Page 1

RSLM high accuracy linear encoder

Installation guide

M-9693-9723-05-D

ATOM

™

linear encoder systems

Page 2

ATO M linear installation guide

Contents

Product compliance 1

Storage and handling 2

ATOM system installation overview 3

RTLF tape scale:

Installation drawing 4

Application methods 5

Mounting (for lengths <500 mm only) 6

Application (any length) 7

Datum clamp 8

End covers 8

Reference mark deselection 8

RCLC glass spar scale:

Installation drawing 9

Mounting 10

System connection:

Readhead only (no interface) 11

ACi interface 13

Ri interface 15

Ti interface 16

Readhead mounting and alignment:

Methods 17

Shim kit (A-9401-0050) 18

Dummy head (A-9401-0072) 19

Accurate bracket and feeler gauge 20

Signal amplitude adjustment 20

Calibration overview 21

System calibration (CAL)

Step 1 - Incremental signal calibration 22

Step 2 - Reference mark phasing 22

Calibration routine - manual exit 22

Restoring factory defaults 22

Switching Automatic Gain Control (AGC) on or off 22

LED diagnostics 23

Troubleshooting 24

ATOM readhead:

Cabled readhead dimensions 26

FPC readhead dimensions 27

Output signals 28

ACi interface:

FPC variant 29

Installation drawing 29

Input signals 29

Output signals 29

Cable variant 30

Installation drawing 30

Readhead cable input connector 30

Input signals 30

Output signals 30

PCB mounting variant 31

Input signals 31

Output signals 31

Speed 32

Ri interface:

Interface drawing 33

Output signals 33

Speed 34

Ti interface:

Interface drawing 35

Output signals 35

Speed 36

Electrical connections 37

Output specications 38

General specications 39

Scale specications 39

Page 3

ATO M linear installation guide

1

Further information

Further information relating to the ATOM encoder range can be found in the ATOM system Data sheet

(L-9517-9563). This can be downloaded from our website www.renishaw.com/encoder and is also available

from your local representative. This document may not be copied or reproduced in whole or in part,

or transferred to any other media or language, by any means without the written prior permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT

IS CORRECT AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Product compliance

ATOM cabled readhead and accessories

C

Renishaw plc declares that ATOM complies with the applicable standards and regulations.

A copy of the EC Declaration of Conformity is available on request.

FCC compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

The user is cautioned that any changes or modications not expressly approved by Renishaw plc or

authorised representative could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must be

used with the unit to ensure compliance.

ATOM FPC readhead and ACi

The FPC ATOM and ACi have been designed as system components and to be compliant with

EMC regulations for products of their type. Care must be taken with shielding and grounding

arrangements to ensure EMC performance once installed. It is the system integrator’s responsibility

to implement, test and prove EMC compliance for the whole machine.

RoHS compliance

Compliant with EC directive 2011/65/EU (RoHS)

Patents

Features of Renishaw’s encoder systems and similar products are the subjects of the following

patents and patent applications:

CN1314511C EP1469969 JP5002559 US8466943

CN101300463B EP1946048 JP5017275 US7624513B2

CN101310165B EP1957943 US7839296 WO2014096764

The use of this symbol on Renishaw products and/or accompanying documentation indicates that

the product should not be mixed with general household waste upon disposal. It is the responsibility

of the end user to dispose of this product at a designated collection point for waste electrical and

electronic equipment (WEEE) to enable reuse or recycling. Correct disposal of this product will help

to save valuable resources and prevent potential negative effects on the environment.

For more information, please contact your local waste disposal service or Renishaw distributor.

The packaging of our products contains the following materials and can be recycled.

Cardboard

Polypropylene

Low Density Polyethylene Foam

Cardboard

High Density Polyethylene Bag

Metalised Polyethylene

Not applicable

PP

LDPE

Not applicable

HDPE

PE

Outer box

Inserts

Bags

Recycling Guidance

ISO 11469

Material

Packaging Component

Recyclable

Recyclable

Recyclable

Recyclable

Recyclable

Recyclable

Page 4

ATO M linear installation guide

2

Storage and handling

RTLF and RCLC scales

+70 °C

-20 °C

Minimum bend radius

RTLF – 150 mm

NOTE: Ensure self-adhesive tape

is on the outside of bend.

95% relative humidity

(non-condensing)

to EN 60068-2-78

Humidity

Storage

+70 °C

0 °C

Operating

N-heptane

CH

3

(CH2)5CH

3

Propan-2-ol

CH3CHOHCH

3

Scale and readhead

RCLC scale only

Page 5

ATO M linear installation guide

3

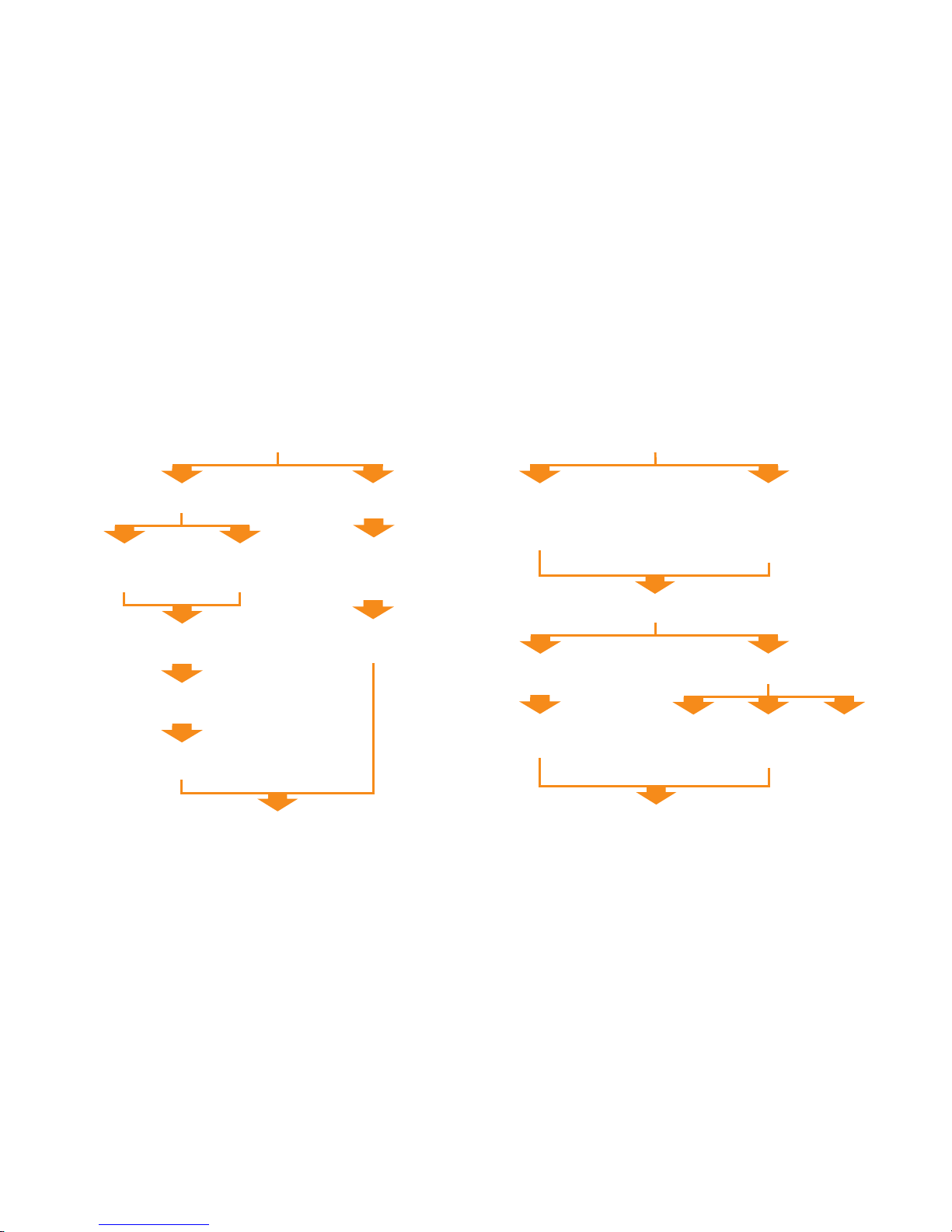

ATOM system installation overview

This section gives an overview of the steps involved in installing, setting-up and calibrating an ATOM system. More detailed information is contained within the rest of the document.

For information on designing the readhead and scale into the system refer to the detailed installation drawings and 3D models on www.renishaw.com or contact your local Renishaw representative.

IMPORTANT: Prior to installing readhead and scale, installation drawings should be reviewed to ensure correct orientation of readhead relative to scale.

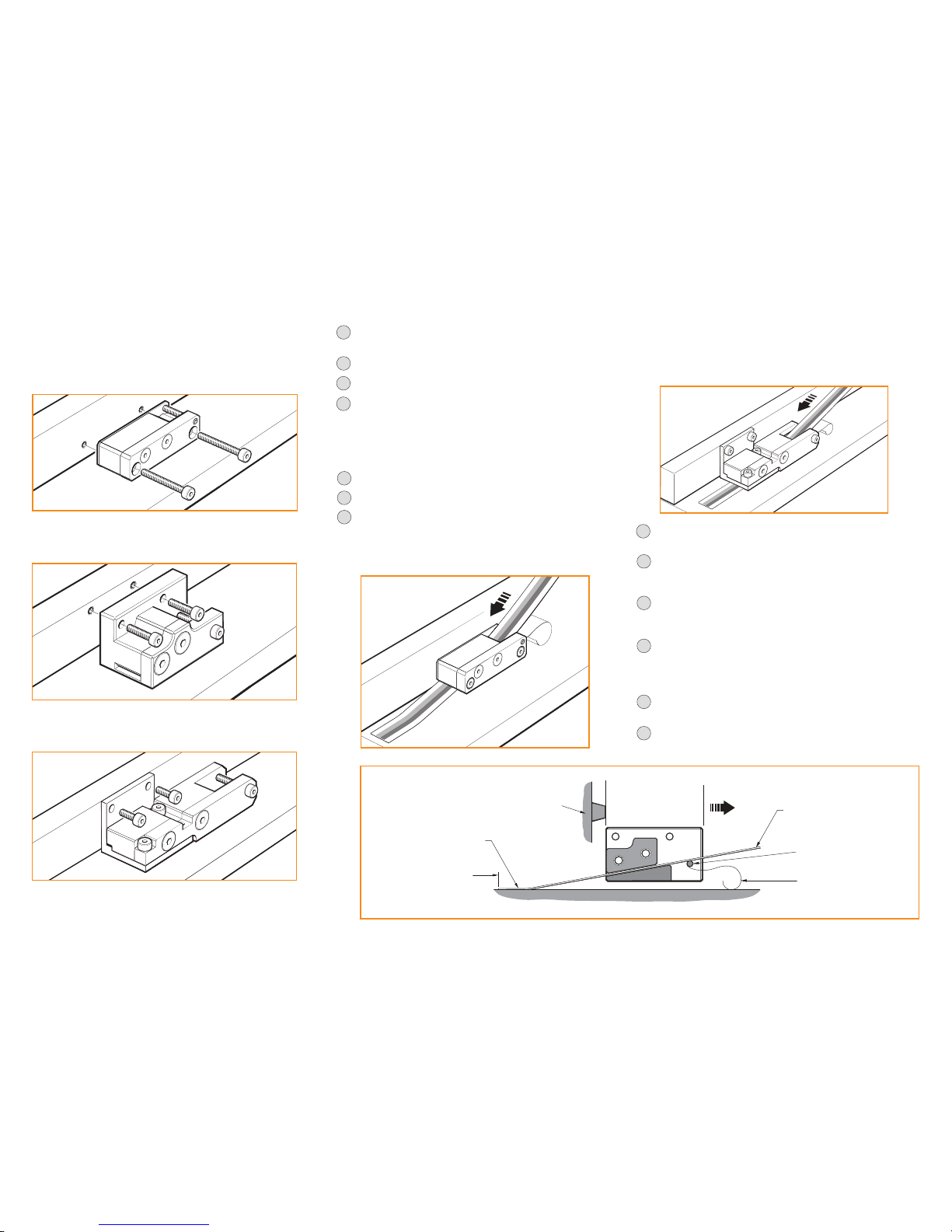

Scale mounting

System connection

RTLF (tape scale)

RCLC (glass spar)

Ledge or dowel mount

<500 mm only.

See page 6.

Ledge or

dowel mount.

See page 10.

Scale applicator

Any length.

See page 7.

Fit datum clamp.

See page 8.

Fit datum clamp.

See page 10.

Deselect unused reference marks.

See page 8.

Fit end covers.

See page 8.

System connection

Calibrate system

See page 22.

No interface

Connect readhead to

customer electronics.

See page 11.

Interface

Plug readhead cable into

the interface and connect to

customer electronics.

See pages 13 to 16.

Fixed mounting

Shim kit

See page 18.

Mount and align readhead

Adjustable bracket

Signal

amplitude

adjustment.

See page 20.

Accurate

bracket.

See page 20.

Dummy head.

See page 19.

Page 6

ATO M linear installation guide

4

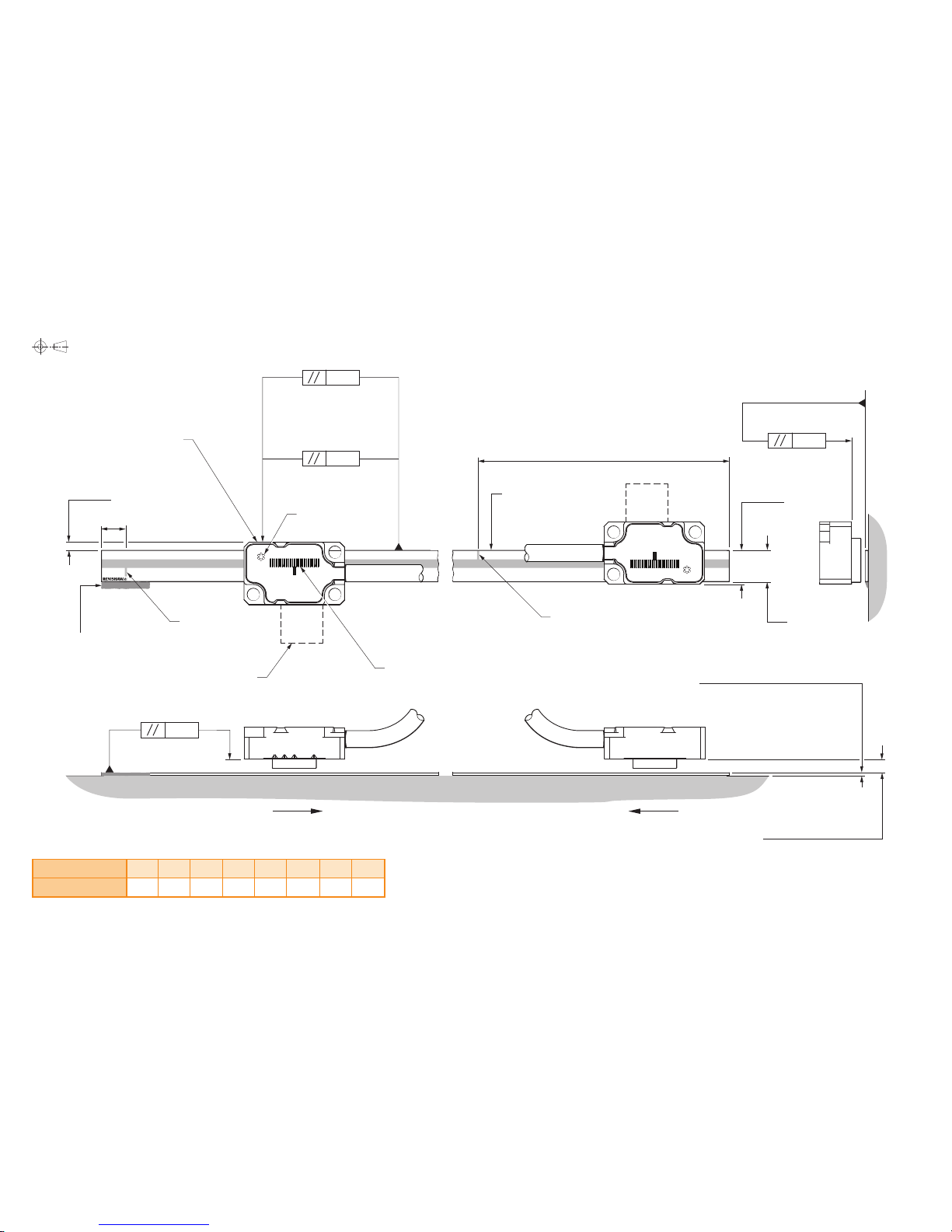

RTLF tape scale: Installation drawing

For dimensioned cabled and FPC readhead drawings see pages 26 and 27.

Dimensions and tolerances in mm

Measuring length = Overall length -3 mm

For detailed installation drawings refer to www.renishaw.com

0.36

0.18

0.22

(Roll tol. ±1°)

40 µm version

(Yaw tol. ±1°)

20 µm version

(Yaw tol. ±0.5°)

8

4.5

12

Scale thickness (including adhesive) 0.41

FPC ribbon cable

Scale datum edge

Datum clamp

(A-9585-0028)

(see page 8)

Set-up LED

1.02 ±0.25

0.36

(Pitch tol. ±1°)

50

50

Reference mark

Reference mark

Forward direction of readhead

relative to scale

Rideheight (for calibration):

2.5 ±0.08 (40 µm version)

2.5 ±0.04 (20 µm version)

Operating rideheight:

2.5 ±0.11 (40 µm version)

2.5 ±0.055 (20 µm version)

Readhead/scale orientation

Page 7

ATO M linear installation guide

5

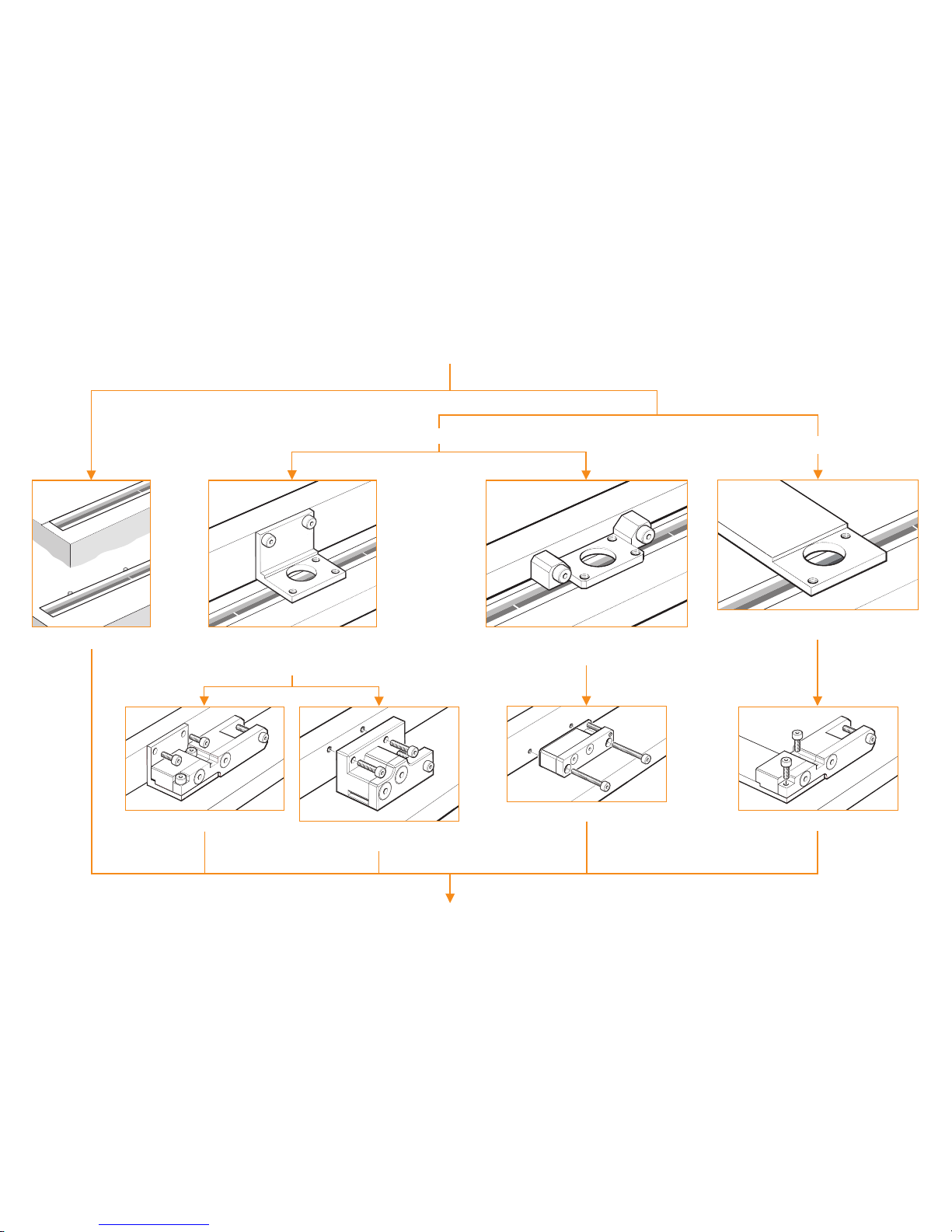

Datum edge of readhead mounted against machine axis.

For use with side mounting bracket A-9401-0103.

or customer designed bracket.

Datum edge of readhead located against a

ledge on the bracket to control yaw.

For use with ‘L’ mounting bracket A-9402-0037

or customer designed bracket.

Readhead mounting is integral to the machine and

does not allow rideheight adjustment.

Slim applicator A-9402-0060. See page 7.

Top mount applicator A-9402-0028.

See page 7.

Side mounted applicator A-9402-0034. Only for

use with ‘L’ mounting bracket A-9402-0037.

See page 7.

Top mount applicator A-9402-0028.

See page 7.

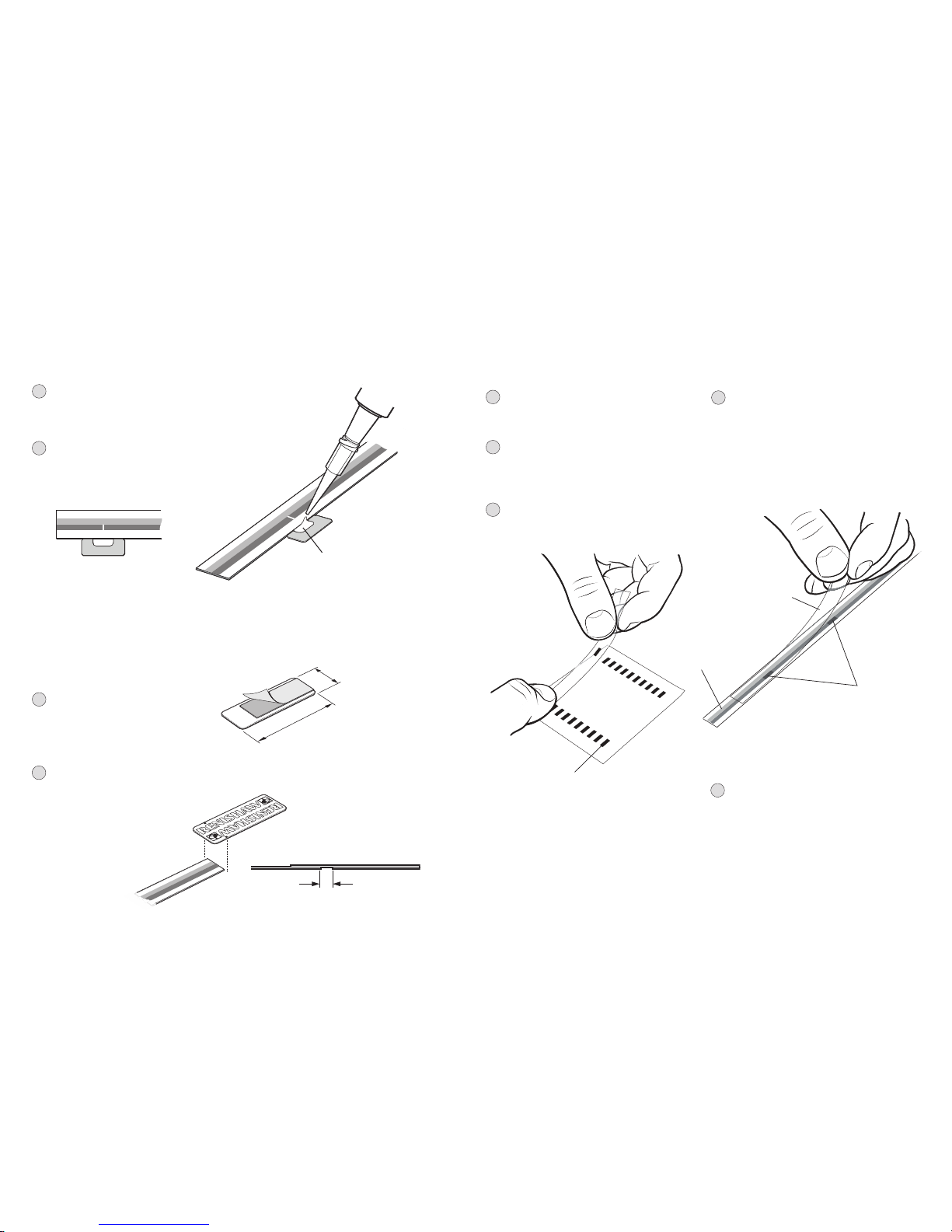

RTLF tape scale: Application methods

RTLF scale application depends upon scale length and bracket type

Mounting (<500 mm only)

RTLF tape scale

Application (any length)

Fixed mounting

Adjustable bracket

Ledge or dowel mounting.

See page 6.

Install datum clamp, end covers and deselect reference marks. See page 8.

Page 8

ATO M linear installation guide

6

Location ledge

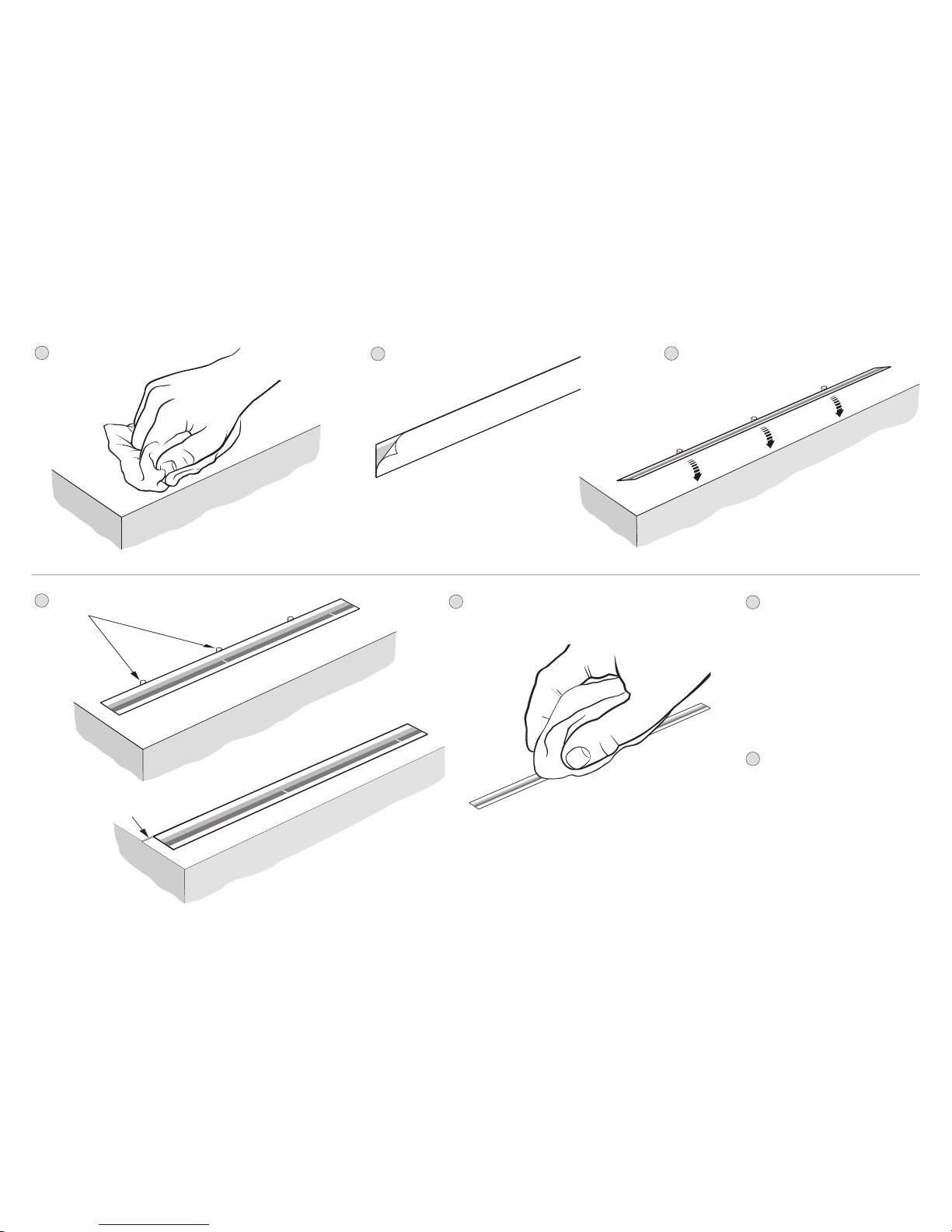

RTLF tape scale: Mounting (for lengths <500 mm only)

4

3

Locate scale against dowels or ledge

and rotate down onto substrate.

*

1

Thoroughly clean and

degrease the

substrate.

2

Remove backing paper from scale.

or

Install datum clamp, end covers and

deselect reference marks as

detailed on page 8.

6

Remove temporary dowels

(if tted).

7

5

Clean scale using Renishaw scale cleaning wipes

(A-9523-4040) or a clean, dry, lint-free cloth.

*

If dowels or ledge are permanent, their maximum

height above substrate is 0.6 mm.

Support

dowels

Page 9

ATO M linear installation guide

7

For more information on designing your bracket and mounting the

chosen scale applicator contact your local Renishaw representative.

RTLF tape scale: Application (any length)

There are three versions of applicator for use with RTLF scale

depending upon the design of the readhead mounting bracket:

Slim applicator (A-9402-0060) which is mounted in place of the

readhead bracket. It can be used in conjunction with the side

mounting bracket (A-9401-0103) or a customer designed bracket.

Top mount applicator (A-9402-0028) which is mounted in place

of the readhead. It can be used in conjunction with the

‘L’ mounting bracket (A-9402-0037) or a customer designed bracket.

Side mount applicator (A-9402-0034) which is mounted in place

of the readhead bracket. It can be used in conjunction with the

‘L’ mounting bracket (A-9402-0037) or a customer designed bracket.

Thoroughly clean and degrease the substrate.

3

4

Slim and side mount applicators:

Mount the applicator in place of the readhead bracket.

Top mount applicator:

Mount the applicator on a specically designed bracket

in place of the readhead.

2

Mark out the start position for the scale on the axis substrate.

1

Allow scale to acclimatize to installation environment

prior to installation.

Side mount applicator shown

Scale

(attached to substrate)

Limit stop

Scale

‘Splitter screw’

Backing paper

Direction of scale application

Start position

Check correct scale orientation.

6

Move axis to start of travel.

5

7

When using the top mount applicator cut the backing paper

approximately 30 mm from the end of the scale. Leaving the

end piece adhering to the scale begin to peel off the remaining

backing paper. Insert the scale into the applicator up to the

start position. Ensure the backing paper feeds out of the

back of the applicator round the splitter screw as shown.

8

Apply pressure via a clean lint free cloth to ensure scale end

adheres well to the substrate.

9

Slowly and smoothly move the applicator through the entire

length of travel, ensuring the backing paper is pulled manually

from the scale and does not catch under the applicator.

12

Clean the scale using Renishaw scale cleaning wipes

(A-9523-4040) or a clean, dry, lint-free cloth.

13

Fit datum clamp and end covers and, if needed, deselect

reference marks that are not required as detailed on page 8.

10

Remove applicator and, if necessary, adhere the remaining scale

manually. NOTE: when using the top mount applicator ensure

the backing paper left at the start of the axis is removed.

Apply a rm nger pressure via a clean lint-free cloth along the

length of the scale after application to ensure complete adhesion.

Slim and side mount applicators:

Fit readhead mounting bracket after removal of scale applicator.

11

When using the slim or side mount applicators begin

to peel off the backing paper from the end of the scale

and insert the scale into the applicator up to the start.

Ensure the backing paper feeds out of the back of the

applicator around the splitter screw as shown.

Page 10

ATO M linear installation guide

8

Datum clamp (A-9585-0028)

The datum clamp xes the RTLF scale rigidly to the substrate at the location chosen.

The metrology of the system may be compromised if the datum clamp is not used.

It can be positioned anywhere along the axis depending upon the customers’ requirements.

2

Align markers on the edges of the end cover with the end

of the scale and place end cover over the scale.

NOTE: There will be a gap* between

the end of the scale and the

adhesive tape on the

end cover.

Reference mark deselection

RTLF scale >100 mm in length has reference marks every 50 mm. Stickers can be used to deselect all

unused reference marks (A-9402-0049 for a sheet of 20). The stickers are aligned on the backing paper

with a 50 mm spacing so two can be selected at once for deselecting two reference marks.

1

Ensure the scale is free from dirt and grease

by cleaning with a scale wipe (A-9523-4040)

or suitable solvent.

2

Place the transparent applicator lm over the

reference mark deselector stickers and rub rmly

until the sticker adheres to the applicator lm.

Two stickers can be selected at once.

3

Remove the applicator lm, complete with

the stickers, from the backing paper.

Self adhesive reference mark deselector

stickers on backing paper

5

Remove applicator lm.

4

Align the stickers on the scale over the

reference marks that are not required,

as shown in the diagram, then rub rmly

on the applicator lm until the stickers

adhere to the scale.

Care should be taken to ensure the stickers

fully cover the reference mark and do not

obscure any of the incremental track.

Deselected

reference marks

Applicator film

End covers

The end cover kit (A-9585-0035) is designed to be used with

RTLF scale to provide protection for exposed scale ends.

NOTE: End covers are optional and can be tted

before or after readhead installation.

1

Remove the backing paper from

the adhesive tape on the back

of the end cover.

22

8

Incremental track

Dimensions in mm

2

Place a small amount of adhesive (Loctite® 435™)

in the cut-out on the datum clamp, ensuring none

of the adhesive wicks onto the scale surface.

Dispensing tips P-TL50-0209 are available.

1

Remove the backing paper from the datum clamp.

Place the datum clamp with cut-out against the

scale at the chosen location.

Ensure the adhesive wicks along

the entire length of cut-out.

*

gap

Page 11

ATO M linear installation guide

9

For detailed installation drawings refer to www.renishaw.com

Dimensions and tolerances in mm

*Can be applied on one or both sides of the scale.

A-9404-4018

0.22

(Roll tol. ±1°)

40 µm version

(Yaw tol. ±1°)

20 µm version

(Yaw tol. ±0.5°)

6.35

6.82 ±0.25

End reference mark

Scale thickness (including adhesive) 1.1

FPC cable

Scale

datum edge

Readhead

datum face

Set-up LED

1.42 ±0.25

0.36

(Pitch tol. ±1°)

End reference mark

readhead orientation

Mid reference mark

readhead orientation

Adhesive datum clamp*

(length 8 - 16, width 1 - 5)

(A-9531-0342)

(see page 10)

L/2

5

Forward direction of readhead

relative to scale

Forward direction of readhead

relative to scale

0.36

0.18

Mid reference mark

Rideheight (for calibration):

2.5 ±0.08 (40 µm version)

2.5 ±0.04 (20 µm version)

Operating rideheight:

2.5 ±0.11 (40 µm version)

2.5 ±0.055 (20 µm version)

RCLC glass spar scale: Installation drawing

For dimensioned cabled and FPC readhead drawings see page 26 and 27.

Readhead/scale orientation

Overall length (L) 10† 18 30 55 80 100 105 130

Measuring length 7 15 27 52 77 97 102 127

†

20 µm pitch RCLC scale only.

Page 12

ATO M linear installation guide

10

Support

dowels

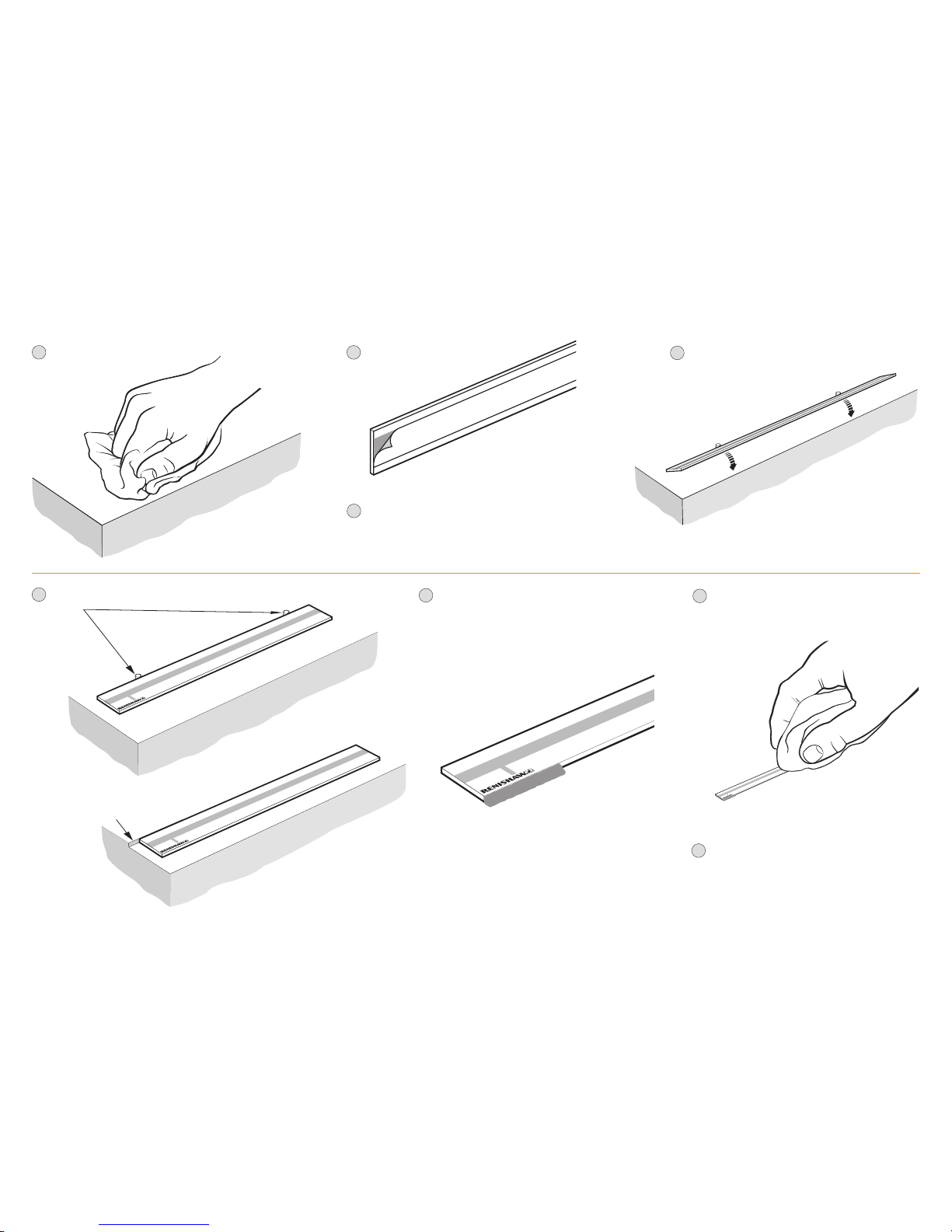

RCLC glass spar scale: Mounting

4

Locate scale against dowels or ledge

and rotate down onto substrate.*

1

Thoroughly clean and

degrease the

substrate.

2

Remove backing paper from scale.

Location ledge

5

or

After 24 hours when adhesive is cured, clean scale

using Renishaw scale cleaning wipes

(A-9523-4040) or a clean, dry, lint-free cloth.

7

Apply llet of adhesive (A-9531-0342). Adhesive can

be applied to one or both sides of the scale.

Ensure adhesive does not wick onto scale surface.

(End reference mark shown).

Datum clamp does not need to be positioned adjacent

to a reference mark. It can be positioned anywhere

along the axis depending upon the

customers’ requirements.

6

*

If dowels or ledge are permanent, their maximum height

above substrate is 1.2 mm.

Remove temporary dowels (if tted).

8

3

Ensure correct orientation of the scale for chosen

reference mark location (middle or end of scale) and

readhead orientation. See ‘RCLC glass spar scale:

Installation drawing’ for details.

Page 13

ATO M linear installation guide

11

System connection: Readhead only (no interface)

The ATOM readhead is available in several variants:

u

Cable variant with a 15 way D-type connector

u

Cable variant with interboard connector

u

FPC variant

None of these readhead variants has an integral calibration (CAL) button. Provision should be made

in the customers’ electronics for momentarily connecting the CAL line to 0 V to initiate the calibration

routine, switch AGC on/off or restore factory defaults. See page 28 for pin-out information.

Calibration is an essential part of system set-up that optimises the incremental signals and

phases the reference mark. See page 22 for information on the calibration routine.

For cable variant with interboard connector

u

Ensure that the interboard connector is inserted into the connector on the customers’ electronics

NOTE: Care should be taken to ensure correct orientation

u

Use a metal clamp around the cable ferrule to ground the readhead cable and ensure continuity

of the shields

u

Provide appropriate strain relief

u

Ensure suitable clamping to retain interboard connector to the mating connector

For FPC variants

Ensure that the FPC cable being used has the following specifications:

u

16 core

u

Conductor pitch 0.5 mm

u

Minimum exposed conductor strip length 1.5 mm

u

Maximum exposed conductor strip length 2.5 mm (to ensure isolation from the body)

Contact your local Renishaw representative for more information of the FPC design requirements.

Shielding

For optimum performance:

u

Ensure 100% shielding

u

Ground the mounting brackets

u

Ensure continuity of all shields

u

Maximise the distance between the encoder and motor cables

u

Provide appropriate strain relief at the readhead

JST 12 way,

single row

12SUR-32S

Interboard connector

14 way, dual row

DF23C-14DS- 0.5 V

1

2

13

14

Interboard

connector

PCB

FPC

connector

FPC

cable

Readhead LED

Shield

connect pad

0-0.5 mm

4 mm

Example of strain relief:

3.25 mm

Page 14

ATO M linear installation guide

12

Removing the FPC cable

1

Placing your finger on the whole of the

locking lever, slowly lift it up and away to

disengage the locking mechanism.

Do not use tools such as screwdrivers

or tweezers to open the locking lever

as this may cause damage to the

connector or pcb.

3

Pull the FPC cable straight back to remove it.

Do not pull upwards or sideways as

this may damage the readhead.

2

Ensure locking lever is fully open before

removing the FPC cable.

Inserting the FPC cable

1

Ensure the locking lever is up (open) before fully

inserting the FPC cable into the connector.

NOTE: Check correct orientation of cable before

inserting into the connector. Readhead will be

shipped with connector in the open position.

3

When the system has been connected, proceed with

‘Readhead mounting and alignment’ and

‘System calibration’ sections.

2

Applying pressure to the whole locking lever

push it down to lock the FPC cable in place.

NOTE: Do not push the locking lever down if

no FPC cable is inserted as this will damage

the locking mechanism.

The FPC cable must be connected before fitting the readhead lid. The lid is secured by the readhead mounting screws.

Approved ESD precautions must be followed at all times during readhead electrical connection.

Page 15

ATO M linear installation guide

13

System connection: ACi interface

FPC variant

Ensure that the FPC cable being used has the following specifications:

u

16 core

u

Conductor pitch 0.5 mm

u

Minimum exposed conductor strip length 1.5 mm

u

Maximum exposed conductor strip length 2.5 mm (to ensure isolation from the body)

Contact your local Renishaw representative for more information of the FPC design requirements.

Shielding

For optimum performance:

u

Ensure 100% shielding

u

Ground the mounting brackets, readhead and FPC cable clamp

u

Ensure continuity of all shields

u

Maximise the distance between the encoder and motor cables

u

Provide appropriate strain relief at the readhead and interface

u

The ACi should be contained within a shielded enclosure

Mounting

ACi can be mounted to customers’ system using 2 off M3 screws or 2 off M2.5 screws for through mounting.

Output

The output connector is a 10 way JST, GH cr imp connector with 1.25 mm pitch.

It is suitable for cable size 26 to 30 AWG. See page 29 for pin-out information.

Connection

For information on inserting and removing the FPC cable to the ACi and readhead see page 12.

Approved ESD precautions must be followed at

all times during readhead electrical connection.

The FPC cable must be connected to the readhead before fitting the lid.

The lid is secured by the readhead mounting screws.

Cable variant

Shielding

For optimum performance:

u

Ensure 100% shielding

u

Ground the mounting brackets

u

Use a metal clamp around the cable ferrule to ground the readhead cable

u

Ensure continuity of all shields

u

Maximise the distance between the encoder and motor cables

u

Provide appropriate strain relief at the readhead and interface

u

The ACi should be contained within a shielded enclosure

u

Ensure suitable clamping to retain interboard connector to the mating connector

Mounting

ACi can be mounted to customers’ system using 2 off M3 screws or 2 off M2.5 screws for through mounting.

Output

The output connector is a 10 way JST, GH cr imp connector with 1.25 mm pitch.

It is suitable for cable size 26 to 30 AWG. See page 30 for pin-out information.

Approved ESD precautions must be followed at

all times during readhead electrical connection.

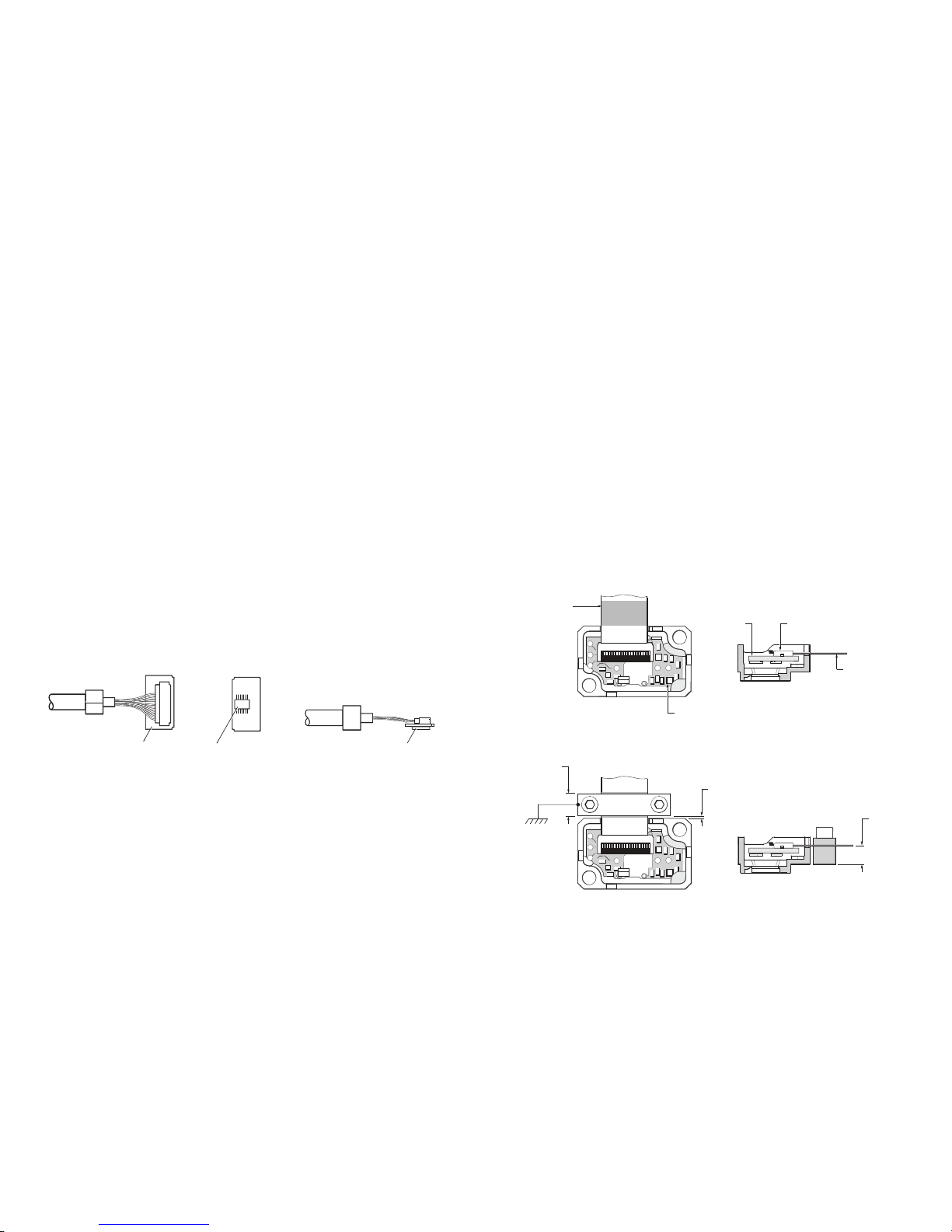

PCB

PCB

FPC

cable

FPC input

connector

*

Ensure suitable clamping to retain interboard connector on ACi.

JST output

connector

2 mounting holes

M3 through

Cable

interboard

connector

*

Ferrule

Cable

interboard

connector

2 mounting holes

M3 through

JST output

connector

FPC input

connector

Pin 1

Pin 1

Page 16

ATO M linear installation guide

14

System connection: ACi interface

PCB mounting: connecting an FPC variant ATOM readhead

Ensure that the FPC cable being used has the following specifications:

u

16 core

u

Conductor pitch 0.5 mm

u

Minimum exposed conductor strip length 1.5 mm

u

Maximum exposed conductor strip length 2.5 mm (to ensure isolation from the body)

Contact your local Renishaw representative for more information of the FPC design requirements.

Shielding

For optimum performance:

u

Ensure 100% shielding

u

Ground the mounting brackets, readhead and FPC cable clamp

u

Ensure continuity of all shields

u

Maximise the distance between the encoder and motor cables

u

Provide appropriate strain relief at the readhead and interface

u

The ACi should be contained within a shielded enclosure

Connection

For information on inserting and removing the FPC cable to the mating socket see page 12.

Approved ESD precautions must be followed at

all times during readhead electrical connection.

The FPC cable must be connected to the readhead before fitting the lid.

The lid is secured by the readhead mounting screws.

PCB mounting: connecting a cable variant ATOM readhead

Shielding

For optimum performance:

u

Ensure 100% shielding

u

Ground the mounting brackets

u

Use a metal clamp around the cable ferrule to ground the readhead cable

u

Ensure continuity of all shields

u

Maximise the distance between the encoder and motor cables

u

Provide appropriate strain relief at the readhead and interface

u

The ACi should be contained within a shielded enclosure

u

Ensure suitable clamping to retain interboard connector to the mating connector

Approved ESD precautions must be followed at

all times during readhead electrical connection.

FPC input

connector

FPC cable

2 mounting holes

M3 through

Output

Customer PCB

Input

ACi interface

Ferrule

2 mounting holes

M3 through

Output

Customer PCB

Input

Cable interboard

connector

*

ACi interface

Pin 1

Pin 1

Page 17

ATO M linear installation guide

15

System connection: Ri interface

Approved ESD precautions must be followed

at all times during readhead and interface

electrical connections.

The readhead is connected to the Ri interface

via a small, rugged connector to allow for easy

feed-through during installation.

NOTE: An optional Ri cable guide (A-9693-2577)

is available to simplify assembly.

For instructions on how to install the Ri cable guide,

download ‘Ri interface cable guide’ from the website at

www.renishaw.com/encoderinstallationguides

Connecting the readhead

1

Open the interface housing by removing

the 2 screws shown.

(4-40 UNC screws and nuts)

2

With the plain side uppermost,

remove the top half of the housing,

so that the interface PCB is exposed

and the readhead connection socket

is visible.

3

Taking care not to touch the pins,

plug the connector into the socket

in the interface, ensuring correct

orientation as shown.

NOTE: Care is required to hold the

assembly together as the PCB is xed

only to the 15 way connector and the

jack screws are loose.

4

Re-assemble the housing ensuring the

cable ferrule is located in the recess

on the inside and no wires are trapped.

5

Ret the screws.

6

When the system has been connected,

proceed with ‘Readhead mounting and

alignment’ and ‘System calibration’ sections

Disconnecting the readhead

1

Disconnect power.

2

Open the interface housing as detailed earlier in this section.

3

Gently lever the connector PCB (on the end of the cable)

out of the socket.

4

Place the connector in an anti-static bag.

5

Re-assemble the interface.

Readhead

connection

socket

Ensure ferrule

is located in housing

recess

Page 18

ATO M linear installation guide

16

System connection: Ti interface

Approved ESD precautions must be followed

at all times during readhead and interface

electrical connection. The readhead is

connected to the Ti interface via a small,

rugged interboard connector to allow for

easy feed-through during installation.

Connecting the readhead

1

Remove the cover plate as shown

(2 off M2.5 hex head screws).

2

Taking care not to touch the pins,

plug the connector into the

socket in the interface,

ensuring correct orientation as shown.

3

Ret the cover plate ensuring the cable ferrule is located in the recess on the inside and no wires are trapped under the cover plate.

4

When the system has been connected proceed with ‘Readhead mounting and alignment’ and ’System calibration’ sections.

Disconnecting the readhead

1

Disconnect power.

2

Remove the cover plate on the interface

(2 off M2.5 hex head screws).

3

Gently lever the connector PCB

(on the end of the cable) out of the socket.

Do not pull the cable to remove the connector.

4

Place the connector in an anti-static bag.

5

Ret the cover plate.

Page 19

ATO M linear installation guide

17

Readhead mounting and alignment: Methods

There is a range of tools available to assist with readhead installation depending upon the system design,

these are detailed below. For more details on designing the mounting bracket and selecting the appropriate

mounting tools contact your local Renishaw representative.

Ensure that the scale, readhead optical window and mounting face are clean and free from obstruction.

Do not saturate the readhead window with cleaning solvent as this may cause contamination on the inside

of the readhead window which cannot be cleaned.

NOTE: For FPC readheads the FPC cable must be tted prior to mounting the readhead. See page 12 for more details.

IMPORTANT: Whichever method is used to mount the readhead, care should be taken to ensure the scale surface is

not damaged during this operation, particularly when metal-to-metal contact is necessary.

Fixed mounting

Readhead mounting

bracket does not

allow for adjustment

of rideheight

Shim kit. See page 18.

Dummy head. See page 19.

Signal amplitude adjustment. See page 20.

Accurate bracket and feeler gauge.

See page 20.

Adjustable

bracket

Readhead mounting

bracket allows

adjustment of

rideheight

Page 20

ATO M linear installation guide

18

2

Subtract the distance measured from the

nominal rideheight of 2.5 mm to calculate

the required shim thickness.

For example if the distance measured

is 2.37 mm the required shim thickness

is 130 µm.

3

Select a combination of two shims that

gets within 10 µm of the difference.

For distances less than 100 µm a single

shim should be used, for distances greater

than 100 µm select one thick ( 100 µm)

and one thin (<100 µm) shim.

In the above example this could either be

1 x 100 µm shim and 1 x 40 µm shim or

1 x 100 µm shim and 1 x 20 µm shim.

4

Place the chosen shim(s) between the

readhead and the bracket.

5

Fix the readhead to the bracket using

2 off M2 x 6 screws in diagonally opposite

xing holes, ensuring readhead is tightened

down evenly and parallel to the bracket face.

6

Connect the system up. See pages 11 to 16

for relevant system connection

7

Check the readhead set-up LED is Green

along the full axis of travel.

8

Proceed with ‘System calibration’ section.

1

Using a digital dial gauge or similar measure

the distance from the readhead mounting

surface to the scale surface.

Care must be taken to ensure the scale

surface is not scratched.

Renishaw offer a DTi adapter (A-9401-0105)

that can be used to assist with this process.

– Insert the gauge into the adapter and

zero the gauge on a at surface.

– Position or x the gauge/adapter in

place of the readhead and measure

the distance to the scale surface.

Contact your local Renishaw representative

for details of the DTi adapter and digital

dial guage.

Shim kit (A-9401-0050)

This method is intended for

applications where the

rideheight of the readhead

cannot be adjusted.

The system should be designed to achieve a

nominal distance of 2.3 mm (±0.2 mm) from

the readhead mounting surface to the top of

the scale.

Shims of a known thickness are inserted between the mounting face of the readhead and the

bracket to give the correct rideheight.

The kit consists of:

2.3 ±0.2 mm

Readhead mounting surface

Part Number:

A-9401 A-9401 A-9401 A- 9401 A-9401 A- 9401 A-9401

-0041 -0042 -0043 -0044 - 0045 - 0046 -0047

Thickness (µm) 20 40 60 80 100 200 300

Quantity in pack 10 10 10 10 20 20 10

DTi adapter

Readhead

mounting

surface

Page 21

ATO M linear installation guide

19

5

Remove the dummy head.

6

Install the ATOM readhead in place of the dummy head using M2 x 6 screws in diagonally opposite

xing h oles. Ensure the readhead is pushed back against the shoulder of the bracket or mounting face.

4

Tighten the bracket xing screws whilst ensuring good contact between the ‘nose’ of the dummy head

and the surface of the scale.

7

Connect the system up. See pages 11 to 16 for relevant system connection.

9

Proceed with ‘System calibration’ section.

8

Check the readhead set-up LED is Green along the full axis of travel.

Dummy head (A-9401-0072)

The reuseable dummy head has the same dimensions as the ATOM readhead

with a longer ‘nose’ that is machined to the optimum rideheight (2.5 mm ±0.02 mm).

It is mounted in place of the readhead directly onto the bracket.

The bracket should have a shoulder to control readhead yaw.

Contact your local Renishaw representative for more information on bracket design.

1

Mount the dummy head onto the bracket using 2 off M2 x 6 screws.

3

Adjust the height of the bracket until the ‘nose’ of the dummy head touches the scale.

2

Loosely mount the readhead bracket onto the axis.

Slim mount bracket

A-9401-0103

Shoulder

‘L’ mount bracket

A-9402-0037

Page 22

ATO M linear installation guide

20

Accurate bracket and feeler gauge

Fix the readhead directly onto a mounting bracket with a thickness of 2 ±0.02 mm

then use a 0.5 mm feeler gauge to set the rideheight.

NOTE: Bracket A-9401-0103 is not suitable for this installation method.

For more information on system tolerances refer to the installation drawings on www.renishaw.com.

For more information on bracket design contact your local Renishaw representative.

1

Mount the readhead onto the bracket using 2 off M2 x 6 screws.

2

Loosely mount the readhead bracket onto the axis.

3

Place the feeler gauge between the readhead bracket and the scale.

4

Tighten the bracket xing screws whilst ensuring good contact between bracket, shim and

surface of the scale.

5

Connect the system up. See pages 11 to 16 for relevant system connection.

6

Check the readhead set-up LED is Green along the full axis of travel.

7

Proceed with ‘System calibraton’ section.

Signal amplitude adjustment

Mount the readhead directly onto a bracket, then, using the Renishaw USB set-up tool kit and software

or oscilloscope, adjust the readhead to maximise the signal size.

For more information on bracket design and the Renishaw USB set-up tool kit contact your local

Renishaw representative.

For more information on system tolerances refer to the installation drawings on www.renishaw.com

1

Mount the readhead onto the bracket using 2 off M2 x 6 screws.

2

Loosely mount the readhead bracket onto the axis.

3

Using the Renishaw USB set-up tool kit or an oscilloscope adjust the yaw, pitch and

rideheight of the readhead to maximise the signal strength.

4

Tighten the bracket and readhead xing screws.

5

Connect the system up. See pages 11 to 16 for relevant system connection.

6

Check the readhead set-up LED is Green along the full axis of travel.

7

Proceed with ‘System calibraton’ section.

Feeler gauge

Rideheight

Rideheight

Pitch

Ya w

Page 23

ATO M linear installation guide

21

Calibration overview

Calibration is an essential operation that completes readhead set-up, with the optimum incremental and reference mark signal settings stored in the readhead’s non-volatile memory.

This section is an overview of the calibration procedure for an ATOM system.

More detailed information on calibrating the system is on page 22.

The system is now calibrated and ready for use.

AGC can now be switched on if required.

NOTE: If calibration fails (readhead set-up LED continues ashing Blue),

restore factory defaults and repeat the calibration routine.

No reference mark

Manually exit calibration routine.

The readhead set-up LED will stop ashing Blue.

Reference mark

Move the readhead back and forth over the chosen reference mark

until the readhead set-up LED stops ashing Blue.

Ensure AGC is switched off.

Systems are shipped with AGC switched off.

When AGC is switched off the readhead set-up LED will be Green, Orange or Red.

Align the readhead to maximise signal strength over the full length of travel.

The readhead set-up LED will be Green.

Initiate Incremental signal calibration routine.

The readhead set-up LED will be single ashing Blue.

Move the readhead along the axis at slow speed (<100 mm/s).

The readhead set-up LED will start double ashing Blue.

Page 24

ATO M linear installation guide

22

System calibration (CAL)

Calibration is an essential operation that completes readhead set-up, with the optimum incremental

and reference mark signal settings stored in the readhead’s non-volatile memory.

Before system calibration:

uClean the scale and readhead optical window

uIf reinstalling, restore factory defaults

uEnsure AGC is switched off (readhead set-up LED is Green, Red or Orange)

uMaximise the signal strength along full length of travel (readhead set-up LED is Green)

NOTE: CAL routine maximum speed <100 mm/s

Step 1 – Incremental signal calibration

uInitiate calibration routine.

u The readhead set-up LED will now periodically single-ash Blue to indicate that it is in the incremental

signal calibration routine. The set-up signal (VX) will be a nominal 0 V.

u Slowly move the readhead along the axis, ensuring you do not pass a reference mark, until the readhead

set-up LED starts double-ashing Blue. This indicates the incremental signal is now calibrated and the

new settings are stored in the readhead memory. The set-up signal (VX) will be a nominal 1.65 V.

u The system is now ready for reference mark phasing.

u For systems without reference mark, go to ‘Calibration routine - manual exit’

u If the system does not automatically enter the reference mark phasing stage (no double-ashing Blue

of the readhead set-up LED) the calibration of the incremental signals has failed. After ensuring failure

is not due to overspeed (>100 mm/s), exit the calibration routine, restore factory defaults and check the

readhead installation and system cleanliness before repeating the calibration routine.

Step 2 – Reference mark phasing

u Slowly move the readhead back and forth over the chosen reference mark until the readhead set-up

LED stops ashing and remains Green. The reference mark is now phased. The set-up signal (VX) will

be a nominal 3.3 V depending upon system set-up (see interface output specications for more details).

NOTE: Only the chosen reference mark that has been used in the calibration routine is guaranteed to

remain phased.

u The system automatically exits the CAL routine and is ready for operation.

u If the readhead set-up LED continues double-ashing Blue after passing the chosen reference mark

many times, it is not detecting the reference mark. Ensure that the readhead orientation and lateral

offset are correct.

Calibration routine – manual exit

u The calibration routine can be exited at any stage. Depending upon the interface used follow the relevant

section in the table below to exit CAL mode.

uOn successful exit the readhead set-up LED will stop ashing Blue and remain Green or Red.

Restoring factory defaults

When realigning the readhead, reinstalling the system, or in the case of continued calibration failure,

factory defaults should be restored.

To restore factory defaults:

u Switch system off, then switch on again using the following methods depending on interface used.

u The readhead set-up LED will ash Blue four times on switch on.

u Release CAL button, CAL pads link or CAL pin ground.

u Check the ‘Readhead mounting /installation’ and recalibrate the system.

NOTE: System must be recalibrated after restoring factory defaults.

Switching Automatic Gain Control (AGC) on or off

AGC can be switched on or off via the interface or the CAL line.

u The readhead set-up LED will be Green with the addition of Blue when AGC is enabled.

NOTE: The system must be calibrated before switching AGC on.

No interface

Ground and hold the

CAL pin whilst switching

the system on.

ACi interface

Connect the CAL pads

together or ground the

remote CAL line (pin 8) whilst

switching the system on.

Ri interface

Press and hold the CAL

button on the side of the

interface whilst switching

the system on.

Ti interface

Press and hold the

CAL button on the end

of the interface whilst

switching the system on.

No interface

Ground the CAL pin for

<2 seconds.

ACi interface

Connect the CAL pads

together or ground the

remote CAL line (pin 8) for

<2 seconds.

Ri interface

Press and hold the CAL

button on the side of the

interface for <2 seconds.

Ti interface

Press the CAL button on

the end of the interface for

<2 seconds.

No interface

Ground the CAL pin for

>3 seconds then remove

ground link.

Ri interface

Press and hold the CAL

button on the side of the

interface for >3 seconds

then release.

ACi interface

Connect the CAL pads

together or ground the

remote CAL line (pin 8) for

>3 seconds then disconn ect.

Ti interface

Press and hold the CAL

button on the end of the

interface for >3 seconds

then release.

Ti interface

Press the CAL button

on the end of the

interface for

<2 seconds

using a

2 mm

allen key or

similar tool.

WARNING! Activating the CAL

switch only requires 2.5 N force.

Applying excess force may

permanently damage the switch.

No interface

Ground the

CAL pin for

<2 seconds

ACi interface

Connect the CAL pads

together or ground the

remote CAL line (pin 8)

for <2 seconds

Ri interface

Press the CAL button

on the side of the

interface for

<2 seconds

using a

2 mm

allen key or

similar tool.

WARNING! Activating the CAL

switch only requires 2.5 N force.

Applying excess force may

permanently damage the switch.

CAL

button

2 CAL

pads

Page 25

ATO M linear installation guide

23

Ti interface

* Alarm output will take the form of 3-state or line driven E- signal depending on interface conguration.

Also, some congurations do not output overspeed alarm. See product nomenclature for details.

-Momentary status only, while fault condition remains.

-Alarm may result in axis position error, re-datum to continue.

Normal setup; signal level 110% to 135%

Optimum setup; signal level 90% to 110%

Normal set-up: signal level 70% to 90%

Acceptable set-up; signal level 50% to 70%

Poor set-up; signal may be too low for reliable operation;signal level <50%

Poor set-up; signal level <20%; system in error

Over speed; system in error

Over signal; system in error

Reference mark detected (speed <100 mm/s only)

Status

Indication

Signal

Purple

Blue

Green

Orange

Red

Red / blank - ashing

Blue / blank - ashing

Purple / blank - ashing

Blank ash

Incremental

Reference mark

Alarm output*

No

No

No

No

No

Ye s

Ye s

Ye s

No

*When stationary will be Green or Red.

=

Flash will effectively be invisible when incremental signal level is >70% when passing reference mark.

‡

When AGC is enabled the LED indication will be as shown but with the addition of a Blue indication.

Normal set-up; signal level >70%, AGC off

Acceptable set-up; signal level 50% to 70%, AGC off

Poor set-up; signal may be too low for reliable operation; signal level <50%, AGC off

Calibrating incremental signals

Calibrating reference mark

Normal phasing

Acceptable phasing

Poor phasing; clean scale and recalibrate if required

Factory defaults restored

Status

Indication

Green

Orange*

Red

Single Blue ashing

Double Blue ashing

Green (ash)

=

Blank (ash)

Red (ash)

4 Blue ashes on switch on

Incremental

(AGC off)

‡

CAL

Reference mark

Restore factory defaults

Signal

LED diagnostics

Readhead

The readhead set-up LED consists of a tri-coloured LED which can display any combination of Red, Blue or Green.

Page 26

ATO M linear installation guide

24

Troubleshooting

LED on the readhead is Blank

LED on the readhead is Red and I can’t

get a Green LED

Unable to get a Green LED over the

complete axis length

Can’t initiate the calibration routine

LED on the readhead remains single

ashing Blue even after moving it along

the full axis length

LED on the readhead appears Purple

There is no power to the readhead

The signal strength is <50%

System run-out is not

within specication

Cabled D-type readhead does not

have CAL button

The system has failed to calibrate the

incremental signals due to the signal

strength being <70% before the

calibration routine was initiated

This is Blue and Red combined

AGC is switched on and

signal level is <50%

Fault Cause

Possible solutions

u

Ensure 5 V supplied at the readhead

u

For cable variants check correct wiring of connector

NOTE: Analogue and digital systems have different pin-outs

u

When using Ti, Ri or cabled ACi interfaces check the interboard connector that plugs in the interface is

properly seated and the correct orientation

u

For FPC variants check correct insertion and orientation of the FPC cable

u

Check the readhead optical window and scale are clean and free from contamination

u

Restore factory defaults (see page 22) and check alignment of the readhead. In particular;

– Rideheight

– Ya w

– Offset

u

Check the scale and readhead orientation

u

Check that the readhead variant is the correct type for the chosen scale

(see the data sheet for details of readhead conguration)

u

Check that the readhead variant is the correct type for the chosen scale

(see the data sheet for details of readhead conguration)

u

Use a DTi gauge and check the run-out is within specications

u

Restore factory defaults

u

Realign readhead to obtain a Green LED at the mid-point of the run-out

u

Recalibrate the system (see page 22)

u

If not using an interface with a CAL button check that the correct pin is being shorted to 0 V for <2 seconds

u

Check that the signal size is >70% before initiating calibration

u

Exit CAL mode and restore factory defaults (see page 22)

u

Check system set-up and realign the readhead to obtain a Green LED along the full axis of travel

before recalibrating

u

Check the readhead optical window and scale are clean and free from contamination

u

Restore factory defaults (see page 22) then check the LED is Green along the full axis and recalibrate

the system (see page 22). If it is not Green check the alignment of the readhead

Page 27

ATO M linear installation guide

25

Troubleshooting (continued)

LED on the readhead appears white with

ashes of other colours as the readhead is

moved along the axis

LED on the readhead is double ashing

Blue even after moving it past the

reference mark several times

No reference mark output

Reference mark is not repeatable

LED on the readhead is ashing Red or

Blank over the reference mark

Multiple reference marks output

Fault Cause

u

Check the readhead optical window and scale are clean and free from contamination

u

Restore factory defaults (see page 22) then check the LED is Green along the full axis and recalibrate

the system (see page 22). If it is not Green check the alignment of the readhead

u

Ensure you are moving the readhead past your chosen reference mark several times

u

Check the scale/readhead orientation

u

Check the scale readhead alignment

u

Check the readhead optical window and scale are clean and free from contamination

u

Check that the readhead variant is the correct type for the chosen scale

(see the data sheet for details of readhead conguration)

u

Ensure you are not over-speeding the readhead during calibration mode (maximum speed <100 mm/sec)

u

Calibrate the system (see page 22)

– If the system completes calibration mode then it has successfully seen and calibrated the reference mark

If you still don’t see a reference mark then check the system wiring

– If the system does not calibrate the reference mark (LED on the readhead double ashes Blue)

see above for possible solutions

u

Ensure you are using the reference mark that has been calibrated for referencing your system

u

The readhead bracket must be stable and not allow any mechanical movement of the readhead

u

Check any unused reference marks have been deselected

u

Clean the scale and readhead optical window and check for damage then recalibrate the system over

the chosen reference mark

u

Ensure you are using the reference mark that has been calibrated for referencing your system as only this

reference mark will be guaranteed to remain phased.

The LED may ash Blank or Red when passing other reference marks if they have not been deselected

(see page 8)

u

Clean the scale and readhead optical window and check for scratches then recalibrate the system over the

chosen reference mark (see page 22)

u

All unused reference marks should be deselected (see page 8) as only the calibrated reference mark will be repeatable

u

Check alignment of deselection stickers

u

Replace damaged FPC (if applicable)

Possible solutions

AGC is switched on and

the signal level is <70%

The readhead is not seeing a

reference mark

Only the chosen reference mark that has

been used in the calibration sequence is

repeatable, other reference marks may

not be phased

The reference mark is not phased

Unused reference marks have not

been deselected or FPC is damaged

Page 28

ATO M linear installation guide

26

ATOM readhead: Cabled readhead dimensions

Dimensions and tolerances in mm

6.45

1.4 (40 µm version)

1.9 (20 µm version)

20.5

16.5

10.25

12.7

8.7

2

4.15

4.85*

3 off mounting holes

Ø2.5 min through

Ø9 max

Set-up

LED

Mounting face

Readhead

datum faces

5 min

Ø

3.5 max

R>20 Dynamic bend radius

R>10 Static bend radius

2

Readhead/scale

orientation

Identification marks for readhead manufacture only.

Notches will vary depending on readhead type.

For detailed installation drawings refer to www.renishaw.com

*Not optical centreline

Page 29

ATO M linear installation guide

27

ATOM readhead: FPC readhead dimensions

Dimensions and tolerances in mm

4.15

NOTE: Readhead is supplied with lid separate. FPC cable must be inserted before fitting the lid.

For detailed installation drawings refer to www.renishaw.com

1.4 (40 µm version)

1.9 (20 µm version)

20.5

16.5

10.25

12.7

8.7

2

5.4

4.85*

2 off mounting holes

Ø2.5 min through

Ø9 max

FPC ribbon cable

Set-up

LED

Mounting face

Readhead

datum faces

2

Readhead/scale

orientation

8.5

4.4

Identification marks for readhead manufacture only.

Notches will vary depending on readhead type.

3.25

*Not optical centreline

Page 30

ATO M linear installation guide

28

ATOM readhead: Output signals

15 way D-type plug

Interboard connector for

connection to Ri,Ti and

cabled ACi interfaces

1

2

13

14

FPC connection

Pin 1

JST connector

Pin 1

Pin 12

*All power connections should be used either to minimise voltage drop down the cable or incorporate voltage sensing.

=

Only available on interboard connector

Power*

Incremental

Reference mark

Set-up

Remote CAL

Shield

Do not connect

Function

Signal

Cosine

Sine

Colour

Brown

White

Red

Blue

Yellow

Green

Violet

Grey

Clear

Orange

Screen

–

5 V

0 V

V

1

V2

V

0

+

-

+

-

+

-

VX

CAL

–

–

Interboard connector

(T)

FPC

(F)

Pin

4

13

9

5

12

14

2

8

6

10

Cable ferrule

1, 3, 7, 11

Pin

9, 10

3, 6, 11, 14

5

4

2

1

13

12

16

15

Readhead body

7, 8

JST=

(on interboard)

Pin

11

5

4

3

7

6

10

9

12

8

Cable ferrule

1, 2

15 way D-type

(D)

Pin

4, 5

12, 13

9

1

10

2

3

11

6

14

Case

7, 8, 15

Page 31

ATO M linear installation guide

29

14.5

25

4.5 x 45°

2

6

10

25

7.7

9.5

4

4.6

5.6

5.6

15.75

12.5

17

2 mounting holes

M3 through

CAL pad

CAL pad

2 mounting

pillars

JST output

connector

*

6.25

FPC input connector

=

4

Pin1

Pin1

Output signals

Pin 1 Pin 10

ACi JST output connector

Pin 1 Pin 16

ACi FPC input connector

Component area

Component area

Component area

ACi interface: FPC variant

Installation drawing

Dimensions and tolerances in mm

Signal

JST connector

A-9412-1001 cable

(15 way D type)

Pin

Function

Power

Incremental

Reference mark

Set-up

Remote CAL

9

10

1

2

3

4

5

6

7

8

7, 8

2, 9

14

6

13

5

12

4

1

11

5 V

0 V

A

B

Z

+

-

+

-

+

-

X

CAL

Input signals

*All power connections should be used either to minimise voltage drop down the cable or incorporate voltage sensing.

Signal

Pin

Function

Power*

Incremental

Reference mark

Set-up

Remote CAL

Do not connect

7, 8

3, 6, 11, 14

12

13

15

16

4

5

1

2

9, 10

5 V

0 V

V1

V2

V

0

+

-

+

-

+

-

VX

CAL

–

*10 way JST, GH crimp connector. 1.25 mm pitch. Suitable for cable size 26 to 30 AWG. 3 m JST to 15 way D-type cable A-9412-1001

=

NOTE: Care must be taken not to damage the FPC connector when tting/removing the cable.

FPC connector

=

FPC cable

Page 32

ATO M linear installation guide

30

Input signals

*All power connections should be used either to minimise voltage drop down the cable or incorporate voltage sensing.

=

Only available on interboard connector

Power*

Incremental

Reference mark

Set-up

Remote CAL

Shield

Do not connect

Function

Signal

Cosine

Sine

Colour

Brown

White

Red

Blue

Yellow

Green

Violet

Grey

Clear

Orange

Screen

–

5 V

0 V

V

1

V2

V

0

+

-

+

-

+

-

VX

CAL

–

–

Interboard

connector

(T)

Pin

4

13

9

5

12

14

2

8

6

10

Cable ferrule

1, 3, 7, 11

JST=

(on interboard)

Pin

11

5

4

3

7

6

10

9

12

8

Cable ferrule

1, 2

Readhead cable input connector

JST connector

Pin 1

Pin 12

9

Interboard connector for

connection to Ri, Ti and

cabled ACi interfaces

1

2

13

14

15

9.5

6.25

2.5

14.5

25

4.5 x 45°

2

6

5

25

9.5

4

4.6

5.6

5.6

15.75

17

2 mounting holes

M3 through

CAL pad

CAL pad

2 mounting

pillars

JST output

connector

*

6.25

Cable input connector

Pin1

Component area

Component area

Component area

10

2.5

7.7

4

*10 way JST, GH crimp connector. 1.25 mm pitch. Suitable for cable size 26 to 30 AWG.

3 m JST to 15 way D-type cable A-9412-1001

ACi interface: Cable variant

Installation drawing

Dimensions and tolerances in mm

Output signals

Signal

JST connector

A-9412-1001 cable

(15 way D type)

Pin

Function

Power

Incremental

Reference mark

Set-up

Remote CAL

9

10

1

2

3

4

5

6

7

8

7, 8

2, 9

14

6

13

5

12

4

1

11

5 V

0 V

A

B

Z

+

-

+

-

+

-

X

CAL

Pin 1 Pin 10

ACi JST output connector

4

21 ±1

Cable ferrule nominal diameter

5.9 ±0.2 mm

Page 33

ATO M linear installation guide

31

ACi interface: PCB mounting variant

Installation drawing

Dimensions and tolerances in mm

16.1

10.1

25

4.5 x 45°

25

4

4

5.6

5.6

12.5

17

2 mounting holes

M3 through

CAL pad

CAL pad

Component area

Component area

5.6

14.5

ACi PCB mounting variant interface (digital output only)

Function

Power

Incremental

Reference mark

Set-up

Remote CAL

Signal

Pin

9

2

4

6

3

1

8

10

7

5

5 V

0 V

V1

V2

V

0

+

-

+

-

+

-

V

X

CAL

Input

Signal

Pin

6

5

8

10

7

9

3

1

4

2

5 V

0 V

A

B

Z

+

-

+

-

+

-

X

CAL

Output

Pin 1

ACi PCB input

connector

Pin 2

Pin 9

Pin 10

Pin 1

ACi PCB output

connector

Pin 2

Pin 9

Pin 10

Recommended mating connector - Samtec CLP-105-02-F-D-P-TR

PCB footprint

1.27

1.27 (typ)

0.74 (typ)

Clearance holes

∅ 0.74

0.5

4.7

(Samtec FTS-105-01-L-DV-P-TR)

Page 34

ATO M linear installation guide

32

Lowest recommended

counter input frequency

(MHz)

Maximum speed (m/s)

0020

(2 µm)

13

13

–

13

–

8

–

0040

(1 µm)

13

13

–

8

–

4

–

0080

(0.5 µm)

13

8

–

4

–

2

–

40

20

12

10

6

5

4

0100

(0.4 µm)

11.6

6.4

–

3.2

–

1.6

–

0200

(0.2 µm)

6

3.2

–

1.6

–

0.8

–

0400

(0.1 µm)

–

–

0.7

–

0.36

–

0.24

1000

(40 nm)

–

–

0.26

–

0.12

–

0.08

2000

(20 nm)

–

–

0.13

–

0.06

–

0.04

40 µm system

ACi interface: Speed

Lowest recommended

counter input frequency

(MHz)

Maximum speed (m/s)

0020

(1 µm)

6.5

6.5

–

6.5

–

4

–

0040

(0.5 µm)

6.5

6.5

–

4

–

2

–

0080

(0.25 µm)

6.5

4

–

2

–

1

–

0100

(0.2 µm)

5.8

3.2

–

1.6

–

0.8

–

0200

(0.1 µm)

3

1.6

–

0.8

–

0.4

–

0400

(50 nm)

–

–

0.35

–

0.18

–

0.12

1000

(20 nm)

–

–

0.13

–

0.06

–

0.04

2000

(10 nm)

–

–

0.065

–

0.03

–

0.02

40

20

12

10

6

5

4

20 µm system

Page 35

ATO M linear installation guide

33

15

1

8

9

CAL button operation

Push and release (<2 seconds) - Calibration (CAL) routine initiation/exit

Push and release (>3 seconds) - Automatic Gain Control (AGC) initiation/exit

Push and hold during power ‘Off/On’ cycle - Restore factory defaults

40

6 min

33.3

R>10 Static bend radius

R>20 Dynamic bend radius

8

4- 40 UNC x 2

52

16

CAL button

access hole

Ø3.15

Ri interface: Interface drawing

Dimensions and tolerances in mm

*

All power connections should be used either to minimise voltage drop down the cable or incorporate voltage sensing.

†

The alarm signal can be output as a line driver signal or 3-state.

Please select the preferred option at time of ordering.

Power*

Incremental

Reference mark

Set-up

Remote CAL

Shield

Do not connect

Function

Signal

Cosine

Sine

5 V

0 V

VX

CAL

–

–

V1

V2

V

0

+

-

+

-

+

-

Pin

4, 5

12, 13

9

1

10

2

3

11

6

14

Case

7, 8, 15

Analogue

Output signals

Digital

Signal

Pin

Function

Power*

Incremental

Reference mark

Alarm

†

Set-up

Shield

Do not connect

7, 8

2, 9

14

6

13

5

12

4

11

3

1

Case

10, 15

5 V

0 V

A

B

Z

E

+

-

+

-

+

-

+

-

X

–

–

Page 36

ATO M linear installation guide

34

Ri interface: Speed

Clocked outputs

Ri0100, Ri0200 and Ri0400 interfaces have clocked outputs.

Customers must ensure they comply with the lowest recommended counter input frequency.

Lowest recommended counter

input frequency

(MHz)

Maximum speed (m/s)

0100

(0.2 µm)

–

–

0.8

0.5

0200

(0.1 µm)

0.8

0.5

0.4

0.25

0400

(50 nm)

0.4

0.25

0.2

0.12

12

10

6

4

20 µm system

40 µm system

0100

(0.4 µm)

–

–

1.6

1.0

0200

(0.2 µm)

1.6

1.0

0.8

0.5

0400

(0.1 µm)

0.8

0.5

0.4

0.24

Non-clocked outputs

Ri0004, Ri0008, Ri0020 and Ri0040 interfaces have non-clocked outputs.

Lowest recommended counter

input frequency

(MHz)

20 µm system

40 µm system

Encoder velocity (m/s)

Resolution (µm)

x 4

safety

factor

Interface

type

0004 (5 µm)

0008 (2.5 µm)

0020 (1 µm)

0040 (0.5 µm)

Maximum

speed

(m/s)

10

10

10

10

Interface

type

0004 (10 µm)

0008 (5 µm)

0020 (2 µm)

0040 (1 µm)

Maximum

speed

(m/s)

20

20

20

20

Analogue speed

40 µm system – 20 m/s (-3dB)

20 µm system – 10 m/s (-3dB)

Page 37

ATO M linear installation guide

35

CAL button operation

Push and release (<2 seconds) - Calibration (CAL) routine initiation/exit

Push and release (>3 seconds) - Automatic Gain Control (AGC) initiation/exit

Push and hold during power ‘Off/On’ cycle - Restore factory defaults

Refer to ‘Readhead LED diagnostics’ and ‘Ti LED diagnostics’ for LED indications

*

All power connections should be used either to minimise voltage drop down the cable or incorporate voltage sensing.

†

Alarm output will take the form of 3-state or line driven E signal depending on interface configuration.

Please select the preferred option at time of ordering.

Power*

Incremental

Reference mark

Set-up

Remote CAL

Shield

Do not connect

Function

Signal

Cosine

Sine

5 V

0 V

VX

CAL

–

–

V1

V2

V

0

+

-

+

-

+

-

Pin

4, 5

12, 13

9

1

10

2

3

11

6

14

Case

7, 8, 15

Analogue

Output signals

Digital

Signal

Pin

Function

Power*

Incremental

Reference mark

Alarm

†

Set-up

Shield

Do not connect

7, 8

2, 9

14

6

13

5

12

4

11

3

1

Case

10, 15

5 V

0 V

A

B

Z

E

+

-

+

-

+

-

+

-

X

–

–

8

15

1

8

9

16

4- 40 UNC x 2

40

6 min

62

67

CAL button access hole Ø2.4

33.3

Interface set-up LED

(

digital interface only

)

Cover plate

R>20 Dynamic bend radius

R>10 Static bend radius

Ti interface: Interface drawing

Dimensions and tolerances in mm

Page 38

ATO M linear installation guide

36

Lowest recommended

counter input frequency

(MHz)

50

40

25

20

12

10

8

6

4

1

Maximum speed (m/s)

0004

(10 µm)

20

20

20

20

20

20

20

20

20

8.4

0020

(2 µm)

20

20

20

20

18

16.2

12.96

9

6.74

1.68

0040

(1 µm)

20

20

16.2

13.5

9

8

6.48

4.5

3.36

0.84

0100

(0.4 µm)

12.96

10.8

6.48

5.4

3.6

3.24

2.58

1.8

1.34

0.32

0200

(0.2 µm)

6.48

5.4

3.24

2.7

1.8

1.62

1.296

0.9

0.676

0.168

0400

(0.1 µm)

3.25

2.7

1.62

1.34

0.9

0.8

0.648

0.45

0.338

0.084

1000

(40 nm)

1.296

1.08

0.648

0.54

0.36

0.324

0.26

0.18

0.136

0.034

2000

(20 nm)

0.648

0.54

0.324

0.27

0.18

0.162

0.13

0.09

0.068

0.016

4000

(10 nm)

0.324

0.27

0.162

0.136

0.09

0.082

0.064

0.046

0.034

0.008

10KD

(4 nm)

0.013

0.108

0.064

0.054

0.036

0.032

0.026

0.018

0.0136

0.0034

20KD

(2 nm)

0.064

0.054

0.032

0.026

0.018

0.0162

0.013

0.009

0.0068

0.0016

40 µm system

Lowest recommended

counter input frequency

(MHz)

50

40

25

20

12

10

8

6

4

1

Maximum speed (m/s)

0004

(5 µm)

10

10

10

10

10

10

10

10

10

4.2

0020

(1 µm)

10

10

10

10

9

8.1

6.48

4.5

3.37

0.84

0040

(0.5 µm)

10

10

8.1

6.75

4.5

4.05

3.24

2.25

1.68

0.42

0100

(0.2 µm)

6.48

5.4

3.24

2.7

1.8

1.62

1.29

0.9

0.67

0.16

0200

(0.1 µm)

3.24

2.7

1.62

1.35

0.9

0.81

0.648

0.45

0.338

0.084

0400

(50 nm)

1.62

1.35

0.81

0.675

0.45

0.405

0.324

0.225

0.169

0.042

1000

(20 nm)

0.648

0.54

0.324

0.27

0.18

0.162

0.13

0.09

0.068

0.017

2000

(10 nm)

0.324

0.27

0.162

0.135

0.09

0.081

0.065

0.045

0.034

0.008

4000

(5 nm)

0.162

0.135

0.081

0.068

0.045

0.041

0.032

0.023

0.017

0.004

10KD

(2 nm)

0.0654

0.054

0.032

0.027

0.018

0.016

0.013

0.009

0.0068

0.0017

20KD

(1 nm)

0.032

0.027

0.016

0.013

0.009

0.0081

0.0065

0.0045

0.0034

0.0008

20 µm system

Analogue speed

20 µm system – 10 m/s (-3dB)

40 µm system – 20 m/s (-3dB)

Ti interface: Speed

Page 39

ATO M linear installation guide

37

Analogue outputs

V0 V1 V2-

V

0

V1 V2+

120R

Remote CAL operation

CAL

0 V

Remote CAL operation is possible

via the CAL pin.

For applications where no interface is used,

remote CAL operation is essential.

Recommended signal termination

Digital outputs

Interface

A B Z E+

Cable Z0 = 120R

Customer

electronics

A B Z E-

120R