Page 1

Installation guide

H-1000-5004-04-B

PI 4‑2 probe interface

EXTENDED WARRANTY

Now available for this product.

Contact your vendor.

www.renishaw.com/ew

Page 2

© 2002 - 2008 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means, without the

prior written permission of Renishaw.

The publication of material within this document does not imply

freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE

THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE

DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR

REPRESENTATIONS REGARDING THE CONTENT. RENISHAW

EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are

registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All other brand names and product names used in this document are

trade names, service marks, trademarks, or registered trademarks of

their respective owners.

Renishaw part no: H-1000-5004-04-B

Issued: 06 2008

Page 3

1

PI 4‑2 interface

Installation guide

Page 4

2

FCC

Information to users (FCC section 15.105)

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case

you will be required to correct the interference at your own expense.

Information to the user (FCC section 15.21)

The user is cautioned that any changes or modifications not expressly approved by

Renishaw plc or authorised representative could void the user’s authority to operate the

equipment.

Special accessories (FCC section 15.27)

The user is also cautioned that any peripheral device installed with this equipment

such as a computer, must be connected with a high-quality shielded cable to insure

compliance with FCC limits.

TÜV

This equipment has been independently certified by TÜV Product Services in

accordance with OSHA (US) and SCC (Canada) requirements to the standards

UL61010-1 Second Edition and CAN/CSA-C22-2 No. 61010-1 Second Edition.

Page 5

3

Safety

Electrical requirement

If this product is not used in its intended manner, any protection provided may be

impaired.

The PI 4-2 is powered from the a.c. mains supply via an IEC 320 connector. The

electrical ratings of the unit are as follows:

100-240 V ac +10%, -15% 47 - 66 Hz 10 W

This equipment must be connected to a protective earth conductor via a three core

mains (line) cable. The mains plug shall be inserted only into a socket outlet provided

with a protective earth contact. The protective earth contact shall not be negated by the

use of an extension cable without protective conductor.

WARNING: Any interruption of the protective conductor may make the

equipment dangerous. Make sure that the grounding requirements are strictly

observed.

Environmental requirements

The following environmental conditions comply with (or exceed) BS EN 61010-1:1993:

Indoor use only

IP30 (no protection against water)

Altitude

Up to 2000 m

Operating temperature

0 °C to +50 °C

Storage temperature

-10 °C to +70 °C

Relative humidity

80% maximum for temperatures up to +31 °C

Linear decreases to 50% at +40 °C

Transient voltages

Installation category II

Pollution degree

2

The PI 4-2 is isolated from AC power by disconnection of the IEC mains connector on

the rear panel. If any additional means of isolation is required, it must be specified and

fitted by the machine manufacturer or the installer of the product. The isolator must

be sited within easy reach of the CMM operator and comply with IEC61010 and any

applicable national wiring regulations for the country of installation.

!

Safety

Page 6

4

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise

measurements and must therefore be treated with care.

Changes to Renishaw products

Renishaw plc reserves the right to improve, change or modify its hardware or software

without incurring any obligations to make changes to Renishaw equipment previously

sold.

Warranty

Renishaw plc warrants its equipment provided that it is installed exactly as defined in

associated Renishaw documentation.

Consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces

and/or cabling) is used or substituted. Failure to comply with this will invalidate the

Renishaw warranty.

Claims under warranty must be made from authorised services centres only, which may

be advised by the supplier or distributor.

Patents

Features of Renishaw’s PI 4-2 and associated products are the subjects of the following

patents and patent applications:

EP 242747 B JP 2,539,824 US 4769919 WO 97/35164

EP 279828 B JP 2,647,881 US 4817362

EP 0392660 JP 3,018,015 US 4916339

EP 548328 B JP 3,294,269 US 5,088,337

EP 0501710 JP 3,279,317 US 5,404,649

JP 2,510,804 US 5,339,535

US 5,323,540

US 5,505,005

US 5,918,378

US 6012230

Care of equipment

Page 7

5

Contents

Contents

1 Introduction and general description ..........................................................................7

2 Specification ..............................................................................................................9

2.1 Physical specification .....................................................................................9

2.2 Environmental conditions ...............................................................................9

2.3 Electrical specification ..................................................................................10

3 Unit configuration ..................................................................................................... 11

3.1 Front panel....................................................................................................11

3.2 Rear panel .................................................................................................... 12

4 System configuration ...............................................................................................16

4.1 System interconnection diagrams ................................................................16

4.2 Cables ..........................................................................................................19

4.2.1 PL22T ..........................................................................................19

4.2.2 PL25T ..........................................................................................19

4.2.3 PL26T ..........................................................................................20

4.2.4 HC-2 hand control .......................................................................20

4.2.5 PICS ............................................................................................21

4.2.6 STOP (pin 1) ................................................................................22

4.2.7 PPOFF (pin 2) .............................................................................22

4.2.8 0 V (pin 3) ....................................................................................22

4.2.9 +5 V (output pin 4) .......................................................................23

4.2.10 SYNC (output pin 5) ....................................................................23

4.2.11 HALT (output pin 6) ......................................................................23

4.2.12 PDAMP (pin 7) .............................................................................23

4.2.13 LEDOFF (pin 8) ...........................................................................24

4.2.14 LED anode (input pin 4) ...............................................................24

4.2.15 PICS pull-up (input pin 6) ............................................................24

4.2.16 Probe input (input pins 5 and 9) ..................................................24

4.2.17 Output timings .............................................................................24

Page 8

6

5 Rack mounting ......................................................................................................... 26

5.1 Mounting alone in a 19” rack ........................................................................26

5.2 Mounting next to a PHC10-2 ........................................................................27

6 Maintenance ............................................................................................................28

7 Fault finding .............................................................................................................29

7.1 POWER ON LED will not light ......................................................................29

7.2 PROBE SEATED LED will not light ..............................................................29

7.3 PROBE SEATED LED remains on ...............................................................30

7.4 PROBE SEATED LED correctly lit but output signals fail to reach CMM

controller .......................................................................................................31

Contents

Page 9

7

Introduction and general description

1 Introduction and general description

The function of a probe interface is to manage the probe to ensure that it produces

repeatable and reliable results over a long service life. This is achieved by careful

control of the probe current, trigger threshold and signal conditioning. A probe interface

also controls the head PROBE STATUS LED and provides clean output signals.

The PI 4-2 is a basic probe interface for use with Renishaw’s conventional touch-trigger

probes (TP1, TP20, TP6, MH20i etc.). It is suitable for use on both manual and direct

computer control (DCC) co-ordinate measuring machines (CMMs).

The PI 4-2 has been introduced as a replacement for the PI 4, PI 9 and PI 12 interfaces

and conforms to the relevant CE directives in force at the time of issue. It is housed

in the modern Renishaw enclosure compatible with the latest PHC10-2 and other

controller/interfaces.

The PI 4-2 interface has both solid state relay (SSR) and Renishaw product interconnection system (PICS) output options. It will also support the remote inhibit hand

control unit (HC-2).

Page 10

8

Introduction and general description

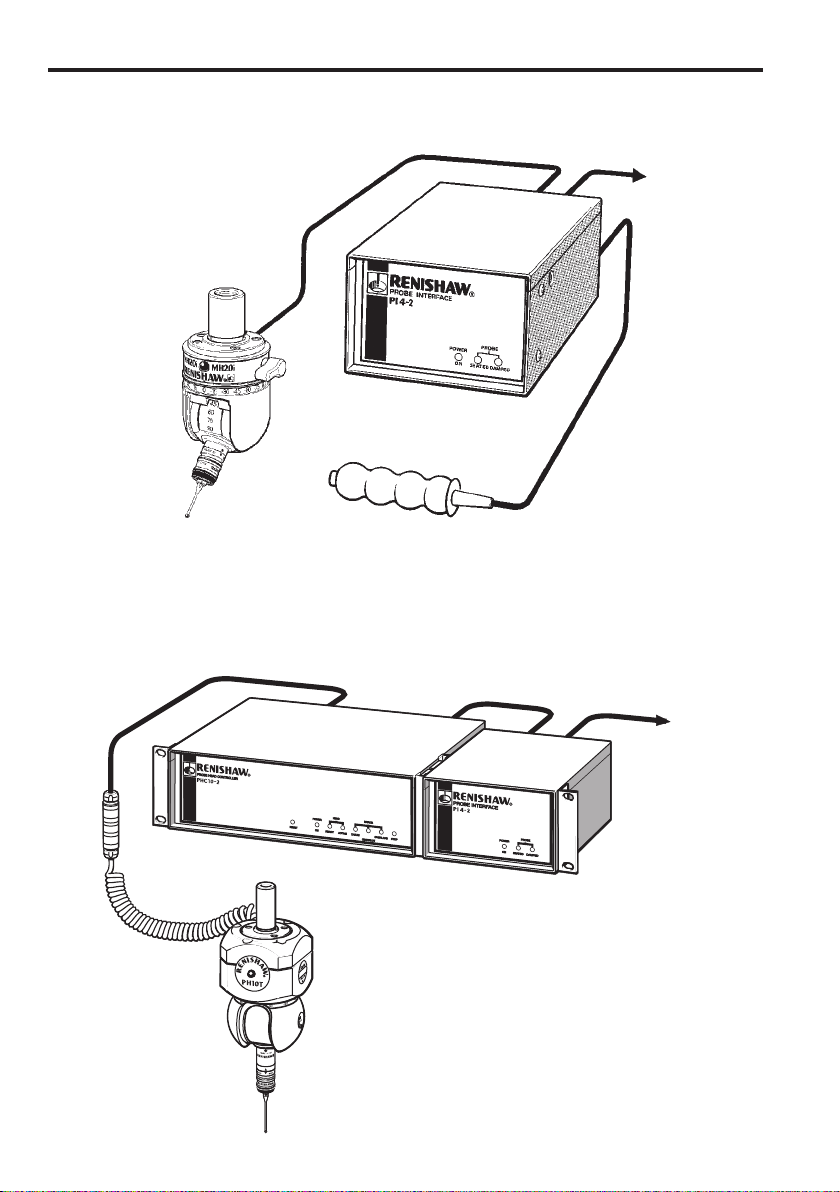

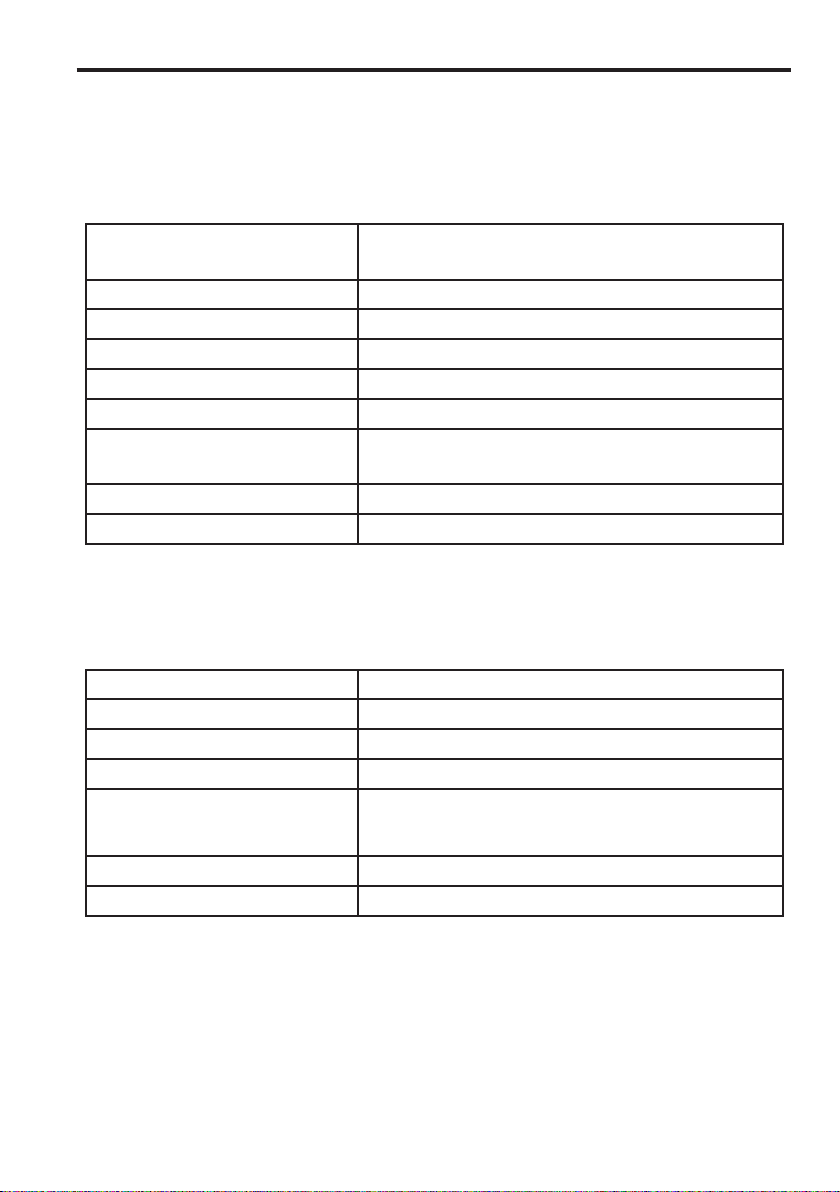

Figure 1

Figure 2

MH20i

PI 4-2

HC-2

to CMM

to CMM

PI 4-2

PHC10-2

PH10T

TP20

Page 11

9

Specification

2 Specification

2.1 Physical specification

Size

1/3 19 ” rack wide × 2U high

(140 mm × 88 mm × 183 mm high)

Mounting

19 ” rack mounting or free standing

Weight

1.6 kg (3.5 lb)

Probe compatibility

Standard probes: TP1, TP20, TP6, MH20i, etc.

Power connector

IEC 320

Probe input connector

9-way D socket (Renishaw PICS standard)

Probe output connector

9-way D plug (Renishaw PICS standard) or 5-pin

DIN SSR socket

System configuration

4 DIL switches

Probe signal cable

50 m, maximum at 24 AWG cores

2.2 Environmental conditions

The following environmental conditions comply with (or exceed) BS EN61010-1:1993

Indoor use only

IP30 (no protection against water)

Altitude

Up to 2000 m

Operating temperature

0 °C to +50 °C

Storage temperature

-10 °C to +70 °C

Relative humidity

80% maximum for temperatures up to +31 °C

Linear decreases to 50% at +40 °C

Transient voltages

Installation category II

Pollution degree

2

Page 12

10

Specification

2.3 Electrical specification

Mains power is supplied on a standard IEC 320 connector.

Power supply

Universal, automatic selection; 100-240 V ac

+10%, -15%, 47-66 Hz

Power consumption

10 W maximum (0.1 A maximum)

Inrush current

40 A, typical at 200 V

SSR contact ratings

±50 V pk

±40 mA pk

NOTE: The PI 4-2 must be earthed.

Page 13

11

Unit configuration

3 Unit configuration

3.1 Front panel

Figure 3

The name, colour and function of the LEDs are given in table 1.

Table 1 ‑ Interface LEDs

Name Colour Function

Power ON Green Mains power ON when lit.

Probe SEATED Green Probe seated when lit.

Probe triggered or not fitted when off.

Probe DAMPED Yellow Lit when PROBE DAMPing has been activated

by the CMM controller or other Renishaw

equipment (PROBE DAMPing reduces the

sensitivity of the probe to unwanted triggers

caused by CMM acceleration or vibration

during position moves).

Page 14

12

Unit configuration

3.2 Rear panel

Figure 4

1 PICS output connector (plug)

The plug configuration is shown below and the pin numbers and designations are given

in table 2.

Table 2 ‑ PICS output connector

Pin number Designation

1

2

3

4

5

6

7

8

9

Body

STOP

Probe power OFF (PPOFF)

0 V

Reserved for Renishaw use

SYNC output (probe trigger)

HALT output

PROBE DAMPing (PDAMP)

LED OFF

Screen

See page 27, ‘Product inter-connection system (PICS)’ for explanation of PICS signals.

1 2 3 4 5

6 7 8 9

1

3

2

4

5

6

7

Page 15

13

Unit configuration

2 PICS input connector (socket)

The socket configuration is shown below and the pin numbers and designations are

given in table 3.

Table 3 ‑ PICS input connector

Pin number Designation

1

2

3

4

5

6

7

8

9

Body

STOP

Probe power OFF (PPOFF)

0 V

Reserved for Renishaw use

Probe signal

+5 V

PROBE DAMPing (PDAMP)

LED OFF

Probe return

Screen

See page 27, ‘Product inter-connection system (PICS)’ for explanation of PICS signals.

5 4 3 2 1

9 8 7 6

Page 16

14

Unit configuration

3 Configuration switches

Switch numbers, positions and designations are given in table 4 (on page 22).

Table 4 ‑ Configuration switches

Switch number Position Designation

1 Up (ON) Output polarity normal:

SYNC high for probe seated, low for probe

triggered

SSR open for probe seated, closed for probe

triggered

Down (OFF) Output polarity reversed

2 Up (ON) Buzzer ON

Down (OFF) Buzzer OFF

3 and 4 * Up (ON) Input polarity normal:

PICS input: Pin 5 = probe input

Pin 9 = 0 V return

Down (OFF) Input polarity reversed:

PICS input: Pin 5 = 0 V return

Pin 9 = probe input

* Switches 3 and 4 must be used together (i.e. BOTH up or BOTH down).

** Although, conventional touch-trigger probes are not polarity sensitive, certain

grounding systems or special probes may require the operation of this switch.

Page 17

15

Unit configuration

4 SSR output (5 pin DIN socket)

The socket configuration is shown below and the pin numbers and designations are

given in table 5.

Table 5 ‑ SSR output

Pin number Designation

1

2

3

4

5

Probe status (a)

Screen

Probe status (b)

Probe status (a)

Probe status (b)

NOTE: The probe status SSR output is connected to pins 1 and 3 and to pins 4 and 5.

5 Mains power connector

This is a standard input plug conforming to IEC 320.

6 Version number label

This label indicates the modification level of the interface. The information may be

relevant when compatibility with other systems is being considered and should always

be quoted when contacting Renishaw for help or service.

7 Serial number

This unique number allocated to your PI 4-2 should be quoted when contacting

Renishaw for help or service.

1

3

4

5

2

Page 18

16

System configuration

4 System configuration

4.1 System interconnection diagrams

Cable A PL22T

Cable B PICS output to CMM (or HC-2)

Cable C SRR output to CMM

Cable D PL1T, 2T, 3T, 4T

NOTE: The cable shown is an alternative output cable.

Figure 5 ‑ PI 4-2 with manual heads

Probe head PH1,

PH6, MH20, MH20i,

MIH, MIH-S

TP20, TP6

Cable D

Cable C

Cable B

Cable A

PI 4-2

Page 19

17

Cable A RS232 or IEEE488 to CMM

Cable B PL25T

Cable C PICS output to CMM

Cable D SSR output to CMM

Cable E PLM 6T, 7T, 8T, 9T

Cable F PL5T, 6T, 12T, 13T

NOTE: The cable shown is an alternative output cable.

Figure 6 ‑ PI 4-2 with PH10T and PHC10-2 controller

System configuration

TP20, TP6

Cable E

Cable D

Cable C

Cable B

PI 4-2

Cable F

Cable A

PHC10-2

AM1

PH10T

Page 20

18

System configuration

TP20, TP6

Cable E

Cable D

Cable C

Cable B

PI 4-2

Cable F

Cable A

PHC10-2

AM1

PH10M

Cable A RS232 or IEEE488 to CMM

Cable B PL25T

Cable C PICS output to CMM

Cable D SSR output to CMM

Cable E PLM 6T, 7T, 8T, 9T

Cable F PL5T, 6T, 12T, 13T

NOTE: The cable shown is an alternative output cable.

Figure 7 ‑ PI 4-2 with PH10-M and PHC10-2 controller

Page 21

19

System configuration

4.2 Cables

Three conventional cables can be used with the PI 4-2: -

• PL22T

• PL25T

• PL26T

Their functions and connections are given below.

4.2.1 PL22T

The PL22T adapts a 5 pin DIN input connector into a 9-pin D-type PICS input.

The 5-pin DIN end is a socket which allows a PI 4-2 input cable to be adapted to a

PICS input (see figure 8).

5-pin DIN socket

5

1

4

3

2

5

3

9

8

6

1

4

Screen

Probe return (low)

Probe signal (high)

0 V

LED anode

Pull-up

STOP

9-pin DIN plug

Figure 8

4.2.2 PL25T

The PL25T is a standard PICS interconnection cable 9-pin D plug to 9-pin D socket. All

connections are pin-to-pin (i.e. 1 to 1, 2 to 2 etc.).

Machine cable PI 4‑2

Page 22

20

System configuration

4.2.3 PL26T

The PL26T cable connects between the 7-pin DIN probe output of a PHC10-2 and the

9-pin D type PICS input of the PI 4-2 (see figure 9).

7-pin DIN plug

5

6

4

7

2

5

2

9

3

8

6

4

Screen

Probe return (low)

Probe signal (high)

Probe inhibit (from PHC9)

0 V

Pull-up

STOP

9-pin DIN plug

PHC9 PI 4‑2

1

3

1

LED anode

Figure 9

4.2.4 HC‑2 hand control

The HC-2 hand control (figure 10) is a simple remote inhibit switch which allows the

machine operator to inhibit the interface while the stylus is changed or the probe head

indexed. It has an LED indicator in the switch button which is lit when the interface is

inhibited.

Figure 10

Page 23

21

System configuration

The HC-2 is intended for use only on manual CMMs and is plugged into the PICS

output connector (see page 18, “Rear panel”)

The socket configuration is shown below and the pin numbers and designations are

given in table 6.

Table 6 ‑ HC‑2 hand control

Pin number Designation

1

2

3

4

5

6

7

8

9

Body

SWITCH (high)

0 V

LED drive

Screen

-

-

-

-

4.2.5 PICS

The product inter-connection system (PICS) has been developed by Renishaw to

simplify the number and variation of cables needed for installations comprising several

controllers/interfaces.

PICS allows a standard method of connection for all real time signals used by current

Renishaw products.

The descriptions given in the following sections are specific to PI 4-2 connections.

For a full explanation of the PICS system see the Renishaw publication PICS

installation guide (part number H-1000-5000).

Table 7 (on page 22) gives pin numbers and input and output functions.

5 4 3 2 1

9 8 7 6

Page 24

22

System configuration

Table 7 ‑ PICS

Pin number PICS output PICS input

1

2

3

4

5

6

7

8

9

STOP

PPOFF (probe power OFF)

0 V

Reserved for renishaw use

SYNC

HALT

PDAMP (probe DAMPing)

LEDOFF

-

STOP

PPOFF (probe power OFF)

0 V

LED anode

Probe signal (high)

PICS pull-up

PDAMP (probe DAMPing)

LEDOFF

Probe return (low)

4.2.6 STOP (pin 1)

This signal is active when low and is responded to, and can be asserted by, the PI 4-2

interface.

It is present on both input and output connectors.

STOP will be asserted only if the internal power rail of the PI 4-2 fails.

If another unit on the PICS bus asserts the stop signal, the PI 4-2 reacts by asserting

both the SYNC and HALT lines irrespective of the status of any of the other PICS lines.

This is carries out to ensure that CMM motion is stopped.

4.2.7 PPOFF (pin 2)

Probe power OFF is an active low inhibit signal produced by another unit on the PICS

bus (the PI 4-2 cannot assert PPOFF).

It is present on both input and output connectors.

The PI 4-2 reacts to PPOFF by inhibiting the SYNC signal (i.e. the output if held high*

irrespective of the probe status). STOP overrides the PPOFF signal.

4.2.8 0 V (pin 3)

This is the common reference and return path for all signals except the un-interfaced

probe inputs on the PICS inputs connector. It is present on both input and output

connectors.

Page 25

23

System configuration

4.2.9 +5 V (output pin 4)

This output is reserved for Renishaw use and consists of a limited +5 V supply to power

certain signal conditioning units.

4.2.10 SYNC (output pin 5)

This is an active low* signal produced by the PI 4-2. It is the output of the probe status,

a normally high* signal which goes low when the probe is triggered.

STOP and PPOFF override the output. STOP forces the signal low. PPOFF forces the

signal high*.

It is present only on the PICS output connector.

4.2.11 HALT (output pin 6)

This is an active low signal produced by the PI 4-2.

It is present only on the PICS Output connector.

The PI 4-2 asserts HALT when the raw probe signal (before debounce) indicates that

the probe has been continuously triggered for at least 5 ms (see figure 11 on page 31).

The function of this output is to indicate the difference between a short vibration trigger

and a genuine trigger event. The scales should be latched when SYNC is received, the

reading accepted and the machine stopped when HALT is received.

* These signals will be inverted if the output polarity switch (SW1) is in the DOWN

position.

4.2.12 PDAMP (pin 7)

PROBE DAMPing is an active low signal produced by another unit on the PICS bus (the

PI 4-2 cannot assert PDAMP).

It is present on both input and output connectors.

PDAMP influences the SYNC output by inhibiting it until the probe has been

continuously triggered for at least 5 ms. Renishaw recommends that PDAMP is

asserted by the CMM controller to reduce the probe’s sensitivity to vibration during

rapid position moves.

Page 26

24

System configuration

4.2.13 LEDOFF (pin 8)

This signal is active when low and can be asserted by the PI 4-2 or another unit in the

PICS bus.

The PI 4-2 asserts LED OFF and the SYNC line at the same time in response to a

trigger event or a STOP signal. The purpose of the LED OFF signal is to control the

LED on the probe signal.

4.2.14 LED anode (input pin 4)

This is a 12 mA LED drive current produced by the PI 4-2 to control the probe head

LED.

It is present on the PICS input only.

This output is connected to the LEDOFF signal at the probe head or its controller to

control the LED.

4.2.15 PICS pull‑up (input pin 6)

This is an 150 W pull-up resistor to +5 V and is used to provide a STOP pull-up for

systems which do not have a probe head controller in the PICS bus.

4.2.16 Probe input (input pins 5 and 9)

These are the probe input connections to the PI 4-2.

4.2.17 Output timings

Standard probe timing

Probe output timings for normal touch-trigger operation are shown in figure 11.

Probe DAMPing

When the probe DAMPing line is pulled low, SYNC will be sent only if the probe is

triggered for longer than 5 ms (see figure 12).

Page 27

25

System configuration

Probe

triggered

Probe

seated

SYNC

SYNC

HALT

Debounce

20 ms

5 ms

NOTE: The HALT signal is a minimum of 20 ms long. If the signal is more than 5 ms

but less than 25 ms these edges will not coincide.

Figure 11

Probe

triggered

Probe

seated

5 ms 5 ms 5 ms

5 ms

delay

Figure 12

Page 28

26

Rack mounting

5 Rack mounting

WARNING: Ensure the PI 4-2 is disconnected from the mains supply during

installation.

WARNING: Take care not to exceed the operation ambient of 50 °C around the

unit. Do not install near sources of heat. Forced cooling may be required in final

installation.

NOTE: Use the mounting screws supplied with this equipment. DO NOT replace with

longer screws as damage could occur.

5.1 Mounting alone in a 19” rack

The PI 4-2 can be used in a 19” rack system or as a stand alone unit.

Figure 13 below shows a PI 4-2 mounted to a 19” rack system.

Remove the blanking plugs from side panels of the PI 4-2 and fit the 1/3 blanking

panels (1) using the screws provided.

Fit the completed assembly to the rack.

Figure 13

!

!

Page 29

27

Rack mounting

The rack mounting bracket kit part no. A-1018-0124.

The enclosure link bracket kit part no. A-1018-0126.

Figure 14

5.2 Mounting next to a PHC10‑2

The 1/3 blanking panel kit part number is A-1018-0123.

Figure 14 (on page 26) shows the PI 4-2 mounted next to a PHC10-2. Fit a rack mount

bracket (1) and an enclosure link bracket (2) using the screws provided.

Remove the blanking plugs from the PHC10-2 (if fitted) and, using the screws provided,

fit an enclosure link bracket and a rack mount bracket.

The enclosure mount brackets must be fitted in the orientations shown. Fit the link

brackets to the units before fitting the link brackets together. Using the screws provided,

fit together to PI 4-2 and the PHC10-2. The complete linked assembly is ready for

fitting to the rack.

Page 30

28

Maintenance

6 Maintenance

There are no user serviceable parts within the PI 4-2.

The PI 4-2 may be wiped clean using a clean dry cloth.

Page 31

29

Fault finding

7 Fault finding

There are several test which can be safely carried out while power to the PI 4-2 is on.

DO not remove the cover in any circumstances.

7.1 POWER ON LED will not light

This will normally indicate that no power is applied to the unit (it is driven from an

internal d.c. supply).

Check that:

• The mains power cable is firmly connected.

• There is mains power to the mains cable.

If these checks do not correct the problem the PI 4-2 should be returned to Renishaw

for repair.

7.2 PROBE SEATED LED will not light

This will normally indicate that the probe is triggered or not connected.

Check that:

• The rear panel switches 3 and 4 are both up or both down (switches 3 and 4 must

always be in the same position, see section 3.3)

• Disconnect the PICS input connector and put a link (short circuit) between pins 5

and 9 of the PI 4-2 input plug. Check that PROBE SEATED LED is still off.

If these checks do not isolate the problem the PI 4-2 should be returned to Renishaw

for repair.

If the link (short circuit), described above, switches the PROBE SEATED LED on, the

fault is in the input (CMM wiring, probe head or probe). See the appropriate product

documentation.

Page 32

30

Fault finding

7.3 PROBE SEATED LED remains on

This will normally indicate that the probe is seated.

Check that:

• The LED goes off when the PICS Input connector is removed.

• The LED goes off when the HC-2 is disconnected (if fitted).

If removing the PICS Input connector switches the PROBE SEATED LED off, the

fault is in the input (CMM wiring, probe head or probe). See the appropriate product

documentation.

If removing the HC-2 input (when not set to inhibit), switches the PROBE SEATED LED

off, the problem is in the HC-2 (which should be returned to Renishaw for repair).

If these checks do not isolate the problem the PI 4-2 should be returned to Renishaw

for repair.

Page 33

31

Fault finding

7.4 PROBE SEATED LED correctly lit but output signals

fail to reach CMM controller

Perform the following procedures -

1. Remove the PICS output connector.

2. Using a voltmeter connected between pin 3 (0 V) and pin 5 (SYNC) on the PICS

output socket.

When the stylus is seated the output voltage should be between 4 V and 5 V d.c. When

the stylus is deflected the output voltage should be between 0 V and 1 V d.c. If switch 1

is DOWN the output voltages will be reversed (i.e. 0 V seated, 5 V deflected).

OR, if the SSR output is being used:

1. Remove the SSR output connector.

2. Using a resistance meter connect the pin 1 (probe status, a) and pin 3

(probe status, b).

When the stylus is seated the resistance should be less than 10 Ω. When the stylus

is deflected the resistance should be greater than 1 MΩ. If switch 1 is DOWN the

resistances will be reversed (i.e. more than 1 MΩ seated, less than 10 Ω deflected).

If these checks do not correct the problem the PI 4-2 should be returned to Renishaw

for repair, otherwise the fault is either in the output cable or the CMM controller input

(see the appropriate product documentation).

Page 34

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details,

please visit our main web site at

www.renishaw.com/contact

*H-1000-5004-04*

Loading...

Loading...