Page 1

RVP user's guide

Part number: H-1000-3322-01-C

RVP user's guide

www.renishaw.com

Issued 03 2019

1

Page 2

General information

© 2015 ‐ 2019 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any means, without

the prior written permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are trade names, service marks, trademarks, or registered trademarks of their

respective owners.

Windows XP, Windows 2000, Vista, Windows 7 and Windows 10 are registered trade names of the Microsoft Corporation.

All trademarks and trade names are acknowledged.

WEEE

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product should not be mixed with the

general household waste upon disposal. It is the responsibility of the end user to dispose of this product at a designated collection point for

waste electrical and electronic equipment (WEEE) to enable reuse or recycling. Correct disposal of this product will help save valuable

resources and prevent potential negative effects on the environment. For more information, please contact your local waste disposal service

or Renishaw distributor.

Warranty

Renishaw plc warrants its equipment for a limited period (as set out in our Standard Terms and Conditions of Sale) provided that it is installed

exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or cabling) is to be used or substituted. Failure

to comply with this will invalidate the Renishaw warranty.

Claims under warranty must be made from authorised service centres only, which may be advised by the supplier or distributor.

RVP user's guide

www.renishaw.com

Issued 03 2019

2

Page 3

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise measurements and must therefore be treated with

care.

Changes to Renishaw products

Renishaw reserves the right to improve, change or modify its hardware or software without incurring any obligations to make changes to

Renishaw equipment previously sold.

Packaging

To aid end user recycling and disposal the materials used in the different components of the packaging are stated here:

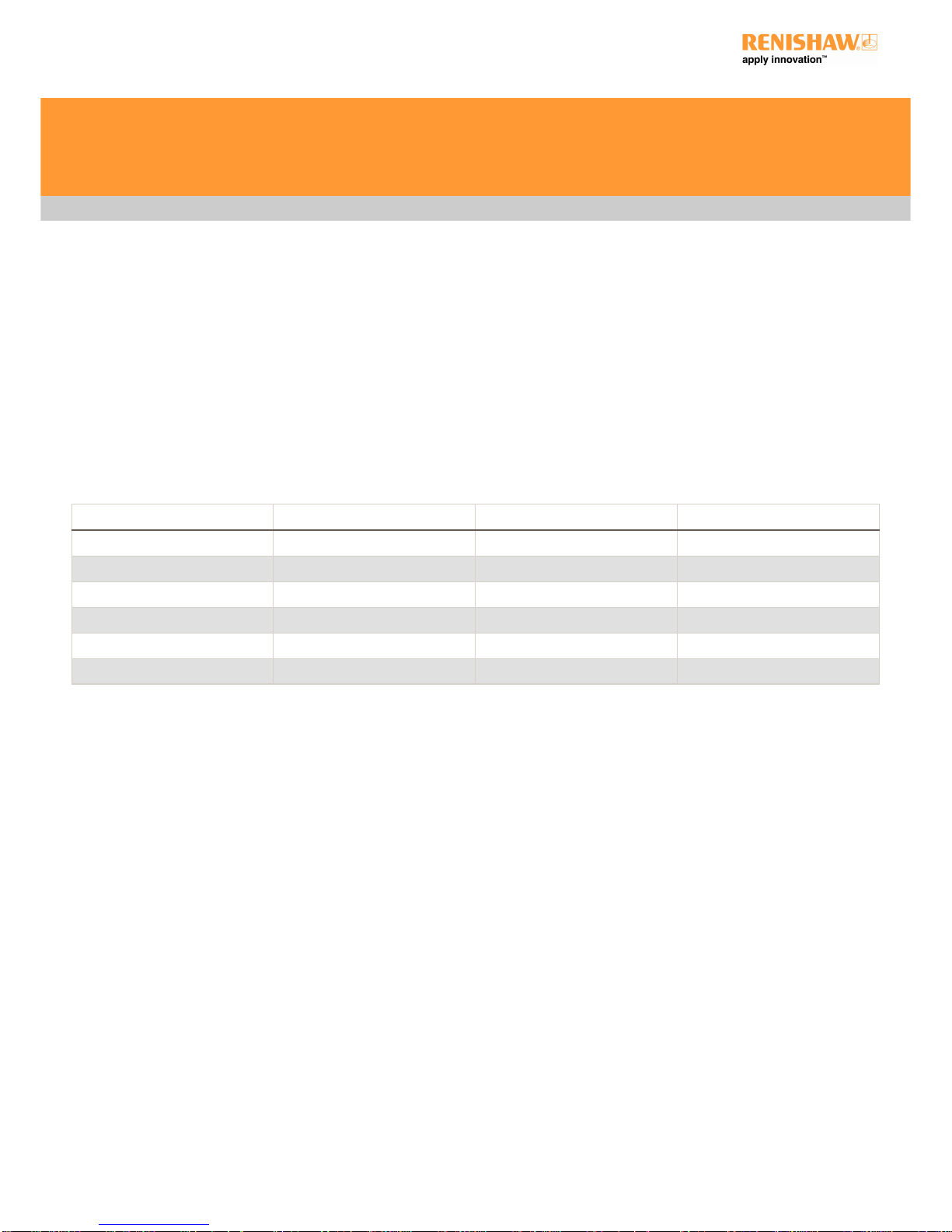

Packaging component Material 94/62/EC code 94/62/EC number

Outer box Non-corrugated fibreboard PAP 21

Storage box Polypropylene PP 05

Packaging insert Corrugated fibreboard PAP 20

Stylus box Polypropylene PP 05

Stylus box label Polypropylene PP 05

Bag Low density polyethylene LDPE 04

RVP user's guide

www.renishaw.com

Issued 03 2019

3

Page 4

Patents

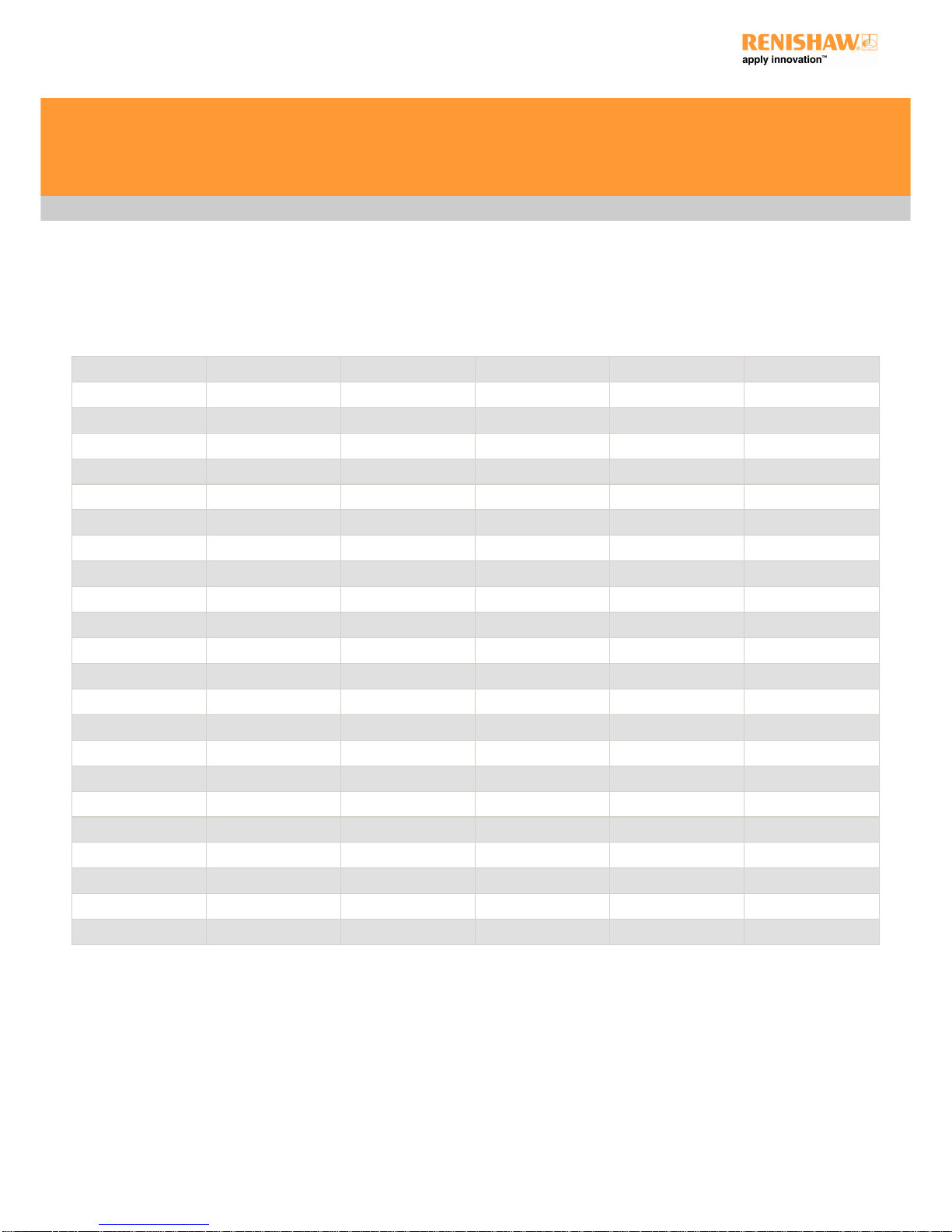

Features of the RVP system and associated products (such as REVO-2), equipment and techniques are the subjects of one or more of the

following patents and patent applications:

CA2925301 CN100453970 EP1086354 IN2017/009615 JP2016-513248 US2015-0362311

CN101166951 EP1687589 IN259801 JP2016-533484 US2016-0238373

CN101166953 EP1877727 IN279118 JP2018-514773 US2018-0058884

CN101405563 EP1877732 IN292511 JP2018-522240 US2018-0156608

CN101405564 EP1989504 IN294476 JP4695762 US6633051

CN101490430 EP2002206 IN295786 JP5196356 US7533574

CN101772690 EP2002207 IN296310 JP5350216 US7809523

CN102037309 EP2035719 WO2006/114603 JP5425476 US7861430

CN102305613 EP2140318 WO2007/107776 JP5638517 US7885777

CN102906533 EP2167911 WO2009/141606 JP5653581 US7971365

CN103842766 EP2291606 WO2011/135282 JP5658863 US8006398

CN105190230 EP2431707 WO2014/122438 JP5706158 US8186882

CN105408723 EP2564151 WO2014/191729 JP5851969 US8302321

CN105793695 EP2764324 WO2015/049341 JP6013533 US8425119

CN107532930 EP2954283 WO2018/091867 JP6199870 US8474148

CN107850425 EP3004797 JP6348577 US8511898

EP3052926 US8601701

EP3289314 US8756973

EP3322959 US8978261

US9038282

US9366519

US9618329

US9903713

RVP user's guide

www.renishaw.com

Issued 03 2019

4

Page 5

Product compliance

EU declaration of conformity

Contact Renishaw plc or visit www.renishaw.com/EU for the full EU declaration.

FCC (USA only)

Information to user (47 CFR 15.105)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case you will be required to correct the interference at your own expense.

Information to user (47 CFR 15.21)

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or authorised representative could void the

user's authority to operate the equipment.

Equipment label (47 CFR 15.19)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

REACH regulation

Information required by Article 33﴾1﴿ of Regulation ﴾EC﴿ No. 1907/2006 ﴾“REACH”﴿ relating to products containing substances of very high

concern (SVHCs) is available at:

www.renishaw.com/REACH

RVP user's guide

www.renishaw.com

Issued 03 2019

5

Page 6

Safety

Before unpacking and installing the RVP system, the user should carefully read the safety instructions below and ensure that they are followed

at all times by all operators.

The RVP vision probe system should only be used with the REVO-2 head.

Operators must be trained in the use and application of the REVO-2 system and accompanying products, in the context of the machine it is

fitted to, before being allowed to operate that machine.

Permanent magnets are used in some components of the REVO-2 system and associated products. It is important to keep them away from

items which may be affected by magnetic fields, e.g. data storage systems, pacemakers and watches.

VM10 and VM11 LED emissions

The VM10 and VM11 vision modules incorporate high power LED lights and should not be used in the event of serious damage to any part of

the VM10 and VM11 modules. In such cases immediately disconnect the power source, remove and do not attempt to reuse the parts. Contact

your supplier for advice.

CAUTION: This equipment uses LED illumination that may flash at a variable rate. Avoid exposure or seek advice from your

medical practitioner if you are susceptible to photosensitivity or related health effects.

RVP user's guide

www.renishaw.com

Issued 03 2019

6

Page 7

Environmental and electrical specifications

Environmental specification

Ambient operating temperature range +10 °C to +40 °C

Storage temperature range ‐25 °C to +70 °C ﴾‐13 °F to 158 °F﴿

Operating humidity 0% to 80% (non-condensing)

Storage humidity 0% to 80% (non-condensing)

Electrical specification

The REVO-2 head and probe electronics are powered from the UCC S5. The head motors are powered from the SPA3. The VPCP and

VMCP are powered by a separate power supply that is supplied by Renishaw. Any additional backlighting is powered by a separate power

supply that is supplied by Renishaw. No additional power supplies are required.

RVP user's guide

www.renishaw.com

Issued 03 2019

7

Page 8

References and associated documents

The following Renishaw documents are referred to in this document or may be a source of further relevant information. They can be

downloaded from www.renishaw.com.

Title Document number

Installation and user's guide: REVO-2 H-1000-7590

Installation guide: UCC S5 H-1000-7598

Installation and user's guide: MCU H-1000-5182

Installation and user's guide: MCU5-2 and MCU W-2 H-1000-5280

RVP user's guide

www.renishaw.com

Issued 03 2019

8

Page 9

System description

RVP is a non-contact vision measurement probe for use with the REVO-2 5-axis measurement system on co-ordinate measuring machines.

RVP increases the multi-sensor capability of REVO-2 by adding non-contact inspection to the existing touch-trigger, high-speed tactile

scanning and surface finish capability of the system.

The RVP system comprises a probe and a range of modules that are automatically interchangeable with all other probe options available for

REVO. This flexibility means that the optimum tool can be selected to inspect a wide range of features, all on one CMM platform.

The RVP system is managed by the same I++ DME compliant interface as REVO-2 and full user functionality is provided by Renishaw's

MODUS metrology software. New MODUS vision software capability includes RVP configuration, image processing with application specific

options and automatic image storage for review and further analysis.

RVP user's guide

www.renishaw.com

Issued 03 2019

9

Page 10

Design principles of the RVP system

The RVP system uses an industry standard CMOS image sensor to capture and then detect the position of features using the contrast between

light and dark areas of the image. Data points are projected on to the location where the image contrast changes from light to dark. A detailed

calibration model of the lens system transforms the co-ordinates of the projected point on the image to real-world, three dimensional coordinates on the part.

RVP user's guide

www.renishaw.com

Issued 03 2019

10

Page 11

System components overview

Key Description Part number

1 REVO-2 head A-5759-0001

2 RVP vision probe A-5378-0080

3 VM10 vision module A-5378-0082

4 VM11 vision module A-5378-0087

5 VPCP probe change port A-5378-0081

6 VMCP module change port A-5378-0083

7 VA10 calibration artefact A-5378-0085

RVP user's guide

www.renishaw.com

Issued 03 2019

11

Page 12

RVP probe

RVP is the probe component of the system that houses the sensor and digital signal processor. There are currently two vision modules that

attach to the probe body that enable the inspection of a range of size and shape features.

The RVP component of the system is automatically interchangeable with other probe options using the VPCP heated change port that can be

fixed to the MRS rack system.

Vision modules

The RVP system features two interchangeable vision modules (VM10 and VM11) which are both tailored to provide inspection capability for

different applications. The vision modules attach to the probe body using the same style kinematic mount utilised by all the current REVO

probes.

VM10 has a wider field of view allowing larger features to be inspected and VM11 has a greater stand-off distance which improves

accessibility when inspecting complex parts with hard to reach features.

VA10 calibration artefact

The VA10 is a dedicated calibration artefact used to calibrate the target feature size and stand-off distance of the RVP system when using a

VM10 or VM11. The calibration routine for RVP is fully automated through MODUS and UCCsuite.

VPCP and VMCP change ports

There are two new change ports that can be mounted to an MRS rack system to allow the automated changing of all the RVP probe and

module components.

The VPCP change port is used to change and house the RVP probe body on the machines rack system. The VMCP change port changes and

houses the vision module components of the RVP system. Both rack ports are temperature controlled to ensure that the housed components

are at the correct and most efficient operating temperature.

RVP user's guide

www.renishaw.com

Issued 03 2019

12

Page 13

Dimensional information

RVP

VM10 and VM11

RVP user's guide

www.renishaw.com

Issued 03 2019

13

Page 14

VPCP and VMCP

VA10

RVP user's guide

www.renishaw.com

Issued 03 2019

14

Page 15

Installation

Fitting VPCP and VMCP to the MRS / MRS2 rack

The VPCP and VMCP heated change ports can be fixed to an MRS or MRS2 rack system. It is recommended that they are attached to the MRS

/ MRS2 rail using the following procedure, where it is assumed that the MRS / MRS2 rack system is correctly installed.

1. Insert one of the fixing screws through the VPCP / VMCP.

2. Position the VPCP / VMCP underneath the rail and locate the respective T-nut within the rail*.

3. Hand tighten the fixing screw into the T-nut and repeat the process for the next fixing screw.

4. Position the VPCP / VMCP and tighten both fixing screws using the hexagonal key supplied.

NOTE: The image above shows the VPCP change port but the procedure is the same for the VMCP change port.

* NOTE: T-nuts must be used with the MRS system. However T-nuts and D-nuts are compatible with the MRS2 system.

RVP user's guide

www.renishaw.com

Issued 03 2019

15

Page 16

Fixing VA10 calibration artefact to CMM

The VA10 calibration artefact is designed to be fixed securely to the bed of the CMM to allow accurate and repeatable calibration of the RVP

system components. The diagrams below show how to fix the VA10 to the bed of the CMM.

1. Locate an appropriate threaded hole in the bed of the machine.

2. Position the artefact plate above the threaded hole.

3. Screw the correct size adaptor stud through the hole into the threaded hole on the machine.

4. Tighten with S spanner supplied.

5. Screw the artefact top component to the adaptor stud.

6. Tighten with S spanner supplied.

RVP user's guide

www.renishaw.com

Issued 03 2019

16

Page 17

Illumination options

RVP lighting techniques

The RVP system has a number of illumination options to ensure that features can be correctly lit allowing accurate and consistent

measurement. Both vision modules have integrated LED illumination to illuminate features that require inspection. The RVP system also uses

a technique which uses back lighting to ensure good contrast of material edges or features.

The lighting technique chosen depends on the type of feature and the material of the part being inspected. RVP system image settings can be

fully customised and adjusted to provide optimum contrast to inspect a range of features.

It is important that the correct exposure is achieved for both front and back lighting applications. The image on the left shows a correctly

exposed back lit hole. The back edge of the hole is sharp and there is good contrast between the material and the white back lit panel.

The image on the right shows a correctly exposed front lit feature. The front edge of the hole is sharp and there is good contrast between the

dark material in the hole and the bright, front lit hole area. When using front lighting, more RVP image settings may need to be adjusted to

get the optimum contrast and to reduce unwanted reflections.

Ambient lighting

Ambient light is an important variable when using the RVP system. For accurate and repeatable inspection, the ambient environment lighting

should be as consistent as possible. Any changes in ambient lighting can potentially affect the system's performance.

RVP user's guide

www.renishaw.com

Issued 03 2019

17

Page 18

Cleaning the RVP system

CAUTION: Always adhere to the safety instructions given on the general safety recommendations and instructions in this

document. Failure to do so could lead to personal injury.

Following the simple procedures given below will prolong the operational life and maintain the high performance of the system. The user

should determine the frequency of inspection and maintenance actions according to the conditions of use.

Kinematic couplings

The kinematic coupling mechanisms incorporated throughout the system have precision ball seating and permanent magnets. It is

recommended that all these features be cleaned before first use, and thereafter at regular intervals.

A cleaning kit for the precision ball seating and permanent magnet is available from your Renishaw supplier (part number A-1085-0016). It

comprises strips of yellow tack material. Use the yellow tack to clean the areas indicated with arrows numbered [1] on the image below.

With clean hands, tear off a small piece, shape into a small ball and press into / onto each of the features in turn, rotating to a fresh piece of

material as you work around.

CAUTION: Ensure no yellow tack debris is left on the surface. The yellow tack should not be used for the electrical contacts [2] or

the optical windows [3].

Electrical contacts

The electrical contacts, indicated with arrows numbered [2] in the image below, should be carefully cleaned with an alcohol-based cleaner (e.g.

IPA) and a lint-free bud. The frequency of cleaning depends on the local environmental conditions, but should be at least every five hundred

changes.

RVP user's guide

www.renishaw.com

Issued 03 2019

18

Page 19

Optical windows

The RVP probe and module optical windows should be cleaned using a proprietary lens cleaning kit to blow or brush debris away from the

window. If debris is still visible, then the optical window should be carefully wiped with a lint free bud and high-purity isopropyl alcohol (IPA).

Extreme care must be taken to avoid damaging the optical coating or scratching the glass. Latex gloves should be worn during the cleaning

procedure and no attempt to directly touch the optical windows should be made.

NOTE: Cleanliness of the optical windows is important to maintain the highest level of performance of the probe and modules. If

any contamination cannot be removed and is resulting in degraded metrology performance, please contact your local Renishaw

office.

RVP user's guide

www.renishaw.com

Issued 03 2019

19

Page 20

Technical terminology

Stand-off

This is the distance between the end of the vision module and the plane at which a feature will be at the sharpest focal distance to provide

optimum image capture.

RVP user's guide

www.renishaw.com

Issued 03 2019

20

Page 21

Field of view

This is the maximum size area that will be projected onto the CMOS sensor when the correct stand-off distance is used. Any feature requiring

inspection with RVP must be located within the field of view to allow inspection.

RVP user's guide

www.renishaw.com

Issued 03 2019

21

Page 22

Depth of field

The depth of field specifies the range over which a feature can deviate from the nominal stand-off distance and still be measured with

acceptable levels of metrology performance. If features are measured outside the recommended depth of field range, metrology performance

and accuracy will decrease.

RVP user's guide

www.renishaw.com

Issued 03 2019

22

Page 23

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

www.renishaw.com/cmmsupport

Issued 03 2019

Loading...

Loading...