Page 1

Information leaflet

H-5465-8102-02-A

Styli recommendations for OSP60

SPRINT™ scanning probes

The SPRINT™ on-machine scanning system can be used with a range of

SPRINT-specific styli to suit individual application requirements, all of which

complement the enhanced capability provided by the OSP60 SPRINT probe.

SPRINT-specific styli are available in two ranges: the SPRINT standard range, which is suitable for the majority of applications,

and the SPRINT calibrated range (UKAS certified), which is designed for the most demanding applications. Both ranges

incorporate a number of design elements which offer improved metrology performance for machine tool scanning applications.

SPRINT standard range

During scanning the stylus is constantly deflected, so the

ceramic stem has been designed to be narrow and therefore

tightly control all squareness tolerances. This ensures that

even when measuring a part with vertical surfaces, such as on

prismatic parts, the risk of the stylus shank contacting the part

before the stylus tip is minimised.

SPRINT calibrated range

In the variable temperature environment typical of a machine

tool, the dimensional variation of the calibration sphere,

compared with the machine structure, can degrade the

performance of the measurement system. In the highest

accuracy applications, this contribution to the overall system

measurement uncertainty can be significant.

To ensure the highest possible measurement accuracy in all

measurement conditions, the ball on each stylus within the

SPRINT calibrated range is measured and UKAS certified.

The exact ball diameter is engraved onto the stylus holder, so

that this highly accurate value can be applied during probe

calibration as an absolute reference.

Page 2

Information leaflet

Styli for the SPRINT system

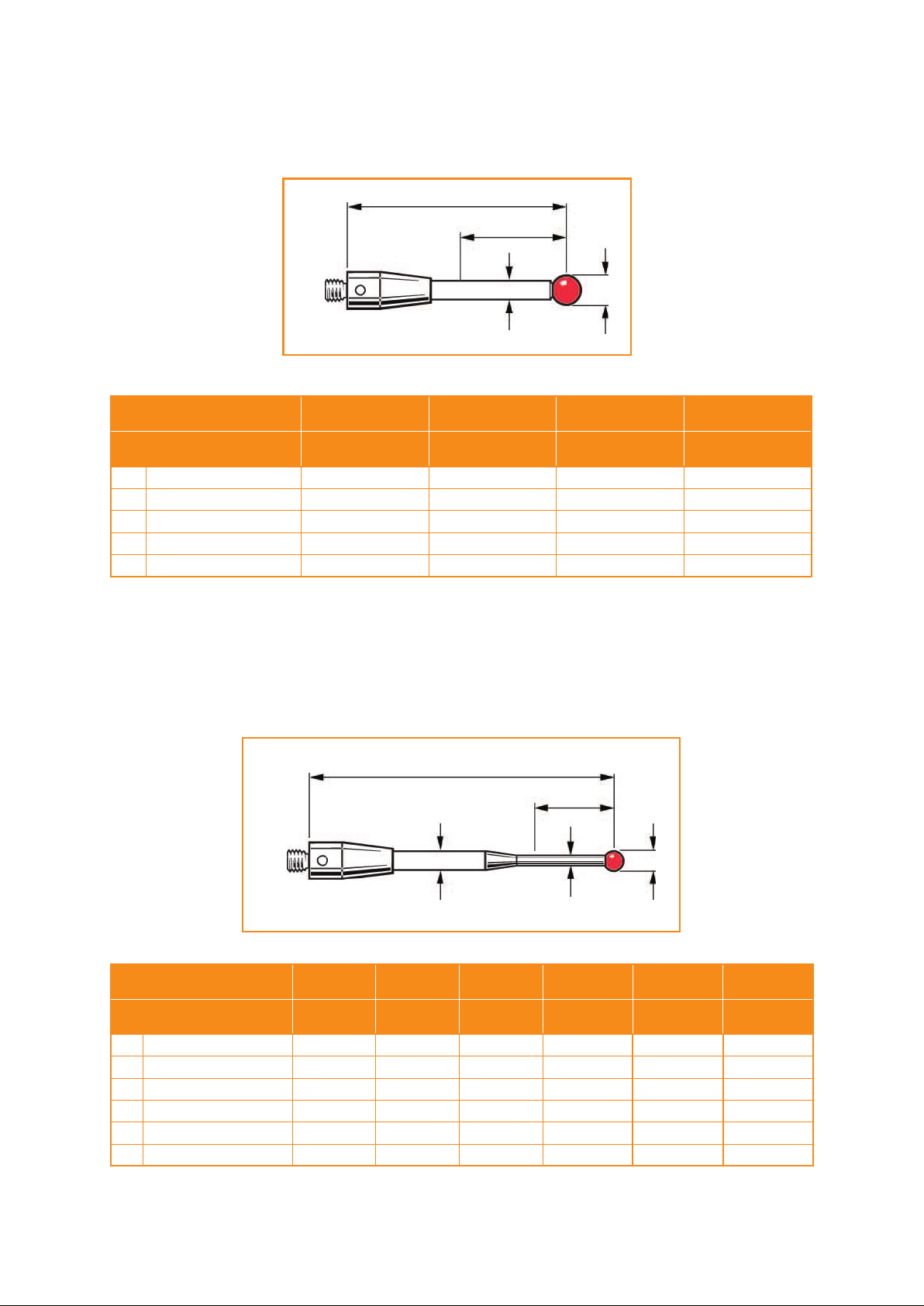

6 mm ball diameter SPRINT styli

B

D

AM4

C

Part number

(standard)

Part number

(calibrated)

A

Ball diameter mm (inch) 6.0 (0.24) 6.0 (0.24) 6.0 (0.24) 6.0 (0.24)

B

C

D

* ESWL = Effective Scanning Working Length, measured from the centre of the ball to the point at which the stem will foul against a vertical face when at the maximum

scanning deflection.

Length mm (inch) 100.0 (3.94) 150.0 (5.91) 100.0 (3.94) 150.0 (5.91)

Stem diameter mm (inch) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15)

ESWL* mm (inch) 62.9 (2.48) 71.5 (2.81) 62.9 (2.48) 71.5 (2.81)

Mass (grammes) 6.5 8.0 6.5 8.0

A-5004-4472

Ruby

A-5465-8576

Ruby

A-5004-4474

Ruby

A-5465-8577

Ruby

A-5004-6470

Silicon nitride

A-5465-5008

Silicon nitride

A-5004-6471

Silicon nitride

A-5465-5009

Silicon nitride

2 mm to 4 mm ball diameter SPRINT styli

B

D

M4

E

Part number

(standard)

Part number

(calibrated)

A

Ball diameter mm (inch) 2.0 (0.08) 3.0 (0.12) 4.0 (0.16) 2.0 (0.08) 3.0 (0.12) 4.0 (0.16)

B

C

D

E

* ESWL = Effective Scanning Working Length, measured from the centre of the ball to the point at which the stem will foul against a vertical face when at the maximum

Length mm (inch) 80.0 (3.15) 100.0 (3.94) 100.0 (3.94) 80.0 (3.15) 100.0 (3.94) 100.0 (3.94)

Stem diameter mm (inch) 1.5 (0.06) 2.0 (0.08) 2.0 (0.08) 1.5 (0.06) 2.0 (0.08) 2.0 (0.08)

ESWL* mm (inch) 10.7 (0.42) 27.0 (1.06) 42.6 (1.68) 10.7 (0.42) 27.0 (1.06) 42.6 (1.68)

Stem diameter mm (inch) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15) 3.8 (0.15)

Mass (grammes) 5.9 7.4 7.4 5.9 7.4 7.4

scanning deflection.

A-5004-6463

Ruby

A-5465-5001

Ruby

A-5004-6464

Ruby

A-5465-5002

Ruby

A-5004-6465

Ruby

A-5465-5003

Ruby

C

A-5004-6467

Silicon nitride

A-5465-5005

Silicon nitride

A

A-5004-6468

Silicon nitride

A-5465-5006

Silicon nitride

A-5004-6469

Silicon nitride

A-5465-5007

Silicon nitride

Page 3

Notes on stylus selection

Standard M4 styli which are not SPRINT-specific may also be used with an OSP60 probe, but the effective scanning working

length (ESWL) will be restricted.

Stylus ball material

The material being scanned dictates the stylus ball material to be used.

• Ruby: Ruby is the optimum stylus ball material for the vast majority of measurement applications. It offers exceptional surface

smoothness, excellent compressive strength and a high resistance to mechanical corrosion.

• Silicon nitride: When scanning titanium alloys with coolant, silicon nitride (a very hard and wear-resistant ceramic) is

recommended.

Stylus ball size

Keep the ball as large as possible, consistent with the features to be scanned. This maximises the ball/stem clearance, which

reduces the chance of fouling on the stylus stem.

Smaller features are best scanned with a smaller ball. The minimum recommended ball size for use with the OSP60 probe is

2 mm (0.08 in).

SPRINT styli ball diameters have a guaranteed ball diameter tolerance of ±2 μm (79 μin).

Stylus ball sphericity

SPRINT styli use Grade 5 balls that have a maximum sphericity of 0.13 μm (5 μin).

Stylus stem length

When using an OSP60 SPRINT probe, Renishaw recommends the use of SPRINT styli with a ball diameter of 2 mm to 6 mm

(0.08 in to 0.24 in) and a stem length of 80 mm to 150 mm (3.15 in to 5.91 in). If the application requires a stylus outside this

range, please contact your local Renishaw distributor.

Stylus stem assembly

Minimise the number of joints in the stylus stem. Every joint between a stylus and any extensions introduces potential

bending and deflection points. SPRINT styli are designed with a minimum number of constituent parts, joined together using

high-specification, oven-cured adhesive.

Stylus stem material

SPRINT styli stems are made of materials that optimise the stiffness and ESWL of the stylus, combining stainless steel,

tungsten carbide and ceramic. Ceramic stems are used for scanning due to their low mass, high stiffness and thermal stability.

Styli with carbon fibre stems are not recommended for use with an OSP60 probe.

Stylus stem type

OSP60 SPRINT probes are only suitable for use with straight styli.

Custom design service

If you cannot achieve your objectives using our range of SPRINT styli, Renishaw can provide you with a solution for your custom

probing scanning applications. Renishaw’s Styli and Fixturing Products Division has supplied over 5,000 different custom styli

into probing applications worldwide. For advice and further details, please contact your local Renishaw distributor.

Always use genuine Renishaw styli or your probe performance will be compromised.

Page 4

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

+44 (0)1453 524524

T

+44 (0)1453 524901

F

uk@renishaw.com

E

www.renishaw.com

For worldwide contact details, please visit our

main web site at www.renishaw.com/contact

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT

AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT.

RENISHAW EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

© 2013–2014 Renishaw plc. All rights reserved. Part no. H-5465-8102-02-A Issued: 09.2014

*H-5465-8102-02*

Loading...

Loading...