

Controlled by

JI switch

Joystick move

All except

Read JI

Version and

Configure

Yes - -

Controlled by

JI switch

Point-to-point

move

Point-to-point

move not

available

- -

Scanning or

No scanning

pencil*

or pencil

moves

available.

* Pencil mode applies to Cyclone class machines only.

5.4.8 Changing modes

If a change occurs due to the Enable command or the joystick/DCC switch which would move the

system from DCC mode to joystick mode, it will not take effect until the system is in a disengaged

or hold state.

If a change occurs which would move the system from joystick mode to DCC mode, it will take

effect as soon as any joystick activity has been terminated by the user and the system is in a

disengaged or hold state.

5.4.9 Moving and touching

When joystick mode is selected, the CMM can be moved by deflecting the joystick levers. The

system behaviour can be modified by the optional primary I/O functions.

In the event of a trigger, the CMM will be stopped and back away from the surface. The back-off

speeds and distances are defined as the maximum values for normal moves and touches in

command 257 (Move configuration).

After backing-off and finally stopping, the joysticks cannot move the machine until all three joystick

signals have been at 0 speed for the null wait time defined in command 396 (Joystick

configuration). The default value is 0.05 seconds.

The back-off direction is the reverse of the direction in which the stylus approached the surface.

Page 35

Joystick interface daughtercard 33

5.4.10 Recording points

It is often necessary to construct a program of moves and touches on the host for a repetitive

measuring procedure. Two of the primary built-in functions are designed to allow the user to log

chosen machine positions on the host as part of that construction.

When the user sends a Record point signal to the JI board, usually by pressing a momentary

switch on the joystick unit, the controller will store the current machine position and set a status

flag to alert the host. The flag is status byte B7, bit 1.

When next requesting position and status, the host should respond to this flag by recording the

position as a ‘way-point’ in the measuring program. Once the point has been read by the host, the

flag is set to zero.

If the user sends a Cancel last point signal to the JI board, usually by pressing a momentary

switch on the joystick unit, the controller will check that the last recorded point has been read by

the host. If it has not yet been read, the point data will be discarded and the Store as recorded

point flag cleared to zero. If the point has been read by the host, the controller will set a flag in

status byte B7, bit 2 to inform the host that the last recorded point it received should be cancelled.

The flag is cleared after it has been read by the host by the next request for position and status.

The cancelling process could be repeated many times and the host main program will use it to

delete multiple stored points.

5.4.11 Probe damping

Probe damping is not initialized by the joystick box, but if damping is asserted through the UCC,

and the system is in joystick mode, then probe damping will be controlled by the joystick fast/slow

switch:

If the joystick fast/slow switch is set for ‘slow’ speed then probe damping, if applied, is overridden

and the probe operates at full sensitivity.

If the joystick fast/slow switch is set for ‘fast’ speed then probe damping, if applied, is still valid and

the probe operates at reduced sensitivity.

If damping is asserted by an external device, such as an HCU1 unit or a connection to the

‘PDAMP’ line of the probe or PICS connector, then probe damping will not be overridden by the

fast/slow switch.

Page 36

34 Joystick interface daughtercard

5.4.12 Joystick orientation

It is assumed that the joystick unit will normally be used in one position relative to the CMM’s table

(the home position) but during use, the joystick user will move freely around the table to control

the CMM.

By operating a switch mounted on the joystick unit, the X and Y joystick deflection signals can be

transposed as required to give instinctive user response for all four sides of the CMM table. The Z

axis is always in the same orientation.

NOTE: Any axis labelling on the joysticks themselves may no longer be correct.

This function is not controlled by command 396 (Joystick configuration), but is a hard-wired option

to the JI connector. The two signal pins which define the required orientation are pins 27 and 28.

C

X

Y

YY

B

X

Position Pin 27 Pin 28

A o/c or high o/c or high

B pulled low o/c or high

C pulled low pulled low

D o/c or high pulled low

Y

X

A

Home position

DCMM table

X

NOTE: If both pins are left unconnected, the joystick unit will operate normally at the default

home position.

Page 37

Joystick interface daughtercard 35

Should the operator switch the joystick unit orientation during use, then it will not change the

active orientation until the UCC is in state 0 (disengaged) or state 2 hold). Therefore the machine

should be left to reach one of these states (i.e. release joystick demand) to allow the change to

occur.

Axis locks are also affected by the joystick axis reorientation. If the user moves to position B or D,

the X and Y joystick axes will be interchanged on the joystick unit. Any existing or new axis locks

applied will also be interchanged when in either of these positions. Moving to a new position will

alter whichever axes are locked as required to maintain consistency with the joystick deflection

directions.

Joystick reorientation will only take effect if Joystick type is equal to analogue and the axis locks

and indicators are set as primary functions.

Page 38

36 MCU1 daughtercard

6 MCU1 daughtercard

NOTE: This daughtercard is only suitable for use in the UCC1 controller. The UCC2 has this

functionality integrated as standard on its motherboard.

6.1 Introduction

The MCU1 daughtercard is one of two joystick interface options offered by the UCC1 and is

normally supplied as part of the UCC1 kit when purchased.

The MCU1 daughtercard provides all the necessary interfacing between the MCU1 joystick and

the UCC1 controller.

NOTE: The UCC2 controller has an integrated MCU interface that removes the requirement for a

separate MCU daughtercard to be fitted.

The MCU1 daughtercard is configured by commands from the front-end software, via the UCC1

controller, to select and respond to functions available from the MCU1 joystick.

Physically, the device comprises a single printed circuit board with a connector to suit the

controller’s internal bus sockets. The board has a metal end plate for fixing to the UCC1 controller.

Attached to this metal plate is a 9-way D-type connector, to connect to the MCU1 joystick, and a

2-way socket dedicated to the wiring from the emergency stop button located on the MCU1

joystick.

The MCU1 daughtercard and MCU1 joystick are powered by the UCC1 controller.

6.2 Connector and pin outs

On the rear panel of the MCU daughtercard are two connectors:

• the connection to the Renishaw MCU joystick unit, via a 9-way D-type connector, labelled MCU

• the connection to the CMMs emergency stop system, via a dedicated 2-way connector,

labelled EMERGENCY STOP

Page 39

MCU1 daughtercard 37

6.2.1 MCU connector

The MCU1 joystick connector is a 9-way D-type socket with the signals as detailed in the table

below:

Pin number Function

1 Not connected

2TX_A

3RX_A

4RX_B

50v

6 ESTOP_A

7 ESTOP_B

8TX_B

9 +15v

Shell Screen

6.2.2 Emergency stop connector

The emergency stop connector is a two pin Lemo connector that is connected directly to pins 6

and 7 of the MCU1 9-way D-type socket connector, these pins should be connected into the

CMMs emergency stop system.

Pin number Function

1 ESTOP_A

2 ESTOP_B

Shell Screen

Page 40

38 MCU1 daughtercard

6.3 Configuration options

6.3.1 Emergency stop signal

The diagram below shows the EMERGENCY STOP signal routing through the MCU1

daughtercard.

NOTE: The emergency stop signal is not connected to any internal circuits within the

daughtercard, the emergency stop signal is routed directly from the 9-way D-type connector to the

emergency stop connector on the rear of the card.

6.4 Operating overview

6.4.1 Method of operation

The MCU daughtercard decodes the input from the MCU1 joystick unit, to give the information

required by the controller.

The MCU daughtercard is software configurable. Please refer to either the COM class

programmers guide (Renishaw part number H-1000-5230) or the UCC command set (Renishaw

part number H-1000-5222) for further details.

Page 41

SP25M daughtercard 39

7 SP25M daughtercard

NOTE: This daughtercard is only suitable for use in the UCC1 controller. The UCC2 has this

functionality integrated as standard on its motherboard.

7.1 Introduction

The UCC1 main unit has an analogue probe port for use with the SP600, TP200 and TP20 range

of probes. This daughtercard adds a further capability to that of the analogue connector permitting

the use of the SP25M probe, whilst still accommodating SP600, TP200 and other standard touch

trigger probes, without the need to change cable connections.

NOTE: The UCC2 controller has an integrated SP25 interface that removes the requirement for a

SP25 daughtercard at be fitted.

7.2 Connectors and pin outs

On the rear panel of the SP25M daughtercard there is a single connector:

• the connection to the multiwire probe cable, via a 15-way HDD connector, labelled analogue

probe

7.2.1 Analogue probe connector

This enables connection of the SP25M, SP600 family, TP20 or TP200 probes to the UCC1.

The connections for the analogue probe connector are shown in the table below.

Jacking posts are fitted to the connector on the rear panel to secure the mating plug.

Pin

number

1 +5v probe supply 9 Reserved

2 Reserved 10 Probe overtravel

3 TTP signal / 0v 11 Channel A

4 Channel B 12 0 V ref

5 Channel C 13 TTP signal

6 +12V 14 Head LED anode

7 -12V 15 Head LED cathode

8 Probe identification Shell Screen

Signal description

Pin

number

Signal description

Page 42

40 SP25M daughtercard

7.3 Operating overview

7.3.1 Method of operation

The SP25M daughtercard is used to interface any SP600, TP200, TP20 or SP25M probe into the

UCC1 system. This card replaces the need to interface some of these probes via the analogue

probe connector on the main UCC1 motherboard.

NOTE: When the SP25M daughtercard is installed into the UCC1 system it will disable the

function offered by the analogue probe connector on the UCC1 main unit. This is no longer

required, since the interface board connects internally to the controller.

Page 43

SP80 daughtercard 41

8 SP80 daughtercard

NOTE: This daughtercard is suitable for use in both UCC1 and UCC2 controllers.

8.1 Introduction

This daughtercard permits the use of the SP80 probe system with the UCC1 or UCC2 controller.

NOTE: This daughtercard is only compatible with the production version of the SP80 probe,

which can be identified by:

Probe status LED = production version (compatible)

No probe status LED = prototype version (not compatible).

8.2 Connector and pin outs

On the rear panel of the SP80 daughtercard there is a single connector:

• Connection to the machine cable, via a 15-way D-type connector, labelled PROBE.

8.2.1 SP80 connector

This 15-way D-type connector permits the connection of the SP80 probe to the UCC1 system.

NOTE: This connection is designed to only accept the production version of the SP80 probe,

fitment of a PH10 system or an early SP80 system to this connector may cause damage to the

daughtercard.

Page 44

42 SP80 daughtercard

Jacking posts are fitted to the connector on the rear panel to secure the mating plug.

Pin

number

1 Cos Y 9 Not connected

2 Not connected 10 Red LED drive

3 Cos Z 11 Cos X

40 V 12Sin X

5 Probe identification 13 Not connected

6 Green LED drive 14 in Y

7 Sin Z 15 Probe power

8 Reference voltage Shell Screen

Signal description

Pin

number

Signal description

8.3 Operating overview

The SP80 daughtercard is used to interface the SP80 probe with the UCC1 or UCC2 system.

When the SP80 probe is detected, all enabled scanning options will be available to the system

user.

Page 45

Additional I/O daughtercard 43

9 Additional I/O daughtercard

NOTE: This daughtercard is suitable for use in both UCC1 and UCC2 controllers.

9.1 Introduction

The additional input / output daughtercard is one of a range of plug-in daughtercards available for

the Renishaw universal CMM controllers.

This card provides sixteen additional uncommitted inputs and sixteen additional uncommitted

outputs.

9.2 Connector and pin outs

On the rear panel of the additional input / output daughtercard there is one connector which is:

• a 37-way D-type connector, labelled additional I/O

9.2.1 Additional I/O connector

This connector permits the connection of input or output signals to or from the UCC1 or UCC2.

Jacking posts are fitted to the connector on the rear panel to secure the mating plug.

Pin number Function Description

1 +24 V dc Provided for use on CMM switches 9.3.2.2

2 Additional output 10 General purpose output signal 9.3.2.2

3 Additional output 9 General purpose output signal 9.3.2.2

4 Additional output 6 General purpose output signal 9.3.2.2

5 Additional output 7 General purpose output signal 9.3.2.2

6 Additional output 0 General purpose output signal 9.3.2.2

7 Additional output 1 General purpose output signal 9.3.2.2

8 Additional output 2 General purpose output signal 9.3.2.2

9 Additional output 3 General purpose output signal 9.3.2.2

10 Additional output 4 General purpose output signal 9.3.2.2

11 Additional output 5 General purpose output signal 9.3.2.2

12 Additional output 6 General purpose output signal 9.3.2.2

13 Additional output 11 General purpose output signal 9.3.2.2

14 Additional output 12 General purpose output signal 9.3.2.2

15 Additional output 13 General purpose output signal 9.3.2.2

16 Additional output 14 General purpose output signal 9.3.2.2

17 Additional output 15 General purpose output signal 9.3.2.2

18 0 V

19 0 V

20 +24 V dc Provided for use on CMM switches 9.3.2.1

21 Additional input 12 General purpose input signal 9.3.2.1

22 Additional input 13 General purpose input signal 9.3.2.1

See

section

Page 46

44 Additional I/O daughtercard

23 Additional input 14 General purpose input signal 9.3.2.1

24 Additional input 15 General purpose input signal 9.3.2.1

25 Additional input 0 General purpose input signal 9.3.2.1

26 Additional input 1 General purpose input signal 9.3.2.1

27 Additional input 2 General purpose input signal 9.3.2.1

28 Additional input 3 General purpose input signal 9.3.2.1

29 Additional input 4 General purpose input signal 9.3.2.1

30 Additional input 5 General purpose input signal 9.3.2.1

31 Additional input 6 General purpose input signal 9.3.2.1

32 Additional input 7 General purpose input signal 9.3.2.1

33 Additional input 8 General purpose input signal 9.3.2.1

34 Additional input 9 General purpose input signal 9.3.2.1

35 Additional input 10 General purpose input signal 9.3.2.1

36 Additional input 11 General purpose input signal 9.3.2.1

37 0 V

Shell Shell and screen

9.3 Operating overview

The additional input / output daughtercard complements the current 6 input and 6 output

uncommitted connections on the UCC1 or UCC2 motherboard. Both the motherboard and the

additional input / output daughtercard takes its power directly from the controller.

9.3.1 Software integration

Software integration details are specified in the UCC command set document (Renishaw part

number H-1000-5222), please refer to this document for full integration details.

9.3.1.1 Read from additional I/O card

Command 343 (refer to UCC command set, Renishaw part number H-1000-5222) is used to read

from the connections on the additional I/O card.

9.3.1.2 Write to additional I/O card

Command 344 (refer to UCC command set, Renishaw part number H-1000-5222) is used to

activate the output connections on the additional I/O card.

Page 47

Additional I/O daughtercard 45

9.3.2 Electrical integration

9.3.2.1 Machine opto-isolated input

The circuit used for the input to the UCC is as outlined below with the electrical characteristics as

detailed:

Machine I/O inputs ratings

Maximum current

Open circuit voltage

Switching values

Max. OFF current

Min. ON current

NOTE: The CMM status switches must be isolated from all other circuits.

Polarity: In the safe operating condition the input should be pulled down to the 0 V return line

(i.e. switch closed).

9.3.2.2 Machine output

The circuit used for the output from the UCC is as outlined below with the electrical characteristics

as detailed:

Machine I/O output ratings

Maximum current

Maximum rated current

Open circuit voltage

2.5 mA

24 V

10 µA

1 mA

500 mA (pulse)

100 mA

24 V

Polarity: The transistor will be conducting for the active state of the output.

Page 48

46 Temperature sensor daughtercard

10 Temperature sensor daughtercard

NOTE: This daughtercard is suitable for use in both UCC1 and UCC2 controllers.

10.1 Introduction

Up to 24 sensors can be monitored, with the information being used to compensate for

measurement errors introduced by thermal expansion. 23 permanently fixed sensors measure the

temperature of the desired parts of the CMM, and an additional sensor can monitor the

temperature of the part under inspection.

The daughtercard is designed for use with Beta Therm NTC 10K3A1 thermistors. These sensors

have an accuracy of up to +/- 0.1 º C (There are several manufacturers who make equivalent

devices). Other types of sensor can be used, however interface card hardware and software will

not be optimised for such devices.

10.2 Connector and pin outs

On the rear panel of the temperature sensor daughtercard there is a single connector:

• a 44-way D-type connector is used for connection of temperature sensors to the UCC system

TEMPERATURE

SENSE

efg

Page 49

Temperature sensor daughtercard 47

10.2.1 44-way connector

This connector permits the connection of the thermistors to the UCC.

The connections for the 44-way D-type connector are shown in the table below.

Jacking posts are fitted to the connector on the rear panel to secure the mating plug.

Pin no. Channel Description Pin no. Channel Description

1 2 Sensor 2 24 Sensor common

2 3 Sensor 3 25 Sensor common

3 4 Sensor 4 26 Sensor common

4 5 Sensor 5 27 Sensor common

5 6 Sensor 6 28 Sensor common

6 7 Sensor 7 29 Sensor common

7 8 Sensor 8 30 Sensor common

8 9 Sensor 9 31 Sensor common

9 11 Sensor 10 32 Part attached

10 13 Sensor 11 33 Sensor common

11 15 Sensor 15 34 Sensor common

12 17 Sensor 17 35 1 Sensor 1

13 19 Sensor 19 36 Sensor common

14 21 Sensor 21 37 10 Sensor 10

15 23 Sensor 23 38 12 Sensor 12

16 Sensor common 39 14 Sensor 14

17 Sensor common 40 16 Sensor 16

18 Sensor common 41 18 Sensor 18

19 Sensor common 42 20 Sensor 20

20 Sensor common 43 22 Sensor 22

21 Sensor common 44 24 Sensor 24

22 Sensor common Shell Screen

23 Sensor common

10.3 Operating overview

The temperature sensor daughtercard has no user selectable settings.

Unused channels will be specified in the software that is downloaded to the UCC. Similarly,

whether the output from channels is to be used to make direct or differential temperature

measurements will also be specified in the downloaded software. This information affects the way

that the UCC1 processes the data from the interface card, but it is not required by the card itself.

Page 50

48 Temperature sensor daughtercard

The temperature sensor daughtercard measures each input in rotation and digitises the result in a

12-bit word. Each measurement is then processed to reduce errors introduced by the electronic

circuit and interference signals before being stored in memory on the card. The resistance of each

sensor is then stored in a unique memory location, where it can be directly accessed by the UCC.

In addition to the sensor’s resistance, the interface provides the controller with the following status

information about each sensor and the card:

• The sensor’s resistance measurement is consistent and can be used by the UCC

• No sensor is connected/ the channel is open circuit

• The channel is faulty/ short circuit

• The temperature sensor interface card is OK

• The sensor is within the defined limits

10.3.1 Software integration

Software integration details are specified in the UCC command set document (Renishaw part

number H-1000-5222), please refer to this document for full integration details.

10.3.1.1 Configure the temperature sensor daughtercard

Command 436 (refer to UCC command set document, Renishaw part number H-1000-5222) is

used to configure the temperature sensor card.

10.3.1.2 Latch the temperature sensor daughtercard

Command 437 (refer to UCC command set document, Renishaw part number H-1000-5222) is

used to start the temperature reading process for the temperature sensor card.

10.3.1.3 Read data and status of temperature sensor daughtercard

Command 438 (refer to UCC command set document, Renishaw part number H-1000-5222) is

used to read the latched temperature and status of the temperature sensor daughtercard.

Page 51

Temperature sensor daughtercard 49

10.3.2 Electrical integration

10.3.2.1 Thermistor connections to daughtercard

The 44-pin high-density D-type connector on the daughtercard has the following connections:

FUNCTION CONNECTION

Part under inspection sensor attached switch 1 pin

Part under inspection’s sensor signal 1 pin

CMM sensors’ signal (23 Channels) 23 pins

Sensors’ common connection (0 V) 19 pins *

Cable screen ground Via connector shell

NOTES:

* Common required for all sensors and part under inspection sensor attached switch common

Unused pins should be left open circuit inside the D type connector.

Each temperature sensor will have two terminals that are connected to the temperature sensor

daughtercard in the UCC.

It is recommended that to avoid having to re-wire the machine if a sensor has to be changed after

installation, the sensor should have connectors attached locally. These should plug into screened

cables that run through the CMM to where the UCC is located. At the UCC, all the cables from the

different temperature sensors should be bought together and wired into a 44-pin high-density

D-type socket connector.

Page 52

50 Additional axis daughtercard

11 Additional axis daughtercard

NOTE: This daughtercard is suitable for use in both UCC1 and UCC2 controllers.

11.1 Introduction

The additional axis daughtercard is one of a range of plug-in daughtercards for the Renishaw

CMM controller products (UCC1 and UCC2).

This daughtercard has been created to enable the following capabilities to be added to the UCC1

system. It is also valid for the UCC2 controller but because the UCC2 is already a four axis

controller it is only needed when a fifth axis is required.

• Rotary table

• Additional axis (scale only)

• Additional axis (scale and drive)

The additional axis daughtercard offers the ability to change its internal reference address

permitting up to four of these cards to be fitted to a UCC.