Page 1

H-2000-6199-02-A

2

1

R25=y

R26=z

R11=h

R25=y

=>?@D

NC1 non-contact

tool setting system

Programming Guide

(Siemens 810D / 840D and FMNC)

Page 2

© 2001 Renishaw. All rights reserved.

Renishaw® is a registered trademark of Renishaw plc.

This document may not be copied or reproduced in whole or in

part, or transferred to any other media or language, by any means

without the written prior permission of Renishaw.

The publication of material within this document does not imply

freedom from the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of

this document are free from inaccuracies and omissions.

However, Renishaw makes no warranties with respect to the

contents of this document and specifically disclaims any implied

warranties. Renishaw reserves the right to make changes to this

document and to the product described herein without obligation

to notify any person of such changes.

Trademarks

All brand names and product names used in this document are

trade names, service marks, trademarks, or registered trademarks

of their respective owners.

Renishaw part no: H-2000-6199-02-A

Issued – February 2001

Page 3

NC1 non-contact

tool setting system

Programming Guide

(Siemens 810D / 840D and FMNC controls)

=>?@D

www.renishaw.com

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR, UK

Tel: +44 (0)1453 524524 [07000 RENISHAW]

Fax: +44 (0)1453 524901

email: uk@renishaw.com

1

Page 4

Cautions

Caution – Laser safety

The laser used in the Renishaw NC1 non-contact tool

setting system emits visible red light at a wavelength of

670nm and has a maximum power output of less than

1mW. It is a Class 2 product as defined by European and

American laser safety standards (EN60825-1:1994 and US Code of

Federal Regulations 21CFR1040).

When using the NC1 system:

n

Do not stare directly into the laser beam. The beam may be

viewed safely from the side.

n

Ensure that the laser beam is not reflected into the eyes of

another person via a mirror or other reflective surface.

n

Do not expose skin to the laser beam for longer than is absolutely

essential.

n

When the system is not being used, cover the laser beam

aperture with the sliding cover.

Caution – Software safety

The software you have purchased is used to control the

movements of a machine tool. It has been designed to

!

cause the machine to operate in a specified manner under

operator control, and has been configured for a particular

combination of machine tool hardware and controller.

Renishaw has no control over the exact program configuration of the

controller with which the software is to be used, nor of the

2

Page 5

Cautions

mechanical layout of the machine. Therefore, it is the responsibility of

the person putting the software into operation to:

n

ensure that all machine safety guards are in position and are

correctly working before commencement of operation;

n

ensure that any manual overrides are disabled before

commencement of operation;

n

verify that the program steps invoked by this software are

compatible with the controller for which they are intended;

n

ensure that any moves which the machine will be instructed to

make under program control would not cause the machine to

inflict damage upon itself or upon any person in the vicinity;

n

be thoroughly familiar with the machine tool and its controller and

know the location of all emergency stop switches.

Related publications

When using the Beam alignment cycle (subroutine L9860) you will

also need to refer to the following Renishaw publication. This contains

instructions on how to physically align the beam at the NC1

transmitter unit.

NC1 Installation Guide and Parts List

(Renishaw Part No. H-2000-5048)

3

Page 6

Contents

Contents

Renishaw NC1 tool setting system ..................................................... 6

Features of the NC1 system software ................................................ 7

Measuring subroutine features .................................................... 7

Calibration subroutine features .................................................... 7

Service subroutine features ......................................................... 8

Software memory requirements ......................................................... 9

Machine tool controllers supported .................................................... 9

Tool-offset types supported .............................................................. 10

Positive tool-offset applications.................................................. 10

Negative tool-offset applications ................................................ 10

Relative to a master tool with zero (0) tool-offset value. ........... 11

Measurement values used in this guide ........................................... 11

Installing the software ....................................................................... 12

Subroutine parameters ..................................................................... 12

Parameter store for calibration data ........................................... 12

Setting-data subroutine L9760 ................................................... 13

Common parameters ................................................................. 19

Customising the subroutines ............................................................ 20

Editing the measure move subroutine L9762 ............................ 20

Orientation of the NC1 system ......................................................... 21

Beam-find and measuring moves ..................................................... 22

Scatter tolerance checking ............................................................... 23

Beam alignment (subroutine L9860) ................................................ 24

Calibrating the NC1 (subroutine L9861) ........................................... 32

Tool length setting (subroutine L9862) ............................................. 38

4

Page 7

Contents

Tool radius/diameter setting (subroutine L9862) .............................. 43

Tool length and radius setting (subroutine L9862) ........................... 49

Cutting edge checking (subroutine L9862) ...................................... 55

Broken tool detection – plunge checking (subroutine L9863) .......... 60

Broken tool detection – radial checking (subroutine L9864) ............ 65

Cutter radius and linear profile checking (subroutine L9865) .......... 70

Temperature compensation tracking (subroutine L9861) ................. 79

Error messages and alarms ............................................................. 85

5

Page 8

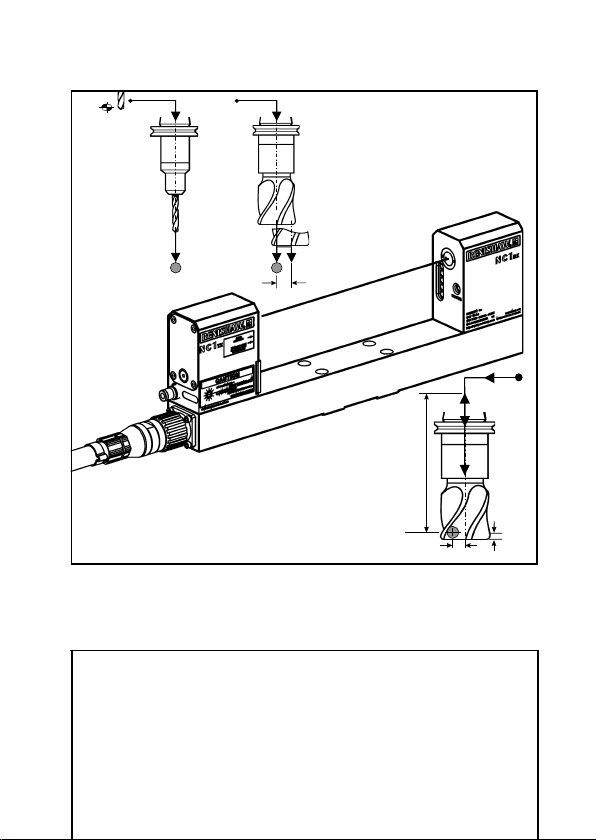

Renishaw NC1 system

Renishaw NC1 tool setting system

This guide describes how to use the Renishaw NC1 non-contact tool

setting system software.

The Renishaw NC1 is a laser-based non-contact tool setting system

that provides high-speed/high-precision measurement of cutting tools

on a machining centre under normal operating conditions.

As a tool is moved through the laser beam, the system detects when

the beam is broken. Output signals sent to the controller allow the

presence of a tool and the position of the tip, a tooth, or a cutting

edge to be established.

The NC1 allows the following parameters to be established:

n

Length and diameter of the cutting tool. Tools as small as 0.2 mm

(0.008 in) diameter can be accurately measured.

n

Detection of a broken tool.

n

Detection of a broken tip or cutting edge, or excessive runout of a

tool.

n

Compensation for thermal changes in the machine tool.

6

Page 9

Software features

Features of the NC1 system software

NC1 system software provides the following measuring and

calibration features:

Measuring subroutine features

Four measuring subroutines provide the following features:

n

L9862 – used for measuring the length and diameter of the

cutting tool and for cutting edge checking.

n

L9863 – used for broken tool detection by plunge measurement.

This is intended for use on vertical machining centres.

n

L9864 – used for broken tool detection by radial measurement.

This is intended for use on horizontal machining centres.

n

L9865 – used for checking the radii and linear profile of the cutter.

Calibration subroutine features

Two calibration subroutines provide the following features:

n

L9860 – used for aligning the laser beam, setting the provisional

positions of the beam in the spindle and radial-measuring axes,

and setting the measuring position along the beam.

n

L9861 – used for calibrating the positions of the laser beam in the

spindle and radial-measuring axes, and for temperature

compensation of the spindle and radial-measuring axes.

7

Page 10

Software features

Service subroutine features

The measuring and calibration subroutines are supported by the

service subroutines listed below.

n

L9760 – used for the settings data.

n

L9761 – used for startup functions.

n

L9762 – used for the measuring routine.

n

L9763 – used for the G31 routine.

n

L9764 – used for the G0/G1 routine.

n

L9765 – used for the G2/G3 routine.

n

L9766 – used for the search routine.

n

L9769 – used for error messages.

n

L9800 – clears global ‘R’ parameters used for subroutine input

data.

NOTE: L9800 Clear global ‘R’ parameters.

The subroutine L9800 is called at the end of every measuring and

calibration subroutine (9800-series) to reset the global ‘R’

parameters, used as inputs, to a default value.

If global ‘R’ parameters R00 to R26 are used for other

programming purposes outside of this tool setting package, it is

recommended that L9800 is called prior to setting them for the

next tool setting routine. All examples in this programming guide

show this being done.

8

Page 11

Software memory requirements

Software memory requirements

NC1 system software requires approximately 28.0Kb (70 metres) of

part-program memory.

If your controller is short of memory, there is no need to load any of

the subroutines listed below if you do not intend using them:

n

L9862 (tool setting routine) 4.0 Kb (10 metres) of memory.

n

L9863 (broken tool – plunge check) 1.2 Kb (3 metres) of

memory.

n

L9864 (broken tool – radial check) 1 Kb (2.5 metres) of memory.

n

L9865 (checking cutter radii and linear profiles) 4.0 Kb

(10 metres) of memory.

You may also remove the following subroutine after you have finished

running the Beam alignment cycle:

n

L9860 (laser beam alignment routine) 1.5 Kb (3.8 metres) of

memory

Machine tool controllers supported

NC1 system software is suitable for use on the following machine tool

controllers:

n

Siemens 810D

n

Siemens 840D

n

Siemens FMNC

9

Page 12

Tool-offset types supported

Tool-offset types supported

Positive tool-offset applications

The NC1 software is ideally suited to setting tools using positive tooloffset values that represent the physical length of the tool.

Throughout this programming guide, descriptions refer to positive

tool-offset applications.

The software can also be used in applications where negative tooloffset values are used or where all tool-offset values are entered as ±

values relative to a master tool. These applications are described

below.

Negative tool-offset applications

The offset value entered is the distance the tool tip must be moved

from the home position to reach the zero (0) position of the part

program (air-gap method), rather than the physical length of the tool.

Example

Home position, to the zero (0) position of the part

program = –1000 mm.

A master calibration tool of 150 mm is used (offset register

value = –850 mm).

The longest tool for the machine is 200 mm long.

The shortest tool for the machine is 50 mm long.

Parameters RENC[10] and RENC[11] must be set in the Setting-data

subroutine (L9760). Set them as follows:

10

Page 13

Tool-offset types supported

RENC[10] = –800.0 Maximum length tool

RENC[11]= –950.0 Minimum length tool

Relative to a master tool with zero (0) tooloffset value.

The master tool-offset register is set to zero (0) and all other tooloffset registers are set as ± values relative to the master tool.

Example

Home position, to the zero (0) position of the part

program = –1000 mm (but this is not important)

A master calibration tool of 150 mm is used (offset register

value = 0).

The longest tool for the machine is 200 mm long.

The shortest tool for the machine is 50 mm long.

Parameters RENC[10] and RENC[11] must be set in the Setting-data

subroutine (L9760). Set them as follows:

RENC[10] = 50.0 Maximum length tool

RENC[11] = -100.0 Minimum length tool

Measurement values used in this guide

Throughout this guide, metric units of measurement, i.e. millimetres,

are used in the examples. The equivalent imperial measurements, i.e.

inches, are shown in brackets.

11

Page 14

Installing the software

Installing the software

Before installing the NC1 software, read the guidelines contained in

the Readme file on the software floppy disk.

Subroutine parameters

The following parameters are used by the NC1 system software:

n

‘RENT’ global parameters – used for the calibration data and

settings data.

n

Global parameters RENC[0] to RENC[49] – used for the settings

data.

n

Local parameters RENL[1] to RENL[32] – used for locally defined

data.

n

Global parameters R01 to R26 – used for subroutine inputs.

Parameter store for calibration data

The following parameters are set automatically during the calibration

cycles.

RENT[20] Z-axis position of the beam, when measured from the

positive side of the beam.

RENT[21] (Reserved)

RENT[22] X or Y-axis position of the beam, when measured from

the negative side of the beam.

RENT[23] X or Y-axis position of the beam, when measured from

the positive side of the beam.

12

Page 15

Parameter store for calibration data

RENT[24] Position along the beam at which measurements are

made.

RENT[26] Spindle (length-measuring) axis temperature

compensation zero offset.

RENT[27] Radial-measuring axis temperature compensation zero

offset.

Setting-data subroutine L9760

Read the following parameter descriptions then edit subroutine L9760

as described.

RENC[5] False trigger retries.

If probe status checking is deactivated (see RENT[5]

parameter), the software defaults to one (1) retry.

Default: 1

RENC[6] Safe return position (in ‘machine’ co-ordinates).

RENC[7] The unit used for setting data in subroutine L9760.

1 = mm, 0.04 = inch

Default: 1 (mm)

RENC[9] Setting for tool offset type, either radius or diameter.

1 = Radius, 2 = Diameter

Default: 1

RENC[10] Maximum length of the tool. This defines the rapid

approach height of the spindle nose above the laser

beam.

13

Page 16

Setting-data subroutine

RENC[11] Minimum length of the tool. This defines the lowest

measuring height of the spindle nose above the laser

beam.

RENC[12] Maximum diameter of the tool. This value is dependent

on the machine tool.

RENC[13] Radial-measuring axis options.

1 = measure from positive side of the beam,

–1 = measure from negative side of the beam,

2 = measure from both sides of the beam.

Default: 2

RENC[14] Radial calibration options.

1 = measure from positive side of the beam,

–1 = measure from negative side of the beam,

2 = measure from both sides of the beam.

Default: 2.

RENC[15] Hardware signal pulse time.

The time that the trigger signal is held on. This is

hardware-dependent. The value is specified when the

NC1 system is ordered.

Check the status LED sequence on power up (for

details, see

RENC[17] Default overtravel distance and radial clearance.

Overtravel is the distance through the beam that the

tool is permitted to move before a BEAM NOT CUT

alarm is initiated.

Radial clearance is the distance between the tool and

“NC1 Installation Guide and Parts List

”).

14

Page 17

Setting-data subroutine

the beam when moving down the side of the beam.

Default: 5 mm (0.197 in)

RENC[18] Default measurement resolution (feedrate-per-rev.).

Typically 0.001 mm (0.0001 in) feed per revolution.

The larger the value, the less accurate measurements

will be.

Default: 0.002 mm (0.0001 in)

RENC[19] Default spindle speed.

Measurement cycles are optimised for a spindle speed

of 3150 rev/min.

Some tools, e.g. those that are unbalanced or large,

must be run at speeds less than 3150 rev/min. This is

the responsibility of the user. Use the R19= input to set

speed.

Measurement cycle times increase with slower speeds.

The minimum speed is 800 rev/min.

Default value: 3150 rev/min

RENC[21] Beam axis.

n

If the laser beam is parallel to the X-axis, select 1.

n

If the laser beam is parallel to the Y-axis, select 2.

n

If the laser beam is parallel to the Z-axis, select 3.

RENC[22] Axis used for radial measurement.

n

If the X-axis is to be used for radial measurement,

select 1.

n

If the Y-axis is to be used for radial measurement,

select 2.

15

Page 18

Setting-data subroutine

n

If the Z-axis is to be used for radial measurement,

select 3.

Default: 2

RENC[23] Axis used for length measurement, i.e. the spindle axis.

n

If the X-axis is to be used for length measurement,

select 1.

n

If the Y-axis is to be used for length measurement,

select 2.

n

If the Z-axis is to be used for length measurement,

select 3.

Default: 3

NOTE: RENC[23] must always define the spindle axis

and the direction in which the tool offset is applied. If

the spindle is in the negative direction, the value

entered must also be negative (–1 = –X axis, –2 = –Y

axis, –3 = –Z axis).

RENC[24] Scatter tolerance value.

For a description of this feature, see the figure in

“Scatter tolerance checking” on page 23.

Default: 0.010 mm (0.0004 in)

RENC[25] Tolerance value for tool runout or cutting edge.

Default: 0.025 mm (0.001 in)

RENC[26] Sample size for scatter.

The number of measurement samples to be taken.

The number of retry attempts is twice this value.

16

Page 19

Setting-data subroutine

For a description of this feature, see the figure in

“Scatter tolerance checking” on page 23.

Default: 3

RENC[27] Rapid traverse feedrate.

Default: 5000 mm/min

RENC[28] Select language.

1 = English, 2 = German, 3 = French, 4 = Italian

RENT[5] Number of the digital input for monitoring the probe

status signal. This can be used only if the machine tool

builder (MTB) has provided the input.

From Siemens 840D version 4 software or 810D

version 2 software, a Probe Status flag is available.

This is used as the default.

Default: 0 (Siemens Probe Status flag)

RENT[7] Measuring input used on I/O interface connector X121.

RENT[7] = 1 Configured for N/O input on MEPUS 0

RENT[7] = -1 Configured for N/C input on MEPUS 0

RENT[7] = 2 Configured for N/O input on MEPUS 1

RENT[7] = -2 Configured for N/C input on MEPUS 1

RENT[9] Tool management system in use.

RENT[9] = n, where ‘n’ is the location number, usually

1, in the tool buffer. This is decided by the MTB during

machine commissioning.

Default: 0 (i.e. disabled)

17

Page 20

Setting-data subroutine

RENT[28] M code number to disable the latch mode. If the latch

mode feature is not to be used, enter 9 to select M9

coolant off (or similar).

RENT[29] M code number to enable the latch mode. If the latch

mode feature is not to be used, enter 9 to select M9

coolant off (or similar).

Editing subroutine L9760

Before running the cycles, edit the settings data between block

numbers LN1 and LN2 .

First, enter the metric/inch units factor (1. or .04) in parameter

RENC[7]. Next, enter data in the other parameters using the same

units.

Sample of subroutine L9760

LN1:

RENC[5]=1; RETRIES

RENC[6]=-1.; SAFE RETURN POSITION

RENC[7]=1; UNITS FOR DATA 1MM .04INCH

RENC[9]=1; OFFSET-RADIUS 1/DIAMETER 2

RENC[10]=200.; MAX TOOL LENGTH (8.0 in)

RENC[11]=70.; MIN TOOL LENGTH (2.75 in)

RENC[12]=80.; MAX CUTTER DIAMETER (3.15 in)

RENC[13]=2; TL SET RADIUS MEAS DIR

RENC[14]=2; CALIB RADIUS MEAS DIR

RENC[15]=.10; NC1-DELAY IN SECS

RENC[17]=5.; DEFAULT OVERTRAVEL (0.197 in)

RENC[18]=.002; MEASURE RESOLUTION (0.0001 in)

18

Page 21

Setting-data subroutine

RENC[19]=3150; DEFAULT RPM

RENC[21]=1; BEAM AXIS

RENC[22]=2; RADIAL MEASURE AXIS

RENC[23]=3; SPINDLE AXIS

RENC[24]=.01; SCATTER TOL (0.0004 in)

RENC[25]=.025; RUN OUT/CUTTING-EDGE TOL (0.001 in)

RENC[26]=1; SAMPLE SCATTER SIZE

RENC[27]=5000; RAPID TRAVERSE

RENC[28]=1; LANGUAGE 1=GB 2=D 3=FR 4=IT

RENT[5]=0;DIGITAL INPUT NO

RENT[7]=1;MEASURE INPUT

RENT[9]=0;MAGAZINE NUMBER FOR TL MANAGEMENT

RENT[28]= ;DISABLE LATCH

RENT[29]= ;ENABLE LATCH

LN2:

Common parameters

The following parameters are loaded automatically each time a cycle

is run.

RENC[16] Active tool length.

RENC[29]

to Used for internal calculations

RENC[47]

RENC[48] Tolerance flag output

(1 = Out of tolerance, 0 = In tolerance)

RENC[49] Used for internal calculations

19

Page 22

Customising the subroutines

Customising the subroutines

In addition to the subroutine customising information described below,

further customising and installation information is included in the

Readme file supplied with the NC1 software.

Editing the measure move subroutine L9762

The back-off move distance can be adjusted for optimisation of the

cycles. The tool must retract out of the beam otherwise the ACTIVE

BEAM CUT alarm will result.

Sample of subroutine L9762

RENL[6]=1.5; EDIT BOF

20

Page 23

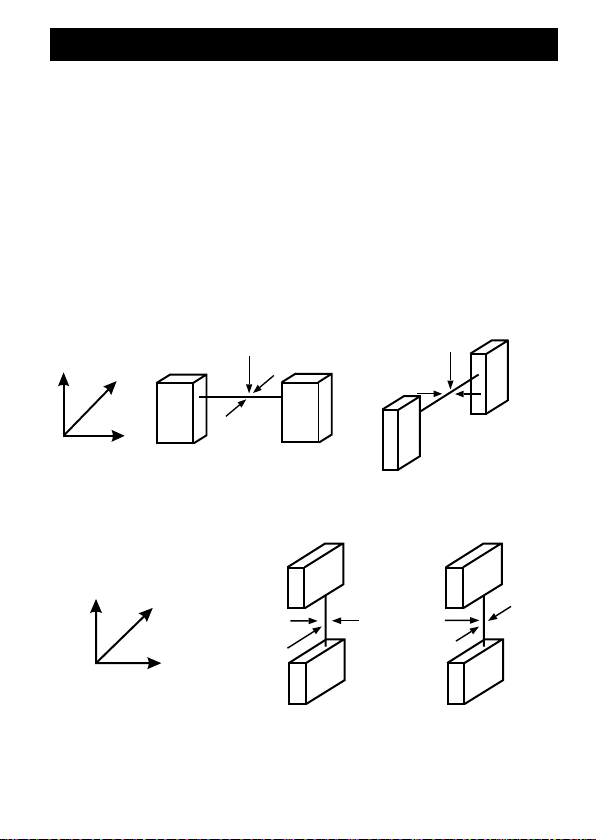

Orientation of the NC1 system

Orientation of the NC1 system

Throughout this guide it has been assumed that the NC1 system is

installed with the laser beam parallel to the X-axis. Length

measurements are made from the Z-axis and radial measurements

are made from the Y-axis.

If your system has been installed in a different orientation, you must

make the necessary adjustments to the axes used for length

measurement and radial measurement (for details, see manually-set

parameters RENC[21], RENC[22], and RENC[23].

Z

Y

X

X-axis beam

Z

Y

X

Z-axis beam (Special)

RENC[21] = 1

RENC[22] = 2

RENC[23] = 3

RENC[21] = 3

RENC[22] = 1

RENC[23] = 2

Y-axis beam

or

RENC[21] = 2

RENC[22] = 1

RENC[23] = 3

RENC[21] = 3

RENC[22] = 2

RENC[23] = 1

21

Page 24

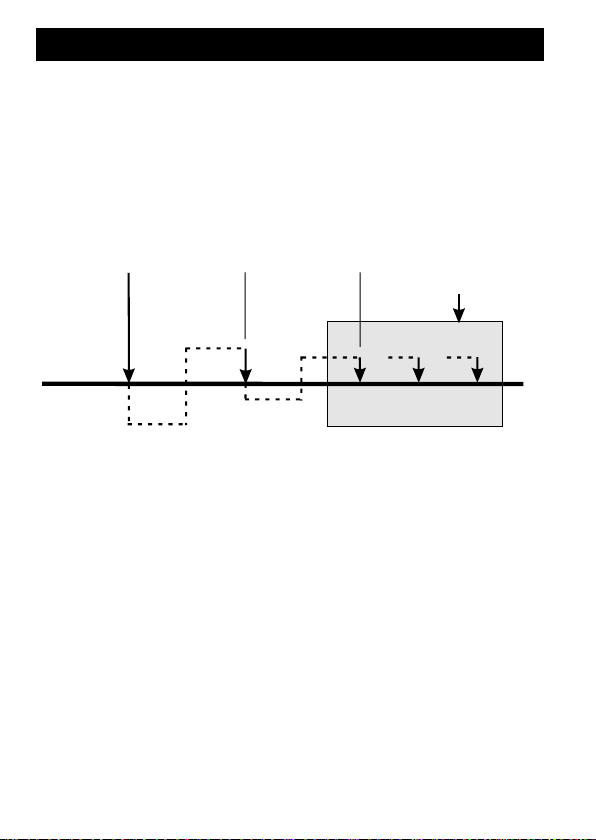

Beam-find and measuring moves

Beam-find and measuring moves

Beam-find moves and measuring moves are all made with the tool

moving into the laser beam, as shown in the figure. Measuring

moves are made with the tool rotating.

22

Fast

feed

Reduced

feed

Measure

feed

Sample

measurements

Page 25

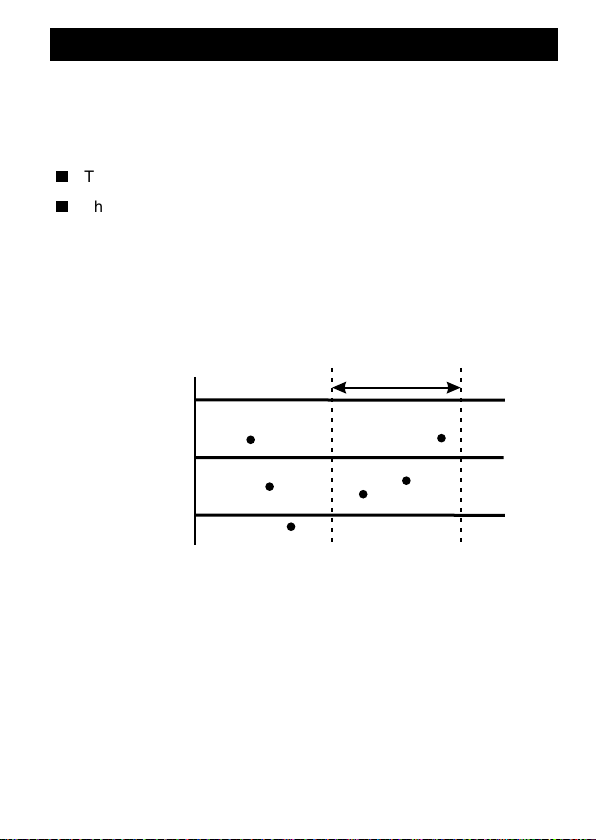

Scatter tolerance checking

Scatter tolerance checking

In the following example:

n

The default sample size setting value RENC[26] = 3 is used.

n

The number of retries is automatically set to twice the sample

size. In this example, six (6).

Sample measurements are taken until either the maximum retries

limit is reached, causing an alarm, or a sample of measurements is

found to be within limits. In this latter case, the average value is found

and measurement is complete.

Sample size

Maximum

Scatter

tolerance

Minimum

23

Page 26

Beam alignment

Beam alignment (subroutine L9860)

NOTE: When installing and setting up the system for the first time,

the Beam alignment subroutine must be run before using subroutine

L9861 to calibrate the system .

Subroutine L9860 is used during installation of the NC1 system to

assist with the alignment of the laser beam. The Beam alignment

cycle is used for the following tasks:

n

Checking that the beam is correctly aligned with the machine

axis.

n

Measuring the provisional position of the laser beam in the Zaxis.

n

Measuring the provisional position of the beam in either the X or

Y-axis. Measurements are taken from the positive and/or negative

sides of the beam.

n

Setting the measuring point along the beam axis at which the tool

is measured.

The provisional values are updated later when the calibration cycle is

run.

Although the Beam alignment subroutine is used mainly during

installation of the NC1 system, it can also be used for routine

24

Page 27

Beam alignment

Jog or

handwheel

to start point

R18=r (+/–)

R7=d

alignment checking.

NOTE: When using the Beam alignment subroutine you will also

need to refer to the following Renishaw publication for instructions on

how to physically align the beam at the transmitter unit:

n

NC1 Installation Guide and Parts List

(Renishaw Part No. H-2000-5048)

R18=r + R17=q

2

Calibration tool required

This cycle requires a calibration tool to be loaded in the spindle of the

machine. Ideally, this should be a solid, flat-bottomed, cylinder-type

tool having minimal runout. The exact setting length and diameter of

this tool must be known.

25

Page 28

Beam alignment

Description

Load the calibration tool in the spindle of the machine. Using either

the jog or handwheel mode, move the tool to the position that is to

be used for tool setting – usually midway along the beam and

approximately 10 mm (0.394 in) above the centre of the beam.

Refer to the figure on page 25. The cycle measures the beam then

returns to the centre position and stops on an M00 program stop.

After beam alignment adjustments have been made, the cycle should

be restarted to identify new alignment errors.

Setting data

Ensure the settings in subroutine L9760 are correct before

proceeding. For details, see “Setting-data subroutine L9760” on page

13.

Format

For beam alignment only

R07=d [R18=r R26=z].

L9860

where [ ] denotes optional inputs

Example R07=100. R18=6. R26=15.

L9860

For beam alignment and setting positions

R02=1. R07=d [R06=k R18=r R26=z]

L9860

26

Page 29

Examples R02=1. R07=100. R06=117. R26=15.

L9860

R02=1. R07=100. R26=15.

L9860

Subroutine inputs

The following inputs are used with this subroutine:

R02=1. Provisional calibration of the system.

Used for checking alignment of the beam and setting

the provisional beam positional data (for details, see

“Parameter store for calibration data” on page 12).

NOTE: When using the R02=1. input, the correct

length of the calibration tool MUST be entered in either

the appropriate tool offset register or as an R06=k

input. By default, the current tool offset length is used

or an alternative tool offset edge (D) can be called by

using the R20=t input).

R02=b (Not used) – beam alignment only.

Beam alignment

R06=k k= Reference length of the calibration tool.

27

Page 30

Beam alignment

CAUTION: R07=d input

When specifying the value of the R07=d input, take care

!

that it will not allow any part of the tool holder to make

contact with the NC1 tool setting system. The projection of the

calibration tool should be at least 35 mm (1.38 in) if the default R26=z

input is used for the incremental measuring depth.

R07=d d= The span between the reference measuring points.

For greatest accuracy, the span value must be as large

as possible, compatible with the gap between the NC1

system transmitter and receiver and the size of the

calibration tool.

R14=t t= Tool offset edge length value to be used in the beam

alignment calculations.

R14=3 Uses the current tool offset, edge D3.

If R14 is not input, the current tool offset edge (D) is

used. The current tool is the number of the tool in the

spindle.

If neither the R06=k nor R14=t input is used, the

current tool offset and tool edge (D) is used for

calibration data.

R17=q q= Overtravel distance and radial clearance.

For details, see “Setting-data subroutine L9760” on

page 13.

Default value: 5.0 mm (0.197 in)

28

Page 31

Beam alignment

Y+

X+

+ error

P2

P1

Y+

X+

+ error

P2

P1

R18=r r= Diameter of tool

This controls the radial clearance move distance. This

can be either a positive (+) or negative (–) value.

Default value: 30 mm (1.18 in)

R26=z z= Incremental measuring depth.

This value determines the depth on the calibration tool

at which calibration takes place.

Default value: 15 mm (0.38 in)

Outputs

The following outputs are set or updated when this cycle is executed:

RENC[1] X-axis beam alignment error

over the measured span.

(This is empty if the X-axis

is the beam axis.)

RENC[2] Y-axis beam alignment error

over the measured span.

(This is empty if the Y-axis is

the beam axis.)

29

Page 32

Beam alignment

Z+

X+

Y+

P2

P1

+ error

RENC[3] Z-axis beam alignment error

over the measured span.

(This is empty if the Z-axis is

the beam axis.)

If the R02=1 input is used, the following outputs are also set:

RENT[20] Provisional Z-axis position of the beam when measured

from the positive side of the beam.

RENT[22] Provisional X or Y-axis position of the beam when

measured from the positive side of the beam.

RENT[23] Provisional X or Y-axis position of the beam when

measured from the negative side of the beam.

RENT[24] Provisional position along the beam axis at which the

tool is measured.

(RENC[23] = 3)

30

Z

RENT[20]

RENT[23]

Y (RENC[22] = 2)

X (RENC[21] = 1)

RENT[22]

RENT[24]

Page 33

Beam alignment

Example

Beam alignment and setting the provisional beam

position

%_N_????

;R02=1 Include approximate set cal. data

;R07=d Axial distance between measures

;R18=r Tool diameter

;R26=z Search distance

T1

M6

D1

G0 G53 X302. Y-236.

M00 ; Handwheel to position

L9800

R02=1.R07=100. NOTE: Do not use the R02=1. input if you

want to keep the current calibration data.

M00

M30

31

Page 34

Calibrating the NC1

Calibrating the NC1 (subroutine L9861)

Subroutine L9861 is used for regular calibration of the NC1 system. It

should also be used after the laser beam has been aligned with the

Beam alignment cycle. The Calibration cycle is used for the following

tasks:

n

Accurately calibrating the positions of the beam in the X, Y and Zaxes.

n

Compensating for variations in the spindle axis and radialmeasuring axis due to temperature changes in the machine tool.

Temperature compensation is described in “Temperature

compensation tracking (subroutine L9861)” on page 79.

CAUTION: Before running this cycle or any other cycle

(except the Beam alignment subroutine L9860), nominal

!

calibration data must be loaded.

This data can be entered automatically using the Beam alignment

subroutine L9860, with the R02=1 input. Alternatively, approximate

data can be entered manually (for details, see “Parameter store for

calibration data” on page 12).

Calibration tool required

This cycle requires a calibration tool to be loaded in the spindle of the

machine and the tool number (T) must be active.

Ideally, this should be a solid, flat-bottomed, cylinder-type tool having

minimal runout. The exact setting length and diameter of this tool

must be known.

32

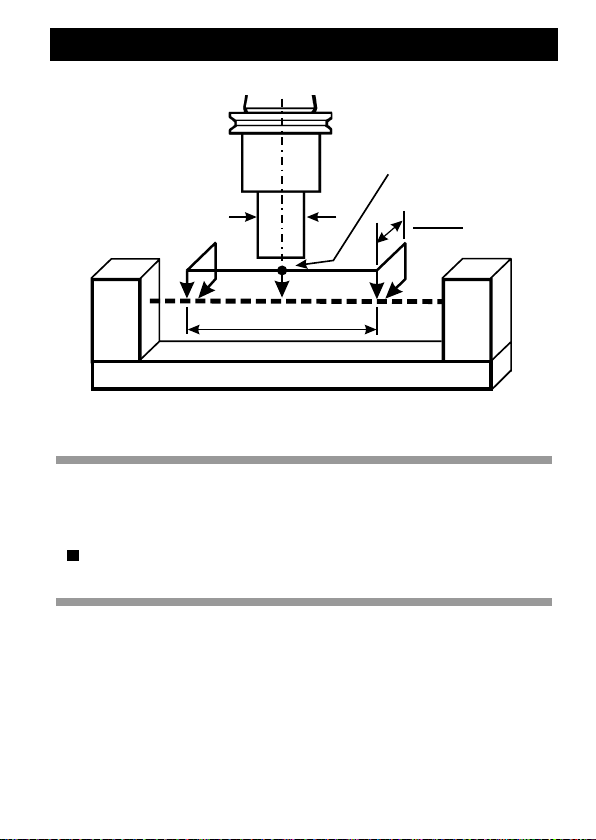

Page 35

Calibrating the NC1

R06=k

R19=s

1

2

R25=y

R17=q

3

R26=z

R18=r

R26=z

4

Description

Load the calibration tool in the spindle of the machine and make the

tool number (T) active before running the cycle.

The position of the beam in the Z-axis and the centre of the beam in

either the X or Y-axis are calibrated while the tool is rotated. The

beam width is then calibrated with the tool static. This eliminates

runout errors that may be introduced by the tool.

Refer to the figure above for cycle moves.

33

Page 36

Calibrating the NC1

Format R02=1. R18=r [R03=c R06=k R17=q R19=s R25=y

R26=z]

L9861

where [ ] denotes optional inputs

Example R02=1. R06=100.210 R18=12. R03=4. R17=5.

R19=2500. R25=5. R26=5.

L9861

Subroutine inputs

The following inputs are used with this subroutine:

R02=1. Calibration of the system.

R03=c c= Zero offset number used to track axis growth.

When used with the R02=b input, it stores the relevant

zero offset values as the reference position ready for

use later.

(See also “Temperature compensation tracking” on

page 79.)

R03=1 to R03=4 (G54 to G57)

R06=k k= Reference length of the calibration tool.

Default value: Value in the selected tool offset register

(which must be an exact known length).

R17=q q= Overtravel distance and radial clearance.

For details, see “Setting-data subroutine L9760” on

page 13.

Default value: 5.0 mm (0.197 in)

34

Page 37

Calibrating the NC1

R18=r r= Reference diameter of the calibration tool.

R19=s s= Spindle speed at which calibration takes place. For

details, see “Setting-data subroutine L9760” on page

13.

Default value: 3150 rev/min

R25=y y= Radial step-over for length calibration.

The offset across the beam at which measurement

takes place. The tool always comes down first on the

beam centre-line.

Default value: On-centre

R26=z z= Measuring height on tool.

Determines the height of the beam on the tool at which

diameter calibration takes place.

Default value: 5 mm (0.197 in)

Outputs

The following outputs are set or updated when this cycle is executed:

RENC[12] Temperature compensation error for length

measurement.

RENC[13] Temperature compensation error for radial

measurement.

RENT[20] Z-axis position of the beam, when measured from the

positive side of the beam.

RENT[22] X or Y-axis position of the beam, when measured from

the positive side of the beam.

35

Page 38

Calibrating the NC1

RENT[23] X or Y-axis position of the beam, when measured from

the negative side of the beam.

RENT[24] Position at which the beam is measured.

RENT[26] Spindle (length-measuring) axis temperature

compensation zero offset.

RENT[27] Radial-measuring axis temperature compensation zero

offset.

Alarms

The following alarms may be generated when this cycle is executed.

ACTIVE BEAM CUT

BEAM NOT CUT

FORMAT ERROR

OUT OF TOLERANCE

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

Example

Calibration

Using a calibration tool T1, which is 88.0 mm (3.46 in) long and

6.0 mm (0.236 in) diameter.

%_N_????

T1

M6

D1

36

Page 39

Calibrating the NC1

L9800

R02=1.R06=88.R18=6.

L9861

M30

IMPORTANT: If you need to track the axis growth caused by

temperature variation during the machining operation, use the R03=c

input to store the relevant zero offset registers as reference values.

Example: R02=1. R06=88. R18=6. R03=1.

L9861

37

Page 40

Tool length setting

Tool length setting (subroutine L9862)

Subroutine L9862 is used to measure the effective length of a cutting

tool. The Tool length measurement cycle is suitable for on-centre

setting of tools such as drills and ball-end mills, and for off-centre

setting of tools such as face mills and end mills.

Description

Tool length is measured while the tool is rotating. The figure shows

the two cycle types.

Length setting

with no R25=y

input

38

1

Length setting

with R25=y

input

2

R25=y

Page 41

Tool length setting

The effective tool length is written to the current tool register and

nominated edge number (D). By default, the current tool number and

edge will be set.

Format [R02=1. R11=h R05=j R13=m R14=t R17=q R19=s

R25=y]

L9862

where [ ] denotes optional inputs

Example R02=1. R11=0.5 R05=0.25 R13=1. R14=2. R17=5.

R19=2500 R25=3.

L9862

Subroutine inputs

The following inputs are used with this subroutine:

R02=1. Set the length of the tool.

R02=1. is the default R02 input.

R05=j j= Experience value for length.

This value is the difference between the measured

length of the tool and the effective length when the tool

is under load during the cutting process. It is used to

refine the measured length, based on previous

experience of how the effective length differs from the

measured length when the tool is being used.

Default value: Not used.

R11=h h= Tolerance value that defines when the tool length is out

of tolerance.

When this input is used, the tool offset is not updated if

39

Page 42

Tool length setting

the tool length is found to be out of tolerance.

Default value: No tolerance check.

R13=1. Tool out of tolerance flag.

Using this flag prevents a tool OUT OF TOLERANCE

alarm from being raised.

R14=t t= Tool offset edge to be updated (usually up to nine

edges).

R14=3 Updates the current tool offset, edge D3.

If R14 is not input, the current tool offset edge (D) is

updated. The current tool is the number of the tool in

the spindle.

R17=q q= Overtravel distance.

For details, see “Setting-data subroutine L9760” on

page 13.

Default value: 5.0 mm (0.197 in)

R19=s s= Spindle speed at which length measurement takes

place. For details, see “Setting-data subroutine L9760”

on page 13.

Default value: 3150 rev/min

R25=y y= Radial step-over for length setting.

This is the offset across the beam at which length

measurement takes place. The value must be less than

the radius of the tool. The tool always comes down first

on the beam centre-line.

Default value: On-centre

40

Page 43

Tool length setting

Outputs

The following outputs are set or updated when this cycle is executed:

Set tool length

RENC[48] Out of tolerance flag. This is set when the measured

tool length is out of tolerance, provided the R11=h input

is used.

(1 = Out of tolerance, 0 = In tolerance)

Alarms

The following alarms may be generated when this cycle is executed.

FORMAT ERROR

OUT OF TOLERANCE

RPM OUT OF RANGE

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

Examples

Tool length setting – on-centre tool

%_N_????

T1

M6

D1

L9800

R02=1. Set tool offset (1) on centre

41

Page 44

Tool length setting

L9862

M30

A different tool edge offset can be set by using the R14=t input on the

call line as follows:

R02=1.R14=2.R19=4000. Set tool offset edge D2 on centre.

L9862 Controlled rev/min.

Tool length setting – off-centre tool

Assume the tool is 80mm (3.15in) diameter.

%_N_????

T1

M6

L9800

R02=1.R25=38.R19=800. Set tool offset (1) at 38 mm (1.496 in)

radial step-over. Controlled rev/min.

L9862

M30

42

Page 45

Tool radius/diameter setting

Tool radius/diameter setting (subroutine

L9862)

Subroutine L9862 is used for measuring the effective radius/diameter

of a tool. The Tool radius measure cycle allows the radius/diameter to

be measured from the positive side of the beam, from the negative

side of the beam, or from both sides of the beam.

Description

The radius/diameter of a tool is measured while the tool is rotating.

The figure shows the cycle moves. Radial measurement (2) can be

1

2

R17=q

R18=r

R24=x

R26=z

43

Page 46

Tool radius/diameter setting

made on either one or both sides of the beam (see setting RENC[13]

in “Setting-data subroutine L9760” on page 13).

The effective radius/diameter is written into the tool offset register.

The wear register is zeroed and the radius/diameter value is placed in

the geometry register.

Format R02=2. [R11=h R04=i R13=m R14=t R17=q R18=r

R19=s R24=x R26=z]

L9862

where [ ] denotes optional inputs

Example R02=2. R11=0.5 R04=0.2 R13=1. R14=2. R17=5.

R18=25. R19=3000 R24=2. R26=6.

L9862

Subroutine inputs

The following inputs are used with this subroutine:

NOTE: If radial measurement at an exact height on the tool is

required, use the tool length and radius setting cycle (input R02=3).

This cycle automatically sets the length accurately before setting the

radius.

R02=2. Measure the radius of the tool.

R04=i i= Experience value for diameter or radius.

This value is the difference between the measured

diameter/radius of the tool and the actual diameter/

radius when the tool is under load during the cutting

process. It is used to define the measured diameter/

44

Page 47

Tool radius/diameter setting

radius, based on previous experience of how the

effective diameter/radius differs from the measured

diameter/radius when the tool is under load.

Default value: Not used.

NOTE: For cutter centre-line programming

applications, entering the nominal size as an

experience value will result in the error being stored

instead of the full radius/diameter of the cutter.

R11=h h= Tolerance value that defines when the tool diameter is

out of tolerance.

When this input is used, the tool offset is not updated if

the tool diameter is found to be out of tolerance.

Default value: No tolerance check.

R13=1. Tool out of tolerance flag.

Using this flag prevents a tool OUT OF TOLERANCE

alarm from being raised.

R14=t t= Tool offset edge to be updated (usually up to nine

edges).

R14=3 Updates the current tool offset, edge D3.

If R14 is not input, the current tool offset edge (D) is

updated. The current tool is the number of the tool in

the spindle.

45

Page 48

Tool radius/diameter setting

R17=q q= Overtravel distance and radial clearance.

For details, see “Setting-data subroutine L9760” on

page 13.

Default value: 5.0 mm (0.197 in)

R18=r r= Diameter of tool.

This is the nominal diameter of the tool.

Default value: Maximum diameter of tool in

RENC[12].

R19=s s= Spindle speed at which diameter measurement takes

place. For details, see “Setting-data subroutine L9760”

on page 13.

Default value: 3150 rev/min

R24=x x= Spindle axis search distance.

This defines a search distance above the R26=z input

measuring height, which can be used to find a radial

high spot on the cutter. It is suitable for single-point

boring bars and cutters with irregular radial profiles.

Cycle time is increased using this input.

Default value: Zero (0)

R26=z z= Measuring height of tool.

This is the Z-axis position from the end face of the tool

at which measurement takes place.

Default value: 5.0 mm (0.197 in)

46

Page 49

Tool radius/diameter setting

Outputs

The following outputs are set or updated when this cycle is executed:

Set tool radius/diameter

RENC[48] Out of tolerance flag. This is set when the measured

tool length is out of tolerance, provided the R11=h input

is used.

(1 = Out of tolerance, 0 = In tolerance)

Alarms

The following alarms may be generated when this cycle is executed.

FORMAT ERROR

OUT OF TOLERANCE

RPM OUT OF RANGE

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

Examples

Tool radius setting 1

Assume the tool is a 10 mm (0.394 in) diameter slot drill.

%_N_????

T1

M6

L9800

47

Page 50

Tool radius/diameter setting

R03=2.R14=2. Inputs to set tool radius edge D2.

L9862

M30

Tool radius setting 2

Assume the tool is an 80 mm (3.15 in) diameter cutter.

%_N_????

T2

M6

L9800

R03=2.R19=800.R18=80. Inputs to set current tool radius

edge (default). Controlled rev/min and

radial clearance.

L9862

M30

48

Page 51

Tool length and radius setting

Tool length and radius setting (subroutine

L9862)

Subroutine L9862 is used for measuring the effective length and

radius/diameter of a tool. The Tool length and radius measure cycle is

particularly suitable for tools such as face mills, end mills, slot cutters,

disc mill cutters, dovetail cutters and boring tools.

1

2

R25=y

R17=q

3

R18=r

R24=x

R26=z

49

Page 52

Tool length and radius setting

Description

This single cycle combines the Tool length measuring cycle (see “Tool

length setting” on page 38) and Tool radius/diameter measuring cycle

(see “Tool radius/diameter setting” on page 43).

The figure shows the combined cycle moves. Radial measurement (3)

can be made on either one or both sides of the beam (see setting

RENC[13] in “Setting-data subroutine L9760” on page 13).

Length and radius values are written into the tool offset register. The

wear registers are zeroed and the values are placed in the geometry

registers.

Format R02=3. [R11=h R04=i R05=j R13=m R14=t R17=q

R18=r R19=s R24=x R25=y R26=z]

L9862

where [ ] denotes optional inputs

Example R02=3. R11=0.2 R04=0.2 R05=0.025 R13=1. R14=2.

R17=5. R18=25. R19=2500 R24=2. R25=3. R26=6.

L9862

Subroutine inputs

The following inputs are used with this subroutine:

R02=3. Measure the length and radius of the tool.

R04=i i= Experience value for diameter or radius.

This value is the difference between the measured

diameter/radius of the tool and the actual diameter/

radius when the tool is under load during the cutting

50

Page 53

Tool length and radius setting

process. It is used to define the measured diameter/

radius, based on previous experience of how the

effective diameter/radius differs from the measured

diameter/radius when the tool is under load.

Default value: Not used.

NOTE: For cutter centre-line programming

applications, entering the nominal size as an

experience value will result in the error being stored

instead of the full radius/diameter of the cutter.

R05=j j= Experience value for length.

This value is the difference between the measured

length of the tool and the actual length when the tool is

under load during the cutting process. It is used to

refine the measured length, based on previous

experience of how the effective length differs from the

measured length when the tool is under load.

Default value: Not used.

R11=h h= Tolerance value that defines when the tool is out of

tolerance.

When this input is used, the tool offset is not updated if

the tool is found to be out of tolerance.

Default value: No tolerance check.

R13=1. Tool out of tolerance flag.

Using this flag prevents a tool OUT OF TOLERANCE

alarm from being raised.

51

Page 54

Tool length and radius setting

R14=t t= Tool offset edge to be updated (usually up to nine

edges).

R14=3 Updates the current tool offset, edge D3.

If R14 is not input, the current tool offset edge (D) is

updated. The current tool is the number of the tool in

the spindle.

R17=q q= Overtravel distance and radial clearance.

For details, see “Setting-data subroutine L9760” on

page 13.

Default value: 5.0 mm (0.197 in)

R18=r r= Diameter of tool.

This is the nominal diameter of the tool.

Default value: Maximum diameter of tool in

RENC[12].

R19=s s= Spindle speed at which length and diameter

measurement takes place. For details, see “Settingdata subroutine L9760” on page 13.

Default value: 3150 rev/min

R24=x x= Spindle axis search distance.

This defines a search distance above the R26=z input

measuring height, which can be used to find a radial

high spot on the cutter. It is suitable for single-point

boring bars and cutters with irregular radial profiles.

Cycle time is increased using this input.

Default value: Zero (0)

52

Page 55

Tool length and radius setting

R25=y y= Radial step-over for length setting.

This is the offset across the beam at which length

measurement takes place. The value must be less than

the radius of the tool. The tool always comes down first

on the beam centre-line.

Default value: On-centre

R26=z z= Measuring height of tool.

This is the Z-axis position from the end face of the tool

at which measurement takes place.

Default value: 5.0 mm (0.197 in)

Outputs

The following outputs are set or updated when this cycle is executed:

Set tool length

Set tool radius/diameter

RENC[48] Out of tolerance flag. This is set when the measured

tool length is out of tolerance, provided the R11=h input

is used.

(1 = Out of tolerance, 0 = In tolerance)

Alarms

The following alarms may be generated when this cycle is executed.

FORMAT ERROR

OUT OF TOLERANCE

RPM OUT OF RANGE

53

Page 56

Tool length and radius setting

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

Examples

Tool length/radius setting 1

Assume the tool is a 10 mm (0.394 in) diameter slot drill.

%_N_????

T1

M6

D1

L9800

R03=3.R14=2. Inputs to set tool length/radius edge D2.

L9862

M30

Tool length/radius setting 2

Assume the tool is an 80 mm (3.15 in) diameter cutter.

%_N_????

T1

M6

D1

L9800

R03=3.R14=2. Inputs to set current tool length at 38 mm

R25=38.R19=800. (1.496 in) radial step-over and radial offset

edge D2. Controlled rev/min.

L9862

M30

54

Page 57

Cutting edge checking

Cutting edge checking (subroutine L9862)

NOTE: This cycle can be used only if the latch mode feature of the

NC1 system is installed and operational.

Subroutine L9862 is used for checking the cutting edges of a tool.

The diameter Cutting edge check cycle checks for either missing or

damaged teeth or for excessive runout of the cutter.

1

2

R25=y

R17=q

3

R18=r

R24=x

R26=z

4

R06=k

55

Page 58

Cutting edge checking

Description

Before a tool is checked for missing teeth or excessive runout, it is

first set for radius/diameter. The diameter Cutting edge check cycle

then moves the rotating tool into the beam until the teeth interfere

with the beam by the cutting edge runout tolerance value. This value

is defined by the R06=k input.

The spindle speed is calculated from the minimum pulse signal delay

RENC[15] of the NC1 system and the number of teeth on the cutting

tool. This ensures that when each tooth enters the beam, a

permanent beam cut signal is held unless a tooth is either missing or

is out of tolerance. The beam cut signal is monitored for a minimum of

two revolutions.

Format R02=2. or R02=3. R03=c [R06=k R13=m R17=q R18=r

R19=s R26=z R24=x R09=f]

L9862

where [ ] denotes optional inputs

Example R02=2. or R02=3. R03=6. R06=0.02 R13=1. R17=5.

R18=25. R19=2500 R26=6. R24=5. R09=0.1

L9862

Subroutine inputs

The following inputs are used with this subroutine:

R02=2. For details of these cycles, see either “Tool radius/

R02=3. diameter setting” on page 43 or “Tool length and radius

setting” on page 49.

R02=4. Cutting edge check without tool offset updating.

56

Page 59

Cutting edge checking

R03=c c= The number of teeth on the tool. This automatically

selects the cutting edge check.

Default value: No default.

R06=k k= The tolerance value that defines when the tool cutting

edge runout is excessive.

Default value: 0.025 mm (0.0098 in)

R09=f f= Feedrate-per-rev. for cylinder profile checking when

using the R24=x input.

Default value: 0.1 mm (0.0394 in)

R13=1. Tool out of tolerance flag.

Using this flag prevents a tool OUT OF TOLERANCE

alarm from being raised.

R17=q q= Overtravel distance and radial clearance.

For details, see “Setting-data subroutine L9760” on

page 13.

Default value: 5.0 mm (0.197 in)

R18=r r= Nominal diameter of the tool.

Default value: Maximum diameter of tool in

RENC[12].

R19=s s= Spindle speed at which radius/diameter measurement

takes place. For details, see “Setting-data subroutine

L9760” on page 13.

The spindle speed for cutting edge checking is set

automatically and is based on the minimum pulse

57

Page 60

Cutting edge checking

signal delay of the control and the number of teeth on

the tool.

Default value: 3150 rev/min.

R24=x x= Cylinder profile checking distance, i.e. the spindle axis

movement, while edge checking. The value is

incremental from the R26=z input radial measuring

position. It is used in conjunction with the R09=f input

feed rate.

Default value: Zero (0)

R26=z z= Measuring height of tool.

This is the Z-axis position from the end face of the tool

at which measurement takes place.

Default value: 5.0 mm (0.197 in)

Outputs

The following output is set or updated when this cycle is executed:

RENC[48] Out of tolerance / Missing edge flag.

This is set when either the tool cutting edge runout is

out of tolerance, provided the R06=k input is used, or

an edge is missing from the tool.

(2 = Out of tolerance / edge missing

0 = In tolerance / no edges missing)

Alarms

The following alarms may be generated when this cycle is executed.

ACTIVE BEAM CUT

58

Page 61

Cutting edge checking

FORMAT ERROR

OUT OF TOLERANCE

RPM OUT OF RANGE

RUN-OUT/EDGE MISSING

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

Examples

Cutting edge checking

Assume a 2-flute slot drill and check for a broken edge 0.5 mm from

the end face of the cutter.

%_N_????

T1

M6

D1

L9800

R02=2.R03=2.R26=0.5

L9862

Cylinder cutting edge checking

%_N_????

T1

M6

D1

L9800

R02=3.R03=2.R26=0.5R24=5.0

L9862

59

Page 62

Broken tool detection (plunge check)

Broken tool detection – plunge checking

(subroutine L9863)

Subroutine L9863 is used to check for breakage of cutting tools. The

Broken tool cycle uses a plunge check, where the tool is moved into

and out of the laser beam in the axis used for length setting. The

cycle can also check for a ‘long tool’ condition, where the tool has

possibly pulled out during machining.

Typically, a tool needs to be checked after a machining operation to

verify that it is not broken before the next tool is selected.

R26=z

60

R11=h

R25=y

Page 63

Broken tool detection (plunge check)

Description

Detection of a broken tool occurs while the tool is rotated in the

beam. Moves into and out of the beam are at the rapid feedrate.

The tool first moves over the beam, in the X and Y axes, to the

measuring position and then moves, in Z, to the tool checking

position.

When a positive R11=h input is used, the tool is checked at the

broken tool position only. When a negative R11=h input is used, the

tool is checked at both the long tool and broken tool positions.

At the end of the cycle, the tool moves out of the beam to the safe

position in the spindle axis only.

Format [R11=h R13=m R19=s R25=y R26=z]

L9863

where [ ] denotes optional inputs

Example R11=5. R13=1. R19=2800. R25=3. R26=6.

L9863

Subroutine inputs

The following inputs are used with this subroutine:

R11=h h= Tolerance value that defines when the tool is defined as

broken. A negative value (R11= –) checks the tool for

both broken and long tool conditions.

Default value: 0.5 mm (0.0197 in).

61

Page 64

Broken tool detection (plunge check)

R13=1. Tool broken flag.

Using this flag prevents a BROKEN TOOL or OUT OF

TOLERANCE alarm from being raised.

R19=s s= Spindle speed at which checking for a broken tool takes

place. For details, see “Setting-data subroutine L9760”

on page 13.

Default value: 3150 rev/min.

R25=y y= Radial step-over distance.

The offset across the beam at which measurement of

the tool length takes place.

Default value: On-centre

R26=z z= Safety plane.

The distance (in the spindle axis) to which the tool is

retracted.

Default value: No retract

Outputs

The following output is always set when this cycle is executed:

RENC[48] Broken tool flag.

(2 = long tool, 1 = broken tool, 0 = good tool)

62

Page 65

Broken tool detection (plunge check)

Alarms

The following alarms may be generated when this cycle is executed.

BROKEN TOOL

FORMAT ERROR

RPM OUT OF RANGE

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

Example

Broken tool detection – plunge check

%_N_????

T1

M6

D1

G0Z200. Move to a safe position where the broken tool

cycle can be called.

X200.Y300.

L9800

R26=100. Make a broken tool check. Either a broken

L9863 tool alarm is raised and the program stops, or

the program continues.

T2 Select the next tool and continue.

M6

(continue machining)

63

Page 66

Broken tool detection (plunge check)

If the broken tool flag method is used, the call cycle is modified as

follows:

L9800

R26=100.R13=1. Make a broken tool check without raising an

alarm.

The RENC[48] flag is set.

L9863

IF RENC[48]==1 GOTOF LN100 Go to LN100

(continue program)

Block LN100 will contain corrective actions. For example, selecting a

sister tool for use, or selecting a new pallet/component.

64

Page 67

Broken tool detection (radial check)

Broken tool detection – radial checking

(subroutine L9864)

Subroutine L9864 is used to check for breakage of cutting tools. The

Broken tool cycle uses a radial check, where the tool is moved

through the laser beam in the direction used for radius/diameter

setting.

Typically, a tool needs to be checked after a machining operation to

verify that it is not broken before the next tool is selected.

Description

Detection of a broken tool occurs while the tool is rotated in the

beam. Moves through the beam are at the rapid feedrate.

R25=y

R26=z

R11=h

65

Page 68

Broken tool detection (radial check)

The cycle rapids the tool to the measuring height at a depth defined

by the broken tool tolerance value (R11=h input) The tool then moves

in rapid through the beam and is monitored for a broken tool

condition, i.e. the beam is not cut. The radial distance moved by the

tool from the beam centre-line is defined by the R25=y input.

At the end of the cycle, the tool moves out of the beam to the safe

position in the spindle axis only.

CAUTION

!

installed and operational if the R25=y input is to be used when

passing the tool through the beam.

2. Before this cycle is called, the tool must be moved to a safe, clear

position in the Z, X, and Y axes. Ensure that the position along the

beam axis to which the tool is moved is safe for radial checking.

1. The latch mode feature of the NC1 system must be

Format [R11=h R13=m R19=s R25=y R26=z]

L9864

where [ ] denotes optional inputs

Example R11=5. R13=1. R19=2800 R25=3. R26=6.

L9864

66

Page 69

Broken tool detection (radial check)

Subroutine inputs

The following inputs may be required for this subroutine:

R11=h h= Tolerance value that defines when the tool is defined as

broken.

Default value: 0.5 mm (0.0197 in).

R13=1. Tool broken flag.

Using this flag prevents a BROKEN TOOL alarm from

being raised.

R19=s s= Spindle speed at which checking for a broken tool takes

place. For details, see “Setting-data subroutine L9760”

on page 13.

Default value: 3150 rev/min.

R25=y y= Monitoring distance past the beam centre-line.

Use a Y– (negative) value for a negative axis move.

Default value: On-centre

R26=z z= Safety plane.

The distance (in the Z-axis) to which the tool is

retracted.

Default value: No retract

Outputs

The following output is always set when this cycle is executed:

RENC[48] Broken tool flag.

(1 = broken tool, 0 = good tool)

67

Page 70

Broken tool detection (radial check)

Alarms

The following alarm may be generated when this cycle is executed.

BROKEN TOOL

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

Example

Broken tool detection – radial check

%_N_????

T1

M6

D1

G0Z200.

(complete the machining sequence with tool T1)

G0Z200. Move to a safe position in the Z-axis

where the broken tool cycle can be

called.

X200.Y300. Move to a safe position in the X and Y

axes where the broken tool cycle can

be called.

L9800

R25=50.R26=100. Make a broken tool check. Either a

L9864 BROKEN TOOL alarm is raised and

the program stops, or the program

continues.

68

Page 71

Broken tool detection (radial check)

T2

M6 Select the next tool and continue.

(continue machining)

If the broken tool flag method is used, the call cycle is modified as

shown:

L9800

R25=50.R26=100.R13=1. Make a broken tool check

L9864 without raising an alarm.

The RENC[48] flag is set.

IF RENC[48]==1 GOTOF LN100 Go to LN100

(continue program)

Block LN100 will contain corrective actions. For example, selecting a

sister tool for use, or select a new pallet/component.

69

Page 72

Cutter radius and linear profile checking

Cutter radius and linear profile checking

(subroutine L9865)

NOTE: This cycle can be used only if the latch mode feature of the

NC1 system is installed and operational.

This cycle is used to check the profile of ballnose cutters, cutters with

corner radii, and cutters with linear profiles. The profile is checked to

find out if it is within a specified form tolerance.

Application

The tool is retracted to the home position for safety before each

profile check unless a secondary profile check is to be performed on

the same tool (see use of inputs R02=4, R02=5, and R02=6). The

tool is positioned over the laser beam and is moved first to the

longest tool position, then to the profile start position with the spindle

rotating. The defined cutter profile is traced at the checking feedrate.

Finally, the tool is retracted out of the beam. An error flag is always

set and an alarm is optionally generated if the cutter is out of

tolerance.

If both + and – tolerance checking is specified with the R02=3 and

R02=6 inputs, the cutter is repositioned after the negative (–)

tolerance check and a reverse profile check is made along the profile.

Finally, the tool is retracted.

70

Page 73

Cutter radius and linear profile checking

With R18=r input

R11=h

R25=y

–Tol.

R06=k

R18=r

R05=j

R17=q

Checking a

linear profile

Format

For radius profile checking

R18=r R24=x [R02=b R03=c R09=f R11=h R05=j

R06=k R13=m R14=t R17=q R19=s R25=y R26=z]

L9865

where [ ] denotes optional inputs

+Tol.

R24=x

No R18=r input

R06=k

R25=y

Checking a profile

with corner radius

–Tol.

+Tol.

R17=q

R24=x

R11=h

71

Page 74

Cutter radius and linear profile checking

Example R18=10. R24=5. R02=3. R03=4. R09=0.3 R11=1.

R05=1. R06=1. R13=1 R14=2. R17=90. R19=4000.

R25=5. R26=50.

L9865

For linear profile checking

R24=x [R02=b R03=c R09=f R11=h R06=k R13=m

R14=t R17=q R19=s R25=y R26=z]

L9865

where [ ] denotes optional inputs

Example R24=5. R02=1. R03=4. R09=0.3 R11=.5 R06=1.

R13=1 R14=2. R17=90. R19=4000. R25=5. R26=50.

L9865

Subroutine inputs

R02=1. Check the cutter profile along the negative (–) tolerance

profile limit (see the figures on page 71).

R02=2. Check the cutter profile along the positive (+) tolerance

profile limit (see the figures on page 71).

R02=3. Combine both R02=1. and R02=2. profile checking in

one operation. This is the default if the R02= input is

not used.

R02=4. These are the same as the R02=1., R02=2., and

R02=5. R02=3. inputs respectively, except that the tool does

R02=6. not retract first. These cycles are suitable for performing

secondary profile checks on the same tool.

72

Page 75

Cutter radius and linear profile checking

TIP: To prevent retracting at the end of the cycle, use

an R26=0 input.

R03=c c= When this input is used, enter the number of cutting

edges on the tool. The spindle speed is then

automatically adjusted to enable errors on each cutting

edge to be checked.

The cycle time using this method is significantly

increased, unless the default 0.1 mm/rev (0.004 in/rev)

is increased using the R09=f input.

Default value: The spindle speed is set by either the

R19=s input, or by the default value defined in the

setting subroutine L9760 when no R19=s input is used.

R03=1. The spindle speed is automatically adjusted for a cutter

with a single cutting-edge to ensure it is properly

checked.

This is also suitable for multiple-tooth cutters, when

only the maximum/minimum cutting-edge profile needs

to be checked. The cycle time will be faster than

checking each individual cutting edge.

R06=k k= The tolerance value that defines when the cutter profile

is out of limits.

Default value: 0.025 mm (0.001 in)

R09=f f= Feedrate specified as feed/rev for profile checking.

Default value: 0.1 mm/rev (0.004 in/rev)

73

Page 76

Cutter radius and linear profile checking

R13=1. Used to prevent an alarm being raised when the profile

is out of limits.

R14=t t= Tool length offset edge.

This is the offset location in which the measured tool

length is stored.

Default value: Current tool edge.

R19=s s= The spindle speed for the cutter.

This value is used for profile checking when no R03=c

input is used; otherwise, the spindle speed is adjusted

automatically for profile checking.

Default value: 3150 rev/min.

R26=z z= Retract distance after profile checking.

The tool reference point is retracted to this position.

Default value: Retract to the home position

Additional subroutine inputs for radius profile checking

only

R05=j j= Start position adjustment relative to the cutter radius

centre for profile checking (see the figures on page 71).

Range: radial ³ 0 <R18=r input

R11=h h= The height from the tool length offset position to the

bottom of the radius profile, i.e. the J0 position (see the

figures on page 71).

Range: ³ 0

Default value: R06=k value.

74

Page 77

Cutter radius and linear profile checking

R17=q q= Included angle of the cutter radius.

Range: ³ 0° £ 90°

R18=r r= The cutter radius value.

R24=x x= Linear distance moved tangentially past the cutter

radius profile (see the figures on page 71).

Range: ³ 0

R25=y y= Radial distance to the cutter radius centre.

Range: ³ 0

Additional subroutine inputs for linear profile checking

only

R11=h h= The height to the first profile checking position (see the

figures on page 71).

This is the height above the tool length offset position.

Range: ³ 0

Default value: R06=k value.

R17=q q= Angle of the linear profile (see the figures on page 71).

Range: ³ 0° £ 90°

R24=x x= Distance along the surface for profile checking (see the

figures on page 71).

Range: ³ 0

R25=y y= Radial position to the first profile checking position.

Range: ³ 0

75

Page 78

Cutter radius and linear profile checking

Outputs

NOTE: When the R02=3. or R02=6. input is used and the tool is

found to be out of tolerance during the negative (–) tolerance profile

check, the cycle is automatically aborted and does not complete the

positive (+) tolerance profile check.

RENC[48]=0 The profile is in tolerance

RENC[48]=1 The profile is out of tolerance during negative (–)

tolerance profile checking

RENC[48]=2 The profile is out of tolerance during positive (+)

tolerance profile checking

Alarms

The following alarms may be generated when this cycle is executed.

FORMAT ERROR

RPM OUT OF RANGE

RUN-OUT/EDGE MISSING

TOOL OUT OF RANGE

For an explanation of the meaning of alarms, see “Error messages

and alarms” on page 85.

76

Page 79

Cutter radius and linear profile checking

Examples

Profile checking a Ø20 mm (0.787 in) ballnose cutter

Check the profile is within ±0.05 mm (0.002 in)

The profile checking starts at 1 mm (0.040 in) radial from the cutter

centre and then moves around the 90° radius, and then a further

15 mm (0.591 in) up the diameter of the tool

%_N_????

T1

M6

D1

L9800

R18=10.R24=15.R05=1.R06=.05

L9865

M30

77

Page 80

Cutter radius and linear profile checking

Profile checking a Ø20 mm (0.787 in) tapered cutter with

10° side taper

Check the profile is within ±0.05 mm (0.002 in).

The profile check starts at 1 mm (0.040 in) high and 10.176 mm

(0.401 in) radial, and then moves along the taper for 30 mm

(1.181 in).

%_N_????

T1

M6

D1

L9800

R11=1.R06=.05R17=80.R24=30.R25=10.176

L9865

M30

78

Page 81

Temperature compensation tracking

Temperature compensation tracking

(subroutine L9861)

Subroutine L9861 can be used to calibrate the NC1 system for

variations in the spindle axis and/or the radial-measuring axis caused

by temperature changes in the machine tool.

Run this cycle on a regular basis during machining operations to

compensate for growth in the spindle axis and/or radial-measuring

axis.

1

2

R25=y

R17=q

3

R18=r

79

Page 82

Temperature compensation tracking

Description

The calibration tool must be loaded in the spindle of the machine.

Refer to the figure showing cycle moves.

The subroutine is used as described previously in “Calibrating the

NC1 (subroutine L9861)” on page 32, but instead of resetting the

calibration data, the beam positions are compared with the original

calibration values. The deviation for each axis is then used to adjust

the relevant zero offset.

NOTE: It is important to use the same calibration tool and input

values that were previously used for calibration, except that input

R02=4., R02=5. or R02=6. is now used.

After the original reference values have been stored, independent

adjustments to the zero offset values are ignored and overwritten by

the temperature tracking cycle.

Format

For full temperature compensation

R02=6. R03=c R06=k R18=r [R17=q R19=s R25=y]

L9861

where [ ] denotes optional inputs

Example R02=6. R03=3. R06=88. R18=6. R17=5. R19=2500

R25=5.

L9861

80

Page 83

Temperature compensation tracking

For spindle axis temperature compensation

R02=4. R03=c R06=k [R17=q R19=s R25=y]

L9861

where [ ] denotes optional inputs

Example R02=4. R03=3. R06=88. R17=5. R19=2500 R25=5.

L9861

For radial measuring axis temperature compensation

R02=5. R03=c R18=r [R17=q R19=s]

L9861

where [ ] denotes optional inputs

Example R02=5. R03=3. R18=6. R17=5. R19=2500.

L9861

Subroutine inputs

The following inputs are used with this subroutine:

R02=4. Temperature compensation tracking in the spindle axis.

This performs a beam find and length measurement in

the spindle axis only.

R02=5. Temperature compensation tracking in the radial-

measuring axis. This performs a beam find and radial

measurement only.

R02=6. Temperature compensation tracking in both the spindle

axis and radial-measuring axis. This performs both

operations described for inputs R02=4. and R02=5.

81

Page 84

Temperature compensation tracking