Page 1

Programming guide

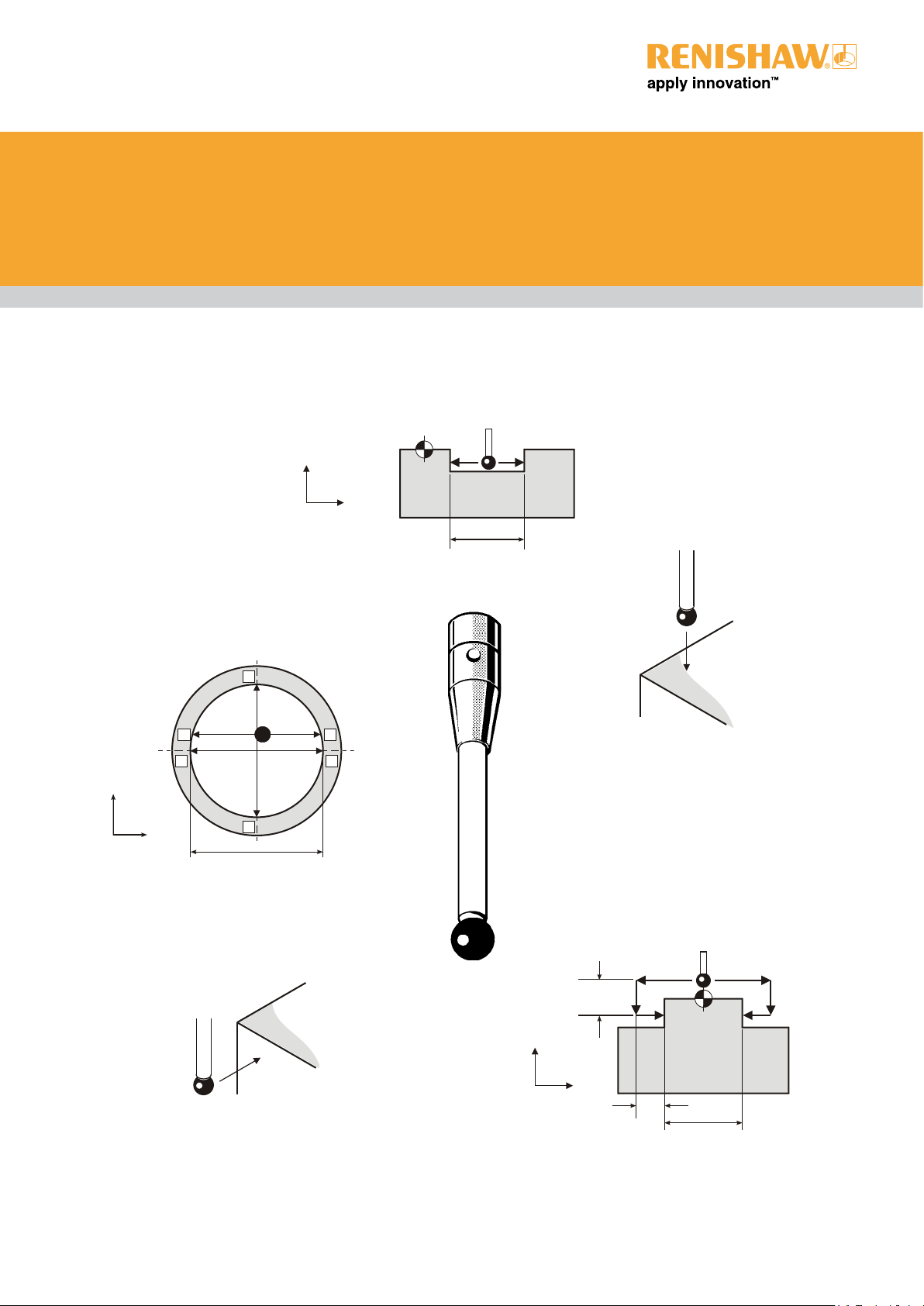

Z

Z

X

Dd

Rr

Dd

Z

X

Zz

X (Y)

4

Y

X

3

1

5

2

6

H-2000-6181-0B-B

EasyProbe cycles for machining

centres

Page 2

© 1999 - 2006 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means, without the prior

written permission of Renishaw.

The publication of material within this document does not imply freedom from

the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of this

document are free from inaccuracies and omissions. However, Renishaw

makes no warranties with respect to the contents of this document and

specifically disclaims any implied warranties. Renishaw reserves the right to

make changes to this document and to the product described herein without

obligation to notify any person of such changes.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are

registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All other brand names and product names used in this document are trade

names, service marks, trademarks, or registered trademarks of their respective

owners.

Renishaw part no: H-2000-6181-0B-B

Issued: 07.2006

Page 3

Contents 1

Contents

About the EasyProbe cycles.............................................................................................. 3

How much memory is required?........................................................................................3

Control parameter setting – retaining the common variables on reset............................... 4

Calibrating a spindle probe................................................................................................ 4

When should a spindle probe be calibrated?.............................................................. 4

How do I calibrate a probe?........................................................................................ 5

Using the ‘C’ input....................................................................................................... 5

Calibrating using experience values........................................................................... 6

Program format..................................................................................................................6

Measuring a single surface................................................................................................ 7

Example 1: Calibrating the probe length..................................................................... 8

Example 2: Measuring the X surface (set G54 to the surface)...................................8

Example 3: Measuring the Z surface (set G54 relative to the surface)....................... 9

Example 4: Applying co-ordinate rotation to the Z axis (C axis).................................9

Example 5: Setting a 4th axis (B axis)...................................................................... 10

Measuring a feature (boss, bore, web, or pocket) ........................................................... 11

Example 6: Calibrating the probe XY offsets and stylus ball radii

(combined operation) ........................................................................... 11

Example 7: Calibrating the probe XY offsets............................................................ 12

Example 8: Calibrating the probe stylus ball radii..................................................... 12

Example 9: Measuring a boss (set G54 to centre).................................................... 13

Example 10: Measuring a bore (set G59 to a referred centre) ................................. 13

Example 11: Measuring a Y axis web (set G54 to centre)........................................ 14

Example 12: Measuring an X axis pocket (set G59 to a referred centre) ................. 14

Programming method ...................................................................................................... 15

Inputs for protected positioning macro O9770.......................................................... 15

Example 13: Setting a part origin in a bore and top face.......................................... 15

Example 14: Setting a 4th axis (A axis).................................................................... 16

Common retained variables............................................................................................. 16

Inspection Plus calibration data variables................................................................. 16

Standard inspection calibration data variables ......................................................... 17

Customising the software ................................................................................................ 18

Testing the software ........................................................................................................ 19

Test 1: Z axis moves................................................................................................. 19

Test 2: Measuring accuracy...................................................................................... 20

Test 3: Fast feedrate optimisation ............................................................................ 20

Test 4: Updating the work offset............................................................................... 20

Publication No. H-2000-6181

Page 4

2 Contents

Inputs............................................................................................................................... 21

For single surface setting – G65P9023 (no Dd input)............................................... 21

For feature setting – G65P9023 (with Dd input) ....................................................... 21

Optional inputs – G65P9023..................................................................................... 22

Angle data........................................................................................................................ 24

Output – angle (#139)...............................................................................................24

Output – angle error (#144) ...................................................................................... 24

4th axis work offset adjustment ................................................................................ 24

Alarms.............................................................................................................................. 25

Common variables used for cycle output results ............................................................. 26

Publication No. H-2000-6181

Page 5

About the EasyProbe cycles

This guide describes how to use the Renishaw EasyProbe cycles. They are intended for

setting up simple jobs and measuring tasks.

By using these cycles, you will not have to create a program to position the probe prior to

the setting cycle call. The software allows you to position the stylus at a suitable start

position, in either the jog or handwheel mode, before running the cycle. Alternatively, the

EasyProbe custom cycles can be written into a part program for automatic programming

applications.

The main cycle is:

O9023 (REN START/SETUP)

This cycle is supported by the service macros listed below. Together, they form a

complete standalone software package that can be loaded into the control part-program

memory area.

About the EasyProbe cycles 3

O9770 (REN PROTECTED MOVE)

O9771 (REN BASIC MEASURE)

O9772 (REN OFFSET TYPE)

O9773 (REN SURFACE)

O9774 (REN FEATURE)

O9775 (REN ANGLE/4TH AXIS)

CAUTION: The EasyProbe cycles should be carefully tested for safe operation in

!

both MDI’ and ‘program’ mode during the commissioning. This will ensure they

are compatible with your machine configuration. If you use the cycles without first testing

them thoroughly for compatibility, serious mispositioning and damage may be caused

(see the section “Testing the software” later in this guide).

How much memory is required?

Loading all the cycles requires approximately 6.0 KB (15.0 metres) of part program

memory.

If you do not expect to use any of the macros listed below, do not load them.

O9773 (REN SURFACE) 0.6 KB (1.5 metres) of memory

O9774 (REN FEATURE) 1.2 KB (3.0 metres) of memory

O9775 (REN ANGLE/4TH AXIS) 0.9 KB (2.3 metres) of memory

Publication No. H-2000-6181

Page 6

4 Calibrating a spindle probe

Control parameter setting – retaining the common variables

on reset

Your machine controller must be set to retain common variables on reset. This is a

parameter setting that allows the angle measure cycle to work, and lets you see the

results written to these variables after the cycle has finished. For detailed information, see

the Readme file that is supplied with the EasyProbe software.

Calibrating a spindle probe

Before a spindle probe is used on a machine tool, it must be calibrated. Calibration

ensures that the length of the probe and the size and centre position of the stylus ball are

known. With this knowledge you can be sure that measurements taken with the probe will

be accurate.

The EasyProbe cycles have built-in calibration routines. Use these whenever a probe

needs to be calibrated.

When should a spindle probe be calibrated?

A probe should be calibrated in the following circumstances:

● Whenever a new stylus is fitted.

● Whenever the probe is exchanged with one from a different machine.

● Whenever a new shank is fitted to the probe.

● If it is suspected that the stylus has become distorted. For example, due to a

collision with part of a feature.

● If any on-centre adjustment has been performed.

● If very tight tolerances are to be achieved during workpiece set-up.

Publication No. H-2000-6181

Page 7

Calibrating a spindle probe 5

How do I calibrate a probe?

Three steps are involved in calibrating a spindle probe.

Step 1 Determine the length of the probe stylus assembly. See “Example 1 –

Calibrating the probe length”.

Step 2 Determine the relationship between the {x,y} centre of the stylus ball and the

machine spindle (the X and Y stylus offsets). See “Example 7 – Calibrating the

probe XY offsets”.

Step 3 Determine the effective size of the stylus ball (the ball radii). See “Example 8 –

Calibrating the probe stylus ball radii”.

Steps 2 and 3 can be carried out either as individual operations, as described above, or

combined into one operation (this is the recommended method). See “Example 6 –

Calibrating the probe XY offsets and stylus ball radii (combined operation)”.

Using the ‘C’ input

Instead of having separate calibration routines, the standard measuring cycles are used

with the ‘C’ input to calibrate the probe.

● C1. – use this input to calibrate the probe for either length or stylus offsets/radii.

● C2. – use this input to calibrate the probe stylus offsets.

● C3. – use this to calibrate the probe stylus radii.

Publication No. H-2000-6181

Page 8

6 Calibrating a spindle probe

Calibrating using experience values

Depending on circumstances, a probe might not always need to be calibrated precisely.

Instead, experience values can be used. To calibrate using experience values, first

mechanically centre the probe stylus so that it runs true. Next, enter the values directly

via the keyboard.

Do this as follows:

1. Enter experience values for the stylus ball radii.

● Actual (experience) stylus radii values are typically 0.030 mm (0.0011 in) less

than the physical radii values.

● For details of where these values are stored, see the section “Common

retained variables”.

2. Set the XY offsets to zero (0).

● For details of where these values are stored, see the section “Common

3. Set the probe tool offset register to the length of the probe/stylus assembly.

● Enter the length into the tool offset register that you have allocated to the

If you use this method, ignore the calibration procedures described previously and all

further examples of probe calibration.

Program format

Standard call G65P9023....inputs....

M-code call M143....inputs....(recommended if an M-code shortcut is to be used).

retained variables”.

probe tool holder.

Publication No. H-2000-6181

Page 9

Measuring a single surface

Description

This cycle is used to measure a single surface feature. It is also used to calibrate the

length of a probe.

Application

Position the probe stylus (using either the jog or handwheel mode) to a start point that is

clear of the surface. Run the cycle, either in MDI mode or by creating a simple part

program.

Format

Measuring a single surface 7

[ ] denotes optional inputs

X surface G65P9023Xx[AaC1.QqSsIi]

Y surface G65P9023Yy[AaC1.QqSsJj]

Z surface G65P9023Zz[AaC1.QqSsKk]

Publication No. H-2000-6181

Page 10

8 Measuring a single surface

Example 1: Calibrating the probe length

Inputs required: C1. and Zz (do not use input Dd)

Z

Y

X

You must set the active co-ordinate system (for example, G54) to the reference surface

position before running the cycle.

1. Position the probe stylus approximately 10 mm (0.394 in) above the surface.

2. Run the cycle, either in MDI mode or by creating a simple part program.

O0000;

G65P9023C1.Z-10.; The probe length is set.

Example 2: Measuring the X surface (set G54 to the

surface)

Inputs required: Xx and Ss

1. Position the probe stylus approximately 10 mm (0.394 in) in front of the surface.

O0000;

G65P9023X-10.S54.; Set the G54 to the X surface position.

Publication No. H-2000-6181

Page 11

Measuring a single surface 9

Example 3: Measuring the Z surface (set G54 relative to

the surface)

Inputs required: Zz and Ss

1. Position the probe stylus approximately 10 mm (0.394 in) above the surface.

O0000;

G65P9023Z-10.S54.K50.; Set the Z surface at 50 mm (1.968 in) relative

to the G54.

Example 4: Applying co-ordinate rotation to the

Z axis (C axis)

The value of the actual angle recorded (in #139) depends on the order in which the

measurement points are taken, i.e. either P1 before P2 or P2 before P1.

1. Position the probe stylus approximately 10 mm (0.394 in) in front of the angled

surface at the first measuring point.

2. Take a measurement at point P1.

3. Move the probe to point P2, using the same Z position. Take a measurement at this

point.

NOTE: An alarm is generated if the X, Y and Z positions are changed for P1 and P2.

Publication No. H-2000-6181

Page 12

10 Measuring a single surface

O0000;

G65P9023Y-10.; Y– single surface measure P1.

G0G91X50.Y15.; Move from P1 to P2. You can use either the jog or

G65P9023A0Y-10.; Y– single surface P2 measure to find the angle error

G68G90C0X0Y0R#144; Apply rotation around the C axis.

NOTE: G68 may be cancelled with G69. The measuring cycles will not run with

G68 active.

handwheel mode to do this.

#144, relative to angle (A=0). The actual angle is in

#139.

Example 5: Setting a 4th axis (B axis)

1. Position the probe stylus approximately 10 mm (0.394 in) above the angled surface

at the first measuring point P1.

2. Take a measurement at point P1.

3. Move the probe to point P2, using the same Y position. Take a measurement at this

point.

O0000;

G65P9023Z-10.; Z– single surface measure P1.

G0G91X50.Z15.; Move from P1 to P2. You can use either the jog or

handwheel mode to do this.

G65P9023A0Z-10.S54; Z– single surface measure P2.

4. Adjust the G54 (B axis) by the angle error to set the surface to zero (0) degrees.

Publication No. H-2000-6181

Page 13

Measuring a feature 11

Measuring a feature (boss, bore, web, or pocket)

Description

This cycle is used to measure a feature. The feature can be a boss, bore, web, or pocket.

The cycle is also used to calibrate the XY axis offsets of a probe and the radii of a probe

stylus ball.

Application

Position the probe stylus (using either the jog or handwheel mode) to a start point. Run

the cycle, either in MDI mode or by creating a simple part program.

Format

[ ] denotes optional inputs

Boss, bore G65P9023Dd[CcQqRrSsIiJjKk]

X (web, pocket) G65P9023DdXx[CcQqRrSsIiJjKk]

Y (web, pocket) G65P9023DdYy[CcQqRrSsIiJjKk]

Example 6: Calibrating the probe XY offsets and stylus

ball radii (combined operation)

Use a ring gauge as a reference feature for this operation. You must accurately

determine the centre position of the ring gauge before calibrating the probe.

Inputs required: C1. and Dd

1. Position the probe stylus ball in the ring gauge at the measuring height. Align the

spindle axis with the exact centre of the gauge.

2. Run the cycle, either in MDI mode or by creating a program.

O0000;

G65P9023C1.D50.002; The size of the ring gauge is 50.002 mm. The XY offsets

Publication No. H-2000-6181

and stylus ball radii calibration are set.

Page 14

12 Measuring a feature

Example 7: Calibrating the probe XY offsets

Use a bored hole as the reference feature for this operation. The centre of the feature

must be generated for accuracy, but the size is not important.

Inputs required: C2. and Dd

1. Position the probe stylus ball in the reference feature at the measuring height. Align

the spindle axis with the exact centre of the bore.

2. Run the cycle, either in MDI mode or by creating a program.

O0000;

G65P9023C2.D50.; The calibrated XY offsets are set.

Example 8: Calibrating the probe stylus ball radii

Use a ring gauge as a reference feature for this operation. The exact position of the

reference feature is not important.

Inputs required: C3. and Dd

1. Position the probe stylus ball in the ring gauge at the measuring height. Align the

spindle axis with the approximate centre of the gauge.

Publication No. H-2000-6181

Page 15

Measuring a feature 13

2. Run the cycle, either in MDI mode or by creating a program.

O0000;

G65P9023C3.D50.002; The size of the ring gauge is 50.002 mm. The stylus ball

radii calibration is set.

Example 9: Measuring a boss (set G54 to centre)

Inputs required: Dd, Ss and Zz

1. Position the probe stylus on the approximate centre of the feature, and

approximately 10 mm (0.394 in) above the feature.

O0000;

G65P9023D50.Z-15.S54.; Set the G54 offset.

Example 10: Measuring a bore (set G59 to a referred

centre)

Inputs required: Dd and Ss

1. Position the probe stylus on the approximate centre of the feature, and in the bore

at the measuring height.

O0000;

G65P9023D50.S59.I50.J50.; Set the centre at X=50 and Y=50 relative to the

Publication No. H-2000-6181

G59X0Y0.

Page 16

14 Measuring a feature

Example 11: Measuring a Y axis web (set G54 to centre)

Inputs required: Dd, Ss, Y1. and Zz

1. Position the probe stylus on the approximate centre of the feature, and

approximately 10 mm (0.394 in) above the feature.

O0000;

G65P9023D50.Y1.Z-15.S54.; Set the G54 offset.

Example 12: Measuring an X axis pocket (set G59 to a

referred centre)

Inputs required: Dd, Ss and X1.

1. Position the probe stylus on the approximate centre of the feature, and in the pocket

at the measuring height.

O0000;

G65P9023D50.X1.S59.I50.; Recommend setting input X = 1. or Y = 1. (but

any value can be used). Set the X surface at

X = 50 relative to the G59X0.

Publication No. H-2000-6181

Page 17

Programming method

Macro O9770 can be used for protected positioning moves as described in the following

examples.

Inputs for protected positioning macro O9770

Xx x = X target position.

Yy y = Y target position.

Zz z = Z target position.

Ff f = Feedrate (the default is set in O9023).

M1. = Set an error flag #148=1 (triggered) or =0 (no trigger). No

Programming method 15

alarm generated. This can be used for testing whether a surface

exists.

Examples 13 and 14 below describe how to use the cycles when they are written into a

part program.

Example 13: Setting a part origin in a bore and top face

O????

M6T20; Select the probe.

G54;

G43Z100.0H20 Apply probe length offset.

G65P9023M1.; Switch probe on.

G65P9770X0Y0Z10.F5000.; Protected move to the centre of the bore.

G65P9770Z-10.; Protected move to the measuring position.

G65P9023D30.S54.M2.; Measure and set the bore to G54X0 Y0.

G65P9770Z10.; Protected move.

G65P9770X25.; Protected move.

G65P9023Z-10.S54.K1.M2.; Set the Z surface to 1 mm (0.040 in) above the

G54Z0 position.

G65P9023M3.; Switch probe off.

G0Z100.; Retract.

Publication No. H-2000-6181

Page 18

16 Common retained variables

Example 14: Setting a 4th axis (A axis)

O????;

M6T20; Select the probe.

G54;

G43Z100.0H20 Apply probe length offset.

G65P9023M1.; Switch probe on.

G65P9770X0Y-25.Z10.F5000.; Protected move to the first measurement point.

G65P9023Z-10.M2.; Z- single surface measure.

G65P9770Y25.; Move along the Y axis parallel to the surface.

G65P9023A90.Z-10.S54.M2.; Z- single surface measure.

G65P9023M3.; Switch probe off.

Adjust the G54 A axis by the angle error to set

the surface to zero (0) degrees.

Common retained variables

The common retained variables used depend upon the inspection software option that is

selected during the initial generation of the EasyProbe software.

● Variables for Inspection Plus software are used when either:

● No Renishaw inspection software is currently installed, or

● Renishaw Inspection Plus software is currently installed.

● Variables for the standard Renishaw inspection software are used when the

standard inspection software is currently installed.

Inspection Plus calibration data variables

Each of the following values is found during the calibration process.

#500 = X axis stylus ball radius.

#501 = Y axis stylus ball radius.

#502 = X axis stylus ball centre offset.

#503 = Y axis stylus ball centre offset.

Publication No. H-2000-6181

Page 19

Common retained variables 17

#506 = Stylus backoff factor adjustment.

This should be optimised during installation. Reducing the value

decreases the distance the stylus will back off from the surface before

making a final measuring move. When the software is set for a one-touch

measuring move, #506 is not used. (See the section “Customising the

software”, variable #118.)

Standard inspection calibration data variables

Each of the following values, with the exception of #506, is found during the calibration

process.

#500 = X+ axis stylus ball radius.

#501 = X

#502 = Y+ axis stylus ball radius.

#503 = Y

#504 = X axis stylus ball centre offset.

#505 = Y axis stylus ball centre offset.

#506 = Stylus backoff factor adjustment.

NOTE: When EasyProbe files are generated using the Haas USA option, the range

of common variables (#100) and common retained variables (#500) are different

from those shown above.

When using this option, all #100 variables are incremented by 50 and the #500

variables by 56. For example, the 4th axis system number setting variable #115

becomes #165 and the probe tool offset number variable #120 becomes #170.

Similarly, the X+ axis stylus ball radius #500 becomes #556 and the backoff factor

#506 becomes #562.

– axis stylus ball radius.

– axis stylus ball radius.

This should be optimised during installation. Reducing the value

decreases the distance the stylus will back off from the surface before

making a final measuring move. When the software is set for a one-touch

measuring move, #506 is not used. (See the section “Customising the

software”, variable #118.)

This is to comply with current Haas USA recommendations for probe variable use

and should avoid conflicts with other systems on the machine.

Publication No. H-2000-6181

Page 20

18 Customising the software

Customising the software

Customising features are provided in the macro O9023 (REN START/SETUP). This

involves adding suitable probe start and stop codes, and editing the default values of

some of the common variables used in the software.

(START CODES) Enter suitable start-up codes at the top of the macro, when

applicable, to switch on the probe. A spindle orientation code, M19,

is already included to consistently position the spindle correctly each

time the cycles are used.

Start codes will usually be M-codes.

(STOP CODES) Enter suitable stop codes at the end of the macro, when applicable,

to switch off the probe.

Stop codes will usually be M-codes.

#115 = 4th axis system number setting and direction (i.e. clockwise or

counter-clockwise). This must be set during the installation if using a

4th axis option (see the section “Testing the software”). The setting

is dependent on the following factors:

● The type of 4th axis used.

● Where it is located or how it has been installed.

NOTE: If no 4th axis is being used, it is important that the default

value of zero (0) is left set.

#116 = This is used to read and apply the active tool offset values.

#118 = Measuring feedrate. The default value of 30 mm/min (1.181 in/min)

is suitable for general applications on most machines using a

two-touch measuring move.

NOTES: Feedrate values must always be entered in mm/min, even

if the Imperial (inches) mode is being used on the machine.

Be aware that measurement accuracy can be compromised by

increasing the measuring feedrate (see the section “Testing the

software”).

Machines with an ‘High Speed Skip’ (fast) measuring input can be

run at faster feedrates – typically 500 mm/min to 1000 mm/min

(20 in/min to 40 in/min).

Publication No. H-2000-6181

Page 21

Testing the software 19

Once the feedrate is increased above 100 mm/min (3.94 in/min), the

cycles change to one-touch measuring. Tests may be required to

find the optimum feedrate for your application.

#119 = Fast feedrate used for protected positioning in XY axis (default

5000 mm/min).

Calculated: Z axis is (#119*.6=) 3000 mm/min.

First-touch measure is (#119*.3=) 1500 mm/min.

#120 = Fix the probe tool offset number used for the measuring cycles

(default = 20). This must be set during installation (see the section

“Testing the software”).

The common variables listed below are also used by the EasyProbe software.

#123 Used for internal calculation or a similar purpose.

to = Not normally of concern to a user.

#132

#135 Used for cycle output results

to = (see "Common variables used for cycle output results" for details).

#148

Testing the software

After you have finished customising the software, or even if no changes have been made,

you should carefully run the cycles to make sure they are compatible with the machine.

You are recommended to carry out each of the tests described below as appropriate.

Test 1: Z axis moves

Run a Z measure cycle clear of any obstruction (ideally at the Z home position). Check

that the axis only moves the incremental programmed distance, and not a large value that

includes the probe length.

If the probe is not triggered, a ‘Probe Fail’ alarm should occur at the end of the move.

Run this test in MDI mode and under program operation. Also run this test immediately

after switching on the machine but before you have selected a tool offset.

Publication No. H-2000-6181

Page 22

20 Testing the software

Test 2: Measuring accuracy

Test that the measuring accuracy is suitable for your application. You must do this if you

have changed the default measuring feedrate.

This test is usually achieved by making repeated measurements on a surface, while

starting the moves from different standoff positions.

Test 3: Fast feedrate optimisation

Test that the fast feedrates are optimised for your machine. For safe operation the

machine must be able to stop during a measuring move within the overtravel of the probe.

The default feedrate values used are usually suitable for small to medium size machines.

TIP: Test the feedrate by positioning the probe stylus to trigger during a skip move on the

edge of a surface, so that the stylus will skid off the surface and prevent excessive

overtravel.

Test 4: Updating the work offset

If the 4th axis measuring feature is to be used, check that the correct work offset is

updated and that it is applied in the correct direction, i.e. clockwise or counter-clockwise.

The axis direction and axis number are set inside macro O9023 using #115 = 4, 5 etc. or

#115 = -4, -5 etc.

.

Publication No. H-2000-6181

Page 23

Inputs

Inputs 21

For single surface setting – G65P9023 (no Dd input)

NOTES:

[ ] denotes optional inputs

*

denotes macro A keyboard inputs (Fanuc controllers only)

[Aa] a = Use this only when measuring an angle. Enter the nominal angle of the

[Ba

] surface (±90 degree range). Make two surface measures along the

*

[C1.] = Indicates a calibration cycle. This is used to adjust the probe tool length

[Fc

] offset.

surface. This input must be used for the second measure (see the section

“Angle data”).

*

Xx x = Approximate distance and direction to the X surface.

Yy y = Approximate distance and direction to the Y surface.

Zz z = Approximate distance and direction to the Z surface (usually a minus

value).

For feature setting – G65P9023 (with Dd input)

Dd d = The nominal size of the feature for measuring a bore/boss or a

web/pocket.

C1. = Complete calibration in one operation, as described in C2. and C3. below.

or

C2. = Calibrate the stylus in the XY axes for stylus ball-to spindle centre line

or offsets.

C3. = Calibrate the stylus ball radius offsets in the XY axes.

X1. = Indicates measuring a web/pocket in the X axis.

or

Y1. = Indicates measuring a web/pocket in the Y axis.

Zz z = Incremental distance and direction to the measuring position in the Z axis

Publication No. H-2000-6181

(usually a minus value). If this is omitted, a bore or pocket cycle is

assumed.

Page 24

22 Inputs

Optional inputs – G65P9023

Probe switch-on/switch-off codes

Mm 1. = Switch probe on only. (No measure cycle.)

Other codes

Qq q = The overtravel of the probe for use whenever the default value is not

2. = Inhibit probe on/off codes. (Run measure cycle.) Include this input in a

program if the cycle is to be run a number of times. This will prevent the

probe from being switched on and off.

3. = Switch probe off only. (No measure cycle.)

suitable.

Default values =

5 mm (0.197 in) for XYZ measurements.

10 mm (0.394 in) for feature measurements.

Rr r = The radial clearance between the stylus and the side of the feature. Use

only to measure an external feature (i.e. web or boss).

Default value = 10 mm (0.394 in)

-r = Use a negative value to run an internal web or boss cycle.

Publication No. H-2000-6181

Page 25

Ss s = The work offset number that is to be set.

S54 to S59 (G54 to G59 Fanuc/Meldas, and G54P1 to G59P1 Yasnac)

S53 external work offset (S52 on Haas)

Fanuc additional offsets

S101 to S400 (G54.1P1 to G54.1P300)

Meldas additional offsets

S101 to S148 (G54.1P1 to G54.1P48)

Haas additional offsets

S110 to S129 (G110 to G129)

S154.01 to S154.99 (G54P1 to G54P99)

Yasnac additional offsets

S54.02 to S59.05 (G54P2 to G59P5) MX3, J50 series

S54.02 to S59.05 (G54P2 to G59P5) I80, J300 series

Ii I = Required X set position of the feature.

Default value = zero (0).

Inputs 23

Jj j = Required Y set position of the feature.

Default value = zero (0).

Kk k = Required Z set position of the feature.

Default value = zero (0).

Publication No. H-2000-6181

Page 26

24 Angle data

Angle data

The normal mathematical convention for angles is used. This means the specified angle

or resultant angle is a positive (counter-clockwise) angle (see the following figures).

This may cause confusion on a machining centre where the normal operator viewpoint is

from the Y– direction (typical) for rotations around the Y axis.

Output – angle (#139)

The cycle calculates the angle using the controller ATAN function, without any

manipulation of the result.

This is an absolute value that is measured as follows:

● ‘A axis’ rotation (around the X axis) is measured from the Y+ axis.

● ‘B axis’ rotation (around the Y axis) is measured from the X+ axis.

● ‘C axis’ rotation (around the Z axis) is measured from the X+ axis.

Output – angle error (#144)

The cycle calculates the angle error from the ‘Aa input’ angle. The result is always given

in the range ±90 degrees.

4th axis work offset adjustment

This is always adjusted by the #144 value, which means the shortest distance (angle

error) used for the update.

To change the update direction to the 4th axis, see the section “Customising the

software”, variable #115.

Publication No. H-2000-6181

Page 27

Alarms

Alarms 25

Message 91 FORMAT ERROR

591 FORMAT ERROR

Action Correct the macro input line and run again.

(This is a reset condition.)

Message 92 PROBE OPEN

592 PROBE OPEN

Action The probe is not switched on, or the stylus is in contact with a surface

before trying to make the move, or the probe triggered during a move.

Correct the error and try again.

(This is a reset condition.)

Message 93 PROBE FAIL

593 PROBE FAIL

Action The probe did not hit the surface during the measure move, or the signal

is not received or actioned by the control.

This alarm is sometimes given if the surface is hit close to the target

overtravel limit. The condition gets worse with higher measuring

feedrates.

Correct the error and try again.

(This is a reset condition.)

Message 95 ANGLE DATA ERROR

595 ANGLE DATA ERROR

Action The macro could not process the angle data provided.

Reasons:

● Two surface measurements are taken at the same position.

● Only one axis positioning move is allowed (not counting the

measuring axis) between the two surface measuring points.

Publication No. H-2000-6181

● Using the Aa input when not trying to measure an angle.

Position correctly from the current position, and try again. (This is a reset

condition.)

Page 28

26 Common variables used for cycle output results

Common variables used for cycle output results

#135 = X actual position output.

#136 = Y actual position output.

#137 = Z actual position output.

#138 = Size of feature output.

#139 = Absolute angle output (see the section “Angle data”).

#140 = X position error output.

#141 = Y position error output.

#142 = Z position error output.

#143 = Size error output (for feature measurement) or height difference output

(for angle measurement).

#144 = Angle error. This is relative to the Aa angle specified. The result is always

in the range ±90 degrees (see the section “Angle data”).

#148 = Macro O9770 flag (0 = no trigger, 1 = triggered). Indicates whether the

probe has triggered during the move.

Publication No. H-2000-6181

Page 29

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details,

please visit our main web site at

www.renishaw.com/contact

*H-2000-6181-0B*

Loading...

Loading...