Page 1

MIHUserGuide

Document part number H-1000-5200-09-A

Page 1 of 44MIH User Guide

19/12/2012file://C:\TEMP\~hhB557.htm

Page 2

Page 2 of 44MIH User Guide

MIHdisclaimer

© 2001 - 20011 Renishaw plc. All rights reserved.

Renishaw® is a registered trademark of Renishaw plc.

This document may not be copied or reproduced in whole or in part, or transferred to any other media

or language, by any means, without the prior written permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of

Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of this document are free from

inaccuracies and omissions. However, Renishaw makes no warranties with respect to the

contents of this document and specifically disclaims any implied warranties. Renishaw reserves the

right to make changes to this document and to the product described herein without obligation

to notify any person of such changes.

Trademarks

All brand names and product names used in this document are trade names, service marks,

trademarks, or registered trademarks of their respective owners.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 3

Page 3 of 44MIH User Guide

FCC(USAonly)

Informationtouser(47CFR§15.105)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the installation manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

you will be required to correct the interference at your own expense.

Informationtouser(47CFR§15.21)

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or

authorised representative could void the user’s authority to operate the equipment.

Labellingrequirements(47CFR§15.19)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

WEEE

The use of this symbol on Renishaw products and/or accompanying documentation

indicates that the product should not be mixed with the general household waste upon

disposal. It is the responsibility of the end user to dispose of this product at a designated

collection point for waste electrical and electronic equipment (WEEE) to enable reuse or

recycling. Correct disposal of this product will help save valuable resources and prevent potential

negative effects on the environment. For more information, please contact your local waste disposal

service or Renishaw distributor.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 4

Page 4 of 44MIH User Guide

MIHgeneralinformation

Careofequipment

Renishaw probes and associated systems are precision tools used for obtaining precise

measurements and must therefore be treated with care.

Changestoequipment

Renishaw reserves the right to improve, change or modify its hardware or software without incurring

any obligations to make changes to Renishaw equipment previously sold.

Warranty

Renishaw plc warrants its equipment provided that it is installed exactly as defined in associated

Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or

cabling) is to be used or substituted for Renishaw equipment. Failure to comply with this will invalidate

the Renishaw warranty.

Claims under warranty must be made from authorised service centres only, which may be advised by

the supplier or distributor.

Patents

The features of Renishaw’s manual indexable head and associated products are the subject of the

following patents, patent applications and registered designs.

EP 0142373 JP 2,098,080 US 4651405

EP 0293036 JP 3,018,015 US 5,088,337

EP 0392660 US Des 327854

Registered design (France): FR 278857

19/12/2012file://C:\TEMP\~hhB557.htm

Page 5

Page 5 of 44MIH User Guide

MIHintroduction

MIH

Renishaw’s MIH is a compact manual indexable probe head which offers the fl exibility and time

saving normally associated with direct computer controlled (DCC) machines and motorised probe

heads.

The MIH is adjustable in two axes, both of which can be unlocked by a single thumbwheel operation.

A probe/stylus combination can be orientated to 720 different positions and, once the head is locked,

each position will be repeatable to 1 μm* (0.00004 in) (2σ). Hence the user can return to any chosen

position without having to requalify the probe/stylus tip.

The current position is shown on the integral liquid crystal display (LCD) and is constantly updated

during moves.

The programmable memory facility allows pre-datumed positions to be stored in a memory within the

head. Direction arrows shown on the LCD take the user back to any one of 20 memorised positions

which can be arranged in any order to suit a particular inspection sequence. The sequence can be

edited as required.

Probes are attached to the MIH by means of the Renishaw autojoint, allowing the user to easily

exchange probes whilst maintaining repeatability to 0.5 μm* (0.00002 in) (2σ). The autojoint is

recessed into the head, thus maximising the valuable working volume of the machine.

* Measured at 67 mm (2.64 in) from autojoint (TP6A probe with 21 mm (0.83 in) stylus).

Features

• Manually indexable in 2 axes

• Positionally repeatable to 1 μm* (0.00004 in) (2σ)

• 720 selectable positions

• LCD display

• Programmable memory function

• Simple operation

• Compact size

• Renishaw autojoint probe mounting

• No special installation required

* Measured at 67 mm (2.64 in) from autojoint (TP6A probe with 21 mm (0.83 in) stylus).

19/12/2012file://C:\TEMP\~hhB557.htm

Page 6

Page 6 of 44MIH User Guide

MIHrecommendations

DO mount the head as rigidly as possible in the CMM quill.

DO ensure that the head is properly locked before attempting to use the probe to take points.

DO support probe/extension set-ups of longer than 150 mm by hand when locking or unlocking the

head.

DO disarm the probe during moves if possible. This can be achieved via the application software and

will avoid false triggers.

DO change the battery when low battery indicator is ON.

DO reposition the head by moving only one axis at a time to ensure best practise.

DO unlock and relock the head after a probe change.

DO NOT rotate the head axes by holding the probe stylus.

DO NOT move the CMM by holding the head.

DO NOT attempt to use a probe whilst the head is unlocked.

DO NOT leave the head unlocked for long periods.

DO NOT use probe extensions over 300 mm long.

DO NOT lock the head in an overtravel position.

DO NOT move the axes beyond overtravel positions.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 7

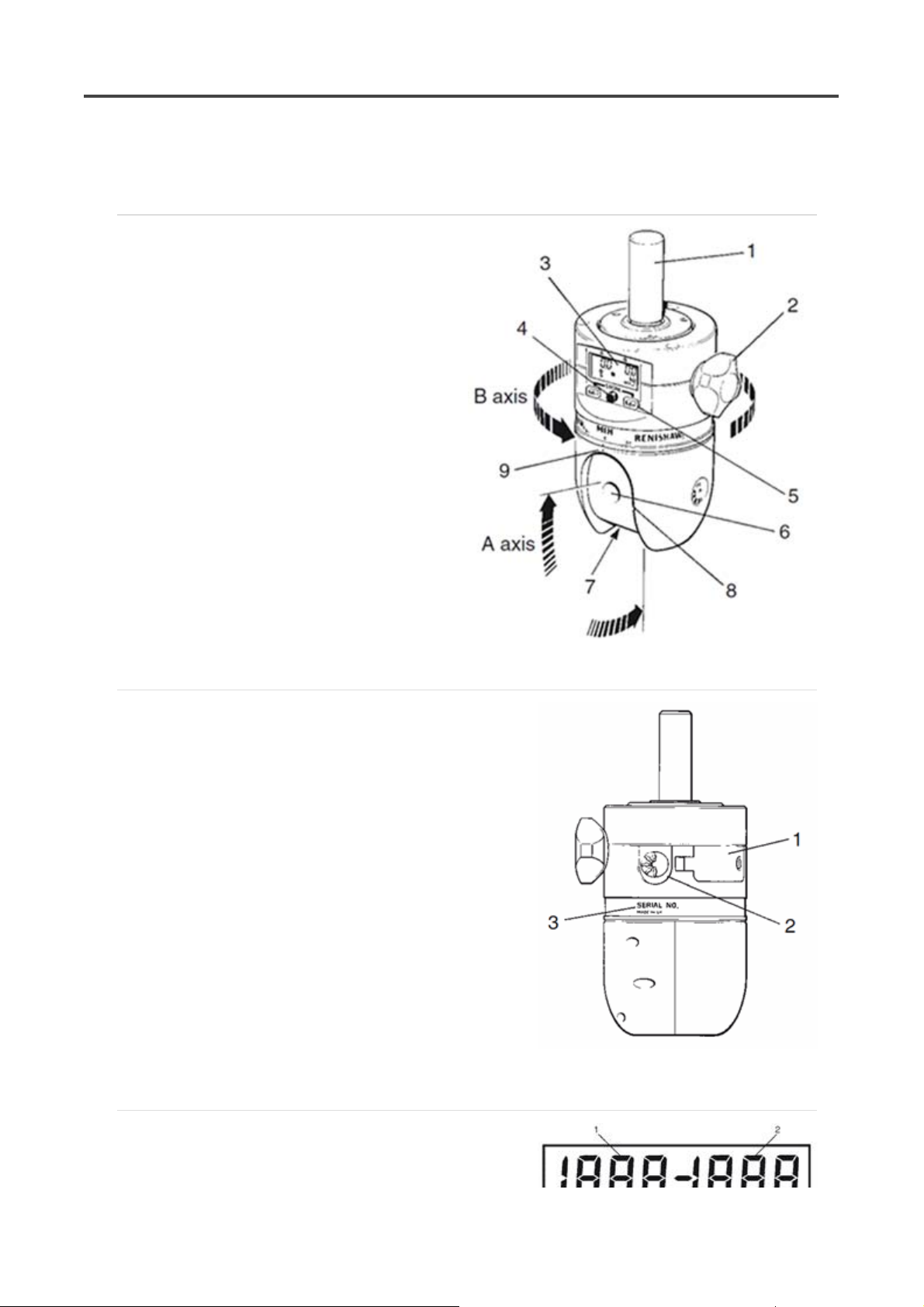

MIHmajorcomponents

MIH‐front

Refer to figure opposite.

1 Mounting shank

2 Lock/unlock thumbwheel

3 LCD display

4 Probe status LED

5 LCD memory programming buttons

6 Probe autojoint lock/unlock access window

Page 7 of 44MIH User Guide

7 Renishaw autojoint probe mounting (recessed

into A axis swivel)

8 A axis zero position markers

9 B axis zero position markers

MIH‐back

Refer to figure opposite.

1 Battery housing

2 5-pin DIN connector

3 Serial number

LCDdisplay

Refer to figure opposite.

1 A axis positional data (0° to +105°)

19/12/2012file://C:\TEMP\~hhB557.htm

Page 8

2 B axis positional data (-180° to +180°)

3 Low battery indicator

4 Head locked symbol

5 Rotation direction arrows

6 Position conf rmation symbol

7 Sequence store indicator

8 Memory mode indicator

9 Memory number

Page 8 of 44MIH User Guide

19/12/2012file://C:\TEMP\~hhB557.htm

Page 9

MIHinstallation

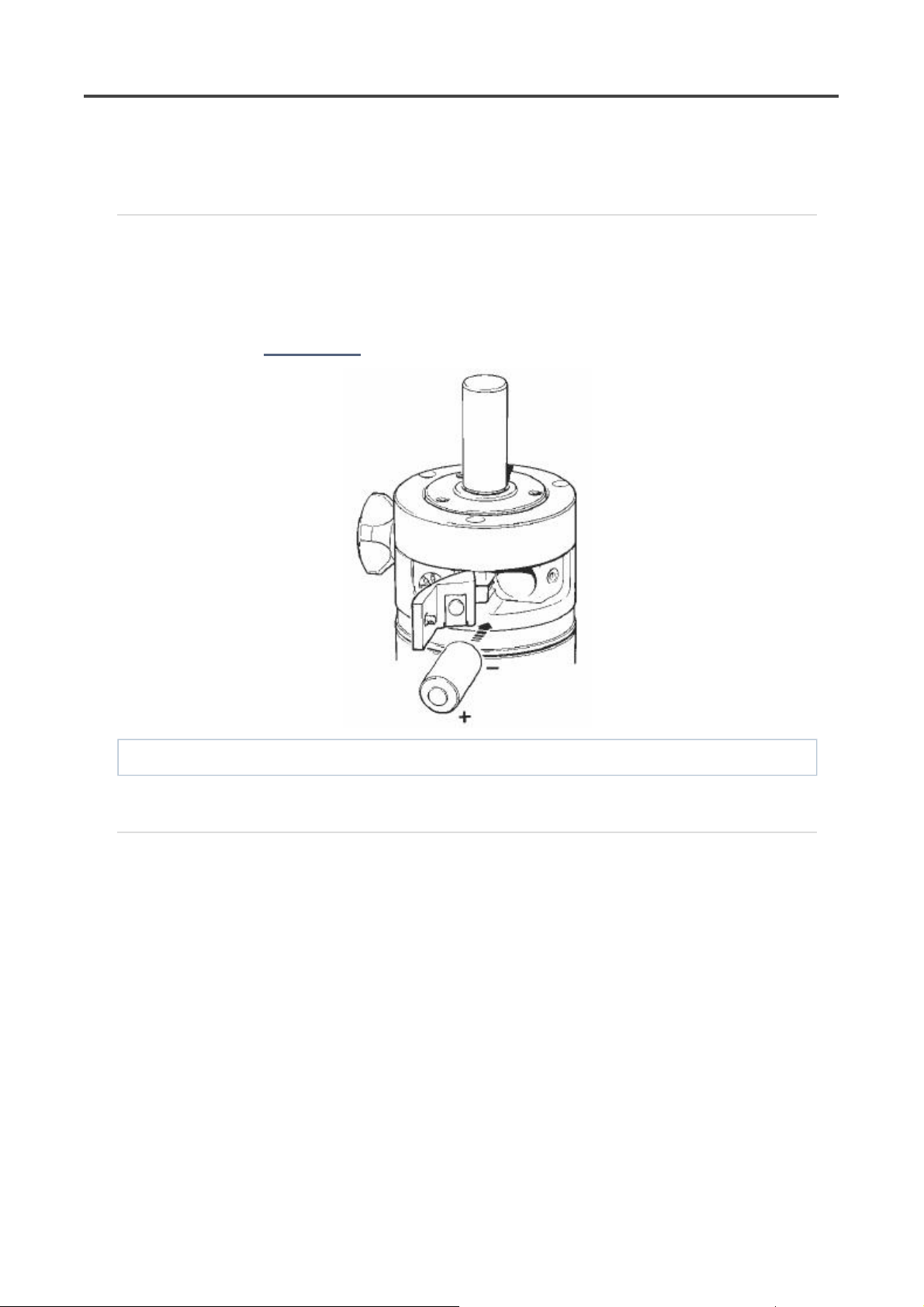

Fittingthebattery

1. Move MIH to axis positions A0.0, B0.0 and lock up.

2. Unscrew housing retaining screw.

3. Open housing door.

4. Insert battery as shown (negative end first).

5. Close door and secure retaining screw (do not overtighten).

6. Reset datum (See ‘

Datum mode’page).

Page 9 of 44MIH User Guide

NOTE: Incorrect insertion of the battery will not cause damage to the MIH.

Fittingtheprobe

1. Offer up the female autojoint with key slot facing as shown.

2. Using an S10 autojoint key, insert into access hole and locate blade in key slot.

3. Rotate clockwise to lock the autojoint.

4. Once qualified, probe/stylus combinations may be interchanged without the need to re-qualify.

5. After changing a probe, unlock and re-lock the head to ensure repeatability.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 10

Page 10 of 44MIH User Guide

Pinconnections

Insert Renishaw 5-pin DIN plug into socket.

1. Head LED cathode

2. Ground

3. Head LED anode

4. Probe circuit

5. Probe circuit

Quillmounting

Ensure that the head is securely mounted onto the CMM quill. Any rotational movement occurring

during use will result in a loss of repeatability of positional data.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 11

Page 11 of 44MIH User Guide

CAUTION: Always fit mounting shanks with the screws supplied (M3 x 5 mm (0.20 in) long). The

use of incorrect screws may cause serious internal damage to the head.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 12

Page 12 of 44MIH User Guide

UsingtheMIH

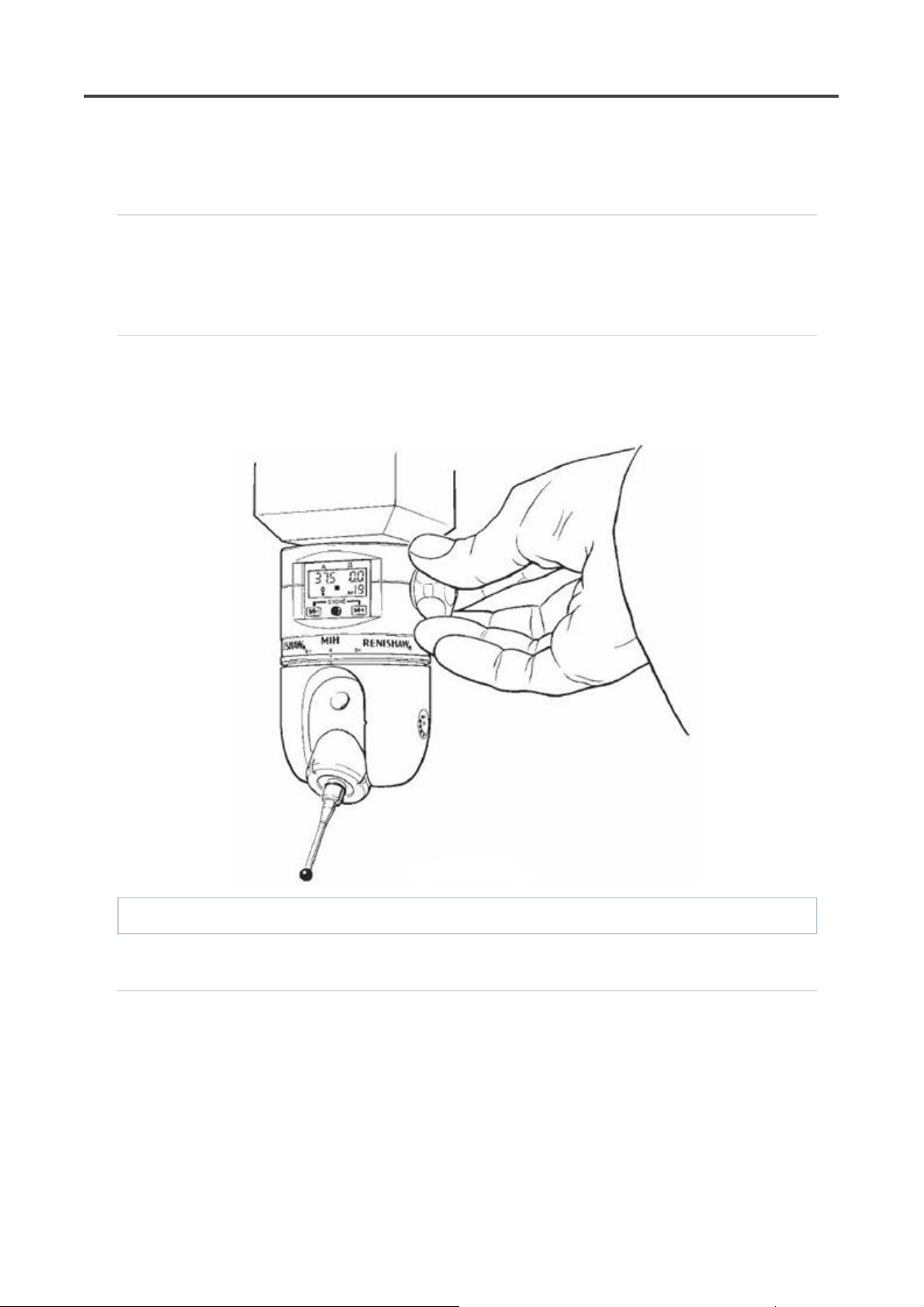

Unlockingthehead

Both A and B axes are unlocked by a single turn of the thumbwheel in a counter-clockwise direction.

The locked (key) symbol on the LCD will disappear. Probes/extensions longer than 150 mm should be

supported by hand when locking or unlocking the head.

Lockingthehead

To lock the head correctly after positioning, support the probe (and extension, if fitted) and turn the

thumbwheel clockwise until a positive “click” is felt. A correct “lock-up” is confirmed by the appearance

of the key symbol on the LCD. To ensure repeatability, it is important to simply support the

probe/extension during lock-up and NOT to constrain it.

NOTE: Do not leave the head unused in an unlocked position as this will shorten battery life.

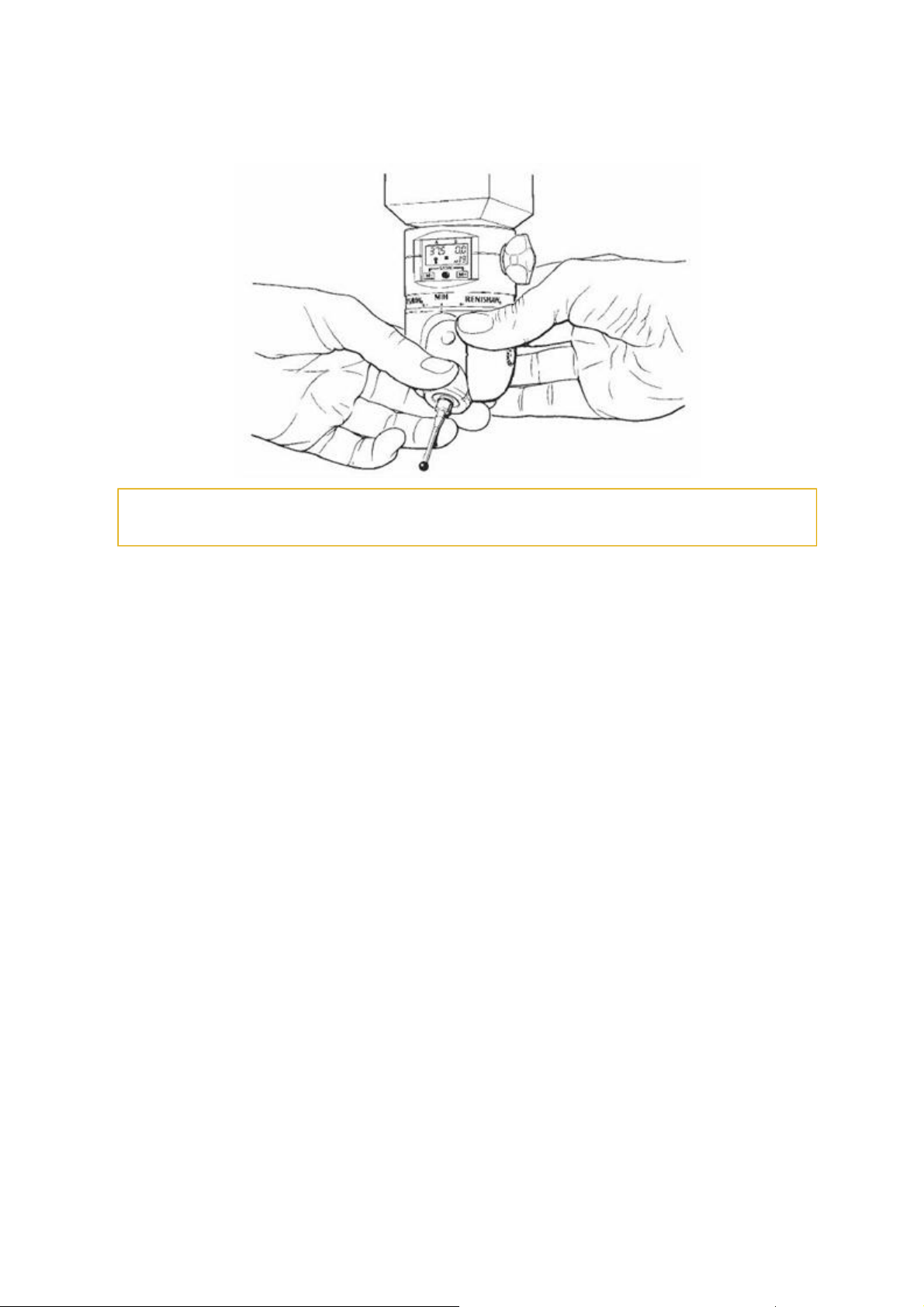

Positioningthehead

Rotation of each axis is achieved against a built-in kinematic mechanism. This provides the user with

discreet 7.5° incremental positions so that the head cannot be locked in a non-repeatable position.

The B axis is positioned by holding the lower housing and rotating until the required position is

reached.

The A axis is positioned by holding the probe or extension body as close to the head as possible and

rotating until the required position is reached.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 13

Page 13 of 44MIH User Guide

To ensure maximum repeatability, each axis should be moved separately, and should not be moved

beyond overtravel positions.

CAUTION : Do not change axis positions by holding the stylus, as this will cause damage to the

probe.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 14

Page 14 of 44MIH User Guide

MIHLCD/softwarefacility

A and B axis positional data is shown on an integral liquid crystal display (LCD). When the head is

unlocked and repositioned, position detectors fitted in each axis update the display which will show

live position data. Power for the LCD/software is supplied by a battery fitted within the head which

should be replaced when the low battery indicator is shown. Under normal use, the head will still

function for many days after the low battery indicator appears.

The MIH also has a user-friendly software facility which is operated by two buttons. The software

facility operates in four modes which are entered and exited by button presses and/or time-out

periods of non-use. The locked symbol and low battery indicator function in all modes.

Datummode

This mode has automatic entry when the battery is first fitted or replaced. Datum mode requires the

user to set the A and B axis position detectors to zero and must be completed successfully before the

LCD can be used. Datum mode may also be automatically entered if an error occurs in the axis

position detectors, caused by mis-use of the head. Again, correct datuming of the head must be

completed before use can commence. See Datum mode

for step-by-step instructions.

Simplemode

The software automatically enters simple mode upon completion of the datuming routine. Following

the time-out of other modes, the MIH software will always return the user to simple mode. This is a

use-only mode in which live A and B axis data will always be shown.

In addition, if the head is locked in a position which corresponds to one which has been previously

stored in memory, the memory number will be displayed on lock-up. See Simple mode

step instructions.

for step-by-

Memorymode

The user can enter memory mode from simple mode by pressing either the M+ or M- button. In this

mode the MIH memory can be programmed or used. In memory mode, chosen head positions can be

stored in up to 20 memory stores. Each position is allocated a memory number (0 to 19). In use, a

chosen memory number is selected and direction arrows on the LCD lead the user to rotate the axis

until the position stored in that memory is achieved. If the user fails to achieve the selected position,

this condition is indicated by the flashing of the direction arrows on lock-up. Once the correct position

is reached, the arrows disappear and the head position confi rmation symbol is shown.

Exit from memory mode will occur after a 10 second period of inactivity and the head will revert to

simple mode. A simple button press will return the user to memory mode. See Memory mode

by-step instructions.

for step-

Sequencemode

Sequence mode can be entered by a 5 second press of both M+ and M- buttons from simple mode.

In sequence mode, pre-memorised head positions can be arranged in any order to suit a particular

sequence of inspection. Up to 20 sequence position numbers are available and the sequence can be

edited as required. In use, the direction arrows lead the user through the pre-programmed sequence

19/12/2012file://C:\TEMP\~hhB557.htm

Page 15

Page 15 of 44MIH User Guide

and will confirm that the head is locked in a correct position. The display automatically indicates the

next position in the sequence when the head is next unlocked. See Sequence

instructions.

mode for step-by-step

Conservingbatterylife

To conserve battery life, the LCD will automatically power down if the head is left in an unlocked state

and remains unused for more than 20 seconds.

The LCD will return to its exact display before the 20 second time-out upon lock-up.

Rotating either axis whilst the LCD is in this powered-down state will return the user to datum mode

upon lock-up (see Datum

This function will automatically operate if the head is left unlocked in any mode.

Stored memories and sequences remain unaffected by this function.

mode).

NOTE: Do not leave the head unused in an unlocked position, as this will shorten battery life.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 16

Page 16 of 44MIH User Guide

Datummode

Datummode

When the battery is first inserted or replaced, the MIH enters a datum mode routine which must be

successfully completed prior to use. The A and B axis position detectors within the head require

datuming to a zero position before the LCD will display the correct A and B axis positions. Datuming

the head will also be required if a head datum error occurs during use.

Step1

On entry into datum mode the LCD shows a datum error. Unlock the head to reset datum.

Step2

Rotate the A and B axes to their zero positions by aligning the zero position markers on both axes.

Step3

Lock the head in this position and press the M+ and M- buttons simultaneously to reset datum.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 17

Page 17 of 44MIH User Guide

Step4

The display will now change to show A and B axis data at A0.0, B0.0. Datum is now set and the A and

B axis displays will show positional data when the head is locked and unlocked.

Step5

Confirm that datum is correctly set by rotating each axis to its extreme positions and check that the

position data on the LCD is correct.

A axis 0° to +105° plus overtravel

B axis ±180° plus overtravel.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 18

Page 18 of 44MIH User Guide

Simplemode

Following insertion of the battery and datuming of the head, the MIH is now ready to be used in

simple mode. All data shown in the A and B axis positions on the LCD will be “live”.

Example: To use the MIH repeatably in positions A0.0, B0.0 and A105.0, B-180.0 (see steps 1 - 3

below).

Step1

Position the head to A0.0, B0.0 and lock in position. Qualify the probe tip on your CMM in the normal

manner. The stored tip number should be noted, together with the corresponding A and B axis

positions on the MIH.

Step2

Unlock the head and rotate the A and B axes until the required position is reached - in this example.

A105.0, B -180.0

If overtravel in either axis occurs, the ‘O-t’ symbol will appear in the axis data on the LCD. Rotate the

head to a valid position.

CAUTION: Do not attempt to lock the head in an overtravel position.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 19

Page 19 of 44MIH User Guide

Step3

Lock the head in a valid position, A105.0, B-180.0. Qualify the probe tip on your CMM in the normal

manner. The stored tip number should be noted, together with the corresponding A and B axis

positions on the MIH.

The MIH can now be used in either of the two pre-qualifi ed positions (A0.0, B0.0 or A105.0, B-180.0)

without the need to re-qualify the probe tip after each move. Simply unlock the head, move to the

required position and lock up. The previously stored tip data for that head position can be recalled

from the CMM computer software ready to take points.

The head can be used in this way in up to 720 repeatable positions. The number of positions which

are to be used will be dictated by the workpiece requiring inspection, but in some cases may be

restricted by the number of storage positions for tip data available on your CMM software. Please

consult your CMM supplier for further details.

Attempting to move the head axes whilst locked will cause damage and may result in movement of

the axis position detectors in severe cases. Should this occur, the MIH software will signal an axis

error message and will ask for a datum reset when unlocked. See step 2 of the datum

details of this routine.

mode page for

If the head is in a locked position which has previously been stored within the head’s programmable

memory function, the memory number corresponding to that position will show on the LCD screen

upon lock-up. For further details on its use see the memory function page.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 20

Page 20 of 44MIH User Guide

Memorymode

Memorymode

When the battery is first fitted, all memory locations are pre-set to A0.0, B0.0. Pressing either the M+

or M- button when in simple mode activates memory mode.

Step1

In this example the head is positioned and locked at A0.0, B0.0 in simple mode.

Step2

The M+ or M- button is pressed to activate memory mode. Memory location 1 is shown on the LCD

and the axis data stored in that location is shown in the A and B axis position displays. Because the

head is at this position (A0.0, B0.0), the direction arrows do not show, only the position confirmation

block shows. If no button presses or head lock/unlock occur within 10 seconds, the LCD reverts to

simple mode.

M1 now = A0.0, B 0.0

Step3

The head is unlocked, repositioned and locked at A30.0, B30.0 in simple mode.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 21

Press M+ to activate memory mode.

Step4

Page 21 of 44MIH User Guide

Memory location M1 is displayed (A0.0, B0.0) since this was the last memory number used.

As the head is not in this position, the direction arrows appear showing the direction in which each

axis must be rotated to achieve the position stored in M1 (A0.0, B0.0).

Step5

To store A30.0, B30.0 in memory location M2, press M+ and the memory number will increment until

M2 is reached.

Currently A0.0, B0.0 is stored in M2 and this is displayed together with the flashing direction arrows

showing how this position can be reached.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 22

Page 22 of 44MIH User Guide

Step6

Pressing the M+ and M- buttons simultaneously for longer than half a second will store A30.0, B30.0

in memory location 2.

The display will then “blink” to show that the position data is stored in the memory.

This is confirmed by A30.0, B30.0 appearing in the A and B axis displays and the direction arrows

disappearing, leaving only the confirmation block.

M2 now = A30.0, B30.0

Step7

To return the head to a previously memorised position M1 (A0.0, B0.0) press M- to decrement the

memory number to M1. The direction arrows flash to show the direction moves required to reach that

position and the axis data stored in M1 (A0.0, B0.0) is displayed.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 23

Page 23 of 44MIH User Guide

Step8

Unlock the head to display live positional data. The direction arrows remain but stop flashing.

Step9

Rotate the A and B axes in the directions indicated by the arrows until both arrows disappear and the

position confirmation block comes on. This confirms that the head is now in the position stored in the

memory location indicated.

NOTE: If you overshoot the target position chosen in either axis, the direction arrows will lead

you back to the required position.

If the head is locked in an incorrect position, the direction arrows will flash. The arrows will stop

19/12/2012file://C:\TEMP\~hhB557.htm

Page 24

Page 24 of 44MIH User Guide

flashing after 10 seconds and the display will return to simple mode showing “live” position data.

If either button is pressed, the screen will return to the last used memory display.

The memory numbers are incremented or decremented by pressing either the M+ or M- buttons

respectively. Pressing either button and keeping it pressed will cause the memory numbers to

scroll up or down at the rate of two per second.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 25

Page 25 of 44MIH User Guide

Sequencemode

When the battery is first inserted, sequence step 1 contains the contents of memory 1, sequence step

2 contains the contents of memory 2 and so on up to sequence step 19. Step 20 contains an end of

sequence marker (E).

By pressing the M+ and M- buttons simultaneously (for 5 seconds) when the head is locked in simple

mode, sequence mode is entered.

The display gives the choice to either use the existing sequence (press M- button) or edit the

sequence to create a new one (press M+). If no choice is made within 5 seconds, the display will

return to simple mode.

Step1

Pressing the M+ button to edit, the sequence is entered at step 1. The existing contents of this step

(in this case memory 1) are also displayed.

Step2

Pressing M+ or M- will increment or decrement the sequence step numbers and the display will show

the memory number stored in each sequence step. Keeping the M+ or M- buttons pressed will scroll

through the sequence steps at the rate of two per second.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 26

Page 26 of 44MIH User Guide

Step3

Once the sequence step to be changed is chosen (in this example step 3 currently containing memory

number 3), pressing the M+ and M- buttons simultaneously for between half a second and 3 seconds*

changes the display.

The S character disappears and the M character will be shown. This confirms that the sequence step

chosen (step 3) is now frozen, and that the new contents can be chosen by pressing either the M+ or

Mbutton to scroll up or down through the memory numbers.

Step4

Once the memory number to be stored in sequence step 3 has been chosen (in this example memory

5), pressing the M+ and M- buttons simultaneously for between half a second and 3 seconds* will

store memory 5 in sequence step 3. This is confirmed by a store (Sto) message appearing on the

display. The M character disappears and the S character reappears, confi rming that the function of

the M+ and M- buttons has been transferred back to selecting sequence steps.

* If the buttons are held for longer than 3 seconds, the display will revert to the ‘End USE’ screen (see

step 7).

19/12/2012file://C:\TEMP\~hhB557.htm

Page 27

Step5

The sequence now has three steps -

step 1 containing memory 1

Page 27 of 44MIH User Guide

step 2 containing memory 2

step 3 containing memory 5.

To end the sequence, the end of sequence marker (E) must be placed in sequence step 4. Pressing

the M+ button will increment the sequence to step 4 and the display will show the current contents as

memory 4.

Step6

Press M+ and M- simultaneously for between half a second and 3 seconds. This changes the display.

The S character is replaced by the M character as before.

Press and hold either the M+ or M- button until the end of sequence marker (E) is displayed. This is

positioned between M19 and M1.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 28

Page 28 of 44MIH User Guide

Store E in sequence step 4 by pressing the M+ and M- buttons simultaneously for between half a

second and 3 seconds.

The sequence is now complete and is as follows -

Step 1 (M1), Step 2 (M2), Step 3 (M5), Step 4 (E).

Step 7

To exit from editing a sequence, press the M+ and M- buttons simultaneously for longer than 3

seconds. The display will give a choice of either ending sequence mode or using the sequence.

Pressing the M- button or taking no action for 5 seconds will return the display to simple mode.

Pressing the M+ button enables use of the stored sequence.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 29

Page 29 of 44MIH User Guide

NOTE: To reset the sequence back to its original form (step 1containing memory 1, step 2

containing memory 2, etc), simply place the end of sequence marker (E) in sequence step 1

during sequence editing.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 30

Page 30 of 44MIH User Guide

UsingasequencewithMIH

When using a sequence, the only requirement is to position the MIH following the axis direction

arrows and lock up once the correct position is reached. On unlock, the sequence will automatically

increment to the next step and the direction arrows will indicate the direction each axis must be

rotated to, in order to achieve the position stored in that step.

Step1

To use a sequence, either press the M- button from the ‘USE Ed’ display or the M+ button from the

‘End USE’ display. Either of these actions will automatically start the sequence at step 1. The memory

contents of sequence step 1 are displayed and the flashing direction arrows indicate the direction in

which each axis must be rotated to achieve the position stored in sequence step 1. If the head is

already in this position, the position confirmation block will be displayed.

If the head is not in this position, unlock the head and follow the direction arrows. The display will

show live positional data and the position confirmation block will confirm when the correct position has

been reached.

Step2

Locking the head in this position returns the display to show the sequence step number and its

contents. The corresponding probe tip number can now be selected and points taken.

Step3

When the head is next unlocked, the direction arrows will show the way to achieve the position stored

in sequence step 3. On locking up in the correct position, the display will show sequence step 3 and

its memory contents, along with the position confi rmation block.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 31

Page 31 of 44MIH User Guide

If the head is locked in an incorrect position, flashing direction arrows will instruct the user to unlock

and try again.

Step4

If the head is accidentally unlocked in a sequence step position before points can be taken, simply relock the head and press the M+ or Mbuttons to step through the sequence until the correct step is

reached.

When the last step in the programmed sequence is reached, the sequence will automatically loop

back to the fi rst step. This will only occur if the end of sequence marker (E) has been correctly placed

during sequence editing.

Step 5

Pressing the M+ and M- buttons simultaneously for longer than 3 seconds will give the choice to

either re-use the sequence (press M+) or end using sequence mode (press M-).

Pressing M+ will take the user back to step 1 in the sequence. Pressing M- or taking no action for 5

seconds will transfer the display back to simple mode.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 32

MIHsummaryofbuttonoperation

Datummode

Button operation Effect

[M+] or [M-] [No change]

[M+] and [M-] Simple mode entered

Simplemode

Button operation Effect

Page 32 of 44MIH User Guide

[M+] or [M-] Memory mode entered

[M+] and [M-] held for longer than 5 seconds Sequence mode entered

Memorymode

Button operation Effect

[M+] Increments memory number

[M-] Decrements memory number

[M+] held for longer than 0.5 seconds Scrolls up memory number

[M-] held for longer than 0.5 seconds Scrolls down memory number

[M+] and [M-] held for longer than 0.5 seconds Stores current position

[No action] for longer than 10 seconds Simple mode entered

Sequencemode

Selectsequencemodefunction

Button operation Effect

[M+] Edit sequence mode entered

[M-] Use sequence mode entered

[No action] for longer than 5 seconds Simple mode entered

Selectsequencestepinsequenceedit

Button operation Effect

19/12/2012file://C:\TEMP\~hhB557.htm

Page 33

[M+] Increments step number

[M-] Decrements step number

[M+] held for longer than 0.5 seconds Scrolls up step number

[M-] held for longer than 0.5 seconds Scrolls down step number

[M+] and [M-] held for longer than 0.5 seconds Selects memory number routine

[No action] for longer than 3 seconds Exits edit sequence mode

Selectmemorynumberinsequenceedit

Button operation Effect

[M+] Increments memory number

[M-] Decrements memory number

Page 33 of 44MIH User Guide

[M+] held for longer than 0.5

seconds

[M-] held for longer than 0.5

seconds

[M+] and [M-] held for longer

than 0.5 seconds

[No action] for longer than 3

seconds

Scrolls up memory number

Scrolls down memory number

Stores memory number in current sequence step and reutnrs to

select sequence step

Exits edit sequence mode

Usesequencemode

Button operation Effect

[M+] Increments step number

[M-] Decrements step number

[M+] held for longer than 0.5 seconds Scrolls up step numbers

[M-] held for longer than 0.5 seconds Scrolls down step numbers

[M+] and [M-] held for less than 3 seconds [No change]

[M+] and [M-] held for longer than 3 seconds Exits edit sequence mode

Exitsequencemode

Button operation Effect

[M+] Use sequence mode entered

[M-] or [No action] for longer than 5 seconds Simple mode entered

19/12/2012file://C:\TEMP\~hhB557.htm

Page 34

Page 34 of 44MIH User Guide

MIHaccessories

MAPS(ManualAutojointProbeStand)

The Renishaw manual autojoint probe stand (MAPS) is a low-cost storage rack for up to six

autojointed probe/extension combinations. As a complementary product to the MIH, MAPS allows the

user to manually insert or remove pre-datumed probe/extension set-ups for protective storage or use

with the MIH. MAPS can be either wall-mounted or bolted directly to the CMM table for easy access.

For further information on MAPS, see user guide, part number H -1000-5300.

Autojointextensions/adaptors

A large range of autojoint probe extensions/adaptors are available from Renishaw providing easy

access to the deepest of features.

Utilising the patented Renishaw autojoint, probing set-ups can be simply locked onto the MIH without

the need to requalify each time, yielding maximum fl exbility and valuable time saving.

Key

1. AM1

2. MIH

3. PAA3

4. PAA2

5. PAA1 Adaptor

6. PEM1

7. PEL3

8. PEL2

9. PEL1

10. TP2

19/12/2012file://C:\TEMP\~hhB557.htm

Page 35

Page 35 of 44MIH User Guide

11. TP2

12. TP6

13. TP6A

14. M2/3 adaptor

15. M2 thread styli

16. M3 thread styli

Shanks

Renishaw provide an extensive range of machine mounting shanks to fi t most makes of CMM.

Please take care when mounting the MIH with a parallel shank, as any rotational movements will

invalidate any stored data.

CAUTION: Always fi t mounting shanks to the MIH by using the screws supplied (M3 x 5 mm

(0.20 in) long). The use of longer screws will cause serious internal damage to the head.

AM1adjustmentmodule

The AM1, Part No. A-1026-0320, is a compact adjustment module for accurately aligning the probe

heads with the CMM axes and/or the Renishaw autochange rack. In addition, an in-built quick release

bayonet mechanism allows the head to be removed for storage and replaced without the need to realign. Limited overtravel protection is also provided by the AM1.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 36

MIHdimensions

Page 36 of 44MIH User Guide

19/12/2012file://C:\TEMP\~hhB557.htm

Page 37

MIHspecification

Mechanicalspecification

Probe mounting Renishaw autojoint

Autojoint repeatability (at the stylus tip) (2σ) 0.5 μm (0.00002 in) *

Page 37 of 44MIH User Guide

Probe status indicator

Swept radius

MIH positional repeatability (at the stylus tip) (2σ)

Accuracy of step spacing from theoretical position in each

axis (at the stylus tip)

Total angular movement A Axis 0° - 105° in 7.5° step = 15

Total angular movement B Axis ±180° in 7.5° steps = 48

Total number of positions 720

Support limit of head (unlocked)

Maximum extension length

Lock/unlock mechanism

LED

62 mm (5.44 in) *

1 μm (0.00004 in) *

±0.3 mm (±0.012 in) *

positions

positions

150 mm (5.91 in) using PAA2

and TP6

300 mm (11.81 in) using PAA3

and TP6

Single thumbwheel rotation

Weight

Working temperature range

* Using a TP6A fi tted with a 21 mm (0.83 in) stylus

Electricalspecification

Probe Connector Renishaw 5-pin DIN connector

Battery type to power

LCD

Battery type Part number

Varta V28PX P-BT03-0011

Alternatives:

Duracell lithium

6 volt silver oxide alkali manganese (Ø12 mm [0.48 in] x 25 mm [0.98

in])

580 g (1.3 lb)

10 °C - 40 °C (50 °F - 105 °F)

19/12/2012file://C:\TEMP\~hhB557.htm

Page 38

Kodak lithium

Varta lithium

CAUTION: Care must be taken when disposing of batteries. DO NOT INCINERATE.

Batterylife

Typical battery life (10 minutes/day unlock time):

Before low battery warning 40 weeks

After low battery warning 11 days

Page 38 of 44MIH User Guide

Battery life with heavy usage (20 minutes/day unlock time):

Before low battery warning 26 weeks

After low battery warning 8 days

19/12/2012file://C:\TEMP\~hhB557.htm

Page 39

MIHtroubleshooting

Page 39 of 44MIH User Guide

Observation Possible causes

Poor repeatability

(probe changing)

Poor repeatability

(probe changing)

Poor repeatability

(probe changing)

Poor repeatability

(probe changing)

Poor repeatability

(head positioning)

Poor repeatability

(head positioning)

Loose mounting Ensure shank mounting screws are thight and shank

Dirty or damaged

autojoint

Autojoint lockprocedure incorrect

Probe extension too

long

Loose mounting.

Head lock-up

procedure incorrect

with long extensions

Checks/Remedial Action

is securely mounted in machine quill

Inspect autojoint probe connection contacts for

damage and contamination.

Clean with a stiff brush if necessary

Ensure probe setup is locked onto the head correctly

using the autojoint key

Ensure maximum extenstion bar (300 mm) isnot

exceeded and the extensions longer than 150mm are

supported on lock up

Ensure shank mounting screws are tight and shank is

securely mounted in machine quill

Ensure maximum extenstion bar (300 mm) isnot

exceeded and the extensions longer than 150mm are

supported on lock up

Incorrect LCD

function

No LCD function No battery present or

Unexpected

software modes

entered

Unexpected

software modes

entered

No probe signal

and/or no probe

status LED

No probe signal

and/or no probe

status LED

Battery power low

battery inserted

incorrectly

Buttons not pressed

simultaneously

Time-out exceeded

Cabling faulty/not

connected

Probe/extension bars

faulty

IF low battery indicator is shown, replace battery. If

not, head may be faulty (see note below)

Ensure battery is present and inserted correctly

Ensure simultaneous operation when appropriate (e.g.

to enter Sequence Mode, if buttons are not pressed

simultaneously, Memory Mode is entered)

On timeout (no button presses or head momevemnt

for a preiod of time) the LCD will revert to Simple

Mode if locked or to a power down state if unlocked

Check continuity of cabling from head to interface

machine control

Check probe/extensions are working correctly by

exchange.elimination/continuity check - if faulty return

to Renishaw Service Centre for repair

No probe signal

and/or no probe

status LED

Probe interface

faulty/not connected

Ensure correct connection of interface/machine control

19/12/2012file://C:\TEMP\~hhB557.htm

Page 40

Page 40 of 44MIH User Guide

When inserting

battery, self test

mode is entered

NOTE: The MIH contains no user serviceable parts and should be returned to Renishaw if

suspected faulty.

Checks/remidial action:

• Ensure shank mounting screws are tight and shank is securely mounted in machine machine quill

• Inspect autojoint probe connection contacts for damage and contamination. Clean with a stiff brush if

necessary.

• Ensure probe set-up is locked onto probe head correctly using the autojoint key.

• Ensure maximum extension bar of 300 mm (11.81 in) is not exceeded and extensions longer than

150 mm (5.91 in) are supported on lock-up.

• If low battery indicator is shown, replace battery. If not, head may be faulty (see note above).

Button pressed during

battery insertion

Re-insert battery ensuring buttons are not pressed OR

press both buttons simultaneously 3 times to enter

Datum Mode

• Ensure battery is present and is inserted correctly (refer to section 4, ‘Installation’ for correct

procedure).

• Ensure simultaneous operation when appropriate (e.g. to enter sequence mode, if buttons are not

pressed simultaneously, memory mode is entered).

• On time-out (no button presses or head movement for a period of time) the LCD will revert to simple

mode if locked, or power down if unlocked.

• Check continuity of cabling from head to interface/machine control (refer to installation section for

pin connections).

• Check probe/extensions are working correctly by exchange/elimination/continuity check - if faulty

return to Renishaw service centre for repair.

• Ensure correct connection of interface/machine control.

• Re-insert battery ensuring buttons are not pressed or press both buttons simultaneously three times

to enter datum mode.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 41

Page 41 of 44MIH User Guide

MIHselftest

NOTE: These tests are for diagnostic purposes only.

The self test function can only be entered by pressing the M+ or M- button whilst the battery is being

inserted. If this should happen accidentally, either refi t the battery or step through the function by

pressing both M+ and M- buttons three times to enter datum mode.

LCDtest

This test cycles round the LCD displaying each segment in turn.

Pressing the M+ button will display all LCD segments simultaneously.

Pressing the M- button will display the MIH software version number.

Press the M+ and M- buttons simultaneously to transfer to the encoder test.

Encodertest

The head should be locked during this test.

Any positional error within the A or B axis encoders will be detected and displayed in the self test.

Press M+ and M- simultaneously to transfer to the battery test.

Batterytest

This function is used by Renishaw when setting the low battery indicator threshold.

To step through this function, press the M+ and M- buttons simultaneously to transfer to datum mode.

19/12/2012file://C:\TEMP\~hhB557.htm

Page 42

Page 42 of 44MIH User Guide

19/12/2012file://C:\TEMP\~hhB557.htm

Page 43

MIHmaintenance

The MIH contains no user serviceable parts.

The MIH may be cleaned by wiping with a dry, lint-free cloth.

Page 43 of 44MIH User Guide

19/12/2012file://C:\TEMP\~hhB557.htm

Page 44

Page 44 of 44MIH User Guide

19/12/2012file://C:\TEMP\~hhB557.htm

Loading...

Loading...