Page 1

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

PH10 PLUS motorised probe head range

PH10 PLUS

The range of PH10 PLUS motorised probe heads increases throughput by giving

automated CMMs the added capability of program controlled probe reorientation.

This enables the inspection of features at different angles without the need for

frequent, time consuming stylus cluster changes.

PH10 PLUS heads are compatible with a range of both contact and

non-contact scanning sensors and touch-trigger probes, allowing the size and

form of critical features to be determined.

When used in conjunction with the PH10M PLUS or PH10MQ PLUS, Renishaw’s

autochange systems provide fast, repeatable probe and extension bar exchange,

without the need for re-qualification of the stylus tip, helping to maximise productivity.

Since 1988 the PH10 heads have been installed on thousands of co-ordinate

measuring machines and Renishaw has engaged on a continuous development

program resulting in several important enhancements through the product’s

history including:

- Significant mechanical design improvements

- Improved repeatability and long term stability

- LED replaced with light guide (red when powered on and white when off)

- Ability to store usage history for subsequent analysis

- 2 year warranty as standard.

Key benefits

Accuracy

Repeatability specification is a market leading 0.4 μm

at a 100 mm radius from the centre of rotation of the axis,

providing accurate positioning even when using

long extensions.

Increased throughput

The PH10’s ability to index automatically reduces the number

of stylus changes required, thereby increasing the throughput

of your CMM. Indexing is faster than stylus changing.

Increased reach and flexibility

Extension bars up to 450 mm long, together with the full range

of Renishaw autojoint and M8 probes, can be used with the

appropriate head types.

Innovations

Repeatable kinematic location

The PH10 PLUS uses a six point kinematic location for each

of its 720 indexable positions, making its locking mechanism

the most repeatable on the market.

The Renishaw autojoint

This industry standard feature allows repeatable automated

probe exchange without the need for stylus requalification.

UCC compatibility

The PH10 PLUS can be used in conjunction with Renishaw’s

UCC controller family, providing a comprehensive retrofit

solution for all types of CMM.

Page 2

Specification

Head type PH10MQ PLUS PH10M PLUS PH10T PLUS

Weight

CMM mounting

Probe mounting

Head controller

Repeatability of

position

Cycle time:

7.5° move

90° move

Total angular move-

ment:

A axis

B axis

Total number

of positions

Maximum drive

output torque

Maximum

extension bar

Temperature range

Operating

Storage

Joystick options

Warranty

730 g

(25.7 oz)

Direct to quill Shank

Renishaw autojoint (multiwired)

M8 threaded probes can be used

with PH10MQ/M PLUS via PAA

probe adaptor

PHC10-3 PLUS, UCC T3 PLUS or UCC S3

0.4 μm (0.00002 in) specified at a distance of

100 mm (3.94 in) from the A-axis centre of rotation

2.5 seconds

3.5 seconds

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

0° to 105° in 7.5 steps

0° to ±180° in 7.5 steps

0.45 Nm

300 mm (11.8 in) using PAA3

probe adaptor

450 mm (17.7 in) using PAACF

special order only extension

10 °C to 40 °C (50 °F to 104 °F)

-10 °C to 70 °C (14 °F to 158 °F)

HCU1 or MCUlite-2, MCU5 or MCU W

2 years

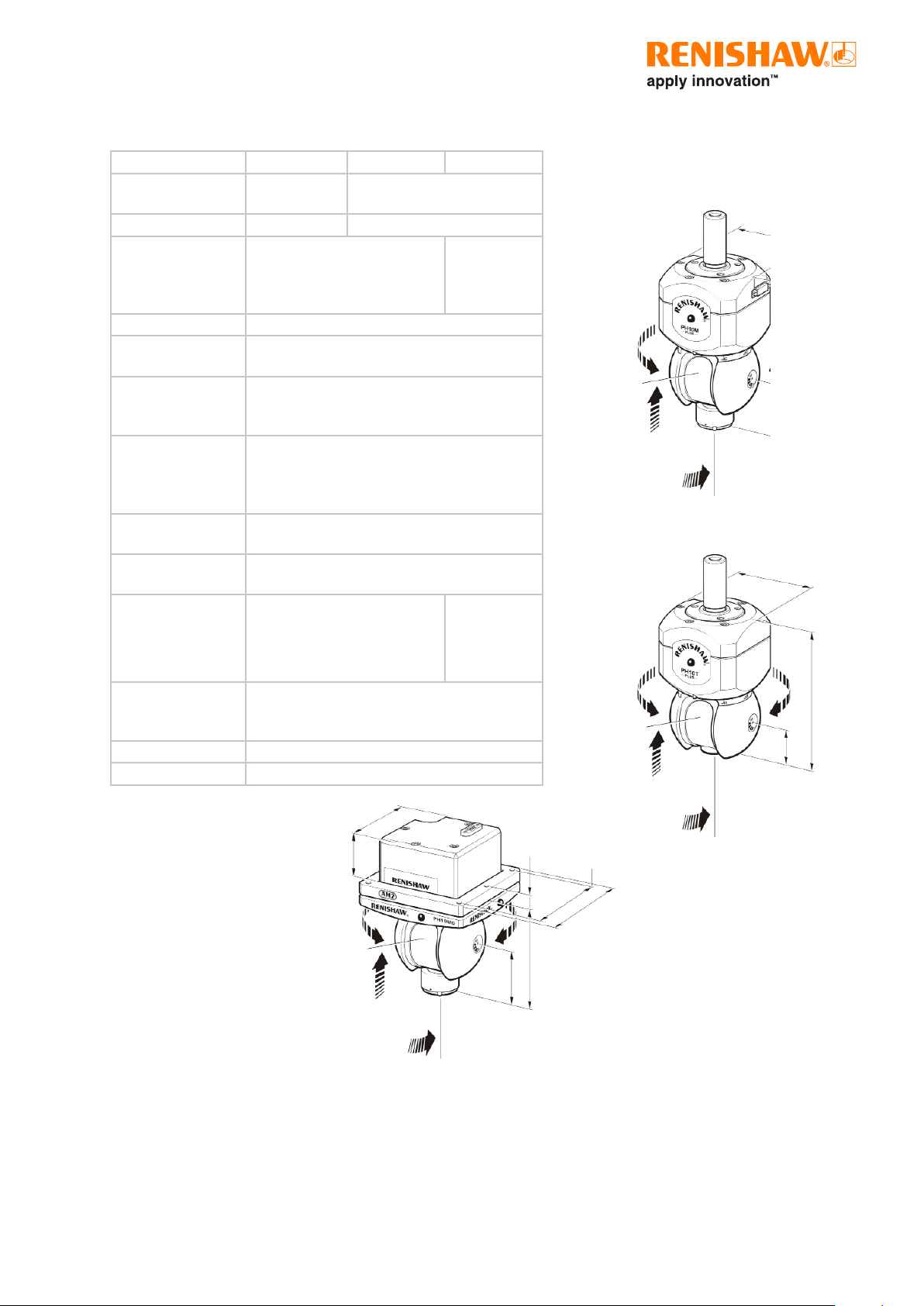

PH10MQ PLUS

34 mm

(1.34 in)

645 g

(22.07 oz)

M8 thread

aaa

720

300 mm (11.8 in)

using PEL4

extension

10 mm

(0.39 in)

PH10M PLUS

B axis

A axis

PH10T PLUS

B axis

70.5 mm

(2.78 in)

square

A axis

62 mm

(2.44 in)

117 mm

(4.6 in)

38 mm

(1.5 in)

62 mm

(2.44 in)

102 mm

(4.0 in)

25 mm

(0.98 in)

B axis

A axis

73 mm

(2.87 in)

38 mm

(1.5 in)

80 mm

(3.12 in)

square

Additional information

A variety of shanks are also available for PH10M PLUS and PH10T PLUS depending on your CMM.

In order to select the correct PH10 PLUS kit for your machine refer to www.renishaw.com/PH10 PLUS.

For worldwide contact details, please visit our main website at www.renishaw.com/contact

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT

AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT.

RENISHAW EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

© 2009 - 2013 Renishaw plc All rights reserved Issued 1013

Part no. H-1000-3310-03-A

Loading...

Loading...