Page 1

User’s guide

H-1000-4010-03-A

AM1 adjustment module

The AM1 adjustment module has been

designed for use with the PH6M and MIH

manual probe heads and the PH10T/M

motorised probe heads. It provides quick and

accurate angular alignment of the probe head

with the CMM’s axes and/or the autochange

rack.

In addition, the quick release mechanism

allows the head to be removed for storage and

subsequently replaced without re-alignment.

Built in overtravel protection decreases the risk

of head damage.

Specification

Size

Adjustment

Overtravel

Mounting

Weight

* Up to ±5.5° in pitch and roll is possible but this is at the expense of overtravel.

60 mm x 15.5 mm (2.36 in x 0.61 in) nominal

±2° in pitch and roll* (recommended)

±1.5° in yaw

±3.5° in pitch and roll

Mounts to quill using shank

Alternatively direct to quill using OEM adaptor

150 g (5.29 oz)

Page 2

1

AM1 adjustment module

Installation

Follow these instructions carefully:

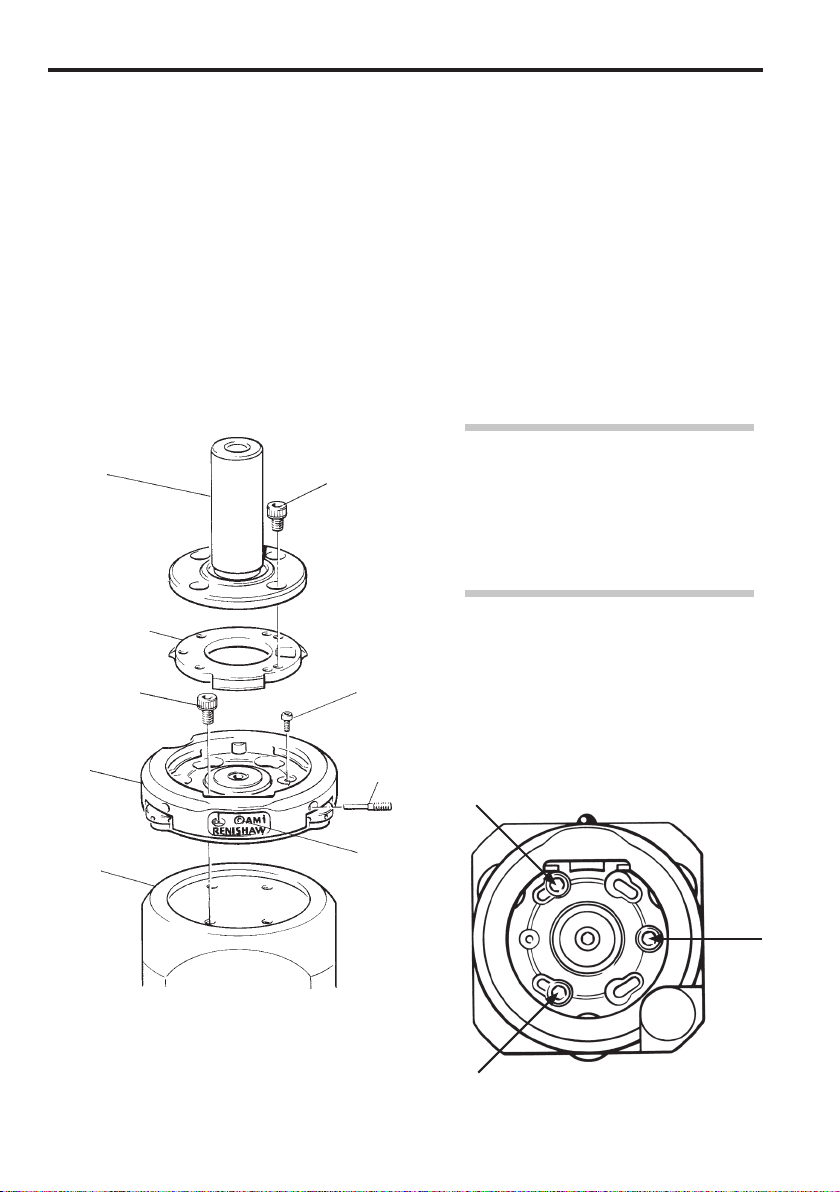

1 Preparation

Remove the safety screws (refer to

figures 1 and 4). Release the lock screw

in the front and the AM1. Unscrew and

retract ONE yaw adjusting screw. Rotate

mounting plate through 60° and remove.

Shank

Mounting plate

M3 x 6 mm

AM1

M3 x 5 mm

Safety

screw

Yaw

adjusting

screw

2 Locate AM1

Locate AM1 body to probe head and

secure with M3 x 6 mm screws. Use

three screws for PH10M and PH10T.

See figure 2 for top views of probe

heads and screw locations.

3 Refitting the mounting plate

Refit mounting plate to AM1 and locate

by rotating through 60°. Screw yaw

adjusting screw against lug.

NOTE: If shank / mounting plate

assembly is to be permanently attached

to the head, the safety screw should be

replaced before assembling the shank

on the mounting plate. Alternatively,

if quick release is required, the screw

should be left out.

4 Secure shank

Secure shank to mounting plate with four

M3 x 5 mm screws provided. Do not use

longer screws.

Probe

head

Figure 1 - AM1 installation

Lock

screw

Figure 2 - PH10M and PH10T

(three mounting screws)

Page 3

5 Roll adjustment

Rotate the roll adjustment capstans equally

and in opposite directions (i.e. one capstan

clockwise and the other anti-clockwise).

Refer to figures 4 and 5.

AM1 adjustment module

2

6 Pitch adjustment

Rotate the pitch adjustment capstan to

increase or decrease pitch. Refer to

figures 4 and 5.

7 Yaw adjustment

Release the lock screw. Rotate the yaw

adjusting screws equally in opposite

directions to provide required yaw. Tighten

the screws against each other without

applying excessive torque. Tighten the

lock screw. Refer to figures 4 and 5.

8 Quick release of AM1 from shank

NOTE: If repeatability of position is

required on re-attachment, DO NOT alter

the centre screw. This repeatability of

position is sufficient for alignment with

the autochange rack, but probes must be

redatumed for measurement.

Rotate AM1 until free and remove.

9 Re-attachment

Locate AM1 against the shank and rotate

until engaged. Tighten the yaw adjustment

screw. Tighten the lock screw.

Roll

adjustment

±2°

Pitch

Overtravel

±3.5°

Yaw

Figure 5 - Pitch, roll and yaw

Pitch adjusting capstan

Yaw adjusting screw

Roll adjusting capstans

Figure 4 - Angular adjustment (adjust the AM1 in the order given above)

Lock screw

Safety screw

Yaw adjusting screw

Roll adjusting capstans

Page 4

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

*H-1000-4010-03*

Loading...

Loading...