Page 1

PHC10-3 PLUS installation guide

Document part number: H-1000-0077-01-A

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 1 of 30

Page 2

General Information

©2012Renishawplc.Allrightsreserved.

This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any means, without

the prior written permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE

DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW

EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and other

countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are trade names, service marks, trademarks, or registered trademarks of their

respective owners.

Windows XP, Windows 2000, Vista and Windows 7 are registered trade names of the Microsoft Corporation.

All trademarks and trade names are acknowledged.

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise measurements and must therefore be treated

with care.

Changes to Renishaw products

Renishaw reserves the right to improve, change or modify its hardware or software without incurring any obligations to make changes to

Renishaw equipment previously sold.

Warranty

Renishaw plc warrants its equipment for a limited period (as set out in our Standard Terms and Conditions of Sale) provided that it is

installed exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or cabling) is to be used or substituted.

Failure to comply with this will invalidate the Renishaw warranty.

Claims under warranty must be made from authorised service centres only, which may be advised by the supplier or distributor.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 2 of 30

Page 3

EC declaration of conformity

Renishaw plc hereby declares that the PHC10-3 PLUS probe head controller is in compliance with the essential requirements and other

relevant provisions of EU Directive 2004/108/EC .

Contact Renishaw plc at www.renishaw.com for the full EC Declaration of Conformity.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 3 of 30

Page 4

FCC (USA only)

Information to user (47CFR section 15.105)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference, in which case you will be required to correct the interference at your own expense.

Information to user (47CFR section 15.21)

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or authorised representative could void

the user's authority to operate the equipment.

Equipment label (47CFR section 15.19)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

WEEE

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product should not be mixed with the

general household waste upon disposal. It is the responsibility of the end user to dispose of this product at a designated collection point

for waste electrical and electronic equipment (WEEE) to enable reuse or recycling. Correct disposal of this product will help save valuable

resources and prevent potential negative effects on the environment. For more information, please contact your local waste disposal

service or Renishaw distributor.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 4 of 30

Page 5

Safety

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. There

are no user serviceable parts inside the equipment.

The PHC10-3 head controller is to be used with the provided PSU - Emerson DP4024N3M. See manufacturer's datasheet at

www.emerson.com

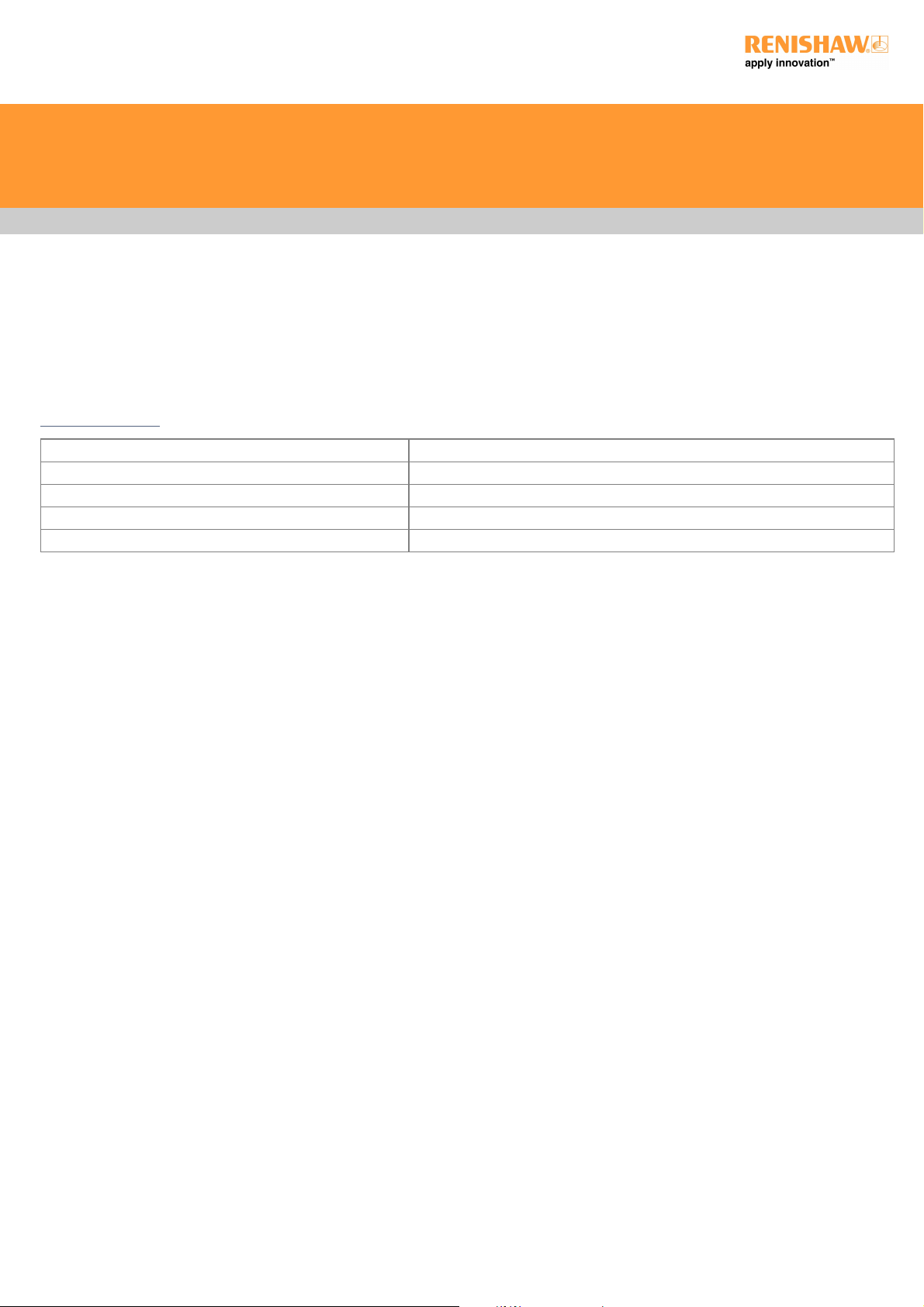

PSU electrical ratings

Supply voltage 100 V - 240 Vac +10% -10%

Frequency range 50 Hz to 60 Hz

Power consumption 49 W max

Transient voltages Installation category II

PHC10-3 is isolated from ac power by disconnection of the IEC mains connector from the supplied PSU. If any additional means of

isolation is required, it must be specified and fitted by the machine manufacturer or installer of the product. The isolator/disconnection

device must be sited within easy reach of the operator and comply with any applicable national wiring regulations for the country of

installation.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 5 of 30

Page 6

Environmental conditions

The following environmental conditions comply with those defined in BS EN61010 - 1:2001

Indoor use IP30 (no protection against water)

Altitude Up to 2000 m

Operating temperature 0°Cto+50°C

Storage temperature 10°Cto+70°C

Relative humidity 80%maximumfortemperaturesupto+31°C

Lineardecreaseto50%at+50°C

Pollution degree 2

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 6 of 30

Page 7

References and associated documents

User's guide: Touch-trigger probes H-1000-5021

User's guide: SP25M H-1000-5104

User's guide: HCU1 H-1000-5016

User's guide: AM1 H-1000-4010

User's guide: AM2 H-1000-2051

Technical specification: Styli and accessories H-1000-3200

Installation guide: PICS H-1000-5000

Installation and user's guide: PH10 PLUS H-1000-7592

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 7 of 30

Page 8

Introduction

The guide gives information on physical installation, system connections, communications and interface settings, as well as assistance in

fault-finding during the installation of PHC10-3 PLUS.

WARNING: The components of PH10 PLUS system are not compatible with PH9 or PH20 system components. No attempt should

be made to connect PH10 PLUS system components to a PH9 or PH20 system, as this will result in damage to the product.

The guide should be read in conjunction with the PH10 PLUS series user's guide in order to fully understand the system's features,

capabilities and operation.

The PH10 PLUS series of motorised probe heads can only be used in conjunction with the PHC10-3 PLUS and the UCC2 PH10

daughtercard. PHC10-3 PLUS has replaced the PHC10-2 and provides support for RS232 and USB communications (IEEE is no longer

supported). PHC10-3 PLUS uses an external power supply for the PH10 PLUS series of heads, manages all the head functions and

communicates via a suitable interface with the CMM's computer. PHC10-3 PLUS does not manage the probe functions but does have the

provision for an interface to be fitted.

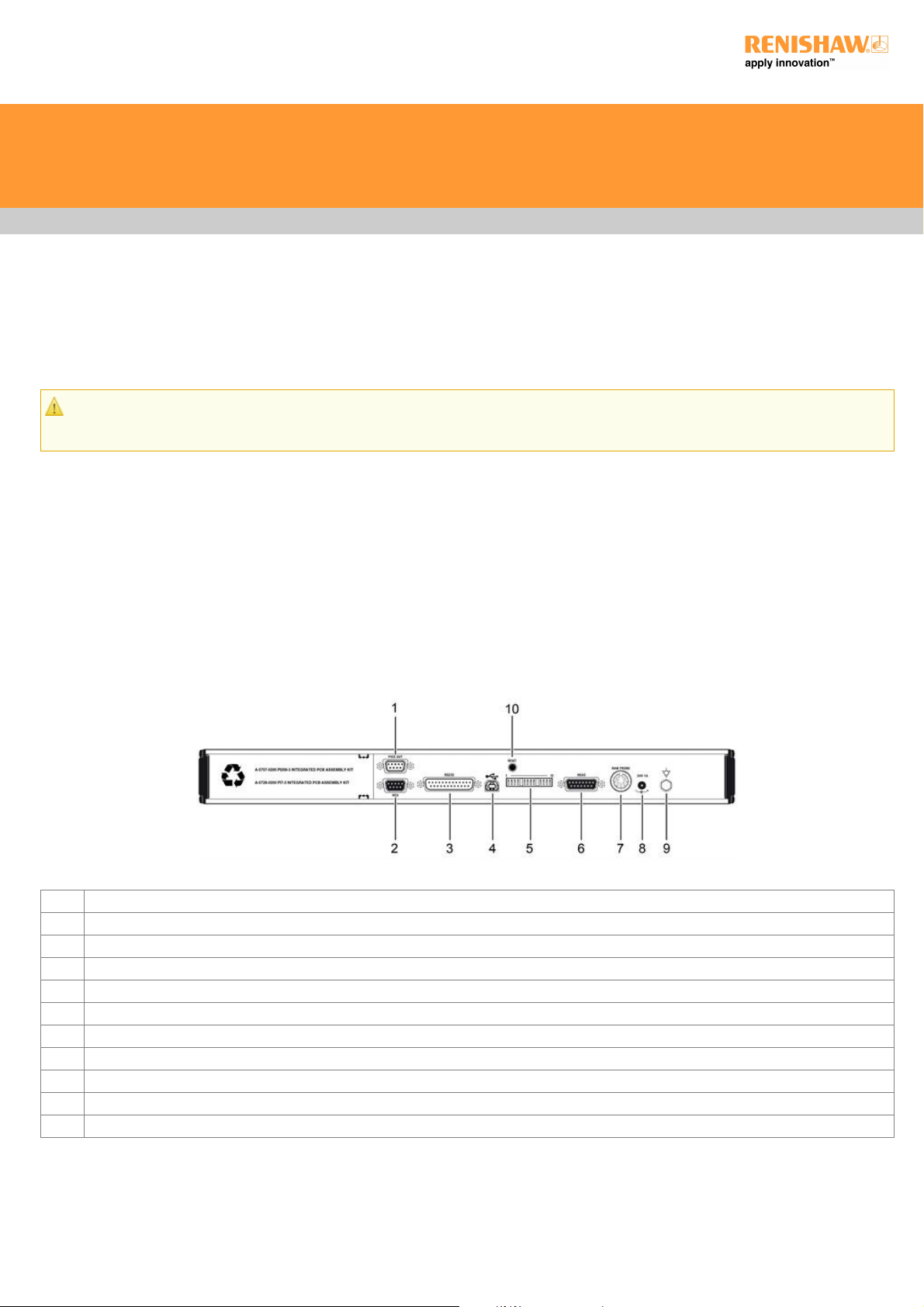

Rear panel layout

Key Description

1 9-way D-type plug for PICS output

2 9-way D-type connector to HCU1

3 25-way D-type plug RS232 communications connector to CMM computer

4 USBtype“B”socket

5 PHC10-3 PLUS configuration switches

6 15-way D-type connector to probe head

7 7-pin DIN raw probe connector to probe interface or multiwire input for internal interfaces

8 DC power jack

9 Equipment bond point

10 Controller reset button

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 8 of 30

Page 9

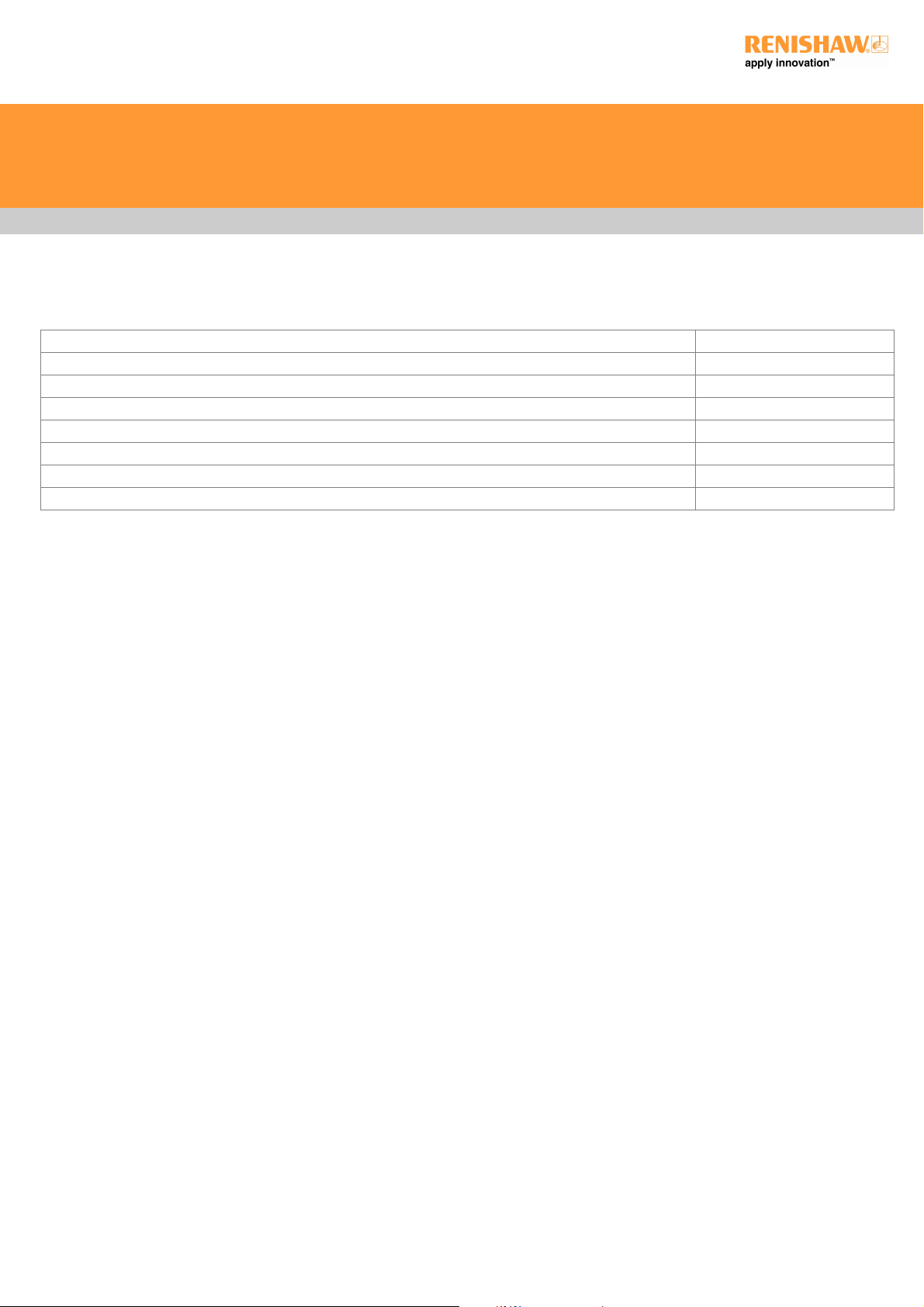

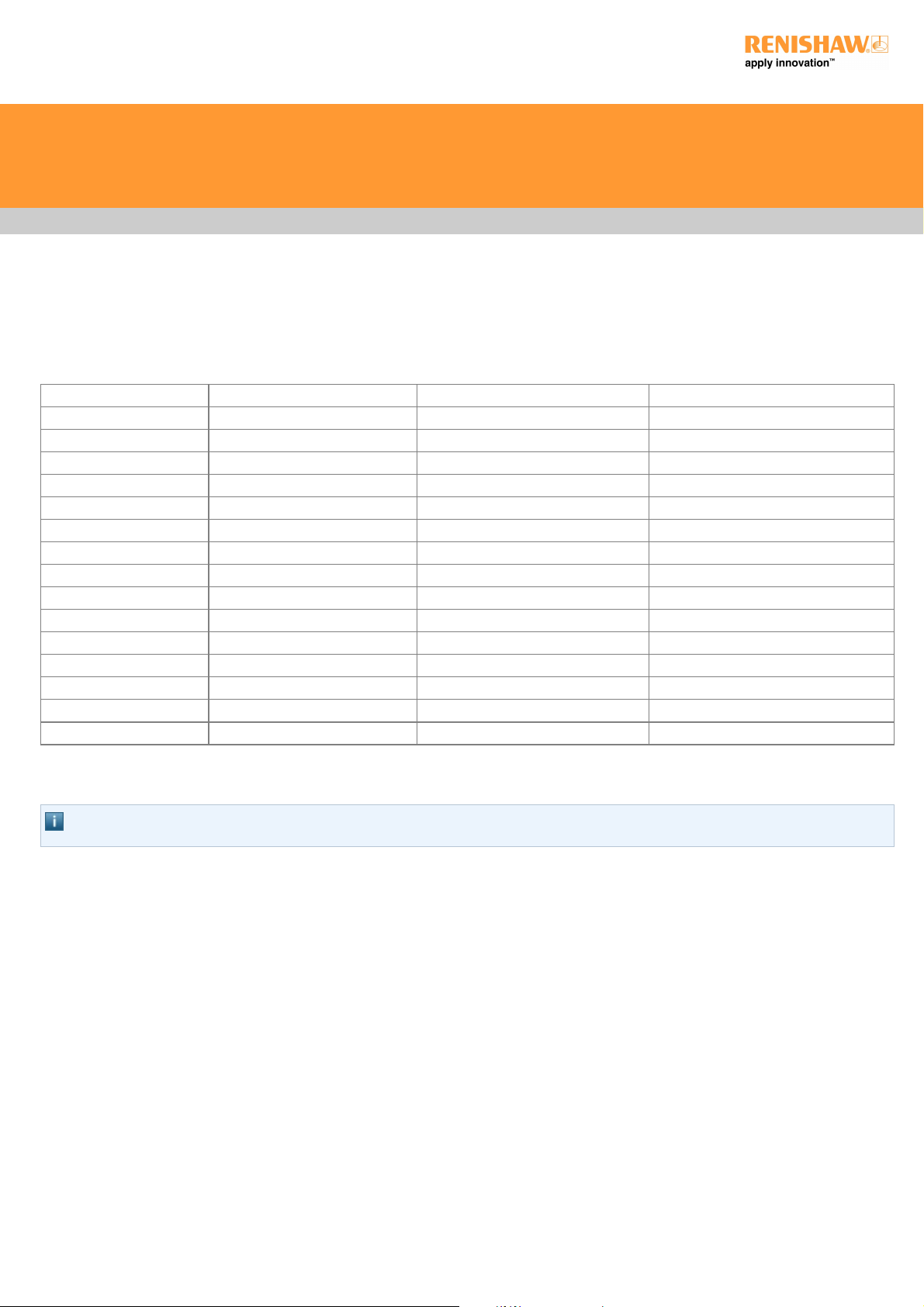

PHC10-3 PLUS configuration switches

PHC10-3 PLUS switch settings

PHC10-3 PLUS switch Function Up Down

Communications

1# Baud rate

2# Baud rate

3# Baud rate

4*# Stop bit 2 stop bits 1 stop bit

5*# CTS protocol CTS on CTS off

6*# LF protocol LF on LF off

9 Command set Extended Basic

Interface

7 PICS configuration PROFF - active during head index PROFF - inactive during head index

8 HCU1 PROBE/DAMP/RESET Enabled Disabled

10 Probe reset time 2 (extended) 1 (standard)

11 Interface connection PICS / 7 pin DIN 5 pin DIN

12 Output configuration PICS DIN

13 Machine cable isolation Machine cable Multiwire

* Operational only when basic command set selected (switch 9 down).

# Not required for USB operation default position = down.

NOTE: Press the reset button after making switch changes.

Conversion from PHC10-2 to PHC10-3 PLUS

PHC10-3 PLUS is designed to be a plug in functional replacement for PHC10-2. There are some differences which the user needs to be

aware of, the connectors have been rearranged on the rear panel but are of the same type and are labelled in the same way. A USB

connector has been added for those requiring USB communications. Unused switches have been removed and the remaining switches

are now grouped in one row. See the next table for changes.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 9 of 30

Page 10

Changes in configuration switches

The table below is a summary of the differences between PHC10-3 PLUS and PHC10-2 configuration switch settings that allows you to

correctly configure your PHC10-3 PLUS when replacing a PHC10-2.

PHC10-2 switch PHC10-3 PLUS switch

equivalent

Function Up Down

Communications

1 1# Baud rate

2 2# Baud rate

3 3# Baud rate

4 (not used)

5 (not used)

6 4*# Stop bit 2 stop bits 1 stop bit

7 5*# CTS protocol CTS on CTS off

8 6*# LF protocol LF on LF off

9 9# Command set Extended Basic

10 10 Probe reset time 2 (extended) 1 (standard)

Interface

11 7 PPOFF PPOFF - active during

head index

PPOFF - inactive during

head index

12 8 HCU1 probe, DAMP and probe

reset buttons

Enabled Disabled

13 (not used)

14 (not used)

15+16 12 Output configuration PICS DIN

17+18 11 Interface connection PICS or 7 pin DIN

operation

5 pin DIN operation only

13 Probe wire isolation Machine cable Multiwire

* Operational only when basic command set selected (switch 9 down)

# Not required for USB operation default position = down

NOTE: Switches 4, 5, 13 and 14 had no function in RS232 PHC10-2. Press the reset switch after making switch position changes.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 10 of 30

Page 11

PICS connection

PICS interface configuration

If PHC10-3 PLUS is to be used in a PICS linked system, the PPOFF configuration is selected using switch 7.

Switch Description Position Information

7 PPOFF UP PPOFF and PDAMP active during head index

7 PPOFF DOWN PDAMP only active during head index

PICS output

Renishaw's PICS (product inter-connection system) allows a standard method of connection for real-time signals used by current

Renishaw products and gives access to probing system control features through the DIN 'raw probe' connection.

The following descriptions are specific to PHC10-3 PLUS PICS connections when an internal interface is not present. Please refer to the

PICS installation guide (Renishaw part number H-1000-5000) for further information when interfaces are fitted.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 11 of 30

Page 12

PinSignal Function -

1 STOP

This signal is active when low and is responded to, and can be asserted by the PHC10-3 PLUS .

Read from PHC10-3

PLUS to indicate an

error in the PH10

system. Pull down to 0

V to indicate a STOP

condition external to the

PH10 system.

2 PPOFF PPOFF is an active low inhibit signal which can be set by the CMM computer or the PHC10-3

PLUS. PPOFF is overridden by the use of the STOP signal.

-

3 0 V This the common reference and return path for all signals. 4 LED

anode

This is a constant current input, normally from the interface to illuminate the head LED. -

5 Probe

Signal

This pin and pin 9 transmit the probe output signals from the PHC10-3 PLUS when a multiwire

cable is not in use. As these signals have not been interfaced, it is important that the PICS cable

between the PHC10-3 PLUS and the interface is less than 0.5 m (1.6 ft) otherwise interference

from other PICS signals can occur.

-

6 SPARE - 7 PDAMP PDAMP is an active low signal which can be set by the CMM computer, the PHC10-3 PLUS or by

the optional HCU1. PDAMP can influence an interface by reducing electronically the sensitivity of a

strain gauge based probe. It can inhibit a Renishaw interface, when standard touch trigger probes

are in use, until the probe has been continuously triggered for at least 5 ms. The signal can be

asserted by the CMM computer to reduce the sensitivity of the probe. This will reduce unwanted

triggers during CMM acceleration, or vibration during position moves, whilst maintaining crash

protection.

Pull down to 0 V to

partially inhibit the

probe during rapid

moves.

8 LEDOFFThis signal is not asserted by the PHC10-3 PLUS, but it responds to LED OFF by switching the

head LED off.

-

9 Probe

Return

See Pin 5 -

- Screen - -

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 12 of 30

Page 13

PHC10-3 PLUS front panel LEDS

PHC10-3 PLUS LED description

Name Colour Function

POWER Green Power on when lit

STOP Red PHC10-3 PLUS asserting PICS STOP when lit

PI 200 asserting PICS STOP when flashing

HEAD READY Green Head ready for use when lit

HEAD ACTIVE Yellow Head indexing when lit

DATUM ERROR Red Head datum error when lit

OBSTRUCT ERROR Red Head obstruct error when lit, non PLUS interface fitted

OVERLOAD ERROR Red Head overload error when lit

TP7 Green TP7 detected when lit

TP200 Green TP200 detected when lit

STD Green TP2 / TP20 / TP6 detected when lit

SEATED Green Probe seated when lit

DAMPED Yellow Probe damped when lit

NOTE: The probe reset button on the front of PHC10-3 PLUS only functions if a probe interface card is installed within the unit.

PHC10-3 PLUS with integrated probe interface

PHC10-3 PLUS is available with an integrated PI 200-3 allowing additional PICS output (Renishaw part number A-5863-0300).

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 13 of 30

Page 14

System interconnection diagrams

This section describes a number of PH10 PLUS system interconnection and recommended interconnection cables

PH10 PLUS system with standard two wired touch-trigger probes

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 14 of 30

Page 15

PH10 PLUS system with standard two wire touch-trigger probe and autochange

1 Communication connection to CMM controller RS232 or USB

3 Communication to CMM controller

4 Communication to autochange rack

5 PICS output to CMM

6 Probe output to CMM controller

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 15 of 30

Page 16

PH10 PLUS system with standard two wire touch-trigger probe, PI 200-3 and autochange

1 Communication connection to CMM controller - RS232 or USB

3 Communication to CMM controller

4 Communication to autochange rack

5 PICS output to CMM controller

6 Raw probe output to CMM contoller

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 16 of 30

Page 17

RS232 setup

RS232 connector pinouts

The PHC10-3 PLUS communicates with the CMM computer via the RS232 cable as shown in the table below:

Pin Signal

1 Screen

2 Transmitted data (Tx) to CMM computer

3 Received data (Rx) from CMM computer

4 RTS (request to send) to CMM computer +12 V after initialisation routing completed

5 CTS (clear to send) from CMM computer

CMM computer disasserts CTS to halt PHC10-3 PLUS transmissions

Connect pin 5 to pin 20 if CTS is not output from CMM computer

7 Signal ground (common)

20 DTR (data terminal ready) to CMM computer signifies PHC10-3 PLUS power ON condition

Baud rate selection

The baud rate is set using switches 1 to 3 as shown in the table below:

Baud rate Switch 1 Switch 2 Switch 3

300 DOWN DOWN DOWN

600 UP DOWN DOWN

1200 DOWN UP DOWN

2400 UP UP DOWN

4800 DOWN DOWN UP

9600 UP DOWN UP

19200 DOWN UP UP

CAUTION: To implement any changes press the "reset" button on the rear rear panel. Failure to do so will be the changes do

not take effect.

Protocol selection

The PHC10-3 PLUS has two switch-settable command sets (basic command set and extended command set) offering different protocol

options. The command set selection is made using switch 9 on the rear panel.

Switch Position Selection

9 UP Extended command set mode (recs) 9 DOWN Basic command set mode

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 17 of 30

Page 18

Basic command set mode

In this mode the PHC10-3 PLUS is fully compatible with existing integration methods in terms of communications protocols, software

command set and RS232 protocol options.

Basic command set protocol

Switch Position Selection

4 UP 2 stop bits

4 DOWN 1 stop bit

5 UP CTS (clear to send) ON

5 DOWN CTS (clear to send) OFF

6 UP LF (line feed) ON

6 DOWN LF (line feed) OFF

Data transmission format is as follows:

1 start bit

7 data bits

1 parity bit (ignored on Rx: always 0 on Tx)

1 or 2 stop bits (switch 4)

Protocols: PHC10-3 PLUS RTS is asserted before first transmission from the head and remains asserted. If switch 5 is UP, CTS must be

asserted by the CMM computer to allow the head to transmit. If switch 6 is UP, the PHC10-3 will add an ASCII LF character to every

transmitted message.

Extended command set mode

In this mode the PHC10-3 PLUS uses the Renishaw extended command set. It is completely different from and incompatible with the

basic command set. The RS232 protocol is fixed with no user selectable options other than baud rate. The extended command set offers

the following advantages over the basic command set:

Software control of the hand control unit (HCU1) functions such as jog and sweep

Software control of selected PICS (product interconnection system) functions such as probe damping, Probe Power OFF and LED

OFF

Software control of selected probe functions (TP200 probe reset) Common communications protocol for products using the extended

command set

As probing systems become increasingly sophisticated and offer a wider range of functions and control options, they will be

incorporated into the new command structure, reducing integration times and costs for CMM manufacturers

The introduction of product identifiers and device numbers will enable control of multiple Renishaw interfaces in future implementations

of the extended command set

Please contact Renishaw for further details of the extended command set.

NOTE: The functions of switches 4, 5 and 6 will have no effect on the system when switch 9 is UP

In extended command set mode, the data transmission and protocol formats are fixed in line with modem RS232 conventions. There are

no user selectable options.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 18 of 30

Page 19

Data transmission format is as follows:

1 start bit

7 data bits

1 even parity bit

1 stop bit

Protocol:

PHC10-3 PLUS RTS is normally asserted. It is unasserted when the PHC10-3 PLUS is unable to receive further transmissions.

The PHC10-3 PLUS CTS must be asserted (by the CMM computer, or by linking DTR to CTS) to allow the PHC10-3 to transmit.

XON/XOFF:

The extended command set supports the use of XON/XOFF flow control by the CMM computer.

If the PHC10-3 PLUS receives an XOFF character, PHC10-3 PLUS transmissions will cease and be buffered until an XON character

is received by the PHC10-3 PLUS or the output buffer overflows.

It is possible to continue transmissions to the PHC10-3 PLUS while it is in the XOFF state, although this is not recommended as it may

cause overflow of the output buffer, resulting in lost responses.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 19 of 30

Page 20

USB communications

USB communication is via the USB type "B" socket on the rear panel. The PHC10-3 PLUS is self powered and therefore takes no power

from the PC bus. The PHC10-3 PLUS will switch automatically from RS232 to communicate via the USB port if a powered up cable is

connected.

NOTE: Only one type of communications cable is to be inserted at any time. If in USB mode and the cable is removed, the PHC10-3

PLUS will assert PICS STOP

Switches 1 to 6 have no function when operating via USB. They may be set to the default down position or left in the RS232 positions.

Switches 7, 8, 9, 11, 12 and 13 will operate as described in the interface switches section.

To operate via the USB port the CMM PC will require the correct USB drivers to be loaded. The signed drivers are available on the CD

provided. To load the drivers power up a PHC10-3 and connect to the CMM PC via a USB cable. The CMM PC operating system should

recognisethenewhardwareandthe‘foundnewhardware'wizardwilloffertosearchforthedriver.

To conform to USB standards a maximum cable length of 5 m may be used. If a longer distance is required a hub may be used to extend

another 5 m. The maximum length of hubs / cables is 30 m. It is suggested that the PHC10-3 should not share its USB port with any high

data rate device which may slow down its response time. Devices such as video cameras and disc drives for example should be avoided

if possible.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 20 of 30

Page 21

Interface switch descriptions

HCU1 operation

When the system is used in conjunction with an HCU1 hand control unit, the probe damp and probe reset buttons on the HCU1 are active.

The probe reset button will pulse the PPOFF PICS line when pressed, but only while the system is in manual mode. The probe damp

button will toggle the PDAMP PICS line when pressed, but only while the system is in manual mode. Both the probe reset and probe damp

buttons on the HCU1 can be made inactive by use of a switch on the rear panel of the PHC10-3.

Switch Description Position

8 Operation of HCU1 probe UP Enabled

8 Damping and probe reset DOWN Disabled

Probe reset time

The extended probe reset timer on the PHC10-3 PLUS unit is designed to be used where the touch probe fails to remain seated following

a head index move. E.g, when using long extension bars.

Switch Description Position

10 Time permitted for probe to reseat following a head index UP Level 2 (extended)

10 Time permitted for probe to reseat following a head index DOWN Level 1 (standard)

Interface connection

SwitchDescription Position

11 Probe

connection

UP PICS or 7-pin DIN operation: the PHC10-3 PLUS internal inhibit realy disables the interface during a

head index

11 Probe

connection

Down 5-pin DIN operation only: the PHC10-3 internal inhibit relay disables the probe during a head index

Output configuration

The PHC10-3 PLUS can be connected to a probe interface via the PICS connection or via the Raw Probe connection (7 pin DIN

connector).

Switch Description Position

12 Probe output configuration UP PICS

12 Probe output configuration DOWN DIN

Probe wire isolation

The probe wires need to be isolated from the machine cable wiring when used with multiwire systems. This is controled by switch 13.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 21 of 30

Page 22

Switch Description Position

13 For use with machine cable UP Machine cable

13 Multiwire option for use with PL172 DOWN Multiwire

The PHC10-3 PLUS will assert STOP under the following conditions:

Condition Notes

Overload error Head has been overloaded when locked causing it to unlock

Obstruct error Head has been obsructed when moving to requested position or is unable to lock into it

Head disconnect STOP will be asserted for two seconds if head is disconnected

Power failure Stop signal will be permanently asserted if mains power is removed from PHC10-3 PLUS

USB cable disconnected PICS STOP will be asserted if USB cable is used and removed during operation

The reaction to assertion of PICS STOP to the system and effect of the signal removal are detailed below:

System state Reaction Removal of external

STOP

STOP asserted on power up head locked

Normal system start up - head will report its position Head movement

commangs accepted

System in manual mode - manual

movement initiated by HCU1 after

STOP asserted

Single step manual movement only - continuous movement is disabled but

head can be moved slowly as a safeguard movement. Head will lock up as

normal when movement key is released

Continuous movement

enabled

System in manual mode - STOP

asserted during manual move by

HCU1

Continuous head movement is immediately disabled - head will continue to

move in single steps. Head will lock up as normal when movement key is

released

Continuous movement

enabled

System in automatic mode - stop

asserted before update command

received

PHC10-3 PLUS will not unlock or index the head Normal system

operation resumed

System in automatic mode - stop

asserted during a head move

Power immediately removed from axis motors - motors braked Update command will

cause the head to

complete its move

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 22 of 30

Page 23

Power supply

Powering the PHC10-3 PLUS

The PH10-3 PLUS head controller is to be used with the provided PSU - (Emerson DP4024N3M ac power adptor). www.emerson.com

Thisisa24Vdc49WsupplyandisconectedtothePHC103PLUSviaØ5.5mmdcjackplug.

PHC10-3 PLUS does not does require a protective earth, however an equipotential bonding point is provided on the rear panel for

connection to the rest of the installation.

PHC10-3 PLUS controller is rated to operate at +24 Vdc 1 A max input current

If an internal interface is fitted with the PHC10-3 PLUS it will obtain its power internally from the PHC10-3 PLUS controller.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 23 of 30

Page 24

Head connector and cables

NOTE: For maximum immunity from electrical noise, Renishaw recommends that:

1. Mating connectors must be metal bodied.

2. The overall cable screen is continuous and connected to the system ground on the user's equipment through the bodies of the

connectors.

CAUTION: For correct system function, the maximum overall single core resistance between the head and PHC10-3 PLUS should

be 2.5 ohm.

Head connector cables

PHC: Probe head cable

MC: Machine cable

MC MC MC MC PHC PHC PHC

Signal name 15-way male D-type Cable PLM 6 - 9 14-way LEMO 12 core 14-way Max line

B-axis feedback 14 Black (F) 1 (M) Yellow E n/a

Ground sense 1 Brown (F) 2 (M) Red D n/a

DC reference 12 V 6 Violet (F) 3 (M) Brown C n/a

0 V 4 Green/red (F) 4 (M) Grey M 1000 mA

Locking motor 8 V dc nominal 10 Green (F) 5 (M) White H 350 mA

A-axis motor 12 V dc nominal 12 Red (F) 6 (M) Green L 350 mA

Head present 2 Turquoise (F) 7 (M) Not connected ------- ------A-axis motor 12 V dc nominal 11 White (F) 8 (M) Dark blue F 350 mA

B-axis motor/probe contact 7 Pink (F) 9 (M) Violet A 350 mA

B-axis motor/probe contact 15 Orange (F) 10 (M) Black B 350 mA

Screen Body Screen (F) 11 (M) Screen N, O ------A-axis feedback 3 Yellow (F) 12 (M) Orange G n/a

LED and datum 8 Blue (F) 13 (M) Turquoise J 15 mA

Motor probe switch 5 Grey (F) 14 (M) Pink K 40 mA

NOTE: The male pins numbered 4 and 7 of the 14 way LEMO connector are linked together.

Motorised head cables

The table below shows the standard range of motorised head cables available from Renishaw:

PHC: Probe head cable

MC: Machine cable

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 24 of 30

Page 25

Cable Name Length Type Connector Connects to Connector Connects to

PHC

PHC

PHC

PHC

PL5

PL6

PL12

PL13

0.1 m to 0.8 m

0.8 m to 1.8 m

0.1 m

0.1 m to 0.2 m

Coiled

Coiled

Plain

Coiled

PH10 style

PH10 style

PH10 style

PH10 style

Head

Head

Head

Head

14-pin LEMO plug

14-pin LEMO plug

14-pin LEMO plug

14-pin LEMO plug

MC

MC

MC

MC

MC

MC

MC

MC

PLM6

PLM7

PLM8

PLM9

6.0 m

4.0 m

6.0 m

4.0 m

Plain

Plain

Plain

Plain

15-pin D-plug

15-pin D-plug

15-pin D-plug

15-pin D-plug

PHC10-3 PLUS

PHC10-3 PLUS

PHC10-3 PLUS

PHC10-3 PLUS

Chassis socket

Chassis socket

Line socket

Line socket

PHC

PHC

PHC

PHC

Raw probe connector pinouts

Pin Description

1 Head LED cathode probe present

2 Ground

3 Head LED cathode

4 Probe return

5 Probe signal

6 Probe inhibit

7 Probe inhibit

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 25 of 30

Page 26

Width 440 mm (17.3 in)

Height 44 mm (1.75 in)

Depth 180 mm (7.1 in)

Weight 1.5 kg (3 lb 3 oz)

Installation

Dimensions

The PHC10-3 PLUS controller can be used in a 19 inch rack system or as a stand-alone unit.

CAUTION: Ensure the controller is disconnected from the power supply during installation.

Stand-alone installation

Four self-adhesive rubber feet are supplied with the unit for stand-alone use.

Mounting in a 19 inch rack

TherackmountingkitA10180189containstwobracketsandfourM5×6mmscrews.AssemblethebracketstothePHC103PLUSas

shown below.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 26 of 30

Page 27

Troubleshooting

This section on troubleshooting is a guide to problems associated with the installation and integration of the system only. Refer to the

'PH10 PLUS installation and user's guide' (Renishaw part number H-1000-5070) regarding problems associated with normal operation of

the system.

The optional HCU1 can also be used to identify system faults. For full details of the use and fault finding capability of the unit see the

'HCU1 hand control unit user's guide' (Renishaw part number H-1000-7592).

Use the table below to identify problems you are experiencing with your system. If you experience problems which you are not able to

identify or solve satisfactorily, please contact Renishaw for further advice.

Power on LED not lit

Possible cause Solution

Power loss Check mains cable connections and integrity

Check power block is supplying 24 V

Check CMM emergency stop condition - power may have been removed by CMM

No head movement in automatic mode

Possible cause Solution

Power loss See above

Cable / connection fault Check connection and integrity of cabling between head and controller

Communications failure Check RS232 baud rate

Incorrect command set selected Check correct command set is selected

No head movement in manual mode

Possible cause Solution

Power loss See above

Cable / connection fault Check connection and integrity of cabling between head and controller

No output signal received by the CMM computer

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 27 of 30

Page 28

Possible cause Solution

Cable / connection fault Check connection and integrity of cabling between head and controller

Check connection and integrity of cabling between controller and interface

Check connection and integrity of cabling between interface and computer

Multiwire bypass connector not

fitted

Fit a multiwire bypass connector with will permit a standard touch-trigger probe signal to reach

controller

Multiwired probe in use Check that the multiwire cable is correctly fitted to the head

Check that the trigger output to the CMM computer is connected to the multiwired probe interface

Poor measurement performance

Possible cause Solution

Loose mounting of head Ensure all mounting screws are tight and mounting to CMM is secure

Probe damping enabled during measurement Ensure probe damping is not enabled during measurement moves

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 28 of 30

Page 29

Maintenance

There are no user serviceable parts inside any PH10 PLUS system units. Units requiring attention must be returned to an authorised

Renishaw customer service centre. The probe head, controller and hand control unit should be cleaned with a soft, dry, lint-free cloth.

PHC10-3 PLUS installation guide

http://www.renishaw.com

Issued 01 2013

Page 29 of 30

Page 30

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

www.renishaw.com/cmmsupport

Issued 01 2013

Loading...

Loading...