Page 1

All information contained in these materials, including products and product specifications,

website (http://www.renesas.com).

RSSKRX23E-A

User’s Manual

Rev.1.10 Mar 2020

32

User’ s Manual

www.renesas.com

represents information on the product at the time of publication and is subject to change by

Renesas Electronics Corp. without notice. Please review the latest information published by

Renesas Electronics Corp. through various means, including the Renesas Electronics Corp.

Page 2

Corporate Headquarters

Contact information

Trademarks

Notice

1. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of semiconductor products

and application examples. You are fully responsible for the incorporation or any other use of the circuits, softw are, and information in the design of your

product or system. Renesas Electronics disclaims any and all liability for any losses and damages incurred by you or third parties arising from the use of

these circuits, software, or information.

2. Renesas Electronics hereby expressly disclaims any warranties against and liability for infringement or any other claims involving patents, copyrights, or

other intellectual property rights of third parties, by or arising from the use of Renesas Electronics products or technical information described in this

document, including but not limited to, the product data, drawings, charts, programs, algorithms, and applicati on examples.

3. No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights of Renesas Electronics or

others.

4. You shall not alter, modify, copy, or reverse engineer any Renesas Electronics product, whether in whole or in part. Renesas Electronics disclaims any

and all liability for any losses or dam ages incurred by you or third parties arising from such alteration, modification, copying or reverse engineering.

5. Renesas Electronics products are classified according to the following two quality grades: “Standard” and “High Quality”. The intended applications for

each Renesas Electronics product depends on the product’s quality grade, as indicated below.

"Standard": Computers; office equipment; communications equipment; test and measurement equipment; audio and visual equipment; home

"High Quality": Transportation equipment (automobiles, trains, ships, etc.); traffic control (traffic lights); large-scale communication equipment; key

Unless expressly designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas

Electronics document, Renesas Electronics products are not intended or authorized for use in products or systems that may pose a direct threat to

human life or bodily injury (artificial life support devices or systems; surgical implantations; etc.), or may cause serious property damage (space system;

undersea repeaters; nuclear power control systems; aircraft control systems; key plant systems; military equipment; etc.). Renesas Electronics disclaims

any and all liability for any damages or losses incurred by you or any third parties arising from the use of any Renesas Electronics product that is

inconsistent with any Renesas Electronics data sheet, user’s manual or other Renesas Electronics document.

6. When using Renesas Electronics products, refer to the latest product information (data sheets, user’s manuals, application notes, “General Notes for

Handling and Using Semiconductor Devices” in the reliability handbook, etc.), and ensure that usage conditions are within the ranges specified by

Renesas Electronics with respect to maximum ratings, operating power supply voltage range, heat dissipation characteristics, installation, etc. Renesas

Electronics disclaims any and all liability for any malfunctions, failure or accident arising out of the use of Renesas Electronics products outside of such

specified ranges.

7. Although Renesas Electronics endeavors to improve the quality and reliability of Renesas Electronics products, semiconductor products have specific

characteristics, such as the occurrence of failure at a certain rate and malfunctions under certain use conditions. Unless designated as a high reliability

product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas Electronics document, Renesas Electronics products

are not subject to radiation resistance design. You are responsible for implementing safety measures to guard against the possibility of bodily injury,

injury or damage caused by fire, and/or danger to the public in the event of a failure or malfunction of Renesas Electronics products, such as safety

design for hardware and software, including but not limited to redundancy, fire control and malfunction prevention, appropriate treatment for aging

degradation or any other appropriate measures. Because the evaluation of microcomputer software alone is very difficult and impractical, you are

responsible for evaluating the safety of the final products or systems manufactured by you.

8. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental compatibility of each Renesas

Electronics product. You are responsible for carefully and sufficiently investigating applicable laws and regulations that regulate the inclusion or use of

controlled substances, including without limitation, the EU RoHS Directive, and using Renesas Electronics products in compliance with all these

applicable laws and regulations. Renesas Electronics disclaims any and all liability for damages or losses occurring as a result of your noncompliance

with applicable law s and regulations.

9. Renesas Electronics products and technologies shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is

prohibited under any applicable domestic or foreign laws or regulations. You shall comply with any applicable export control laws and regulations

promulgated and administered by the governments of any countries asserting jurisdiction over the parties or transactions.

10. It is the responsibility of the buyer or distributor of Renesas Electronics products, or any other party who distributes, disposes of, or otherwise sells or

transfers the product to a third party, to notify such third party in advance of the contents and conditions set forth in this document.

11. This document shall not be reprinted, reproduced or duplicated in any form, in whole or in part, without prior written consent of Renesas Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this document or Renesas

Electronics products.

(Note1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its directly or indirectly controlled

(Note2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

subsidiaries.

electronic appliances; machine tools; personal electronic equipment; industrial robots; etc.

financial terminal systems; safety control equipment; etc.

(Rev.4.0-1 November 2017)

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

www.renesas.com

Renesas and the Renesas logo are trademarks of Renesas

Electronics Corporation. All trademarks and registered trademarks

are the property of their respective owners.

For further information on a product, technology, the most up-to-date

version of a document, or your nearest sales office, please visit:

www.renesas.com/contact/

.

© 2020 Renesas Electronics Corporation. All rights reserved.

Page 3

General Precautions in the Handling of Microprocessing Unit and Microcontroller Unit Products

The following usage notes are applicable to all Microprocessing unit and Microcontroller unit products from Renesas. For detailed usage notes on the products

covered by this document, refer to the relevant sections of the document as well as any technical updates that have been issued for the products.

1. Precaution against Electrostatic Discharge (ESD)

A strong electrical field, when exposed to a CMOS device, can cause destruction of the gate oxide and ultimately degrade the device operation. Steps

must be taken to stop the generation of static electricity as much as possible, and quickly dissipate it when it occurs. Environmental control must be

adequate. When it is dry, a humidifier should be used. This is recommended to avoid using insulators that can easily build up static electricity.

Semiconductor devi ces must be stored and transported in an anti-static contai ner, static shielding bag or conductive material. All test and measurement

tools including work benches and floors must be grounded. The operator must also be grounded using a wrist strap. Semiconductor devices must not be

touched with bare hands. Similar precautions must be taken for printed circuit boards with mounted semiconductor devices.

2. Processing at power-on

The state of the product is undefined at the time when power is supplied. The states of internal circuits in the LSI are indeterminate and the states of

register settings and pins are undefined at the time when power is supplied. In a finished product where the reset signal is applied to the external reset

pin, the states of pins are not guaranteed from the time when power is supplied until the reset process is completed. In a similar way, the states of pins in

a product that is reset by an on-chip power-on reset function are not guaranteed from the time when power is supplied until the power reaches the level

at which resetting is specified.

3. Input of signal during power-off state

Do not input signals or an I/O pull-up power supply while the device is powered off. The current injection that results from input of such a signal or I/O

pull-up power supply may cause malfunction and the abnormal current that passes in the device at this time may cause degradation of internal elements.

Follow the guideline for input signal during power-off state as described in your product documentation.

4. Handling of unused pins

Handle unused pins in accordance with the directions given under handling of unused pins in the manual. The input pins of CMOS products are

generally in the high-impedance state. In operation with an unused pin in the open-circuit state, extra electromagnetic noise is induced in the vicinity of

the LSI, an associated shoot-through current flows internally, and malfunctions occur due to the false recognition of the pin state as an input signal

become possible.

5. Clock signals

After applying a reset, only release the reset line after the operating clock signal becomes stable. When switching the clock signal during program

execution, wait until the target clock signal is stabilized. When the clock signal is generated with an external resonator or from an external oscillator

during a reset, ensure that the reset line is only released after full stabilization of the clock signal. Additionally, when switching to a clock signal produced

with an external resonator or by an external oscillator while program execution is in progress, wait until the target clock signal is stable.

6. Voltage application waveform at input pin

Waveform distortion due to input noise or a reflected wave may cause malfunction. If the input of the CMOS device stays in the area between V

and V

(Min.) due to noise, for example, the device may malfunction. Take care to prevent chattering noise from entering the device when the input level

IH

is fixed, and also in the transition period when the input level passes through the area between V

7. Prohibition of access to reserved addresses

Access to reserved addresses is prohibited. The reserved addresses are provided for possible future expansion of functions. Do not access these

addresses as the correct operation of the LSI is not guaranteed.

8. Differences between products

Before changing from one product to another, for example to a product with a different part number, confirm that the change will not lead to problems.

The characteristics of a microprocessing unit or microcontroller unit products in the same group but having a different part number might differ in terms of

internal memory capacity, layout pattern, and other factors, which can affect the ranges of electrical characteristics, such as characteristic values,

operating margins, immunity to noise, and amount of radiated noise. When changing to a product with a different part number, implement a system-

evaluation test for the given product.

(Max.) and VIH (Min.).

IL

(Max.)

IL

Page 4

CAUTION

This is a ‘Class A’ (CISPR11:2009+A1:2010) equipment. This equipment can

cause radio frequency noise when used in the residential area. In such cases,

the user/operator of the equipment may be required to take appropriate

countermeasures under his responsibility.

CAUTION

This equipment should be handled like a CMOS semiconductor device. The

user must take all precautions to avoid build-up of static electricity while working

with this equipment. All test and measurement tool including the workbench

must be grounded. The user/operator must be grounded using the wrist strap.

The connectors and/or device pins should not be touched with bare hands.

European Union Regulatory Notices:

The WEEE (Waste Electrical and Electronic Equipment)

regulations put responsibilities on producers for the collection

and recycling or disposal of electrical and electronic waste.

Return of WEEE under these regulations is applicable in the

European Union only. This equipment (including all

accessories) is not intended for household use. After use the

equipment cannot be disposed of as household waste, and the

WEEE must be treated, recycled and disposed of in an

environmentally sound manner. Renesas Electronics Europe

GmbH can take back end of life equipment, register for this

service at http://www.renesas.eu/weee

Page 5

Disclaimer

By using this Renesas Solution Starter Kit (RSSK), the user accepts the following terms:

The RSSK is not guaranteed to be error free, and the entire risk as to the results and performance of the RSSK is

assumed by the User. The RSSK is provided by Renesas on an “as is” basis without warranty of any kind whether

express or implied, including but not limited to the implied warranties of satisfactory quality, fitness for a particular

purpose, title and non-infringement of intellectual property rights with regard to the RSSK. Renesas expressly

disclaims all such warranties. Renesas or its affiliates shall in no event be liable for any loss of profit, loss of data,

loss of contract, loss of business, damage to reputation or goodwill, any economic loss, any reprogramming or

recall costs (whether the foregoing losses are direct or indirect) nor shall Renesas or its affiliates be liable for any

other direct or indirect special, incidental or consequential damages arising out of or in relation to the use of this

RSSK, even if Renesas or its affiliates have been advised of the possibility of such damages.

Precautions

The following precautions should be observed when operating this RSSK:

This RSSK is only intended for use in a laboratory environment under ambient temperature and humidity

conditions. A safe separation distance should be used between this and any sensitive equipment. Its use outside

the laboratory, classroom, study area or similar such area invalidates conformity with the protection requirements of

the Electromagnetic Compatibility Directive and could lead to prosecution.

The product generates, uses, and can radiate radio frequency energy and may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment causes harmful interference to radio or television reception, which can be determined by turning the

equipment off or on, you are encouraged to try to correct the interference by one or more of the following measures;

• ensure attached cables do not lie across the equipment

• reorient the receiving antenna

• increase the distance between the equipment and the receiver

• connect the equipment into an outlet on a circuit different from that which the receiver is connected

• power down the equipment when not in use

• consult the dealer or an experienced radio/TV technician for help NOTE: It is recommended that wherever

possible shielded interface cables are used.

The product is potentially susceptible to certain EMC phenomena. To mitigate against them it is recommended that

the following measures be undertaken;

• The user is advised to use the cable that is less than 3m in length to be connected to the product

• The user is advised that mobile phones should not be used within 10m of the product when in use.

• The user is advised to take ESD precautions when handling the equipment.

The RSSK does not represent an ideal reference design for an end product and does not fulfil the regulatory

standards for an end product.

Page 6

How to Use This Manual

within the body of the text, at the end of each section, and in the Usage Notes section.

the manual for details.

User's Manual

Explanation of the RSSKRX23E-A

RSSKRX23E-A

Quick Start Guide

Provides simple instructions to setup

RSSKRX23E-A

R20QS0007EJ0100

User's Manual: Hardware

Explanation of RX23E-A hardware

RX23E-A Group User's

R01UH0801EJ0100

1. Purpose and Target Readers

This manual is provided to help the users understand the outline and electrical characteristics of the board of

Renesas Solution Starter Kit for RX23E-A (called “RSSKRX23E-A board” or “the board” below)

Although this manual contains an overview of the RSSKRX23E-A board functions, it is not written as a built-in

programming or hardware design guide.

Particular attention should be paid to the precautionary notes when using RSSKRX23E-A board. These notes occur

The revision history summarizes the locations of revisions and additions. It does not list all revisions. Refer to the text of

or Renesas Solution Starter Kit for RX23E-A the following documents are available. The newest versions of

F

the documents listed may be obtained from the Renesas Electronics Web site.

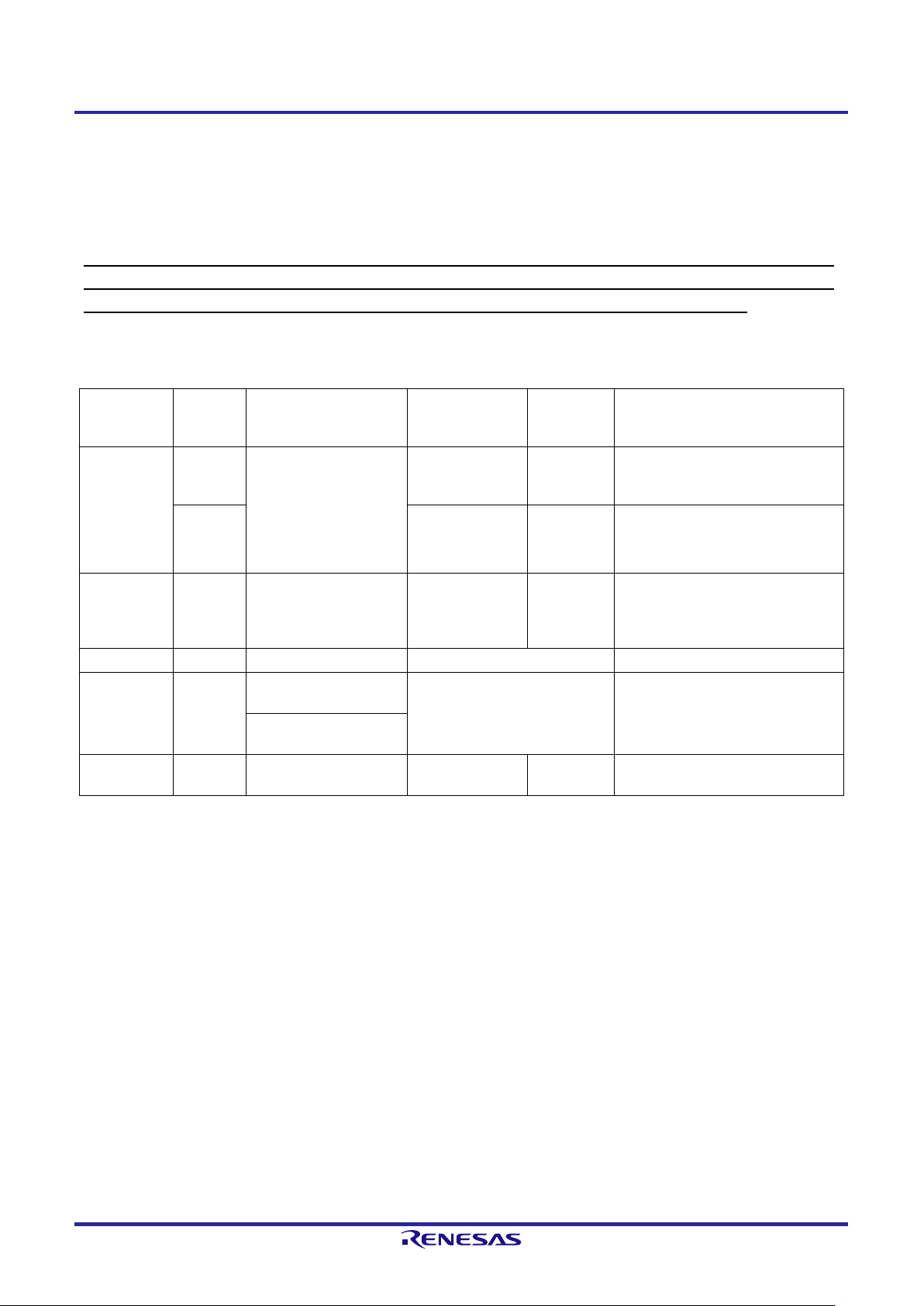

Document Type Description Document Title Document No.

R20UT4542EJ0110

board hardware specifications

the RSSKRX23E-A board and run PC

tool program

PC Tool Program Explanation of PC tool program that

communicates with the RSSKRX23E-A

board,

sets the AFE/DSAD of RX23E-A, and

obtains A/D conversion values

or specifications of RX23E-A: R5F523E6ADFL mounted on the board, the following documents are

F

User's Manual

Quick Start Guide

RSSKRX23E-A

PC Tool Program

Operation Manual

(this document)

R20AN0540EJ0110

available. The newest versions of the documents listed may be obtained from the Renesas Electronics Web

site.

specifications (pin layout, memory map,

peripheral function specifications,

electrical characteristics, and timing)

and operation

* For details on how to use peripheral

functions, refer to "Application Notes".

Manual: Hardware

Page 7

2. For Your Safety

Do not fail to read this manual before using the board

• Follow the indications in this manual when using the board

• Keep this manual near the board so you can refer to it whenever necessary.

• Transfer or sale of the board to third parties is prohibited without written approval.

• The purchaser or importer of the board is responsible for ensuring compliance with local regulations.

In addition, the customer is responsible for ensuring that the board is handled correctly and safely, in

accordance with the laws of the customer’s country (region).

• The manual for the board, and specification (the documents) are the tool that was developed for

the function and performance evaluation of Renesas Electronics semiconductor device (Renesas Electronics

device) mounted on the board, and not guarantee the same quality, function and performance.

• By purchasing the board or downloading the documents from Renesas Electronics website, the support

services provided from Renesas Electronics is not guaranteed.

• All information contained in this manual represents information on products at the time of publication

of this manual. Please note that the product data, specification, sales offices, contents of website, address,

etc., are subject to change by Renesas Electronics Corporation without notice due to product improvements

or other reasons. Please confirm the latest information on Renesas Electronics website.

Page 8

Meaning of Notations

is not specified.

static electricity

In this manual, items related to the safe use of the product are indicated as described below.

The degree of injury to persons or damage to property that could result if the designated content in this

manual is not followed is indicated as follows.

Warning

Caution

Note 1. Injury refers to conditions for which treatment would necessitate hospitalization or regular hospital

visits.

Note 2. Physical damage refers to damage affecting the wider surroundings, such as the user’s home or

property.

Requirements related to the handling of the product are classified into the following categories.

• Marks indicating that an action is prohibited.

General Prohibition

The indicated action is prohibited.

• Marks indicating that an action is alerted

General Caution

Indicates a general need for caution that

Indicates content that, if not followed, could result in death or serious injury to

the user.

Indicates content that, if not followed, could result in injury*1 to persons or

physical damage.*2

Example: Caution - Static Electricity!

Indicates the possibility of injury due to

• Marks directing that the specified action is required.

General Instruction

The specified action is required.

Example:

Turn Off (Disconnect) Power Supply!

Instructs the user to turn off (disconnect)

the power supply to the product.

Page 9

Warnings Regarding Use of the Product

Always insert plugs, connectors, and cables securely, and confirm that they are fully

• Incomplete connections could cause fire, burns, electric shock, or injury.

•

Disconnect the power supply and unplug all cables when the system will not be used for a

•

• This will protect the system against damage due to lightning.

Use a mechanism (switch, outlet, etc.) located within reach to turn off (disconnect) the power

• In case of emergency, it may be necessary to cut off the power supply quickly.

•

shock.

•

•

• The product may not perform as expected if used for other than its intended purpose.

Incorrect modification or retrofitting may cause heat generation and device failures.

• Failure to do so could cause overheating or malfunction.

• Failure to do so could cause device failures or malfunction by external noise.

•

Danger Items

Warning

inserted.

Use the power supply apparatus specified in the manual.

Failure to do so could cause fire, burns, electric shock, injury, or malfunction.

period of time or when moving the system.

Failure to do so could cause fire, burns, electric shock, or malfunction.

supply.

Turn off the power supply immediately if you notice abnormal odor, smoke, abnormal sound,

or overheating.

Continuing to use the system in an abnormal condition could cause fire, burns, or electric

Do not integrate the product or any part of it into other equipment.

Do not insert or remove cables or connectors when the product is powered on.

The product has no safety case.

Failure to observe the above could cause fire, electric shock, burns, or malfunction.

Caution Items

Before modifying any part of this product, carefully check the manual.

•

Follow the procedure specified in the manual when powering the system on or off.

Use the cable that is less than 3m in length to be connected to the product.

Caution

Caution – Static Electricity

Use the antistatic band. Failure to do so could cause malfunction or unstable motion.

Page 10

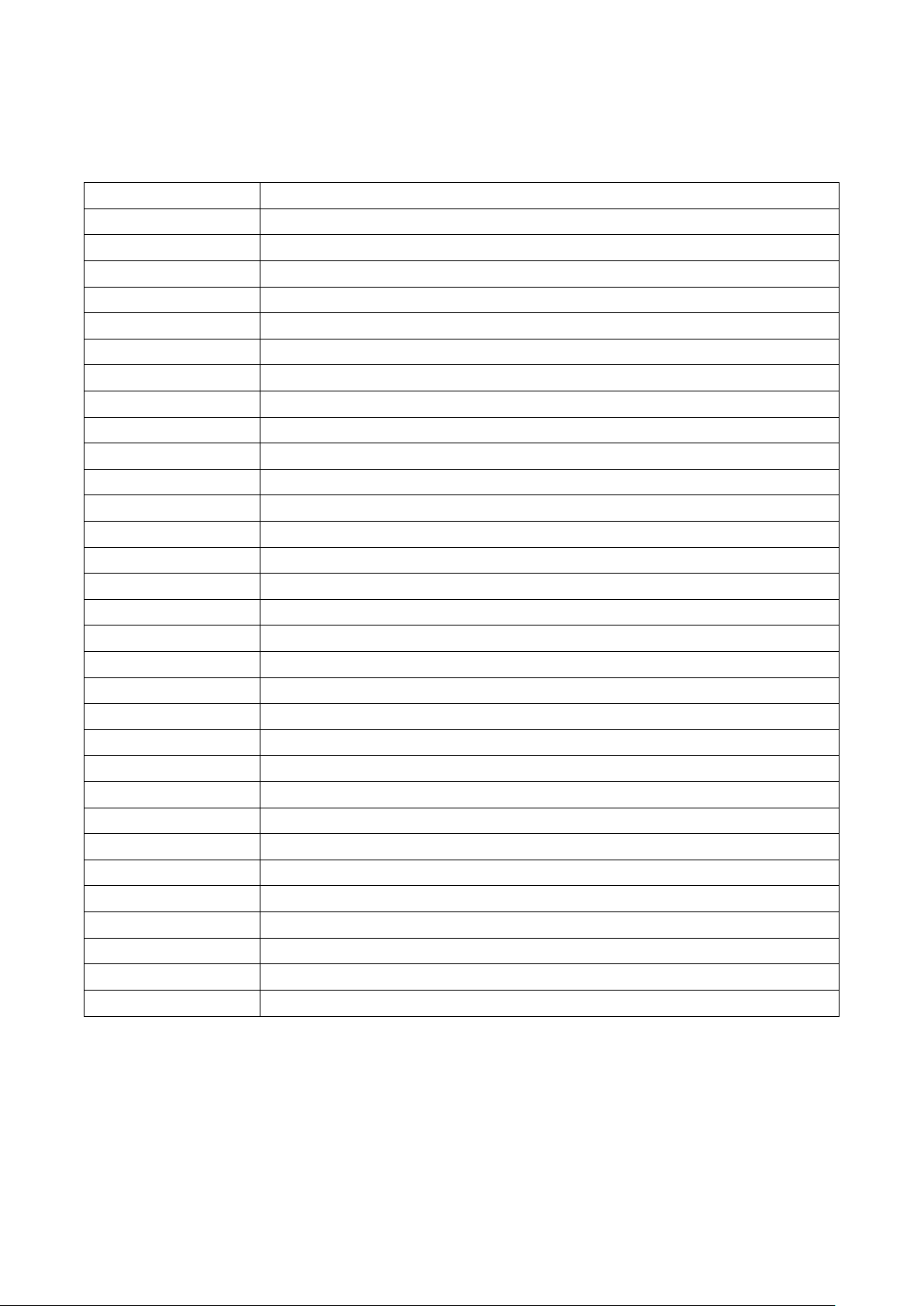

3.List of Abbreviations and Acronyms

Abbreviation

Full Form / Description

ADC

Analog to Digital Converter

AFE

Analog Front End

AMUX

Analog Multiplexer

BUF

Buffer Amplifier

CAN

Controller Area Network

CPU

Central Processing Unit

DSAD

Delta-Sigma Analog-to-Digital Converter

E2 Lite

Renesas On-chip Debugging Emulator

FW

Firmware

GUI

Graphical User Interface

I2C (IIC)

Philips™ Inter-Integrated Circuit Connection Bus

I/F

Interface

LDO

Low Dropout regulator

LED

Light Emitting Diode

LSW

Low Side Switch

MCU

Micro Controller Unit

NM

Not Mounted

PC

Personal Computer

PGA

Programmable Gain Amplifier

PROFIBUS DP

PROFIBUS Decentralized Peripherals

PWM

Pulse Width Modulation

RAM

Random Access Memory

ROM

Read Only Memory

RS-485

Recommended Standard 485

RTD

Resistance Temperature Detector

SARADC

Successive-Approximation-Register Analog-to-Digital Converter

SCI

Serial Communications Interface

SPI

Serial Peripheral Interface

UART

Universal Asynchronous Receiver/Transmitter

UM

User’s Manual

USB

Universal Serial Bus

All trademarks and registered trademarks are the property of their respective owners.

Page 11

Table of Contents

1.

Overview ........................................................................................................................................................ 1

1.1 Purpose ............................................................................................................................................................. 1

1.2 Mounted MCU ................................................................................................................................................... 1

1.3 Functions and Features .................................................................................................................................. 2

1.4 Specifications .................................................................................................................................................... 3

1.5 System Block Diagram .................................................................................................................................... 4

1.6 Overview and Layout ....................................................................................................................................... 5

2. Using the RSSKRX23E-A Board ................................................................................................................... 6

2.1 Operating Conditions ....................................................................................................................................... 6

2.2 Selecting Power Supplies ............................................................................................................................... 7

2.3 Connecting a PC to the Board ....................................................................................................................... 8

2.4 Using the Analog Input Circuit ........................................................................................................................ 9

2.4.1 Overview of the Analog Input Circuit .................................................................................................... 9

2.4.2 DSAD Measurement Circuit ................................................................................................................ 11

2.4.3 Thermocouple Measurement Circuit .................................................................................................. 12

2.4.4 Reference Junction Compensation Circuit Using the On-Board RTD .......................................... 13

2.4.5 Four-Wire RTD Measurement Circuit................................................................................................. 14

2.4.6 Three-Wire RTD Measurement Circuit .............................................................................................. 15

2.4.7 Strain Gage Measurement Circuit ...................................................................................................... 16

2.4.8 Handling Unused Pins in the Analog Input Circuit ........................................................................... 18

3. Microcontroller Peripheral Circuits .............................................................................................................. 19

3.1 USB Serial Communication Circuit .............................................................................................................. 19

3.2 Emulator Peripheral Circuit ........................................................................................................................... 20

3.3 RS-485 Communication Circuit .................................................................................................................... 21

3.4 CAN Communication Circuit ......................................................................................................................... 21

3.5 LED Circuit ...................................................................................................................................................... 22

3.6 Switch Input Circuit ........................................................................................................................................ 22

3.7 External Clock Input Circuit .......................................................................................................................... 23

4. Board Information ........................................................................................................................................ 24

4.1 Using Terminal Blocks ................................................................................................................................... 24

4.2 Connectors ...................................................................................................................................................... 25

4.3 Pin Headers for Communication Interfaces ............................................................................................... 29

Page 12

4.4 Jumper Pins .................................................................................................................................................... 30

4.5 Universal Through-Holes .............................................................................................................................. 33

4.6 Through-Hole Taps ........................................................................................................................................ 36

4.7 Test Points ...................................................................................................................................................... 36

4.8 Short Pads....................................................................................................................................................... 37

4.9 Initial Settings of MCU Pins .......................................................................................................................... 38

Appendix ................................................................................................................................................................ i

Appendix 1. Board Diagrams ........................................................................................................................................ i

Appendix 2. Circuit Diagram ........................................................................................................................................ iv

Appendix 3. Parts List ................................................................................................................................................... vi

Page 13

RSSKRX23E-A

MCU model name

R5F523E6ADFL

Number of bits

32

ROM

256 KB

Operating temperature range

-40 to +85°C

Renesas Solution Starter Kit for RX23E-A

1. Overview

1.1 Purpose

The board of Renesas Solution Starter Kit for RX23E-A (called “RSSKRX23E-A board” or “the board” below)

is an evaluation tool for the Renesas microcontroller RX23E-A. This manual describes the hardware aspect of

the RSSKRX23E-A board in detail. The manual also describes how to connect the board to a PC and sensors

for evaluation.

1.2 Mounted MCU

Table 1-1 lists the specifications of the MCU mounted on the board. The RX23E-A MCU mounted on the

board contains two low-noise 24-bit ∆-Σ A/D converters (DSADs). A DSAD contains a programmable gain

instrumentation amplifier (PGA). The gain can be selected from x1, x2, x4, x8, x16, x32, x64, and x128. It also

contains an analog front-end (AFE) circuit suitable for measuring sensors such as a thermocouple, RTD, and

strain gage. Up to 6 channels of measurement can be performed by switching the analog multiplexer (AMUX)

in the AFE.

For details on the MCU operating conditions, and DSAD and AFE settings, refer to “RX23E-A Group User's

Manual: Hardware”.

Table 1-1 Mounted MCU

Product group RX23E-A

Maximum CPU operating frequency 32 MHz

Package/number of pins LFQFP/48

RAM 32 KB

Storage temperature range -55 to +125°C

R20UT4542EJ0110 Rev.1.10 Page 1 of 39

Mar.30.20

Page 14

RSSKRX23E-A 1. Overview

1.3 Functions and Features

The board has the following functions and features.

(1) Functions and features for hardware and system design engineers

• A/D converter evaluation circuit

• Thermocouple measurement circuit

• Resistance temperature detector (RTD) measurement circuit

• Strain gage measurement circuit

• Power supply selection circuit

• FW controlling DSAD and AFE operation

• Transmission of measurement results and reception of AFE settings using USB communication

(2) Functions and features for software design engineers

• RX23E-A programming and debugging

• Switches, LEDs, and other user interfaces

The board has all circuits required for microcontroller operation.

R20UT4542EJ0110 Rev.1.10 Page 2 of 39

Mar.30.20

Page 15

RSSKRX23E-A 1. Overview

1.4 Specifications

Table 1-2 Specifications of the RSSKRX23E-A Board

Item Specification

Board model name RTK0ESXB10C00001BJ

MCU input clock 8-MHz external crystal oscillator

Applicable emulator E1, E2, and E2 Lite

Power input terminal block

Signal input terminal block CN2: Signal input terminal block (13-pin)

Analog power output terminal block CN1: Analog power output terminal block (2-pin)

Thermocouple connector CN3: Miniature thermocouple socket (2-pin) Material: copper-copper

Emulator connector CN7: 14-pin interface connector

On-board RTD Pt100 Class F0.3 (Class B) Model: PTS060301B100RP100

Connector CN6: USB serial communication connector USB mini-B

Driver U3: FT232RL

Connector J6: Pin header (3-pin 2.54mm pitch)

Driver U5: R2A25416SP

Connector J7: Pin header (3-pin 2.54mm pitch)

Driver ISL3159EFUZ

Communication

interfaces

On-board LDO

USB

CAN

RS-485

Model ISL80410IBEZ

Device specifications

CN4: System power input terminal block (2-pin)

CN5: Analog power input terminal block (2-pin)

Operating voltage range: 6 to 40 V (Note)

Output setting: 5 V (2.5 to 12 V variable output)

User interfaces

LEDs

Switches SW1: User switch SW2: External MCU reset switch

Universal through-holes

Board outline 120mm x 92mm

Operating temperature Room temperature

Operating humidity No condensation allowed

Note When the on-board LDO is used, the operating voltage range of this product is 6.5 to 12 V due to limitations of

peripheral components.

LED2: Power LED (VCC) Color: Green

LED1: User LED (PH2) Color: Red

2.54-mm pitch

J1: 4-pin through holes

J2: 12-pin through holes

J3, J4: 10-pin through holes

R20UT4542EJ0110 Rev.1.10 Page 3 of 39

Mar.30.20

Page 16

RSSKRX23E-A 1. Overview

RX23E-A

USB

mini B

Terminal

Bloc ks

USB

Se ri al

Conv erter

Crystal

Oscill ator

RX23E-A RSSK

The rmo coupl e

Connector

Em ula tor

Con nect or

User ’s

Swi tch

RESET

Swi tch

Passive

Filters

and

Sens or

Selection

Circuit s

Analog Plane Dig ital P la ne

Terminal

Bloc ks

User ’s

LED

Terminal

Bloc ks

Pin

Head ers

USB S erial

Comm unica tion

Analo g Power

Suppl y

Va

5V

LDO

AVCC0

VCC

CAN

Driv er

VLD O

Vd Vbus

UART Commun ication

Terminal

Bloc ks

VCC

E1, E2, E2 Lite

RS-485

Driv er

CAN C ommun icatio n

JP1 4

TXD1 R XD1 #RTS 1

Th ro ugh

Hole s

Th ro ugh

Hole s

Powe r

LED

MD/FI NED #RE S

Si gnals

Pin

Head ers

TXD1 RXD1

CTXD0 CRXD0

CTXD CRXD

Terminal

AV SS0

AVCC0

LSW

Analo g

Si gnals

Analo g

Si gnals

Analo g

Si gnals

Exciting Voltage

Out put

Sens ors

Ther moco uple

Vd

Sy st e m Po w er

Suppl y

Vbus

JP1 5

RS-485

Comm unica tion

Shiel d wire

Analo g Signal

Refe rence Voltage

AVCC0

Va

Univ ersa l

Th ro ugh

Hole s

CN1

CN2

CN3

CN5 CN4

U2

J1

J5

TH1

U1

Y1

J2, J3, J4

SW1

SW2

CN7

U4

U5

U3

J6

J7

CN6

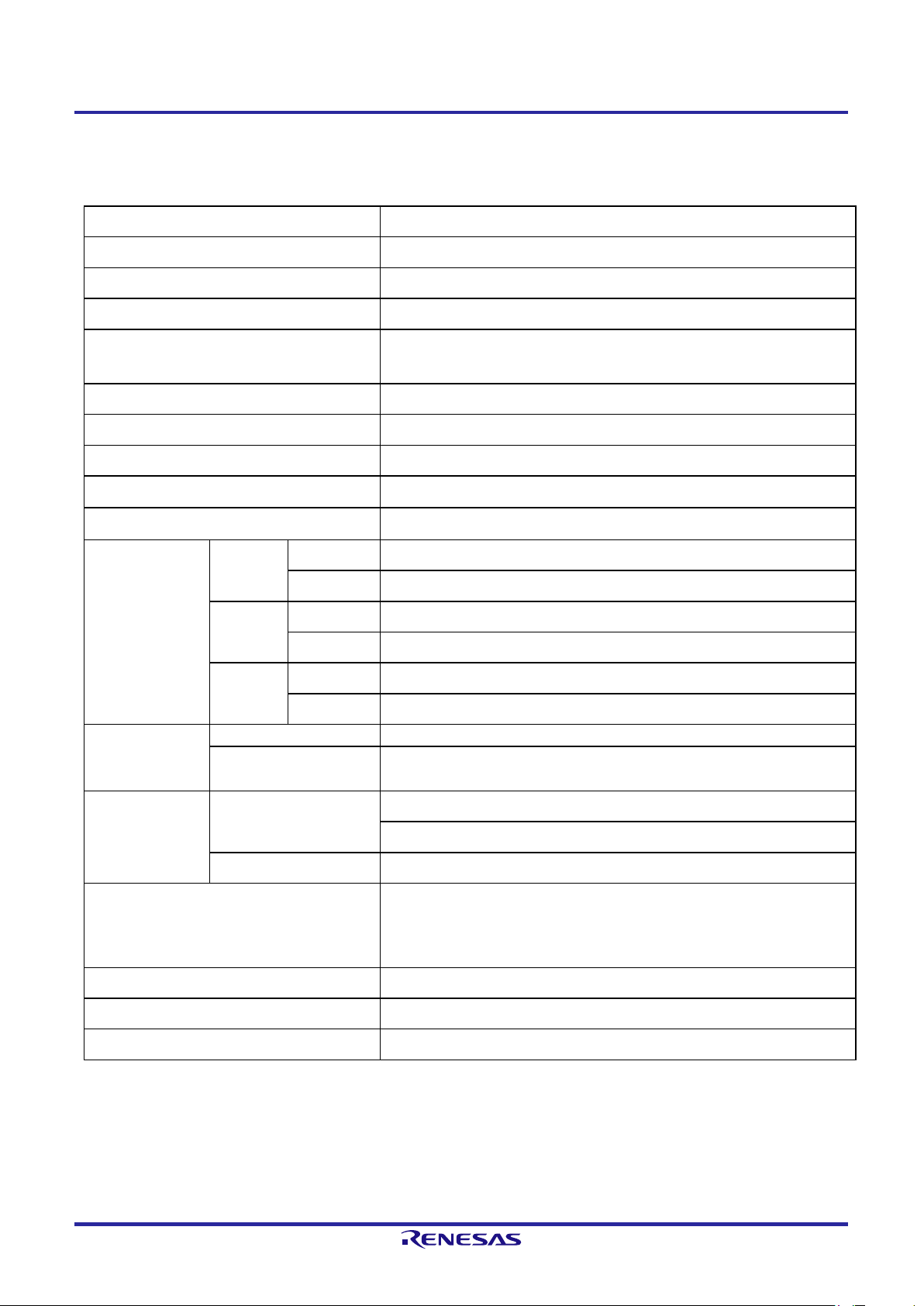

1.5 System Block Diagram

Figure 1-1 RSSKRX23E-A Board System Block Diagram

R20UT4542EJ0110 Rev.1.10 Page 4 of 39

Mar.30.20

Page 17

RSSKRX23E-A 1. Overview

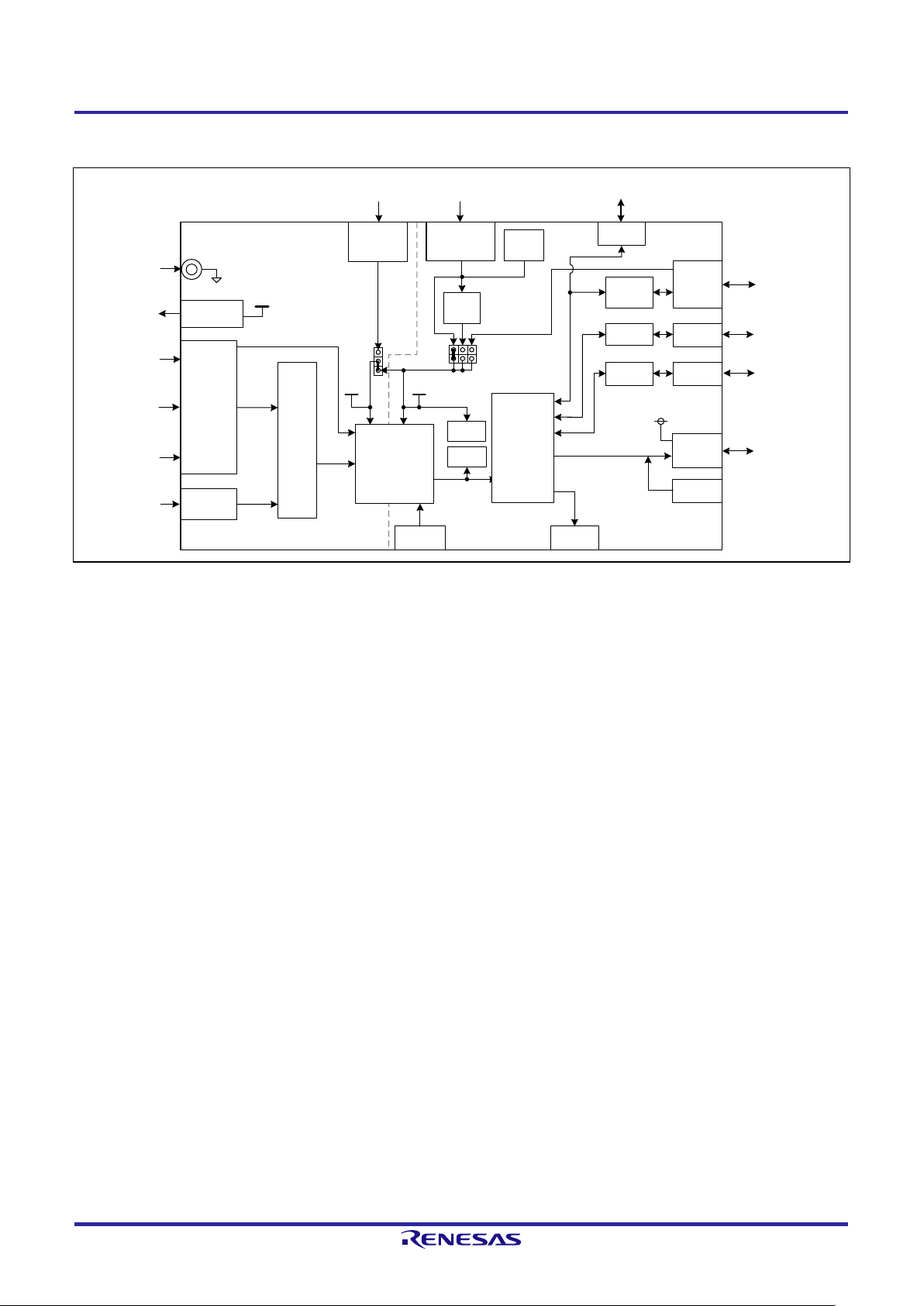

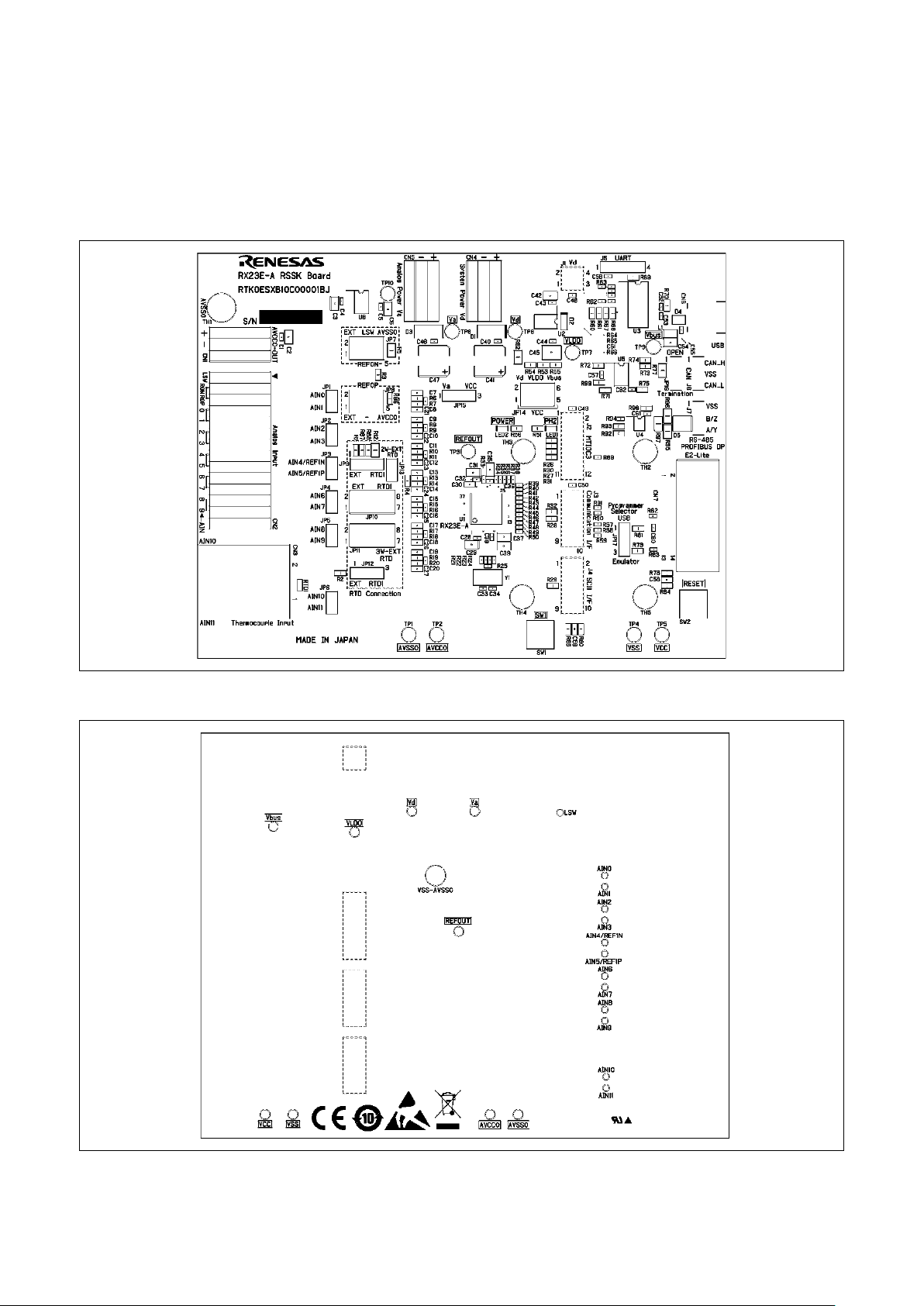

1.6 Overview and Layout

Figure 1-2 Overview of the RSSKRX23E-A Board (Front Side)

Figure 1-3 Overview of the RSSKRX23E-A Board (Back Side)

R20UT4542EJ0110 Rev.1.10 Page 5 of 39

Mar.30.20

Page 18

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

When analog and digital power

CN2

CN2

2. Using the RSSKRX23E-A Board

2.1 Operating Conditions

Table 2-1 lists the recommended operating conditions of the board.

Observe the recommended operating conditions when using the board. The use of the board without

observing any recommended operating condition may cause unpredictable operation. The use of the

board without observing any maximum rating may cause a failure or damage to the board.

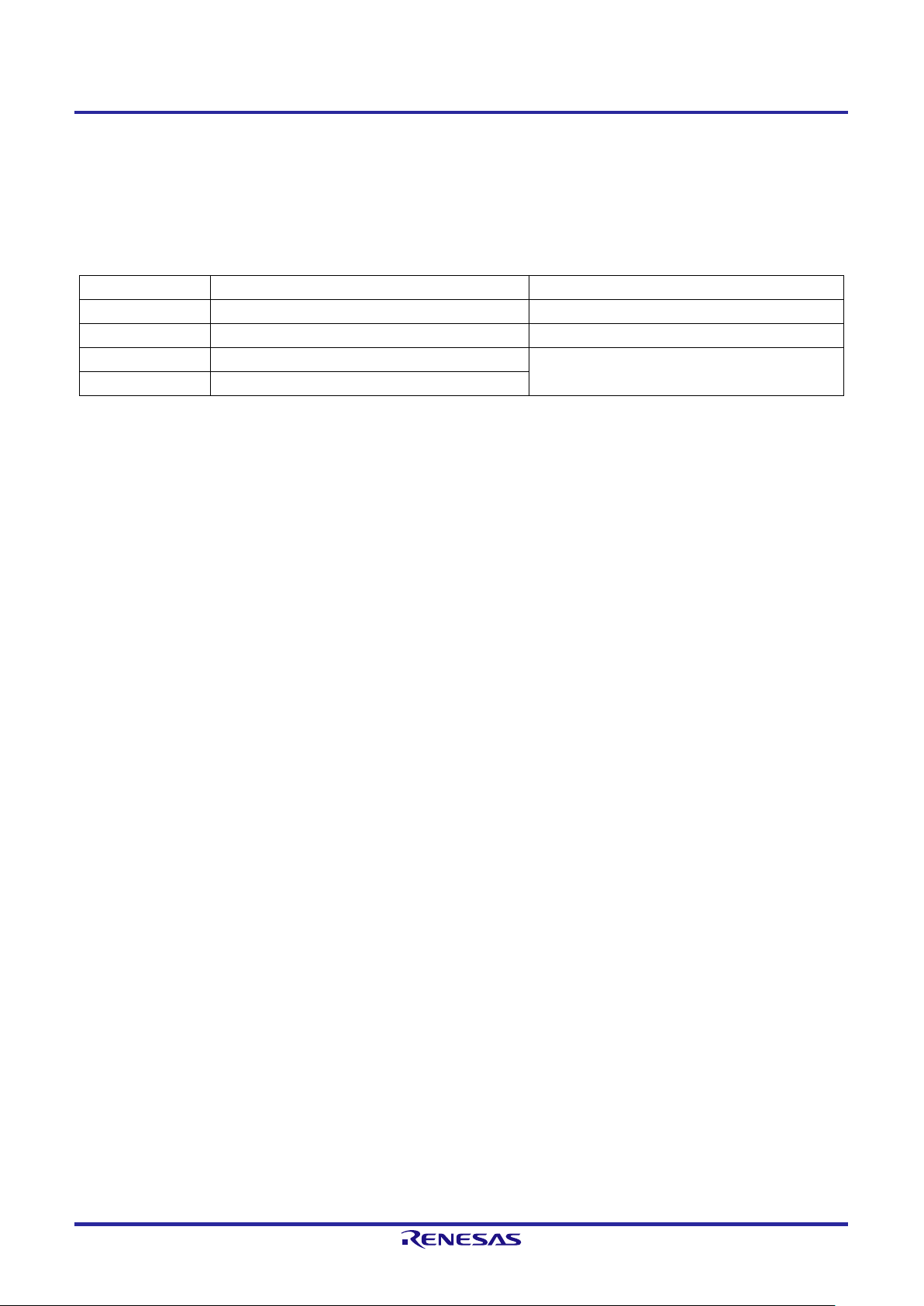

Table 2-1 Recommended Operating Conditions

Condition: VSS = AVSS0 = 0 V

Recommended

Item Symbol Input pin

Vd

System

power

supply

Analog

power

supply

Digital pin VIN See Section 4.5. -0.3 to VCC + 0.3 Absolute maximum rating

Analog pin V

LSW pin I

Note 1. Operation of USB serial communication, CAN communication, and RS-485 communication are guaranteed

Note 2. Although the operating voltage of the LDO (ISL80410) is 6 to 40 V, the recommended LDO operating range

Note 3. Supply the power to VCC and AVCC0 simultaneously or sequentially in this order.

Note 4. The R0N pin is connected to the LSW pin when pins 3 and 4 of JP7 are connected.

Note 5. When pins 1 and 2 are connected, Vd is directly connected to VCC.

(VCC)

CN4

Vd

AVCC0 CN5

AIN

LSW

only in condition of inside recommended operating range (4.5~5.25V). RX23E-A can operate at 1.8 to 5.5 V.

on the board is 6.5 to 12 V, considering the capacitor rated voltage, power line voltage drop, and heat

generation of the LDO.

When pins 5 and 6 are connected, VBUS (USB power supply) is connected to VCC.

(R0P, R0N, 0~9)

CN3

(AN10, AN11)

(LSW, R0N (Note 4))

operating

range

4.5 to 5.25 V

(Note 1)

6.5 to 12 V

(Note 2)

2.7 to 5.5 V

(Note 3)

-0.3 to AVCC0 + 0.3 Absolute maximum rating

- 30 mA When the LSW is switched ON

Maximum

rating

6.0 V

20 V

6.5 V

Condition

When the LDO is not used

(when pins 1-2 or 5-6 of JP14

are connected) (Note 5)

When the LDO is used (when

pins 5-6 of JP14 are connected)

supplies are separated (when

pins 1-2 of JP14 are connected)

and VCC > 2.7 V

R20UT4542EJ0110 Rev.1.10 Page 6 of 39

Mar.30.20

Page 19

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

Analog power

Separate analog/digital

Pins 2-3

USB operation for

Pins 1-2

Do not supply the

Vd

RX23E-A

Vbus

LDO

Va

Vd

VLD O

JP1 4

JP1 5

Sy st e m P o we r

Select Jumper

Analo g P ower

Select Jumper

Sy ste m Po wer Supply

USB B us Power

Analo g P ower Supp ly

VCC

E2 Lite

Emula tor Power Su pply

AVCC0

241

6

5

3

Vbus

1

2

3

CN7

CN8

CN4

CN5

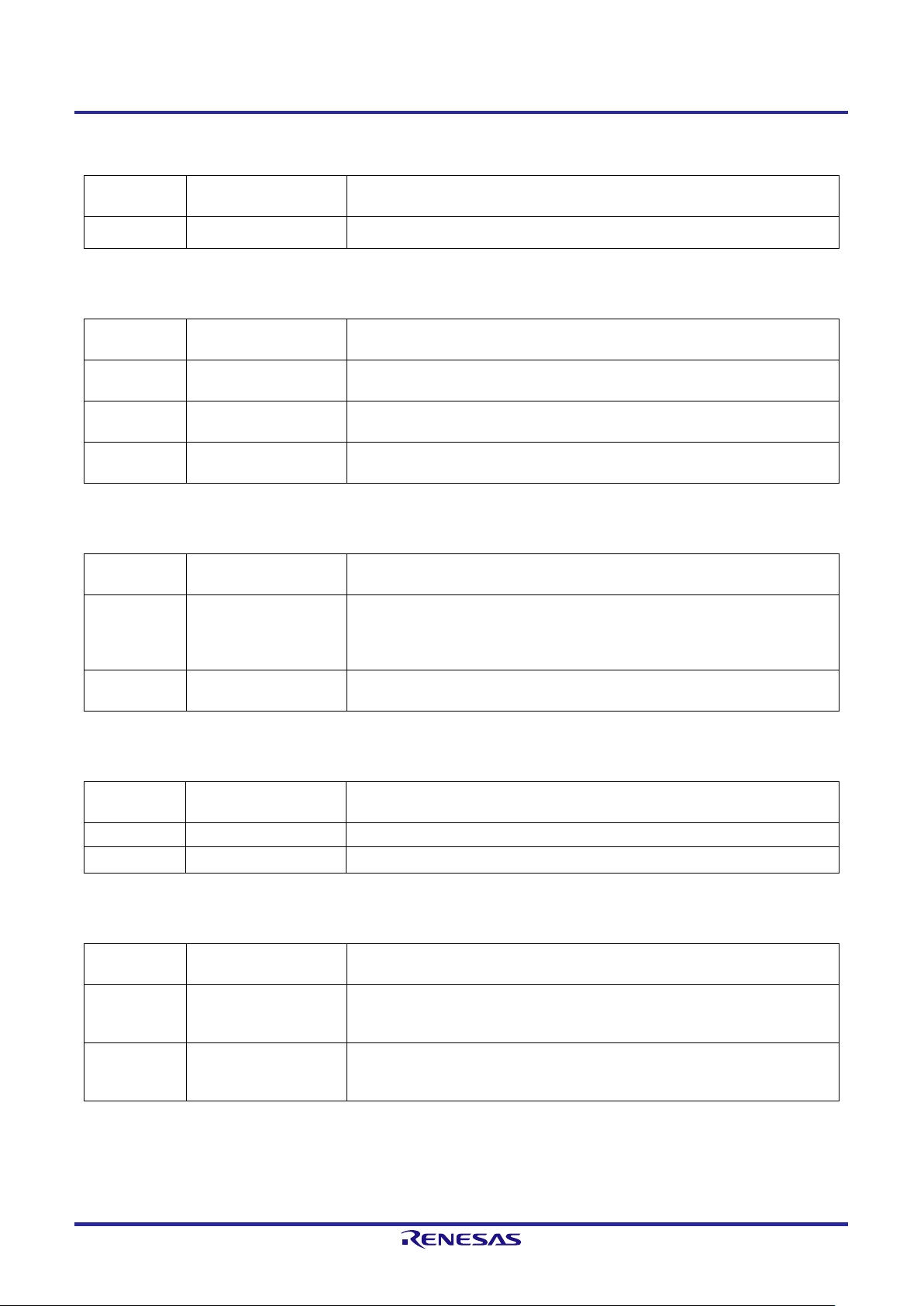

2.2 Selecting Power Supplies

Figure 2-1 shows the power supply configuration of the board. Table 2-2 shows how to select each power

supply on the board. Before using a combination of power supplies not listed in Table 2-2, carefully check the

recommended operating conditions in Table 2-1.

Figure 2-1 Power Supply Configuration of the RSSKRX23E-A Board

Table 2-2 Power Selection Methods

Input power

supply

Vd

Vbus Vbus Vbus Pins 5-6

Emulator

Note 1. When connecting pins 2 and 3 of JP15, do NOT supply the power to Va. If the power is supplied to Va,

VCC and AVCC0 are connected on the board, resulting in a short-circuit between Va and VCC.

Note 2. The emulator power supply is connected to VCC. If pins 3 and 4 of JP14 are left connected and the power

is supplied from the emulator, voltage is applied to the output of U2 and U2 may be damaged. Never

supply the power from the emulator when the pins are connected.

Digital power

supply VCC

supply

AVCC0

JP14

connection

Vd Vd Pins 1-2

Vd Va Pins 1-2 Pins 1-2

VLDO VLDO Pins 3-4

Emulator Emulator

Emulator Va

Pins 1-2

(Note 2)

(Note 2)

JP15

connection

Pins 2-3

(Note 1)

Pins 2-3

(Note 1)

(Note 1)

Pins 2-3

(Note 1)

Pins 1-2

Remarks

Initial default setting

power supplies

simple check

Do not supply the

power to Vd or Vbus.

power to Vd or Vbus.

R20UT4542EJ0110 Rev.1.10 Page 7 of 39

Mar.30.20

Page 20

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

When pins 1-2 are connected

When pins 2-3 are connected

USB serial

RSSKRX23E-A EVB

RX23E

USB-

mulator

Connector

USB 2.0FS

2.3 Connecting a PC to the Board

Figure 2-2 shows a configuration used when a PC is connected to the board. Table 2-3 lists functions

available when a PC is connected to the board.

When connecting a PC to the board, supply the power to the board as described in "2.2 Selecting Power

Supplies".

The board can be connected to the Renesas on-chip debugging emulator (E1, E2, E2 Lite) to debug user

code. When using the emulator, connect the 14-pin interface cable attached with the emulator to CN7. Before

supplying the power from the emulator, check that the following conditions are satisfied. If any of the

conditions is not satisfied, a failure may occur in the board, power supply, and/or emulator.

• The power is NOT supplied to VCC.

• Pins 3 and 4 of JP14 are NOT connected.

3.3-V power is supplied from E2 Lite. Note that USB serial communication, RS-485 communication, and CAN

communication do not operate. When using the emulator, refer to the user's manual of the emulator.

The board contains a USB serial conversion IC. SCI1 interface of the MCU and USB serial conversion IC are

connected and communication with a PC is available by USB serial communication. To use USB serial

communication, connect a USB cable to CN6 (USB mini-B connector).

For details on PC Tool Programs, refer to the “RSSKRX23E-A PC Tool Program Operation Manual”.

For details on the circuits around CN6 and CN7, see “3.1 USB Serial Communication Circuit” and “3.2

Emulator Peripheral Circuit”.

UART

COM

-A

I/F

Figure 2-2 Connecting a PC

Table 2-3 Functions Available When a PC Is Connected

Item Connected to

Emulator CN7 Disabled

communication

CN6 FW write via the SCI interface Communication with PC Tool Program

mini-B

USB

E

Emulator

JP17 connection and function

Code debugging

FW write via the FINE interface

PC Tool

Program

R20UT4542EJ0110 Rev.1.10 Page 8 of 39

Mar.30.20

Page 21

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

2.4 Using the Analog Input Circuit

2.4.1 Overview of the Analog Input Circuit

The analog input circuit on the board has the following functions.

• DSAD measurement circuit

• Thermocouple measurement circuit

• Reference junction compensation circuit using the on-board RTD

• Four-wire RTD measurement circuit

• Three-wire RTD measurement circuit

• Strain gage measurement circuit

This manual covers the circuit configuration required for implementing each function and the relationship

between the DSAD measurement result and input signal in two’s complement format. For details on

processing for converting the DSAD measurement result to a physical quantity, refer to the application notes

related to sensor measurement.

To switch the function, it is necessary to change the jumper pin connection and DSAD and AFE settings. The

jumper pin connection and built-in FW are factory-set for the DSAD measurement circuit using AIN3 and AIN2

or AIN9 and AIN8.

Table 2-4 lists each function of the analog input circuit and corresponding jumper pin connection. Table 2-5

lists factory settings of the DSAD and AFE.

R20UT4542EJ0110 Rev.1.10 Page 9 of 39

Mar.30.20

Page 22

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

Connection

X X X X X X AIN3

AIN2

N/A

Thermocouple

Three-wire

AIN4(REF1N)

Strain gage

976.563

976.563

Table 2-4 Functions of the Analog Input Circuit and Corresponding Jumper Settings

Jumper pin connection Used pins of the MCU (pin function)

Function

Factory

settings

DSAD

measurement

circuit

JP7 JP8 JP9 JP10 JP11 JP12

5-6 5-6 1-2

1-2 and

X X X X

3-4

1-2 and

3-4

1-2 and

3-4

1-2 N/A N/A N/A

1-2 AIN9 AIN8 N/A

Positive

side

input

Negative

side

input

Others

measurement

X X X X X X AIN11 AIN10 N/A

circuit

Reference

junction

compensation

X X 2-3

5-6 and

7-8

1-2 and

3-4

2-3 AIN7 AIN6

circuit

RTD

measurement

X X 1-2

1-2 and

3-4

5-6 and

7-8

1-2 AIN7 AIN6

circuit

Four-wire RTD

measurement

circuit

measurement

circuit

X X 1-2

3-4 or

5-6

5-6 X X X X AIN1 AIN0

1-2 and

3-4

1-2 and

3-4

1-2 AIN7 AIN6

X: Don't care N/A: Not applicable

Note The thermocouple measurement circuit is independent of the JP7 to JP12 jumper pin connection.

Table 2-5 Factory Settings of the DSAD and AFE

Setting value

Item Symbol

Polarity DSAD0 DSAD1

Remarks

AIN4(REF1N)

AIN5(REF0N)

AIN9(IEXC)

AIN5(REF1P)

AIN8(IEXC)

AIN9(IEXC)

AIN4(REF1N)

AIN5(REF1P)

AIN9(IEXC)

REF0N,

REF0P

Note The bias voltage generator and excitation current source are not used in the factory setting.

R20UT4542EJ0110 Rev.1.10 Page 10 of 39

Mar.30.20

Measurement pin ―

Positive AIN3 AIN9

Negative AIN2 AIN8

Positive REFOUT REFOUT

Reference voltage VREF

Negative AVSS0 AVSS0

Gain GAIN ― 1x 1x

Data rate DR ―

SPS

SPS

Directly connected to the DSAD

(Both the PGA and buffer amplifier are

bypassed)

Internal reference voltage used.

REFOUT: 2.5 Vtyp.

Oversampling ratio: 512

Page 23

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

AIN 2 (Lo)

U1

RX23 E-A

AIN 8 (Lo)

AIN9 (Hi)

AIN3 (Hi)

Volt age

Measurement

8

9

2

3

AIN

R10 (0Ω)

41

42

C23

C12

NM

NM

NM

R11 (0Ω)

C11

R17 (0Ω)

47

48

C26

C18

NM

NM

NM

R18 (0Ω)

C17

Commo n mode I np ut

123

4

567

8

1 2 3

JP1 2

JP1 1

Signal Inp ut

Signal Inp ut

Volt age

Measurement

CN2

RSSKRX23E-A

2.4.2 DSAD Measurement Circuit

Figure 2-3 shows an example usage of the DSAD measurement circuit on the board.

Figure 2-3 Example Usage of DSAD Measurement Circuit

The FW built onto the board at shipment is set to measure the differential voltage between AIN3 and AIN2 and

that between AIN9 and AIN8 using two channels DSAD0 and DSAD1 in the MCU. The input voltage between

pins 3 and 2 of CN2 (between AIN3 and AIN2) and between pins 9 and 8 of CN2 (between AIN9 and AIN8)

are being used for the measurement. The differential input voltage VID can be obtained from the DSAD

measurement result ADDATA using the following expression.

Before applying voltage to the DSAD measurement circuit, check the following conditions. If either condition is

not satisfied, measurement cannot be performed correctly.

The absolute input voltage range and differential voltage input range depend on the DSAD settings. For

details, refer to "RX23E-A Group User's Manual: Hardware".

During evaluation with the DSAD measurement circuit, self-noise of the DSAD and PGA can be measured by

short-circuiting input pins using JP2 and JP5. To short-circuit input pins, fix the input pin potential to satisfy

condition (1). The PGA input bias current may cause the input pin potential to be outside the absolute input

voltage range. Sample methods for fixing the input pin potential are listed below.

When using method (a) or (b) for measurement, check that the applied voltage is within the range of condition

(1). Depending on connection, the differential input impedance becomes imbalanced, and the circuit may be

susceptible to common mode noise.

R20UT4542EJ0110 Rev.1.10 Page 11 of 39

Mar.30.20

=

× 2

×

[V]

2

(1) The voltage between each AIN and AVSS0 is within the absolute input voltage range for DASD

measurement.

(2) The voltage between AIN pins is within the differential voltage input range.

(a) Connect an external stable potential to one measurement pin.

(b) Connect one measurement pin to GND via a resistor.

(c) Apply bias voltage to one measurement pin using the AFE bias voltage generator.

Page 24

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

1

Thermocoupl e

2

AIN11 (Hi)

AIN 1 0 (Lo )

CN3

1

2

AIN 1 0 (Lo )

AIN11 (Hi)

R19

R20

C27

C20

C19

Thermocoupl e

Measurement

U1

RX23 E-A

RSSKRX23E-A

2.4.3 Thermocouple Measurement Circuit

Figure 2-4 shows the thermocouple measurement circuit on the board.

Figure 2-4 Thermocouple Measurement Circuit

CN3 is a connector socket on board the RSSKRX23E-A (material : copper-copper) used for the thermocouple

input pins. Thermocouple attached with the board can be connected to CN3 for measurement.

Connect the positive side of the thermocouple to AIN11 pin of CN3 and the negative side to AIN10 pin. The

output from the thermocouple (thermoelectromotive force) is input to AIN11 and AIN10 and the differential

voltage between AIN11 and AIN10 is measured with the DSAD. The thermoelectromotive force V

obtained from the DSAD measurement result AD

using the following expression.

DATA

× 2

=

×

[]

2

For thermocouple measurement, fix the input pin potential. The PGA input bias current may cause the input

pin potential to be outside the absolute input voltage range.

Measuring a temperature with the thermocouple requires cold junction compensation or reference junction

compensation. The board enables reference junction compensation using the on-board RTD. For details on

the reference junction compensation circuit using the on-board RTD, see 2.4.4 “Reference Junction

Compensation Circuit Using the On-Board RTD”

TEMP

can be

R20UT4542EJ0110 Rev.1.10 Page 12 of 39

Mar.30.20

Page 25

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

R13

R14

C14

C13

Refe rence

Resistor

1

Ther moco upl e

2

AIN11 (Hi)

AIN 10 (L o)

REF1N(AIN4)

U1

RX23 E-A

CN3

1

2

AIN 10 (L o)

AIN11 (Hi)

IEXC0 (AIN9)

AIN8 (Unused)

R17 (0Ω)

47

48

C26

C18

NM

NM

R19

R20

C27

C20

C19

NM

R18 (0Ω)

AIN 6 (Lo)

45

46

C25

RTD1

pt10 0

5.1kΩ

R12

390Ω

I

EXC0

Refe rence Buffer

Head room Res ist or

AIN7 (Hi)

REF 1P(A IN5)

R15

R16

C16

C15

C24

RTD

Measurement

Exci tation

Curr ent

Out put

Ther moco upl e

Measurement

Ext ernal

Refe rence

Inpu t

43

44

8

9

6

7

4

5

1

2

3

123

4

5

678

123

4

567

8

1 2 3

R4

JP9

JP1 0

SO10

JP1 2

CN2

0.1% 15pp m

C17

AIN

JP1 1

RSSKRX23E-A

2.4.4 Reference Junction Compensation Circuit Using the On-Board RTD

Figure 2-5 shows the reference junction compensation circuit on the board.

On the board, the temperature near CN3 is detected with the on-chip resistance temperature detector, RTD1,

for reference junction compensation for thermocouple measurement. For RTD1 measurement, a four-wire

ratiometric measurement method is used. The excitation current I

in the path shown by the arrow. The voltages at both ends of RTD1 are input to AIN7 and AIN6 and they are

measured with the DSAD. The voltages at both ends of the reference resistor R4 are input to REF1P (AIN5)

and REF1N (AIN4) and used as DSAD external reference voltages. The RTD1 resistance can be indicated

using the DSAD measurement result AD

× 1 =

When I

is deleted from both sides,

EXC0

Figure 2-5 Reference Junction Compensation Circuit

× × 2

×

as shown below.

DATA

[]

2

EXC0

is output from AIN9 and is made to flow

×

2

[]

EXC0

1 =

With the above expression, the RTD1 resistance can be obtained independently of the excitation current I

Use a built-in reference buffer (RBUF) with AFE for external reference inputs REF1N and REF1P. The use of

the RBUF can reduce the current input to the external reference input pin. Note that the use of the RBUF

narrows the absolute input voltage range for external reference. R12 is provided to make the voltages at both

ends of R4 fall within the absolute input voltage range for external reference when the RBUF is used.

× 2

R20UT4542EJ0110 Rev.1.10 Page 13 of 39

Mar.30.20

.

Page 26

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

R13

R14

C14

C13

Refe re nce

Resistor

REF1N(AIN4)

U1

RX23 E-A

IEXC0 (AIN9 )

AIN8 (Unused)

R17 (0Ω)

47

48

C26

C18

NM

NM

NM

R18 (0Ω)

AIN 6 (L o)

45

46

C25

5.1kΩ

R12

390Ω

IEXC0

AIN7 (Hi)

REF 1P(AIN5)

R15

R16

C16

C15

C24

RTD

Measure ment

Exci tation

Curr en t

Out put

Ext ernal

Refe re nce

Inpu t

43

44

8

9

6

7

4

5

1

2

3

123

4

5

678

123

4

567

8

1 2 3

R4

JP9

JP1 0

JP1 1

JP1 2

CN2

0.1% 15ppm

C17

4-wire

RTD

-

+

AIN

SO10

RSSKRX23E

-A

Refe re nce Buff er

Headroom Res istor

2.4.5 Four-Wire RTD Measurement Circuit

Figure 2-6 shows the four-wire RTD measurement circuit on the board.

Figure 2-6 Four-Wire RTD Measurement Circuit

A configuration similar to that for on-board RTD measurement is used for four-wire RTD measurement.

Connect two pins of same polarity of a four-wire RTD to pins 9 (AIN9) and 7 (AIN7) of CN2 and two pins of the

other polarity to pins 6 (AIN6) and 5 (AIN5) of CN2. The excitation current I

made to flow in the path shown by the arrow. The voltages at both ends of the RTD are input to AIN7 and

AIN6 as detection signals and they are measured with the DSAD. The voltages at both ends of the reference

resistor R4 are input to REF1P (AIN5) and REF1N (AIN4) and used as DSAD external reference voltages.

The RTD resistance RTD

×

When I

is deleted from both sides,

EXC0

With the above expression, the RTD resistance RTD

current I

EXC0

.

In the same way as for on-board RTD measurement, RBUF is used for external reference input.

R20UT4542EJ0110 Rev.1.10 Page 14 of 39

Mar.30.20

× 2

=

can be indicated using the DSAD measurement result AD

4-wire

× × 2

=

×

2

×

[]

2

[]

can be obtained independently of the excitation

4-wire

is output from AIN9 and is

EXC0

as shown below.

DATA

Page 27

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

R13

R14

C14

C13

Refe re nce

Resistor

REF1N(AIN4)

U1

RX23 E-A

IEXC0 (AIN9)

IEXC1

(AIN8)

R17 (0Ω)

47

48

C26

C18

NM

NM

NM

R18 (0Ω)

AIN 6 (L o)

45

46

C25

5.1kΩ

R12

390Ω

IEXC0

AIN7 (Hi)

REF 1P(AIN5)

R15

R16

C16

C15

C24

RTD

Measurement

Exci tation

Curr en t

Out put

Ext ernal

Refe re nce

Inpu t

43

44

8

9

6

7

4

5

1

2

3

123

4

5

678

1

234

567

8

1 2 3

R4

JP9

JP1 0

JP1 1

JP1 2

CN2

0.1% 15ppm

C17

3-wire

RTD

-

+

AIN

IEXC1

RSSKRX23E

-A

Refe re nce Buff er

Headroom Res istor

2.4.6 Three-Wire RTD Measurement Circuit

Figure 2-7 shows the three-wire RTD measurement circuit on the board.

Figure 2-7 Three-Wire RTD Measurement Circuit

Connect one pin at one side of a three-wire RTD to pin 7 (AIN7) of CN2 and two pins of the other polarity to

pins 6 (AIN6) and 5 (AIN5) of CN2. The excitation currents I

are made to flow in the path shown by the arrow. The voltages at both ends of the RTD are input to AIN7 and

AIN6 as detection signals and they are measured with the DSAD. The voltages at both ends of the reference

×

resistor R4 are input to REF1P (AIN5) and REF1N (AIN4) and used as DSAD external reference voltages.

The RTD resistance RTD

When

With the above expression, when the excitation currents I

RTD

can be obtained independently of the excitation currents.

3-wire

× 4

=

+

) × × 2

+

[]

is indicated using the DSAD measurement result AD

3-wire

(

=

=

×

,

2

×

= 2 ×

2

. When I

[]

EXC0

EXC1

and I

and I

EXC0

are output from AIN8 and AIN9 and

EXC0

DATA

is deleted from both sides,

are equal, the RTD resistance

EXC1

as shown below.

In the same way as for on-board RTD and four-wire RTD measurement, RBUF is used for external reference

input.

R20UT4542EJ0110 Rev.1.10 Page 15 of 39

Mar.30.20

Page 28

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

CN2

C21

C8

C7

R6(0 Ω)

R7(0

Ω)

REF 0N

U1

RX23 E-A

AIN 0 (L o)

39

40

C22

AIN1 (Hi)

REF 0P

R8

R9

C10

C9

Strain Gauge

Measure ment

Ext ernal

Refe rence

37

38

0

1

R0N

R0P

1

3

5

JP7

AVCC0

36

LSW

LSW Low S ide Switch

2 4 6

JP8

2 4 6

1

3

5

EXC Lo

Str ain

Gauge

1-Gauge 4

-Wir e

AIN

EXC Hi

Si g na l Lo

Si g nal Hi

TH1

Shielded Wire

RSSKRX23E-A

2.4.7 Strain Gage Measurement Circuit

Figure 2-8 shows the measurement circuit for a strain gage (four-wire, single-gage method) on the board.

Figure 2-8 Strain Gage (Four-wire, Single-gage Method) Measurement Circuit

For the board, as an example of strain gage measurement, a measurement circuit for the four-wire, single-

gage method using a Wheatstone bridge is used.

Connect a strain gage that configured a bridge circuit to R0N pin (REF0N), R0P pin (REF0P), pin 0 (AIN0),

and pin 1 (AIN1) of CN2. Use AVCC0 and AVSS0 as excitation voltage sources to drive the bridge circuit. The

voltages of the output pins of the strain gage are input to AIN0 and AIN1 and the differential voltage is

measured with the DSAD. AVCC0 and AVSS0 are used as external reference inputs. When the strain gage

has a shielded wire, it can be connected to TH1 or the negative pin of CN1.

As an external reference input, LSW can be connect instead of AVSS0. The LSW pin is connected to AVSS0

via an analog switch in the MCU. This switch can be changed according to the MCU register setting. Power

supply to the strain gauge can be supplied by turning on the switch, and power supply to the strain gauge can

be stopped by turning off the switch. Supplying the power to the strain gage only during measurement can

reduce power consumption. The allowable current to the LSW pin is 30 mA. When using the LSW pin,

consider the allowable current.

If the LDO is used as the power supply for strain gage measurement (by connecting pins 3 and 4 of JP14), be

careful about the LDO output current. The maximum output current of the LDO mounted on the board,

ISL80410, is 150 mA. If current exceeding the maximum output current is required, do not use the

LDO.

R20UT4542EJ0110 Rev.1.10 Page 16 of 39

Mar.30.20

Page 29

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

In this circuit, the relationship between the differential voltage between AIN0 and AIN1 V

can be indicated using the gage coefficient K (strain gage sensitivity) as shown below.

1

=

× × ×(0 0)[V]

4

The differential voltage V

can be indicated using the DSAD measurement result AD

strain

expression.

2 × (0 0)

=

×

2

When V

, AVCC0, and AVSS0 are deleted from the above two expressions, the strain ratio ε can be

strain

indicated with the following expression.

=

2 × 4

×

×

2

and strain ratio ε

strain

with the following

DATA

R20UT4542EJ0110 Rev.1.10 Page 17 of 39

Mar.30.20

Page 30

RSSKRX23E-A 2. Using the RSSKRX23E-A Board

Pin name

Handling result

Handling method

REF0N

Connected to AVSS0 directly or via a resistor.

Connect pins 5-6 of JP7.

LSW

Connected to AVSS0 directly or via a resistor.

2.4.8 Handling Unused Pins in the Analog Input Circuit

If there is an unused pin in the analog input circuit, handling the unused pin according to Table 2-6 is

recommended. If the unused pin is not handled accordingly, the circuit becomes susceptible to external noise

and static electricity, which may deteriorate performance and cause a failure.

Table 2-6 Handling Unused Pins in the Analog Input Circuit

REF0P Connected to AVCC0 directly or via a resistor. Connect pins 5-6 of JP8.

AIN0 to AIN11 Connected to AVSS0 directly or via a resistor.

Use a soldering side short pad (SO1-SO13) to

connect the pin to AVSS0.

R20UT4542EJ0110 Rev.1.10 Page 18 of 39

Mar.30.20

Page 31

RSSKRX23E-A 3. Microcontroller Peripheral Circuits

VSS

U1

RX23E-A

TXD

D4

14

16

VCC

R47

VCC

13

R60

R69

R64

R61

R65

RXD

RTS#

3

1

5

CTS #

CN6

USB mi ni-B

Vbus

(To JP14)

VSS

VBUS

GN D

USBDM

USBDP

NC

VSS

VCC IO

VCC

USBDM

U3

FT232RL

USBDP

R68

Zdiff = 90Ω±15%

USB2.0 Differential Impedance

11

4

20

C55C54

L1

C52

16

15

1

2

3

4

5

C51

USB-Serial C onverter

3. Microcontroller Peripheral Circuits

3.1 USB Serial Communication Circuit

Figure 3-1 shows the USB serial communication circuit on this board.

Figure 3-1 USB Serial Communication Circuit

The board has a USB serial communication conversion IC (U3: FT232RL). The FT232RL operating voltage

range is 4.0 to 5.25 V. To use USB serial communication, make the following settings.

• Apply 4.0 to 5.25 V to VCC.

• Connect pins 2 and 3 of JP17.

(For details on the JP17 circuit configuration, see “3.2 Emulator Peripheral Circuit”.)

R20UT4542EJ0110 Rev.1.10 Page 19 of 39

Mar.30.20

Page 32

RSSKRX23E-A 3. Microcontroller Peripheral Circuits

Boot mode

Writes the FW using the SCI

Allows you to write the FW using

VCC

VSS

RESET(SW2)

CN7

U1

RX23E-A

1

3

5

7

9

11

13

2

4

6

8

10

12

14

R78

R79

11

5

C60

VSS

VSS

VSS

R81

JP17

1

2

3

R82

R83

R84

C58

Emulator

USB

Programmer

Selector

VCC

VCC

3.2 Emulator Peripheral Circuit

Figure 3-2 shows the emulator peripheral circuit on the board. Table 3-1 lists the JP17 connections and

corresponding functions.

Figure 3-2 Emulator Peripheral Circuit

Table 3-1 JP17 Connections and Corresponding Functions

JP17

connection

Pins 1-2

Pins 2-3 Single-chip mode

Operating mode Function Remarks

(SCI interface)

interface.

Debugs and writes the FW using

the emulator.

USB serial communication (CN6).

Applicable emulator:

E1, E2, and E2 Lite

When using the emulator, connect it to CN7. Before supplying the power from the emulator, carefully

check that the power does not collide with the input power supply or LDO output.

By pressing the RESET button (SW2) MCU RES# pin can be reset.

The MCU operating mode can be selected from the boot mode (SCI interface) or single-chip mode by

changing the JP17 setting. During power on, never change the JP17 setting. The MCU may perform

unpredictable operation.

For details on the reset operation, and boot mode operation and functions, refer to “RX23E-A Group User's

Manual: Hardware”.

For details on how to use the emulator, refer to the user's manual of the emulator.

R20UT4542EJ0110 Rev.1.10 Page 20 of 39

Mar.30.20

Page 33

RSSKRX23E-A 3. Microcontroller Peripheral Circuits

VCC

21

VSS

120Ω

R57

U1

RX23E-A

U5

J6

1

2

3

CAN Transceiver

S

TXD

VCC

RXD

GN D

CAN_ L

CAN_ H

R77

OPEN

1

Ter mination

JP16

VSS

20

19

R43

R44

R42

3

8

1

4

2

7

6

C57

CAN_ H

VSS

CAN_ L

NM

2

3

REF

VSS

5

C62

24

R94

U1

RX23E-A

U4

ISL3159EF

J7

1

2

RS-485 Driver

RO

DI

DE

RE#

GN D

VSS

23

28

R40

R35

1

4

3

2

6

7

VSS

A/Y

B/Z

A/Y

VCC

R93

R92

VSS

5

NM

8

VSS

B/Z

3

C61

VSS

R96 390Ω

R97

220Ω

D5

VCC

VCC

VCC

VSS

R95 390Ω

3.3 RS-485 Communication Circuit

Figure 3-3 shows the RS-485 communication circuit on the board.

The RS-485 communication circuit on the board has a PROFIBUS DP-compliant, half-duplex communication

RS-485 driver ISL3159EFUZ. A 220-Ω termination resistor and a 390-Ω failsafe bias resistor are mounted on

R95, R96, and R97.

Figure 3-3 RS-485 Communication Circuit

3.4 CAN Communication Circuit

Figure 3-4 shows the CAN communication circuit on the board.

Figure 3-4 CAN Communication Circuit

The CAN communication circuit on the board has a CAN transceiver. The CAN bus can be connected directly

from J6. As a termination resistor, a 120-Ω resistor is connected between CAN-H and CAN-L. When the

termination resistor is required, connect pins 2 and 3 of JP16. When it is not required, connect pins 1 and 2 of

JP16.

R20UT4542EJ0110 Rev.1.10 Page 21 of 39

Mar.30.20

Page 34

RSSKRX23E-A 3. Microcontroller Peripheral Circuits

VCC

LED1

Red

U1

RX23E-A

R51

VSS

R56

LED2

Green

22

VSS

SW1

VCC

U1

RX23E-A

R80

R85

C59

15

VSS

3.5 LED Circuit

Figure 3-5 shows the LED drive circuit on the board.

ON/OFF of LED1 (red) can be controlled by a port of MCU (PH2). LED2 (green) is a VCC power indicator.

Figure 3-5 LED Drive Circuit

3.6 Switch Input Circuit

Figure 3-6 shows the switch input circuit on the board.

For details on the RESET switch (SW2), see “3.2 Emulator Peripheral Circuit”.

Figure 3-6 Switch Input Circuit

R20UT4542EJ0110 Rev.1.10 Page 22 of 39

Mar.30.20

Page 35

RSSKRX23E-A 3. Microcontroller Peripheral Circuits

VSS

U1

RX23E

-A

C34

C33

6

8

3.7 External Clock Input Circuit

Figure 3-7 shows the external clock input circuit on the board.

The board has an 8-MHz external crystal oscillator as an external clock input source.

Figure 3-7 External Clock Input Circuit

R20UT4542EJ0110 Rev.1.10 Page 23 of 39

Mar.30.20

Page 36

RSSKRX23E-A 4. Board Information

Applicable crimp

Terminal-applicable

4. Board Information

4.1 Using Terminal Blocks

Table 4-1 lists the part used for terminal blocks CN1, CN2, CN4, and CN5, recommended crimp terminal,

crimping tool, and terminal-applicable wire diameter.

Table 4-1 Terminal Blocks and Applicable Crimp Terminal

Part model name

FFKDS/H-2,54

(Note)

Note FFKDSA1/H-5,08 is used as each connector termination.

terminal

AI0.25-8 CRIMPFOX CENTRUS 10S and others AWG 24

Crimping tool

wire diameter

If you want to use an applicable crimp terminal, you can push in the crimp terminal to connect it to a connector

(push-in type). If a crimp terminal or crimping tool is unavailable, you can connect a stripped wire. To use a

stripped wire, follow the procedure below.

i) Push and hold the orange button into the board.

ii) Insert a stripped wire into the pin insertion hole.

iii) Release the orange button slowly.

iv) Lightly pull the wire to confirm that it is fixed.

To remove the crimp terminal and the wire, follow the procedure below.

i) Push and hold the orange button into the board.

ii) Remove the crimp terminal and the wire from the pin insertion hole.

iii) Release the orange button slowly.

R20UT4542EJ0110 Rev.1.10 Page 24 of 39

Mar.30.20

Page 37

RSSKRX23E-A 4. Board Information

Power Output

Terminal block for outputting an analog power supply.

Signal Input

Terminal block for inputting an analog power supply.

USB Serial

Connector for USB serial communication.

Connector for connecting an emulator.

4.2 Connectors

Table 4-2 lists the connectors on the board.

Table 4-2 Connectors

Reference Connector Name Explanation

CN1

CN2

CN3

CN4

CN5

CN6

CN7 Emulator Connector

Terminal Block

Terminal Block

Thermocouple

Connector

System Power Input

Terminal Block

Analog power Input

Terminal Block

Communication

Connector

Use this connector as an excitation voltage source for a strain gage, etc.

Terminal block for inputting analog signals

Miniature thermocouple input socket.

Copper is used for the material of both terminals.

The terminal screws are soldered to the board. Do NOT rotate them.

Terminal block for inputting a system power supply

Use this connector to supply an analog power supply separately from the

system power supply.

The connector type is USB mini-B. Use this connector for communication

with PC Tool Program.

Use the 14-pin interface cable supplied with the emulator.

The applicable emulator is E1, E2, and E2 Lite.

R20UT4542EJ0110 Rev.1.10 Page 25 of 39

Mar.30.20

Page 38

RSSKRX23E-A 4. Board Information

Silk

GND output

Analog GND output for an external device.

Positive reference voltage input pin.

1

AIN1

I/O

Analog signal input pin

3

AIN3

I/O

Analog signal input pin

Analog signal input pin and positive reference voltage input pin.

Analog signal input pin.

Analog signal input pin and excitation current output pin.

Table 4-3 to

Table 4-9 detail each connector.