Page 1

Installation

H-2000-501

and

user’s

8-06-D

guide

RENISHAW

apply

innovation’"

TS27R

i

tool

setting

:

probe

:

r

m

1

English

Francais

Deutsch

Itaiiano

Page 2

1

Installation

user's

and

TS27R

guide

C€

English

2

Frangais

3

Deutsch

4

Italian©

Tool

Manuel

Installations-

TS27R

Manuale

d'installation

Palpeur

Werkzeugmess-System

zur

Werkzeugeinstellung

Sonda

degli

setting

d’outil

und

d’installazione

la

per

utensili

probe

et

reglage

de

TS27R

Benutzerhandbuch

regolazione

TS27R

d'utilisation

e

d’uso

C€

C€

C€

I

:

,

Page 3

FCC

This

Section

device

15.19

complies

conditions:

This

1.

2.

This

undesired

FCC

Section

This

equipment

pursuant

against

equipment

used

in

may

device

device

must

operation.

15.105

to

Part

harmful

generates,

accordance

communications.

interference,

FCC

user

The

pic,

or

FCC

Section

The

user

computer,

limits.

Section

is

cautioned

authorised

is

also

must

in

15.21

15.27

with

not

cause

accept

been

has

of

the

15

interference

uses,

the

with

Operation

which

case

that

representative

cautioned

be

connected

1

Part

harmful

any

tested

FCC

rules.

when

and

instruction

this

of

you

will

any

changes

that

any

with

FCC

DECLARATION

the

of

5

FCC

interference.

interference

and

found

These

the

equipment

can

radiate

manual,

equipment

be

required

or

could

void

peripheral

high-quality

a

rules.

Operation

received,

comply

to

limits

radio

are

is

frequency

may

a

in

to

correct

including

with

designed

operated

cause

residential

modifications

the

user's

authority

device

installed

shielded

(USA)

the

harmful

the

expressly

not

cable

energy

subject

is

interference

limits

foraClass

to

provide

in

a

commercial

and,

interference

is

likely

area

interference

approved

to

operate

this

with

to

insure

to

the

following

that

A

reasonable

environment.

if

installed

not

cause

to

your

at

the

equipment.

equipment

compliance

may

cause

digital

to

radio

harmful

own

by

Renishaw

such

with

two

device,

protection

This

and

expense.

as

a

FCC

TS27R

probe

Operation

Specification

Interface

Dimensions

Installation

Wiring

connection

The

TS27R

Before

starting

and

the

power

systc

unit

c

system

work

suppl

Page 4

TS27R

tool

setting

probe

TS27R

Operation

Specification

Interface

Dimensions

Installation

Wiring

The

Before

and

probe

unit

connection

TS27R

starting

power

the

system

system

work,

supply

diagrams

must

be

ensure

the

to

Installation

by

competent

the

machine

8-4

a

disconnected.

installed

that

8/MI

Ml

user's

and

Contents

-4

-6

SAFETY

in

is

Fitting

Break

Stylus

Square

Service

Diaphragm

Parts

person,

a

1-1

1-2

1-3

1-3

1

1-5

1

tool

list

safe

guide

the

stylus

stem

setting

level

stylus

and

maintenance

maintenance

observing

condition

captive

and

alignment

relevant

with

the

.

link

safety

power

precautions.

switched

OFF

1-10

1-11

1-12

1-13

1-14

1-15

1-16

Page 5

to

equipment

reserves

without

machine

machine

tools

persons

the

of

probe

components

and

logo

in

pic

innovation

names

brand

are

registered

or

owners.

notice

products

of

products,

patent

and

righttochange

the

notice.

always

must

accordance

in

instructions.

system

reasonably

the

the

are

is

trade

UK

a

emblem

probe

registered

other

and

trademarkofRenishaw

and

product

names,

trademarksoftheir

in

shown

subject

are

the

applications:

GB

2277593

IT

1273643

1,445/1997

JP

2,098,080

JP

320,394/1994

JP

be

operated

with

clean.

trademarks

countries.

names

service

this

user's

of

JP

US

US

US

US

by

the

in

used

of

used

marks,

guide,

following

the

2002-531,839

5,446,970

5,647,137

5,669,151

6,470,584

the

pic.

in

and

B1

i

CNC

machine

controi

I

The

TS27R

CNC

machini

For

tool

detection,

in

stylus

in

X

and

adjust*

Screw

the

with

interface

An

probe

the

Cabl

lengt

the

the

for

Y

mact

anc

p

1

i

in

or

of

Changes

Renishaw

specifications

CNC

CNC

competent

manufacturer’s

Care

Keep

Trademarks

RENISHAW®

RENISHAW

Renishaw

apply

other

All

this

document

trademarks,

respective

Patent

Features

of

related

patents

4413968

DE

0293036

EP

0695926

EP

0748669

EP

1051668

EP

©

1

995

-

This

document

or

whole

language,

permission

The

publication

does

not

Renishaw

2005

in

part,

by

of

imply

pic.

Renishaw

may

not

or

transferred

means,

any

Renishaw.

of

material

freedom

be

from

pic.

All

copied

to

without

within

the

rights

reproduced

or

other

any

prior

the

this

document

patent

reserved.

media

written

of

rights

Disclaimer

to

free

to

the

disclaims

the

right

the

product

to

to

notify

warranty

claims

have

8-06-D

ensure

that

from

Renishaw

contents

any

implied

make

to

any

must

be

will

has

been

been

made

Considerable

the

contents

inaccuracies

makes

this

document

warranties.

changes

described

person

*

Warranty

Equipment

be

returned

considered

misused,

attempted

Renishaw

warranties

no

Renishaw

to

this

herein

such

of

requiring

to

where

repairs

or

by

part

effort

this

of

and

and

document

changes.

your

unauthorised

no:

been

has

document

omissions.

with

specifically

reserves

obligation

without

attention

supplier.

Renishaw

adjustments

or

H-2000-501

are

However,

respect

and

under

No

equipment

persons.

Issued:

04.05

Page 6

Cable

:

1

CNC

machine

control

i

i

Alternative

nnRENlSHAW.

j

j

r

.

T

Iff

®

II

Mi

8-4

jÿHRENISHAW*

t.

|fe>~“£'nE"f*eE

-

m

Ml

interface

INTERFACE

PROBE

sss®

interface

8

interface

'OS

setting

tool

1-1

in

-

a

TS27R

PROBE

SYSTEM

Diameter

units

__

-”-f

H

n

i

TS27R

10

probe

7

5V

Z

X/Y

=

V

Rotate

reverse

c!;i'

direction

//

&

t.®

i!

7

<<3

9

H

4

2

I

3

:

6

m

8

Machine

Stylus

setting

broken

the

probe

be

can

aligned

be

between

on

tool

set

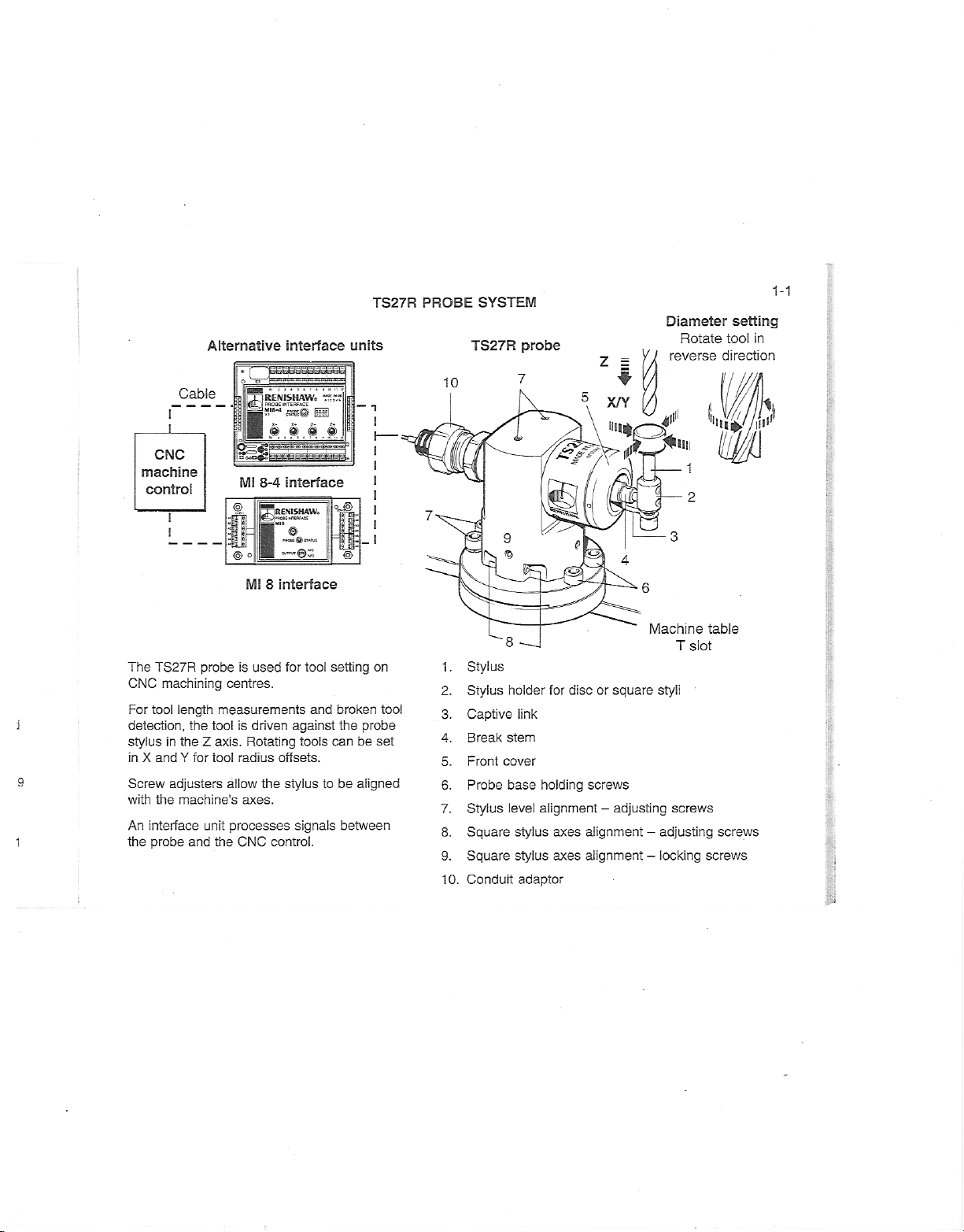

The

CNC

For

j

9

1

tool

detection,

stylus

in

X

Screw

with

interface

An

the

probe

TS27R

machining

length

the

theZaxis.

in

and

for

Y

adjusters

the

machine's

and

probe

is

used

centres.

measurements

is

driven

tool

Rotating

radius

tool

allow

axes.

unit

processes

the

CNC

offsets.

the

control.

for

tool

against

tools

stylus

signals

and

to

1

2.

3.

4.

5.

6.

7.

8.

9.

10.

.

Stylus

Captive

Break

Front

Probe

Stylus

Square

Square

Conduit

holder

link

stem

for

disc

cover

base

holding

alignment-adjusting

level

stylus

axes

axes

stylus

adaptor

or

square

styli

screws

alignment-adjusting

alignment

-

locking

T

slot

screws

table

screws

screws

=

i

Page 7

1-2

OPERATION

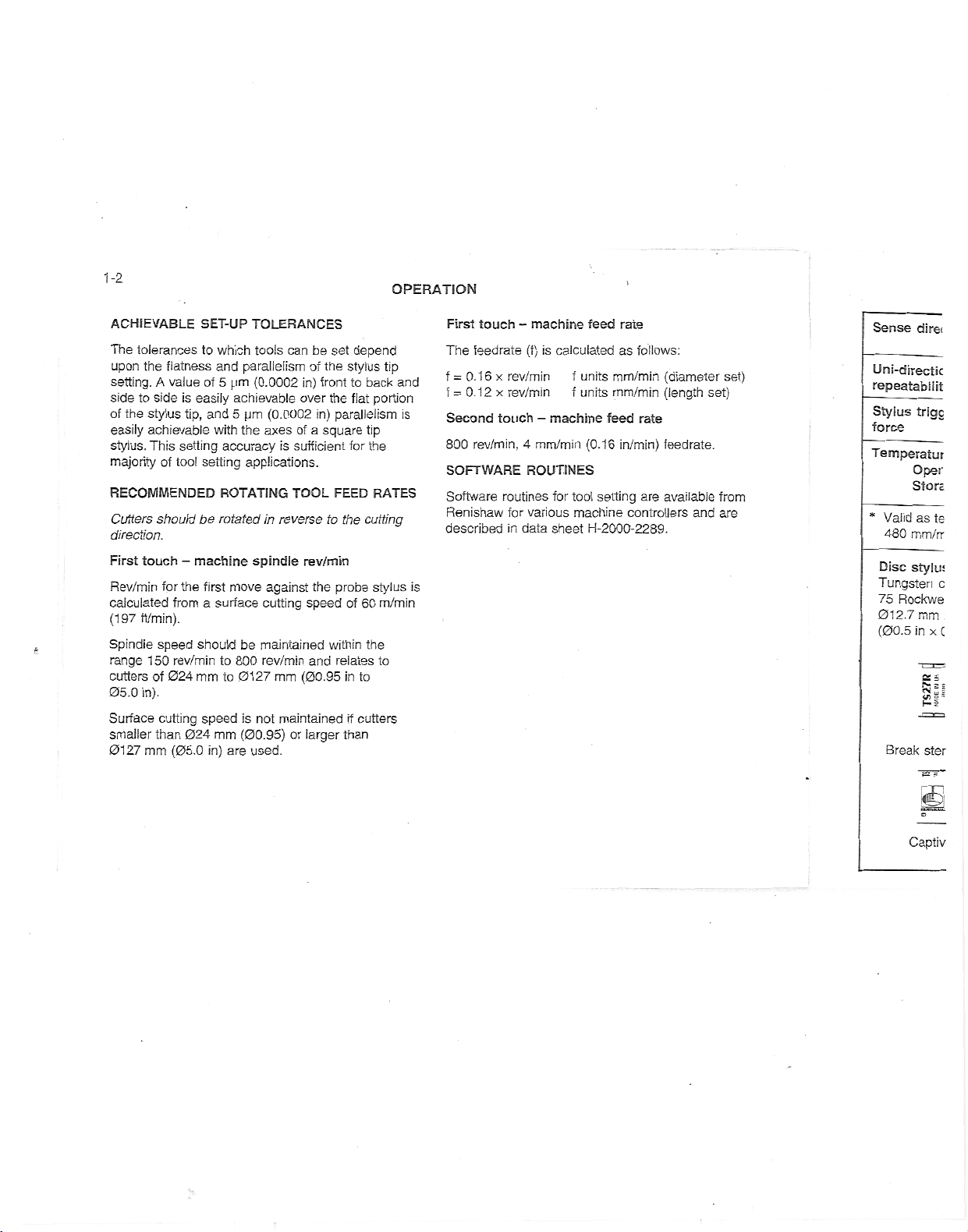

ACHIEVABLE

The

tolerances

upon

the

setting.

side

to

of

stylus

the

easily

achievable

stylus.

This

majority

flatness

value

A

side

of

SET-UP

is

easily

tip,

setting

tool

to

of

setting

RECOMMENDED

Cutters

should

be

direction.

First

touch-machine

Rev/min

calculated

(197

Spindle

range

cutters

05.0

Surface

smaller

0127

for

ft/min).

speed

150

of

in).

cutting

than

mm

the

from

rev/min

024

mm

024

(05.0

first

a

should

speed

which

and

parallelism

5

pm

achievable

and

5

pm

with

the

accuracy

applications.

ROTATING

rotated

move

surface

be

to

800

01

to

is

(00.95)

mm

in)

are

TOLERANCES

tools

can

be

the

of

(0.0002

spindle

in)

over

(0.0002

axes

of

is

sufficient

TOOL

reverse

in

rev/min

against

cutting

maintained

rev/min

(00.95

mm

27

not

maintained

or

front

in)

square

a

to

the

speed

and

larger

the

within

used.

set

depend

stylus

back

to

portion

flat

parallelism

tip

for

the

FEED

RATES

the

cutting

stylus

probe

60

m/min

of

the

relates

to

to

in

if

cutters

than

tip

and

is

is

First

touch-machine

The

feedrate

x

0.16

f

=

f

Second

800

SOFTWARE

Software

x

0.12

=

touch-machine

rev/min,

routines

Renishaw

described

is

(f)

rev/min

rev/min

4

mm/min

ROUTINES

various

for

data

in

feed

calculated

f

units

f

units

(0.16

for

tool

machine

H-2000-2289.

sheet

rate

as

mm/min

mm/min

feed

in/min)

setting

follows:

(diameter

(length

rate

feedrate.

available

are

controllers

and

set)

set)

from

are

Sense

direi

Uni-directic

repeatabilit

Stylus

trigc

force

Temperatur

Oper

Store

Valid

480

Disc

as

mm/rr

stylus

*

Tungsten

75

Rockwe

012.7

mm

(00.5

in

x

st

§i>

Break

ster

te

c

C

i

=

s

Captiv

Page 8

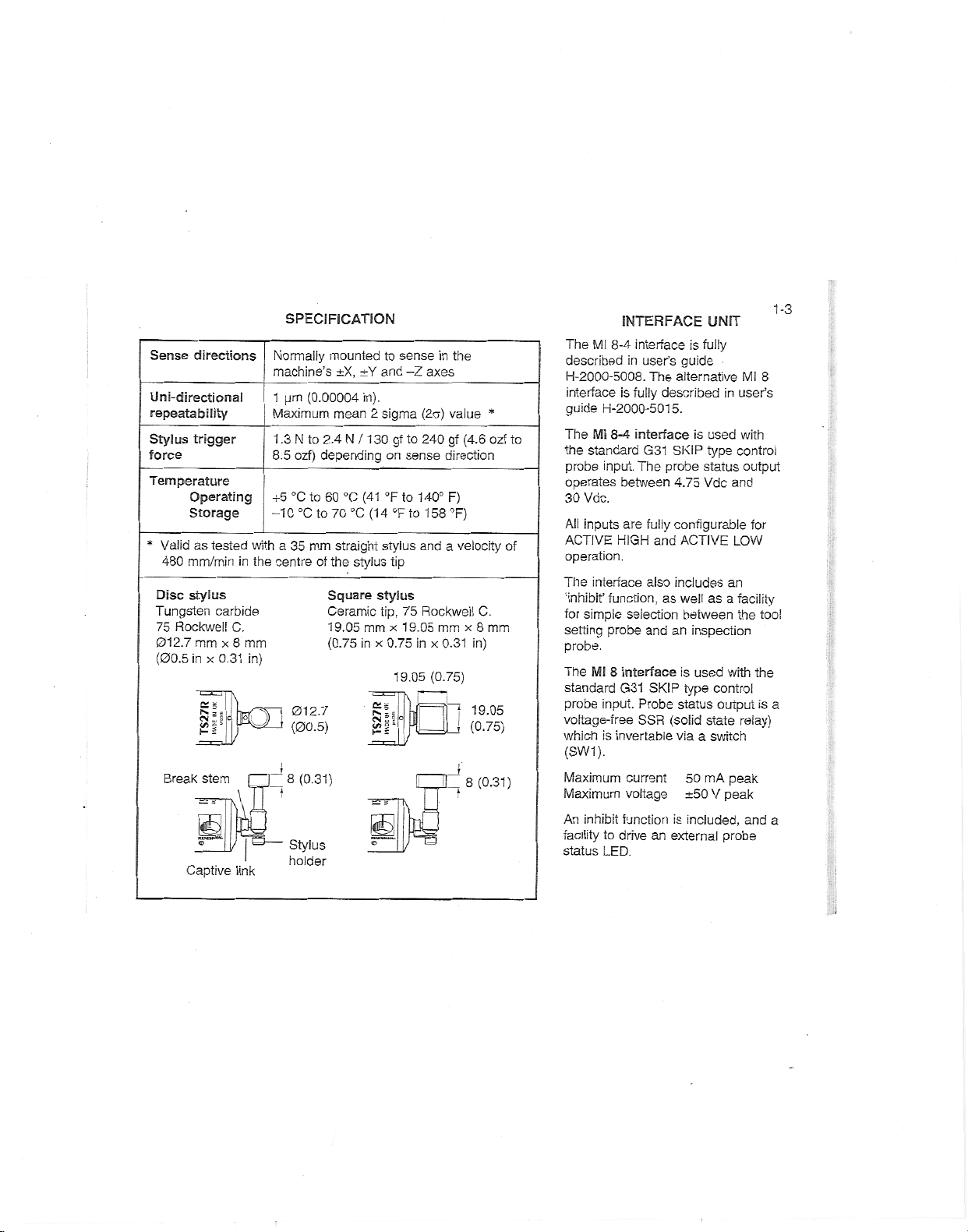

Sense

directions

Uni-directional

repeatability

Stylus

trigger

force

Temperature

Operating

Storage

Valid

as

*

480

Disc

Tungsten

75

012.7

(00.5

tested

mm/min

stylus

carbide

Rockwell

mm

x

in

2=5

gjllBCC

Break

stem

Captive

C.

x

0.31

Tl

in

8

link

SPECIFICATION

Normally

machine’s

1

pm

Maximum

1

N

.3

ozf)

8.5

°C

+5

°C

-10

a

35

with

the

centre

mm

in)

i

012.7

(00.5)

8

(0.31)

Stylus

holder

mounted

±X,

(0.00004

mean

to

2.4

depending

to

60

°C

70

to

straight

mm

of

the

Square

Ceramic

19.05

(0.75

N

°C

stylus

±Y

/

in

in).

2

1

(41

(14

mm

to

and

sigma

30

on

°F

stylus

stylus

tip,

x

x

0.75

S*

S

£2

sense

-Z

to

gf

sense

to

to

°F

tip

75

19.05

19.05

in

axes

(2ct)

value

gf

240

direction

140°

F)

°F)

158

a

and

Rockwell

mm

in

x

0.31

(0.75)

T|

iU

IL.

the

(4.6

velocity

C.

x

8

in)

19.05

|

(0.75)

8

(0.31)

*

ozf

mm

user’s

control

and

LOW

an

a

facility

the

with

relay)

peak

Ml

8

with

output

for

tool

the

is

and

1-3

a

a

INTERFACE

Ml

The

described

H-2000-5008.

interface

guide

to

of

The

the

probe

operates

30

Vdc.

All

inputs

ACTIVE

operation.

The

‘inhibit’

simple

for

setting

probe.

The

standard

probe

voltage-free

interface

8-4

in

user’s

fully

is

H-2000-5015.

8-4

Mi

interface

standard

input.

between

G31

The

are

HIGH

interface

function,

selection

probe

Mi

8

interface

G31

input.

Probe

SSR

The

fully

and

also

and

SKIP

whichisinvertable

(SW1).

Maximum

Maximum

An

facility

status

inhibit

to

LED.

current

voltage

function

drive

an

UNIT

is

fully

guide

alternative

described

is

used

SKIP

type

status

probe

4.75

Vdc

configurable

ACTIVE

includes

well

as

as

between

an

inspection

is

used

type

control

status

(solid

state

viaaswitch

50

mA

V

±50

is

included,

external

in

output

peak

probe

I

Page 9

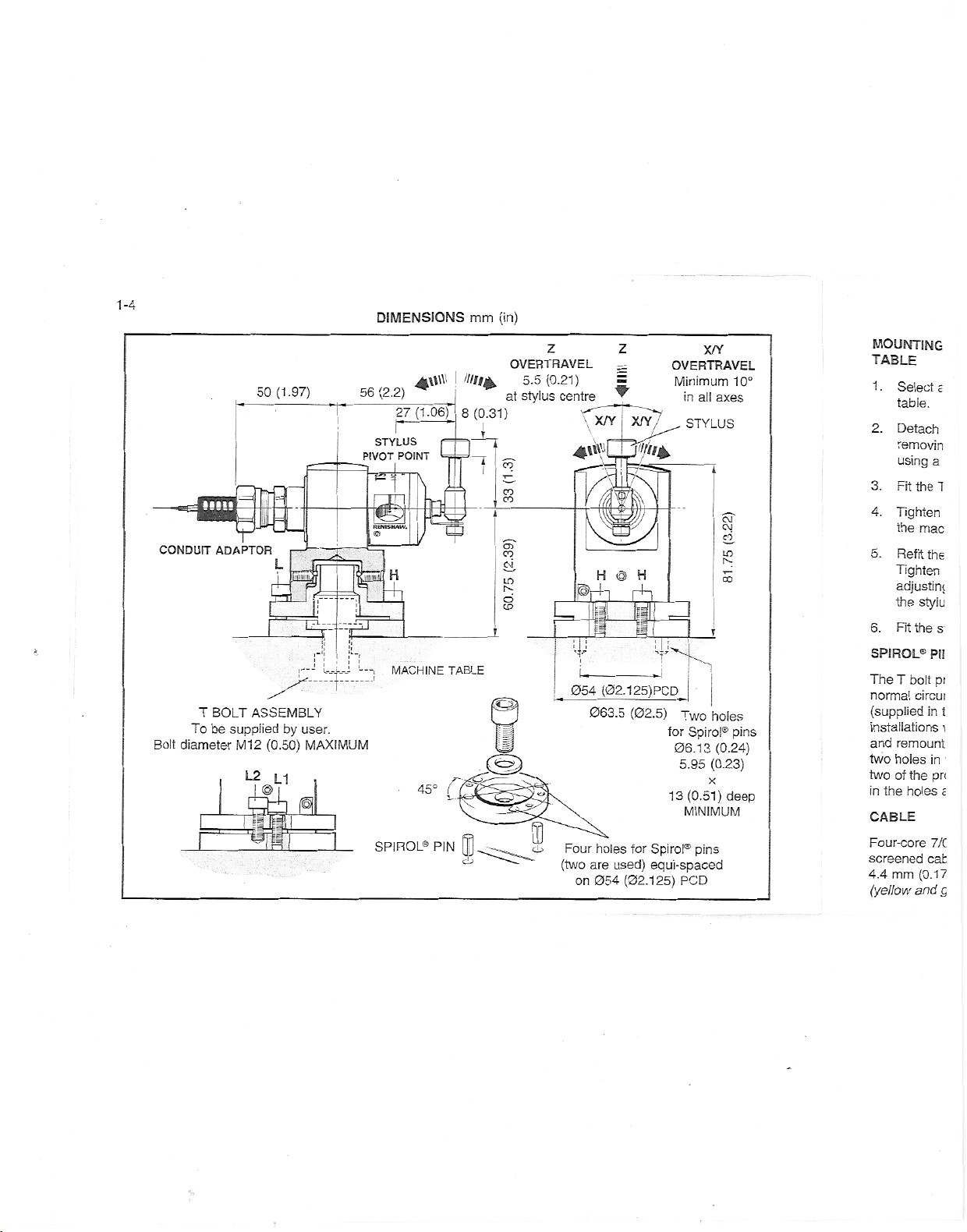

1-4

DIMENSIONS

mm

(in)

CONDUIT

Bolt

diameter

aaaaa

T

To

I

r

be

-

V-

ADAPTOR

BOLT

supplied

M12

L2

ijjfjjll

ifr

50

(1.97)

TV-

1

SI

—

j

‘“Ml

I

r'i

!'

ASSEMBLY

by

user.

(0.50)

MAXIMUM

L1

&

I

I

¥

j

32

56

(2.2)

STYLUS

PIVOT

PC

e

_1

M

L.

SPIROL®

4\\Wj////14

(1.06)

27

!

POINT

:

/

MACHINE

45°

PIN

_

I

8

¥

TABLE

Crt

!-•

ff

CD

(0.31)

l

I

1

H

tl

at

3-

LO

o

:z

Z

OVERTRAVEL

(0.21)

5.5

stylus

centre

4\WQ3ÿ.

Prh

_

054

cu

Four

(two

on

z

X/Y

X/Y

Jr-

H@H

rh

li

V

(02.125)PCD

(02.5)

063.5

for

holes

used)

are

(02.125)

054

X/Y

OVERTRAVEL

Minimum

in

all

STYLUS

I

J

Two

for

Spiral®

06.13

5.95

X

13

(0.51)

MINIMUM

Spiral®

pins

equi-spaced

PCD

10°

axes

CM

Si

£2.

Lfl

!

5

holes

pins

(0.24)

(0.23)

deep

MOUNTING

TABLE

1.

Select

table.

2.

Detach

removin

using

a

3.

Fit

the

4.

Tighten

the

mac

5.

Refit

the

Tighten

adjusiini

the

styiu

6.

Fit

the

SPIROL®

The

normal

(supplied

installations

and

two

two

in

CABLE

Four-core

screened

4.4

(yellow

T

remount

holes

of

the

mm

bolt

circui

the

holes

(0.17

and

PI!

pi

in

in

pr<

7/C

cat

E

1

s

t

\

c

5

Page 10

r

IL

ns

l)

ep

MOUNTING

TABLE

Select

1.

table.

Detach

2.

removing

using

Fit

3.

theTbolt

Tighten

4.

the

machine

5.

Refit

the

Tighten

adjusting

stylus

the

6.

the

Fit

SPIROL®

The

T

bolt

normal

circumstances.

(supplied

in

installations

and

remount

holes

two

of

the

two

in

the

holes

CABLE

Four-core

screened

mm

(0.17

and

4.4

(yellow

THE

a

position

the

the

a

mm

4

the

probe

the

screws

alignment

stylus

PINS

provides

the

where

the

in

the

probe

and

7/0.2

cable

in).

green

PROBE

for

the

probe

base

screws

two

AF

hexagon

(not

supplied

T

two

(see

probe

TS27R.

machine

base

refit

polyurethane

10m

bolt

table.

onto

screws

L1

(see

page

adequate

there

the

(32.8

Probe

not

secure

to

the

andL2loose

(see

pages

However

kit)

may

is

To

table

holes.

probe

circuit

used).

THE

ON

probe

the

from

H

and

key.

by

the

base

H

firmly.

page

1-10

1-4)

ciamping

two

be

a

requirement

fit

the

to

correspond

Place

base.

insulated

ft)

long.

-

red

MACHINE

machine

on

the

by

probe

the

screw

Renishaw).

base

probe

the

fit

and

Keep

the

before

1-12).

1-11).

and

ail

for

Spiral®

fitted

on

to

Spiral®

pins,

the

Spiral®

and

diameter

Cable

blue

and

INSTALLATION

L1

to

screws.

setting

pins

remove

drill

with

pins

NOTE

The

100

possible

cores

connected

EXTENSION

Probe

permitted

to

7/0.2

cable.

Maximum

Two-core

screened

joins.

CONDUIT

conduit,

1

mm

Conduit

recommends

(0.43

Renishaw

EF

installations.

01

Cable

Conduit

:

cable

screen

capacitor

nF

earth

to

CABLE

interface

mm

FOR

or

a

The

in)

adaptor

loops.

the

m

(15

length:

cable

-

m

25

polyurethene

Maintain

CABLE

the

PROTECTION

that

TS27R

flexible

alternative,

conduit

conduit.

suitable

T

:

n

E

is

connectedtothe

inside

the

TS27R

Ensure

appropriate

maximum

(82

ft)

long

insulated

screen

Thomas

adaptor

BS

G

H

n

to

the

cable

on

input

extension)

through

and

is

fitted

s

machine

prevent

screen

the

and

the

Betts

Type

all

to

accepts

via

is

interface.

1-5

a

til

Page 11

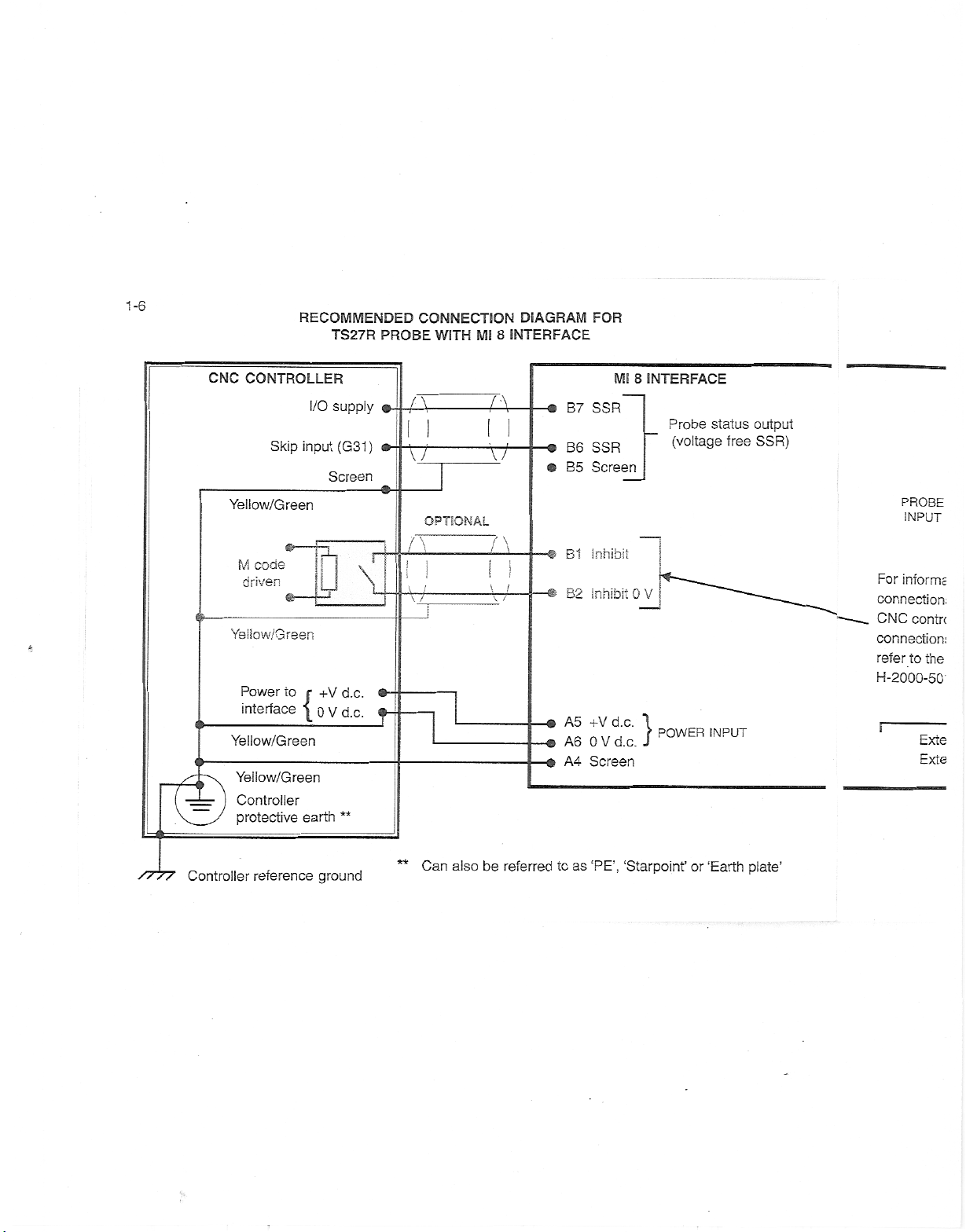

1-6

CNC

CONTROLLER

Yellow/Green

M

driven

6-

Yellow/Green

*

RECOMMENDED

I/O

input

Skip

code

*ÿ

TS27R

supply

(G31)

Screen

u

r

\

CONNECTION

PROBE

©-

A

a-

X7

I

WITH

OPTIONAL

INTERFACE

8

Ml

A

tt

n

_

\

i

.

.

DIAGRAM

B7

-c

B6

a

B5

B1

B2

FOR

Mi

SSR

SSR

Screen

Inhibit

inhibit

8

INTERFACE

Probe

(voltage

OV

status

free

output

SSR)

PROBE

INPUT

For

informs

connection.

CNC

contrc

connection:

refer

to

the

H-2000-50'

d.c.

**

s>

f

A5+Vd.c.

A6

•o

A4

-®

OVd.c.

Screen

POWER

}

INPUT

Exte

Exte

<ÿ

Power

to

interface

Yeliow/Green

Yellow/Green

Controller

protective

{

earth

+V

OVd.c.

also

Can

//

//

Controller

reference

ground

**

be

referred

as

to

‘PE’,

‘Starpoinf

or

‘Earth

plate’

Page 12

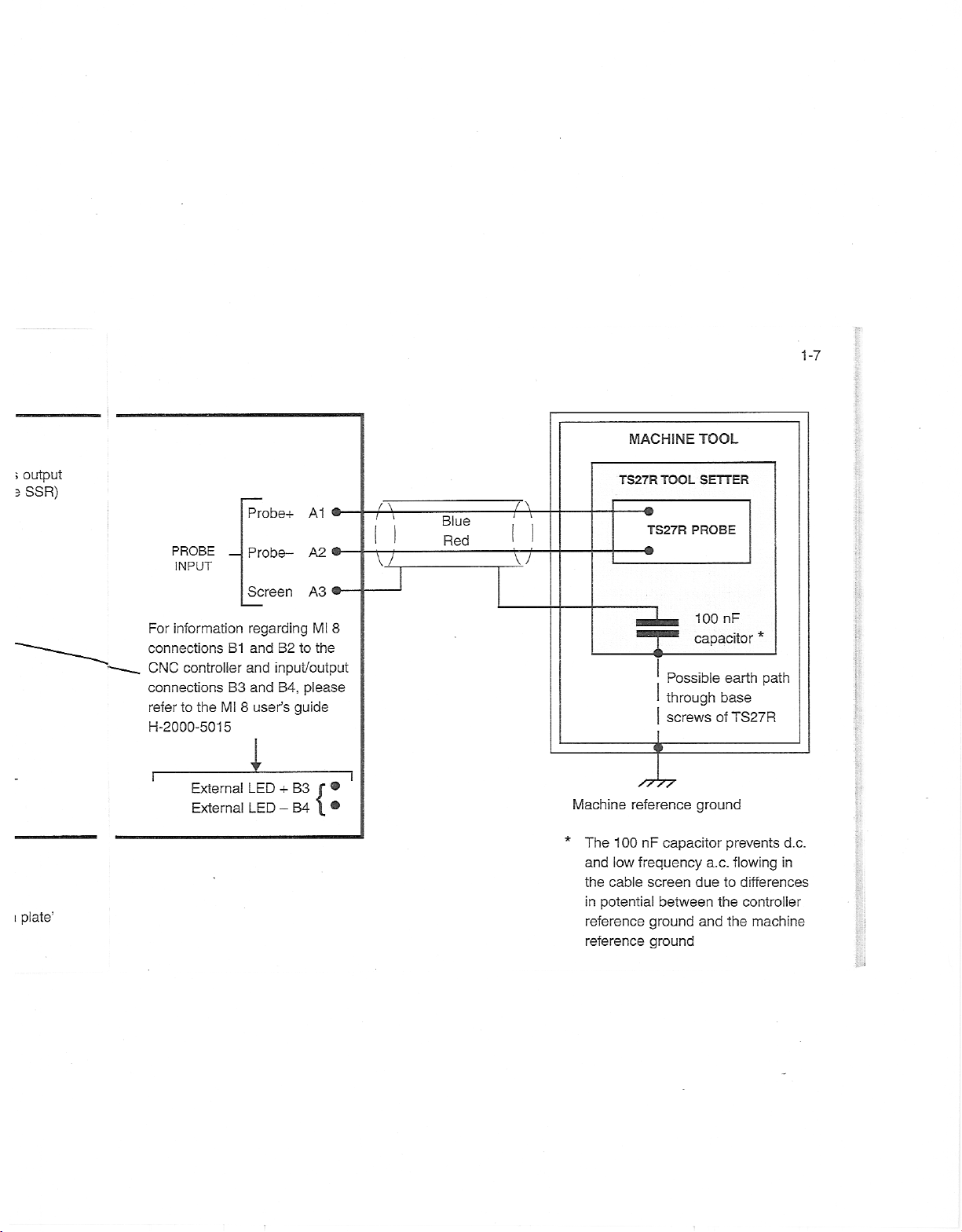

1-7

;

output

SSR)

3

i

plate’

Probe+

PROBE

INPUT

For

information

connections

CNC

controller

connectionsB3and

refer

H-2000-5015

r

the

to

External

External

B1

Ml

i

Probe-

Screen

regarding

and

and

user’s

8

LED

LED

A1

®-

A2

®-

A3

8

Mi

the

to

B2

input/output

B4,

please

guide

B3

+

{:

-

B4

TOOL

TOOL

SETTER

PROBE

Blue

Red

MACHINE

TS27R

\

/

-©

TS27R

-O

XI

nF

100

capacitor

o

Possible

through

screws

i

Machine

The

*

in

reference

1

00

and

low

the

cable

potential

reference

reference

capacitor

nF

frequency

screen

between

ground

ground

ground

a.c.

due

and

earth

base

of

TS27R

prevents

flowing

to

differences

the

controller

the

*

path

d.c.

in

machine

j

Page 13

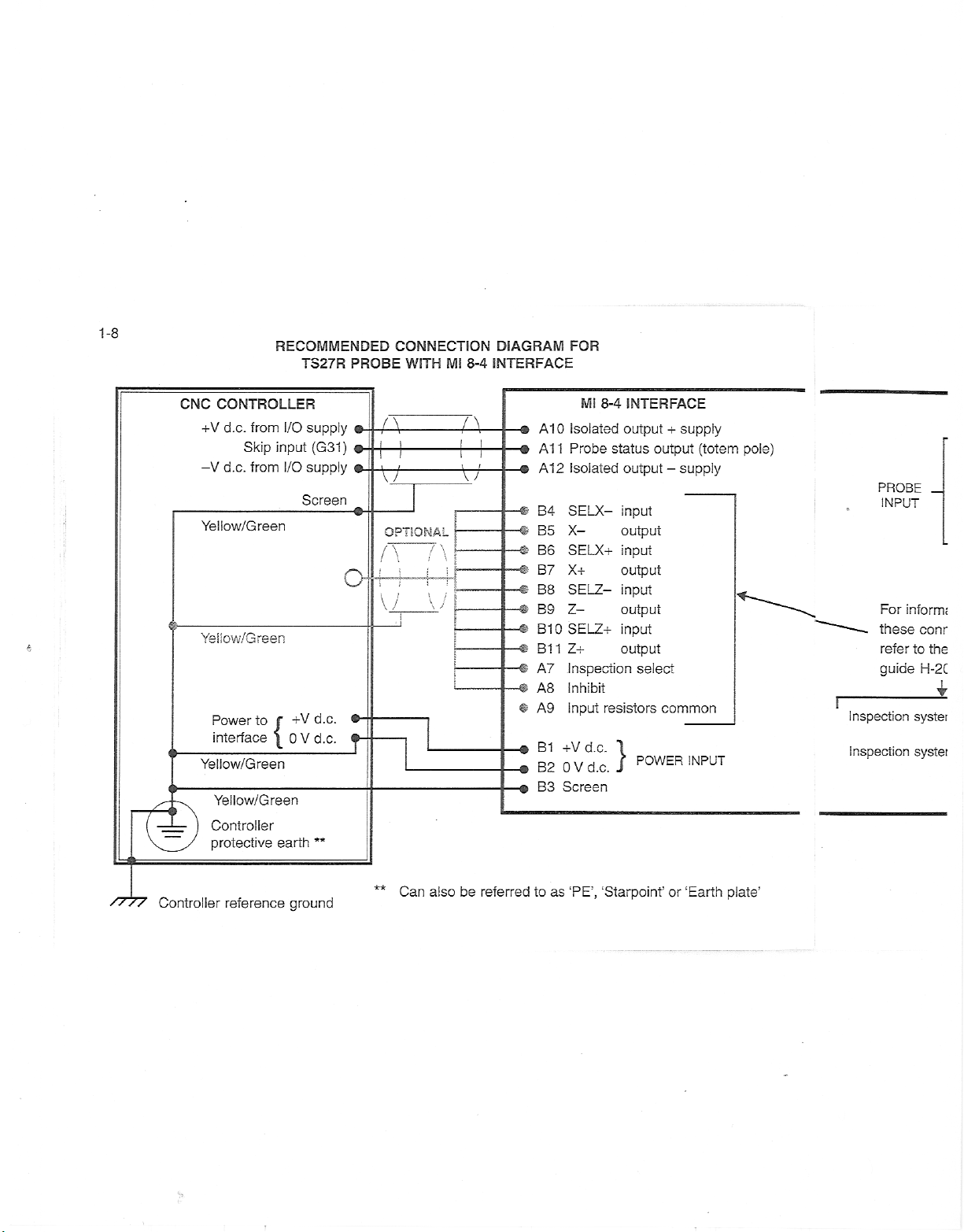

1-8

CNC

CONTROLLER

+V

d.c.

d.c.

-V

Yellow/Green

Yeiiow/Green

*

Power

interface

<ÿ

Yellow/Green

<ÿ

Yellow/Green

RECOMMENDED

TS27R

from

Skip

from

to

I/O

input

I/O

{

supply

supply

Screen

+V

V

0

(G31)

d.c.

d.c.

PROBE

*ÿ

A

©ÿ

©.

v

OPTIONAL

i

\j

f-

CONNECTION

Ml

8-4

WITH

n

7

v7

:

DIAGRAM

INTERFACE

-©

-©

-&

4b

«

#

©

-9

«

A1

A1

A12

B4

B5

B6

B7

B8

B9

B10

B11

AT

A8

A9

B1

B2

B3

0

1

FOR

Ml

8-4

Isolated

Probe

status

Isolated

SELX-

X-

SELX+

X+

SELZ-

Z—

SELZ+

Z+

Inspection

Inhibit

resistors

Input

+V

d.c.

V

d.c.

0

Screen

INTERFACE

output

+

output

-

output

input

output

input

output

input

output

input

output

select

common

POWER

}

supply

(totem

supply

INPUT

pole)

r

Inspection

Inspection

PROBE

INPUT

inform;

For

these

refer

guide

conr

to

the

H-2C

systet

systei

Controller

protective

earth

**

Can

//

//

Controller

reference

ground

**

also

be

referred

as

to

‘PE’,

‘Starpoint’

or

‘Earth

plate’

Page 14

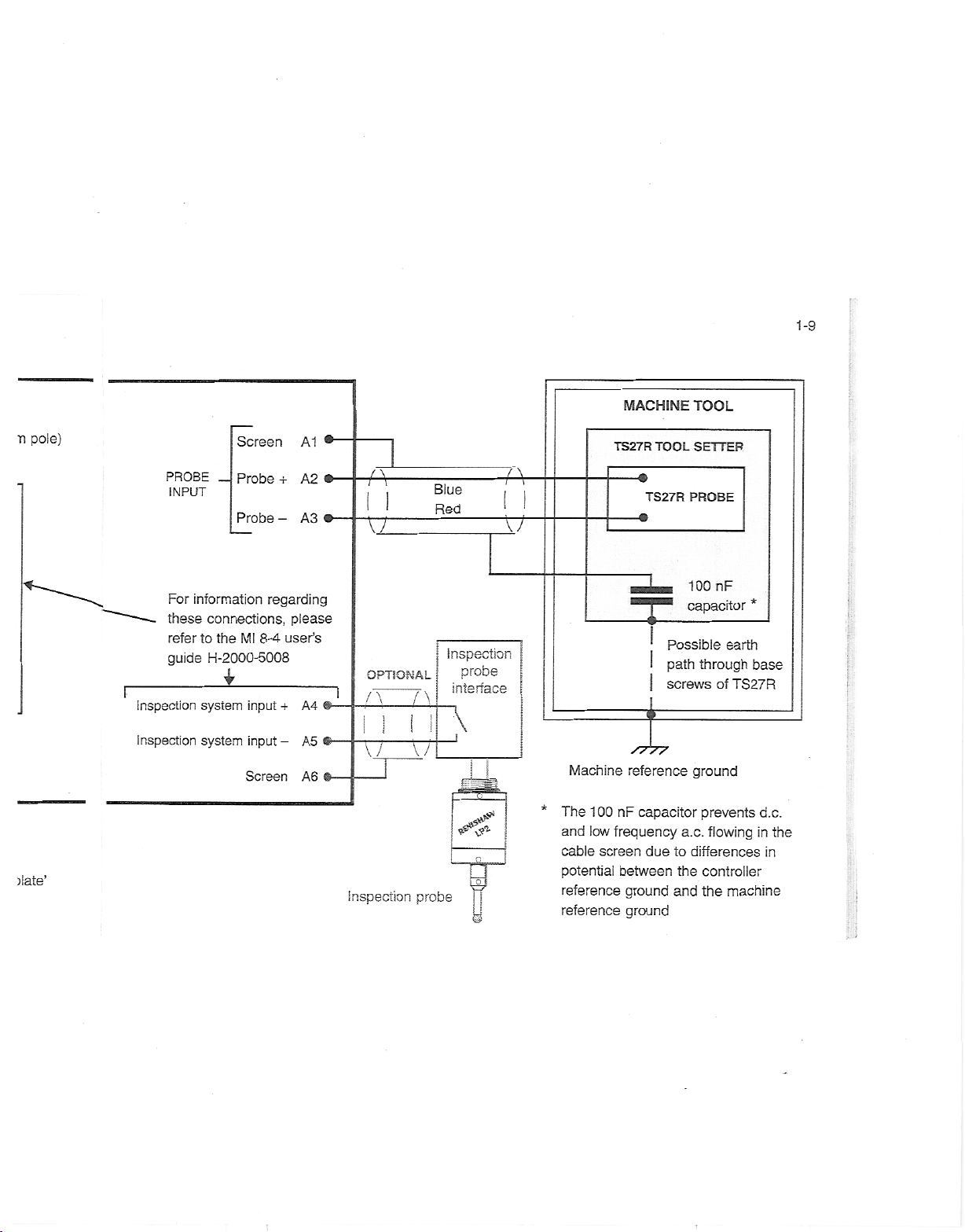

1-9

n

)late’

pole)

r

Inspection

Inspection

PROBE

INPUT

For

information

these

refer

guide

Screen

Probe

Probe

connections,

the

to

MI

8-4

H-2000-5008

i

input

system

input

system

Screen

A1

-T-

A2

A3

-

regarding

please

user’s

A4

+

A5

-

A6

®-

®-

@-

Inspection

A

XT

OPTIONAL

n

IX

i

Y7

J

T7

probe

Blue

Red

Inspection

probe

interface

\

-Q—

A

tr

Machine

The

*

and

cable

potential

reference

reference

TS27R

00

1

low

frequency

screen

MACHINE

TOOL

TS27R

-•

t-

-<

reference

capacitor

nF

due

between

ground

ground

TOOL

SETTER

PROBE

100

capacitor

Possibie

path

through

screws

ground

prevents

a.c.

to

differences

the

controller

and

the

nF

earth

of

TS27R

flowing

machine

*

base

d.c.

in

in

the

;

Page 15

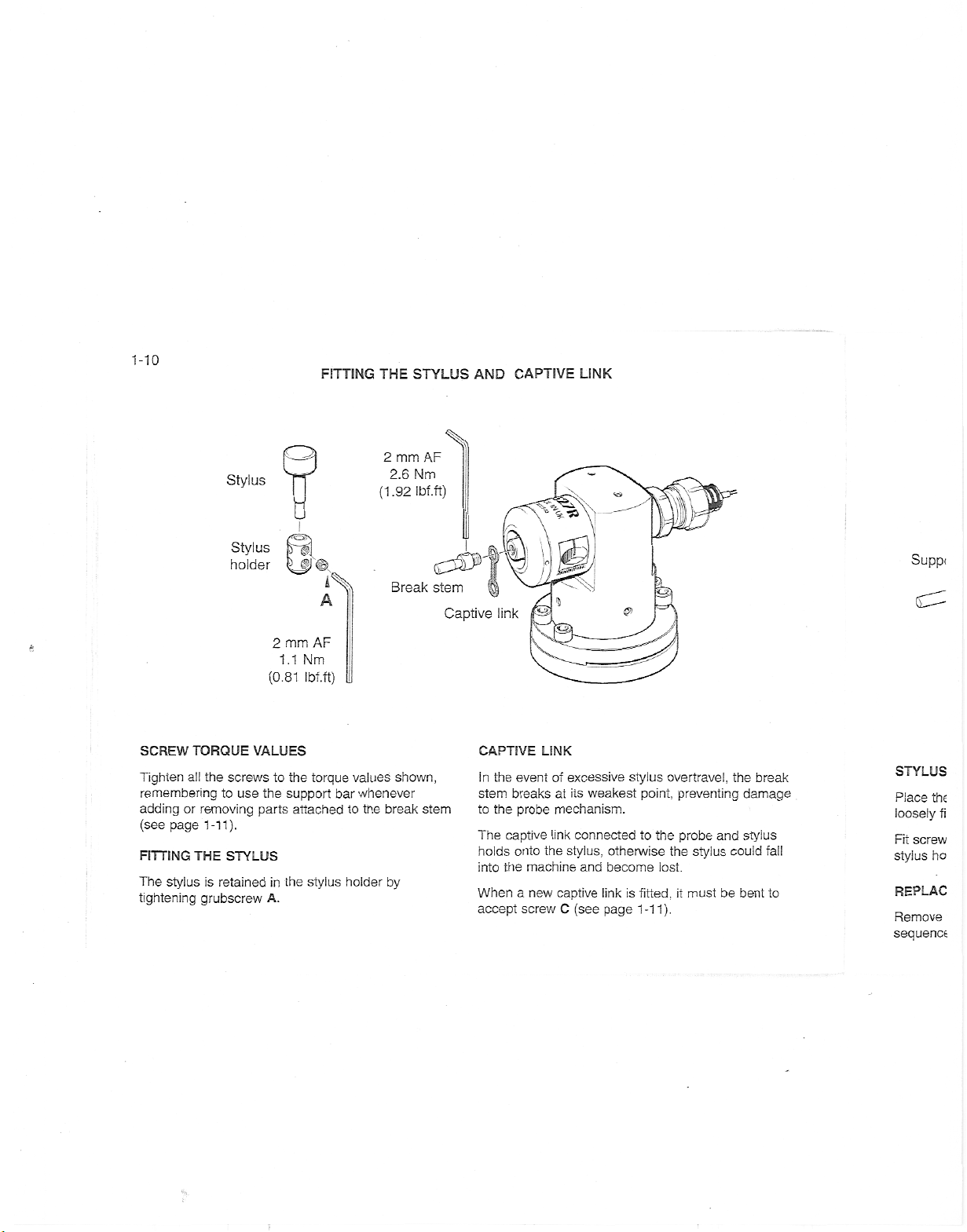

1-10

FITTING

THE

STYLUS

AND

CAPTIVE

LINK

X

AF

2

Stylus

0

Stylus

holder

k

AF

2

*

mm

1.1

(0.81

Nm

Ibf.ft)

2.6

(1

mm

Nm

Ibf.ft)

.92

Break

stem

Captive

link

sÿ-

e

—

;

Supp<

C'

0c

all

or

page

stylus

TORQUE

removing

1-11).

THE

grubscrew

SCREW

Tighten

remembering

adding

(see

FITTING

The

tightening

VALUES

screws

the

use

the

to

parts

STYLUS

is

retainedinthe

to

A.

the

torque

support

attached

stylus

values

whenever

bar

to

holder

the

shown,

break

by

stem

CAPTIVE

the

In

event

breaksatits

stem

probe

the

to

The

captive

holds

onto

the

into

When

a

accept

LINK

of

mechanism.

link

the

machine

new

screw

excessive

weakest

connected

stylus,

and

captive

C

(see

stylus

otherwise

become

is

link

page

1-11).

point,

the

to

lost.

fitted,

overtravel,

preventing

probe

the

stylus

it

must

and

be

the

damage

stylus

could

bent

break

fall

to

STYLUS

Place

the

loosely

fi

screw

Fit

ho

stylus

REPLAC

Remove

sequence

Page 16

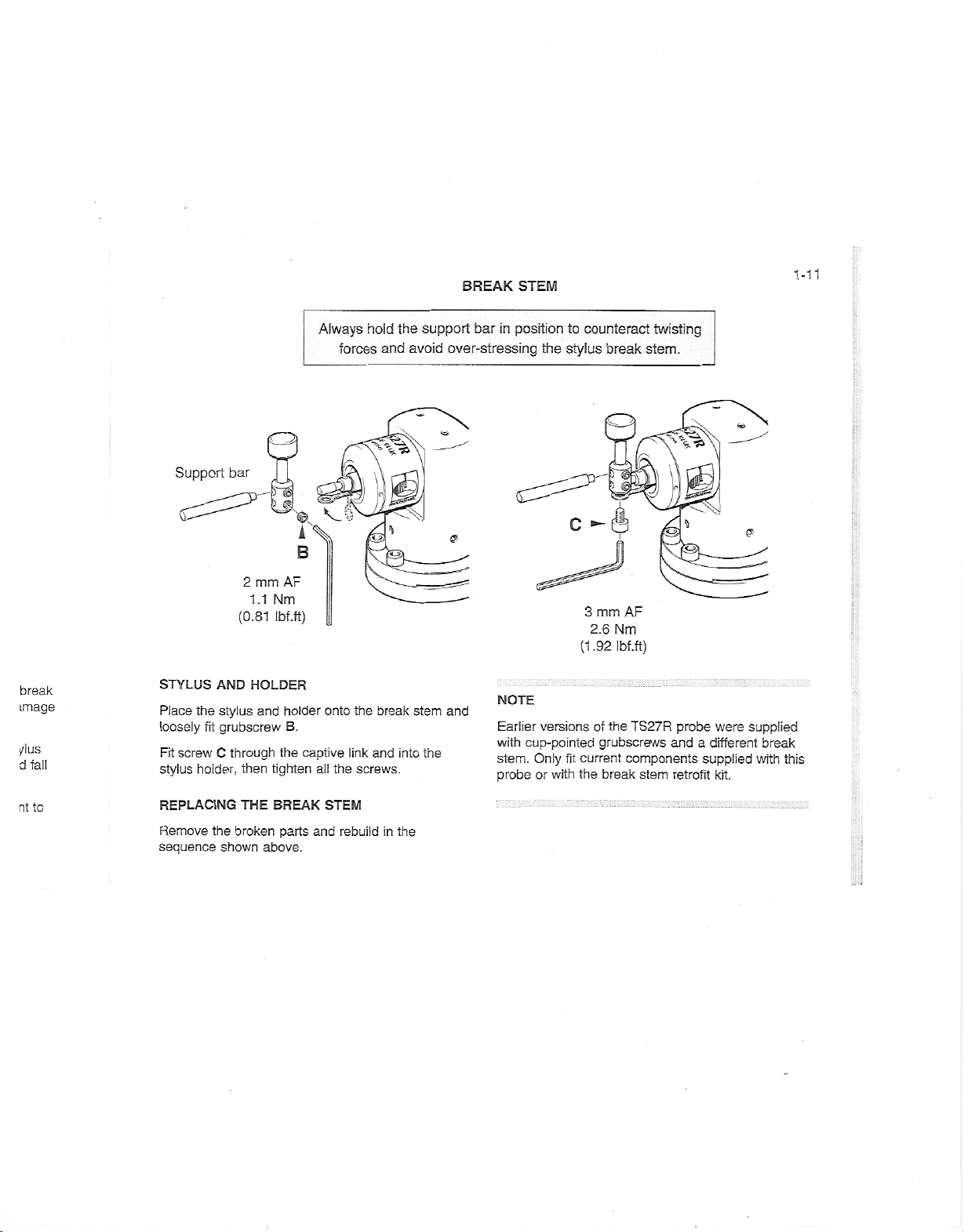

BREAK

STEM

1-11

break

image

/lus

d

fall

Support

STYLUS

Place

the

loosely

Fit

screw

stylus

holder,

bar

(0.81

AND

stylus

grubscrew

fit

C

through

mm

2

Nm

1.1

Ibf.ft)

HOLDER

and

tighten

then

AX

B

AF

holder

B.

the

Always

onto

captive

all

forces

the

link

the

screws.

hold

and

break

and

the

support

avoid

over-stressing

%

'G)

into

stem

the

a

and

bar

position

in

NOTE

Earlier

with

stem.

probe

cup-pointed

to

counteract

stylus

the

c

-

mm

3

2.6

(1.92

versionsofthe

Only

or

with

current

fit

the

grubscrews

break

break

stem.

ft

AF

Nm

Ibf.ft)

TS27R

components

stem

twisting

'

%

r<

probe

and

retrofit

were

a

different

supplied

kit.

<0

&

supplied

break

with

this

parts

STEM

and

rebuildinthe

j

THE

to

nt

REPLACING

Remove

sequence

the

shown

BREAK

broken

above.

Page 17

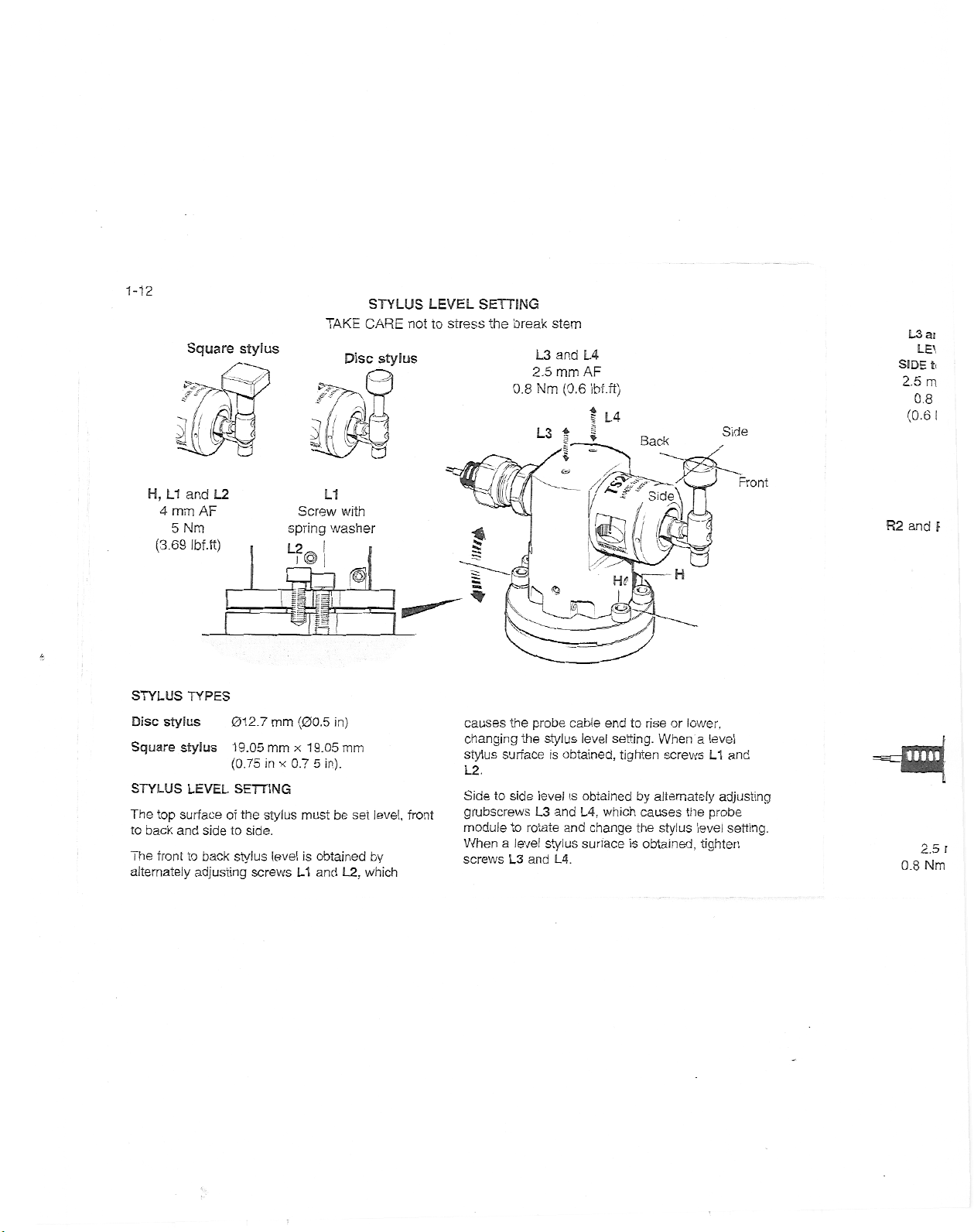

1-12

Square

Yo

V

stylus

TAKE

W,

Ml

Disc

STYLUS

CARE

stylus

_

j

LEVEL

nottostress

SETTING

the

break

0.8

L3

2.5

Nm

L3

stem

and

mm

(0.6

|

L4

AF

Ibf.ft)

I

|

L4

Back

Side

L3

SIDE

2.5

0.8

(0.6

ai

LE\

t.

m

I

H,

4

(3.69

L1

mm

5

Nm

and

AF

Ibf.ft)

L2

Screw

spring

L2

SZI

L1

with

washer

fl

/

(I

,

Side

s)

<

I

l

m

K

H

teg

Front

R2

and

F

Ir

*

STYLUS

Disc

Square

STYLUS

The

to

The

alternately

top

back

front

stylus

stylus

surface

and

TYPES

19.05

LEVEL

of

sidetoside.

back

to

adjusting

mm

012.7

mm

(0.75

in

SETTING

the

stylus

stylus

level

screws

x

(00.5

x

0.7

must

L1

19.05

is

in)

mm

5

in).

be

obtained

and

L2,

set

level,

by

which

front

the

causes

surface

side

to

to

L3

the

rotate

and

changing

stylus

L2.

Side

grubscrews

module

Whenalevel

screws

cable

level

obtained,

L4,

which

and

change

surface

end

probe

stylus

is

levelisobtained

L3

and

stylus

L4.

to

setting.

tighten

by

causes

the

obtained,

is

or

lower,

rise

When

screws

alternately

the

stylus

a

level

L1

adjusting

probe

level

tighten

and

setting.

mu

0.8

2.5

Nm

J

1

r

Page 18

de

Front

i

and

ijusting

ae

setting.

sn

R2

L3

SIDE

2.5

0.8

(0.6

and

0.8

and

LEVEL

to

mm

Nm

Ibf.ft)

R3

2.5

Nm

L4

SIDE

AF

R2

mm

(0.6

u

AF

Ibf.ft)

L3

4\\w

II

-k.

q:i

M-

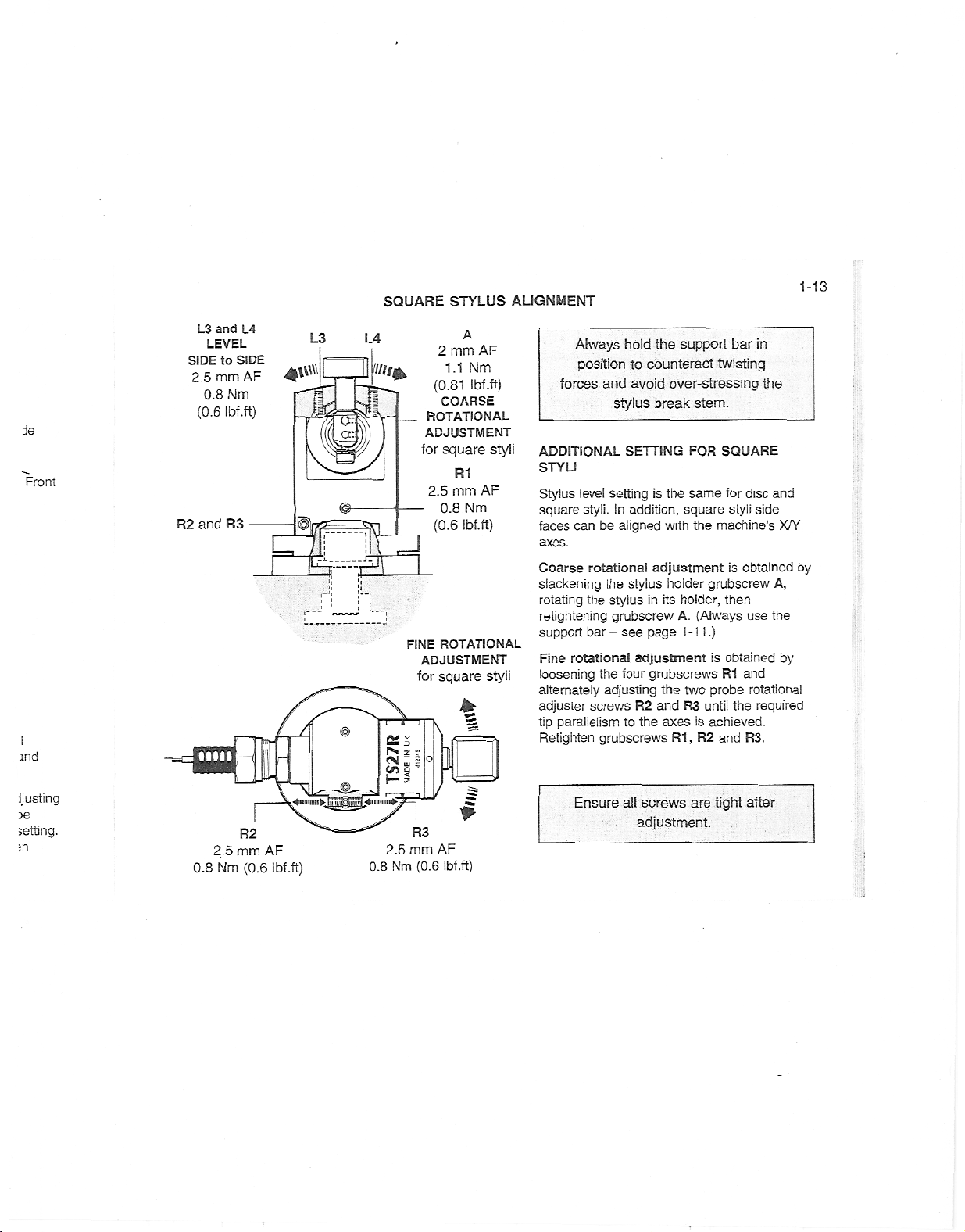

SQUARE

L4

ll

/////£.

j

.

st

2.5

0.8

ROTATIONAL

ADJUSTMENT

for

2.5

FINE

ADJUSTMENT

for

es

i

R3

mm

(0.6

Nm

STYLUS

A

2

AF

mm

1.1

Nm

Ibf.ft)

(0.81

COARSE

R1

mm

Ibf.ft)

styli

AF

Nm

styli

square

0.8

(0.6

ROTATIONAL

square

%

§

“

AF

Ibf.ft)

ALIGNMENT

Always

position

forces

ADDITIONAL

STYLI

level

Stylus

styli.

square

can

faces

axes.

Coarse

slackening

rotating

retightening

support

Fine

rotational

loosening

alternately

adjuster

parallelism

tip

Retighten

Ensure

hold

and

stylus

SETTING

setting

In

addition,

be

aligned

rotational

stylus

the

the

stylus

grubscrew

bar

see

-

four

the

adjusting

screws

to

grubscrews

all

support

the

counteract

to

over-stressing

avoid

break

the

is

square

with

adjustment

holder

holder,

its

in

A.

1-11.)

page

adjustment

grubscrews

the

two

the

and

axes

R3

R1,

R2

screws

adjustment.

stem.

FOR

same

the

machine’s

grubscrew

(Always

is

probe

until

achieved.

is

R2

are

tight

bar

twisting

SQUARE

disc

for

styli

obtained

is

then

use

obtained

and

R1

rotational

the

R3.

and

after

1-13

in

the

and

side

X/Y

by

A,

the

by

required

Page 19

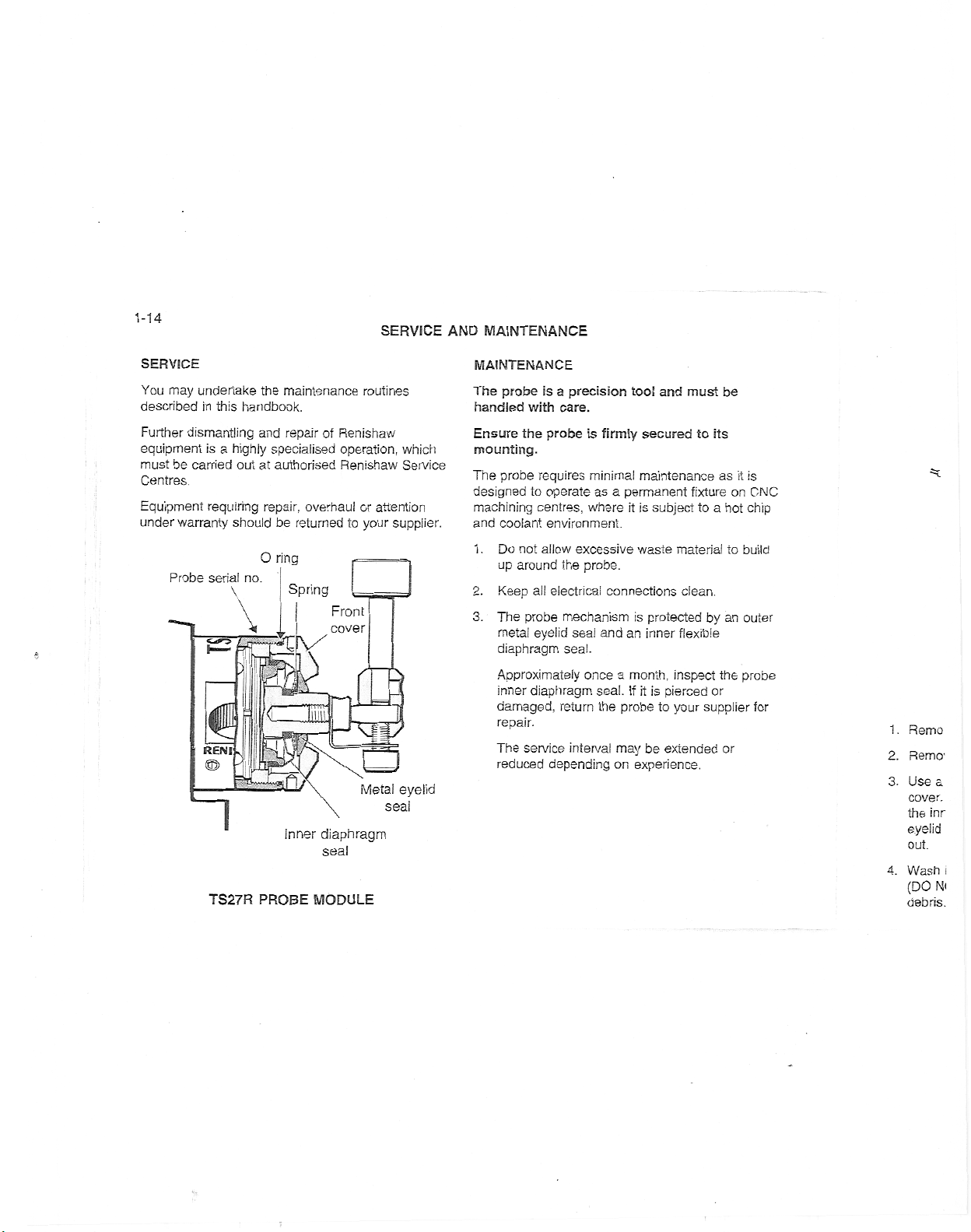

1-14

SERVICE

AND

MAINTENANCE

SERVICE

You

may

described

Further

dismantling

equipment

must

be

undertake

in

is

carried

this

handbook.

a

highly

out

the

maintenance

repair

and

specialised

at

authorised

Renishaw

of

operation,

Renishaw

routines

which

Service

Centres.

Equipment

under

warranty

Probe

requiring

serial

should

O

no.

repair,

overhaulorattention

be

returned

ring

Spring

supplier.

your

to

Front

cover

*

I

J

'

REN

I

r5I

a

Metal

eyelid

seal

1

TS27R

Inner

PROBE

diaphragm

seal

MODULE

MAINTENANCE

probe

The

handled

Ensure

mounting.

probe

The

designed

machining

and

coolant

1.

Do

up

Keep

2.

3.

The

metal

diaphragm

Approximately

inner

damaged,

repair.

The

reduced

is

with

the

probe

requires

operate

to

centres,

environment.

not

allow

around

all

electrical

probe

eyelid

diaphragm

service

depending

a

precision

care.

is

firmly

minimal

as

a

whereitis

excessive

the

probe.

connections

mechanism

sea!

and

seal.

once

seal.

return

the

interval

too!

securedtoits

maintenance

permanent

subject

waste

is

protected

an

inner

a

month,

it

is

If

probe

may

be

on

experience.

and

must

fixture

material

clean.

flexible

inspect

pierced

to

your

extended

be

as

a

to

hot

an

by

the

or

supplier

or

on

to

it

is

CNC

chip

build

outer

probe

for

1

.

2.

3.

4.

Remo

Remo1

a

Use

cover.

the

inr

eyelid

out.

Wash

(DO

Ni

debris.

i

Page 20

s

CNC

:hip

jiid

uter

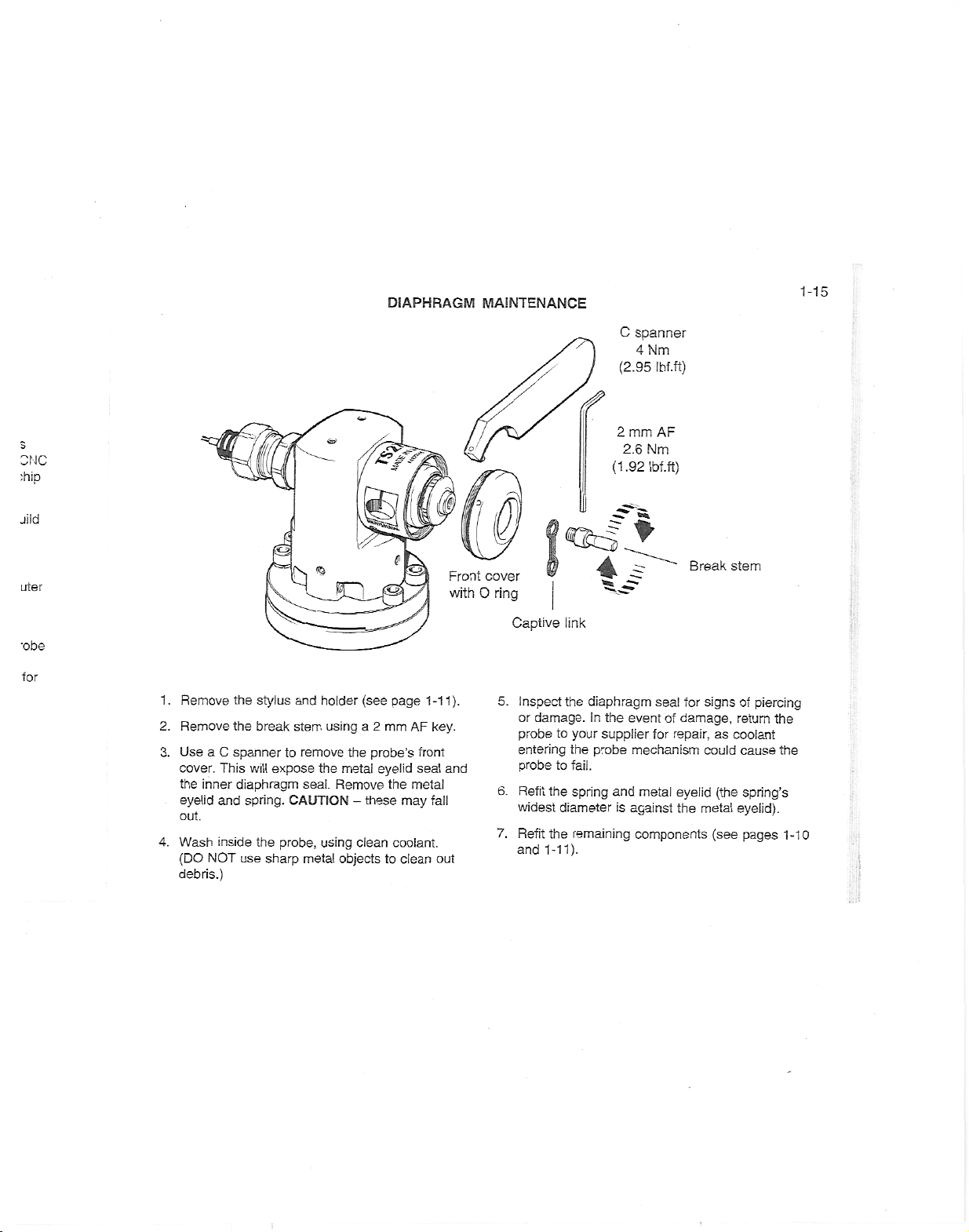

DIAPHRAGM

f)

'TZs'

Front

MAINTENANCE

//

Pi

cover

with

ring

O

C

(2.95

(f

2

(1

«fcf

-4

spanner

4

Nm

mm

2.6

Nm

.92

Ibf.ft)

*

s

Ibf.ft)

AF

Break

1-15

stem

for

.

1

2.

3.

4.

Remove

Remove

a

Use

cover.

the

inner

eyelid

out.

Wash

(DO

NOT

debris.)

the

the

C

spanner

This

will

diaphragm

and

spring.

inside

use

stylus

break

expose

the

sharp

and

stem

to

remove

seal.

CAUTION

probe,

metal

holder

using

the

Remove

using

objects

(see

a

the

metal

-

clean

mm

2

probe’s

eyelid

the

these

to

page

AF

front

seal

metal

may

coolant.

clean

1-11).

key.

and

fall

out

Captive

5.

6.

7.

Inspect

or

damage.

probe

entering

probe

Refit

the

widest

Refit

the

and

1-11).

link

the

diaphragm

In

to

your

the

to

fail.

spring

diameter

remaining

the

supplier

probe

and

is

for

sea!

of

event

mechanism

against

damage,

for

repair,

eyelid

metal

the

components

signs

as

could

(the

metal

(see

of

piercing

return

coolant

cause

spring’s

eyelid).

pages

the

the

1-10

Page 21

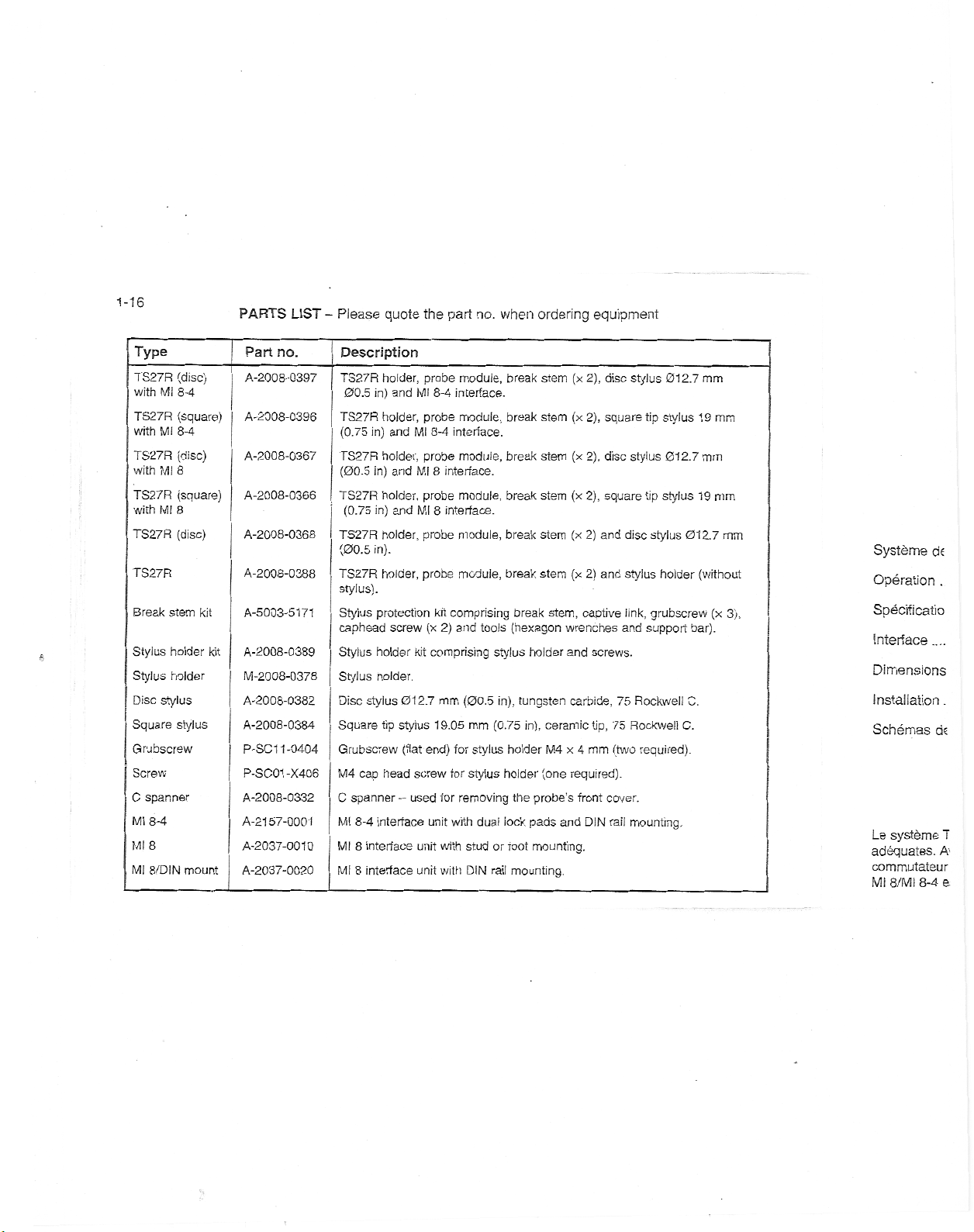

1-16

PARTS

LIST

Please

-

quote

the

part

no.

when

ordering

equipment

Type

(disc)

TS27R

with

8-4

Ml

TS27R

(square)

with

8-4

Ml

TS27R

(disc)

8

with

Ml

TS27R

(square)

8

with

Ml

TS27R

(disc)

TS27R

Break

stem

Stylus

Stylus

Disc

Square

holder

holder

stylus

stylus

*

Grubscrew

Screw

spanner

C

Ml

8-4

Ml

8

Ml

8/DIN

mount

kit

kit

Part

no.

A-2008-0397

A-2008-0396

A-2008-0367

A-2008-0366

A-2008-0368

A-2008-0388

A-5003-5171

A-2008-0389

M-2008-0378

A-2008-0382

A-2008-0384

P-SC1

1-0404

-X406

P-SC01

A-2008-0332

57-0001

A-21

A-2037-0010

A-2037-0020

Description

holder,

TS27R

in)

00.5

TS27R

holder,

(0.75

in)

holder,

TS27R

(00.5

in)

holder,

TS27R

in)

(0.75

holder,

TS27R

(00.5

in).

holder,

TS27R

stylus).

Stylus

protection

caphead

Stylus

holder

Stylus

holder.

Disc

stylus

Square

tip

Grubscrew

cap

head

M4

spanner

C

8-4

Ml

interface

8

Ml

interface

8

Ml

interface

and

and

and

and

screw

012.7

stylus

(flat

used

-

probe

8-4

Ml

probe

8-4

Ml

probe

8

interface.

Ml

probe

interface.

Ml

8

probe

probe

kit

2)

(x

comprising

kit

mm

1

9.05

end)

screw

for

unit

unit

with

unit

with

module,

interface.

module,

interface.

module,

module,

module,

module,

comprising

and

tools

stylus

(00.5

in),

(0.75

mm

for

stylus

stylus

for

removing

dual

with

or

stud

rail

DIN

break

break

break

break

break

break

break

(hexagon

holder

tungsten

in),

holder

holder

probe’s

the

iock

pads

foot

mounting.

mounting.

stem

stem

stem

stem

stem

stem

stem,

ceramic

M4

(one

and

disc

(x

2),

(x

square

2),

(x

2),

disc

(x

2),

square

(x

2)

and

2)

(x

and

captive

wrenches

and

screws.

carbide,

tip,

x

mm

4

required).

front

cover.

DIN

stylus

stylus

disc

stylus

link,

and

75

Rockwell

75

(two

rail

mounting.

012.7

stylus

tip

012.7

stylus

tip

stylus

holder

grubscrew

support

Rockwell

required).

1

19

012.7

(without

bar).

C.

C.

mm

9

mm

(x

mm

mm

mm

3),

Systeme

Operation

cte

.

Specificatio

Interface

Dimensions

Installation

Schemas

Le

adequates.

commutateur

Ml

systeme

8-4

8/MI

ds

A'

.

T

e.

Page 22

reglage

Palpeur

Manuel

n

n

de

d'lnstallatlon

Table

des

d’outil

et

matieres

TS27R

d'utilisation

im

jut

3),

Systeme

de

Operation

Specification

Interface

Dimensions

Installation

systeme

8/MI

8-4

de

Schemas

Le

adequates.

commutateur

Ml

palpeur

cablage

TS27R

Avant

de

bien

est

TS27R

doit

commencer

de

sous

mise

coupee.

etre

installe

tension

par

un

est

CONSIGNE

une

travail,

bien

2-1

2-2

2-3

2-3

2-4

2-5

2-6

personne

verifier

OFF

sur

Montage

Adaptateur

Regiage

Alignement

Entretien

Maintenance

Nomenclature

SECURITE

DE

qualifiee

la

machine-outil

que

(Arret)

du

de

et

respectueuse

que

I’alimentation

et

stylet

[’attache

de

et

fragilise

du

niveau

du

stylet

maintenance

stylet

carre

delamembrane

consignes

des

c’est-a-dire

sure,

est

en

de

...

electricite

retenue

de

securite

le

que

de

I’interface

2-1

2-11

2-12

2-13

2-14

2-15

2-16

0

Page 23

1

©

995-2005

Ce

document

reproduit

autre

moyen

Renishaw.

publication

La

document

responsabilite

de

Renishaw

Limites

efforts

Des

contenu

d’omissions.

garantie

particulier

Renishaw

b

changements

presentes

quiconque.

Garantie

Tout

equipement

reparation

fournisseur.

Renishaw,

reglage

auraient

N°

de

Revisee

Renishaw

integralement

support

ce

que

ne

degage

pic.

de

garantie

importants

ce

de

Cependant

concernant

reconnaTt

ne

se

reserve

pages

quelconque

L’utilisation

au

meme

effectues

pour

effet

piece

Renishaw

:

peut

ne

ou

dans

soit

sans

des

informations

egard

en

document

le

au

document

sans

sous

titre

par

d’annuler

pic.

Tous

en

aucun

en

ou

partie,

un

autre

I’autorisation

pas

I’utilisateur

droits

aux

ont

ete

soit

depourvu

Renishaw

contenu

aucune

le

droit

d’apporter

et

obligation

garantie

doit

etre

abusive

qu’une

personnes

des

cette

:

H-2000-501

04.05

reserves.

droits

etre

ou

copie

transfere

cas

langage,

prealable

contenues

mis

sa

de

conferes

ceuvre

en

d’erreurs

n’offre

ce

de

document

garantie

au

necessitant

reexpedie

d’equipements

produit

d’en

implicite.

des

decrit

informer

reparation

non

garantie.

8-06-D

ou

par

quelque

ecrite

ce

dans

aux

brevets

pour

aucune

et

dans

une

au

ou

un

qualifiees,

sur

que

et

en

Modifications

Renishaw

specifications

un

Machineacommande

de

Uexploitation

confiee

conformer

Entretien

Maintenez

raisonnable.

le

Marques

RENISHAW®

logo

RENISHAW

Renishaw

apply

Tous

dans

innovation

les

ce

les

marques

deposees

Avis

de

caracteristiques

Les

manuel

apparentes,

brevets

4413968

DE

EP

0293036

EP

0695926

EP

0748669

EP

1051668

des

se

reserve

ses

de

machines-outils

de

personnes

des

a

aux

instructions

du

systeme

les

composants

fabrique

de

et

I’embleme

Royaume

pic

au

noms

autres

document

service,

de

de

leurs

brevet

d’utilisation,

assujetties

sont

ci-dessous

GB

IT

JP

JP

JP

appareiis

ie

droit

produits

numerique

qualifiees,

de

palpeur

des

sont

est

une

marques

de

des

sont

marques

proprietaires

produits

des

ainsi

que

:

2277593

1273643

1,445/1997

2,098,080

320,394/1994

de

modifier

sans

CNC

fabricant.

du

un

dans

capteur

de

marques

Uni

et

marque

marques

de

respectifs.

presentes

celles

aux

brevets

preavis.

doit

qui

devront

etat

utilisee

deposees

dans

Renishaw

de

de

et

de

fabrique

des

JP

US

US

US

US

les

toujours

de

etre

se

proprete

dans

de

d’autres

pays.

pic.

produits

utilises

commerce,

ou

marques

dans

ce

produits

et

depots

de

2002-531,839

5,446,970

5,647,137

5,669,151

6,470,584

B1

I

1

Comm;

CN(

Le

I

I

palpt

le

machine

numeriq

Pour

m«

d’outil,

c

outils

ro

Y

poi

et

c

Les

vis

sur

a

les

L’interfar

le

palpei

Page 24

•s

etre

3

ete

Ians

le

pays.

pic.

'

s

utilises

erce,

larques

SYSTEME

PALPEUR

DE

TS27R

Reglage

2-1

de

diametre

voter

pi

Interfaces

possibles

Us

Cable

RSSKSBS*

as®

Ml

RENISHAW,

m

Ml

i

yas

8-4

8

I

i

i’

Commande

CNC

le

!

I

°

Interface

f.

Pi

O

©

Interface

™

S™"*"

Palpeur

10

7

TS27R

7

9

5V

H

f

Z

=

v

X/Y

4

—•

8

table

Faire

I’outil

sens

2

3

6

RainureaTde

machine-outil

de

dans

contraire

/

m

le

3

3

its

>31

970

137

151

584

ce

de

,839

B1

palpeur

Le

machine

numerique.

Pour

d’outil,

outils

et

Les

sur

mesurer

Y

pour

vis

les

universelle

on

rotatifs

de

axes

L’interface

le

palpeur

TS27R

des

accoste

peuvent

decalages

les

reglage

de

sert

la

et

au

sert

d’usinage

longueurs

stylet

le

etre

de

permettent

machine.

la

traitement

au

commande

reglage

a

d’outils

selon

regies

rayon

d’aligner

des

CNC.

d’outils

commande

ou

un

Z.

les

sur

d’outil.

signaux

Les

axes

le

I’axe

sur

bris

stylet

entre

Stylet

1.

stylets

socle

du

du

stylet

du

du

a

palpeur

-

stylet

stylet

de

de

pour

retenue

fragilise

frontal

du

niveau

des

des

gaine

de

axes

axes

2.

Porte-stylet

3.

Attache

Adaptateur

4.

5.

X

Couvercle

Vis

6.

7.

Reglage

Alignement

8.

9.

Alignement

1

0.

Adaptateur

d’attache

disque

ou

vis

carre

carre

de

carres

reglage

vis

-

vis

-

de

de

reglage

blocage

Page 25

2-2

TOLERANCES

Les

tolerances

dependent

regiage

une

gauche

touche

s’obtient

touche

dans

deiatouche

valeur

-

du

faciiement

carree.

la

plupart

VITESSE

PRECONISEE

pivoter

Faire

oppose

Premier

delamachine

La

contre

d’une

La

1

024

Lutilisation

a

maintenir

a

contact

rotation

le

vitesse

vitessedela

tr/min

50

mm

mm

24

DE

de

de

la

planeite

d’equilibrage

droite

de

stylet,

et

Un

des

D’AVANCE

outils

les

ia

direction

-

en

tr/min

stylet

du

coupe

de

broche

tr/min

et

800

0127

d’outils

superieur

une

vitesse

mm.

a

ou

PARAMETRAGE

parametrage

du

pm

5

parallelisme

un

avec

regiage

parallelisme

du

et

styiet.

On

longitudinal

la

partie

sur

axes

les

d’une

applications

D’OUTIL

tourner

a

coupe.

de

la

en

doit

pour

tourner

127

a

coupe

de

en

premiere

calcule

se

surface

etre

des

d’un

mm

rotation

de

palpeur

a

POSSIBLES

des

outils

obtient

d’equilibrage

et

plate

5

de

stylet

d’un

telle

precision

regiage

de

ROTATIF

dans

le

tr/min

de

manipulation

en

de

60

maintenue

a

outils

diametre

ne

permet

constante.

du

faciiement

de

la

pm

a

d’outils.

sens

la

broche

fonction

m/min.

entre

tourner

inferieur

pas

OPERATION

Premier

machine

La

f

=

f

=

Second

suffit

machine

Vitesse

PROGRAMMES

Les

d’outil

divers

sur

machine-outil).

de

de

contact

d’avance

vitesse

x

tr/min

0,16

x

tr/min

0,12

contact

d’avance

programmes

sont

disponibies

controleurs

demande

-

vitesse

unites

f

f

unites

vitesse

-

800

LOGICIELS

logiciels

de

aupres

ou

d’avance

(f)

calcule

se

mm/min

mm/min

d’avance

tr/min,

4

mm/min.

prevus

aupres

de

machine

(iiste

du

constructeurdevotre

de

comme

(regiage

(regiage

de

les

pour

Renishaw

jour

a

ia

suit

:

diametre)

longueur)

la

reglages

pour

disponible

Sens

de

Repetabiliti

unidirectio

Force

de

du

stylet

Temperatu

Fonctic

Stocka

Valide

*

480

mm

Stylet

a

Carbure

Rockw

75

012,7

mn

K

IP

Adaptatei

fragilis

po

d

a

d

c

S

Page 26

imetre)

igueur)

jlages

jour

iponible

otre

SPECIFICATION

Sens

de

pose

Repetabiiite

unidirectionnelie

Forcededeclenchement

stylet

du

Temperature

Fonctionnement

Stockage

Vaiide

*

480

mm/s

Stylet

Carbure

Rockwell

75

012,7

Ip°

Adaptateur

fragilise

s

avec

a

disque

de

mm

un

sur

le

tungstene,

C.

x

mm

8

BQJ

Attache

stylet

centre

|

—

i

Porte-

stylet

de

012’7

8

35

de

de

retenue

Normalement

dans

palper

±X,

±Y,

-Z

Moyenne

pm.

1

2

1

en

entre

entre

I’embout

Stylet

Touche

75

19,05

sigma

a

N

,3

fonction

+5

-10

mm,

vitesse

carre

Rockwell

mm

(2cr)

2,4

°C

°C

de

ceramique,

x

M

installe

sens

le

machine.

de

la

maximale

*

30

1

N

/

sens

du

et

°C

60

°C

70

et

d’accostage

stylet.

C.

mm

19,05

19,05

des

gf

de

pour

axes

a

240

pose

x

8

19,05

8

gf

mm

Ml

description

d’utilisation

description

autre

interface

le

dans

H-2000-5015.

[.’interface

standard

“skip”.

une

et

Toutes

pour

Linterface

fonction

dispositif

palpeur

de

L’interface

avec

statut

contact

Relay),

interrupteur

Courant

Tension

Une

ainsi

d’une

manuel

La

tension

30

CC.

V

les

fonctionner

‘interdiction’

de

controle.

fonction

la

du

flottant

a

maxi.

maxi.

fonction

qu’un

LED

avec

sortie

entrees

integre

simpiifiant

reglage

palpeur

logique

externe

INTERFACE

I’objet

8-4

fait

integrale

dans

H-2000-5008.

integrale

Ml

comprise

de

possible,

d’utilisation

utilisee

est

8-4

la

fonction

palpeur

entre

sont

en

logique

egalement

ainsi

selection

ia

d’outil

utilisee

8

Ml

est

G31

et

est

disponible

de

type

inversable

(SW1).

mA

50

V

±

50

d’interdiction

dispositif

de

d’etat

d’une

manuel

le

Une

est

Ml

fournie

I’interface

vous

en

et

I’option

G31

fonctionne

V

4,75

configurables

1

ou

0.

une

qu’un

du

du

palpeur

ou

standard

en

t’option

“skip”.

sur

(Solid

SSR

un

via

(Crete)

(crete)

est

incluse,

commande

palpeur.

du

2-3

8,

avec

CC

Le

un

state

Page 27

2-4

DIMENSIONS

dimensions

en

mm

MONTAGE

OUTIL

1

.

machine-i

2.

et

3.

Installer

Renishaw

4.

Serrer

du

5.

Remonter

Serrer

reglage

stylet

6.

Installer

GOUPILLES

Dans

rainure

deux

peuvent

demonte,

Spirol®,

de

fagon

du

palpeur.

remonter

CABLE

Cable

polyuretnanne

cable

(

jaune

centre

.1

Quatre

(deux

les

Z

X/Y X/Y

H

a

J

1

PCD

soni

uns

DEPLACEMENT

Z

H

a

i

IF

054

053,5

pour

trous

utilises)

des

autres

minimum

10°

tous

confondus

STYLET

f

Deux

goupilie

0

1

3

de

MINIMUM

goupilie

equidistance

a

sur

axes

LO

5

i

trous

Spirol®

6,13

5,95

x

profondeur,

Spirol®

054

PCD

X/Y

pour

DEPLACEMENT

5,5

au

stylet

du

co

co

w

o'

o

aaaia

ADAPTATEUR

DE

Y

GAINE

50

?

E

.

7

I—

t

_

i

Sr

i

'!

56

PIVOT

STYLET

a

I

TABLE

27

DU

DE

I

Hill

8

'

7

1

MACHINE-OUTIL

1"

s

ENSEMBLE

A

Diametre

BOULON

par

fournir

du

L2

L1

:

II

m

POUR

RAINURE

I’utilisateur

boulon12maxi.

3!

1

AT

45°

GOUPILLE

SPIROL®

r&

<zC

liRi

IB

o

cb

Choisir

Separer

L1

a

palpeu

(voir

des

aT

goupilles

etre

puis

percer

a

le

quatre

a

4,4

mm.

et

vert

t

I’e

l<

I's

u

le

dei

Li

le

circc

sir

ce

Pla

so

t

!

ir

r

Page 28

INSTALLATION

2-5

JT

X/Y

urn

s

is

7

5

is

pour

Spiral®

3

5

dndeur,

IUM

pirol®

tance

054

MONTAGE

OUTIL

1.

2.

3.

Installer

Renishaw).

4.

du

5.

Serrer

reglage

stylet

Installer

6.

Choisir

I’emplacement

machine-o

Separer

L1

I’aide

a

et

Serrer

le

palpeur

Remonter

deux

L1

(voir

le

DU

un

GOUPILLES

Dans

des

circonstances

a

goupilles

percer

fagon

palpeur.

quatre

a

T

suffisent

etre

puis

a

ce

Placer

le

socle

rainure

deux

peuvent

demonte,

Spiral®,

de

du

remonter

CABLE

Cable

polyurethanne

4,4

cable

(

jaune

mm.

et

vert

PALPEUR

du

util.

le

socle

du

palpeur

d’une

c!easix

boulon

pour

pour

boulon

a

palpeur

le

vis

et

pages

stylet

SPIROL®

Spiral®

installees

remonte.

deux

qu’ils

fils

blinde

Circuit

non

rainure

la

tabledemachine-outil.

sur

a

fond.

H

L2

avant

2-12).

(voir

les

(voir

normales,

pour

bloquerlepalpeur.

(incluses

lorsque

Pour

danslatable

trous

coincident

les

goupilles

du

palpeur.

7/0,2

mm

de

10

de

palpeur

utilises).

SUR

TABLE

palpeur

en

retirant

pans

rainure

a

T

son

socleetinstaller

pas

Ne

d’effectuer

pages

page

2-4)

les

dans

TS27R

le

installer

avec

Spiral®

a

gaine

de

long.

m

-

fils

DE

sur

la

de

4

(non

T

a

fixer

pour

serrer

I’alignement

2-10

et

boulons

le

kit

doit

les

goupilles

de

deux

trous

dans

isolante

Diametre

rouge

MACHINE-

tabledela

les

deux

vis

mm.

pas

fourni

le

socle

vis.

les

les

vis

de

du

2-11).

pour

Ceci

dit,

de

palpeur)

etre

machine-outil

du

socle

les

trous

de

du

bleu

et

RALLONGE

Longueur

Palpeur

Cable

H

polyurethanne

des

GAINE

Renishaw

Betts

installations

TS27R

011

et

REMARQUE:

Le

condensateur

prevenir

blindage

I’interface.

(15

maximale

interface

a

a

deux

branchements.

DE

PROTECTION

preconise

de

Type

confondues.

compatible

est

mm.

Adaptateur

Cable

Gaine

blindage

tout

du

du

risque

cable

m

7/0,2

fils

blinde.

EF

ou

de

cable

de

1

est

maximum)

de

cable

25

m

-

mm

Preserver

le

montage

d’une

Ladaptateur

avec

gaine

n

E

est

connecte

nF

a

00

de

boucle

connecte

authorisee

de

long.

a

gaine

le

CABLE

DU

de

alternative

gaine

une

n

i’interieur

de

terre.

a

I’entree

isolante

blindage

gaines

appropriee,

de

flexible

s

E=

tCNtStttW.

©

H

la

a

machine

du

TS27R

S’assurer

:

de

au

niveau

Thomas

du

gaine

de

par

pour

appropriee

and

toutes

un

que

le

sur

Page 29

2-6

SCHEMA

CABLAGE

DE

TS27R

RECOMMANDE

AVEC

L’INTERFACE

POUR

Ml

LE

8

PALPEUR

COMMANDE

Entree

Jaune/Vert

Active

code

<-

Jaune/Vert

Alimentation

de

I’interface

*

c>

Jaune/Vert

O-

Jaune/Vert

Terre

controleur

CNC

Alimentation

palpage

Blindage

©ÿ

par

M

©ÿ

{

protection

de

£K

+V

0

V

**

E/S

(G31)

c.c.

c.c.

du

»

©

o

©

f

A

xt

FACULTATIF

A

i_L

w

A

Xf

A

•s

•

-®

-©

B7

B6

B5

B1

32

A5

A6

A4

INTERFACE

SSR

SSR

Blindage

inhibition

inhibition

+V

c.c.

V

c.c.

0

Blindage

Ml

Sortie

(sortie

—

statique

j

0

V

ENTREE

}

ALIMENTATION

8

etat

a

palpeur

reiais

SSR)

-

ENTREE

PALPEUR

Pour

des

concernan!

B2

de

Ml

et

les

conn

B3

et

B4,

Putilisateur

r

LED

LED

ir

8

c

////

Terre

de

reference

du

controleur

**

Aussi

“Plaque

appele

de

“PE”

terre”

(Terre

de

protection),

“Point

etoile”

ou

Page 30

2-7

3

etat

a

relais

e

-

ATION

etoile”

palpeur

SSR)

ou

ENTREE

PALPEUR

des

Pour

concernant

de

B2

les

et

B3

B4,

et

I’utilisateur

r

Palpeur+

Palpeur-

Blindage

informations

les

connexions

8

Ml

a

la

connexions

consulter

8

Ml

externe

LED

LED

externe

A1

A2*

A3*

B1

commande

CNC

d’entree/sortie

manuel

le

H-2000-5015.

B3

+

{:

-

B4

MACHINE-OUTIL

DE

D1SPOS1TIF

D’OUTIL

/

>

*

Bleu

Rouge

XI

et

de

I

/

xx

Terre

Le

*

que

alternatif

s’echappent

blindage

potentiel

du

condensateur

controleur

le

courant

<5

/r7i77

de

reference

basse

a

cause

entre

dans

TS27R

PALPEUR

TS27R

Condensateur

100

i

Passage

terre

|

vis

les

I

TS27R

'

100

continu

frequence

le

cable

des

la

terre

celledela

et

REGLAGE

nF*

vers

possible

du

socle

machine

la

de

empeche

nF

etlecourant

du

differences

de

reference

machine.

la

par

du

de

Page 31

2-8

SCHEMA

DE

CABLAGE

TS27R

RECOMMANDE

AVEC

L’INTERFACE

POUR

Ml

8-4

LE

PALPEUR

COMMANDE

+V

c.c.

de

Entree

c.c.

-V

de

Jaune/Vert

I

V

Jaune/Vert

A

Alimentation

(’interface

de

<ÿ

CNC

I’aiimentation

palpage

I’alimentation

Blindage

+V

{

0

V

E/S

(G31

E/S

c.c.

c.c.

e-

)

o-

«.

0-1

&ÿ

9-

A

t7

FACULTATIF

(

I

T

v/

\

\

1

\y

A

V7

-©

-e

-S-

-*

-©

-®

-©

%

Jaune/Vert

e-

-9

Jaune/Vert

Terre

de

controieur

protection

**

du

-®

A1

A1