Page 1

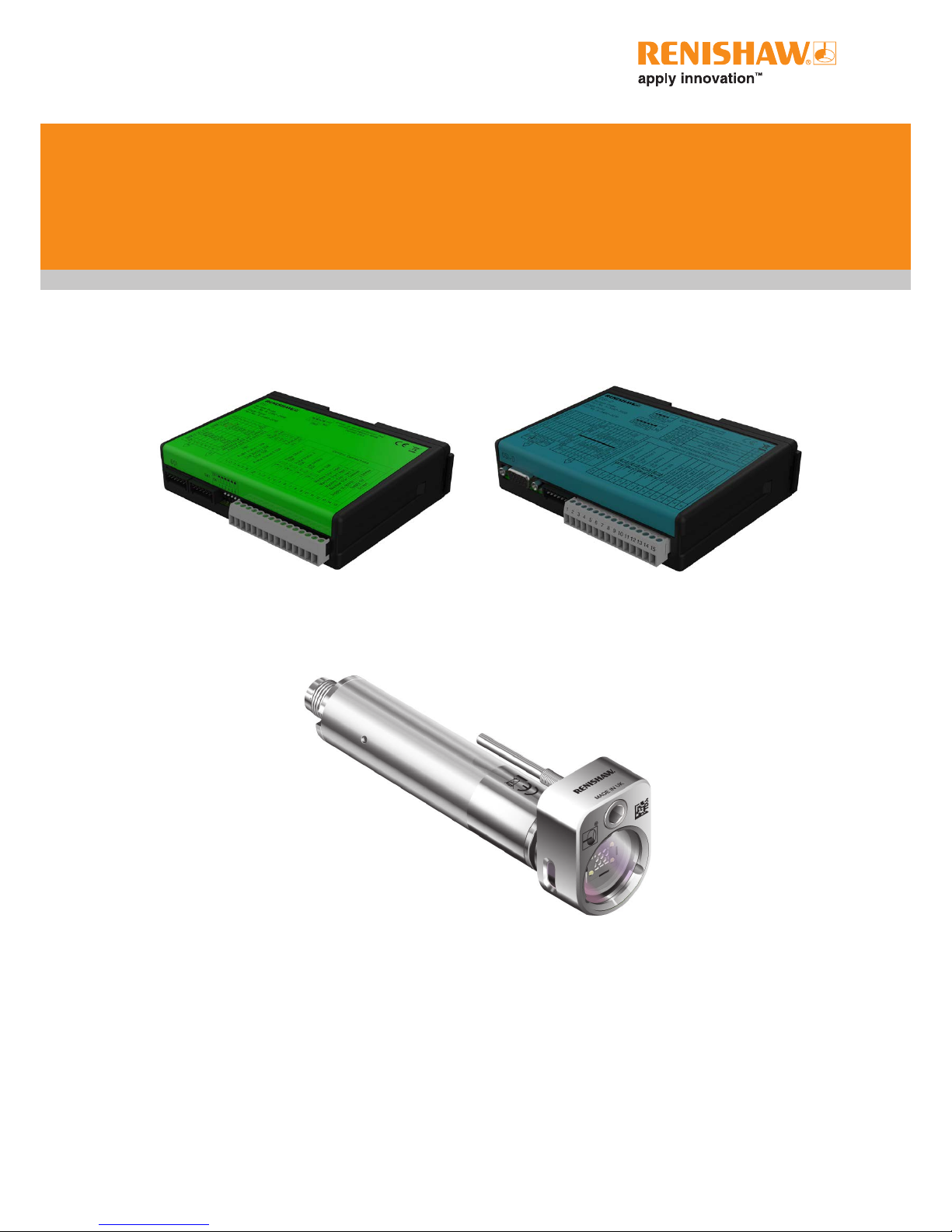

OSI/OSI-D with OMM-2C multiple optical

probe interface system

Installation guide

H-5991-8504-03-A

Page 2

Renishaw part no: H-5991-8504-03-A

First issued: 05.2017

Revised: 02.2019

© 2017–2019 Renishaw plc. All rights reserved.

This document may not be copied or reproduced

in whole or in part, or transferred to any other

media or language, by any means, without the

prior written permission of Renishaw plc.

The publication of material within this document

does not imply freedom from the patent rights of

Renishaw plc.

Page 3

i

Contents

Before you begin .............................................................1.1

Before you begin

............................................................1.1

Disclaimer

..............................................................1.1

Trade marks

.............................................................1.1

Warranty

................................................................1.1

Changes to equipment

.....................................................1.1

CNC machines

...........................................................1.1

Care of the system components

.............................................1.1

Patents

.................................................................1.2

OSI EU declaration of conformity

...............................................1.3

OSI-D EU declaration of conformity

.............................................1.3

OMM-2C EU declaration of conformity

...........................................1.3

WEEE directive

.............................................................1.3

REACH regulation

...........................................................1.3

FCC information to user (USA only)

.............................................1.4

Safety

....................................................................1.5

OSI/OSI-D with OMM-2C basics ...............................................2.1

Introduction

................................................................2.1

OSI-D interface

...........................................................2.1

OSI/OSI-D inputs

............................................................2.2

OSI/OSI-D outputs

..........................................................2.2

OSI components

............................................................2.3

OSI-D components

..........................................................2.4

OMM-2C (A) connector (7-way/15-way)

........................................2.5

OMM-2C (B) connector (7-way)

..............................................2.5

Control connector block (15-way)

.............................................2.5

Switch SW1 output conguration

.............................................2.6

Switch SW2 output conguration

.............................................2.7

OSI/OSI-D input mode congurations

............................................2.8

Single probe mode

........................................................2.8

Multiple probe mode

.......................................................2.8

Page 4

OSI/OSI-D with OMM-2C installation guide

ii

Contents

Switch-on / switch-off method ...............................................2.9

Start-up times ............................................................ 2.9

Synchronisation recovery ...................................................2.9

Multiple probe mode timing diagrams ........................................2.10

OSI/OSI-D output waveforms .................................................2.11

OSI/OSI-D dimensions ......................................................2.12

OSI/OSI-D specification .....................................................2.12

OMM-2C visual diagnostics – system status LEDs .................................2.13

START SIGNAL (blue, yellow, violet) .........................................2.14

ACTIVE SYSTEM (blue, yellow, violet) .......................................2.14

ERROR and STANDBY (red) ...............................................2.14

OVERCURRENT (ashing red) .............................................2.14

CORRUPTED SIGNAL (white) ..............................................2.14

OMM-2C dimensions ........................................................2.15

OMM-2C specification .......................................................2.15

OSI/OSI-D with OMM-2C system used in single probe mode .........................2.16

OSI/OSI-D with OMM-2C system used in multiple probe mode .......................2.17

System installation ...........................................................3.1

Typical OMM-2C system installation .............................................3.1

Introduction .............................................................3.1

Single conguration .......................................................3.1

Tandem conguration ......................................................3.2

OMM-2C application ......................................................3.3

OMM-2C cable ...........................................................3.3

Mounting the OSI/OSI-D to a DIN rail ............................................3.4

Performance envelope of OMM-2C with OMP600 or OMP60 ..........................3.5

Performance envelope of OMM-2C with OMP400, OMP40-2 or OLP40 ..................3.6

Performance envelope of OMM-2C with OTS ......................................3.7

Wiring diagram (with output groupings shown) .....................................3.8

Integral airblast installation (optional) ............................................3.9

Integral airblast application ..................................................3.9

Connecting and purging the air supply .........................................3.9

Maintenance .................................................................4.1

Maintenance ...............................................................4.1

Cleaning the interface .....................................................4.1

Removing the OMM-2C ....................................................4.2

Maintenance – air regulator unit ..............................................4.2

Page 5

iii

Contents

Fault-finding .................................................................5.1

Parts list .....................................................................6.1

Page 6

OSI/OSI-D with OMM-2C installation guide

iv

Contents

This page is intentionally left blank.

Page 7

1.1

Before you begin

Before you begin

Disclaimer

RENISHAW HAS MADE CONSIDERABLE

EFFORTS TO ENSURE THE CONTENT OF THIS

DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES

OR REPRESENTATIONS REGARDING

THE CONTENT. RENISHAW EXCLUDES

LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Trade marks

RENISHAW and the probe symbol used in the

RENISHAW logo are registered trade marks of

Renishaw plc in the United Kingdom and other

countries. apply innovation and names and

designations of other Renishaw products and

technologies are trade marks of Renishaw plc or

its subsidiaries.

All other brand names and product names used

in this document are trade names, trade marks, or

registered trade marks of their respective owners.

Warranty

Equipment requiring attention under warranty

must be returned to your equipment supplier.

Unless otherwise specifically agreed in writing

between you and Renishaw, if you purchased

the equipment from a Renishaw company, the

warranty provisions contained in Renishaw’s

CONDITIONS OF SALE apply. You should consult

these conditions in order to find out the details

of your warranty but, in summary, the main

exclusions from the warranty are if the equipment

has been:

• neglected, mishandled or inappropriately used;

or

• modified or altered in any way except with the

prior written agreement of Renishaw.

If you purchased the equipment from any other

supplier, you should contact them to find out what

repairs are covered by their warranty.

Changes to equipment

Renishaw reserves the right to change equipment

specifications without notice.

CNC machines

CNC machine tools must always be operated by

fully trained personnel in accordance with the

manufacturer's instructions.

Care of the system components

Keep system components clean and treat with

care. Do not apply labels to the front of the

OMM-2C or otherwise obstruct the window.

Page 8

OSI/OSI-D with OMM-2C installation guide

1.2

Before you begin

EP 0974208

EP 1503524

JP 4294101

US 6839563

Patents

Features of OMM-2C and OSI/OSI-D (and

features of similar products) are the subject of

one or more of the following patents and/or patent

applications:

Page 9

1.3

Before you begin

C

OSI EU declaration of conformity

Renishaw plc declares under its sole responsibility

that the OSI is in conformity with all relevant

Union legislation.

The full text of the EU declaration of conformity is

available at:

www.renishaw.com/mtpdoc

OSI-D EU declaration of

conformity

Renishaw plc declares under its sole responsibility

that the OSI-D is in conformity with all relevant

Union legislation.

The full text of the EU declaration of conformity is

available at:

www.renishaw.com/mtpdoc

OMM-2C EU declaration of

conformity

Renishaw plc declares under its sole responsibility

that the OMM-2C is in conformity with all relevant

Union legislation.

The full text of the EU declaration of conformity is

available at:

www.renishaw.com/mtpdoc

C

WEEE directive

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with

general household waste upon disposal. It is the

responsibility of the end user to dispose of this

product at a designated collection point for waste

electrical and electronic equipment (WEEE) to

enable reuse or recycling. Correct disposal of

this product will help to save valuable resources

and prevent potential negative effects on the

environment. For more information, please contact

your local waste disposal service or Renishaw

distributor.

REACH regulation

Information required by Article 33(1) of Regulation

(EC) No. 1907/2006 (“REACH”) relating to

products containing substances of very high

concern (SVHCs) is available at:

www.renishaw.com/REACH

C

Page 10

OSI/OSI-D with OMM-2C installation guide

1.4

Before you begin

FCC information to user (USA

only)

47 CFR Section 15.19

This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful

interference, and

2. This device must accept any interference

received, including interference that may

cause undesired operation.

47 CFR Section 15.21

The user is cautioned that any changes or

modifications not expressly approved by

Renishaw plc or authorised representative could

void the user’s authority to operate the equipment.

47 CFR Section 15.105

This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment

in a residential area is likely to cause harmful

interference in which case the user will be

required to correct the interference at his own

expense.

Page 11

1.5

Before you begin

Safety

Information to the user

In all applications involving the use of machine

tools or CMMs, eye protection is recommended.

The OMM-2C has a glass window. Handle with

care if broken to avoid injury.

Information to the machine supplier/

installer

It is the machine supplier's responsibility to

ensure that the user is made aware of any

hazards involved during operation, including those

mentioned in Renishaw product literature, and to

ensure that adequate guards and safety interlocks

are provided.

Under certain circumstances, the probe signal

may falsely indicate a probe seated condition. Do

not rely on probe signals to halt the movement of

the machine.

Information to the equipment installer

All Renishaw equipment is designed to comply

with the relevant EU and FCC regulatory

requirements. It is the responsibility of the

equipment installer to ensure that the following

guidelines are adhered to, in order for the product

to function in accordance with these regulations:

• any interface MUST be installed in a position

away from any potential sources of electrical

noise, i.e. power transformers, servo drives etc;

• all 0V/ground connections should be

connected to the machine “star point” (the “star

point” is a single point return for all equipment

ground and screen cables). This is very

important, and failure to adhere to this can

cause a potential difference between grounds;

• all screens must be connected as outlined in

the user instructions;

• cables must not be routed alongside high-

current sources, i.e. motor power supply cables

etc, or be near high-speed data lines;

• cable lengths should always be kept to a

minimum.

• the dc supply to this equipment must be

derived from a source which is approved to

IEC/BS/EN 60950-1.

Equipment operation

If this equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

Optical safety

This product contains LEDs that emit both visible

and invisible light.

OMM-2C is ranked Risk Group: Exempt (safe by

design).

The product was evaluated and classified using

the following standard:

BS EN 62471:2008 The photobiological

(IEC 62471:2006) safety of lamps and lamp

systems.

Renishaw recommends that you do not stare at or

look directly into any LED device, irrespective of

its risk classification.

Page 12

OSI/OSI-D with OMM-2C installation guide

1.6

Before you begin

This page is intentionally left blank.

Page 13

2.1

Introduction

CNC machine tools using Renishaw spindle

probes with optical signal transmission for

workpiece inspection, or tool setters with optical

signal transmission, require an interface system

to convert the signals from the probe into

voltage-free solid state relay (SSR) outputs for

transmission to the CNC machine controller.

Typically installed within the CNC machine

controller’s cabinet and located away from

sources of interference such as transformers and

motor controls, the OSI can draw its power from

the machine’s nominal 12 Vdc to 30 Vdc supply.

The OSI has an input voltage range of 12 Vdc to

30 Vdc. The supply is protected by a 1.1 A selfresetting fuse (the current, when connected to

an OMM-2C, is either 400mA max. @ 12 V or

200 mA max. @ 24 V with tandem OMM-2C). To

reset the fuse, remove the power then identify and

rectify the cause of the fault.

The OSI can be used with either a single or

tandem OMM-2C configuration, housed within

the machining environment. The OMM-2C is

an optical receiver designed for fitment in the

machine spindle. It transmits control signals to the

spindle probe or tool setter, and receives probe

data signals for onward transmission to the OSI

and CNC controller. Power is supplied from the

OSI interface. Visual indication of system status is

provided via the LEDs located on the OMM-2C.

The OSI with OMM-2C system operates using

a ‘modulated’ optical transmission mode and is

compatible with machine probes that also operate

in ‘modulated’ mode.

When in operation, the OMM-2C displays its

present status via three multi-coloured LEDs

located behind the front window (see “OMM-2C

visual dignostics – system status LEDs” on page

2.12).

OSI/OSI-D with OMM-2C basics

OSI-D interface

The OSI-D interface is a variant of the standard

OSI interface, and has been designed for easy

installation to CNC machine controllers using a

15-way HD D type connector for probe input.

The OSI-D interface shares all functionality

and wiring connections with the standard OSI

interface, the only difference being the OMM-2C

connector (A).

NOTE: Throughout this installation guide, the term

OSI and any OSI images refers to both OSI or

OSI-D, unless otherwise specied.

Page 14

OSI/OSI-D with OMM-2C installation guide

2.2

OMM-2C basics

OSI/OSI-D inputs

There are three inputs:

• Probe 1 start

• Probe 2 start

• Probe 3 start

Switch SW2 can be configured to accept either

a pulsed output or level output from the machine

control.

Probe 1 start

Level 8 V to 30 V (4 mA @ 15 V, 7 mA @ 24 V)

When the input is active, the probe is

switched on.

Pulsed 8 V to 30 V (4 mA @ 15 V, 7 mA @ 24 V)

The probe toggles between being

switched on and off. The minimum pulse

width is 10ms.

Probe 2 and probe 3 start

Level 10 V to 30 V (10 mA @ 24 V)

When the input is active, the probe is

switched on.

Pulsed 10 V to 30 V (10 mA @ 24 V)

The probe toggles between being

switched on and off. The minimum pulse

width is 10ms.

The OSI uses level and pulsed machine inputs to

define the active probe. When the respective input

is active, the probe is switched on.

If all inputs are simultaneously active, the system

will default to error.

OSI/OSI-D outputs

There are four outputs:

• Probe status 1 (SSR)

• Probe status 2 (SSR)

• Error (SSR)

• Low battery (SSR)

All outputs can be inverted by using switch SW1,

(see “Switch SW1 output conguration” on page

2.5).

Probe status 1, Error, Low battery (SSR):

• ‘On’ resistance = 50 W max.

• Load voltage = 40 V max.

• Load current = 100 mA max.

Switching times (with 10 mA load)

• Open to closed = 100 µs max.

• Closed to open = 25 µs max.

Both probe status outputs indicate the status

of the selected probe (only one probe can be

selected at a time). They are both individually

configurable.

The OMM-2C LEDs will start flashing red when an

output overload has occurred. Probe status output

will be triggered (SSR open). If this occurs, turn

off the power supply and remove the source of the

problem. Turning on the power supply will reset

the OSI.

CAUTIONS:

Power supply voltage

Do not exceed 30 V between the following:

• the 0 V and the screen wire;

• the 12 V to 30 V supply wire and screen wire;

• the 12 V to 30 V supply wire and 0V wires.

This could result in permanent damage to the

OSI, OMM-2C and/or the power supply.

The use of in-line fuses at the machine cabinet

end is recommended to provide protection for the

OSI, OMM-2C and cable.

Screen connection

A good connection must be made to the machine

ground (‘star point’).

Output

Ensure the output from the OSI does not exceed

the specied current ratings.

Page 15

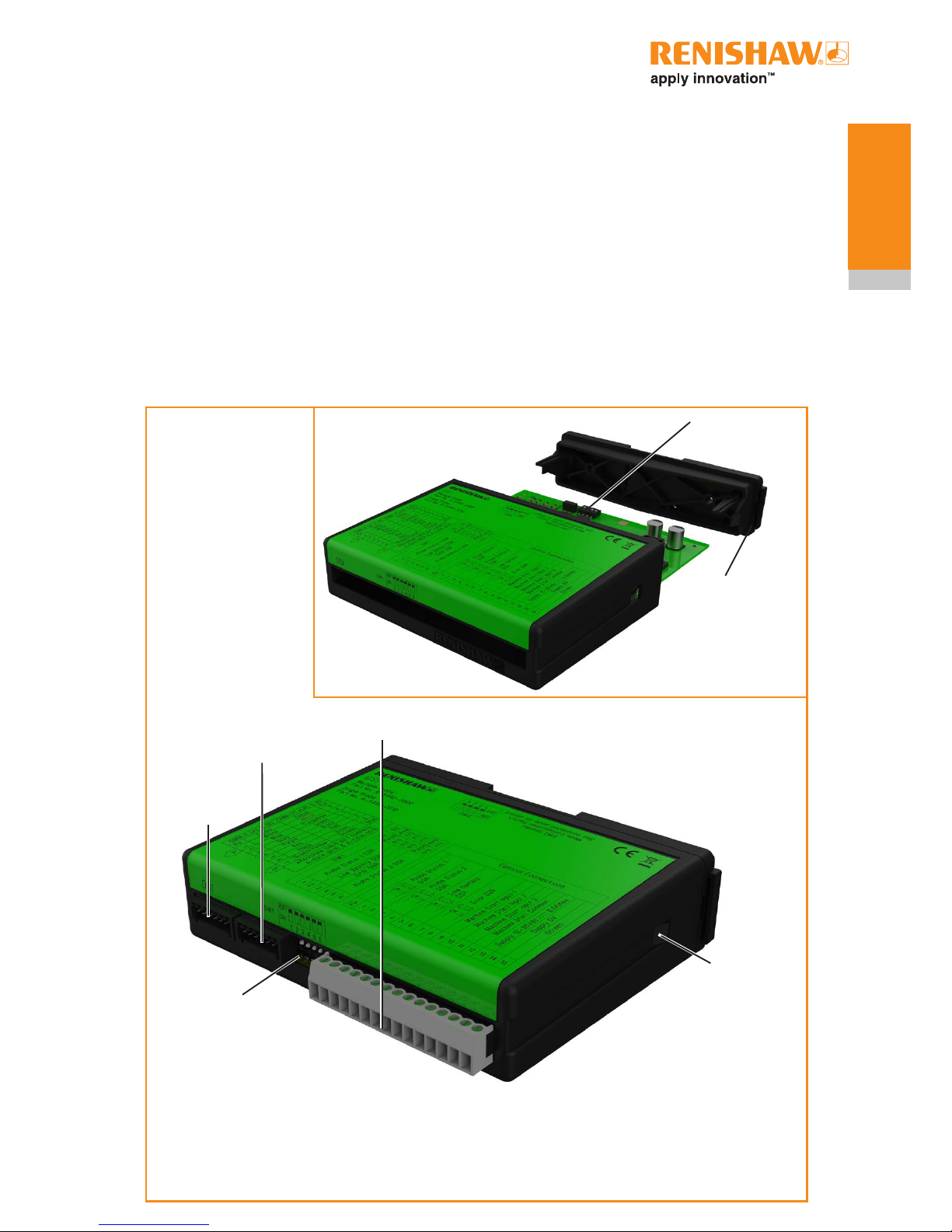

OSI components

The following components are housed within

the front face of the OSI (as shown in the figure

below):

• OMM-2C (A) connector (7-way);

• OMM-2C (B) connector (7-way);

• Control connector block (15-way);

• SSR configuration switch SW1.

OMM-2C (A)

connector

(7-way)

Control connector

block (15-way)

OMM-2C (B)

connector

(7-way)

SSR configuration

switch SW1

Cover tab –

depress to

remove cover

The following components are housed within the

body of the OSI:

• Mode configuration switch SW2.

Access to switch SW1 and switch SW2 is required

during installation only.

Mode configuration

switch SW2

Removable cover

(used to access SW2)

2.3

OMM-2C basics

Page 16

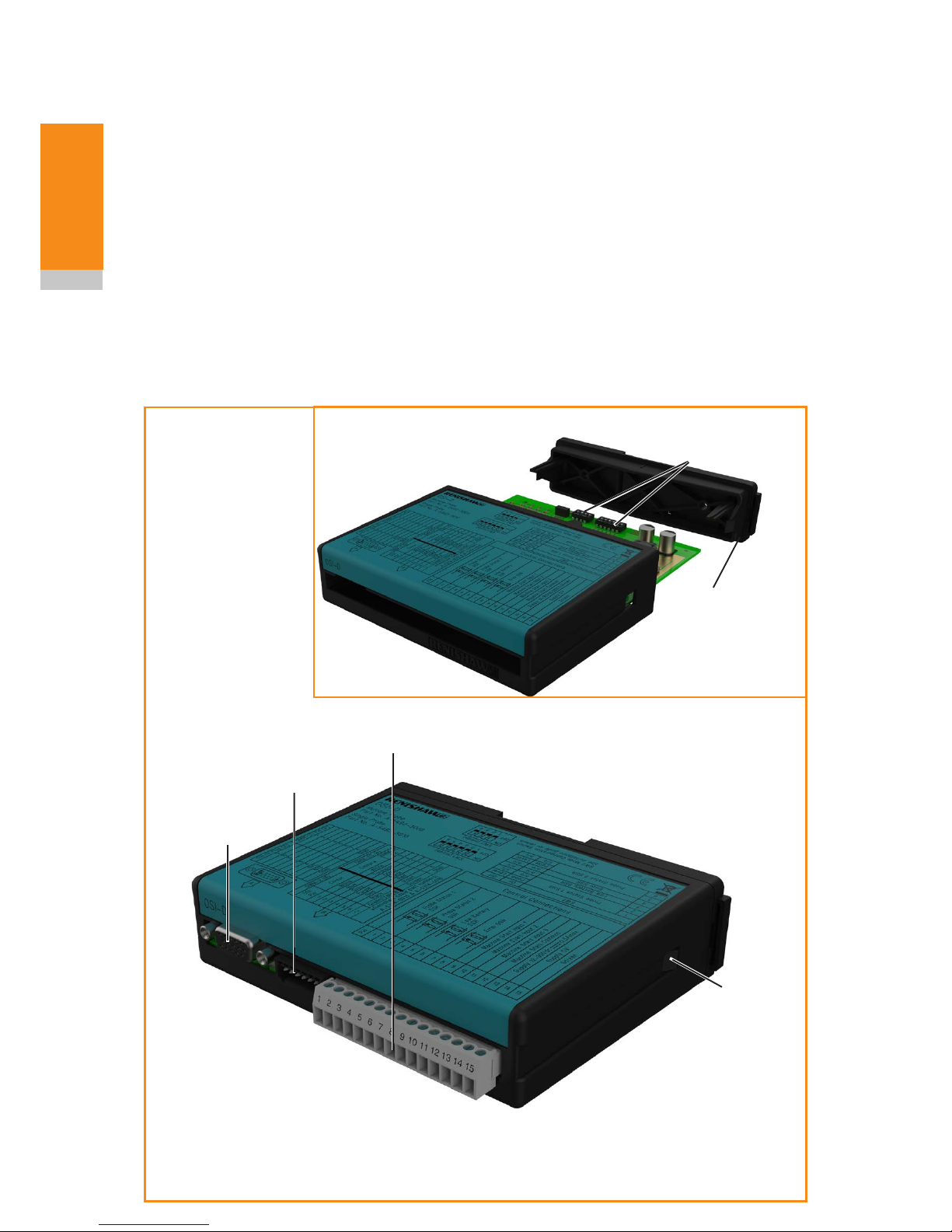

OSI-D components

The following components are housed within the

front face of the OSI-D (as shown in the figure

below):

• OMM-2C (A) connector (15-way HD D type);

• OMM-2C (B) connector (7-way);

• Control connector block (15-way);

OMM-2C (A)

connector

(15-way HD D type)

Control connector

block (15-way)

OMM-2C (B)

connector

(7-way)

Cover tab –

depress to

remove cover

The following components are housed within the

body of the OSI-D:

• SSR configuration switch SW1.

• Mode configuration switch SW2.

Access to switch SW1 and switch SW2 is required

during installation only.

Mode configuration

switches SW1 and SW2

Removable cover

(used to access SW1

and SW2)

OSI/OSI-D with OMM-2C installation guide

2.4

OMM-2C basics

Page 17

OMM-2C (A) connector (7-way/15-way)

OSI

This is a seven-pin connector and is designed to

connect to the Renishaw OMM-2C.

OSI-D

This is a fifteen-pin D type connector and is

designed to connect to the Renishaw OMM-2C.

OMM-2C (B) connector (7-way)

This is a seven-pin connector and is designed to

connect to the Renishaw OMM-2C.

Control connector block (15-way)

This is a fifteen-pin connector and is designed to

connect the OSI to the CNC machine controller

and appropriate power supply as follows:

Pins 1 and 2 are used to connect the ‘Probe

status 1 SSR’ function.

Pins 3 and 4 are used to connect the ‘Probe

status 2 SSR’ function.

Pins 5 and 6 are used to connect the ‘Low battery

SSR’ function.

Pins 7 and 8 are used to connect the ‘Error SSR’

function.

Pins 9 to 12 are used to supply a start signal to

the probe:

• pin 9 is used to transmit a ‘Machine

startinput1’ signal;

• pin 10 is used to transmit a ‘Machine

startinput2’ signal;

• pin 11 is used to transmit a ‘Machine

startinput3’ signal;

• pin 12 is used as ‘Machine start common’.

Pins 13 to 15 are used to supply power and

screen earth to the interface.

2.5

OMM-2C basics

Page 18

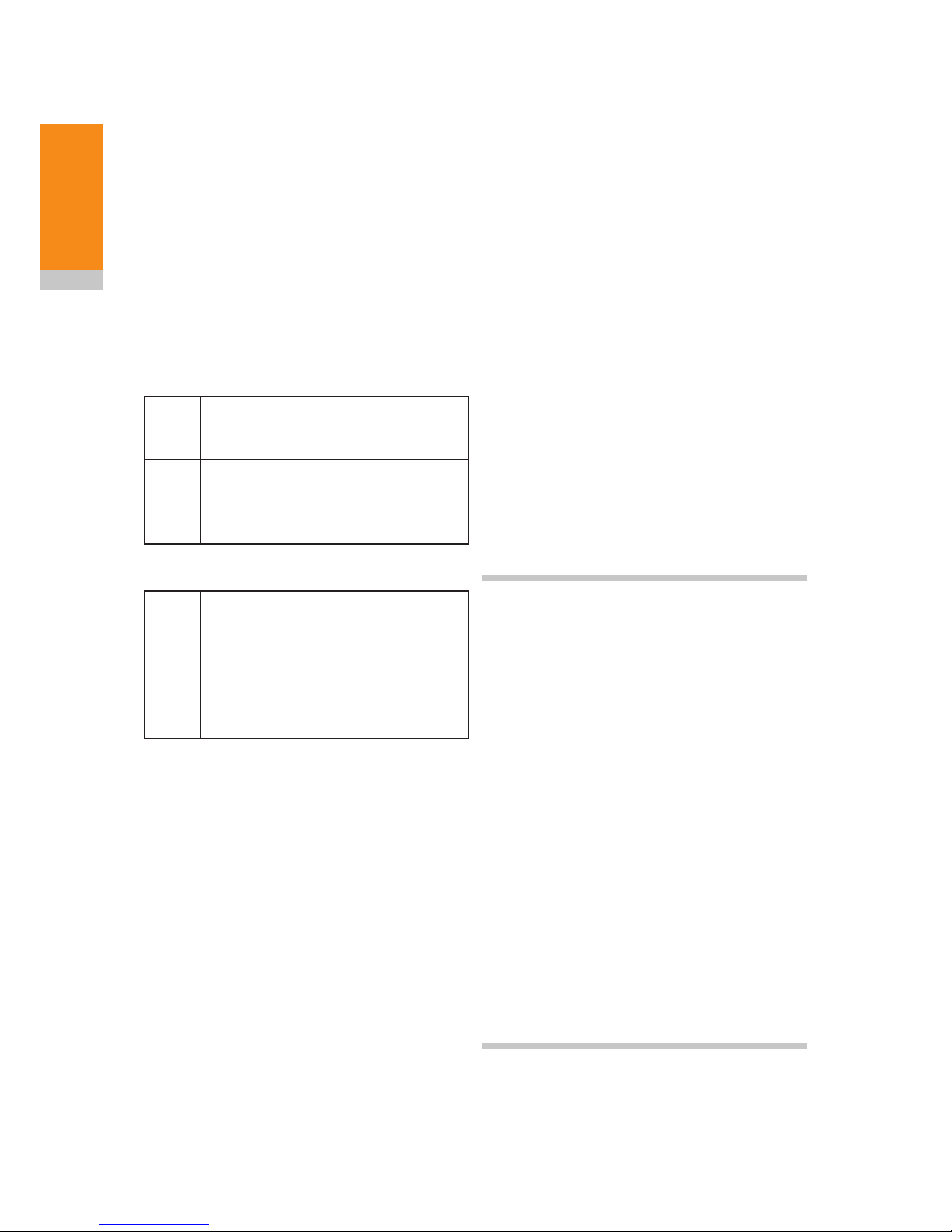

Switch SW1 output conguration

Switch SW1 enables the user to configure the

probe system SSR outputs.

Pin SW1 ON OFF

1

Probe status 1 SSR

Pulse Level

2 Normally open Normally closed

3 Low battery SSR Normally open Normally closed

4 Error SSR Normally open Normally closed

5

Probe status 2 SSR

Pulse Level

6 Normally open Normally closed

Factory switch settings shown

are for A-5492-2000

(multiple probe mode)

CAUTION: Take electrostatic discharge (ESD) precautions when handling the PCB.

OSI

Factory switch settings shown

are for A-5492-3000

(multiple probe mode)

OSI-D

OSI/OSI-D with OMM-2C installation guide

2.6

OMM-2C basics

Page 19

Switch SW2 output conguration

Switch SW2 enables the user to configure the OSI

to be used in either single probe mode or multiple

probe mode.

Factory switch settings

shown are for A-5492-2000

(multiple probe mode)

Mode

Switch settings

POLE

Visual

representation

1 2 3 4

Single probe mode, Auto Start off, pulsed machine

M-code.

(Factory setting for A-5492-2010 and A-5492-3010)

ON OFF OFF OFF

Single probe mode, Auto Start off, level machine M-code. ON OFF OFF ON

Single probe mode, Auto Start on. ON ON OFF OFF

Multiple probe mode, two machine M-codes, short time

delay of 10 ms.

OFF ON OFF OFF

Multiple probe mode, two machine M-codes, medium

time delay of 50 ms.

OFF ON ON OFF

Multiple probe mode, two machine M-codes, long time

delay of 100 ms.

OFF ON OFF ON

Multiple probe mode, three machine M-codes, level start.

(Factory setting for A-5492-2000 and A-5492-3000)

OFF OFF ON ON

Multiple probe mode, three machine M-codes, common

start, pulsed machine output.

OFF OFF OFF OFF

Multiple probe mode, three machine M-codes, common

start, level machine output.

OFF OFF OFF ON

OSI

Factory switch settings shown

are for A-5492-3000

(multiple probe mode)

OSI-D

2.7

OMM-2C basics

Page 20

OSI/OSI-D input mode

congurations

Single probe mode

Single probe mode enables one Renishaw probe

to be operated. The probe should be configured as

Probe 1.

Single probe mode provides the option for Auto

Start to be selected. With Auto Start on, the

system will send a start signal once every second

if the probe is off and does not require a CNC

machine output.

Auto Start should only be used when no output

from the machine control is available. If Auto

Start is selected, care should be taken to ensure

system signals are not being received from

probing systems on other machines.

If Auto Start is off, the interface will respond to an

output from the machine controller. Switch SW2

can be configured to accept either a pulsed output

or a level output.

In pulsed mode the interface will react to a pulse

width of 10 ms minimum from a leading edge

signal.

In level mode the probe will be off when the level

is low, and on when the level is high.

Multiple probe mode

Multiple probe mode enables two or three

Renishaw probes to be operated. This can be

achieved by using either two or three outputs from

the machine controller.

If two machine outputs (for three probes) are

used, a coded switch-on technique is used to

switch on / switch off the selected probe. When

using this technique, it is necessary for the two

machine outputs to be sent in short succession

by the controller. To allow for a delay between the

machine outputs, three user-selectable options

are provided:

• a short time delay of 10 ms;

• a medium time delay of 50 ms;

• a long time delay of 100 ms.

If three machine outputs are used, the following

start configurations are available which provide

flexibility for interface integration.

Dedicated start (level mode)

In dedicated start, a machine start input is

required per probe that is configured for optical

switch-on.

Machine start

inputs

Probe selected

P1 P2 P3

None

¬

Probe 1 on

¬

Probe 2 on

¬

Probe 3 on

¬ Machine start input active. Any attempt to switch on more

than one probe simultaneously will result in an error

condition.

Common start (level mode)

In common start (level mode), machine start

inputs P2 and P3 are used to select the probe,

and machine start input P1 is used to start the

selected probe. All inputs are level.

Machine start inputs

P1, P2 and P3

Probe

selected

Probe

start

P1

Probe selection

inputs

P2 P3

¬

Probe 1

¬ ¬

Probe 2

¬ ¬

Probe 3

¬ Machine start input active.

When P1 is off, all probes are off.

When P1 is active, the selected probe will be on.

NOTE: Any change to the probe selection inputs

P2 and P3 whilst the probe is operating will result

in an error condition.

OSI/OSI-D with OMM-2C installation guide

2.8

OMM-2C basics

Page 21

Common start (pulsed mode)

In common start (pulsed mode), machine start

inputs P2 and P3 are level inputs used to select

the probe. Machine start input P1 is a pulsed input

used to start the selected probe.

Machine start inputs

P1, P2 and P3

Probe

selected

Probe

start

P1

Probe selection

inputsV

P2V P3V

Probe 1

¬

Probe 2

¬

Probe 3

Machine start input pulsed, so the selected probe will

change state.

V Probe selection inputs are level signals.

¬ Machine start input active.

NOTES:

OMP600, OMP400, OMP60, OMP40-2, OLP40

or OTS can be congured as Probe 1, Probe 2 or

Probe 3.

For more information, see your probe installation

guide or contact your local Renishaw ofce.

Switch-on / switch-off method

Single probe mode

In pulsed or level mode, the following switch-on /

switch-off methods may be used.

• Optical on / optical off

• Optical on / time off

• Spin on / spin off

• Spin on / time off

• Shank switch on / shank switch off

For Auto Start, only the following switch-on /

switch-off method may be used.

• Optical on / time off

Multiple probe mode

In multiple probe mode, only the following switchon / switch-off method may be used.

• Optical on / optical off

Start-up times

For information on probe start-up times, see

“Multiple probe mode timing diagrams” on page

2.9.

The switch-off time is 0 seconds.

When changing from one selected probe to

another, allow 1 second between the cancelling

of one machine start input (machine output) and

raising of the other start input.

Synchronisation recovery

Under abnormal operating situations, when used

in multiple probe mode, the system may lose

synchronisation between the receiver and the

probes. An internal synchronisation recovery

will be initiated when the next machine input is

received.

The maximum time for system recovery from

an abnormal operating situation is 7.5 seconds.

Such a time delay could cause a machine alarm if

controllers require ready signals within less than

5.5 seconds.

2.9

OMM-2C basics

Page 22

Two machine outputs (for three probes)

Three machine outputs (Dedicated start)

Three machine outputs (Common start / pulsed mode )

Three machine outputs (Common start / level mode)

Probe start-up time = 410 ms max. for kinematic probes and

1 s max. + delay (10, 50, 100 ms) for strain gauge probes.

Probe start-up time = 410 ms max. for kinematic probes and

1 s max. for strain gauge probes.

Probe start-up time = 410 ms max. for kinematic probes and

1 s max. for strain gauge probes.

Probe start-up time = 410 ms max. for kinematic probes and

1 s max. for strain gauge probes.

Machine start

input 1

Machine start

input 1

Machine start

input 1

Machine start

input 1

Machine start

input 2

Machine start

input 2

Machine start

input 2

Machine start

input 2

Machine start

input 3

Machine start

input 3

Machine start

input 3

Start

Stop

Stop

10, 50, 100 ms

delay options

Probe 1

Probe 1

Probe 1

Probe 1

Probe 2

Probe 2

Probe 2

Probe 2

Probe 3

Probe 3

Probe 3

Probe 3

Multiple probe mode timing diagrams

Start

Stop

Start

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

Start

Stop

10, 50, 100 ms

delay options

OSI/OSI-D with OMM-2C installation guide

2.10

OMM-2C basics

Page 23

Signal delays

Transmission delay From probe trigger to output change of state = 2.5 ms max.

OSI/OSI-D output waveforms

NOTE: Pulsed outputs are 40 ms ±1 ms duration

SSR closed

SSR open

Probe

OSI

SSR

output

SSR closed

SSR open

Normally

open

Probe status

1 & 2 (level)

Probe status

1 & 2 (pulsed)

Normally

open

Probe

switch

on

Seated

Stand-

by

Probe

trigger

Triggered

Probe

reseat

Seated Error

e.g.

low signal

Stand-by

Low

battery

Probe

switch

on

Normally

open

Low

battery

Normally

closed

Error

SSR closed

SSR open

SSR closed

SSR open

2.11

OMM-2C basics

Page 24

OSI/OSI-D dimensions

OSI/OSI-D specification

110 (4.33)

134 (5.28)

35 (1.38)

Dimensions given in mm (in)

Principal application The OSI processes signals from RENGAGE™ or standard probes

via single or tandem OMM-2Cs or OMM-2s and converts them into

machine outputs, which are then transmitted to the CNC control. The

system allows up to three probes to be used with one interface.

Transmission type Infrared optical transmission (modulated)

Probes per system Up to three

Supply voltage 12 Vdc to 30 Vdc

Supply current 200 mA max. @ 24 V with tandem OMM-2C

Configurable M-code input Pulsed or level

Output signals

Probe Status 1, Probe Status 2, Low Battery, Error

Voltage-free solid-state relay (SSR) outputs, congurable as normally

open or normally closed.

Input/output protection Supply protected by a 1.1 A resettable fuse.

Outputs protected by overcurrent protection circuit.

Environment

(as defined in

BS EN 61010-1:2001)

IP rating IP20 (BS 5490, EN/IEC 60529)

Storage temperature

−10 °C to +70 °C (14 °F to 158 °F)

Operating temperature +5°C to +55°C (+41°F to +131°F)

OSI/OSI-D with OMM-2C installation guide

2.12

OMM-2C basics

Page 25

2.13

OMM-2C basics

OMM-2C visual diagnostics –

system status LEDs

A visual indication of system status is provided by

three LEDs. Indication is provided for:

• START SIGNAL;

• ACTIVE SYSTEM;

• ERROR and STANDBY;

• OVERCURRENT;

• CORRUPTED SIGNAL.

Status LEDs

Page 26

OSI/OSI-D with OMM-2C installation guide

2.14

OMM-2C basics

START SIGNAL (blue, yellow, violet)

This will flash when a machine control start signal

is commanded; blue denotes Probe 1 start, yellow

denotes Probe 2 start and violet denotes Probe 3

start.

A successful probe start will cause the ‘ACTIVE

SYSTEM’ LED to become lit and a failed start will

result in an ‘ERROR’ being displayed.

ACTIVE SYSTEM (blue, yellow, violet)

In single probe mode the system will be constantly

lit blue to show that the input is active.

In multiple probe mode the system will be

constantly lit blue to denote Probe 1 is active,

yellow to denote Probe 2 is active and violet to

denote Probe 3 is active.

If any ambiguous start information is received, the

system will flash repeatedly (blue – yellow – violet

– cyan) in sequence until the start input is cleared.

ERROR and STANDBY (red)

When lit constant red it indicates a transmission

error condition, such as optical beam obstructed /

probe out of optical range / probe switched off

(standby) / dead battery.

OVERCURRENT (ashing red)

The system will start flashing red when an output

overload has occurred. All outputs will be switched

off.

If this occurs, turn off the power and remove

the source of the problem. Turning on the power

supply will reset the system.

CORRUPTED SIGNAL (white)

If the system displays a constant white LED, then

either a second modulated probe signal has been

received or the probe trigger instant has been

delayed due to interference or a weak probe

signal.

NOTE: In single probe mode the constant white

error condition resulting from the loss of a good

probe signal will persist until the machine start is

activated or 1 hour has elapsed. In multiple probe

mode the indication will persist until the active

system input (Probe1, Probe 2 or Probe 3) is

deactivated.

Command LED display

Error / standby

Operating Probe 1

Probe 2

Probe 3

Overcurrent protection

Failed start (1 second

ash of attempted

probe start)

Probe 1

Probe 2

Probe 3

Invalid start signal

Interference or second probe received

Single probe mode

with Auto Start

Auto Start mode only standby

Auto Start mode second probe signal received

Key to the symbols

LED short flash

LED solid on

Page 27

OMM-2C specification

Principal application The OMM-2C transmits control signals to the probe and receives probe

data signals for onward transmission to the OSI and CNC control.

Transmission type Infrared optical transmission (modulated)

Probes per system Up to three

Compatible probes OMP40-2, OMP40M, OLP40, OMP60, OMP60M, OMP400, OMP600 and

OTS

Operating range Up to 3 m (9.8 ft)

Weight (excluding

cable)

with airblast 80 g (2.82 oz)

without airblast 80 g (2.82 oz)

Cable

(not supplied) Specification Ø4.75 mm (0.19 in), 12 core screened cable

each core 7 × 0.1 mm

Length 8 m (26.2 ft), 15 m (49.2 ft)

Mounting Specifically designed for mounting in the machine spindle.

Diagnostic LEDs Start, error, active system and signal condition.

Pneumatic supply Ø3 mm (0.12 in) pneumatic fitting, 9 bar (130.5 psi) max. The air supply to

the OMM-2C must conform to ISO 8573-1: Class 1.7.2.

Environment IP rating IPX6 (EN/IEC 60529) [for product]

IPX8 (EN/IEC 60529) [for glass window]

IK rating IK04 (EN/IEC 62262) [for glass window]

Storage temperature

−25 °C to +70 °C (−13 °F to +158 °F)

Operating temperature +5°C to +55°C (+41°F to +131°F)

2.15

OMM-2C basics

OMM-2C dimensions

Dimensions mm (in)

M4 × 11.0 (0.43) MIN

Ø20.0 (0.79)

Ø18.7 (0.74)

Bore diameter

Ø18.02 (0.709)

Ø18.00 (0.708)

30.0 (1.18)

30.0 (1.18)

4.8 (0.19)

14.0 (0.55)

11.0 (0.43)

Ø17.7 (0.69)

66.0 (2.60)

22.0

(0.87)

2.8 (0.11) MAX

30°

15°

Ra 1.6 (64)

10.0 (0.39)

Installation

detail

Binder connector

(series 702)

09-0427-90-08

× 6.0 (0.24) MIN DEPTH

Page 28

OMM-2C

OSI

OMP

CNC machine control

OSI/OSI-D with OMM-2C installation guide

2.16

OMM-2C basics

OSI/OSI-D with OMM-2C system

used in single probe mode

The system can be used with any Renishaw

OMP, OLP or OTS probe system. The following

descriptions use OMP60 as an example.

In single probe mode, the system will interface a

single Renishaw machine probe with the machine

controller. It is possible for either a single OMM-2C

or tandem OMM-2C/OMM-2 to be connected to

the OSI. The selected configuration will depend on

the machine application.

When the OMM-2C is used in tandem, both

receivers will simultaneously provide an indication

of system status. Tandem OMM-2C can be used

on twin-spindle machines to maintain probe

communications when a probe is in the second

spindle. Tandem OMM-2C and OMM-2 allows

for uninterrupted probe communications where

line-of-sight issues become apparent when only a

single receiver is used.

The illustration below shows a typical OSI with

OMM-2C system used in single probe mode.

Alternatively, the system can be used to interface

a single OTS (optical tool setter) instead of the

OMP (optical machine probe) shown.

Page 29

OSI/OSI-D with OMM-2C system

used in multiple probe mode

In multiple probe mode, the system will

sequentially interface up to three separate

Renishaw optical machine probes with the

machine controller. It is possible to have either a

single OMM-2C or a tandem OMM-2C or OMM-2

configuration to best suit the application.

Application of the system in multiple probe mode

is suited to many machine applications. Typical

examples are as follows:

1 × OMP with 2 × OTS (optical tool setter)

(illustrated below).

This arrangement is suitable for a machine

application that has a partitioned machining area

with an OTS positioned in each area. An OMP

in the spindle is used in both areas. The OMP is

assigned as Probe 1 and the 2 × OTS assigned

as Probe 2 and Probe 3 .

2 × OMP with 1 × OTS

This arrangement is suitable for a machine

application that requires two different stylus

configurations. The 2 × OMP are assigned as

Probe 1 and Probe 2 and the OTS is assigned as

Probe 3.

3 × OTS

This arrangement is suitable for a pallet loaded

machine application with an OTS installed on

three pallets, each communicating with an

OMM-2C in the machine. The 3 × OTS are

assigned as Probe 1, Probe 2 and Probe 3.

3 × OMP

This arrangement is suitable for a machine

application which requires three different stylus

or probe configurations; for example, 2 × strain

gauge probes and 1 × modular probe. For this

configuration to be compatible, one probe should

have Probe 3 functionality.

OSI

OTS

OTS

OMP

OMM-2C

2.17

OMM-2C basics

Page 30

OSI/OSI-D with OMM-2C installation guide

2.18

OMM-2C basics

This page is intentionally left blank.

Page 31

3.1

System installation

Typical OMM-2C system installation

Introduction

WARNING: Ensure the machine tool is in a safe

condition and power is removed before removing

covers. Only qualied persons should adjust

switches.

The OMM-2C should be mounted as near to the

machine spindle as possible (as shown below).

When mounting the OMM-2C, it is important that

the sealing ring forms a tight seal around the rim

of the bore into which the body of the OMM-2C is

to be located.

CAUTION: Make sure the sealing ring and

air tting screw (if applicable) are clean and

lubricated prior to being mounted in the machine

spindle.

NOTE: Do not overtighten the mounting screw.

Maximum torque is 1.5 Nm (1.11 lbf.ft.).

Single conguration

CNC machining

centre spindle

Cable

CNC

machine

control

OMM-2C

(optical module

machine)

OMP

Stylus

Workpiece

Serial No. V68739

OSI

OTS tool setting probe

Page 32

OSI

OSI-D

For tandem installations

Cable Cable

Cable

OMM-2 (B)

OMM-2C (B)

OMM-2C (A)

OSI-D

To CNC machine control

OSI/OSI-D with OMM-2C installation guide

3.2

System

installation

Tandem conguration

For tandem installations

Cable Cable

Cable

OMM-2 (B)

OMM-2C (B)

OMM-2C (A)

OSI

To CNC machine control

Page 33

3.3

System

installation

OMM-2C application

OSI

A single, tandem or combination of OMM-2C and

OMM-2 configuration can be connected to the

OSI. Each OMM-2 / OMM-2C is connected to the

interface by a 7-way connector block (as shown in

the wiring diagram on page 3.8).

OSI-D

One OMM-2C is connected to connector ‘A’ of the

interface using a 15-way HD D type connector.

The second OMM-2C is connected to connector

‘B’ of the interface using a 7-way connector block

(as shown in the wiring diagram on page 3.8).

A single OMM-2 can be connected to the OSI-D

using a 7-way connector block (as shown in the

wiring diagram on page 3.8).

When a tandem OMM-2 / OMM-2C configuration

is used, there will be a simultaneous indication

of system status on both receivers (for OMM-2C,

see Chapter 2, “OMM-2C basics”, or for OMM-2

see the OSI with OMM-2 multiple optical probe

interface system installation guide (Renishaw part

no. H-5492-8504).

Tandem OMM-2C can be used in machines with

two separate spindles. It is not necessary to

shield one receiver from the other, and operating

envelopes can overlap.

OMM-2C cable

Cable termination

Suitable ferrules should be crimped onto each

cable wire for a more positive connection at the

terminal box.

Standard cable variants

The OMM-2C standard polyurethane cables are

supplied in 8 m (26 ft) and 15 m (49 ft) lengths.

Please contact Renishaw for other cable lengths if

required.

NOTE: The maximum permissible length of cable

is 30 m (98 ft).

Cable specication

Ø4.75 mm (0.19 in), 12 core, screened cable,

each core consisting of 7 × 0.1 mm wires.

Cable sealing

Coolant and dirt are prevented from entering the

OMM-2C by the cable connector. The OMM-2C

cable can be protected against physical damage

by fitting flexible conduit if required.

NOTE: Do not overtighten cable connector.

Maximum torque is 2 Nm (1.48 lbf.ft.).

Page 34

M4 (× 2)

Standard DIN rail mounting

Alternative mounting

79.75

(3.14)

NOTE: Lift spring end plate to attach OSI to DIN rail.

OSI/OSI-D with OMM-2C installation guide

3.4

System

installation

Mounting the OSI/OSI-D to a DIN

rail

Dimensions mm (in)

Page 35

Range m (ft)

Switch on / switch off

Operating – standard power mode

Operating – low power mode

Typical plot at 20 °C (68 °F)

360° transmission around

probe axis in metres (feet)

OMP600 or

OMP60

75°

60°

45°

30°

15°

0°

15°

30°

45°

60°

75°

2.5 (8.2)

2.0 (6.5)

1.5 (4.9)

1.0 (3.3)

0.5 (1.6)

75°

60°

45°

30°

15°

0°

15°

30°

45°

60°

OMM-2C

75°

Optical centre line

3.0 (9.8)

3.5

System

installation

Performance envelope of

OMM-2C with OMP600 or OMP60

Reflective surfaces within the machine cabinet

may increase the signal transmission range.

Coolant residue accumulating on the windows of

the OMM-2C and OMP will have a detrimental

effect on transmission performance. Wipe the

windows clean as often as necessary to maintain

unrestricted transmission.

For best system performance, ensure the

OMM-2C is mounted in a position which is not

directly in front of a light source.

The probe and OMM-2C may deviate from the

optical centre line, provided opposing light cones

always overlap, with transmitters and receivers in

the other’s field of view (eye-to-eye).

In multiple probe mode applications, OMP600 or

OMP60 may be configured as Probe 1, Probe 2 or

Probe 3.

CAUTION: If two systems are operating in close

proximity, take care to ensure that the signals

transmitted from the OMP on one machine are not

received by the OMM-2C on another machine and

vice versa.

2.5 (8.2)

2.0 (6.5)

1.5 (4.9)

1.0 (3.3)

0.5 (1.6)

3.0 (9.8)

Page 36

Typical plot at 20 °C (68 °F)

360° transmission around

probe axis in metres (feet)

Range m (ft)

Switch on / switch off

Operating – standard power mode

Operating – low power mode

Typical plot at 20 °C (68 °F)

360° transmission around

probe axis in metres (feet)

OMP400,

OMP40-2

or OLP40

75°

60°

45°

30°

15°

0°

15°

30°

45°

60°

75°

75°

60°

45°

30°

15°

0°

15°

30°

45°

60°

OMM-2C

75°

Optical centre line

2.5 (8.2)

2.0 (6.5)

1.5 (4.9)

1.0 (3.3)

0.5 (1.6)

OSI/OSI-D with OMM-2C installation guide

3.6

System

installation

Performance envelope of

OMM-2C with OMP400, OMP40-2

or OLP40

Reflective surfaces within the machine cabinet

may increase the signal transmission range.

Coolant residue accumulating on the windows of

the OMM-2C and OMP will have a detrimental

effect on transmission performance. Wipe the

windows clean as often as necessary to maintain

unrestricted transmission.

For best system performance, ensure the

OMM-2C is mounted in a position which is not

directly in front of a light source.

The probe and OMM-2C may deviate from the

optical centre line, provided opposing light cones

always overlap, with transmitters and receivers in

the other’s field of view (eye-to-eye).

In multiple probe mode applications, OMP400

may be configured as Probe 1 or Probe 2 and

OMP40 or OLP40 may be configured as Probe 1,

Probe 2 or Probe 3.

CAUTION: If two systems are operating in close

proximity, take care to ensure that the signals

transmitted from the OMP on one machine are not

received by the OMM-2C on another machine and

vice versa.

2.5 (8.2)

2.0 (6.5)

1.5 (4.9)

1.0 (3.3)

0.5 (1.6)

Page 37

Range m (ft)

Switch on / switch off

Operating – standard power mode

Operating – low power mode

3.7

System

installation

Performance envelope of

OMM-2C with OTS

Reflective surfaces within the machine cabinet

may increase the signal transmission range.

Coolant residue accumulating on the windows

of the OMM-2C and OTS will have a detrimental

effect on transmission performance. Wipe the

windows clean as often as necessary to maintain

unrestricted transmission.

For best system performance, ensure the

OMM-2C is mounted in a position which is not

directly in front of a light source.

The probe system should be positioned so that

the signal transmission is maintained when the

OTS is positioned below the machine spindle.

The OTS and OMM-2C may deviate from the

optical centre line, provided opposing light cones

always overlap, with transmitters and receivers in

the other’s field of view (eye-to-eye).

In multiple probe mode applications, OTS may be

configured as Probe 1, Probe 2 or Probe 3.

CAUTION: If two systems are operating in close

proximity, take care to ensure that the signals

transmitted from the OTS on one machine are not

received by the OMM-2C on another machine and

vice versa.

Typical plot at 20° C (68° F)

Transmission around probe axis

in metres (feet)

OTS

75°

60°

45°

30°

15°

0°

15°

30°

45°

60°

75°

75°

60°

45°

30°

15°

0°

15°

30°

45°

60°

OMM-2C

75°

Optical centre line

2.5 (8.2)

2.0 (6.5)

1.5 (4.9)

1.0 (3.3)

0.5 (1.6)

2.5 (8.2)

2.0 (6.5)

1.5 (4.9)

1.0 (3.3)

0.5 (1.6)

Page 38

Wiring diagram (with output groupings shown)

White

Turquoise

Green

Black

Red

Violet

Screen

OMM-2C

(A)

OSI

OMM-2C

(B)

Probe Status 1 (SSR)

Probe Status 2 (SSR)

Low Battery (SSR)

Error (SSR)

CNC

machine

control

Powe r

supply

Machine star ground point

Machine start common

12 V to 30 V

+ 24 V

0 V

0 V

Power supply (12 V to 30 V)

Screen

1

2

3

4

5

6

7

White

Turquoise

Green

Black

Red

Violet

Screen

Machine start input 1 (Machine output)

Machine start input 2 (Machine output)

Machine start input 3 (Machine output)

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

OSI-D

OSI/OSI-D with OMM-2C installation guide

3.8

System

installation

CAUTIONS:

The power supply 0 V should be terminated at the machine ground (“star point”). If a negative supply is

used, then the negative output must be fused.

The dc supply to this equipment must be derived from a source which is approved to

IEC/BS/EN60950-1.

Renishaw cable part nos.:

A-5314-0015, 8 m (26 ft)

A-5314-0016, 15 m (49 ft)

OMM-2C OSI Colour

Pin 1 Pin 4 Black

Pin 2 Pin 5 Red

Pin 3 Pin 1 White

Pin 4 Pin 2 Turquoise

Pin 5 Pin 3 Green

Pin 6 Pin 6 Violet

Pin 7 Not used Grey

Pin 8 Not used Not used

Shell Pin 7 Screen

View A

View A

View A

OMM-2C OSI-D

Pin 1 Pin 9

Pin 2 Pin 10

Pin 3 Pin 6

Pin 4 Pin 2

Pin 5 Pin 3

Pin 6 Pin 4

Pin 7 Not used

Pin 8 Not used

Shell Shell

Page 39

Integral airblast installation

(optional)

Integral airblast application

The OMM-2C is available with an integral optional

airblast facility. An air supply is connected to the

OMM-2C through the special mounting screw

and the air feed is internally routed to air nozzles

around the OMM-2C front window which assists

with keeping the optical window clear of swarf and

debris.

It is recommended that a switched air supply

is used prior to any probing routine and the air

supply to the OMM-2C is switched off after the

probing routine has finished.

Connecting and purging the air supply

CAUTIONS:

Do not connect the OMM-2C system to an oiled

air supply. Purge all piping prior to connection.

Safety glasses must be worn.

1. Locate a source of clean air that conforms to

ISO 8573-1: Air quality of class 5.9.4.

2. Connect a suitable pipe to the air supply.

3. Before connecting the pipe to the inlet of the

air regulator unit, briefly switch on the air

supply to clear out all debris from the pipe.

4. Connect one end of the Ø4 mm air pipe into

the air regulator unit.

5. Cut the Ø4 mm pipe to length, ensuring that

the length of the pipe is as short as possible

to minimise the drop in air pressure.

6. Temporarily tape over the free end of the pipe

to ensure that no coolant or debris is able to

enter it.

7. Push the free end of the air supply pipe

through the air pipe spring conduit.

8. Remove the tape from the end of the air pipe.

Before connecting the pipe to the inlet of the

OMM-2C unit, briefly switch on the air supply

to clear out any debris from the pipe.

9. Connect the free end of the pipe to the

OMM-2C unit using a 4 mm to 3 mm air

fitting.

NOTE: The integral airblast facility should not be

used as a replacement for routine maintenance

checks or relied on to ensure the optical window is

kept clean of debris and swarf.

3.9

System

installation

OMM-2C

unit

Purge the air supply to dislodge

debris from the pipework

prior to connection, as small

particles may block the air

nozzle.

Air outlet

Air regulator unit

Air supply

Æ

Page 40

This page is intentionally left blank.

OSI/OSI-D with OMM-2C installation guide

3.10

System

installation

Page 41

4.1

Maintenance

Maintenance

You may undertake the maintenance routines

described in these instructions.

Further dismantling and repair of Renishaw

equipment is a highly specialised operation,

which must be carried out at authorised Renishaw

Service Centres.

Equipment requiring repair, overhaul or attention

under warranty should be returned to your

supplier.

Cleaning the interface

Wipe the window of the interface with a clean

cloth to remove machining residue. This should

be done on a regular basis to maintain optimum

transmission.

CAUTION: The OMM-2C has a glass window.

Handle with care if broken to avoid injury.

Page 42

Removing the OMM-2C

WARNING: Ensure the machine tool is in a safe

condition and power is removed before removing

covers. Only qualied persons should work on a

machine tool.

In the event that you need to remove the

OMM-2C, the receiver incorporates a jacking

thread to aid removal.

1. Purge machine air supply (if air blast fitted)

and remove power from the OSI.

2. Clean the OMM-2C prior to disassembly to

ensure no debris enters the unit.

3. Disconnect air pipe from the OMM-2C and

remove cap from both ends (if applicable)

4. Unscrew cable connector from rear of the

OMM-2C and secure.

5. Carefully remove mounting screw/air feed

screw from OMM-2C ensuring ‘O’ rings are

kept clean.

6. Insert an M5 screw (not supplied) into the

threaded mounting hole.

7. Tighten the screw to lift the OMM-2C out of

the machine spindle bore. When clear of the

spindle, remove the screw completely and

refit the original mounting screw / airscrew to

prevent debris entering air chamber.

Maintenance – air regulator unit

The procedures described in this section apply

only to the air regulator system (A-2253-5120)

that is available from Renishaw plc.

Checking the liquid level

Regularly check the level of the accumulated

liquid in each of the filter bowls. It is important that

the level is kept below the filter element.

Draining the liquid

Drain the liquid that has accumulated in the filter

bowls as follows:

1. Make a note of the air supply pressure, then

switch off the air supply. A quantity of liquid

will drain from the bowls.

2. Switch on the air supply and set the pressure

to the value noted in step 1.

3. Repeat steps 1 and 2 until the bowls are

empty.

OSI/OSI-D with OMM-2C installation guide

4.2

Maintenance

Air pressure regulator

filter bowl

Air pressure

adjusting knob

Oil removal

filter bowl

OMM-2C

Mounting

screw

M5 screw

(not supplied)

Page 43

Removing and retting lter elements

Regularly inspect the filter element in each filter

bowl. They should be replaced when dirty or wet

and at least once each year. For each filter bowl,

do this as follows:

1. Make a note of the air supply pressure, then

switch off the air supply.

2. Unscrew the filter bowl by hand (see the

figure on page 4-4).

3. Remove the O-ring from the recess in the

filter bowl. Discard the O-ring.

4. Unscrew and remove the filter element.

5. Fit the replacement filter and, where

applicable, the O-ring. These are shown in

dotted box A in the figure on page 4.4.

6. Fit a new O-ring into the recess in the filter

bowl.

7. Refit the filter bowl and screw hand tight.

8. Switch on the air supply and set the pressure

to the value noted in step 1.

Replacing other service kit components

1. Make a note of the air supply pressure, then

switch off the air supply.

2. Using a 38 mm AF spanner, remove the

regulator head.

3. Remove the components (shown in dotted

box B in the figure on the page 4.4) from the

body of the regulator.

4. Fit the new components to the regulator body.

5. Refit the regulator head and tighten to 7.7Nm

(5.7 lbf.ft).

6. Switch on the air supply and set the pressure

to the value noted in step 1.

4.3

Maintenance

Air pressure regulator filter

bowl

Oil removal

filter bowl

Page 44

OSI/OSI-D with OMM-2C installation guide

4.4

Maintenance

A

B

NOTE: Items shown within dotted boxes A and B

are included in the air lter service kit obtainable

from Renishaw (see the Parts lists on page 6.1).

Page 45

5.1

Fault-finding

Symptom Cause Action

Probe fails to switch on

or switch off.

Installation / CNC program fault. Correct M-code and/or wiring from

machine to OSI and from OSI to

OMM-2C and/or CNC program.

OMM-2C flashes blue,yellow,

violet and cyan due to

ambiguous start information

being received.

Correct M-codes in CNC program

when two are used. To reset the

error, deactivate all active machine

start inputs. Select 50 ms or

100ms delay.

The probe is out of the start

range.

Change the CNC program to bring

the probe within the start range of

the receiver.

The transmission beam is

obstructed.

Clean the receiver window and

remove any obstructions.

Incompatible probe /

probe transmission setting.

Ensure the probe switch-on /

switch-off method is set to optical

on / optical off.

Change the probe or probe setting

to modulated and appropriate start

code.

Incorrect Machine Start setting. Recongure the Machine Start

setting switch SW2.

Dead probe batteries. Replace the probe batteries.

Optical interference is blocking

the start signal.

Remove the source of interference

and ensure that interfering light

does not shine onto the receiver

window or probe window.

Page 46

OSI/OSI-D with OMM-2C installation guide

5.2

Fault-finding

Symptom Cause Action

Probe 2 or Probe 3 fails

to switch on.

OSI in single probe mode. Change OSI to multiple probe

mode.

A time delay exists between

machine inputs from the controller.

Increase selected time delay.

The probe stops in

mid-cycle.

or

An unexpected error

occurs during a

probing cycle.

or

An unexpected trigger

occurs during the

probing cycle.

The transmission beam is

obstructed.

Remove the obstruction.

Optical interference. Remove the source of interference

and ensure that interfering light

does not shine into the receiver

window.

Intermittent wiring fault. Correct wiring.

The probe has moved outside the

reception range.

Change the CNC program to bring

the probe within the reception

range of the receiver.

The probe has not been triggered

for more than 90 minutes.

Restart the probe and ensure

that the probe is not idle for

90minutes.

The probe switches on,

but the OMM-2C LED is

lit red or white.

Interfering light source is shining

directly into the receiver window.

Remove the source of interference

and ensure that the interfering light

does not shine into the receiver

window.

The probe is out of the reception

range.

Change the CNC program to move

the probe into the reception range

of the receiver.

A signal is being received

from a probe on an adjacent

machine tool.

Change the adjacent probe to low

power mode.

Installation / CNC program fault. Check wiring and CNC program.

Page 47

5.3

Fault-finding

Symptom Cause Action

The probe indicates

low battery condition,

but the machine control

does not.

Installation / CNC program fault.

Machine may not have the facility

integrated.

Correct low battery SSR wiring

and/or CNC program.

The machine control

does not respond to the

probe being triggered or

seated.

Probe is not switched on. Attempt to switch it on.

Probe is out of range. Change the CNC program to bring

the probe within the reception

range.

Installation / CNC program fault. Correct M-code and/or wiring from

machine to OSI and from OSI to

OMM-2C and/or CNC program.

A signal is being received

from a probe on an adjacent

machine tool.

Change the adjacent probe to low

power mode.

Probe triggers but

the OMM-2C does not

respond.

The OMP400 or OMP600 has

the 3 second switch-on delay

selected.

Reconfigure the OMP400

or OMP600 to the standard

switch-on delay.

The probe is out of range. Review the performance

envelopes.

The transmission beam is

obstructed.

Check that the probe and receiver

windows are clean, and remove

any obstruction.

The probe is set to legacy

transmission.

Recongure to modulated

transmission.

No air from airblast. No air to OMM-2C. Check air supply to OMM-2C and

rectify.

CNC program fault. Correct CNC program.

Air supply pipe damaged or

kinked.

Check air supply pipe.

Air blast blocked. Unblock air blast.

Page 48

OSI/OSI-D with OMM-2C installation guide

5.4

Fault-finding

This page is intentionally left blank.

Page 49

6.1

Parts list

Item Part number Description

OSI interface A-5492-2000 OSI (multiple probe mode) with DIN rail mounting, terminal

block and quick-start guide.

OSI interface A-5492-2010 OSI (single probe mode) with DIN rail mounting, terminal block

and quick-start guide.

OSI-D interface A-5492-3000 OSI-D (multiple probe mode) with DIN rail mounting, terminal

block and quick-start guide.

OSI-D interface A-5492-3010 OSI-D (single probe mode) with DIN rail mounting, terminal

block and quick-start guide.

OMM-2C

(standard

non-airblast)

A-5991-0001 OMM-2C (non-integrated airblast) with 7-way socket and quick-

start guide.

OMM-2C

(optional airblast)

A-5991-0005 OMM-2C (integrated airblast) with 7-way socket and

quick-start guide.

OSI terminal

block (15-way)

P-CN25-0009 15-way socket terminal for OSI.

OMM-2C terminal

block (7-way)

P-CA79-0021 7-way socket terminal for OMM-2C.

OMM-2C cable A-5314-0015 OMI-2C/OMM-2C cable assembly, with 8 m (26 ft) of cable

(7-way connector not included).

OMM-2C cable A-5314-0016 OMI-2C/OMM-2C cable assembly, with 15 m (49 ft) of cable

(7-way connector not included).

Mounting screw

(standard)

A-5991-0113 Replacement standard mounting screw. For use with

A-5991-0001.

Mounting screw

(air blast option)

A-5991-0112 Replacement mounting screw for the optional integral air blast

OMM-2C. For use with A-5991-0005.

OSI-D cable A-5492-0042 OSI-D 15-way HD D type connector to 15-way D type adaptor,

with 3 m (9.8 ft) of cable.

OSI-D cable A-5492-0043 OSI-D 15-way controller connector to 15 way HD D type

adaptor, with 3 m (9.8 ft) of cable.

OSI-D cable A-5492-0044 OSI-D 15-way controller connector to 15-way D type, with 3 m

(9.8 ft) of cable.

OSI-D cable A-5492-0045 OSI-D to OMM-2C extension cable 15-way HD D type

connector, with 3 m (9.8 ft) of cable.

Air assembly kit A-2253-5120 Filter/regulator, Ø4 mm tube × 25 m air tube,

Ø4 mm tee fitting.

Page 50

OSI/OSI-D with OMM-2C installation guide

6.2

Parts list

Item Part number Description

Air adaptor kit M-4179-0161

Ø3 mm × 5 m air tube, Ø3 mm to Ø4 mm straight fitting

blanking cap.

Nylon tube

(Ø3 mm)

P-PF26-0014 Ø3 mm × 25 m air tube (coil).

Nylon tube

(Ø4 mm)

P-PF26-0010 Ø4 mm × 25 m air tube (coil).

Equal tee fitting P-PF04-0010 Ø4 mm push-fit pneumatic adaptor.

Straight fitting

(Ø4 mm to

Ø4 mm)

P-PE02-0020 Ø4 mm to Ø4 mm push-fit pneumatic adaptor.

Straight fitting

(Ø4 mm to

Ø3 mm)

P-PE02-0019 Ø4 mm to Ø3 mm push-fit pneumatic adaptor.

Pneumatic

blanking cap

P-BG03-0029 Pneumatic blanking cap.

Air filter service

kit

P-FI01-S002 Replacement filter and seals for air filter/regulator unit.

Deluxe air filter P-FI01-0008 For filtering large quantities of contaminated air.

Publications. These can be downloaded from our website at www.renishaw.com

OMM-2C H-5991-8500 Quick-start guide: for rapid set-up of the OMM-2C optical

module machine.

OSI H-5492-8500 Quick-start guide: for rapid set-up of the OSI optical system

interface.

OSI-D H-5492-8575 Quick-start guide: for rapid set-up of the OSI-D optical system

interface.

OMP40-2 H-4071-8500 Quick-start guide: for rapid set-up of the OMP40-2 optical

machine probe.

OLP40 H-5625-8500 Quick-start guide: for rapid set-up of the OLP40 optical lathe

probe.

OMP400 A-5069-8500 Quick-start guide: for rapid set-up of the OMP400 optical

machine probe (includes CD with installation guide).

OMP60 A-4038-8501 Quick-start guide: for rapid set-up of the OMP60 optical

machine probe (includes CD with installation guide).

OMP600 H-5180-8500 Quick-start guide: for rapid set-up of the OMP600 optical

machine probe.

OTS H-5401-8500 Quick-start guide: for rapid set-up of the OTS optical tool

setting probe.

NOTE: The serial number of each OMM-2C unit is found on the receiver body.

Page 51

This page is intentionally left blank.

Page 52

Renishaw plc

New Mills, Wotton-under-Edge

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F

+44 (0)1453 524901

E

uk@renishaw.com

www.renishaw.com

For worldwide contact details, visit

www.renishaw.com/contact

*H-5991-8504-03*

© 2017–2019 Renishaw plc

Issued: 02.2019

Part no. H-5991-8504-03-A

Loading...

Loading...