Page 1

Installation guide

M-9414-9447-01-A

ATOM DX

RSLM high accuracy linear encoder

™

rotary encoder systems

Page 2

Contents

Product compliance 1

Storage and handling 2

ATOM DX system installation overview 3

RCDM rotary disc

Installation drawing 4

Mounting the disc 5

Aligning the disc 6

System connection: Top exit readhead 8

Readhead mounting and alignment:

Methods 9

Shim kit (A-9401-0050) 9

Dummy head (A-9401-0072) 10

ATOM DX calibration overview 11

System calibration 12

Restoring factory defaults 12

Enabling/disabling AGC 12

Readhead LED diagnostics 12

Troubleshooting 13

ATOM DX

Cabled readhead dimensions 15

Top exit readhead dimensions 16

Output signals 17

Speed 18

Electrical connections 19

General specications 20

Disc specications 20

ATOM DX rotary installation guide

Page 3

Product compliance

C

Renishaw plc declares that ATOM DX complies with the applicable standards and regulations.

A copy of the EU Declaration of Conformity is available from our website at

www.renishaw.com/productcompliance

FCC compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

The user is cautioned that any changes or modications not expressly approved by Renishaw plc

or authorised representative could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must

be used with the unit to ensure compliance.

ATOM DX top exit readhead

The ATOM DX top exit readhead has been designed as a system component and to be compliant with

EMC regulations for products of its type. Care must be taken with shielding and grounding arrangements

to ensure EMC performance once installed. It is the system integrator’s responsibility to implement,

test and prove EMC compatibility for the whole machine

Further information

Further information relating to the ATOM DX encoder range can be found in the ATOM DX system Data

sheet (L-9517-9736), Advanced Diagnostic Tool ADTi -100 Data sheet (L-9517-9699), Advanced Diagnostic

Tool ADTi -100 and ADT View software quick-start guide (M-6195-9321), and the Advanced Diagnostic Tool

ADTi -100 and ADT View software user guide (M-6195-9413). These can be downloaded from our website at

www.renishaw.com /opticalencoders and are also available from your local representative. This document

may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any

means without the written prior permission of Renishaw. The publication of material within this document does

not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT

IS CORRECT AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

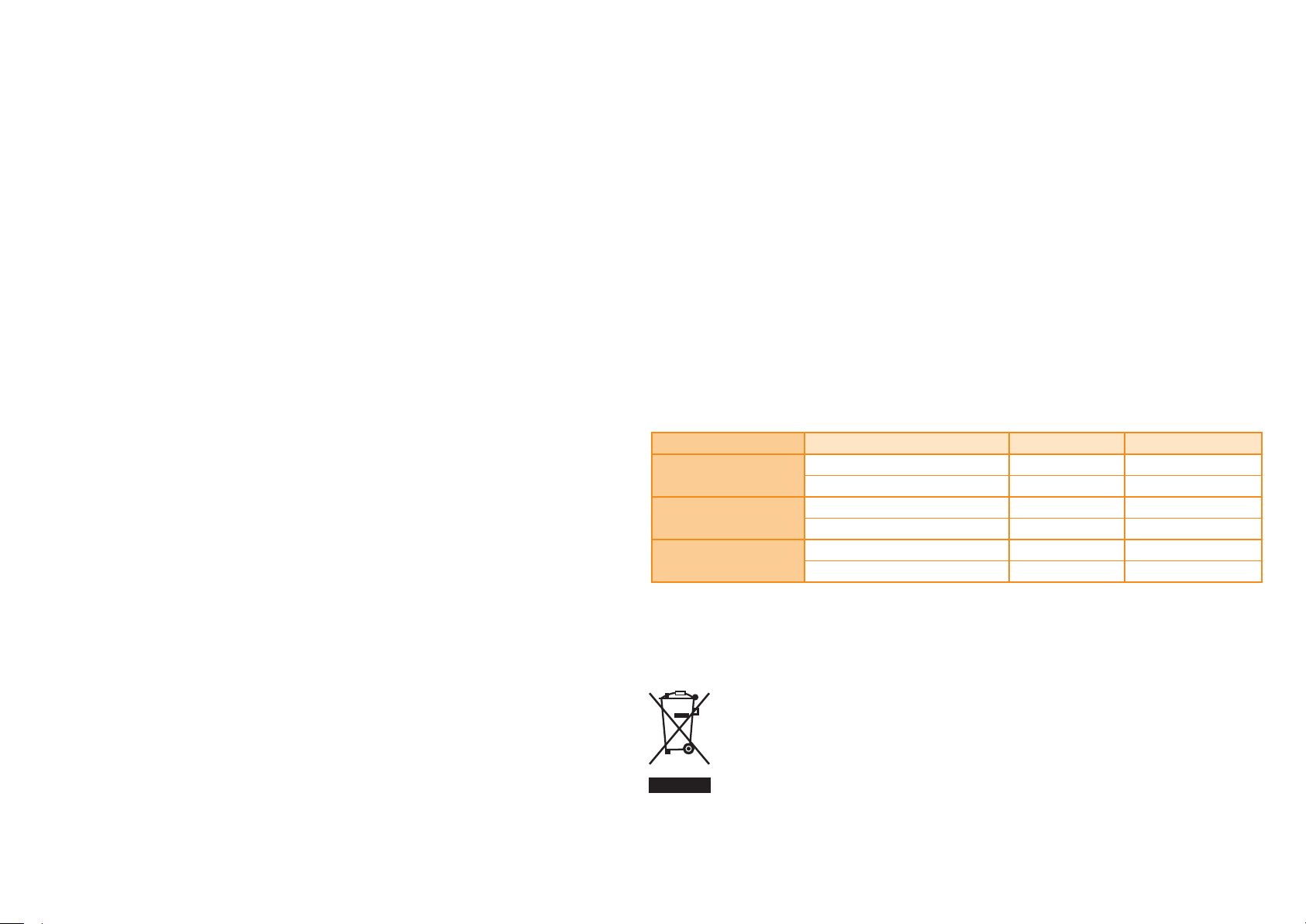

The packaging of our products contains the following materials and can be recycled.

Packaging Component Material ISO 11469 Recycling Guidance

Outer box

Inserts

Bags

Low Density Polyethylene Foam LDPE Recyclable

High Density Polyethylene Bag HDPE Recyclable

Cardboard Not applicable Recyclable

Polypropylene PP Recyclable

Cardboard Not applicable Recyclable

Metalised Polyethylene PE Recyclable

Patents

Features of Renishaw’s encoder systems and similar products are the subjects of the following

patents and patent applications:

CN101300463 EP1946048 JP5017275 US7624513

CN101310165B EP1957943 US7839296 CN105008865

US9952068 CN109477736 EP3465099 US2017203210

ATOM DX rotary installation guide

REACH regulation

Information required by Article 33(1) of Regulation (EC) No. 1907/2006 (“REACH”) relating to products

containing substances of very high concern (SVHCs) is available at: www.renishaw.com / REACH

The use of this symbol on Renishaw products and/or accompanying documentation indicates that

the product should not be mixed with general household waste upon disposal. It is the responsibility

of the end user to dispose of this product at a designated collection point for waste electrical and

electronic equipment (WEEE) to enable reuse or recycling. Correct disposal of this product will help

to save valuable resources and prevent potential negative effects on the environment.

For more information, please contact your local waste disposal service or Renishaw distributor.

1

Page 4

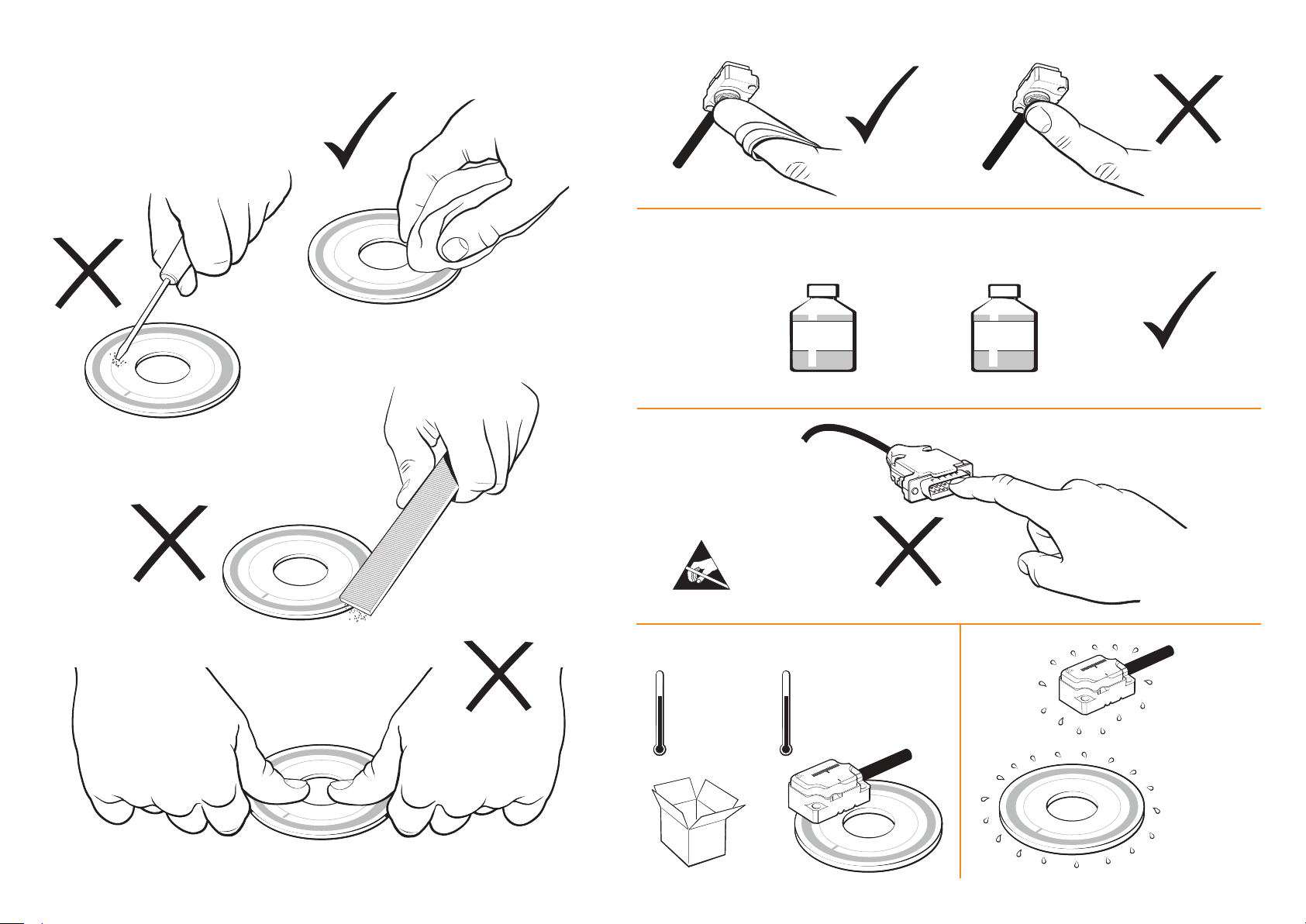

Storage and handling

Disc and readhead

Storage

+70 °C

−20 °C

N-heptane

CH

(CH2)5CH

3

Operating

3

+70 °C

0 °C

Propan-2-ol

CH3CHOHCH

Humidity

3

ATOM DX rotary installation guide

95% relative humidity

(non-condensing) to

EN 60068-2-78

2

Page 5

ATOM DX system installation overview

This section gives an overview of the steps involved in installing, setting-up and calibrating an ATOM DX encoder system.

More detailed information is contained within the rest of the document.

For information on designing the readhead and disc into the system refer to the detailed installation drawings

and 3D models at www.renishaw.com /opticalencoders or contact your local Renishaw representative.

For information on the ATOM DX product range refer to the ATOM DX data sheet L-9517-9736.

IMPORTANT: Prior to installing readhead and disc, installation drawings should be reviewed to ensure correct orientation of readhead relative to disc.

Disc alignment

Optical alignment

using a microscope.

(see page 6).

Shim kit.

(see page 9).

Electrical alignment

Using two readheads.

(see page 7).

Mount and align readhead

Dummy head.

(see page 10).

Calibrate system

(see page 11).

ATOM DX rotary installation guide

3

Page 6

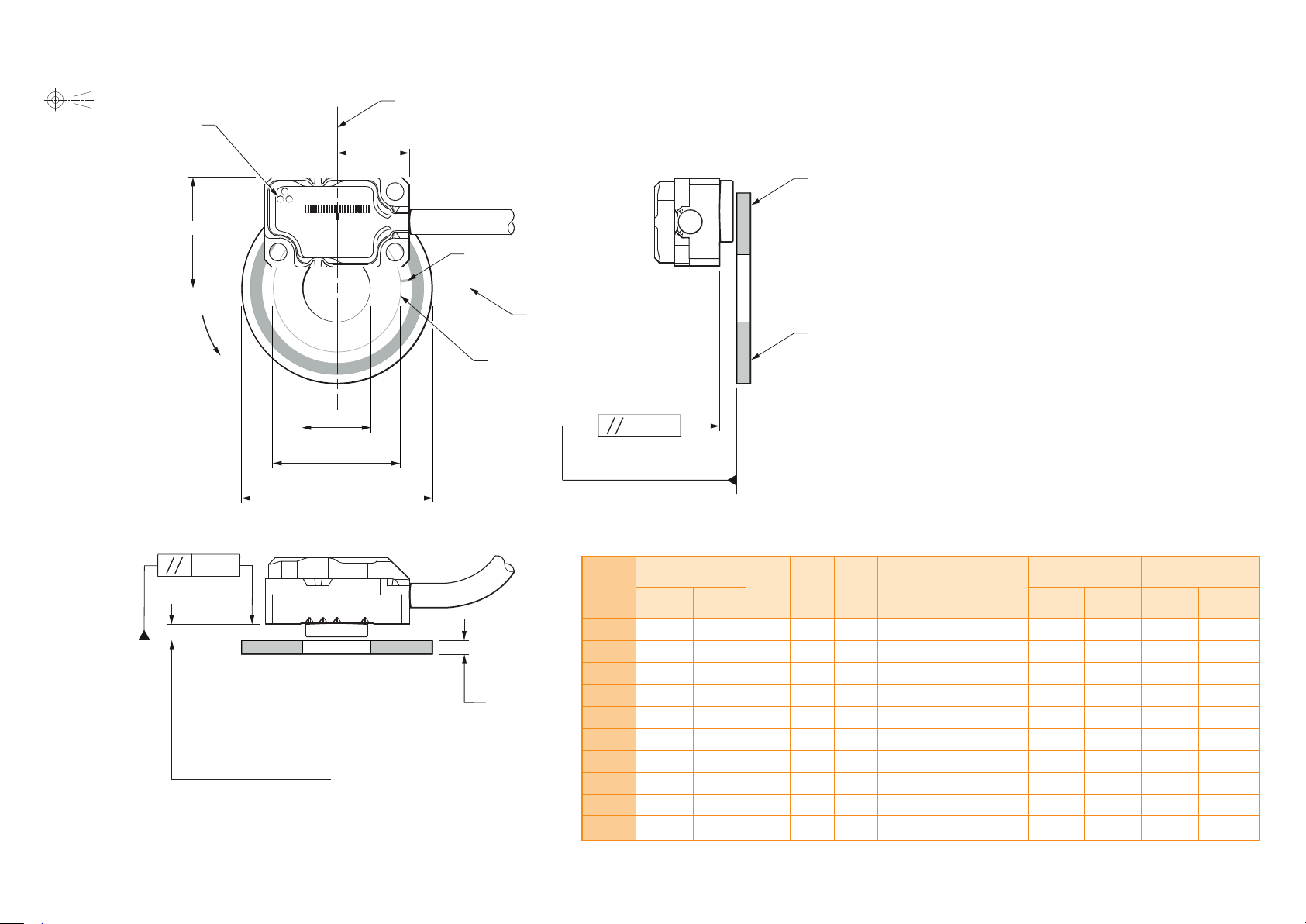

RCDM rotary disc: Installation drawing (Cabled readhead shown)

For dimensioned readhead drawings see pages 15 and 16.

Centre of alignment band

Set-up LED

10.25 ± F

A ± E

Reference mark

Dimensions and tolerances in mm

Glass disc

Forward direction

of disc

(increasing count)

(Pitch tol. ±1°)

0.36

Rideheight (for calibration):

2.5 ±0.08 (40 µm version)

2.5 ±0.04 (20 µm version)

Operating rideheight:

2.5 ±0.11 (40 µm version)

2.5 ±0.055 (20 µm version)

D1

D2

D3

Centre of

alignment band

Alignment band for

aligning the disc

on the hub/shaft

2.3

Black mask 10 µm (±5 µm) thick on reverse of disc

underneath incremental and reference track

(Roll tol. ±1°)

0.22

For detailed installation drawings, including tolerances, refer to www.renishaw.com /opticalencoders

Disc

size

(mm)

17 – 1 024 3.275 8.10 16.9 13.04 10.63 – 0.1 – 0.1

20 – 1 250 3.275 11.00 19.9 15.92 12.07 – 0.1 – 0.1

25 – 1 650 6.46 16.10 24.9 21.01 14.62 – 0.125 – 0.075

27 – 1 800 9.625 18.00 26.9 22.92 15.57 – 0.125 – 0.075

30 4 096 2 048 12.8 21.15 29.9 26.08 17.15 0.1 0.125 0.075 0.125

36 5 000 2 500 12.8 26.90 35.9 31.83 20.03 0.125 0.175 0.075 0.2

50 7 200 3 600 25.5 40.90 49.9 45.84 27.03 0.125 0.2 0.075 0.2

56 8 192 4 096 25.5 47.25 55.9 52.15 30.19 0.125 0.2 0.1 0.225

68 10 000 5 000 25.5 58.55 67.9 63.66 35.94 0.15 0.2 0.125 0.3

108 16 384 8 192 50.9 99.20 107.9 104.30 56.26 0.2 0.2 0.225 0.3

Line count

20 µm

version

40 µm

version

D1

(mm)

D2

(mm)

D3

(mm)

Optical diameter

(mm)

(mm)

Radial tolerance

A

20 µm

version

E (mm)

40 µm

version

Longitudinal

tolerance F (mm)

20 µm

version

40 µm

version

ATOM DX rotary installation guide

4

Page 7

Mounting the disc

Mounting surface design

The recommended mounting surface (hub / shaft) profile must allow for the following features:

u

Overspill areas either side of the adhesive mounting surface for excess adhesive to run-off.

u

Sufcient clearance between the disc ID and hub / shaft to allow correct alignment.

u

A small height clearance between the disc contact surface and the adhesive mounting surface

to allow application of a controlled thin lm of adhesive.

u

A maximum outer diameter of the disc contact surface to ensure it is not touching the black mask

on the reverse of the disc. See table below for dimensions.

Disc size (mm) 17 20 25 27 30 36 50 56 68 108

Maximum OD

of disc contact

surface (mm)

*

17 mm disc can be mounted on black mask due to space constraints. All other size discs the black mask must not impede the disc contact surface.

9.52 14.2 16.12 19.28 25.04 39.04 45.36 56.66 97.3

*

Gluing the disc

There are 2 recommended types of adhesives for bonding the disc to the hub / shaft:

u

UV cure adhesive (such as Dymax OP4, gel version)

u

Room cure 2-part epoxy (such as Araldite 2014)

1

Apply a thin bead of adhesive to the

adhesive mounting surface.

It should be of sufficient quantity only to

fill the gap between the hub and disc.

Small amounts may run-off into adhesive

overspill areas but these areas should not

be filled with adhesive.

See cross section drawing

Cross section of typical hub and disc assembly

Clearance between disc ID

Black mask

Disc contact surface

and hub / shaft

Adhesive

mounting surface

Customer hub

Adhesive overspill areas

Contact your local Renishaw representative for more information on designing the

mounting surface, suggested materials and adjustment methods.

ATOM DX rotary installation guide

RCDM disc

Bead of

adhesive

Disc contact

surface

Adhesive

mounting surface

2

Using a weight (or similar) ensure the disc touches the hub / shaft over the entire disc contact surface.

Weight

Weight

Movement of disc during

alignment procedure

3

Align the disc so it is concentric with the hub / shaft.

4

Cure the adhesive.

5

Page 8

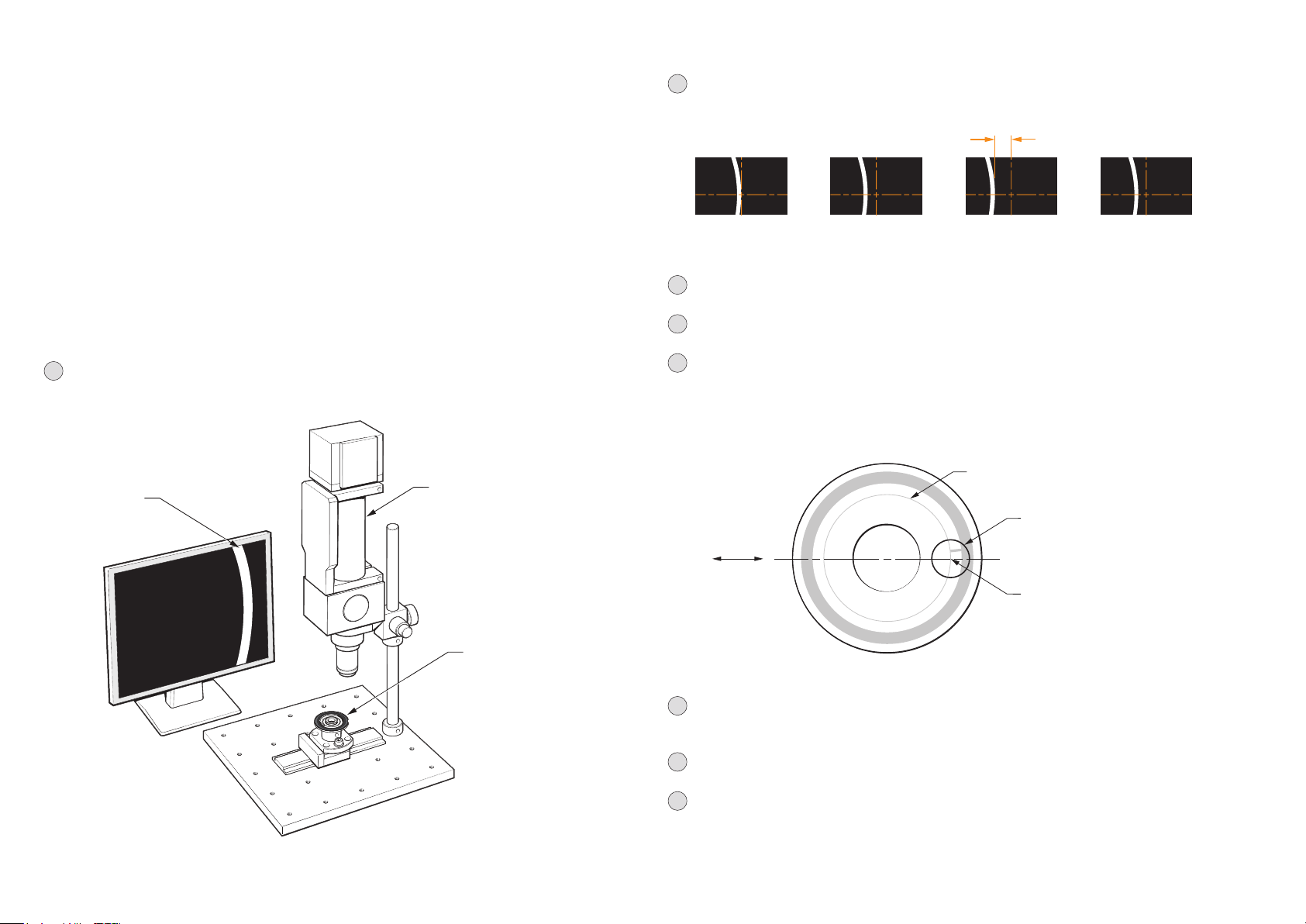

Aligning the disc

There are two possible ways to accurately align the disc to minimise eccentricity:

u

Optical alignment using a microscope

u

Electrical alignment using two readheads

The method chosen to align the disc on the system depends upon the application and available

space, etc. It should be noted that the graduations and alignment band are accurately concentric

with each other but not with the glass disc. The following sections outline how to align the disc

using these methods.

NOTE:

The disc should not be mounted on the black mask on the reverse of the disc

(apart from 17 mm disc).

Optical alignment

This method uses a microscope, which could be connected to a camera,

to monitor the movement of the alignment band as the disc is rotated.

Position the microscope / camera over the alignment band on the disc so that any

1

displacement of the alignment band due to rotation of the disc / hub assembly

can be observed.

Alignment

band

Microscope

and camera

2

Rotate the disc / hub assembly and observe the maximum and minimum limits of movement

of the alignment band as shown below.

Maximum movement

Minimum movement

0° Rotation

3

Note the axis position at the limits of movement.

4

Rotate the disc so either of these limits of movement is located under the microscope.

5

Gently move the disc relative to the hub in a radial direction so the alignment band

90° Rotation 180° Rotation 270° Rotation

moves half way between the limits of movement.

NOTE: The alignment band is 30 µm wide.

Position of disc at limit of movement of alignment band.

Alignment band

Direction of

movement

Microscope

ATOM DX rotary installation guide

RCDM disc / hub

assembly

Position of maximum or

minimum limit of movement

of the alignment band

6

Rotate the assembly and repeat steps 3 to 5 until the total alignment band

movement is within the design specications.

7

Cure the adhesive.

8

Recheck the run-out.

Contact your local Renishaw representative for more information on aligning the disc.

6

Page 9

Electrical alignment

This method involves monitoring the output signals of two readheads mounted 180 degrees apart

and adjusting the disc to minimise the difference in count between the two heads.

NOTE: Due to spacing it is not possible to use this method on discs smaller than 22 mm diameter.

This requires:

u

A DSi interface

u

A digital counter

The clock frequency of the DSi, readheads and digital counter must be matched to ensure there is no

miscounting. For more information on choosing appropriate DSi and readheads for your system contact

your local Renishaw representative. For more information on the DSi refer to the TONiC DSi data sheet

(L-9517-9466).

INPUT 1

DSi

INPUT 2

Customer

counter

4

Restore factory defaults on both ATOM DX readheads by obscuring the readhead windows whilst

switching the system on. This can be done individually or whilst the readheads are plugged into the DSi.

See page 12 for more information.

5

Using a custom designed bracket adjust both readheads to maximise the signal strength for

a complete rotation of the axis (readhead set-up LED should be ashing Green on both readheads)

6

Rotate the axis until the count displayed on the customer counter is at its minimum.

NOTE: If the count continues to increase then the orientation switch on the DSi is not in the

correct position.

7

Rotate the axis to the minimum count position and reset the counter to zero.

8

Rotate the axis until a maximum count is displayed. This should be ~180° from the position when

the count is minimum.

9

Gently move the disc relative to the hub in a radial direction at 90° to the readheads, as shown below,

until the count displayed on the customer counter is reduced by approximately half.

Direction of

movement

1

Connect system as shown above.

2

Set the orientation switch on the reverse of the DSi to ‘difference’ mode.

Factory

setting

Difference mode

or

3

Power the system.

ATOM DX rotary installation guide

10

Repeat steps 6 to 9 until the difference in (maximum count) – (minimum count) is within

the design specications.

11

Cure the adhesive.

12

Recheck the run-out.

Contact your local Renishaw representative for more information on aligning the disc.

7

Page 10

System connection: Top exit readhead

A range of cables for top exit readheads are available;

15 way D-type connector 10 way JST

Top exit readhead (with readhead cable inserted)

Cable length (m) Part number

0.5 A-9414-1223

1.0 A-9414-1225

1.5 A-9414-1226

3.0 A-9414-1228

u

Provide appropriate strain relief at the readhead. The Renishaw top exit cables

are fitted with a P-clip to ensure appropriate cable strain relief.

u

When using Renishaw’s top exit cables ensure that the P-clip is mounted within a

50mm radius of the readhead cable exit.

u

Minimum static bend radius of cores is 3 mm.

u

For challenging dynamic applications consider additional strain relief of the cores.

u

Ensure there is no relative movement between the readhead and the P-clip.

u

The maximum number of insertions for the readhead connector is 20 cycles.

Care should be taken when removing the connector to avoid pulling out cores

from the cable connector.

Cable length (m) Part number

0.5 A-9414-1233

1.0 A-9414-1235

1.5 A-9414-1236

3.0 A-9414-1238

Shielding

For optimum performance:

u

Ensure 100% shielding.

u

Ground the mounting brackets.

u

Ensure continuity between the readhead body and cable shield. For Renishaw

top exit cables the P-clip provides electrical connection to the cable shield.

u

Maximise the distance between the encoder and motor cables.

A

Detail B: P-clip dimensions

10

4

11.07

B

Detail A: Connector (readhead end) and P-clip

88

6.8

2.5

5.7 ±0.05

P-clip

Use M2 tapping drill

(∅1.6) as clearance

for pin

ATOM DX rotary installation guide

∅1.5 ±0.05

2.09

5

2

Hole for M2 screw

8

Page 11

Readhead mounting and alignment: Methods

There is a range of tools available to assist with readhead installation depending upon the system design:

u Shim kit.

u Dummy head.

For more details on designing the mounting bracket and selecting the appropriate mounting tools contact your

local Renishaw representative.

Ensure that the disc, readhead optical window and mounting face are clean and free from obstruction.

Do not saturate the readhead window with cleaning solvent as this may cause contamination on the inside

of the readhead window which then cannot be cleaned.

IMPORTANT: Whichever method is used to mount the readhead, care should be taken to ensure the disc

surface is not damaged during this operation.

NOTE: Cabled readhead shown but the same readhead mounting and alignment methods are applicable for

top exit readheads.

Shim kit (A-9401-0050)

This method is intended

for applications where the

rideheight of the readhead

cannot be adjusted.

2

Subtract the distance measured from the nominal

rideheight of 2.5 mm to calculate the required

shim thickness. For example, if the distance

measured is 2.37 mm, the required shim thickness

is 130 µm.

Select a combination of two shims that gets

3

within 10 µm of the difference. For distances less

than 100 µm a single shim should be used,

for distances greater than 100 µm select one

thick (≥100 µm) and one thin (<100 µm) shim.

In the above example this could either be:

1 × 100 µm shim and 1 × 40 µm shim or

1 × 100 µm shim and 1 × 20 µm shim.

4

Place the chosen shim(s) between the readhead

and the bracket.

5

Fix the readhead to the bracket using 2 off

M2 × 6 screws in diagonally opposite xing holes

ensuring that the readhead is tightened down evenly

and parallel to the bracket face.

6

Connect the readhead to the receiving electronics

and power-up.

DTI adapter

RCDM

disc

Mounting

bracket

Disc

Location pins

2.3 ±0.2 mm

The system should be

designed to achieve a

nominal 2.3 mm (±0.2 mm)

from the readhead mounting

surface to the disc surface.

Shims of a known thickness are inserted between the mounting face of the readhead and the bracket to give

the correct rideheight of 2.5 mm (±0.2 mm).

The kit consists of:

Part number:

Thickness

(µm)

Quantity in

pack

1

Using a digital dial gauge or similar measure the distance from the readhead mounting surface to the

A-9401-

0041

20 40 60 80 100 200 300

10 10 10 10 20 20 10

A-9401-

0042

A-9401-

0043

A-9401-

0044

A-9401-

0045

A-9401-

0046

A-9401-

0047

disc surface. Care must be taken to ensure the disc surface is not scratched.

Renishaw offer a DTI adapter (A-9401-0105) that can be used to assist with this process.

u Insert the gauge into the adapter and zero the gauge on a at surface.

u Position or x the gauge/adapter in place of the readhead and measure the distance to the disc surface.

Contact your local Renishaw representative for details of the DTI adapter and digital dial guage.

ATOM DX rotary installation guide

Using location pins / shoulder:

Ensure the readhead is pushed back against

7

the location pins or shoulder.

8

Tighten the readhead xing screws.

9

Check the readhead set-up LED is ashing

Green around the full axis of rotation.

10

Proceed with ‘System calibration’ section (see page 12).

Not using location pins:

11

Adjust longitudinal and radial offset of the

readhead to obtain a ashing Green

readhead set-up LED around the full

axis of rotation. An oscilloscope or

Advanced Diagnostic Tool (ADTi-100) and

ADT View software can be used to help

maximise the signal size.

12

Tighten the readhead xing screws.

13

Proceed with ‘System calibration’ section (see page 12).

*

For more details refer to the ‘Advanced Diagnostic Tool ADTi-100 and ADT View software quick start guide’ (M-6195-9321)

and ‘Advanced Diagnostic Tool ADTi-100 and ADT View software user guide’ (M-6195-9413).

*

9

Page 12

Dummy head (A-9401-0072)

The reuseable dummy head has the same mounting holes as the

ATOM DX readhead with a longer ‘nose’ that is machined to the

optimum rideheight (2.5 mm ±0.02 mm). It is mounted in place of the

readhead directly onto the bracket. The bracket should have location

pins or a shoulder to control readhead yaw. Contact your local

Renishaw representative for more information on bracket design.

1

Mount the dummy head onto the bracket using 2 off M2 × 6 screws.

2

Loosely mount the readhead bracket onto the axis.

3

Adjust the height of the bracket or disc assembly until the ‘nose’ of the dummy head

just touches the disc.

Install the ATOM DX readhead in place of the dummy head using 2 off M2 × 6 screws

6

in diagonally opposite xing holes.

Connect the readhead to the receiving electronics and power-up.

7

Using location pins / shoulder:

Ensure the readhead is pushed back against the location pins or shoulder.

8

9

Tighten the readhead xing screws.

10

Check the readhead set-up LED is ashing Green around the full axis of rotation.

11

Proceed with ‘System calibration’ section (see page 12).

Not using location pins:

4

Tighten bracket xing screws whilst ensuring good contact between the ‘nose’ of the

dummy head and the surface of the disc.

5

Remove the dummy head.

ATOM DX rotary installation guide

12

Adjust longitudinal and radial offset of the readhead to obtain a ashing Green readhead

set-up LED around the full axis of rotation. An ADTi and ADT View software can be used

to help maximise the signal size.

13

Tighten the readhead xing screws.

14

Proceed with ‘System calibration’ section (see page 12).

10

Page 13

ATOM DX calibration overview

This section is an overview of the calibration procedure for an ATOM DX encoder system.

More detailed information on calibrating the readhead is on page 12 of this installation guide.

The optional Advanced Diagnostic Tool ADTi-100* (A-6165-0100) and ADT View software† can be used to aid installation and calibration.

Calibrate system

Ensure the readhead set-up LED is ashing Green around the full axis of rotation before system calibration.

See page 9 and page 10 for more information on readhead mounting and alignment.

Cycle the power to the readhead to initiate the calibration routine. The LED will single ash Blue.

Rotate the disc at slow speed (<100 mm/s), without passing a reference mark, until the LED starts double ashing Blue.

*

For more details refer to the ‘Advanced Diagnostic Tool ADTi-100 and ADT View software quick start guide’ (M-6195-9321) and ‘Advanced Diagnostic Tool ADTi-100 and ADT View software user guide’ (M-6195-9413).

ATOM DX rotary installation guide

No reference mark

If a reference mark is not being used, the calibration

routine should now be exited by cycling the power.

The LED will stop ashing.

The system is now calibrated and ready for use. Calibration values, Automatic Gain Control (AGC) and

Automatic Offset Control (AOC) status are stored in readhead non-volatile memory at power down.

NOTE: If calibration fails (LED remains single ashing Blue), restore factory defaults by obscuring the

readhead optical window on power-up (see page 12) then repeat the installation and calibration routine.

†

The software can be downloaded for free from www.renishaw.com /adt.

Reference mark

Rotate the readhead back and forth over the

reference mark until the LED stops ashing.

11

Page 14

System calibration

NOTE: System calibration (CAL), restoring factory defaults, and enabling / disabling AGC functions can

also be carried out using the optional ADTi-100 and ADT View software. See www.renishaw.com/adt

for more information.

Ensure signal strength has been optimised around the full axis of rotation, the LED will be ashing Green.

Cycle the power to the readhead or connect the ‘Remote CAL’ output pin to 0 V for <3 seconds.

The readhead will then single ash Blue to indicate it is in calibration mode. The readhead will only enter

calibration mode if the LED is ashing Green.

Step 1 – Incremental signal calibration

uRotate the axis at slow speed (<100 mm/s or less than the readhead maximum speed, whichever is

slowest), ensuring the readhead does not pass a reference mark, until the LED starts double-ashing.

This indicates that the incremental signals are now calibrated and the new settings are stored in the

readhead memory.

uThe system is now ready for reference mark phasing. For systems without a reference mark,

cycle the power to the readhead or connect the ‘Remote CAL’ output pin to 0 V for <3 seconds to

exit calibration mode.

uIf the system does not automatically enter the reference mark phasing stage (LED continues single

ashing) the calibration of the incremental signals has failed. After ensuring failure is not due to

overspeed (>100 mm/s or exceeding the readhead maximum speed), exit the calibration routine,

restore factory defaults as detailed below and check the readhead installation and system

cleanliness before repeating the calibration routine.

Restoring factory defaults

When re-installing the system, or in the case of continued calibration failure, factory defaults should be restored.

To restore factory defaults:

uSwitch system off.

uObscure the readhead optical window or connect the ‘Remote CAL’ output pin to 0 V.

uPower the readhead.

uRemove the obstruction or, if using, the connection from the ‘Remote CAL’ output pin to 0 V.

uThe LED will start continuously ashing indicating factory defaults have been restored and the readhead

is in installation mode (ashing set-up LED).

uRepeat ‘Readhead set-up’ procedure.

Enabling/disabling AGC

The AGC is automatically enabled once the system has been calibrated (indicated by a Blue LED). AGC can be

manually switched off by connecting the ‘Remote CAL’ output pin to 0 V for >3 seconds <10 seconds. The LED

will then be solid Green.

Readhead LED diagnostics

Step 2 – Reference mark phasing

uMove the readhead back and forth over the reference mark until the LED stops ashing and remains

solid Blue. The reference mark is now phased.

uThe system automatically exits the calibration routine and is ready for operation.

uAGC is automatically switched on once calibration is complete. To switch off AGC refer to the

‘Enabling / disabling AGC’ section.

uIf the LED continues double-ashing after repeatedly passing the reference mark it is not being detected.

- Ensure that the readhead orientation and alignment are correct.

Calibration routine manual exit

uTo exit the calibration routine at any stage cycle the power to the readhead or connect the

‘Remote CAL’ output pin to 0 V for <3 seconds. The LED will then stop ashing.

LED Settings stored

Blue single ashing None, restore factory defaults and recalibrate

Blue double ashing Incremental only

Blue (auto-complete) Incremental and reference mark

ATOM DX rotary installation guide

Mode LED Status

Installation mode

Calibration mode

Normal operation

Alarm 4 red ashes Low signal or over signal; system in error

Green ashing Good set-up, maximise ash rate for optimum set-up

Orange ashing Poor set-up, adjust readhead to obtain Green ashing LED

Red ashing Poor set-up, adjust readhead to obtain Green ashing LED

Blue single ashing Calibrating incremental signals

Blue double ashing Calibrating reference mark

Blue AGC on, optimum set-up,

Green AGC off, optimum set-up,

Red Poor set-up; signal may be too low for reliable operation

Blank ash Reference mark detected (visible indication at speed <100mm/s only)

12

Page 15

Troubleshooting

Fault Cause Possible solutions

LED on the readhead is Blank There is no power to the readhead

LED on the readhead is Red and

The signal strength is <50%

I can’t get a Green LED

Unable to get a ashing Green LED

System run-out is not within specication

around the full axis of rotation

Can’t initiate the calibration routine Signal size is <70%

u

Check you have 5 V at the readhead

u

For cable variants check correct wiring of connector

u

Check the readhead optical window and disc are clean and free from contamination

u

Restore factory defaults (see page 12) and check alignment of the readhead. In particular;

– Rideheight

– Longitudinal and radial offset

u

Check the disc and readhead orientation

u

Check that the readhead variant is the correct type for the chosen disc

(see the ATOM DX data sheet (L-9517-9736) for details of readhead conguration)

u

Check that the readhead variant is the correct type for the chosen disc

(see the ATOM DX data sheet (L-9517-9736) for details of readhead conguration.

u

Use a DTI gauge and check the run-out is within specications

u

Restore factory defaults

u

Realign readhead to obtain a Green LED at the mid-point of the run-out

u

Recalibrate the system (see page 12)

u

Restore factory defaults

u

Realign readhead to obtain a Green ashing LED

LED on the readhead remains single

ashing Blue even after moving it

around the full axis of rotation

ATOM DX rotary installation guide

The system has failed to calibrate the

incremental signals due to the signal

strength being <70%

u

Exit CAL mode and restore factory defaults (see page 12)

u

Check system set-up and realign the readhead to obtain a ashing Green LED around the full axis of rotation

before recalibrating

13

Page 16

Troubleshooting (continued)

Fault Cause Possible solutions

During calibration the LED on the

readhead is double ashing Blue even

The readhead is not seeing a

reference mark

after moving it past the reference mark

several times

No reference mark output

Reference mark is not repeatable The reference mark is not

calibrated

LED on the readhead is ashing Red

The reference mark is not phased

over the reference mark

u

Check the disc/readhead orientation

u

Check the disc/readhead alignment

u

Check the readhead optical window and disc are clean and free from contamination

u

Check that the readhead variant is the correct type for the chosen disc

(see the ATOM DX data sheet (L-9517-9736) for details of readhead conguration)

u

Ensure you are not over-speeding the readhead during calibration mode (maximum speed <100 mm/sec)

u

Calibrate the system (see page 12)

– If the system completes calibration mode then it has successfully seen and calibrated the reference mark

If you still don’t see a reference mark then check the system wiring

– If the system does not calibrate the reference mark (readhead set-up LED remains double ashing Blue)

see above for possible solutions

u

The readhead bracket must be stable and not allow any mechanical movement of the readhead

u

Clean the disc and readhead optical window and check for damage then recalibrate the system (see page 12).

u

Clean the disc and readhead optical window and check for scratches then recalibrate the system (see page 12).

ATOM DX rotary installation guide

14

Page 17

ATOM DX cabled readhead dimensions

Dimensions and tolerances in mm

1.4 (40 µm version)

1.9 (20 µm version)

12.7

Readhead / disc

8.7

orientation

2

Set-up LED

2

16.5

20.5

5 min

Readhead datum faces

3

11.7

R>20 Dynamic bend radius

R>10 Static bend radius

Ø3.5 max

4.15

6.45

Datum face

10.25

Ø9 max

3 off mounting holes

Ø2.5 min through

4.85

*

*

Not optical centreline

For detailed installation drawings refer to www.renishaw.com /opticalencoders

ATOM DX rotary installation guide

Identification marks for readhead manufacture only.

Notches will vary depending on readhead type.

15

Page 18

ATOM DX top exit readhead dimensions

Set-up LED

11

10.45

Readhead datum faces

6.45

1.4 (40 µm version)

1.9 (20 µm version)

Dimensions and tolerances in mm

2

10.25

12.7

Readhead / disc orientation

8.37

16.5

20.5

8.7

*

4.85

2.8

Datum face

4.15

2

3 off mounting holes Ø2.5 min through

Ø9 max

*

Not optical centreline

For detailed installation drawings refer to www.renishaw.com /opticalencoders

ATOM DX rotary installation guide

Identification marks for readhead manufacture only.

Notches will vary depending on readhead type.

16

Page 19

Output signals

Cabled

Function Signal Colour

Power

Incremental

Reference

mark

5 V Brown 5 7, 8 4, 12 10 10

0 V White 1 2, 9 2, 10 2 9

+ Red 2 14 1 9 5

A

− Blue 6 6 9 7 6

+ Yellow 4 13 3 4 8

B

− Green 8 5 11 1 7

+ Violet 3 12 14 8 4

Z

− Grey 7 4 7 5 3

9 way D-type

(A)

15 way D-type

(D)

15 way D-type

alternative

pin-out (H)

10 way JST

(K)

†

10 way JST

Alarm E − Orange – 3 13 6 2

Remote CAL CAL Clear 9 1 5 3 1

Shield – Screen Case Case Case Ferrule –

†

PCB mount mating connectors - Top entry: BM10B-SRSS-TB Side entry: SM10B-SRSS-TB.

‡

Connector on top exit readhead only. Mating connector 10SUR - 32S.

Top Exit

‡

(Z)

ATOM DX rotary installation guide

17

Page 20

Speed

20 µm encoder

Clocked

output option

(MHz)

50 10 10 10 7.25 3.63 1.813 1.450 0.725 0.363 0.181 0.091 25.1

40 10 10 10 5.80 2.90 1.450 1.160 0.580 0.290 0.145 0.073 31.6

25 10 10 9.06 3.63 1.81 0.906 0.725 0.363 0.181 0.091 0.045 51.0

20 10 10 8.06 3.22 1.61 0.806 0.645 0.322 0.161 0.081 0.040 57.5

12 10 10 5.18 2.07 1.04 0.518 0.414 0.207 0.104 0.052 0.026 90.0

10 10 8.53 4.27 1.71 0.85 0.427 0.341 0.171 0.085 0.043 0.021 109

08 10 6.91 3.45 1.38 0.69 0.345 0.276 0.138 0.069 0.035 0.017 135

06 10 5.37 2.69 1.07 0.54 0.269 0.215 0.107 0.054 0.027 0.013 174

04 10 3.63 1.81 0.73 0.36 0.181 0.145 0.073 0.036 0.018 0.009 259

01 4.53 0.91 0.45 0.18 0.09 0.045 0.036 0.018 0.009 0.005 0.002 1038

40 µm encoder

Clocked

output option

(MHz)

50 20 20 20 20 18.13 7.25 3.63 1.813 1.450 0.725 0.363 0.181 25.1

40 20 20 20 20 14.50 5.80 2.90 1.450 1.160 0.580 0.290 0.145 31.6

25 20 20 20 18.13 9.06 3.63 1.81 0.906 0.725 0.363 0.181 0.091 51.0

20 20 20 20 16.11 8.06 3.22 1.61 0.806 0.645 0.322 0.161 0.081 57.5

12 20 20 20 10.36 5.18 2.07 1.04 0.518 0.414 0.207 0.104 0.052 90.0

10 20 20 17.06 8.53 4.27 1.71 0.85 0.427 0.341 0.171 0.085 0.043 109

08 20 20 13.81 6.91 3.45 1.38 0.69 0.345 0.276 0.138 0.069 0.035 135

06 20 20 10.74 5.37 2.69 1.07 0.54 0.269 0.215 0.107 0.054 0.027 174

04 20 18.13 7.25 3.63 1.81 0.73 0.36 0.181 0.145 0.073 0.036 0.018 259

01 9.06 4.53 1.81 0.91 0.45 0.18 0.09 0.045 0.036 0.018 0.009 0.005 1038

*

For a readhead with a 1 m cable.

Angular speed depends on disc diameter - use the following equation to convert to rev /min.

Angular speed (rev/min) =

D

(5 µm)

T

(10 µm)

V × 1000 × 60

p D

X

(1 µm)

D

(5 µm)

Where V = maximum linear speed (m / s) and D = optical diameter of RCDM (mm)

(2

(0.5 µm)

G

µm)

Z

(1 µm)

W

(0.2 µm)

X

(0.5 µm)

Z

Maximum speed (m/s)

Readhead type

Y

(0.1 µm)

(50 nm)

Maximum speed (m/s)

Readhead type

W

(0.2 µm)

H

(0.1 µm)

*

M

(40 nm)

I

(20 nm)

O

(10 nm)

Q

(5 nm)

R

(2.5 nm)

*

Y

H

(50 nm)

M

(40 nm)

I

(20 nm)

O

(10 nm)

Q

(5 nm)

Minimum edge

separation

Minimum edge

separation

*

(ns)

*

(ns)

ATOM DX rotary installation guide

18

Page 21

Electrical connections

Grounding and shielding

Cabled readhead

Shield

IMPORTANT: The shield should be connected to the machine earth (Field Ground).

For JST variants the ferrule should be connected to the machine earth.

Top exit

readhead

IMPORTANT: The shield should be connected to the machine earth (Field Ground).

NOTE: For Renishaw top exit readhead cables the shield connection is provided by the P-clip.

Readhead

termination/connector

Shield

Customer

electronics

5 V

0 V

Customer

electronics

5 V

Output signals

0 V

Output signals

Recommended signal termination

Digital outputs

0 V

Readhead

A B Z+

Cable Z0 = 120R

A B Z−

Standard RS422A line receiver circuitry

Capacitors recommended for improved noise immunity

Single ended alarm signal termination

(Not available with ‘A’ cable termination)

Readhead

E−

100R

4k7

120R

0 V

5 V

4k7

1k8

100nF

Customer

220 pF

electronics

220 pF

Customer

electronics

Maximum readhead cable length: 3 m

Maximum extension cable length: Dependent on cable type, readhead cable length and clock speed.

Contact your local subsidiary for more information.

ATOM DX rotary installation guide

Remote CAL operation

CAL

Remote system calibration (CAL) is possible via the CAL pin.

0 V

19

Page 22

Output specications

Digital output signals

Form – Square wave differential line driver to EIA RS422A

Incremental

*

2 channels A and B in quadrature (90° phase shifted)

Signal period

A

B

Reference

*

Z

*

Inverse signals not shown for clarity

Alarm

Line driven (Asynchronous pulse)

(Not available with ‘A’ cable termination)

Resolution

Synchronised pulse Z,

duration as resolution.

Bi-directionally repeatable

Resolution option

code

†

T

P (μm) S (μm)

40 10

D 20 5

†

G

8 2

X 4 1

Z 2 0.5

W 0.8 0.2

Y 0.4 0.1

H 0.2 0.05

M 0.16 0.04

I 0.08 0.02

O 0.04 0.01

Q 0.02 0.005

‡

†

R

40 μm ATOM DX only ‡ 20 μm ATOM DX only

0.01 0.0025

>15 ms

E−

Alarm asserted when:

– Signal amplitude <20% or >135%

– Readhead speed too high for reliable operation

or 3-state alarm

Differentially transmitted signals forced open circuit for >15 ms when alarm conditions valid.

ATOM DX rotary installation guide

20

Page 23

General specications

Disc specications

Power supply 5 V −5 /+10% Typically <200 mA fully terminated

Power from a 5 V dc supply complying with the requirements

for SELV of standard IEC BS EN 60950-1

Ripple 200 mVpp maximum@frequency up to 500 kHz

Temperature Storage −20 °C to +70 °C

Operating 0 °C to +70 °C

Humidity 95% relative humidity (non-condensing) to EN 60068-2-78

Sealing IP40

Acceleration (system) Operating 400 m/s², 3 axes

Shock (system) Operating 1000 m/s², 6 ms, ½ sine, 3 axes

Vibration Operating 100 m/s² max @ 55 Hz to 2000 Hz, 3 axes

Mass Standard readhead 3.2 g

Top exit readhead 2.9 g

Cable 18 g/m

Cable 10 core, high ex, EMI screened cable, outside diameter

3.5 mm maximum

Flex life >20 × 10 6 cycles at 20 mm bend radius,

maximum length 3 m

(Extension cable up to 25 m when using Renishaw approved

extension cable)

UL recognised component

Top exit cables available in lenghts from 0.5 m to 3 m

with 15 way D-type or 10 way JST (SH) connector options.

Cabled connector options 9 way D-type

15 way D-type (standard and alternative pin out)

10 way JST (SH)

Top exit readhead connector 10 way JST (SUR)

Typical Sub-Divisional

Error (SDE)

20 µm version <±75 nm

40 µm version <±120 nm

Material Soda lime glass

Form

Reference mark Single reference mark

Graduation accuracy Discs <100 mm ±0.5 µm

Disc size (mm) 17 20 25 27 30 36 50 56 68 108

Graduation accuracy

(arc seconds)

Coefcient of thermal expansion ~8 µm/m/°C

Nominal outer diameter (mm) 40 µm 17, 20, 25, 27, 30, 36, 50, 56, 68, 108

15.81 12.95 9.82 9.0 7.91 6.49 4.5 3.95 3.24 2.78

2.3 mm thick

Discs >100 mm ±0.7 µm

20 µm 30, 36, 50, 56, 68, 108

Renishaw encoder systems have been designed to the relevant EMC standards but must be correctly

integrated to achieve EMC compliance. In particular, attention to shielding arrangements is essential.

ATOM DX rotary installation guide

21

Page 24

Renishaw plc

New Mills, Wotton-under-Edge

Gloucestershire, GL12 8JR

United Kingdom

RSLM high accuracy linear encoder

T +44 (0) 1453 524524

F +44 (0) 1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details, visit www.renishaw.com/contact

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

© 2017-2019 Renishaw plc. All rights reserved.

Renishaw reserves the right to change specifications without notice.

RENISHAW and the probe symbol used in the RENISHAW logo are registered trade marks of Renishaw plc in the United Kingdom and other countries.

apply innovation and names and designations of other Renishaw products and technologies are trade marks of Renishaw plc or its subsidiaries.

All other brand names and product names used in this document are trade names, trade marks or registered trade marks of their respective owners.

*M-9414-9447-01*

Part no.: M-9414-9447-01-A

Issued: 07.2019

Loading...

Loading...