Page 1

Programming manual

H-2000-6021-0E-A

Inspection software for lathes

for Fanuc 0, 6, 10–15, 16, 18, 21T and iT,

and Y asnac LX3 controllers

Page 2

© 1998–2013 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in

part, or transferred to any other media or language, by any means,

without the prior written permission of Renishaw plc.

The publication of material within this document does not imply

freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE

THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE

DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR

REPRESENTATIONS REGARDING THE CONTENT. RENISHAW

EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Trade marks

RENISHAW and the probe symbol used in the RENISHAW logo are

registered trade marks of Renishaw plc in the United Kingdom and

other countries. apply innovation and names and designations

of other Renishaw products and technologies are trade marks of

Renishaw plc or its subsidiaries.

All other brand names and product names used in this document

are trade names, trade marks, or registered trade marks of their

respective owners.

Renishaw part no: H-2000-6021-0E-A

Issued: 07.2013

Page 3

IMPORTANT – PLEASE READ CAREFULLY

RENISHAW PRODUCT LICENCE

Licensee: you, the person, firm or company accepting the terms of this Licence

Renishaw: Renishaw plc, New Mills, Wotton-under-Edge, Gloucestershire, GL12 8JR, United Kingdom

Product: the software, which is designed to operate on machine tool numeric controllers, supplied by

Renishaw for use with Renishaw’s machine tool probing systems

Licence to use: a non-exclusive licence to use the Product on a single machine tool only

By installing and/or using the Product you indicate your acceptance of the terms of this Licence.

Renishaw grants the Licensee a Licence to use the Product on condition the Licensee accepts the following

terms and conditions:

1. All rights in and title to the Product are and shall remain vested in Renishaw and its licensors.

2. Renishaw shall replace or repair the Product if it does not materially perform to specification under proper use

within 90 days of delivery. This warranty does not apply where the Product has been modified in any manner

that is not specifically described in the Product or in the installation or programming manuals supplied with the

Product, or where the Product is used with probing systems that have not been produced by Renishaw.

Except as stated in this paragraph, all warranties, conditions and terms implied by law are excluded. In

particular, no warranty is given that the Product is bug or error-free.

3. NOTE - LIMITATION OF LIABILITY IN CONNECTION WITH USE OF THE PRODUCT

Renishaw does not exclude liability for personal injury or death caused by Renishaw’s negligence.

Renishaw’s liability is limited to (a) the warranty contained in paragraph 2 and (b) direct losses up to a

maximum of £50,000.

Renishaw has no liability to the Licensee for any indirect, consequential or economic loss (including,

without limitation, loss of data, profits or goodwill).

The Product has been designed for use with Renishaw’s machine tool probing systems. Renishaw has

no liability for the results of using the Product with another manufacturer’s machine tool probing systems.

By accepting the terms of this Licence the Licensee agrees that this limitation of liability is reasonable.

4. The Licensee may not make any copies of the Product except as provided in this Licence or as permitted by

applicable law. The Licensee is authorised to make a backup copy of the Product for security purposes. The

Licensee must not remove any licence and copyright notices, labels or marks contained in the original and shall

ensure all copies contain such notices without modification.

5. If the Product contains electronic manuals the Licensee may print out the manuals in part or in full, provided

that the print outs or copies are not supplied to any third party that is not an employee or contractor for the

Licensee without Renishaw’s written permission

6. The Licensee shall not reverse engineer, decompile, or modify the Product or re-use any components

separately from the Product unless permitted by a specific instruction contained in the Product or the

programming or installation manuals supplied with the Product or by applicable law provided that in the latter

case, Licensee has first contacted Renishaw to request any information required to interface with Licensee’s

other software.

7. The Licensee shall not make the Product available to any third party in any manner whatsoever nor may this

Licence and the Product be transferred to a third party without Renishaw’s prior written agreement. Any

agreement by Renishaw is conditional on the permitted transferee agreeing to all terms of this Licence and the

Licensee not retaining any copies of the Product. Where the Licensee is a reseller of Renishaw’s machine

tool probing systems, Licensee may transfer the Product for ultimate use by an end user with Renishaw’s

machine tool probing systems.

8. Renishaw shall have the right to terminate this Licence immediately if the Licensee fails to comply with any of

these terms and conditions. The Licensee agrees upon receipt of notice of termination from Renishaw to

immediately return or destroy all copies of the Product in its possession or control.

9. This Licence is governed by English law and the parties submit to the exclus ive jurisdiction of the English

courts.

Renishaw Product Licence (EN) – Issue 1: February 2007

Page 4

Page 5

Form 1

has been filled in.

EQUIPMENT REGISTRATION RECORD

Please complete this form (and Form 2 overleaf if applicable) after the Renishaw equipment has been installed on your machine.

Keep one copy yourself and return a copy to your local Renishaw Customer Support office (see www.renishaw.com/contact for

the address and telephone number). The Renishaw Installation Engineer should normally complete these forms.

MACHINE DETAILS

Machine description ...........................................................................................................................................

Machine type ......................................................................................................................................................

Controller ............................................................................................................................................................

Special control options .......................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

RENISHAW HARDWARE

Inspection probe type ............................................

Interface type .........................................................

Tool setting probe type ..........................................

Interface type .........................................................

SPECIAL SWITCHING M-CODES (OR OTHER) WHERE APPLICABLE

Switch (Spin) probe on ..........................................

Switch (Spin) probe off ..........................................

Start/Error signal ....................................................

ADDITIONAL INFORMATION

RENISHAW SOFTWARE

Inspection disk(s) ...........................................................

........................................................................................

........................................................................................

Tool setting disk(s) ........................................................

........................................................................................

........................................................................................

Dual systems only

Switch on inspection probe ............................................

Switch on tool setting probe ..........................................

Other ..............................................................................

........................................................................................

Tick box if Form 2 overleaf

Customer's name ............................................................................

Customer's address .........................................................................

..........................................................................................................

..........................................................................................................

..........................................................................................................

Customer's tel. no ............................................................................

Customer's contact name ................................................................

Date installed ........................................

Installation engineer ..............................

Date of training ......................................

Page 6

SOFTWARE DEVIATION RECORD

Standard Renishaw kit no. Software disk nos.

Reason for deviation

Software no. and macro no. Comments and corrections

Form 2

The software product for which these changes are authorised is subject to copyright.

A copy of this deviation sheet will be retained by Renishaw plc.

A copy of the software amendments must be retained by the customer – they cannot be retained by

Renishaw plc.

Page 7

Cautions i

!

Caution – Software safety

The software you have purchased is used to control the movements of a machine tool. It

has been designed to cause the machine tool to operate in a specified manner under

operator control, and has been configured for a particular combination of machine tool

hardware and controller.

Renishaw has no control over the exact program configuration of the controller with which

the software is to be used, nor over the mechanical layout of the machine tool. Therefore,

it is the responsibility of the person putting the software into operation to:

ensure that all machine tool safety guards are in position and working correctly

before commencement of operation;

ensure that any manual overrides are disabled before commencement of operation;

verify that the program steps invoked by this software are compatible with the

controller for which they are intended;

ensure that any moves that the machine tool will be instructed to make under

program control will not cause the machine tool to inflict damage upon itself or upon

any person in the vicinity;

be thoroughly familiar with the machine tool and its controller, understand the

operation of work co-ordinate systems, tool offsets, program communication

(uploading and downloading) and the location of all emergency stop switches.

IMPORTANT: This software makes use of controller variables in its operation. During its

execution, adjustment of these variables, including those listed within this manual, or of

tool offsets and work offsets, may lead to malfunction.

Publication No. H-2000-6021

Page 8

ii

This page is intentionally left blank

Publication No. H-2000-6021

Page 9

Contents iii

Contents

Before you begin

Before you begin ................................................................................................................. 1

Measurement values used in this manual .......................................................................... 2

Associated publications ...................................................................................................... 2

About the Inspection software ............................................................................................ 2

Software kit no. A-4012-0541 ............................................................................................. 2

File1: Probe horizontal cycles ...................................................................................... 2

File2: Probe vertical cycles .......................................................................................... 3

File3: C-axis cycles ...................................................................................................... 3

Macro memory requirements .............................................................................................. 3

Macro numbers and functions ............................................................................................ 4

Measurement errors............................................................................................................ 5

Renishaw customer services .............................................................................................. 5

Calling Renishaw ......................................................................................................... 5

Chapter 1 Installing the software

Installing the software ...................................................................................................... 1-2

Using the wizard ....................................................................................................... 1-2

Editing macros manually .......................................................................................... 1-2

Setting and adjusting the software ................................................................................... 1-2

Chapter 2 Optional inputs

Optional inputs ................................................................................................................. 2-2

Chapter 3 Variable outputs

Table 1 Variable outputs with probe vertical .................................................................... 3-2

Table 2 Variable outputs with probe horizontal ............................................................... 3-2

Chapter 4 Protected positioning cycles

Probe protected positioning (probe vertical) – O9610 ..................................................... 4-2

Probe protected positioning (probe horizontal) – O9810 ................................................. 4-4

Chapter 5 Calibrating the probe

Why calibrate a probe and stylus? ................................................................................... 5-2

Single-sided calibration .................................................................................................... 5-2

Double-sided calibration .................................................................................................. 5-3

Publication No. H-2000-6021

Page 10

iv Contents

Calibrating the probe length ............................................................................................. 5-3

Calibration cycles ............................................................................................................. 5-3

Calibrating the probe length (probe vertical) – O9601..................................................... 5-5

Calibrating the stylus Z tool offset double-sided (probe vertical) – O9602 ...................... 5-7

Calibrating the stylus ball radius double-sided (probe vertical) – O9603 ........................ 5-9

Calibrating the stylus single-sided (probe vertical) – O9604 ......................................... 5-11

Calibrating the probe length (probe horizontal) – O9801 .............................................. 5-13

Calibrating the stylus X tool offset double-sided (probe horizontal) – O9802 ............... 5-15

Calibrating the stylus ball radius double-sided (probe horizontal) – O9803 .................. 5-17

Calibrating the stylus single-sided (probe horizontal) – O9804 ..................................... 5-19

Chapter 6 Standard measuring cycles

XZ single surface measurement (probe vertical) – O9611 .............................................. 6-2

Web/pocket measurement (probe vertical) – O9612 ....................................................... 6-5

XZ single surface measurement (probe horizontal) – O9811 .......................................... 6-8

Web/pocket measurement (probe horizontal) – O9812................................................. 6-11

Chapter 7 Additional cycles

Storing multi-stylus data (probe vertical) – O9630 .......................................................... 7-2

Loading multi-stylus data (probe vertical) – O9631 ......................................................... 7-4

Storing multi-stylus data (probe horizontal) – O9830 ...................................................... 7-6

Loading multi-stylus data (probe horizontal) – O9831 ..................................................... 7-8

Chapter 8 C-axis cycles

C-axis find (probe vertical) – O9650 ................................................................................ 8-2

C-axis find (probe horizontal) – O9850 ............................................................................ 8-4

Chapter 9 Alarms and error messages

General alarms ................................................................................................................ 9-2

Chapter 10 Settings, macros and variables

Customising the software .............................................................................................. 10-2

Editing the settings macro (O9524 or O9724) ........................................................ 10-2

Setting #33 .............................................................................................................. 10-3

Variable base number setting (#111 and #112) ..................................................... 10-3

Alarm settings (#110).............................................................................................. 10-3

Process alarms ....................................................................................................... 10-4

Work offset update tests ................................................................................................ 10-4

Publication No. H-2000-6021

Page 11

Contents v

Use of macro variables .................................................................................................. 10-4

Local variables ........................................................................................................ 10-4

Common variables .................................................................................................. 10-5

Common retained variables .................................................................................... 10-6

Chapter 11 General information

Tolerances ..................................................................................................................... 11-2

Experience values Ee .................................................................................................... 11-3

Reason for using this option ................................................................................... 11-3

Printing a macro output – an example ........................................................................... 11-3

Appendix A Features, cycles and limitations

Features of the Inspection software................................................................................. A-2

Cycles .............................................................................................................................. A-2

Limitations ........................................................................................................................ A-2

Appendix B Co-ordinate systems used on lathes

Example 1 Tool offset geometry ..................................................................................... B-2

Example 2 Using either G54 to G59 or G50 to define the component zero ................... B-3

G54 to G59 method .................................................................................................. B-3

G50 method setting a program shift to the turret reference position ........................ B-4

Example 3 Using G10 to define the component zero ..................................................... B-5

Example 4 Using either G92 or G50 to define the component zero-to-tool tip

position ......................................................................................................................... B-6

Publication No. H-2000-6021

Page 12

vi Contents

This page is intentionally left blank.

Publication No. H-2000-6021

Page 13

Before you begin 1

Before you begin

This programming manual contains detailed information on using the Inspection software

for programming, operating and controlling 2-axis lathes.

Comprising 11 self-contained chapters and two appendices, the manual is structured to

provide the information you require to use the Inspection software effectively.

Chapter 1, “Installing the software”, describes how to install the Inspection software

on your machine.

Chapter 2, “Optional inputs”, describes the optional inputs that are required by many

of the cycles.

Chapter 3, “Variable outputs”, lists the optional outputs that are produced by many

of the cycles.

Chapter 4, “Protected positioning cycles”, describes how to use the protected

positioning macros (O9610 and O9810). When correctly used, these macros

prevent damage to the stylus in the event of the probe colliding with the workpiece.

Chapter 5, “Calibrating the probe”, describes how to use the macros that are

provided for calibrating a probe. Cycles are provided for calibrating an inspection

probe when it is vertically mounted and horizontally mounted.

Chapter 6, “Standard measuring cycles”, describes how to use the non-vector

measuring cycles.

Chapter 7, “Additional cycles”, describes how to use the four macro cycles that are

not described in previous chapters.

Chapter 8, “C-axis cycles”, describes how to use two C-axis measuring cycles.

Chapter 9, “Alarms and error messages”, describes the macro alarm numbers and

messages that are displayed on the screen of the controller when an error occurs.

An explanation of the meaning and possible cause of each alarm message is

provided, together with typical actions you must take to correct the fault causing the

message.

Chapter 10, “Settings, macros and variables”, describes how to customise the

Inspection software on your machine. It also covers setting information and details

about the macro variables used in the software.

Chapter 11, “General information”, contains general information and reference

material that is relevant to the Inspection software package.

Publication No. H-2000-6021

Page 14

2 Before you begin

Measurement values used in this manual

Throughout this manual metric units of measurement (for example, millimetres) are used

in the examples. Where appropriate, the equivalent imperial values (for example, inches)

are shown in brackets.

Associated publications

When you are using the Inspection software, you may find it useful to refer to the following

Renishaw publications:

Installation manual Probe systems for machine tools (Renishaw part no.

H-2000-6040).

Data sheets Probe software for machine tools (Renishaw part nos. H-2000-2289

and H-2000-2298).

About the Inspection software

For a comprehensive description of the facilities provided by the Inspection software and

also the limitations of the software, refer to Appendix A, “Features, cycles and limitations”.

Software kit no. A-4012-0541

This kit comprises the following item:

CD assembly (one CD) – part no. A-4012-0480.

The CD contains the following data:

Probe horizontal cycles File1 (40121191)

Probe vertical cycles File2 (40121192)

C-axis cycles File3 (40121193)

ReadMe (N-4012-1194)

File1: Probe horizontal cycles

O9721 O9724 O9726 O9730 O9732 O9801 O9802

O9803 O9804 O9810 O9811 O9812 O9830 O9831

Publication No. H-2000-6021

Page 15

Before you begin 3

File2: Probe vertical cycles

O9521 O9524 O9526 O9530 O9532 O9601 O9602

O9603 O9604 O9610 O9611 O9612 O9630 O9631

File3: C-axis cycles

O9550 O9551 O9650 O9850

Macro memory requirements

This section lists the amount of memory (in kilobytes) that is required by all macros

contained on the software CD. Before you load macros, first calculate the total amount of

memory required by the macros you wish to load. Next, check that the machine controller

has sufficient memory capacity for these macros.

If memory capacity of the controller is stated in “metres of tape”, use the following data to

convert from kilobytes to length or vice-versa:

Conversion: 1 KB = 2.5 m (8.2 ft) of software tape.

8 KB = 20 m (65.6 ft) of software tape.

File1: total amount of memory = 16 KB.

File2: total amount of memory = 16 KB.

File3: total amount of memory = 6 KB.

Publication No. H-2000-6021

Page 16

4 Before you begin

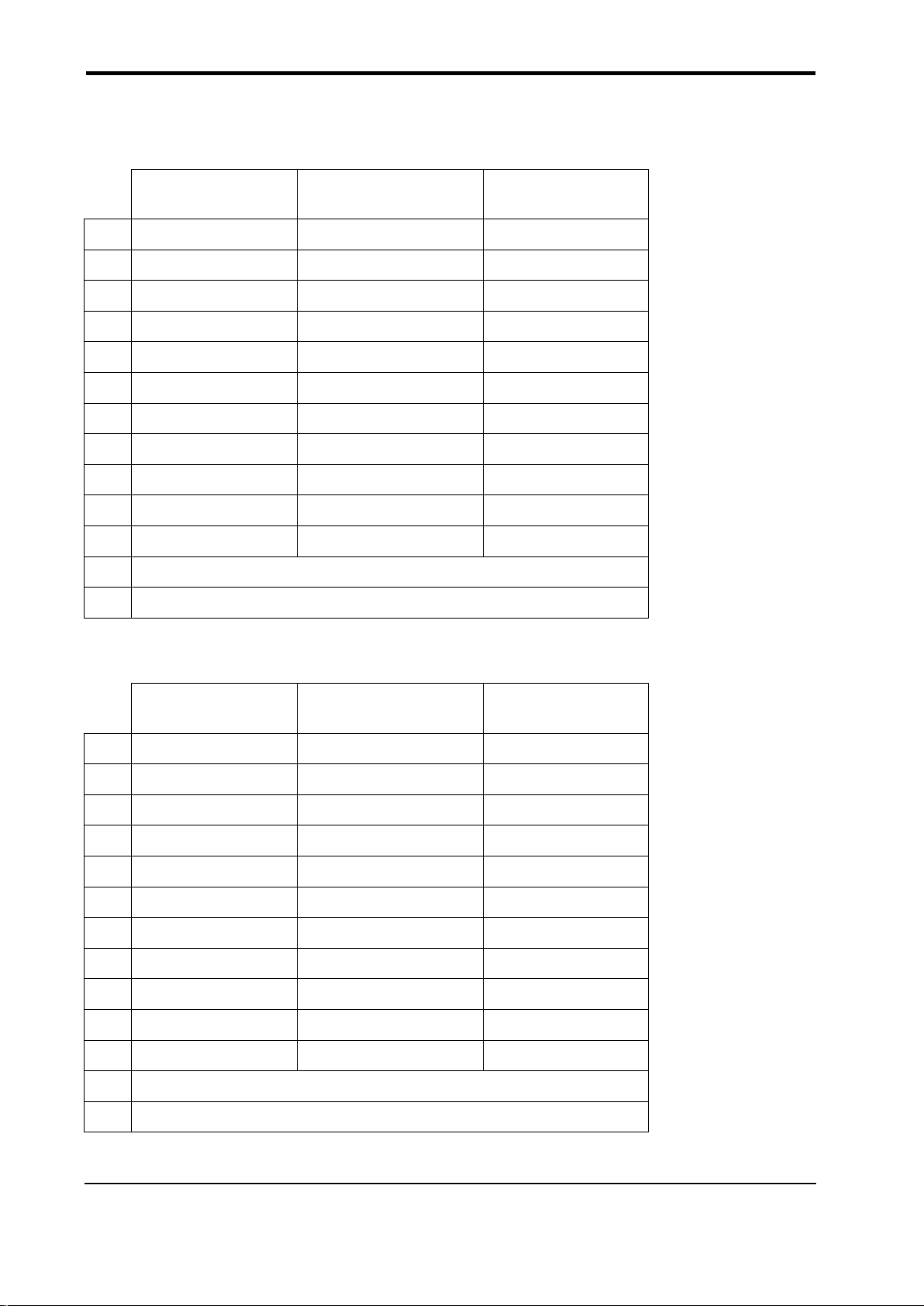

Macro numbers and functions

Macro No. Function

File 1

O9721 X diameter move

O9724 Settings macro

O9726 XZ basic move

O9730 Print macro

O9732 Offset update macro

O9801 Probe length calibration

O9802 Stylus offset (double-sided

calibration)

O9803 Stylus ball radius (double-

sided calibration)

O9804 Single-sided calibration

O9810 Protected positioning

O9811 XZ single surface measure

O9812 Web/pocket measure

O9830 Multi-stylus stor e

Macro No. Function

File 2

O9521 Z diameter move

O9524 Settings macro

O9526 XZ basic move

O9530 Print macro

O9532 Offset update macro

O9601 Probe length calibration

O9602 Stylus offset (double-sided

calibration)

O9603 Stylus ball radius (double-

sided calibration)

O9604 Single-sided calibration

O9610 Protected positioning

O9611 XZ single surface measure

O9612 Web/pocket measure

O9630 Multi-stylus stor e

O9831 Multi-stylus load

O9631 Multi-stylus load

File 3

O9550 C-axis basic move

O9551 C-axis offset update

O9650 C-axis measure – vertical

O9850 C-axis measure – horizontal

Publication No. H-2000-6021

Page 17

Before you begin 5

Measurement errors

When you fit your Renishaw probe into the machine’s shank/holder, the probe’s stylus

may not be in the correct theoretical position. An error may mean the stylus is either

above or below the centre line. Take care to minimise this error otherwise measurements

will be taken across a chord and will not be a true diametral or radial dimension.

The measuring cycles do not mathematically calculate on-centre errors. However, these

errors are usually small, particularly when the probe and stylus have been calibrated on a

diameter that is similar in size to the feature being measured. For a description of how to

calibrate a probe and stylus assembly, see Chapter 5, “Calibrating the probe”.

Renishaw customer services

Calling Renishaw

If you have a question about the software, first consult the documentation and other

information included with your product. If you cannot find a solution, you can receive

information on how to obtain customer support by contacting the Renishaw company that

serves your country (for worldwide contact details, see our main website at

www.renishaw.com/contact).

When you call, it will help the Renishaw support staff if you have the appropriate product

documentation at hand. Please be prepared to provide the following information (as

applicable):

The version of the product you are using (see the Equipment registration record

form).

The type of hardware that you are using (see the Equipment registration record

form).

The exact wording of any messages that appear on your screen.

A description of what happened and what you were doing when the problem

occurred.

A description of how you tried to solve the problem.

Publication No. H-2000-6021

Page 18

6 Before you begin

This page is intentionally left blank

Publication No. H-2000-6021

Page 19

Installing the software 1-1

Chapter 1

Installing the software

This chapter describes how to load the Inspection software. It supplements the

information described in the “Software installation” section of the installation manual titled

Probe systems for machine tools (Renishaw part no. H-2000-6040) and the Readme file

on the CD.

Contained in this chapter

Installing the software ...................................................................................................... 1-2

Using the wizard ....................................................................................................... 1-2

Editing macros manually ........................................................................................... 1-2

Setting and adjusting the software ................................................................................... 1-2

Publication No. H-2000-6021

Page 20

1-2 Installing the software

Installing t he software

Using the wizard

The Inspection software is supplied on CD. When the CD is inserted into the CD drive of

the PC, it automatically launches a wizard. The screen displays the following options:

Programming manual

Installation manual

Readme file

Generate macros

1. Click on Generate macros.

2. Enter appropriate values in the fields. Information is displayed to help you.

3. After you have completed all fields, click the Run button at the bottom of the screen.

The system will generate the macros that are required for your machine set-up. The

macros are stored on your PC in the folder and file that is shown above the Run

button.

The macros can now be loaded into the machine.

Editing macros manually

If, for any reason, the wizard does not work, you will need to edit the macros manually to

suit your machine. Do this as follows:

1. From your PC, explore the CD and locate the folder named Macros.

2. Open the Macros folder and locate a file named Macros.

3. Select the files appropriate to your machine (probe vertical or probe horizontal

and/or C axis) and copy them to your PC.

4. Either edit these files on your PC or load them into your machine and edit them

there.

Setting and adj usting the software

After installing the software, you will need to customise the settings. Chapter 10, “Settings,

macros and variables”, describes general software settings, customising the software,

and how to configure the option settings.

Publication No. H-2000-6021

Page 21

Optional inputs 2-1

Chapter 2

Optional inputs

Many of the macros make use of standard optional inputs. Instead of describing them

each time they are required, they are described once in this chapter. You will be referred

to this chapter from other chapters whenever a standard optional input is required.

Details of each non-standard optional input that is required by a macro is provided in the

relevant macro description.

Contained in this chapter

Optional inputs ................................................................................................................. 2-2

Publication No. H-2000-6021

Page 22

2-2 Optional inputs

Optional inputs

The examples given below assume that the controller has been configured for metric

values (millimetres). The equivalent inch measurement values are shown in brackets.

Ee e = Experience value.

Ff f = This can be either one of the following:

Specify the number of a spare tool offset where an adjustment value to

the measured size is stored (see Chapter 11, “General information”).

Example: E21. causes the experience value stored in tool offset 21 to be

applied to the measured size.

1. The percentage feedback that is used when updating a tool offset

(see Chapter 10, “Settings, macros and variables”).

Enter a value between 0 and 1 (0% and 100%).

Default: 1 (100%).

2. The feedrate that is used in protected positioning macros O9610 and

O9810 (see Chapter 4, “Protected positioning cycles”).

Example: F3000 sets a feedrate of 3000 mm/min.

(F120 sets a feedrate of 120 in/min.)

Hh h = The tolerance value of a feature dimension being measured.

Example: For dimension 50.0 mm +0.4 mm –0 mm, the nominal

tolerance is 50.2 mm with H.2.

(For dimension 1.968 in +0.016 in –0 in, the nominal

tolerance is 1.976 in with H.008.)

Mm m = The true position tolerance of a feature. This is a cylindrical zone about

the theoretical position.

Example: M.1 sets a true position tolerance of 0.1 mm.

(M.004 sets a true position tolerance of 0.004 in.)

Qq q = This is the probe overtravel distance for use when the default values are

unsuitable. The probe will then travel beyond the expected position when

it searches for a surface.

Default: 4 mm (0.16 in) in the Z axis

10 mm (0.394 in) in the X axis.

Example: Q8. sets an overtravel distance of 8 mm.

(Q.3 sets an overtravel distance of 0.3 in.)

Publication No. H-2000-6021

Page 23

Optional inputs 2-3

Rr r = This is an incremental dimension that is used on external features, such

as bosses and webs, to give a radial clearance from the nominal target

surface prior to a Z-axis move.

Default: 5 mm (0.200 in).

Example: R10. sets a radial clearance of 10 mm.

(R.4 sets a radial clearance of 0.4 in.)

R–r –r = This is similar to Rr, except that the clearance is applied in the opposite

direction to force an internal boss or web cycle.

Default: 5 mm (0.200 in).

Example: R–10.sets a radial clearance of –10 mm.

(R–.4 sets a radial clearance of –0.4 in.)

Ss s = The number of the work offset to be updated.

S0 The external work offset.

S1 to S6 G54 to G59.

S7 Update G10P0XZ.

S8 The incremental G50W- - move will be active until another

G50 is read.

Example: S3 will set G56

Tt t = The tool offset that is to be updated.

T<1000 The X wear or Z wear will be updated.

T>1000 The radius wear of a milling tool will be updated.

Example: T1 = update the X-wear or Z-wear compensation.

T1001 = update the R-wear compensation.

Uu u = Upper tolerance limit.

If this value is exceeded, no tool offset or work offset is updated and the

cycle stops with an alarm. Where applicable, this tolerance applies to both

size and position.

Example: U2. to set the upper tolerance limit to 2 mm.

(U.08 to set the upper tolerance limit to 0.08 in.)

Vv v = Null band.

This is the tolerance zone where no tool offset adjustment occurs.

Default: 0.

Example: V.5 for a tolerance zone of ±0.5 mm.

(V.02 for a tolerance zone of ±0.02 in.)

Publication No. H-2000-6021

Page 24

2-4 Optional inputs

Ww w = Print the output data.

W1. Increment the feature number only.

W2. Increment the component number and reset the feature number.

Example: W1.

Publication No. H-2000-6021

Page 25

Variable outputs 3-1

Chapter 3

Variable outputs

This chapter lists the variable outputs that may be produced by some of the macros. You

will be referred to this chapter from other chapters when a variable output is produced.

Contained in this chapter

Table 1 Variable outputs with probe vertical .................................................................... 3-2

Table 2 Variable outputs with probe horizontal ................................................................ 3-2

Publication No. H-2000-6021

Page 26

3-2 Variable outputs

Table 1 Variable outputs with probe vertical

#135 X position X position

#137 Z position Z position

#138 Size Size

#139 C position

#140 X error X error

#142 Z error Z error

#143 Size error Size error

#144 C error

#145 True position error True position error

#146 Metal condition Metal condition

#147 Direction indicator Direction indicator

#148 Out of tolerance flag

#149 Probe error flag

Single surface

G65P9611

Web/pocket diameter

G65P9612

C-axis measure

G65P9650

Table 2 Variable outputs with probe horizontal

#135 X position X position

#137 Z position Z position

#138 Size Size

#139 C position

#140 X error X error

#142 Z error Z error

#143 Size error Size error

#144 C error

#145 True position error True position error

#146 Metal condition Metal condition

#147 Direction indicator Direction indicator

#148 Out of tolerance flag

Single surface

G65P9811

Web/pocket diameter

G65P9812

C-axis measure

G65P9850

#149 Probe error flag

Publication No. H-2000-6021

Page 27

Protected positioning cycles 4-1

Chapter 4

Protected positioning cycles

As the probe moves around the workpiece it is important that the stylus is protected

against a collision with the workpiece. This chapter describes how to use the protected

positioning cycles. After they are set correctly, the probe will stop moving in the event of a

collision.

Contained in this chapter

Probe protected positioning (probe vertical) – O9610 ..................................................... 4-2

Probe protected positioning (probe horizontal) – O9810 ................................................. 4-4

Publication No. H-2000-6021

Page 28

4-2 Protected positioning cycles (probe vertical)

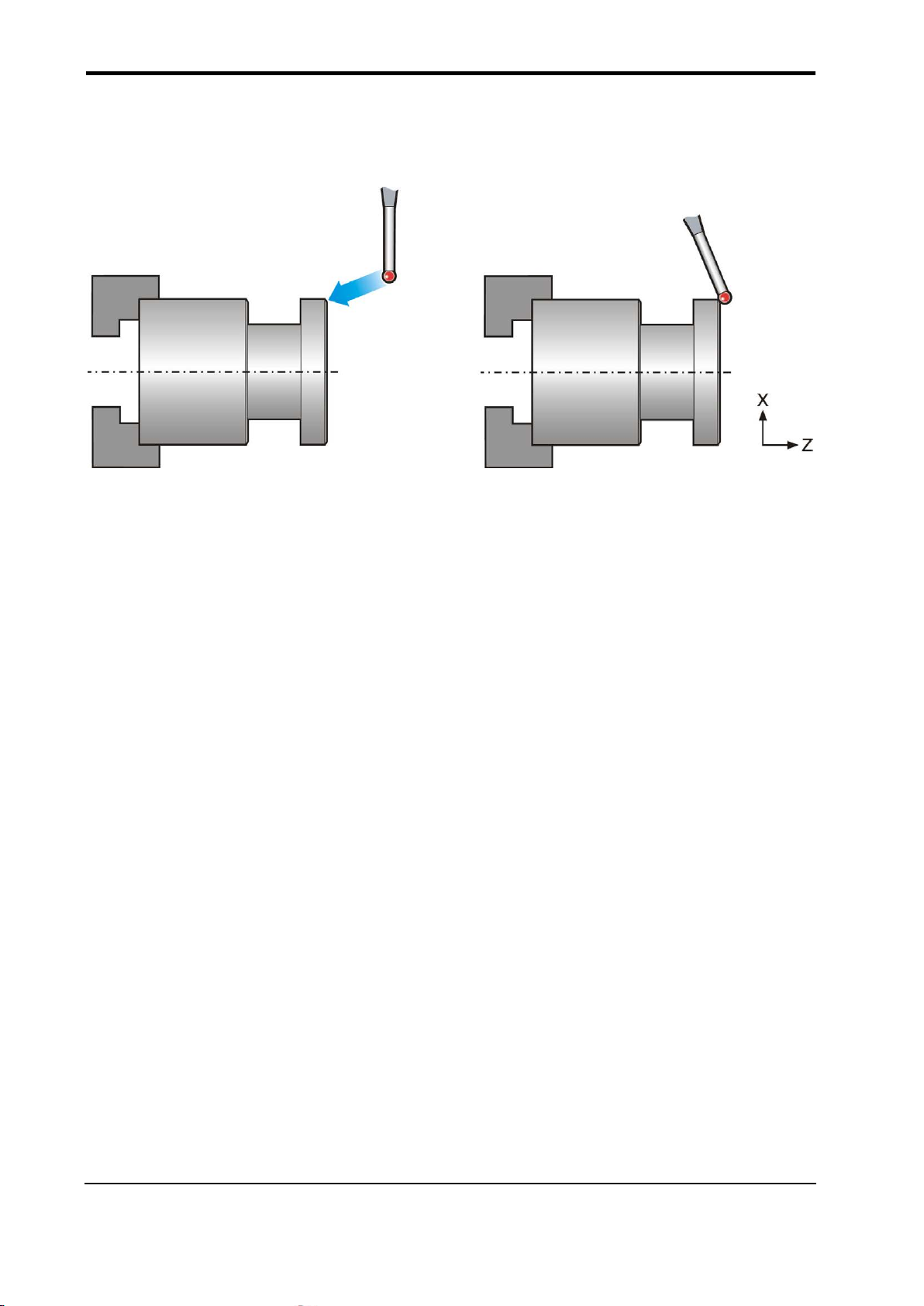

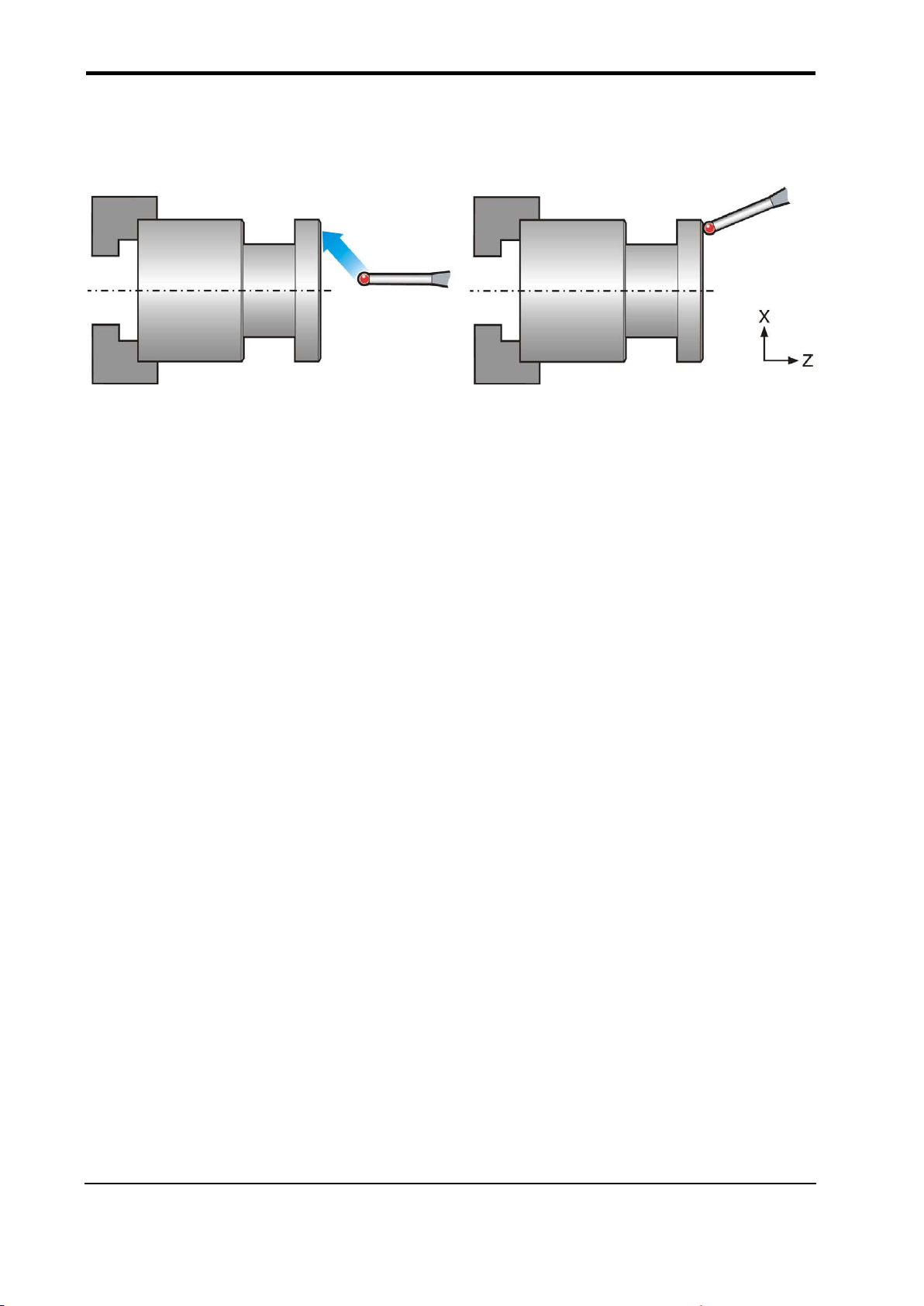

Probe protect ed positioning (probe vertical) – O9610

Figure 4.1 Probe pro tected positioning (probe vertical)

Description

It is important to protect the probe’s stylus against damage should it collide with an

obstacle as the probe moves around the workpiece. When this cycle is used, the machine

will stop in the event of a collision.

Application

The probe is selected and moved to a safe plane. At this point the probe is made active. It

then moves to a measuring position using this macro call.

In the event of a collision the machine will stop. Either a PATH OBSTRUCTED alarm is

generated or error flag #148 is set (see the Mm input).

Format

G65 P9610 Xx and/or Zz [ Ff Mm ]

where [ ] denote optional inputs.

Example: G65 P9610 Z10. F3000. M1.

Publication No. H-2000-6021

Page 29

Protected positioning cycles (probe vertical) 4-3

Xx

x =

The target diameter position for the probe positioning move.

and/or

Zz

z =

The target position for the probe positioning move.

#148 = 7 Probe triggered.

Proprietary G and M codes.

T???

Select the probe.

M??

Switch on the probe.

G65P9610Z-10.X30.F3000

Protected positioning move.

G65P9611X20.T3.

Single surface measure.

M??

Switch off the probe.

Compulsory inputs

Optional inputs

Ff f = The modal feedrate for all protected positioning moves.

The feedrate will be modal to this macro and subsequent feedrate

calls are unnecessary unless a change of feedrate is required. The

maximum safe fast feedrate established during installation must not

be exceeded.

M1. This will set a probe trigger flag (but with no PATH OBSTRUCTED

alarm).

Example

#148 = 0 No probe trigger.

Publication No. H-2000-6021

Page 30

4-4 Protected positioning cycles (probe horizontal)

Xx

x =

The target diameter position for the probe positioning move.

and/or

Zz

z =

The target position for the probe positioning move.

Probe protect ed positioning (probe horizontal) – O9810

Figure 4.2 Probe pro tected positioning (probe horizontal)

Description

It is important to protect the probe’s stylus against damage should it collide with an

obstacle as the probe moves around the workpiece. When this cycle is used, the machine

will stop in the event of a collision.

Application

The probe is selected and moved to a safe plane. At this point the probe is made active. It

then moves to a measuring position using this macro call.

In the event of a collision, the machine will stop. Either a PATH OBSTRUCTED alarm is

generated or error flag #148 is set (see the Mm input).

Format

G65 P9810 Xx and/or Zz [ Ff Mm ]

where [ ] denote optional inputs.

Example: G65 P9810 Z10. F3000. M1.

Compulsory inputs

Publication No. H-2000-6021

Page 31

Protected positioning cycles (probe horizontal) 4-5

be exceeded.

#148 = 7 Probe triggered.

Optional inputs

Ff f = The modal feedrate for all protected positioning moves.

The feedrate will be modal to this macro and subsequent feedrate

calls are unnecessary unless a change of feedrate is required. The

maximum safe fast feedrate established during installation must not

M1. This will set a probe trigger flag (but with no PATH OBSTRUCTED

alarm).

#148 = 0 No probe trigger.

Example

Proprietary G and M codes.

T??? Select the probe.

M?? Switch on the probe.

G65P9810X30.Z-10.F3000 Protected positioning move.

G65P9811X20.T8 Single surface measure.

M?? Switch off the probe.

Publication No. H-2000-6021

Page 32

4-6 Protected positioning cycles (probe horizontal)

This page is intentionally left blank.

Publication No. H-2000-6021

Page 33

Calibrating the probe 5-1

Chapter 5

Calibrating the probe

Before a probe and stylus are used, they must be calibrated correctly. Only when they

have been calibrated acc urately can you achieve total qualit y control ov er your

manufacturing process.

This chapter explains why it is so important that the probe and stylus are calibrated and

then describes how to use the macros that are provided to calibrate them.

Contained in this chapter

Why calibrate a probe and stylus? ................................................................................... 5-2

Single-sided calibration .................................................................................................... 5-2

Double-sided calibration .................................................................................................. 5-3

Calibrating the probe length ............................................................................................. 5-3

Calibration cycles ............................................................................................................. 5-3

Calibrating the probe length (probe vertical) – O9601..................................................... 5-5

Calibrating the stylus Z tool offset double-sided (probe vertical) – O9602 ...................... 5-7

Calibrating the stylus ball radius double-sided (probe vertical) – O9603 ........................ 5-9

Calibrating the stylus single-sided (probe vertical) – O9604 ......................................... 5-11

Calibrating the probe length (probe horizontal) – O9801 .............................................. 5-13

Calibrating the stylus X tool offset double-sided (probe horizontal) – O9802 ............... 5-15

Calibrating the stylus ball radius double-sided (probe horizontal) – O9803 .................. 5-17

Calibrating the stylus single-sided (probe horizontal) – O9804 ..................................... 5-19

Publication No. H-2000-6021

Page 34

5-2 Calibrating the probe

Why calibrate a pro b e and stylus?

When you fit a probe into the machine’s shank/holder it is not necessary for the probe’s

stylus to run true to the spindle centre line. A small amount of run-out can be tolerated.

However, it is good practice to mechanically adjust the stylus so that it is true to the

virtual Y axis. This helps reduce the effects of cosine errors when measuring different

sizes.

Calibrating the probe and stylus ensures that run-out is automatically accounted for.

Without calibration, run-out will lead to inaccurate results.

It is important that you calibrate the stylus of a Renishaw inspection probe in the following

circumstances:

When a probe and stylus are to be used for the first time.

When a new stylus is fitted to the probe.

When it is suspected that the stylus has become distorted or that the probe has

crashed.

At regular intervals to compensate for mechanical changes of your lathe.

Three different operations are used to calibrate a stylus. They are:

Calibrating single-sided.

Calibrating double-sided.

Calibrating the probe length.

Single-sided calibration

Single-sided calibration determines the error value for the stylus ball in relation to a

known surface. This value is stored in the tool wear offset and is used automatically in the

measuring cycles.

NOTE: Only one edge of the stylus is calibrated. Therefore, all subsequent measuring

cycles must use only this calibrated edge.

Publication No. H-2000-6021

Page 35

Calibrating the probe 5-3

Double-sided calibration

Double-sided calibration determines the stylus offset and the radius of the stylus ball. The

offset is stored in the tool wear offset while the radius is stored in a macro variable. Both

values are used automatically in the measuring cycles.

NOTE: Both edges of the stylus are calibrated. Therefore, measuring cycles that use

both sides of the stylus can be used.

Calibrating the probe length

Calibrating a probe on a known reference surface determines the length of the probe,

based on the electronic trigger point. The stored value for length is different from the

physical length of the probe assembly.

Additionally, the operation can automatically compensate for machine and fixture height

errors by adjusting the length value of the probe that is stored.

Calibration cycles

Eight calibration cycles are provided with the Inspection software. Four are for calibrating

a probe positioned vertically and four are for calibrating a probe positioned horizontally.

They may be used in conjunction with one another for complete calibration of the probe.

The purpose of each macro is summarised below.

Macros O9601 and O9801 Used to establish the length of the probe in the tool

Macros O9602 and O9802 Used to establish the stylus offset (for double-sided

Macros O9603 and O9803 Used to establish the radius values of the stylus ball (for

Macros O9604 and O9804 Used to establish the error value of the st ylus ball (for

shank.

calibration only).

double-sided calibration only).

single-sided calibration only).

For complete calibration of a probe system, use the macros as follows:

For double-sided calibration of a vertica ll y mounted probe, use macros O9601,

O9602 and O9603.

For double-sided calibration of a horizontally-mounted probe, use macros O9801,

O9802 and O9803.

Publication No. H-2000-6021

Page 36

5-4 Calibrating the probe

For single-sided calibration of a vertically mounted probe, use macros O9601 and

O9604.

For single-sided calibration of a horizontally-mounted probe, use macros O9801

and O9804.

The Renishaw calibration cycles are split into separate cycles for flexibility.

Publication No. H-2000-6021

Page 37

Calibrating the probe (probe vertical) 5-5

Tt

Calibrating the probe length (probe vertical) – O9601

Tool offset

Xx

reference

size

Figure 5.1 Calibrating the probe length (probe vertical)

Description

The probe is positioned adjacent to an X-axis reference surface. When the calibration

cycle is completed the active tool offset is adjusted to the reference surface.

Application

An approximate tool offset is loaded. The probe is positioned adjacent to the reference

surface.

When the cycle is run, the surface is measured and the tool offset is reset to a new value.

The probe is then returned to the start position.

Format

G65 P9601 Xx Tt

Example: G65 P9601 X50. T20

Publication No. H-2000-6021

Page 38

5-6 Calibrating the probe (probe vertical)

Tt

t =

The active tool offset number.

Xx

x =

The size of the reference surface.

O0001

Proprietary G and M codes

T0101

Select the probe.

M??

Switch on the probe.

G65P9610X60.F3000

Protected positioning move.

G65P9601X50.T1

Calibrate in the X direction and update tool offset 1.

G65P9610X100.

Protected positioning move.

M??

Switch off the probe.

Compulsory inputs

Outputs

The active tool offset is set.

Example: Probe length calibration

Publication No. H-2000-6021

Page 39

Calibrating the probe (probe vertical) 5-7

Tt

t =

The tool offset number that will be updated.

Zz

x =

The nominal size of the feature.

A

B

Calibrating the stylus Z tool offset double-sided (probe vertical) – O9602

Figure 5.2 Calibrating the stylus Z tool offset

double-sided (probe vertical)

Description

Before the cycle is run, the probe is positioned either above a pre-machined web (A) or

inside a pre-machined groove (B). When the cycle is completed, the tool offset is set to

the centre of the stylus in the Z axis.

Application

Pre-machine either a web or a groove with a suitable tool so that the exact centre of the

feature is known. Position the probe to the centre of the web or groove.

When the cycle is run, two measuring moves are made to determine the Z offset of the

stylus. The probe is then returned to the start position.

Format

G65 P9602 Zz Tt [ Rr Xx ]

where [ ] denote optional inputs.

Example: G65 P9602 Z50.005 T8. X50.

Compulsory inputs

Publication No. H-2000-6021

Page 40

5-8 Calibrating the probe (probe vertical)

feature. If this is omitted, a groove cycle is assumed.

O0002

T0101

Select the probe.

M??

Switch on the probe.

G54

Select the work offset.

G65P9610Z-20.F3000

Protected positioning move over the groove.

G65P9610X20.

Protected positioning move into the groove.

G65P9602Z50.T1

Calibrate in a 50 mm (1.97 in) groove and update tool offset 1.

G65P9610X100.

Protected positioning move retract to 100 mm (3.94 in).

M??

Switch off the probe.

M30

End of the program.

Optional input

Xx x = The absolute X-axis measuring position when calibrating on an external

For the Rr optional input, see Chapter 2, "Optional inputs".

Outputs

The Z tool offset will be updated to the centre of the stylus.

Example: Calibrating the stylus Z offset

Run a complete positioning and calibration program as follows.

Set the exact X and Z feature positions in a work offset (for example, using G54).

Publication No. H-2000-6021

Page 41

Calibrating the probe (probe vertical) 5-9

Zz

z =

The nominal size of the reference web or groove.

A

B

Calibrating the stylus ball radius double-sided (probe vertical) – O9603

Figure 5.3 Calibrating the stylus ball radius

double-sided (probe vertical)

Description

Before the cycle is run, the probe is positioned either a bov e a pre-machined web (A) or

inside a pre-machined groove (B). When the cycle is completed, the radius values of the

stylus ball are stored.

Application

The probe to be calibrated is positioned either above the web or inside the groove of

known size. The position of the web or groove is not critical.

When the cycle is run, two moves are made to determine the radius values of the stylus

ball. The probe is then returned to the start position.

Format

G65 P9603 Zz [ Rr Xx ]

where [ ] denote optional inputs.

Example: G65 P9603 Z50.005 X50.

Compulsory input

Publication No. H-2000-6021

Page 42

5-10 Calibrating the probe (probe vertical)

feature. If this is omitted, a groove cycle is assumed.

O0004

T0101

Select the probe.

G54

Select the work offset.

M??

Switch on the probe.

G65P9610Z-20.F3000

Protected positioning move over the groove.

G65P9610X20.

Protected positioning move into the groove.

G65P9603Z15.001

Calibrate in a 15.001 mm (0.5905 in) groove.

G65P9610X100.

Protected positioning move retract to 100 mm (3.94 in).

M??

Switch off the probe.

M30

End of the program.

Optional input

Xx x = The absolute X-axis measuring position when calibrating on an external

For the Rr optional input, see Chapter 2, "Optional inputs".

Outputs

The following data will be stored:

#503 Stylus ball radius in Z.

NOTE: The actual variable is dependent on #112 that is set in O9724.

Example: Calibrating the radius of a stylus ball

Run a complete positioning and calibration program as follows.

Set the approximate X and Z feature positions in a work offset (for example, using G54).

Publication No. H-2000-6021

Page 43

Calibrating the probe (probe vertical) 5-11

A

B

OR

Calibrating the stylus single-sided (probe vertical) – O9604

NOTE: When this method is used for calibrating a stylus, only the calibrated edge of the

stylus must be used in subsequent measuring cycles.

Figure 5.4 Calibrating the stylus single-sided (probe vertical)

Description

Before the cycle is run, the probe is positioned adjacent to a Z axis reference surface.

When the cycle is completed, the active probe tool offset is adjusted to the reference

surface.

Application

An approximate tool offset is loaded. The probe is positioned adjacent to the reference

surface.

When the cycle is run, the surface is measured and the tool offset is reset to a new value.

The probe is then returned to the start position.

Format

G65 P9604 Zz Tt

Example: G65 P9604 Z0. T1.

Compulsory inputs

Tt t = The active tool offset number.

Zz z = The position of the reference surface.

Publication No. H-2000-6021

Page 44

5-12 Calibrating the probe (probe vertical)

O0002

T0101

Select the probe.

M??

Switch on the probe.

G54

Select the work offset.

G65P9610Z10.F3000

Protected positioning move.

G65P9610X20.

Protected positioning move.

G65P9604Z0.T1

Calibrate in the Z direction and update tool offset 1.

G65P9610X100.

Protected positioning move retract to 100 mm (3.94 in).

M??

Switch off the probe.

M30

End of the program.

Outputs

The Z tool offset will be updated to the edge of the stylus.

Example: Calibrating a stylus edge

Run a complete positioning and calibration program as follows.

Set the exact X and Z feature positions in a work offset (for example, using G54).

Publication No. H-2000-6021

Page 45

Calibrating the probe (probe horizontal) 5-13

Tt tool offset

Zz reference height

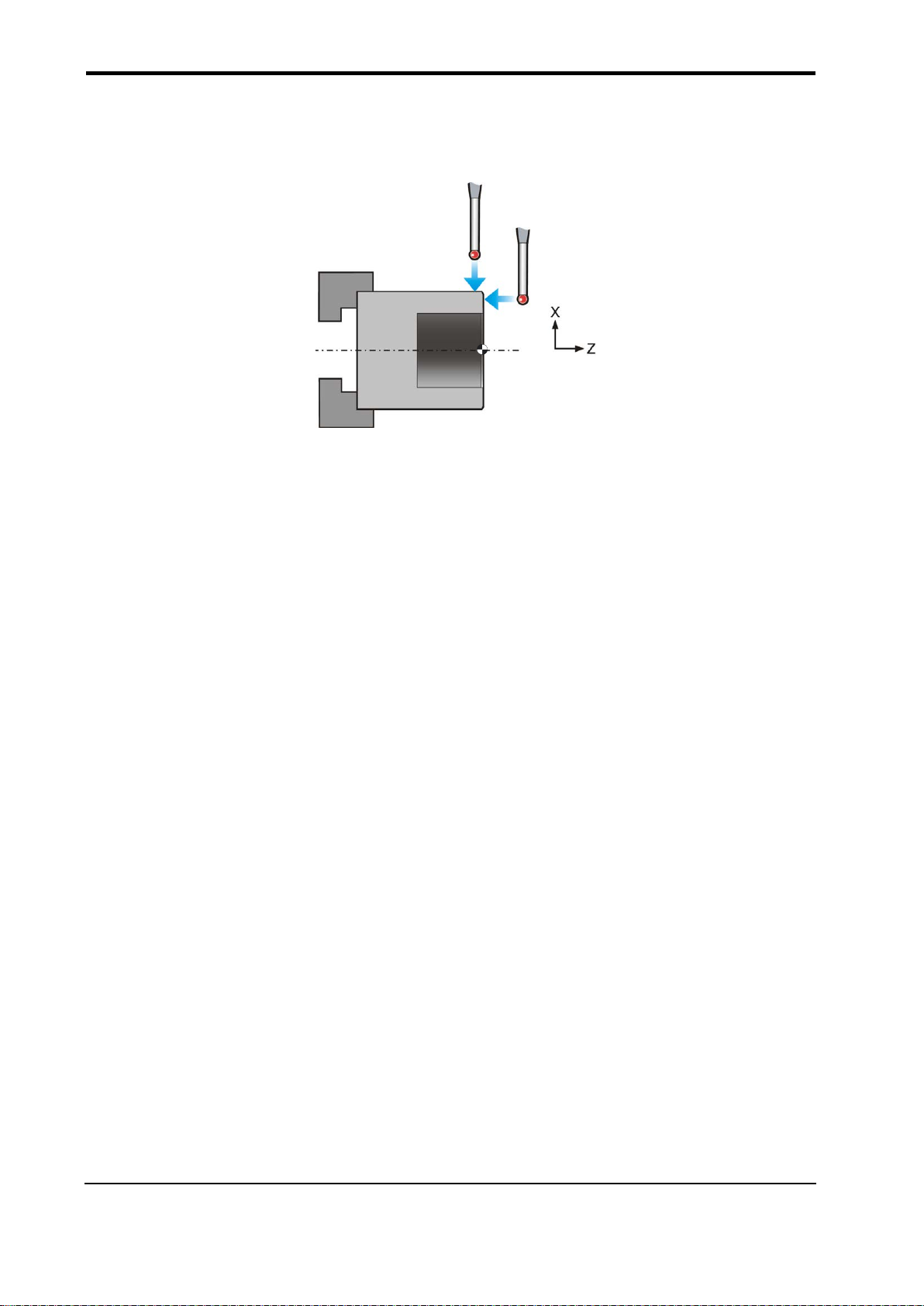

Calibrating the probe length (probe horizontal) – O9801

Figure 5.5 Calibrating the probe length

(probe horizontal)

Description

The probe is positioned adjacent to a Z-axis reference surface for calibration. When the

cycle is completed, the active probe tool offset is adjusted to the reference surface.

Application

An approximate tool offset is loaded. The probe should be positioned adjacent to the

reference surface.

When the cycle is run, the surface is measured and the tool offset is reset to a new value.

The probe is then returned to the start position.

Format

G65 P9801 Zz Tt

Example: G65 P9801 Z–10. T20

Publication No. H-2000-6021

Compulsory inputs

Tt t = The active tool offset number.

Zz z = The position of the reference surface.

Page 46

5-14 Calibrating the probe (probe horizontal)

O0001

T0101

Select the probe.

G54

Select the work offset.

M??

Switch on the probe.

G65P9810Z10.F3000

Protected positioning move.

G65P9801Z-10.T1

Calibrate in the Z direction and update tool offset 1.

G65P9810Z100.

Protected positioning move.

M??

Switch off the probe.

M30

End of the program.

Outputs

The active tool offset is set.

Example: Probe length calibration

Publication No. H-2000-6021

Page 47

Calibrating the probe (probe horizontal) 5-15

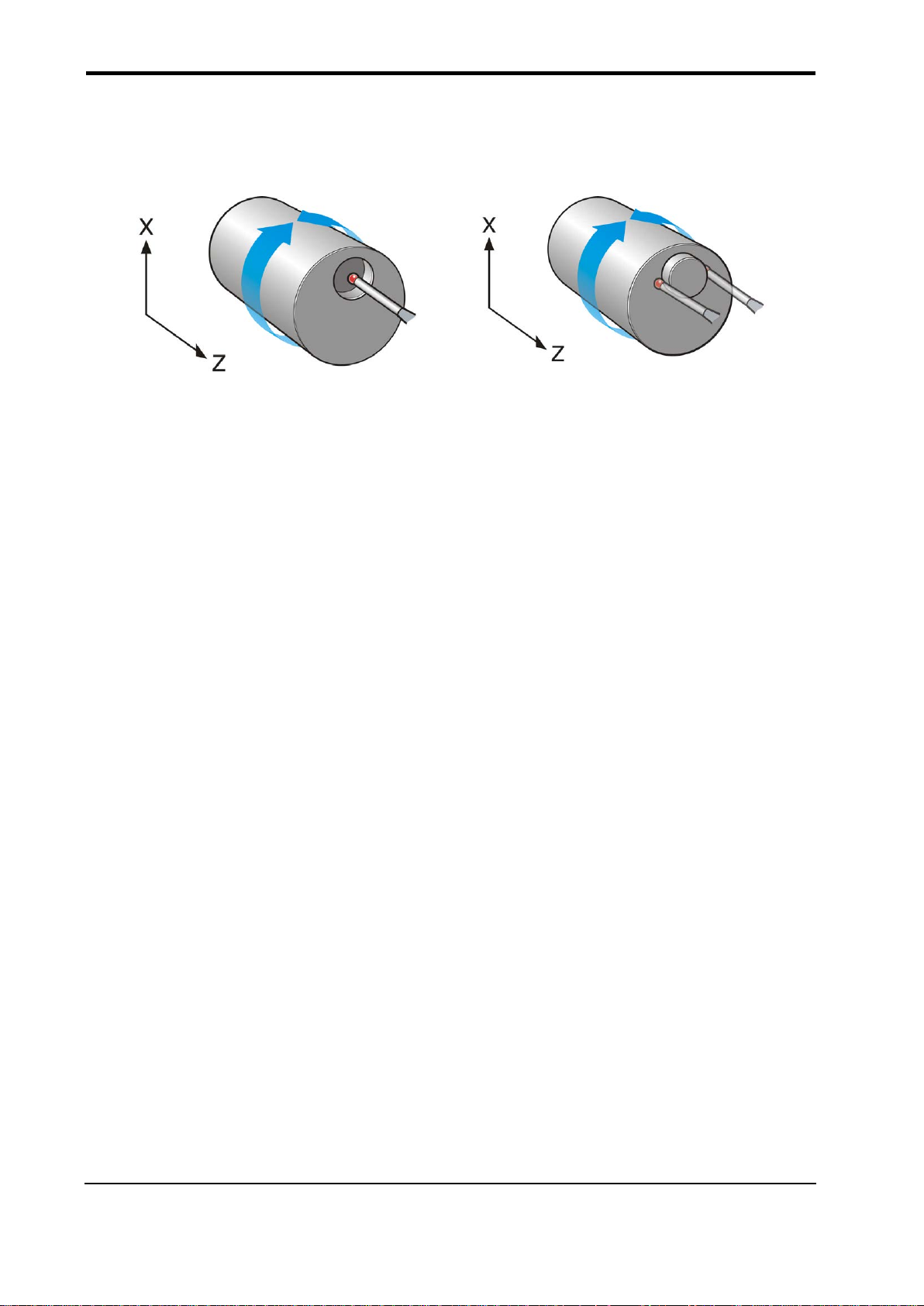

Calibrating the stylus X tool offset double-sided (probe horizontal) – O9802

Figure 5.6 Calibrating the stylus X tool o ffset

double-sided (probe horizontal)

Description

Before the cycle is run, the probe is positioned in front of the diameter (A) or inside the

bore (B). When this cycle is completed, the centre of the stylus is updated to the tool

offset.

Application

Pre-machine either a hole with a suitable boring bar or a diameter with a turning tool.

Position the probe as described above.

When the cycle is run, two measuring moves are made to determine the X offset of the

stylus. The probe is then returned to the start position.

Format

G65 P9802 Xx Tt [ Rr Zz ]

where [ ] denote opti ona l i nputs.

Example: G65 P9802 X50.005 T8. Z50.

Publication No. H-2000-6021

Page 48

5-16 Calibrating the probe (probe horizontal)

Tt

t =

The tool offset number that will be updated.

Xx

x =

The nominal size of the feature.

feature. If this is omitted, a bore cycle is assumed.

O0002

T0101

Select the probe.

M??

Switch on the probe.

G65P9810X0.Z10.F3000

Protected positioning move over the hole.

G65P9810Z–5.

Protected positioning move into the hole.

update tool offset 1.

G65P9810Z100.

Protected positioning move retract to 100 mm (3.94 in).

M??

Switch off the probe.

M30

End of the program.

Compulsory inputs

Optional input

Zz z = The absolute Z-axis measuring position when calibrating on an external

For the Rr optional input, see Chapter 2, "Optional inputs".

Outputs

The X tool offset will be updated to the centre of the stylus.

Example: Calibrating the stylus X offset

Run a complete positioning and calibration program as follows.

Set the exact X and Z feature positions in a work offset (for example, using G54).

G65P9802X50.T1 Calibrate in a 50 mm (1.97 in) diameter bored hole and

Publication No. H-2000-6021

Page 49

Calibrating the probe (probe horizontal) 5-17

Calibrating the stylus ball radius double-sided (probe horizontal) – O9803

Figure 5.7 Calibrating the stylus ball radius

double-sided (probe horizontal)

Description

Before the cycle is run, the probe is positioned either in front of the diameter (A) or inside

the bore (B). When the cycle is completed, the stylus centre is updated to the tool offset.

Application

Pre-machine either a hole with a suitable boring bar or a diameter with a turning tool.

Position the probe as described above.

When the cycle is run, two measuring moves are made to determine the X radius values

of the stylus ball. The probe is then returned to the start position.

Format

G65 P9803 Xx [ Rr Zz ]

where [ ] denote optional inputs.

Example: G65 P9803 X50.005 Z50.

Publication No. H-2000-6021

Page 50

5-18 Calibrating the probe (probe horizontal)

Xx

x =

The nominal size of the feature.

feature. If this is omitted, a ring gauge cycle is assumed.

O0004

T0101

Select the probe.

M??

Switch on the probe.

G65P9810X0.Z10.F3000

Protected positioning move over the hole.

G65P9810Z–5.

Protected positioning move into the hole.

G65P9803X50.001

Calibrate in a 50.001 mm (1.9685 in) diameter ring gauge.

G65P9810Z100.

Protected positioning move retract to 100 mm (3.94 in).

M??

Switch off the probe.

M30

End of the program.

Compulsory input

Optional input

Zz z = The absolute Z-axis measuring position when calibrating on an external

For the Rr optional input, see Chapter 2, "Optional inputs".

Outputs

The following data will be stored:

#500 Stylus ball radius in X (XRAD)

NOTE: The actual variable is dependent on #111 that is set in O9724.

Example: Calibrating the radius of a stylus ball

Run a complete positioning and calibration program as follows.

Set the approximate X and Z feature positions in a work offset (for example, using G54).

Publication No. H-2000-6021

Page 51

Calibrating the probe (probe horizontal) 5-19

Tt

t =

The active tool offset number.

OR

Calibrating the stylus single-sided (probe horizontal) – O9804

NOTE: When this method is used for calibrating a stylus, only the calibrated edge of the

stylus must be used in subsequent measuring cycles.

Figure 5.8 Calibrating the stylus single-sided (probe horizontal)

Description

Before the cycle is run, the probe is positioned either above a diameter (A) or inside a

diameter (B). When the cycle is completed, the edge of the stylus is updated to the tool

offset.

Application

Pre-machine either a hole with a suitable boring bar or a diameter with a turning tool.

Position the probe as described above and run the cycle.

When the cycle is run, a measuring move is made to determine the X offset of the stylus.

The probe is then returned to the start position.

Format

G65 P9804 Xx Tt

Example: G65 P9804 X50.005 T8.

Publication No. H-2000-6021

Compulsory inputs

Xx x = The nominal diameter of the feature.

Page 52

5-20 Calibrating the probe (probe horizontal)

O0002

T0808

Select the probe.

M??

Switch on the probe.

G65P9810X50.Z-6.F3000

Protected positioning move over the hole.

tool offset 8.

G65P9810Z100.

Protected positioning move retract to 100 mm (3.94 in).

M??

Switch off the probe.

M30

End of the program.

Outputs

The X tool offset will be updated to the edge of the stylus.

Example: Single-sided stylus calibration

Run a complete positioning and calibration program as follows.

Set the exact X and Z feature positions in a work offset (for example, using G54).

G65P9804X40.T8 Calibrate against a 40 mm (1.57 in) diameter and update

Publication No. H-2000-6021

Page 53

Standard measuring cycles 6-1

Chapter 6

Standard measuring cycles

This chapter describes how to use the non-vector measuring cycles with verticallymounted and horizontally-mounted probes.

Contained in this chapter

XZ single surface measurement (probe vertical) – O9611 .............................................. 6-2

Web/pocket measurement (probe vertical) – O9612 ....................................................... 6-5

XZ single surface measurement (probe horizontal) – O9811 .......................................... 6-8

Web/pocket measurement (probe horizontal) – O9812 ................................................. 6-11

Publication No. H-2000-6021

Page 54

6-2 Standard measuring cycles (probe vertical)

Xx

x =

The size of the target surface.

or

Zz

z =

The position of the target surface.

XZ single surface measurement (probe vertical) – O9611

Figure 6.1 Measurement of a single surface (probe vertical)

Description

This cycle measures a surface to establish the size or position.

Application

The probe, with its tool offset active, should be positioned adjacent to the surface. The

cycle measures the surface and returns to the start position.

There are two possibilities, as follows:

1. The surface can be treated as a size, where the tool offset is updated in conjunction

with the Tt and the Hh input.

2. The surface can be treated as a reference surface position, for the purpose of

adjusting a work offset using the Ss and Mm inputs.

Format

G65 P9611 Xx or Zz [ Cc Ee Ff Hh Ii Qq Ss Tt Uu Vv Ww ]

where [ ] denote optional inputs.

Example: G65 P9611 X50. C1. E90. F0.8 H0.2 I0.5 Q10. S1. T20. U.5 V.5 W2.

Compulsory inputs

Publication No. H-2000-6021

Page 55

Standard measuring cycles (probe vertical) 6-3

Cc

c = 1.

Takes the error from the reference diameter and stores it in #134.

diameter.

Ii

i =

This is the maximum tolerance used with the C input.

Chuck

C = 1

C = 2

1

2 3 4 5 6 7

Optional inputs

Inputs Cc and Ii are used with the reference touch option. This option eliminates thermal

growth errors from within the probe results, helping to maintain measuring accuracy.

For other optional inputs, see Chapter 2, "Optional inputs".

c = 2.

Takes the error stored in #134 and adds it to the results of the measured

Figure 6.2 Reference touch option

Example: X and Z single surface measurement

Publication No. H-2000-6021

Figure 6.3 Probe movements

Page 56

6-4 Standard measuring cycles (probe vertical)

T???? Select the probe.

M?? Switch on the probe.

1. G65P9610X50.Z10.F3000 Protected positioning move to the start position.

2. G65P9610X15. Protected positioning move.

3. G65P9611Z0.T2 Single surface measure.

4. G65P9610X80. Protected positioning move.

5. G65P9610Z–6. Protected positioning move.

6. G65P9611X40.T4 Single surface measure.

7. G65P9610X100. Protected positioning move.

M?? Switch off the probe.

continue

Tool offset 2 (Z wear) and tool offset 4 (X wear) will be updated.

Publication No. H-2000-6021

Page 57

Standard measuring cycles (probe vertical) 6-5

Web/pocket measurement (probe vertical) – O9612

NOTE: This cycle must not be used unless double-sided calibration has taken place.

Figure 6.4 Measurement of a web or pocket feature (probe vertical)

Description

This cycle measures a web or pocket feature. It uses two measuring moves along the

Z axis.

Application

Position the probe to the expected centre line of the feature and at a suitable position in

the X axis with the probe and probe offset active. Run the cycle with suitable inputs as

described.

Format

G65 P9612 Zz [ Ee Ff Hh Mm Qq Rr Ss Tt Uu Vv Ww ]

or

G65 P9612 Xx Zz [ Ee Ff Hh Mm Qq Rr Ss Tt Uu Vv Ww ]

where [ ] denote optional inputs.

Example: G65 P9612 X50. Z100. E91 F0.8 H0.2 M.2 Q10. R10. S1. T20. U.5 V.5 W2.

Publication No. H-2000-6021

Page 58

6-6 Standard measuring cycles (probe vertical)

omitted, a pocket cycle is assumed.

Zz

z =

The nominal size of the feature when measured in the Z axis.

G54

T?????

Select the probe.

M??

Switch on the probe.

1.

G65P9610Z20.X60.F3000

Protected positioning move.

2.

G65P9610Z0.

Protected positioning move.

3. and 4.

G65P9612X40.Z10.S2

Measure a 10.0 mm (1.968 in) wide web.

1 2 3

4

5

Compulsory inputs

Xx x = The absolute X-axis position when measuring a web feature. If this is

Optional inputs

See Chapter 2, "Optional inputs".

Outputs

See Chapter 3, "Variable outputs".

Example 1: Measuring a web

Figure 6.5 Probe movements

Publication No. H-2000-6021

Page 59

Standard measuring cycles (probe vertical) 6-7

G54

T?????

Select the probe.

M??

Switch on the probe.

1.

G65P9610X100.Z20.F3000

Protected positioning move.

2.

G65P9610Z–20.

Protected positioning move.

3.

G65P9610X40.

Protected positioning move.

4.

G65P9612Z10.S2

Measure a 10.0 mm (1.181 in) wide pocket.

5.

G65P9610X100.

Protected positioning move.

M??

Switch off the probe.

continue

1

2

3 4 5

5. G65P9610X100. Protected positioning move.

M?? Switch off the probe.

continue

The centre line of the feature in the X axis is stored in the work offset 02 (G55).

Example 2: Measuring a pocket (referred datum)

Figure 6.6 Probe movements

The error of the centre line is referred to the datum point Z0 and the revised Z0 position is

set in work offset 02 (G55).

Publication No. H-2000-6021

Page 60

6-8 Standard measuring cycles (probe horizontal)

Xx

x =

The size of the target surface.

or

Zz

z =

The position of the target surface.

XZ single surface measurement (probe horizontal) – O9811

Figure 6.7 Measurement of a single surface (probe horizontal)

Description

This cycle measures a surface to establish the size or position.

Application

The probe, with its tool offset active, should be positioned adjacent to the surface. The

cycle measures the surface and returns to the start position.

There are two possibilities, as follows:

1. The surface can be treated as a size, where the tool offset is updated in conjunction

with the Tt and the Hh input.

2. The surface can be treated as a reference surface position, for the purpose of

adjusting a work offset using the Ss and Mm inputs.

Format

G65 P9811 Xx or Zz [ Cc Ee Ff Hh Ii Qq Ss Tt Uu Vv Ww ]

where [ ] denote optional inputs.

Example: G65 P9811 X50. C1. E90 F0.8 H0.2 I0.5 Q10. S1. T20. U.5 V.5 W2.

Compulsory inputs

Publication No. H-2000-6021

Page 61

Standard measuring cycles (probe horizontal) 6-9

Cc

c = 1.

Takes the error from the reference diameter and stores it in #134.

diameter.

Ii

i =

This is the maximum tolerance used with the C input.

G54

T?????

Select the probe.

Figure 6.8 Reference touch option

Chuck

C = 1

C = 2

1

2 3 4 5 6

7

Optional inputs

Inputs Cc and Ii are used with the reference touch option. This option eliminates thermal

growth errors from within the probe results, helping to maintain measuring accuracy.

c = 2. Takes the error stored in #134 and adds it to the results of the measured

For other optional inputs, see Chapter 2, "Optional inputs".

Example: X and Z single surface measurement

Figure 6.9 Probe movements

Publication No. H-2000-6021

Page 62

6-10 Standard measuring cycles (probe horizontal)

M?? Switch on the probe.

1. G65P9810Z10.F3000 Protected positioning move.

2. G65P9810X20. Protected positioning move to the start position.

3. G65P9811Z0.T2 Single surface measure.

4. G65P9810X80. Protected positioning move.

5. G65P9810Z–20. Protected positioning move.

6. G65P9811X60.T4 Single surface measure.

7. G65P9810X100. Protected positioning move.

M?? Switch off the probe.

continue

Tool offset 2 (Z wear) and tool offset 4 (X wear) will be updated.

Publication No. H-2000-6021

Page 63

Standard measuring cycles (probe horizontal) 6-11

Web/pocket measurement (probe horizontal) – O9812

NOTE: This cycle must not be used unless double-sided calibration has taken place.

Figure 6.10 Measurement of a web or pocket feature (probe horizontal)

Description

This cycle measures a web or pocket feature. It uses two measuring moves along the X axis.

Application

Position the probe to the expected centre line of the feature and at a suitable position in

the Z axis with the probe and probe offset active. Run the cycle with suitable inputs as

described.

Format

G65 P9812 Xx [ Ee Ff Hh Mm Qq Rr Ss Tt Uu Vv Ww ]

or

G65 P9812 Xx Zz [ Ee Ff Hh Mm Qq Rr Ss Tt Uu Vv Ww ]

where [ ] denote optional inputs.

Example: G65 P9812 X50. Z100. E92 F0.8 H0.2 M.2 Q10. R10. S1. T20. U.5 V.5 W2.

Publication No. H-2000-6021

Page 64

6-12 Standard measuring cycles (probe horizontal)

Xx

x =

The nominal size of the feature.

or

omitted, a pocket cycle is assumed.

1

2 3 4

5

6

7

Compulsory inputs

Zz z = The absolute Z-axis position when measuring a web feature. If this is

Optional inputs

See Chapter 2, "Optional inputs".

Outputs

See Chapter 3, "Variable outputs".

Example 1: Measuring a web

Figure 6.11 Probe movements

G54

T????? Select the probe.

M?? Switch on the probe.

G65P9810.Z10.F3000 Protected positioning move.

1. G65P9810X0. Protected positioning move.

2 to 7. G65P9812X50.Z–10.S2 Measure a 50.0 mm (1.968 in) wide web.

G65P9810Z10. Protected positioning move.

Publication No. H-2000-6021

Page 65

Standard measuring cycles (probe horizontal) 6-13

T?????

Select the probe.

M??

Switch on the probe.

1.

G65P9810Z10.F3000

Protected positioning move.

2.

G65P9810Z-10.

Protected positioning move.

3.

G65P9812X30.S2

Measure a 30.0 mm (1.181 in) wide pocket.

G65P9810Z10.

Protected positioning move.

M??

Switch off the probe.

continue

1

2

3

M?? Switch off the probe.

continue

The centre line of the feature in the X axis is stored in work offset 02 (G55).

Example 2: Measuring a pocket

Figure 6.12 Probe movements

The centre line of the feature in the X axis is stored in work offset 02 (G55).

Publication No. H-2000-6021

Page 66

6-14 Standard measuring cycles (probe horizontal)

This page is intentionally left blank.

Publication No. H-2000-6021

Page 67

Additional cycles 7-1

Chapter 7

Additional cycles

The Inspection software contains four macro cycles that cannot be described under the

headings used in previous chapters (see chapters 4 to 6 inclusive). This chapter

describes how to use these cycles.

Contained in this chapter

Storing multi-stylus data (probe vertical) – O9630 ........................................................... 7-2

Loading multi-stylus data (probe vertical) – O9631.......................................................... 7-4

Storing multi-stylus data (probe horizontal) – O9830 ....................................................... 7-6

Loading multi-stylus data (probe horizontal) – O9831 ..................................................... 7-8

Publication No. H-2000-6021

Page 68

7-2 Additional cycles (probe vertical)

K1

K2

Probe 1

Probe 2

Storing multi-s tylus data (probe vertical) – O9630

Calibration data

Figure 7.1 Storing multi-stylus data (probe vertical)

Calibration data

Description

The macro is used to store the stylus calibration data that is established during the

calibration cycles. The data is stored in a spare set of macro variables.

Stored data for each probe can be recalled using macro O9631.

Application