Page 1

MRS installation and user's guide

Documentation part number H-1000-5088-06-A

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

1

Page 2

General information

©20012014Renishawplc.Allrightsreserved.

This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any means, without

the prior written permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE

OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES

LIABILITY, HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and other

countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are trade names, service marks, trademarks, or registered trademarks of their

respective owners.

Windows XP, Windows 2000, Vista and Windows 7 are registered trade names of the Microsoft Corporation.

All trademarks and trade names are acknowledged.

WEEE

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product should not be mixed with the

general household waste upon disposal. It is the responsibility of the end user to dispose of this product at a designated collection point for

waste electrical and electronic equipment (WEEE) to enable reuse or recycling. Correct disposal of this product will help save valuable

resources and prevent potential negative effects on the environment. For more information, please contact your local waste disposal service

or Renishaw distributor.

Warranty

Renishaw plc warrants its equipment for a limited period (as set out in our Standard Terms and Conditions of Sale) provided that it is

installed exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or cabling) is to be used or substituted.

Failure to comply with this will invalidate the Renishaw warranty.

Claims under warranty must be made from authorised service centres only, which may be advised by the supplier or distributor.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

2

Page 3

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise measurements and must therefore be treated with

care.

Changes to Renishaw products

Renishaw reserves the right to improve, change or modify its hardware or software without incurring any obligations to make changes to

Renishaw equipment previously sold.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

3

Page 4

References and associated documents

For instructions on fitting, datuming and operation of the ACR3, FCR25, SCP80, SCR600, RCP rack and port assemblies, please refer to

the following documents:

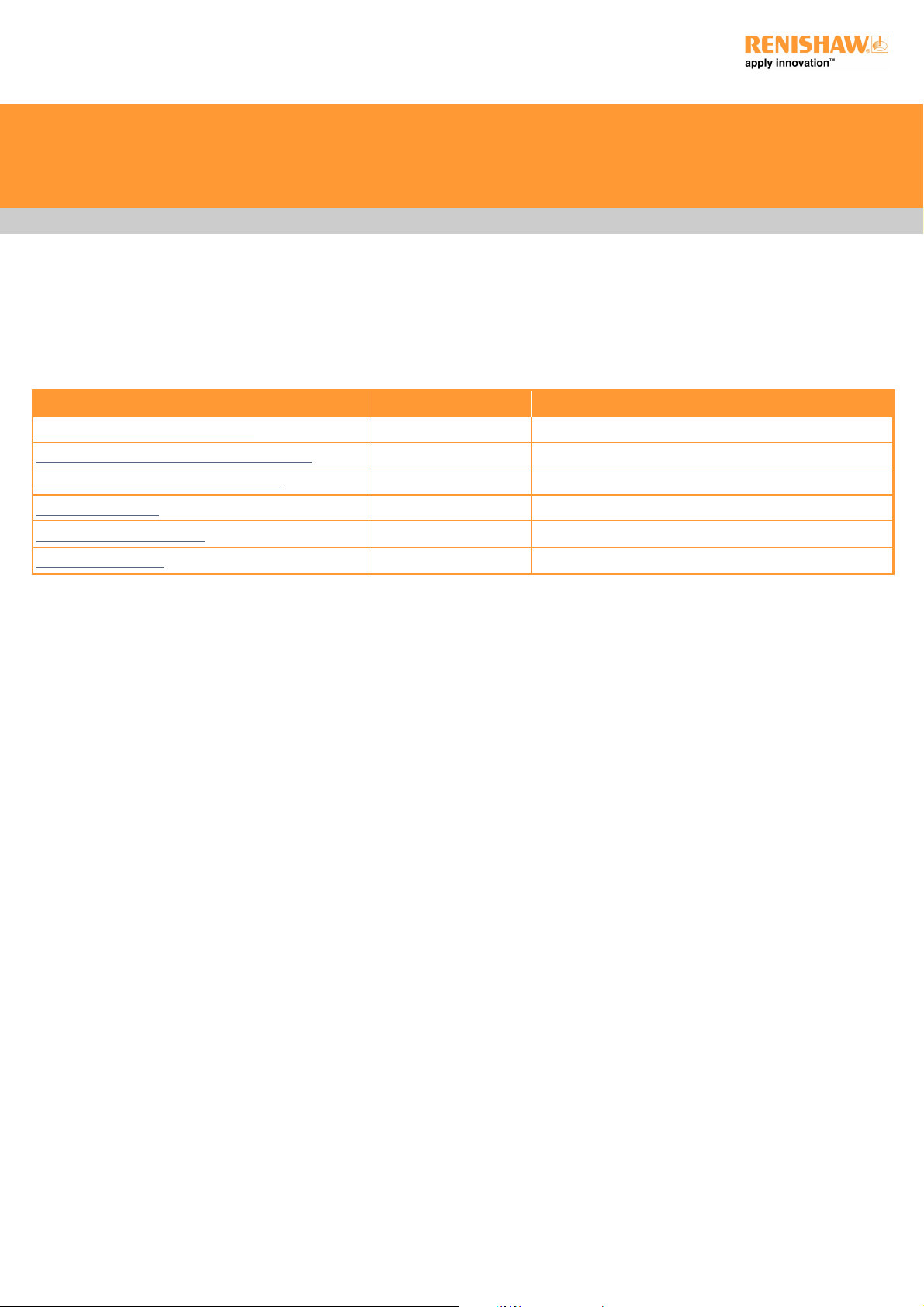

Title Document number Relevant topics

Installation and user's guide: ACR3 H-1000-5087 ACR3 autochange rack

Installation and user's guide: SP25M system H-1000-5104 FCR25 and FRC25 TC

Installation and integration guide: SP80 H-1000-5212 SCP80 stylus change port

User's guide: SP80 H-1000-5213 SCP80 stylus change port

Installation leaflet: SCP600 H-1000-5097 SCP600 stylus change port

User's guide: REVO H-1000-5129 RCP, RCP TC-2, SFCP, SFA, TDA and REVO

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

4

Page 5

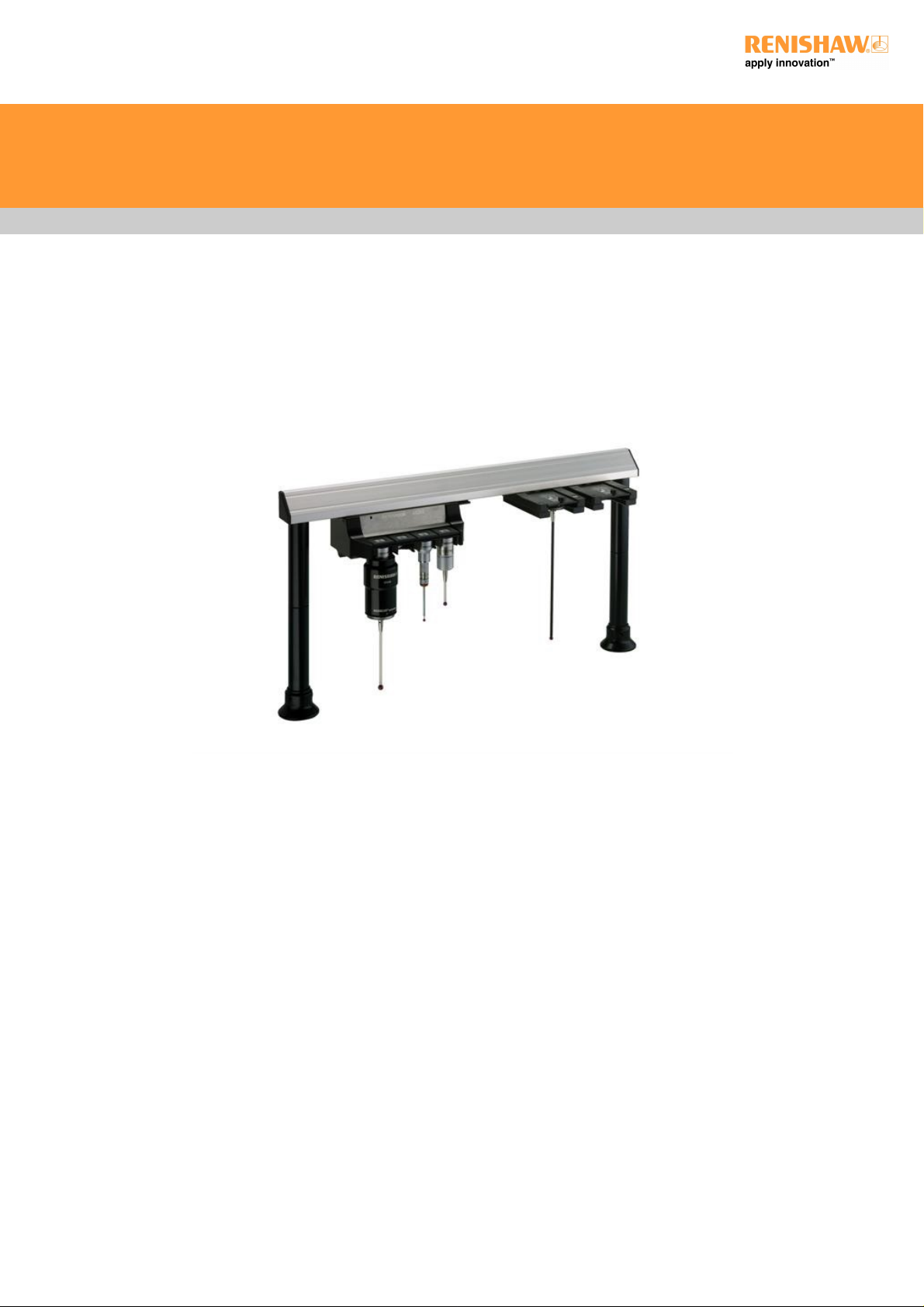

System description

The MRS is designed to provide a flexible platform for Renishaw probe and stylus changing racks.

The system comprises of an extruded aluminium rail mounted to the CMM table by two leg assemblies. It is available in rail lengths of 400

mm (15.75 in), 600 mm (23.62 in), 900 mm (35.43 in) and 1000 mm (39.37 in) to suit a variety of port and rack changing requirements.

Custom rail lengths are also available.

The MRS can be placed at different heights from the CMM table by using multiples of the MRS standard and heavy duty legs, thus allowing

clearance for long styli and extension bars.

The interconnecting MRS legs supplied (four per kit) are each 125 mm (4.92 in) long. A maximum recommended leg length of 500 mm

(19.69 in) can be achieved by purchasing additional legs. These are available in either 62.5 mm (2.46 in) or 125 mm (4.92 in) lengths. The

combined MRS rack and leg assembly is mounted on the CMM table via two MRS feet (see item 7 in illustration below). These extend the

overall height by 35 mm allowing a maximum clearance of 535 mm between the CMM table and the underside of the MRS rail.

Modular rack system compatibility

The MRS is compatible with the following Renishaw port and change rack systems:

ACR3 (autochange rack)

FCR25 (flexible change rack)

FRC25 TC (thermally controlled flexible change rack)

SCP80 (stylus change port for SP80)

SCP600 (stylus change port for SP600, SP600M and SP600Q)

RCP TC-2 (thermally controlled REVO change port)

RCP2 (change port for RSH stylus holders)

SFA and SFCP (for REVO surface finish probe)

TDA (REVO tip datum artefact)

Key

1. MRS rail

2. Port or rack

3. Fixing screw

4. MRS leg

5. Leg to foot adaptor

6. Grubscrews

7. MRS foot

8. Step-back adaptor

9. M8 screw

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

5

Page 6

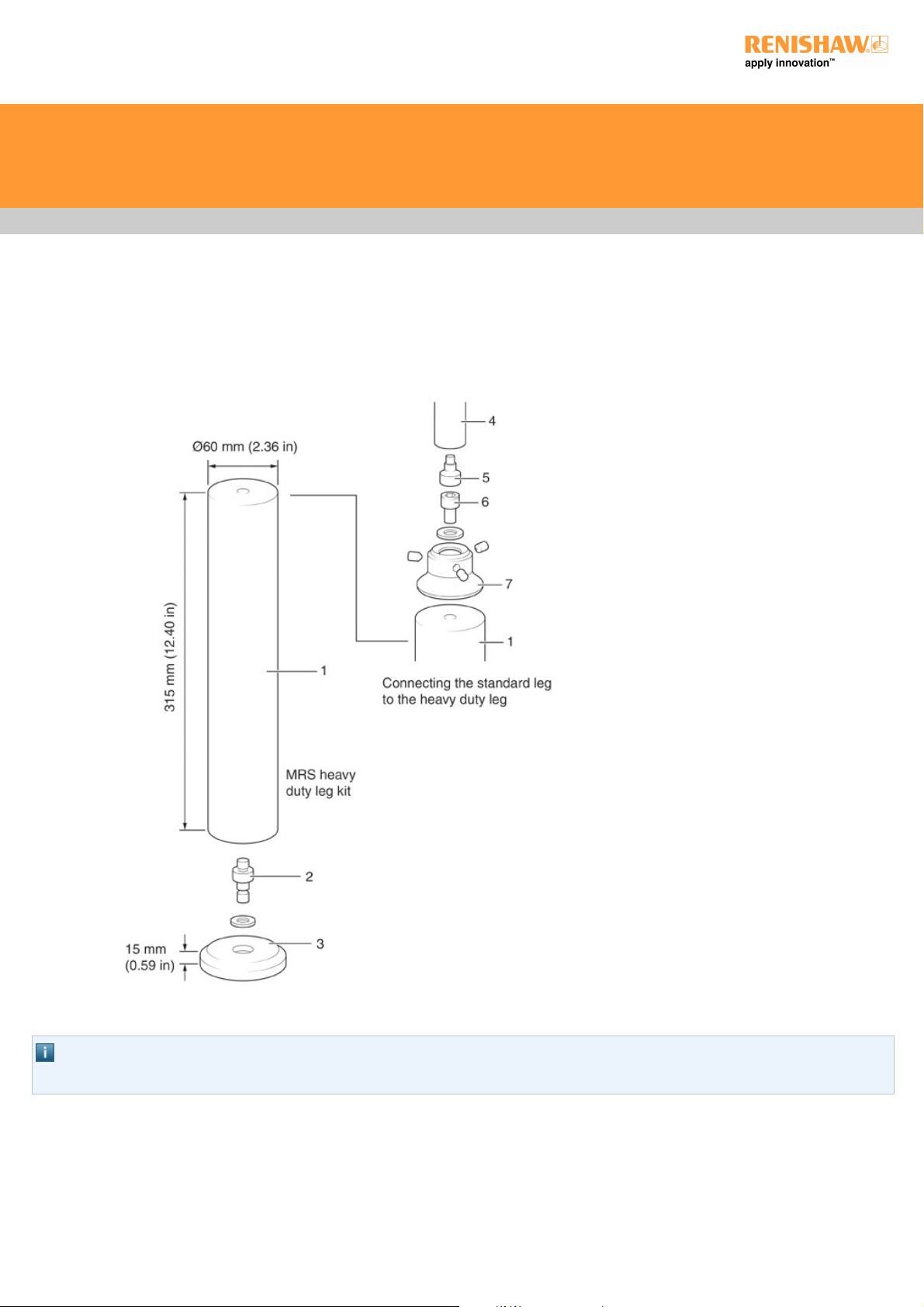

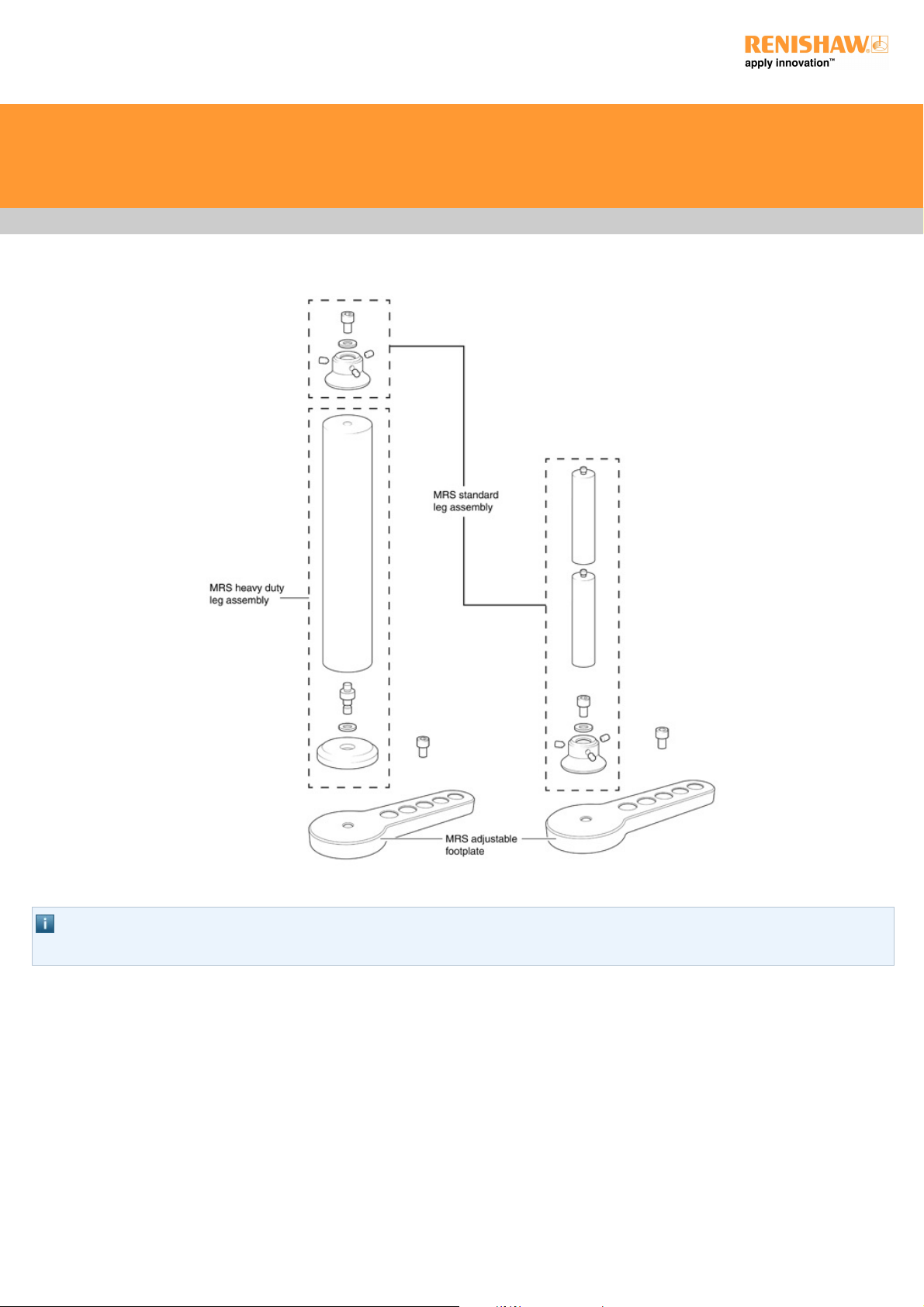

MRS heavy duty legs

Where heavier rack systems or longer styli configurations are used, such as multiple SCP80s or RCP TC-2s, the MRS system can be

upgraded by using optional heavy-duty legs that are 60 mm (2.36 in) in diameter and 350 mm (13.78 in) long. These legs are mounted to

the CMM table beneath the standard legs and feet.

Key

1. Heavy-duty leg

2. Leg to foot adaptor and washer

3. Footplate

4. Standard MRS leg

5. Leg to foot adaptor

6. M8 or M10 screw and washer

7. Standard MRS foot

NOTE: The MRS heavy-duty leg kit part number is A-4192-0020 and comprises one heavy-duty leg assembly. Two kits are required

for each MRS installation.

MRS adjustable footplates

By using optional MRS adjustable footplates, the MRS rail can be set back on the CMM table to maximise the available working volume of

the machine. The MRS adjustable footplates can be used with both standard and heavy-duty leg arrangements. Adjustment is set by the

footplate bolt hole spacing in increments of 25 mm, 50 mm, 75 mm, 100 mm (0.98 in, 1.97 in, 2.95 in, 3.94 in).

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

6

Page 7

NOTE: The MRS adjustable footplate kit part number is A-4192-0702 and comprises two footplates. One kit is required for each

MRS installation.

Step back adaptor

Step back adaptors can be used to set the MRS rail back on the CMM bed to maximise the available working volume of the machine.

A step back spacer is available to allow the RCP TC-2 to fit in front of the MRS leg.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

7

Page 8

Key

1. Standard MRS leg

2. MRS rail

3. Step back adaptor

4. T-nut and screw

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

8

Page 9

Fitting the MRS feet

Fitting the MRS feet to the CMM

The MRS feet should be fitted to the CMM table along either the X or Y axis. The following procedure details the installation.

1. Place the MRS foot (item 3 in illustration below) on the CMM table and position it over the chosen mounting hole. The feet do not require

any rotational alignment.

2. Two pairs of screws are supplied with the MRS*, one pair of M10 and one pair of M8 (item 1) with washers (item 2). The appropriate

screw size should be used to secure the MRS foot to the CMM table.

3. Tighten the bolt using the hexagonal key supplied.

4. Fit the second foot at the appropriate distance along the chosen axis following steps 1 to 3 above.

* If the bolts supplied do not fit the CMM table then suitable alternatives should be found.

Key

1. Screw

2. Washer (optional)

3. MRS foot

Aligning the MRS feet to a CMM axis

To ease installation of the rail to the MRS it is recommended that the MRS feet be aligned to a CMM axis. The procedure is as follows:

1. Measure the internal diameter of one of the MRS feet and make this a datum.

2. Measure the internal diameter of the other MRS foot.

3. Calculate the out-of-position angle of the MRS feet using the following formula:

Iftheangleexceeds0.5°thenadjustmentisnecessary.Changingtherelativefootpositionisachievedbyreleasingtheboltthatholdsthe

foot to the CMM table, moving the foot and then re-tightening the bolt. Steps 1 to 3 above should then be repeated.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

9

Page 10

Fitting standard legs to the MRS

Two options are available for mounting the legs to the rail of the MRS. The direct fitting option allows legs to be attached onto the underside

of the rail. Using the step-back adaptor option allows legs to be fitted to the back of the rail and provides more measuring volume.

Recommended procedures for these two options are detailed in this section.

WARNING: The MRS rail is shipped without the plastic end-caps fitted. Therefore there is a possibility that sharp edges could be

exposed.

Direct fitting of legs to the MRS rack

The method for directly fitting legs to the MRS rack is as follows:

1. Referring to the illustration below, slide the T-nuts (item 1) into the T-nut slot in the underside of the MRS rail (item 2), one Tnut is required for each leg. Ensure that the longer portion of the T-nut is facing away from the end of the rail. The appropriate number of

T-nuts should be placed into the slot for the change port or rack device to be used.

2. Once all the T-nuts have been installed in the correct orientation, the plastic end caps (item 3) can be pressed into the rail.

3. Referring to the image below, connect the required number of legs and / or leg extensions (item 1) (up to a maximum of four per leg

assembly) and hand-tighten. The MRS leg-to-foot adaptors (item 2) can now be screwed into the bottom of each leg and hand-tightened.

4. Place the MRS legs into the MRS feet (item 3) on the CMM table and adjust the three grubscrews (item 4) so that the legs locate in the

MRS feet but are still able to rotate.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

10

Page 11

CAUTION: The MRS rack is top heavy. Whilst performing steps 5 and 6, the rail of the MRS must be supported.

5. Referring to the image below, screw the MRS legs (item 3) into the T-nuts (item 1) at each end of the MRS rack (item 2) and handtighten.

6. When the MRS rack is firmly located on the MRS legs, tighten the three grubscrews on each MRS foot using the hexagonal key provided.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

11

Page 12

Fitting MRS legs with step-back adaptors

The following method describes the attachment of MRS legs with step-back adaptors to the MRS rack:

1. Referring to the image below, insert the asymmetrical T-nut (item 3) for the step-back attachment into the rear T-nut slot of the MRS rail

(item 2). Ensure that the longer portion of the T-nut is facing away from the end of the rail.

2. The relevant port or rack mounting T-nuts (item 1) should be installed in the T-nut slot in the underside of the rail. The longer portion of the

T-nut should face towards the centre of each respective port.

3. Once all the T-nuts have been installed in the correct orientation, the plastic end caps (item 4) can be pressed into the ends of the MRS.

4. Referring to the image in below, insert the M8 screw (item 1) into the step-back adaptor (item 2). Screw the MRS leg (item 3) into the

step-back adaptor and hand-tighten. Then screw the required number of leg extensions (up to a maximum of four per leg assembly) into

the MRS leg and hand-tighten.

5. Referring to the image below, once the required number of legs or leg extensions have been attached, the MRS leg-to-foot

adaptors (item 2) can be screwed into the bottom of each MRS leg assembly (item 1) and hand-tightened.

6. Place the MRS legs into the MRS feet (item 3) on the CMM table. Loosely adjust the three grubscrews (item 4) on each MRS foot so that

the legs locate in the MRS feet but are free to rotate.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

12

Page 13

7. If no step back spacer that is required for the RCP and RCP TC-2, position the MRS (item 1) to the step-back adaptor (item 2) and

orientate the step-back adaptor so that the M8 screw (item 3) is properly aligned to the MRS T-nut. Screw the step-back adaptor to the

MRS using the M8 screw (item 3).

8. If the step back spacer is required, fit the step back spacer onto the step back adaptor (item 2) as shown in the image below. Position

the MRS rail (item 1) to the step back spacer (item 4) and orientate the step back spacer and adaptor assembly so that the M8 screw

(item 3) is properly aligned to the MRS T-nut (item 5). Screw the step back assembly to the MRS using the M8 screw (item 3)

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

13

Page 14

9. Repeat the relevent previous steps for the second MRS leg, hand-tightening the M8 screw on each step-back adaptor.

10. Adjust the position of the rail as required by slackening the M8 screw in the step-back adaptor and sliding the rail into position. Retighten the M8 screws using the hexagonal key supplied.

NOTE: Ensure the three grubscrews on each MRS foot are tightened using the hexagonal key provided.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

14

Page 15

Fitting heavy-duty legs to the MRS

Where an MRS installation has numerous SCP80s containing heavy stylus arrangements, or vertical stylus arrangements exceeding

190 mm, it is recommended that the optional MRS heavy duty leg kits are used to provide additional rigidity / height. These kits can be

purchased separately to match the number of legs used on the MRS.

NOTE:TheMRSheavydutylegkitpartnumberisA41920020andcomprises1×heavydutyleg(Ø60×350mmlong,1×footplate

and a selection of double-ended threaded studs)

Key

1. Heavy-duty leg

2. Leg to foot adaptor and washer

3. Footplate

4. Standard MRS leg

5. Leg to foot adaptor

6. M8 or M10 screw or washer

7. MRS foot

8. MRS rail

9. Step back adaptor

10. T-nut and screw

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

15

Page 16

Installation procedure

NOTE: The MRS heavy-duty leg kit must be used in conjunction with the standard MRS leg assembly. The legs should be mounted

using the step back adaptor method.

1. Locate the first footplate (item 3) with a suitable threaded stud on the CMM table having consideration for the required position of the

MRS rail that will accommodate all loaded racks within the working volume. Fasten the footplate to the table using the double-ended

threaded stud* (item 2).

2. Locate the second footplate (item 3) at the appropriate distance along the chosen CMM axis and follow step 2 above.

3. Screw the heavy duty leg (item 1) to the top of the threaded stud (item 2) and hand-tighten. Repeat for second leg assembly.

4. Place the first MRS foot (item 7) (part of the standard MRS leg assembly) on top of the heavy duty leg (item 1) and secure using the

M10 screw (item 6). Repeat for the second leg assembly.

5. Proceed with the remaining construction of the MRS system as described in the pages detailed:

•Aligning the MRS feet to the CMM axis.

•Fixing the standard MRS legs to the rail using step back adaptors.

•Fixing the standard MRS legs to the MRS foot.

* Two sets of double ended threaded studs are provided to suit different CMM table configurations. The thread sizes supplied are M10, M8

and M6. Alternatively, 3/16 " UNC and 5/16 " UNC can be obtained on request from your Renishaw supplier.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

16

Page 17

Fitting MRS adaptor feet

By using the optional MRS adjustable footplates shown below, the MRS rail can also be placed at different positions on the CMM's bed

which ensures that a maximised working volume can be achieved. The MRS adjustable footplates can be used with the MRS standard leg

and the MRS heavy duty leg arrangements.

NOTE: The MRS adjustable footplates kit part number is A-4192-0702 and comprises two footplates.

Fitting standard legs to the adjustable footplate

Key

1. Standard MRS leg

2. M8 or M10 screws

3. Washer

4. Grubscrews

5. MRS foot

6. MRS adjustable footplate

1. Fit the MRS adjustable footplate to the CMM bed.

2. Locate the first footplate with a suitable screw onto the adjustable footplate.

3. Follow steps 3 - 6 of the installation procedure for fitting heavy duty legs.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

17

Page 18

Fitting heavy duty legs to the adjustable footplate

Key

1. MRS heavy duty leg

2. Leg to foot adaptor

3. Washer

4. Footplate

5. M8 or M10 screw

6. MRS adjustable footplate

1. Fit the MRS adjustable footplate to the CMM bed.

2. Follow the steps on fitting the MRS feet and instead of fitting the feet to the CMM bed fit them to the adjustable footplate.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

18

Page 19

Specification summary

400 mm rail 600 mm rail 900 mm rail 1000 mm rail

Rail length

NOTE: Allow additional 10 mm (0.39 in) for plastic end caps

400 mm

(15.75 in)

600 mm

(23.62 in)

900 mm

(35.42 in)

1000 mm

(39.37 in)

Number of legs required (recommended) 2 2‡ 2‡ 2‡

Maximum usable rail length

With two legs mounted to underside of rail (as shown)

With legs mounted via step back adaptor (see detail)

320 mm

(12.6 in)

400 mm

(15.75 in)

520 mm

(20.47 in)

600 mm

(23.62 in)

820 mm

(32.28 in)

900 mm

(35.42 in)

920 mm

(36.22 in)

1000 mm

(39.37 in)

Height to top of rail (using legs supplied with MRS kit)

H1 = With two legs mounted to underside of rail (as shown)

H2 = With legs mounted via step back adaptor (see detail)

325 mm

(12.6 in)

317 mm

(12.48 in)

325 mm

(12.6 in)

317 mm

(12.48 in)

325 mm

(12.6 in)

317 mm

(12.48 in)

325 mm

(12.6 in)

317 mm

(12.48 in)

Height of additional single leg

Two versions available

62.5 mm

(2.46 in)

125 mm

(4.92 in)

62.5 mm

(2.46 in)

125 mm

(4.92 in)

62.5 mm

(2.46 in)

125 mm

(4.92 in)

62.5 mm

(2.46 in)

125 mm

(4.92 in)

Height of additional heavy duty single leg

Ø60mm(2.36in)

330 mm

(12.99 in)

330 mm

(12.99 in)

330 mm

(12.99 in)

330 mm

(12.99 in)

Height of additional adjustable footplate 16 mm

(0.63 in)

16 mm

(0.63 in)

16 mm

(0.63 in)

16 mm

(0.63 in)

‡Centrelegmayberequiredincertainapplications

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

19

Page 20

Distance from port centre to leg centre (in docking axis)

D1

Legs mounted to

underside of rail (as

shown)

D2

Legs mounted via step

back adaptor (see detail)

D3

Legs mounted via step back adaptor

and step back spacer (see detail)

Rail length required

per changer unit

FCR25 and

FCR25 TC

42.8 mmm (1.69 in) 95.8 mm (3.77 in) 115.8 mm 94.56 in) 115.8 mm (4.56 in) *

ACR3 58.1 mm (2.29 in) 111.1 mm (4.37 in) 131.1 mm (5.16 in) 277 mm (10.91 in) **

SCP600 69.2 mm (2.72 in) 122.2 mm (4.81 in) 142.2 mm (5.6 in) 87 mm (3.43 in) *

SCP80 142.5 mm (5.61 in) 195.5 mm (7.7 in) 215.5 mm (8.48 in) 130 mm (5.12 in) *

RCP2 84.6 mm (3.33 in) 137.6 mm (5.42 in) 157.6 mm (6.2 in) 66 mm (2.6 in) *

RCP TC-2 85.6 mm (3.37 in) 138.6 mm (5.46 in) 158.6 mm (6.24 in) 94 mm (3.7 in) *

TDA n/a n/a n/a 18 mm (0.71 in) *

SFCP n/a n/a n/a 72 mm (2.84 in) *

SFA n/a n/a n/a 54 mm (2.13 in) *

* Includes 2 mm (0.08 in) extra allowance per unit

** Includes 5 mm (0.2 in) extra allowance per unit

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

20

Page 21

Accessories and spare parts

As the MRS is part of a modular system offered by Renishaw, all part numbers for the MRS system components are specified below:

Item Quantity and description Part number

MRS rail 1×400mmlong

1×600mmlong

1×900mmlong

1×1000mmlong

A-4192-0050

A-4192-0051

A-4192-0063

A-4192-0052

MRS leg 1×62.5mmlong

1×125mmlong

A-4192-0061

A-4192-0053

MRS heavy-duty leg 60mmdiameter×330mmlong A-4192-0020

MRS adjustable footplates 2×footplates A-4192-0702

MRS feet 1×fixedfoot A-4192-0056

MRS step-back adaptor 1×adaptor A-4192-0058

MRS leg-to-foot adaptor 1×adaptor A-4192-0055

T-nut 1×M8threadnut P-NU18-0005

MRS 4-leg kit 4×125mmlong A-4192-0060

MRS 2-leg kit 2×125mmlong A-4192-0059

TK63 MRS tool kit 1×toolkit A-4192-0070

MRS step back spacer 2×spacers A-4192-0014

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

21

Page 22

Maintenance and cleaning

The MRS has no user serviceable parts, should the unit become defective, it should be returned to the local Renishaw service centre.

Clean the MRS with a dry, lint-free cloth.

MRS installation and user's guide

http://www.renishaw.com

Issued 12 2014

22

Page 23

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

www.renishaw.com/cmmsupport

Issued 12 2014

Loading...

Loading...