Page 1

Rev.1.02 Apr 2020

Renesas Synergy™ Platform

Synergy

Kits:

www.renesas.com

All information conta ined in these materi als, includin g products and pr oduct specificat ions, represe nts

Target Board Kit S5D3 (TB-S5D3)

User’s Manual

User’s Manual

Tools & Kits

TB-S5D3 v1.0

information on the product at the time of publicat ion and is subject t o change by Renesas El ectronics

Corp. without notice. Please review the latest information published by Renesas Electronics Corp.

through various means, in cluding the Renesas Electronics Corp. website (http://www.renesas. com ) .

Page 2

Corporate Headquarters

Contact information

www.renesas.com

Trademarks

of their respective owners.

Notice

1. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of semiconductor products

and application examples. You are fully responsible for the incorporation or any other use of the circuits, software, and information in the design of your

product or system. Renesas Electronics disclaims any and all liability for any losses and damages incurred by you or third parties arising from the use

of these circuits, software, or information.

2. Renesas Electronics hereby expressly disclaims any warranties against and liability for infringement or any other claims involving patents, copyrights,

or other intellectual property rights of third parties, by or arising from the use of Renesas Electronics products or technical information described in this

document, including but not limited to, the product data, drawings, charts, programs, algorithms, and application examples.

3. No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights of Renesas Electronics

or others.

4. You shall not alter, modify, copy, or reverse engineer any Renesas Electronics product, whether in whole or in part. Renesas Electronics disclaims any

and all liability for any losses or damages incurred by you or third parties arising from such alteration, modification, copying or reverse engineering.

5. Renesas Electronics products are classified according to the following two quality grades: “Standard” and “High Quality”. The intended applications for

each Renesas Electronics product depends on the product’s quality grade, as indicated below.

"Standard": Computers; office equipment; communications equipment; test and measurement equipment; audio and visual equipment; home

"High Quality": Transportation equipment (automobiles, trains, ships, etc.); traffic control (traffic lights); large-scale communication equipment; key

Unless expressly designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas

Electronics document, Renesas Electronics products are not intended or authorized for use in products or systems that may pose a direct threat to

human life or bodily injury (artificial life support devices or systems; surgical implantations; etc.), or may cause serious property damage (space

system; undersea repeaters; nuclear power control systems; aircraft control systems; key plant systems; military equipment; etc.). Renesas Electronics

disclaims any and all liability for any damages or losses incurred by you or any third parties arising from the use of any Renesas Electronics product

that is inconsistent with any Renesas Electronics data sheet, user’s manual or other Renesas Electronics document.

6. When using Renesas Electronics products, refer to the latest product information (data sheets, user’s manuals, application notes, “General Notes for

Handling and Using Semiconductor Devices” in the reliability handbook, etc.), and ensure that usage conditions are within the ranges specified by

Renesas Electronics with respect to maximum ratings, operating power supply voltage range, heat dissipation characteristics, installation, etc.

Renesas Electronics disclaims any and all liability for any malfunctions, failure or accident arising out of the use of Renesas Electronics products

outside of such specified ranges.

7. Although Renesas Electronics endeavors to improve the quality and reliability of Renesas Electronics products, semiconductor products have specific

characteristics, such as the occurrence of failure at a certain rate and malfunctions under certain use conditions. Unless designated as a high reliability

product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas Electronics document, Renesas Electronics

products are not subject to radiation resistance design. You are responsible for implementing safety measures to guard against the possibility of bodily

injury, injury or damage caused by fire, and/or danger to the public in the event of a failure or malfunction of Renesas Electronics products, such as

safety design for hardware and software, including but not limited to redundancy, fire control and malfunction prevention, appropriate treatment for

aging degradation or any other appropriate measures. Because the evaluation of microcomputer software alone is very difficult and impractical, you

are responsible for evaluating the safety of the final products or systems manufactured by you.

8. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental compatibility of each Renesas

Electronics product. You are responsible for carefully and sufficiently investigating applicable laws and regulations that regulate the inclusion or use of

controlled substances, including without limitation, the EU RoHS Directive, and using Renesas Electronics products in compliance with all these

applicable laws and regulations. Renesas Electronics disclaims any and all liability for damages or losses occurring as a result of your noncompliance

with applicable laws and regulations.

9. Renesas Electronics products and technologies shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is

prohibited under any applicable domestic or foreign laws or regulations. You shall comply with any applicable export control laws and regulations

promulgated and administered by the governments of any countries asserting jurisdiction over the parties or transactions.

10. It is the responsibility of the buyer or distributor of Renesas Electronics products, or any other party who distributes, disposes of, or otherwise sells or

transfers the product to a third party, to notify such third party in advance of the contents and conditions set forth in this document.

11. This document shall not be reprinted, reproduced or duplicated in any form, in whole or in part, without prior written consent of Renesas Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this document or Renesas

Electronics products.

(Note1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its directly or indirectly contr ol led

(Note2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

subsidiaries.

electronic appliances; machine tools; personal electronic equipment; industrial robots; etc.

financial terminal systems; safety control equipment; etc.

(Rev.4.0-1 Novembe r 201 7)

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

Renesas and the Renesas logo are trademarks of Renesas Electronics

Corporation. All trademarks and registered trademarks are the property

For further information on a product, technology, the most up-to-date

version of a document, or your ne are s t sales office, please visit:

www.renesas.com/contact/

.

© 2019 Renesas Electronics Corporation. All rights reserved.

Page 3

Renesas Synergy™ Target Board Kit S5D3 (TB-S5D3) Disclaimer

By using this TB-S5D3, the user accepts the following terms, which are in addition to, and control in the event of disagreement, with Renesas’ General

Terms and Conditions available at https://www.renesas.com/en-us/legal/disclaimer.html.

The TB-S5D3 is not guaranteed to be error free, and the entire risk as to the results and performance of the TB-S5D3 is assumed by the User. The TBS5D3 is provided by Renesas on an “as is” basis without warranty of any kind whether express or implied, including but not limited to the implied warranties

of satisfactory quality, fitness for a particular purpose, title, and non-infringement of intellectual property rights with regard to the TB-S5D3. Renesas

expressly disclaims all such warranties.

Renesas does not consid er the TB-S5D3 a finished product and therefore the TB-S5D3 may not yet comply with some requirements applicable to finished

products, including, but not limited to recycling (WEEE), CE, UL, restricted substances (ROHS), FCC, FEE, and electromagnetic compatibility regulations.

Renesas or its affiliates shall in no event be liable for any loss of profit, loss of data, loss of contract, loss of business, damage to reputation or goo dwi ll , any

economic loss, any reprogramming or recall costs (whether the foregoing losses are direct or indirect) nor shall Renesas or its affiliates be liable for any

other direct or indirect special, incidental or consequential damages arising out of or in relation to the use of this TB-S5D3, even if Renesas or its affiliates

have been advised of the possibility of such damages.

Renesas has used reasonable care in preparing the information included in this document, but Renesas does not warrant that such information is error free

nor does Renesas guarantee an exact match for every application or parameter to part numbers designated by other vendors listed herein. The information

provided in this document is intended solely to enable the use of Renesas products. No express or implied license to any intellectual property right is

granted by this document or in connection with the sale of Renesas products. Renesas reserves the right to make changes to specifications and product

descriptions at any time without notice. Renesas assumes no liability for any damages incurred by you resulting from errors in or omissions from the

information included herein. Renesas cannot verify, and assumes no liability for, the accuracy of information available on another company’s website.

Precautions

This Renesas Synergy™ Target Board Kit is only intended for use in a laboratory environment under ambient temperature and humidity conditions. A safe

separation distance should be used between this and any sensitive equipment. Its use outside the laboratory, classroom, study area, or similar such area

invalidates conformity with the protection requirements of the Electromagnetic Compatibility Directive and could lead to prosecution.

The product generates, uses, and can radiate radio frequency energy and may cause harmful interference to radio communications. There is no guarantee

that interference will not occur in a particular installation. If this equipment causes harmful interference to radio or television reception, which can be

determined by turning the equipment off or on, you are encouraged to try to correct the interference by one or more of the following measures:

• Ensure attached cables do not lie across the equipment.

• Reorient the receiving antenna.

• Increase the distance between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that which the receiver is connected.

• Power down the equipment when not in use.

• Consult the dealer or an experienced radio/TV technician for help.

Note: It is recommended that wherever possible shielded interface cables are used.

The product is potentially susceptible to certain EMC phenomena. To mitigate against them it is recommended that the following measures be undertaken:

• The user is advised that mobile phones should not be used within 10 m of the product when in use.

• The user is advised to take ESD precautions when handling the equipment.

The Renesas Synergy™ Target Board Kit does not represent an ideal reference design for an end product and does not fulfill the regulatory standards for

an end product.

Page 4

User’s Manual

Renesas Synergy™ P latform

Target Board Kit S5D3 (TB-S5D3)

Contents

1. Overview ................................................................................................................................. 3

2. Kit Contents ............................................................................................................................. 6

3. Getting Started with Embedded Application Development on TB-S5D3 ................................... 6

4. TB-S5D3 Hardware Details ...................................................................................................... 7

4.1 Jumpers and DIP Switch Settings ........................................................................................................... 7

4.1.1 Copper Jumpers .................................................................................................................................... 7

4.1.2 Default Board Configuration .................................................................................................................. 8

5. Hardware Layout ..................................................................................................................... 9

5.1 System Block Diagram ............................................................................................................................ 9

5.2 Power Requirements ............................................................................................................................. 10

5.2.1 Power Supply Options ......................................................................................................................... 10

5.2.2 Powering up the Board ........................................................................................................................ 12

5.2.3 Battery Supply Configuration ............................................................................................................... 12

5.2.4 Measuring Current Consumption ........................................................................................................ 12

5.3 Main Components ................................................................................................................................. 14

5.4 Connectivity and Settings ...................................................................................................................... 15

5.4.1 Device USB ......................................................................................................................................... 15

5.4.2 Debug USB .......................................................................................................................................... 15

5.4.3 JTAG/SWD .......................................................................................................................................... 16

5.4.4 LEDs .................................................................................................................................................... 17

5.4.5 Switches .............................................................................................................................................. 17

5.4.6 PMOD A .............................................................................................................................................. 19

5.4.7 PMOD B .............................................................................................................................................. 19

5.4.8 User Capacitive Touch Button ............................................................................................................. 20

5.5 Target Board Pin Headers ..................................................................................................................... 21

5.5.1 Pin Header J1 ...................................................................................................................................... 23

5.5.2 Pin Header J2 ...................................................................................................................................... 24

5.5.3 Pin Header J3 ...................................................................................................................................... 25

5.5.4 Pin Header J4 ...................................................................................................................................... 26

5.6 Additional Features................................................................................................................................ 27

5.6.1 Reference Voltages VREF and VR EF0 .............................................................................................. 27

5.6.2 Analog Voltage AVCC0/AVSS0 .......................................................................................................... 27

5.6.3 On-Board Clock Crystals ..................................................................................................................... 27

R12UM0032EU0102 Rev.1.02 Page 1 of 33

Apr.21.20

Page 5

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

5.6.4 User Potentiometer ............................................................................................................................. 28

5.6.5 Boot Configuration ............................................................................................................................... 29

5.6.6 Miscellaneous Signals ......................................................................................................................... 29

6. Certifications .......................................................................................................................... 31

6.1 EMC/EMI Standards .............................................................................................................................. 31

6.2 Material Selection, Waste, Recycling and Disposal Standards ............................................................ 31

6.3 Safety Standards ................................................................................................................................... 31

7. Design and Manufacturing Information .................................................................................. 32

Website and Support .................................................................................................................... 32

Revision History ............................................................................................................................ 33

R12UM0032EU0102 Rev.1.02 Page 2 of 33

Apr.21.20

Page 6

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

1. Overview

The Target Board Kit S5D3 (TB-S5D3) enables developers to get started with initial firmware development

and evaluate the Synergy Software Package (SSP) on the S5D3 MCU Group.

• Renesas Syner gy™ S5D 3 Micr ocont ro ll er Group

R7FS5D37A3A01CFP

100-pin Low Profile Quad Flat Pack (LQFP) package

120 MHz Arm

256 KB SRAM

512 KB code flash memory

8 KB data flash memory

• Connectivity

A Device USB connector for the Main MCU

S124 MCU-based SEGGER J-Link® On-board (OB) interface for debugging and programming of the

S5D3 MCU. A 10-pin JTAG/SWD interface is also provided for connecting optional external debuggers

and programmers.

Two PMOD connectors, allowing use of appropriate PMOD compliant peripheral plug-in modules for

rapid prototyping

Pin headers for access to power and signals for the Main MCU

• Multiple clock sources

Main MCU oscillator crystals, providing precision 12.000 MHz and 32,768 Hz reference clocks

Additional low-precision clocks are available internal to the Main MCU

• MCU reset push-button switch

®

Cortex®-M4 core with Floating Point Unit (FPU)

• MCU boot configuration jumper

• General purpose I/O ports

One jumper to allow measuring of Main MCU current

Copper jumpers on PCB bottom side for configuration and access to selected MCU signals

• Operating voltage

External 5 V input through the Debug USB connector supplies the on-board power regulator to power

the Target Board logic and interfaces. External 5 V or 3.3 V may be also supplied through alternate

locations on the Target Board.

• A two-color board status LED indicating availability of regulated power and connection status of the J-Link

interface

• A red User LED, controlled by the Main MCU firmware

• A User Push-Button switch, User Capacitive Touch Button sensor, and an optional User Potentiometer,

all of which are controlled by the Main MCU firmware

R12UM0032EU0102 Rev.1.02 Page 3 of 33

Apr.21.20

Page 7

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

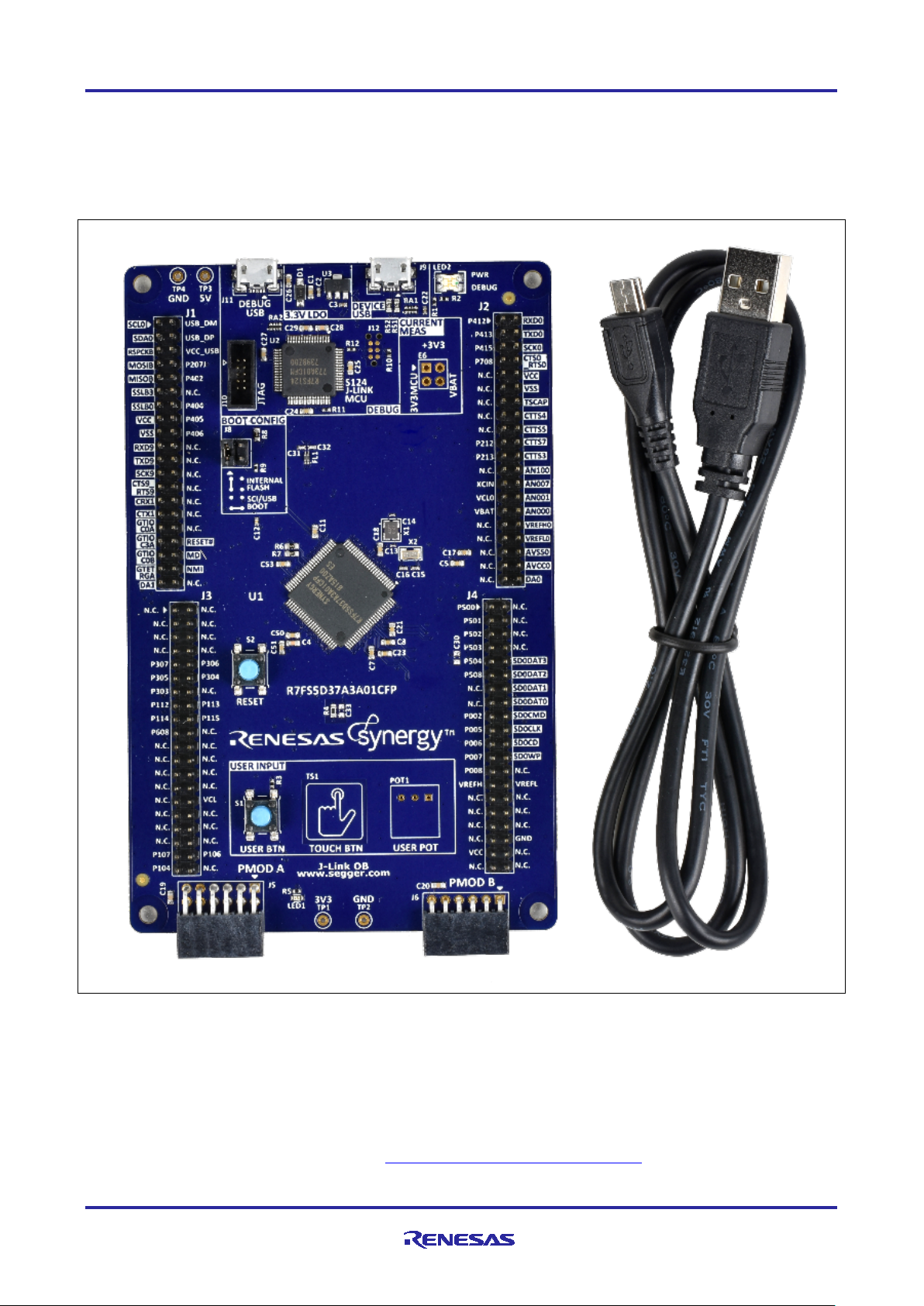

Figure 1. TB-S5D3 Top Side

R12UM0032EU0102 Rev.1.02 Page 4 of 33

Apr.21.20

Page 8

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

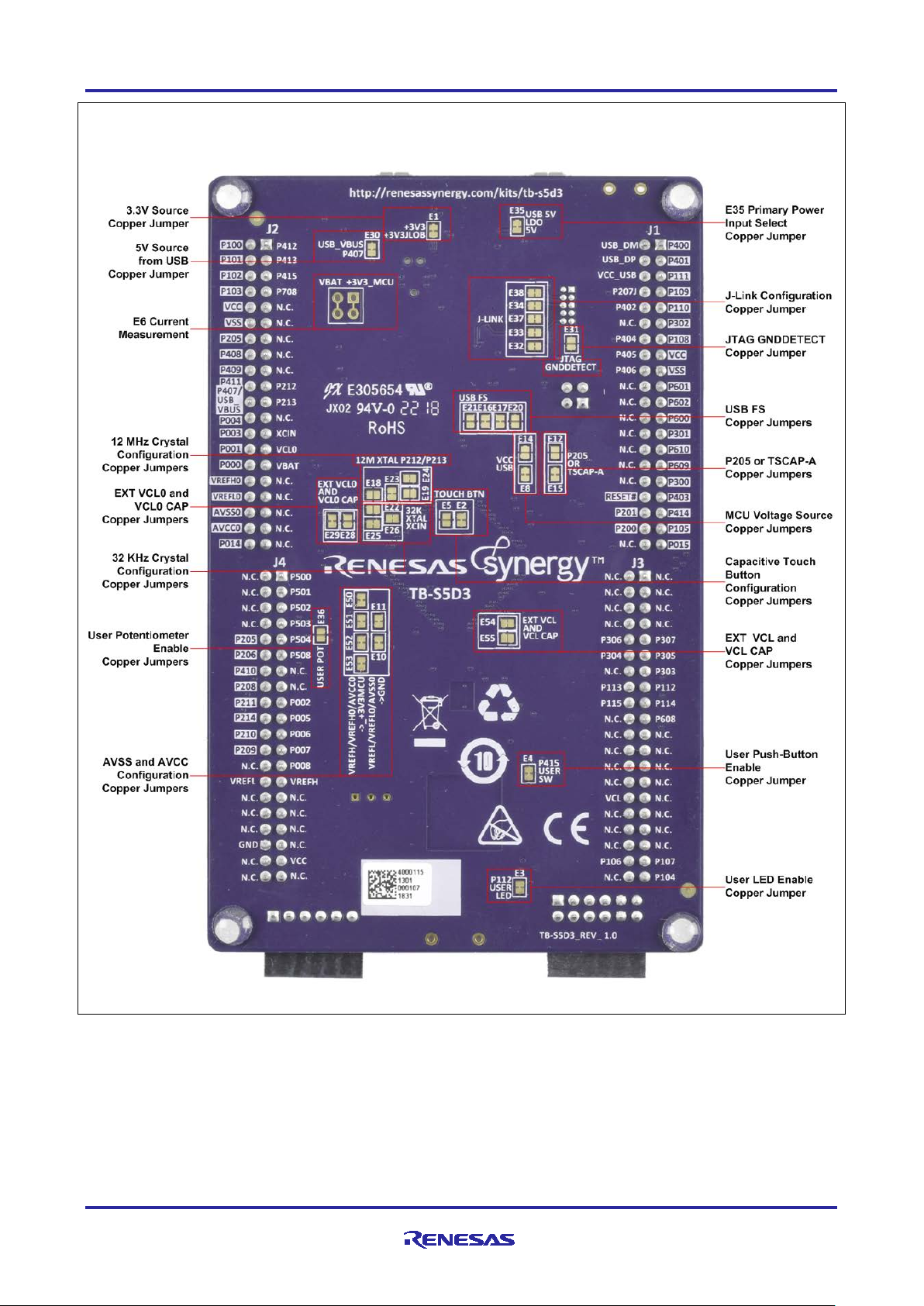

Figure 2. TB-S5D3 Bottom Side

R12UM0032EU0102 Rev.1.02 Page 5 of 33

Apr.21.20

Page 9

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

2. Kit Contents

The following components are included in the Tar get Boar d Kit S5D3 (TB-S5D3):

• 1x TB-S5D3 board

• 1x USB Type-A to USB Micro-B cable

Figure 3. TB-S5D3 Contents

3. Getting Started with Embedded Application Development on TB-S5D3

To develop and execute embedded applications on the TB-S5D3 using the Synergy Platform, Synergy

Software Package and development tools are required to be installed on your computer.

Step 1: Create My Renesas Account (if you do not have one alread y)

You need a My Renesas account to download software, development tools, and application projects. Log in

to or Sign up for a My Renesas account at www.update.renesas.com/SSO/login

R12UM0032EU0102 Rev.1.02 Page 6 of 33

Apr.21.20

.

Page 10

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Step 2: Download and Install Synergy Software Package and Development Tools

The Synergy Software Package, J-Link USB drivers, and one of the two supported tool chains are bundled

and available as single downloada ble file as follow s:

®

A. IAR Platform Installer installs Syner gy Software Package and IAR Embedded Workbench

Renesas Synergy™ IDE with IAR complier and J-Link USB drivers.

Download from www.renesas.com/synergy/ewsynergy

B. e2 studio Platform Installer installs Synergy Software Package and e2 studio for Synergy IDE with

IAR complier and J-Link USB drivers.

Download from www.renesas.com/synergy/e2studio

Note: The TB-S5D3 uses J-Link® On-board (OB) debug inter fac e. While J-Link drivers are necessary to

establish debug connection between the host PC and the TB-S5D3, they are not required to run the

Out-of-Box (OoB) Demonstration (Blinky) Application that the TB-S5D3 comes pre-programmed with.

Refer to the TB-S5D3 Quick Start Guide for more details.

Step 3: Explore Existing Application Projects for the TB-S5D3

Renesas provides several application projects to demonstrate different capabilities of the S5D3 MCU Group.

These application projects can also serve as a good starting point for you to develop your custom

applications. Application projects available for the TB-S5D3 are listed at www.renesas.com/synergy/tb-s5d3

Notes: 1. Every application project includes the project files, an application note, and instructions to import

the application project.

2. On downloading the application project from the website to your computer, the application projects

have to be built using one of the two supported tool chains before they can be downloaded on to

the TB-S5D3 board.

.

.

for

.

4. TB-S5D3 Hardware Details

4.1 Jumpers and DIP Switch Settings

4.1.1 Copper Jumpers

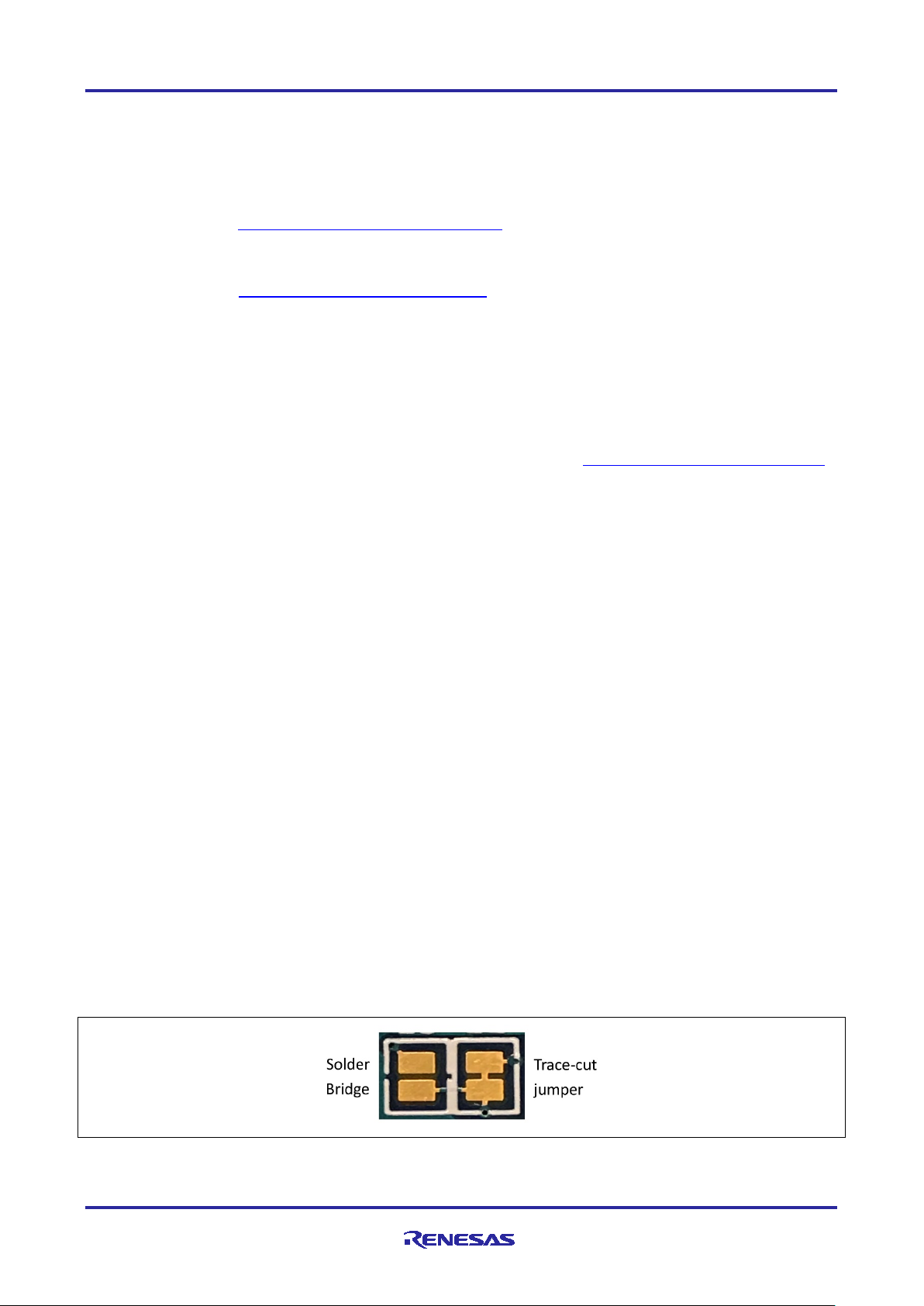

Copper jumpers are of two types, designated trace-cut and solder-bridge.

A trace-cut jumper is provided with a narrow copper trace connecting its pads. The silk screen overlay

printing around a trace-cut jumper is a solid box. To isolate the pads, cut the trace between pads adjacent to

each pad, then remove the connecting copper foil either mechanically or using heat. Once the etched copper

trace is removed, the trace-cut jumper is turned into a solder-bridge jumper for any later changes.

A solder-bridge jumper is provided with two isolated pads that may be joined together by one of three

methods:

• Solder may be applied to both pads to develop a bulge on each and the bulges joined by touching a

soldering iron across the two pads.

• A small wire may be placed across the two pads and soldered in place.

• A SMT resistor, size 0805, 0603, or 0402, may be placed across the two pads and soldered in place. A

zero-ohm resistor shorts the pads together.

The silk screen overlay printing around a solder-bridge jumper is a box with a gap in the lines adjacent to the

isolation region between the pads.

For any copper jumper, the connection is considered closed if there is an electrical connection between the

pads (default for trace-cut jumpers.) The connection is considered open if there is no electrical connection

between the pads (default for the solder-bridge jumpers.)

Figure 4. Copper Jumpers

R12UM0032EU0102 Rev.1.02 Page 7 of 33

Apr.21.20

Page 11

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Location

Circuit Group

Default

Closed

Function

J8

MCU Mode Config

Shunt

pins 1-2

Sets the MCU Mode to boot from Internal Flash

E18

12M Crystal

Open

Connects MCU P213 to pin header

E19

Open

Connects MCU P212 to pin header

E23

Closed

Connects 12.000 MHz Crystal to MCU P213

E24

Closed

Connects 12.000 MHz Crystal to MCU P212

E1

3.3 V Linear Regulator

Closed

Alternate 3.3 V source (+3V3JLOB)

E22

32K Crystal

Open

Connects MCU XCIN to pin header

E25

Closed

Connects 32.768 kHz Crystal to MCU XCIN

E26

Closed

Connects 32.768 kHz Crystal to MCU XCOUT

E10

AVCC0/AVSS0

Closed

Connects MCU AVCC0 TO +3V3MCU

E11

Closed

Connects MCU AVSS0 to Ground

E2

Capacitive Touch

Closed

Enable/Disable Capacitive Touch Button

E5

Open

Connects MCU P207 to pin header

E28

EXT VCL and VCL

Open

Connects VCL0 to MCU

E29

Closed

Connects MCU VCL0 to capacitor

E32

J-Link

Closed

Connects the S124 MCU to the J-Link signal JLED

E33

Closed

Connects the S124 MCU to the J-Link signal RESET#

E34

Closed

Connects the S124 MCU to the J-Link signal

E37

Closed

Connects the S124 MCU to the J-Link signal

P108/SWDIO

E38

Closed

Connects the S124 MCU to the J-Link signal

E35

J-Link® OB USB

Closed

Connects the J-Link OB USB 5 V input to the primary

5 V->3.3 V voltage regulator

E31

JTAG Connector

Open

JTAG Ground Detect. Connects the JTAG connector

E14

LDO and VCC USB

Open

Connects VCC_USB to MCU VCC_USB

E8

Closed

Connects +3V3MCU to MCU VCC_USB

E12

P205 or TSCAP-A

Open

Connects MCU P205 to pin header

E15

Closed

Connects MCU P205 to TSCAP-A

E30

USB Device Interface

Closed

Connects the Device USB 5 V input to MCU P407

E16

USB FS

Closed

Connects MCU USB_DM to USB Device Connector J9

E17

Closed

Connects MCU USB_DP to USB Device Connector J9

E20

Open

Connects MCU USB_DP to pin header

E21

Open

Connects MCU USB_DM to pin header

E3

User LED

Closed

Enable/Disable User LED

E36

User Potentiometer

Open

Enable/Disable User Potentiometer

E4

User Push-Button

Closed

Enable/Disable User Push-Button switch

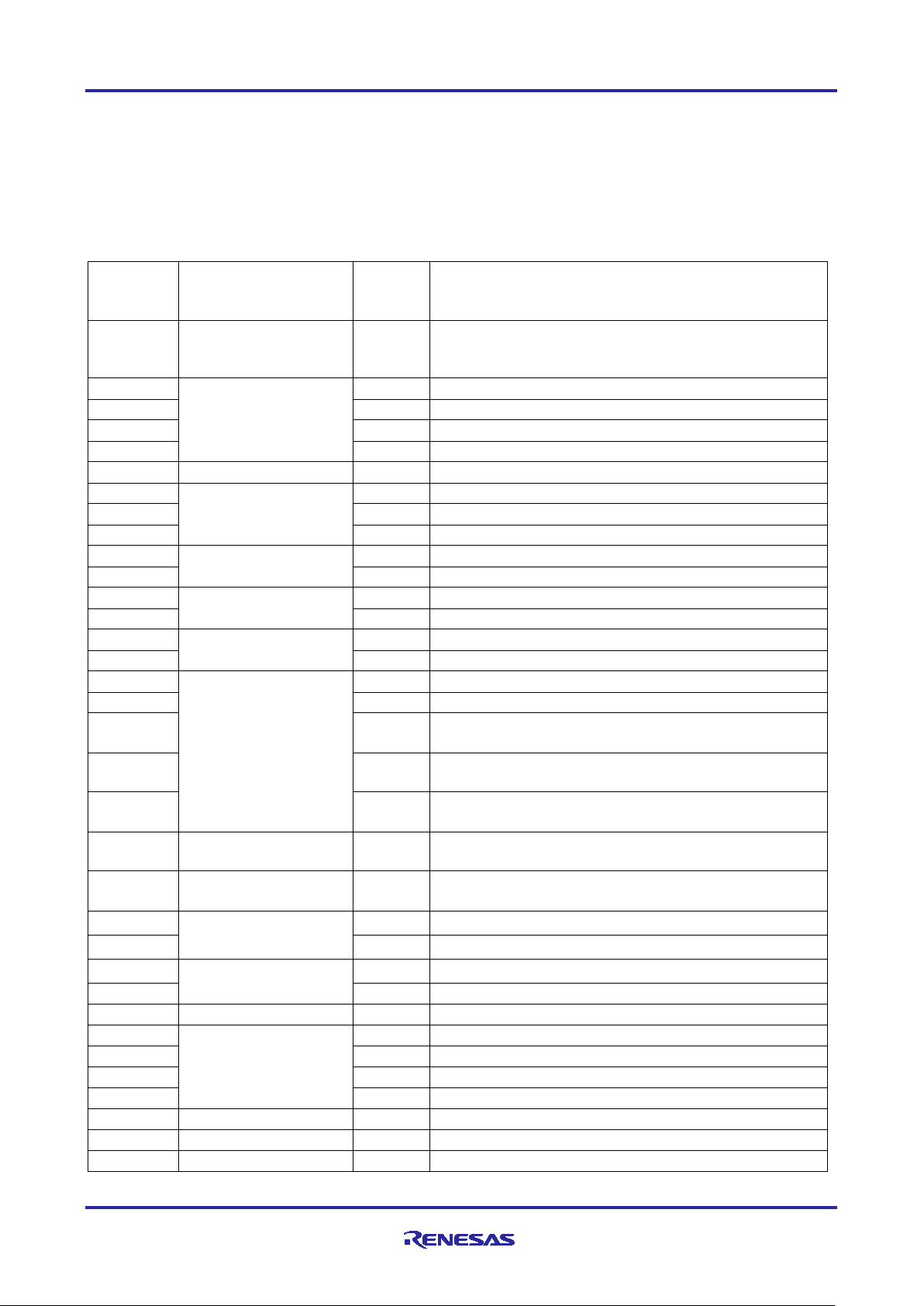

4.1.2 Default Board Configuration

The following table describes the default settings for each jumper on the TB-S5D3. This includes traditional

pin jumpers (Jx designation) and copper jumpers (Ex designation).

The Circuit Group for each jumper is the designation found in the board schematic. Functional details for

many of the listed jumpers may be found in section 5.4, Connectivity and Settings and section 5.6, Additional

Features.

Table 1. Default Jumper Settings

Open/

on

Button

CAP

TDO(/SWO) P109

P300/SWCLK

pin 9 to Ground.

R12UM0032EU0102 Rev.1.02 Page 8 of 33

Apr.21.20

Page 12

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Location

Circuit Group

Default

Closed

Function

E6

VBAT +3V3_MCU

Closed

Dual Jumper.

Pins 2-4 connect +3V3 to VBAT.

E54

VCL

Closed

Connects MCU VCL to capacitor

E55

Open

Connects MCU VCL to pin header

E52

VREFH/VREFL

Closed

Connects MCU VREFH to +3V3MCU

E53

Closed

Connects MCU VREFL to Ground

E50

VREFH0/VREFL0

Closed

Connects MCU VREFH0 to +3V3MCU

E51

Closed

Connects MCU VREFL0 to Ground

Open/

Pins 1-3 connect +3V3 to +3V3MCU.

5. Hardware Layout

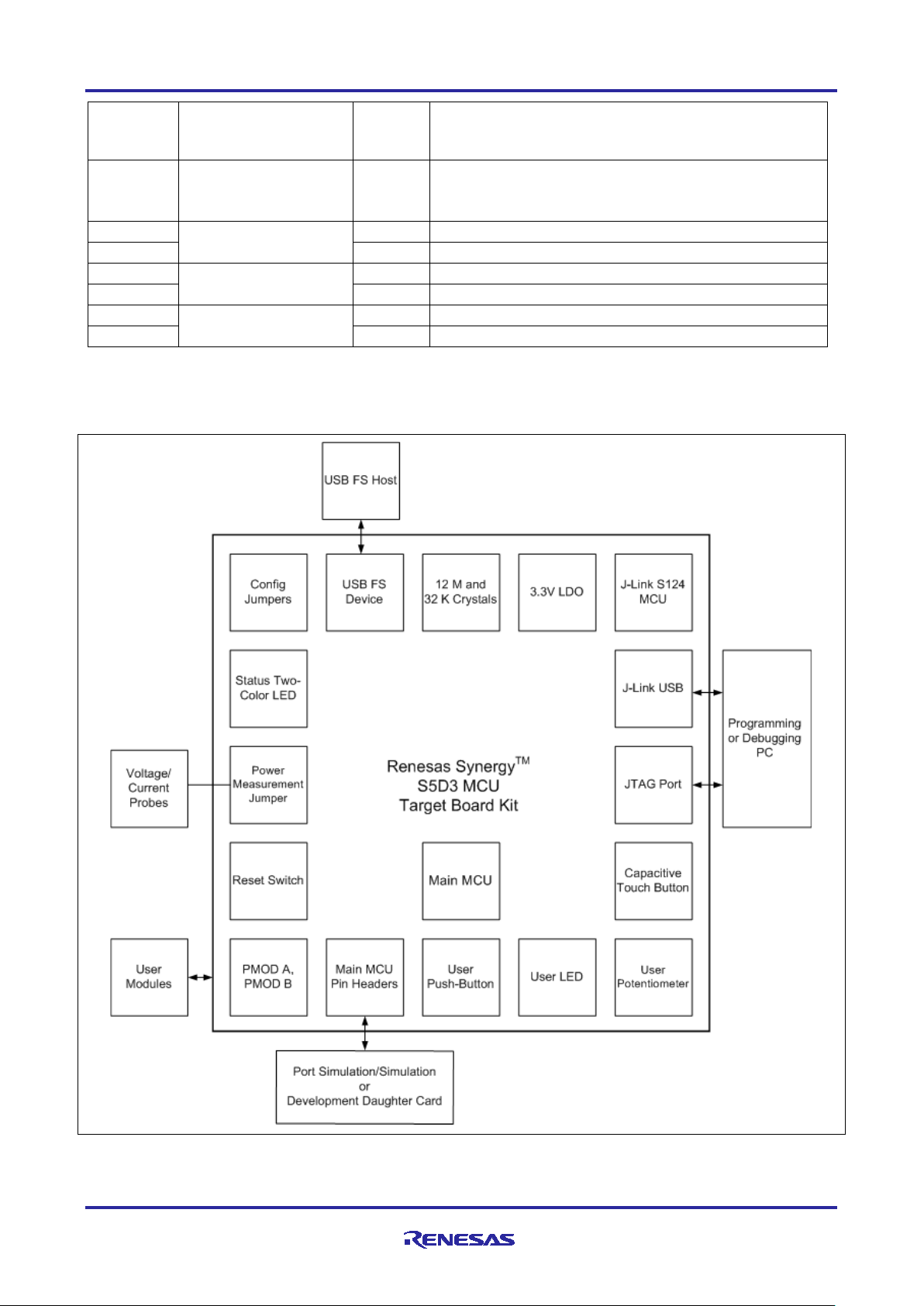

5.1 System Block Diagram

R12UM0032EU0102 Rev.1.02 Page 9 of 33

Apr.21.20

Figure 5. TB-S5D3 Block Diagram

Page 13

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

5.2 Power Requirements

The TB-S5D3 is designed for 3.3 V operation. This also means that 5 V PMOD de v ices cannot be us ed

together with the TB-S5D3 unless they are powered separately.

The total current available from the LDO regulator for all connected circuits is 600 mA or less, depending on

the 5 V power source used.

5.2.1 Power Supply Options

The TB-S5D3 can be powered in several different ways as described in this section.

Figure 6. Power Supply Options

5.2.1.1 Option 1: Debug USB (Default)

The default power source is 5 V, supplied from an external USB host to the USB

Debug connector labelled DEBUG USB on the top surface of the board. A low dropout regulator (LDO) is used to convert the 5 V signal to 3.3 V, which then is used to

power the MCU and any connected devices.

Copper jumper E35 selects the source for the primary power input to the LDO

regulator. By default, this jumper is configured to provide power through the Debug

USB connector. Copper jumper E35 is closed for this configuration.

5.2.1.2 Option 2: Test Points TP3 and TP4

The TB-S5D3 board can also be powered by installing a 5 V power source across TP3 (positive input) and

TP4 (negative input). Copper jumper E35 must be opened to enable powering the board using these test

points.

The on-board Low Dropout Regulator (see section 5.3, Main Components) has an input

voltage range of +3.3 V to +5.5 V, and a built-in current limit of 600 mA. Make sure any

external power source connected to TP3 and TP4 meets these requirements.

Figure 7. TP3 and TP4 on the Target Board

R12UM0032EU0102 Rev.1.02 Page 10 of 33

Apr.21.20

Page 14

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

5.2.1.3 Option 3: Test Points TP1 and TP2

The TB-S5D3 board can also be powered by installing a 3.3 V source across TP1 (positive input) and TP2

(negative input). Copper jumper E35 must be open to enable powering the board using these test points .

Figure 8. TP1, TP2, and LED1 on the Target Board

These test points supply voltage directly to the S5D3 MCU, the S124 J-Link MCU, and other

on-board circuitry. Use caution to ensure that any voltage connected in this manner meets

the power requirements for the active features. Power sources that are outside of the

published operating range for the active devices may cause degraded performance or

damage the board.

5.2.1.4 Option 4: Pin Headers

TB-S5D3 can also be powered through the follow in g pin headers on the board:

• J1 (pin J1-15 for +3.3 V, pin J1-17 for Return)

• J2 (pin J2-10 for +3.3 V, pin J2-12 for Return)

• J4 (pin J4-37 for +3.3 V, pin J4-36 for Return)

Copper jumper E35 must be open for any of these configurations.

The pin headers supply voltage directly to the S5D3 MCU, the S124 J-Link MCU, and other

on-board circuitry. Use caution to ensure that any voltage connected in this manner

meets the power requirements for the active features. Power sources that are outside of

the published operating range for the active devices may cause degraded performance or

damage the board.

See Section 5.5, Target Board Pin Headers for more information on the Pin Headers.

Figure 9. 5 V Power Input Circuit

R12UM0032EU0102 Rev.1.02 Page 11 of 33

Apr.21.20

Page 15

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Figure 10. 3.3 V Power Regulator Circuit

5.2.2 Powering up the Board

When powered up, the green LED to the right of the DEVICE USB connector (LED2) lights up.

The red LED in the same LED package functions as a status indicator for the J-Link® On-board (OB) debug

interface on the board. If both LEDs in the LED2 package are lit, LED2 appears orange.

Figure 11. LED2 on the Target Board (Top Side)

5.2.3 Battery Supply Configuration

An external battery may be connected according to the methods outlined in Section 5.2.1, Power Supply

Options, provided that it meets the minimum voltage and current requirements.

Additionally, an external battery source may be connected to VBAT at Pin Header location J2-29 (J2-12

ground return) to maintain the MCU Realtime Clock (RTC) when other main power sources are disconnected

from the TB-S5D3 board.

5.2.4 Measuring Current Consumption

Pads 1 and 3 of copper jumper E6, which is a dual trace-cut jumper, allow measurement of +3V3 MCU

supply current. Pads 2 and 4 of E6 allow measurement of VBAT supply current. Both traces are connected

by default. These traces should be cut to enable power measurement. Care must be taken when cutting the

trace to not cause damage to PCB layers below the trace.

The actual current consumed by the S5D3 MCU is dependent on many factors, including ambient

temperature, internal clock speed, input voltage level, and device activity. The actual current consumed by

the MCU can vary from less than 1 mA to nearly 40 mA. See the S5D3 User’s Manual for more information

on the electrical characteristics of the MCU.

R12UM0032EU0102 Rev.1.02 Page 12 of 33

Apr.21.20

Page 16

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Figure 12. MCU Current Measurement Circuit

Figure 13. E6 on the Target Board (Top Side)

Figure 14. E6 on the Target Board (Bottom Side)

Once the shorting traces have been removed, there are several options to measure current:

• Pins can be installed that allow connection of a precision multi-meter or bench meter, or leaded current

shunt to allow oscilloscope or data logger connection. When not measuring current, this allows easily

installed and removed shunts to be used to short the jumper terminals.

• Another option is to install current sense resistors between pads 1 and 3 for +3V3MCU, and between

pads 2 and 4 for VBAT. Pr e c ision non-inductive film or foil resistors are recommended for use in this

application, and the value of each resistor should be caefully considered.

For example, if the expected current requirement for the +3V3 MCU supply voltage is 10 mA, and the

user would expect to measure a 10 mV drop across the current measurement resistor, then a 1.0-ohm

resistor should be selected and installed.

The actual value selected should be based on the operating conditions of the MCU for the specific user

application, and the sensitivity of the measurement equipment used.

R12UM0032EU0102 Rev.1.02 Page 13 of 33

Apr.21.20

Page 17

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

5.3 Main Components

• Main MCU

Renesas Synergy™ S5D3 MCU device, part number R7FS5D37A3A01CFP#AA0 (U1)

• J-Link MCU

Renesas Synergy™ S124 MCU devic e, part numb er R7FS124773A01CFM#AA0 (U2)

• USB Connectors

FCI, part number 10118192-0001LF (J9, J11)

• Micro USB 2.0 Female connector

• Primary communication with Main MCU and J-Link MCU

• Push-Buttons

C&K, part number PTS645SM43SMTR92 LFS (S1, S2)

• Momentary push-button switch

• Used for system reset and user defined functions

• LDO Regulator

Diodes Inc., part number AP7215-33YG-13 (U3)

• Low-drop out linear regulator

• Generates system 3.3 V from J-Link USB 5 V input

• PMOD A Connector

Samtec, part number SSW-106-02-F-D-RA (J5)

• 12-pin right angle connector for PMOD A

• PMOD B Connector

Samtec, part number SSW-106-02-FM-S-RA (J6)

• 6-pin right angle connector for PMOD B

• Pin Headers

Sullins, part number PRPC020DAAN-RC (J1, J2, J3, J4)

• 40 position pin header, 0.1” pitch

• Provides signal breakout and access for Main MCU signals

• System LED

Dialight, part number 598-8610-207F (LED2)

• Dual color red/green LED

• System status indicator for power and J-Link status

• User LED

Lite-On, part number LTST-C191KRKT (LED1)

• User defined

• Single color red LED as needed for user environment

• User Potentiometer

Bourns, part number 3352T-1-1-3LF (POT1)

• User defined

• Provides variable resistance as needed for user environment

R12UM0032EU0102 Rev.1.02 Page 14 of 33

Apr.21.20

Page 18

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

USB Device Connector

TB-S5D3

Pin

Description

Signal/Bus

+5VDC, connected to a sense voltage 2/3 divider to allow

+5VUSB

P407/USB_VBUS = 2/3(5VUSB)

2

Data-

P915/USB_DM

3

Data+

P914/USB_DP

4

USB ID, jack internal switch, cable inserted

N.C.

5

Ground

GND

5.4 Connectivity and Settings

Throughout this section, feature configuration using copper jumpers is described. See Section 4.1.1, Copper

Jumpers for information on using copper jumpers.

5.4.1 Device USB

The DEVICE USB Micro-B connection jack connects the Main MCU to an external

USB Host, FS capable, allowing communications for testing and use of the Main

MCU firmware. Power for the Target Board cannot be received from this connector.

The DEVICE USB interface can detect the presence of power from the USB Host

PC. USB Host power received at the DEVICE USB interface is not connected to

the Target Board 5 V power bus.

Table 2. DEVICE USB Connector (J9)

1

Connections in Table 2 are based on the condition of

copper jumpers E16, E17, E20, E21, and E3 0 matc hing

their default state. By default, E16 and E17 are closed,

E20 and E21 are open, and E30 is closed.

Alternatively, the Device USB signals to the Main MCU may be connected to MCU Pin Header J1. To enable

this configuration, copper jumpers E16 and E17 should be open, and E20 and E21 should be closed.

Main MCU sensing of Host presence

5.4.2 Debug USB

The DEBUG USB Micro-B connection jack connects the S124 J-Link MCU to an

external USB Host, FS capable, allowing re-programming and debugging of the Main

MCU firmware. Power for the Target Board may be received from this connector.

The J-Link® OB interface is multiplexed with the JTAG interface and can

collectively be referred to as the Programming Interface. While the J-Link® OB

interface and the JTAG interface do not conflict, the J-Link® OB signals may be

isolated from the programming int erfac e by changing the associated copper

jumpers.

J-Link Disconnect Copper Jumpers E32, E33, E34, E37, and E38 connect the JLink signals to the MCU programming interface. To isolate the J-Link signals from

the JTAG interface, these copper jumpers must be open. To allow use of the

J-Link interface, each copper jumper must be closed.

J-Link MCU Power Copper Jumper, E1, connects the main +3.3 V power to the JLink +3.3 V power. The default condition for E1 is closed, which connects the J-Link

MCU power to the main +3.3 V power. If J-Link signals are disconnected, the power

to the J-Link MCU should also be removed by changing E1 to open.

R12UM0032EU0102 Rev.1.02 Page 15 of 33

Apr.21.20

Page 19

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

DEBUG USB Connector

TB-S5D3

Pin

Description

Signal/Bus

1

+5VDC

+5V_JUSB

2

Data-

U2 USB_DM (U2-18)

3

Data+

U2 USB_DP (U2-19)

4

USB ID, jack internal switch, cable inserted

N.C.

5

Ground

GND

Programming Interface

Conflicting Interface

Port

Use

Interface

Use

P108

SWDIO/JTAG TMS

SPI

SSLB0 fixed function, J1-13

P109

SWO/JTAG TDO

SPI

MOSIB fixed function, J1-7

P300

SWCLK/JTAG TCK

GPT

GTIOC0A fixed function, J1-31

JTAG Connector

TB-S5D3

Pin

JTAG pin name

SWD pin name

Signal/Bus

1

VTref

VTref

+3V3

2

TMS

SWDIO

U1 P108/SWDIO (U1-51)

3

GND

GND

GND

4

TCK

SWCLK

U1 P300/SWCLK (U1-50)

5

GND

GND

GND

6

TDO

SWO

U1 P109 (U1-52)

7

Key

Key

N.C.

8

TDI

NC/EXTb

U1 P110 (U1-53)

9

GNDDetect

GNDDetect

N.C. (short E31 to connect to GND)

10

nSRST

nSRST

U1 RESET# (U1-38)

Table 3. DEBUG USB Connector (J11)

Three of the J-Link ports (P108, P109, and P300) conflict with the SPI interface, as shown in the following

table.

Table 4. J-Link Interface Conflicts

5.4.3 JTAG/SWD

A 10-pin Cortex® Debug Connector is provided at J10.

Table 5. JTAG/SWD Connector (J10)

The Cortex® Debug Connector is fully described in the Arm® CoreSight™ Architecture Specification.

The J-Link MCU Power copper jumper and J-Link Disconnects copper jumpers may be open for proper

operation of the JTAG interface to prevent interactions with the J-Link MC U. See s ection 5.4.2 for details.

®

If a JTAG adapter is in use that properly interprets the Arm

Cortex® 10-pin Debug

Connector assignment of pin 9 to GND, JTAG GNDDetect copper jumper E31 should

be closed. If the JTAG adapter used is one of several that may be confused or

damaged by the presence of GND at pin 9, E31 should be open (as shipped).

The J-Link® OB interface is multiplexed with the JTAG interface and can collectively be

referred to as the Programming Interface. While the J-Link® OB interface and the JTAG

interface do not conflict, the J-Link® OB signals may be isolated from the programming

interface by changing the copper jumpers as described in section

5.4.2, Debug USB.

R12UM0032EU0102 Rev.1.02 Page 16 of 33

Apr.21.20

Page 20

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Programming Interface

Conflicting Interface

Port

Use

Interface

Use

P108

TMS/J-Link SWDIO

SPI

SSLB0_B fixed function, J1-13

P109

TDO/J-Link SWO

SPI

MOSIB_B fixed function, J1-7

P110

TDI

SPI

MISOB_B fixed function, J1-9

P300

SWCLK

GPT

GTIOC0A_A fixed function, J1-31

Designator

Color

Function

MCU control port

MCU pin

LED1

Red

User LED

U1 P112

U1-55

LED2

Red

J-Link Indicator

JLED (U2 P103)

U2-45

LED2

Green

3.3 V Power Available

+3V3

N.A.

Designator

Function

MCU Control Port

MCU Pin

S1

User Switch

U1 P415/IRQ8

U1-17

S2

MCU Reset Switch

RESET#

U1-38

Four of the JTAG ports (P108, P109, P110 and P300) conflict with the SPI interface, as shown in the

following table.

Table 6. JTAG Interface Conflicts

5.4.4 LEDs

Two LEDs are provided on the TB-S5D3. Target Board U1 is the Main MCU, and directly controls LED1. See

Figure 8 for LED1 location, Figure 11 for LED2 location, and Figure 10 for LED2 circuit. Target Board U2 is

the J-Link MCU and controls the red LED in LED2.

Figure 15. LED1 Control Circuit

The behavior of the LEDs is described in the following table.

Table 7. Target Board LED Functions

To disconnect the User LED from the MCU signal P112, copper jumper E3 must be open.

5.4.5 Switches

Two miniature, momentary, mechanical push-button type SMT switches are mounted on

the Target Board. Pressing the RESET Switch generates a reset signal to restart the Main

MCU. To disconnect the User Switch from the MCU signal P415/IRQ8, copper jumper E4

must be open.

Table 8. Target Board Switches

R12UM0032EU0102 Rev.1.02 Page 17 of 33

Apr.21.20

Page 21

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Figure 16. User Switch Circuit

Figure 17. User Switch (S1) on the Targe t Board

Figure 18. Reset Switch Circuit

R12UM0032EU0102 Rev.1.02 Page 18 of 33

Apr.21.20

Page 22

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

PMOD A Connector

TB-S5D3

Pin

Description

Signal/Bus

1

SS (low to select slave)

U1 P103, SSLA0_A (U1-72)

2

MOSI

U1 P101, MOSIA_A (U1-74)

3

MISO

U1 P100, MISOA_A (U1-75)

4

SCK

U1 P102, RSPCKA_A (U1-73)

5

GND

GND

6

VCC

+3V3

7

INT (slave to master)

U1 P304, IRQ1 (U1-44)

8

RESET (master to slave)

U1 P404, GPIO (U1-5)

9

Not Specified

U1 P402, GPIO (U1-3)

10

Not Specified

U1 P405, GPIO (U1-6)

11

GND

GND

12

VCC

+3V3

Figure 19. Reset Switch (S2) on the Target Board

5.4.6 PMOD A

A 12-pin PMOD type 2A connector is provided at PMOD A. The interface is

powered for 3.3 V modules only. The Main MCU acts as the SPI master, and

the connected module acts as an SPI slave device. This interface may

additionally be re-configured in firmware as several other PMOD types.

Signals on PMOD A are shared with Main MCU Pin Header J1 and J2. Care

must be taken to ensure that shared signals are not used concurrently.

Table 9. PMOD A Connector (J5)

Limits of the 3.3 V regulator on the Target Board, and limits of the power source supplying that regulator

(especially for USB Host devices), including the to-be-connected PMOD device, must be considered prior to

connecting a module to a PMOD connector.

5.4.7 PM OD B

A 6-pin PMOD type 4 connector is provided at PMOD B. The interface is

powered for 3.3 V modules only. The Main MCU acts as the UART DCE, and

the connected module acts as the UART DTE. This interface may additionally

be re-configured in firmware as some other PMOD type.

Signals on PMOD B are shared with Main MCU Pin Header J1 and J2. Care

must be taken to ensure that shared signals are not used concurrently.

R12UM0032EU0102 Rev.1.02 Page 19 of 33

Apr.21.20

Page 23

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

PMOD B Connector

TB-S5D3

Pin

Description

Signal/Bus

1

CTS (from module)

U1 P107, CTS8 (U1-68)

2

TXD

U1 P105, TXD8 (U1-70)

3

RXD

U1 P104, RXD8 (U1-71)

4

RTS (from Main MCU)

U1 P106, GPIO (U1-69) (for RTS by Main MCU firmware)

5

GND

GND

6

VCC

+3V3

Designator

Function

MCU Control Port

MCU Pin

TS1

Capacitive Touch Button

U1 P207 (TS2)

U1-30

-

TSCAP Support

U1 P205 (TSCAP-A)

U1-32

Table 10. PMOD B Connector (J6)

Limits of the 3.3 V regulator on the Target Board, and limits of the power source supplying that regulator

(especially for USB Host devices), including the to-be-connected PMOD device, must be considered prior to

connecting a module to a PMOD connector.

5.4.8 User Capacitive Touch Button

A capacitive sensor region for use as a Capacitive Touch button is provided in the board

USER INPUT region. A support circuit, TSCAP, is required for proper operation of

Capacitive Touch button(s) by the Main MCU. To disconnect the Capacitive Touch

Button from the MCU, copper jumper E2 must be open. To connect MCU signal P207 to

Pin Header J1, copper jumper E5 must be closed.

Note: Capacitor C33 is optional. This design does not include a dielectric overlay, so C33 is added to

reduce the sensitivity of the Capacitive Touch Button. This capacitor is not required by the MCU

specification.

Table 11. Target Board Capacitive Touch Button Sensor

Figure 20. Capacitive Touch Button Circuit

R12UM0032EU0102 Rev.1.02 Page 20 of 33

Apr.21.20

Page 24

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Figure 21. Capacitive Touch TSCAP Circuit

Figure 22. Capacitive Touch Button on the Target Board (Top Side)

5.5 Target Board Pin Headers

The Target Board Pin Headers J1, J2, J3, and J4, provide access to all Main MCU interface signals, and to

voltages for all Main MCU power ports.

Fixed Function Pin Assignments

For consistency across all Synergy Target Board Kits, some pin assignments on the headers have fixed

function signal assignments. This provides specific signals and functions to be at a common pin header

location on all Target Boards for a particular Synergy MCU group (for example, S1/S3/S5/S7) and, where

possible, across all Synergy Target Boards.

On the TB-S5D3 board, 40 pins of the pin headers are set aside for fixed function assignment. These pins

are odd-numbered pins of J1 and even-numbered pins of J2.

Pin Header Fixed Function Pins are labeled on the Target Board with dark text on a white background. Pins

that are not Fixed Function pins are labeled with white text on a dark background. On the top side of the

board is the functional label for the fixed location. On the bottom side of the board is the port information for

the same pin.

R12UM0032EU0102 Rev.1.02 Page 21 of 33

Apr.21.20

Page 25

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Figure 23. Fixed Function Pin Label Exa mple

There are several pins in the headers that are Secondary Fixed Function Pins. These Secondary Fixed

Function Pins share common pin assignments with other Target Boards that have Main MCUs with the same

functionality. The Secondary Fixed Function Pins are also labeled with the top side having a functional label,

and the bottom side having a port label.

Figure 24. TB-S5D3 Pin Headers Circuit

R12UM0032EU0102 Rev.1.02 Page 22 of 33

Apr.21.20

Page 26

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

100p S5D3 Pin

S5D3 Signal

J1 Pins

S5D3 Signal

100p S5D3 Pin

1

P400

1 2 USBPH_N

27

2

P401

3 4 USBPH_P

28

54

P111

5 6 VCC_USB

29

52

P109

7 8 P207J

30

53

P110

9

10

P402

3

48

P302

11

12

(None)

NC

51

P108

13

14

P404

5

15

VCC

15

16

P405

6

12

VSS

17

18

P406

7

66

P601

19

20

(None)

NC

65

P602

21

22

(None)

NC

67

P600

23

24

(None)

NC

49

P301

25

26

(None)

NC

61

P610

27

28

(None)

NC

60

P609

29

30

(None)

NC

50

P300

31

32

(None)

NC

4

P403

33

34

RESET#

38

18

P414

35

36

P201

39

18

P105

37

38

P200

40

84

P015

39

40

(None)

NC

Primary Fixed Function Pins

Secondary Fixed Function Pins

5.5.1 Pin Header J1

Pin Header J1 is a 2-column by 20-row through-hole header on 2.54 mm centers.

Table 12. Pin Header J1 Pin Assignment

Color Key

R12UM0032EU0102 Rev.1.02 Page 23 of 33

Apr.21.20

Page 27

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

100p S5D3 Pin

S5D3 Signal

J2 Pins

S5D3 Signal

100p S5D3 Pin

20

P412

1 2 P100

75

19

P413

3 4 P101

74

17

P415

5 6 P102

73

16

P708

7 8 P103

72

NC

(None)

9

10

VCC

46

NC

(None)

11

12

VSS

45

NC

(None)

13

14

P205

32

NC

(None)

15

16

P408

24

NC

(None)

17

18

P409

23

14

P212

19

20

P411

21

13

P213

21

22

P407/USB_VBUS

25

NC

(None)

23

24

P004

96

10

XCIN

25

26

P003

97

9

VCL0

27

28

P001

99 8 VBAT

29

30

P000

100

NC

(None)

31

32

VREFH0

91

NC

(None)

33

34

VREFL0

90

NC

(None)

35

36

AVSS0

89

NC

(None)

37

38

AVCC0

88

NC

(None)

39

40

P014

85

Primary Fixed Function pins

Secondary Fixed Function pins

5.5.2 Pin Header J2

Pin Header J2 is a 2-column by 20-row through-hole header on 2.54 mm centers.

Table 13. Pin Header J2 Pin Assignment

Color Key

R12UM0032EU0102 Rev.1.02 Page 24 of 33

Apr.21.20

Page 28

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

100p S5D3 Pin

S5D3 Signal

J3 Pins

S5D3 Signal

100p S5D3 Pin

NC

(None)

1 2 (None)

NC

NC

(None)

3 4 (None)

NC

NC

(None)

5 6 (None)

NC

NC

(None)

7 8 (None)

NC

41

P307

9

10

P306

42

43

P305

11

12

P304

44

47

P303

13

14

(None)

NC

55

P112

15

16

P113

56

57

P114

17

18

P115

58

59

P608

19

20

(None)

NC

NC

(None)

21

22

(None)

NC

NC

(None)

23

24

(None)

NC

NC

(None)

25

26

(None)

NC

NC

(None)

27

28

(None)

NC

NC

(None)

29

30

VCL

64

NC

(None)

31

32

(None)

NC

NC

(None)

33

34

(None)

NC

NC

(None)

35

36

(None)

NC

68

P107

37

38

P106

69

71

P104

39

40

(None)

NC

Secondary Fixed Function pins

5.5.3 Pin Header J3

Pin Header J3 is a 2-column by 20-row through-hole header on 2.54 mm centers.

Table 14. Pin Header J3 Pin Assignment

Color Key

R12UM0032EU0102 Rev.1.02 Page 25 of 33

Apr.21.20

Page 29

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

100p S5D3 Pin

S5D3 Signal

J4 Pins

S5D3 Signal

100p S5D3 Pin

76

P500

1 2 (None)

NC

77

P501

3 4 (None)

NC

78

P502

5 6 (None)

NC

79

P503

7 8 (None)

NC

80

P504

9

10

P205

32

881

P508

11

12

P206

32

NC

(None)

13

14

P410

22

NC

(None)

15

16

P208

37

98

P002

17

18

P211

34

95

P005

19

20

P214

33

94

P006

21

22

P210

35

93

P007

23

24

P209

36

92

P008

25

26

(None)

NC

87

VREFH

27

28

VREFL

86

NC

(None)

29

30

(None)

NC

NC

(None)

31

32

(None)

NC

NC

(None)

33

34

(None)

NC

NC

(None)

35

36

GND

63

62

VCC

37

38

(None)

NC

NC

(None)

39

40

(None)

NC

Secondary Fixed Function pins

5.5.4 Pin Header J4

Pin Header J4 is a 2-column by 20-row through-hole header on 2.54 mm centers.

Table 15. Pin Header J4 Pin Assignment

Color Key

R12UM0032EU0102 Rev.1.02 Page 26 of 33

Apr.21.20

Page 30

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

5.6 Additional Features

5.6.1 Reference Voltages VREF and VREF0

Capacitor C21 provides noise-bypass capability for VREFH0 and VREFL0, and

capacitor C23 provides nois e-bypass capability for VREFH and VREFL. See

Figure 24 for the circuit design.

By default, VREFH and VREFH0 are connected to the MCU supply voltage

(+3V3MCU) and VREFL and VREFL0 are connected to the system ground.

To disconnect VREFH from the MCU supply voltage, E52 must be open. To

disconnect VREFL from the system ground, E53 must be open. To disconnect

VREFH0 from the MCU supply voltage, E50 must be open. To disconnect

VREFL0 from the system ground, E51 must be open. See Figure 25 for the

circuit design.

5.6.2 Analog Voltage AVCC0/AVSS0

By default, AVCC0 is connected to the MCU supply voltage (+3V3MCU) and AVSS0 is connected to the

system ground.

To disconnect these references from the AVCC0 and AVSS0 lines, copper jumpers E10 and E11 must be

open.

See Figure 25 for the circuit design.

Figure 25. Analog and Reference Volta g es

5.6.3 On-Board Clock Crystals

The TB-S5D3 includes two precision crystal clock sources. A precision

12.000 MHz crystal is installed at location X1, and a precision 32.768 kHz

crystal is installed at location X2. These crystal clock sources are connected

to the Main MCU by default.

The MCU pins for the 12 MHz clock crystal may be connected to P212 and

P213. To disconnect the 12 MHz crystal, open copper jumpers E23 and E24,

and close copper jumpers E18 and E19.

The 32.768 kHz clock crystal may be replaced by an external clock source

connected to XCIN. To disconnect the 32.768 kHz crystal, open copper

jumpers E25 and E26, and close copper jumper E22.

R12UM0032EU0102 Rev.1.02 Page 27 of 33

Apr.21.20

Page 31

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Designator

Function

MCU Control Port

MCU Pin

POT1

User Potentiometer

U1 P004 (AN100)

U1-96

Figure 26. Crystal Clock Sources

5.6.4 User Potentiometer

A footprint for installation of a potentiometer and a recommended noise-bypass capacitor are

provided on the Target Board. The footprint was designed for installation of a Bourns P/N 3352T-1103LF, or equivalent, as the potentiometer, and a Samsung P/N CL10B104KB8NNNC, or similar, as

the noise-bypass capacitor.

When the User Potentiometer is installed, copper jumper E36 must be closed to connect the User

Potentiometer to the MCU.

Table 16. Target Board User Potentiometer

Figure 27. User Potentiometer Circuit

R12UM0032EU0102 Rev.1.02 Page 28 of 33

Apr.21.20

Page 32

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Boot Configuration

J8 Shunt Location

Normal Boot (default)

Pins 1 and 2

SCI/USB Boot

Pins 1 and 3

Figure 28. User Potentiometer on the Target Board (Top Side)

5.6.5 Boot Configuration

The BOOT CONFIG jumper, J8, is used to configure the operating mode of the S5D3 MCU at boot.

Table 17. Boot Configuration

Figure 29. Boot Config Jumper J8

5.6.6 Miscellaneous Signals

5.6.6.1 VCL

By default, the Main MCU pin VCL is connected to reference capacitor C51.

To connect this pin to MCU Pin Header J3, solder bridge E55 must be closed.

To disconnect the reference capacitor C51, copper jumper E54 must be open.

Figure 30. VCL and VCL Capacitor

R12UM0032EU0102 Rev.1.02 Page 29 of 33

Apr.21.20

Page 33

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

5.6.6.2 VCC_USB

By default, the Main MCU pin VCC_USB is connected to the +3V3 MCU supply voltage.

Alternatively, this pin may be connected to MCU Pin Header J1. To do this, copper jumper

E8 must be open, and copper jumper E14 must be closed.

Figure 31. VCC_USB Circuit

5.6.6.3 Signal P205

By default, the Main MCU pin P205 is connected to a TSCAP-A capacitor. This pin may

be connected to MCU Pin Header J2. To do this, copper jumper E12 must be closed.

The TSCAP-A capacitor may be disconnected by making copper jumper E15 open.

Figure 32. P205 Circuit

R12UM0032EU0102 Rev.1.02 Page 30 of 33

Apr.21.20

Page 34

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

6. Certifications

The TB-S5D3 v1 meets the following certifications/standards. See page 3 of this user’s manual for the

disclaimer and precautions .

6.1 EMC/EMI Standards

• FCC Notice (Class A)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

NOTE- This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a resident ia l instal lat ion. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/television technician for help.

• CE Class A (EMC)

This product is herewith confirmed to comply with the requirmeents set out in the Council

Directives on the Approximation of the laws of the Member States relating to electromagnetic

Compatibility Directive 2004/108/EEC.

Warning – This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be requried to take adequate measures to correct this

interference.

6.2 Material Selection, Waste, Recycling and Disposal Standards

• EU RoHS

• China SJ/T 113642014, 10-year environmental protection use period.

6.3 Safety Standards

• UL 94V-0

R12UM0032EU0102 Rev.1.02 Page 31 of 33

Apr.21.20

Page 35

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

File Type

Content

File/Folder Name

File (PDF)

Schematics

tb-s5d3-v1.2-schematics

File (PDF)

Mechanical Drawing

tb-s5d3-v1.2-mechdwg

File (PDF)

3D Drawing

tb-s5d3-v1.2-3d

File (PDF)

BOM

tb-s5d3-v1.2-bom

Folder

Manufacturing Files

Manufacturing Files

Folder

Design Files

Design Files - Altium

7. Design and Manufacturing Information

The design and manufacturing information about TB-S5D3 v1 board are available in the “TB-S5D3 v1 Design

Package” available on renesas.com/synergy/tb-s5d3

• Design package file name: tb-s5d3-v1.2-designpackage.zip

• Design package contents

under the Downloads tab.

Website and Support

Visit the following vanity URLs to learn about key elements of the Synergy Platform, download components

and related documentation, and get support.

TB-S5D3 Resources renesas.com/synergy/tb-s5d3

Synergy Software renesas.com/synergy/software

Synergy Software Package renesas.com/synergy/ssp

Software add-ons renesas.com/synergy/addons

Software glossary renesas.com/synergy/softwareglossary

Development tools renesas.com/synergy/tools

Synergy Hardware renesas.com/synergy/hardware

Microcontrollers renesas.com/synergy/mcus

MCU glossary renesas.com/synergy/mcuglossary

Parametric search renesas.com/synergy/parametric

Kits renesas.com/synergy/kits

Synergy Solutions Gallery renesas.com/synergy/solutionsgallery

Partner projects renesas.com/synergy/partnerprojects

Application projects renesas.com/synergy/applicationprojects

Self-service support resources:

Documentation renesas.com/synergy/docs

Knowledgebase renesas.com/synergy/knowledgebase

Forums renesas.com/synergy/forum

Training renesas.com/synergy/training

Videos renesas.com/synergy/videos

Chat and web ticket renesas.com/synergy/resourcelibrary

R12UM0032EU0102 Rev.1.02 Page 32 of 33

Apr.21.20

Page 36

Renesas Synergy™ Platform Target Board Kit S5D3 (TB-S5D3)

Rev.

Date

Description

Page

Summary

1.01

Feb.08.19

-

Initial release

1.02

Apr.21.20

-

Updates to sections 5.4.8, 6, and 7

Revision History

R12UM0032EU0102 Rev.1.02 Page 33 of 33

Apr.21.20

Page 37

Published by: Renesas Electr onics Corporation

Target Board Kit S5D3 (TB-S5D3) User’s Manual

Publication Date: Apr.21.20

Page 38

R12UM0032EU0102

Renesas Synergy™ Platform

Target Board S5D3 (TB-S5D3)

Loading...

Loading...