Page 1

APPLICATION NOTE

Vector Control for Permanent Magnet Synchronous

Motor with Encoder (Implementation)

RX13T, For “Evaluation System for BLDC Motor”

Abstract

This application note aims to explain the sample programs for a permanent magnet synchronous motor with

encoder, by using functions of RX13T. The explanation includes, how to use the library of ‘Renesas Motor

Workbench’ tool, that is support tool for motor control development. This software also uses the Smart

Configurator tool, especially the Motor component that provides driver configuration of multi-function timer

pulse unit and 12-bit A/D converter for motor control.

The target software of this application note is only to be used as reference and Renesas Electronics

Corporation does not guarantee the operations. Please use them after carrying out a thorough evaluation in a

suitable environment.

Operation Checking Device

Operations of the target software of this application note are checked by using the following device.

• RX13T (R5F513T5ADFL)

Target Software

The target programs of this application note are as follows.

• RX13T_MRSSK2_SPM_ENCD_FOC_CSP_RV100 (IDE: CS+)

• RX13T_MRSSK2_SPM_ENCD_FOC_E2S_RV100 (IDE: e

• Vector control with encoder software for ‘Evaluation System For BLDC Motor’ and ‘RX13T CPU Card’

2

studio)

Reference

• RX13T Group User’s Manual: Hardware (R01UH0822)

• Application note: ‘Vector control for permanent magnet synchronous motor with encoder (Algorithm)’

(R01AN3789)

• Renesas Motor Workbench User’s Manual (R21UZ0004)

• Evaluation System For BLDC Motor User’s Manual (R12UZ0062)

• RX13T CPU CARD User’s Manual (R12UZ0051)

• Smart Configurator User’s Manual: RX API Reference (R20UT4360)

• RX Smart Configurator User’s Guide: CS+ (R20AN0470)

• RX Smart Configurator User’s Guide: e

2

studio (R20AN0451)

R01AN5790EJ0100 Rev.1.00 Page 1 of 41

Mar.12.21

Page 2

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Contents

1. Overview .................................................................................................................................... 3

1.1 Development environment ...................................................................................................................... 3

2. System overview ....................................................................................................................... 4

2.1 Hardware configuration ........................................................................................................................... 4

2.2 Hardware specifications .......................................................................................................................... 5

2.2.1 User interfaces ...................................................................................................................................... 5

2.2.2 Peripheral functions ............................................................................................................................... 6

2.3 Software configuration ............................................................................................................................. 7

2.3.1 Software file configuration ..................................................................................................................... 7

2.3.2 Smart Configurator File Configuration ................................................................................................... 8

2.3.3 Module configuration ........................................................................................................................... 11

2.4 Software specifications .......................................................................................................................... 12

3. Descriptions of the Control Program ....................................................................................... 13

3.1 Contents of Control ............................................................................................................................... 13

3.1.1 Motor Start/Stop .................................................................................................................................. 13

3.1.2 A/D Converter ...................................................................................................................................... 13

3.1.3 Position Profile Generation (Position Profile of Trapezoidal Curve for Speed Command Value) ....... 14

3.1.4 Speed Measurement ........................................................................................................................... 15

3.1.5 Modulation ........................................................................................................................................... 16

3.1.6 State Transition ................................................................................................................................... 18

3.1.7 Startup Method .................................................................................................................................... 19

3.1.8 System Protection Function ................................................................................................................ 20

3.2 Function Specifications of Vector Control using Encoder Software ...................................................... 21

3.3 Macro Definitions of Vector Control Software Using Encoder .............................................................. 25

3.4 Control Flowcharts ................................................................................................................................ 27

3.4.1 Main Process ....................................................................................................................................... 27

3.4.2 Carrier Synchronous Interrupt Handling (100 [µs]) ............................................................................. 28

3.4.3 1 [ms] Interrupt Handling ..................................................................................................................... 29

3.4.4 Over Current Detection Interrupt Handling .......................................................................................... 30

3.4.5 Encoder Count Capture Interrupt Handling ......................................................................................... 31

3.4.6 Hall Signal Interrupt Handling .............................................................................................................. 32

4. Motor Control Development Support Tool ‘Renesas Motor Workbench’ ................................. 33

4.1 Overview ................................................................................................................................................ 33

4.2 List of Variables for Scope Function ‘Analyzer’ ..................................................................................... 34

4.3 Operation Example for Analyzer ........................................................................................................... 37

4.4 Operation Example for User Button ...................................................................................................... 39

Revision History .............................................................................................................................. 41

R01AN5790EJ0100 Rev.1.00 Page 2 of 41

Mar.12.21

Page 3

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Microcontroller

Evaluation board

Motor*3

RX13T

(R5F513T5ADFL)

48V 5A Inverter Board For BLDC Motor &

RX13T CPU Card*1

FH6S20E-X81*2

IDE version

Smart Configurator for RX

Toolchain version*4

CS+ V8.04.00

Standalone Version 2.7.0

CC-RX: V3.02.00

e2 studio version 2020-10

Bundled with e2 studio as plug-in

1. Overview

This application note aims to explain the sample programs for a permanent magnet synchronous motor

(PMSM)*

‘Renesas Motor Workbench’ tool, that is support tool for motor control development.

Note that these sample programs use the algorithm described in the application note ‘Vector control for

permanent magnet synchronous motor with encoder (Algorithm)’.

Note: 1. PMSM is also known as brushless DC motor (BLDC).

1

with encoder, by using functions of RX13T. The explanation includes, how to use the library of

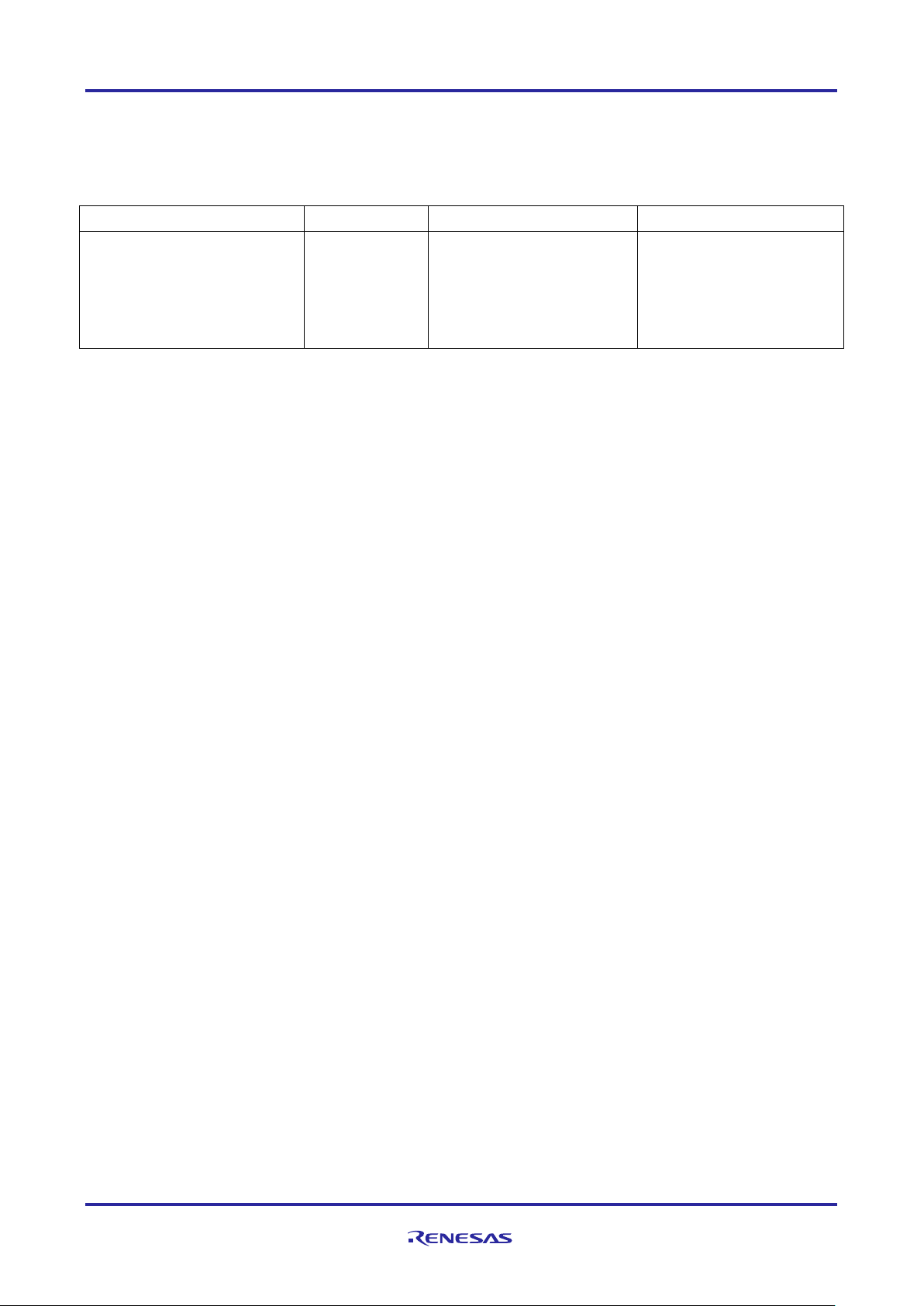

1.1 Development environment

Table 1-1 and Table 1-2 show development environment of the sample programs explained in this application

note.

Table 1-1 Hardware Development Environment

Table 1-2 Software Development Environment

For purchase and technical support, contact sales representatives and dealers of Renesas Electronics

Corporation.

Notes: 1. 48V 5A Inverter Board For BLDC Motor (RTK0EM0000B10021BJ) and RX13T CPU Card

(RTK0EMXA10C00000BJ) are products of Renesas Electronics Corporation. 48V 5A Inverter

Board For BLDC Motor is included in Evaluation System For BLDC Motor

(RTK0EMX270S00020BJ).

2. FH6S20E-X81 is a product of NIDEC SERVO CORPORATION.

NIDEC SERVO (http://www.nidec-servo.com/)

3. Motors conforming to the inverter specifications listed in chapter 2 of Evaluation System For BLDC

Motor User’s Manual (R12UZ0062) can be connected to the product. When using motors other

than the one included with the product, make sure to check the motor specifications carefully.

4. If the same version of the toolchain (C compiler) specified in the project is not in the import

destination, the toolchain will not be selected and an error will occur.

Check the selected status of the toolchain on the project configuration dialog

For the setting method, refer to FAQ 3000404.

(https://en-support.renesas.com/knowledgeBase/18398339)

R01AN5790EJ0100 Rev.1.00 Page 3 of 41

Mar.12.21

Page 4

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

A/D converter input

Bus vo ltage

Rotat ion spe ed com mand

PWM output

Over cu rrent detect ion

Power supply circuit

Switch in put

Motor rotation start/stop

Error reset

LED outpu t

Over cu rrent detect ion inpu t

Inverter circuit

Phase current

detec tion

Phase

curren t

Encode r inp ut

RX13T

V

dc

GND

Input DC24V

VR1

SW1

SW2

LED1 LED2

U

p

V

p

W

p

V

n

U

n

W

n

OC

V

u

V

vVw

I

u

I

w

PB5

PB4

P46 / AN00 6

P47 / AN00 7

PD6

PD4

P71 / MT IOC3B (Up)

P72 / MT IOC4A (V

p

)

P73 / MT IOC4B (Wp)

P74 / MT IOC3D (Un)

P75 / MT IOC4C (Vn)

P76 / MT IOC4D (Wn)

PE2

/ P OE10#

PMSM

P40 / AN 000

IU_AIN

I

v

P42 / AN 002

IW_AIN

PB0 / MTCLKB

PB1 / MTCLKA

Hall I nput

P93 / IRQ0

P94 / IRQ1

PA2 / IRQ4

U port

W po rt

V port

HU port

HW p ort

HV port

GND port

V

cc

port

ENC_Z p ort

ENC_A port

ENC_B port

GND port

V

cc

port

LED3

PB3

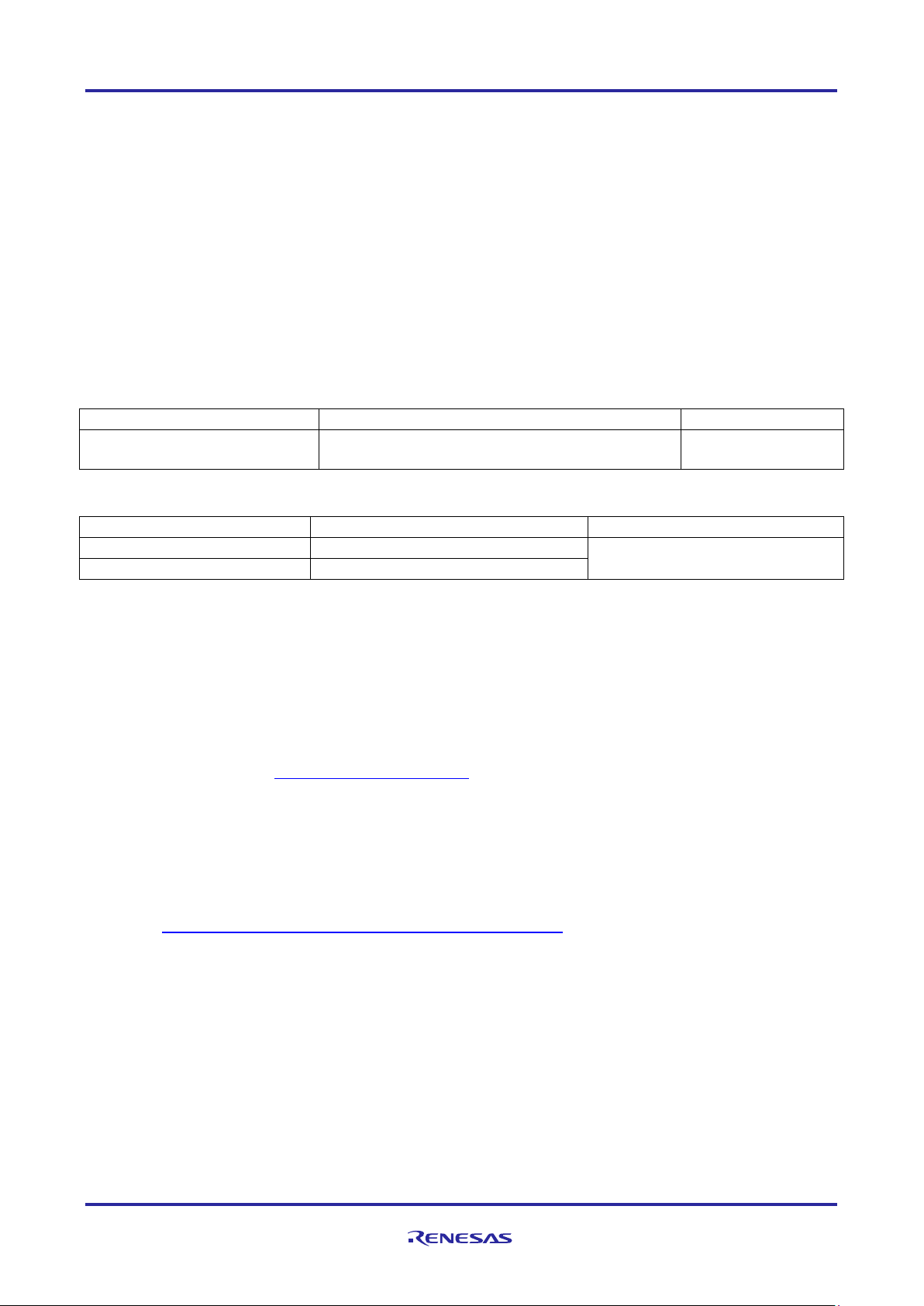

2. System overview

Overview of this system is explained below.

2.1 Hardware configuration

The hardware configuration is shown below.

Figure 2-1 Hardware Configuration Diagram

R01AN5790EJ0100 Rev.1.00 Page 4 of 41

Mar.12.21

Page 5

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Item

Interface component

Function

Rotation position /

Variable resistor (VR1)

Reference value of rotation position / speed input

START/STOP

Toggle switch (SW1)

Motor rotation start/stop command

ERROR RESET

Push switch (SW2)

Command of recovery from error status

LED1

Orange LED

• At the time of motor rotation: ON

• At the time of stop: OFF

LED2

Orange LED

• At the time of error detection: ON

At the time of normal operation: OFF

LED3

Orange LED

• Complete of positioning: ON

Uncomplete of positioning: OFF

RESET

Push switch (RESET1)

System reset

R5F513T5ADFL port name

Function

P46 / AN006

Inverter bus voltage measurement

P47 / AN007

For position / speed command value input (analog value)

PB5

START/STOP toggle switch

PB4

ERROR RESET toggle switch

PD6

LED1 ON/OFF control

PD4

LED2 ON/OFF control

PB3

LED3 ON/OFF control

P40 / AN000

U phase current measurement

P42 / AN002

W phase current measurement

P71 / MTIOC3B

PWM output (Up) / Low active

P72 / MTIOC4A

PWM output (Vp) / Low active

P73 / MTIOC4B

PWM output (Wp) / Low active

P74 / MTIOC3D

PWM output (Un) / High active

P75 / MTIOC4C

PWM output (Vn) / High active

P76 / MTIOC4D

PWM output (Wn) / High active

P93 / IRQ0

Hall Phase-U signal input

P94 / IRQ1

Hall Phase-V signal input

PA2 / IRQ4

Hall Phase-W signal input

PB1 / MTCLKA

Encoder Phase-A signal input

PB0 / MTCLKB

Encoder Phase-B signal input

PE2 / POE10#

PWM emergency stop input at the time of over-current detection

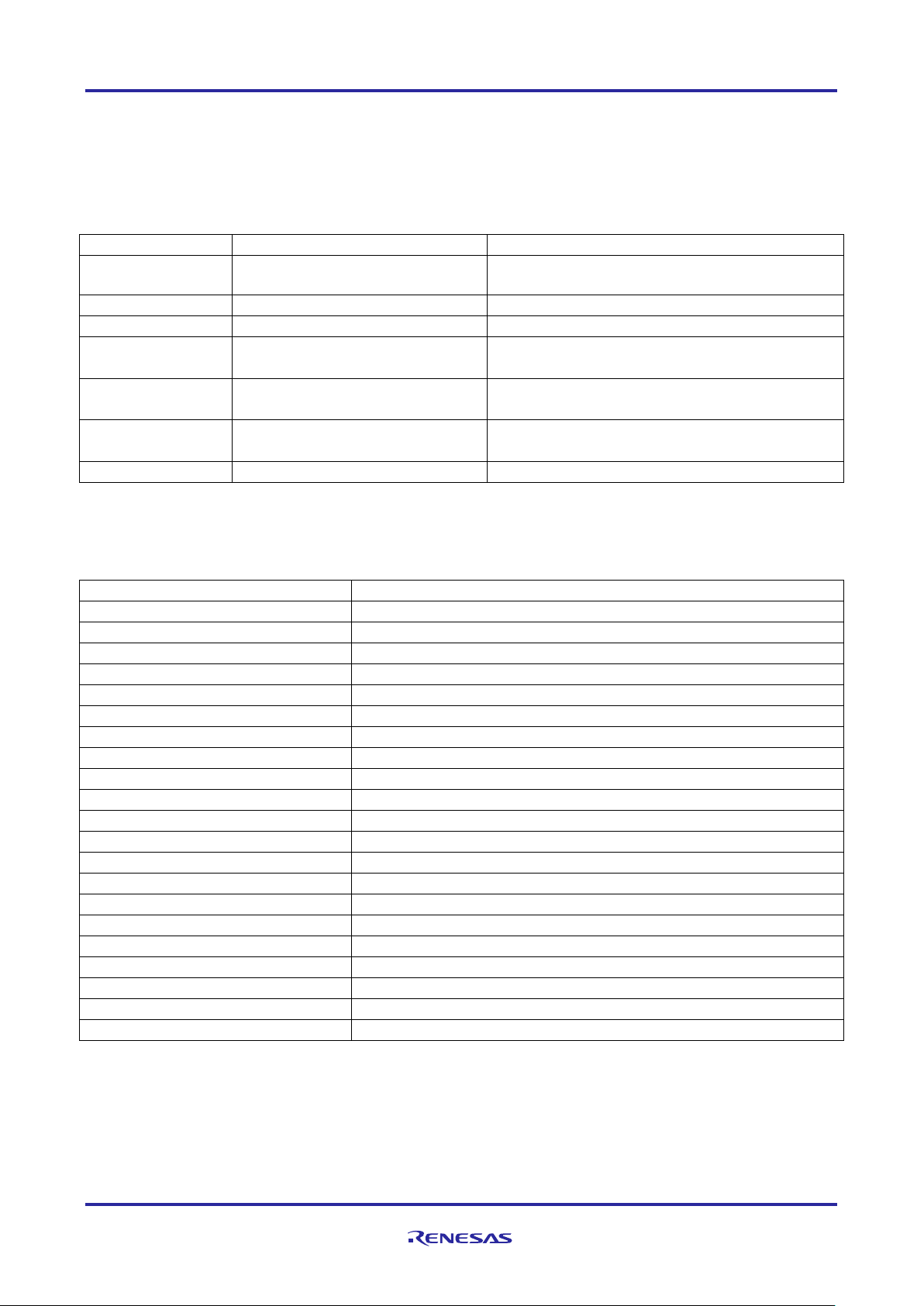

2.2 Hardware specifications

2.2.1 User interfaces

List of user interfaces of this system is given in Table 2-1.

Table 2-1 User Interfaces

speed

List of port interfaces of this system is given in Table 2-2.

Table 2-2 Port Interfaces

(analog value)

•

•

R01AN5790EJ0100 Rev.1.00 Page 5 of 41

Mar.12.21

Page 6

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

•

measurement

•

2.2.2 Peripheral functions

List of the peripheral functions used in this system is given in Table 2-3.

Table 2-3 List of the Peripheral Functions

12-bit A/D CMT MTU3 POE3C

Rotation speed command value

input

• Current of each phase U and W

measurement

1 [ms] interval timer

Complementary PWM output

• Encoder phase counter

• Encoder count capture

• Inverter bus voltage

(1) 12-bit A/D converter (S12ADF)

U phase current (I

W phase current (Iw), inverter bus voltage (Vdc) and rotation speed reference are

u),

measured by using the single scan mode (use hardware trigger). The sample-and-hold function is used for

U phase current (I

and W phase current (Iw) measurement.

u)

(2) Compare match timer (CMT)

The channel 0 of the compare match timer is used as 1 [ms] interval timer.

(3) Multi-function timer pulse unit 3 (MTU3c)

The operation mode varies depending on channels. On the channels 3 and 4, output (p-side is active low,

n-side is active high) with dead time is performed by using the complementary PWM mode.

The channel 1 of MTU3 operate in phase counting mode, the counter is incremented or decremented

according to the phase difference between Phase-A and Phase-B signals from the encoder.

The channel 0 of MTU3 is used as free-run timer for speed measurement.

(4) Port output enable 3 (POE3C)

PWM output ports are set to high impedance state when an overcurrent is detected (when a falling edge of

the POE10# port is detected).

Set PWM output ports to high

impedance state to stop the PWM

output.

R01AN5790EJ0100 Rev.1.00 Page 6 of 41

Mar.12.21

Page 7

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

r_mtr_common.h: Common definition

(Project Folder)

‘In Circuit Scope’) is attached to the name of folders, files, functions, variables related to ‘Renesas Motor Workbench’.

demo

motor_module

application

controller

lib

ics

lib

ref

src

controller

functions

mode

main.h, main.c: User main function

r_mtr_board.h, r_mtr_board.c: Function definition for board UI

r_mtr_ctrl_mcu.h: Common definition depends on MCU

r_mtr_config.h: Common definition for software configuration

r_mtr_control_parameter.h: Configuration definition for control parameters

r_mtr_ipd.h, r_mtr_ipd.obj: Function definition of IPD controller

speed observer

r_mtr_ics.h, r_mtr_ics.c: Function definition for Analyzer UI

r_mtr_ctrl_encoder.h, r_mtr_ctrl_encoder.c: Function definition of encoder

r_mtr_mod.h, r_mtr_mod.c: Function definition for modulation

r_mtr_statemachine.h, r_mtr_statemachine.c:

src

smc_gen

Smart Configurator generated driver, API

Smart Configurator configuration file

r_mtr_ctrl_mrssk.h, r_mtr_ctrl_mrssk.c:

Function definition depends on inverter

r_mtr_driver_access.h, r_mtr_driver_access.c: User access function definition

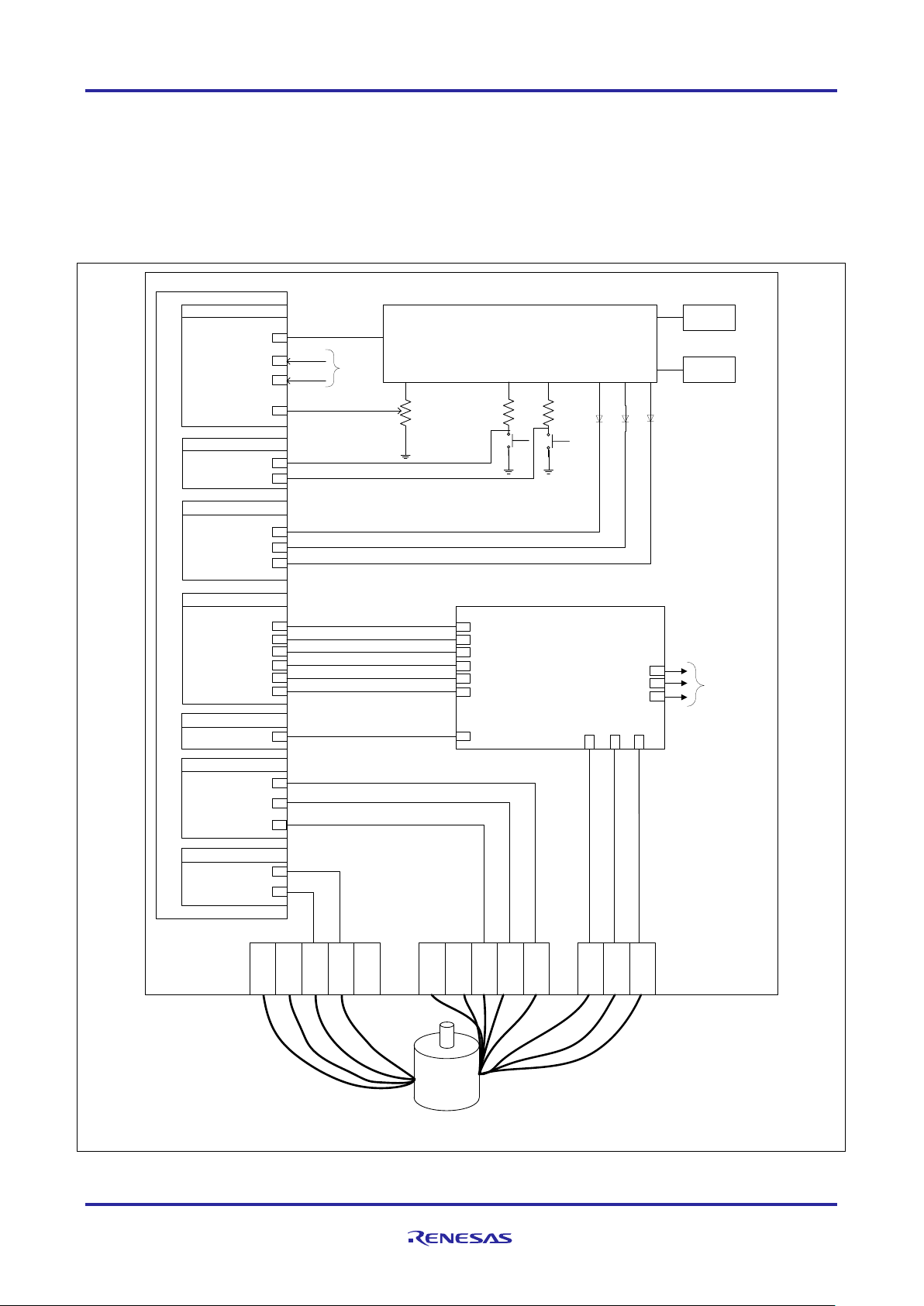

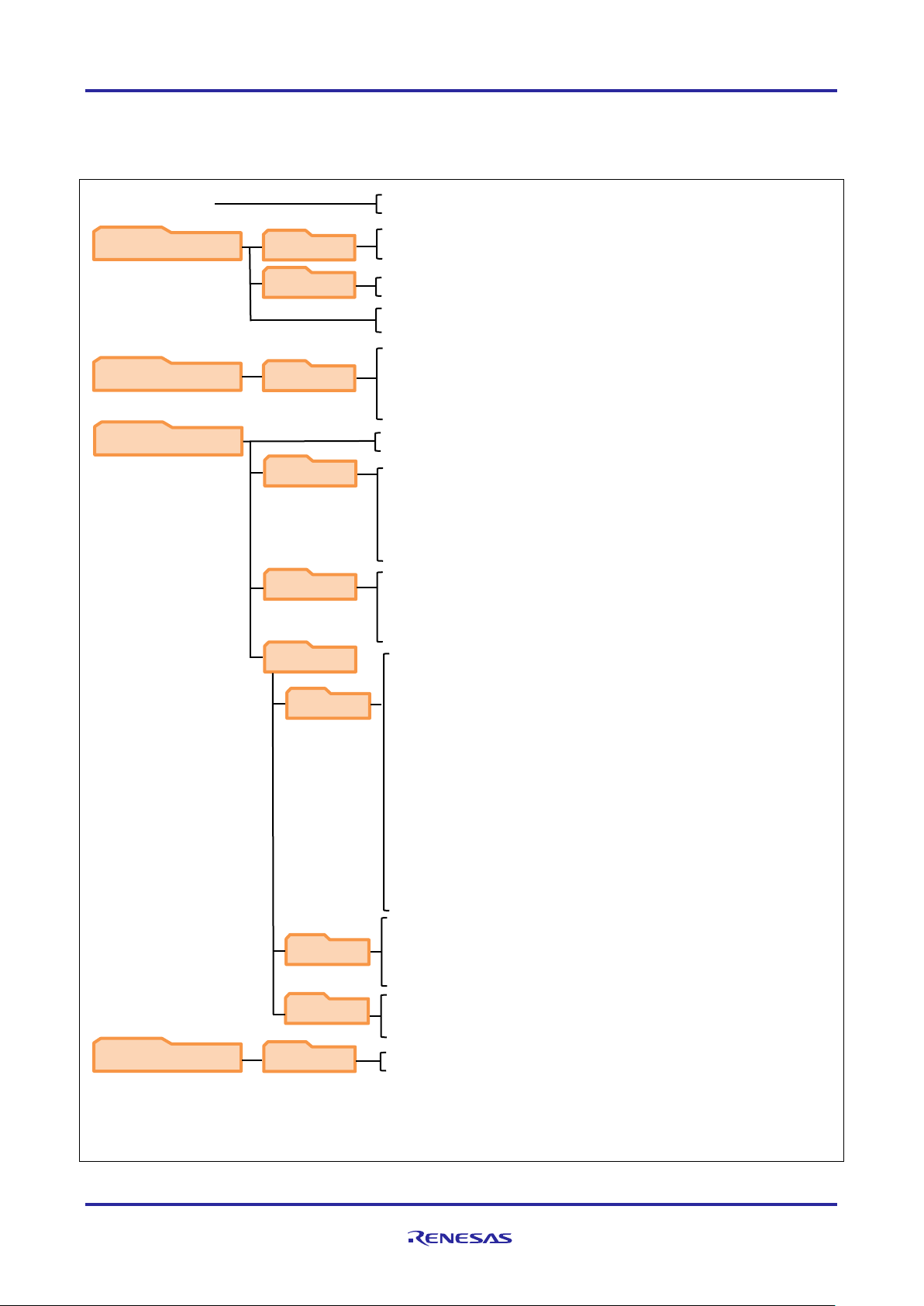

2.3 Software configuration

2.3.1 Software file configuration

Folder and file configuration of the sample programs are given below.

RX13T_MRSSK2_SPM_ENCD_FOC_xxx_RVyyy*1:

ICS2_RX13T.lib: Communication library for GUI tool

ICS2_RX13T.h: Function definition for GUI tool

r_mtr_interrupt.c: Interrupt function definition for Analyzer*

r_mtr_volt_err_comp.h, r_mtr_volt_err_comp.obj: Function definition for voltage

error compensation

r_mtr_ctrl_gain_calc.obj: Function definition for calculation of control gains

r_mtr_speed_observer.h, r_mtr_speed_observer.obj: Function definition for

2

r_mtr_motor_parameter.h: Configuration definition for motor parameters

r_mtr_inverter_parameter.h: Configuration definition for inverter parameters

r_mtr_pi_control.h, r_mtr_pi_control.c: Function definition for PI control

r_mtr_transform.h, r_mtr_transform.c: Function definition for coordinate transform

r_mtr_foc_control_encd_position.h, r_mtr_foc_control_encd_position.c:

r_mtr_foc_current.h, r_mtr_foc_current.c: Function definition for current control

r_mtr_foc_speed.h, r_mtr_foc_speed.c: Function definition for speed control

r_mtr_foc_position.h, r_mtr_foc_position.c: Function definition for position control

r_mtr_interrupt_carrier.c: Function definition of carrier interrupt

r_mtr_interrupt_1ms.c: Function definition of 1ms interrupt

r_mtr_interrupt_sensor.c: Function definition of sensor signal interrupt

r_mtr_parameter.h: Various parameter definition

r_mtr_position_profiling.h, r_mtr_position_profiling.c: Function definition of

r_mtr_ctrl_rx13t.h, r_mtr_ctrl_rx13t.c: Function definition depends on MCU

r_mtr_ctrl_hall.h, r_mtr_ctrl_hall.c: Function definition of hall

r_mtr_filter.h, r_mtr_filter.c: Function definition for general purpose filters

r_mtr_foc_action.c: Action function definition

Function definition of FOC control

position profiling.

Function definition for state transition

Notes: 1. xxx: CSP refers to CS+ version. E2S refers to e2 studio version. yyy: revision version number eg. 100: Rev.version 1.00

2 Regarding the specification of Analyzer function in the motor control development support tool ‘Renesas Motor

Workbench’, please refer to the section 4.The identifier ‘ics/ICS (ICS is previous motor control development support tool

Figure 2-2 Folder and file configuration

R01AN5790EJ0100 Rev.1.00 Page 7 of 41

Mar.12.21

Page 8

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

(Smart Configurator Output Folder)

src

smc_gen

Config_PORT

Config_S12AD0

Config_IWDT

Peripherals driver for GPIO ports. Unused ports are also configured here.

Config_CMT0

Config_POE

Config_befoc

General*

3

r_bsp*

3

r_config*

3

r_pincfg*

3

Peripheral driver for single scan mode 12-bit A/D conversion for VR1

Peripheral driver for watch-dog timer.

Config_IWDT_user.c: User function for Watchdog timer

Peripheral driver for compare match timer of 1ms interval

Config_CMT0_user.c: User function for Compare match timer

Peripheral driver for port output enable that places PWM output in

Config_POE_user.c: User function for Port Output Enable

Peripheral drivers for multi-function timer pulse unit (MTU) and 12-bit A/D converter

for Motor control

r_cg_hardware_setup.c: Peripheral initialization

< various BSP package files *1 >

BSP: Board Support Package

Notes: 1. Regarding BSP package files, please refer to README.txt file in <r_bsp> folder

3. Refer to Section 6.2 in “RX Smart Configurator User’s Guide:e2 studio (R20AN0451)” for explanation of these files and folder

< for FIT configuration files*2 >

< for pin code generation >

Config_MTU0

Peripheral driver for Normal Mode Timer configuration for speed measurement

Config_MTU0_user.c: User function to process interrupt for speed calculation

Config_MTU1

Peripheral driver for Normal Mode Timer configuration for phase measurement

Config_ICU

Peripheral driver to configure interrupt requests for external Hall interrupt

Config_ICU_user.c: User function for Hall interrupt service

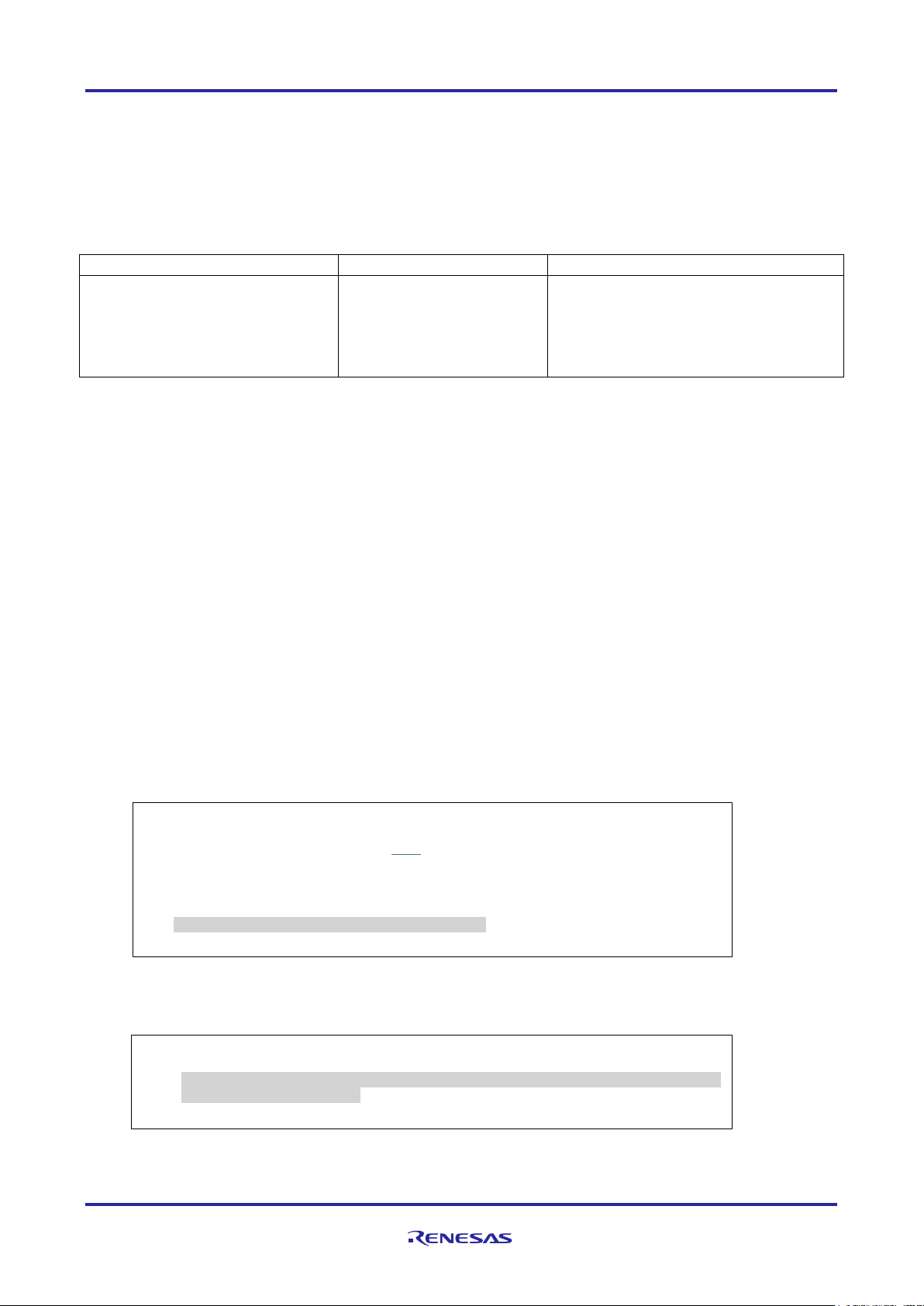

2.3.2 Smart Configurator File Configuration

Peripheral drivers were configured easily by using Smart Configurator tool for this project. In this tool, a

dedicated configurator for motor drive application related peripherals is used to configure multi-function timer

and 12-bit A/D converter.

Smart Configurator saves information such as the target MCU, peripheral, clock and pin functions setting for

the project in *.scfg file.

Refer to the file, RX13T_MRSSK2_SPM_ENCD_FOC_xxx_RVyyy.scfg, in the root folder to see the

peripheral settings of this project.

(xxx: CSP refers to CS+ version. E2S refers to e

Folder and file configuration of Smart Configurator generated output are shown below.

Config_PORT.h, Config_PORT.c: Driver and API for Port

Config_PORT_user.c: User function for Port

Config_S12AD0.h, Config_S12AD0.c: Driver and API for AD port

Config_S12AD0_user.c: User function for AD function of Board UI

Config_IWDT.h, Config_IWDT.c: Driver and API for Watchdog timer

2

studio version. yyy: revision version number)

Config_CMT0.h, Config_CMT0.c: Driver and API for Compare match timer

high-impedance state when over-current or output short-circuit occurs

Config_POE.h, Config_POE.c: Driver and API for Port Output Enable

Config_MTU0.h, Config_MTU0.c: Driver and API for free-run timer

Config_MTU1.h, Config_MTU1.c: Driver and API for phase counting mode

Config_MTU1_user.c: User function to start timer

Config_ICU.h, Config_ICU.c: Driver and API for IRQ external pin interrupt

(S12AD) for basic motor control.

Config_befoc.h, Config_befoc.c: Driver and API for Multi-function timer and AD

Config_befoc_user.c: User function for Multi-function timer and AD conversion

r_smc_entry.h: Includes header files of generated code of peripheral drivers added to

<various header files> project

conversion for Motor control

FIT: Firmware Integration Technology

2. r_config is created by e2studio project creation utilizing Smart Configurator tool. FIT is not used in this sample software

Figure 2-3 Smart Configurator Folder and File Configurations

R01AN5790EJ0100 Rev.1.00 Page 8 of 41

Mar.12.21

Page 9

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Type of motor

Type of sensor

Motor drive method

s: stepping motor

r: resolver

foc: field-oriented control

void R_Config_befoc_Create_UserInit(void)

/* End user code. Do not edit comment generated here */

/* Configure S12AD as single scan mode AD converter */

S12AD.ADSTRGR.WORD = _0900_MTR_AD_TRSA_TRG4AN;

Smart Configurator Motor component configuration name is named according to the following convention.

Configuration filename format: Config_<Type of motor><Type of sensor><Motor drive method>

The table below shows various motor types, sensor types and motor drive method for defining the Motor

configuration filename.

Table 2-4 Smart Configurator Motor configuration filename format

b: brushless DC Motor (BLDC)

i: induction motor

e: encoder

m: magnetic encoder

120: 120-degree conduction control

s: sensor-less

h: hall sensor

In this project, the type of motor used is BLDC motor and driven with encoder field-oriented control. Therefore,

the configuration name is Config_befoc.

Tips:

The application-specific Smart Configurator Motor component is presented in a simple and easy to

understand GUI that consolidates several peripherals to configure peripherals required for basic motor drive

in one interface. These peripherals include the multi-function timer pulse unit (MTU) and AD converter.

While benefiting from the ease of configuring Motor driver related peripherals in single interface, it is important

to note that the Motor component set-up the same registers that could been set-up by other components, (eg.

AD converter) and vice-versa. This will cause overwriting of registers that are commonly set-up by both the

Motor or AD converter component. This is expected and user must pay attention to these circumstances and

to take appropriate countermeasure. User can make use of the generated <Configuration_name>_user.c of

affected component to perform the countermeasure.

An example can be found in this project in the Config_befoc_user.c file. This file implements the device driver

for Motor peripheral module of Smart Configurator. In its user’s initialization API, A/D Channel select register

S12AD.ADANSA0 is updated to select AN007 as highlighted in the sample code below.

{

/* Start user code for user init. Do not edit comment generated here */

R_Config_befoc_StartTimerCount();

R_Config_befoc_StartAD();

R_Config_MTU1_Start();

R_Config_MTU0_Start();

S12AD.ADANSA0.WORD |= _0080_AD_ANx07_USED;

An overwriting of S12AD.ADANSA0 register occurred in Config_befoc.c file that caused AN007 to be

deselected. Below shows the code in Config_befoc.c where the overwriting of S12AD.ADANSA0 occurred.

S12AD.ADCSR.WORD = _0000_MTR_AD_SINGLE_SCAN_MODE;

S12AD.ADANSA0.WORD = _0001_MTR_AD_AN000_USED | _0004_MTR_AD_AN002_USED |

_0040_MTR_AD_AN006_USED;

R01AN5790EJ0100 Rev.1.00 Page 9 of 41

Mar.12.21

Page 10

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

/* Set channels and sampling time */

S12AD.ADSSTR7 = _0D_AD0_SAMPLING_STATE_7;

AN007 had been selected earlier in Config_S12AD0.c file in R_Config_S12AD0_Create API. Below shows

the code where AN007 was originally selected when A/D converter peripheral driver was set-up.

S12AD.ADANSA0.WORD = _0080_AD_ANx07_USED;

R01AN5790EJ0100 Rev.1.00 Page 10 of 41

Mar.12.21

Page 11

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

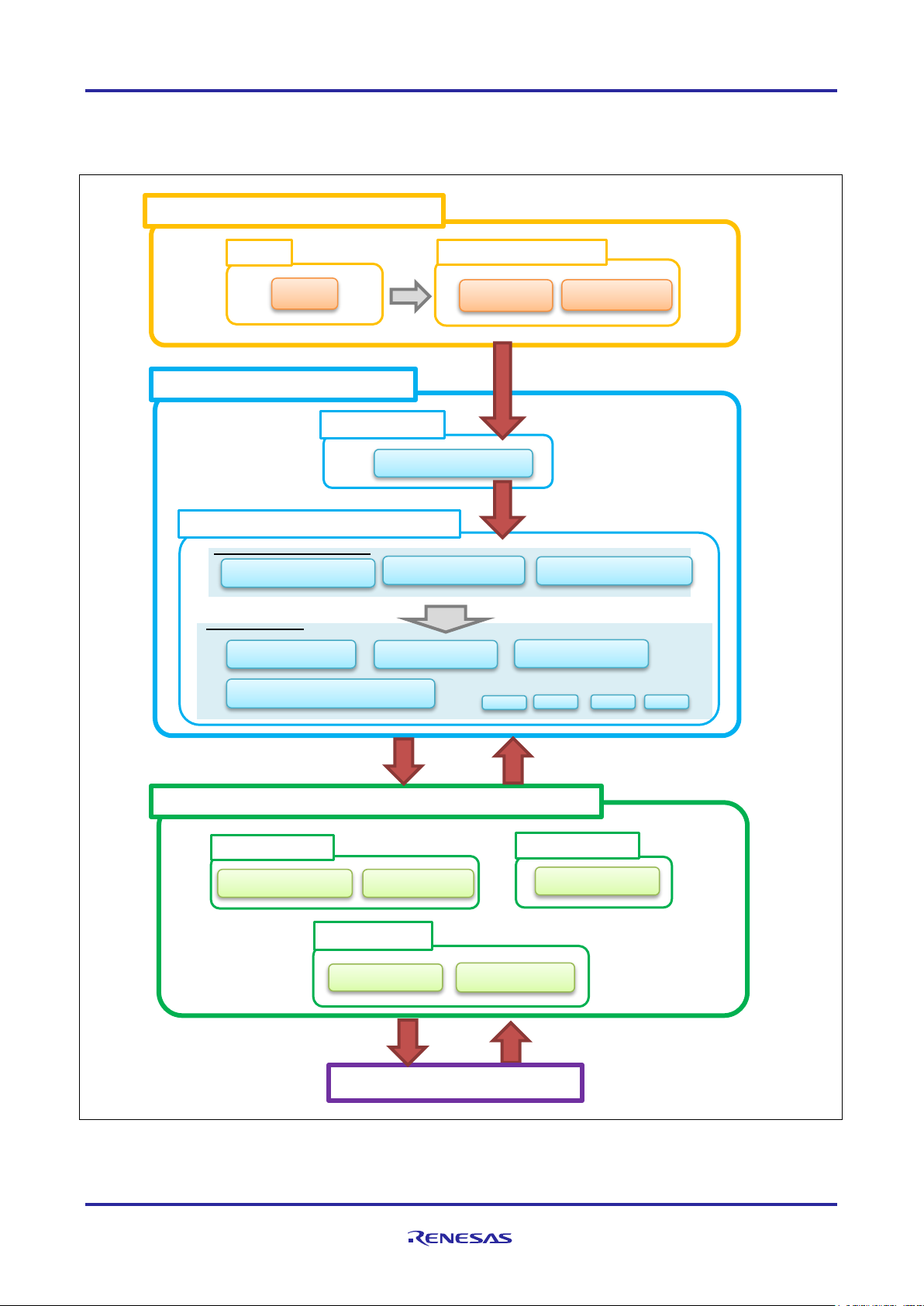

Application Layer (User Application)

main.c

User Interface Module

Main

r_mtr_ics.c

r_mtr_board.c

Middle Layer (Motor Control Process)

r mtr driver access.c

Interface Module

Control Module (FOC, Feedback Loop Control)

r_mtr_interrupt_carrier.c

r_mtr_foc_control_encd_position.c

r_mtr_foc_current.c

r_mtr_interrupt_1ms.c

r_mtr_interrupt_sensor.c

r_mtr_foc_speed.c

r_mtr_foc_position.c

Other Control Modules

Device Layer (MCU Register Access, Inverter Driver, Sensor Driver)

Inverter Module

r_mtr_ctrl_mrssk.c

r_mtr_ctrl_encoder.c

r_mtr_ctrl_hall.c

MCU Module

r_mtr_interrupt.c

r_mtr_ctrl_rx13t.c

H/W Layer (MCU Inverter)

Function Call

Function Call

Set User Command to Buffer

Set Control Gain & Command

Set PWM duty

Get Voltage, Current & Angle/Speed

Interrupt Process Modules

Control Modules

Get A/D Converter Data & Sensor Signal

Output PWM Signal

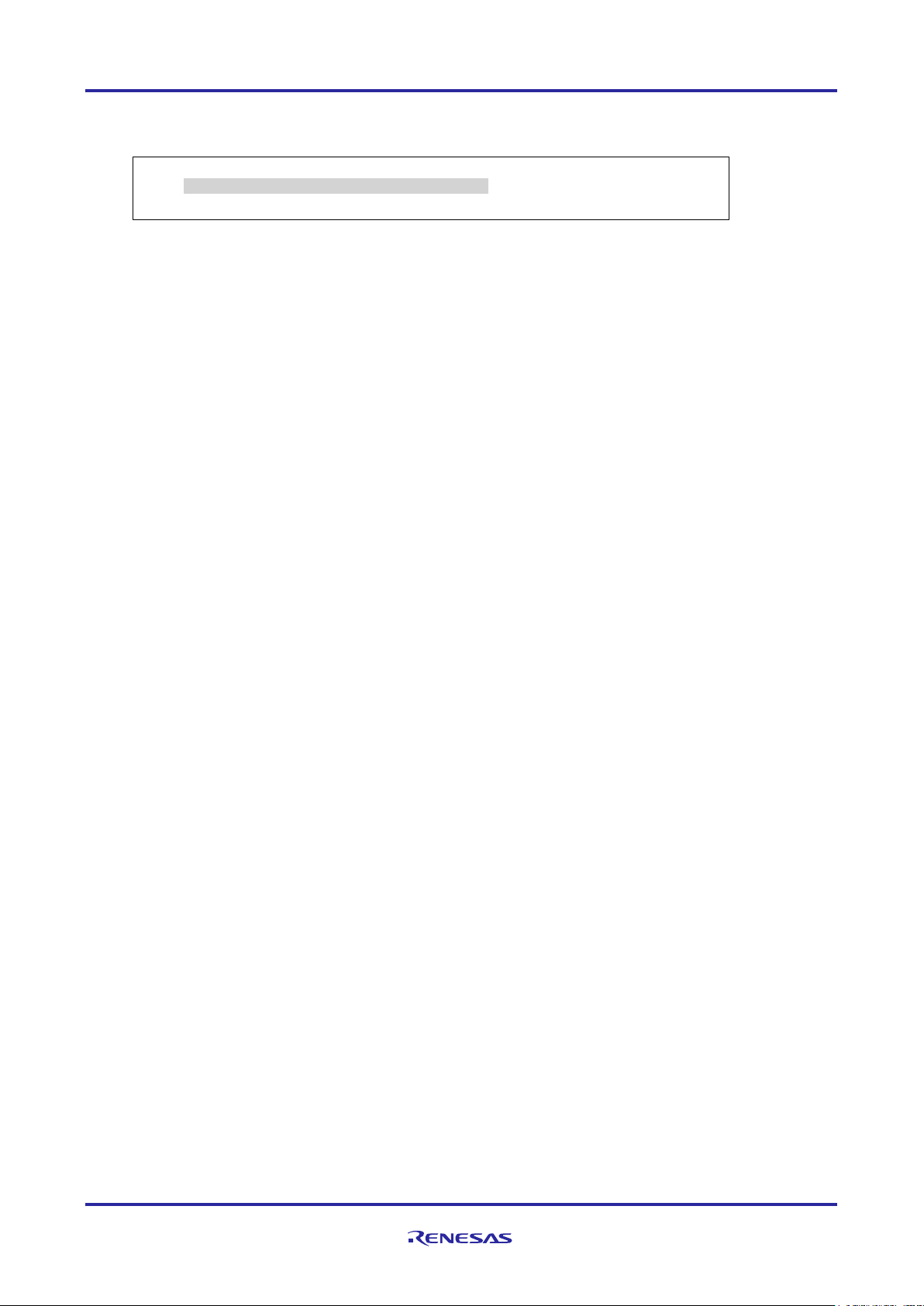

2.3.3 Module configuration

Module configuration of the sample programs is described below.

Figure 2-4 Module Configuration

R01AN5790EJ0100 Rev.1.00 Page 11 of 41

Mar.12.21

Page 12

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Item

Content

Control method

Vector control

from Analyzer

Position detection of rotor

Incremental encoder (A-B Phase), Hall sensor (UVW Phase)

Input voltage

DC 24 [V]

Main clock frequency

32 [MHz]

Carrier frequency (PWM)

20 [kHz] (carrier cycle: 50 [µs])

Dead time

2 [μs]

(Current loop)

Control cycle

1 [ms]

-180° to 180°

ICS UI

Position command generation: Position profile of

Accuracy of position

0.3° (Encoder pulse: 300[ppr] 4 for multiplying 1200 [cpr])

Dead band of position *

Encoder count ±1 [cpr] (±0.3°)

Position control system: 10 Hz

Optimization setting for

Optimization level

2 (-optimize = 2) (default)

Optimization method

Size priority (default)

ROM/RAM size

ROM: 23.1 KB

port is detected), the PWM output ports are set to high impedance state.

2.4 Software specifications

Table 2-5 shows basic software specification of this system. For details of the vector control, refer to the

application note ‘Vector control of permanent magnet synchronous motor with encoder: algorithm’.

Table 2-5 Basic Specifications of Vector Control PMSM with Encoder Software

Motor control start/stop Determined depending on the level of SW1 (“Low”: control start “High”: stop) or input

magnetic pole

Control cycle

(Speed and Position loop)

Management of position

command value

Management of speed

command value

Natural frequency of each

control system

compiler

100 [μs] (twice the carrier cycle)

Board UI Position command generation: Direct input of VR1

(input range)

trapezoidal curve for speed command value

(input range)

-32768° to 32767°

(Max speed)

CW / CCW: 2000 [rpm]

CW: 0 [rpm] to 2000 [rpm]

CCW: 0 [rpm] to 2000 [rpm]

Current control system: 300 Hz

Speed control system: 30 Hz

RAM: 5.6 KB

Processing stop for protection Motor control signal outputs (six outputs) will be disabled, under any of the following

conditions.

1.

Current of each phase exceeds 3.82 [A] (monitored every 100 [μs])

Inverter bus voltage exceeds 28 [V] (monitored every 100 [μs])

2.

Inverter bus voltage is less than 14 [V] (monitored every 100 [μs])

3.

4. Rotation speed exceeds 3000 [rpm] (monitored every 100 [μs])

When an external over current signal is detected (when a falling edge of the POE10#

Note: * Dead zone is provided to prevent hunting in positioning.

R01AN5790EJ0100 Rev.1.00 Page 12 of 41

Mar.12.21

Page 13

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Item

Conversion ratio

(Command value: A/D conversion value)

Channel

Rotation position

command value

CW

0° to 180°: 07FFH to 0000H

AN007

CCW

0° to -180°: 0800H to 0FFFH

Rotation speed

CW

0 [rpm] to 2000[rpm]: 07FFH to 0000H

CCW

0 [rpm] to 2000[rpm]: 0800H to 0FFFH

Item

Conversion ratio

(Inverter bus voltage: A/D conversion value)

Channel

Inverter bus voltage

0 [V] to 111 [V]: 0000H to 0FFFH

AN006

Item

Conversion ratio

(U, W phase current: A/D conversion value)

Channel

U, W phase current

-12.5 [A] to 12.5 [A]: 0000H to 0FFFH *

Iu: AN000

3. Descriptions of the Control Program

The target sample programs of this application note are explained here.

3.1 Contents of Control

3.1.1 Motor Start/Stop

The start and stop of the motor are controlled by input from Analyzer function of ‘Renesas Motor Workbench’

or SW1 switch of inverter board.

A general-purpose port is assigned to SW1. The port is read within the main loop. When the port is at a ‘Low’

level, the software determines that the motor should be started. Conversely, when the level is switched to

‘High’, the program determines that the motor should be stopped.

3.1.2 A/D Converter

(1) Motor Rotation Position and Speed Command Value

The motor rotation position and speed command value can be set by Analyzer input or A/D conversion of

the VR1 output value (analog value). The A/D converted VR1 value is used as rotation speed command

value, as shown below.

Table 3-1 Conversion Ratio of the Rotation Position and Speed Command Value

command value

(2) Inverter Bus Voltage

Inverter bus voltage is measured as given in Table 3-2.

It is used for modulation factor calculation, under-voltage detection and over-voltage detection. (When an

abnormality is detected, PWM is stopped.)

Table 3-2 Inverter Bus Voltage Conversion Ratio

(3) U, W Phase Current

The U and W phase currents are measured as shown in Table 3-3 and used for vector control.

Table 3-3 Conversion Ratio of U and W Phase Current

Note: * For more details of A/D conversion characteristics, refer to RX13T Group User’s Manual: Hardware.

.

Iw: AN002

R01AN5790EJ0100 Rev.1.00 Page 13 of 41

Mar.12.21

Page 14

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

u1_ref_pos_status

u1_ref_pos_mode

Time[s]

Time[s]

Speed

Position

Constant Speed

com_u2_max_speed_rpm

com_u2_pos_interval_time

MTR_CTRL_TRIANGLE

MTR_CTRL_TRAPEZOIDAL

MTR_CTRL_TRIANGLE : f4_accel_max_speed * f4_accel_time >= f4_pos_dt_rad

MTR_CTRL_TRAPEZOIDAL : f4_accel_max_speed * f4_accel_time < f4_pos_dt_rad

com_s2_ref_position_deg

MTR_POSITION_STEADY_STATE

MTR_POSITION_TRANSITION_STATEE

MTR_POSITION_STEADY_STATE

MTR_POSITION_TRANSITION_STATE

com_s2_ref_position_deg

Reference

Position

3.1.3 Position Profile Generation (Position Profile of Trapezoidal Curve for Speed Command Value)

In vector control software for PMSM with encoder, the position profile generation is used to create command

value (input position value). The implementation of command value is each control cycle is used as method of

managing acceleration and the maximum speed value with respect to target position value.

E

Figure 3-1 Position Profile Generation

Enter the following variables from the Analyzer to create a command value.

• Position reference [degree] (com_s2_ref_position_deg)

• Acceleration time (com_f4_accel_time)

• Maximum speed command value (com_u2_max_speed_rpm)

• Position stabilization wait time (com_u2_pos_interval_time)

R01AN5790EJ0100 Rev.1.00 Page 14 of 41

Mar.12.21

Page 15

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

2π/Pulses per Rotation

Timer Counter

Capture Capture

Counter Difference

Phase-A

Encoder Signal

Phase

-B

Encoder Signal

2π/Pulses per Rotation

CaptureCaptureCaptureCaptureCapture

MTU0.TCNT

3.1.4 Speed Measurement

In order to obtain better real-time performance and higher speed resolution at low speed, this system use

encoder signal edge interval to calculate speed, the speed extrapolation is used in PI control calculation. In

addition, taking the difference between rise time and fall time and the accuracy of quadrature of encoder

signal into consideration, the speed is calculated with time elapsed and angle changed in one period of

encoder Phase-A or Phase-B signals.

(1) Speed Calculation

Motor Rotation Speed[rad/s] =

Figure 3-2 Speed Calculation using Encoder

/

R01AN5790EJ0100 Rev.1.00 Page 15 of 41

Mar.12.21

Page 16

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

U V

W

ωt

ωt

ω

t

ωt

Modulation wave: command voltage

Carrier wave (triangular wave): PWM timer count

U phase switching

waveform

V phase switching

waveform

Voltage between U – V

Lines: (U phase waveform)

ー(V phase waveform

)

3.1.5 Modulation

The target software of this application note uses pulse width modulation (hereinafter called PWM) to generate

the input voltage to the motor. And the PWM waveform is generated by the triangular wave comparison

method.

(1) Triangular Wave Comparison Method

The triangular wave comparison method is used to output the voltage command value. By this method, the

pulse width of the output voltage can be determined by comparing the carrier waveform (triangular wave)

and voltage command value waveform. The voltage command value of the pseudo sinusoidal wave can

be output by turning the switch on or off when the voltage command value is larger or smaller than the

carrier wave respectively.

Figure 3-3 Conceptual Diagram of the Triangular Wave Comparison Method

R01AN5790EJ0100 Rev.1.00 Page 16 of 41

Mar.12.21

Page 17

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Average

voltage

t

V

T

ON

T

OFF

T

ON

+ T

OFF

T

ON

Duty =

× 100 [%]

E

V

m =

m: Modulation factor V: Voltage command value E: Inverter bus voltage

Here, as shown in the Figure 3-4, ratio of the output voltage pulse to the carrier wave is called duty.

Figure 3-4 Definition of Duty

Modulation factor m is defined as follows.

The voltage command can be generated by setting PWM compare register properly to obtain the desired

duty.

R01AN5790EJ0100 Rev.1.00 Page 17 of 41

Mar.12.21

Page 18

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

SYSTEM MODE

INACTIVE

ERROR

POWER ON/

RESET

[RESET EVENT]

[ACTIVE EVENT]

[INACTIVE EVENT]

[ERROR EVENT]

RUN MODE

INIT

BOOT

Control Config

Current

Speed

Position

Torque

Voltage

DRIVE

ACTIVE

[MTR_ID_ZERO_CONST

== st_g.u1_flag_id_ref

]

[g_f4_offset_calc_time

== st_g.u2_cnt_adjust]

[ERROR EVENT]

[RESET EVENT]

EVENT

INACTIVE

ACTIVE

ERROR

RESET

MODE

INACTIVE ACTIVE ERROR

INACTIVE

INACTIVE INACTIVE

ACTIVE

ERROR ERROR

ERROR

ERROR

ERROR

INACTIVE

ACTIVE

ERROR

[MTR_LOOP_POSITION ==

com_u1_ctrl_loop_mode

]

[MTR_LOOP_SPEED ==

com_u1_ctrl_loop_mode

]

Control Config

Current

Speed

Position

Torque

Voltage

Control Config

Current

Speed

Position

Torque

Voltage

EVENT name

Occurrence factor

INACTIVE

by user operation

ACTIVE

by user operation

ERROR

when the system detects an error

RESET

by user operation

3.1.6 State Transition

Figure 3-5 is a state transition diagram of the vector control software. In the target software of this application

note, the software state is managed by ‘SYSTEM MODE’ and ‘RUN MODE’. And ‘Control Config’ shows the

active control system in the software.

Figure 3-5 State Transition Diagram of Vector Control PMSM with Encoder Software

(1) SYSTEM MODE

‘SYSTEM MODE’ indicates the operating states of the system. The state transits on occurrence of each

event (EVENT). ‘SYSTEM MODE’ has 3 states that are motor drive stop (INACTIVE), motor drive

(ACTIVE), and abnormal condition (ERROR).

(2) RUN MODE

‘RUN MODE’ indicates the condition of the motor control. ‘RUN MODE’ transits sequentially as shown in

Figure 3-5 when ‘SYSTEM MODE’ is ‘ACTIVE’.

(3) EVENT

When ‘EVENT’ occurs in each ‘SYSTEM MODE’, ‘SYSTEM MODE’ changes as shown the table in Figure

3-5, according to that ‘EVENT’.

Table 3-4 List of EVENT

R01AN5790EJ0100 Rev.1.00 Page 18 of 41

Mar.12.21

Page 19

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

MTR_ID_CONST

(

1)

I

d

reference

[

A]

I

q

reference

[

A]

Speed reference

[rpm]

com

_

f4

_ref

_

id

MTR_

ID

_ZERO

_CONST

(

3)

I

d

=0

control

MTR_

MODE

_BOOT

RUN MODE

I

d

reference status

speed PI output

0

0

0

I

q

reference status

Speed reference status

MTR_

MODE

_INIT

MTR_

ID

_UP

(

0)

MTR_

ID

_ZERO

_CONST

(

3)

MTR_

I

Q_

ZERO_

CONST

(0

)

MTR

_

SPEED_

ZERO_

CONST

(0

)

MTR_

IQ

_SPEED

_PI

_

OUTPUT

(

1

)

MTR

_POSITION

_CONTROL

_

OUTPUT

(

1

)

MTR

_

MODE_

DRIVE

MTR

_ID

_CONST

(

1)

MTR_

ID

_UP

(

0)

MTR

_POSITION

_

CONST

(

0

)

Position reference status

MTR

_POSITION

_

TRAPEZOID

(

1

)

Position reference

[

degree

]

0

com

_

s2

_ref_position_deg

[

s

]

[s

]

[

s]

[

s]

MTR_ID_CO NST

(1)

Id reference[A]

Iq reference[A]

Speed reference

[rpm]

com_f4_ref _id

MTR_ID_ZERO_CONS T

(3)

z

Id=0 control

MTR_MODE_B OOT

RUN MO DE

I

d

reference status

speed PI output

0

0

0

Iq reference status

Speed reference status

MTR_MODE_IN IT

MTR_ID_UP

(0)

MTR_ID_ZERO_CONS T

(3)

MTR_IQ_ZERO_CONS T

(0)

MTR_SP EED_ZERO_CO NST

(0)

MTR_IQ_SP EED_PI_O UTPU T

(1)

MTR_SP EED_CHANGE

(2)

MTR_MODE_D RIVE

MTR_ID_CO NST

(1)

MTR_ID_UP

(0)

[s]

[s]

[s]

com_s2_ref _speed_ rpm

3.1.7 Startup Method

Figure 3-6 shows the software implementation of d-axis and encoder alignment method. The d-axis alignment

method used as startup control of position control method, in initialization mode (MTR_MODE_INIT) and Boot

mode (MTR_MODE_BOOT). In drive mode (MTR_MODE_DRIVE) vector control is implemented for PMSM

with Encoder. Each reference value setting of d-axis current, q-axis current and speed is managed by

respective status.

Figure 3-6 Startup Position Control of Vector Control PMSM with Encoder Software

For details of the position control of a vector controlled PMSM using encoder, refer to the application note

‘Vector control of permanent magnet synchronous motor with encoder: algorithm’.

Figure 3-7 Startup Speed Control of Vector Control PMSM with Encoder Software

R01AN5790EJ0100 Rev.1.00 Page 19 of 41

Mar.12.21

Page 20

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Over-current error

Over-current limit value [A]

3.82

Monitoring cycle [µs]

100

Over-voltage error

Over-voltage limit value [V]

28

Monitoring cycle [µs]

100

Under-voltage error

Under-voltage limit value [V]

14

Monitoring cycle [µs]

100

Over-speed error

Speed limit value [rpm]

3000

Monitoring cycle [µs]

100

3.1.8 System Protection Function

This control program has the following error status and executes emergency stop functions in case of

occurrence of respective errors. Table 3-5 shows each setting value for the system protection function.

• Over-current error

The over current detection is performed by both hardware detection method as well as software detection

method. In response to over-current detection an emergency stop signal is generated from the hardware

(hardware detection). When the emergency stop signal is generated, the PWM output ports are set to high

impedance state.

In addition, U, V, and W phase currents are monitored in over current monitoring cycle. When an over

current is detected, the CPU executes emergency stop (software detection). The over current limit value is

calculated from the nominal current of the motor [MP_NOMINAL_CURRENT_RMS].

• Over-voltage error

The inverter bus voltage is monitored in over-voltage monitoring cycle. When an over-voltage is detected,

the CPU performs emergency stop. Here, the over-voltage limit value is set in consideration of the error of

resistance value of the detect circuit.

• Under-voltage error

The inverter bus voltage is monitored in under-voltage monitoring cycle. The CPU performs emergency

stop when under-voltage is detected. Here, the low voltage limit value is set in consideration of the error of

resistance value of the detect circuit.

• Over-speed error

The rotation speed is monitored in rotation speed monitoring cycle. The CPU performs emergency stop

when the speed is over the limit value.

Table 3-5 Setting Values of the System Protection Function

R01AN5790EJ0100 Rev.1.00 Page 20 of 41

Mar.12.21

Page 21

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Decoupl ing

Control

PWM

Current

PI

Speed

PI

dq

UVW

dq

UVW

Encoder

ω*

i

d

*

ω

i

q

*

v

d

*

θ

i

d

i

q

i

u

i

w

θ

v

u

v

v

v

w

+

-

+

+

Positi on P

+ Speed F F

θ*

θ

i

q

i

d

vd**

v

q

**

Voltage

Limit

iq**

v

q

* vq*

M

Voltage

err or

Compe n

-sati on

v

u

v

v

v

w

Hal l

Encod er Interrup t

Carrier Interrupt

Switch Position & Speed

Calculation Mode

ω

θ

Switch

Positi on/Speed

Loop mode

Speed

Obse rver

Positi on

Profil ing

θ_

refe ren ce

IPD Con troler

+ Positi on P + Speed F F

Switch

Positi on/Speed L oop Control ler

Carrier I nterru pt Process

1ms Interrup t Process

Encoder Interrupt Process

Encod er

A/B

Phase

sign al

ω*

ω*

iq*id*

ω

_

refe ren ce

Hall I nte rru pt

Process

Rotor A ngle

Detection

Switch Angle

Adj ust mod e

File name

Function name

Process overview

• Current PI control

Speed PI control

• Disable Hall interrupt

Speed calculation

3.2 Function Specifications of Vector Control using Encoder Software

The control process of the target software of this application note is mainly consisted of 100[µs] period

interrupt (carrier interrupt) and 1[ms] period interrupt. As following Figure 3-8, the control process in the red

broken line part is executed every 100[µs] period, and the control process in the blue broken line part is

executed every 1[ms] period.

Figure 3-8 System Block of Vector Control with Encoder

This chapter shows the specification of 4 interrupt functions and functions executed in each interrupt cycle. In

the following tables, only essential functions of the vector control are listed. Regarding the specification of

functions not listed in following tables, refer to source codes.

Table 3-6 List of Control Functions ‘mtr_interrupt.c’

r_mtr_interrupt_carrier.c mtr_foc_carrier_interrupt

Input: (mtr_foc_control_t *) st_foc / Structure pointer for

vector control Output: None

r_mtr_interrupt_1ms.c mtr_foc_1ms_interrupt

Input: (mtr_foc_control_t *) st_foc / Structure pointer for

vector control

Output: None

r_mtr_interrupt_sensor.c mtr_angle_adj_hall_interrupt

Input: (mtr_foc_control_t *) st_foc / Structure pointer for

vector control

Output: None

mtr_encd_pos_speed_calc_interrupt

Input: (mtr_foc_control_t *) st_foc / FOC motor structure

Output: None

R01AN5790EJ0100 Rev.1.00 Page 21 of 41

Mar.12.21

Calling every 100 [μs]

• Current and voltage monitoring

• Error detection

• Current offset detection

• Vector calculation

Calling every 1 [ms]

• Startup control

• d-axis/q-axis current and speed

reference set

•

Called when the Hall phase signals

(Phase-U/V/W)

• Get Hall signal

• Rotor phase calculation

• Hall error process

Called when the encoder phase counts

(Phase-A and B)

• Rotor phase calculation

•

Page 22

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

File name

Function name

Process overview

Table 3-7 List of Functions for 100μs interrupt [1/2]

r_mtr_ctrl_mrssk.c mtr_get_current_iuiw

Input: (float*) f4_iu_ad / U phase current A/D conversion value

(float*) f4_iw_ad / W phase current A/D conversion value

(uint8_t) u1_id / Motor ID

Output: None

mtr_get_vdc

Input: (uint8_t) u1_id / Motor ID

Output: (float) f4_temp_vdc / Vdc value

r_mtr_foc_control_

encd_position.c

r_mtr_foc_current.c mtr_current_pi_control

r_mtr_transform.c mtr_transform_uvw_dq_abs

mtr_error_check

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

Output: None

mtr_current_offset_adjustment

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

Output: None

mtr_calib_current_offset

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

Output: None

mtr_encd_pos_speed_calc

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

Output: None

mtr_foc_voltage_limit

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

Output: None

mtr_angle_speed

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

Output: None

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

Output: None

mtr_decoupling_control

Input: (mtr_foc_control_t *) st_foc / Structure pointer for vector control

(float)f4_speed_rad / speed

(mtr_parameter_t*) mtr_para / motor parameter structure

Output: None

Input: (const mtr_rotor_angle_t *) p_angle /

Structure pointer for phase management

(const float*)f4_uvw / UVV phase pointer

(float*)f4_dq / dq-axis pointer

Output: None

mtr_transform_dq_uvw_abs

Input: (const mtr_rotor_angle_t *) p_angle /

Structure pointer for phase management

(const float*)f4_dq / dq-axis pointer

(float*)f4_uvw / UVW phase pointer

Output: None

Obtaining the UVW phase current

Obtaining the Vdc

Error monitoring

UVW phase current offset

adjustment

UVW phase current offset

calculation

Position and speed calculation for

encoder pulse

Voltage command value limit

Rotor phase and speed related

process (Switching calculation

method)

Current PI

Decoupling control

Coordinate transform UVW to dq

Coordinate transform dq to UVW

R01AN5790EJ0100 Rev.1.00 Page 22 of 41

Mar.12.21

Page 23

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

File name

Function name

Process overview

Table 3-7 List of Functions for 100μs Interrupt [2/2]

r_mtr_volt_err_comp.obj mtr_volt_err_comp_main

Input: (mtr_volt_comp_t *) st_volt_comp /

Voltage error compensation structure

(float*) p_f4_v_array / Three phase voltage compensation

value array pointer

(float*) p_f4_i_array / Three phase current compensation value

array pointer

(float) f4_vdc / Vdc value

Output: None

r_mtr_ctrl_rx13t.c mtr_inv_set_uvw

Input: (float) f4_modu / U phase modulation factor

(float) f4_modv / V phase modulation factor

(float) f4_modw / W phase modulation factor

(uint8_t) u1_id / Motor ID

Output: None

Voltage error compensation

PWM output setting

R01AN5790EJ0100 Rev.1.00 Page 23 of 41

Mar.12.21

Page 24

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Table 3-8 List of Functions for 1ms Interrupt

File name Function name Process overview

r_mtr_ctrl_hall.c mtr_angle_adj_hall_init

Input: (mtr_hall_t *) st_hc / Hall sensor structure

Output: (float) f4_hall_angle_rad / angle of signal detection for Hall

sensor

r_mtr_ctrl_encoder.c mtr_set_encd_tcnt

Input: (uint8_t) u1_id / Motor ID

(uint16_t) u2_cnt_value / counter value

Output: None

mtr_encd_cnt_reset

Input: (uint8_t) u1_id / Motor ID

(uint16_t) u2_cnt_value / counter value

Output: None

r_mtr_ctrl_rx13t.c mtr_irq_interrupt_enable

Input: (uint8_t) u1_id / Motor ID

Output: None

r_mtr_foc_control_encd_

position.c

Config_MTU0.c mtr_speed_calc_timer_start

mtr_hall_error

Input: (mtr_foc_control_t *) st_foc / FOC motor structure

(float) f4_hall_angle_rad / angle of Hall

Output: None

mtr_set_pos_ref

Input: (mtr_foc_control_t *) st_foc / FOC motor structure

Output: (float32) f4_ref_pos_rad_calc / position command value

mtr_set_speed_ref

Input: (mtr_foc_control_t *) st_foc / FOC motor structure

Output: (float32) f4_speed_ref_rad _calc / speed command value

mtr_set_iq_ref

Input: (mtr_foc_control_t *) st_foc / FOC motor structure

Output: (float32) f4_iq_ref_calc / q-axis current command value

mtr_set_id_ref

Input: (mtr_foc_control_t *) st_foc / FOC motor structure

Output: (float32) f4_id_ref_calc / d-axis current command value

Input: (uint8_t) u1_id / Motor ID

Output: None

Initialize rotor angle detection for

Hall sensor

Set for encoder count resister

Initialize encoder timer counter

value

Enable Hall interrupt

Hall sensor error process

Setting the command value for

position control

Setting the command value for

speed control

Setting the q axis current command

value

Setting the d axis current command

value

Start for encoder timer

R01AN5790EJ0100 Rev.1.00 Page 24 of 41

Mar.12.21

Page 25

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

File name

Macro name

Definition value

Remarks

MP_POLE_PAIRS

7

Number of pole pairs

MP_MAGNETIC_FLUX

0.006198f

Flux [Wb]

MP_RESISTANCE

0.453f

Resistance [Ω]

MP_D_INDUCTANCE

0.0009447f

d-axis Inductance [H]

MP_Q_INDUCTANCE

0.0009447f

q-axis Inductance [H]

MP_ROTOR_INERTIA

0.00000962f

Rotor inertia [kgm^2]

MP_NOMINAL_CURRENT_RMS

1.8f

Nominal torque [Arms]

File name

Macro name

Definition value

Remarks

CP_CURRENT_ZETA

1.0f

Damping ratio of the current loop

CP_SPEED_ZETA

1.0f

Damping ratio of the speed loop

[Hz]

CP_MIN_SPEED_RPM

0

Minimum speed (mechanical) [rpm]

CP_SPEED_LIMIT_RPM

3000

Limit speed (mechanical) [rpm]

File name

Macro name

Definition value

Remarks

IP_DEADTIME

2.0f

Deadtime [µs]

IP_CURRENT_RANGE

25.0f

current sensing range

IP_VDC_RANGE

111.0f

voltage sensing range

IP_INPUT_V

24.0f

input DC voltage [V]

IP_CURRENT_LIMIT

10.0f

Current limit[A] *

IP_OVERVOLTAGE_LIMIT

28.0f

Over voltage limit [V]

IP_UNDERVOLTAGE_LIMIT

14.0f

Under voltage limit [V]

3.3 Macro Definitions of Vector Control Software Using Encoder

Lists of macro definitions used in this control program are given below.

Table 3-9 List of Macro Definitions ‘r_mtr_motor_parameter.h’

r_mtr_motor_parameter.h

Table 3-10 List of Macro Definitions ‘r_mtr_control_parameter.h’

r_mtr_control_parameter.h CP_CURRENT_OMEGA 300.0f Natural frequency of the current loop [Hz]

CP_SPEED_OMEGA 30.0f Natural frequency of the speed loop [Hz]

CP_POS_OMEGA 10.0f Natural frequency of the position loop [Hz]

CP_SOB_OMEGA 200.0f Natural frequency of the speed observer

CP_SOB_ZETA 1.0f Damping ratio of the speed observer

CP_MAX_SPEED_RPM 2000 Maximum speed (mechanical) [rpm]

CP_OL_ID_REF 1.5f d-axis current command value [A]

Table 3-11 List of Macro Definitions ‘r_mtr_inverter_parameter.h’

r_mtr_inverter_parameter.h

Note: * This value is calculated from the rated power of the shunt resistance.

R01AN5790EJ0100 Rev.1.00 Page 25 of 41

Mar.12.21

Page 26

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

File name

Macro name

Definition value

Remarks

Table 3-12 List of Macro Definitions ‘r_mtr_config.h’

r_mtr_config.h RX13T_MRSSK — MCU select macro

IP_MRSSK — Inverter select macro

MP_FH6S20EX81 — Motor select macro

CP_FH6S20EX81 —

CONFIG_DEFAULT_UI ICS_UI Select default UI

ICS_UI: Use the Analyzer for RMW

BOARD_UI: Use board interface

USE_VOLT_ERR_COMP 1 Voltage error compensation

0: Disable

1: Enable

ANGLE_ADJUST_MODE MTR_ANGLE_ADJ_EXCIT Select angle adjust mode

MTR_ANGLE_ADJ_EXCIT:

MTR_ANGLE_ADJ_HALL: Hall mode

POS_CTRL_MODE MTR_CTRL_IPD Select position control mode

MTR_CTRL_PID: PID controller

MTR_CTRL_IPD: IPD controller

LOOP_MODE MTR_LOOP_POSITION Select control loop mode

MTR_LOOP_SPEED: speed loop

MTR_LOOP_POSITION: position loop

GAIN_MODE MTR_GAIN_DESIGN_MODE Gain mode

MTR_GAIN_DESIGN_MODE:

MTR_GAIN_DIRECT_MODE:

MOD_METHOD MOD_METHOD_SVPWM modulation method

MOD_METHOD_SPWM:

MOD_METHOD_SVPWM:

Forced excitation mode

PI gain design mode

PI gain direct input mode

Sinusoidal PWM

Space Vector PWM

R01AN5790EJ0100 Rev.1.00 Page 26 of 41

Mar.12.21

Page 27

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

BSP main process

Initialization of

peripheral fun ctions

Init ializat ion of variables use d

in the main proces s

Init ializat ion of sequenc e

proc ess

Initialization of Ana lyzer

Wat chdog tim er clea r

UI ?

[Board]

[Analyzer]

Power su pply voltage

stabilization wait

Rotation

Position comma nd

value se tting

Determine r otat ion position.

Res et pro ce ss

LED cont rol

Chan ge m otor operation m ode

according to SW status.

LED cont rol

Inp ut p arameters .

Chan ge m otor operation m ode

base d on the v alue of

com_u1_m ode _system.

Application main process

3.4 Control Flowcharts

3.4.1 Main Process

Figure 3-9 Main Process Flowchart

R01AN5790EJ0100 Rev.1.00 Page 27 of 41

Mar.12.21

Page 28

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Carrier synchronous interrupt

End

(UVW)- (d-q) Transform

PWM register setting

Current PI control

Get U phase and W phase current values

Get inverter bus voltage value.

Angle and speed related Process

Decoupling control

PWM duty calculation

Voltage limit

U phase and W phase current

offset adjustment

Error check

SYSTEM MODE

offset adjustment

[ACTIVE]

[INACTIVE]

[confirmed]

[unconfirmed]

Current offset detection

Calculate V-phase current

Voltage error compensation

(d-q)-(UVW) Transform

Angle and speed calculation

Encoder counter processing

Phase-lead compensation

3.4.2 Carrier Synchronous Interrupt Handling (100 [µs])

Figure 3-10 Carrier Synchronous Interrupt Handling (100 [µs])

R01AN5790EJ0100 Rev.1.00 Page 28 of 41

Mar.12.21

Page 29

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

1 [ms] interrupt

SYSTEM MODE

End

[INACTIVE]

[ACTIVE]

RUN MODE

Position reference setting

Current offset adjustment

[INIT MODE]

[BOOT MOD E]

[DRI VE MO DE]

[Unconfirmed]

[Confirmed]

d-axis current const setting

Run mode transition to DRIVE MODE

[Unconfirmed]

[Confirmed]

Speed reference setting

q-axis current reference setting

d-Axis cur rent reference setting

Position reference setting

Speed reference setting

q-axis current reference setting

d-Axis cur rent reference setting

Decide direction

To BOOT MODE

To D RIVE MODE

Magnetic pole position

detection mode

Detection of Hall initial angle

Error handling of Hall detection angle

Initialize encoder counter

Encoder timer start

Enable Hall interrupt

[Initial position

detection by Hall]

[Forced excitation]

3.4.3 1 [ms] Interrupt Handling

Figure 3-11 1 [ms] Interrupt Handling

R01AN5790EJ0100 Rev.1.00 Page 29 of 41

Mar.12.21

Page 30

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Over current detection interrupt

End

Motor stop process

Clearing high impedance status

3.4.4 Over Current Detection Interrupt Handling

The over current detection interrupt occurs when POE10# pin detects falling-edge. Therefore, when this

interrupt process is executed, PWM output pins are already in high-impedance state and the output to the

motor is stopped.

Figure 3-12 Over Current Detection Interrupt Handling

R01AN5790EJ0100 Rev.1.00 Page 30 of 41

Mar.12.21

Page 31

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Encoder count capture interrupt

End

Encoder alignment finished

Encoder phase counter cumulation

Encoder position calculation

Encoder speed calculation

[

YES

]

[

NO

]

Encoder edge interval cumulation

Zero speed detection

Encoder edge interval moving average

3.4.5 Encoder Count Capture Interrupt Handling

Figure 3-13 Encoder Count Capture Interrupt Handling

R01AN5790EJ0100 Rev.1.00 Page 31 of 41

Mar.12.21

Page 32

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Hall signal interrupt

End

RUN MODE

[DRIVE MODE]

[Other than

DRIVE MODE]

Detection of Hall signal

Disable Hall interrupt

Error handling of Hall detection angle

Calculate of rotor angle

3.4.6 Hall Signal Interrupt Handling

Figure 3-14 Hall Signal Interrupt Handling

R01AN5790EJ0100 Rev.1.00 Page 32 of 41

Mar.12.21

Page 33

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Scope Window

Control Window

4. Motor Control Development Support Tool ‘Renesas Motor Workbench’

4.1 Overview

‘Renesas Motor Workbench’ is support tool for development of motor control system. ‘Renesas Motor

Workbench’ can be used with target software of this application note to analyze the control performance. The

user interfaces of ‘Renesas Motor Workbench’ provide functions like rotating/stop command, setting rotation

speed reference, etc. Please refer to ‘Renesas Motor Workbench User’s Manual’ for usage and more details.

‘Renesas Motor Workbench’ can be downloaded from Renesas Electronics Corporation website.

Figure 4-1 Renesas Motor Workbench – Appearance

Set up for ‘Renesas Motor Workbench’

(1) Start ‘Renesas Motor Workbench’ by clicking this icon.

(2) Click on [ File ] and select [Open RMT File(O)] from drop down Menu.

Select the RMT file from following location of e2studio/CS+ project folder.

‘[Project Folder]/ application/user_interface/ics/’

(3) Use the ‘Connection’ [COM] select menu to choose the COM port.

(4) Click on the ‘Analyzer’ icon of Select Tool panel to open Analyzer function window.

(5) Please refer to ‘4.3 Operation Example for Analyzer’ for motor driving operation.

R01AN5790EJ0100 Rev.1.00 Page 33 of 41

Mar.12.21

Page 34

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Variable name

Type

Content

1: Board user interface use

3: Reset

1: CCW

1: Position control (default)

FF: Feed-forward control

2: Position profiling (default)

1: Position detection using Hall signal

com_s2_ref_position_deg

int16_t

Position command value [degree]

com_s2_ref_speed_rpm

int16_t

Speed command value [rpm]

com_u2_min_speed_rpm

uint16_t

Minimum speed [[rpm]

com_u2_max_speed_rpm

uint16_t

Maximum speed [rpm]

com_u2_overspeed_limit_rpm

uint16_t

Overspeed Limit [rpm]

com_u2_hs_change_speed_rpm

uint16_t

Speed calculation mode switch speed [rpm]

com_u2_hs_change_margin_rpm

uint16_t

Speed calculation mode switch margin speed [rpm]

com_u2_pos_interval_time

uint16_t

Time interval of the position command changes [s]

com_u2_pos_dead_band

uint16_t

Dead band of position

com_u2_pos_band_limit

uint16_t

Positioning complete range

com_u2_encd_cpr_mech

uint16_t

Encoder pulse count (4 for multiplying)

com_u2_offset_calc_time

uint16_t

Current offset value calculation time [ms]

com_u2_mtr_pp

uint16_t

Number of pole pairs

com_f4_mtr_r

float

Resistance [Ω]

com_f4_mtr_ld

float

d-axis Inductance [H]

com_f4_mtr_lq

float

q-axis Inductance [H]

com_f4_mtr_m

float

Flux [Wb]

com_f4_mtr_j

float

Inertia [kgm^2]

com_f4_nominal_current_rms

float

Nominal current [Arms]

4.2 List of Variables for Scope Function ‘Analyzer’

Table 4-1 is a list of variables for Analyzer. These variable values are reflected to the protect variables when

the same values as of g_u1_enable_write are written to com_u1_enable_write. However, note that variables

with (*) do not depend on com_u1_enable_write.

Table 4-1 List of Variables for Analyzer (1/2)

com_u1_sw_userif (*) uint8_t User interface switch

0: ICS user interface use (default)

com_u1_mode_system (*) uint8_t State management

0: Stop mode

1: Run mode

com_u1_direction uint8_t Rotation direction

0: CW

com_u1_ctrl_loop_mode uint8_t Control loop mode switch

0: Speed control

com_u1_ctrl_method_mode uint8_t Control method switch

0: PID control (Position P/Speed PI/Current PI)

1: IPD control (position

+ Position FF + Speed FF + Position P / Current PI) (default)

• Speed IPD

com_u1_position_input_mode uint8_t Position reference input mode switch

0: 0 output

1: Direct input

com_u1_encd_angle_adj_mode uint8_t Angle detection mode switch

0: Forced excitation (default)

R01AN5790EJ0100 Rev.1.00 Page 34 of 41

Mar.12.21

Page 35

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Table 4-1 List of Variables for Analyzer (2/2)

Variable name Type Content

com_f4_current_omega float Natural frequency of the current loop [Hz]

com_f4_current_zeta float Damping ratio of the current loop

com_f4_speed_omega float Natural frequency of the speed loop [Hz]

com_f4_speed_zeta float Damping ratio of the speed loop

com_f4_pos_omega float Natural frequency of the position loop [Hz]

com_f4_sob_omega float Natural frequency of the speed observer [Hz]

com_f4_sob_zeta float Damping ratio of the speed observer

com_f4_id_kp float d axis current PI control proportional term gain

com_f4_id_ki float d axis current PI control integral term gain

com_f4_iq_kp float q axis current PI control proportional term gain

com_f4_iq_ki float q axis current PI control integral term gain

com_f4_speed_kp float Speed PI control proportional term gain

com_f4_speed_ki float Speed PI control integral term gain

com_f4_pos_kp float Position control proportional term gain

com_f4_ipd_speed_k_ratio float Speed control gain ratio for IPD

com_f4_ipd_pos_kp_ratio float Position control proportional term gain ratio for IPD

com_f4_ipd_err_limit_1 float Position error limit for IPD

com_f4_ipd_err_limit_2 float Position error limit for IPD

com_f4_accel_time float Acceleration time [s] (for position control)

com_f4_ol_ref_id float d-axis current command value [A]

com_f4_id_up_time float d-axis current command value addition time [ms]

com_f4_limit_speed_change float Acceleration limit [s] (for speed control)

com_u1_enable_write uint8_t Enabled to rewriting variables

R01AN5790EJ0100 Rev.1.00 Page 35 of 41

Mar.12.21

Page 36

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

Vector Control

Type

Content

The primary variables that are frequently observed when the motor driving evaluation are listed in Table 4-2.

Please refer when using Analyzer function. Regarding variables not listed in Table 4-2, refer to source codes.

Table 4-2 List of Primary variable for Encoder Vector Control

Name of primary variable for Encoder

g_st_foc.u2_error_status uint16_t error status

g_st_foc.st_cc.f4_id_ref float d-axis current command value [A]

g_st_foc.st_cc.f4_id_ad float d-axis current [A]

g_st_foc.st_cc.f4_iq_ref float q-axis current command value [A]

g_st_foc.st_cc.f4_iq_ad float q-axis current [A]

g_st_foc.f4_iu_ad float W phase current A/D conversion value [A]

g_st_foc.f4_iv_ad float V phase current A/D conversion value [A]

g_st_foc.f4_iw_ad float W phase current A/D conversion value [A]

g_st_foc.st_cc.f4_vd_ref float d-axis output voltage command value [V]

g_st_foc.st_cc.f4_vq_ref float q-axis output voltage command value [V]

g_st_foc.f4_refu float U phase voltage command value [V]

g_st_foc.f4_refv float V phase voltage command value [V]

g_st_foc.f4_refw float W phase voltage command value [V]

g_st_foc.st_sc.f4_ref_speed_rad_ctrl float Command value for speed PI control (Electrical) [rad/s]

g_st_foc.st_sc.f4_speed_rad float Speed (Electrical) [rad/s]

g_st_foc.st_pc.f4_ref_pos_rad_ctrl float Command value for Position control (Electrical) [rad]

g_st_foc.st_pc.f4_pos_rad float Position (Electrical) [rad]

R01AN5790EJ0100 Rev.1.00 Page 36 of 41

Mar.12.21

Page 37

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

RX13T

4.3 Operation Example for Analyzer

This section shows an example below for motor driving operation using Analyzer. Operation is using 'Control

Window' of analyzer. Regarding specification of ‘Control Window’, refer to ‘Renesas Motor Workbench User’s

Manual’.

By default, the control loop mode is Position control mode. Setting up control loop mode as Speed control

mode is necessary to drive the motor in the following example. Execute the following to change from Position

control mode to Speed control mode.

Check [W?] column and input ‘0’ to Write column for ‘com_u1_ctrl_loop_mode’. Click the ‘Write’ button.

Figure 4-2 Procedure — Driving the motor

Driving the motor

① Confirm the check-boxes of column [W?] for ‘com_u1_mode_system’, ‘com_s2_ref_speed_rpm’,

‘com_u1_enable_write’

② Input a reference speed value in the [Write] box of ‘com_s2_ref_speed_rpm’.

③ Click the ‘Write’ button.

④ Click the ‘Read’ button. Confirm the [Read] box of ‘com_s2_ref_speed_rpm’, ‘g_u1_enable_write’.

⑤ Set a same value of ‘g_u1_enable_write’ in the [Write] box of ‘com_u1_enable_write’. Click ‘Write’

button.

⑥ Write ‘1’ in the [Write] box of ‘com_u1_mode_system’.

⑦ Click the ‘Write’ button.

④Click“Read”button

③⑦Click“Write”button

①Check

⑤Write(“0”or“1”)

Figure 4-3 Procedure – Driving the motor

⑥Write“1”

②Writereferencespeed

R01AN5790EJ0100 Rev.1.00 Page 37 of 42

Mar.12.21

Page 38

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

RX13T

Stop the motor

① Write ‘0’ in the [Write] box of ‘com_u1_mode_system’

② Click the ‘Write’ button.

②Click“Write”button

①Write“0”

Figure 4-4 Procedure – Stop the motor

Error cancel operation

① Write ‘3’ in the [Write] box of ‘com_u1_mode_system’

② Click the ‘Write’ button.

②Click“Write”button

Figure 4-5 Procedure – Error cancel operation

①Write“3”

R01AN5790EJ0100 Rev.1.00 Page 38 of 42

Mar.12.21

Page 39

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

4.4 Operation Example for User Button

The section shows an example below for motor driving operation using User Button.

• Driving or Stop the motor in position control mode

By setting as shown in Figure 4-6, driving and stopping change each time the button is pressed.

Figure 4-6 Driving or Stop the Motor in position control mode

• Change position

By setting as shown in Figure 4-7, enter the command position and press the button to change the

position.

R01AN5790EJ0100 Rev.1.00 Page 39 of 41

Mar.12.21

Figure 4-7 Change position

Page 40

RX13T

Vector Control for Permanent Magnet Synchronous Motor

with Encoder (Implementation)

• Driving or Stop the motor in speed control mode

By setting as shown in Figure 4-8, driving and stopping change each time the button is pressed.

Figure 4-8 Driving or Stop the Motor in speed control mode

• Change speed

By setting as shown in Figure 4-9, enter the command speed and press the button to change the speed.

R01AN5790EJ0100 Rev.1.00 Page 40 of 41

Mar.12.21

Figure 4-9 Change speed

Page 41

RX13T