Page 1

Installation and user’s guide

H-1000-5180-01-A

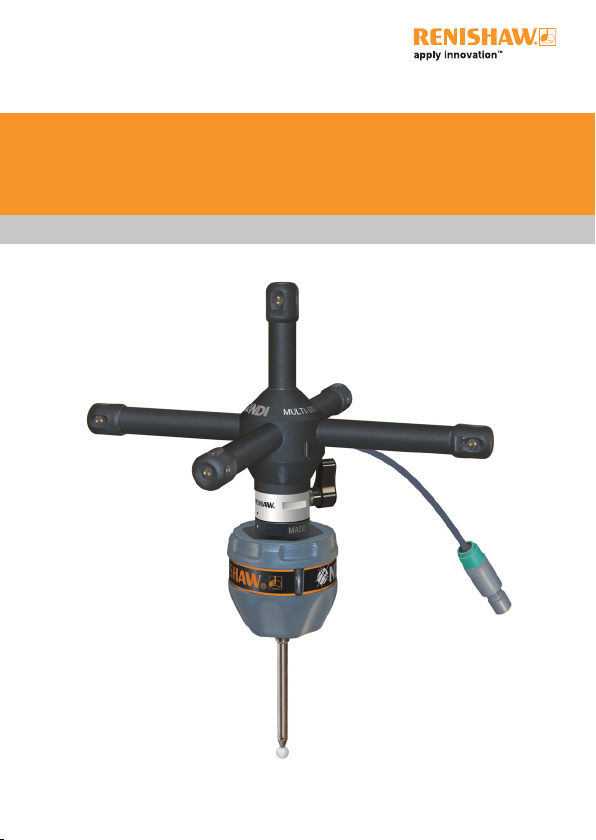

NDI AUTOsense

touch trigger module

Page 2

© 2008 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means, without the

prior written permission of Renishaw.

The publication of material within this document does not imply freedom

from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE

THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS

DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are

registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All other brand names and product names used in this document are

trade names, service marks, trademarks, or registered trademarks of their

respective owners.

Renishaw part no: H-1000-5180-01-A

Issued: 11 2008

Page 3

NDI AUTOsense touch trigger module

installation and user’s guide

Page 4

2

Care of equipment

Renishaw probes and associated systems are precision tools used for

obtaining precise measurements and must therefore be treated with

care.

Changes to equipment

Renishaw reserves the right to improve, change or modify its

hardware or software without incurring any obligations to make

changes to Renishaw equipment previously sold.

Care of equipment

CAUTION: The product should not be included in general

rubbish.

Page 5

Care of equipment

!

Warranty

Renishaw plc warrants its equipment provided that it is installed

exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw

equipment (e.g. interfaces and/or cabling) is to be used or substituted

for Renishaw equipment. Failure to comply with this will invalidate the

Renishaw warranty.

Claims under warranty must be made from authorised service

centres only, which may be advised by the supplier or distributor.

Patents

Aspects of the NDI AUTOsense touch trigger module system have

patents applied for.

CAUTION: The NDI AUTOsense touch trigger module will only

work with genuine AUTOsense module styli. When switching

on the module ensure a genuine stylus is fitted and that the

stylus is not in contact with any surface until the module status

LED turns green.

3

Page 6

4

EC DECLARATION OF CONFORMITY

Renishaw plc declare that the product:

Name(s): MSP3

Description: NDI AUTOsense touch trigger module

Part no.: A-3053-2300

has been manufactured in conformity with the following standards:

BS EN 61326-1:2006 Electrical equipment for

measurement, control and laboratory

use - EMC requirements -

Part 1: General requirements

Immunity to Table 2 - industrial locations.

Emission to Class A - industrial

locations.

and that it complies with the requirements of the following directive:

2004/108/EC Electromagnetic compatibility

The above information is summarised from the full EC Declaration of

Conformity. A copy is available from Renishaw on request.

Page 7

Contents

Contents

1 Introduction ...................................................................................6

2 Product description .......................................................................7

2.1 The AUTOsense touch trigger module kit ............................7

2.1.1 The AUTOsense module ......................................... 8

3 Product installation ........................................................................ 9

3.1 Cre ating and connecting an AUTOsens e stylus

ass embly ........................................................................... 10

4 Product operation ........................................................................ 13

4.1 Operational modes ............................................................. 13

4.2 Operation ........................................................................... 14

4.3 Accuracy of measurement.................................................. 14

4.4 Calibration .......................................................................... 15

5 Technical data ............................................................................ 16

5.1 Measuring performance .....................................................16

5.1.1 Technical specification ........................................... 16

6 Applications guide ....................................................................... 17

6.1 Stylus selection ..................................................................17

6.1.1 The list of available styli ......................................... 18

6.1.2 Recommended stylus limits ................................... 18

7 Product maintenance .................................................................. 19

5

Page 8

6

Introduction

1 Introduction

This installation and user’s guide is for the NDI AUTOsense touch

trigger module (see figure 1):

The AUTOsense module is a dual function stylus holder that enables

touch trigger probing for both single-point and scanning. The

AUTOsense module is only compatible with supported NDI hand-held

probes.

Figure 1 - NDI AUTOsense touch trigger module

Page 9

Product description

2 Product description

2.1 The AUTOsense touch trigger module kit

The standard AUTOsense module kit (Renishaw part no.

A-3053-4200) comprises the following components (see figure 2):

• NDI AUTOsense module A-3053-2300

• Ø 4 mm (0.16 in) x 30 mm

(1.18 in) stylus

• Ø 6 mm (0.24 in) x 60 mm

(2.36 in) stylus

• Two M4 stylus tools (boxed) A-3053-2196

• Cleaning kit A-1085-0016

• System installation and

user’s guide CD

• Kit box A-1015-8550

A-5004-1188

A-5004-1189

H-1000-5181

7

Page 10

8

2.1.1 The AUTOsense module

The module body incorporates a kinematic connector that attaches to

the stylus assembly mount on supported NDI hand-held probes.

Product description

Figure 2 - The NDI AUTOsense touch trigger module boxed kit

Page 11

Product installation

3 Product installation

Before using the NDI AUTOsense system assemble a supported

stylus to the module, connect the stylus assembly to the probe and

qualify it. Once qualified the AUTOsense stylus assembly can be

attached to and removed from the probe with no additional calibration.

Supported

NDI probe

Stylus

assembly

mount

Quick

release

AUTOsense touch

trigger module

9

AUTOsense

stylus assembly

Supported stylus

Figure 3 - The NDI AUTOsense system components

Page 12

10

Product installation

3.1 Creating and connecting an AUTOsense stylus assembly

1. Screw/thread a stylus into the AUTOsense module by hand.

2. Hold the AUTOsense module in one hand and insert a stylus tool

through the eyehole of the supported stylus.

3. Tighten the supported stylus to a maximum tightening torque

of 2 Nm - 17.7 ibf.in.

AUTOsense touch

trigger module

Supported

stylus

Stylus tool

Figure 4 - Stylus fitting

Page 13

Product installation

4. Connect the AUTOsense stylus assembly to the stylus assembly

mount so the alignment marks line up.

Alignment

marks

Figure 5 - NDI AUTOsense module alignment

11

Page 14

12

5. Tighten the connection by turning the quick release lever until it

6. Perform a stylus calibration as described in the ‘OPTOTRAK

Product installation

stops.

PROseries User Documentation’.

Quick

release

lever

Figure 6 - NDI AUTOsense module fitting

Page 15

Product operation

4 Product operation

4.1 Operational modes

The various modes of the NDI AUTOsense module are indicated by

the two status LED’s on the side of the module:

13

Solid Blue Module is in sleep mode. If the probe is not used

Flashing Blue Module is auto-zeroing which may take 8 seconds

Solid Green Module has auto-zeroed successfully and is ready

Solid Red Module auto-zeroed successfully and is in

Flashing Red Module failed to auto-zero and will NOT take data

NOTE: Whilst the module is auto-zeroing ensure the stylus does NOT

come into contact with any surface.

Always recalibrate the module and stylus if the stylus has been

removed.

for a period of time the module is switched into

sleep mode. The software will automatically wake

the probe.

to find optimum sensitivity for the stylus connected.

to measure. Green also indicates the module is not

in contact with a surface.

measuring mode contacting the surface. Position

data signals are being generated.

points. Check that a stylus is present and that the

stylus is correctly tightened.

Page 16

14

Product operation

4.2 Operation

NOTE: When the stylus has been replaced or changed, the auto

zeroing will take up to 8 seconds.

NDI AUTOsense module auto zero results in flashing red:

• Ensure that the stylus mounting threads on the stylus and the

AUTOsense module are clean

• Ensure the stylus ball and shank are entirely free of contacts

during the auto-zeroing process

• You must only use NDI AUTOsense module styli

NOTE: While flashing red, the module will not sense surfaces.

4.3 Accuracy of measurement

Operator variability when measuring with the NDI AUTOsense module

can be significantly reduced by careful selection of the measuring

mode and stylus configuration for the job in hand. Following these

simple rules will result in successful data collection.

Use scanning mode only when:

• The part is rigid – for example an engine block.

Always use point measurement mode when:

• The part is not rigid (sheet metal or plastic components).

Page 17

Product operation

Whilst measuring :

• Do not touch the stylus tip or stylus shank with any part of the

body as this can issue false triggers.

• Only touch the surface being measured with the stylus tip.

• Use consistent amount of force between the stylus tip and part.

• Use consistent amount of force when calibrating and when

measuring.

• Use the minimum amount of force required to trigger the probe

when measuring.

4.4 Calibration

Perform a stylus calibration as described in the ‘OPTOTRAK

PROseries User Documentation’.

15

Page 18

16

Technical data

5 Technical data

5.1 Measuring performance

NOTE: The following data is derived from high accuracy test rig with a

Ø 6 mm (0.24 in) x 30 mm (1.18 in) stylus measurements and may not

represent the performance achievable on a probe.

5.1.1 Technical specification

Product compatibility

Dimensions

Diameter

Length

Probe mount

Stylus mount

Sensing directions

Sealing

Repeatibility

Trigger force

Pre-travel

Pre-travel variation

Weight

The NDI AUTOsense module is suitable

for use with supported NDI hand-held

probes.

51 mm (2.01 in)

62.85 mm (2.47 in)

Renishaw autojoint

Thread M4 x 0.7 mm

6-way (±X, ±Y, ±Z)

IP30

1 µm 2 σ (0.0000394 in)

0.02 - 0.04 Nm (2 - 4 gf)

4.5 µm (0.000177 in)

1 µm (0.0000349 in)

161 g (5.68 oz)

Page 19

Applications guide

17

6 Applications guide

6.1 Stylus selection

The NDI AUTOsense module comes supplied with two matching styli

which are specially designed for the highest accuracy and sensitivity.

The stylus design is carefully matched to the module contact sensing

system. Third par ty styli should not be used.

NOTE: Choosing the best stylus for a given application is an

important factor in achieving optimum probe performance.

When selecting a stylus, it is important that the stylus length is kept to

the minimum required to access all features to be measured.

It is also important to ensure that the stylus ball diameter chosen is as

large as is practical. This not only ensures that the stylus will be as

stiff as possible, but also reduces the stylus susceptibility to surface

form and surface finish.

Page 20

18

6.1.1 The list of available styli

Applications guide

Part number

A-5004-1188 4 (0.16) 30 (1.18) 6.5 (0.26)

A-5004-1189 6 (0.24) 60 (2.36) 55.5 (2.19)

A-5004-0291 3 (0.12) 30 (1.18) 6.5 (0.25)

A-5004-0293 6 (0.24) 30 (1.18) 25.4 (1.0)

* Effective working length.

6.1.2 Recommended stylus limits

Owing to the modular construction of the NDI AUTOsense module,

it is recommended that the limits shown in figure 7 are applied when

selecting styli to be used.

• No star or cranked styli

Ball Ø

mm (in)

Length

mm (in)

ELW*

mm (in)

Max: 60 mm

Max Ø: 6 mm

Figure 7 - Recommended stylus limits

Page 21

Product maintenance

19

7 Product maintenance

NOTE: Maintenance of the NDI AUTOsense module is restricted

to the periodic cleaning of the stylus M4 mating faces and the three

rollers and three sets of balls. To aid cleaning of these couplings, each

NDI AUTOsense module is supplied with a Renishaw cleaning kit.

Each Renishaw cleaning kit contains a specialised material to

effectively remove contamination from location faces.

Styli that are not attached to the probe should be stored in their

transport boxes, to prevent contamination and damage.

Page 22

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

For worldwide contact details, please

www.renishaw.com/contact

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

visit our main website at

*H-1000-5180-01*

Loading...

Loading...