Page 1

Installation guide

H-1000-5029-05-B

PI 200 interface for the TP200 system

Page 2

© 2002 - 2007 Renishaw plc. All rights reserved.

Renishaw® is a registered trademark of Renishaw plc.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means, without the

prior written permission of Renishaw.

The publication of material within this document does not imply

freedom from the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of

this document are free from inaccuracies and omissions. However,

Renishaw makes no warranties with respect to the contents of this

document and specifically disclaims any implied warranties. Renishaw

reserves the right to make changes to this document and to the

product described herein without obligation to notify any person of

such changes.

Trademarks

All brand names and product names used in this document are trade

names, service marks, trademarks, or registered trademarks of their

respective owners.

Renishaw part no: H-1000-5029-05-B

Issued: 10 2007

Page 3

1

PI 200

interface for TP200 probe system

installation guide

Page 4

2

FCC

Information to user (FCC section 15.105)

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case

you will be required to correct the interference at your own expense.

Information to user (FCC section 15.21)

The user is cautioned that any changes or modifications not expressly approved by

Renishaw plc or authorised representative could void the user’s authority to operate the

equipment.

Special accessories (FCC section 15.27)

The user is also cautioned that any peripheral device installed with this equipment

such as a computer, must be connected with a high-quality shielded cable to insure

compliance with FCC limits.

TÜV

This equipment has been independently certified by TÜV Product Services in

accordance with OSHA (US) and SCC (Canada) requirements to the standards

UL61010-1 Second Edition and CAN/CSA-C22-2 No. 61010-1 Second Edition.

Page 5

3

Care of equipment

Your Renishaw probe and accessories are precision instruments. Please use and

maintain the products in accordance with these instructions. Retain the transit box for

storing the components when not in use.

CAUTION:

The TP200 probe contains sensitive strain sensors. Permanent

damage may be caused if the probe is dropped or subjected to severe shock

as may be caused by misuse.

Changes to Renishaw products

Renishaw plc reserves the right to improve, change or modify its hardware or software

without incurring any obligations to make changes to Renishaw equipment previously

sold.

Warranty

Renishaw plc warrants its equipment provided that it is installed exactly as defined in

associated Renishaw documentation.

Consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces

and/or cabling) is used or substituted. Failure to comply with this will invalidate the

Renishaw warranty.

Claims under warranty must be made from authorised services centres only, which may

be advised by the supplier or distributor.

Patents

Aspects of the TP200 system and aspects of similar systems are the subjects of the

following patents and patent applications:

EP 0243766 JP 2,545,082 US 4813151 US 5,755,038

EP 0388993 JP 2,539,824 US 4817362 US 5,918,378

EP 242747 B JP 2,647,881 US 4916339 US 6012230

EP 279828 B JP 3,004,050 US 5,228,352

EP 0470234 JP 3,346,593 US 5,327,657

EP 0521703 JP 3,294,269 US 5,404,649

EP 548328 B JP 3,279,317 US 5,339,535

EP 566719 B JP 2,510,804 US 5,323,540

EP 0501710 JP 3,634,363 US 5,505,005

EP 0641427 JP 3,018,015 US 5,671,542

EP 0392660 JP 3,546,057 US 4769919

EP 0740768 US 5,088,337 WO 97/35164

Care of equipment

!

Page 6

4

Safety

Safety

If this product is not used in its intended manner, any protection provided may be

impaired.

There are no user serviceable parts inside this equipment.

The PI 200 interface unit must be connected to a supply incorporating a protective

earth conductor via a three-core mains cable (line cord).

Electrical ratings

Supply voltage range

100 - 240 V ac + 10%, -15%

Power frequency range

47 Hz - 63 Hz

Power consumption

10 W

SSR contact ratings

±50 V pk. ±40 mA pk.

Operating conditions

The PI 200 interface unit is specified to operate under the following conditions as

defined in BS EN 61010-1:2001.

Protection provided by

enclosure

IP30

Altitude

Maximum 2000 m

Operating temperature

0 °C to +50 °C

Storage temperature

-10 °C to +70 °C

Relative humidity

Maximum 80% RH up to +31 °C, decreasing

linearly to a maximum 50% at +40 °C.

Transient overvoltage

Installation category II

Pollution degree

2

The PI 200 is isolated from AC power by disconnection of the IEC mains connector on

the rear panel. If any additional means of isolation is required, it must be specified and

fitted by the machine manufacturer or the installer of the product. The isolator must

be sited within easy reach of the CMM operator and comply with IEC61010 and any

applicable national wiring regulations for the country of installation.

Page 7

5

Contents

Contents

1 Introduction ................................................................................................................7

2 Product description ....................................................................................................

9

2.1 System overview ............................................................................................

9

2.2 Probe status signal (SYNC) ............................................................................

9

2.3 Trigger confirmation signal (HALT) ...............................................................

10

2.4 SYNC and HALT debounce ..........................................................................

12

2.5 Probe damped signal (PDAMP)

....................................................................13

2.6 Stylus mass and ambient temperature compensation ..................................

14

2.7 RESET button ...............................................................................................

14

2.8 Front panel indicators ...................................................................................

15

2.9 Audible indicator ...........................................................................................

16

2.10 Rear panel switches and connectors ............................................................

16

2.11 Configuration switches

..................................................................................17

2.12 Probe polarity switch ....................................................................................

21

3 Connector pin-outs ..................................................................................................

22

3.1 PICS input connector ....................................................................................

22

3.2 PICS output connector .................................................................................

23

3.3 Solid state relay (SSR) output connector .....................................................

24

3.4 Stylus change rack (SCR) output connector ................................................

25

3.5 Remote reset ................................................................................................

25

4 PI 200 dimensions and cable data ...........................................................................

26

5 Part number summary .............................................................................................

27

5.1 Replacements ...............................................................................................

28

5.2 Accessories ..................................................................................................

28

6 Installation procedure ..............................................................................................

29

6.1 Rack mounting ..............................................................................................

29

6.2 Mounting with older style Renishaw control units .........................................

30

6.3 System interconnection ................................................................................

31

6.4 Using TP200 with the ACR1 autochange system .........................................

36

6.5 SCR200 stylus change rack .........................................................................

37

6.6 Interconnection cables ..................................................................................

38

6.7 Upgrading older probe systems to TP200 (retrofitment) ...............................

39

Page 8

6

Contents

7 PICS terminations ....................................................................................................40

8 Summary of changes from earlier versions .............................................................

41

9 Maintenance ............................................................................................................

42

9.1 PI 200 ...........................................................................................................

42

9.2 TP200 probe and stylus module ...................................................................

42

9.3 SCR200 rack ................................................................................................

42

10 Fault finding .............................................................................................................

43

Page 9

7

Introduction

1 Introduction

The TP200 probe system comprises the TP200 probe sensor and stylus module, the

PI 200 interface and the optional SCR200 stylus change rack.

The TP200 is a 13.5 mm diameter touch-trigger probe with the facility to quickly change

stylus configurations without the need for requalification. This is achieved by carrying

the stylus on a detachable module that is located on the probe sensor body by a

highly repeatable kinematic coupling and held in place by magnetic force. After initial

qualification of the stylus tip, the module may be removed and replaced as required

without additional requalification by simply recalling the initial qualification data.

The probe sensor uses electronic strain sensing techniques that provide better form

measuring accuracy and operating life than can be achieved with kinematic switching

probes.

The SCR200 stylus change rack provides storage for pre-qualified stylus assemblies

and facilitates automatic stylus changing under measurement programme control.

The dedicated PI 200 interface supplies power and controls the operation of the TP200

probe and SCR200 rack. Communication with other Renishaw equipment and the CMM

controller is via the PICS (product interconnection system) ports.

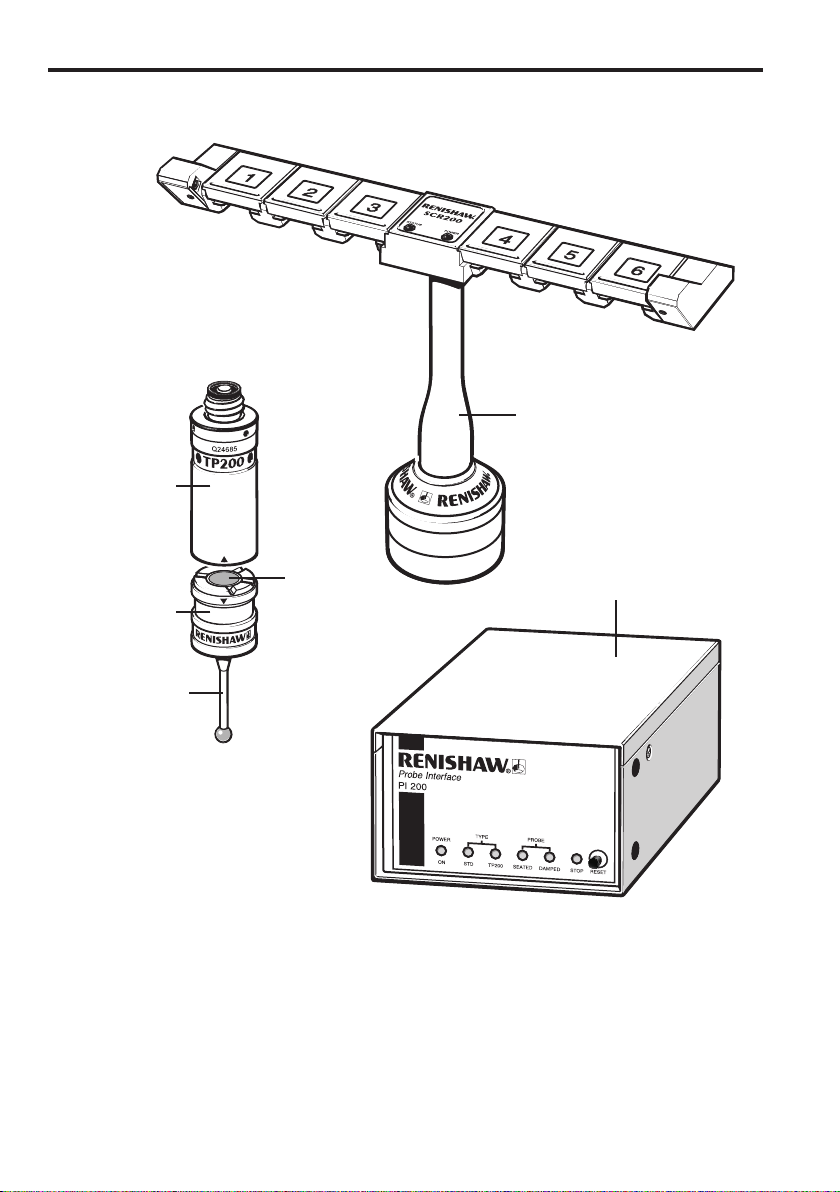

The TP200 system components (probe sensor, stylus module, PI 200 interface and

SCR200 stylus change rack), illustrated in figure 1, are described in the TP200 probe

system user’s guide (Renishaw part number H-1000-5014).

A version number label (e.g. V9) on the PI 200 rear panel indicates the modification

level of the unit. A summary of the changes made at each level is included later in this

document.

Page 10

8

Introduction

TP200 probe

sensor

TP200 stylus

module

Stylus

Kinematic

coupling

SCR200 stylus

change rack

PI 200 interface

Figure 1 -

TP200 precision touch-trigger probe system

Page 11

9

Product description

2 Product description

2.1 System overview

A small deflection of the stylus tip produces a force which is applied via the stylus

module and kinematic coupling to the strain sensing structure housed in the probe

body. Electronic processing, based on a customised mixed signal integrated circuit

and hybrid microcircuit construction contained within the probe, converts the sensor

responses to a current proportional to strain. The probe output requires only two wires

for transmission to the PI 200 interface, enabling the TP200 to use the existing M8

mounting connector system fitted to a wide range of probe heads and extension bars.

In the PI 200 interface, the probe current is compared with pre-set reference levels

to determine the status of the probe, which may be armed (seated) or triggered. The

probe status (SYNC) and the trigger confirmation (HALT) signals are asserted when the

appropriate conditions are met.

At power-up, or when a probe is first connected, the PI 200 recognises whether

the probe is a kinematic switching probe (TP20/TP6/TP2 type) or a TP200, and

automatically selects the appropriate operating mode.

When using the SCR200 change rack to perform automatic stylus changing, the PI 200

inhibits probe triggers and resets the TP200 probe sensor to account for the loading

effects of the new stylus assembly on the strain sensors. Collision damage is prevented

by an overtravel mechanism and a limit switch in the base of the SCR200. A small

displacement will cause the PI 200 to assert the SYNC, HALT and STOP signals to

stop CMM motion.

2.2 Probe status signal (SYNC)

SYNC is the real time PICS trigger signal used to trigger recording of the machine scale

coordinates when taking a gauge point. SYNC may also initiate the process of stopping

and reversing CMM motion (sometimes called ‘back-off’) to the pre-hit point.

When the stylus contacts the workpiece, a change of strain occurs in the sensing

structure, causing the probe current to increase. SYNC is asserted when the probe

current exceeds the trigger reference level. When the stylus backs off from the

workpiece, the probe current will fall below the trigger reference level and SYNC will be

cleared to the armed state.

Page 12

10

Product description

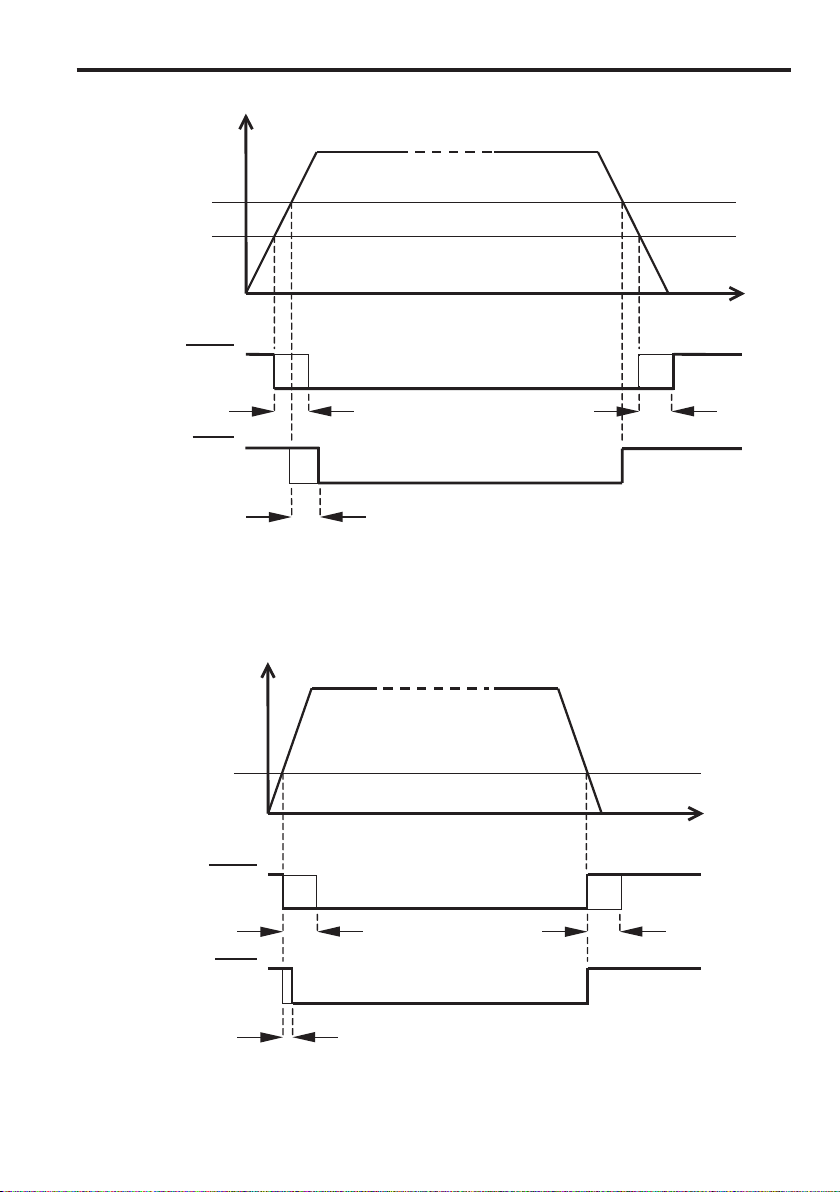

The timing relationships for an idealised probe signal are indicated in figure 2.

A solid state relay (SSR) output is provided which mimics the PICS-SYNC output for

connection to older CMM controllers that require voltage-free contacts to simulate the

trigger signal of a kinematic switching probe.

2.3 Trigger confirmation signal (HALT)

To allow the CMM controller to distinguish between a valid trigger and a spurious trigger

caused by vibration or shock, a trigger confirmation signal (HALT) is provided on the

PICS port. HALT will be asserted if the probe current remains greater than trigger level

2 for a pre-set delay time, determined by the settings of configuration switches 11

and 12. The timing relationships for an idealised TP200 probe signal are indicated in

figure 2.

Should the probe current fail to reach the trigger level or drop below the reseat level

before the delay time has expired, as might be the case for a vibration-induced signal,

HALT will not be asserted. The CMM controller may then assume the trigger was

spurious and reject the coordinate data.

When a kinematic switching probe (TP20, TP6, TP1, TP2) is connected, the HALT delay

time is fixed at 5 milliseconds as indicated in figure 3.

Page 13

11

Product description

Trigger level 2

and HALT

Trigger level 1

Probe signal

V

t

Debounce times set by

switch 6 and switch 7

Delay time set by

switch 11 and switch 12

SYNC

HALT

Figure 2 - SYNC and HALT signal timing for a TP200 gauge point

Figure 3 -

SYNC and HALT signal timing for a gauge point when

a kinematic probe is connected

Trigger level

Probe signal

V

t

Debounce fixed

20 ms

Delay time fixed 5 ms

SYNC

HALT

Page 14

12

Product description

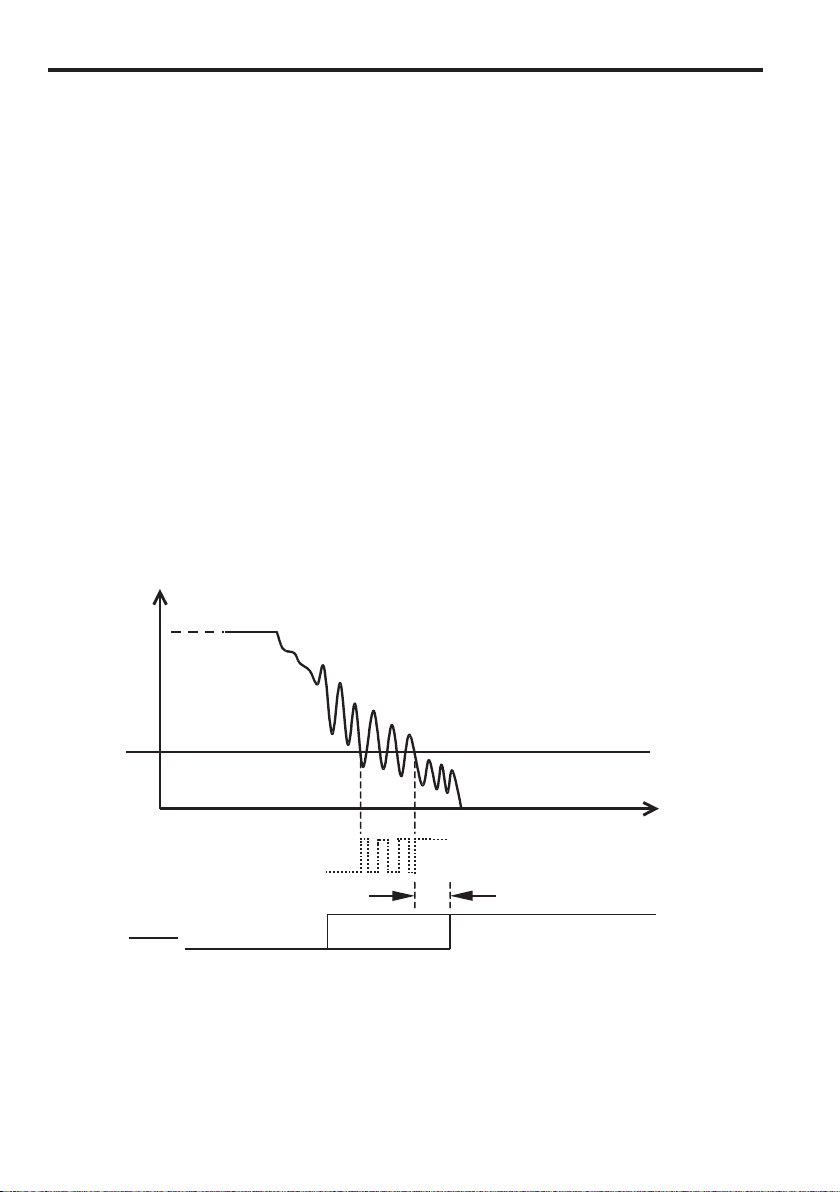

2.4 SYNC and HALT debounce

The SYNC and HALT signals are debounced to prevent spurious triggers occurring

as a result of CMM or stylus vibration when the stylus makes contact with or leaves

the surface of the workpiece. A range of switch selectable timing options is provided

to suit the requirements of different types of CMM. Alternatively, the debounce may

be switched off to allow greater flexibility for the CMM’s controller to manage the

PICS signals. Refer to the section ‘configuration switches’ for more information on the

debounce options.

The ‘adaptive’ settings ensure that combinations of CMM vibration and large stylus

assemblies do not cause a false indication of probe status during the back-off move.

Referring to figure 4, it may be seen that the debounce time increases in increments

of either 20 milliseconds or 100 milliseconds until the probe signal remains below the

trigger level for one complete timing period.

When a kinematic switching probe (TP20, TP6, TP1, TP2) is connected, the debounce

times are fixed as indicated in figure 3.

Figure 4 -

Adaptive debounce

Trigger level

V

t

Debounce timer

SYNC

Debounce times set by switch 6

Page 15

13

Product description

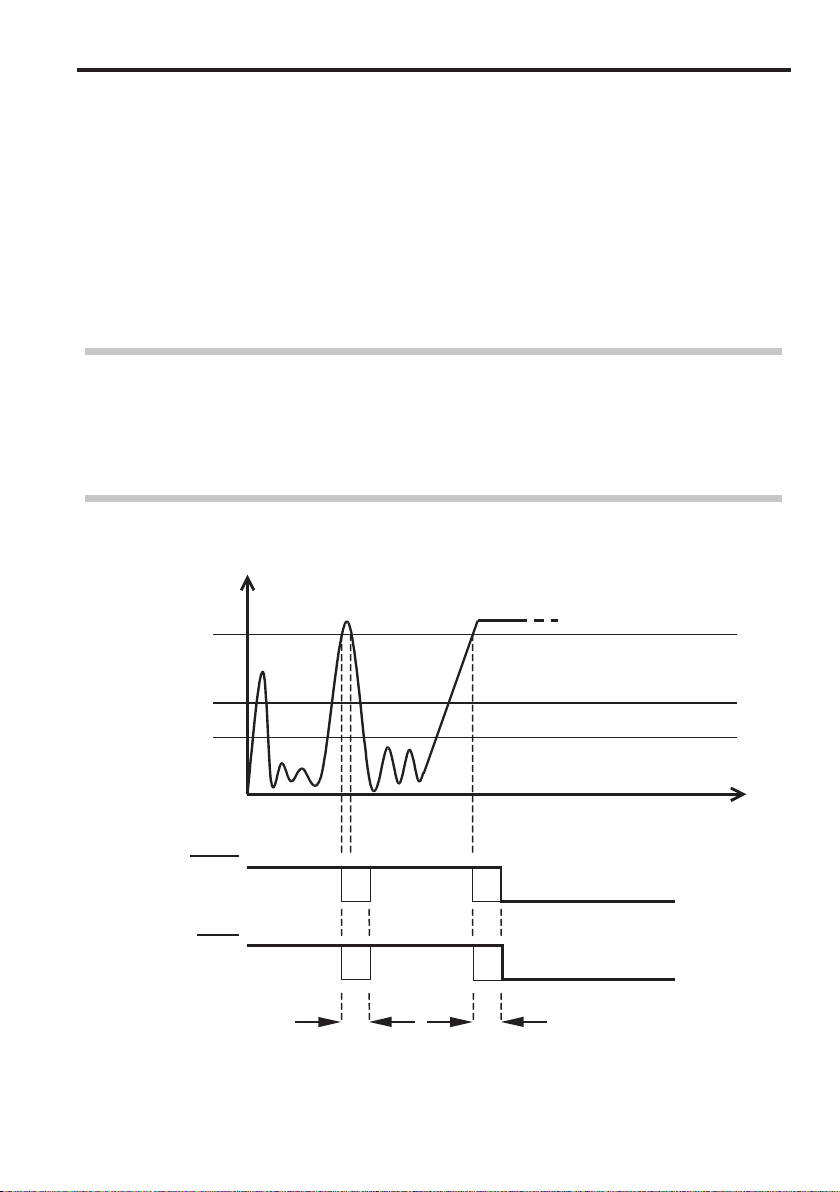

2.5 Probe damped signal (PDAMP)

During high-speed position moves (fast traverse), it is necessary to reduce probe

sensitivity to prevent vibration causing unwanted triggers. The CMM controller must

assert the PDAMP signal on the PICS port, to switch the PI 200 into the low sensitivity

mode known as ‘probe damped’. In this mode, deflection of the stylus will generate

SYNC and HALT simultaneously, but only if the probe signal remains above the

damped trigger level for longer than the time delay selected by switches 11 and 12 as

indicated in figure 5.

NOTE:

The probe cannot take accurate points when damped mode is active, and the

CMM controller must clear the PDAMP signal to return the probe to normal sensitivity

before taking a gauge point. It is important that PDAMP is only cleared when vibrations

of the CMM and probe stylus have reduced to a sufficiently low level to avoid spurious

re-triggering at the end of the position move.

Probe damped mode is indicated by an LED on the PI 200 front panel.

Trigger level 2

Probe signal

V

t

Delay time set by

switch 11 and switch 12

SYNC

HALT

Trigger level 1

Probe damped

level

Figure 5 -

SYNC and HALT signal timing for a trigger in damped mode

Page 16

14

Product description

2.6 Stylus mass and ambient temperature

compensation

In the TP200, probe a reference strain sensor, outside the strain path, adjusts the

current in the active strain sensors to provide compensation for slow, uniform, changes

of ambient temperature.

Fine compensation for thermal drift is provided by a system known as ‘autozero’ that

nulls the sensor amplifiers at a slow rate when the probe is armed. Under the control

of the PI 200 interface, the autozero automatically switches to a fast rate to reset

the probe sensors during a stylus change with the SCR200 change rack or during

reorientation of a motorised probe head.

When the probe is in the triggered state, the compensation is switched off. If the stylus

remains deflected for longer than 10 seconds, drift of the zero reference may occur.

The audible warning will sound after this period to indicate that the probe must be reset

manually.

2.7 RESET button

CAUTION: Probe triggers are inhibited when the RESET button is pressed.

Before pressing the button, the CMM must be stationary in manual mode with

the probe stylus clear of the workpiece.

The RESET button on the front panel selects fast autozero to rapidly null the sensor

amplifiers.

This may be necessary when:

1. The probe does not arm after manually changing the stylus.

2. The audible alarm is sounding a continuous tone to warn that the stylus has been

deflected for longer than 10 seconds.

NOTE: Alternatively, the probe may be reset by the action of unlocking and locking the

PH10T or PH10M motorised head. Refer also to the ‘remote reset’ section.

!

Page 17

15

Product description

2.8 Front panel indicators

Figure 6 - PI 200 interface front panel

Table 1 - Front panel indicators

Indicator Colour Function

POWER ON Green Mains power on

TYPE

STD Green Kinematic probe selected

TP200 Green TP200 probe selected

PROBE

SEATED Green

ON - probe armed (seated)

OFF - probe triggered or no probe

connected

DAMPED Yellow PICS - PDAMP asserted

STOP Red PICS - STOP asserted

Page 18

16

Product description

2.9 Audible indicator

The audible indicator has two functions:

1. To provide a brief indication that a probe trigger has occurred. This function may

be disabled by configuration switch 5.

2. To warn, by a continuous tone, that the stylus has remained deflected for longer

than 10 seconds. The alarm can be cleared by operation of the RESET button

on the front panel. Refer to the section ‘Reset button’ for more information on

resetting the probe.

2.10 Rear panel switches and connectors

Figure 7 - PI 200 interface back panel

Page 19

17

Product description

2.11 Configuration switches

CAUTION: Check the PI 200 version number on the rear panel. The switch

information in table 2 refers to PI 200 versions V9 or later. Refer to the

‘Summary of changes from earlier versions’ section in this handbook for details

of previous revisions.

All switches are hardware controlled and a change to any switch setting is effective

immediately.

Table 2 - Configuration switch functions

Switch

number

Function

Switch

position

Description

1 HALT polarity

UP

DOWN

HALT active HIGH

HALT active LOW

2 Head LED control

UP

DOWN

External control via PICS

LED mimics SYNC

3 STOP disabled

UP

DOWN

PI 200 ignores PICS - STOP

STOP asserts HALT/SYNC

4 SYNC polarity

UP

DOWN

SYNC HIGH and SSR closes on trigger

SYNC LOW and SSR opens on trigger

5 Audible indicator

UP

DOWN

No beep on trigger

Indicator beeps on trigger

6 Debounce time

Selects SYNC debounce time

Refer to figure 8

7 Debounce mode

Selects SYNC debounce mode

Refer to figure 8

8 Zero debounce

UP

DOWN

Sets debounce time <2 ms

Debounce set by switches 6 and 7

9 Probe signal filter

UP

DOWN

Filter active

Filter off

10 Trigger level

UP

DOWN

Trigger level 2 selected

Trigger level 1 selected

11

PDAMP/HALT

filter delay

Coded to select delay time

Refer to table 3

12

!

Page 20

18

Product description

Switch 1:

Inverts the polarity of the HALT output.

Switch 2:

Selects control of the LEDOFF output to either internal PI 200 control according to the

status of SYNC, or sets the output to high impedance for control of the head LED by

external switching.

Switch 3:

Sets the PI 200’s response to STOP when asserted from an external source. When

enabled, the PI 200 will assert SYNC, HALT and open the SSR relay.

Switch 4:

Inverts the polarity of the SYNC and SSR relay outputs.

Switch 5:

When enabled, a tone will sound for approximately 160 milliseconds when the probe

triggers and SYNC is asserted. When disabled, the tone will activate only when the

stylus has remained deflected for 10 seconds.

Switches 6 and 7:

These switches select the debounce time and mode of operation as indicated in

figure 8.

Switch 8:

Overrides the settings of switches 6 and 7, reducing the trigger and reseat debounce

times to less than 2 milliseconds.

Switch 9:

The probe signal filter has a 300 µs time constant to reduce the effects of stylus

vibration when the stylus makes contact with the workpiece. Renishaw recommends

that this switch is set to the UP position for normal use.

Page 21

19

Product description

Figure 8 - SYNC debounce options

Trigger level

Probe signal

V

t

Switch 6 - Down

Switch 7 - Down

SYNC

SYNC

SYNC

SYNC

20 ms 20 ms

adaptive

100 ms 100 ms

adaptive

20 ms 20 ms

100 ms 80 ms

Switch 6 - Up

Switch 7 - Down

Switch 6 - Down

Switch 7 - Up

Switch 6 - Up

Switch 7 - Up

Page 22

20

Product description

Switch 10:

In operating situations where there is an unusually high level of background vibration,

it may be necessary to reduce the sensitivity of the TP200 to avoid false ‘air’ triggers.

These may occur on some types of CMM when large steel stylus arrangements are

used or where the CMM is inadequately isolated from the floor transmission of vibration

from nearby machinery or vehicle traffic.

Trigger level 1 is the highest sensitivity mode and provides the best measuring

performance.

Trigger level 2 reduces the vibration sensitivity from level 1 for a small loss of

measuring accuracy.

CAUTION:

All stylus tips must be requalified if the trigger level

is changed.

Switches 11 and 12:

To prevent a HALT signal (or HALT and SYNC if probe damped mode is set) from being

falsely asserted when the probe is subjected to vibration, a time delay filter is applied.

Refer to the description in ‘trigger confirmation signal (HALT)’ section.

If a collision occurs at fast traverse speed (i.e. a position move), the filter delay time

will incur additional CMM overtravel before motion stops. It is important that the CMM

motion can stop within the available overtravel, particularly if collisions can occur

directly along the main axis of the probe in the +Z direction. To minimise the overtravel

in a collision situation, the filter delay time must be set to the shortest possible time that

will prevent ‘air’ triggers from occurring during fast traverse moves when probe damped

mode is asserted.

Switches 11 and 12 are used to select the nominal filter times indicated in table 3.

Table 3 - Function of switches 11 and 12

Time delay Switch 11 Switch 12

2.0 ms DOWN DOWN

7.5 ms DOWN UP

15.0 ms UP DOWN

50.0 ms UP UP

!

Page 23

21

Product description

2.12 Probe polarity switch

The TP200 probe is polarity sensitive and must be connected to the PI 200 such

that the centre contact of the M8 connector is positive and the thread is ground (0

V). A reversed polarity connection will cause the POWER and STOP indicators to

be illuminated on the front panel. Sliding the switch to the REV position should allow

normal operation. Incorrect setting of the polarity switch should not damage the probe.

Page 24

22

Connector pin-outs

3 Connector pin-outs

3.1 PICS input connector

The PICS input connector is a 9 pin ‘D’ type socket. The pin numbers are illustrated in

figure 9 and their functions are shown in table 4.

9

8

7

6

5

4

3

2 1

Figure 9 - PICS input connector pin numbers

Table 4 - PICS input connector

Pin number

Description

1 STOP

2 PPOFF

3 Ground (0 V)

4 Reserved

5 Probe signal input

6 STOP +5 V pull-up

7 PDAMP

8 LEDOFF

9 Probe signal ground

Shell Screen

Page 25

23

Connector pin-outs

9

8

7

6

5

4

3

2

1

Figure 10 - PICS output connector pin numbers

Table 5 - PICS output connector

Pin number

Description

1 STOP

2 PPOFF

3 Ground (0 V)

4 Reserved

5 SYNC

6 HALT

7 PDAMP

8 LEDOFF

9 Not used

Shell Screen

3.2 PICS output connector

The PICS output connector is a 9 pin ‘D’ type plug. The pin numbers are illustrated in

Figure 10 and their functions are shown in table 5.

Page 26

24

Connector pin-outs

3.3 Solid state relay (SSR) output connector

The solid state relay output connector is a 7 pin DIN socket. The pin numbers are

illustrated in figure 11 and their functions are shown in table 6.

7 6

3

1

5

4

2

Figure 11 - SSR output connector (view on rear panel)

Table 6 - SSR output connector

Pin number

Description

1 Not used

2 Screen

3 Not used

4 SSR 1

5 SSR 2

6 Not used

7 Not used

Shell Screen

Page 27

25

Connector pin-outs

3.4 Stylus change rack (SCR) output connector

The SCR200 stylus change rack is connected to the PI 200 via a 6 pin miniature DIN

socket. The pin numbers are illustrated in figure 12 and their functions are shown in

table 7.

Figure 12 - SCR200 output connector (view on rear panel)

Table 7 - SCR output connector

Pin number

Description

1 Reset

2 Fault

3 Inhibit

4 +5 V

5 Ground (0 V)

6 Not used

3.5 Remote reset

There are two methods of connection to a remote push button that will achieve the

same effect as the RESET button on the front panel of the PI 200 interface. Such a

facility may be useful if manual stylus changing is to be frequently used, or if the PI 200

is difficult for the operator to access.

A momentary action push button or switch may be connected to pins 1 and 5 on the

SCR200 miniature DIN connector on the rear panel. If the connector is already in use

for connection of a SCR200 stylus change rack, a dual rack cable type PL97 (refer to

table 8, cable no. 11) may be used to provide an additional connector.

Alternatively, the button may be directly wired to the PPOFF and ground (0 V) pins (pins

2 and 3) on either of the PICS connectors on the rear panel of the PI 200.

Page 28

26

PICS dimensions and cable data

4 PI 200 dimensions and cable data

Dimensions

1/3 rack wide x 2U high

140 mm x 88 mm x 183 mm deep

Weight

1.25 kg

Mounting method

19 in rack or freestanding

Mounting screws

M5 x 8 mm maximum penetration

Probe voltage (open circuit)

12.4 V

Probe cable resistance

Max. 5 W/conductor

Probe cable length

Max. 50 m

Wire gauge

0.22 mm

2

Page 29

27

Part number summary

5 Part number summary

PI 200 interface A-1207-0050

Contents: PI 200 interface unit

Installation guide

Rubber feet (self-adhesive)

Rack mounting hardware:

1/3 x 2U blanking panel A-1018-0123

Rack mounting bracket A-1018-0124

Link bracket A-1018-0126

TP200 probe kit - standard force A-1207-0001

TP200 probe kit - low force A-1207-0002

Contents: TP200 probe sensor

Stylus module (standard or low force)

Tools/cleaning kit

Test certificate

User’s guide

Stylus module - standard force A-1207-0010

Stylus module - low force A-1207-0011

Stylus change rack kit - standard force A 1207-0030

Stylus change rack kit - low force A-1207-0070

Contents: 1 x SCR200 rack

3 x stylus modules (standard or low force)

Mounting kit

Datuming stylus (PS2R)

SCR200 cable - 5 m long (PL63) A-1016-7630

SCR200 cable - 10 m long (PL64) A-1016-7631

SCR200 cable - 20 m long (PL65) A-1016-7632

Dual SCR200 cable adaptor (PL97) A-1016-7660

M12 location piece (for SCR200) M-1371-0298

Page 30

28

Part number summary

5.1 Replacements

TP200 probe system user’s guide H-1000-5014

(English + multilingual CD)

PI 200 interface for TP200 probe H-1000-5029

system installation guide (English)

Cleaning material A-1085-0016

S1 ‘C’ spanner A-1042-1486

S9 double-ended ‘C’ spanner A-1047-3932

S7 M2 stylus pin spanner M-5000-3540

Hexagon key 1.5 mm AF P-TL03-0150

Datuming stylus (PS2R) A-5000-3603

Rubber feet (for PI 200) P-FE01-0003

5.2 Accessories

Refer to ‘Probing systems for coordinate measuring machines’ (Renishaw part number

H-1000-5050) for details of the available range of probe heads, extension bars and

other accessories.

High performance GF stylus kit A-5003-2310

Autojoint to M8 adaptor: PAA1 A-1051-0417

Rotary adjustment module: M8 - M8 A-1047-7022

Rotary adjustment module: autojoint to M8 A-1051-0679

Module storage rack for manually operated stylus changing applications:

MSR1 (wall mounted) A-1371-0330

MSR1 (CMM table mounted) A-1371-0347

Page 31

29

Installation procedure

6 Installation procedure

WARNING: Ensure the PI 200 is disconnected from the mains supply during

installation.

WARNING: Take care not to exceed the operation ambient of 50 °C around

the unit. Do not install near sources of heat. Forced cooling may be required

in final installation.

6.1 Rack mounting

The PI 200 may be mounted in a standard 19 in equipment rack either alone or

alongside a Renishaw controller as indicated in figures 13 and 14.

POWER

TYPE

PROBE

RESET

ON STD

TP200 SEATED

DAMPED

STOP

PROBE INTERFACE

R

Figure 13 - Mounting the PI 200

To mount the PI 200 as indicated in figure 13 requires 2 x 1/3 blanking panel kits (part

number A-1018-0123). Remove the blanking plugs from both sides of the PI 200 and fit

the panels using the M5 x 6 mm long screws provided.

A-1018-0123

Figure 14 -

PI 200 with PHC10-2

To mount the PI 200 adjacent to a Renishaw controller, as indicated in figures 14 and

15, the following parts are required:

• Rack mounting bracket - part number A-1018-0124

• Enclosure link bracket - part number A-1018-0126

!

!

Page 32

30

Installation procedure

Figure 15 - Mounting the PI 200 adjacent to the Renishaw PHC10-2

Remove the blanking plugs from the sides of each unit. Separate the halves of the link

bracket and screw them to the interface/controller units, using the M5 x 6 mm long

screws provided. Bring the units together and screw the brackets together. Screw the

rack mounting brackets to the free ends of each unit and assemble into the equipment

rack.

6.2 Mounting with older style Renishaw control units

To fit the PI 200 into an existing installation adjacent to an older style PHC10 or ACC2

(with extruded aluminium side panels), a link bracket (part no. M-1018-0097) and 2 ×

M5 × 6 mm long screws (part no. P-SC29-0506) are required.

Remove the blanking plugs from the sides of the PI 200 and screw the bracket in place.

On the older style enclosure, prise out the rubber cover from the corner moulding

and loosen the two screws at the top and bottom of the moulding. Locate the bracket

between the corner moulding and the unit’s front panel, tighten the screws and replace

the rubber cover. Fit the rack mounting bracket to the other end of the PI 200 and

assemble into the equipment rack.

Page 33

31

Installation procedure

Figure 16 - System interconnection - MH8 head

Cable 2

Cable 1

MH8

TP200

PI 200

PICS output

CMM controller

6.3 System interconnection

Interconnection diagrams for the most common product combinations are given in

figures 16 - 21. The standard interconnection cables are listed in table 8. Contact

Renishaw for other cable lengths, cable specification or special configurations.

Consult the appropriate product installation guide for information about setting the

configuration switches of the PHC10-2 or ACC2-2 system controllers:

• PH10 series installation guide - part number H-1000-5071

• Autochange system installation guide - part number H-1000-6010

Page 34

32

0

Installation procedure

Figure 17 - System interconnection - MIH head

Cable 2

Cable 1

MIH

TP200

PI 200

PICS output

CMM controller

PAA1 adaptor

Figure 18 - System interconnection - PH10T head

Cable 4

Cable 3

SCR200

TP200

PI 200

Communications to

CMM controller

PH10T

PHC10-2

PICS output

CMM controller

Cable 5

Cable 6

Page 35

33

Serial

MADE IN

UK

V.

PICS OUT

HEAD

RS

232

1

11

14

HCU

15 18

OUTPUT

10

Installation procedure

Figure 19 - System interconnection - PH10M head

Cable 4

Cable 3

SCR200

TP200

PI 200

Communications to

CMM controller

PH10M

PHC10-2

PICS output

CMM controller

Cable 5

Cable 6

PAA1 adaptor

Page 36

34

SP

600

M

Installation procedure

Figure 20 - System interconnection - SP600M scanning probe and autochange

Cable 4

Cable 3

AC2

PI 200

Communications to

CMM controller

PH10M

PHC10-2

PICS output CMM controller

Cable 7

To ACR1 rack

PAA1

adaptor

SP600M

Cable 8

Cable 9

Cable 10

ACC2-2

Communications to

CMM controller

TP200

Page 37

35

Installation procedure

Figure 21 - System interconnection - TP7M touch-trigger probe and autochange

Cable 4

Cable 3

PI 7-2

Communications to

CMM controller

PH10M

PHC10-2

PICS output CMM controller

Cable 7

To ACR1 rack

PAA1

adaptor

Cable 8

Cable 5

ACC2-2

Communications to

CMM controller

TP200

PI 200

TP7M

Page 38

36

Installation procedure

6.4 Using TP200 with the ACR1 autochange system

Figure 22 - Shock absorbing pad fitted to PH10M

The CMM controller must assert the probe damping signal (PDAMP) on the PICS port

when the probe is approaching the rack, to prevent a false trigger being generated

when the probe contacts the docking port lid.

If this is not possible, a shock absorbing pad (part number A-1085-0294 supplied

with ACR1) must be fitted to the autojoint connector on the probe head at the point of

contact with the port lid. Refer to figure 22.

A

0

10

5

Page 39

37

Installation procedure

6.5 SCR200 stylus change rack

The miniature DIN connector on the base of the SCR200 rack is connected to the

‘SCR200’ connector on the PI 200 rear panel using cable PL63/PL64/PL65 according to

the length required. Refer to table 8, cable number 12.

For applications requiring two racks, a dual rack splitter cable is needed. Refer to table

8, cable number 11 and figure 23.

The dual SCR200 adaptor cable must be fitted at the PI 200 end.

Figure 23 - Connection of dual SCR200 stylus change racks

Refer to the ‘TP200 and SCR200 user’s guide’ (Renishaw part number H-1000-5014)

for information on setting up and operating the SCR200 rack.

SCR200 SCR200

Cable 12 Cable 12

PI 200

Page 40

38

Installation procedure

6.6 Interconnection cables

Table 8 - Interconnection cables

Cable

number

Cable

ident.

Length (m) Part number Notes

1

PL1 0.26 - 0.71 A-1016-0004 Coiled

PL2 0.41 - 1.27 A-1016-0006 Coiled

PL3 0.68 - 2.32 A-1016-0012 Coiled

PL4 4.5 A-1016-0001 Plain

PL27 0.225 A-1016-6370 Coiled

PL29 0.74 A-1016-6420 Coiled

2 PL22 0.4 A-1057-0131

3

PL5 0.40 - 0.80 A-1016-0131 Coiled

PL6 0.80 - 1.60 A-1016-7673 Coiled

PL12 0.10 A-1016-7674 Plain

PL13 0.10 - 0.20 A-1016-7675 Coiled

4

PLM6 6 A-1016-7564 Unterminated one end

PLM7 4 A-1016-7563 Unterminated one end

PLM8 6 A-1016-7677

PLM9 4 A-1016-7678

5 PL25 0.30 A-1016-0124

6

PL63 5 A-1016-7630

PL64 10 A-1016-7631

PL65 20 A-1016-7632

7

PL38 25 A-1016-7625 Unterminated one end

PL42 15 A-1016-7624 Unterminated one end

PL56 12 A-1016-7626 Unterminated one end

PL44 8 A-1016-7627 Unterminated one end

PL46 3.7 A-1016-7628 Unterminated one end

PL45 1.8 A-1016-7629 Unterminated one end

8 PL70 2 A-1016-7634

9 PL76 1 A-1016-7643

Page 41

39

Installation procedure

Table 8 - Interconnection cables continued

Cable

number

Cable

ident.

Length (m) Part number Notes

10 PL112 1 A-2172-0004

11 PL97 0.25 A-1016-7660

12

PL63 5 A-1016-7630

PL64 10 A-1016-7631

PL65 20 A-1016-7632

6.7 Upgrading older probe systems to TP200

(retrofitment)

To successfully retrofit a TP200 probe system, the following points will need to be

considered:

• The CMM controller must service the PICS - PDAMP control signal. Upgrade of the

controller may be necessary if this signal is not available.

• The probe signal wires from the M8 connector on the probe head must be routed

directly to the PI 200 interface. If an in-line interface for kinematic switching probes

(TP1/TP2/TP6) is present, it must be removed.

• The signal wire resistance must be less than 5 ohms per conductor.

• Some experimentation with typical stylus arrangements may be necessary to obtain

a satisfactory setting for the PDAMP/HALT filter delay time. The trigger/reseat

debounce time and other configuration options will also need to be set. Refer to the

‘configuration switches’ section for more information.

• If upgrading from TP2, measurement programs may need to be changed to suit the

length of the TP200, which is 5 mm longer than the TP2.

• If upgrading from TP2, star or offset (cranked) stylus arrangements will require a

minimum 5 mm extension piece to be added for use with the TP200.

• If cables other than those supplied by Renishaw are used, equivalent cable

screening and connector bonding must be used to maintain compliance with the

EMC standards.

Page 42

40

PICS terminations

7 PICS terminations

The Renishaw product interconnection system (PICS) has been developed to

standardise the format for real-time communications between Renishaw products and

the CMM controller. PICS facilitates the integration of multiple probe interfaces and

system controllers without the need for additional hardware or software overheads on

the CMM controller.

Refer to the section ‘connector pin-outs’ for the pin assignments used on the 9 way ‘D’

type PICS connector ports.

Refer to figures 16 - 21 in the section ‘system interconnection’ for examples of the

PICS connections for typical installations. Note that the order in which the system

components are connected is important. In particular, the autochange controller

(ACC2-2) should be the last in the chain before the CMM controller (figures 20 and 21)

to allow it to disable probe damping (PDAMP) during the ACR1 set-up procedure.

Installations incorporating the PI 800-2 probe interface are an exception and the

TP800-2 installation guide (Renishaw part number H-1000-5111) should be consulted

for further information.

For further information, please refer to the PICS installation guide (H-1000-5000).

Page 43

41

Summary of changes from earlier versions

8 Summary of changes from earlier versions

The table below summarises the changes made from version V7 - V11 as indicated by

the label on the rear panel of the PI 200.

NOTE:

No changes have been made that affect measuring accuracy.

Table 9 - Summary of changes from earlier versions

Part number

Version

label

Summary of changes

A-1207-0050-10 V11

PCB layout and component changes due to component

obsolescence.

Layout of rear panel changed and IEC mains connector

now unfiltered. Text appearance changed on front

panel and RESET button now adjacent to STOP LED.

New PLD, mains power supply and 5 V to 15 V dc-dc

converter.

Functionality identical.

A-1207-0050-09 V10 Withdrawn.

A-1207-0050-08 V9

Additional PDAMP filter delay time option (2.0 ms and

7.5 ms) added. Switches 11 and 12 coded to offer the

four delay options.

Switch 10 function deleted - now trigger level selector

(was switch 11).

Mounting brackets removed from kit.

A-1207-0050-07 V8

PL25 and PL26 cables removed from the top level kit.

Circuit changes to improve immunity to ESD applied to

the probe stylus when in TP2 mode.

A-1207-0050-06 V7

Early reseat, short debounce option (switch 7 UP, switch

6 DOWN) changed from 20/80 ms to 20/20 ms.

Fault corrected that caused fast autozero to latch on if

PI 200 was powered up with PPOFF asserted and no

TP200 connected.

Change to prevent a false audible alarm after a rapid

series of soft (low signal level) triggers.

Page 44

42

Maintenance

9 Maintenance

9.1 PI 200

Periodically check the security of mounting screws and electrical connectors.

Periodic electrical safety checks should include inspection of the mains cable for

damage and safe connections. An earth continuity (ground bonding) test may be

applied between the protective earth pin of the mains connector and the metal case at

a test current no greater than 25 A.

Remove dust from the external surfaces with a proprietary cleaning cloth.

9.2 TP200 probe and stylus module

The kinematic coupling mechanism, connecting the probe sensor to the stylus module,

incorporates precision ball/V groove seatings. The coupling mechanism has been

tested in a wide range of environments and is highly tolerant of non-metallic dust, but

regular inspection and cleaning with the material supplied is recommended to ensure

continued high performance.

Instructions for use are included with the cleaning material (Renishaw part number

A-1085-0016).

The user should determine the frequency of cleaning according to the conditions of use.

Stylus balls, threads and mating faces should be cleaned with proprietary cloths or

solvent.

Stylus modules that are not in use should be stored in spare ports in the SCR200 rack

or in their transport boxes.

9.3 SCR200 rack

Periodic cleaning of the rack ports, lids and outer surfaces using a proprietary cloth is

recommended to prevent contamination of the modules.

Page 45

43

Fault finding

10 Fault finding

Table 10 - The CMM will not register a probe trigger, but the probe operates

normally when the stylus is deflected by hand.

PI 200 indicators:

‘STOP’ LED is ON.

‘TP200’ LED is ON.

‘SEATED’ LED operates normally.

Possible cause

Checks/remedies

•

The CMM controller or a

Renishaw system has activated

the STOP signal.

•

The SCR200 overtravel

mechanism is deflected.

•

Check the status of the Renishaw

motorised probe head or other systems.

•

Check the status of the Renishaw

motorised probe head or other systems.

Table 11 - The probe fails to trigger and the probe LEDs glow only dimly when

the stylus touches the workpiece, but the probe operates normally when the

stylus is deflected by hand.

PI 200 indicators:

‘SEATED’ LED is ON.

Possible cause

Checks/remedies

•

The trigger speed is too slow.

•

The stylus is too heavy.

•

Probe normally to the workpiece surface.

•

Increase the gauging speed.

Table 12 - The probe will not arm or the probe does not stay armed when the

RESET button is released. The probe LEDs are always OFF.

PI 200 indicators:

‘STD’ LED is ON.

‘SEATED’ LED is OFF.

Possible cause

Checks/remedies

•

The probe sensor is faulty.

•

The probe wiring is open circuit.

•

Remove the probe and test by

substitution.

•

Check the wiring from the probe to the

PI 200 interface.

Page 46

44

Fault finding

Table 13 - The probe will not arm or the probe does not stay armed when the

RESET button is released. The probe LEDs are always ON.

PI 200 indicators:

‘TP200’ LED is ON.

‘SEATED’ LED is OFF.

Possible cause

Checks/remedies

•

The probe sensor is faulty or has

been damaged by a collision.

• Remove the probe and test by

substitution.

Table 14 - False (‘air’) triggers occur while the CMM is stationary and the probe

LEDs flicker.

PI 200 indicators:

‘TP200’ LED is ON.

‘SEATED’ LED operates normally.

Possible cause

Checks/remedies

•

The probe sensor is faulty.

•

The probe is loose in the probe

head.

•

There is excessive vibration from

an external source.

•

There is excessive vibration from

the CMM.

•

Remove the probe and test by

substitution.

•

Correctly tighten the probe.

•

Remove the cause or isolate the CMM.

•

Check the CMM’s air supply.

•

Maintain the CMM’s air bearing system.

Table 15 - False (‘air’) triggers occur at gauging speed and the probe LEDs

flicker.

PI 200 indicators:

‘DAMPED’ LED is OFF.

‘SEATED’ LED operates normally.

Possible cause

Checks/remedies

•

The stylus is too large or too

heavy.

•

There is excessive vibration from

the CMM.

•

Use stylus arrangements within

recommendations.

•

Check the CMM’s air supply.

•

Maintain the CMM’s air bearing system.

Page 47

45

Fault finding

Table 16 - False (‘air’) triggers occur at traverse speed and the probe LEDs

flicker.

PI 200 indicators:

‘DAMPED’ LED is ON.

‘SEATED’ LED operates normally.

Possible cause

Checks/remedies

•

The stylus is too large or too

heavy.

•

There is excessive vibration from

the CMM.

•

The traverse speed is too high.

•

Use stylus arrangements within

recommendations.

•

Check the CMM’s air supply.

•

Maintain the CMM’s air bearing system.

•

Reduce the traverse speed.

Table 17 - The probe triggers during an SCR200 stylus change.

PI 200 indicators:

‘SEATED’ LED operates normally.

Possible cause

Checks/remedies

•

The SCR200 is not connected to

the PI 200.

•

Incorrect SCR200 operating

mode.

•

Check the SCR200 indicator lamps.

•

Reconnect the cable.

Page 48

46

Fault finding

Table 18 - There is an unexpected loss of accuracy.

PI 200 indicators:

‘TP200’ LED is ON.

‘SEATED’ LED operates normally.

Possible cause

Checks/remedies

•

The stylus ball is damaged or dirty.

•

The stylus is too large or too

heavy.

•

The probe is loose or not correctly

assembled.

•

The kinematic coupling is

damaged or dirty.

•

The gauging speed has been

changed.

•

The trigger threshold has been

changed.

•

Clean the stylus ball, or replace and

requalify the stylus.

•

Use stylus arrangements within

recommendations.

•

Check the stylus joints.

•

Ensure the module is correctly seated

and the probe is tight in the probe head.

•

Inspect and clean the kinematic coupling.

•

Requalify the stylus tips.

Table 19 - The deflection alarm is active.

PI 200 indicators:

Audible indicator is ON.

Possible cause

Checks/remedies

•

The stylus is or was deflected for

longer than 10 seconds.

•

The stylus module was changed

manually.

•

Move the stylus clear of any obstruction

and press the RESET button.

Table 20 - TP200 fails to work.

PI 200 indicators:

‘STOP’ LED ON.

‘POWER’ LED ON.

Possible cause

Checks/remedies

•

The M8 bush polarity is incorrect. • Change the PI 200 probe polarity switch

to the opposite state.

Page 49

Page 50

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

*H-1000-5029-05-B*

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

Loading...

Loading...