Page 1

User’s guide

H-1000-5001-03-A

PH6M probe head

Page 2

© 2001 - 2005 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means, without the

prior written permission of Renishaw.

The publication of material within this document does not imply freedom

from the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of this

document are free from inaccuracies and omissions. However, Renishaw

makes no warranties with respect to the contents of this document and

specifi cally disclaims any implied warranties. Renishaw reserves the right

to make changes to this document and to the product described herein

without obligation to notify any person of such changes.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are

registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are trade

names, service marks, trademarks, or registered trademarks of their

respective owners.

Renishaw part no: H-1000-5001-03-A

Issued: 10 2005

Page 3

PH6M

user’s guide

1

Page 4

2

Care of equipment

Renishaw probes and associated systems are precision tools used for

obtaining precise measurements and must therefore be treated with

care.

Changes to equipment

Renishaw reserves the right to improve, change or modify its hardware

or software without incurring any obligations to make changes to

Renishaw equipment previously sold.

Warranty

Renishaw plc warrants its equipment provided that it is installed

exactly as defi ned in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw

equipment (e.g. interfaces and/or cabling) is to be used or substituted

for Renishaw equipment. Failure to comply with this will invalidate the

Renishaw warranty.

Claims under warranty must be made from authorised service centres

only, which may be advised by the supplier or distributor.

Page 5

Contents

Contents

1 Introduction ...................................................................................4

2 Installation and connection ............................................................5

3 Dimensions ...................................................................................6

4 Operation ......................................................................................7

5 System connection ........................................................................9

6 Interconnecting cables ................................................................10

7 Specifi cation ................................................................................11

8 Probe compatibility ......................................................................12

9 Accessories and parts list ...........................................................14

9.1 Accessories ........................................................................14

9.2 Parts list .............................................................................14

3

Page 6

4

Introduction

1 Introduction

The PH6M is a shank mounted, fi xed orientation, probe head

incorporating the Renishaw autojoint probe connector.

The PH6M is compatible with the AM1 adjustment module to allow

precise autojoint alignment with machine axes, enabling trouble-free

autochange operation.

Probe reach may be extended using the PEM range of extension bars

for multiwired probes or the PAA series for adapting to M8 connected

probes.

Electrical connection is made via a 15-pin micro ‘D’ type connector.

A range of mating cables is available with the remote end either

terminated or unterminated according to installation requirements.

An integral LED indicates the status of touch-trigger probes.

Page 7

Installation and connection

2 Installation and connection

The PH6M is fi tted with an integral 15-pin micro ‘D’ socket. If required,

this socket can be adapted by using a suitable cable to which a 5-pin

DIN socket has been fi tted.

Locking and unlocking the autojoint is performed either manually

using the S10 joint key (supplied) or automatically using the Renishaw

autochange system. This allows probes to be changed without the

need to requalify.

5

Page 8

6

Dimensions

3 Dimensions

40 mm

(1.57 in)

60 mm (2.36 in)

Figure 1 - PH6M dimensions

Page 9

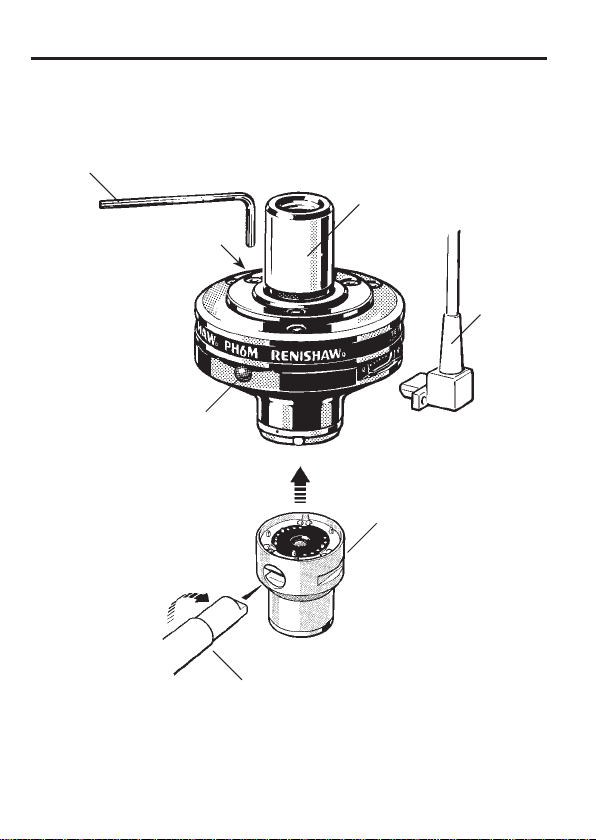

Operation

4 Operation

The autojoint is a highly repeatable coupling mechanism which will

minimise the need for tip re-qualifi cation after the exchange of probes

or extension bars. The locking mechanism is operated by rotating an

actuator contained in the mating half of the coupling, which is located

on the probe or extension bar. The actuator has a drive slot which

may be operated using an S10 joint key for manual probe or extension

bar changing applications (see fi gure 2 on page 8). Automatic probe

or extension bar changing is possible using the Renishaw ACR1 or

ACR3 autochange systems.

The status of the probe is indicated by the probe status LED. This is

normally lit when the probe is ready for use and extinguishes as the

probe triggers.

7

Page 10

8

Operation

Allen key

2.5 AF

M3 x 8 socket head

screws

(3 off)

Probe

status LED

Shank

Multiwire

probe

cable

Autojoint

adaptor

S10 joint key

Figure 2 - PH6M

Page 11

5 System connection

System connection

9

PI 7-2 interface PI 200 interface

PLM 38/42

D

PL47 + PL26

Probe:

TP2

TP20

TP200

SP25MTP7M PAA1

AC3

Abcd

2

AC

Efg

PLM 38/42

Figure 3 - System connection

Page 12

10

Interconnecting cables

6 Interconnecting cables

There is a choice of standard cables to connect from PH6M to probe

interfaces PI 7-2, PI 200, OPI6, the AC2 card for SP600M or the ACR3

card for SP25M.

Connectors shown in brackets are supplied in kit form. The cable

is supplied with the micro ‘D’ connector fi tted and the remote end

prepared, but unterminated, to facilitate assembly into machine looms.

Termination Length Ident

(15-way high

density ‘D’)

(15-way high

density ‘D’)

Unterminated 12 m PL56 A-1016-7626

(15-way high

density ‘D’)

(15-way high

density ‘D’)

(15-way high

density ‘D’)

Please contact Renishaw for details of cables for PI 200.

25 m PL38 A-1016-7625

15 m PL42 A-1016-7624

8 m PL44 A-1016-7627

3.7 m PL46 A-1016-7628

1.9 m PL45 A-1016-7629

Part

number

unterminated

unterminated

No connector

unterminated

unterminated

unterminated

Notes

Supplied

Supplied

supplied

Supplied

Supplied

Supplied

Page 13

7 Specifi cation

Specifi cation

11

Repeatability

Probe compatibility

Dimensions

Weight

Probe mount

Number of sockets

Style of probe joint

Probe status indication

Cable connection

1 µm (2σ) at stylus tip 50 mm (1.97 in)

from connector face.

Direct fi tting of SP25M, TP7M, OTP6M,

SP600M and TP6A.

PAA series adaptor/extension required for

M8 connector probes TP200, TP20 and

TP2.

Length: 40 mm (1.57 in) – without shank

Diameter: 60 mm (2.36 in)

160 g (0.36 lb)

Multiwired autojoint

One

Multiwired autojoint

One LED

15-way micro ‘D’ connector

Page 14

12

Probe compatibility

8 Probe compatibility

PH6M †

PAA

PEL1

PK1

PEL2

PAA2

PEL3

TP20

M2 thread

styli

TP2-5W

TP200‡*

PEL4

Q24885

PAA3

TP6

M3/M2

adaptor

Page 15

Probe compatibility

13

TP6A

M3 thread

styli

PEM25

PEM1

SP25M‡

PEM3 PEM25

PEM1

PEM2

SP600‡

D

TP7M‡

M4/M3

adaptor

M4 thread

styli

Page 16

14

Accessories and parts list

9 Accessories and parts list

9.1 Accessories

Part Description Part number

AM1 Adjustment module for precise alignment

of the head axes with the CMM or

autochange rack.

S10 Autojoint key A-1051-0040

9.2 Parts list

Please quote the part number when ordering.

Type Part number

PH6M + MS1 shank A-1074-0031

PH6M + MS2 shank A-1074-0032

PH6M + MS3 shank A-1074-0033

PH6M + MS9 shank A-1074-0039

PH6M + MS13 shank A-1074-0043

PH6M + MS15 shank A-1074-0045

A-1026-0320

Page 17

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

*H-1000-5001-03*

Loading...

Loading...