Page 1

User’s guide

H-1000-5190-05-A

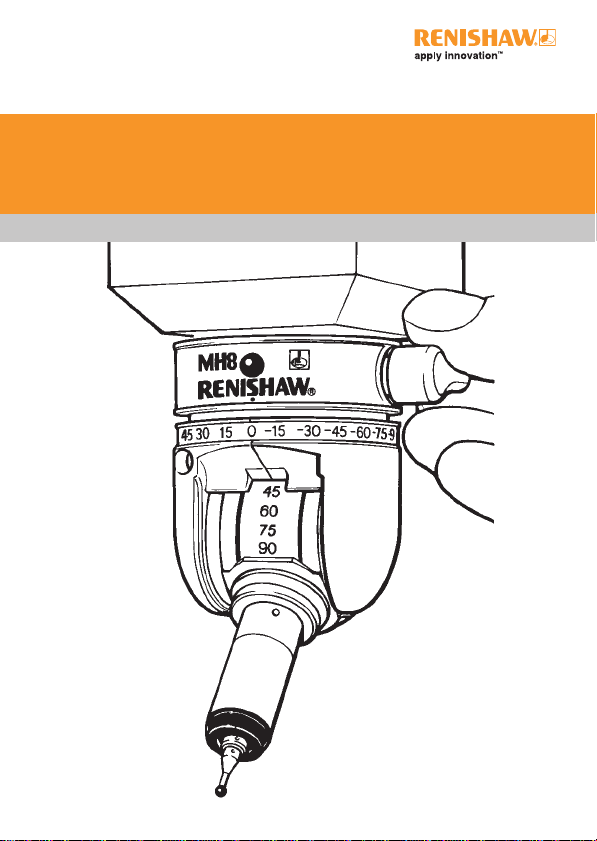

MH8

Page 2

© 2003 - 2004 Renishaw plc. All rights reserved.

Renishaw® is a registered trademark of Renishaw plc.

This document may not be copied or reproduced in whole or

in part, or transferred to any other media or language, by any

means, without the prior written permission of Renishaw.

The publication of material within this document does not imply

freedom from the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents

of this document are free from inaccuracies and omissions.

However, Renishaw makes no warranties with respect to the

contents of this document and specifi cally disclaims any implied

warranties. Renishaw reserves the right to make changes to this

document and to the product described herein without obligation

to notify any person of such changes.

Trademarks

All brand names and product names used in this document

are trade names, service marks, trademarks, or registered

trademarks of their respective owners.

Renishaw part no: H-1000-5190-05-A

Issued: 08 2004

Page 3

Renishaw plc

MH8 user’s guide

English - see part 1

Manuel de l’utilisateur MH8

Français - voir patie 2

Benutzerhandbuch MH8

Deutsch - siehe Abschnitt

Guida per l’utente MH8

Italiano - vedi Sez.

1

Page 4

2

This page intentionally left blank

Page 5

MH8 user’s guide

Part 1 - English

MH8 user’s guide

3

Page 6

4

© 2001 - 2004 Renishaw. All rights reserved.

Renishaw® is a registered trademark of Renishaw plc.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means without the

written prior permission of Renishaw.

The publication of material within this document does not imply freedom

from the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of this

document are free from inaccuracies and omissions. However, Renishaw

makes no warranties with respect to the contents of this document and

specifi cally disclaims any implied warranties. Renishaw reserves the right

to make changes to this document and to the product described herein

without obligation to notify any person of such changes.

Care of equipment

Your Renishaw probe and accessories are precision instruments. Please

use and maintain the products in accordance with these instructions and

retain the transit box for storing the components when not in use.

Changes to specifi cation

Renishaw plc may modify or change its products or specifi cations without

notice and without obligation.

Warranty

Renishaw plc warrants its products provided they are installed as defi ned in

the associated Renishaw documentation.

Consent must be obtained from Renishaw plc if non-Renishaw equipment

(such as interfaces or cabling) is to be used or substituted. Failure to do

this may invalidate the Renishaw warranty.

Patents

Aspects of the MH8 indexable probe and aspects of similar systems are

the subjects of the following patents and patent applications.

EP 0392660 JP 3,018,015 US 5,088,337

MH8 user’s guide

Page 7

Contents

Contents

1 Introduction ...................................................................................6

2 Product description .......................................................................7

2.1 Part number summary ........................................................10

3 Installation procedure ..................................................................11

3.1 Mounting the shank on the probe head ..............................11

3.2 Mounting the head on the CMM .........................................11

3.3 Electrical connection ..........................................................12

3.4 Mounting the probe to the probe head ...............................12

3.5 Extension bars ...................................................................13

4 Head operation ............................................................................14

4.1 To change the orientation of the probe ...............................14

5 Dimensions .................................................................................16

6 Technical specifi cation ................................................................17

6.1 Measuring performance .....................................................17

6.2 Technical data ....................................................................17

7 Maintenance ................................................................................18

5

8 Fault fi nding .................................................................................19

Page 8

6

Introduction

1 Introduction

The MH8 is a manually operated, indexing probe head that

articulates to provide orientation of the stylus. The head can carry

probes fi tted with a Renishaw M8 connector. The TP20 and TP6

touch trigger probes are recommended. The MH8 is available with a

range of shanks to suit the mounting arrangement specifi ed by the

manufacturer of the CMM.

Page 9

Product description

2 Product description

The MH8 has 2 axes. The probe connector is carried on the A axis

which can rotate the probe through 90° in the Z plane. The B axis can

rotate the probe through ±180° in the X-Y plane.

A lever actuated mechanism locks both axes in the desired position for

gauging the workpiece. The axes are unlocked to allow free rotation to

another position. The locked positions are set at angular increments of

15° in each axis, providing a total of 168 positions.

When the head orientation is locked, the probe is kinematically

constrained in a highly repeatable spatial position. This means that

after initial qualifi cation of the stylus tip, in the positions required for

gauging the workpiece, the probe may be reorientated to any of the

qualifi ed positions without the need for requalifi cation.

A red LED is provided on the front of the head to indicate the

probe’s status. The LED may be driven by the CMM controller or by

a Renishaw probe interface. It is convention for the LED to be ON to

indicate a seated (armed) probe and to be OFF to indicate a triggered

probe.

Electrical connection is via a 5 pin DIN connector.

7

Page 10

8

Product description

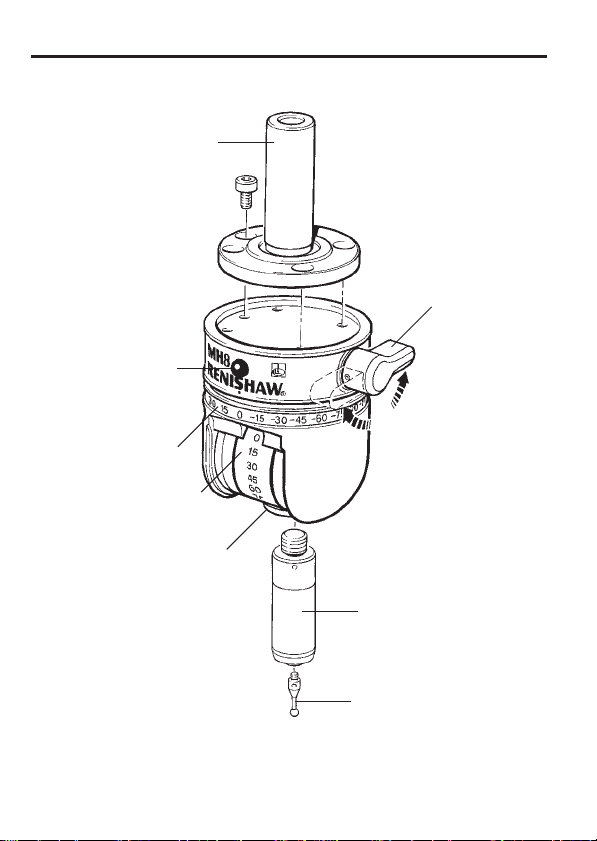

Probe status LED

B axis scale

A axis scale

M8 probe connector

Shank

Lock lever

Probe

Stylus

Figure 1 - The MH8 indexible head (front)

Page 11

Product description

9

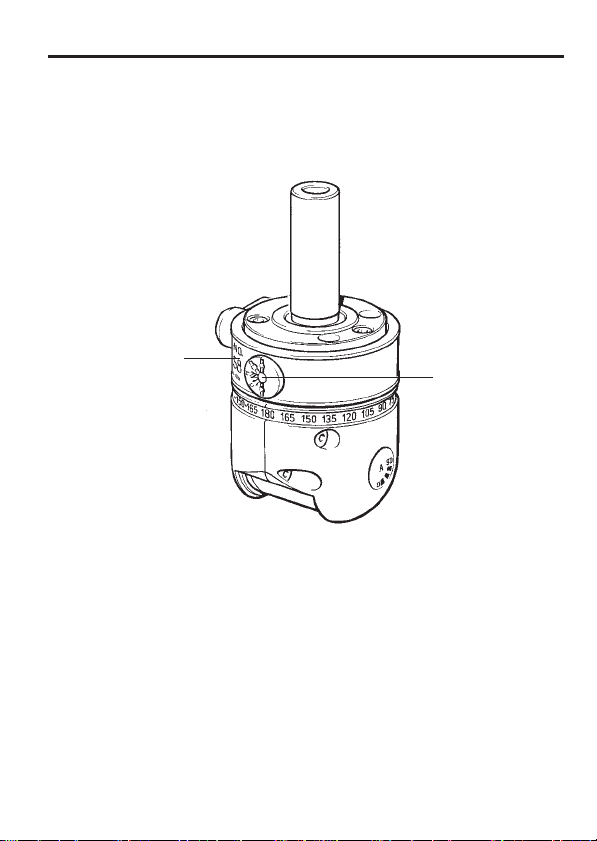

Serial number

label

Figure 2 - The MH8 indexible head (back)

5 pin DIN

connector

Page 12

10

Product description

2.1 Part number summary

Part number Descritpion

A-1332-0013 MH8 probe head + MH8 user’s guide (H-1000-5190)

A-1332-0002 MH8 probe head + TK4 probe tools (no shank)

A-1332-0003 MH8 + TK4 + MS1 shank

A-1332-0004 MH8 + TK4 + MS2 shank

A-1332-0005 MH8 + TK4 + MS4 shank

A-1000-0006 MH8 + TK4 + MS5 shank

A-1332-0007 MH8 + TK4 + MS7 shank

A-1332-0008 MH8 + TK4 + MS9 shank

A-1332-0009 MH8 + TK4 + MS10 shank

A-1332-0010 MH8 + TK4 + MS13 shank

A-1332-0011 MH8 + TK4 + MS15 shank

A-1332-0014 MH8 + TK4 + MS17 shank

A-1332-0012 MH8 + TK4 + D shank

A-1042-1486 S1 ‘C’ spanner

A-1047-3932 S9 double ended ‘C’ spanner

M-5000-3540 S7 stylus tightening tool

P-TL03-0150 Hexagon key, 1.5 mm AF (TP2/TP6 adjustment)

Page 13

Installation procedure

11

3 Installation procedure

3.1 Mounting the shank on the probe head

• Hold the shank in the recess on the top face of the MH8.

• Rotate the shank until 3 screw holes are aligned.

• Fix the shank in place using only the M3 x 5 mm screws

(supplied).

• Progressively tighten using the 2.5 mm A/F hexagon key

(supplied).

3.2 Mounting the head on the CMM

The head will normally be attached to the quill of the CMM using a

standard shank, specifi ed by the CMM manufacturer.

Standard shanks are listed in the section 2.1, ‘Part number summary’.

Special or customised mounting arrangements are possible. Please

contact your supplier or Renishaw, for details of our custom products

service.

The mounting must be absolutely rigid, as any movement during

normal operation of the head will add errors to the measurement

system.

If the head is replaced or repositioned in the quill, it will be necessary

to requalify all of the head positions in current use.

Page 14

12

Installation procedure

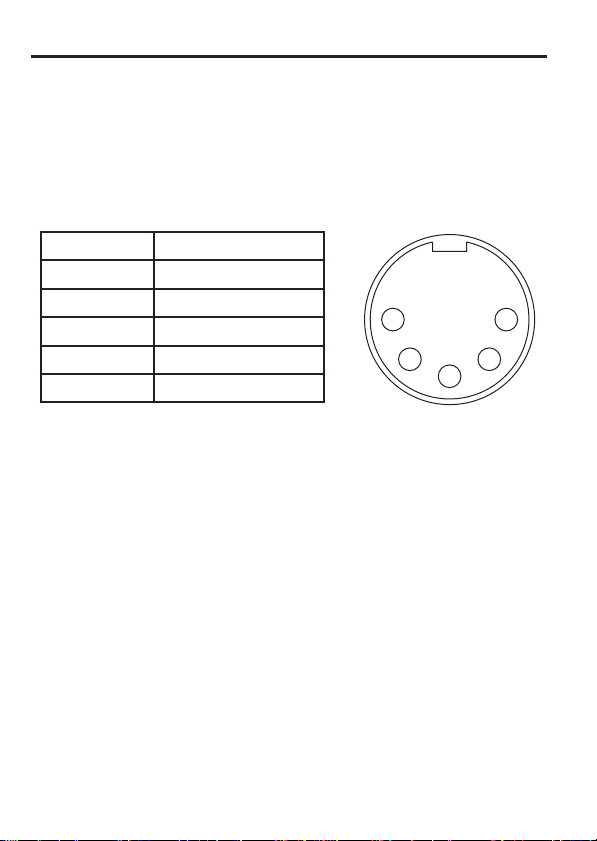

3.3 Electrical connection

Connection is by means of a 5 pin DIN connector on the side of the

heads (see fi gure 2).

The pin numbering functions are given in the table below:

Pin number Designation

1 LED cathode

2 Ground

3 LED anode

4 Probe circuit

5 Probe circuit

5

4

1

2

3

3.4 Mounting the probe to the probe head

If fi tting a TP20 probe, mount the probe body to the probe head before

fi tting the probe module and stylus.

• Screw the threaded end of the probe into the M8 connector on the

probe head until it is fi nger tight.

• Fit the S1 ‘C’ spanner (supplied) to the location holes in the probe

body and tighten by hand.

• The recommended tightening torque is 0.3 Nm – 0.5 Nm.

Refer also to the user’s guide for the probe type being used.

Page 15

Installation procedure

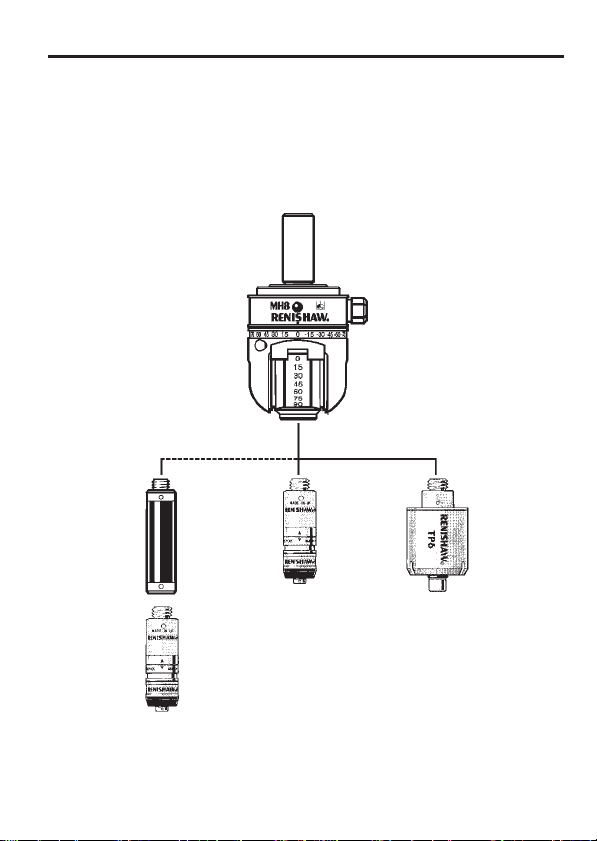

3.5 Extension bars

Probe reach may be extended by 50 mm using a PEL1 extension

bar. Use of the PEL2, PEL3 or PE series extension bars is not

recommended.

13

PEL1

TP20

TP20

TP6

Figure 3 - Using extension bars

Page 16

14

Head operation

4 Head operation

NOTE: Ensure that the lock lever is turned fully clockwise to the

locked position, before taking gauge points.

4.1 To change the orientation of the probe

(refer to fi gure 4)

• Unlock the head by turning the lock lever to the fully anti-clockwise

position.

• Grip the body of the probe (avoid touching the stylus) and rotate

the ‘B’ axis until the desired angle indication on the scale (in

increments of 15°) is adjacent to the ‘B’ axis reference mark.

Rotate the ‘A’ axis until the desired angle indication on the scale

(in increments of 15°) is at the ‘A’ axis reference position.

• Lock the head by turning the lock lever to the fully clockwise

position.

• Qualify the stylus tip(s) according to the CMM supplier’s

instructions.

• Change the orientation of the probe to the next desired position

and qualify the stylus tip(s).

• Repeat the qualifi cation process for all desired orientations and

stylus tips.

• Commence gauging, ensuring that the correct qualifi cation data is

recalled for each head position.

Page 17

Head operation

Periodic requalifi cation should be performed according to the following

considerations:-

• CMM supplier’s recommendations, particularly in respect of

temperature changes.

• At the start of the working day or shift.

• After an accidental collision.

• After changing any measuring system component (except a prequalifi ed TP20 module).

• If the initial state is unknown or uncertain.

15

B axis

reference mark

B axis scale

A axis scale

Lock lever

Unlock

Lock

A axis

reference mark

Figure 4 - Locking lever operation

Page 18

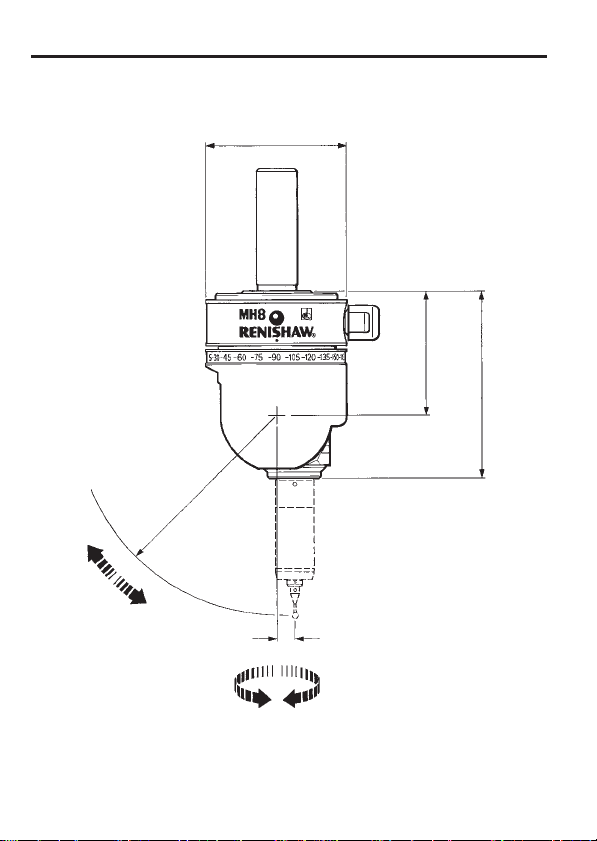

16

Dimensions

5 Dimensions

R70 *

A axis

0° - 90°

Ø48 mm

43 mm

65 mm

5.7 mm

* Using TP20 with LF/

B axis

±180°

Figure 5 - MH8 dimensions

SF/MF/EF module

and 10 mm stylus

Page 19

Technical specifi cation

6 Technical specifi cation

Refer to fi gure 5 for overall dimensions.

6.1 Measuring performance

Positional repeatability (2σ) 1.5 µm

(At stylus tip with TP20 probe, standard force

module and 10 mm stylus length)

Positional repeatability (2σ) 2.5 µm

with 50 mm extension bar (PEL1)

(At stylus tip with TP20 probe, standard force

module and 10 mm stylus length)

6.2 Technical data

17

Range of articulation

Maximum load

Operating temperature

range

Storage temperature range

Probe connector

Electrical connector

Sealing

Weight

A axis: 0° to 90° in 15° increments

B axis: ±180° in 15° increments

TP6 - no extension allowed

TP20 or TP2 probe + 50 mm

extension (PEL1)

+10 °C to +40 °C

-10 °C to +70 °C

Renishaw M8 x 1.25 x 5 mm

5 pin DIN (180°)

IP30

205 g (without shank)

Page 20

18

Maintenance

7 Maintenance

This product is intended for use in a protected metrology environment

and therefore accumlations of dust or swarf should not occur.

In common with all precision measuring equipment, regular

inspection and cleaning are recommended to ensure continued high

performance.

Maintenance is limited to wiping the outer surfaces, axes scale labels

and mounting face of the probe connector with a clean, dry cloth or

proprietary cleaning material.

Page 21

Fault fi nding

8 Fault fi nding

Refer also to the appropriate user’s guide for the probe.

Loss of measuring accuracy

Possible causes Remedy

Mounting not secure. Check that the MH8 is correctly

mounted to the shank and that

the screws are secure. Check

the clamping mechanism in the

CMM quill.

MH8 not fully locked. Ensure that the lock lever is

turned fully clockwise.

Excessive force imparted to

probe after locking.

MH8 overloaded. Use only with the specifi ed

Faulty probe. Check by substitution.

MH8 worn or damaged. Check by substitution or return

Axes ‘rattle’ when rotated

Possible causes Remedy

MH8 not fully unlocked. Turn lock lever fully anti-

Unlock and re-lock the MH8.

probe and extension

combinations.

to Renishaw or your supplier.

clockwise before attepting to reorientate probe.

19

Page 22

20

Manuel de l’utilisateur MH8

Page vide

Page 23

Manuel de l’utilisateur MH8

Partie 2 - Français

Manuel de l’utilisateur MH8

21

Page 24

22

© 2001 Renishaw. Tous droits réservés.

Renishaw® est une marque déposée de Renishaw plc.

Ce document ne peut être copié ni reproduit, dans sa totalité ni en partie, ni

transféré sous une autre forme ou langue, par des moyens quelconques, sans

l’autorisation écrite de Renishaw.

La publication d’informations contenues dans ce document n’implique en

aucun cas une exemption des droits de brevets de Renishaw plc.

Dénégation

Un effort considérable a été fourni afi n d’assurer que le contenu de ce

document ne contient aucune omission ni inexactitude. Cependant, Renishaw

ne garantit aucunement le contenu de ce document et dénie en particulier

toutes garanties supposées. Renishaw se réserve le droit d’apporter des

modifi cations à ce document et au produit qu’il décrit sans obligation d’en

informer quiconque.

Precautions d’emploi

Votre palpeur Renishaw et ses accessoires sont des instruments de précision

que nous vous recommandons d’utiliser et entretenir conformément à ce

mode d’emploi. Nous vous recommandons également de conserver son

emballage de transport afi n de pouvoir y ranger les composants après emploi.

Changement de caractéristiques

Renishaw plc se réserve le droit de modifi er ou changer ses produits ou leurs

caractéristiques sans préavis et sans obligations vis-à-vis des clients.

Garantie

La garantie prévue par Renishaw plc s’applique aux produits Renishaw

installés conformément aux données de la documentation y afférente.

Le matériel ne provenant pas de Renishaw (interfaces ou câblage, par

exemple) ne peut être utilisé ou substitué sans l’accord préalable de

Renishaw plc. Tout manquement à cette règle pourrait entraîner l’annulation

de la garantie Renishaw.

Brevets

Les aspects du palpeur réglable MH8 et d’autres systèmes ont fait l’objet des

brevets et dépôts de brevet suivants :

EP 0392660 JP 3,018,015 US 5,088,337

Manuel de l’utilisateur MH8

Page 25

Sommaire

23

Sommaire

1 Introduction .................................................................................24

2 Description du produit .................................................................25

2.1 Références des MH8 avec attachement ............................28

3 Procédure d’installation ...............................................................29

3.1 Montage de l’attachement sur la tête MH8 ........................29

3.2 Montage de la tête sur la MMT ..........................................29

3.3 Raccordement électrique ...................................................30

3.4 Montage du capteur sur la tête MH8 ..................................30

3.5 Allonges .............................................................................31

4 Fonctionnement de la tête ...........................................................32

4.1 Pour changer l’orientation du palpeur ................................32

5 Dimensions .................................................................................34

6 Caractéristiques techniques ........................................................35

6.1 Contrôle du fonctionnement ...............................................35

6.2 Fiche technique ..................................................................35

7 Entretien ......................................................................................36

8 Dépannage ..................................................................................37

Page 26

24

Introduction

1 Introduction

La MH8 est une tête articulée manuelle, permettant d’orienter

le capteur. La tête utilise les capteurs équipés d’un fi letage M8

Renishaw. Nous préconisons l’emploi des capteurs à déclenchement

de type TP20 et TP6 ou TP2. La tête MH8 se monte sur le coulisseau

de la MMT grâce à un attachement vissé sur sa partie supérieure. Les

dimensions de cet attachement dépendent de la marque et du type de

machine à mesurer MMT sur laquelle la MH8 doit être installée.

Page 27

Description du produit

25

2 Description du produit

Là tête MH8 est munie de deux axes pivotants. Le connecteur est

situé sur la partie fi xe supérieure. L’axe A permet de faire pivoter le

palpeur de 0° à 90° par rapport au plan Z. L’axe B permet d’orienter le

palpeur sur “180° sur le plan X/Y.

Un mécanisme à levier verrouille les deux axes dans la position

voulue pour mesurer la pièce. Le déverrouillage des axes permet

de faire pivoter le palpeur et l’orienter dans une autre position. Les

positions de verrouillage sont fi xées par paliers de 15° sur chaque axe.

L’utilisateur bénéfi cie par conséquent, de 168 positions différentes.

Une fois la tête verrouillée, le palpeur est bloqué dans une position

répétable. Autrement dit, après qualifi cation sur la sphère d’étalonnage

du stylet suivant les différentes positions, le palpeur peut être orienter

en fonction des points à palper sur la pièce à contrôler sans avoir à requalifi er sa position.

La MH8 est munie d’une LED rouge indiquant l’état du palpeur. La

LED peut être commandée par le contrôleur de la MMT ou par le biais

d’une interface Renishaw. Selon la convention généralement adoptée,

une LED allumée indique un palpeur au repos (hors matière), une

LED éteinte indique un palpeur déclenché (contact avec matière).

La connexion électrique du palpeur se fait par l’intermédiaire d’un

connecteur spécifi que DIN 5 broches 180°.

Page 28

26

Description du produit

Attachement

LED d’état du

palpeur

Echelle graduée

de l’axe B

Echelle graduée de

Fixation du capteur à

Levier de

verrouillage

l’axe A

fi letage M8

Capteur

Stylet

Figure 1 - Tête réglable MH8 (avant)

Page 29

Description du produit

27

Numéro de série

Figure 2 - Tête réglable MH8 (arrière)

Connecteur

DIN à 5

broches

Page 30

28

Description du produit

2.1 Références des MH8 avec attachement

Référence Désignation

A-1332-0013 Tête MH8 + guide de l’utilisateur du palpeur MH8

(H-1000-5190)

A-1332-0002 Tête MH8 et outils de palpeur TK4 (sans

attachement)

A-1332-0003 MH8 + TK4 + attachement MS1

A-1332-0004 MH8 + TK4 + attachement MS2

A-1332-0005 MH8 + TK4 + attachement MS4

A-1000-0006 MH8 + TK4 + attachement MS5

A-1332-0007 MH8 + TK4 + attachement MS7

A-1332-0008 MH8 + TK4 + attachement MS9

A-1332-0009 MH8 + TK4 + attachement MS10

A-1332-0010 MH8 + TK4 + attachement MS13

A-1332-0011 MMH8 + TK4 + attachement MS15

A-1332-0014 MH8 + TK4 + attachement MS17

A-1332-0012 MH8 + TK4 + attachement D

A-1042-1486 Clé ‘C’ S1

A-1047-3932 Clé ‘C’ à deux bouts S9

M-5000-3540 Outil de serrage du stylet S7

P-TL03-0150 Clé hexagonale AF 1,6 mm (réglage TP2/TP6)

Page 31

Procédure d’installation

29

3 Procédure d’installation

3.1 Montage de l’attachement sur la tête

MH8

• Maintenir l’attachement dans la gorge située sur la face

supérieure de la MH8.

• Faire pivoter l’attachement jusqu’à ce que les trois trous de vis

soient alignés.

• Bloquer l’attachement en place en utilisant uniquement des vis

M3 x 5 mm (fournies).

• Serrer progressivement à l’aide de la clé hexagonale A/F de

2,5 mm (fournie).

3.2 Montage de la tête sur la MMT

La tête se monte normalement sur le coulisseau de la MMT l’aide d’un

attachement standard spécifi é par le fabricant de la machine.

Un montage spécial ou une utilisation spécifi que de la MH8 peuvent

être envisagés. Veuillez contacter votre fournisseur ou Renishaw pour

de plus amples détails sur notre service de fourniture de produits

spéciaux.

Le montage doit être absolument rigide. En effet, tout mouvement

survenant pendant le fonctionnement normal de la tête entraînerait

des erreurs au niveau du système de mesure.

Tout démontage de la tête ou modifi cation de sa position par

rapport au coulisseau de la MMT obligent à procéder à une nouvelle

qualifi cation des positions du palpeur.

Page 32

30

Procédure d’installation

3.3 Raccordement électrique

La connexion de la MH8 s’effectue par le biais d’une prise DIN à 5

broches située sur le côté de la tête (voir Figure 2).

Les fonctions de chaque broche sont indiquées dans le tableau cidessous.

Réf. fi che Dénomination

1 Cathode LED

2 Masse

3 Anode LED

4 Circuit palpeur

5 Circuit palpeur

5

4

1

2

3

3.4 Montage du capteur sur la tête MH8

En cas de montage du capteur TP20, visser le corps du TP20 sur la

tête avant de monter le module et son stylet.

• Visser et serrer à la main l’extrémité fi letée du capteur dans le

connecteur M8 de la MH8.

• Utiliser la clé S1 ‘C’ (fournie) dans les trous de centrage du corps

du capteur et serrer à la main.

• Le couple de serrage recommandé se situe entre 0,3 et 0,5 Nm.

Consulter également le guide utilisateur se rapportant au type de

capteur utilisé.

Page 33

Procédure d’installation

3.5 Allonges

La portée du palpeur peut être prolongée de 50 mm par ajout d’une

rallonge PEL1.

L’utilisation d’allonges des séries PEL2, PEL3 ou PE n’est pas

recommandée.

31

PEL1

TP20

TP20

TP6

Figure 3 – Montage d’une allonge

Page 34

32

Fonctionnement de la tête

4 Fonctionnement de la tête

REMARQUE: Vérifi er que le levier de verrouillage est bien tourné à

fond dans le sens horaire en position verrouillée, avant toute mesure.

4.1 Pour changer l’orientation du palpeur

(voir fi gure 4)

• Déverrouiller la tête en faisant tourner le levier de verrouillage à

fond, dans le sens anti-horaire.

• Bien tenir le corps du palpeur (en évitant de toucher au stylet) et

faire tourner l’axe ‘B’ jusqu’à ce que le repère d’angle voulu de

l’échelle graduée (par paliers de 15°) tombe en face du repère de

référence de l’axe ‘B’. Faire tourner l’axe ‘A’ jusqu’à ce le repère

d’angle voulu de l’échelle graduée (par paliers de 15°) tombe en

face du repère de référence de l’axe ‘A’.

• Bloquer la tête en faisant tourner le levier de verrouillage à fond

dans le sens horaire.

• Etalonner le capteur et son stylet conformément aux instructions

du fabricant de la MMT.

• Changer l’orientation du palpeur suivant la prochaine position

souhaitée et procéder à un nouvel étalonnage.

• Répéter le processus d’étalonnage pour chaque nouvelle

orientation du capteur et de son stylet.

• Effectuer la gamme de mesures en vérifi ant que les valeurs

d’étalonnage sont bien réinitialisées pour chaque position de la

tête.

Page 35

Fonctionnement de la tête

La procédure d’étalonnage ou qualifi cation doit être suivie

régulièrement, en tenant compte des aspects suivants:

• Recommandations du fabricant de la MMT, surtout en ce qui

concerne les fl uctuations de température.

• En début de journée ou lors de la mise en route de la MMT.

• Après une collision accidentelle.

• Après remplacement de l’un des éléments du système de palpage

(à l’exception du module TP20 pré-positionné).

• En cas d’état initial inconnu ou de doute à ce sujet.

33

Echelle

graduée de

l’axe B

Repère de

référence de

l’axe B

Repère de

référence de

l’axe A

Echelle graduée

de l’axe A

Levier de

verrouillage

Déverrouiller

Verrouiller

Figure 4 - Fonctionnement du levier de verrouillage

Page 36

34

Dimensions

5 Dimensions

R70

Axe A

0° - 90°

Ø48 mm

43 mm

5.7 mm

Axe B

±180°

Figure 5 – Dimensions du palpeur MH8

Page 37

Technical specifi cation

6 Caractéristiques techniques

Consulter la fi gure 5 pour ce qui concerne les dimensions hors tout.

6.1 Performances du système de palpage

Répétabilité de positionnement (2σ) 1.5 µm

(Avec palpeur TP20, module de force

standard et stylet de 10 mm de long)

Répétabilité de positionnement (2σ) 2.5 µm

avec rallonge de 50 mm (PEL )

(Avec palpeur TP20, module de force

standard et stylet de 10 mm de long)

6.2 Fiche technique

Indexation paliers do 15° Axe A De 0 à 90° par paliers de 15°

Axe B ±180° par paliers de 15°

Charge maximale Palpeur TP6 - rallonge proscrite

TP20 ou TP2 + Allonge PEL1 50 mm

Plage de température

d’utilisation

Plage de température de

stockage

Connecteur de palpeur Renishaw M8 x 1,25 x 5 mm

Connecteur électrique DIN 5 fi ches (180°)

Protection IP30

Masse 205 g (sans attachement)

+10 à +40 °C

-10 à +70 °C

35

Page 38

36

Entretien

7 Entretien

Ce produit est conçu pour être utilisé dans un environnement de

métrologie protégé et ne doit par conséquent pas être soumis à des

risques d’accumulation de poussières ou de copeaux.

Comme c’est le cas pour tous les instruments de mesure de précision,

nous vous recommandons de contrôler et nettoyer régulièrement votre

tête MH8 pour garantir des performances optimales.

L’entretien se limite à l’essuyage de ses surfaces externes, étiquettes

d’échelle graduée d’axe et côté taraudage M8 à l’aide d’un chiffon

propre et sec ou d’un produit de nettoyage reconnu.

Page 39

Dépannage

8 Dépannage

Consulter également le guide de l’utilisateur prévu pour le capteur.

Perte de précision

Cause possible Solution

Fixation mal bloquée. Vérifi er que la MH8 est bien

MH8 mal verrouillé. Vérifi er que le levier de

Déplacement du palpeur après

verrouillage.

Surcharge du MH8. Utiliser seulement avec la

Palpeur défectueux. Vérifi er par remplacement.

MH8 usé ou endommagé. Vérifi er par remplacement ou

Les axes ‘vibrent’ en rotation.

Cause possible Solution

Le MH8 n’est pas complètement

déverrouillé.

montée sur l’attachement et

que les vis sont bien serrées.

Vérifi er le mécanisme de fi xation

de fi xation de la MH8 sur le

coulisseau de la MMT.

verrouillage est bien tourné à

fond dans le sens horaire.

Déverrouiller et verrouiller de

nouveau la MH8.

combinaison palpeur / rallonge

spécifi ée.

renvoyer à Renishaw ou à votre

fournisseur..

Faire pivoter le levier de

verrouillage à fond dans le sens

anti-horaire avant d’essayer de

réorienter la tête.

37

Page 40

38

MH8 Benutzerhandbuch39MH8 Benutzerhandbuch

Leere Seite

Page 41

Abschnitt 3 - Deutsch

MH8 Benutzerhandbuch

Page 42

40

© 2001 Renishaw. Alle Rechte vorbehalten.

Renishaw® ist ein eingetragenes Warenzeichen von Renishaw plc.

Dieses Dokument darf ohne vorherige schriftliche Genehmigung von Renishaw

weder ganz noch teilweise kopiert oder vervielfältigt werden oder auf irgendeine

Weise auf andere Medien oder in eine andere Sprache übertragen werden.

Die Veröffentlichung von Material in diesem Dokument impliziert keine Freiheit

von den Patentrechten von Renishaw plc.

Haftungsausschlußklausel

Es wurden beträchtliche Anstrengungen unternommen, um sicherzustellen, daß

der Inhalt dieses Dokuments frei von Ungenauigkeiten und Auslassungen ist.

Renishaw übernimmt jedoch keine Garantien für den Inhalt dieses Dokuments

und lehnt insbesondere jede implizite Garantie ab. Renishaw behält sich das

Recht vor, Änderungen an diesem Dokument und dem darin beschriebenen

Produkt vorzunehmen, ohne die Verpfl ichtung einzugehen, irgendeine Person

über solche Änderungen zu informieren.

Gerätepfl ege

Ihr Messtaster und Zubehör von Renishaw sind Präzisionsinstrumente.

Benutzen und pfl egen Sie diese Produkte bitte in Übereinstimmung mit

diesen Anleitungen und bewahren Sie sie bei Nichtbenutzung in ihren

Verpackungskartons auf.

Änderung technischer Daten

Renishaw kann Produkte oder technische Daten ohne vorherige Mitteilung und

unverbindlich ändern oder modifi zieren.

Garantie

Renishaw plc garantiert seine Produkte, solange sie in Übereinstimmung mit

den Defi nitionen in der entsprechenden Dokumentation von Renishaw installiert

werden.

Sollen Geräte von Fremdherstellern (wie zum Beispiel Interfaces oder

Kabel) benutzt oder ersetzt werden, ist eine Genehmigung von Renishaw plc

einzuholen. Ein Nichteinhalten dieser Bestimmung kann zur Ungültigkeit der

Renishaw-Garantie führen.

Patente

Teile des indexierbaren Messtasters sowie Teile ähnlicher Systeme sind

Gegenstand der folgenden Patente und Patentanmeldungen:

EP 0392660 JP 3,018,015 US 5,088,337

MH8 Benutzerhandbuch

Page 43

Inhalt

41

Inhalt

1 Einleitung ....................................................................................42

2 Produktbeschreibung ..................................................................43

2.1 Übersicht der MH8-Bestellnummern ..................................46

3 Installation ...................................................................................47

3.1 Montage des Aufnahmeschaftes am MH8-Tastkopf ...........47

3.2 Montage des MH8-Tastkopfes am KMG ...........................47

3.3 Elektrischer Anschluss .......................................................48

3.4 Montage eines Messtasters am Tastkopf ...........................48

3.5 Verlängerungen / Messtasterkonfi gurationen .....................49

4 Benutzung des Tastkopfes ..........................................................50

4.1 Positionieren des Tastkopfes ..............................................50

5 Abmessungen .............................................................................52

6 Technische Spezifi kation .............................................................53

6.1 Messleistung ......................................................................53

6.2 Technische Daten ...............................................................53

7 Wartung .......................................................................................54

8 Fehlersuche ................................................................................55

Page 44

42

Einleitung

1 Einleitung

Der MH8 ist ein manuell indexierbarer Tastkopf mit Dreh- und

Schwenkfähigkeit, um das Positionieren der Tasterkonfi guration zu

ermöglichen. Der Tastkopf kann mit Messtastern verwendet werden,

die mit einer Renishaw M8 Aufnahme ausgestattet sind. Empfohlen

werden die taktil schaltenden Messtaster TP20 bzw. TP6. Der MH8 ist,

je nach der vom KMG-Hersteller spezifi zierten Schaftaufnahme der

KMG-Pinole, mit verschiedenen Aufnahmeschäften lieferbar.

Page 45

Produktbeschreibung

43

2 Produktbeschreibung

Der MH8 ist mit zwei indexierbaren Gelenkachsen A und B versehen.

Die Messtasteraufnahme befi ndet sich auf dem Gelenk der A-Achse,

über die der Messtaster von 0° bis auf 90° in der Z-Ebene geschwenkt

werden kann. Die B-Achse kann den Messtaster auf der Ebene X-Y

um ±180° bewegen.

Über einen hebelbetriebenen Mechanismus werden beide Achsen

zum Messen des Werkstückes in der gewünschten Position

verriegelt. Die Achsen werden entriegelt, um eine freie Dreh/Schwenkbewegung in eine andere Position zu ermöglichen. Die zum

Messen des Werkstückes erforderlichen Positionen können in beiden

Achsen in 15° Schritten eingestellt werden. Insgesamt stehen also 168

Positionen zur Verfügung.

Im verriegelten Zustand des MH8 befi ndet sich die

Messtasterkonfi guration in einer kinematisch reproduzierbaren

räumlichen Position. Dies bedeutet, dass die Messtasterkonfi guration

nur einmal in der für die Messaufgabe erforderlichen Position kalibriert

werden muss. Danach kann diese Position immer wieder exakt

eingenommen werden.

Ein rotes LED an der Frontseite des MH8 Tastkopfes zeigt den

Status des Messtasters an. Das LED kann von der KMG-Steuerung

oder von einem Renishaw Messtaster Interface betrieben werden.

Normalerweise leuchtet die LED im Ruhezustand und erlischt bei

ausgelenktem Messtaster, um damit ein Tastsignal anzuzeigen.

Der elektrische Anschluss erfolgt über eine 5-polige DIN

Steckverbindung.

Page 46

44

Positionsmarkierung

Produktbeschreibung

Aufnahmeschaft

LED für

Messtaster-Status

für B-Achse

Positionsmarkierung

für A-Achse

Messtasteraufnahme

mit M8-Gewinde

Klemmhebel

Messtaster

Tasteinsatz

Abbildung 1 – Manuell indexierbarer Tastkopf MH8

(Vorderansicht)

Page 47

Produktbeschreibung

45

Seriennummer

5-polige DinSteckverbindung

Abbildung 2 – Der indexierbare Tastkopf des MH8

(Rückansicht)

Page 48

46

Produktbeschreibung

2.1 Übersicht der MH8-Bestellnummern

Bestellnummer Beispiel

A-1332-0013 Tastkopf MH8 + Bedienungsanleitung MH8

(H-1000-5190)

A-1332-0002 Tastkopf MH8 und TK4 Messtaster-

Montagewerkzeug (ohne Aufnahmeschaft)

A-1332-0003 MH8 + TK4 + MS1 Aufnahmeschaft

A-1332-0004 MH8 + TK4 + MS2 Aufnahmeschaft

A-1332-0005 MH8 + TK4 + MS4 Aufnahmeschaft

A-1000-0006 MH8 + TK4 + MS5 Aufnahmeschaft

A-1332-0007 MH8 + TK4 + MS7 Aufnahmeschaft

A-1332-0008 MH8 + TK4 + MS9 Aufnahmeschaft

A-1332-0009 MH8 + TK4 + MS10 Aufnahmeschaft

A-1332-0010 MH8 + TK4 + MS13 Aufnahmeschaft

A-1332-0011 MH8 + TK4 + MS15 Aufnahmeschaft

A-1332-0014 MH8 + TK4 + MS17 Aufnahmeschaft

A-1332-0012 MH8 + TK4 + D Aufnahmeschaft

A-1042-1486 S1 C-Spannschlüssel

A-1047-3932 S9 ‘Doppelter C-Spannschlüssel

M-5000-3540 S7 Stiftschlüssel für M8/M3 Tastereinsätze

P-TL03-0150 S3 1,5 mm Sechskantschlüssel (TP2/TP6-

Einstellung)

Page 49

Installation

47

3 Installation

3.1 Montage des Aufnahmeschaftes am

MH8-Tastkopf

• Setzen Sie den Aufnahmeschaft in die Aussparung an der

Oberseite des MH8-Tastkopfes.

• Drehen Sie den Aufnahmeschaft, bis alle Schraubenlöcher

aufeinander ausgerichtet sind.

• Befestigen Sie den Aufnahmeschaft. Benutzen sie dazu nur die

(mitgelieferten) M3 x 5 mm Schrauben.

• Ziehen Sie die Schrauben nach und nach an. Verwenden Sie dazu

den (mitgelieferten) 2,5 mm A/F Sechskantstiftschlüssel.

3.2 Montage des MH8-Tastkopfes am KMG

Der MH8-Tastkopf wird in der Regel unter Verwendung eines vom

Hersteller spezifi zierten Standardschaftes an die KMG-Pinole

befestigt.

Standardschäfte sind im Abschnitt „Übersicht der MH8Bestellnummern” aufgeführt.

Spezielle oder kundenspezifi sche Montageanordnungen sind möglich.

Für Einzelheiten über unseren Sonderprodukt-Service setzen Sie sich

bitte mit Ihrem Händler oder Renishaw in Verbindung.

Die Montage muss vollkommen starr sein, da eine Bew egung während

des Normalbetriebs des Tastkopfes zu möglichen Fehlern im MessSystem führen kann.

Wird der Tastkopf ersetzt oder seine Position an der Pinole geändert,

ist es erforderlich, alle gegenwärtig benutzten Kopfpositionen erneut

zu kalibrieren.

Page 50

48

Installation

3.3 Elektrischer Anschluss

Der Anschluss erfolgt über eine 5-polige DIN 180° Anschlußbuchse

seitlich am Kopf (siehe Abbildung 2).

Die Funktionen der einzelnen Stiftnummern sind der nachstehenden

Tabelle zu entnehmen:

Stiftnummer Bezeichnung

1 LED-Kathode

2 Masse

3 LED-Anide

4 Messtaster-Schaltkreis

5 Messtaster-Schaltkreis

5

4

1

2

3

3.4 Montage eines Messtasters am Tastkopf

Wird ein Messtaster TP20 angebracht, muss das Messtastergehäuse

vor Befestigung des Messtastermoduls und des Tasteinsatzes

montiert werden.

• Drehen Sie das Gewindeende des Messtasters in die M8Aufnahme am MH8-Tastkopf und ziehen Sie es handfest an.

• Setzen Sie den (mitgelieferten) S1 C Spannschlüssel in die

Positionslöcher im Messtastergehäuse ein und ziehen Sie es

handfest an.

• Das empfohlene Drehmoment ist 0,3 Nm bis 0,5 Nm.

Siehe auch die Bedienungsanleitung für den benutzten Messtastertyp.

Page 51

Installation

49

3.5 Verlängerungen /

Messtasterkonfi gurationen

Die Reichweite des Messtasters kann um 50 mm erweitert werden,

indem eine PEL1 Verlängerung benutzt wird. Die Verwendung von

Verlängerungen der Serien PEL2, PEL3 oder PE wird nicht empfohlen.

PEL1

TP20

TP20

TP6

Abbildung 3 – Verlängerungen /

Messtasterkonfi gurationen

Page 52

50

Benutzung des Tastkopfes

4 Benutzung des Tastkopfes

HINWEIS: Vergewissern Sie sich, dass der Klemmhebel bis zum

Endanschlag im Uhrzeigersinn gedreht wurde, bevor Messpunkte

aufgenommen werden.

4.1 Positionieren des Tastkopfes (siehe

Abbildung 4)

• Lösen Sie den Tastkopf, indem Sie den Klemmhebel bis zum

Endanschlag gegen den Uhrzeigersinn drehen.

• Halten Sie das Gehäuse der Messtasterkonfi guration fest

(ohne den Tastereinsatz zu berühren) und drehen Sie die BAchse in 15° Stufen, bis die gewünschte Winkelstufe auf der

Positionsmarkierung der B-Achse erscheint. Schwenken Sie

anschließend die A-Achse, bis die gewünschte Winkelstufe im

Positionsfenster der A-Achse erscheint. Nicht beide Achsen

gleichzeitig verstellen.

• Verriegeln Sie den Tastkopf fest, indem Sie den Sperrhebel bis zur

Feststellposition im Uhrzeigersinn drehen.

• Kalibrieren Sie die Tastereinsatzkonfi guration(en) nach Anweisung

ihres KMG-Herstellers.

• Verändern Sie die Position der Messtasterkonfi guration zur

nächsten gewünschten Position und kalibrieren diese im

Anschluss.

• Wiederholen Sie dieses Verfahren bis alle gewünschten Positionen

und Messtasterkonfi gurationen kalibriert sind.

• Beginnen Sie den Messvorgang und achten Sie darauf, dass

für jede einzelne Kopfposition und Messtasterkonfi guration die

entsprechenden Verrechnungsdaten aktiviert werden.

Page 53

Benutzung des Tastkopfes

Periodisches Nachkalibrieren sollte unter folgenden Bedingungen

durchgeführt werden:

• Nach Empfehlungen des KMG-Herstellers, insbesondere in Bezug

auf T emperaturänderungen.

• Zu Beginn des Arbeitstages oder der Schicht.

• Nach einer Kollision.

• Nach Änderung der Messtasterkonfi guration (mit Ausnahme eines

bereits kalibrierten TP20 Moduls).

• Wenn die Messabweichung zu hoch ist.

51

Positionsskala

der B-Achse

Positionsfenster

der B-Achse

Positionsskala

der A-Achse

Positionsfenster

der A-Achse

Abbildung 4 – Benutzung des Klemmhebels

Klemmhebel

Lösen

Feststellen

Page 54

52

Abmessungen

5 Abmessungen

Ø48 mm

R70

A-Achse

0° - 90°

43 mm

5.7 mm

B-Achse

±180°

Abbildung 5 – Abmessungen des MH8

Page 55

Technische Spezifi kation

6 Technische Spezifi kation

Für Gesamtabmessungen siehe Abbildung 5, Seite 50.

6.1 Messleistung

Reproduzierbarkeit von Tastkopfpositionen (2σ) 1.5 µm

(An der Tastspitze mit Messtaster TP20-SF und

10 mm Tastereinsatzlänge)

Wiederholbarkeit von Positionen (2σ) 2.5 µm

mit 50 mm Verlängerung (PEL1)

(An der Tastspitze mit Messtaster TP20-SF und

10 mm Tastereinsatzlänge)

6.2 Technische Daten

53

Schwenkbereich

Höchstlast

Temperaturbereich /

Betrieb

Temperaturbereich /

Lagerung

Messtasteraufnahme

Elektrische Verbindung

Einsatz in Gebäuden

Gewicht

A-Achse: 0° bis 90° in 15° Schritten

B-Achse: ± 180° in 15° Schritten

TP6 Messtaster -Verlängerung (PEL)

nicht zulässig

TP20 oder TP2 Messtaster + 50 mm

Verlängerung (PEL1)

+10 °C bis +40 °C

-10 °C bis +70 °C

Renishaw M8 Aufnahme

Anschlussbuchse 5-polig DIN 180°

IP30

205 g (ohne Aufnahmeschaft)

Page 56

54

Wartung

7 Wartung

Dieses Produkt ist für einen Einsatz in geschützten Messräumen

bestimmt, so dass Ansammlungen von Staub oder Spänen nicht

auftreten dürfen.

Wie alle Präzisionsmessinstrumente werden regelmäßige

Untersuchungen und Reinigung empfohlen, um anhaltend hohe

Leistungen zu gewährleisten.

Die Wartung ist auf ein Abreiben der Außenfl ächen, der

Messtasteraufnahme, der Positionsskalierung und der Montagefl ächen

der Messtasteraufnahme mit einem sauberen, trockenen Tuch oder

einem Markenreiniger beschränkt.

Page 57

Fehlersuche

8 Fehlersuche

Siehe auch die entsprechenden Bedienungsanleitungen für den

Messtaster.

Verminderte Messgenauigkeit

Mögliche Ursachen Korrektive Maßnahme

Montage nicht gesichert. Prüfen Sie, dass der MH8 richtig

MH8 nicht komplett verriegelt. Vergewissern Sie sich, dass

Nach dem Verriegeln wird Druck

/ Kraft auf den auf den MH8

Tastkopf ausgeübt.

MH8 überlastet.(Z.B.

unzulässige Verlängerung)

Fehlerhafter Messtaster. Tauschen sie den defekten

MH8 abgenutzt oder schadhaft. Tauschen Sie den defekten

am Aufnahmeschaft angebracht

ist und die Schrauben fest

angezogen sind. Prüfen Sie den

Klemm-Mechanismus in der

KMG-Pinole.

der Klemmhebel des MH8

Tastkopfes bis zum Anschlag im

Uhrzeigersinn gedreht wurde.

Entriegeln Sie den MH8 Tastkopf

und verriegeln ihn wieder.

Verwenden Sie den

MH8 Tastkopf nur mit

den max. zulässigen

Messtasterkombinationen.

Messtaster aus.

MH8-Tastkopf aus oder senden

Sie ihn an Renishaw oder Ihren

Händler zurück.

55

Page 58

56

Fehlersuche

Achsen ‘rattern’ beim Positionieren

Mögliche Ursachen Korrektive Maßnahme

MH8 wurde nicht vollkommen

entriegelt

Drehen Sie den Klemmhebel

bis zum Endanschlag gegen

den Uhrzeigersinn, bevor Sie

versuchen, den Messtaster neu

auszurichten.

Page 59

MH8 Istruzioni per l’uso

Sez. 4 - Italiano

MH8 Istruzioni per l’uso

57

Page 60

58

© 2001 Renishaw plc. Tutti i diritti riservati.

Renishaw ® è un marchio registrato della Renishaw plc.

È vietato copiare, riprodurre o trasmettere alcuna parte del documento

in qualsiasi forma ed in qualsiasi lingua, per qualsivoglia scopo e con

qualsiasi mezzo, senza l’espresso consenso della Renishaw plc.

La pubblicazione del materiale qui contenuto non esonera l’utente dai diritti

di brevetto della Renishaw plc.

Limite di responsabilità

Il presente documento è stato preparato con la massima attenzione per

garantire che sia esente da errori ed omissioni. La casa non garantisce

comunque la precisione delle informazioni qui contenute ed in particolare

respinge la garanzia implicita. Renishaw plc si riserva il diritto di apportare

modifi che al documento ed alle apparecchiature trattate senza incorrere

alcun obbligo di notifi ca.

Cura della prodotto

La sonda e i relativi accessori Renishaw sono strumenti di precisione. Si

prega di usare e sottoporre a manutenzione gli apparecchi osservando

le istruzioni qui fornite, nonché di conservare la scatola di spedizione per

tenervi i vari componenti quando non sono usati.

Modifi che della specifi ca

Renishaw plc può modifi care o cambiare i propri prodotti, o le loro

specifi che, senza preavviso e senza impegno.

Garanzia

Renishaw plc garantisce i propri prodotti purché siano installati come

specifi cato nell’allegata documentazione Renishaw.

Se si devono usare o sostituire apparecchiature (quali interfacce e cavi)

non di produzione Renishaw, bisogna ottenere innanzi tutto l’assenso della

Renishaw, altrimenti la garanzia Renishaw può risultare invalida.

Brevetti

Certi aspetti della testa indexabile MH8 e di sistemi simili sono oggetto dei

seguenti brevetti e domande di brevetto.

EP 0392660 JP 3,018,015 US 5,088,337

MH8 Istruzioni per l’uso

Page 61

Indice

59

Indice

1 Introduzione ................................................................................60

2 Descrizione del prodotto .............................................................61

2.1 Sommario dei codici pezzo ................................................62

3 Procedura d’installazione ............................................................65

3.1 Montaggio del codolo sulla testa MH8 ...............................65

3.2 Montaggio della testa sulla CMM .......................................65

3.3 Connessione elettrica .........................................................66

3.4 Montaggio del codolo sulla testa ........................................66

3.5 Barre di prolunga ................................................................67

4 Funzionamento della testa ..........................................................68

4.1 Per cambiare l’orientamento della sonda di misura ...........68

5 Dimensioni ..................................................................................70

6 Specifi ca tecnica .........................................................................71

6.1 Prestazioni di misurazione .................................................71

6.2 Dati tecnici ..........................................................................71

7 Manutenzione ..............................................................................72

8 Ricerca dei guasti ........................................................................73

Page 62

60

Introduzione

1 Introduzione

La MH8 è una testa index manuale che si articola per fornire

l’orientamento dello stilo di misura. La testa può accettare tastatori

dotati di connettore M8 Renishaw. Si raccomanda l’uso di tastatori

TP20 e TP6. La testa MH8 è disponibile con una vasta gamma di

codoli per adattarsi al sistema di montaggio specifi cato dal costruttore

della CMM.

Page 63

Descrizione del prodotto

61

2 Descrizione del prodotto

La MH8 ha 2 assi di rotazione. Il connettore della sonda viene montato

sulla parte girevole dell’asse A, che consente di far ruotare la sonda di

90° nel piano Z. L’asse B consente di fare ruotare la sonda di ±180°

nel piano X-Y.

Un meccanismo azionato a leva blocca entrambi gli assi sulla

posizione voluta. Gli assi possono essere sbloccati per consentire

la libera rotazione su un’altra posizione. Le posizioni bloccate sono

impostate con incrementi angolari di 15° per ciascun asse, per un

totale di 168 posizioni.

Quando la testa viene bloccata dopo l’orientamento, la sonda è

completamente vincolata cinematicamente in una posizione spaziale

altamente ripetibile. Ciò signifi ca che dopo la qualifi cazione iniziale

della punta dello stilo nelle posizioni richieste, la sonda può essere

nuovamente orientata su una qualsiasi delle posizioni qualifi cate

senza bisogno di riqualifi cazione.

Un LED rosso montato sulla parte anteriore della testa indica lo stato

della sonda. Il LED può essere comandato dall’unità di controllo della

CMM, oppure da un’interfaccia Renishaw della sonda. È convenzione

normale che il LED sia acceso per indicare che la sonda è posizionata

(armata) per la misura, e spento per indicare che la sonda è stata

azionata e delessa.

Le connessioni elettriche sono effettuate tramite un connettore DIN a

5 poli.

Page 64

62

Descrizione del prodotto

LED di stato

della sonda

Scala dell’asse B

Scala dell’asse A

Connettore sonda

Codolo

M8

Sonda

Leva di

bloccaggio

Stilo

Figura 1 – La testa indexabile MH8 (vista anteriore)

Page 65

Descrizione del prodotto

63

Etichetta del

numero di serie

Connettore

DIN a 5 poli

Figura 2 – La testa indexabile MH8 (vista posteriore)

Page 66

64

Descrizione del prodotto

2.1 Sommario dei codici pezzo

N. di codice Descrizione

A-1332-0013 Testa MH8 + guida d’uso utente (H-1000-5190)

A-1332-0002 Testa MH8 e set di utensili TK4 ( senza codolo)

A-1332-0003 MH8 + TK4 + codolo MS1

A-1332-0004 MH8 + TK4 + codolo MS2

A-1332-0005 MH8 + TK4 + codolo MS4

A-1000-0006 MH8 + TK4 + codolo MS5

A-1332-0007 MH8 + TK4 + codolo MS7

A-1332-0008 MH8 + TK4 + codolo MS9

A-1332-0009 MH8 + TK4 + codolo MS10

A-1332-0010 MH8 + TK4 + codolo MS13

A-1332-0011 MH8 + TK4 + codolo MS15

A-1332-0014 MH8 + TK4 + codolo MS17

A-1332-0012 MH8 + TK4 + codolo D

A-1042-1486 Chiave S1

A-1047-3932 Chiave S9

M-5000-3540 Utensile S7 di serraggio stilo

P-TL03-0150 Chiave esagonale da 1,5 mm AF (regolazione di

TP2/TP6)

Page 67

Procedura d’installazione

65

3 Procedura d’installazione

3.1 Montaggio del codolo sulla testa MH8

• Posizionare il codolo nell’incavo della superfi cie superiore della

MH8.

• Fare ruotare il codolo fi no ad allineare i 3 fori delle viti.

• Fissare il codolo in posizione usando solo le 3 viti M3 x 5 mm

(fornite).

• Serrare progressivamente usando la chiave esagonale da 2,5 mm

A/F (fornita).

3.2 Montaggio della testa MH8 sulla CMM

La testa viene normalmente fi ssata alla colonna della CMM usando un

codolo specifi cato dal fabbricante della CMM.

I codoli standard sono elencati nel capitolo “Sommario dei codici

pezzo”.

Si possono usare sistemi di montaggio speciali o personalizzati.

Contattare il proprio fornitore, o la Renishaw, per i particolari del

nostro servizio di personalizzazione dei prodotti.

Il montaggio deve essere assolutamente rigido, poiché qualsiasi

movimento durante il normale funzionamento della testa

aggiungerebbe errori al sistema di misurazione.

Se la testa, o la sua posizione sulla colonna, viene cambiata bisogna

riqualifi care tutte le posizioni della testa usate correntemente.

Page 68

66

Procedura d’installazione

3.3 Connessione elettrica

La connessione avviene tramite una presa DIN a 5 poli montata sul

lato della testa (vedere fi gura 2).

La tabella qui sotto descrive le funzioni di ciascun terminale.

Piedino Funzione

1 Catodo del LED

2 Massa

3 Anodo del LED

4 Circuito della sonda

5 Circuito della sonda

5

4

1

2

3

3.4 Montaggio della sonda sulla testa MH8

Se viene inserita una sonda TP20, montare il corpo della sonda sulla

testa e poi il modulo e lo stilo della sonda.

• Avvitare l’estremità fi lettata della sonda nel connettore M8 della

testa fi no a serrarlo con le dita.

• Inserire la chiave S1 a ‘ C’ (fornita) nei fori di posizionamento del

corpo della sonda, e serrare a mano.

• La coppia di serraggio raccomandata è 0,3-0,5 Nm.

Consultare anche la guida utente per il tipo di sonda usata.

Page 69

Procedura d’installazione

67

3.5 Barre di prolunga

La distanza d’azione della sonda può essere estesa di 50 mm usando

una barra di prolunga PEL1. Non si consiglia di usare le barre di

prolunga serie PEL2, PEL3 o PE.

PEL1

TP20

TP20

Figura 3 – Uso delle barre di prolunga

TP6

Page 70

68

Funzionamento della testa

4 Funzionamento della testa

NOTA: Prima di effettuare qualsiasi misura, assicurarsi che la leva di

bloccaggio sia ruotata completamente in senso orario sulla posizione

di blocco.

4.1 Per cambiare l’orientamento della

sonda, procedere come segue (vedere la

fi gura 4)

• Sbloccare la testa ruotando la leva di bloccaggio in senso

antiorario.

• Afferrare il corpo della sonda (evitando di toccare lo stilo) e

ruotare l’asse “B” fi no a quando l’indicazione dell’angolo

desiderato della scala (in incrementi di 15º) è adiacente al segno

di riferimento dell’asse “B”. Ruotare quindi l’asse “A” fi no a quando

l’indicazione dell’angolo desiderato della scala (in incrementi di

15°) è sulla posizione di riferimento dell’asse “A”.

• Bloccare la testa ruotando la leva di bloccaggio in senso orario.

• Qualifi care la punta dello stilo seguendo le istruzioni del fornitore

della CMM.

• Cambiare l’orientamento della sonda sulla successiva posizione

desiderata e qualifi care la punta dello stilo.

• Ripetere il processo di qualifi cazione per tutti gli orientamenti

desiderati ed ogni punta dello stilo.

• Prima della misura, assicurarsi che per ciascuna posizione della

testa vengano richiamati i corretti dati di qualifi cazione.

Page 71

Funzionamento della testa

Le riqualifi cazioni periodiche devono essere eseguite tenendo conto

delle seguenti considerazioni:

• Le raccomandazioni del fornitore della CMM, particolarmente per

quanto riguarda i cambiamenti di temperatura.

• All’inizio del giorno o del turno lavorativo.

• Dopo una collisione accidentale.

• Dopo avere cambiato qualsiasi componente del sistema di

misurazione (eccetto un modulo TP20 già qualifi cato).

• Se la condizione iniziale è ignota o incerta.

69

Segno di

riferimento

dell’asse “B”

Scala dell’asse

“B”

Scala dell’asse

“A”

Segno di riferimento

Bloccare

dell’asse “A”

Figura 4 – Funzionamento della leva di bloccaggio

Leva di

bloccaggio

Sbloccare

Page 72

70

Dimensioni

5 Dimensioni

R70

Asse A

0° - 90°

Ø48 mm

43 mm

5.7 mm

Asse B

±180°

Figura 5 – Dimensioni MH8

Page 73

Specifi ca tecnica

6 Specifi ca tecnica

Per le misure d’ingombro, vedere la fi gura 5.

6.1 Prestazioni di misurazione

Ripetibilità di posizione (2σ) 1.5 µm

(Alla punta dello stilo con la sonda TP20,

modulo di forza standard e stilo lungo 10 mm)

Ripetibilità di posizione (2σ) 2.5 µm

con barra di prolunga di 50 mm (PEL1)

(Alla punta dello stilo con la sonda TP20,

modulo di forza standard e stilo lungo 10 mm)

6.2 Dati tecnici

71

Campo di orientamento

Carico massimo

Campo di temperatura

Campo di temperatura

Connettore della sonda

Connettore elettrico

Tenuta

Peso

Asse A da 0° a 90° in incrementi

di 15°

Asse B ±180° in incrementi di 15°

Sonda TP6 - nessuna prolunga

consentita

Sonda TP20 o TP2 + prolunga di

50 mm (PEL1)

da +10 °C a +40 °C di funzionamento

da –10°C a +70 °C di stoccaggio

Renishaw M8 x 1,25 x 5 mm

5 poli DIN (180°)

IP30

205 g (senza stelo)

Page 74

72

Manutenzione

7 Manutenzione

È inteso che questo prodotto debba essere usato in un ambiente

protetto di metrologia, per cui non dovrebbero verifi carsi accumuli di

polvere o di sfridi.

Come per tutte le apparecchiature di misura di precisione, si

raccomanda di controllare e pulire l’apparecchio con regolarità per

garantirne le continue alte prestazioni.

La manutenzione si limita a passare un panno pulito e asciutto, o

prodotti specializzati di pulizia, sulle superfi ci esterne, sulle etichette

delle scale degli assi e sulla superfi cie di montaggio del connettore

della sonda.

Page 75

Ricerca dei guasti

8 Ricerca dei guasti

Consultare anche l’appropriata guida utente della sonda di misura.

Perdita di precisione della misurazione

Cause possibili Rimedio

Montaggio non sicuro. Controllare che la MH8 sia

MH8 non bloccata

completamente.

Applicata forza alla sonda dopo

il bloccaggio.

MH8 sovraccaricata. Usare solo le combinazioni di

Sonda difettosa. Controllare sostituendo.

MH8 usurata o danneggiata. Controllare sostituendo, oppure

Gli assi producono un rumore secco durante la

rotazione

Cause possibili Rimedio

La MH8 non è completamente

sbloccata.

montata correttamente sulla

colonna e che le viti siano

serrate bene. Controllare il

meccanismo di serraggio testa

della CMM .

Assicurarsi che la leva

di bloccaggio sia ruotata

completamente in senso orario.

Sbloccare e bloccare

nuovamente la MH8.

sonda e prolunga specifi cate.

rimandare alla Renishaw o al

proprio fornitore.

Ruotare la leva di bloccaggio

completamente in senso

antiorario prima di tentare di

orientare nuovamente la sonda.

73

Page 76

747576

Page 77

Page 78

Page 79

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

For worldwide contact details, please

www.renishaw.com/contact

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

visit our main website at

*H-1000-5190-05*

Loading...

Loading...