Page 1

KIT USER MANUAL

RL78

DETECT-IT !

RL78/I1D detector boards kit

UM-YDETECT-IT-

Rev.1.30

Feb 24, 2015

Kit User manual

Introduction

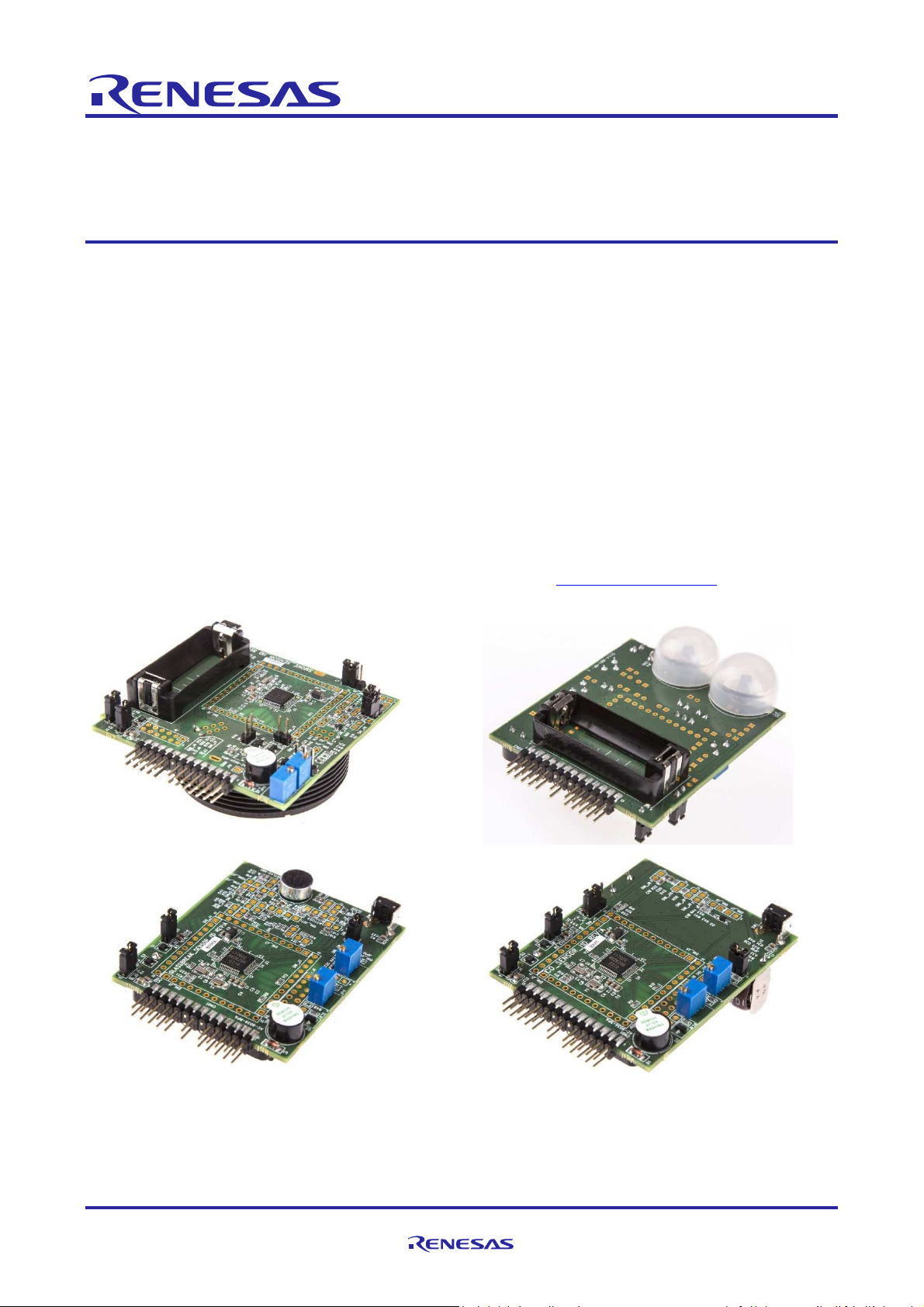

The Renesas kit Detect it! is based on the low power 16-bit microcontroller RL78/I1D.

The kit contains 4 boards which are demonstrators of the most common detector types available in the market:

- Glass break detector and motion detector used mainly in security & surveillance system

- Monoxide carbon detector and smoke detector used in human protection system.

The user can easily test these 4 detector boards. Indeed all the boards contained into the Detect it! kit are

preprogrammed and ready for quick demonstration.

The boards demonstrate the new Renesas microcontroller RL78/I1D specifically designed for detector applications,

thanks to its low power features, enhanced analog front end and smart peripherals.

The boards are designed to allow some flexibility. For example, nearly all pins of the microcontroller are connected to

some header, the user can chose between power by line or power from a battery, the user can easily add a PMOD

extension thanks to the 12 bit standard pin header sold onto the board.

User can connect the boards to external tool for debugging and flashing the boards.

Update information about this kit can be found on the following webpage : www.renesas.eu/detector/

Target Device

RL78/I1D devices, Family part numbers starting with R5F117.

UM-YDETECT-IT-RL78 V1.30 Page 1 of 59

Page 2

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Contents

1. Hardware overview ......................................................................................................... 5

2. Detector application brief explanation .......................................................................... 5

Glass Break detector board design explanation ..................................................................... 5

CO detector design explanation ................................................................................................ 6

Motion detector design explanation ......................................................................................... 8

Smoke detector design explanation ......................................................................................... 9

3. Boards layout ............................................................................................................... 10

Glass Break detector board layout ......................................................................................... 10

CO detector board layout ......................................................................................................... 11

Motion detector board layout................................................................................................... 13

Smoke detector board layout................................................................................................... 15

4. Content of the CD-ROM ............................................................................................... 17

5. Board description ......................................................................................................... 19

Glass Break detector board ..................................................................................................... 19

5.1.1 Oscillators ............................................................................................................................. 20

5.1.2 Description of Jumper J ........................................................................................................ 20

5.1.3 Description of Potentiometer JP ........................................................................................... 21

5.1.4 Buzzer: .................................................................................................................................. 21

5.1.5 Description of Push Button ................................................................................................... 21

5.1.6 Battery place holder .............................................................................................................. 22

5.1.7 Microcontroller RL78/I1D ...................................................................................................... 22

5.1.8 Description of PMOD connector J9....................................................................................... 24

5.1.9 Description of board edge connectors CN01 and CN02 ...................................................... 24

CO detector board ..................................................................................................................... 25

5.2.1 Oscillators ............................................................................................................................. 26

5.2.2 Description of Jumper J ........................................................................................................ 26

5.2.3 Description of Potentiometer JP ........................................................................................... 27

5.2.4 Buzzer: .................................................................................................................................. 27

5.2.5 Description of Push Button ................................................................................................... 27

5.2.6 Battery place holder: ............................................................................................................. 28

5.2.7 Microcontroller RL78/I1D ...................................................................................................... 28

5.2.8 Description of PMOD connector J9....................................................................................... 30

5.2.9 Description of board edge connectors CN01 and CN02 ...................................................... 30

Motion detector board .............................................................................................................. 31

5.3.1 Oscillators ............................................................................................................................. 32

5.3.2 Description of Jumper J ........................................................................................................ 32

5.3.3 Description of Potentiometer JP ........................................................................................... 33

UM-YDETECT-IT-RL78 V1.30 Page 2 of 59

Page 3

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5.3.4 Buzzer ................................................................................................................................... 34

5.3.5 Description of Push Button ................................................................................................... 34

5.3.6 Battery place holder .............................................................................................................. 34

5.3.7 Microcontroller RL78/I1D ...................................................................................................... 34

5.3.8 Description of PMOD connector J9....................................................................................... 36

5.3.9 Description of board edge connectors CN01 and CN02 ...................................................... 36

Smoke detector board .............................................................................................................. 37

5.4.1 Sensor connection ................................................................................................................ 38

5.4.2 Oscillators ............................................................................................................................. 38

5.4.3 Description of Jumper J ........................................................................................................ 38

5.4.4 Description of Potentiometer JP ........................................................................................... 39

5.4.5 Buzzer ................................................................................................................................... 39

5.4.6 Description of Push Button ................................................................................................... 39

5.4.7 Battery place holder .............................................................................................................. 40

5.4.8 Microcontroller RL78/I1D ...................................................................................................... 40

5.4.9 Description of PMOD connector J9....................................................................................... 42

5.4.10 Description of board edge connectors CN01 and CN02 ...................................................... 42

6. Theory of operation ...................................................................................................... 43

Glass Break detector theory of operation .............................................................................. 43

6.1.1 Analog Front End circuit of Glass Break detector ................................................................. 43

6.1.2 MCU/digital system and maintain low current drain for long battery life ............................... 44

CO detector theory of operation .............................................................................................. 44

6.2.1 Analog Front End circuit of CO detector ............................................................................... 44

6.2.2 MCU/digital system and maintain low current drain for long battery life ............................... 45

Motion detector theory of operation ....................................................................................... 46

6.3.1 Analog Front End circuit of Motion Detector ......................................................................... 46

6.3.2 MCU/digital system and maintain low current drain for long battery life ............................... 47

Smoke detector theory of operation ....................................................................................... 47

6.4.1 Analog Front End circuit of Smoke detector ......................................................................... 47

6.4.2 MCU/digital system and maintain low current drain for long battery life ............................... 49

7. How to start the boards for Battery operation ............................................................ 49

Glass Break detector demonstration using battery .............................................................. 49

CO detector demonstration using battery .............................................................................. 49

Motion detector demonstration using battery ....................................................................... 49

Smoke detector demonstration using battery ....................................................................... 50

8. How to start the boards with IAR ................................................................................ 50

9. Notes and comments about board operation ............................................................. 56

Glass Break detector operation ............................................................................................... 56

9.1.1 Glass break Sensor Testing results ...................................................................................... 56

UM-YDETECT-IT-RL78 V1.30 Page 3 of 59

Page 4

DETECT-IT RL78/I1D detector boards kit Kit User Manual

9.1.2 Glass break Sensor Current consumption results ................................................................ 56

CO Sensor Operation ................................................................................................................ 57

9.2.1 CO Sensor Testing results .................................................................................................... 57

9.2.2 CO Sensor Current Consumption results ............................................................................. 57

9.2.3 CO Sensor Calibration method ............................................................................................. 58

Motion Detector Operation ....................................................................................................... 59

9.3.1 Motion Detector Testing results ............................................................................................ 59

9.3.2 Motion detector Current consumption results ....................................................................... 59

Smoke Sensor Operation ......................................................................................................... 59

9.4.1 Smoke Detector Testing results ............................................................................................ 59

9.4.2 Smoke detector Current consumption results ....................................................................... 59

10. Support ......................................................................................................................... 60

Revision History .................................................................................................................... 1

General Precautions in the Handling of MPU/MCU Products ............................................. 2

UM-YDETECT-IT-RL78 V1.30 Page 4 of 59

Page 5

DETECT-IT RL78/I1D detector boards kit Kit User Manual

1. Hardware overview

The solution kit Detect it! includes 4 different types of detector demonstrator:

- Glass Break detector demonstrator

- Carbon Monoxide detector demonstrator (CO detector)

- Motion detector demonstrator

- Smoke detector demonstrator

The purpose of those boards is to show that the Renesas microcontroller RL78/I1D MCU - used in each board - is a

perfect device for implementing low power sensor designs for detectors with a minimum of external components. In

each case, the board shows a different detection using the RL78/I1D and its embedded analog peripherals such as

internal operational-amplifiers, comparators and optimized power saving MCU features. The new RL78/I1D has some

major advantages for detection against previous RL78 MCU families.

The Renesas MCU RL78/I1D has specific features that can benefit to such type of detectors/sensors, for example

usually requiring low power features like low average current drain and long battery life.

The RL78/I1D MCU has low power clock/timer and safety features in STOP mode that needs less than 1µA total, even

when Real-Time-Counter operated with 32kHz crystal, Watchdog timer operated with 15kHz clock, 12-bit interval

timer and Low Voltage Detect functions are all enabled, and all RAM data retained.

The RL78/I1D also has integrated operational amplifiers and comparators that can be used for sensor measurements at

low power. Current drain for the RL78/I1D integrated operational amplifiers and comparators depends on factors such

as external bias resistor values, which operational amplifier and comparator modes are used and how many channels are

enabled during standby. The integrated operational amplifiers of the RL78/I1D have both a low power mode and high

speed mode. In Low Power mode, the operational amplifier is typically drawing about 2.5µA typical for the first

channel (plus ~2.0µA per each additional channel) with GainBandWidth (GBW) = 40kHz. In High Speed mode, the

current draw is around 140µA typical for first channel (plus ~120µA per each additional channel) with GBW =

1.7MHz.

All boards have a different sensor depending on the measurement that needs to be done:

Glass Break detector demonstrator use a microphone to detect noise that emulate glass break event.

Carbon monoxide detector (CO detector) demonstrator uses a chemical sensor

Motion detector demonstrator use a specific PIR sensor based on infrared technology to detect movement.

Smoke detector demonstrator use a smoke chamber, with emitter and receptor diode

All boards are processing the measurement coming from these sensors with amplification and filtering stage done by the

microcontroller.

There is possibility to power each board by battery (3V lithium battery) or by power supply. All the detector boards

demonstrate a low current consumption. For the purpose of the demonstration, the goal was to achieve a battery life of 4

years or more using a CR123 lithium battery. Further optimization can be done in true application to minimize further

the current consumption of the board. Only one battery CR123 is provided into the kit for the 4 boards.

2. Detector application brief explanation

Here are brief explanation of function of each board, including top level block diagram.

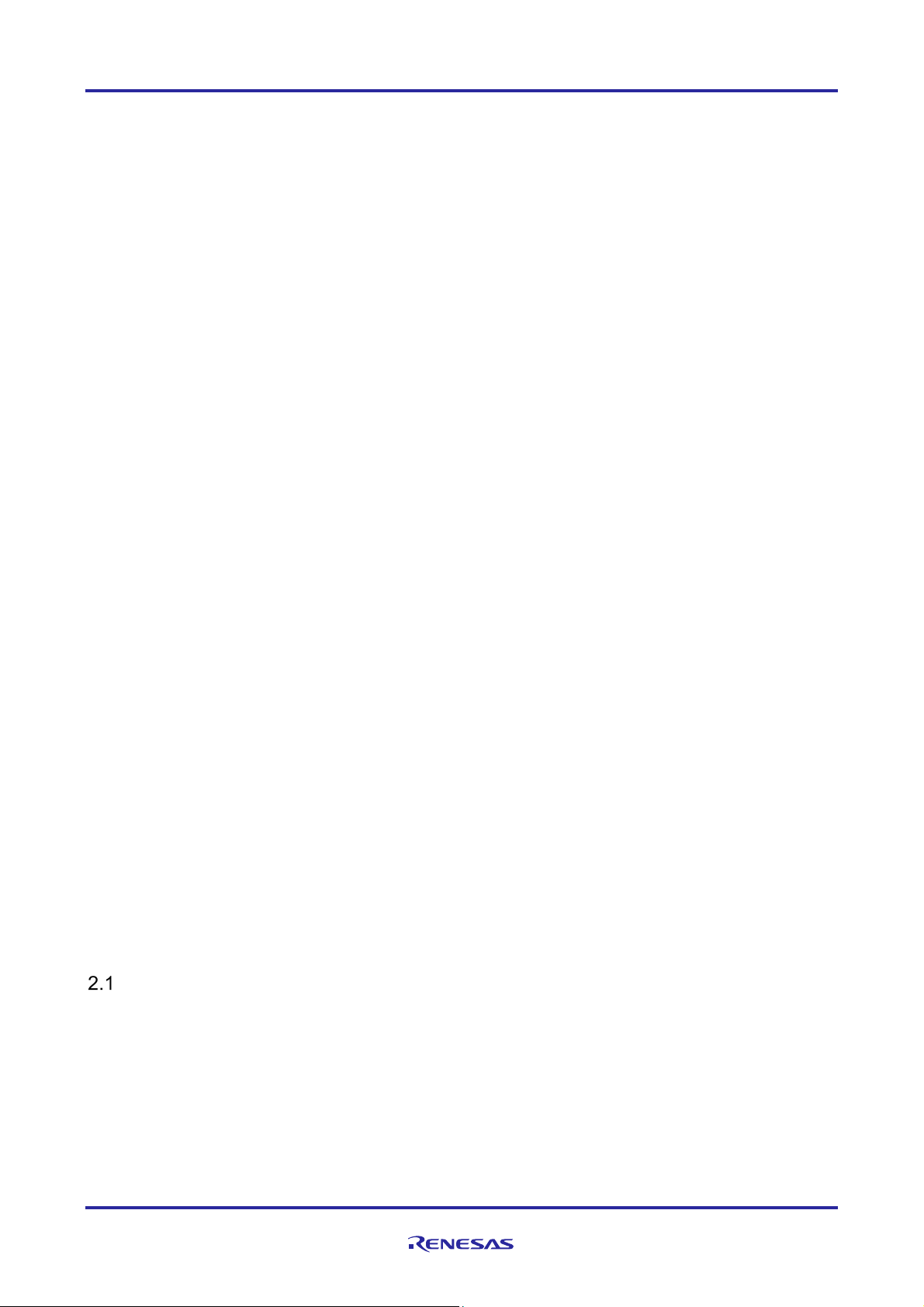

Glass Break detector board design explanation

The Glass Break detector is designed to start alarm when a glass break sound event occurred. By consequence the goal

is to start alert when high frequency sound is detected, and to filter all loud sounds such as loud hand clap, slamming

door, book slammed down on a table or barking dog. It was designed to detect simulated glass break event, such as

emulated by the Interlogix 5709C-W glass break simulator.

UM-YDETECT-IT-RL78 V1.30 Page 5 of 59

Page 6

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Glass Break sensor block diagram

The microphone is the first element of the analog front end. The microphone is used as the sensor for glass break event.

The microphone used is an Electret with frequency response from 25Hz to 16kHz.

The microphone is AC coupled to both a low pass and high pass sections, so that microphone output DC bias variations

does not affect the operational amplifier filter bias points:

• 2-stage low pass filter uses 2 channels (Ch0 and Ch1) of RL78/I1D internal operational amplifiers in low power

mode at about 4.5µA typical current drain total.

The first stage has a nominal gain of 31 and a roll-off/cut-off frequency @ 34Hz.

The second stage has a nominal gain of 26 at roll-off/cut-off frequency @ 154Hz.

Therefore in both cases, GBWP (gain x frequency product) used on each stage is less that the operational

amplifier GBW = 40 kHz rating in low power mode. Since the operational amplifiers have a low current drain in

low power mode, they can be left on constantly to monitor a loud transient sound event.

• 2-stage high pass filter uses 2 channels (Ch2 and Ch3) of RL78/I1D internal operational amplifiers in high speed

mode at about 262µA total for both channels typical current drain.

The first stage has a nominal gain of 20 and upper roll-off/cut-off frequency @ 24kHz.

The second stage has a nominal gain of 5 and upper roll-off/cut-off frequency @ 1447Hz.

Therefore in both cases, the GBWP (gain x frequency product) used is less that the operational amplifier GBW =

1.7 MHz rating in high speed mode. Since the operational amplifiers have a higher current drain (>100µA per

channel) in high speed mode, they are only turned on intermittently when analyzing a loud sound transient event.

So in glass break detector demonstration, the 4 operational amplifiers are used.

A buzzer is used to give the alarm, it is managed by the MCU (transistor driver).

The push button is used for the reset function.

The board can be powered by a 3V lithium battery (CR123). It can also be powered by power supply (E1 power supply

or external power). One battery CR123 is provided into the kit for the 4 boards. The E1 debugger is not provided.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01.

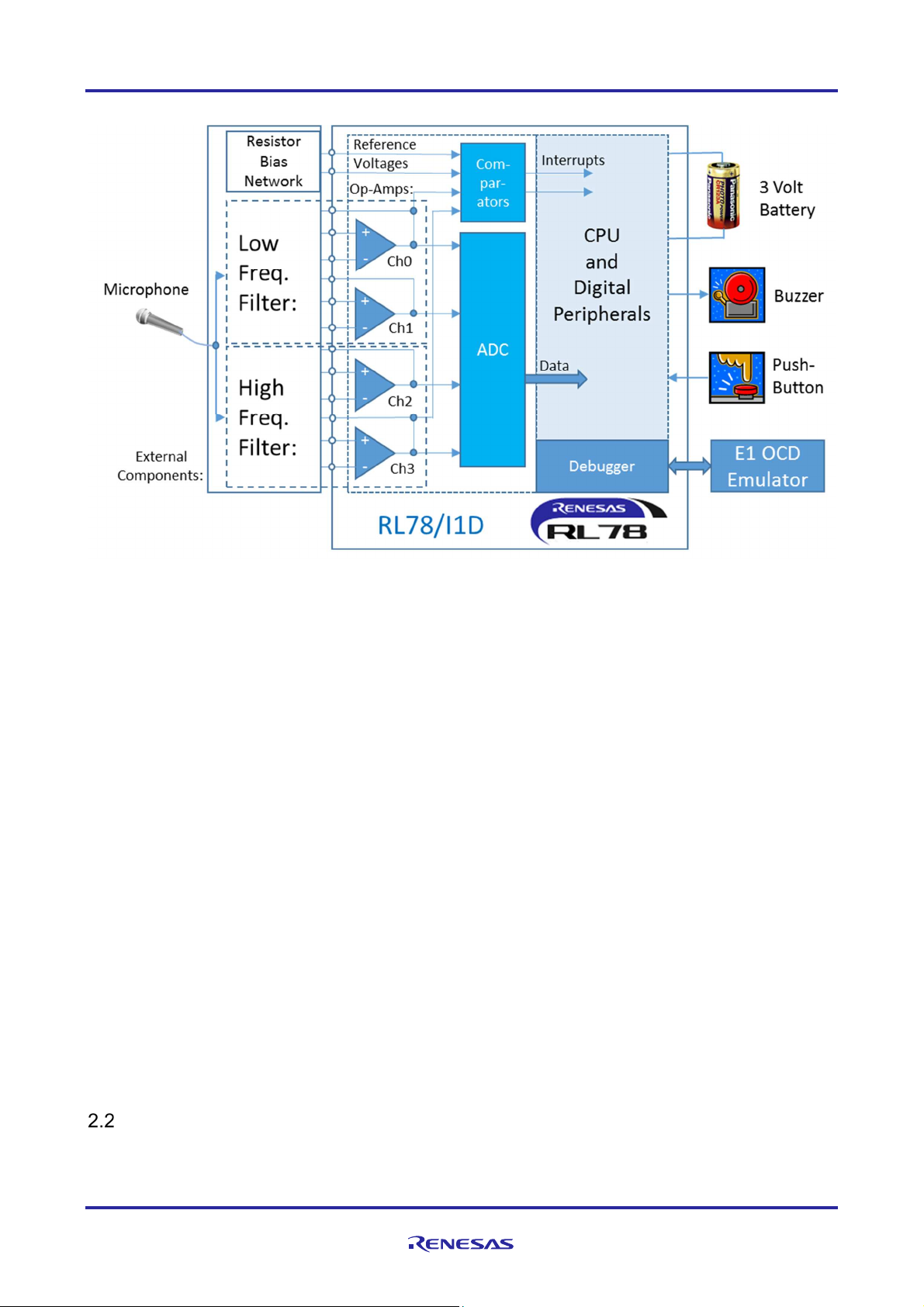

CO detector design explanation

The carbon monoxide detector is designed to alarm when the concentration of CO gas is measured at a preset level of

100ppm. A higher threshold level can be set in software if desired.

UM-YDETECT-IT-RL78 V1.30 Page 6 of 59

Page 7

DETECT-IT RL78/I1D detector boards kit Kit User Manual

The chemical sensor CO sensor canister is used to detect CO gas at 100ppm +/- 10 ppm and greater. An aerosol such as

CO Check ™ or Model HO-CO rev2 test CO gas can be used to simulate an event.

In the case of the CO detector, only 2 operational amplifiers are used: they are used to process CO sensor current to

voltage and look for CO gas exceeding the pre-determined threshold.

Figure CO sensor block diagram

The CO chemical sensor is the first element of the analog front end. The CO gas sensor is used as the sensor for

concentration of CO gas. It is a CO sensor canister (Figaro TGS5042 CO gas sensor) and it is used to provide a linear

output current that is proportional with CO gas concentration. Its specification is 1.2nA-2.4nA per PPM, and the

calibrated output value is printed on the canister (for example 1402 indicates 1.402nA/PPM).

The CO sensor is connected to 2-stage processing analog front end:

1 stage DC bias: uses single channel (Ch1) of RL78/I1D internal operational amplifier in low power mode at

about 2.25µA typical current drain. This stage implements a voltage follower configuration from a resistive

divider at VDD/11 (nominally 0.3Volt @ VDD = 3.3V) and provides a low impedance to the CO sensor

negative terminal bias point.

1 stage Trans-conductance amplifier: uses single channel (Ch0) of RL78/I1D internal operational amplifier in

low power mode at about 2.25µA typical current drain.

For the both the DC bias and Trans conductance amplifier configurations, the required frequency response is less

than 1Hz and the operational amplifier GBW = 40kHz rating in low power mode is more than adequate. Since

the 2 operational amplifier channels together have ~4.5µA typical current drain in low power mode, they can be

left on without a huge increase in STOP/standby mode current. As the CO sensor has a relatively long time

constant (>10 seconds) to fully react to the CO gas concentration levels, the operational amplifiers need to be left

on constantly.

So in this CO sensor detector demonstration, only 2 operational amplifiers are used.

A buzzer is used to give the alarm, it is managed by the MCU (transistor driver).

The push button is used connected, but not used in the CO detector demonstrator.

The board can be powered by a 3V lithium battery (CR123). It can also be powered by power supply (E1 power supply

or external power). One battery CR123 is provided into the kit for the 4 boards. The E1 debugger is not provided.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01.

UM-YDETECT-IT-RL78 V1.30 Page 7 of 59

Page 8

DETECT-IT RL78/I1D detector boards kit Kit User Manual

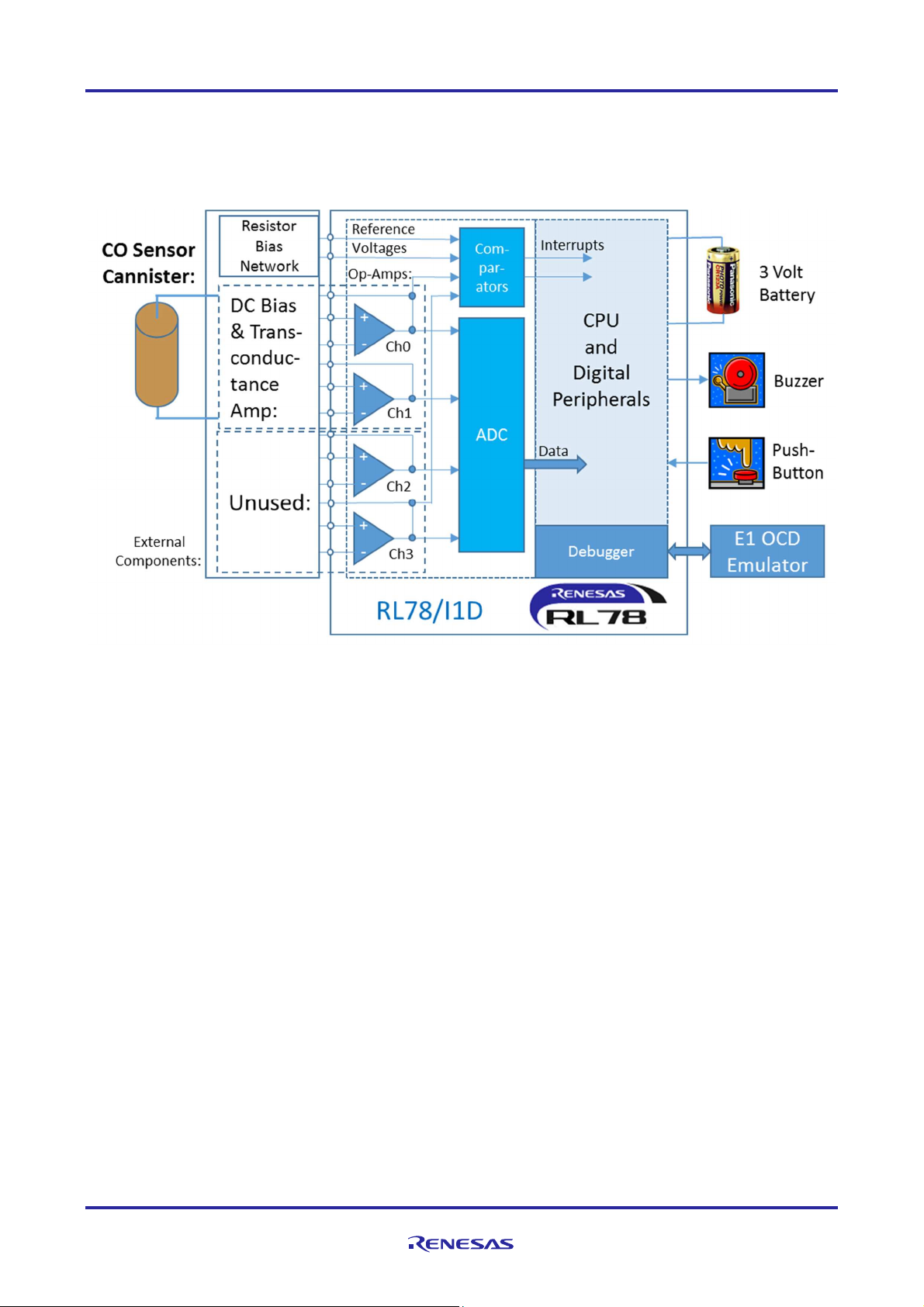

Motion detector design explanation

The Motion detector demonstration can alarm when a human moves within 4 meters in front of the PIR (Pyroelectric

InfraRed) sensor within an angle of +/-45degrees vertically, and +/-70 degrees horizontally as measured from the

normal (apex) point perpendicular to the front of PIR sensor surface.

For this Motion sensor design, the 2 integrated operational amplifiers are used to monitor PIR sensor amplified voltage

and look for PIR levels exceeding the pre-determined thresholds. The operational amplifiers are used in high speed

mode in this Motion sensor demonstrator.

Figure Motion sensor block diagram:

The PIR (Pyroelecctric InfraRed) sensor is the first element of the Analog Front End. The muRata part number IRAE700STO PIR sensor is used to detect IR energy changes that are detected when a warm object such as a human being

comes into the range of the sensor. PIR sensing of infrared energy is further enhanced by a white, translucent Fresnel

lens placed in front of the PIR transducer. The Fresnel lens has a hemispheric shape with a honey comb shaped cells in

the plastic mold. These Fresnel lens cell shapes then enhance the sensed IR energy peak-to-peak voltage changes as the

human being advances across the front of PIR sensor

The PIR sensor is connected to 2-stage processing analog front end:

The first stage AC amplifier uses single channel Ch1 of RL78/I1D internal operational-amplifier in low power

mode at about 2.25µA typical current drain. This stage is AC coupled from the PIR sensor output to Ch1, so as

to eliminate any PIR DC bias variations. The stage 1 amplifier has a nominal gain of x101, and an upper roll-off

frequency ~15.9Hz.

The second stage AC amplifier: uses single op-amp channel Ch0 has a nominal gain of x33.9 max (x6.7min) at

roll-off/cut-off frequency @32.9HZ max (6.5HZ min). The gain of this 2nd stage is adjust by the 900KΩ

potentiometer (labeled JP9). The input of the 2nd stage is AC coupled (DC-blocked) from 1st stage (AMP1O)

output. However the output of 2nd stage (AMP0O) is DC coupled to ADC input ANI4 and Comparator input

IVREF0. In all cases of the 1st stage and 2nd stage Amplifier settings, GBWP (gain x frequency product) used on

each stage is less that the op-amp GBW = 40KHZ rating in low power mode. Since the op-amps have a low

current drain in low power mode, they can be left on constantly to monitor PIR sensor pulse energy. The output

of AMP0O is monitored by Comparator input IVCMP0, which is on the same MCU pin as AMP0O. The

explanation of Comparator function to trigger MCU wakeup is below.

So in this Motion sensor detector demonstration, only 2 operational amplifiers are used.

UM-YDETECT-IT-RL78 V1.30 Page 8 of 59

Page 9

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Note : The motion sensor board has a second/alternate PIR sensor connected to MCU internal operational amplifier

channels Ch2 and Ch3. However, these Ch2/Ch3 operational amplifiers are not currently activated by the

current Firmware revision, then the second PIR sensor will not draw current. (However there is an additional

current drain thru R67 and R93 of about 0.34uA @3.3V that could be eliminated by removing either of these

resistors).

A buzzer is used to give the alarm, it is managed by the MCU (transistor driver).

The push button is used for the reset function.

The board can be powered by a 3V lithium battery (CR123). It can also be powered by power supply (E1 power supply

or external power). One battery CR123 is provided into the kit for the 4 boards. The E1 debugger is not provided.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01.

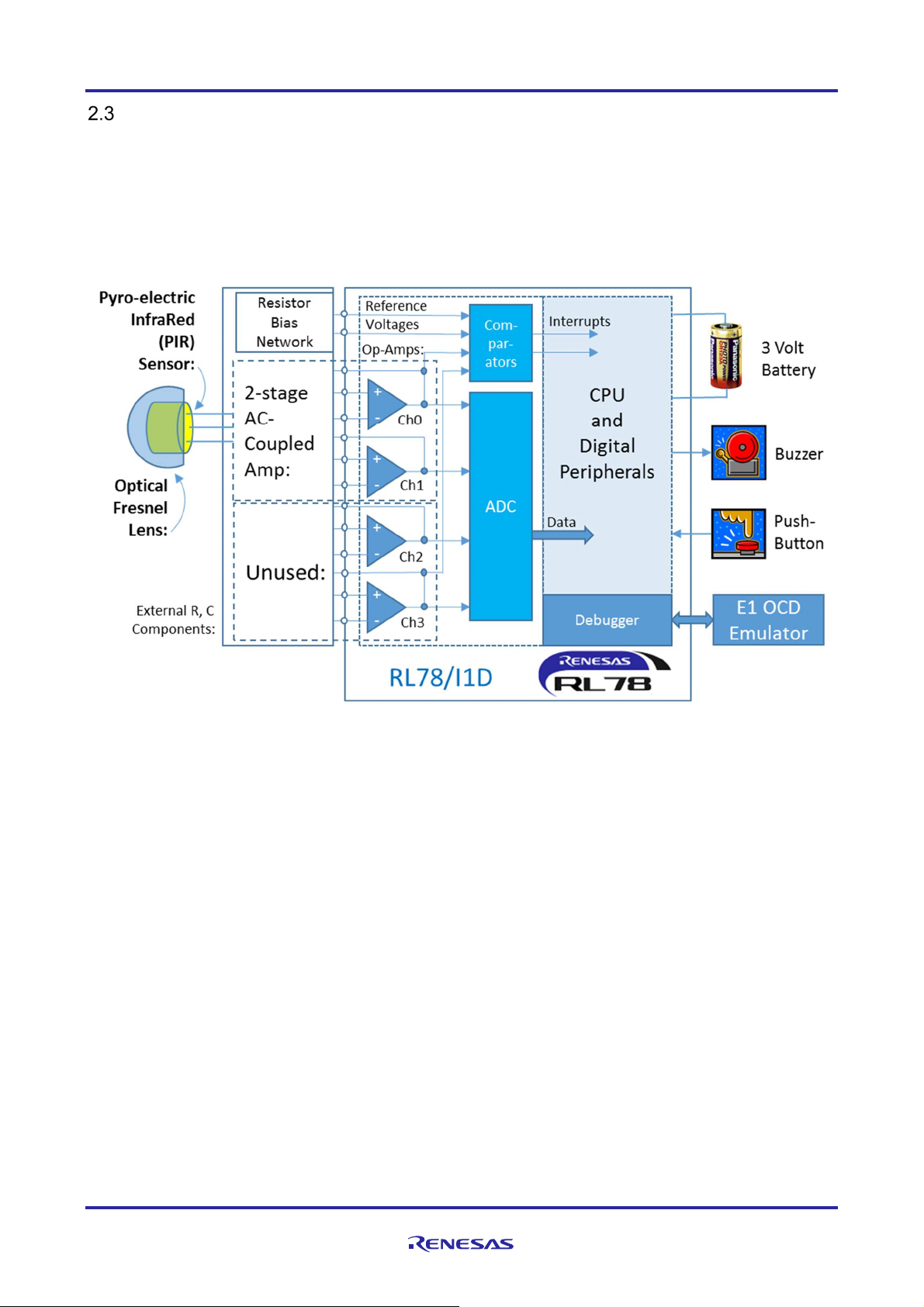

Smoke detector design explanation

The Smoke detector is an infrared reflective smoke sensor type. It will alert when smoke (or simulated smoke) is

detected for 3 seconds.

In order to test the smoke detector board, you can use product like “smoke check” or “smoke in a can” brand spray in

order to simulated smoke. The board will work with real smoke as well. The board is designed to reject any ambient

infrared light from direct/indirect sunlight or man-made IR sources. For the smoke sensor, the integrated operational

amplifiers of the RL78/I1D are used to perform the current to voltage (trans-conductance) conversion needed to detect

IR photodiode avalanche (reverse bias) current when reflected IR light is present. Only 2 operational amplifiers are used

in the Smoke detector demonstrator, and they are operating in High Speed mode. The RL78/I1D comparators are not

used for this Smoke detector design.

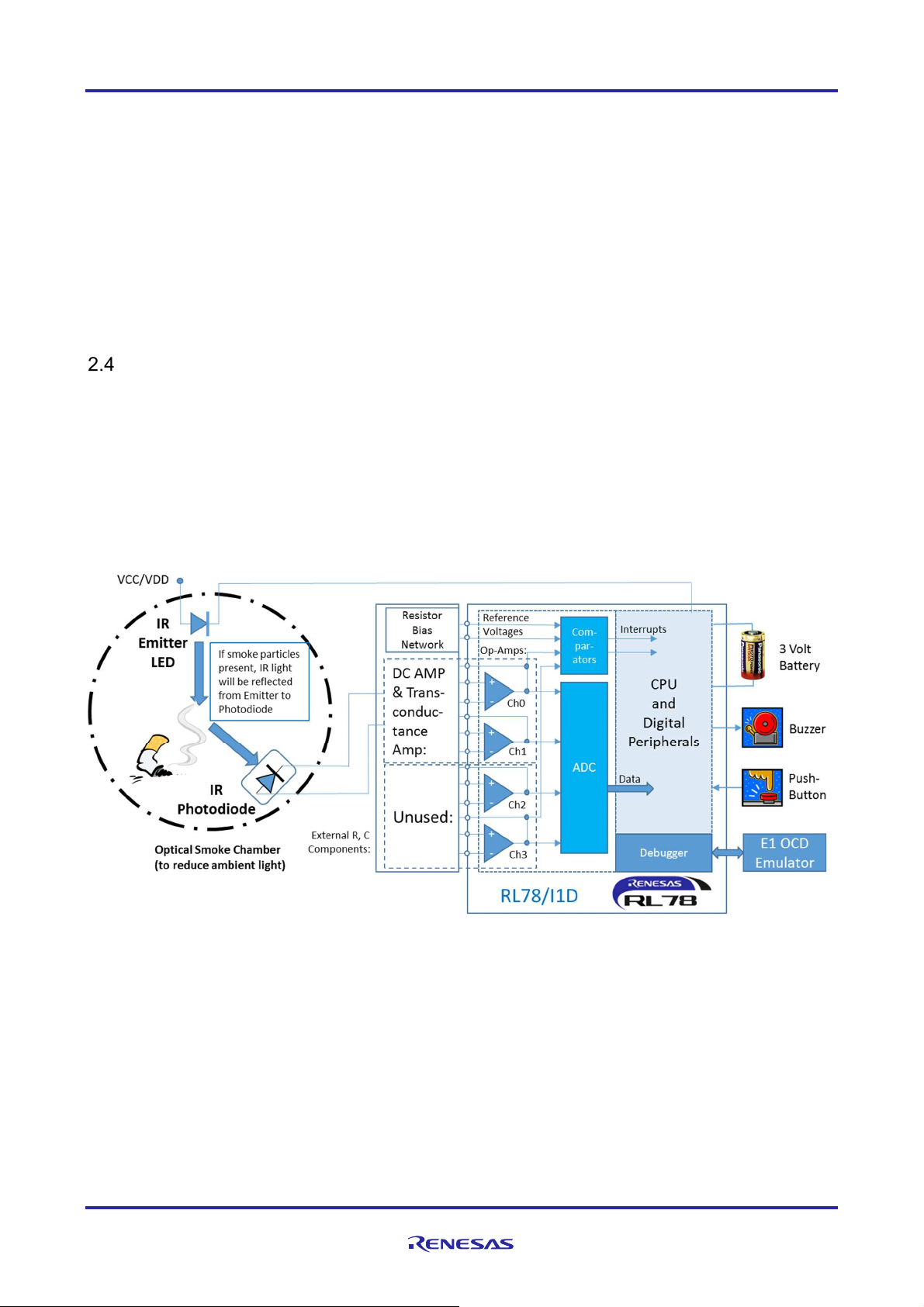

Figure Smoke sensor block diagram

The optical smoke chamber is the first element of the analog front end, this chamber is used to reduce the ambient light.

Inside an Infrared emitting LED and Infrared Photodiode are used to detect smoke particles by reflected IR light.

This optical smoke chamber is connected to 2 operational amplifiers of the RL78/I1D:

- First stage (DC) trans-conductance (current to voltage) amplifier

- Second stage DC amplifier, to provided additional DC gain.

The on-chip comparators are not used in the Smoke sensor board.

A buzzer is used to give the alarm, it is managed by the MCU (transistor driver).

The push button is used for the reset function.

UM-YDETECT-IT-RL78 V1.30 Page 9 of 59

Page 10

DETECT-IT RL78/I1D detector boards kit Kit User Manual

The board can be powered by a 3V lithium battery (CR123). It can also be powered by power supply (E1 power supply

or external power). One battery CR123 is provided into the kit for the 4 boards. The E1 debugger is not provided.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01.

3. Boards layout

Below are pictures of each board with short explanation of the main parts. The name of each board is written, on the

PCB (Please look at the PCB to identify each board).

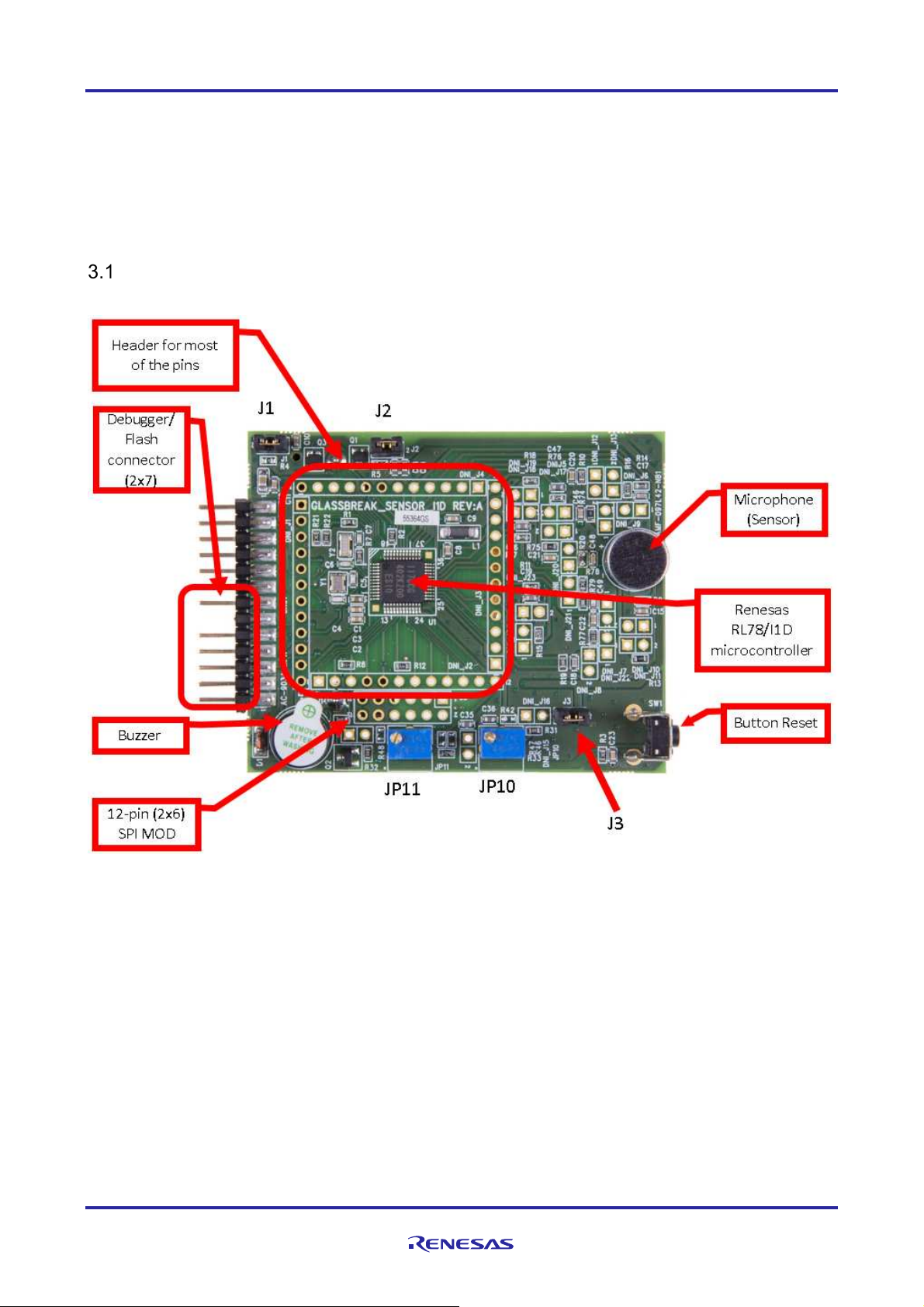

Glass Break detector board layout

Please check the name of the board you are looking “GLASSBREAK_SENSOR_I1D”

Figure Glass break detector top view

UM-YDETECT-IT-RL78 V1.30 Page 10 of 59

Page 11

DETECT-IT RL78/I1D detector boards kit Kit User Manual

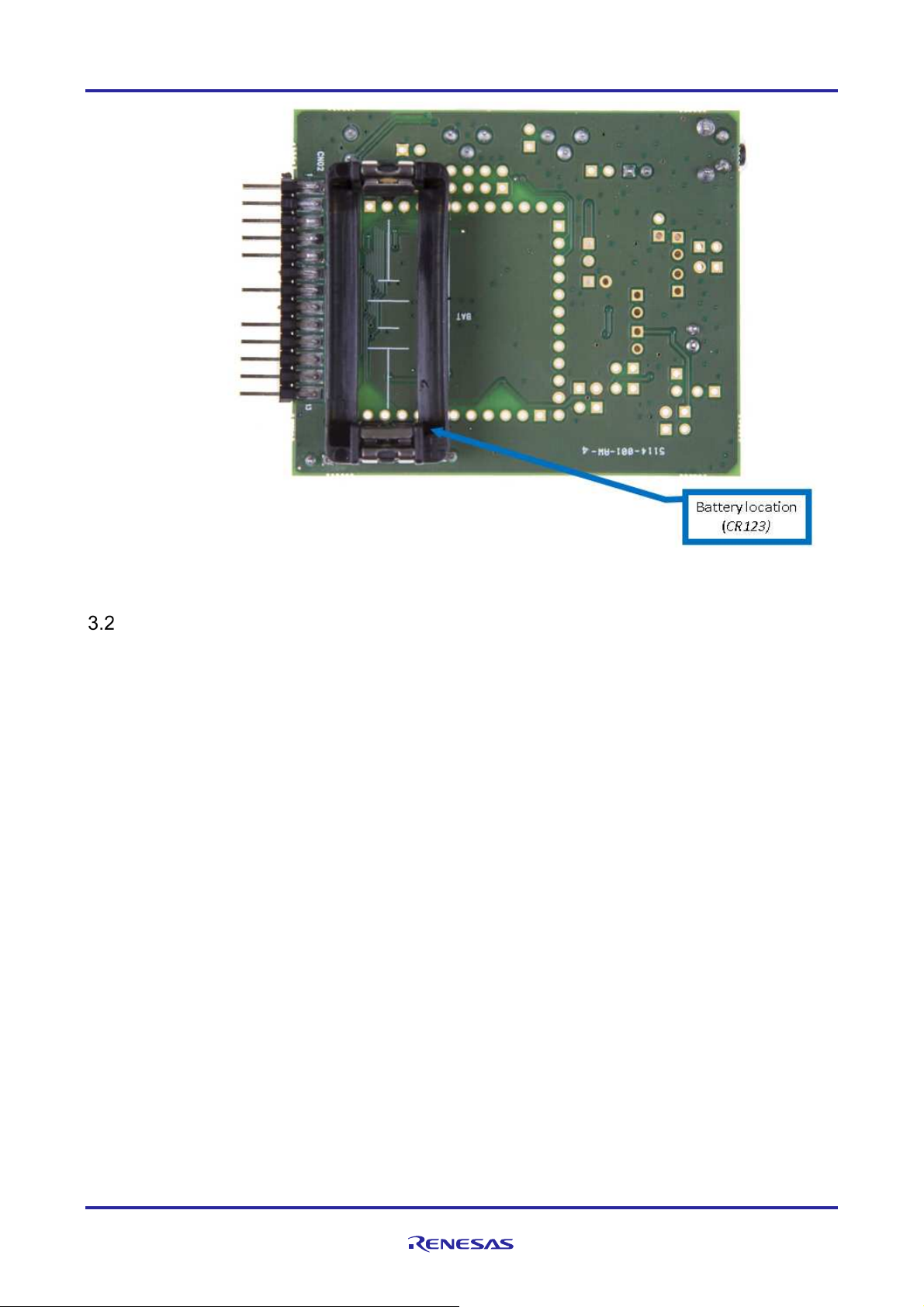

Figure Glass break detector bottom view

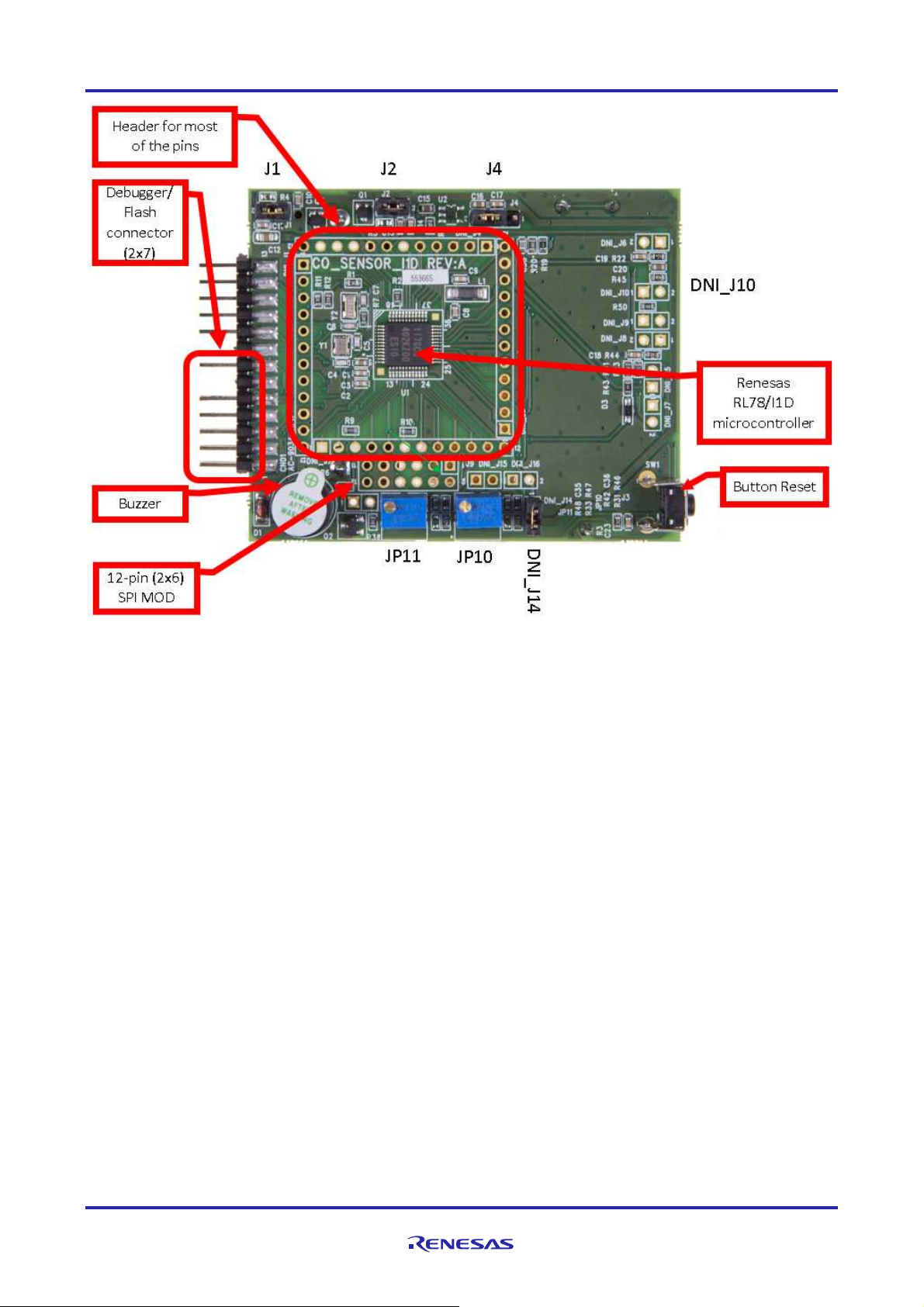

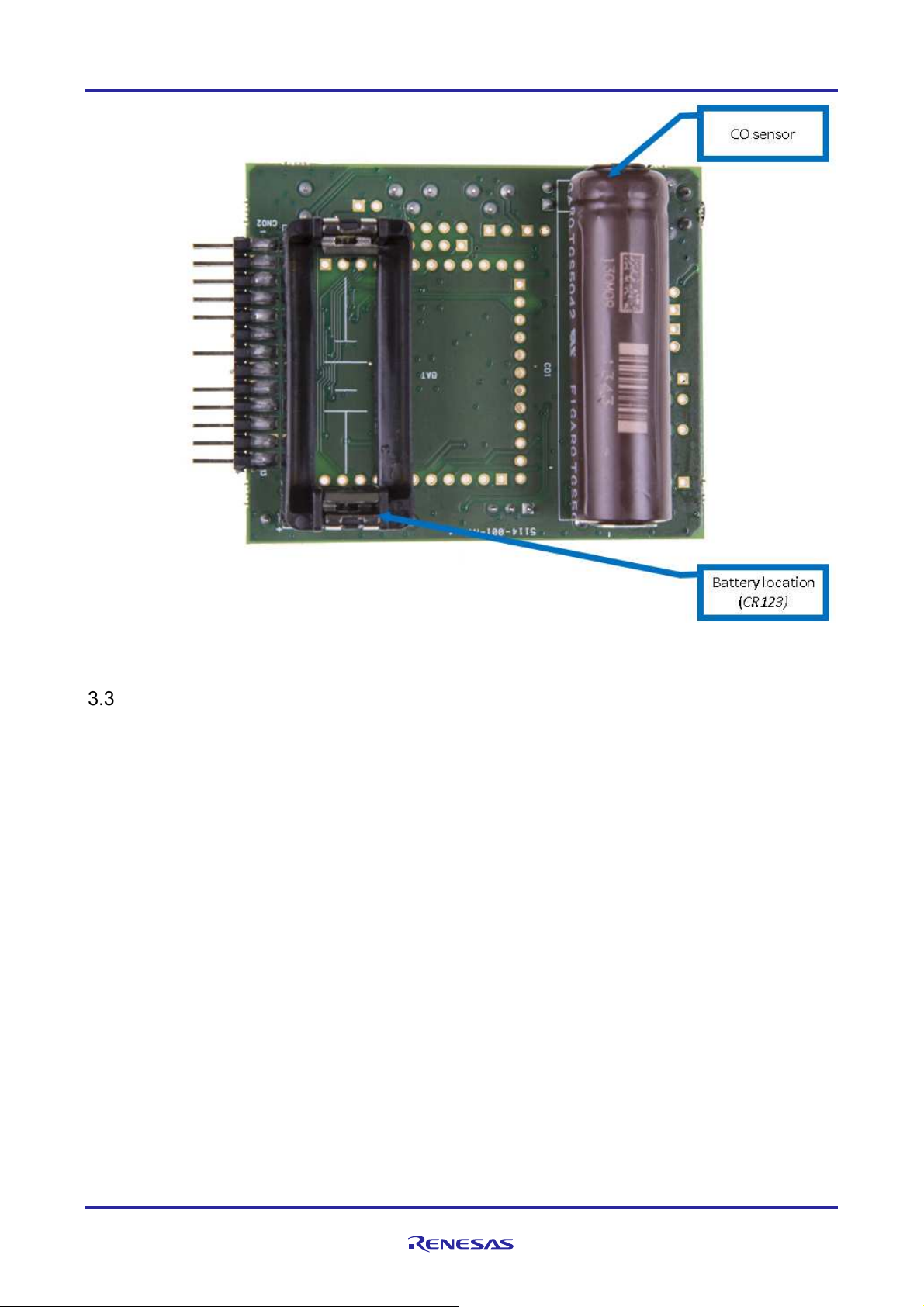

CO detector board layout

Please check the name of the board you are looking “CO_SENSOR_I1D”

UM-YDETECT-IT-RL78 V1.30 Page 11 of 59

Page 12

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure CO detector top view

UM-YDETECT-IT-RL78 V1.30 Page 12 of 59

Page 13

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure CO detector bottom view

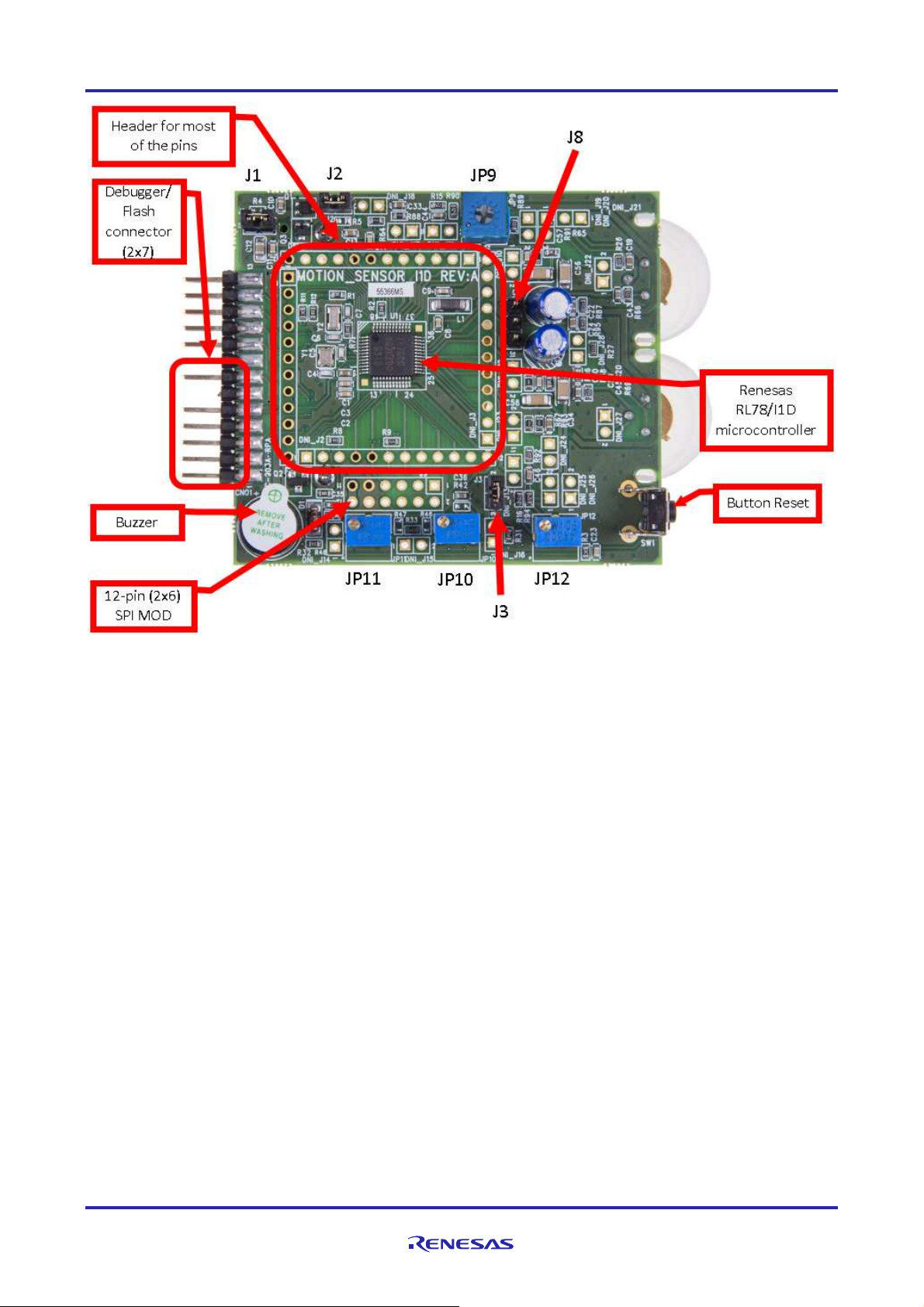

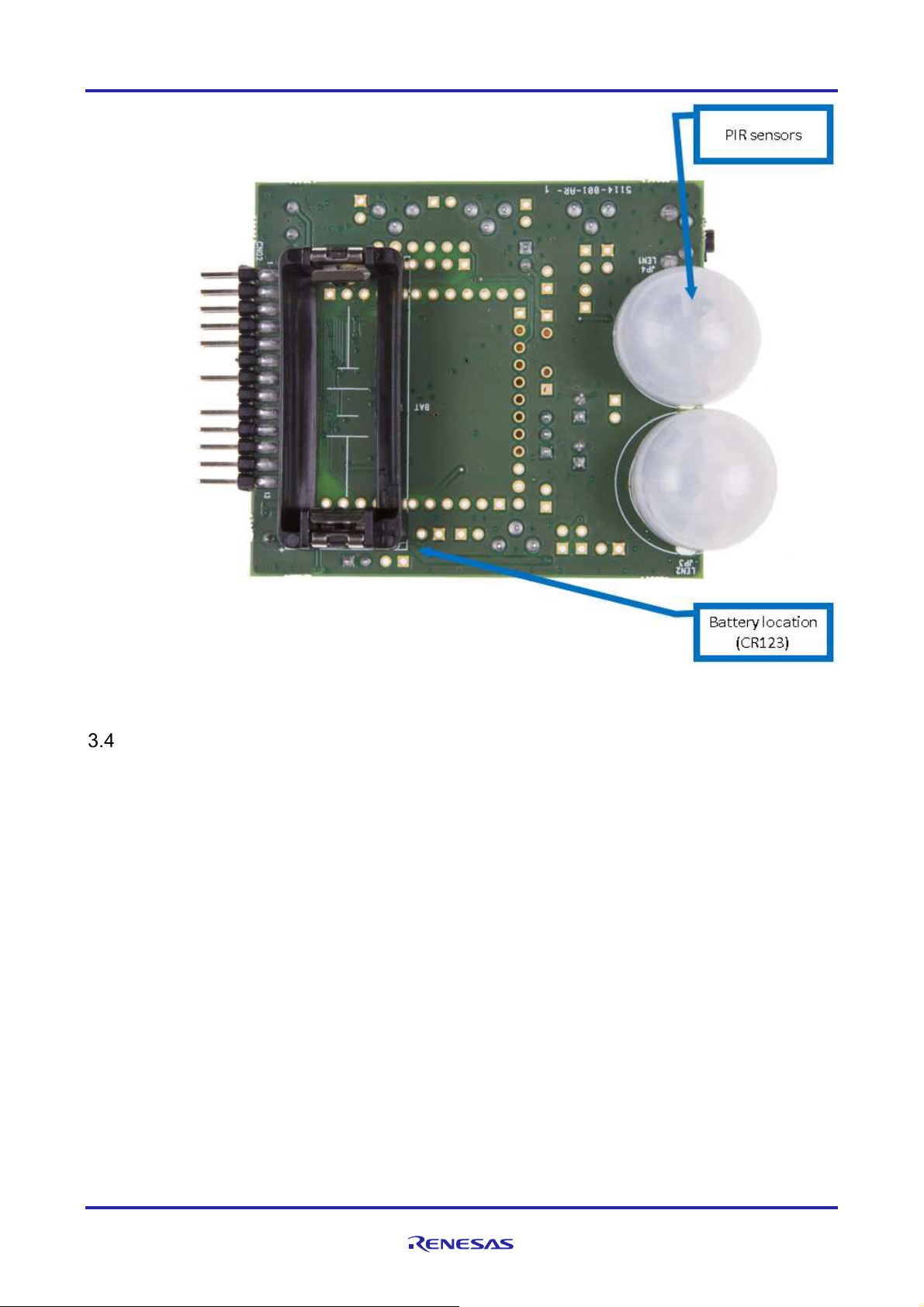

Motion detector board layout

Please check the name of the board you are looking “MOTION_SENSOR_I1D”

UM-YDETECT-IT-RL78 V1.30 Page 13 of 59

Page 14

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Motion detector top view

UM-YDETECT-IT-RL78 V1.30 Page 14 of 59

Page 15

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Motion detector bottom view

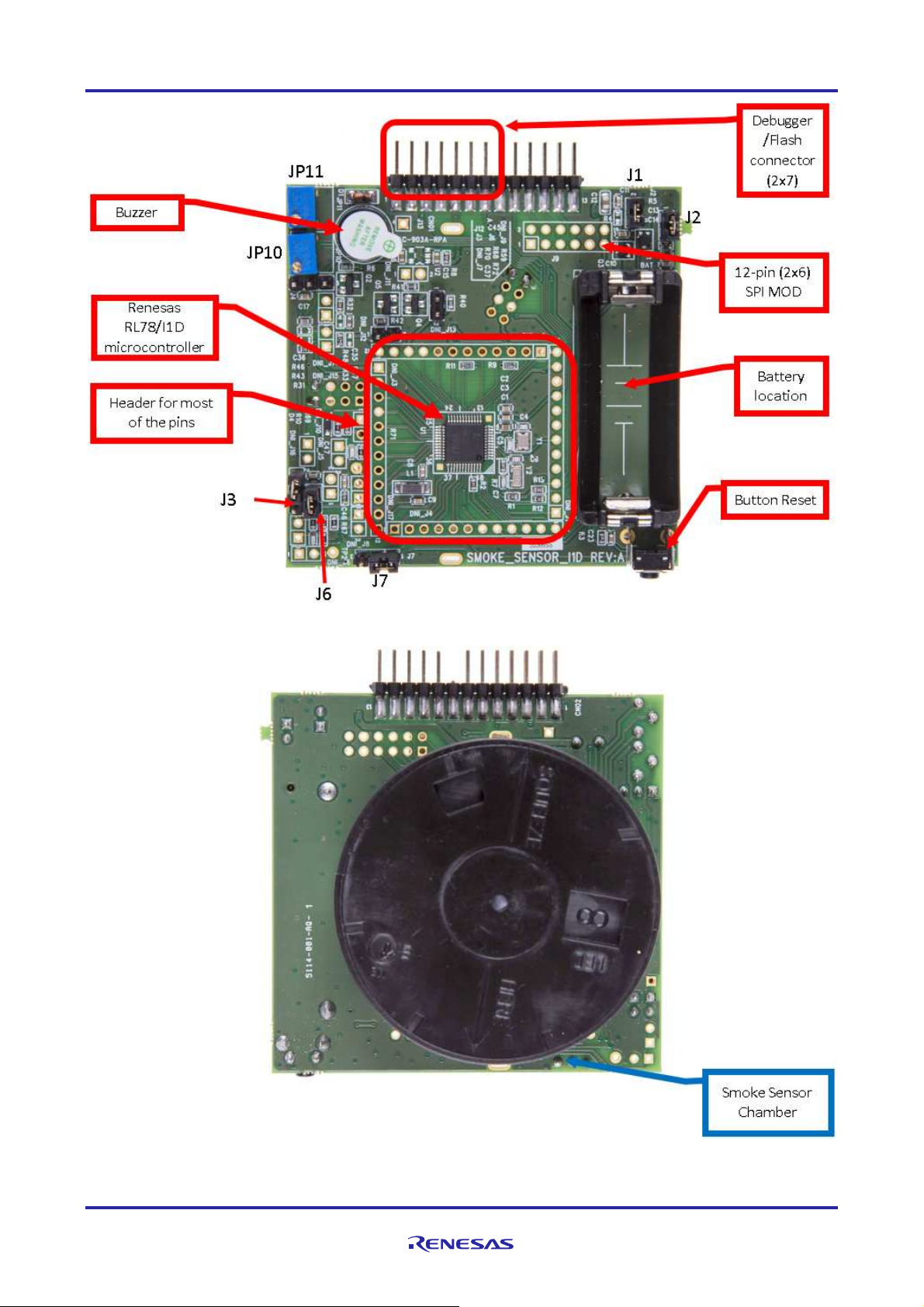

Smoke detector board layout

Please check the name of the board you are looking “SMOKE_SENSOR_I1D”

UM-YDETECT-IT-RL78 V1.30 Page 15 of 59

Page 16

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Smoke detector top view

Figure Smoke detector equipped with Smoke chamber bottom view

UM-YDETECT-IT-RL78 V1.30 Page 16 of 59

Page 17

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Smoke detector without Smoke chamber bottom view

4. Content of the CD-ROM

The CD content is listed here:

Table CD ROM content list

UM-YDETECT-IT-RL78 V1.30 Page 17 of 59

Page 18

DETECT-IT RL78/I1D detector boards kit Kit User Manual

CD ROM folder Description of resources

Samples Programs IAR Samples programs for each demonstrators boards

• IAR samples program for Glass Break demonstrator

• IAR samples program for CO demonstrator

• IAR samples program for Motion demonstrator

• IAR samples program for Smoke demonstrator

Documentation

Acroread PDF reader

Application Leading Tool Latest version of Code generator tool provided by Renesas for RL78 series

Renesas Flash

Programmer

Videos

• User manual of the Detect it! kit

• User manual of the microcontroller RL78/I1D

• Quick start guide of the Detect it! Kit

• Datasheets of the various sensors and crystals used.

For each demonstrator boards :

• Schematics

• Gerber files

• Bill of Material

including RL78/I1D

Latest version of Flash Programmer tool provided by Renesas for all MCU

• Detect it! Kit Promotion video

• Detect it! Kit Technical video

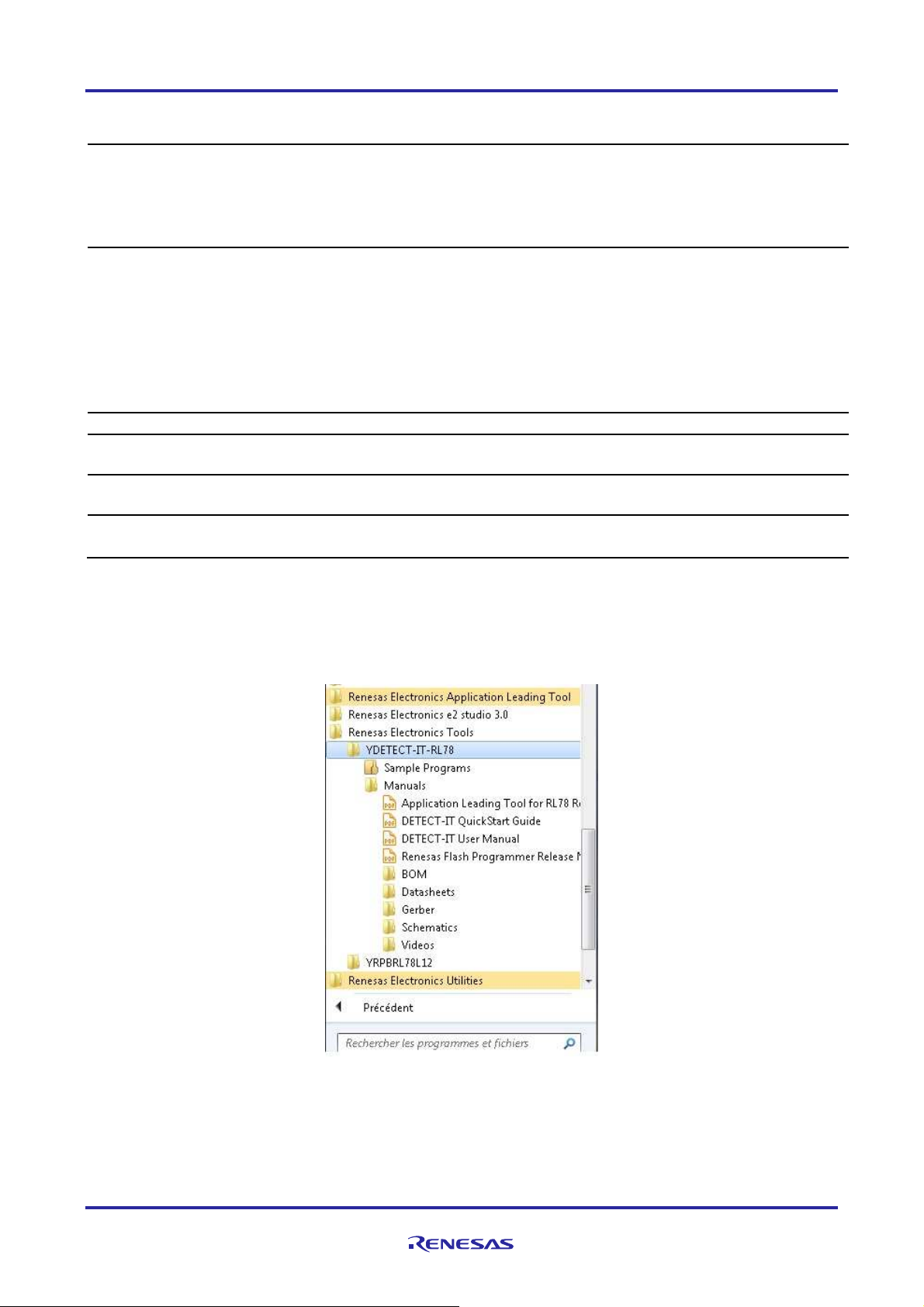

By default, all the content of the kit will be installed in the following folder on your local PC:

<C:\Renesas\Workspace\YDETECT-IT-RL78 >

You can easily access to the content via the “Start” menu, in the “Program” sections under <Renesas Electronics

Tools> then <YDETECT-IT-RL78> . Just click on the document you want to open.

Figure Opening Detect it! content via Start menu

You can go also directly to <C:\Renesas\Workspace\YDETECT-IT-RL78 > which is the default installation program to

open the documentation provided with the kit.

UM-YDETECT-IT-RL78 V1.30 Page 18 of 59

Page 19

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5. Board description

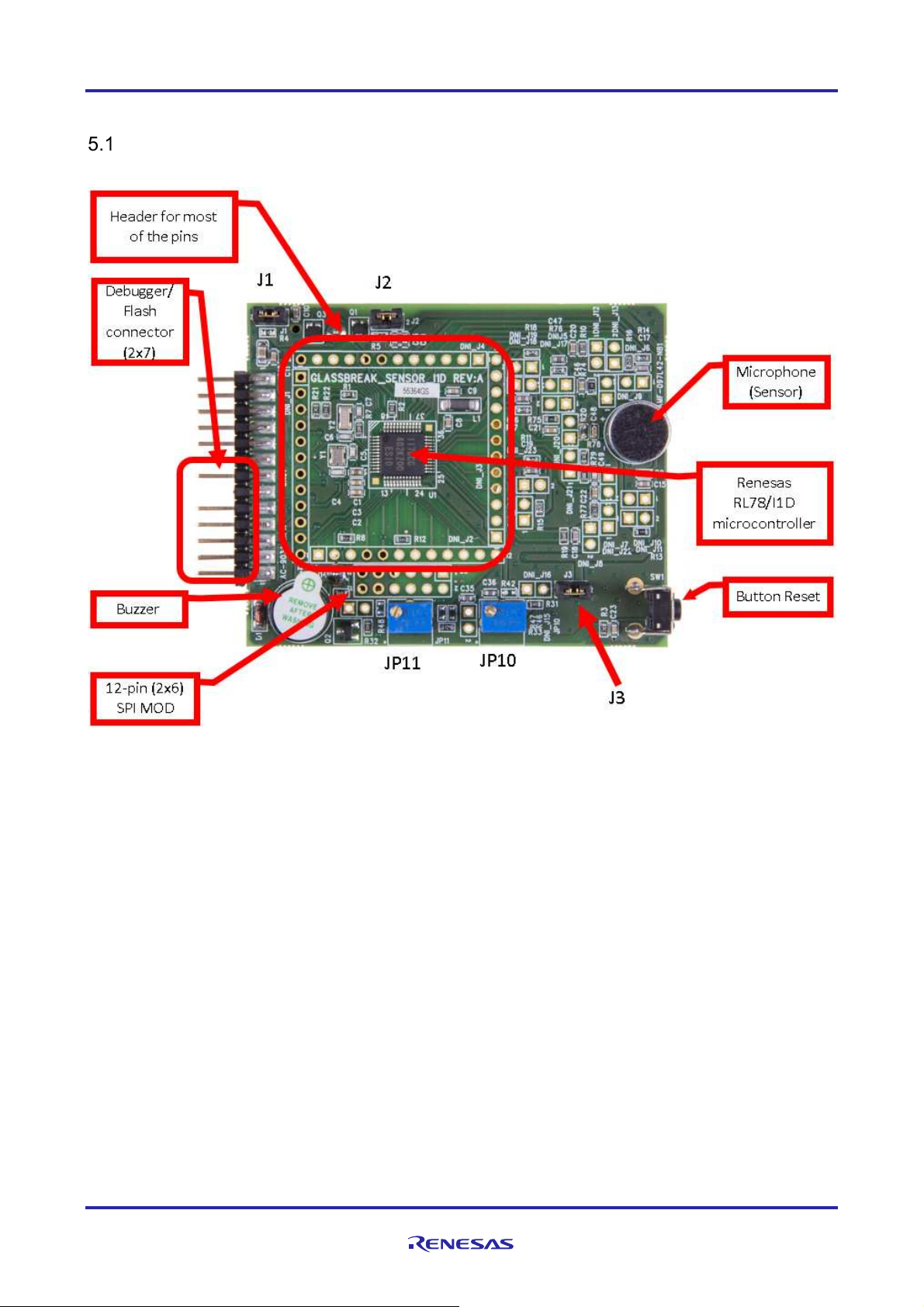

Glass Break detector board

Here are the pictures of the Glass Break sensor board

Figure Glass Break detector components top view

UM-YDETECT-IT-RL78 V1.30 Page 19 of 59

Page 20

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Glass Break detector components bottom view

5.1.1 Oscillators

Each board is equipped with 2 oscillators:

• A 20MHz oscillator

The 20MHz oscillator is sold onto each board and connected to the MCU. But it is not used by the application.

Instead the internal High Speed on-chip oscillator of the RL7/I1D is used by each application. So pin P121/X1

and pin P122/X2 are used as Input.

• Please change the settings if you wish to use the external oscillator.

• A 32,768kHz quartz

It is connected to the MCU

It is operating and used by the application (especially by the RTC).

5.1.2 Description of Jumper J

Table Description of jumper of Glass Break detector

UM-YDETECT-IT-RL78 V1.30 Page 20 of 59

Page 21

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Jumper Status Function

J1 Closed Power supply of the MCU and others components [MCU, Alarm/buzzer,

AVDD via L1, U1 Vin (optional), pull up resistors, R16/R10 and R13/R19]:

power from battery or power from E1 via CN01-pin 5, CN02-pin 4

Caution: Battery should never be installed when using E1 power supply or

external power supply via CN02/CN01

Open Current measurement of the MCU and others components [MCU,

Alarm/buzzer, L1and AVDD, U2 Vin (optional), pull up resistors] by

connection of the ampere meter

J2 Closed Power supply of some components [R18, R17, R15, R11, J3] on glass break

detectors board

Open Current measurement of some components [R18, R17, R15, R11, J3] by

connection of the ampere meter

J3 Closed Usage of RL78/I1D comparators

(motion detector and glass break detector board)

Open Comparators are not used, IVREF0 & IVREF1 are not used

(CO detector and smoke detector board)

In order to start the demonstration of the Glass Break detector, please ensure that this initial configuration is done:

• J1 should be closed

• J2 should be closed

• J3 should be closed

5.1.3 Description of Potentiometer JP

Table Description of potentiometer of Glass Break detector

Potentiometer Function Comment

JP10 IVREF1

comparator 1

JP11 IVREF0

comparator 0

Set JP10 potentiometer for IVREF1 (DNI_J3, pin 1) = 2.0V

Approximately (0.58*VDD) at VDD = 3.4V

(Use a voltmeter with at least 10MΩ input impedance as lower

impedance (such as 1MΩ) will significantly load down the resistor bias

chain).

Set JP11 potentiometer for IVREF0 (DNI_J2, Pin 12) = 1.2V

Approximately. (0.35*VDD) at VDD = 3.4V

(Use a voltmeter with at least 10MΩ input impedance as lower

impedance (such as 1MΩ) will significantly load down the resistor bias

chain).

5.1.4 Buzzer:

The buzzer is used for alarm by the application. It is connected to MCU pin P01/PCLBUZ1

5.1.5 Description of Push Button

The push button is connected MCU pin P137 / INTP0 via R3, and used as “Reset” function. The Interrupt function can

be found in the project file “r_cg_intc_user.c”

Table Description of push button of Glass Break detector

UM-YDETECT-IT-RL78 V1.30 Page 21 of 59

Page 22

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Button Status Function

SW1 Un-pressed INTP0 is high – no operation

Pressed INTP0 goes low – interrupt function is executed which defeats alarm

(software depending)

5.1.6 Battery place holder

Each board is equipped with a CR123 battery holder. There is a reverse polarity protection (P-channel MOSFET).

Only one battery CR123 is provided into the kit for the 4 boards.

Be careful when placing the battery to pay attention to the polarity.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01.

5.1.7 Microcontroller RL78/I1D

The Renesas 48-pin RL78/I1D MCU is the main element of the demonstrator board.

The reference used in this demonstrator is the biggest component of the family RL78/I1D. It is a 48 pin QFP package

with 32kB Flash and 3kB RAM embedded. The part number is: R5F117GCGFB.

The 48-pin RL78/I1D MCU has 4 channels of operational amplifier, 2 channels of comparators, and a total of 41 I/O

lines (including digital and analog interfaces).

4 headers of 12-pin each that bring out most of the MCU I/O pins. Pins for access to device port: all pins of the

RL78/I1D MCU are connected to:

UM-YDETECT-IT-RL78 V1.30 Page 22 of 59

Page 23

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Connector Pin RL78/I1D port name Function

DNI_J1 1 P01/PCLBUZ1 BUZZER

2 P00 P00

3 /RESET RESET

4 P124/XT2/EXCLKS XT1

5 P132/XT1 XT2

6 P137/INTP0 SW1 input

7 P122/X2/EXCLK P122

8 P121/X1 P121

9 REGC REGC

10 VSS VSS

11 VDD VDD

12 P60 P60

DNI_J2 1 P61

2 P62

3 P63/SSI00

4 P57/(TI03/TO03)/INTP4/VCOUT1

5 P56/SCK00/SCL00/INTP3

6 P55/SI00/RxD0/SDA00/INTP2/TOOLRXD

7 P54/SO00/TxD0/INTP1/TOOLTXD

8 P53/KR2/SO01/VCOUT0

9 P52/KR1/SI01/SDA01/TI03/TO03

10 P51/KR0/SCK01/SCL01/TI02/TO02 OUT2

11 P50/(TI00/TO01)/RTC1HZ OUT1

12 P30/(SCK00)/(SCL00)/TI00/TO01/IVREF0 IVREF0

DNI_J3 1 P31/TI01/TO00/PCLBUZ0/IVREF1 IVREF1

2 P32/KR3/(TI01/TO00)/INTP6 P32

3 P33/(TI02/TO02)/INTP5 P33

4 P20/ANI13/IVCMP1/AMP3O AMP3O

5 P21/ANI12/AMP3- AMP36 P22/ANI11/AMP3+ AMP3+

7 P23/ANI10/AMP2O AMP2O

8 P24/ANI9/AMP2- AMP29 P25/ANI8/AMP2+ AMP2+

10 AVDD AVDD

11 AVSS AVSS

12 P17/ANI7/AMP1O AMP1O

DNI_J4 1 P16/ANI6/AMP1- AMP1-

2 P15/ANI5/AMP1+ AMP1+

3 P14/ANI4/IVCMP0/AMP0O AMP0O

4 P13/ANI3/AMP0- AMP05 P12/ANI2/AMP0+ AMP0+

6 P11/ANI1/AVREFM

7 P10/ANI0/AVREFP

8 P130

9 P40/TOOL0

10 P04/ANI18

11 P03/ANI17

12 P02/ANI16

UM-YDETECT-IT-RL78 V1.30 Page 23 of 59

Page 24

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5.1.8 Description of PMOD connector J9

It is a 12-pin (2x6) SPI PMOD standard interface: It can be used to add external application boards such as WiFi/wireless.

Table Description of PMOD connector of Glass Break detector

Connector Pin Function

J9 1 MCU P63

2 MCU P57

3 MCU P54

4 MCU P32

5 MCU P55

6 MCU P52

7 MCU P56

8 MCU P33

9 GND

10 GND

11 VDD

12 VDD

5.1.9 Description of board edge connectors CN01 and CN02

There are a 14/26 dual row edge connector that has dual use of:

• E1 on-chip debug/flash connection :

This interface can be used with for debug session or for flash programming session.

E1 on-chip emulator and flash programmer 14-pin ribbon cable is connected to CN01 (pins 1-7) and CN02 (pins 1-

7) for debug and flash programming. Pin 1 of E1 ribbon cable is oriented to CN01-pin 1. However, reverse

connection between E1 and CN01/CN02 pins 1-7 will not cause board damage.

• 26-pin TK-interface board.

Table Description of board edge connector of Glass Break detector

Connector Pin # Function E1

pin #

CN01 1 No Connect (E1) 1 CN02 1 GND (E1) 2

2 No Connect (E1) 3 2 No Connect (E1) 4

3 Tool0 (E1) 5 3 T_RESET (RESET

4 No Connect (E1) 7 4 VDD (E1) 8

5 VDD (E1) 9 5 RESET (E1) 10

6 No Connect (E1) 11 6 GND (E1) 12

7 RESET (E1) 13 7 GND (E1) 14

8 No pin ` 8 No pin `

9 MCU P63 ` 9 No Connect `

10 MCU P54 ` 10 No Connect `

11 MCU P55 ` 11 No Connect `

12 MCU P56 ` 12 No Connect `

13 No Connect ` 13 No Connect `

Connector Pin # Function E1

IN) (E1)

pin #

6

UM-YDETECT-IT-RL78 V1.30 Page 24 of 59

Page 25

DETECT-IT RL78/I1D detector boards kit Kit User Manual

CO detector board

Here are the pictures of the CO sensor board

Figure CO detector components top view

UM-YDETECT-IT-RL78 V1.30 Page 25 of 59

Page 26

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure CO detector components bottom view

5.2.1 Oscillators

Each board is equipped with 2 oscillators:

• A 20 MHz oscillator

The 20 MHz oscillator is sold onto each board and connected to the MCU. But it is not used by the application.

Instead the internal High Speed on-chip oscillator of the RL7/I1D is used by each application. So pin P121/X1

and pin P122/X2 are used as Input.

• Please change the settings if you wish to use the external oscillator.

• A 32,768kHz quartz

It is connected to the MCU

It is operating and used by the application (especially by the RTC).

5.2.2 Description of Jumper J

Table Description of jumper of CO detector

UM-YDETECT-IT-RL78 V1.30 Page 26 of 59

Page 27

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Jumper Status Function

J1 Closed Power supply of the MCU and others components [MCU, Alarm/buzzer,

AVDD via L1, U1 Vin (optional), pull up resistors, R16/R10 and R13/R19]:

power from battery or power from E1 via CN01-pin 5, CN02-pin 4

Caution : Battery should never be installed when using E1 power supply or

external power supply via CN02/CN01

Open Current measurement of the MCU and others components [MCU,

Alarm/buzzer, L1and AVDD, U2 Vin (optional), pull up resistors] by

connection of the ampere meter

J2

J4 Opened Normal operation

DN_J10

DN_J14

Closed

Open

1-2 Optional REGC = 1.8V to AVREFP (with SW change)

2-3 Optional AIC1702L-25 output = 2.5V to AVREFP (with SW change)

Closed

Open Filter (R45 & C20 used) between Amp0 Out and Amp0 –

Closed

Open

Power supply of some components [R18, R17, R15, R11, J3] on glass break

detectors board

Current measurement of some components [R18, R17, R15, R11, J3] by

connection of the ampere meter

Use less – no amplification of trans impedance amplifier

May bypass with Resistor to change the Impedance

Direct connection to Ground (please check schematics for more details) - no

influence for the CO detector application

R32 is used (please check schematics for more details) - no influence for the

CO detector application

In order to start the demonstration of the CO detector, please ensure that this initial configuration is done:

• J1 should be closed

• J2 should be closed

• DN_J10 should be open

• DN_J14 can be closed or opened

5.2.3 Description of Potentiometer JP

Table Description of potentiometer of CO detector

Potentiometer Status Function

JP10 IVREF1

comparator 1

JP11 IVREF0

comparator 0

Could be used when J3 is closed (please check schematics for more details).

Could be used when J3 is closed (please check schematics for more details).

5.2.4 Buzzer:

The buzzer is used for alarm by the application. It is connected to MCU pin P01/PCLBUZ1

5.2.5 Description of Push Button

The push button is connected MCU pin P137 / INTP0 via R3. It is not used in the current CO detector application.

Table Description of push button of CO detector

Button Status Function

SW1 Un-pressed INTP0 is High – no operation

Pressed INTP0 goes Low – no operation

UM-YDETECT-IT-RL78 V1.30 Page 27 of 59

Page 28

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5.2.6 Battery place holder:

Each board is equipped with a CR123 battery holder. There is a reverse polarity protection (P-channel MOSFET).

Be careful when placing the battery to pay attention to the polarity.

Only one battery CR123 is provided into the kit for the 4 boards.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01

5.2.7 Microcontroller RL78/I1D

The Renesas 48-pin RL78/I1D MCU is the main element of the demonstrator board.

The reference used in this demonstrator is the biggest component of the family RL78/I1D. It is a 48 pin QFP package

with 32kB Flash and 3kB RAM embedded. The part number is: R5F117GCGFB.

The 48-pin RL78/I1D MCU has 4 channels of operational amplifier, 2 channels of comparators, and a total of 41 I/O

lines (including digital and analog interfaces)

4 headers of 12-pin each that bring out most of the MCU I/O pins. Pins for access to device port: all pins of the

RL78/I1D MCU are connected to:

Table Description of connector of CO detector

UM-YDETECT-IT-RL78 V1.30 Page 28 of 59

Page 29

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Connector Pin RL78/I1D port name Function

DNI_J1 1 P01/PCLBUZ1 BUZZER

2 P00 P00

3 /RESET RESET

4 P124/XT2/EXCLKS XT1

5 P132/XT1 XT2

6 P137/INTP0 SW1 input

7 P122/X2/EXCLK P122

8 P121/X1 P121

9 REGC REGC

10 VSS VSS

11 VDD VDD

12 P60 P60

DNI_J2 1 P61

2 P62

3 P63/SSI00

4 P57/(TI03/TO03)/INTP4/VCOUT1

5 P56/SCK00/SCL00/INTP3

6 P55/SI00/RxD0/SDA00/INTP2/TOOLRXD

7 P54/SO00/TxD0/INTP1/TOOLTXD

8 P53/KR2/SO01/VCOUT0

9 P52/KR1/SI01/SDA01/TI03/TO03

10 P51/KR0/SCK01/SCL01/TI02/TO02 OUT2

11 P50/(TI00/TO01)/RTC1HZ OUT1

12 P30/(SCK00)/(SCL00)/TI00/TO01/IVREF0 IVREF0

DNI_J3 1 P31/TI01/TO00/PCLBUZ0/IVREF1 IVREF1

2 P32/KR3/(TI01/TO00)/INTP6 P32

3 P33/(TI02/TO02)/INTP5 P33

4 P20/ANI13/IVCMP1/AMP3O AMP3O

5 P21/ANI12/AMP3- AMP36 P22/ANI11/AMP3+ AMP3+

7 P23/ANI10/AMP2O AMP2O

8 P24/ANI9/AMP2- AMP29 P25/ANI8/AMP2+ AMP2+

10 AVDD AVDD

11 AVSS AVSS

12 P17/ANI7/AMP1O AMP1O

DNI_J4 1 P16/ANI6/AMP1- AMP1-

2 P15/ANI5/AMP1+ AMP1+

3 P14/ANI4/IVCMP0/AMP0O AMP0O

4 P13/ANI3/AMP0- AMP05 P12/ANI2/AMP0+ AMP0+

6 P11/ANI1/AVREFM

7 P10/ANI0/AVREFP

8 P130

9 P40/TOOL0

10 P04/ANI18

11 P03/ANI17

12 P02/ANI16

UM-YDETECT-IT-RL78 V1.30 Page 29 of 59

Page 30

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5.2.8 Description of PMOD connector J9

It is a 12-pin (2x6) SPI PMOD standard interface: It can be used to add external application boards such as WiFi/wireless

Table Description of PMOD of CO detector

Connector Pin Function

J9 1 MCU P63

2 MCU P57

3 MCU P54

4 MCU P32

5 MCU P55

6 MCU P52

7 MCU P56

8 MCU P33

9 GND

10 GND

11 VDD

12 VDD

5.2.9 Description of board edge connectors CN01 and CN02

There are a 14/26 dual row edge connector that has dual use of:

• E1 on-chip debug/flash connection :

This interface can be used with for debug session or for flash programming session.

E1 on-chip emulator and flash programmer 14-pin ribbon cable is connected to CN01 (pins 1-7) and CN02 (pins 1-

7) for debug and flash programming. Pin 1 of E1 ribbon cable is oriented to CN01-pin 1. However, reverse

connection between E1 and CN01/CN02 pins 1-7 will not cause board damage.

• 26-pin TK-interface board.

Table Description of edge connector of CO detector

Connector Pin # Function E1

pin #

CN01 1 No Connect (E1) 1 CN02 1 GND (E1) 2

2 No Connect (E1) 3 2 No Connect (E1) 4

3 Tool0 (E1) 5 3 T_RESET (RESET

4 No Connect (E1) 7 4 VDD (E1) 8

5 VDD (E1) 9 5 RESET (E1) 10

6 No Connect (E1) 11 6 GND (E1) 12

7 RESET (E1) 13 7 GND (E1) 14

8 No pin ` 8 No pin `

9 MCU P63 ` 9 No Connect `

10 MCU P54 ` 10 No Connect `

11 MCU P55 ` 11 No Connect `

12 MCU P56 ` 12 No Connect `

13 No Connect ` 13 No Connect `

Connector Pin # Function E1

IN) (E1)

pin #

6

UM-YDETECT-IT-RL78 V1.30 Page 30 of 59

Page 31

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Motion detector board

Here are the pictures of the motion sensor board

Figure Motion detector components top view

UM-YDETECT-IT-RL78 V1.30 Page 31 of 59

Page 32

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Motion detector components bottom view

5.3.1 Oscillators

Each board is equipped with 2 oscillators:

• A 20 MHz oscillator

The 20 MHz oscillator is sold onto each board and connected to the MCU. But it is not used by the application.

Instead the internal High Speed on-chip oscillator of the RL7/I1D is used by each application. So pin P121/X1

and pin P122/X2 are used as Input.

• Please change the settings if you wish to use the external oscillator.

• A 32,768kHz quartz

It is connected to the MCU

It is operating and used by the application (especially by the RTC).

5.3.2 Description of Jumper J

Table Description of jumper of Motion detector

UM-YDETECT-IT-RL78 V1.30 Page 32 of 59

Page 33

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Jumper Status Function

J1 Closed Power supply of the MCU and others components [MCU, Alarm/buzzer,

L1and AVDD, U1 Vin (optional), pull up resistors]: power from battery or

power from E1 via CN01-pin 5, CN02-pin 4

Caution : Battery should never be installed when using E1 power supply or

external power supply via CN02/CN01

Open Current measurement of the MCU and others components [MCU,

Alarm/buzzer, L1and AVDD, U2 Vin (optional), pull up resistors] by

connection of the ampere meter

J2

J3

J8

Closed

Open

Closed

Open

Open Single PIR sensor operation (Second PIR sensor is not powered)

1-2

2-3

Power supply of some components [R87, R95, R64/R88, R67/R93, J3] on

motion detector board

Current measurement of some components [R87, R95, R64/R88, R67/R93,

J3] by connection of the ampere meter

Usage of RL78/I1D comparators

(motion detector and glass break detector board)

Comparators are not used, IVREF0 & IVREF1 are not used

(CO detector and smoke detector board)

Dual PIR sensor operation with single bias - second PIR is powered with

same power supply as first PIR sensor, via the same resistor R87. (Some

software change is necessary to use dual PIR operation with single bias)

Dual PIR sensor operation with separate bias (with SW change) - second PIR

is powered with independent power supply. (Some software change is

necessary to use dual PIR operation with separate bias)

In order to start the demonstration of the Motion detector, please ensure that this initial configuration is done:

• J1 should be closed

• J2 should be closed

• J3 should be closed

• J8 should be opened

5.3.3 Description of Potentiometer JP

Table Description of potentiometer of Motion detector

UM-YDETECT-IT-RL78 V1.30 Page 33 of 59

Page 34

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Potentiometer Status Function

JP9 Used to set the

2nd operation

amplifier Gain

(for Sensor 1)

JP10 Used to set up

IVREF1

JP11 Used to set up

IVREF0

JP12 Used to set the

2nd operation

amplifier Gain

(for Sensor 2)

5.3.4 Buzzer

The buzzer is used for alarm by the application. It is connected to MCU pin P01/PCLBUZ1.

Set JP9 potentiometer for about 50% (mid-point) of rotation, and CW

rotation of JP9 increases motion sensitivity. The Motion sensor can

be empirically tested to alarm starting at 4-5 meter distance by

rotating JP9 potentiometer clockwise to increase sensitivity.

However, too much sensitivity may cause some false alarms due to

ambient IR light sources (incident outside light, etc).

Set JP10 potentiometer for IVREF1 (DNI_J3, pin 1) = 2.1V

Approximately (0.62*VDD) at VDD = 3.4V

(Use a voltmeter with at least 10MΩ input impedance as lower

impedance (such as 1Meg) will significantly load down the resistor

bias chain).

Set JP11 potentiometer for IVREF0 (DNI_J2, Pin 12) = 0.85V

Approximately (0.25*VDD) at VDD = 3.4V

(Use a voltmeter with at least 10MΩ input impedance as lower

impedance (such as 1Meg) will significantly load down the resistor

bias chain).

Same function as JP9, but for Sensor 2 (beside C25)

5.3.5 Description of Push Button

The push button is connected MCU pin P137 / INTP0 via R3, and used as “Reset” function. The Interrupt function can

be found in the project file “r_cg_intc_user.c”

Table Description of push button of Motion detector

Button Status Function

SW1 Un-pressed INTP0 is high – no operation

Pressed INTP0 goes low – interrupt function is executed which defeats alarm

(software depending)

5.3.6 Battery place holder

Each board is equipped with a CR123 battery holder. There is a reverse polarity protection (P-channel MOSFET).

Be careful when placing the battery to pay attention to the polarity.

Only one battery CR123 is provided into the kit for the 4 boards.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01.

5.3.7 Microcontroller RL78/I1D

The Renesas 48-pin RL78/I1D MCU is the main element of the demonstrator board.

The reference used in this demonstrator is the biggest component of the family RL78/I1D. It is a 48 pin QFP package

with 32kB Flash and 3kB RAM embedded. The part number is: R5F117GCGFB.

The 48-pin RL78/I1D MCU has 4 channels of operational amplifier, 2 channels of comparators, and a total of 41 I/O

lines (including digital and analog interfaces).

4 headers of 12-pin each that bring out most of the MCU I/O pins. Pins for access to device port: all pins of the

RL78/I1D MCU are connected to:

Table Description of connector of Motion detector

UM-YDETECT-IT-RL78 V1.30 Page 34 of 59

Page 35

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Connector Pin RL78/I1D port name Function

DNI_J1 1 P01/PCLBUZ1 BUZZER

2 P00 P00

3 /RESET RESET

4 P124/XT2/EXCLKS XT1

5 P132/XT1 XT2

6 P137/INTP0 SW1 input

7 P122/X2/EXCLK P122

8 P121/X1 P121

9 REGC REGC

10 VSS VSS

11 VDD VDD

12 P60 P60

DNI_J2 1 P61

2 P62

3 P63/SSI00

4 P57/(TI03/TO03)/INTP4/VCOUT1

5 P56/SCK00/SCL00/INTP3

6 P55/SI00/RxD0/SDA00/INTP2/TOOLRXD

7 P54/SO00/TxD0/INTP1/TOOLTXD

8 P53/KR2/SO01/VCOUT0

9 P52/KR1/SI01/SDA01/TI03/TO03

10 P51/KR0/SCK01/SCL01/TI02/TO02 OUT2

11 P50/(TI00/TO01)/RTC1HZ OUT1

12 P30/(SCK00)/(SCL00)/TI00/TO01/IVREF0 IVREF0

DNI_J3 1 P31/TI01/TO00/PCLBUZ0/IVREF1 IVREF1

2 P32/KR3/(TI01/TO00)/INTP6 P32

3 P33/(TI02/TO02)/INTP5 P33

4 P20/ANI13/IVCMP1/AMP3O AMP3O

5 P21/ANI12/AMP3- AMP36 P22/ANI11/AMP3+ AMP3+

7 P23/ANI10/AMP2O AMP2O

8 P24/ANI9/AMP2- AMP29 P25/ANI8/AMP2+ AMP2+

10 AVDD AVDD

11 AVSS AVSS

12 P17/ANI7/AMP1O AMP1O

DNI_J4 1 P16/ANI6/AMP1- AMP1-

2 P15/ANI5/AMP1+ AMP1+

3 P14/ANI4/IVCMP0/AMP0O AMP0O

4 P13/ANI3/AMP0- AMP05 P12/ANI2/AMP0+ AMP0+

6 P11/ANI1/AVREFM

7 P10/ANI0/AVREFP

8 P130

9 P40/TOOL0

10 P04/ANI18

11 P03/ANI17

12 P02/ANI16

UM-YDETECT-IT-RL78 V1.30 Page 35 of 59

Page 36

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5.3.8 Description of PMOD connector J9

It is a 12-pin (2x6) SPI PMOD standard interface: It can be used to add external application boards such as WiFi/wireless.

Table Description of PMOD of Motion detector

Connector Pin Function

J9 1 MCU P63

2 MCU P57

3 MCU P54

4 MCU P32

5 MCU P55

6 MCU P52

7 MCU P56

8 MCU P33

9 GND

10 GND

11 VDD

12 VDD

5.3.9 Description of board edge connectors CN01 and CN02

There are a 14/26 dual row edge connector that has dual use of:

• E1 on-chip debug/flash connection :

This interface can be used with for debug session or for flash programming session.

E1 on-chip emulator and flash programmer 14-pin ribbon cable is connected to CN01 (pins 1-7) and CN02 (pins 1-

7) for debug and flash programming. Pin 1 of E1 ribbon cable is oriented to CN01-pin 1. However, reverse

connection between E1 and CN01/CN02 pins 1-7 will not cause board damage.

• 26-pin TK-interface board.

Table Description of edge connector of Motion detector

Connector Pin # Function E1

pin #

CN01 1 No Connect (E1) 1 CN02 1 GND (E1) 2

2 No Connect (E1) 3 2 No Connect (E1) 4

3 Tool0 (E1) 5 3 T_RESET (RESET

4 No Connect (E1) 7 4 VDD (E1) 8

5 VDD (E1) 9 5 RESET (E1) 10

6 No Connect (E1) 11 6 GND (E1) 12

7 RESET (E1) 13 7 GND (E1) 14

8 No pin ` 8 No pin `

9 MCU P63 ` 9 No Connect `

10 MCU P54 ` 10 No Connect `

11 MCU P55 ` 11 No Connect `

12 MCU P56 ` 12 No Connect `

13 No Connect ` 13 No Connect `

Connector Pin # Function E1

IN) (E1)

pin #

6

UM-YDETECT-IT-RL78 V1.30 Page 36 of 59

Page 37

DETECT-IT RL78/I1D detector boards kit Kit User Manual

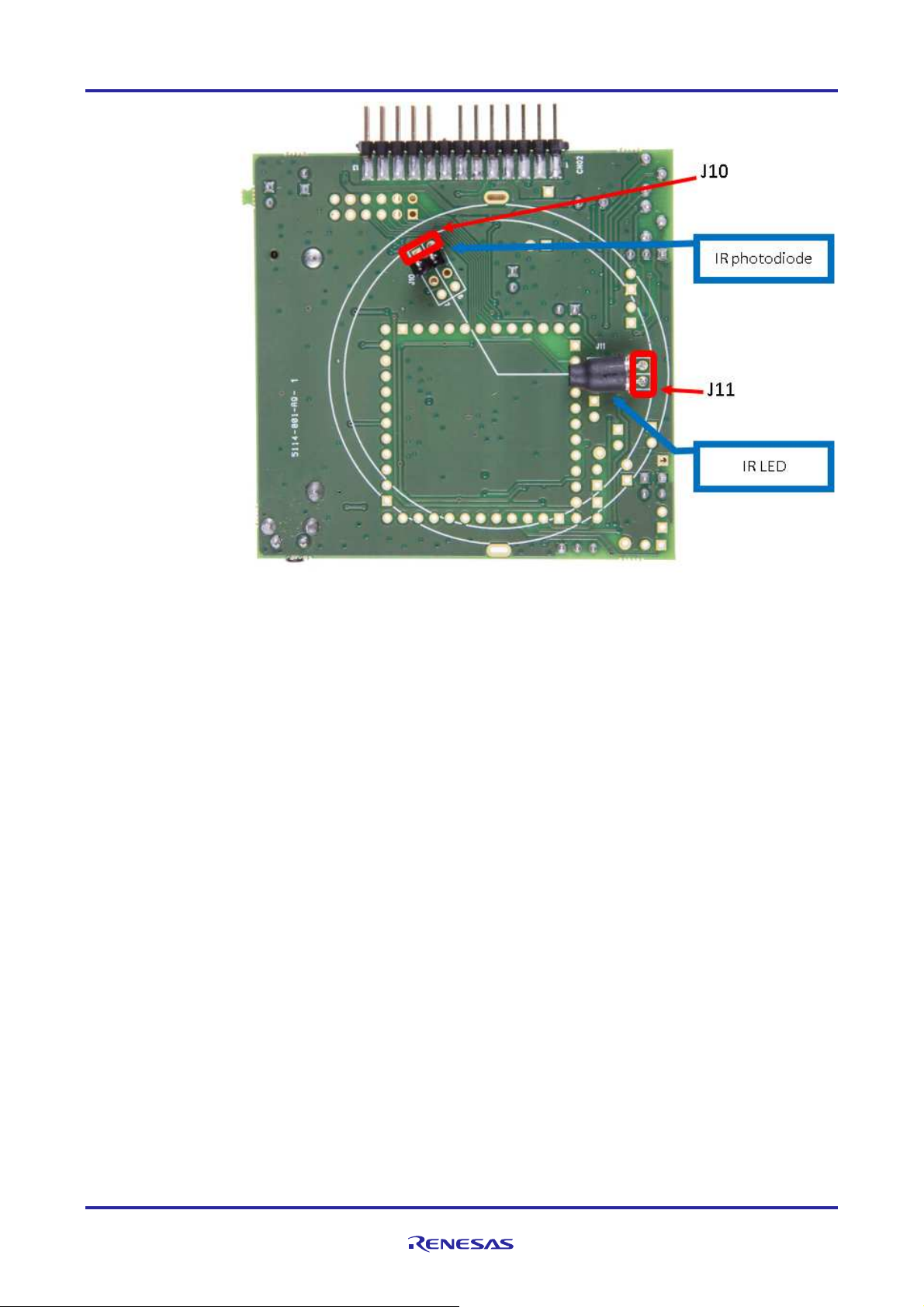

Smoke detector board

Here are the pictures of the smoke sensor board:

Figure Smoke detector components top view

UM-YDETECT-IT-RL78 V1.30 Page 37 of 59

Page 38

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Figure Smoke detector components bottom view

5.4.1 Sensor connection

Please be careful when connecting the IR LED and IR photodiode.

Table Description of sensor connector of Smoke detector

Sensor Connector & pins Function

IR

photodiode

IR LED J11 – pins 1 & 2

J10 – pins 7 & 8

receive

transmit

Connection of IR photodiode : Cathode K on pin 8 (J10-pin8), Anode

A on pin 7 (J10-pin7)

Connection of IR LED : Cathode K on pin 1 (J11-pin 1), Anode A on

pin 2 (J11-pin 2)

5.4.2 Oscillators

Each board is equipped with 2 oscillators:

• A 20 MHz oscillator

The 20 MHz oscillator is sold onto each board and connected to the MCU. But it is not used by the application.

Instead the internal High Speed on-chip oscillator of the RL7/I1D is used by each application. So pin P121/X1

and pin P122/X2 are used as Input.

• Please change the settings if you wish to use the external oscillator.

• A 32,768kHz quartz

It is connected to the MCU

It is operating and used by the application (especially by the RTC).

5.4.3 Description of Jumper J

Table Description of jumper of Smoke detector

UM-YDETECT-IT-RL78 V1.30 Page 38 of 59

Page 39

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Jumper Status Function

J1

Closed

Open

J2 Closed Power supply of some components [R67/68, J6] on motion detector board

Open

J3

J6 Closed Enable IR LED transmission (Provide CON2/J11 with VDD_Sensor)

J7 Closed 1-2 Enable IR LED photodiode reception (Normal Operation)

Closed

Open

Opened Disable IR LED transmission.

Closed 2-3

Power supply of the MCU and others components [MCU, Alarm/buzzer, AVDD

via L1, U1 Vin (optional), pull up resistors]: power from battery or power from

E1 via CN01-pin 5, CN02-pin 4

Caution: Battery should never be installed when using E1 power supply or

external power supply via CN02/CN01

Current measurement of the MCU and others components [MCU,

Alarm/buzzer, L1and AVDD, U2 Vin (optional), pull up resistors] by connection

of the ampere meter

Current measurement of some components [R67/R68, J6] by connection of the

ampere meter

Usage of Rl78/I1D comparators

(motion detector and glass break detector board)

Comparators are not used, IVREF0 & IVREF1 are not used

(CO detector and smoke detector board)

Disable IR LED photodiode transmission, could be used by test mode (with SW

change)

In order to start the demonstration of the Smoke detector, please ensure that this initial configuration is done:

• J1 should be closed

• J2 should be closed

• J3 should be open

• J6 should be closed

• J7 (pins 1-2) should be closed

• Please check that IR photodiode and IR LED are in place .

5.4.4 Description of Potentiometer JP

Table Description of potentiometer of Smoke detector

Potentiometer Status Function

JP10 IVREF1

comparator 1

JP11 IVREF0

comparator 0

Could be used when J3 is closed (please check schematics for more

details).

Could be used when J3 is closed (please check schematics for more

details).

5.4.5 Buzzer

The buzzer is used for alarm by the application. It is connected to MCU pin P01/PCLBUZ1

5.4.6 Description of Push Button

The push button is connected MCU pin P137 / INTP0 via R3, and used as “Reset” function. The Interrupt function can

be found in the project file “r_cg_intc_user.c”

Table Description of Push button of Smoke detector

Button Status Function

SW1 Un-pressed INTP0 is high – no operation

Pressed INTP0 goes Low – interrupt function is executed which defeats alarm

(software depending)

UM-YDETECT-IT-RL78 V1.30 Page 39 of 59

Page 40

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5.4.7 Battery place holder

Each board is equipped with a CR123 battery holder. There is a reverse polarity protection (P-channel MOSFET).

Be careful when placing the battery to pay attention to the polarity.

Only one battery CR123 is provided into the kit for the 4 boards.

Caution: Battery should never be installed when using E1 power supply or external power supply via CN02/CN01

5.4.8 Microcontroller RL78/I1D

The Renesas 48-pin RL78/I1D MCU is the main element of the demonstrator board.

The reference used in this demonstrator is the biggest component of the family RL78/I1D. It is a 48 pin QFP package

with 32kB Flash and 3kB RAM embedded. The part number is: R5F117GCGFB.

The 48-pin RL78/I1D MCU has 4 channels of operational amplifier, 2 channels of comparators, and a total of 41 I/O

lines (including digital and analog interfaces).

4 headers of 12-pin each that bring out most of the MCU I/O pins. Pins for access to device port: all pins of the

RL78/I1D MCU are connected to:

Table Description of connector of Smoke detector

UM-YDETECT-IT-RL78 V1.30 Page 40 of 59

Page 41

DETECT-IT RL78/I1D detector boards kit Kit User Manual

Connector Pin RL78/I1D port name Function

DNI_J1 1 P01/PCLBUZ1 BUZZER

2 P00 P00

3 /RESET RESET

4 P124/XT2/EXCLKS XT1

5 P132/XT1 XT2

6 P137/INTP0 SW1 input

7 P122/X2/EXCLK P122

8 P121/X1 P121

9 REGC REGC

10 VSS VSS

11 VDD VDD

12 P60 P60

DNI_J2 1 P61

2 P62

3 P63/SSI00

4 P57/(TI03/TO03)/INTP4/VCOUT1

5 P56/SCK00/SCL00/INTP3

6 P55/SI00/RxD0/SDA00/INTP2/TOOLRXD

7 P54/SO00/TxD0/INTP1/TOOLTXD

8 P53/KR2/SO01/VCOUT0

9 P52/KR1/SI01/SDA01/TI03/TO03

10 P51/KR0/SCK01/SCL01/TI02/TO02 OUT2

11 P50/(TI00/TO01)/RTC1HZ OUT1

12 P30/(SCK00)/(SCL00)/TI00/TO01/IVREF0 IVREF0

DNI_J3 1 P31/TI01/TO00/PCLBUZ0/IVREF1 IVREF1

2 P32/KR3/(TI01/TO00)/INTP6 P32

3 P33/(TI02/TO02)/INTP5 P33

4 P20/ANI13/IVCMP1/AMP3O AMP3O

5 P21/ANI12/AMP3- AMP36 P22/ANI11/AMP3+ AMP3+

7 P23/ANI10/AMP2O AMP2O

8 P24/ANI9/AMP2- AMP29 P25/ANI8/AMP2+ AMP2+

10 AVDD AVDD

11 AVSS AVSS

12 P17/ANI7/AMP1O AMP1O

DNI_J4 1 P16/ANI6/AMP1- AMP1-

2 P15/ANI5/AMP1+ AMP1+

3 P14/ANI4/IVCMP0/AMP0O AMP0O

4 P13/ANI3/AMP0- AMP05 P12/ANI2/AMP0+ AMP0+

6 P11/ANI1/AVREFM

7 P10/ANI0/AVREFP

8 P130

9 P40/TOOL0

10 P04/ANI18

11 P03/ANI17

12 P02/ANI16

UM-YDETECT-IT-RL78 V1.30 Page 41 of 59

Page 42

DETECT-IT RL78/I1D detector boards kit Kit User Manual

5.4.9 Description of PMOD connector J9

It is a 12-pin (2x6) SPI PMOD standard interface: It can be used to add external application boards such as WiFi/wireless.

Table Description of PMOD of Smoke detector

Connector Pin Function

J9 1 MCU P63

2 MCU P57

3 MCU P54

4 MCU P32

5 MCU P55

6 MCU P52

7 MCU P56

8 MCU P33

9 GND

10 GND

11 VDD

12 VDD

5.4.10 Description of board edge connectors CN01 and CN02

There are a 14/26 dual row edge connector that has dual use of:

• E1 on-chip debug/flash connection :

This interface can be used with for debug session or for flash programming session.

E1 on-chip emulator and flash programmer 14-pin ribbon cable is connected to CN01 (pins 1-7) and CN02 (pins 1-

7) for debug and flash programming. Pin 1 of E1 ribbon cable is oriented to CN01-pin 1. However, reverse

connection between E1 and CN01/CN02 pins 1-7 will not cause board damage.

• 26-pin TK-interface board.

Table Description of edge connector of Smoke detector

Connector Pin # Function E1

pin #

CN01 1 No Connect (E1) 1 CN02 1 GND (E1) 2

2 No Connect (E1) 3 2 No Connect (E1) 4

3 Tool0 (E1) 5 3 T_RESET (RESET

4 No Connect (E1) 7 4 VDD (E1) 8

5 VDD (E1) 9 5 RESET (E1) 10

6 No Connect (E1) 11 6 GND (E1) 12

7 RESET (E1) 13 7 GND (E1) 14

8 No pin ` 8 No pin `

9 MCU P63 ` 9 No Connect `

10 MCU P54 ` 10 No Connect `

11 MCU P55 ` 11 No Connect `

12 MCU P56 ` 12 No Connect `

13 No Connect ` 13 No Connect `

Connector Pin # Funtion E1

IN) (E1)

pin #

6

UM-YDETECT-IT-RL78 V1.30 Page 42 of 59

Page 43

DETECT-IT RL78/I1D detector boards kit Kit User Manual

6. Theory of operation

Glass Break detector theory of operation

6.1.1 Analog Front End circuit of Glass Break detector

The Analog Front End circuit consists of a microphone, low pass filter and high pass filter. To implement a glass break

sensor an Electret microphone monitors ambient sound so that sound amplitude, frequency band and sound duration are

analyzed to distinguish between ordinary sharp/loud sounds versus actual glass break events. Any sudden change in

sound level will have some low frequency (envelope) content or “thud” event, even if the event mainly has high

frequency components like breaking glass. Generally a true glass break event will have high frequency sound

components greater than 1 KHz, and at least 100ms duration.

• Low pass filter with comparator interrupt

At MCU power startup, the low pass filter operational amplifiers are initialized and biased at VDD/2, where VDD

depends on the CR123 lithium battery voltage (2.7V to ~3.1V). With no sound events, both low pass operational

amplifier stage outputs will be at VDD/2 (1.35V to 1.55V). Even though this audio filter is referred to as “Low

Pass/Low Frequency” there is AC coupling between the microphone and first stage of low pass filter, and AC coupling

between the first stage output (Operational amplifier Ch1) and the second stage input (Operational amplifier Ch0).

Therefore any DC bias variations are eliminated between operational amplifier analog front end stages, and besides, the

microphone will not reproduce sounds much below 25Hz frequency.

The output of low pass second stage (Operational amplifier Ch0) is DC coupled into the Comparator input and ADC

input of the MCU (since they connected internally on the same MCU pin 39). For a sufficiently loud sound event, the

RL78/I1D MCU internal comparator triggers an MCU interrupt (when IVREF voltage threshold is exceeded), which

wakes up the MCU out of STOP mode.

If a Low Frequency amplitude output from AMP0O triggers the Comparator 0 window interrupt, then the AMP2 and

AMP3 operational amplifiers are turned on in High Speed mode. At this point, further Operational amplifier AMP0

output and Comparator 0 interrupts are ignored. After 2ms stabilization wait time, Comparator 1 windowed interrupt is

enabled and a 200ms time interval is started. If the Comparator 1 window interrupt occurs before 200ms timeout, then

the Glass Break alarm is sounded. If no Comparator 1 window interrupt occurs before 200ms, then no Glass Break is

sounded and the MCU configures the AMP1 and AMP0 operational amplifiers back to Low Power consumption mode

and turns off AMP2 and AMP3 off. Then MCU returns to STOP mode, waiting for next loud sound event.

Note: All four RL78/I1D operational amplifiers must either be placed in low power or high speed mode together.

Therefore, the low pass filter (Operational amplifier channels Ch0 and Ch1) are ignored when the high pass

filter is enabled.

• High Pass Filter:

Since the high pass filter needs both high gain and high frequency response up to ~15kHz range, the high speed

operational amplifier mode is needed (with GBW = 1.7MHz). The high pass filter is not powered on until after a loud

sound event occurs, since high speed operational amplifier mode draws ~260µA for 2 operational amplifier channels.

After enabling the 2 operational amplifiers channels in high pass filter, approximately 1ms of stabilization time is

required. The high pass filter second stage output (Operational amplifier Ch3) is also DC coupled into a second ADC

input channel and that ADC input is sampled for 100ms after first low frequency sound event is detected. If a minimum

of 100ms of high frequency activity is detected, the glass break sensor alarm is sounded for a minimum of 2 seconds.

After sampling, the high pass filter and 100ms have elapsed with < 100ms high frequency detection the high pass filter

is turned off and the low pass filter operational amplifiers are turned on again. Otherwise if the >100ms threshold for

high frequency content is exceeded (and alarm enabled), the high pass filter can be turned off and low pass filter turned

back on (operational amplifier in low speed mode), to look for a new sound event.

Note: all four RL78/I1D operational amplifiers must either be placed in low power or high speed mode together.

Therefore, the low pass filter outputs are ignored when the high pass filter stages are enabled.

As summary, here is the method how the Glass Break detector works generally:

UM-YDETECT-IT-RL78 V1.30 Page 43 of 59

Page 44

DETECT-IT RL78/I1D detector boards kit Kit User Manual

1. AMP1 and AMP0 are always powered in Low Power consumption mode (GBW = 40KHZ), with the MCU in

Stop mode. Comparator 0 is always powered in Low Speed mode also, and is configured for Window

Comparator interrupt mode.

2. When a sound event occurs and is loud enough, a low frequency (envelope) waveform can occur at AMP0O

output. If AMP0O output is > IVREF1 or <IVREF0, then a comparator interrupt will wake up the MCU.

3. After MCU wakes up, AMP2 and AMP3 are turned on in High Speed mode (GBW = 1.7MHZ). At this point

all operational amplifiers are in High Speed mode, since there is only one setting for all 4 operational

amplifiers. (It is impossible to set AMP1 and AMP0 in Low Power mode with AMP2 and AMP3 in High

Speed mode.) Then a 2ms time interval is started and comparator interrupts disabled to wait for AMP2 and

AMP3 stabilization. At this point, the AMP0O output (and Comparator 0 interrupt) is ignored.

4. At the end of 2ms interval, 2 interrupts are enabled, but Comparator 0 interrupt is disabled.

5. Enable Comparator 1 (from AMP3O) interrupt in window mode.

6. Start 200ms timer interval for interrupt.

7. If a High frequency wave component from AMP3O triggers Comparator 1 window interrupt (AMP3O >

IVREF1 or AMP3O < IVREF0), then the Glass Break alarm is sounded for 2 seconds minimum.

8. However, if 200ms timer interrupt occurs without any Comparator 1 window interrupt, then no Glass Break

alarm is sounded. Then the MCU changes operational amplifiers mode back to AMP1 and AMP0 in Low

Power consumption with AMP2 and AMP3 turned off again. Then MCU goes back to Stop mode.

9. VDD_Sensor = VDD is always enabled on AMP2, AMP3 and Comparator IVREF1/IVREF0 reference resistor

chain.

6.1.2 MCU/digital system and maintain low current drain for long battery life

• Low power interval timers like Real Time Counter, 12-bit Interval Timer, 2 units of 8-bit Interval Timer:

The low power interval timers are used to time the monitoring of high frequency content by sampling the high pass

filter every 100ms or so after the low frequency sound envelope is detected. If a glass break event threshold is observed,

the alarm is turned on for 2 second minimum by counting 1 second interrupts.

• Medium speed On-Chip Oscillator (4 MHz MOCO) and special Low Power CPU run mode:

The usage of this Low Power mode and this 4MHz MOCO oscillator allow both a fast (4µs typical) wake-up time and

low current drain (134µA @ 1MHz). Since CPU performance is usually not critical for sensor applications, a lower

speed native clock at 1MHz/2MHz/4MHz can be used instead of the High Speed On-Chip Oscillator (24MHz HOCO).

CO detector theory of operation

6.2.1 Analog Front End circuit of CO detector

The Analog Front End circuit consists of the CO sensor canister, DC bias amplifier, and trans-conductance amplifier.

• CO sensor canister

The Figaro TGS5042 CO canister can typically detect 0-10 000ppm of CO gas concentration in a linear fashion and has

good accuracy when the unit calibration value (stamped on outside) is incorporated into the current-to-voltage

conversion equations.

From experimentation, it was found that this CO sensor has a relatively slow reaction time, confirmed in the

specification - typically needing >~60 seconds to fully register an accurate CO gas concentration level. Also, once the

CO gas has entered the canister and chemically combined on the anode and cathode, there is a long reaction time

(>~120 seconds per specification) for the CO sensor current to decay back to zero for ambient CO gas concentration of

0ppm.

Note Operation Principle (extracted from TECHNICAL INFORMATION FOR TGS5042 document:

5042TechnicalInfo0512.pdf)

The electrolyte of TGS5042 is a very low concentration of mixed/prepared alkaline electrolyte consisting of

KOH, KHCO3, and K2CO3. The mixed alkaline electrolyte acts as a buffer solution with a pH value maintained

between 7~10. When CO passes through the backing layer and reaches to the working electrode, electrons are

generated resulting from the reaction between CO and anions in the electrolyte such as OH-, HCO3-, and

CO32- . By creating a short circuit between the working and counter electrodes with external wiring, electrons

move to the counter electrode through the external wiring. At that point, the consumed anions in the electrolyte

at the working electrode are replenished and move to the electrolyte by the reaction of CO2, water, and

electrons.

UM-YDETECT-IT-RL78 V1.30 Page 44 of 59

Page 45

DETECT-IT RL78/I1D detector boards kit Kit User Manual

(chemical equations can be seen in full Technical Information for TGS5042 document)

• DC bias amplifier (Ch1 operational amplifier)

At MCU power startup Ch0 and Ch1 operational amplifiers are initialized in low power mode. Ch1 is biased at

VDD/11, where VDD depends on the CR123 lithium battery voltage (2.7V to ~3.1V) or slightly higher if E1 debugger

is used for power (often around 3.3V) . The resistor bias network for Ch1 plus (+) input draws less than 0.7µA over the

possible VDD power supply range. However the buffered output of Ch1 operational amplifier presents a low impedance

and constant voltage even as the CO Sensor sources possibly >10µA when CO Gas concentration of 10,000ppm or

more. Since the resistor bias network voltage can vary slightly with resistor tolerance, the ~VDD/11 bias level output on

Ch1 AMP1O output is measured by ADC input ANI7 to serve as the baseline for CO sensor current-to-voltage

measurements.

• Current-to-voltage trans-impedance amplifier (Ch0 operational amplifier)