Page 1

To our customers,

Old Company Name in Catalogs and Other Documents

On April 1st, 2010, NEC Electronics Corporation merged with Renesas Technology

Corporation, and Renesas Electronics Corporation took over all the business of both

companies. Therefore, although the old company name remains in this document, it is a valid

Renesas Electronics document. We appreciate your understanding.

Renesas Electronics website: http://www.renesas.com

April 1

Renesas Electronics Corporation

Issued by: Renesas Electronics Corporation (http://www.renesas.com)

st

, 2010

Send any inquiries to http://www.renesas.com/inquiry.

Page 2

Notice

1. All information included in this document is current as of the date this document is issued. Such information, however, is

subject to change without any prior notice. Before purchasing or using any Renesas Electronics products listed herein, please

confirm the latest product information with a Renesas Electronics sales office. Also, please pay regular and careful attention to

additional and different information to be disclosed by Renesas Electronics such as that disclosed through our website.

2. Renesas Electronics does not assume any liability for infringement of patents, copyrights, or other intellectual property rights

of third parties by or arising from the use of Renesas Electronics products or technical information described in this document.

No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights

of Renesas Electronics or others.

3. You should not alter, modify, copy, or otherwise misappropriate any Renesas Electronics product, whether in whole or in part.

4. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of

semiconductor products and application examples. You are fully responsible for the incorporation of these circuits, software,

and information in the design of your equipment. Renesas Electronics assumes no responsibility for any losses incurred by

you or third parties arising from the use of these circuits, software, or information.

5. When exporting the products or technology described in this document, you should comply with the applicable export control

laws and regulations and follow the procedures required by such laws and regulations. You should not use Renesas

Electronics products or the technology described in this document for any purpose relating to military applications or use by

the military, including but not limited to the development of weapons of mass destruction. Renesas Electronics products and

technology may not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited

under any applicable domestic or foreign laws or regulations.

6. Renesas Electronics has used reasonable care in preparing the information included in this document, but Renesas Electronics

does not warrant that such information is error free. Renesas Electronics assumes no liability whatsoever for any damages

incurred by you resulting from errors in or omissions from the information included herein.

7. Renesas Electronics products are classified according to the following three quality grades: “Standard”, “High Quality”, and

“Specific”. The recommended applications for each Renesas Electronics product depends on the product’s quality grade, as

indicated below. You must check the quality grade of each Renesas Electronics product before using it in a particular

application. You may not use any Renesas Electronics product for any application categorized as “Specific” without the prior

written consent of Renesas Electronics. Further, you may not use any Renesas Electronics product for any application for

which it is not intended without the prior written consent of Renesas Electronics. Renesas Electronics shall not be in any way

liable for any damages or losses incurred by you or third parties arising from the use of any Renesas Electronics product for an

application categorized as “Specific” or for which the product is not intended where you have failed to obtain the prior written

consent of Renesas Electronics. The quality grade of each Renesas Electronics product is “Standard” unless otherwise

expressly specified in a Renesas Electronics data sheets or data books, etc.

“Standard”: Computers; office equipment; communications equipment; test and measurement equipment; audio and visual

equipment; home electronic appliances; machine tools; personal electronic equipment; and industrial robots.

“High Quality”: Transportation equipment (automobiles, trains, ships, etc.); traffic control systems; anti-disaster systems; anti-

crime systems; safety equipment; and medical equipment not specifically designed for life support.

“Specific”: Aircraft; aerospace equipment; submersible repeaters; nuclear reactor control systems; medical equipment or

systems for life support (e.g. artificial life support devices or systems), surgical implantations, or healthcare

intervention (e.g. excision, etc.), and any other applications or purposes that pose a direct threat to human life.

8. You should use the Renesas Electronics products described in this document within the range specified by Renesas Electronics,

especially with respect to the maximum rating, operating supply voltage range, movement power voltage range, heat radiation

characteristics, installation and other product characteristics. Renesas Electronics shall have no liability for malfunctions or

damages arising out of the use of Renesas Electronics products beyond such specified ranges.

9. Although Renesas Electronics endeavors to improve the quality and reliability of its products, semiconductor products have

specific characteristics such as the occurrence of failure at a certain rate and malfunctions under certain use conditions. Further,

Renesas Electronics products are not subject to radiation resistance design. Please be sure to implement safety measures to

guard them against the possibility of physical injury, and injury or damage caused by fire in the event of the failure of a

Renesas Electronics product, such as safety design for hardware and software including but not limited to redundancy, fire

control and malfunction prevention, appropriate treatment for aging degradation or any other appropriate measures. Because

the evaluation of microcomputer software alone is very difficult, please evaluate the safety of the final products or system

manufactured by you.

10. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental

compatibility of each Renesas Electronics product. Please use Renesas Electronics products in compliance with all applicable

laws and regulations that regulate the inclusion or use of controlled substances, including without limitation, the EU RoHS

Directive. Renesas Electronics assumes no liability for damages or losses occurring as a result of your noncompliance with

applicable laws and regulations.

11. This document may not be reproduced or duplicated, in any form, in whole or in part, without prior written consent of Renesas

Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this

document or Renesas Electronics products, or if you have any other inquiries.

(Note 1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its majority-

owned subsidiaries.

(Note 2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

Page 3

Application Note

Inverter Control by V850 Series

120° Excitation Method Control by Zero-Cross Detection

V850E/IA1

V850E/IA2

V850E/IA3

V850E/IA4

V850E/MA3

Document No. U17209EJ1V0AN00 (1st edition)

Date Published September 2004 N CP(K)

2004

Printed in Japan

Page 4

[MEMO]

2

Application Note U17209EJ1V0AN

Page 5

NOTES FOR CMOS DEVICES

1

VOLTAGE APPLICATION WAVEFORM AT INPUT PIN

Waveform distortion due to input noise or a reflected wave may cause malfunction. If the input of the

IL

CMOS device stays in the area between V

malfunction. Take care to prevent chattering noise from entering the device when the input level is fixed,

and also in the transition period when the input level passes through the area between V

IH

(MIN).

V

HANDLING OF UNUSED INPUT PINS

2

Unconnected CMOS device inputs can be cause of malfunction. If an input pin is unconnected, it is

possible that an internal input level may be generated due to noise, etc., causing malfunction. CMOS

devices behave differently than Bipolar or NMOS devices. Input levels of CMOS devices must be fixed

high or low by using pull-up or pull-down circuitry. Each unused pin should be connected to V

via a resistor if there is a possibility that it will be an output pin. All handling related to unused pins must

be judged separately for each device and according to related specifications governing the device.

3

PRECAUTION AGAINST ESD

A strong electric field, when exposed to a MOS device, can cause destruction of the gate oxide and

ultimately degrade the device operation. Steps must be taken to stop generation of static electricity as

much as possible, and quickly dissipate it when it has occurred. Environmental control must be

adequate. When it is dry, a humidifier should be used. It is recommended to avoid using insulators that

easily build up static electricity. Semiconductor devices must be stored and transported in an anti-static

container, static shielding bag or conductive material. All test and measurement tools including work

benches and floors should be grounded. The operator should be grounded using a wrist strap.

Semiconductor devices must not be touched with bare hands. Similar precautions need to be taken for

PW boards with mounted semiconductor devices.

(MAX) and VIH (MIN) due to noise, etc., the device may

IL

(MAX) and

DD

or GND

4

STATUS BEFORE INITIALIZATION

Power-on does not necessarily define the initial status of a MOS device. Immediately after the power

source is turned ON, devices with reset functions have not yet been initialized. Hence, power-on does

not guarantee output pin levels, I/O settings or contents of registers. A device is not initialized until the

reset signal is received. A reset operation must be executed immediately after power-on for devices

with reset functions.

5

POWER ON/OFF SEQUENCE

In the case of a device that uses different power supplies for the internal operation and external

interface, as a rule, switch on the external power supply after switching on the internal power supply.

When switching the power supply off, as a rule, switch off the external power supply and then the

internal power supply. Use of the reverse power on/off sequences may result in the application of an

overvoltage to the internal elements of the device, causing malfunction and degradation of internal

elements due to the passage of an abnormal current.

The correct power on/off sequence must be judged separately for each device and according to related

specifications governing the device.

6

INPUT OF SIGNAL DURING POWER OFF STATE

Do not input signals or an I/O pull-up power supply while the device is not powered. The current

injection that results from input of such a signal or I/O pull-up power supply may cause malfunction and

the abnormal current that passes in the device at this time may cause degradation of internal elements.

Input of signals during the power off state must be judged separately for each device and according to

related specifications governing the device.

Application Note U17209EJ1V0AN

3

Page 6

These commodities, technology or software, must be exported in accordance

with the export administration regulations of the exporting country.

Diversion contrary to the law of that country is prohibited.

•

The information in this document is current as of July, 2004. The information is subject to change

without notice. For actual design-in, refer to the latest publications of NEC Electronics data sheets or

data books, etc., for the most up-to-date specifications of NEC Electronics products. Not all

products and/or types are available in every country. Please check with an NEC Electronics sales

representative for availability and additional information.

No part of this document may be copied or reproduced in any form or by any means without the prior

•

written consent of NEC Electronics. NEC Electronics assumes no responsibility for any errors that may

appear in this document.

•

NEC Electronics does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from the use of NEC Electronics products listed in this document

or any other liability arising from the use of such products. No license, express, implied or otherwise, is

granted under any patents, copyrights or other intellectual property rights of NEC Electronics or others.

Descriptions of circuits, software and other related information in this document are provided for illustrative

•

purposes in semiconductor product operation and application examples. The incorporation of these

circuits, software and information in the design of a customer's equipment shall be done under the full

responsibility of the customer. NEC Electronics assumes no responsibility for any losses incurred by

customers or third parties arising from the use of these circuits, software and information.

•

While NEC Electronics endeavors to enhance the quality, reliability and safety of NEC Electronics products,

customers agree and acknowledge that the possibility of defects thereof cannot be eliminated entirely. To

minimize risks of damage to property or injury (including death) to persons arising from defects in NEC

Electronics products, customers must incorporate sufficient safety measures in their design, such as

redundancy, fire-containment and anti-failure features.

•

NEC Electronics products are classified into the following three quality grades: "Standard", "Special" and

"Specific".

The "Specific" quality grade applies only to NEC Electronics products developed based on a customerdesignated "quality assurance program" for a specific application. The recommended applications of an NEC

Electronics product depend on its quality grade, as indicated below. Customers must check the quality grade of

each NEC Electronics product before using it in a particular application.

"Standard": Computers, office equipment, communications equipment, test and measurement equipment, audio

and visual equipment, home electronic appliances, machine tools, personal electronic equipment

and industrial robots.

"Special": Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support).

"Specific": Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems and medical equipment for life support, etc.

The quality grade of NEC Electronics products is "Standard" unless otherwise expressly specified in NEC

Electronics data sheets or data books, etc. If customers wish to use NEC Electronics products in applications

not intended by NEC Electronics, they must contact an NEC Electronics sales representative in advance to

determine NEC Electronics' willingness to support a given application.

(Note)

(1) "NEC Electronics" as used in this statement means NEC Electronics Corporation and also includes its

majority-owned subsidiaries.

(2) "NEC Electronics products" means any product developed or manufactured by or for NEC Electronics (as

defined above).

M8E 0 2. 11-1

4

Application Note U17209EJ1V0AN

Page 7

Regional Information

Some information contained in this document may vary from country to country. Before using any NEC

Electronics product in your application, pIease contact the NEC Electronics office in your country to

obtain a list of authorized representatives and distributors. They will verify:

•

Device availability

•

Ordering information

•

Product release schedule

•

Availability of related technical literature

•

Development environment specifications (for example, specifications for third-party tools and

components, host computers, power plugs, AC supply voltages, and so forth)

•

Network requirements

In addition, trademarks, registered trademarks, export restrictions, and other legal issues may also vary

from country to country.

[GLOBAL SUPPORT]

http://www.necel.com/en/support/support.html

NEC Electronics America, Inc. (U.S.)

Santa Clara, California

Tel: 408-588-6000

800-366-9782

N

EC Electronics (Europe) GmbH

Duesseldorf, Germany

Tel: 0211-65030

•

Sucursal en España

Madrid, Spain

Tel: 091-504 27 87

•

Succursale Française

Vélizy-Villacoublay, France

Tel: 01-30-67 58 00

•

Filiale Italiana

Milano, Italy

Tel: 02-66 75 41

•

Branch The Netherlands

Eindhoven, The Netherlands

Tel: 040-244 58 45

•

Tyskland Filial

Taeby, Sweden

Tel: 08-63 80 820

•

United Kingdom Branch

Milton Keynes, UK

Tel: 01908-691-133

NEC Electronics Hong Kong Ltd.

Hong Kong

Tel: 2886-9318

NEC Electronics Hong Kong Ltd.

Seoul Branch

Seoul, Korea

Tel: 02-558-3737

NEC Electronics Shanghai Ltd.

Shanghai, P.R. China

Tel: 021-5888-5400

NEC Electronics Taiwan Ltd.

Taipei, Taiwan

Tel: 02-2719-2377

NEC Electronics Singapore Pte. Ltd.

Novena Square, Singapore

Tel: 6253-8311

J04.1

Application Note U17209EJ1V0AN

5

Page 8

INTRODUCTION

Target Readers This application note is intended for users who understand the functions of the

V850E/IA1, V850E/IA2, V850E/IA3, V850E/IA4, and V850E/MA3, and who design

application systems that use these microcontrollers. The applicable products are shown

below.

• V850E/IA1

Standard products:

Special products:

• V850E/IA2:

Standard products:

Special products:

• V850E/IA3

Standard products:

• V850E/IA4

Standard products:

• V850E/MA3

Standard products:

703132Y, 703132AY, 703133, 703133A, 703133Y, 703133AY,

703134, 703134A, 703134Y, 703134AY, 70F3134, 70F3134A,

70F3134Y, 70F3134AY

Purpose The purpose of this application note is to help the user understand how a brushless DC

motor is controlled via the 120° sensorless drive excitation method that uses PWM

output and A/D converter input as a system example of the timer/counter function of the

V850E/IA1, V850E/IA2, V850E/IA3, V850E/IA4, and V850E/MA3.

Organization This application note is divided into the following sections.

• Control method • Software configuration

• Hardware configuration • Program list

How to Use This Manual It is assumed that the reader of this application note has general knowledge in the fields

of electrical engineering, logic circuits, and microcontrollers.

Cautions 1. Application examples in this manual are intended for the “standard”

quality models for general-purpose electronic systems. When using

an example in this manual for an application that requires the

“special” quality grade, evaluate each component and circuit to be

actually used to see if they satisfy the required quality standard.

2. To use this manual for special-grade products, read the part

numbers as follows:

µ

PD703114 → µPD703114(A)

µ

PD70F3114 → µPD70F3114(A)

µ

PD703116 → µPD703116(A), 703116(A1)

µ

PD70F3116 → µPD70F3116(A), 70F3116(A1)

µ

PD703116, 70F3116

µ

PD703116(A), 703116(A1), 70F3116(A), 70F3116(A1)

µ

PD703114, 70F3114

µ

PD703114(A), 70F3114(A)

µ

PD703183, 70F3184

µ

PD703185, 703186, 70F3186

µ

PD703131, 703131A, 703131Y, 703131AY, 703132, 703132A,

6

Application Note U17209EJ1V0AN

Page 9

For details of hardware functions (especially register functions, setting methods, etc.)

and electrical specifications

→ See the V850E/IA1 Hardware User’s Manual, V850E/IA2 Hardware User’s

Manual, V850E/IA3, V850E/IA4 Hardware User’s Manual, and V850E/MA3

Hardware User’s Manual.

For details of instruction functions

→ See the V850E1 Architecture User’s Manual.

Conventions Data significance: Higher digits on the left and lower digits on the right

Active low representation: xxx (overscore over pin or signal name)

Memory map address: Higher addresses on the top and lower addresses on

the bottom

Note: Footnote for item marked with Note in the text

Caution: Information requiring particular attention

Remark: Supplementary information

Numeric representation: Binary ... xxxx or xxxxB

Decimal ... xxxx

Hexadecimal ... xxxxH

Prefix indicating the power

of 2 (address space,

memory capacity): K (kilo): 2

M (mega): 2

G (giga): 2

10

= 1,024

20

= 1,0242

30

= 1,0243

Data type: Word: 32 bits

Halfword: 16 bits

Byte: 8 bits

Related documents The related documents indicated in this publication may include preliminary versions.

However, preliminary versions are not marked as such.

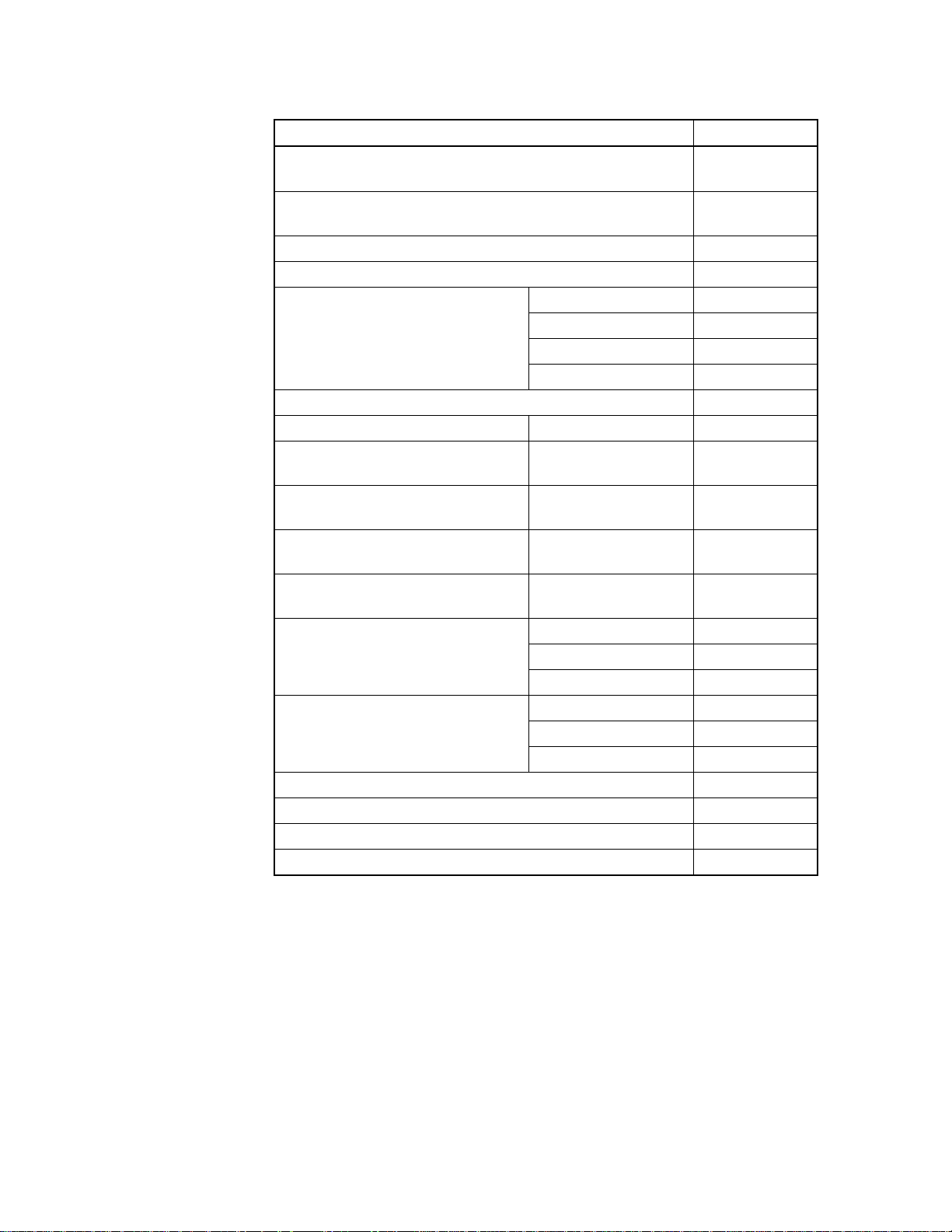

Documents related to V850E/IA1, V850E/IA2, V850E/IA3, V850E/IA4, V850E/MA3

Document Name Document No.

V850E1 Architecture User’s Manual U14559E

V850E/IA1 Hardware User’s Manual U14492E

V850E/IA2 Hardware User’s Manual U15195E

V850E/IA3, V850E/IA4 Hardware User’s Manual U16543E

V850E/MA3 Hardware User’s Manual U16397E

V850E/IA1, V850E/IA2 AC Motor Inverter Control Using Vector

Operation Application Note

Inverter Control by V850 Series 120° Excitation Method Control by Zero-

Cross Detection Application Note

U14868E

This manual

Application Note U17209EJ1V0AN

7

Page 10

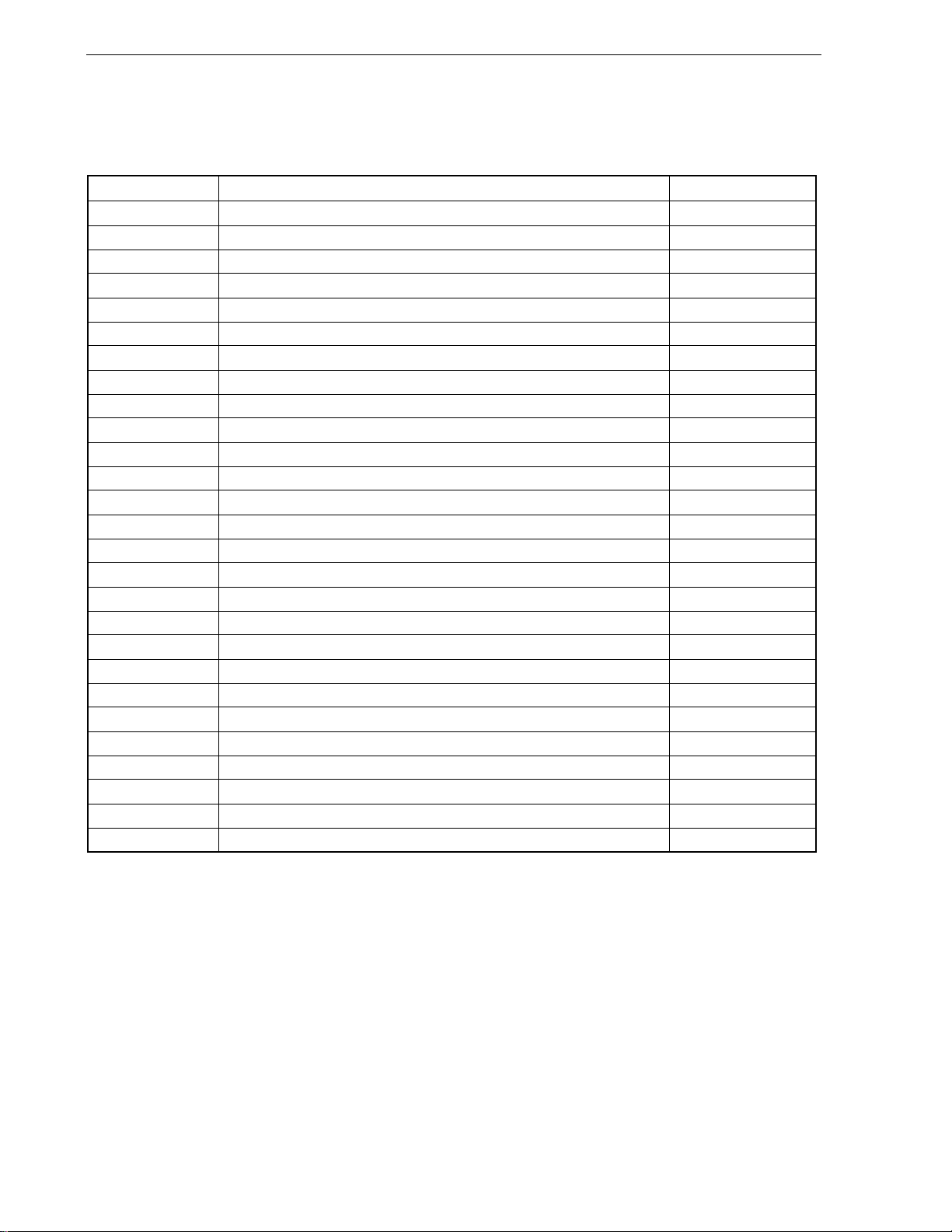

Documents related to development tools (user’s manuals)

Document Name Document No.

IE-V850E-MC, IE-V850E-MC-A (In-Circuit Emulator for V850E/IA1,

V850E/IA2)

IE-V850E1-CD-NW (PCMCIA Card Type On-Chip Debug Emulator for

V850E/IA3, V850E/IA4, V850E/MA3)

IE-703116-MC-EM1 (In-Circuit Emulator Option Board for V850E/IA1) U14700E

IE-703114-MC-EM1 (In-Circuit Emulator Option Board for V850E/IA2) U16533E

CA850 Ver. 2.70 C Compiler Package

PM plus Ver. 5.20 U16934E

ID850 Ver. 2.50 Integrated Debugger Operation U16217E

ID850NW Ver. 2.51 Integrated Debugger

(for V850E/MA3)

ID850NWC Ver. 2.51 Integrated Debugger

(for V850E/IA3, V850E/IA4, V850E/MA3)

SM850 Ver. 2.50 System Simulator

(for V850E/IA1, V850E/IA2)

SM850 Ver. 2.00 or Later System

Simulator (for V850E/IA1, V850E/IA2)

RX850 Ver. 3.13 or Later Real-Time OS

RX850 Pro Ver. 3.15 Real-Time OS

RD850 Ver. 3.01 Task Debugger U13737E

RD850 Pro Ver. 3.01 Task Debugger U13916E

AZ850 Ver. 3.10 System Performance Analyzer U14410E

PG-FP4 Flash Memory Programmer U15260E

Operation U16932E

C Language U16930E

Assembly Language U16931E

Link Directive U16933E

Operation U16454E

Operation U16525E

Operation U16218E

External Part User Open

Interface Specifications

Basics U13430E

Installation U13410E

Technical U13431E

Basics U13773E

Installation U13774E

Technical U13772E

U14487E

U16647E

U14873E

8

Application Note U17209EJ1V0AN

Page 11

CONTENTS

CHAPTER 1 CONTROL METHOD..........................................................................................................12

1.1 Outline of Brushless DC Motor Control.................................................................................. 12

CHAPTER 2 HARDWARE CONFIGURATION.......................................................................................17

2.1 Configuration ............................................................................................................................ 17

2.2 Circuit Diagram ......................................................................................................................... 19

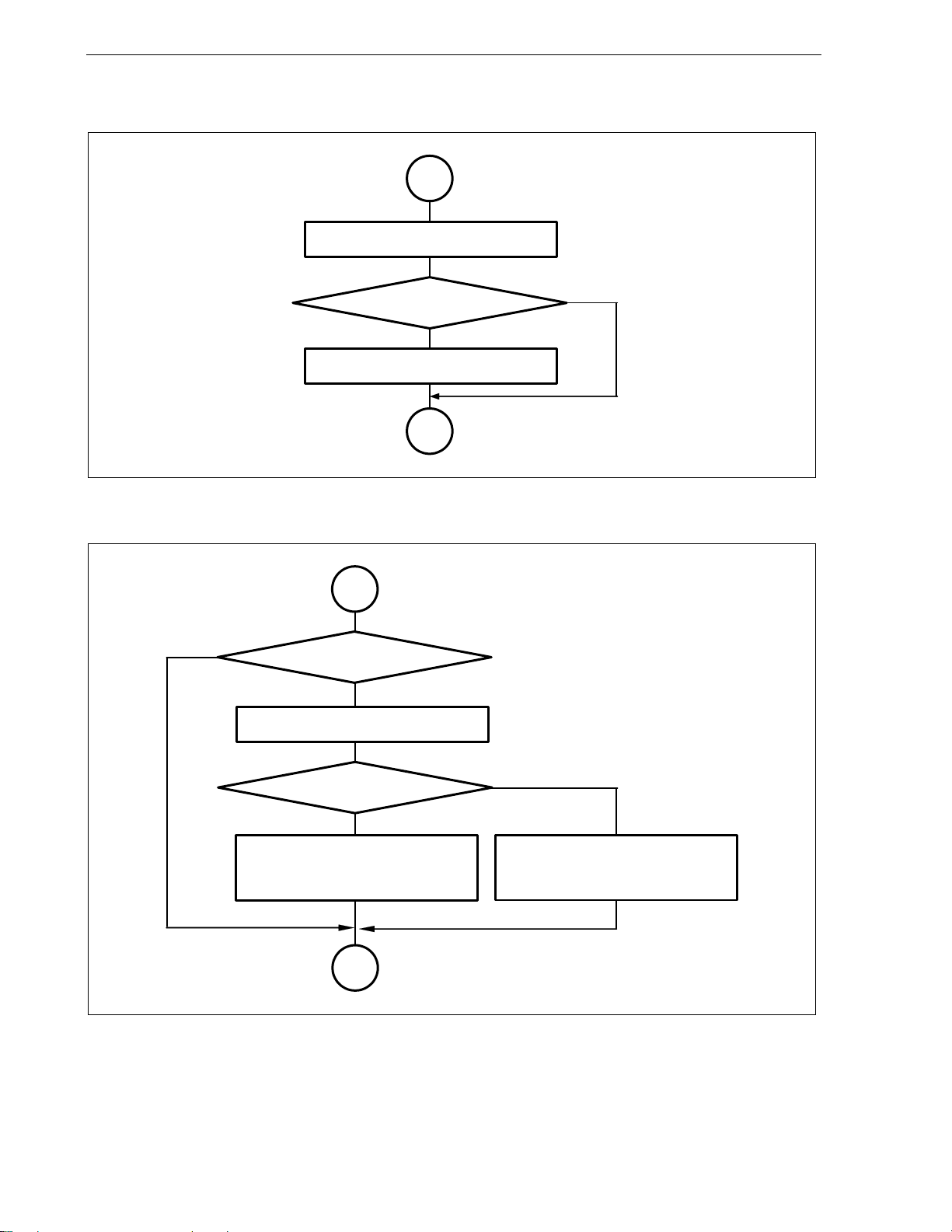

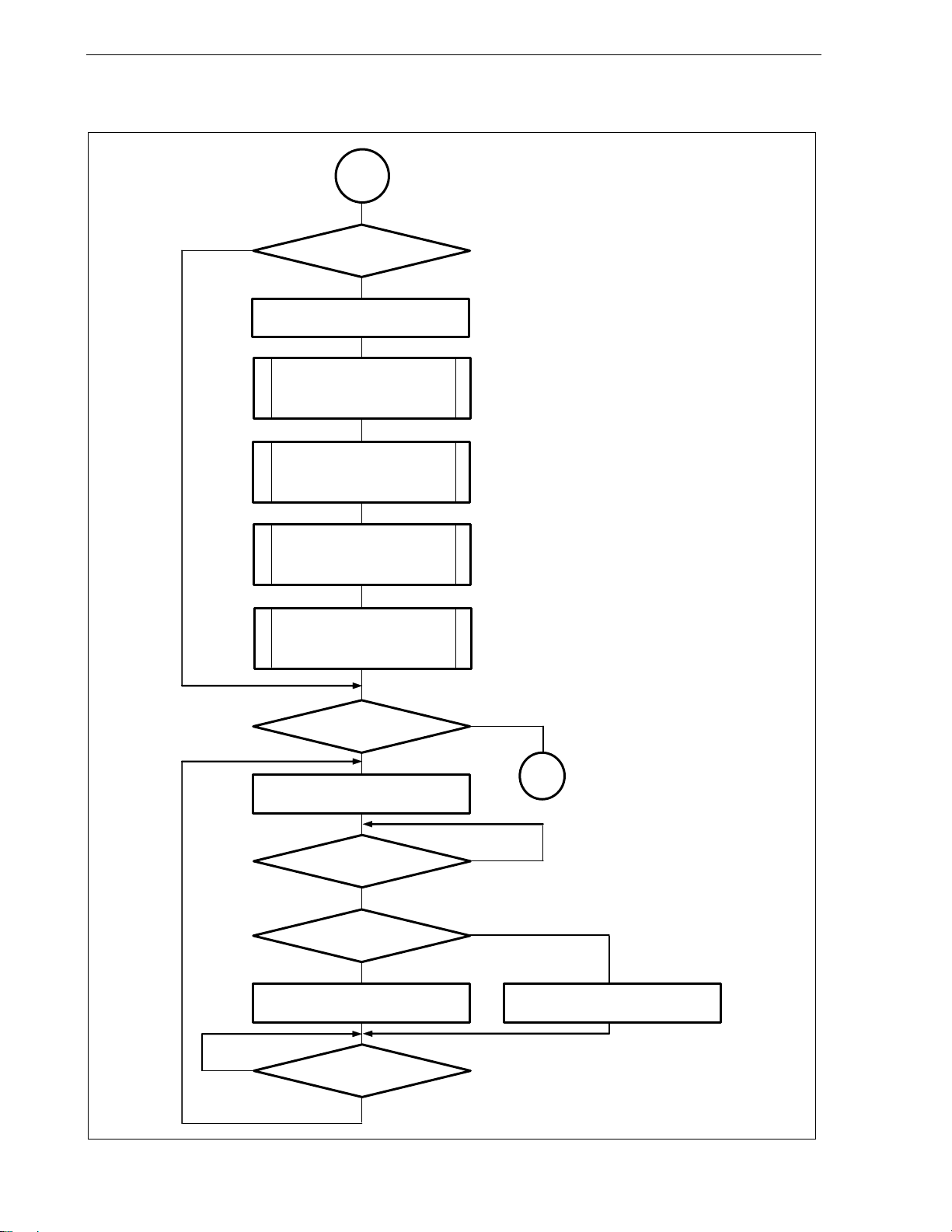

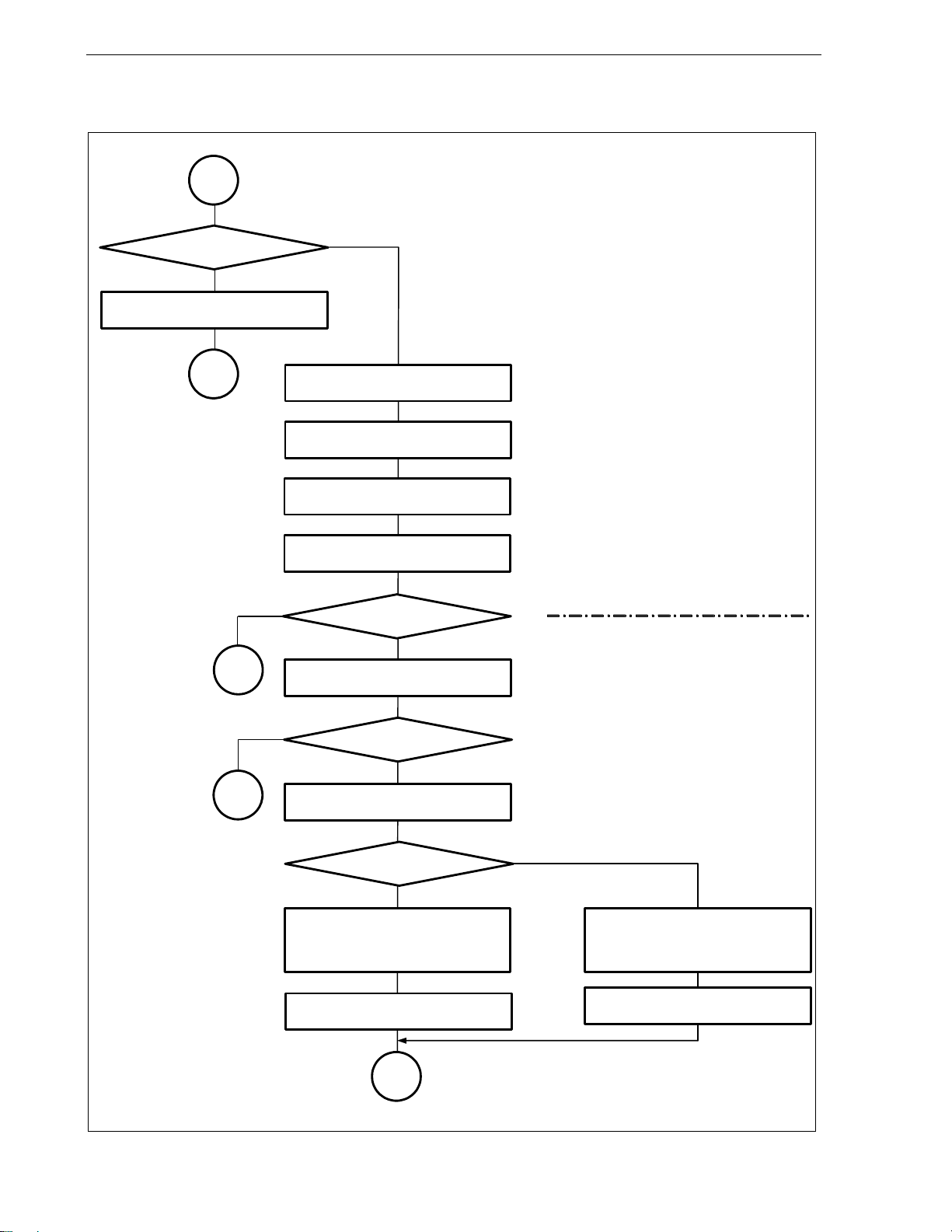

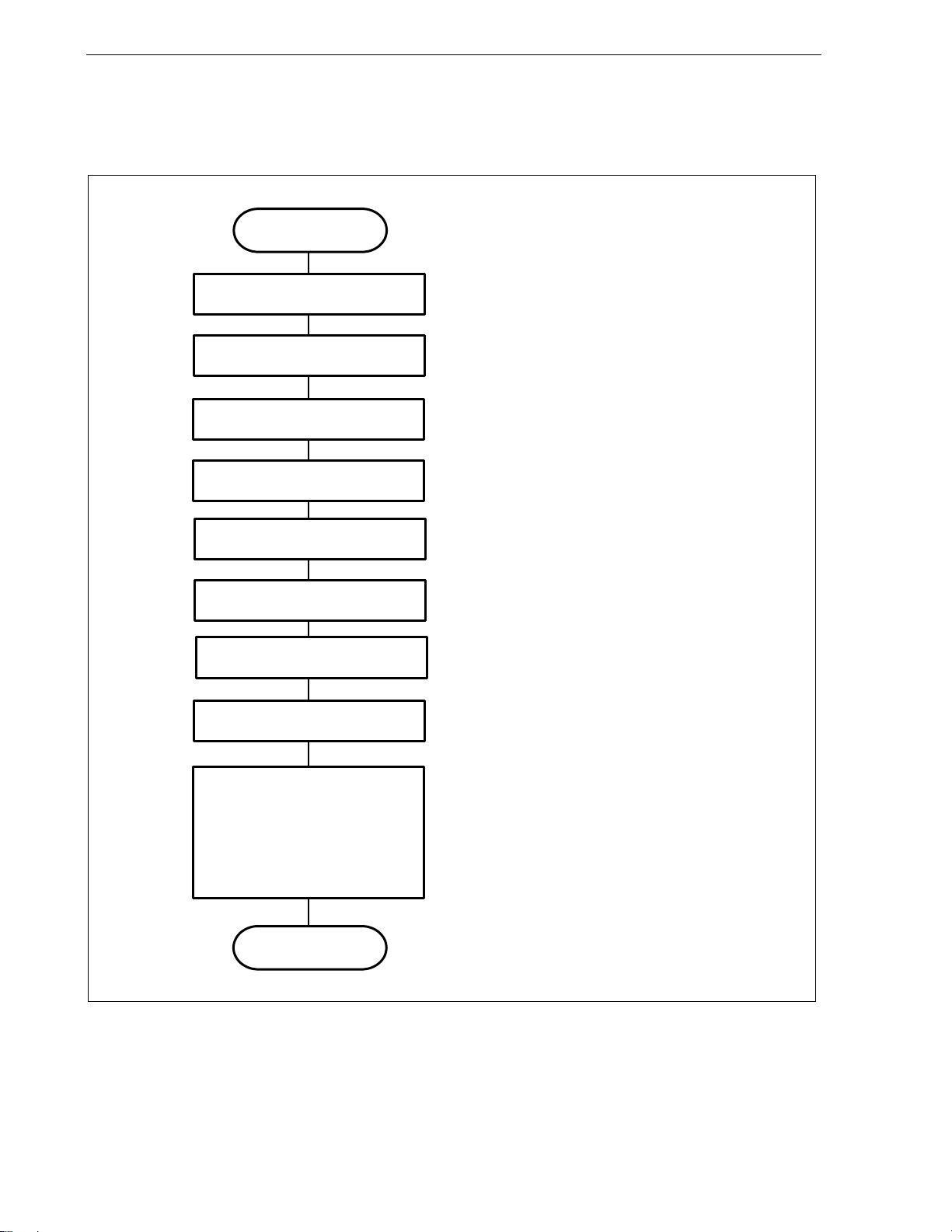

CHAPTER 3 SOFTWARE CONFIGURATION........................................................................................31

3.1 Control Block ............................................................................................................................ 31

3.2 Peripheral I/O............................................................................................................................. 32

3.3 Software Processing Structure ............................................................................................... 34

3.4 Flowchart................................................................................................................................... 36

3.4.1 Main processing...........................................................................................................................36

3.4.2 Motor control processing..............................................................................................................45

3.4.3 U zero-cross point interrupt processing........................................................................................50

3.4.4 V zero-cross point interrupt processing........................................................................................51

3.4.5 W zero-cross point interrupt processing.......................................................................................52

3.4.6 10 mSEC interval interrupt processing.........................................................................................53

3.4.7 A/D converter channel 0 interrupt processing ..............................................................................54

3.4.8 A/D converter channel 1 interrupt processing ..............................................................................55

3.4.9 Hardware initialization ..................................................................................................................56

3.4.10 Common area initialization...........................................................................................................57

3.4.11 Revolution start initialization.........................................................................................................57

3.4.12 LED display..................................................................................................................................58

3.5 Common Areas ......................................................................................................................... 59

3.6 Tables......................................................................................................................................... 60

3.7 Constant Definitions................................................................................................................. 62

CHAPTER 4 PROGRAM LIST ................................................................................................................63

4.1 Program List (V850E/IA1)......................................................................................................... 63

4.1.1 Symbol definition..........................................................................................................................63

4.1.2 Constant definition........................................................................................................................64

4.1.3 Interrupt handler setting ...............................................................................................................67

4.1.4 Startup routine setting ..................................................................................................................69

4.1.5 Main processing function..............................................................................................................72

4.1.6 LED display function.....................................................................................................................76

4.1.7 Motor control interrupt processing function ..................................................................................77

4.1.8 Zero-cross interrupt processing function ......................................................................................81

4.1.9 10 mSEC interval interrupt processing function ...........................................................................83

4.1.10 A/D converter interrupt processing function .................................................................................84

4.1.11 Hardware initialization processing function ..................................................................................84

4.1.12 Common area initialization processing function...........................................................................86

4.1.13 Revolution start initialization processing function.........................................................................86

4.1.14 Link directive file for V850E/IA1....................................................................................................87

4.2 Program List (V850E/IA2)......................................................................................................... 89

Application Note U17209EJ1V0AN

9

Page 12

4.2.1 Symbol definition......................................................................................................................... 89

4.2.2 Constant definition....................................................................................................................... 90

4.2.3 Interrupt handler setting............................................................................................................... 93

4.2.4 Startup routine setting ................................................................................................................. 95

4.2.5 Main processing function............................................................................................................. 98

4.2.6 LED display function...................................................................................................................102

4.2.7 Motor control interrupt processing function.................................................................................103

4.2.8 Zero-cross interrupt processing function ....................................................................................107

4.2.9 10 mSEC interval interrupt processing function..........................................................................109

4.2.10 A/D converter interrupt processing function................................................................................110

4.2.11 Hardware initialization processing function.................................................................................110

4.2.12 Common area initialization processing function..........................................................................112

4.2.13 Revolution start initialization processing function.......................................................................112

4.2.14 Link directive file for V850E/IA2..................................................................................................113

4.3 Program List (V850E/IA3) ....................................................................................................... 115

4.3.1 Symbol definition........................................................................................................................115

4.3.2 Constant definition......................................................................................................................116

4.3.3 Interrupt handler setting..............................................................................................................119

4.3.4 Startup routine setting ................................................................................................................121

4.3.5 Main processing function............................................................................................................124

4.3.6 LED display function...................................................................................................................128

4.3.7 Motor control interrupt processing function.................................................................................129

4.3.8 Zero-cross interrupt processing function ....................................................................................132

4.3.9 10 mSEC interval interrupt processing function..........................................................................135

4.3.10 A/D converter interrupt processing function................................................................................135

4.3.11 Hardware initialization processing function.................................................................................136

4.3.12 Common area initialization processing function..........................................................................138

4.3.13 Revolution start initialization processing function.......................................................................138

4.3.14 Link directive file for V850E/IA3..................................................................................................138

4.4 Program List (V850E/IA4) ....................................................................................................... 140

4.4.1 Symbol definition........................................................................................................................140

4.4.2 Constant definition......................................................................................................................141

4.4.3 Interrupt handler setting..............................................................................................................144

4.4.4 Startup routine setting ................................................................................................................146

4.4.5 Main processing function............................................................................................................149

4.4.6 LED display function...................................................................................................................153

4.4.7 Motor control interrupt processing function.................................................................................154

4.4.8 Zero-cross interrupt processing function ....................................................................................157

4.4.9 10 mSEC interval interrupt processing function..........................................................................160

4.4.10 A/D converter interrupt processing function................................................................................160

4.4.11 Hardware initialization processing function.................................................................................161

4.4.12 Common area initialization processing function..........................................................................163

4.4.13 Revolution start initialization processing function.......................................................................163

4.4.14 Link directive file for V850E/IA4..................................................................................................163

4.5 Program List (V850E/MA3)..................................................................................................... 165

4.5.1 Symbol definition........................................................................................................................165

4.5.2 Constant definition......................................................................................................................166

4.5.3 Interrupt handler setting..............................................................................................................169

10

Application Note U17209EJ1V0AN

Page 13

4.5.4 Startup routine setting ................................................................................................................171

4.5.5 Main processing function............................................................................................................174

4.5.6 LED display function...................................................................................................................178

4.5.7 Motor control interrupt processing function ................................................................................179

4.5.8 Zero-cross interrupt processing function ....................................................................................182

4.5.9 10 mSEC interval interrupt processing function .........................................................................184

4.5.10 A/D converter interrupt processing function ...............................................................................185

4.5.11 Hardware initialization processing function ................................................................................185

4.5.12 Common area initialization processing function.........................................................................187

4.5.13 Revolution start initialization processing function.......................................................................187

4.5.14 Link directive file for V850E/MA3................................................................................................188

Application Note U17209EJ1V0AN

11

Page 14

CHAPTER 1 CONTROL METHOD

1.1 Outline of Brushless DC Motor Control

A brushless DC (BLDC) motor consists of a stator, coil, and rotor. The rotor, which includes a permanent magnet,

is rotated by the action of the magnetic field generated by the coil of the stator.

The magnetic field is generated by exciting the coil wound around the stator in a specific sequence. By controlling

the intensity and cycle of the magnetic field with a microcontroller, the torque response and the number of revolutions

of the motor can be controlled.

This section explains how to control a BLDC motor without a sensor by using the V850E/IA1, V850E/IA2,

V850E/IA3, V850E/IA4, or V850E/MA3.

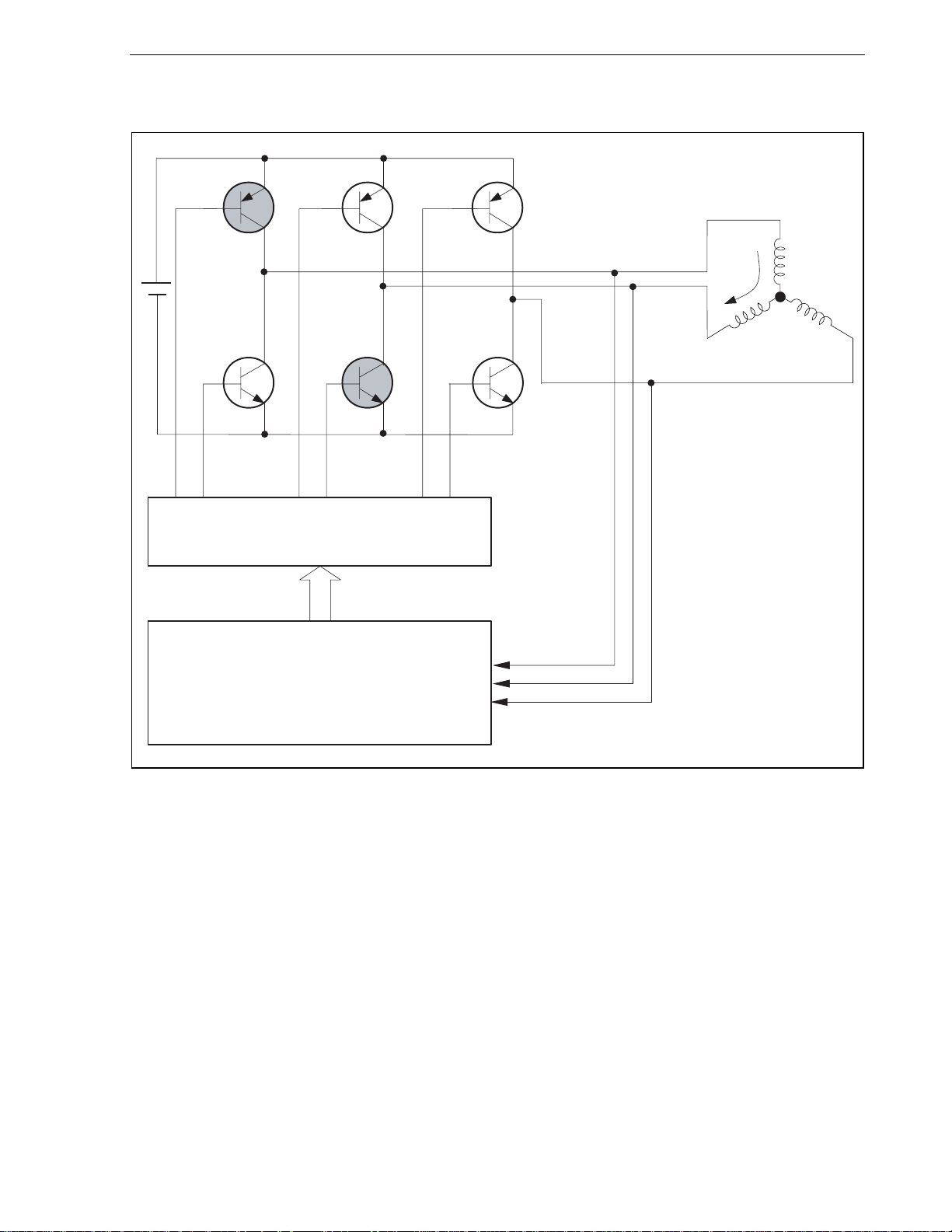

Figure 1-3 shows an example of the circuit of a three-phase brushless DC motor. The internal PWM output

function of the microcontroller is used to control the current that flows through the motor, by using a transistor array

consisting of six transistors.

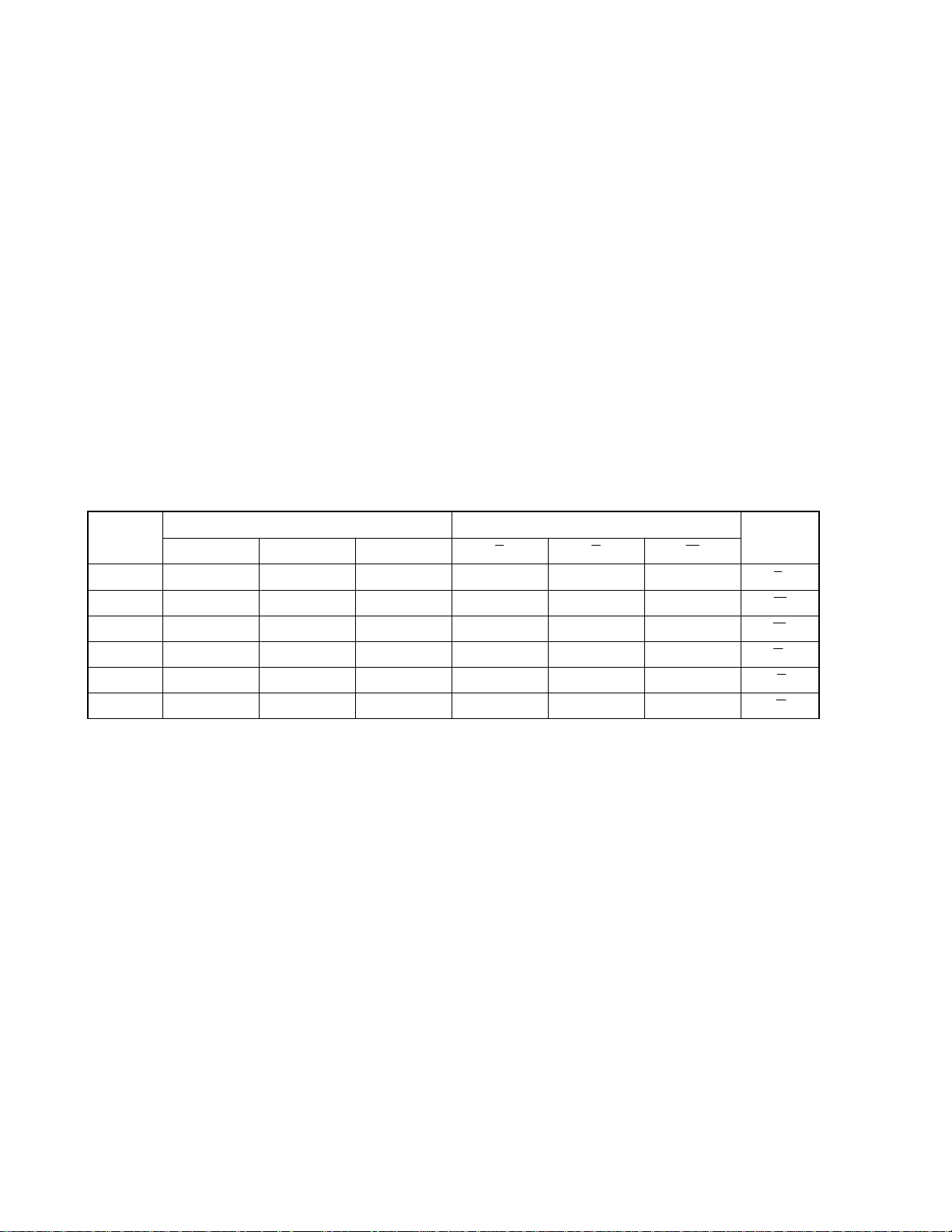

The magnetic field is generated by controlling the excitation pattern of the six transistors as shown in Table 1-1.

Table 1-1. Excitation Pattern

Upper Arm Lower Arm Excitation

Pattern

<1> Active Inactive Inactive Inactive Active Inactive U → V

<2> Active Inactive Inactive Inactive Inactive Active U → W

<3> Inactive Active Inactive Inactive Inactive Active V → W

<4> Inactive Active Inactive Active Inactive Inactive V → U

<5> Inactive Inactive Active Active Inactive Inactive W → U

<6> Inactive Inactive Active Inactive Active Inactive W → V

U V W U V W

Excitation

Direction

12

Application Note U17209EJ1V0AN

Page 15

CHAPTER 1 CONTROL METHOD

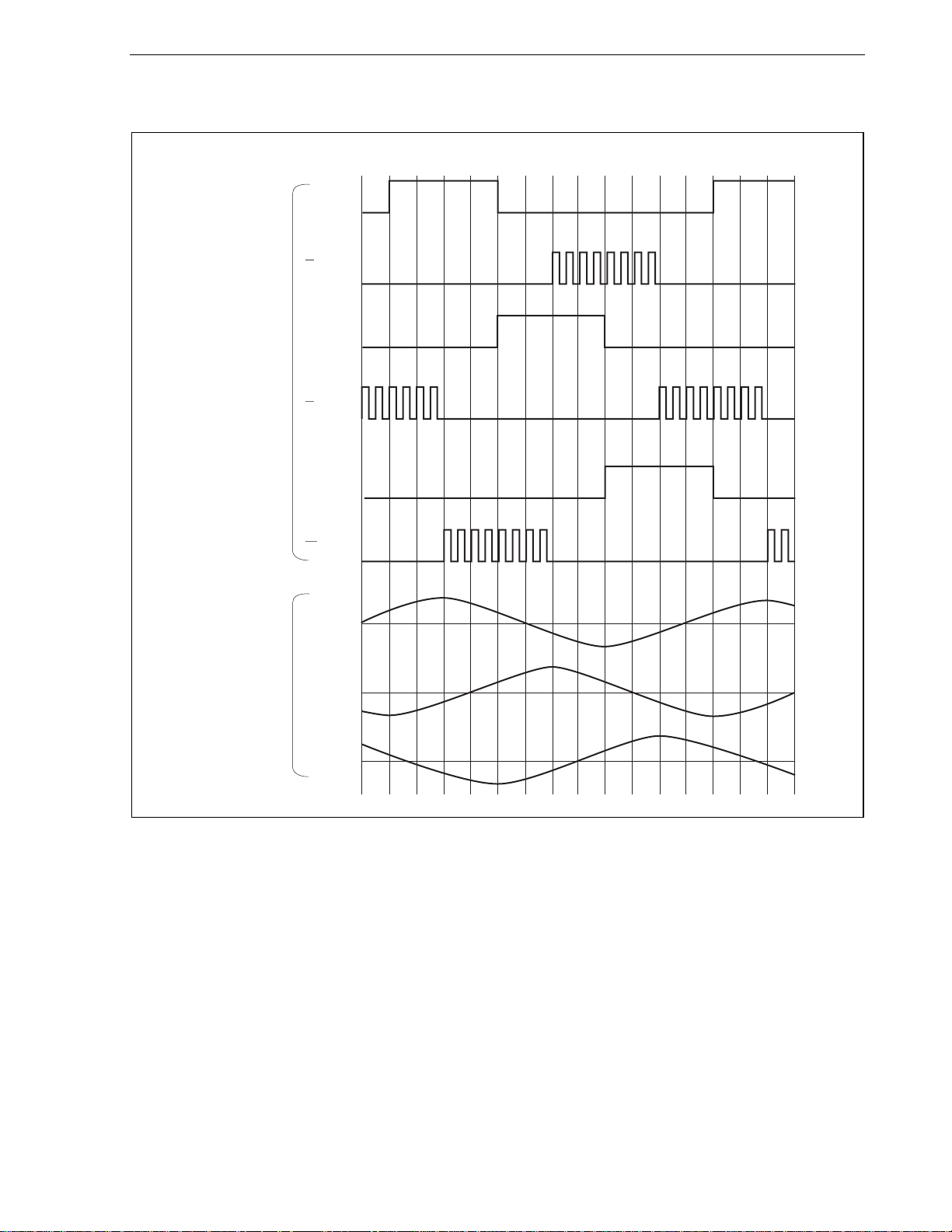

Figure 1-1. Three-Phase DC Motor Voltage Waveform

<1> <2> <3> <4> <5> <6>

U phase

U phase

Driving voltage

waveform

V phase

V phase

W phase

W phase

U phase

Induced voltage

waveform

V phase

W phase

Application Note U17209EJ1V0AN

13

Page 16

Magnetic

flux

CHAPTER 1 CONTROL METHOD

Figure 1-2. Rotor Position Detection Principle

CC

V

N

U

A

W-phase stator

is located in the

center of the N pole

and S pole of a

S

magnet rotor

S

V

CC

N

U

A

S

V

W

V

WC

N

(a) Rotor position <1> … U-phase stator: S pole

V-phase stator: N pole

W-phase stator: Center point

S

U

N

N

V

W

V

WC

A

V

CC

S

= 0

= 0

S

V

VC

= 0

V

W

N

(b) Rotor position <2> … U-phase stator: S pole

V-phase stator: Center point

W-phase stator: N pole

S

U

V

N

CC

V

N

W

S

V

UC

= 0

A

(d) Rotor position <4> … U-phase stator: N pole

V-phase stator: S pole

W-phase stator: Center point

S

U

N

V

VC

= 0

V

W

S

A

(e) Rotor position <5> … U-phase stator: N pole

V-phase stator: Center point

W-phase stator: S pole

14

(c) Rotor position <3> … U-phase stator: Center point

V-phase stator: S pole

W-phase stator: N pole

N

U

S

V

UC

= 0

Return to (a)

N

V

S

V

CC

A

W

N

V

CC

(f) Rotor position <6> … U-phase stator: Center point

V-phase stator: N pole

W-phase stator: S pole

Application Note U17209EJ1V0AN

Page 17

CHAPTER 1 CONTROL METHOD

Figure 1-3. Configuration of Three-Phase Brushless DC Motor

TrU

TrU

1

TrV

1

On Off Off

U

V

2

TrV

2

Off On Off

PWM control

TrW

TrW

1

U

W

V

W

2

U

Zero-cross point detection

V

W

Application Note U17209EJ1V0AN

15

Page 18

CHAPTER 1 CONTROL METHOD

The 120° control method for a BLDC motor without a sensor is described below.

To control a BLDC motor, the rotor position must be known.

To control a BLDC motor without a senso r, the rotor position is estimated using induced voltage.

The induced voltage is in phase with the driving voltage waveform and its waveform is close to a sine wave, as

shown in Figure 1-1. Figure 1-2 illustrates how the polarity of the stator of the motor is switched and how the magnet

rotor revolves.

As shown in Figures 1-1 and 1-2, a three-phase DC motor rotates its rotor by switching the three driving current

patterns on the three coil phases.

During period <1> in Figure 1-1, for example, transistor Tr U

1 in Figure 1-3 is turned on by the U-phase dr iving pin,

and TrV2 is turned on by the V-phase driving pin, causing the current to flow from the U-phase driving pin toward the Vphase driving pin. At this time, the W-phase coil seems to be disconnected from the driver circuit and induced voltage

is generated.

This induced voltage is used to detect the rotor position.

To control the number of revolutions of the motor, the voltage applied to the motor is controlled to change the

current flowing through the coil. To change the voltage, a waveform that is controlled by PWM is applied to the

transistor.

The voltage is changed by applying a waveform (PWM waveform) in proportion to the voltage to be applied, to the

transistors on the lower arm side (TrU

2, TrV2, and TrW2) while the transistors on the upper arm side (TrU1, TrV1, and

TrW1) are on.

16

Application Note U17209EJ1V0AN

Page 19

CHAPTER 2 HARDWARE CONFIGURATI ON

This chapter describes the hardware configuration.

2.1 Configuration

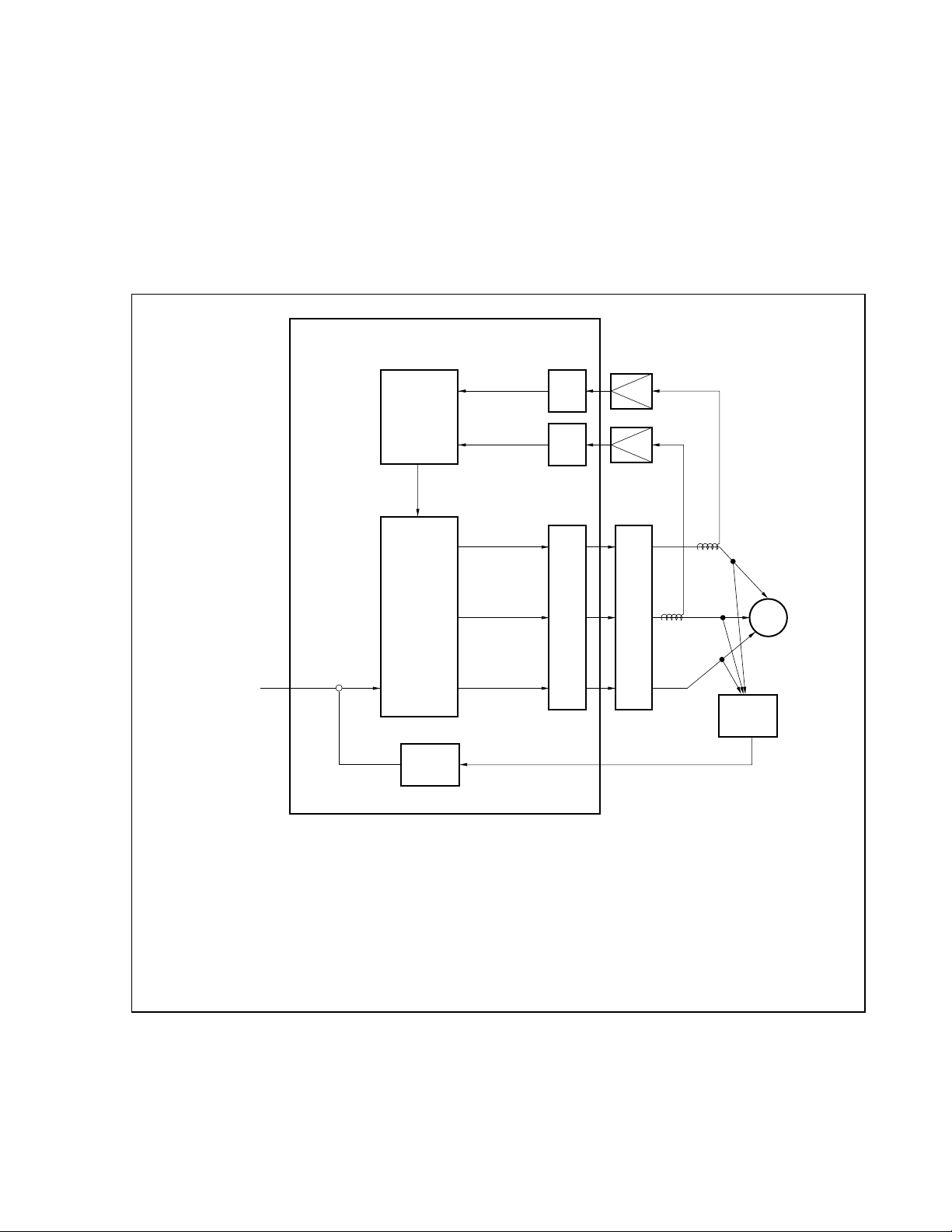

The reference system’s main functions are described below. In this reference system, when the revolution

specification switch is pressed after power application, the motor starts revolving in the direction specified.

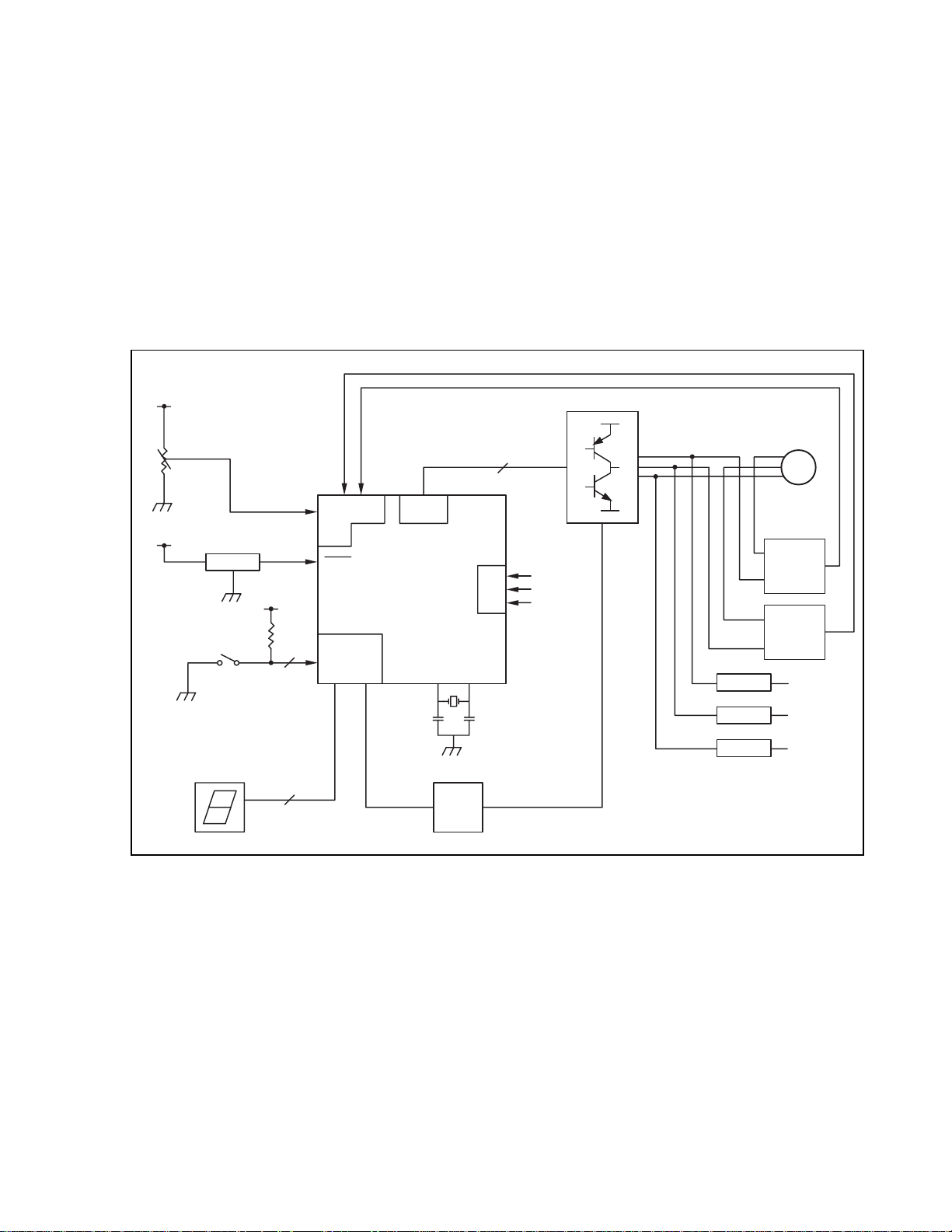

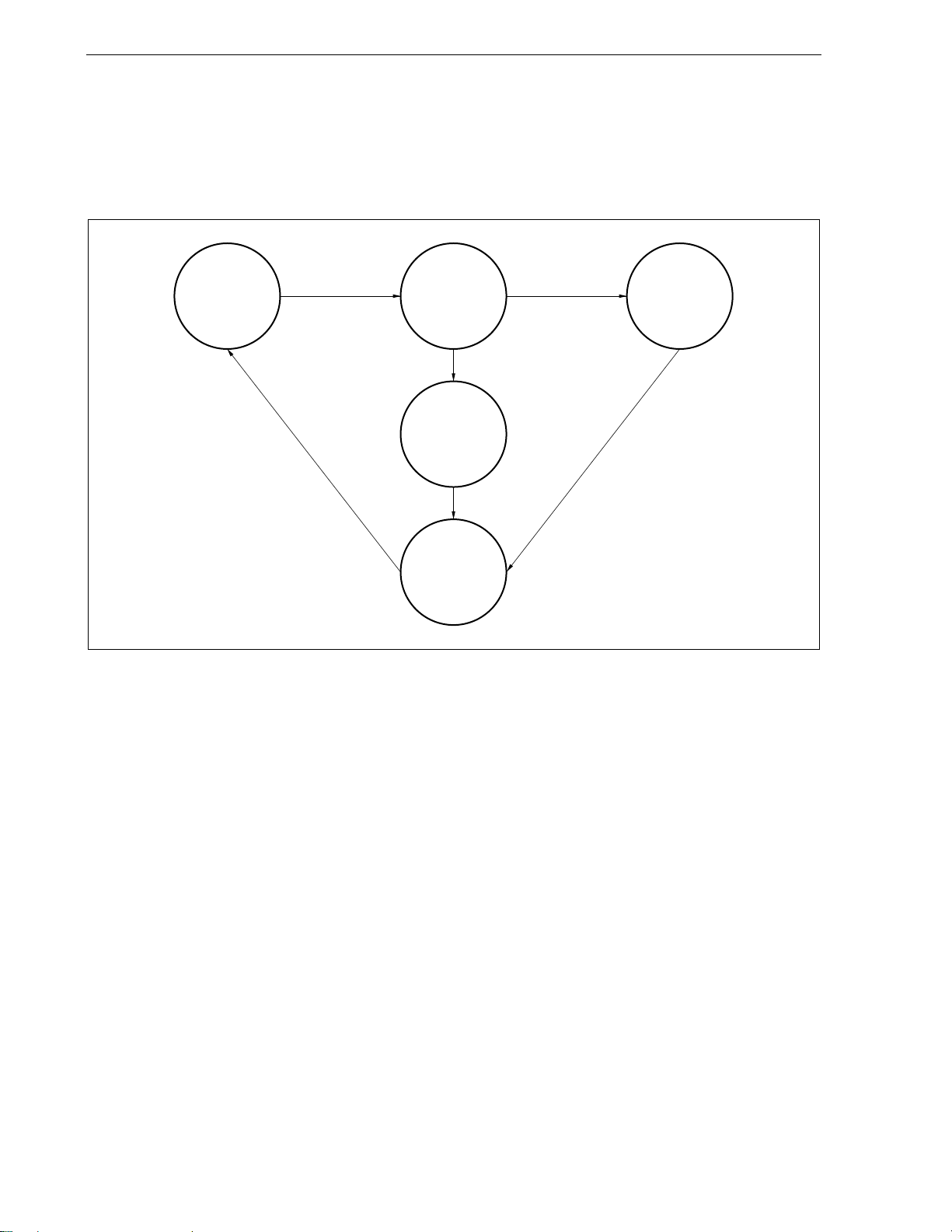

Figure 2-1. Overall System Configuration

Volume for

speed control

Driver IC

Reset circuit

Revolution

specification SW

LED display

3

13

A/D converter

RESET

Port

Timer

Microcontroller

WDT

6

V-U

V-V

V-W

Interrupt

Position

detection

Position

detection

Position

detection

M

Current voltage

conversion

Current voltage

conversion

V-U

V-V

V-W

Application Note U17209EJ1V0AN

17

Page 20

CHAPTER 2 HARDWARE CONFIGURATION

(1) Volume for speed control

Volume for increasing and decreasing the number of revolutions of the motor

(2) Revolution specification SW

CW, CCW, and STOP switches

(3) LED display

LED displaying the number of revolutions, operation time, etc.

(4) WDT

Watchdog timer

(5) Driver IC

Driver for driving motor

(6) Current voltage converter

Converting the motor driving current to voltage, used for detecting overcurrent

(7) Position detector

Rotor position estimation signal output from the induced voltage

18

Application Note U17209EJ1V0AN

Page 21

CHAPTER 2 HARDWARE CONFIGURATION

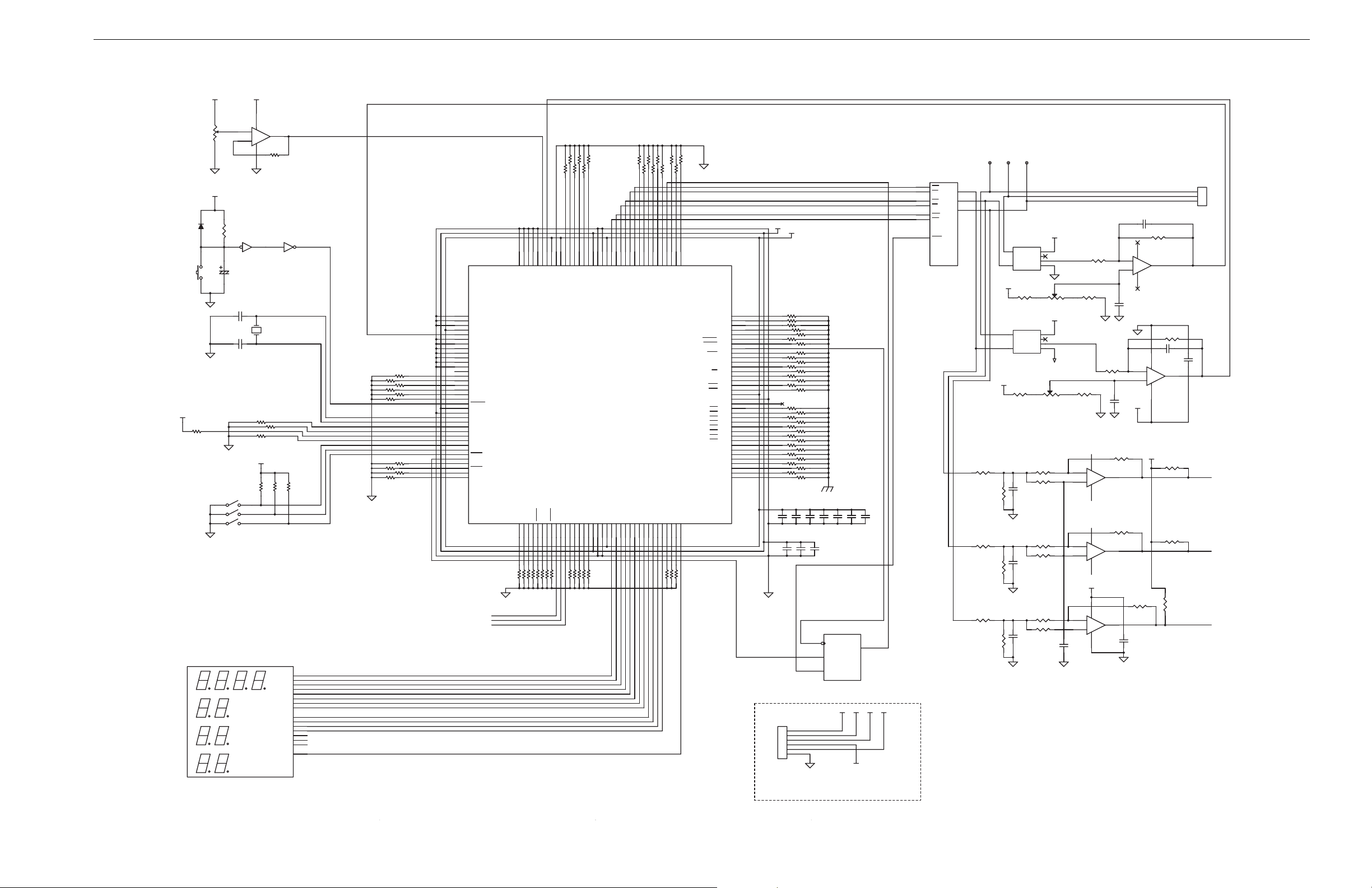

2.2 Circuit Diagram

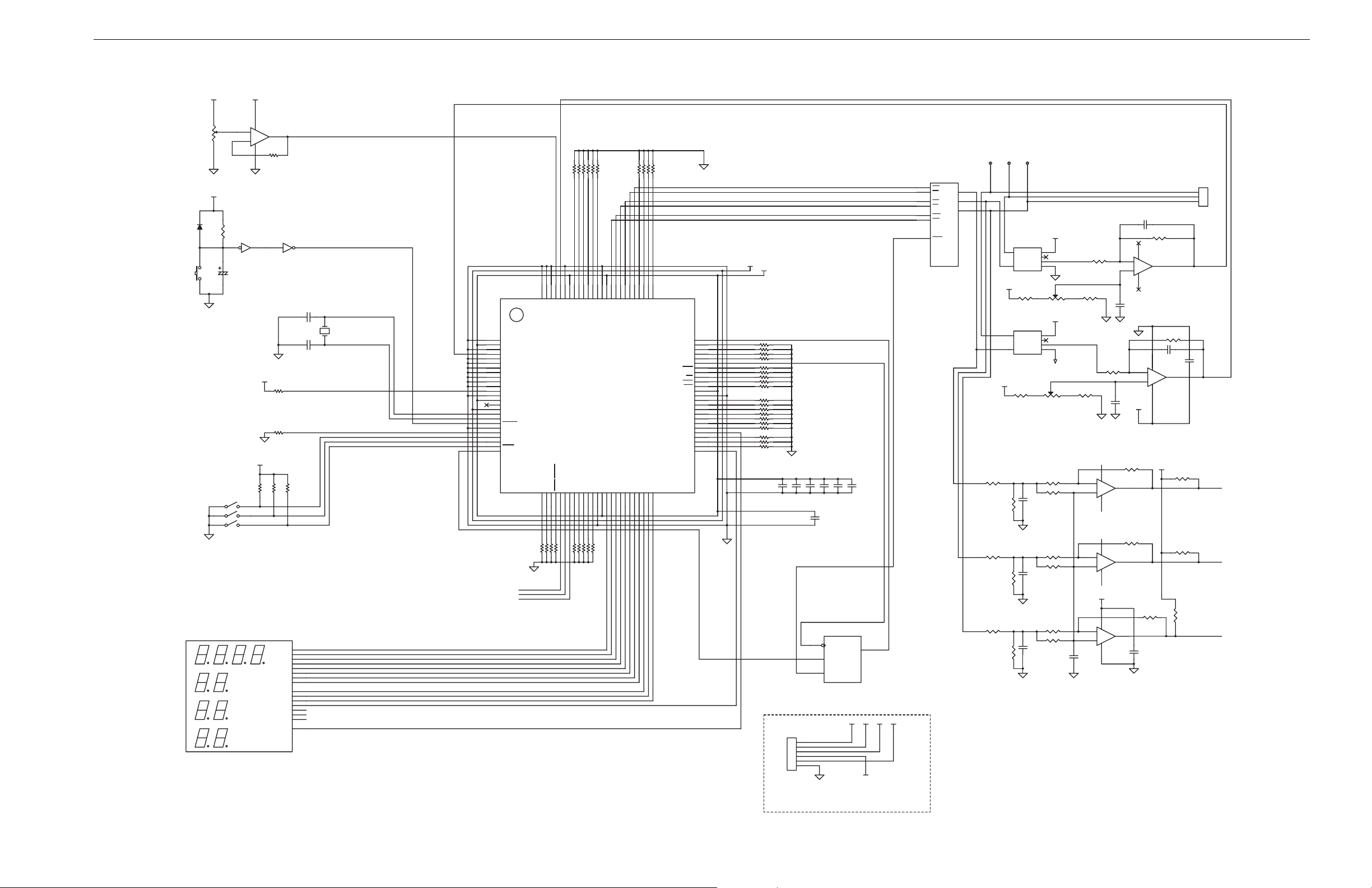

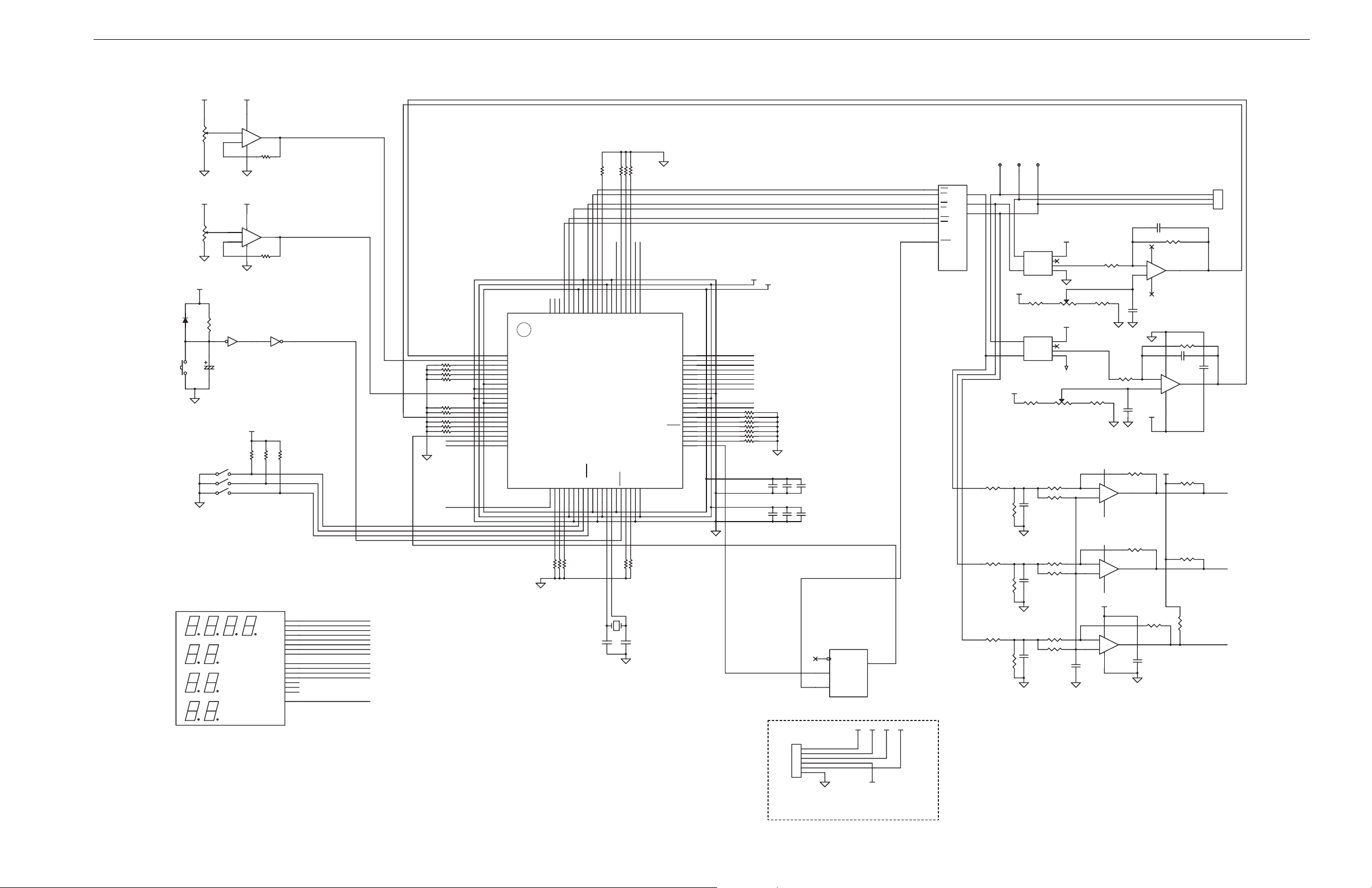

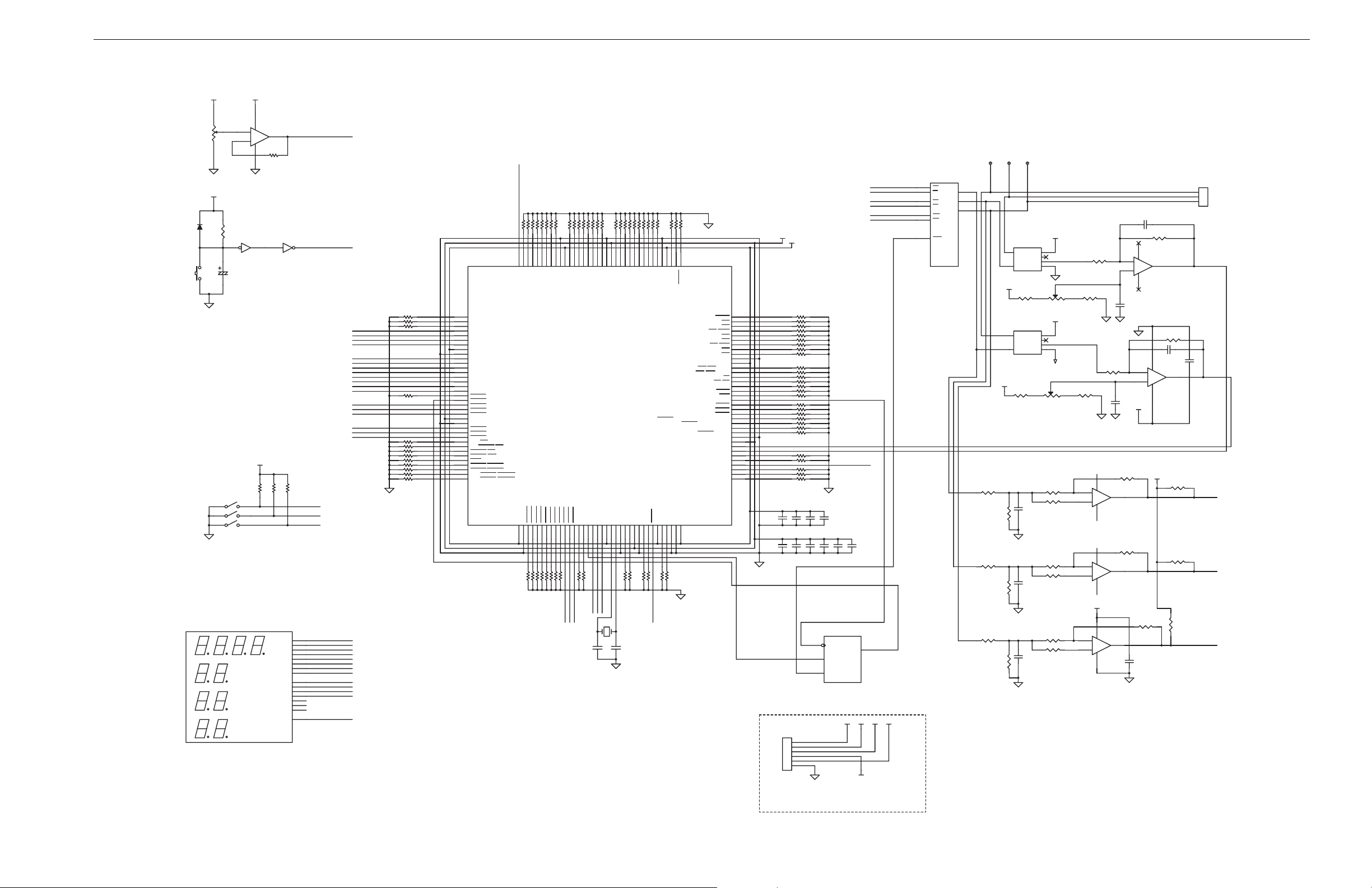

Figures 2-2 to 2-6 show diagrams of the sample reference system circuit.

This sample reference system circuit diagram includes the V850E/IA1, V850E/IA2, V850E/IA3, V850E/IA4, or

V850E/MA3, a reset circuit, oscillator, a pin handling microcontroller peripheral block, operation mode switch block,

LED output block, watchdog timer circuit block, drive circuit block, motor controller, and motor revolution indicator.

(1) Microcontroller and microcontroller peripheral block

The V850E/IA1, V850E/IA2, V850E/IA3, V850E/IA4, or V850E/MA3 includes a reset circuit, an oscillator that

uses a resonator, and a block for handling the MODE pin and unused pins.

(2) Operation mode switch block

This includes switches that set the operation mode as CW or CCW operation.

(3) LED output block

This block includes 16 LEDs, which are used to indicate the revolution speed (rpm), errors, etc.

(4) Watchdog timer circuit block

This block uses the

V850E/IA3, V850E/IA4, or V850E/MA3 stops for one ms or longer.

(5) Drive circuit block

The 6-phase outputs from the inverter timer are converted to U-, V-, and W-phase output for the motor driver.

This drive circuit is not shown in detail in this example, since it varies depending on the motor’s specifications.

(6) Motor controller

This block includes the HPS-3-AS, LM324, and other devices that are used to measure the motor’s U and V

drive currents via A/D conversion.

(7) Motor rotation indicator

This block includes a volume adjuster and the LM324 for setting the motor’s revolution speed (rpm).

µ

PD74HC123A to output stop signals when pulse output from the V 850E/IA1, V850E/IA2,

Application Note U17209EJ1V0AN

19

Page 22

[MEMO]

CHAPTER 2 HARDWARE CONFIGURATION

20

Application Note U17209EJ1V0AN

Page 23

CHAPTER 2 HARDWARE CONFIGURATION

Figure 2-2. Circuit Diagram of V850E/IA1

41

Speed

Cont.

+5V

D1

21

RESE

T

SW

SW1

+5V

47Ω

R55

SW_CW

SW_CCW

SW_STOP

7SEGLED1

SW2

SW3

SW4

3

VR1A

10KΩ

3

2

R17

10KΩ

U3A

12

74ACT14

C2

47uF

C4

33pF

C5

33pF

10KΩ

KHz

uSEC

uSEC

+7V+5V

+

-

R77

4

U1A

LM324

11

RESET

5MHz

CLOCK

5MHz

+5V

R78

10KΩ

7SEG_LEDx8

1

R1

2.2KΩ

U3B

34

74ACT14

CKSEL

R51

R53

47Ω

47Ω

R57

47Ω

MODE

R79

10KΩ

A

B

C

rpm

D

E

F

G

DP

DG1

DG2

DG3

DG4

DG5

DG6

DG7

WE

Velocity

141

142

143

144

ANI04

ANI05

ANI06

1

ANI07

2

AVDD

3

AVSS

4

AVREF1

5

ANI10

6

ANI11

7

ANI12

8

ANI13

9

ANI14

10

ANI15

11

ANI16

12

ANI17

13

R36 10KΩ

R38 10KΩ

R40 10KΩ

R42 10KΩ

R44 10KΩ

R47 10KΩ

R65 10KΩ

R67 10KΩ

R70 10KΩ

R74 10KΩ

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

18

LED_Seg1

LED_Seg2

LED_Seg3

LED_Seg4

LED_Seg5

LED_Seg6

LED_Seg7

LED_Seg8

LED_Dig1

LED_Dig2

LED_Dig3

LED_Dig4

LED_WE

TRIG_DBG

14

AD3_DBG

15

AD2_DBG

16

AD1_DBG

17

AD0_DBG

18

SYNC

19

CLK_DBG

20

RESET

21

CVDD

22

CVSS

23

X1

24

X2

25

CKSEL

26

MODE0

27

MODE1

28

MODE2

29

SI0/P40

30

SO0/P41

31

SCK0/P42

32

SI1/P43

33

SO1/P44

34

SCK1/P45

35

CRXD/P46

36

CTXD/P47

uPD70F3116GJ

V_U

V_V

V_W

RXD0/P3037TXD0/P3138RXD1/P3239TXD1/P33

40

R88 10KΩ

R89 10KΩ

R90 10KΩ

R87 10KΩ

135

136

137

138

139

140

AVSS

ANI00

ANI01

ANI02

ANI03

AVREF0

ASCK1/P34

RXD2/P3542TXD2/P3643ASCK2/P3744TI2/INTP20/P20

41

45

46

R92 10KΩ

R93 10KΩ

R91 10KΩ

R94 10KΩ

R10 10KΩ

R11 10KΩ

R12 10KΩ

R2 10KΩ

R3 10KΩ

129

130

131

132

133

134

AVDD

TO011

TO012

TO013

TO014

TO015

TCLR2/INTP25/P25

TI3/INTP30/TCLR3/P26

TO21/INTP21/P21

TO22/INTP22/P22

TO23/INTP23/P23

TO24/INTP24/P24

47

48

49

50

51

52

R95 10KΩ

R96 10KΩ

R97 10KΩ

R98 10KΩ

R99 10KΩ

R4 10KΩ

126

127

128

VSS5

VSS3

VDD3

TO010

TO3/INTP31/P27

VDD353VSS354VSS555VDD5

P53

P54

P55

R5 10KΩ

R6 10KΩ

R13 10KΩ

116

117

118

119

120

121

122

123

124

125

VDD5

TO000

TO001

TO002

TO003

TO004

TO005

AD0/PDL057AD1/PDL158AD2/PDL259AD3/PDL360AD4/PDL461AD5/PDL562AD6/PDL663AD7/PDL764AD8/PDL865AD9/PDL966AD10/PDL1067AD11/PDL1168AD12/PDL1269AD13/PDL1370AD14/PDL1471AD15/PDL15

56

P56

INTP4/P05

INTP5/P06

INTP6/P07

R7 10KΩ

R14 10KΩ

R15 10KΩ

R8 10KΩ

R16 47Ω

110

111

112

113

114

115

NMI/P00

ESO0/INTP0/P01

ESO1/INTP1/P02

ADTRG0/INTP2/P03

ADTRG1/INTP3/P04

TCLR11/INTP111/P15

R100 10KΩ

R101 10KΩ

R102 10KΩ

R9 10KΩ

109

TCUD11/INTP110/P14

TIUD11/TO11/P13

TCLR10/INTP101/P12

TCUD10/INTP100/P11

TIUD10/TO10/P10

HLDRQ/PCM3

HLDAK/PCM2

CLKOUT/PCM1

WAIT/PCM0

ASTB/PCT6

UWR/PCT1

LWR/PCT0

CS7/PCS7

CS6/PCS6

CS5/PCS5

CS4/PCS4

CS3/PCS3

CS2/PCS2

CS1/PCS1

CS0/PCS0

A23/PDH7

A22/PDH6

A21/PDH5

A20/PDH4

A19/PDH3

A18/PDH2

A17/PDH1

A16/PDH0

72

PCM4

PCT7

PCT5

RD/PCT4

PCT3

PCT2

VDD5

VSS5

VPP

1

100KΩ

R80

10KΩ

100KΩ

R86

10KΩ

100KΩ

R108

10KΩ

+12V

TP2

LC-2-G

1

6

5

+12V

6

5

R45

[W]

HPS-3-AS

CT1

IN-

IN+

R20

HPS-3-AS

CT2

IN-

IN+

C9

0.1uF

C20

0.1uF

C21

0.1uF

TP3

LC-2-G

1

10KΩ

R106

R107

+12V

GND

+12V

GND

R73

R76

R84

R85

[MOT OUT]

J1

1

2

3

100KΩ

LM324

8

R103

4.7KΩ

C6

100KΩ

4.7KΩ

4.7KΩ

0.1uF

CN 3P

I_V

C7

I_U

V_U

V_V

V_W

C1

0.01uF film

LM339

LM339

LM339

22KΩ

0.1uF

C8

R104

6

5

C3

0.1uF

1MΩ

1MΩ

0.1uF

+

+12V

C22

R18

LM324

U1B

7

411

R28

-

9

+

10

4 11

+5V

1MΩ

0.01uF film

U1C

R69

R82

+12V

1

2

NC

3

OUT

4

VR2

10KΩ

1KΩ

+12V

1

2

NC

3

OUT

4

AGND

VR3

R46

1KΩ

10KΩ

10KΩ

10KΩ

10KΩ

10KΩ

10KΩ

C23

1uF

22KΩ

R19

R21

2.2KΩ

R35

2.2K

Ω

R64

U6A

312

7

+

1

6

-

R81

U6B

312

5

+

2

4

-

+12V

U6C

312

9

+

14

8

-

TP1

LC-2-G

[U] [V]

U2

1

HU

2

LU

3

HV

4

LV

5

HW

6

LW

7

ERR

OU

OV

OW

MOT_DRV

U

8

V

9

W

10

R72

R83

R105

C14

0.1uF

WDO

C15

0.1uF

13

C16

0.1uF

Mot_Stop

Mot_UH

Mot_UL

Mot_VH

Mot_VL

Mot_WH

Mot_WL

+3.3V

+5V

C10

0.1uF

C17

0.1uF

C11

0.1uF

R22 10KΩ

R23 10KΩ

R24 10KΩ

R25 10KΩ

R26 10KΩ

R27 10KΩ

R29

R30

R31 10KΩ

R32 10KΩ

R33 10KΩ

R34 10KΩ

R37 10KΩ

R39 10KΩ

R41 10KΩ

R43 10KΩ

R48 10KΩ

R49 10KΩ

R50 10KΩ

R52 10KΩ

R54 10KΩ

R56 10KΩ

R58 10KΩ

R59 10KΩ

R60 10KΩ

R61 10KΩ

R62 10KΩ

R63 10KΩ

R66 10KΩ

R68 10KΩ

R71 10KΩ

R75 10KΩ

C18

0.1uF

C12

0.1uF

10KΩ

10KΩ

C19

0.1uF

C13

0.1uF

U7A

1

CLK

2

W_CLR

3

ERR

WDT

108

P108

107

106

105

104

P104

103

P103

102

P102

101

P101

100

P100

99

P99

98

P98

97

P97

96

P96

95

P95

94

P94

93

P93

92

P92

91

P91

90

P90

89

P89

88

P88

87

P87

86

P86

85

P85

84

P84

83

P83

82

P82

81

P81

80

P80

79

P79

78

P78

77

P77

76

P76

75

P75

74

P74

73

P73

WD_CLR

Watch Dog & Error

+12V +7V

J2

CON6

1

2

3

4

5

6

+5V +3.3V

-7V

POWER

Application Note U17209EJ1V0AN

21

Page 24

Speed

Cont.

D1

RESET

SW

SW1

21

7SEGLED1

+5V

VR1A

41

10KΩ

SW2SW_CW

SW3SW_CCW

SW4SW_STOP

3

R12

10KΩ

C2

47uF

KHz

uSEC

uSEC

+7V+5V

411

U1A

LM324

3

+

2

-

U3A

12

74ACT14

RESET

+5V

+5V

R47

R48

10KΩ

10KΩ

1

R1

2.2KΩ

34

R28

MODE0

CKSEL

R38

R49

10KΩ

rpm

7SEG_LEDx8

U3B

74ACT14

47Ω

47Ω

A

B

C

D

E

F

G

DP

DG1

DG2

DG3

DG4

DG5

DG6

DG7

WE

CHAPTER 2 HARDWARE CONFIGURATION

Figure 2-3. Circuit Diagram of V850E/IA2

Velocity

R2 10KΩ

R3 10KΩ

R4 10KΩ

R5 10KΩ

R6 10KΩ

R7 10KΩ

100

96

95

94

88

U4

ANI04

ANI0399ANI0298ANI0197ANI00

SI1/RXD1/P3227SO1/TXD1/P33

TXD0/P31

26

28

29

R53 10KΩ

R54 10KΩ

R55 10KΩ

R42 10KΩ

AVSS0

SCK1/ASCK1/P34

TI2/INTP20/P20

TO21/INTP21/P21

30

31

C4

33pF

C5

33pF

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

18

4MHz

CLOCK

4MHz

LED_Seg1

LED_Seg2

LED_Seg3

LED_Seg4

LED_Seg5

LED_Seg6

LED_Seg7

LED_Seg8

LED_Dig1

LED_Dig2

LED_Dig3

LED_Dig4

LED_WE

1

ANI05

2

AVDD1

3

AVSS1

4

ANI10

5

ANI11

6

ANI12

7

ANI13

8

ANI14

9

ANI15

10

ANI16

11

ANI17

12

MODE0

13

VSS3

14

RVDD

15

REGOUT

16

REGIN

17

X1

18

X2

19

RESET

20

CVSS

21

CKSEL

22

SI0/P40

23

SO0/P41

24

SCK0/P42

25

RXD0/P30

uPD70F3114GC

V_U

V_V

V_W

87

TO01593TO01492TO01391TO01290TO01189TO010

AVDD0

TO23/INTP23/P23

TCLR2/INTP25/P25

TI3/INTP30/TCLR3/P26

TO3/INTP31/P27

VSS38VDD39PDL0/AD040PDL1/AD141PDL2/AD242PDL3/AD343PDL4/AD444PDL5/AD545PDL6/AD646PDL7/AD747PDL8/AD848PDL9/AD949PDL10/AD10

TO22/INTP22/P22

TO24/INTP24/P24

32

33

34

35

36

37

R56 10KΩ

R57 10KΩ

R58 10KΩ

R59 10KΩ

R60 10KΩ

86

VSS

VDD

TO00585TO00484TO00383TO00282TO00181TO000

R8 10KΩ

R9 10KΩ

R10 10KΩ

R11 10KΩ

80

79

78

77

76

ESO1/INTP1/P02

INTP4/TO3OFF/P05

ADTRG1/INTP3/P04

ADTRG0/INTP2/P03

TCLR10/INTP101/P12

TCUD10/INTP100/P11

50

ESO0/INTP0/P01

NMI/P00

TIUD10/TO10/P10

PCM1/CLKOUT

PCM0/WAIT

PCT6/ASTB

PCT4/RD

PCT1/UWR

PCT0/LWR

VSS3

MODE1/VPP

PDH5/A21

PDH4/A20

PDH3/A19

PDH2/A18

PDH1/A17

PDH0/A16

PDL15/AD15

PDL14/AD14

PDL13/AD13

PDL12/AD12

PDL11/AD11

TP1

LC-2-G

[U] [V]

Mot_UH

Mot_UL

Mot_VH

Mot_VL

Mot_WH

Mot_WL

+3.3V

+5V

C11

0.1uF

Mot_Stop

C12

C13

C14

0.1uF

0.1uF

0.1uF

C16

0.1uF

U6A

1

CLK

2

W_CLR

3

ERR

WDT

WDO

13

75

74

73

72

71

70

69

68

67

66

65

64

VDD

63

62

61

60

59

58

57

56

55

54

53

52

51

R18 10KΩ

R19 10KΩ

R20 10KΩ

R21 10KΩ

R22 10KΩ

R23 10KΩ

R25 10KΩ

R26 10KΩ

R27 10KΩ

MODE1

R31 10KΩ

R32 10KΩ

R33 10KΩ

R34 10KΩ

R35 10KΩ

R36 10KΩ

R37 10KΩ

R39 10KΩ

R40 10KΩ

R41 10KΩ

WD_CLR

C9

0.1uF

C10

0.1uF

U2

1

HU

2

LU

3

HV

4

LV

5

HW

6

LW

7

ERR

OU

OV

OW

MOT_DRV

U

8

V

9

W

10

R45

R62

R68

TP3

TP2

LC-2-G

LC-2-G

[W]

+12V

100KΩ

10KΩ

100KΩ

10KΩ

100KΩ

10KΩ

+12V

R29

R51

R65

R71

1

HPS-3-AS

CT1

6

5

R15

HPS-3-AS

CT2

6

5

1

C1

0.01uF film

R43

R52

22KΩ

0.1uF

1

LM339

2

LM339

14

LM339

R13

11

-

U1B

6

+

5

4

C3

0.1uF

9

10

C8

+12V

1MΩ

1MΩ

R67

C19

0.1uF

+12V

1

+12V

IN-

2

NC

3

OUT

4

GND

IN+

VR2

10KΩ

1KΩ

+12V

1

+12V

IN-

2

NC

3

OUT

4

GND

IN+

AGND

VR3

10KΩ

C15

0.1uF

C17

0.1uF

C18

0.1uF

R30

1KΩ

10KΩ

R46

10KΩ

R50

10KΩ

R63

R64

10KΩ

R69

10KΩ

R70

10KΩ

22KΩ

R14

2.2KΩ

R16

R24

2.2KΩ

U5A

312

7

+

6

-

U5B

312

5

+

4

-

+12V

U5C

312

9

+

8

-

C20

1uF

LM324

7

R17

0.01uF film

-

U1C

+

4 11

+5V

1MΩ

100KΩ

LM324

8

R44

R61

[MOT OUT]

J1

1

2

3

CN 3P

I_V

100KΩ

C6

C7

0.1uF

I_U

4.7KΩ

V_U

4.7KΩ

V_V

R66

4.7KΩ

V_W

1

Watch Dog & Error

V

+12V +7V

J2

CON6

1

2

3

4

5

6

+5 +3.3V

-7V

Application Note U17209EJ1V0AN

POWER

23

Page 25

D1

RESET

SW

SW1

Speed

Cont.

Comp.

Ref.

SW_CW

SW_CCW

SW_STOP

CHAPTER 2 HARDWARE CONFIGURATION

Figure 2-4. Circuit Diagram of V850E/IA3

PDL9

PDL8

PDL7

PDL6

PDL4

PDL3

PDL2

VSS

VDD

PDL1

PDL0

1

100KΩ

R40

10KΩ

+12V

TP2

LC-2-G

1

6

5

+12V

6

5

R18

[W]

HPS-3-AS

CT1

IN-

IN+

R9

HPS-3-AS

CT2

IN-

IN+

C10

0.1uF

TP3

LC-2-G

1

10KΩ

R39

+12V

OUT

GND

+12V

OUT

GND

R38

NC

10KΩ

NC

[MOT OUT]

J1

1

2

3

100KΩ

LM324

14

C3

100KΩ

4.7KΩ

0.1uF

CN 3P

I_V

C5

I_U

V_U

C1

0.01uF film

22KΩ

0.1uF

C6

10

C2

0.1uF

9

1MΩ

R7

-

U1C

+

411

13

12

+12V

LM324

8

R12

0.01uF film

-

U1D

+

411

+5V

R36

+12V

1

2

3

4

VR2

1KΩ

+12V

1

2

3

4

AGND

VR3

R19

1KΩ

10KΩ

10KΩ

22KΩ

R8

2.2KΩ

R10

R17

2.2KΩ

R35

U5A

312

7

+

1

6

LM339

TP1

LC-2-G

[U] [V]

Mot_UH

Mot_UL

Mot_VH

Mot_VL

Mot_WH

Mot_WL

+2.5V

+5V

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

LED_Dig2

LED_Dig1

LED_Seg8

LED_Seg7

LED_Seg6

LED_Seg5

LED_Seg4

LED_Seg3

LED_Seg2

LED_Seg1

R21 10KΩ

R23 10KΩ

R25 10KΩ

R27 10KΩ

R29 10KΩ

R30 10KΩ

R31 10KΩ

C7

0.1uFC80.1uFC90.1uF

C12

C13

C11

0.1uF

0.1uF

0.1uF

U2

1

HU

2

LU

3

HV

4

LV

5

HW

6

LW

7

ERR

OU

OV

OW

MOT_DRV

U

8

V

9

W

10

R37

+7V+5V

VR1A

4

10KΩ

3

1

4

U1A

LM324

3

+

1

2

-

11

R2

2.2KΩ

Velocity

R4 10KΩ

R5 10KΩ

R6 10KΩ

R3 10KΩ

FLMD0

+7V+5V

51

VR1B

10K

Ω

4

U1B

5

+

6

-

11

U4A

12

74ACT14

RESET

+5V

R32

10KΩ

LM324

7

34

R33

10KΩ

R1

2.2KΩ

U4B

74ACT14

R34

10KΩ

R13 10KΩ

R14 10KΩ

R15 10KΩ

R16 10KΩ

R20 10KΩ

R22 10KΩ

R24 10KΩ

R26 10KΩ

R28 10KΩ

V_U

V_V

V_W

1

ANI00

2

ANI01

3

P70/ANI20

4

P71/ANI21

5

P72/ANI22

6

P73/ANI23

7

AVDD

8

AVSS

9

CMPREF

10

AVSS

11

AVDD

12

P74/ANI24

13

P75/ANI25

14

ANI10

15

ANI11

16

ANI12

17

ANI13

18

P00/INTP0/TOQ0OFF

19

P02/INTP2/TOP2OFF

20

P03/INTP3

uPD70F3184GC

U3

75

80

79

78

77

76

PLLSIN

P17/TOP21/TIP21

P16/TOQ00/TIP20

P13/TOQ0B2/TIQ00

P14/TOQ0T3/EVTQ0

P15/TOQ0B3/TRGQ0

VDD25VSS

P04/INTP4/ADTRG0

P05/INTP5/ADTRG1

P06/INTP623P07/INTP7

21

22

24

26

74

73

72

71

70

69

68

67

VDD

EVSS

EVDD

FLMD0

P10/TOQ0T1/TIQ01/TOQ01

P12/TOQ0T2/TIQ03/TOQ03

P11/TOQ0B1/TIQ02/TOQ02

EVDD30EVSS

P40/SIB027P41/SOB028P42/SCKB0

CVDD

29

31

32X233X134

LED_Dig4

LED_WE

66

VSS

RESET36P43/TOP00/TIP00

P44/TOP01/TIP01

CVSS

35

37

38

LED_Dig3

61

PDL10

PDL1162PDL1263PDL1364PDL1465PDL15

P35/TIUD10/TO10

P33/SOB1/TXDA1

P32/SIB1/RXDA1

VSS39VDD

40

PDL5/FLMD1

P37/TCLR10

P36/TCUD10

P34/SCKB1

P31/TXDA0

P30/RXDA0

2

+5V

R11

2 1

10KΩ

C4

47uF

SW2

SW3

SW4

7SEGLED1

KHz

uSEC

uSEC

rpm

DG1

DG2

DG3

DG4

DG5

DG6

DG7

7SEG_LEDx8

R41

2

LM339

14

LM339

1MΩ

R42

4.7KΩ

V_V

1MΩ

R52

4.7KΩ

V_W

R53

C18

0.1uF

U5B

C19

0.1uF

312

5

+

4

-

+12V

U5C

312

9

+

8

-

100KΩ

R48

KΩ

R43 10KΩ

R44 10

R45 10KΩ

1

A

2

B

3

C

4

D

5

E

6

F

7

G

8

DP

10

11

12

13

14

15

16

18

WE

LED_Seg1

LED_Seg2

LED_Seg3

LED_Seg4

LED_Seg5

LED_Seg6

LED_Seg7

LED_Seg8

LED_Dig1

LED_Dig2

LED_Dig3

LED_Dig4

LED_WE

15pF

R46 10KΩ

R47 10KΩ

4MHz

C15

C16

15pF

WD_CLR

U6A

1

CLK

2

W_CLR

3

ERR

WDT

WDO

13

Watch Dog & Error

+12V +7V

+5V +3.3V

J2

1

2

3

4

5

6

CON6

-7V

R51

10KΩ

100KΩ

R54

R57

10KΩ

C14

0.1uF

0.1uF

R49

10KΩ

R50

10KΩ

R55

10KΩ

R56

10KΩ

C17

POWER

Application Note U17209EJ1V0AN

25

Page 26

RESE

SW

Speed

Cont.

Comp.

Ref.

D1

SW1

+5V

21

T

7SEGLED1

CHAPTER 2 HARDWARE CONFIGURATION

Figure 2-5. Circuit Diagram of V850E/IA4

PDL9

PLD8

EVDD

EVSS

PDL7

PDL6

PDL5/FLMD1

PDL4

PDL3

PDL2

VSS

VDD

PDL1

PDL0

P27/TOP31

P26/TOQ10

P37/TCLR10

P36/TCUD10

P34/SCKB1

P31/TXDA0

P30/RXDA0

VSS

1

100KΩ

10KΩ

100KΩ

10KΩ

100KΩ

10KΩ

TP3

TP2

LC-2-G

LC-2-G

[V]

[W]

1

1

C1

22KΩ

C6

0.1uF

10

C2

0.1uF

R77

9

1MΩ

1MΩ

0.1uF

R14

11

-

U1C

+

4

-

13

12

+12V

+5V

1MΩ

C19

C13

0.1uF

C15

0.1uF

C18

0.1uF

10KΩ

R56

R80

+12V

+12V

R52

R61

R74

R79

OUT

GND

OUT

GND

NC

10KΩ

NC

VR2

AGND

VR3

+12V

1

2

3

4

1KΩ

+12V

1

2

3

4

R29

1KΩ

10KΩ

10KΩ

10KΩ

10KΩ

10KΩ

10KΩ

C20

0.1uF

22KΩ

R15

2.2KΩ

R18

R27

2.2KΩ

R49

U5A

312

7

+

1

6

LM339

R58

U5B

312

5

+

2

4

LM339

+12V

U5C

312

9

+

14

8

LM339

HPS-3-AS

CT1

6

IN-

5

IN+

+12V

R17

HPS-3-AS

CT2

6

IN-

5

IN+

+12V

R28

R57

R75

R81

0.01uF film

LM324

8

R19

0.01uF film

11

U1D

+

4

R50

R59

100KΩ

LM324

14

R76

4.7KΩ

[MOT OUT]

J1

1

2

3

CN 3P

I_V

100KΩ

C4

C5

0.1uF

I_U

4.7KΩ

V_U

4.7KΩ

V_V

V_W

TP1

LC-2-G

[U]

Mot_UH

Mot_UL

Mot_VH

Mot_VL

Mot_WH

Mot_WL

+2.5V

+5V

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

LED_Dig2

LED_Dig1

LED_Seg8

LED_Seg7

LED_Seg6

LED_Seg5

LED_Seg4

LED_Seg3

LED_Seg2

LED_Seg1

WD_CLR

R32 10KΩ

R34 10KΩ

R36 10KΩ

R37 10KΩ

R39 10KΩ

R41 10KΩ

R42 10KΩ

R43 10KΩ

R45 10KΩ

R48 10KΩ

C7

0.1uFC80.1uFC90.1uF

C10

C11

C12

0.1uF

0.1uF

0.1uF

C14

0.1uF

Mot_Stop

U6A

1

CLK

2

W_CLR

3

ERR

WDT

WDO

13

U2

1

HU

2

LU

3

HV

4

LV

5

HW

6

LW

7

ERR

OU

OV

OW

MOT_DRV

U

8

V

9

W

10

R51

R60

R78

Watch Dog & Error

+12V +7V

J2

CON6

1

2

3

4

5

6

+5V +2.5V

-7V

+7V+5V

41

VR1A

10KΩ

3

5

VR1B

10KΩ

2

1

SW2SW_CW

SW3SW_CCW

P

SW4SW_STO

R16

10KΩ

U4A

12

74ACT14

C3

47uF

KHz

uSEC

411

U1A

LM324

3

+

1

2

-

R2

2.2KΩ

+7V+5V

411

U1B

LM324

5

+

7

6

-

R1

2.2KΩ

U4B

34

74ACT14

RESET

+5V

R53

R54

R55

10KΩ

10KΩ

10KΩ

rpm

Velocity

R3 10KΩ

R4 10KΩ

R5 10KΩ

R6 10KΩ

R7 10KΩ

R8 10KΩ

R9 10KΩ

R11 10KΩ

R12 10KΩ

R13 10KΩ

R10 10KΩ

FLMOD0

LED_Dig3

LED_Dig4

LED_WE

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

78

77

PDL1581PDL1480PDL1379PDL12

P51/DCK/TCUD11

P50/DDI/TIUD11/TO11

RESET47P43/TOP00/TIP00

CVDD

CVSS

43X244X145

46

48

R72 10KΩ

C16

15pF

76

PDL11

PDL10

P35/TIUD10/TO10

P33/SOB1/TXDA1

P32/SIB1/RXDA1

P44/TOP01/TIP0149VDD

50

R73 10KΩ

4MHz

C17

15pF

U3

VSS

EVSS

EVDD

FLMD0

P13/TOQ0B2/TIQ00

P10/TOQ0T1/TIQ01/TOQ01

P12/TOQ0T2/TIQ03/TOQ03

P11/TOQ0B1/TIQ02/TOQ02

P21/TOQ1B1

EVDD38EVSS39P23/TOQ1B2

P41/SOB033P42/SCKB0

P20/TOQ1T1

P22/TOQ1T2

34

35

36

37

R66 10KΩ

R67 10KΩ

R68 10KΩ

VDD

40

41

KΩ

R69 10

R70 10KΩ

P24/TOQ1T3

42

R71 10KΩ

P52/DMS/TCLR11

P25/TOQ1B3

DDO

DRST

PLLSIN

P17/TOP21/TIP21

1

R20 10KΩ

R21 10KΩ

R22 10KΩ

R23 10KΩ

R24 10KΩ

R25 10KΩ

R26 10KΩ

R30 10KΩ

R31 10KΩ

R33 10KΩ

R35 10KΩ

R38 10KΩ

R40 10KΩ

R82 10KΩ

V_U

V_V

V_W

LED_Seg1

1

A

LED_Seg2

2

B

LED_Seg3

3

C

LED_Seg4

4

D

LED_Seg5

5

E

LED_Seg6

6

F

LED_Seg7

7

G

LED_Seg8

8

DP

DG1

DG2

DG3

DG4

DG5

DG6

DG7

WE

LED_Dig1

10

LED_Dig2

11

LED_Dig3

12

LED_Dig4

13

14

15

16

LED_WE

18

ANI00

2

ANI01

3

ANI02

4

ANI03

5

P70/ANI20

6

P71/ANI21

7

P72/ANI22

8

P73/ANI23

9

AVDD

10

AVSS

11

CMPREF

12

AVSS

13

AVDD

14

P74/ANI24

15

P75/ANI25

16

P76/ANI26

17

P77/ANI27

18

ANI10

19

ANI11

20

ANI12

21

ANI13

22

P00/INTP0/TOQ0OFF

23