Page 1

Installation and user’ s guide

H-2000-5059-05-A

MP10 probe system

Page 2

© 2003 - 2005 Renishaw. All rights reser ved.

This document may not be copied or

reproduced in whole or in part, or transferred

to any other media or language, by any

means, without the prior written permission

of Renishaw.

The publication of material within this

document does not imply freedom from

the patent rights of Renishaw plc.

Renishaw part no: H-2000-5059-05-A

Issued: 08.05

Disclaimer

Considerable effort has been made to ensure

that the contents of this document are free from

inaccuracies and omissions. However,

Renishaw makes no warranties with respect to

the contents of this document and specifically

disclaims any implied warranties. Renishaw

reserves the right to make changes to this

document and to the product described herein

without obligation to notify any person of such

changes.

Trademarks

Renishaw® and the probe emblem used in the

RENISHAW logo are registered trademarks of

Renishaw plc in the UK and other countries.

apply innovation is a trademark of

Renishaw plc.

All brand names and product names used in

this document are trade names, service marks,

trademarks, or registered trademarks of their

respective owners.

Page 3

FCC DECLARATION (USA)

FCC Section 15.19

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired

operation.

FCC Section 15.105

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

you will be required to correct the interference at your own expense.

FCC Section 15.21

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc, or

authorised representative could void the user's authority to operate the equipment.

FCC Section 15.27

The user is also cautioned that any peripheral device installed with this equipment such as a

computer, must be connected with a high-quality shielded cable to insure compliance with FCC limits.

Page 4

Installation and users guide - English

ASSOCIATED SYSTEM HANDBOOKS

Description Part No.

H-2000-5044

H-2000-5073

H-2000-5062

H-2000-5057

Optical module machine (OMM)

MI 12 interface unit

Optical machine interface (OMI)

PSU3 power supply unit

SAFETY

Before working inside machines, ensure

machine is in a safe condition

Switch off power before making electrical

connections, changing probe and receiver

settings and replacing components

WARRANTY

Equipment requiring attention under warranty

must be returned to your supplier. No claims

will be considered where Renishaw equipment

has been misused, or repairs or adjustments

have been attempted by unauthorised persons.

CHANGES TO EQUIPMENT

Renishaw reserves the right to change

specifications without notice.

CNC MACHINE

CNC machine tools must always be operated

by competent persons in accordance with

manufacturers instructions.

CARE OF THE PROBE

Keep system components clean and treat the

probe as a precision tool.

PROBE IP RATING X8

PATENT NOTICE

Features of MP10 probes and features of

similar probes are the subject of one or more of

the following patents and/or patent

applications:

EP 0337669

EP 0390342

EP 0695926

JP 2,945,709

JP 2,944,401

US 5,150,529

US 5,040,931

US 5,669,151

Page 5

Contents

1-1

Software requirements ...................... 1-23

Typical probe cycles ..........................1-24

System flow charts.............................1-26

SERVICE and MAINTENANCE........1-29

Weak link for styli with steel shaft......1-29

Diaphragm inspection ........................ 1-30

Diaphragm replacement ....................1-31

SCREW TORQUE VALUES ............. 1-32

FAULT FINDING ............................... 1-34

APPENDIX 1

ADAPTOR and EXTENSIONS ..........1-37

APPENDIX 2 PSU3 ..........................1-38

APPENDIX 3 OMM............................1-38

APPENDIX 4 MI 12 ...........................1-39

APPENDIX 5 OMI..............................1-40

PARTS LIST......................................1-42

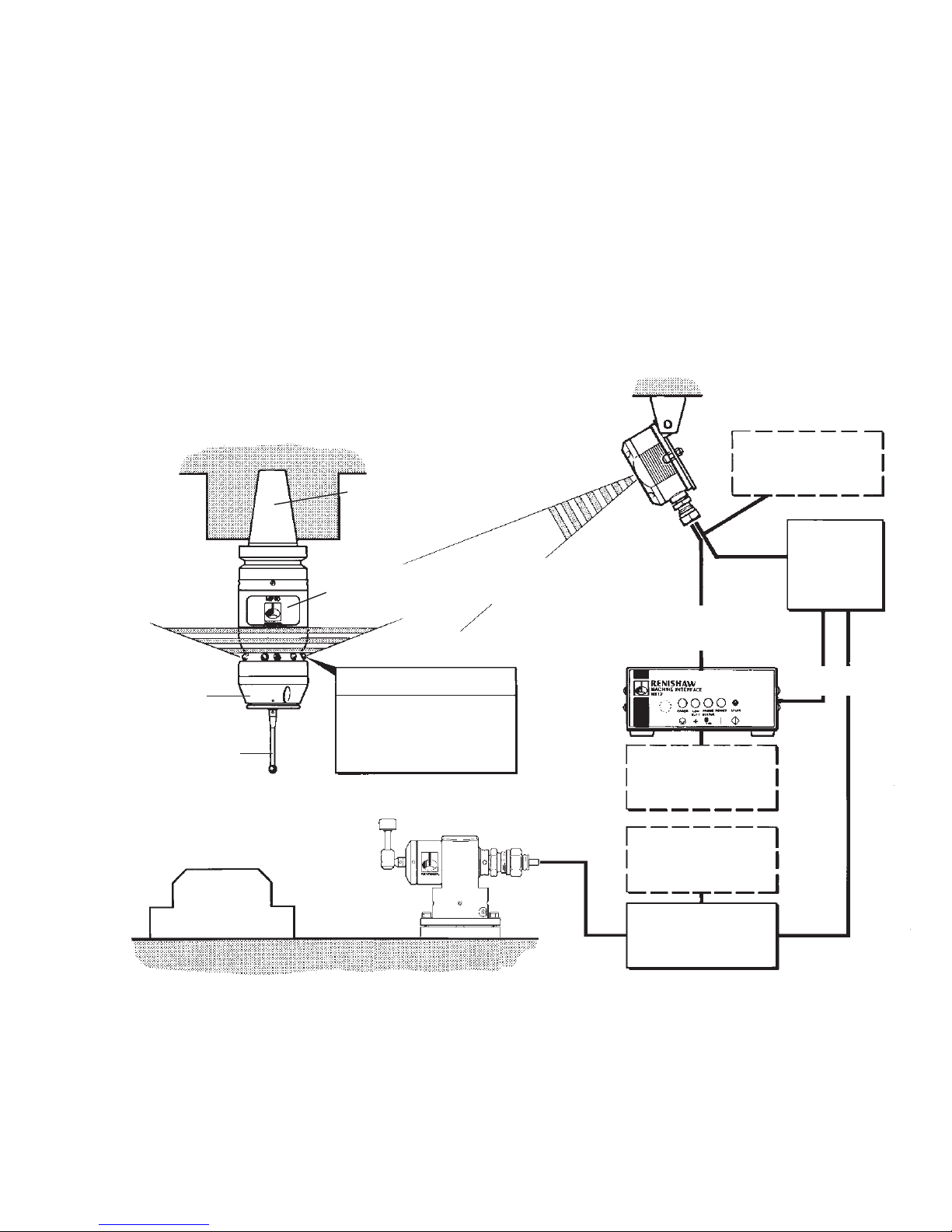

SYSTEM INSTALLATION

Typical probe systems .......................1-2

Two OMMs and remote indicator ......1-3

Performance envelope ...................... 1-4

System performance..........................1-8

MP10 features ...................................1-9

MP10 dimensions .............................. 1-10

Modes of operation ............................1-11

Options setting switch........................1-12

Enhanced trigger circuit .....................1-12

Battery covers and battery.................1-13

Stylus spring pressure adjustment ....1-15

Stylus on-centre adjustment ..............1-16

Probe/shank mounting.......................1-16

OPERATION

LEDs ..................................................1-2

Switch-on/switch-off...........................1-11

Probe moves......................................1-22

Page 6

A workpiece set-up and inspection probe is in effect another

tool in the system. A probe cycle may be included at any

stage of the machining process.

Signals are transmitted between the probe and the machine

control, via the OMP and OMM + MI 12 or alternatively the

OMP and OMI.

TYPICAL PROBE SYSTEMS

1-2

Workpiece

Probe head

Stylus

Machine spindle

Typical tool

setting probe

CNC

machine

control

Cable

Battery cover

Shank (size 25 - 50)

Optional - PSU3

power supply unit

Optional - PSU3

power supply unit

OMP - LEDs

Mounting bracket

OMI (one only)

+ CNC control

Optional - PSU3

power supply unit

MP10

inspection

probe

3 x Receive diodes

6 x Transmit LEDs

1 x Probe status LED

MI 12 interface unit

or MI 12 board

OMM (one or two)

+ MI 12

+ CNC control

MI 5, MI 8 or

MI 8-4

interface

unit

SEE PAGES 1-38, 1-39 & 1-40

OMM - Optical module machine

OMP - Optical module probe

OMI - Optical machine interface

Page 7

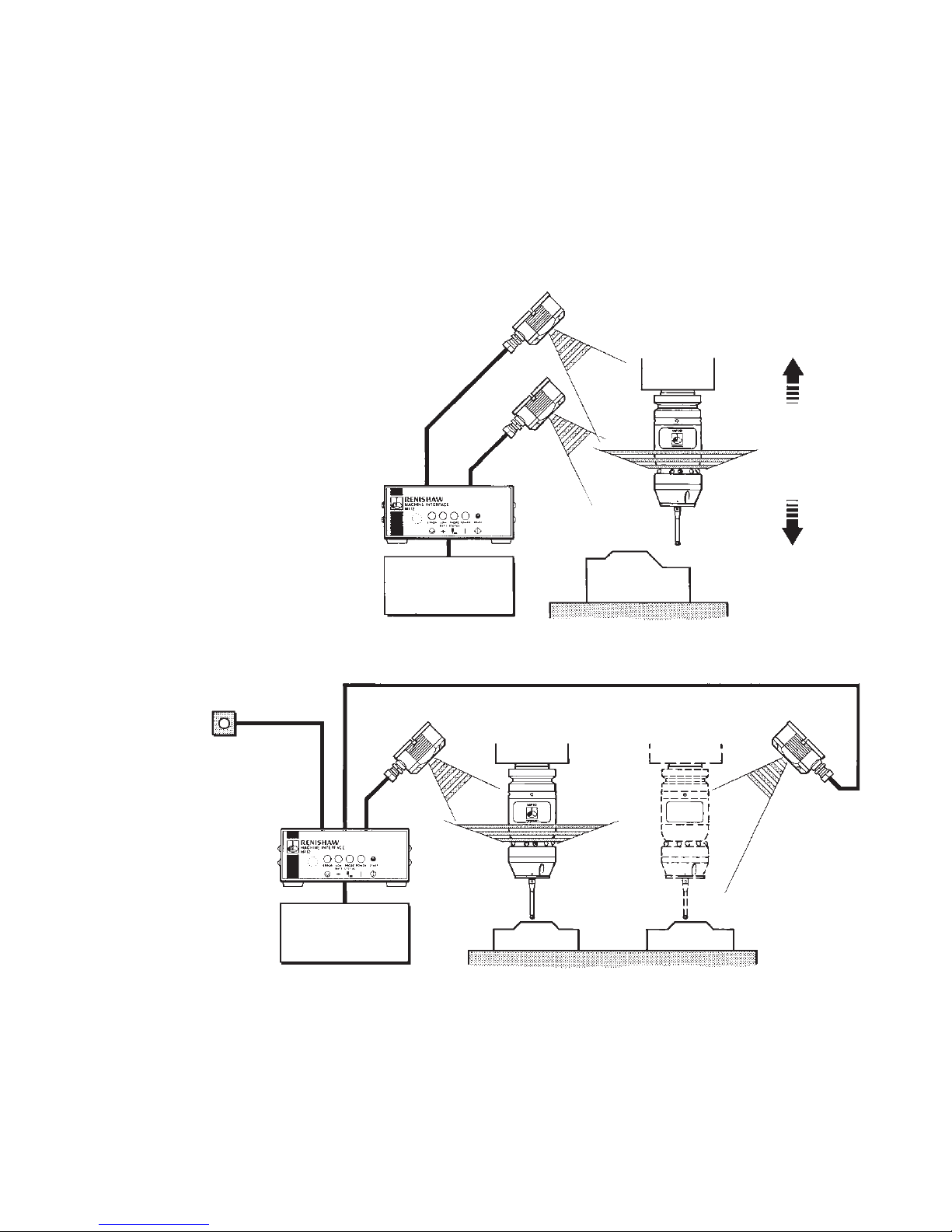

OMM TANDEM MOUNTING

Installations with exceptionally long

spindle travel, may require a

second OMM to cover signal

reception over the full working

envelope of the probe.

The reception cones of OMM 1

and OMM 2 overlap, so they

act as one receiver.

REMOTE INDICATOR

When the probe contacts a surface

an MI 12 LED changes state and a

bleep is emitted.

If the MI 12 is hidden from the

operator, a remote lamp or bleeper

may be placed in a position where

it is easily seen or heard.

OMM TWIN MOUNTING

Each spindle of a twin

spindle machine can

accept a probe.

Although both OMM 1

and OMM 2 are

switched on, only one

probe may be used at

any one time.

1-3

TWO OMMs AND REMOTE INDICATOR

CNC machine

control

MI 12

OMM 1

Spindle

travel

OMM 2

OMM 1

MI 12

Remote

indicator

CNC machine

control

OMM 2

Page 8

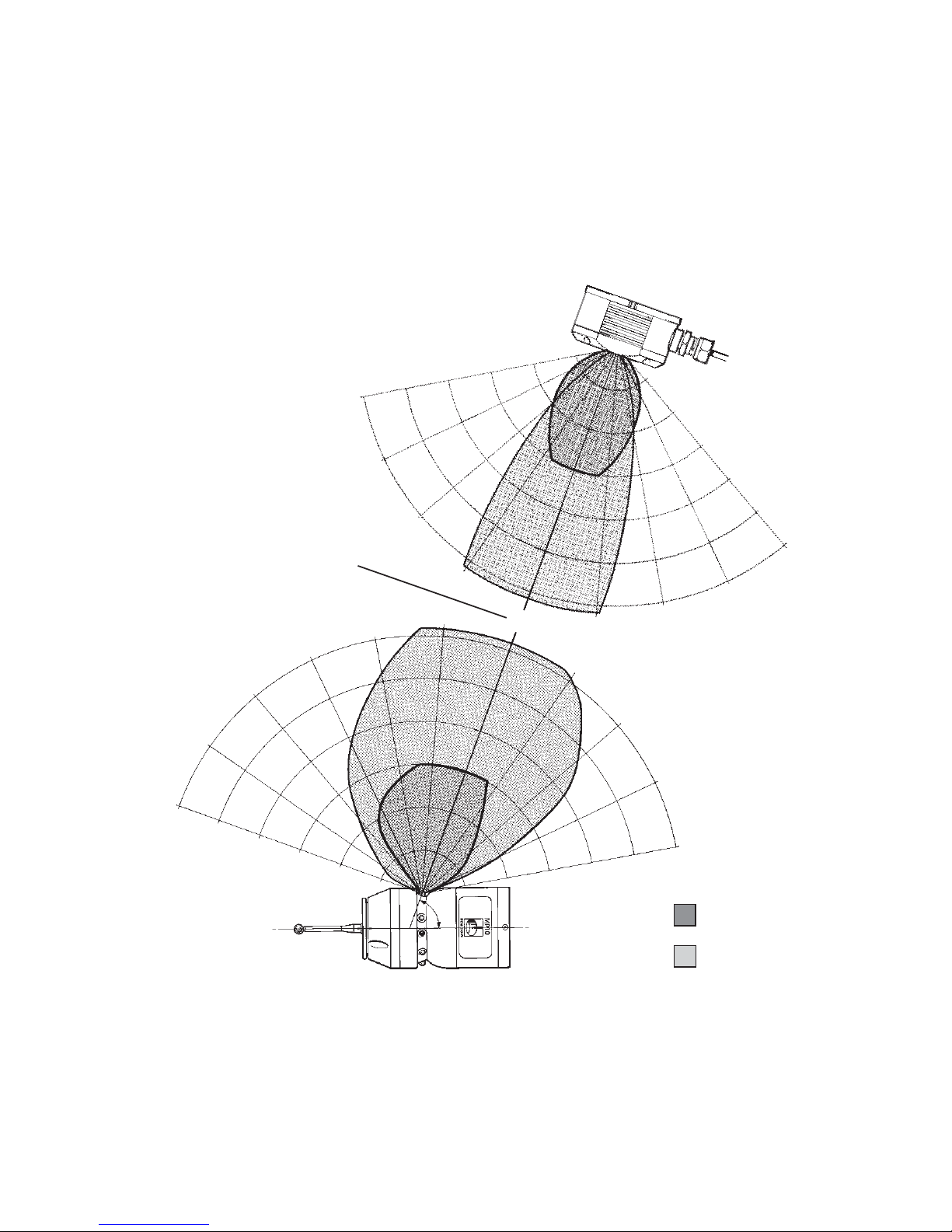

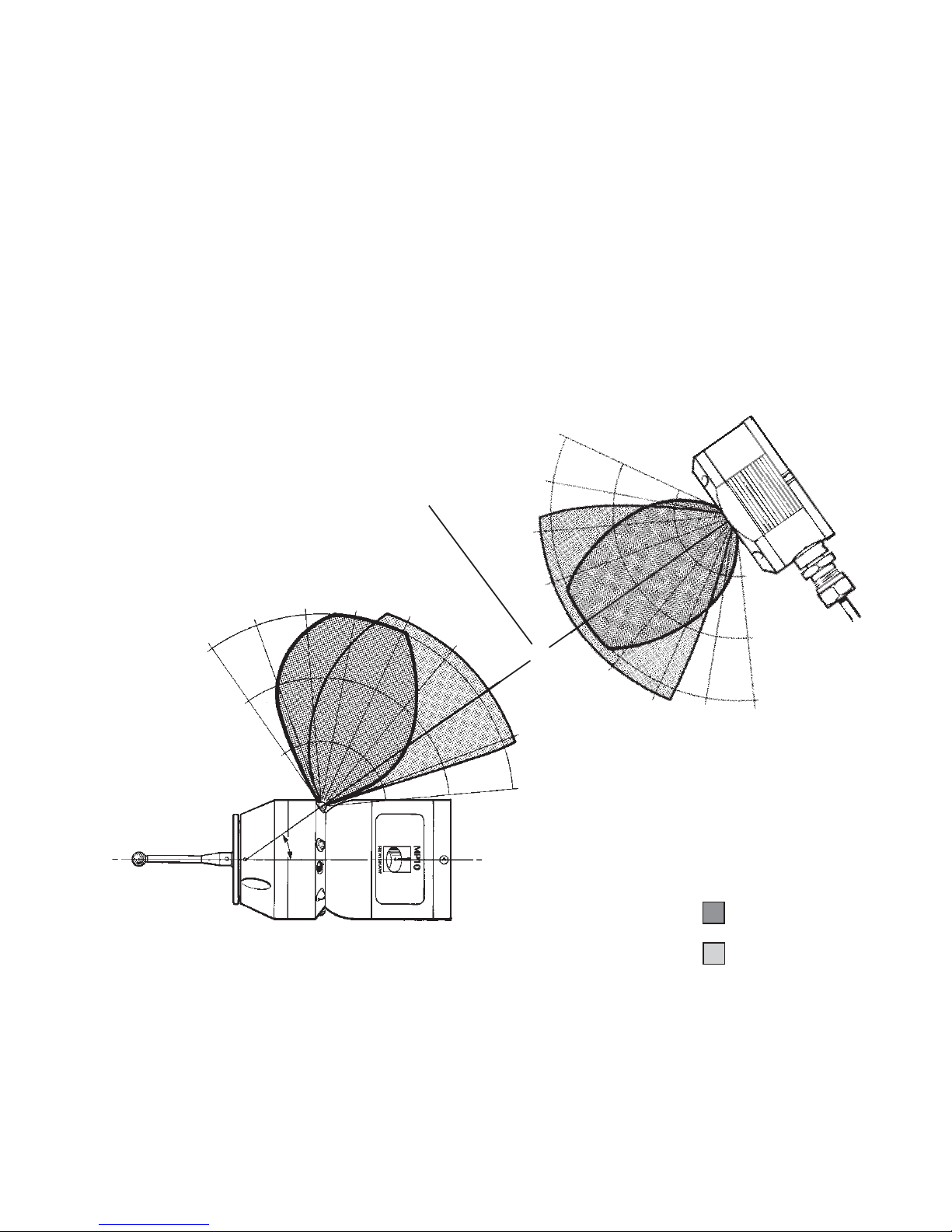

MP10 35° OUTPUT PROBE + OMM

Probe and OMM diodes must be

mutually in each others field of view,

and within the performance envelope

shown.

OPERATING RANGE

The OMP must be within

6 m (19.6 ft) of the OMM.

PERFORMANCE ENVELOPE

1-4

SWITCH-ON/OFF RANGE

The OMP must be within

3 m (9.8 ft) of the OMM.

35° OMP

Optical

centre

line

OMM

60°

45°

60°

45°

15°

30°

30°

15°

0°

SWITCH ON/OFF

OPERATING

Range metres (feet)

2 (6.5)

1 (3.3)

3 (9.8)

4 (13.1)

5 (16.4)

6 (19.6)

45°

90°

15°

60°

15°

75°

45°

30°

30°

2 (6.5)

1

(3.3)

3 (9.8)

4 (13.1)

5 (16.4)

6 (19.6)

Page 9

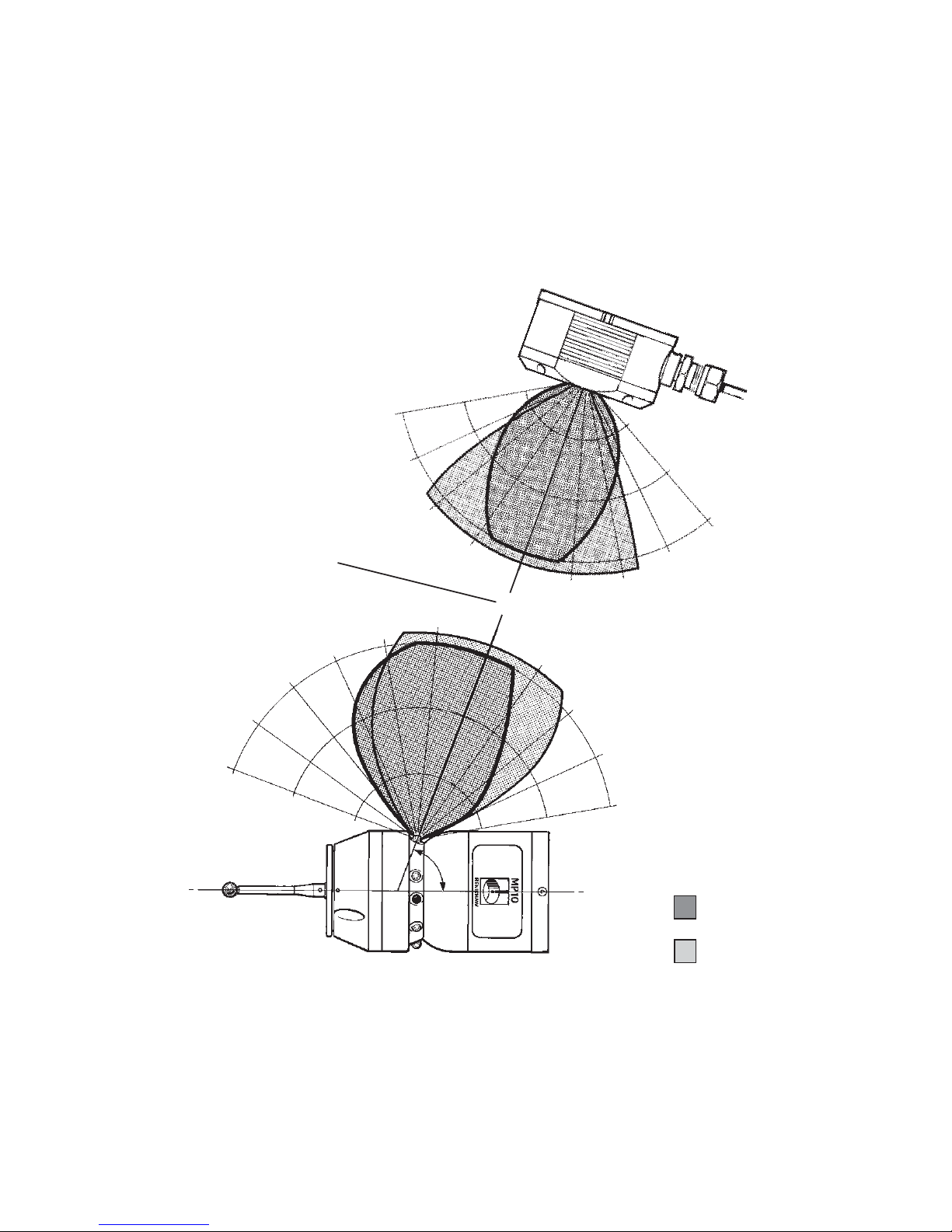

2 (6.5)

1 (3.3)

3 (9.8)

4 (13.1)

5 (16.4)

6 (19.6)

45°

90°

15°

60°

15°

75°

45°

30°

30°

60°

Probe and OMM diodes must be

mutually in each others field of view,

and within the performance

envelope shown.

SWITCH-ON/OFF RANGE

The OMP must be within

3 m (9.8 ft) of the OMM.

OPERATING RANGE

The OMP must be within

6 m (19.6 ft) of the OMM.

MP10 70° OUTPUT PROBE + OMM

PERFORMANCE ENVELOPE

1-5

SWITCH ON/OFF

OPERATING

Range metres (feet)

Optical

centre

line

2 (6.5)

3 (9.8)

4 (13.1)

5 (16.4)

6 (19.6)

OMM

60°

45°

60°

45°

15°

30°

30°

15°

1 (3.3)

70° OMP

0°

Page 10

0°

1

(3.3)

3 (9.8)

OMI

60°

45°

60°

45°

15°

30°

30°

15°

2 (6.5)

1-6

PERFORMANCE ENVELOPE

MP10 35° OUTPUT PROBE + OMI

Probe and OMI diodes must be

mutually in each others field of view,

and within the performance envelope

shown.

SWITCH-ON/OFF RANGE

and OPERATING RANGE

The OMP must be within

3 m (9.8 ft) of the OMI.

Optical

centre

line

35° OMP

2 (6.5)

1 (3.3)

3 (9.8)

90°

15°

60°

15°

75°

30°

30°

SWITCH ON/OFF

OPERATING

Range metres (feet)

0°

45°

Page 11

Optical

centre

line

MP10 70° OUTPUT PROBE + OMI

Probe and OMI diodes must be mutually in

each others field of view, and within the

performance envelope shown.

SWITCH-ON/OFF RANGE

and OPERATING RANGE

The OMP must be within

3 m (9.8 ft) of the OMI.

1-7

PERFORMANCE ENVELOPE

70° OMP

1 (1.33)

3 (9.8)

OMI

60°

45°

60°

45°

15°

30°

30°

15°

2 (6.5)

1 (1.33)

3 (9.8)

45°

90°

60°

15°

75°

30°

2 (6.5)

SWITCH ON/OFF

OPERATING

Range metres (feet)

15°

30°

45°

60°

0°

Page 12

TEMPERATURE

Operating 5 °C to 50 °C

(41 °F to 122 °F)

PROBE/OMP

OMM

MI 12 INTERFACE

OMI

PSU3

ENVIRONMENT

Storage -10 °C to 70 °C

(14 °F to 158 °F)

OPERATING ENVELOPE

Natural reflective surfaces within the machine may

increase the signal transmission range.

Coolant residue accumulating on the OMP diodes

and OMM or OMI window, will have a detrimental

effect on transmission performance. Wipe clean

as often as is necessary to maintain unrestricted

transmission.

Operation in temperatures of 0 °C to 5 °C or 50 °C to

60 °C (32 °F to 41 °F or 122 °F to 140 °F) will result in

some reduction in range.

WARNING

If two systems are operating in close proximity

take care to ensure that signals transmitted from

the OMP on one machine, are not received by the

OMM or OMI on the other machine, and vice

versa.

OMM and OMI POSITION

To assist finding the optimum position of the OMM

during system installation, signal strength outputs

are available on the MI 12 interface.

OMI signal strength is displayed on an OMI

multicoloured LED.

PROBE REPEATABILITY

Maximum 2 sigma (2

σσ

σσ

σ) value

Repeatability of 1.0 µm (0.00004 in) is valid for

test velocity of 480 mm/min (1.57 ft/min) at

stylus tip, using stylus 50 mm (1.97 in) long.

STYLUS TRIGGER FORCE

Set at factory using stylus 50 mm (1.97 in) long.

X and Y trigger forces vary around the stylus seating.

X/Y direction lowest force 0.75 N/75 gf (2.64 ozf)

X/Y direction highest force 1.4 N/140 gf (4.92 ozf)

Z direction 4.2 N/420 gf (14.83 ozf)

STYLUS OVERTRAVEL

See page 1-21.

SYSTEM PERFORMANCE

1-8

Page 13

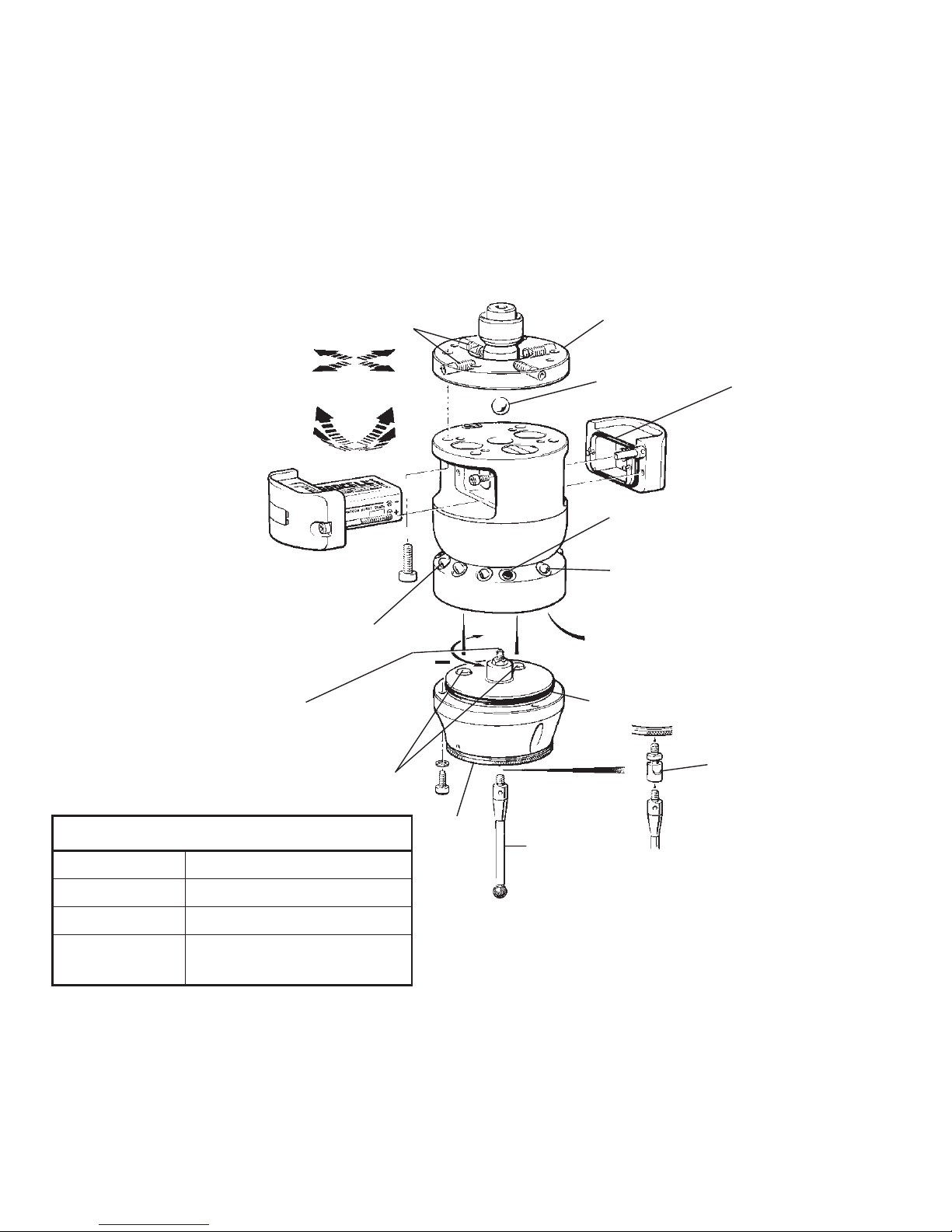

1-9

MP10 FEATURES

COLLISION PROTECTION

optional

A weak link is fitted between the

probe and stylus, to protect the

probe in the event of excessive

stylus overtravel.

Battery cover

Battery

cover seal

Stylus spring

pressure adjustment

Probe setting switch and

enhanced trigger circuit

6 x Transmit LED (Tx)

natural colour - clear

3 x Receive diode (Rx)

natural colour - black

On-centre

adjusting plate

Ø8 mm Ball

(optional)

OMP

(optical module probe)

1 x Probe status LED

red/green

natural colour - white

Align head contacts

with OMP contacts

Probe

head

'O' Ring

Weak link

Stylus

+

Translation

screw adjusters

Probe status

Stylus seated.

Stylus deflected (triggered).

LED colour

Flashing GREEN

Flashing RED

Constant RED

Probe status LED

Battery dead.

(replace battery to continue).

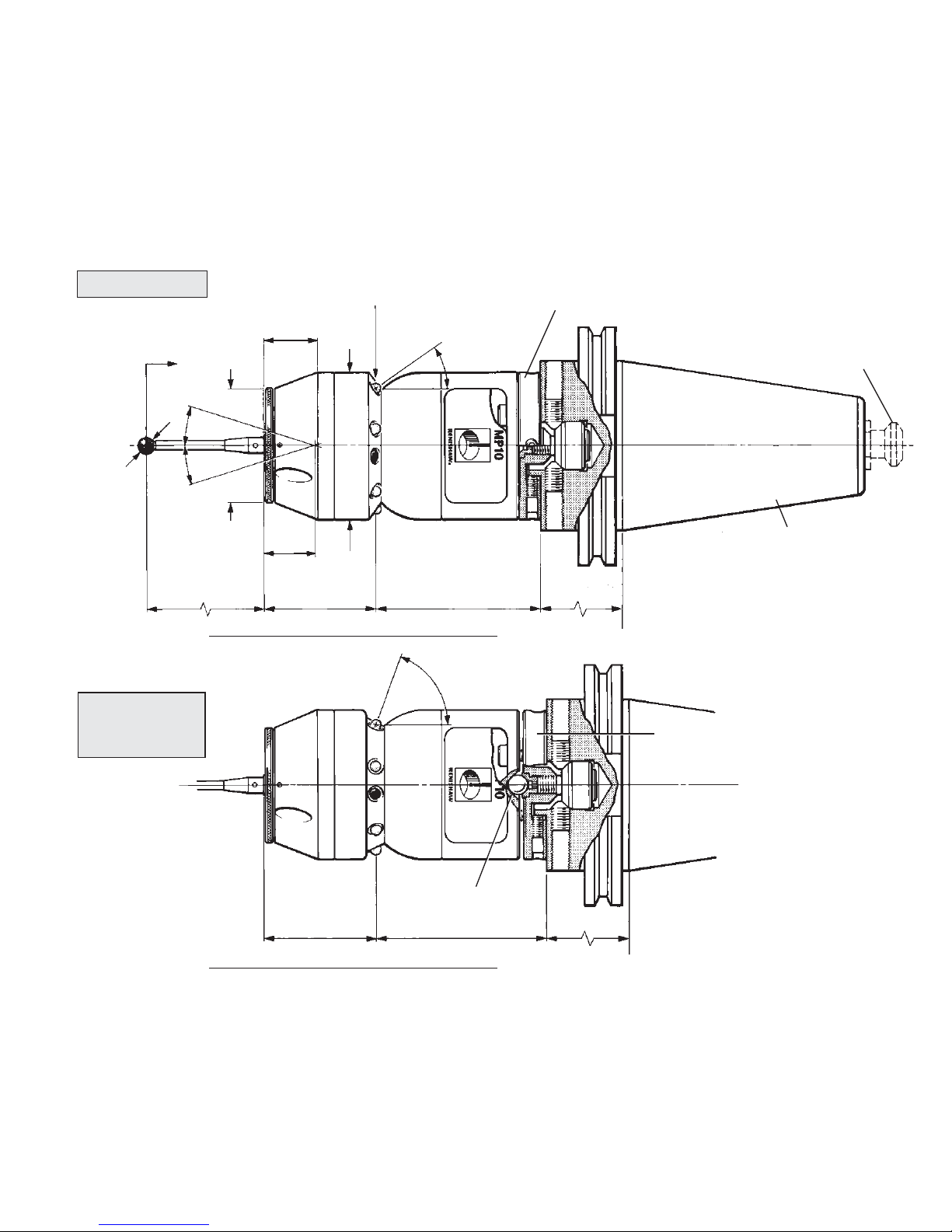

Page 14

X-Y overtravel 17.5°

Z overtravel 8 (0.31)

Translational on-centre

adjustment with adjusting plate

Pull stud

(not supplied

by Renishaw)

Typical

taper shank

A

Ø6

(0.24)

22

(0.87)

Probe output

35°

21.5

(0.85)

17.5°

17.5°

Stylus 50

(1.96) long.

Other length

styli may be

used

1-10

MP10 dimensions mm (in)

A

GAUGE LINE

GAUGE LINE

Probe Output

70° OMP shown

with optional

Ø8 mm ball

70°

35° OMP shown

Ø48

(Ø1.89)

Ø62

(Ø2.44)

Ø8 mm ball

See Data sheet taper shanks H-

2000-2011 for dimension A

69.3 (2.73)

71.2 (2.80)

35° OMP 48.8 (1.92)

70° OMP 46.4 (1.82)

Translational on-centre adjustment

(with optional angular adjustment

using centre ball)

67.9 (2.67)

69.8 (2.75)

35° OMP 48.8 (1.92)

70° OMP 46.4 (1.82)

LED

See Data sheet taper shanks H-

2000-2011 for dimension A

Page 15

1-11

Switch-off options are selected by operating an

internal probe switch - see opposite.

1. Optical-on and timer-off (time out)

factory set.

A timer switch automatically returns the probe

to the stand-by mode after 33 or 134 seconds.

The timer is factory set to 134 seconds.

The 33 second option is selected by resetting

the internal probe switch. The timer is reset for

afurther 33 or 134 seconds on, each time the

probe triggers during the operating mode.

Note : A start signal received during the time

the probe is on, also resets the timer for a further

33 or 134 seconds on.

2. Optical-on and optical-off (

optional)

Optical switch-off is commanded by a software

M code. Debounce times apply.

Modes of operation

The MP10 has two modes of operation.

1. Stand-by mode - The OMP uses a small

current, while passively waiting for the

switch on signal.

2. Operating mode - Activated by one of the

methods described below. Probe signals

are only transmitted during the operating

mode.

MP10 power on/off

MP10 power switch on/off, only occurs when the

MP10 is located within the switch on/off envelope

of the OMP and OMM/OMI.

Debounce time

After the probe is switched on there is a time

delay before it can be switched off. This delay is

factory set to 5 sec or it can be reset to 9 sec by

switching the internal probe switch. A similar

delay occurs after switch off, before it can be

switched on again.

SWITCH-ON SWITCH-OFF

Switch-on options are selected by MI 12 or OMI

switch settings - see MI 12 or OMI handbook.

1. Manual start (optical-on) - MI 12 start button.

2. Machine start (optical-on) - optical switch-on

via software M code command -

factory set.

3. Auto start (optical-on) causes the system to

send an optical start signal once every second

and does not require a machine control input.

Note : Auto start should not be selected when the

MP10 is set to the optical-on / optical-off option.

(An auto start signal will force the MP10 to switch on

then off at 5 or 9 second intervals).

Following switch-on, debounce time must elapse,

before the probe is switched off.

MODES OF OPERATION

Page 16

Only qualified persons

should change settings

Remove the probe head to gain

access to the switches and sockets.

OPTIONS SETTING SWITCH

System settings are shown

opposite.

ENHANCED TRIGGER CIRCUIT

Probes subjected to high levels of

vibration or shock loads, may

release spurious readings. The

enhanced trigger circuit improves

the probes resistance to these

effects.

When the circuit is enabled, a

constant nominal 7 millisecond

delay is introduced to the probe

output.

It may be necessary to revise

program software to allow for the

increased stylus overtravel.

To activate the enhanced trigger

circuit, the wire link is transferred

manually :

From SKT 1-2 (factory set)

To SKT 3-2 (enabled)

TAKE CARE

KEEP ALL COMPONENTS CLEAN DO NOT ALLOW COOLANT OR

PARTICLES TO ENTER THE PROBE.

DO NOT TOUCH ELECTRONIC

COMPONENTS WHEN CHANGING

SWITCH SETTINGS.

MODE

Optical on

Optical off

(factory set)

A-2033-1115/1116

MODE

Optical on

Time out

(factory set)

A-2033-1099/1100

TIME-OUT

134 seconds

(factory set)

TIME-OUT

33 seconds

DEBOUNCE

5 seconds

(factory set)

12

3

OPTIONS SETTING SWITCH

DEBOUNCE

9 seconds

2 3

1

OPTIONS SWITCH

ENHANCED TRIGGER CIRCUIT

Align head - OMP contacts

before fitting head onto OMP

Do not rotate head when

located in OMP housing

Grease 'O' ring

before refitting head

1-12

OPTIONS SETTING SWITCH AND ENHANCED TRIGGER CIRCUIT

see page 1-42

SOCKET (SKT) 1-2

SOCKET (SKT) 2-3

ENHANCED

CIRCUIT

2

13

Page 17

1-13

BATTERY COVERS AND BATTERY

To replace battery covers

4. Check that battery cover seals are seated,

and lubricate seals lightly with a mineral oil

or grease.

5. Replace cover (5) -

with Renishaw logo

.

6. Replace battery with polarity as shown on label,

7. Replace battery cover (1) -

with battery symbol

.

Tighten battery cover screws to 1.1 Nm

(0.8 lbf.ft).

To replace exhausted battery - remove cover

1. Slacken screws (1) and remove battery

cover (2).

2. Remove battery (3).

Do not remove second cover, to change

battery.

Probe/shank mounting and stylus on-centre

adjustment - remove second cover

3. Remove screw (4) and battery cover (5).

- see pages 1-17 and 1-19.

DO NOT leave exhausted battery in probe

Dispose of exhausted batteries in

accordance with local regulations

IMPORTANT

Insert battery as

shown on label

(5)

Battery

cover

Battery

cover

(2)

Label

(4)

Screw

2.5 mm AF

(1)

Screw

Probe status LED.

Constant red indicates

battery dead.

Cover

seal

(3)

Battery

Page 18

OPTICAL ON

OPTICAL OFF

OPTICAL ON

TIMER OFF

OPTICAL ON

OPTICAL OFF

OPTICAL ON

TIMER OFF

CONTINUOUS USE

5% USAGE - 72 min/day

STAND-BY LIFE

Minimum Minimum Minimum Minimum Minimum

98 days365 days 80 days 140 hrs 110 hrs

BATTERY LIFE EXPECTANCY

Alkaline battery

Duracell type MN 1604 or equivalent

Typical battery reserve life.

Using an alkaline battery at 5% usage,

the probe will typically continue to

operate for 8 hours, after the

MI 12/OMI low battery LED lights up.

Dead battery indication

When the battery voltage drops below

the threshold where performance can

be guaranteed, the MP10 probe status

LED will change to constant red.

The probe output relay will also be

forced into its open state, causing the

machine to stop, until a new battery is

inserted.

The probe will revert to the stand-by

mode after changing the battery.

1-14

Probe battery

Power for the probe is supplied by a type PP3

9V battery.

The Probe status LED indicates when the

battery has come to the end of its useful life.

Low battery indication

When MI 12 or OMI low battery LED lights up,

battery voltage is low and the end of useable

battery life is approaching.

(The low battery LED will only light up during

the probe operating mode)

- see APPENDIX pages 1-39 and 1-40.

The machine control may also be programmed

to flag up a low battery alarm.

Page 19

Stylus

Spring pressure within the probe

causes the stylus to sit in one unique

position, and return to this position

following each stylus deflection.

Stylus pressure is set by Renishaw.

The user should only adjust spring

pressure in special circumstances

e.g. excessive machine vibration or

insufficient pressure to support the

stylus weight.

To adjust spring pressure, remove

the probe head to gain access to the

spring pressure adjusting screw.

Slacken the locknut, and turn the

adjusting screw anticlockwise to

reduce pressure (more sensitive)

or clockwise to increase pressure

(less sensitive).

A stop prevents damage, which

could be caused by overtightening

the adjusting screw.

Finally tighten the locknut to 1 Nm

(0.74 lbf.ft) and replace the probe

head.

ENSURE THAT THE OMP IS KEPT

CLEAN.

DO NOT ALLOW COOLANT OR

PARTICLES TO ENTER THE PROBE.

STYLUS SPRING PRESSURE

ADJUSTMENT AND USE OF STYLI

OTHER THAN CALIBRATION STYLUS

TYPE, MAY CAUSE REPEATABILITY TO

1-15

STYLUS SPRING PRESSURE ADJUSTMENT - Gauging force

DO NOT rotate probe head

when located in OMP housing

2.5 mm AF

Locknut 7 mm AF

Stop

Adjusting screw

2.0 mm AF

Align contact pins before

connecting probe head.

OMP

Probe

head

Page 20

Two probe/shank mounting configurations are

used to obtain the stylus on-centre setting.

1. Adjusting plate

Translational adjustment allows the probe to

slide across the shank end face.

2. Combination of adjusting plate and centre

ball

Translational adjustment + centre ball pivot,

for applications where the stylus stem must

be parallel to the side of a bored hole, to avoid

stem contact.

Stylus on-centre adjustment

Stylus alignment with the spindle centre line need

only be approximate, except in the following

circumstances.

1-16

SHANK MOUNTING AND STYLUS ON-CENTRE ADJUSTMENT

1. When probe vector software is used.

2. When the machine control software

cannot compensate for an offset stylus.

How to check stylus position

Stylus tip and stem position are established

using a low force (less than 0.2 Nm/ 0.045 lbf)

dial test indicator or setting gauge.

Alternatively rotate the stylus ball against a flat

surface. Alignment is good when the stylus ball

maintains a consistent distance from the flat

surface.

Cover

screw

Battery

cover

Shank/adjusting plate

screw

Adjusting

plate

Centre ball

(optional)

Seal

On-centre adjusting screw

Shank

OMP/adjusting plate

screw

Cover

screw

MP10 probe

Battery

Battery

cover

Page 21

Adjusting plate

1-17

Note :

1. DURING ADJUSTMENT CARE

SHOULD BE TAKEN NOT TO

ROTATE THE PROBE RELATIVE

TO THE SHANK.

2. IF A PROBE/SHANK UNIT IS

ACCIDENTALLY DROPPED, IT

SHOULD BE CHECKED FOR

ON-CENTRE POSITION.

3. DO NOT HIT OR TAP THE PROBE

TO ACHIEVE ON-CENTRE

ADJUSTMENT.

Stage 1 Probe/shank mounting

1. Remove battery covers and battery

- see page 1-13.

2. Tighten probe/adjusting plate screws A

to 5.1 Nm (3.76 lbf.ft) using special

4 mm AF hexagon key (supplied in tool kit).

3. Fully slacken four screws B.

4. Grease two screws C, and fit into shank.

5. Fit probe onto the shank, and visually

position the probe centrally relative to

the shank.

Partially tighten screws C to

2 - 3 Nm (1.47 - 2.2 lbf.ft).

6. Mount the probe/shank assembly into

machine spindle.

PROBE/SHANK MOUNTING WITH ADJUSTING PLATE

SHANK

A

B

C

Special 4 mm AF

short arm

hexagon key

PROBE

Page 22

2.5 mm AF

4 mm AF

Stage 2 on-centre adjustment

7. Each of the four screws B will move the

probe relative to the shank, in the X or Y

direction as pressure is applied.

Tighten individually, backing off after

each movement.

8. When the stylus tip run-out is less than

20 µm, fully tighten screws C to 6 - 8 Nm

(4.4 - 5.9 lbf.ft).

9. For final centering use screws B to move

the probe, progressively slackening on

oneside and tightening the opposite

screw, as the final setting is approached,

using two hexagon keys.

Tip run out of 5 µm (0.0002 in) should

be achievable.

10. It is important that all four screws B are

tight or tightened to 1.5 - 3.5 Nm

(1.1 - 2.6 lbf.ft) once the final setting

has been achieved.

11. When on-centre adjustment is completed,

replace battery and covers - see

page 1-13.

1-18

STYLUS ON-CENTRE ADJUSTMENT WITH ADJUSTING PLATE

SHANK

PROBE

B

Adjusting plate

C

Page 23

Ø8 mm

ball

SHANK

PROBE

B

C

A

Adjusting plate

1-19

Note :

1. DURING ADJUSTMENT CARE SHOULD

BE TAKEN NOT TO ROTATE THE PROBE

RELATIVE TO THE SHANK.

2. IF A PROBE/SHANK UNIT IS

ACCIDENTALLY DROPPED, IT SHOULD

BE CHECKED FOR ON-CENTRE

POSITION.

3. DO NOT HIT OR TAP THE PROBE TO

ACHIEVE ON-CENTRE ADJUSTMENT.

Stage 1 Probe/shank mounting

1. Remove the battery covers and battery

- see page 1-13. Then remove the adjusting

plate from the probe body.

2. Refit the adjusting plate onto the probe

body, with the Ø8 mm centre ball

located between the adjusting plate

and probe. Tighten fixing screws A lightly

using special 4 mm AF hexagon key

(supplied in toolkit).

3. Fully slacken screws B.

4. Grease screws C, and fit into shank.

5. Fit the probe with adjusting plate and ball

onto the shank and visually position the

probe centrally relative to the shank.

Partially tighten, screws C to 2 - 3 Nm

(1.47 - 2.2 lbf.ft)

6. Mount the probe/shank assembly into

the machine spindle.

PROBE/SHANK MOUNTING WITH ADJUSTING PLATE + CENTRE BALL

Special 4 mm AF

short ar m

hexagon key

Page 24

2.5 mm AF

Adjusting

plate

B

A

C

4 mm AF

PROBE

SHANK

1-20

Stage 2 On-centre adjustment

7. Check the stylus for vertical alignment

relative to the bore hole. Adjust screws A

if alignment is required, and then fully

tighten screws A to 5.1 Nm (3.76 lbf.ft).

8. Each of the four screws B will move the

probe relative to the shank, in the X or Y

direction as pressure is applied.

Tighten individually, backing off after

each movement.

9. When the stylus tip run-out is less than

20 µm,

fully tighten screws C to 6 - 8 Nm

(4.4 - 5.9 lbf.ft).

10. For final centering use screws B to move

the probe, progressively slackening on one

side and tightening the opposite screw,

as

the final setting is approached, using two

hexagon keys.

Tip run out of 5 µm (0.0002 in) should

be achievable.

11. It is important that all four screws B are tight

or tightened to 1.5 - 3.5 Nm (1.1 - 2.6 lbf.ft)

once the final setting has been achieved.

12. When on-centre adjustment is completed,

replace battery and covers - see page 1-13.

Special 4 mm

AF

short arm

hexagon key

STYLUS ON-CENTRE ADJUSTMENT WITH ADJUSTING PLATE + CENTRE BALL

Page 25

17.5° 17.5°

110.2 mm

(4.34 in)

21.5 mm

(0.85 in)

Ø62 mm

(Ø2.24 in)

Z

X - Y X - Y

A probe trigger signal is generated

when the probe is in the operating

mode and the stylus is driven

against a surface and is deflected.

The machine control records the

probe contact position and instructs

machine motion to stop.

High probing speeds are desirable,

however a probing velocity must

be chosen which allows the

machine to stop within the limits

of stylus overtravel. Follow feed

rate guidelines given by supplier.

To ensure a trigger signal is given,

drive the probe against the

workpiece to a target beyond the

expected surface, but within the

limits of stylus overtravel.

After the probe’s stylus touches the

surface, reverse clear of the surface.

Probe gauging moves should be

made at constant speed.

Single and double touch

If the probe operating sequence is

based on a single touch, then the

probe may be returned to its start

point, following a gauging move.

1-21

PROBE MOVES

Stylus overtravel limits

21.5 mm

(0.84 in)

8 mm

(0.31 in)

8 mm

(0.31 in)

Stylus

length

50 mm

(1.96 in)

X - Y

Z

36.5 mm

(1.43 in)

100 mm

(3.93 in)

Page 26

1-22

PROBE MOVES

Single and double touch (continued)

With some types of controllers, it is an advantage to use the two touch method. The first move finds

the surface quickly. Then the probe is reversed to a position clear of the surface, before making the

second touch at a slower feed rate, thereby recording the surface position at a higher resolution.

Gauging speed

Gauging speeds are not limited by the transmission system delay, which has a repeatability of less than

2 µs. System delays are constant for each direction measurement is taken. These delays are

automatically cancelled out and need not be taken into account, provided a datum move is made in

the same direction and velocity as each measurement move.

Signal delay times

1. Error signal delay

A delay of 48 ms maximum for the OMM + MI 12 or 41 ms maximum for the OMI, will elapse

between an error occurring and the output indicating error.

2. Probe signal delay

The speeds will be limited by the ability of the machine tool control system to process the

probe interface signal, and bring the machine to a halt within the probe overtravel limits.

There is a nominal delay of 140 µs with a repeatability of 2 µs for each interface, from the time the

probe actually operates to the MI 12/OMI interface indicating a probe change of state.

Enabling the enhanced trigger circuit will add a further nominal 7 milliseconds.

Page 27

1-23

VERIFY YOUR SOFTWARE

1-1 Does your software have calibration routines which compensate for stylus on centre errors? If

not you must set the probe stylus on centre mechanically.

Note : When using probe styli which are not on spindle centre. Spindle orientation positioning

repeatability is important to avoid probe measurement errors.

1-2 Does your software compensate for probe

triggering characteristics in all measuring directions.

2-1 JOB SET-UP REQUIREMENTS

Does the software automatically adjust the program coordinate system to the relevant set-up

feature on the component.

3-1 INSPECTION REQUIREMENTS

Simple to use canned cycles for standard features :

Bore/boss. Web/pocket. Single surface.

Simple to use canned cycles for optional features :

Angle measurement.

Vector 3 point bore/boss.

Vector single surface.

Good software will allow the following functions :

❋ Update work coordinate systems for positioning.

❋ Report measured sizes and update tool offsets for automatic tool offset compensations.

❋ Print data in the form of an inspection report to

an external PC/printer.

❋ Set tolerances on features.

SOFTWARE REQUIREMENTS

Page 28

TOOL SETTING

PROBE

Length setting

(rotating and

non rotating)

Diameter setting

(rotating)

Broken tool detection

PROBE COLLISION

PROTECTION

Stylus ball radius

Probe length

CALIBRATION

Internal and external

corner find

Web and pocket measure

Probe XY offset Bore and boss

measure

INSPECTION

Inspection printout

COMPONENT No. 1

OFFSET NO. NOMINAL TOLERANCE DEVIATION FROM COMMENTS

DIMENSION NOMINAL

99 1.5000 .1000 .0105

97 200.0000 .1000 .2054 OUT OF TOL

XYZ single surface

position

SOFTWARE FOR MACHINING CENTRES

Simple to use canned cycles for basic features

1-24

Page 29

Feature to feature measure

4th axis measure

Bore and boss on PCD

INSPECTION

Bore and boss (three point)

Stock allowance

Angled surface measure

Angled web and pocket

measure

SOFTWARE FOR MACHINING CENTRES

Simple to use canned cycles for additional features

1-25

Page 30

NO

PROBE READY

FOR USE

see page 1-27

START

The flow chart is provided as a guide

only. Gauge moves are dependant on

the control system.

If there is a system fault alarm, the

operator should check if the probe

status LED is constant red, indicating

battery dead.

OUTPUT ALARM

SYSTEM FAULT

IS

LOW BATTERY

CLEAR ?

READ

LOW BATTERY

SIGNAL

SEND OPTICAL

SIGNAL

WAIT 1 SECOND

READ ERROR

SIGNAL AND

STATUS SIGNAL

NO

YES

YES

NO

NO

YES

ORIENTATE PROBE

TO FIXED

POSITION FOR USE

END

OUTPUT ALARM

SWITCH ON

FAILURE

YES

OUTPUT ALARM

LOW BATTERY

APPROXIMATELY

8 HOURS MAXIMUM

USEABLE LIFE

REMAINS

END

IS ERROR

CLEAR AND STATUS

READY ?

IS ERROR

PRESENT AND STATUS

NOT READY ?

IS ERROR

CLEAR AND STATUS

READY ?

1-26

MP10 - OPTICAL ON

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

CALL

OPERATOR

CALL

OPERATOR

➤

➤

➤

➤

Page 31

PROBE READY

FOR USE

MEASURING

MOVE

TO TARGET

IS

ERROR

CLEAR ?

NO

YES

OUTPUT ALARM

NO TRIP OCCURRED

OPTIONAL

RECOVERY

LOOP

OUTPUT ALARM

TRANSMISSION

LOST

YES

YES

NO

NO

READ AND

STORE

INTERRUPT

POSITION

IS

TARGET

REACHED ?

IS

STYLUS

DEFLECTED ?

The flow chart is provided as a guide only.

Gauge moves are dependant on the control system.

READ AND STORE

START POSITION

REGISTERS

RETURN TO

START POSITION

see page 1-28

optical switch off

MP10

(optical switch off)

RETURN TO

START POSITION

A timer switches

probe off.

Note:

Stylus trigger

resets OMP timer

MP10

(timer off option)

GAUGING MOVES FOR PROBE

1-27

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

Page 32

NO

YES

END

START

IS ERROR

CLEAR AND STATUS

READY ?

NO

END

CALL

OPERATOR

CALL

OPERATOR

READ ERROR

SIGNAL AND

STATUS SIGNAL

SEND OPTICAL

SIGNAL

WAIT 1 SECOND

YES

NO

OUTPUT ALARM

SYSTEM FAULT

YES

IS ERROR

PRESENT AND STATUS

NOT READY ?

IS ERROR

PRESENT AND STATUS

NOT READY ?

The flow chart is provided as a guide only.

Gauge moves are dependant on the control

system.

PROBE OFF

OUTPUT ALARM

SWITCH OFF

FAILURE

1-28

MP10 - OPTICAL OFF

➤➤

➤

➤

➤

➤

➤

➤

➤

➤

➤➤

➤

➤

➤

➤

➤

Page 33

WEAK LINK FOR STYLI WITH STEEL SHAFT - optional

In the event of excessive stylus overtravel the weak link stem is

designed to break, thereby protecting the probe from damage.

THE PROBE IS A PRECISION TOOL HANDLE WITH CARE

ENSURE THE PROBE IS FIRMLY SECURED IN ITS MOUNTING

Although Renishaw probes require little maintenance, their performance

will be adversely affected if dirt, chips or liquids are allowed to enter the sealed

working parts. Therefore keep all components clean and free from grease and oil.

Periodically check cables for signs of damage, corrosion or loose connections.

SERVICE AND MAINTENANCE

1-29

To remove a broken stem

Note: THE WEAK LINK IS NOT USED WITH CERAMIC SHAFT STYLI

12 mm

(0.47 in)

Fitting stylus with weak link onto probe

Take care to avoid stressing the weak link

during assembly - see page 1-32

➤

➤

Page 34

11

Lightly

grease

here

STYLUS HOLDER

OUTER DIAPHRAGM

INNER DIAPHRAGM

STYLUS

TOOL

STYLUS 1 12

2

PROBE DIAPHRAGMS

The probe mechanism is protected

from coolant and debris by two

diaphragms. These provide adequate

protection under normal working

conditions.

The user should periodically check the

outer diaphragm, for signs of damage

and coolant leakage. If this is evident

replace the outer diaphragm.

The outer diaphragm is resistant to

coolant and oils. However, if the outer

diaphragm is damaged, the inner

diaphragm could become weakened

with prolonged immersion in certain

coolants and oils.

The user must not remove the inner

diaphragm. If damaged, return the

probe to your supplier for repair.

WARNING: NEVER ATTEMPT TO REMOVE DIAPHRAGM WITH METAL OBJECTS

1-30

DIAPHRAGM INSPECTION

3

Page 35

OUTER DIAPHRAGM INSPECTION

1. Remove the stylus.

2. Unscrew the front cover.

3. Inspect outer diaphragm for

damage.

4. To remove outer diaphragm, grip

near the middle and pull upwards.

INNER DIAPHRAGM INSPECTION

5. Inspect inner diaphragm for

damage.

If damaged return the probe to

your supplier for repair.

WARNING: DO NOT REMOVE INNER DIAPHRAGM.

OUTER DIAPHRAGM REPLACEMENT

6.Screw tool fully into stylus holder.

7. Fit new diaphragm.

8. The diaphragm must locate centrally in the

stylus holder groove.

9. Press diaphragm to expel

trapped air.

10. Remove tool.

11. Lightly smear medium grease on

front cover lower surface, then refit cover

and tighten.

12. Refit stylus.

4

7 9

6 10

5

8

1-31

Page 36

SCREW TORQUE VALUES - Nm (lbf.ft)

1-32

2.5 mm AF

1.5 Nm

(1.10 lbf.ft)

Weak link

optional

7 mm AF

1 Nm

(0.74 lbf.ft)

Align electrical

contacts

OMP

2.5 mm AF

1.1 Nm

(0.8 lbf.ft)

Ø8 mm Ball

Optional

Adjusting plate

Shank

Special 4 mm AF

5.1 Nm

(3.76 lbf.ft)

2.5 mm AF

1.1 Nm

(0.8 lbf.ft)

5 mm AF

2 Nm (1.7 lbf.ft)

2.5 mm AF

1.5 - 3.5 Nm

(1.1 - 2.6 lbf.ft)

4 mm AF

6 - 8 Nm

(4.4 - 5.9 lbf.ft)

3 mm AF

2 Nm (1.47 lbf.ft)

25 mm AF

25 Nm

(18.44 lbf.ft)

OMM or OMI

HOLD

8 mm AF

5 Nm

(3.68 lbf.ft)

Probe

head

2 Nm

(1.7 lbf.ft)

2.0 mm AF

Stylus

Page 37

Align electrical

contacts

Align electrical

contacts

C spanner

normal

10-12 Nm

(7.37-8.84 lbf.ft)

maximum

20 Nm (14.74 lbf.ft)

Automatic

electrical

connection

Align electrical

contacts

HOLD

LPE

extension

Bar

M16

thread

SCREW TORQUE VALUES - Nm (lbf.ft)

MP10

probe head

LP2 probe

Shank

OMP

MA6

adaptor

Shank

OMP

MPE

extension

housing

2.5 mm AF

1.5 Nm

(1.10 lbf.ft)

2.5 mm AF

1.5 Nm

(1.10 lbf.ft)

2.5 mm AF

1.5 Nm

(1.10 lbf.ft)

1-33

Page 38

1-34

FAULT FINDING - If in doubt, consult your probe supplier.

PROBE FAILS TO SWITCH ON

Probe is already If necessary switch

switched on. probe off.

Dead battery. Change battery.

Battery installed Check battery

incorrectly. installation.

Probe not properly Check alignment and

aligned with OMM/OMI. if OMM/OMI fixing is

secure.

Beam obstructed. Check if OMM/OMI

window is clean/

remove obstruction.

OMM/OMI signal See performance

too weak. envelope.

See pages 1-4 and 1-6.

No OMI start signal See page 1-40.

No power to MI 12 Check if stable 24 V

or OMI supply is available.

Check connections and

fuses.

PROBE STOPS IN MID-CYCLE

Beam obstructed. Check OMI/MI 12 error

LED.

Remove obstruction.

Probe collision. Find cause and rectify.

Damaged cable. Check cables.

Power supply lost. Check power supply.

Probe unable to find Part missing or out of

target surface. position.

PROBE CRASHES

Inspection probe When two systems active,

using tool setting isolate tool setting probe.

probe signals.

Workpiece obstructing Review probe software.

probe path.

Probe length offset Review probe software.

missing.

POOR PROBE REPEATABILITY

Debris on part. Clean part.

Tool change Verify probe repeatability

repeatability poor. using single point move.

Loose mounting of Check and tighten as

probe on shank/loose appropriate.

stylus.

Probe orientated Verify probe position,

180° from calibrated check on-centre setting.

position, or due to

M19 orientation.

Calibration and Review probe software.

update of offsets

not occuring.

Calibration and Review probe software.

probing speeds not

the same.

Calibrated feature has Check position.

moved.

Measurement occurs Review probe software.

as stylus leaves surface.

Page 39

POOR PROBE REPEATABILITY (continued)

Probing occurs within Review probe software.

machine’s acceleration

and deceleration zones.

Probe feedrate too Perform simple

high. repeatability trials at

various speeds.

Temperature variation Minimise temperature

causes excessive changes.

machine and Increase frequency

workpiece movement. of calibration.

Machine has poor Perform health check on

repeatability due to machine.

loose encoders,

tight slideways and/or

accident damage.

PROBE FAILS TO SWITCH OFF

Probe in time out Wait a minimum 2 min

mode. 20 sec for probe to

switch off.

Probe placed in User lighter styli.

carousel, during time Review use of time out

out mode can be reset mode.

by carousel activity.

Probe is inadvertently Increase distance

switched on by between probe and

OMM/OMI. OMM/OMI.

Reduce OMM/OMI signal

strength.

No line of sight between Ensure line of sight is

probe and OMM/OMI. maintained.

PROBE STATUS LED FAILS TO ILLUMINATE

Battery installed Check battery installation.

incorrectly.

MI 12 POWER LED FAILS TO ILLUMINATE

WITH POWER ON

Faulty electrical Check all connections.

contact.

Fuse blown. Locate and replace blown

fuse.

Incorrect power supply. Ensure power supply is

24 Vdc.

MI 12 LOW BATTERY LED REMAINS

ILLUMINATED

Battery installed Check battery installation.

incorrectly.

Battery dead. Replace battery.

PROBE STATUS LED REMAINS ILLUMINATED

Battery voltage below Replace battery.

useable level.

FAULT FINDING - If in doubt, consult your probe supplier.

1-35

Page 40

PROBE IS TRANSMITTING SPURIOUS READINGS

Damaged cables. Check and replace cable if damage is found.

Electrical interference. Move transmission cables away from other

cables carrying high currents.

System malfunction or Shield from intense light sources

inducing intermittent e.g. xenon beams.

errors.

Electrically isolate OMM from the machine

to prevent any possibility of earth loop.

Ensure there are no arc welders, stroboscopes

or other high intensity light sources in close

proximity to the probe system.

Poorly regulated power Ensure power supply is correctly regulated.

power supply.

Excessive machine Eliminate vibration.

vibration.

Loose mountings or styli. Check and tighten loose connections.

PROBE FAILS TO RESEAT CORRECTLY

Probe trigger occurred Move stylus clear of workpiece.

on reseat.

Inner and/or outer probe Inspect/replace outer diaphragm.

diaphragm is damaged. Return to supplier if inner diaphragm

is damaged.

1-36

FAULT FINDING - If in doubt, consult your probe supplier.

Page 41

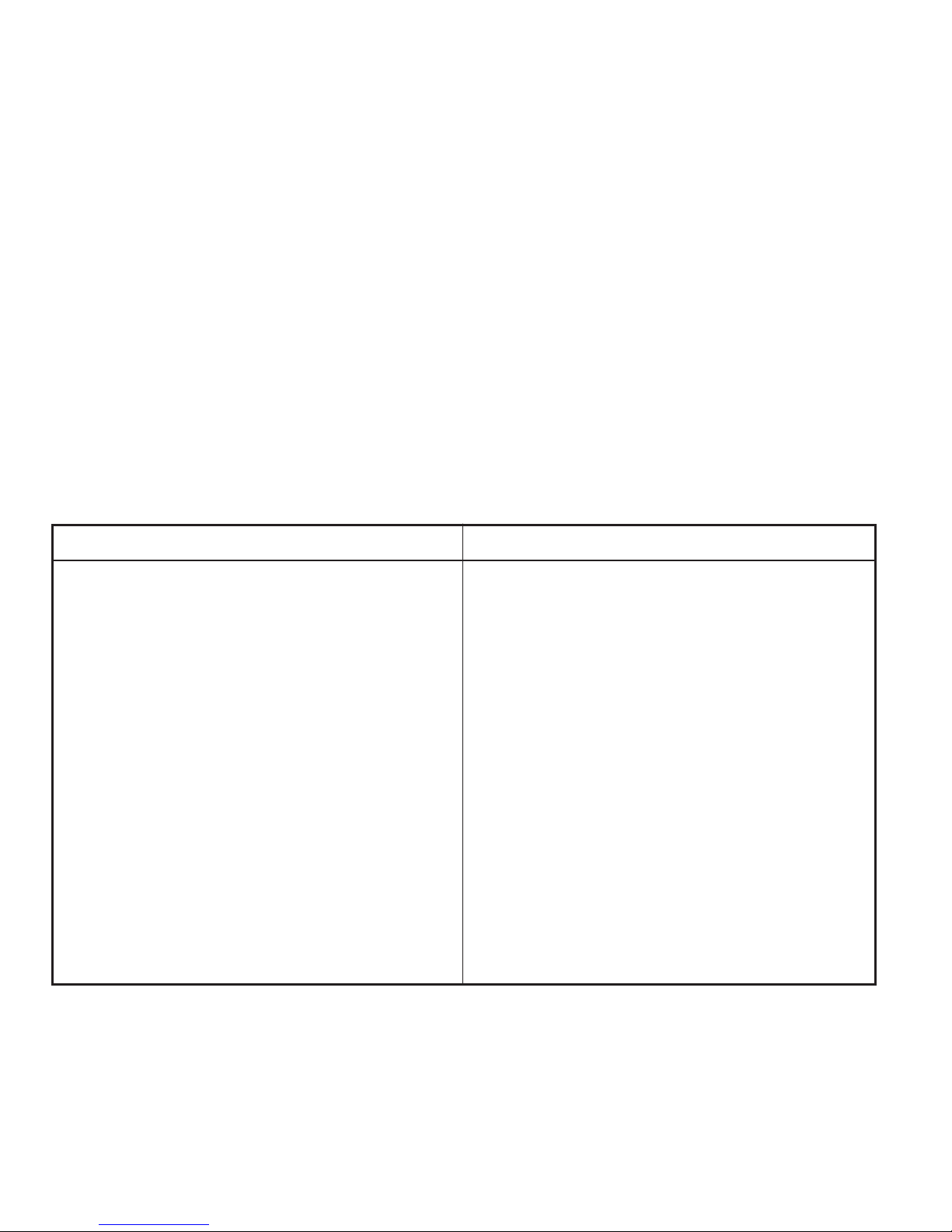

EXTENSION HOUSING

Extension housings allow deeper

access into workpiece features.

Extension housings fit between

the OMP and probe head.

ADAPTOR + EXTENSION BAR

Features with restricted access

can be probed using an LP2

probe.

The MA6 adaptor allows an LP2

probe to be used in place of the

MP10 probe head, which is

removed and replaced with an

MA6 + LP2.

Further reach is obtained by

adding an LPE extension

between the MA6 adaptor and

LP2 probe.

Probe head

Ø62 (2.44)

MPE

extension

housing

OMP

Ø62 (2.44)

Stylus

Shank

APPENDIX 1

ADAPTOR AND EXTENSIONS

A maximum of one extension housing or extension bar is permitted per installation

1-37

35° OMP 87.9 (3.46)

70° OMP 87.4 (3.44)

30

(1.18)

MPE1 100 (3.94)

MPE2 150 (5.90)

MPE3 200 (7.87)

dimensions mm (in)

MP10 probe head replaced with

MA6 adaptor + LPE extension + LP2 probe

LP2 probe

Stylus

MA6

adaptor

Shank

LPE

extension bar

Ø25 (0.98)

OMP

Ø62 (2.44)

40.8

(1.6)

LPE1 50 (1.96)

LPE2 100 (3.94)

LPE3 150 (5.90)

25

(0.98)

35° OMP 87.9 (3.46)

70° OMP 87.4 (3.44)

Page 42

1. Red LED

Lit when power is on.

2. LEDs x 3

Transmit infrared control signals

to the probe.

3. Green LED

Lit when signal is received from

the probe.

4. Yellow LED

Lit when the MI 12 sends a start,

error, reset signal to the probe.

Rear View

Mains switch

On/off

Front View

The PSU3 provides a +24 V supply for

Renishaw interface units when a power

supply is not available from the CNC

machine control.

Power LED

When the green LED is lit,

the power supply is on.

KEEP WINDOW CLEAN

To fully maintain

effective signal

transmission

1-38

APPENDIX 2

PSU3 POWER SUPPLY UNIT

The PSU3 is fully described in

User's guide H-2000-5057

APPENDIX 3

OMM (OPTICAL MODULE MACHINE)

The OMM is fully described in

User's guide H-2000-5044

1

2

3

4

Page 43

MI 12

MI 12-B

1 2 3 4 5 6

4. LED probe status

Lit when probe is seated.

Off when stylus is deflected or an error

has occurred.

5. LED power

Lit when power is on.

6. Start button - switch SW1

Manual start push button.

Press button to switch system to operating

mode. Alternatively a signal from the machine

control can be used for the same purpose.

1. Audible indicator (bleeper)

The speaker is behind the front panel.

2. LED error

Lit when optical beam obstructed,

probe out of range, probe switched off,

etc.

3. LED low battery

Replace probe battery as soon as

practicable, after this LED lights up.

APPENDIX 4

MI 12 INTERFACE UNIT

The MI 12 is fully described in

User's guide H-2000-5073

1-39

Page 44

1. LED (yellow) – START signal status.

Lit when a START signal is transmitted

to the probe.

This LED will either flash once when a

machine controlled START signal is

commanded, or flash continuously at

one second intervals when the system

is set to 'Auto–Start' mode and is

awaiting a probe transmission signal.

2. LED (red) – LOW BAT.

When the OMP battery voltage

falls below a set level, the low

battery output device changes

state, and causes the LOW BAT LED

to commence flashing on and off

4 times per second.

Replace the OMP battery as soon

as is practicable after the LED

starts flashing.

1-40

APPENDIX 5

OMI (OPTICAL MACHINE INTERFACE)

The OMI is fully described in

User's guide H-2000-5062

MAGNETIC LABEL

To assist the machine

operator, a summary of OMI

LED activity is provided on a

magnetic label. The label is

simply placed on an easily

viewed flat metal surface.

KEEP THE

WINDOW CLEAN

4

6

1

2

3

5

6

6

Abc

D

Page 45

3. LED (red, green) – PROBE STATUS.

This bicolour LED is lit when the OMI

is powered.

Green - Probe is seated.

Red - Probe is triggered or

an error has occurred.

The change of colour of this LED will

coincide with the probe status output

devices changing state.

4. LED (red) – ERROR.

Lit when an error condition exists.

i.e. optical beam obstructed, probe out

of optical range, probe has switched off

or battery is exhausted.

When an error condition exists the

probe status output will be held in a

triggered state and the probe status

LED will be RED.

The error LED illuminating will coincide

with the error output device changing

state.

5. LED (red, yellow, green) – Infrared SIGNAL

strength received from probe.

As long as there is power to the system, this LED

will always be lit. It is a tricolour LED and indicates

as follows :

Red - Signal received from the probe is

either

too weak or not there at all

(i.e. no signal).

Yellow - Signal received is marginal.

i.e. The OMI is at the edge of its

operating envelope. Correct operation

in this region cannot be guaranteed.

Green - Signal received is good and system

will operate correctly.

Note :

1. During a start transmission, the SIGNAL

LED will change through red to yellow and

green.

This is the normal power up sequence.

2. The SIGNAL LED will flash (yellow or green)

if optical interference is being received whilst

the probe is not transmitting.

6. LED x 3 groups (clear)

These LEDs transmit infrared control signals

to the probe.

1-41

Page 46

1-42

PARTS LIST - Please quote the Part No. when ordering equipment

MP10 kit A-2033-1101 MP10 35° probe + battery, stylus, OMM, MI 12 interface and toolkit.

MP10 kit A-2033-1102 MP10 70° probe + battery, stylus, OMM, MI 12 interface and toolkit.

MP10 A-2033-1099 MP10 35° probe + battery and Ø8 mm centre ball - factory set to time out.

MP10 A-2033-1100 MP10 70° probe + battery and Ø8 mm centre ball - factory set to time out.

MP10 A-2033-1115 MP10 35° probe + battery and Ø8 mm centre ball - factory set to optical off .

MP10 A-2033-1116 MP10 70° probe + battery and Ø8 mm centre ball - factory set to optical off .

MP10 OMP

A-2085-0080 MP10 35° OMP kit and accessories.

MP10 OMP

A-2085-0081 MP10 70° OMP kit and accessories.

ACCESSORIES

Stylus A-5000-3709 PS3-1C ceramic stylus 50 mm long with Ø6 mm ball.

- Styli are fully listed in Renishaw Styli guide H-1000-3200.

W link kit A-2085-0068 Weak link kit comprising: Two stylus weak link stems and spanner.

Weak link M-2085-0069 Stylus weak link stem.

Spanner P-TLO9-0007 Spanner for stylus weak link stem.

Battery P-BT03-0001 9V alkaline battery.

DK1 A-2051-7105 Probe outer diaphragm replacement kit.

Shank mtg A-2107-0123 Stainless steel shank adaptor kit.

Tool kit A-2085-0020 Probe tool kit for MP10 comprising: Ø1.98 mm stylus tool and

hexagon

keys 1.5 mm AF, 2.0 mm AF, 2.5 mm AF (two), 3.0 mm AF and 4.0 mm AF (short).

OMM A-2033-0576 OMM complete with cable Ø5.1 mm x 25 m (Ø0.2 in x 82 ft).

Win kit A-2115-0002 OMM/OMI window replacement kit.

Type Part No. Description

Page 47

ACCESSORIES continued

MP10 A-2085-0064 MP10 battery replacement kit.

PCB kit A-2031-0043 OMM PCB replacement kit.

OMI A-2115-0001 OMI complete with cable 8 m long (26.2 ft).

Extn cable M-2115-0045 Extension cable 10 m long (32.8 ft long) 12 x 7/0.2 for OMI.

Extn cable M-2115-0046 Extension cable 20 m long (65.6 ft long) 12 x 7/0.2 for OMI.

Mtg brkt A-2033-0830 OMM/OMI mounting bracket complete with fixing screws, washers and nuts.

MI 12 A-2075-0142 MI 12 interface unit.

MI 12-B A-2075-0141 MI 12 interface board.

Panel mtg A-2033-0690 Panel mounting kit for MI 12 interface unit.

PSU3 A-2019-0018 PSU3 power supply unit 85-264 V input.

EXTENSIONS and ADAPTOR

MPE1 A-2033-6571 MPE1 extension housing Ø62 x 100 mm long with holding screws and washers.

MPE2 A-2033-6595 MPE2 extension housing Ø62 x 150 mm long with holding screws and washers.

MPE3 A-2033-6667 MPE3 extension housing Ø62 x 200 mm long with holding screws and washers.

MA6 A-2063-7774 MA6 adaptor - allows LP2 probe to be used in place of MP10 probe.

LPE1 A-2063-7001 LPE1 extension bar Ø25 x 50 mm long.

LPE2 A-2063-7002 LPE2 extension bar Ø25 x 100 mm long.

LPE3 A-2063-7003 LPE3 extension bar Ø25 x 150 mm long.

SOFTWARE

Software — Probe software for machine tools - See Data sheet H-2000-2289.

PARTS LIST - Please quote the Part No. when ordering equipment

1-43

Type Part No. Description

Page 48

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

*H-2000-5059-05*

Loading...

Loading...