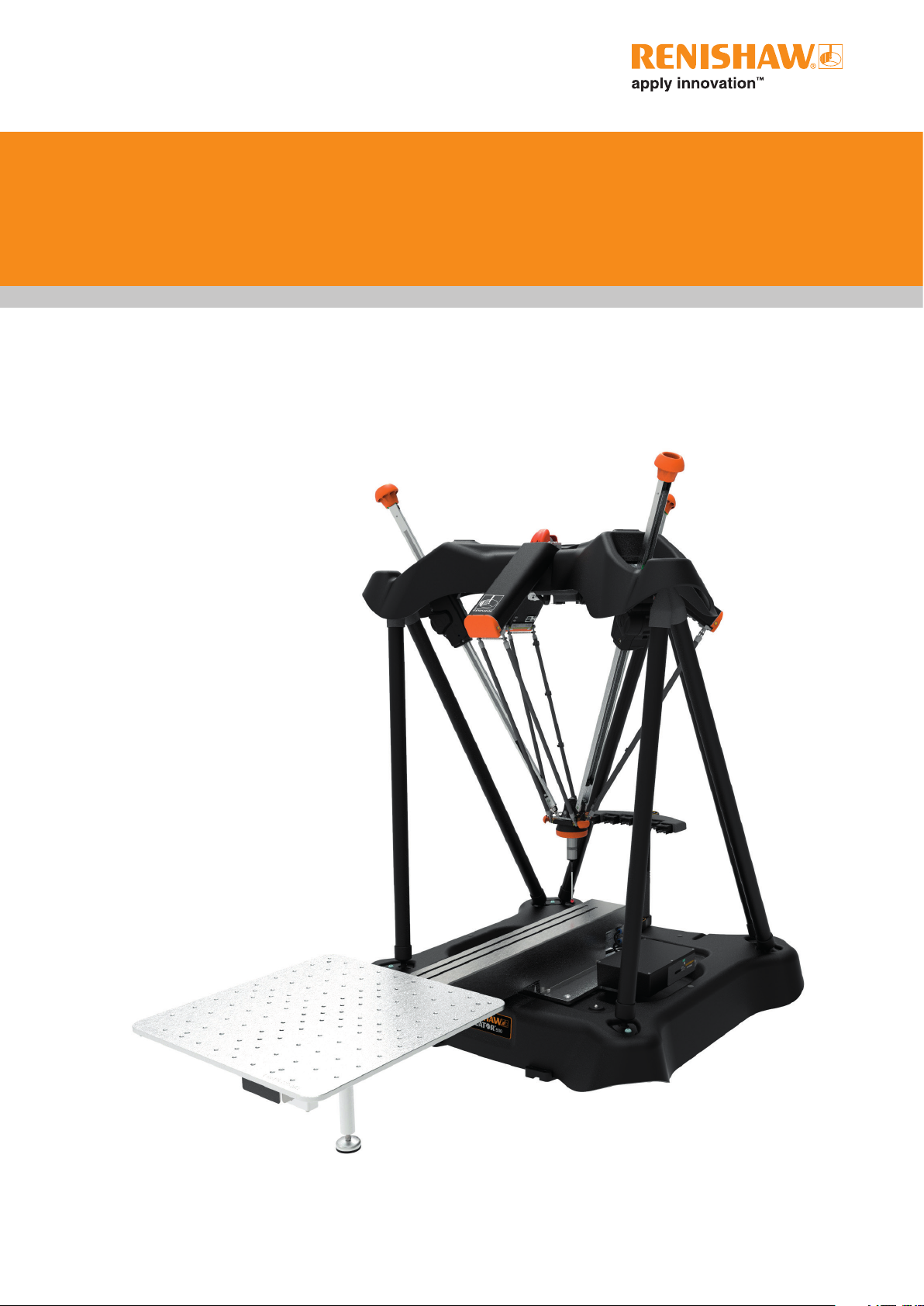

Page 1

Installation guide

ATS 40-800 Installation and User Guide

for EQ500 Gauge

www.renishaw.com/gauging

Page 2

2

© 2018 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any

means, without the prior written permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT

AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT.

RENISHAW EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and

other countries.

apply innovation is a trademark of Renishaw plc.

All other brand names and product names used in this document are trade names, service marks, trademarks, or registered

trademarks of their respective owners.

Renishaw part no: H-6242-8502-02-A

Issued: 02.2019

Page 3

Contents

1. Before you begin ..........................................................................................................................4

2. Safety and warnings.....................................................................................................................5

3. Product information ......................................................................................................................8

4. Hardware .....................................................................................................................................9

5. Product installation .....................................................................................................................10

6. Installation in Renishaw Enclosure ............................................................................................17

3

Page 4

1. Before you begin

4

Changes to equipment

Renishaw reserves the right to change specifications without notice.

Warranty

Equipment requiring attention under warranty must be returned to our supplier. No claims will be considered where equipment

has been incorrectly installed or misused, or where repairs or adjustments have been attempted by unauthorised persons. Prior

consent must be obtained in instances where Renishaw equipment is to be substituted or omitted. Failure to comply with this

requirement will invalidate the warranty.

WEEE directive

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product

should not be mixed with general household waste upon disposal. It is the responsibility of the end user to

dispose of this product at a designated collection point for waste electrical and electronic equipment (WEEE)

to enable reuse or recycling. Correct disposal of this product will help to save valuable resources and prevent

potential negative effects on the environment. For more information, please contact your local waste disposal

service or Renishaw distributor.

FCC Information to user (USA only)

47 CFR Section 15.19

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

This device may not cause harmful interference, and

This device must accept any interference received, including interference that may cause undesired operation.

47 CFR Section 15.21

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or authorised

representative could void the user’s authority to operate the equipment.

REACH regulation

Information required by Article 33(1) of Regulation (EC) No. 1907/2006 (“REACH”) relating to products containing substances of

very high concern (SVHCs) is available at:

www.renishaw.com/REACH

Page 5

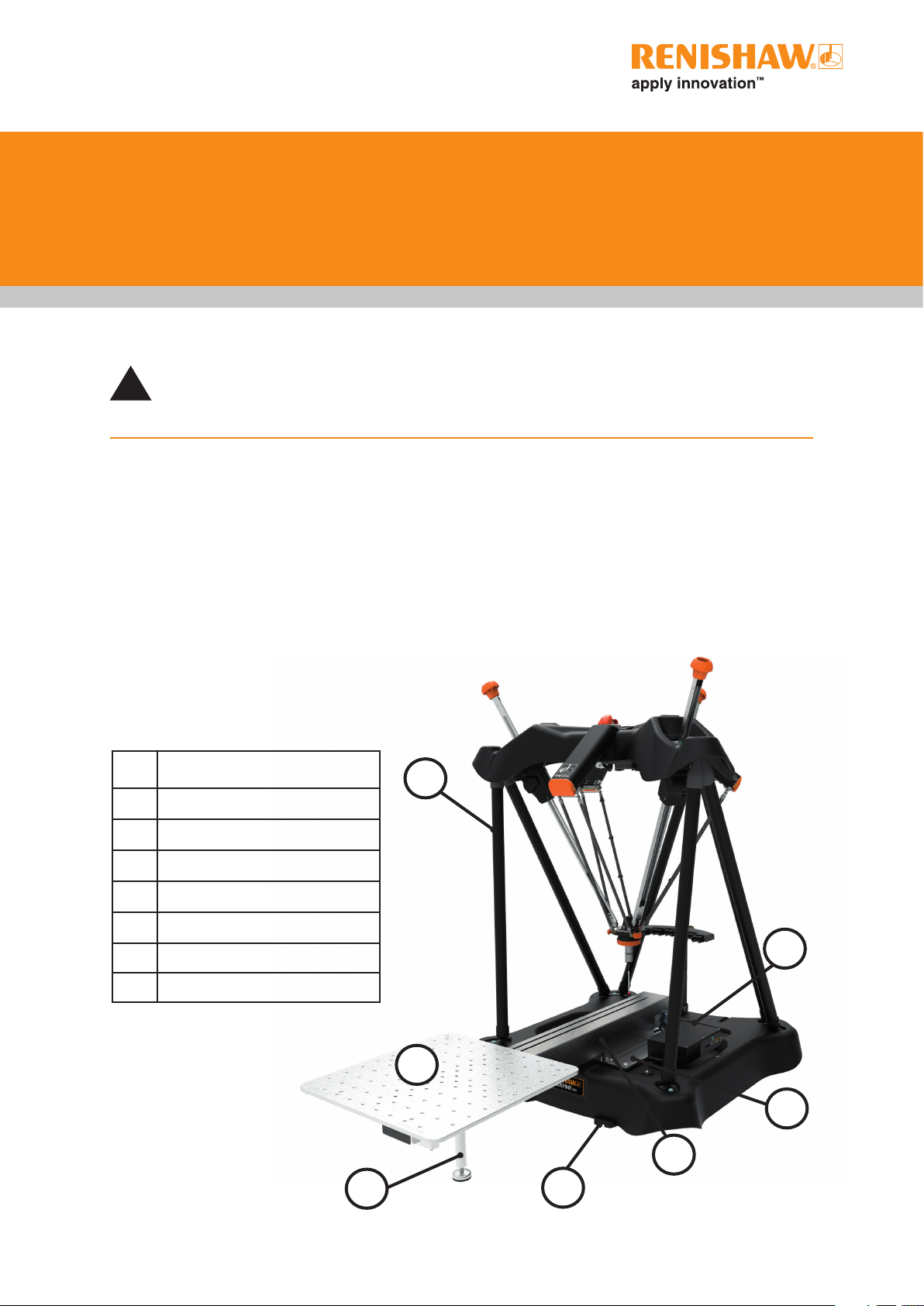

2. Safety and warnings

!

Safety and warnings

Residual Risk Summary

1. There is a potential crushing hazard between the rear corners of the EQ500 fixture plate (C) and the front support legs (E)

of the EQ500.

2. There is a potential impact injury if a user stands in the area where the EQ-ATS extends to the out position.

3. The stop button mount (G) on the EQ500 is obscured when the EQ-ATS is fitted, therefore, the stop button must be moved

to an alternative accessible position.

5

Item Description

A Cylinder

B Control box

C Fixture plate (M6 and M8)*

D Support Leg

E Support Strut

F Base Plate

G Stop Button Mount

* M6 and M8 fixture plates are orderable seperately

D

E

B

C

F

A

G

Page 6

Safety and

Warnings

6

1. There is a potential crushing hazard between the rear corners of the EQ500 fixture plate (C) and the front support

legs (E) of the EQ500.

2. There is a potential impact injury if a user stands in the area where the EQ-ATS extends to the out position.

Page 7

3. The stop button mount (G) on the EQ500 is obscured when the EQ-ATS is fitted, therefore, the stop button must be

moved to an alternative accessible position.

In order to mitigate these residual risks, the following can be purchased at an additional cost:

Part Part Number

Table Extension and Wings A-6242-0350

Equator 500 Enclosure Table A-5924-0290

Equator 500 Enclosure Sides A-5924-0400

Equator 500 Foot Kit A-5924-0275

Safety and

Warnings

7

Safety and warnings (continued)

!

Care should be taken when handling this product. If the product is dropped or receives an impact, it must be assumed that it is

not suitable for use and Renishaw should be contacted with reference to a replacement.

Safety shoes and glasses should be worn at all times during installation and use of the EQ-ATS.

The Equator foot stud installation kit, included with the EQ-ATS, must be used to secure the Equator gauging system onto a

fixed surface to ensure stability during use.

The weight of the EQ-ATS is 26.4 kg. The weight of the EQ-ATS with packaging is 32.4 kg.

When connecting or disconnecting the EQ-ATS to an Equator system, the Equator system must be shut down and

disconnected from the mains power supply. Not doing so can cause damage to the electronics.

Users should ensure that parts are fixtured securely to the EQ-ATS before using the machine.

Due to risk of entanglement, loose items must not be worn near the equipment.

The user must not touch the EQ-ATS whilst it is in motion, as this may cause measurement errors.

Ensure parts are securely clamped and constrained in the Y axis.

If this equipment is not used in its intended manner, any protection provided may be impaired and the warranty may be voided.

Emergency situation information

If the system begins to behave in an unexpected manner, press the stop button to reduce the risk of damage or injury. In

the case of fire, use fire extinguishers for electrical fires. There are no potential chemical leaks from the system.

Page 8

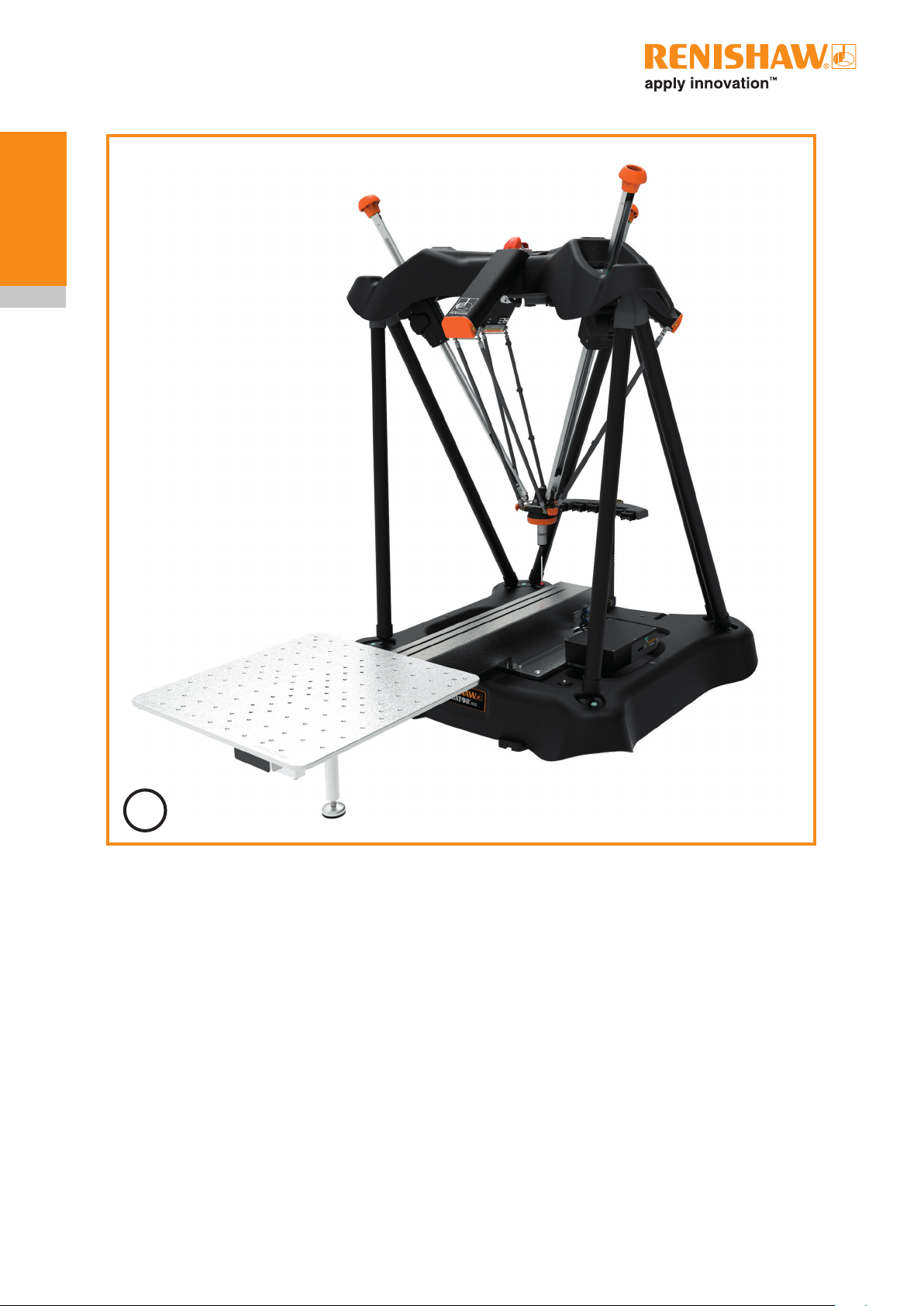

3. Product information

8

The EQ-ATS improves consistency and reliability of loading large parts into the working volume of the Equator

system, as well as offering better access for loading parts to fixture plates outside the working volume.

The EQ-ATS transfers the loaded part from outside the Equator working volume into the working volume for inspection to take

place. Once inspected, the part is then transferred back outside the working volume to allow removal / replacement of the part.

The part can be loaded onto the EQ-ATS manually or by robot. The EQ-ATS suits parts and fixtures up to 50 kg. Please contact

Renishaw if there is a requirement to support heavier parts.

The distance from the fixture plate to the top of the working volume, with a standard Ø8 mm x 75 mm long stylus, is 250 mm for

an Equator 500 extended height.

TM

gauging

Equator 500 extended height

250 mm

Page 9

4. Hardware

EQ-ATS kit

5

9

1

3

A

9

C

B

D

E

F

Item Description

1 EQ-ATS

2 M8 Fixture Plate

3 Air pressure regulator

4 Pneumatic tube (2 m)

2

4

8

7

6

5 Hex key (5 mm A) (4 mm B) and bolts

6 PS/2 to 9-pin D-type cable (sold separately)*

7 Stop Button with 9-pin D-type connector (sold separately)*

8 EQ-CM1 (sold separately)

9 Support Leg (assembled)

* Required for Equator 500 systems with a Stop Button (PS/2 connector) and no joystick

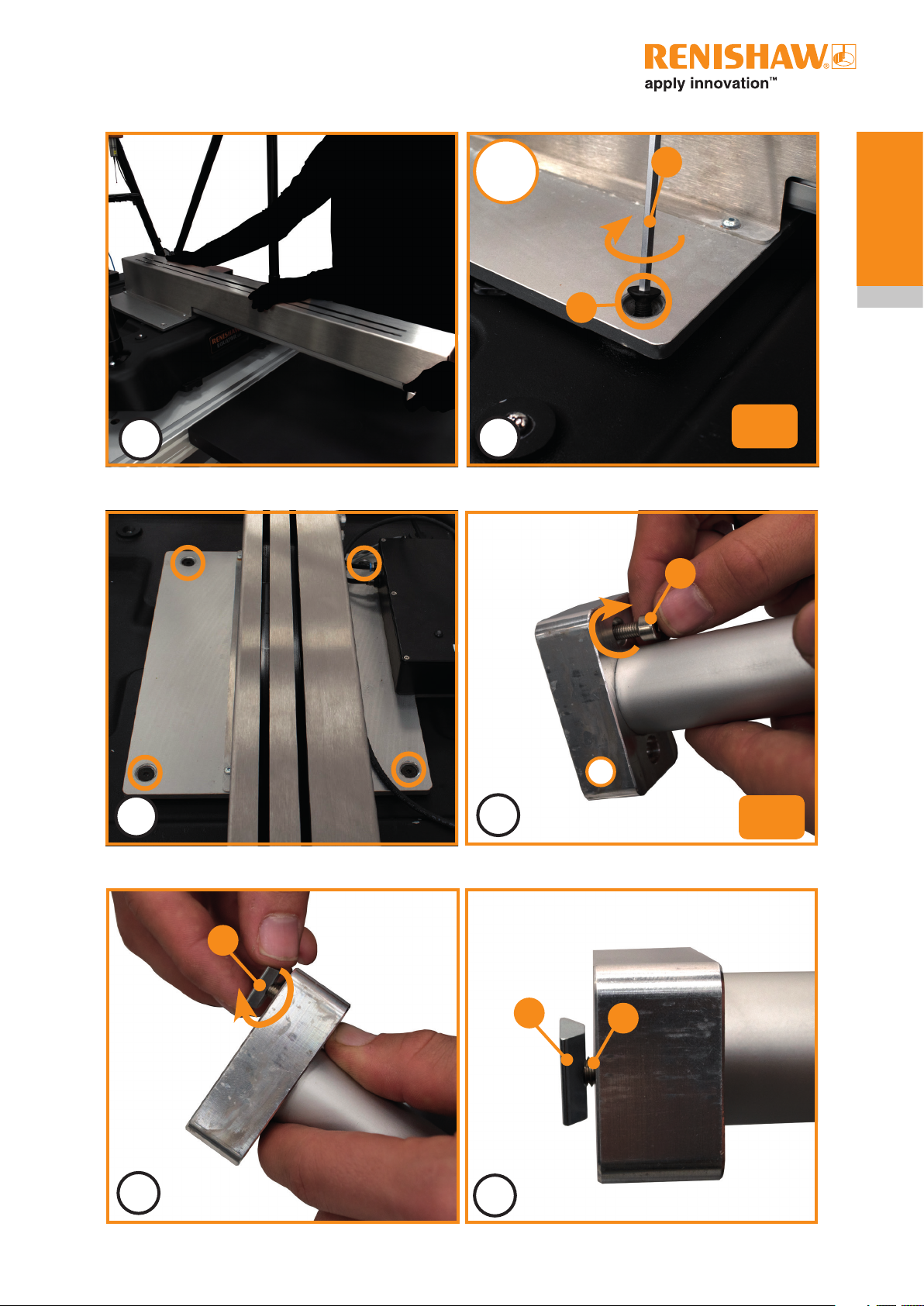

Page 10

10

5. Product installation

The Equator gauging system must be turned off prior to installation and fully secured to the surface of the Equator Enclosure,

or equivalent table, using the Equator foot stud installation kit (7) supplied with the EQ-ATS. Please follow the instructions in the

Equator foot stud installation kit.

Assembling the EQ-ATS

A

1

3 4

2

1

Page 11

5.1 Nm

A

Product

installation

5

6

F

11

x4

E

7

9

D

8

10

D

9

x2

E

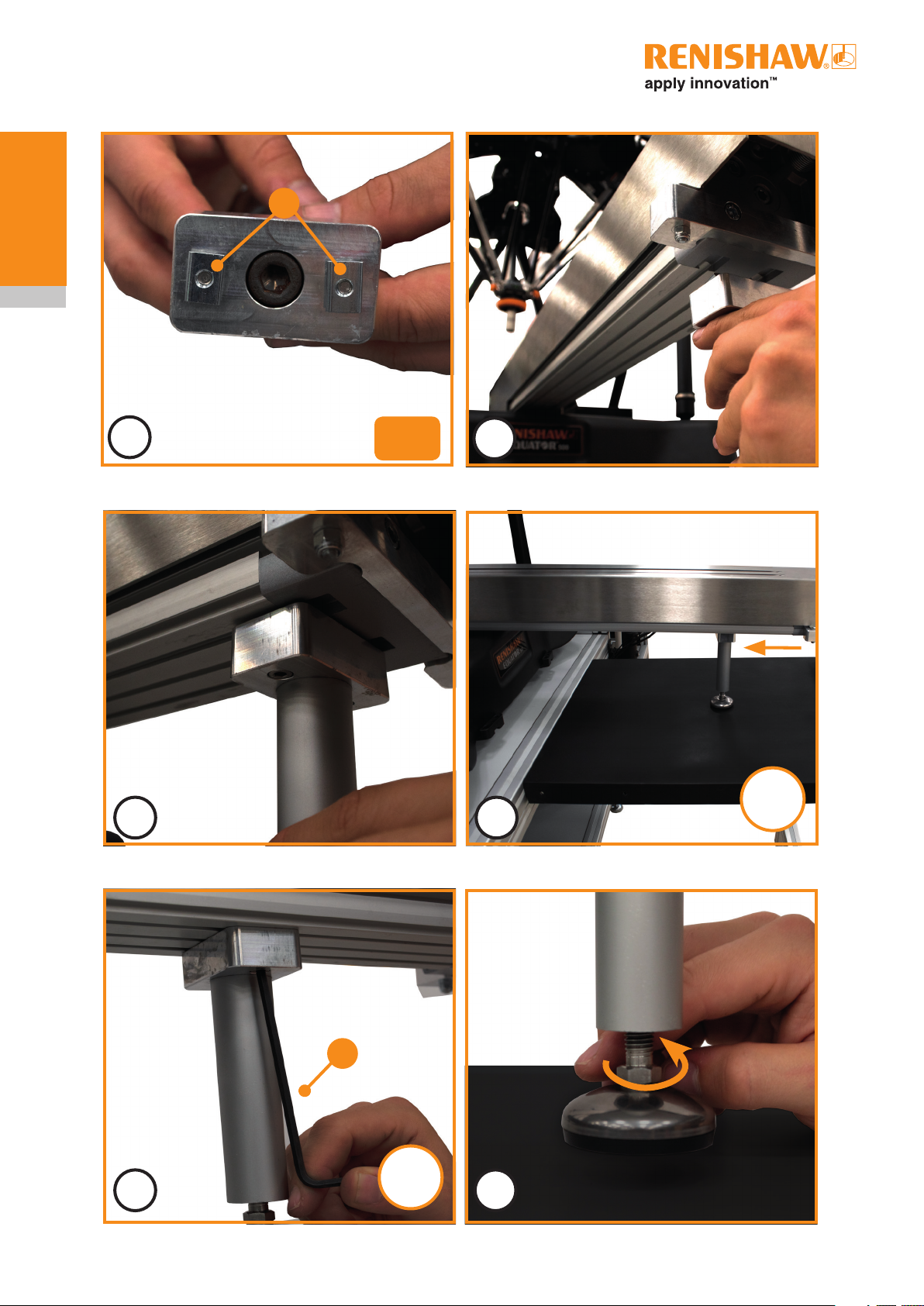

Page 12

Product

installation

12

D

11

13

x2

12

116mm

14

B

5.1 Nm

15 16

Page 13

17 18

2

B

2 Nm

Product

installation

13

19 20

5.1 Nm

2

21

22

x2

B

x8

Page 14

Product

installation

14

23

25

24

4

8

26

A-5923-0020

EQ-CM1 User Guide

27

3

9 Nm

28

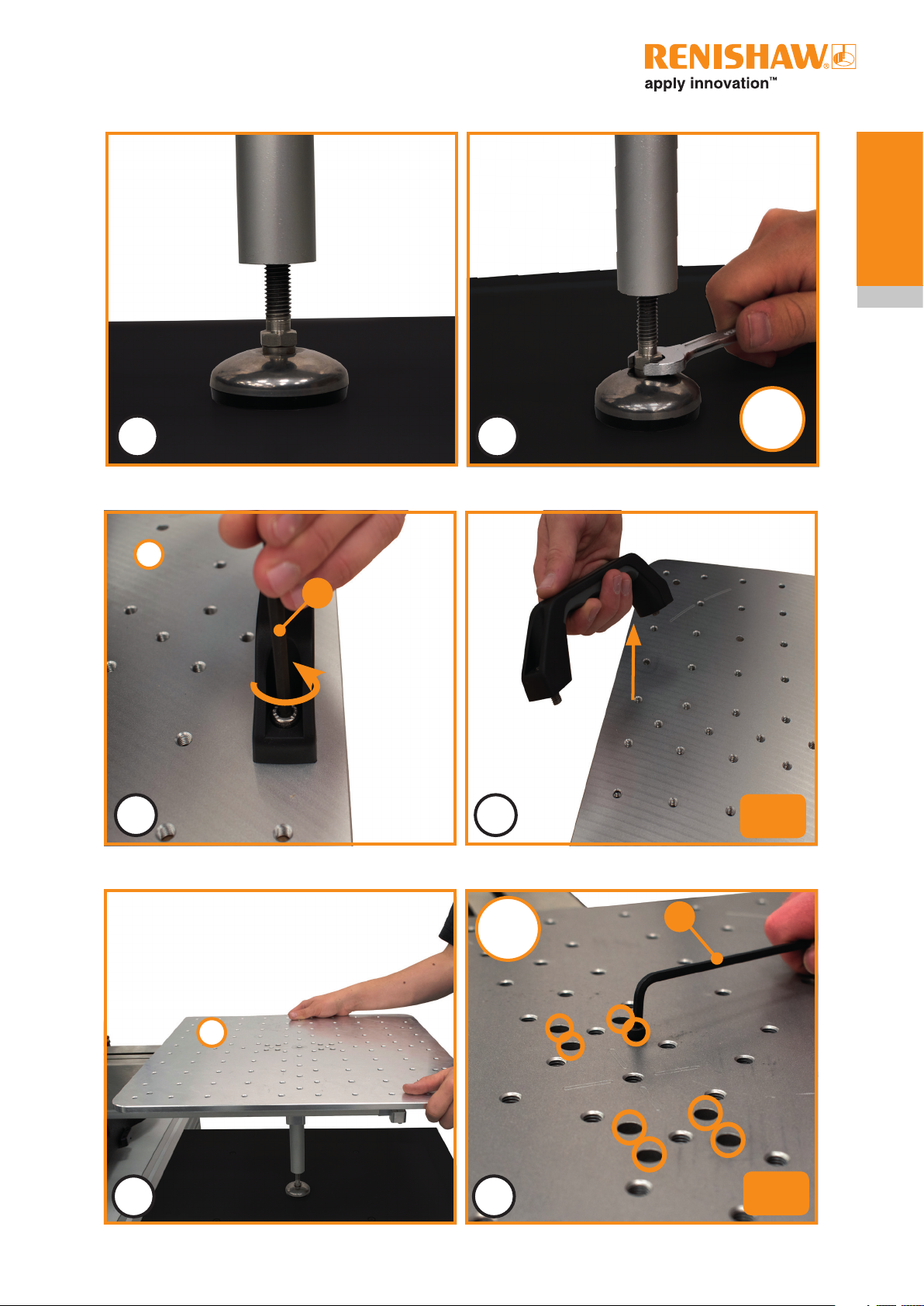

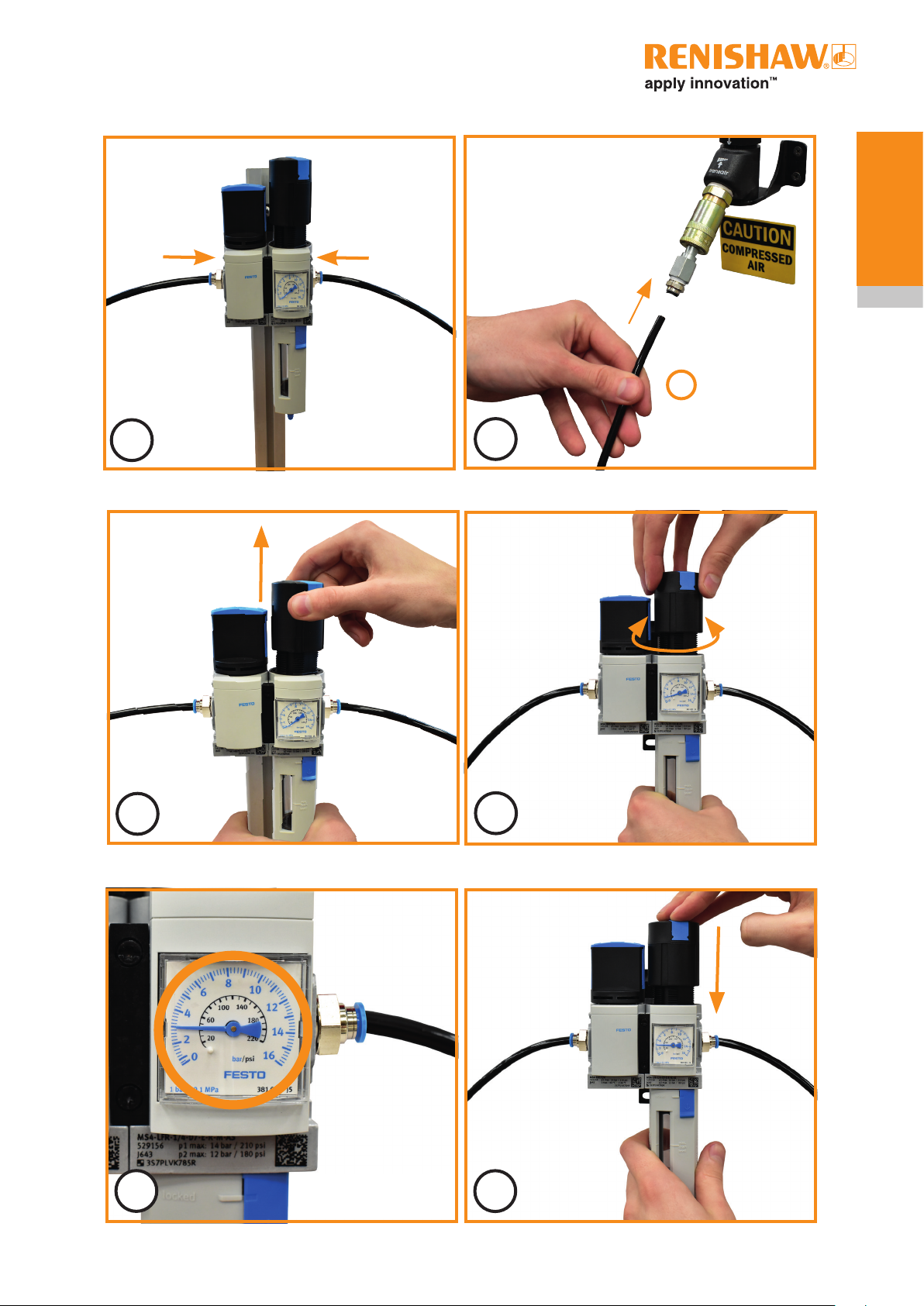

Page 15

1 m

max

Product

installation

15

4

29

31

30

32

:6 mm

33

Set to 3 bar

34

Page 16

Product

installation

16

30

Page 17

6. Installation in Renishaw Enclosure

17

Please note: Additional base plates including M6, M8 and 1/4” are available. Please contact

Renishaw for further information.

!

Warning:

• Parts should be clamped securely when in use.

• Please ensure that the Equator has been turned off when disconnecting the EQ-ATS.

Page 18

Page intentionally left blank

Page 19

Page intentionally left blank

Page 20

Renishaw plc

New Mills, Wotton-under-Edge

Gloucestershire, GL12 8JR

United Kingdom

T

+44 (0) 1453 524524

F

+44 (0) 1453 524901

E

uk@renishaw.com

www.renishaw.com

About Renishaw

Renishaw is an established world leader in engineering technologies, with a strong history of innovation in product development

and manufacturing. Since its formation in 1973, the company has supplied leading-edge products that increase process

productivity, improve product quality and deliver cost-effective automation solutions.

A worldwide network of subsidiary companies and distributors provides exceptional service and support for its customers.

Products include:

• Additive manufacturing and vacuum casting technologies for design, prototyping, and production applications

• Dental CAD/CAM scanning systems and supply of dental structures

• Encoder systems for high-accuracy linear, angle and rotary position feedback

• Fixturing for CMMs (co-ordinate measuring machines) and gauging systems

• Gauging systems for comparative measurement of machined parts

• High-speed laser measurement and surveying systems for use in extreme environments

• Laser and ballbar systems for performance measurement and calibration of machines

• Medical devices for neurosurgical applications

• Probe systems and software for job set-up, tool setting and inspection on CNC machine tools

• Raman spectroscopy systems for non-destructive material analysis

• Sensor systems and software for measurement on CMMs

• Styli for CMM and machine tool probe applications

For worldwide contact details, visit www.renishaw.com/contact

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

© 2018 Renishaw plc. All rights reserved.

Renishaw reserves the right to change specifications without notice.

RENISHAW and the probe symbol used in the RENISHAW logo are registered trade marks of Renishaw plc in the United Kingdom and other countries.

apply innovation and names and designations of other Renishaw products and technologies are trade marks of Renishaw plc or its subsidiaries.

All other brand names and product names used in this document are trade names, trade marks or registered trade marks of their respective owners.

*H-6242-8502-02*

Part no.: H-6242-8502-02-A

Issued: 02.2019

Loading...

Loading...