Renishaw PI, PR3DTS, PRPS User Manual

Primo™ system

© 2013 Renishaw plc. All rights reserved.

This document may not be copied or reproduced

in whole or in part, or transferred to any other

media or language, by any means, without the

prior written permission of Renishaw plc.

The publication of material within this document

does not imply freedom from the patent rights

of Renishaw plc.

I

Contents

Contents

Before you begin......................................................................................................................... 1.1

Before you begin....................................................................................................................1.1

Disclaimer................................................................................................................. 1.1

Trademarks............................................................................................................... 1.1

Warranty................................................................................................................... 1.1

Changes to equipment.............................................................................................. 1.1

CNC machines............................................................................................................1.1

Care of the Primo equipment................................................................................... 1.1

Patents................................................................................................................................... 1.2

EC declaration of conformity................................................................................................. 1.3

WEEE directive.......................................................................................................... 1.3

FCC declaration (US)................................................................................................. 1.3

Radio approvals..................................................................................................................... 1.4

Safety..................................................................................................................................... 1.5

Information to the equipment installer................................................................................. 1.6

Primo training programme.................................................................................................... 1.7

Radio Part Setter & Radio 3D Tool Setter Basics 2.1

Introduction........................................................................................................................... 2.1

Getting started.......................................................................................................... 2.1

Credit........................................................................................................................ 2.1

Modes of operation.................................................................................................. 2.1

Configurable settings............................................................................................................. 2.2

Switch on/switch off methods.................................................................................. 2.2

Enhanced trigger filter.............................................................................................. 2.2

Recalibration............................................................................................................. 2.2

Acquisition mode...................................................................................................... 2.2

Primo credit token................................................................................................................. 2.3

Upgrade credit token................................................................................................ 2.3

Credit transfer........................................................................................................... 2.3

Four low credit indicators......................................................................................... 2.3

Radio Part Setter & Radio 3D Tool Setter operation............................................................. 2.4

Achievable set-up tolerances.................................................................................... 2.4

Software routines.................................................................................................................. 2.5

Interface basics 3.1

Introduction........................................................................................................................... 3.1

Power supply............................................................................................................ 3.1

Input voltage ripple................................................................................................... 3.1

Primo installation guide

Interface inputs...................................................................................................................... 3.2

Interface outputs................................................................................................................... 3.2

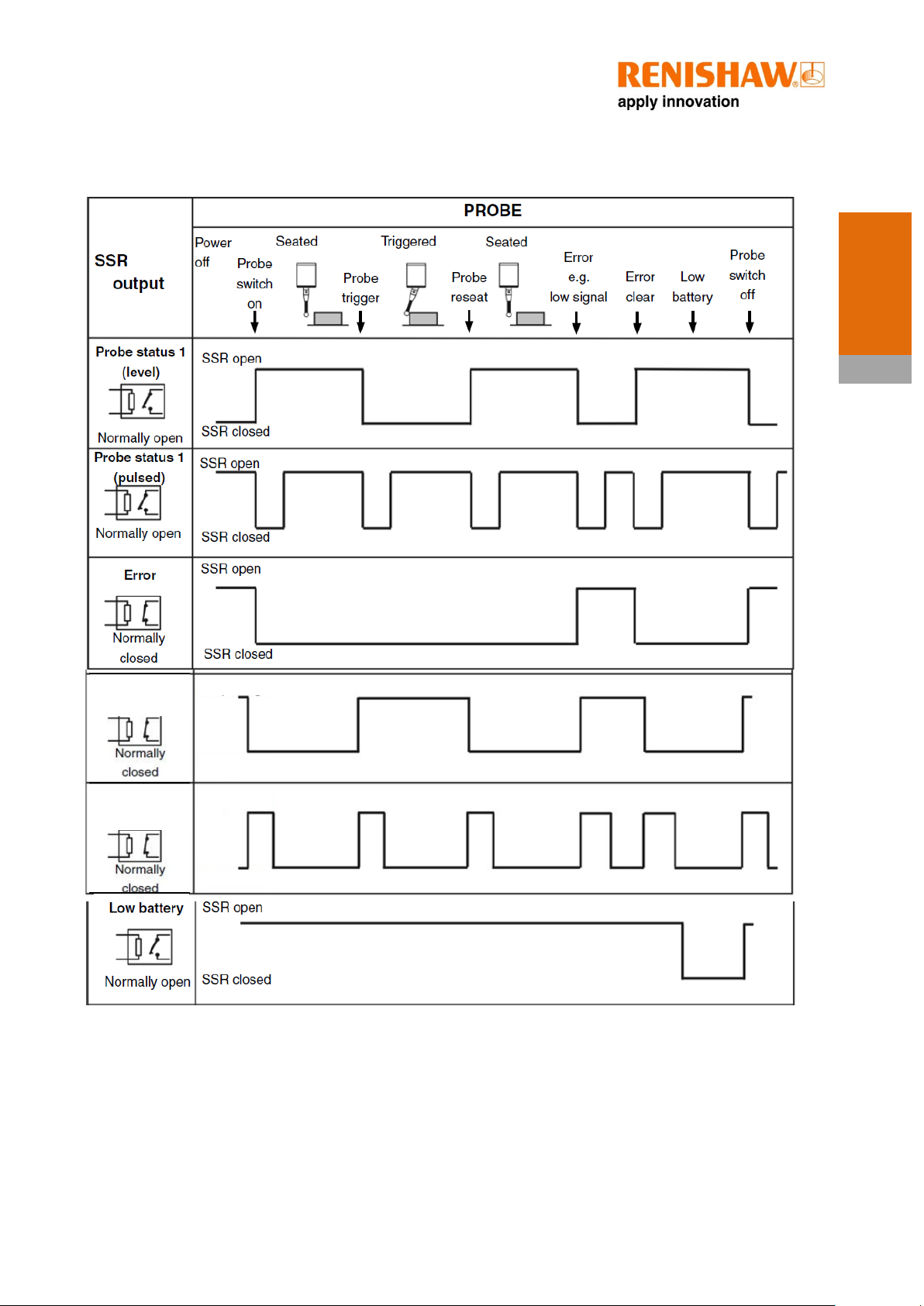

Interface output waveform.................................................................................................... 3.3

Contents

Dimensions and specifications 4.1

System installation 5.1

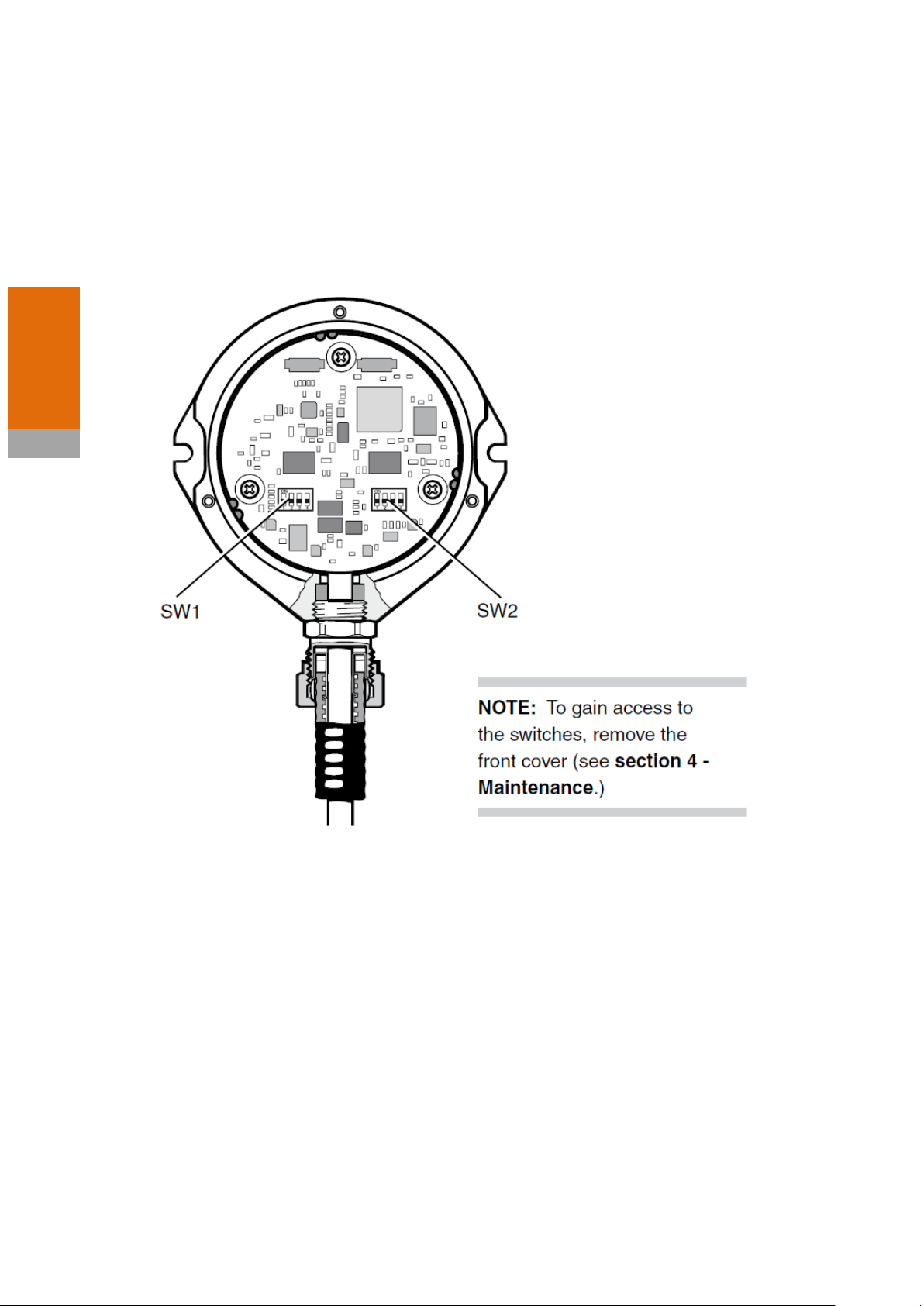

Switches SW1 and SW2.......................................................................................................... 3.4

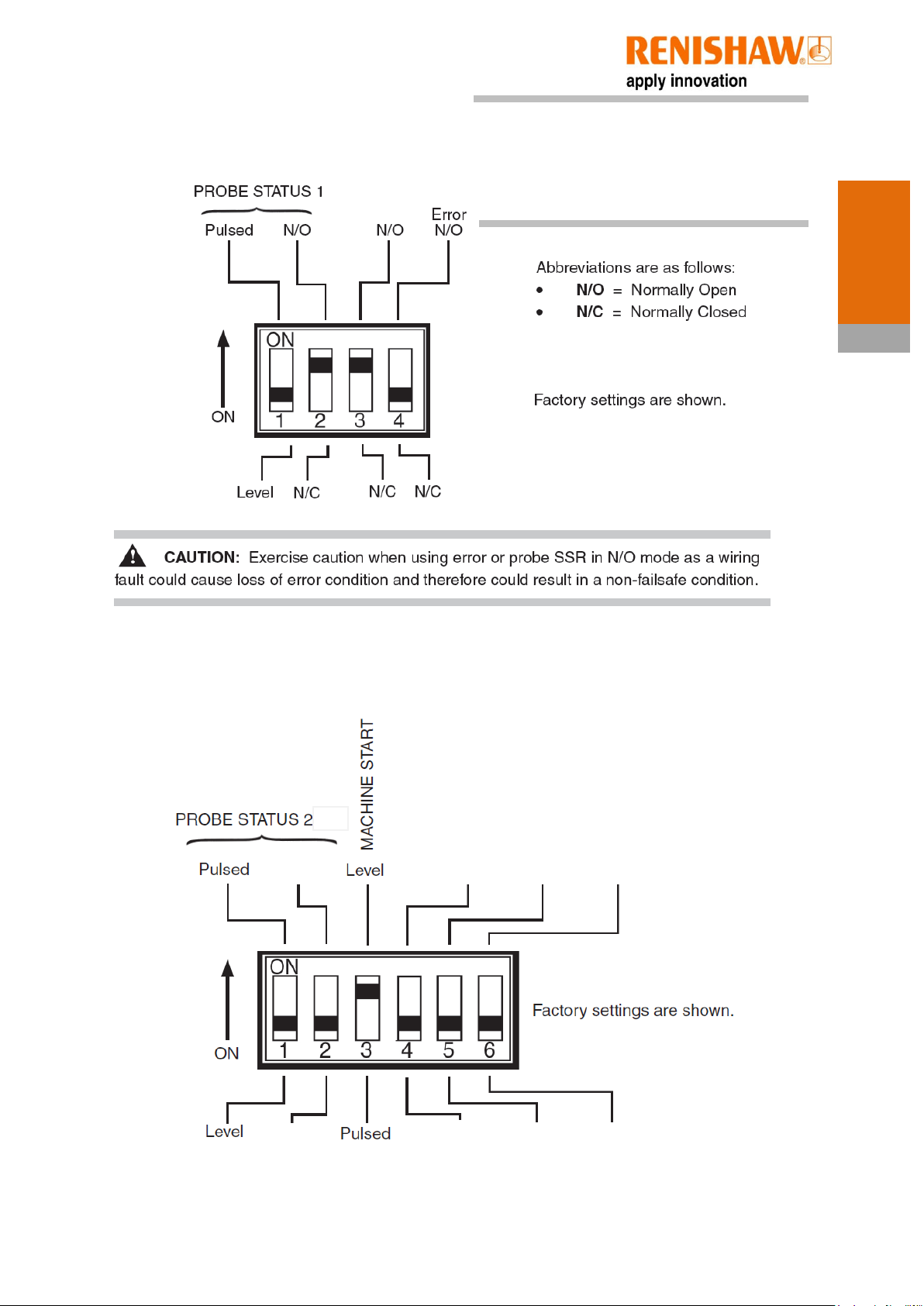

Switch SW1 output configuration.......................................................................................... 3.5

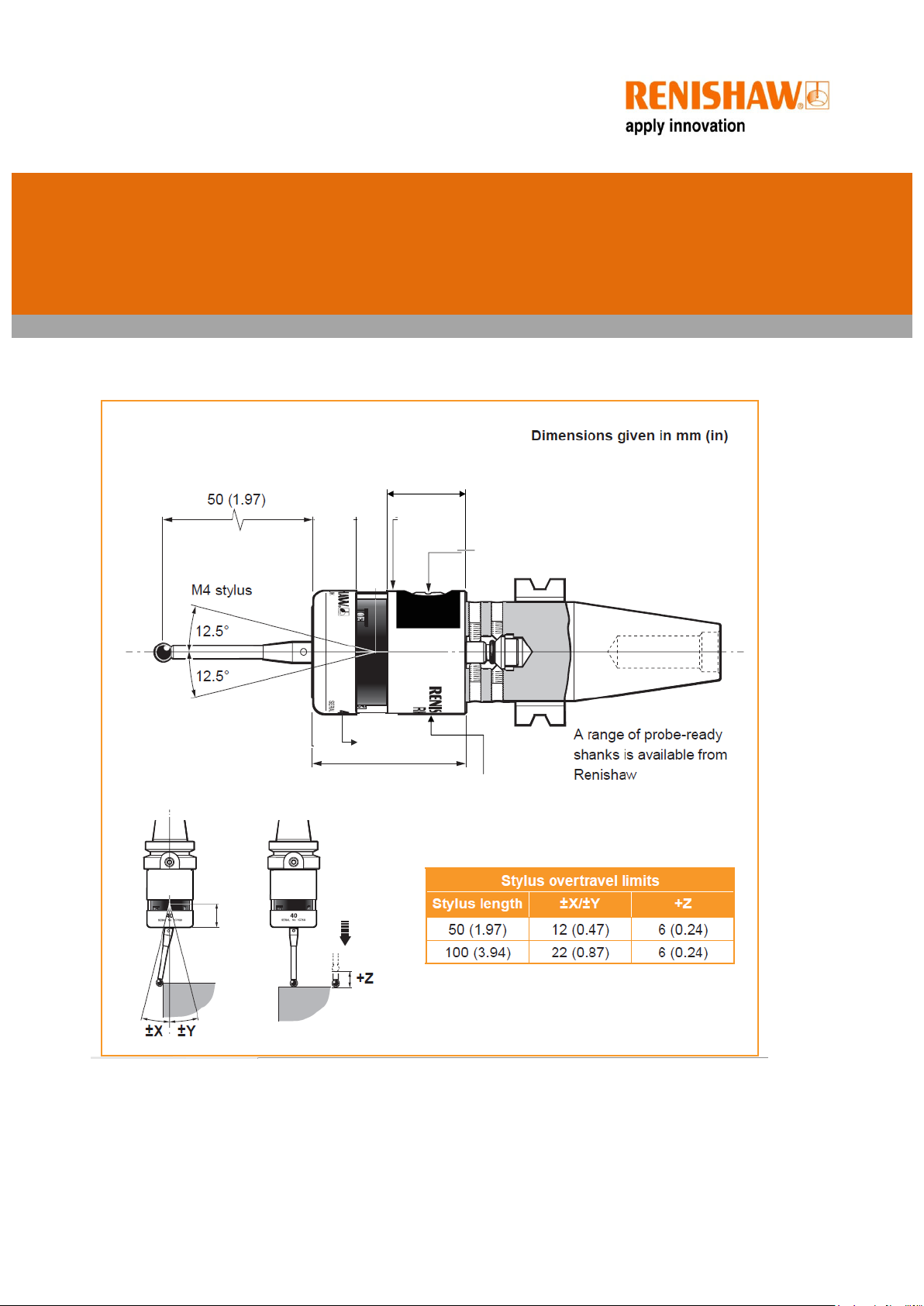

Radio Part Setter dimensions.................................................................................................4.1

Radio 3D Radio Tool Setter dimensions................................................................................. 4.2

Interface dimensions............................................................................................................. 4.3

Radio Part Setter specification............................................................................................... 4.4

3D Radio Tool Setter specification......................................................................................... 4.5

Interface specification........................................................................................................... 4.6

Operating envelope............................................................................................................... 5.1

Signal Strength LED…………………………………………………………………………………………………………….5.1

Performance envelope........................................................................................................... 5.2

Preparing the Radio Part Setter for use................................................................................. 5.3

Fitting the stylus..................................................................................................................... 5.3

Installing the battery.............................................................................................................. 5.4

Mounting the Radio Part Setter on a shank........................................................................... 5.5

Radio Part Setter stylus on-centre adjustment...................................................................... 5.6

Preparing the Radio 3D Tool Setter for use........................................................................... 5.7

Fitting the stylus, break stem and captive link....................................................................... 5.7

Installing the battery.............................................................................................................. 5.8

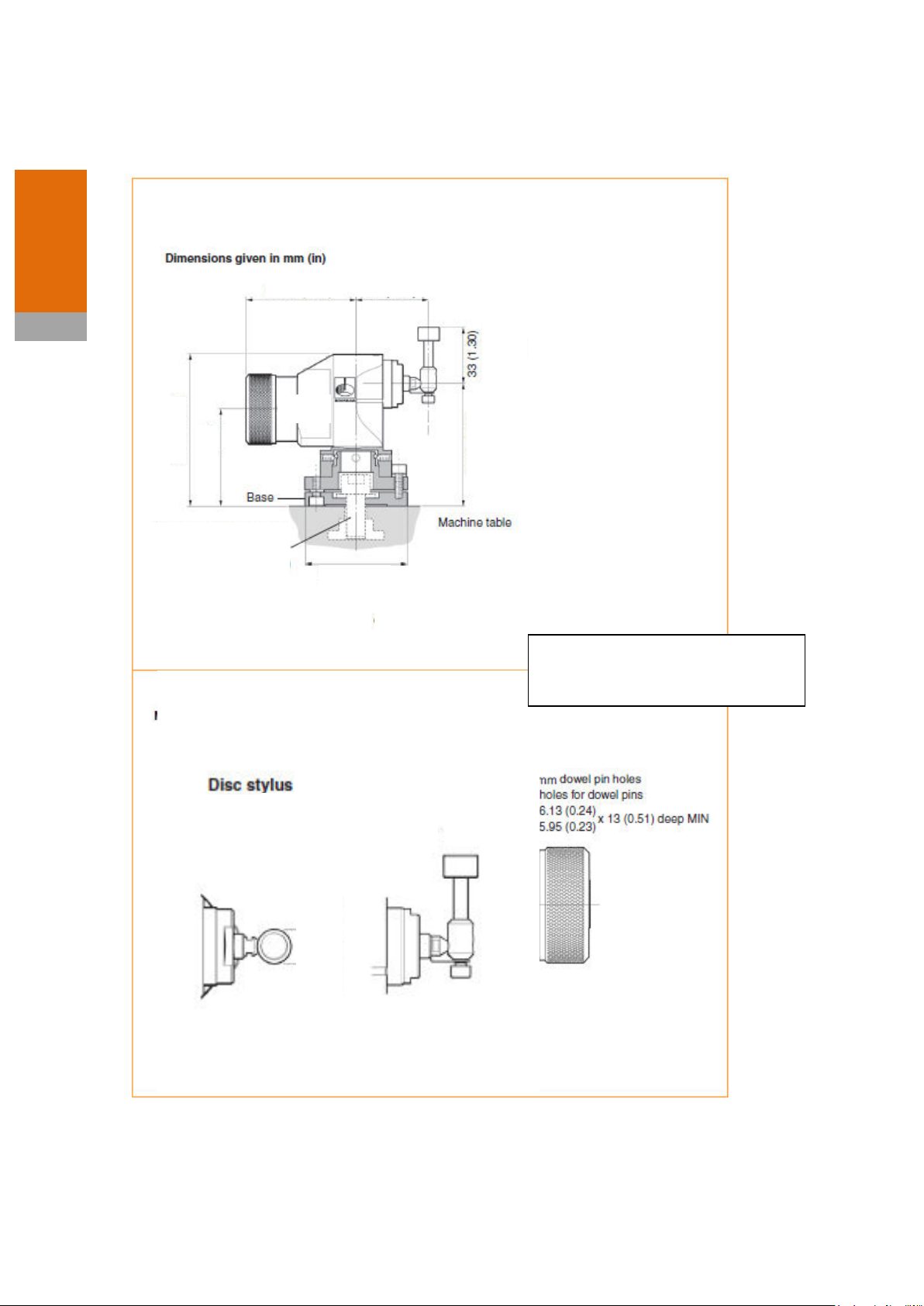

Mounting the 3D Tool Setter on a machine table............................................................... 5.9

Radio 3D Tool Setter stylus level setting.............................................................................. 5.10

Preparing the Interface for use............................................................................................ 5.11

Wiring diagram.................................................................................................................... 5.12

Interface cable..................................................................................................................... 5.13

Interface screw torque values............................................................................................. 5.14

Calibrating the Primo System.............................................................................................. 5.15

Radio Part Setter LED guide................................................................................................. 5.16

Start up................................................................................................................................ 5.16

Acquisition mode................................................................................................................. 5.16

Operational mode................................................................................................................ 5.16

Errors................................................................................................................................... 5.16

Credit transfer mode (Radio Part Setter only)..................................................................... 5.16

Interface LED signals............................................................................................................ 5.17

Acquisition mode................................................................................................................. 5.17

Credit transfer...................................................................................................................... 5.17

Renikey...................................................................................................................... 3.1

Interface visual diagnostics....................................................................................... 3.1

SSR output specifications.......................................................................................... 3.2

Switch SW2 output configuration............................................................................. 3.5

Radio Part Setter – Interface positioning.................................................................. 5.2

Performance envelope.............................................................................................. 5.2

Mounting bracket................................................................................................... 5.11

Cable specification.................................................................................................. 5.13

Cable sealing........................................................................................................... 5.13

Fitting flexible conduit............................................................................................ 5.13

Why calibrate?........................................................................................................ 5.15

Operational mode................................................................................................................ 5.17

Error states.......................................................................................................................... 5.17

Interface digital display codes............................................................................................. 5.18

Credit codes............................................................................................................ 5.18

Error codes.............................................................................................................. 5.18

Method of partnership........................................................................................................ 5.19

Inserting Primo Credit Token……………………………………………………………………………………………5.20

Method of credit transfer.................................................................................................... 5.21

Maintenance............................................................................................................................... 6.1

Maintenance.......................................................................................................................... 6.1

Cleaning.................................................................................................................... 6.1

Changing the batteries........................................................................................................... 6.2

Radio Part setter.................................................................................................................... 6.2

Radio 3D Tool Setter.............................................................................................................. 6.3

Allowed battery types............................................................................................................ 6.4

Interface cover....................................................................................................................... 6.5

Removing the Interface cover................................................................................................ 6.5

Routine Radio 3D Tool Setter maintenance........................................................................... 6.6

Inspecting the inner diaphragm seal...................................................................................... 6.6

Fault finding 7.1

Radio Part setter.................................................................................................................... 7.1

Radio 3D Tool Setter.............................................................................................................. 7.2

Interface................................................................................................................................. 7.3

Parts list 8.1

Appendix 1: Primo Radio Part Setter and Primo Length Tool Setter combination relay

configurations

Contents

Before you begin

Before you begin

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO

ENSURE THE CONTENT OF THIS DOCUMENT IS

CORRECT AT THE DATE OF PUBLICATION BUT

MAKES NO WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW EXCLUDES

LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the

RENISHAW logo are registered trademarks of

Renishaw plc in the UK and other countries. Apply

innovation™ and Primo™ are trademarks of

Renishaw plc. All other brand names and product

names used in this document are trade names,

service marks, trademarks, or registered

trademarks of their respective owners.

Warranty

Equipment requiring attention under warranty

must be returned to your equipment supplier. No

claims will be considered where Renishaw

equipment has been misused, or where repairs or

adjustments have been attempted by

unauthorised persons. Prior consent must be

obtained in instances where Renishaw equipment

is to be substituted or omitted. Failure to comply

with this requirement will invalidate the warranty.

1.1

Changes to equipment

Renishaw reserves the right to change equipment

specifications without notice.

CNC machines

CNC machine tools must always be operated by

fully trained personnel in accordance with the

manufacturer’s instructions.

Care of the Primo equipment

Keep systems clean and treat the equipment as

precision tools.

Primo installation guide

begin

1.2

Patents

Features of the Primo system, and other similar

Renishaw products, are the subject of one or more

of the following patents and/or patent

applications:

Publication No CountryIPSS Ref

Before you

CN100416216 China0589/CNw/0

CN100466003 China0583/CNw/0

CN101476859 China0589/CNw/2

CN101354230 China0737/CN/0

CN101354266 China0738/CN/0

CN101482402 China0583/CNw/2

EP0695926 Europe0334/EP/

EP0967455 Europe0426/EP/

EP1185838 Europe 0466/EP/

EP1373995 Europe 0492/EP/

EP1425550 Europe 0522/EP/

EP1457786 Europe 0587/EP/

EP1477767 Europe 0466/EP/

EP1477768 Europe 0466/EP/

EP1576560 Europe 0583/EP/

EP1613921 Europe 0589/EP/

EP1701234 Europe 0492/EP/

EP1734426 Europe 0492/EP/

EP1804020 Europe 0522/EP/

EP1988439 Europe 0492/EP/

EP2018935 Europe 0737/EP/

EP2019284 Europe 0738/EP/

EP2216761 Europe 0583/EP/

IN215787 India 0583/INw/0

IN234921 India 0589/INw/0

IN8707/DELNP/2008 India 0589/INw/2

JP2009-053187 Japan 0738/JP/0

JP2013-101685 Japan 0583/JP/3

JP2013-137313 Japan 0737/JP/2

JP3967592 Japan 0466/JPw/0

JP4237051 Japan 0522/JPw/0

JP4398011 Japan 0426/JP/0

JP4575781 Japan 0583/JPw/0

JP4754427 Japan 0466/JPw/2

JP4773677 Japan 0492/JPw/0

JP4851488 Japan 0492/JP/2

JP4852411 Japan 0589/JPw/0

JP5238749 Japan 0583/JP/2

JP5254692 Japan 0737/JP/0

KR1001244 Korea (South)

0583/KRw/0

TW 1380025 Taiwan 0738/TW/0

TW 200912579 Taiwan 0737/TW/0

US 2009/0028286 USA 0763/US/2

US 2011/0002361 USA

US 2013/0152418 USA 0738/US/2

US 2013/0159714 USA 0737/US/2

US5669151 USA 0334/US/0

US6275053 USA 0426/US/0

US6776344 USA 0466/USw/0

US6941671 USA 0522/USw/0

US7145468 USA 0492/USw/0

US7285935 USA 0587/US/0

US7316077 USA 0589/USw/0

US7441707 USA 0466/USw/2

US7486195 USA 0492/USw/2

US7812736 USA 0492/US/3

US7821420 USA 0583/USw/0

US8437978 USA 0738/US/0

US8464054 USA 0737/US/0

0583/US/2

begin

1.3

EC Declaration of conformity

Renishaw plc hereby declares that the Primo Radio

Part Setter, Radio 3D Tool Setter and Interface are

in compliance with the essential requirements and

other relevant provisions of Directive 1995/5/EC.

Contact Renishaw plc at www.renishaw.com for

the full EC Declaration of Conformity.

WEEE directive

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with general

household waste upon disposal. It is the

responsibility of the end user to dispose of this

product at a designated collection point for waste

electrical and electronic equipment (WEEE) to

enable reuse or recycling. Correct disposal of this

product will help to save valuable resources and

prevent potential negative effects on the

environment. For more information, please

contact your local waste disposal service or

Renishaw distributor.

Battery disposal

The crossed out wheeled bin symbol on the

batteries used in this product indicate that

batteries must be collected and disposed of

separately from household waste in accordance

with EU battery directive 2006/66/EC . Please

contact your local authority about the rules on the

separate collection of batteries because correct

disposal helps to prevent negative consequences

for the environmental and human health.

FCC declaration (US)

FCC section 15.19

This device complies with Part 15 of the FCC rules.

Operation is subject to the two conditions:

1. This device may not cause harmful

interference.

2. This device may accept any interference

received, including interference that may

cause undesired operation.

FCC section 15.21

The user is cautioned that any changes or

modifications not expressly approved by Renishaw

plc, or an authorized representative, could void

the user’s authority to operate the equipment.

Before you

Primo installation guide

begin

1.4

Radio approvals (radio

Radio equipment – Canadian warning

statements

approvals needed)

Approvals that are planned to be granted for

launch:

• Europe (EU & EFTA)

Before you

• USA

• Canada

• Japan

• China

• South Korea

• India

• Indonesia

• Malaysia

• Singapore

• Taiwan

• The Philippines

• Vietnam

• Australia

• New Zealand

Radio Regulations

Extract from Taiwanese radio regulations

低功率電波輻性電機管理辦法

第十二條經型式認證合格之低功率射頻電

機,非經許可,公司、商號或使用者均不

得擅自變更頻率、加大功率或變更原設計

之特性及功能。

第十四條低功率射頻電機之使用不得影響

飛航安全及干擾合法通信;經發現有干擾

現象時,應立即停用,並改善至無干擾時

方得繼續使用。前項合法通信,指依電信

規定作業之無線電信。低功率射頻電機須

忍受合法通信或工業、科學及醫療用電波

輻射性電機設備之干擾。

English

"Under Industry Canada regulations, this radio

transmitter may only operate using an

antenna of a type and maximum (or lesser)

gain approved for the transmitter by Industry

Canada.

To reduce potential radio interference to

other users, the antenna type and its gain

should be so chosen that the equivalent

isotropically radiated power (e.i.r.p.) is not

more than that necessary for successful

communication."

"This device complies with Industry Canada

licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1)

this device may not cause interference, and

(2) this device must accept any interference,

including interference that may cause

undesired operation of the device."

Français

"Conformément à la réglementation

d'Industrie Canada, le présent émetteur radio

peut fonctionner avec une antenne d'un type

et d'un gain maximal (ou inférieur) approuvé

pour l'émetteur par Industrie Canada.

Dans le but de réduire les risques de

brouillage radioélectrique à l'intention des

autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la

puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité nécessaire

à l'établissement d'une communication

satisfaisante."

"Le présent appareil est conforme aux CNR

d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes: (1)

l'appareil ne doit pas produire de brouillage,

et (2) l'utilisateur de l'appareil doit accepter

tout brouillage radioélectrique subi, même si

le brouillage est susceptible d'en

compromettre le fonctionnement."

begin

1.5

Safety

Information to the user

The Primo Radio Part Setter and the Radio 3D Tool

Setter are both supplied with one 3 Volt CR2

Lithium Manganese battery each. 3.6 Volt ½ AA

Lithium Thionyl Chloride batteries may also be

used (see section 4.2).

Lithium batteries must be approved to IEC 62133.

Please dispose of the batteries on accordance with

your local environmental laws once the charge has

depleted. Do not attempt to recharge these

batteries.

Please ensure replacement batteries are fitted in

accordance with the instructions in this manual

and as indicated on the product. For specific

battery operating, safety and disposal guidelines

please refer to the battery manufacturer’s

literature.

CAUTIONS:

• Do not leave dead batteries in the

equipment.

• Do not allow coolant or debris to enter

the battery compartment.

• When changing the battery check that the

battery polarity is correct.

• Do not store batteries in direct sunlight or

rain.

• Avoid forced discharge of the batteries.

• Do not short-circuit the batteries.

• Do not disassemble, pierce, deform or

apply excessive pressure to the batteries.

• Do not swallow the batteries.

• Keep the batteries out of the reach of

children.

• Do not get batteries wet.

• If a battery is damaged, make sure to

exercise caution when handling it.

• Never dispose of batteries in fire.

NOTES:

Always ensure that the gasket and mating surfaces

are clean and free from dirt before reassembly.

After removing the old battery, wait more than 5

seconds before inserting the new battery.

If a dead battery is inadvertently inserted into the

probe then the LEDs will remain a constant red.

Please ensure that you comply with international

and national battery transport regulations when

transporting batteries or the products; Lithium

batteries are classified as dangerous goods and

strict controls apply on their shipment by air. If

you should need to return your Primo Radio Part

Setter or Radio 3D Tool Setter to Renishaw for any

reason, do not return any batteries to reduce

shipment delays.

In all applications involving the use of machine

tools eye protection is recommended.

The Primo Radio 3D Tool Setter has a glass window

around it. Handle with care if broken to avoid

injury.

Information to the machine

supplier/installer

It is the machine supplier's responsibility to ensure

that the user is made aware of any hazards

involved in operation, including those mentioned

in Renishaw product literature, and to ensure that

adequate guards and safety interlocks are

provided.

Under certain circumstances, the probe signal may

falsely indicate a probe seated condition. Do not

rely on the probe signals to halt the movement of

the machine and always programme an over travel

distance stop into the machining programme.

Before you

begin

1.6

Primo installation guide

Information to the equipment

installer

All Renishaw equipment is designed to comply

with the relevant EC and FCC regulatory

requirements. It is the responsibility of the

equipment installer to ensure that the following

Before you

guidelines are adhered to, in order for the product

to function in accordance with these regulations:

• Any interface must be installed in a

position away from any potential sources

of electrical noise, i.e. power

transformers, servo drives etc.

• All ground connections should be

connected to the machine 'star point' (the

'star point' is a single point return for all

equipment ground and screen cables).

Failure to adhere to this can cause a

potential difference between grounds.

• All screens must be connected as outlined

in the user instructions.

• Cables must not be routed alongside high

current sources (i.e. motor power supply

cables etc), or be near high speed data

lines.

• Cable lengths should always be kept to a

minimum.

Equipment operation

If the equipment is used in a way not specified by

the manufacturer, the protection provided by the

equipment may be impaired.

Primo training programme

Primo installation guide

The Primo system has been designed to be the ideal

package for customers who are new to using metrology

To ensure that customers achieve the best results from

their purchased system Primo comes with a training

package designed especially for Primo.

The Primo training programme consists of self study

modules with a number of exercises in measuring a

d part that is provided with the kit. This should give

all of the equipment users a high level of confidence in the

Each Primo System should be supplied with a Primo

from your Machine Tool

supplier. If you have not received the Primo Training

Package or any elements are missing please contact your

sit www.renisaw.com

The Primo training programme covers key routines and

skills in the following areas:

Work piece set up

Broken tool detection

As you progress through the training programme more

routines and training areas are unlocked.

Once all of the training areas are complete each user

will be sent a digital certificate to prove that

completed the Primo Training Programme.

Primo System ‘Smiley’ training work piece

begin

1.7

devices on their machine tools.

standar

equipment and their ability to use it.

Training Programme package

local Renishaw office.

To find this please vi

• Calibration

•

• Tool setting

•

and coordinate setting

they have

Before you

Setter basics

Primo Radio Part Setter and Radio 3D Tool

2.1

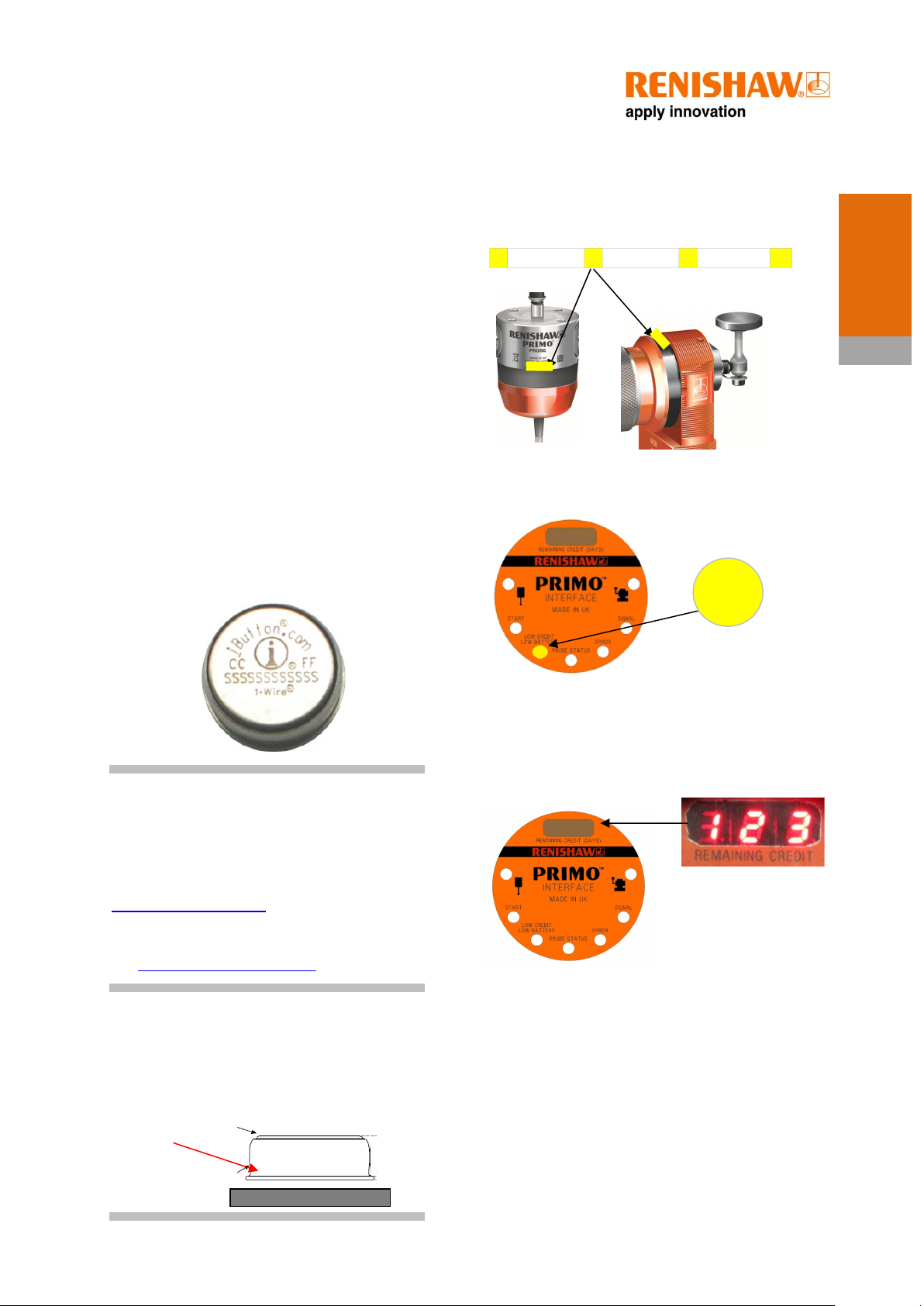

Introduction

Credit

When used within a system:

• The Radio Part Setter enables part setup

and inspection on machining centres.

• The Radio 3D Tool Setter enables broken

tool detection and tool setting

(length/diameter).

Primo Radio Part Setter and Radio 3D Tool Setter;

The Primo system requires credit to function;

• Credit is in the form of a Primo credit

token.

• This is inserted into the Radio Part Setter

which then transfers the credit to the

Primo Interface. Section 5.29.

• Deliver interference-tolerant radio

transmission through the use of the FHSS

(Frequency Hopping Spread Spectrum).

o Allows multiple systems to work

in the same machine shop

without interference.

o Using radio transmission enables

non line-of-sight operation.

Getting started

The Primo Radio Part Setter and Radio 3D Tool

Setter have LEDs to provide visual indication of

their status as well as overall system status.

• See section 5.21 for an LED guide.

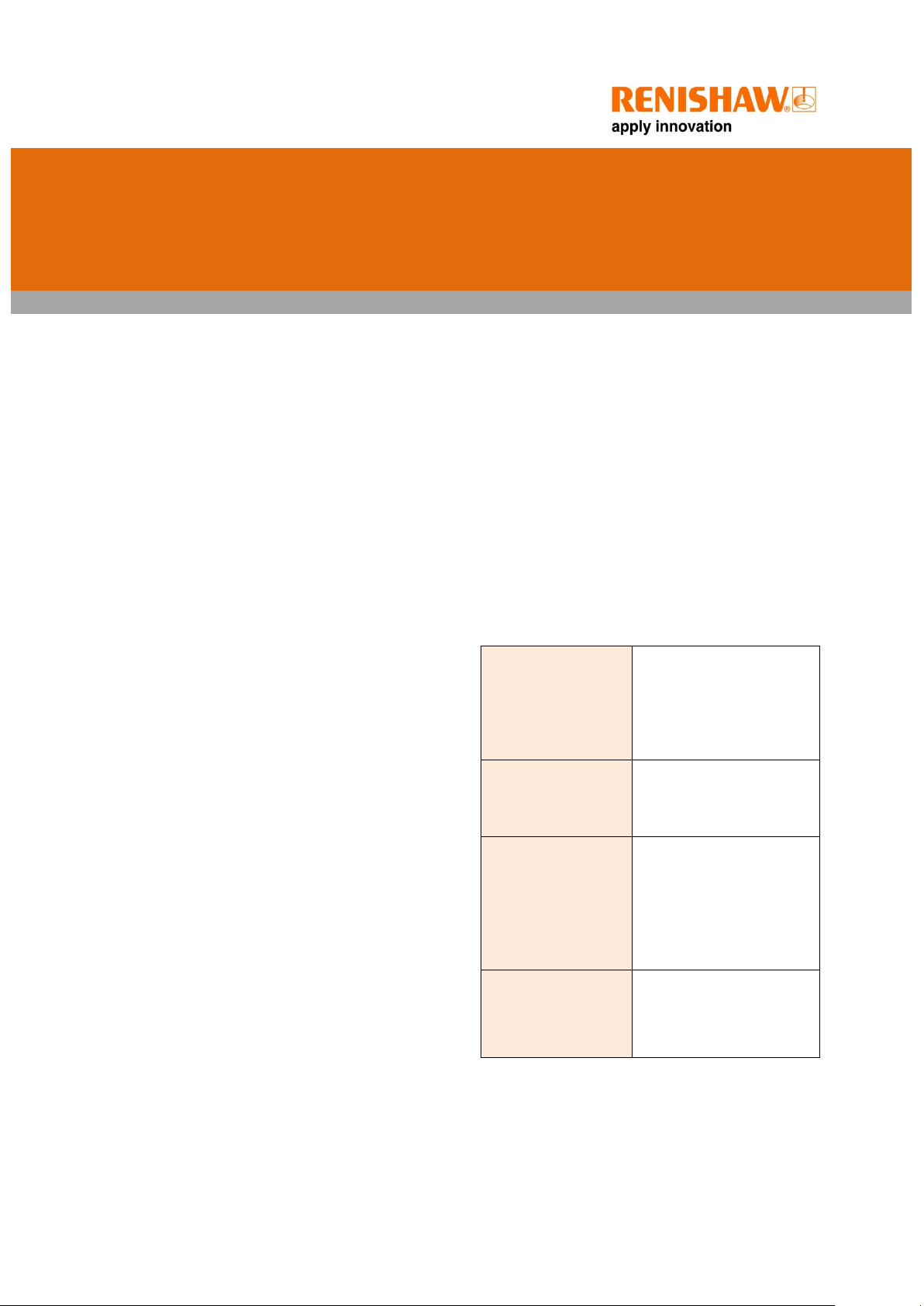

Modes of operation

Standby mode The equipment is waiting

for a switch on signal and

the Interface is waiting to

send a switch on signal

after receiving a signal

from the machine tool.

Operational mode Activated by a switch on

signal from the Interface

or a Spin. The equipment

is ready for use.

Acquisition mode Used to configure the

partnering of the Primo

Radio Part Setter and

Radio 3D Tool Setter with

the Interface. The

acquisition method is

described in section 5.28.

Credit transfer mode

(Radio Part Setter

only)

Used to transfer credit

from the Radio Part Setter

to the Interface. Section

5.29.

Primo installation guide

probes

2.2

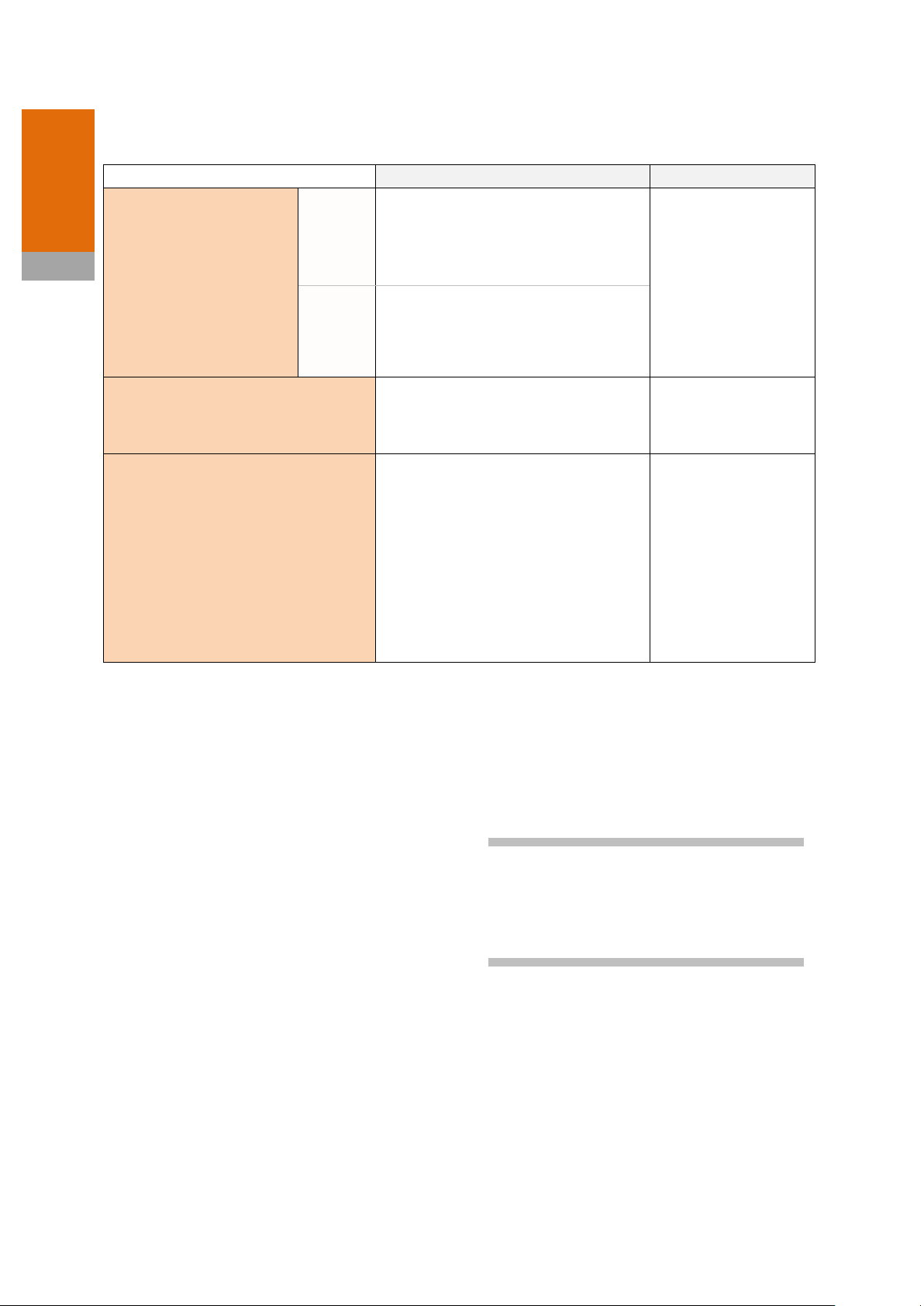

Equipment switch on/

switch off method

The basics –

Radio

on/off

Commanded by machine output.

Description Factory setting

Radio on/off

Spin

on/off

Enhanced trigger filter

Hibernation mode

Spin at 1000 rpm for 1.5 s minimum.

(Radio Part Setter only)

The enhanced trigger filter improves the

equipments’ resistance to triggering and

triggering without contacting a surface.

When the Primo Radio Part Setter or 3D

Tool Setter are in standby and the Primo

Interface is powered off or out of range,

the equipment enters hibernation; a low

power mode. The Part Setter or 3D Tool

Setter ‘wake’ from hibernation to

periodically check for their partnered

Interface. The ‘wake up’ frequency is

sent every 30 seconds when hibernation

is activated.

Enhanced trigger filter

OFF

Hibernation mode

ON

Configurable settings

Radio 3D Tool Setter switch on/off

The switch on/off method for the Radio 3D Tool

Setter is not user configurable. The method used is

radio on/off.

Enhanced trigger filter

When the filter is enabled a constant 10 ms filter

delay is introduced to the equipment output.

• It may be necessary to reduce the Radio

Part Setters approach speed to allow for

the increased stylus overtravel during the

extended time delay.

Re-calibration

If settings are changed via the Interface switches,

it is vital that the equipment is re-calibrated; See

sections 5.17 – 5.20.

Acquisition mode

The partnering of the Primo Radio Part Setter or

Radio 3D Tool Setter and the Interface described in

section 5.28.

NOTE:

To enter the Interface into acquisition mode,

Renikey or a power cycle will need to be used.

Locate the Renikey manual before starting the

partnership process. See 3.1.

Partnering is required during initial system set up

or if the Radio Part Setter turn on method had

changed.

• Partnering will not be lost by

reconfiguration of the equipment settings

or when changing batteries.

• Partnering can take place anywhere

within the performance envelope

(section 5.2).

Primo installation guide

Constant

Flashing

probes

2.3

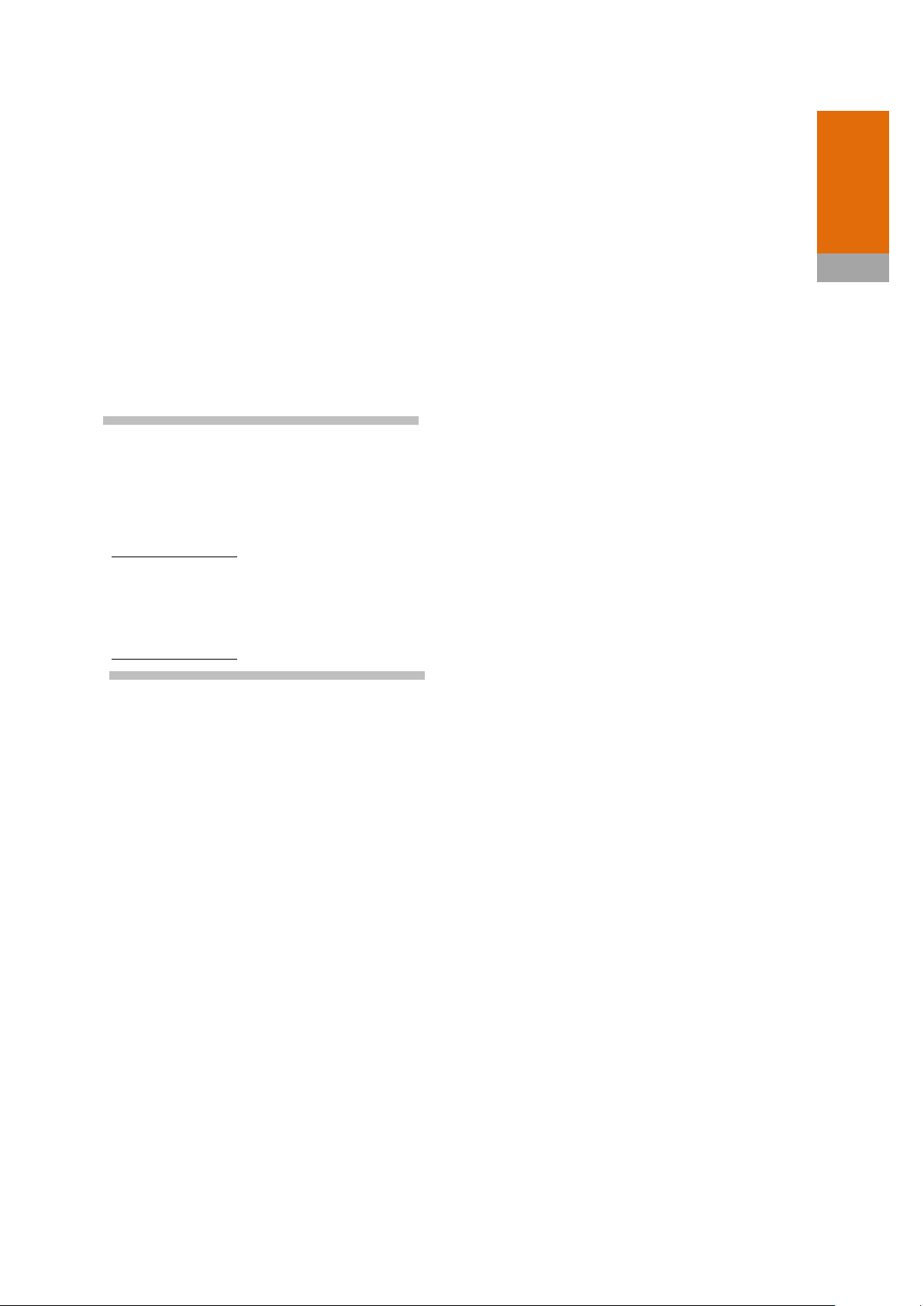

Primo credit token

Primo credit token contains the credit that allows

the Primo probing system to function.

The Primo system will not work without credit

being available in the system.

The standard Primo credit token contains 6

months worth of credit.

Upgrade credit token

Another credit token available is the Upgrade

token; this allows the Primo system to work for an

unlimited period.

Credit transfer

Credit is loaded into the Primo System by

transferring Credit from the Credit token and into

the Primo Interface. See section 5.29.

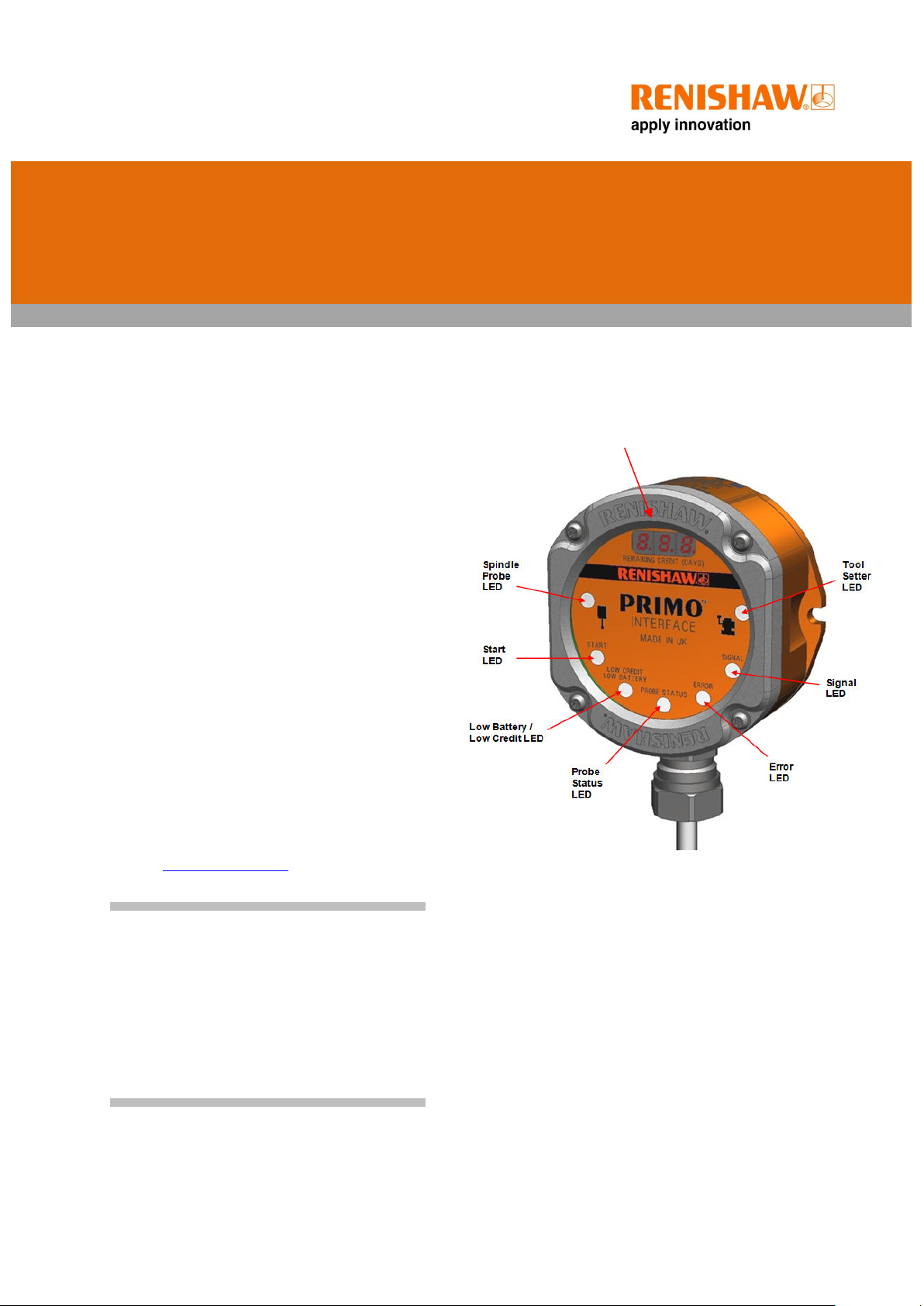

Four low

When any of these low

credit indicators

1.

Equipment LEDs

2.

Interface low battery/credit LED

credit indicators are shown

it is recommended that a

new Primo Credit Token is

loaded into the system.

The basics –

NOTE:

How to purchase credit:

A new 6 month credit token, or an Upgrade credit

token can be purchased from the Primo website

www.primoprobing.com.

You can also contact your local Renishaw supplier.

See www.renishaw.com/contact.

Installation:

Please ensure that the Primo Credit Token is

installed in the Radio Part Setter in the orientation

shown with the lip of the Token inboard. Failing to

do this will result in the Credit not being

transferred

.

3.

Interface digital display (123 days remaining

shown). When the remaining credit display reads 0

days then the Primo System will stop working and

new credit will need to be loaded into the system.

4.

Low battery/credit output from the Interface,

which can be connected to the machine control.

When credit is running low, an alarm will be sent

to the control.

probes

2.4

Primo Radio Part Setter

operation

The Primo Radio Part Setter operates as a highly

accurate and repeatable mechanical switch that

triggers as the stylus deflects against a surface.

The basics –

• The Radio Part Setter can measure in the

• The Primo Radio Part Setter can be used

• A trigger signal is sent directly to the CNC

X, Y and Z axis.

for work co-ordinate setting and for work

piece measurement.

controller so that offsets can be updated

– no manual intervention is required.

Primo Radio 3D Tool Setter

operation

The Radio 3D Tool Setter enables accurate

machining by measuring the length and diameter

of tools using the same highly accurate and

repeatable switch mechanism has the Primo Radio

Part Setter.

• The tool is set in the Z axis for tool length

measurement and broken tool detection.

• Rotating tools are set in the X and Y axes

for tool radius measurement.

probes

2.5

Primo installation guide

Software routines

Primo Software caters for 3-axis applications and

covers basic probing routines.

• Calibration

• Tool setting

• Broken tool detection

• Work piece set-up

• Work piece measurement

For further information refer to the Primo

Software Programming Guide H – 54XXXX

NOTES:

Software routines for tool setting are available

from Renishaw and are described in data sheet H2000-2289, which can be found at

www.renishaw.com.

Software upgrades - Purchase an upgrade to the

Inspection+ and Five Face Tool Setting package, as

well as the Productivity+ package. See

www.renishaw.com

The basics –

Digital ‘remaining credit’

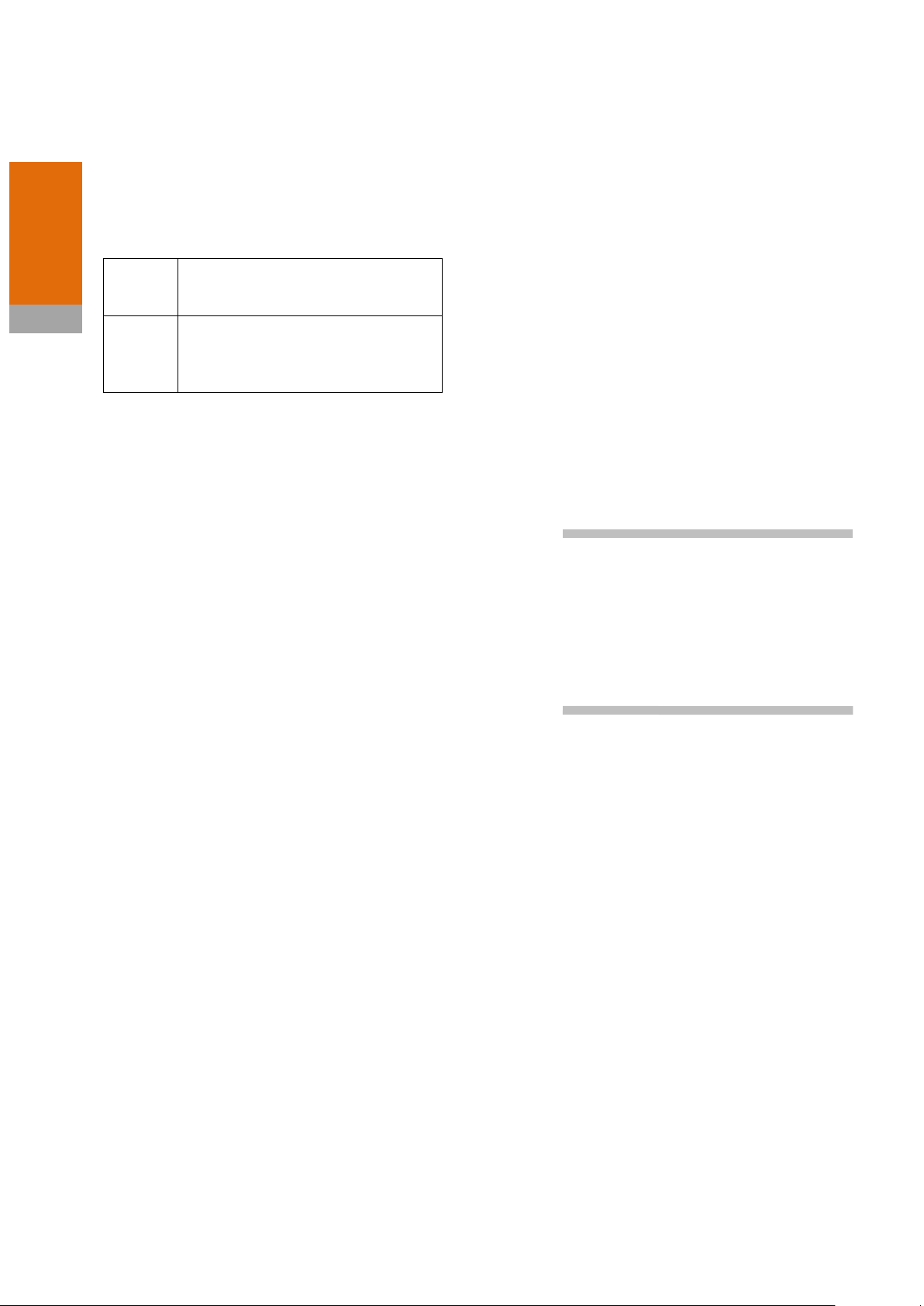

Primo Interface basics

Introduction

Interface visual diagnostics

The Primo Interface enables communication

between the Machine Tool, Radio Part Setter and

the Radio 3D Tool Setter using radio frequencies.

Power supply

The Interface requires a 12 Vdc to 30 Vdc supply

capable of supplying 150 mA minimum (TBC).

display and Error code

display

3.1

Input voltage ripple

The input voltage ripple must not cause the

voltage to fall below 12 V or go above 30 V.

ReniKey

Renikey is a Renishaw machine programme which

is used while partnering the equipment with the

Interface. Refer to the ReniKey programming

manual for instructions on how to use ReniKey or

refer to www.renishaw.com.

Note:

If the Primo System is using a Primo Upgrade

Credit Token and the Primo Interface is returned

to Renishaw then the Primo Upgrade Credit

Token must be returned with the interface for

identification purposes.

Level

Pulsed

Primo installation guide

Interface

3.2

Interface inputs

Machine start inputs:

‘Machine start’ is configurable as a level or pulsed

signal.

12 to 30 Vdc

The basics -

See section 5.14 for the full wiring diagram.

When input is active probe is switched

on.

12 to 30 Vdc

Part Setter toggles from being

switched on/off. Minimum pulse width

is 10 ms.

Interface outputs

There are four SSR outputs:

• Probe status 1

• Probe status 2

• Error

• Low battery/credit

All outputs can be inverted by using switches SW1

and SW2 (see section 3.5 for more info).

Note:

The term ‘Probe Status’ refers to the

measurement hardware in the system

interacting with the interface and can

therefore refer to the Primo Radio Part

Setter and the Primo Radio 3D Tool

Setter.

SSR outputs specifications:

• Maximum ‘on’ resistance = 25 ohm

• Maximum load voltage = 30 V

• Maximum load current = 100 mA

Interface

3.3

Interface

/credit

Probe status 2

Probe

status 2

Interface output waveform

Primo

The basics -

(level)

(pulsed)

Signal delays:

1. Transmission delay Probe trigger to output change of state = 10 ms ± 10 µs without enhanced

trigger filter

2. Start delay Time from initiation to start of signal to valid signal transmission = 1 s max

SSR open

SSR closed

SSR open

SSR closed

Interface

3.4

Primo installation guide

Switches SW1 and SW2

PCB diagram like below for Primo

The basics -

N/O

N/C

M-code

START

ENHANCED

HIBERNATION MODE

LOW

Interface

3.5

Disabled

Enabled

Switch SW1 output configuration

BATTERY

/CREDIT

Note:

If an error code E08 appears on the Primo Interface

Credit remaining/error code display when a switch

setting has been changed the Primo Radio Part Setter

or Primo Radio 3D Tool Setter must be re-acquired.

The basics -

Switch SW2 output configuration

TRIGGER FILTER

Spin

On

Enabled

Off

Disabled

61.25 (2.41

)

Battery cover

Primo credit

Ø

51 (2.00)

21 (0.83)

29.4

(1.16)

Ø

48.5 (1.91)

Primo

Primo

Dimensions and specifications

Part Setter dimensions

4.1

token cover

Primo installation guide

& Specs

4.2

Ø?

44.551

(1.75)

68.75

(2.70)

93 (3.66)

55 (2.17)

?

?

?

25mm

(Ø

0.98 in x 0.16)

X 4mm

4 (0.16)

Ø

25 (

Ø

0.09)

Primo

3D Tool Setter dimensions

Dimensions

?

Ensure this shows the new, larger disk

stylus

Loading...

Loading...