Page 1

Application Note

R01AN5516EJ0100 Rev.1.00 Page 1 of 48

2020.08.01

RL78/G1M

120-degree conducting control of permanent magnetic synchronous motor

(Implementation)

Summary

This application note explains the sample programs driving a permanent magnet synchronous motor in the

120-degree conducting method using the RL78/G1M microcontroller. This note also explains how to use the

motor control development support tool, ’Renesas Motor Workbench (RMW)’.

These sample programs are only able to be used as references, and Renesas Electronics Corporation

does not guarantee their operation. Please use them after carrying out a thorough evaluation in a suitable

environment.

Operation checking device

Operations of the sample programs have been checked using the following device.

RL78/G1M (R5F11W68ASM)

Target sample programs

This application note regards the following sample programs.

RL78G1M_MRSSK_120_CSP_CC_V100 (IDE: CS+ for CC)

RL78G1M_MRSSK_120_E2S_CC_V100 (IDE: e2studio)

For the 24 V Motor Control Evaluation System & RL78/G1M CPU card:

RL78/G1M 120-degree conducting control sample program

The Hall effect sensor and sensorless mode can be changed by rewriting “MTRCONF_SENSOR_MODE”

in the configuration definition file “r_mtr_config.h” to 0: HALL and 1: LESS, and compiling.

Reference

RL78/G1M User's Manual: Hardware (R01UH0904EJ0100)

Application note: ‘120-degree conducting control of permanent magnet synchronous motor: algorithm’

(R01AN2657EJ0120)

Renesas Motor Workbench V.2.00 User’s Manual (R21UZ0004EJ0202: Renesas-Motor-Workbench-

V2-0d)

Renesas Solution Starter Kit 24V Motor Control Evaluation System for RX23T User’s Manual

(R20UT3697EJ0120)

R01AN5516EJ0100

Rev.1.00

2020.08.01

Page 2

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 2 of 48

2020.08.01

Contents

1. Overview .......................................................................................................................................3

2. System overview ..........................................................................................................................4

3. Descriptions of the control program ...........................................................................................10

4. Usage of Motor Control Development Support Tool, ‘Renesas Motor Workbench’..................45

Page 3

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 3 of 48

2020.08.01

1. Overview

This application note explains how to implement the 120-degree conducting control sample programs of the

permanent magnet synchronous motor (PMSM) using the RL78/G1M microcontroller, and how to use the

motor control development support tool, “Renesas Motor Workbench”. Note that these sample programs use

the algorithm described in the application note “120degree conducting control of permanent magnet

synchronous motor: algorithm”.

1.1 Development environment

Table 1-1 and Table 1-2 show the development environment of the sample programs explained in this

application note.

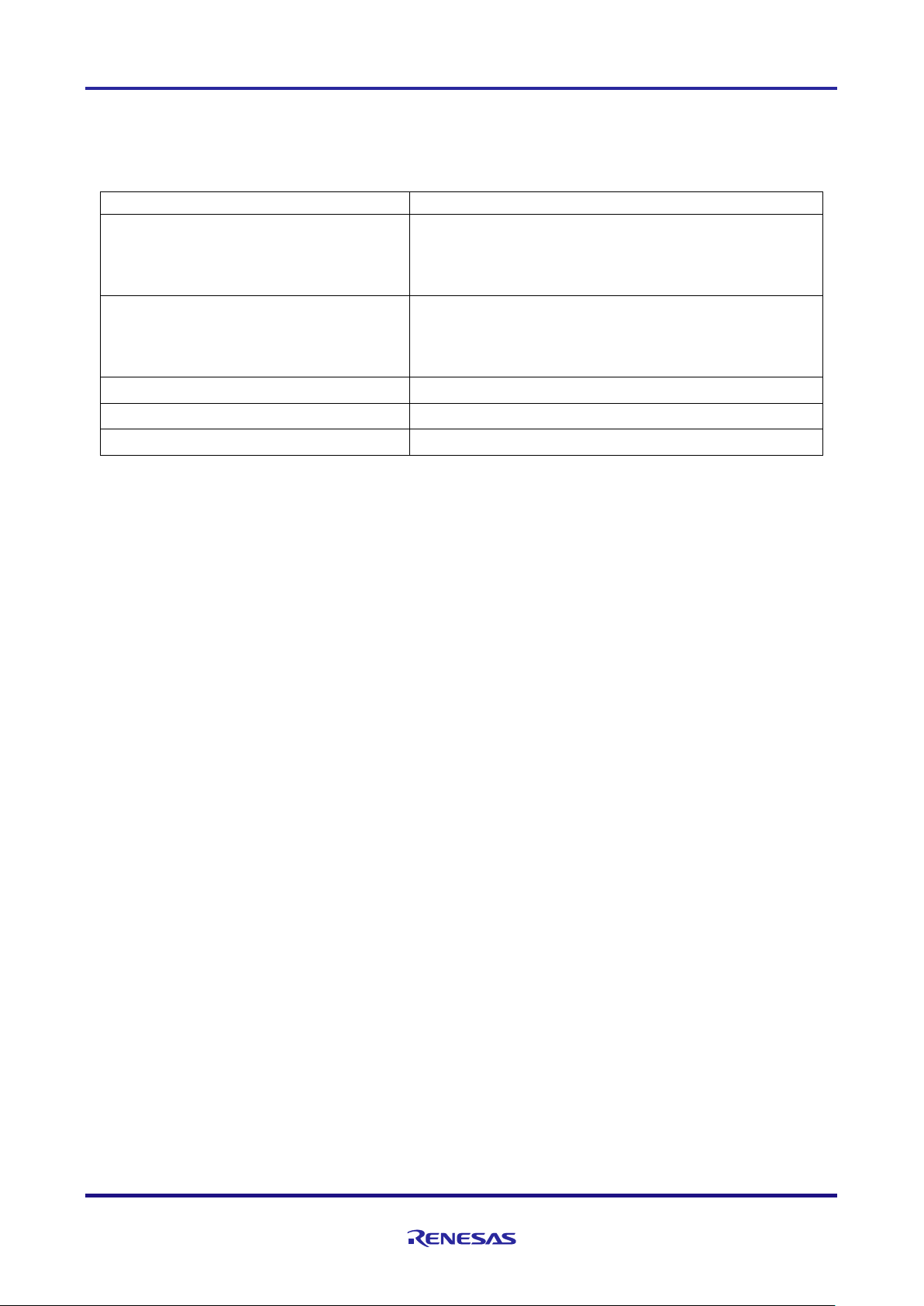

Table 1-1 – Development Environment of the Sample Programs (H/W)

Microcontroller

Evaluation board

Motor

RL78/G1M

(R5F11W68ASM)

24V inverter board1 & RL78/G1M CPU card2

TSUKASA2

TG-55L

Table 1-2 – Development Environment of the Sample Programs (S/W)

CS+ version

Build tool version

V8.03.00

CC-RL V1.09.00

e2studio version

Build tool version

2020-07

CC-RL V1.09.00

For purchase and technical support, please contact sales representatives and dealers of Renesas

Electronics Corporation.

Notes:

1. 24V inverter board (RTK0EM0001B00012BJ) is a product of Renesas Electronics Corporation.

2. The following RL78/G1M CPU cards can be used.

T5108: Desk Top Laboratories Inc. (http://desktoplab.co.jp/)

3. TG-55L is a product of TSUKASA ELECTRIC.

TSUKASA ELECTRIC. (https://www.tsukasa-d.co.jp/en/)

Page 4

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 4 of 48

2020.08.01

2. System overview

An overview of this system is provided below.

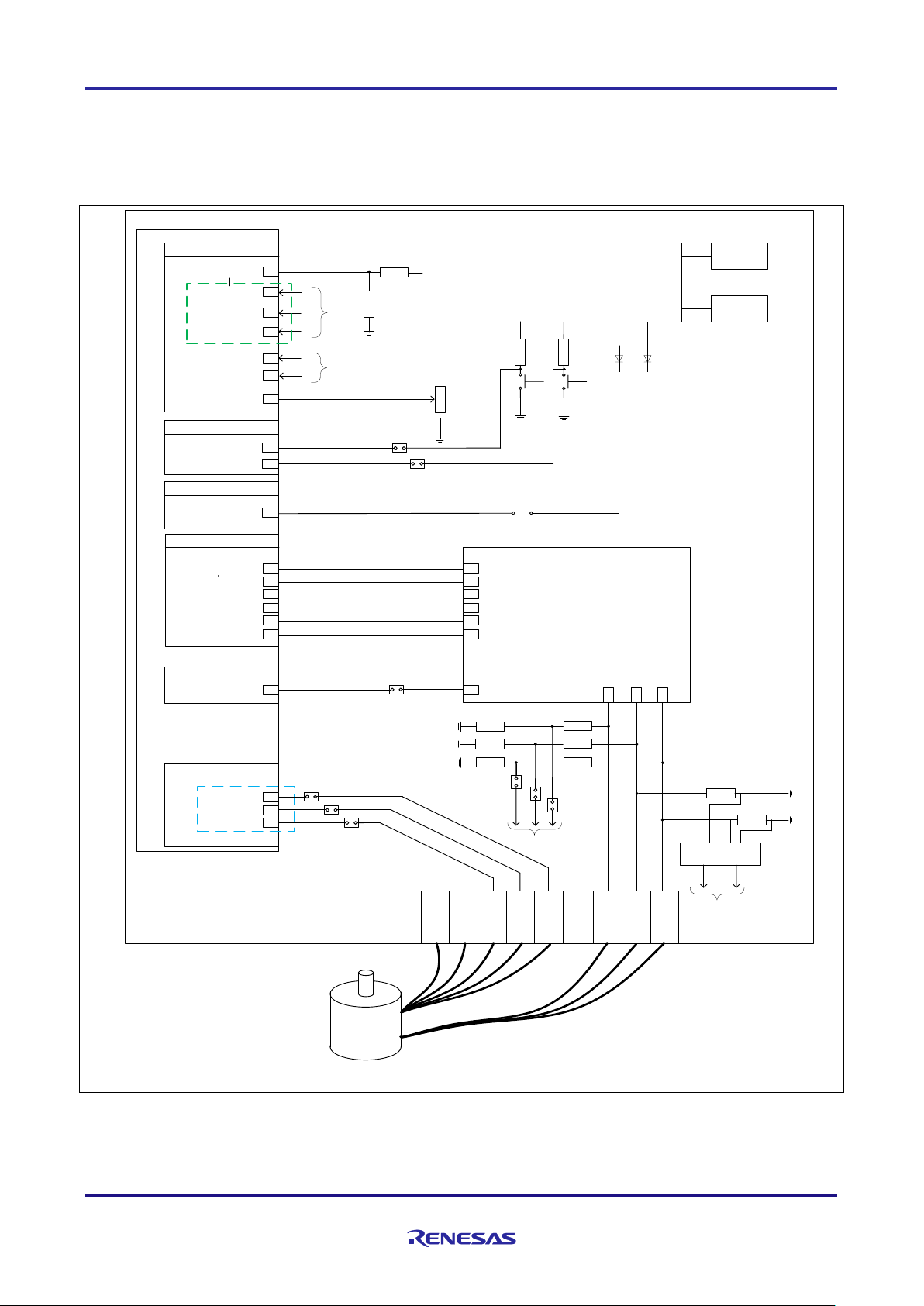

2.1 Hardware configuration

The hardware configuration is shown below.

RL78G1M

A/D converter input

Bus voltage

Rotational speed command

RTO output

Over current detection

Hall sensor input

V

dc

GND

Power supply circuit(5V/12V)

DC24V input

U port

W port

V port

HU port

HW port

HV port

GND port

V

cc

port

VR1

SW1

SW2

Switch input

LED output

LED1 LED2

過電流検出 入力

U

p

V

p

W

p

V

n

U

n

W

n

Inverter circuit

OC

P15 / ANI6

P16 / ANI7

P40

P10 / RTIO00

P11 / RTIO01

P12 / RTIO02

P13 / RTIO03

P14 / RTIO04

P15 / RTIO05

P137 / INTP0

P12

P13

P14

PMSM

P13 / ANI4

P12 / ANI3

P14 / ANI5

Hall control mode

V

u

V

v

V

w

W V U

V

w

V

u

V

v

Sensorless control mode

P125

P137

JP4

JP5

JP5

JP3

JP2

JP1

JP3

JP1

JP2

OPamp IC

P11 / ANI2

P10 / ANI1

I

u

I

v

I

u

I

v

A/D converter

A/D converter

(not used in this system)

LED1 and P40 are disconnected at the time of purchase.

Figure 2-1 – Hardware Configuration Diagram

Page 5

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 5 of 48

2020.08.01

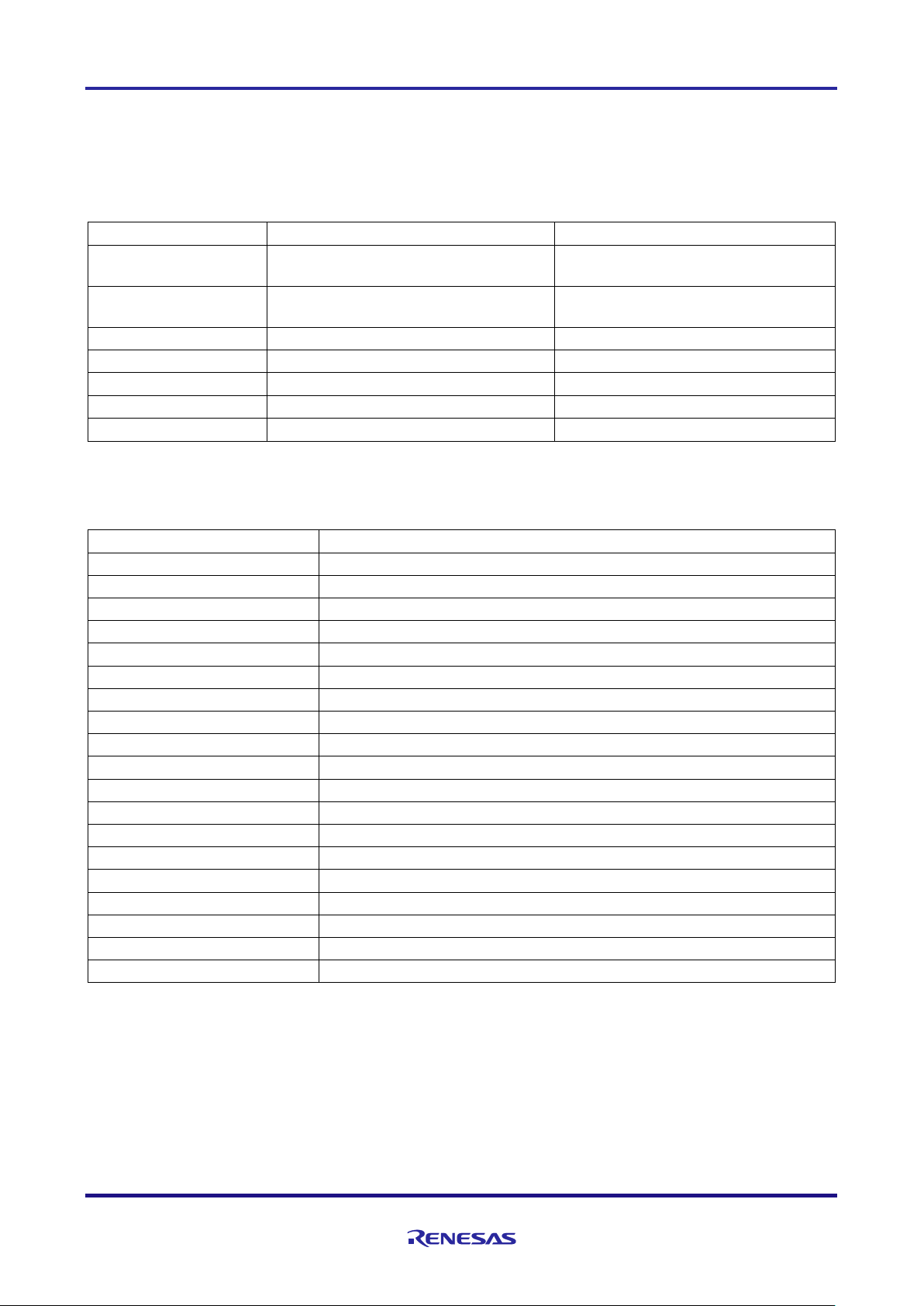

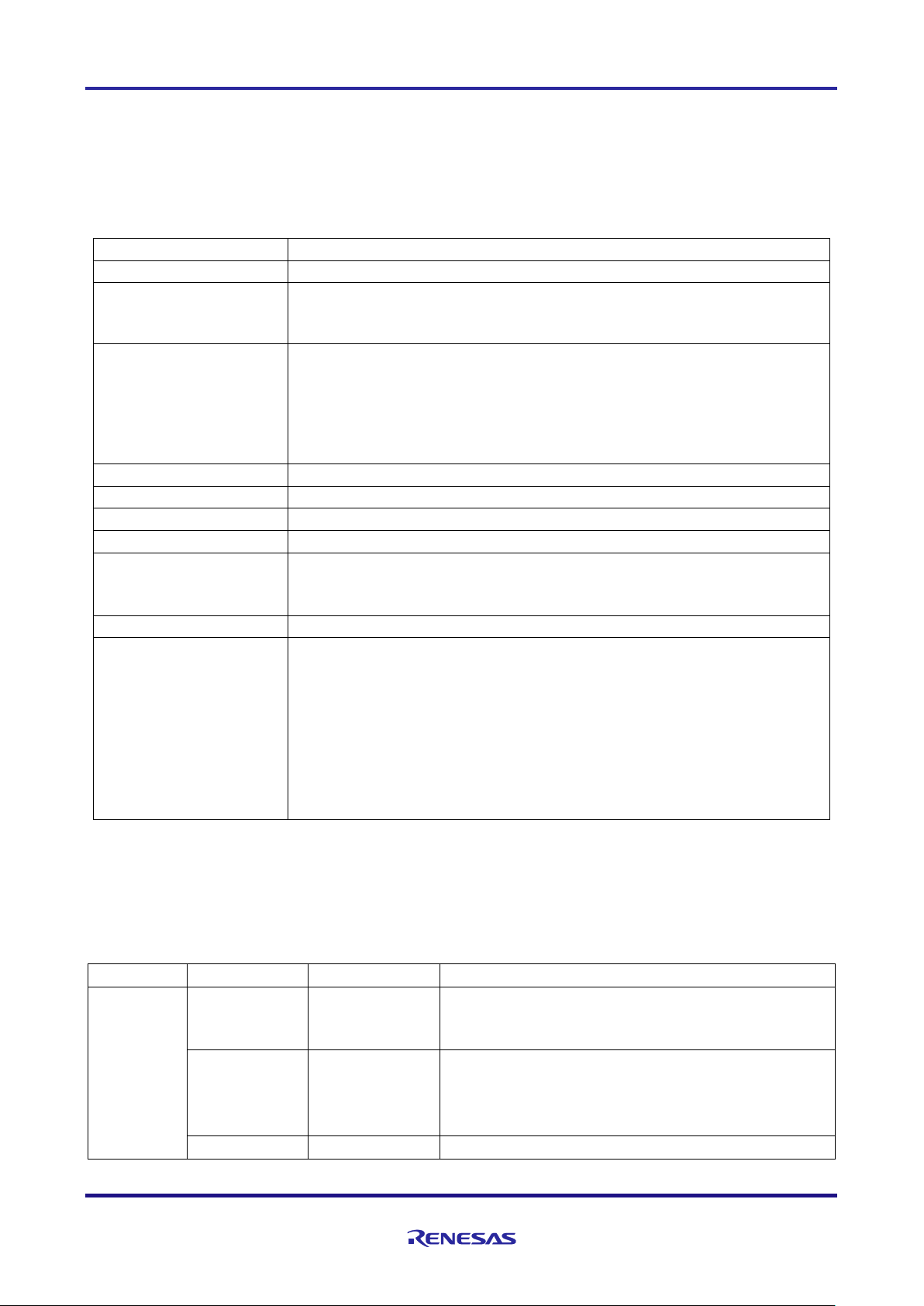

2.2 Hardware specifications

2.2.1 User interface

Table 2-1 is a list of user interfaces of this system.

Table 2-1 – User Interface

Item

Interface component

Function

VR1

Variable resistor

Rotational speed command value

input (analog values)

SW1

Toggle switch

Command of recovery from error

status

SW2

Toggle switch

(Not used in this system)

LED1

Yellow green LED

(Not used in this system)

LED2

Yellow green LED

(Not used in this system)

LED3

Yellow green LED

(Not used in this system)

RESET

Push switches

(Not used in this system)

The system's RL78/G1M microcontroller port interfaces are listed in Table 2-2.

Table 2-2 – Port Interface

R5F11W68ASM Port Names

Function

P15 / ANI6

Inverter bus voltage measurement

P16 / ANI7

Rotational speed command values input (analog values)

P125

ERROR RESET toggle switch 3

P137

Toggle switch (not used in this system) 4

P40

LED1 on/off control (not used in this system)

P12 / ANI3

U phase voltage measurement (A/D) 2

P13 / ANI4

V phase voltage measurement (A/D) 2

P14 / ANI5

W phase voltage measurement (A/D) 2

P12

Hall effect sensor input

1,2

(HU)

P13

Hall effect sensor input

1,2

(HV)

P14

Hall effect sensor input

1,2

(HW)

P00 / RTIO00

PORT output / PWM output (Up)

P01 / RTIO01

PORT output / PWM output (Vp)

P02 / RTIO02

PORT output / PWM output (Wp)

P03 / RTIO03

PORT output / PWM output (Un)

P04 / RTIO04

PORT output / PWM output (Vn)

P05 / RTIO05

PORT output / PWM output (Wn)

P125 / RESET

System reset (not used in this system)

3

P137 / INTP0

PWM emergency stop input at the time of overcurrent detection

4

1

: When Hall effect sensors on the motor included in the 24V inverter kit are used, equip the ferrite core included in this

kit with cables for 3 Hall effect sensors to avoid sensor noise.

2

: Short 2-3 of JP1-3 in Hall effect sensor control mode, or 1-2 in senseless control mode.

3

: In this system, because P125 is used to detect the status of SW1, short 2-3 of JP4. (However, when writing a program

to the microcontroller, by using the E1emulator, short 1-2.)

4

: In this system, P137 is used for overcurrent detection, so short 1-2 of JP5.

Page 6

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 6 of 48

2020.08.01

2.2.2 Peripheral functions

Table 2-3 is a list of peripheral functions used in this system.

Table 2-3 – List of Peripheral Functions

Peripheral Function

Usage

10-bit A/D converter

Rotational speed command value input (Board UI

mode)

Inverter bus voltage measurement

Voltage of each phase U, V, and W measurement

Timer Array Unit (TAU)

PWM output

Free-running timer for rotational speed measurement

Delay timer for changing conducting pattern

(sensorless control mode)

12-bit Interval timer (IT)

1 [ms] interval timer

Real-time output control circuit

Output waveform and output port control

External interrupt (INTP0)

Overcurrent detection

(1) 10-bit A/D converter

The rotational speed command value input, U phase voltage (Vu), V phase voltage (Vv), W phase

voltage (Vw), and inverter bus voltage (Vdc) are measured by using the “10-bit A/D converter”.

(2) Timer Array Unit (TAU)

a. PWM output

Used to output non-complementary PWM.

b. Free-running timer for rotational speed measurement

This channel 1 of TAU is used as a free-running counter for rotational speed calculation.

c. Delay timer for changing conducting pattern

The channel 3 of TAU is used as delay timer for changing conducting pattern with π/6 phase from

the zero-crossing point.

(3) 12-bit Interval timer (IT)

Used as a 1 millisecond interval timer.

(4) Real-time output control circuit (RTO)

Sets the Up to Wn PWM, high level and low output.

In addition, by using the forced cutoff function, all output terminals are set to low level output when

overcurrent is detected.

(5) External interrupt (INTP0)

An overcurrent is detected by an external circuit.

Page 7

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 7 of 48

2020.08.01

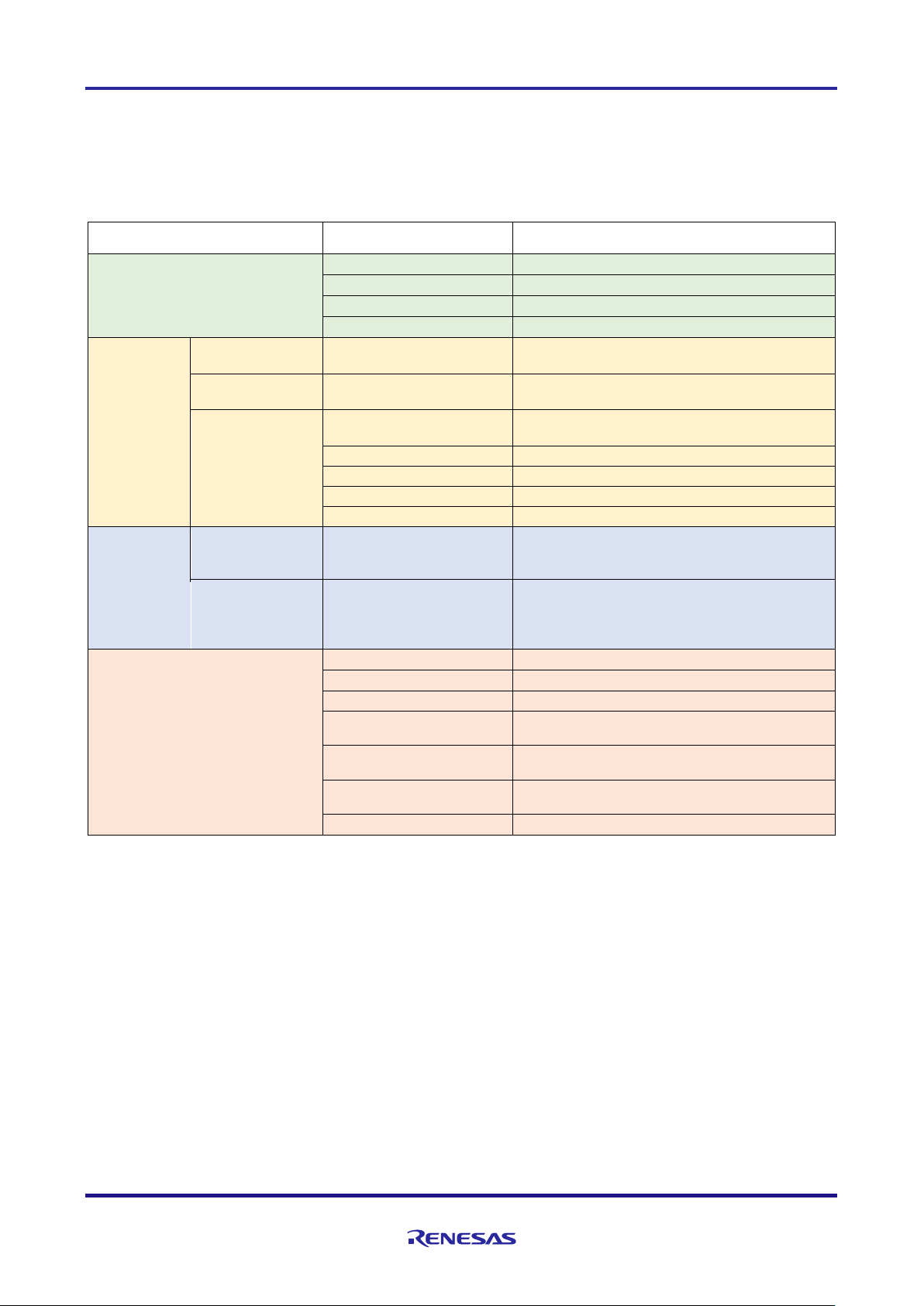

2.3 Software structure

2.3.1 Software file structure

The folder and file configurations of the sample programs Table 2-4 are given below.

Table 2-4 – Folder and File Configuration of the Sample Program

Folder

file

content

config

r_mtr_config.h

Common definition for software configuration

r_mtr_motor_parameter.h

Configuration definition for motor parameters

r_mtr_control_parameter.h

Configuration definition for control parameters

r_mtr_inverter_parameter.h

Configuration definition for inverter parameters

application

main

main.h

main.c

Main function

board

r_mtr_board.h

r_mtr_board.c

Function definition for board UI

ics

r_mtr_ics.h

r_mtr_ics.c

Function definition for Analyzer

(Note1)

UI

ICS_define.h

CPU definition for RMW

RL78G1M_vector.c

Interrupt vector function definition for RMW

Ics2_RL78G1M.h

Function declaration for RMW

ICS2_RL78G1M.lib

Communication library for RMW

driver

auto_generation

cstart.asm

hdwinit.asm

iodefine.h

Auto generation files

mtr_ctrl_mrssk.h,

mtr_ctrl_mrssk.c

Function definition for inverter board control

r_mtr_ctrl_rl78g1m.h,

r_mtr_ctrl_rl78g1m.c

Function definition for MCU control

middle

r_mtr_fixed.h

Fixed point definition

r_mtr_common.h

Common definition

r_mtr_parameter.h

Various parameter definition

r_mtr_driver_access.h,

r_mtr_driver_access.c

Function definition for User access

r_mtr_statemachine.h,

r_mtr_statemachine.c

Function definition for state transition

r_mtr_120.h

r_mtr_120.c

Function definition for 120-degree conducting control

r_mtr_interrupt.c

Interrupt function definition

Note 1: Regarding the specification of the Analyzer function in the motor control development support tool “Renesas Motor Workbench

(RMW)”, please refer to Chapter 4.

The identifier ‘ics/ICS (ICS is the previous motor control development support tool, ‘In Circuit Scope’) is attached to the name of

folders, files, functions, and variables related to ‘Renesas Motor Workbench’.

Page 8

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 8 of 48

2020.08.01

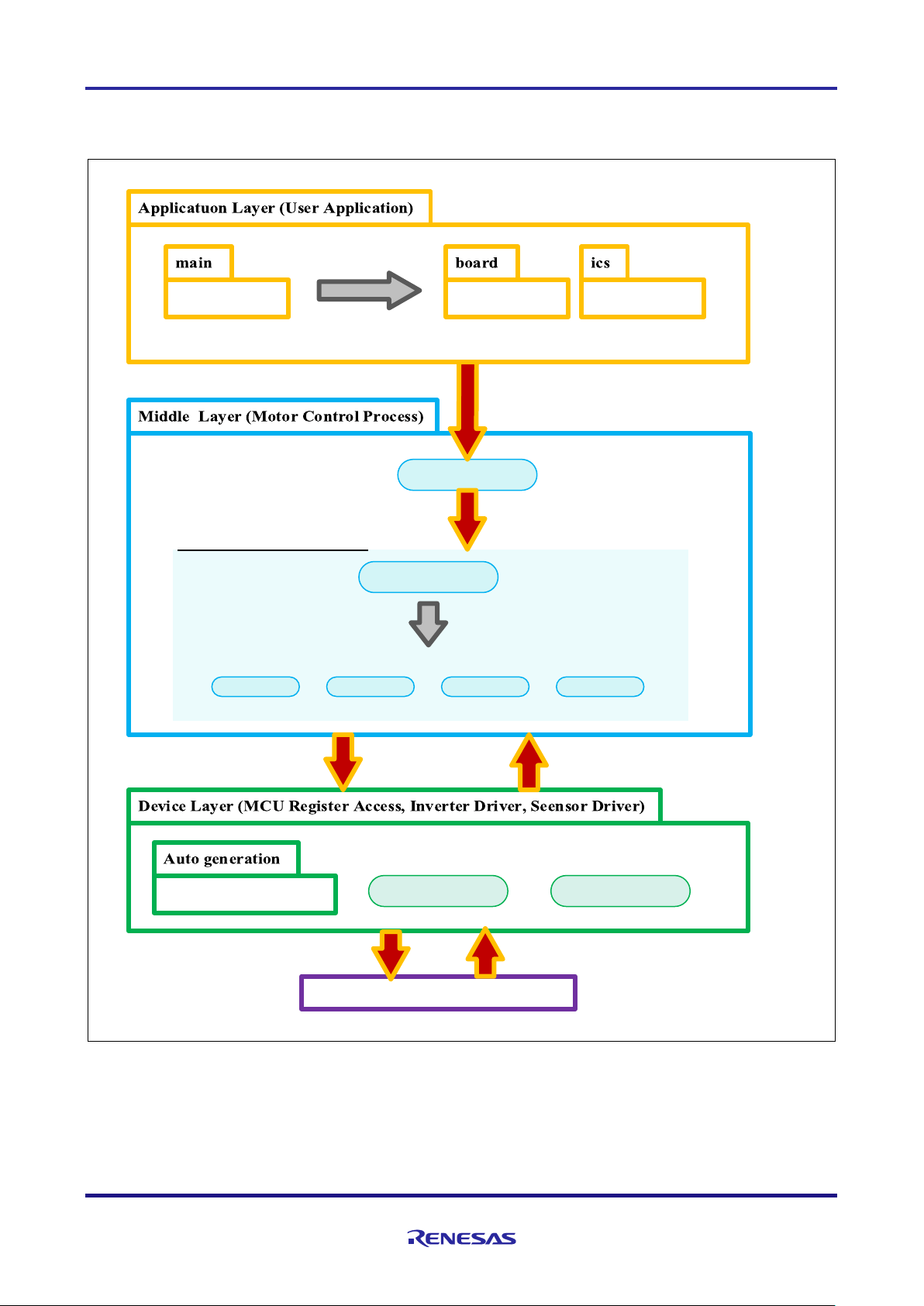

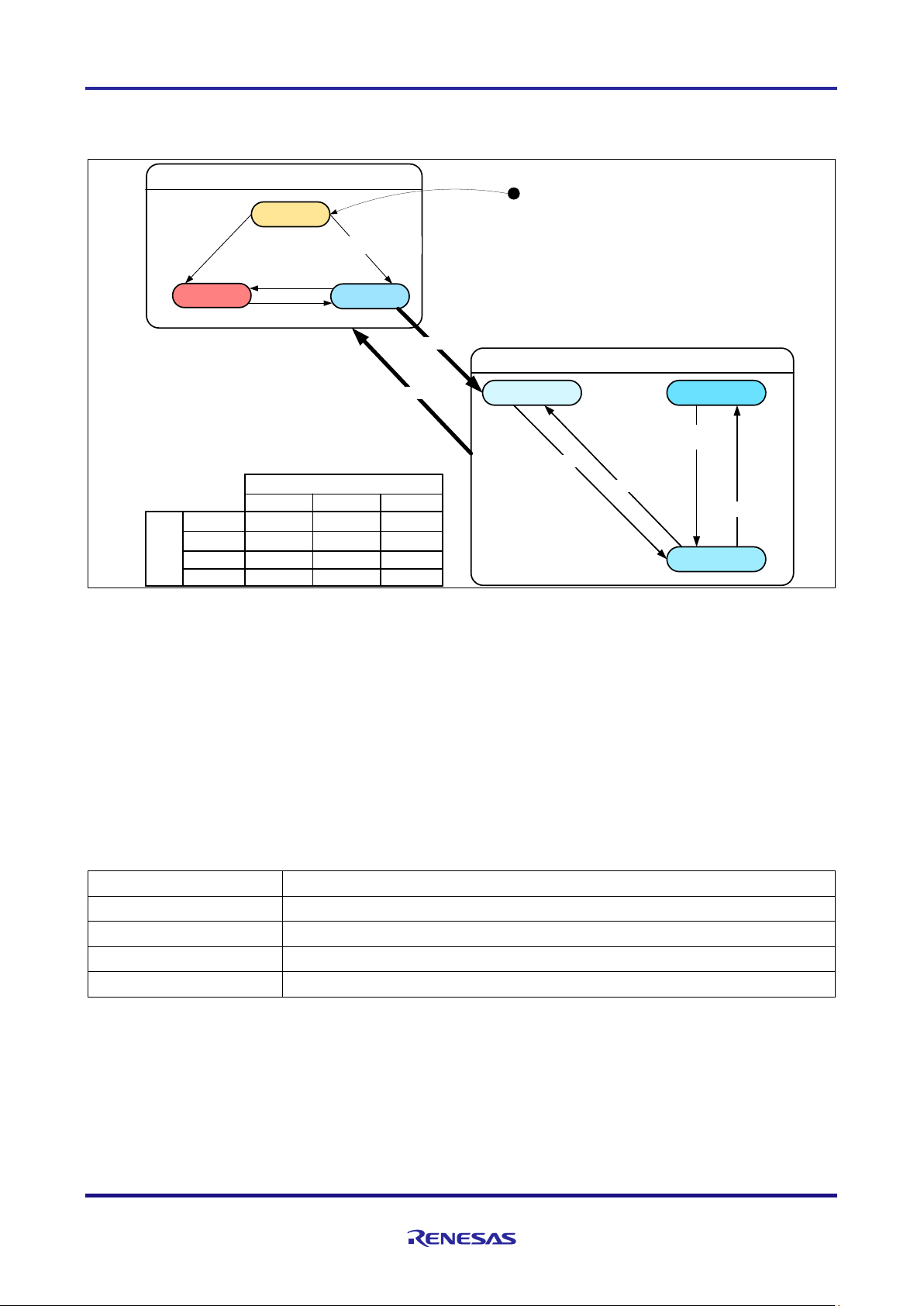

2.3.2 Module configuration

Figure 2-2 shows module configuration of the sample programs.

Function Call

driver_access

Set Control Parameter & Command

Motor Control Process Modules

interrupt

Function Call

Other Control Modules

MCU Inverter

Set PWM duty

Voltage, Sensor signals

H/W Layer (MCU, Inverter)

Output PWM Signal A/D Convertor, PORT

Figure 2-2 – Module Configuration of the Sample Programs

Page 9

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 9 of 48

2020.08.01

2.4 Software specifications

Table 2-5 shows the basic specifications of target software of this application note. For details on 120degree conducting control, refer to the application note “120-degree conducting control of permanent magnet

synchronous motor: algorithm”.

Table 2-5 – Basic Specifications of Software

Item

Content

Control method

120-degree conducting method (chopping upper arm)

Motor rotation start/stop

Determined based on the input value of VR1 (P16) (minimum speed or

more: rotation starts, less than minimum speed: stop)

or input from Renesas Motor Workbench

Position detection of rotor

magnetic pole

Hall effect sensor: Position detection based on signal from Hall effect

sensors (every 60 degrees)

Sensorless: Position detection based on induced voltage measured by A/D

converters (every 60 degrees)

・When position of rotor is detected, PWM duty and conducting pattern are

set.

Input voltage

DC24[V]

Main clock frequency

CPU clock: f

CLK

20 [MHz]

Carrier frequency (PWM)

20 [kHz]

Control cycle

Speed PI control: every 1 [ms]

Rotational speed control

range

Hall effect sensor control mode: 530 [rpm] to 3200 [rpm]

(Note1)

Sensorless control mode: 265 [rpm] to 3200 [rpm]

(Note1)

Both CW and CCW are supported

Optimization

Perform the default optimization (None)

Processing stop for

protection

・Disables the motor control signal output (six outputs), under any of the

following conditions.

1. Inverter bus voltage exceeds 28 V (monitored per 1 [ms])

2. Inverter bus voltage is less than 15 V (monitored per 1 [ms])

3. Rotational speed exceeds 3900 rpm (monitored per 1 [ms])

4. Hall pattern change or zero-crossing are not detected for 200 [ms].

5. Detection of unexpected output voltage pattern

6. Detection of overcurrent by external circuit (low level input in INTP0

port)

Note1 : Please refrain from driving motor over rated speed for a long period.

2.5 User option bytes

The settings of the user option byte area of the RL78/G1M flash memory are shown below.

Table 2-6 – User option byte settings

Setting

Address

value

Description

F2E3F9

000C0H

11110010B

Enable watchdog timer counter operation

(Starts counting after reset is released)

Overflow time: 7.36 [ms]

000C1H

11100011B

・P125/KR1/RESET pin: Port function

・Selectable power-on reset detection voltage

Rising edge: 4.28 [V]

Falling edge: 4.20 [V]

000C2H

11111001B

CPU clock fCLK: 20 [MHz]

Page 10

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 10 of 48

2020.08.01

3. Descriptions of the control program

The target sample programs of this application note are explained here.

3.1 Contents of control

3.1.1 Motor start/stop

Starting and stopping of the motor are controlled by input from Renesas Motor Workbench or VR1. In

addition, an analog input port is assigned to VR1. The input is A/D converted within the main loop to generate a

rotational speed command value. When the rotation command value exceeds the minimum speed (Hall

control mode: 530 [rpm], sensorless control mode: 265 [rpm]), the rotation starts, and when it is less than the

minimum speed, the rotation stops.

3.1.2 A/D Converter

(1) Motor rotational speed command value

The motor rotational speed command value can be set by Renesas Motor Workbench input or A/D

conversion of the VR1 output value (analog value). The A/D converted VR1 value is used as rotational speed

command value, as shown below. Maximum value of conversion ratio is set to achieve maximum speed by

VR1 input. Only higher 8bits are used for calculation of rotational speed command value.

Table 3-1 – Conversion Ratio of the Rotation Speed Command Value

Item

Conversion ratio

(Command value: A/D conversion value)

Channel

Rotational speed

command value

CW

0 [rpm] to 3200 [rpm] : 01FFH to 03FFH

ANI7

CCW

-3200 [rpm] to 0 [rpm] : 0000H to 01FFH

(2) Inverter bus voltage

Inverter bus voltage is measured as given in Table 3-2. It is used for modulation factor calculation and

over/low voltage detection. (When an abnormality is detected, PWM is stopped). Only higher 8bits are used

for calculation of bus voltage.

Table 3-2 – Inverter Bus Voltage Conversion Ratio

Item

Conversion ratio

(Inverter bus voltage: A/D conversion value)

Channel

Inverter bus voltage

0 [V] to 111 [V] : 0000H to 03FFH

ANI6

(3) U phase, V phase, and W phase voltage

The U, V and W phase voltages are measured as shown in Table 3-3 and are used for determining zerocrossing of induced voltage.

Table 3-3 – Conversion Ratio of U, V, and W Phase Voltage

Item

Conversion ratio

(U, V, and W phase voltage: A/D conversion value)

Channel

U, V, W phase

voltages

0 [V] to 111 [V] : 0000H to 03FFH

ANI12, ANI13,

ANI14

Note: For more details on A/D conversion, refer to RL78/G1M User’s Manual: Hardware.

Page 11

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 11 of 48

2020.08.01

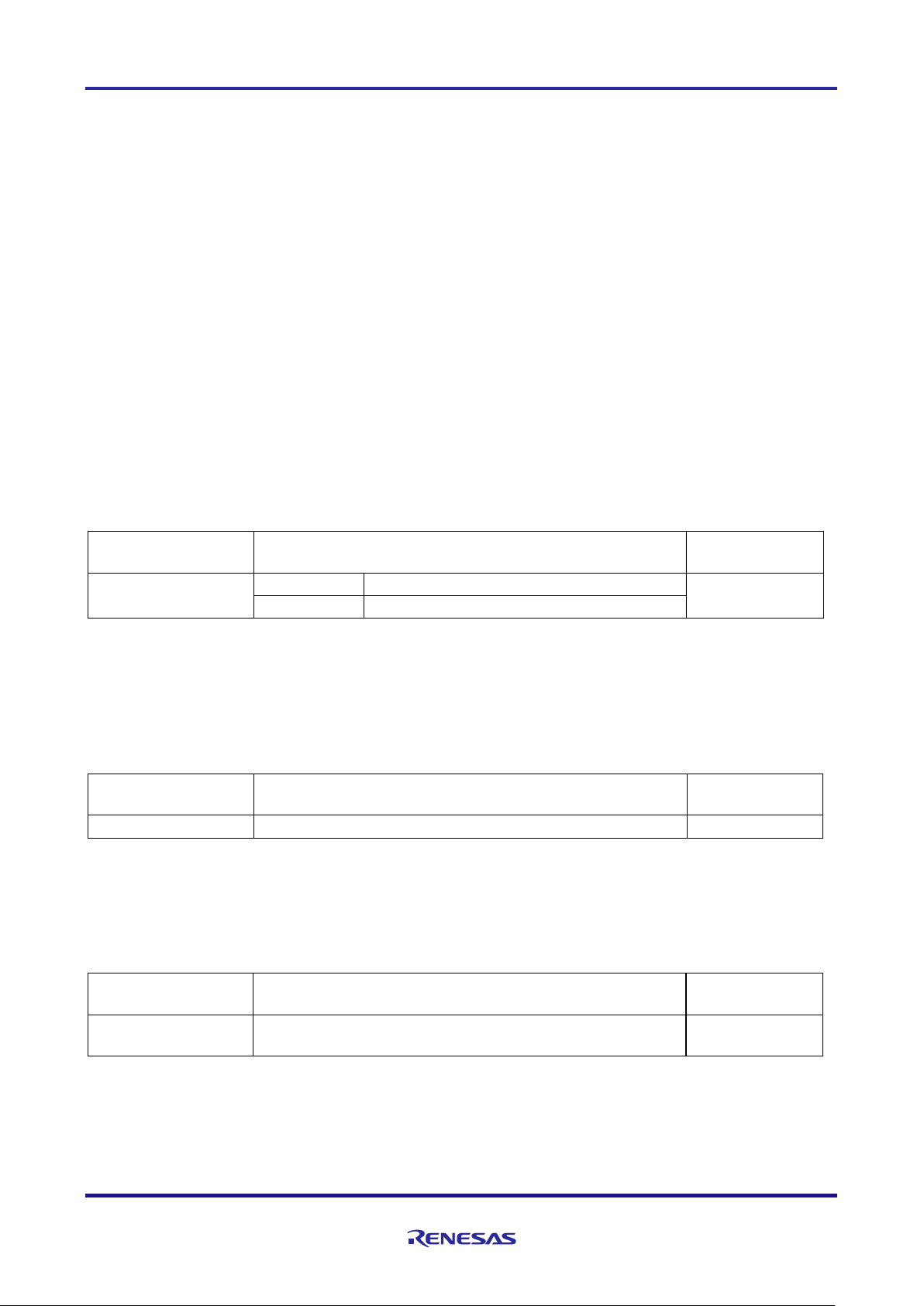

3.1.3 Speed control

In this system, rotational speed is calculated from the difference between the current timer value and the

previous timer value 2π [rad]. The timer values are obtained when patterns are switched after Hall effect

sensor pattern change at Hall effect sensor control mode or zero-crossing of induced voltage at sensorless

control mode, while having the timer of performed free running.

U phase pattern

2p

Timer counter

Check Check Check Check Check Check Check

Counter value difference

Motor rotational speed [rad/s] = (2π × frequency of timer) / (difference of timer counts)

V phase pattern

W phase pattern

2p

2p

Figure 3-1 – Method of Calculation for Rotational Speed

The target sample software of this application note uses PI control for speed control. A voltage command

value is calculated by the following formula of speed PI control.

))((

*

−+=

s

K

Kv

I

P

𝑣

∗

: Voltage command value : Speed command value : Rotation speed

: Speed PI proportional gain : Speed PI integral gain 𝑠: Laplace operator

For more details on PI control, please refer to specialized books.

Page 12

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 12 of 48

2020.08.01

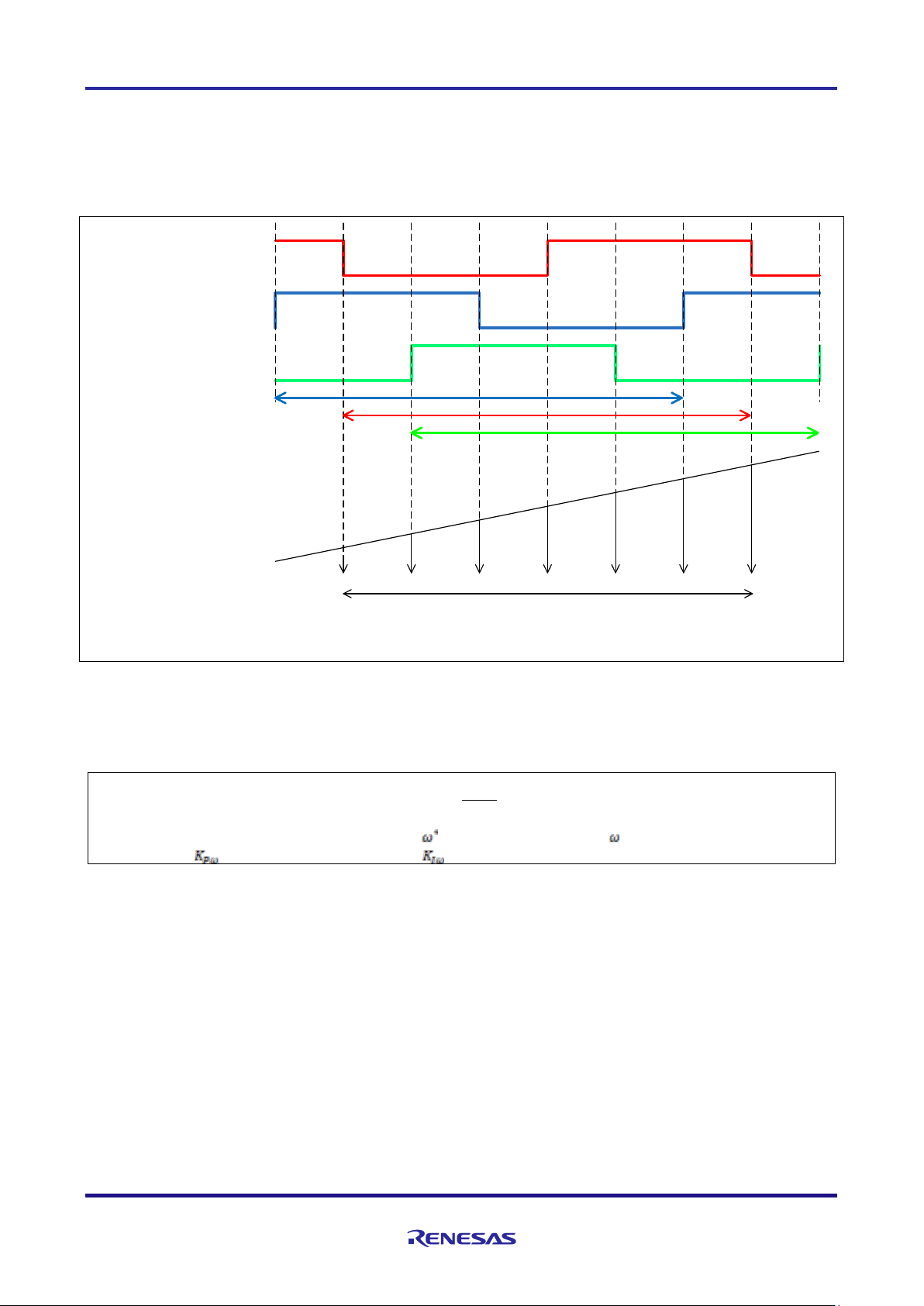

3.1.4 Voltage control by PWM

PWM control is used for controlling output voltage. The PWM control is a control method that continuously

adjusts the average voltage by varying the duty of pulse, as shown in Figure 3-2.

Average

voltage

t

V

T

ON

T

OFF

T

ON

+ T

OFF

T

ON

Duty = × 100 [%]

Figure 3-2 – PWM Control

Here, modulation factor “m” is defined as follows.

𝑚 =

𝑉

𝐸

This modulation factor is set to resisters for PWM duty in TAU.

In the target software of this application note, non-complementary upper arm chopping is used to control

the output voltage and speed. Figure 3-3 shows an example of output waveforms when upper arm chopping

is used.

UP

UN

VP

VN

WP

WN

Figure 3-3 – Non-Complementary Upper Arm Chopping

𝑚: Modulation factor 𝑉: Command value voltage 𝐸: Inverter bus voltage

Page 13

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 13 of 48

2020.08.01

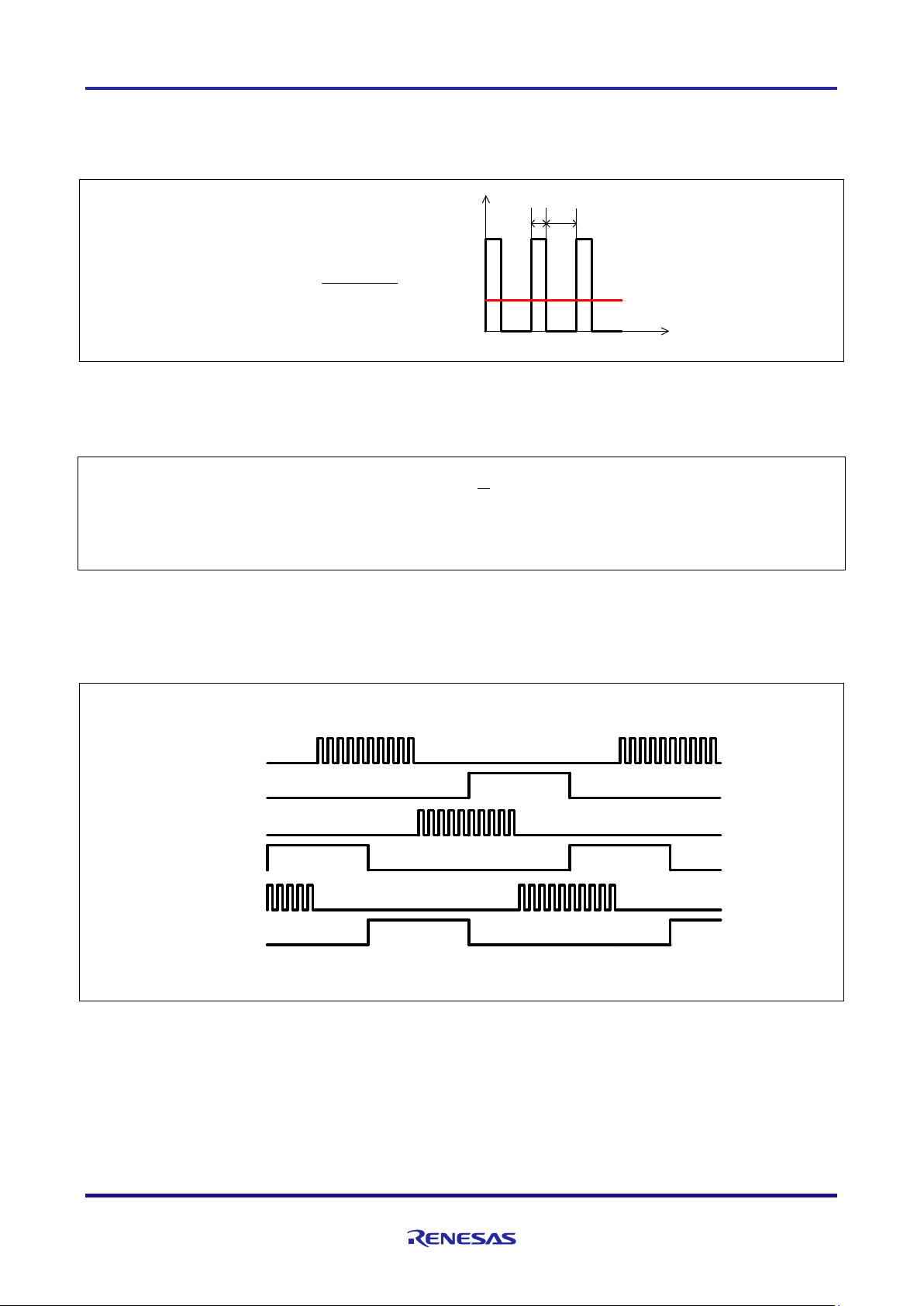

3.1.5 State transitions

Figure 3-4 shows state transition diagrams of 120-degree conducting control software.

SYSTEM MODE (User System)

INACTIVE

ERROR

POWER ON/

HARDWAE RESET

[INIT ERROR]

RUN MODE (Motor Control)

INIT

STOP

DRIVE

ACTIVE

[ERROR]

[RESET]

STOP

DRIVE

ERROR

RESET

RUN MODE

INIT DRIVE STOP

STOP

INIT INIT

INIT

STOP STOP

DRIVE

STOP

DRIVE

STOP

DRIVE

STOP

EVENT

[HW INIT END]

[RESET EVENT]

[DRIVE EVENT]

[ERROR EVENT]

[STOP EVENT]

[STOP EVENT]

[INIT EVENT]

[ERROR STATUS]

Figure 3-4 – State Transition Diagram 120-degree Conducting Control Software

(1) SYSTEM MODE

“SYSTEM MODE” indicates the operating states of the system. “SYSTEM MODE” has 3 states, which are

motor drive stop (INACTIVE), motor drive (ACTIVE), and abnormal condition (ERROR).

(2) RUN MODE

“RUN MODE” indicates the condition of the motor control. The state is changed by occurrence of “EVENT”.

(3) EVENT

“Event” indicates the change of “RUN MODE”. When “EVENT” occurs, “RUN MODE” changes as shown

table in Figure 3-4. Each “Event” is caused by occurrence as shown in Table 3-4.

Table 3-4 – List of “EVENT”

“EVENT” name

Occurrence factor

STOP

By user operation

DRIVE

By user operation

ERROR

When the system detects an error

RESET

By user operation

Page 14

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 14 of 48

2020.08.01

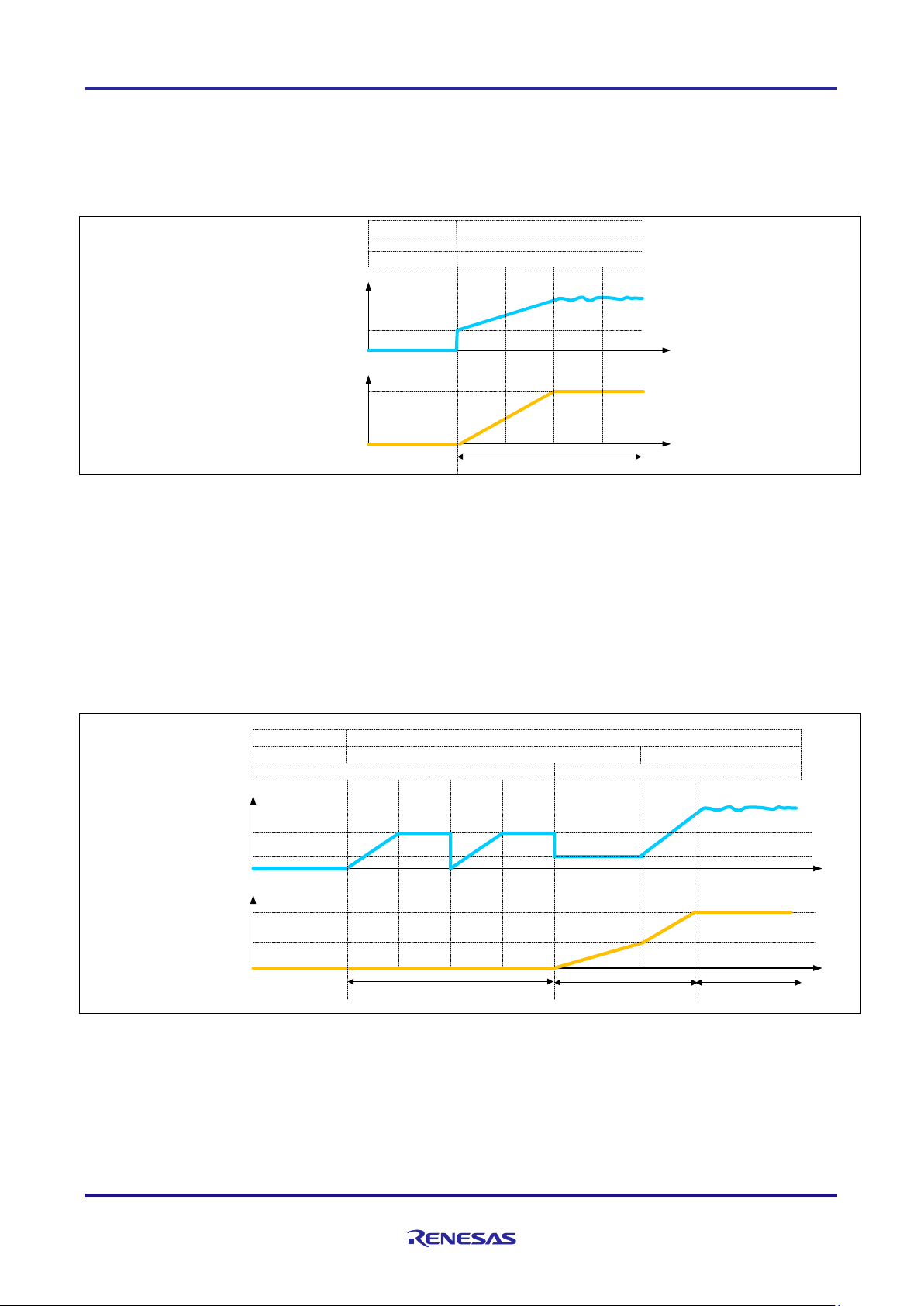

3.1.6 Start-up method

(1) Hall effect sensor control mode

In the Hall effect sensor control mode, after changing to “MTR_MODE_DRIVE”, the output pattern is

selected from the initial Hall effect sensor signal. Then, voltage is applied and the state is changed to PI

control mode. The rotational speed is calculated after the second hall effect sensor interruption.

Voltage

[V]

RUN MODE

0

0

Reference voltage status

Reference speed status

MTR_SPEED_MANUAl

(1)

Speed

[rad/s]

g_st_120.st_hall_

s2_start_ref_v

g_st_120.s2_ref_speed_rad_ctrl

Speed PI control

MTR_V_PI_OUTPUT

(2)

MTR_V_ZERO_CONST

(0)

MTR_SPEED_ZERO_CONST

(0)

MTR_MODE_DRIVEMTR_MODE_STOP

Figure 3-5 – Start-up sequence (hall effect sensor control mode)

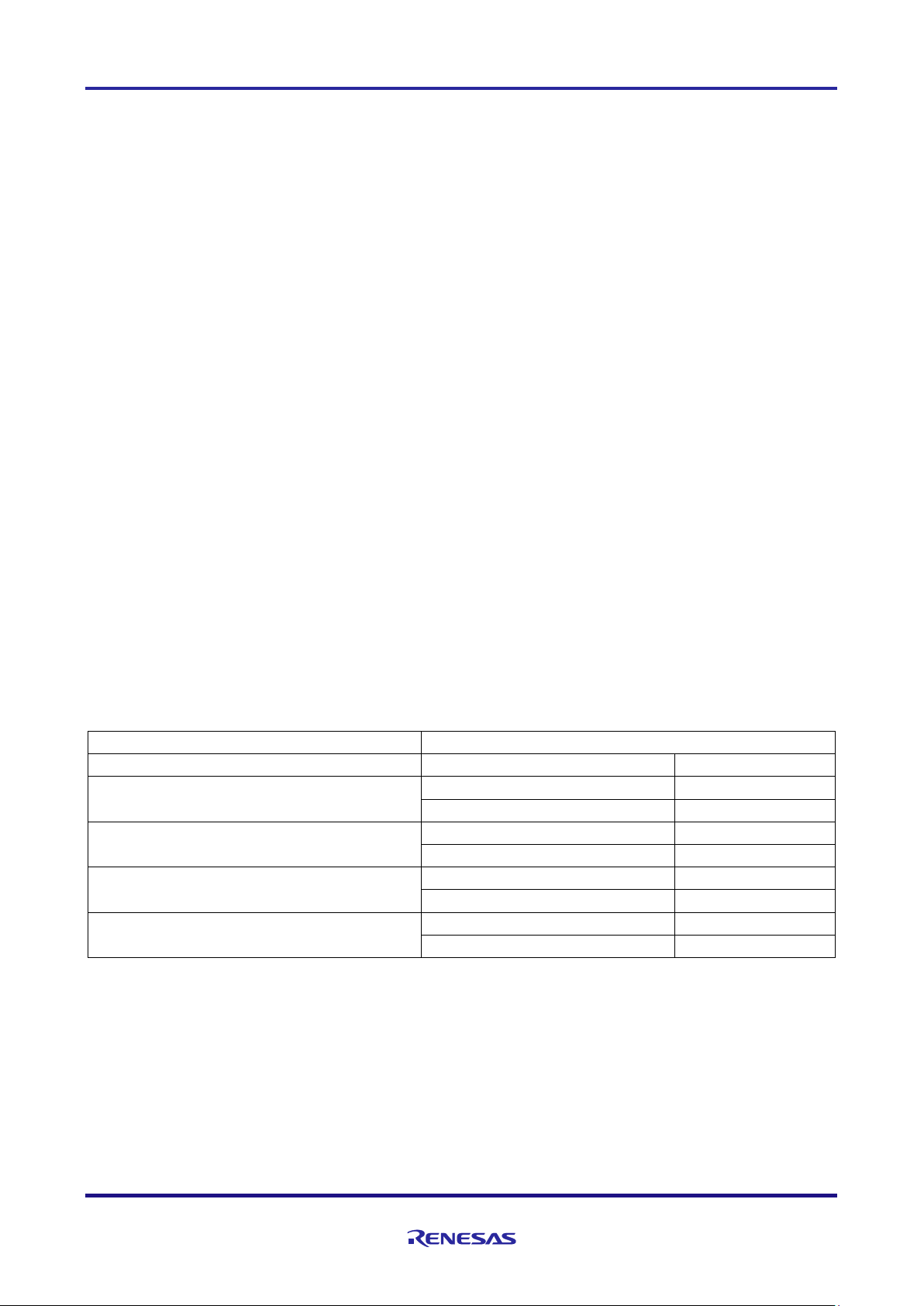

(2) Sensorless control mode

In sensorless control mode, the position of the magnetic poles is estimated every 60 degrees from induced

voltage that is generated from the variation of magnetic flux due to the rotation of the permanent magnet

(rotor). However, since the induced voltage is generated by the rotation, at low speed it is difficult to estimate

the position of the rotor.

Therefore, the method to generate a rotating magnetic field by forcibly switching conducting pattern in the

synchronous speed regardless of the position of the rotor, is often used.

Figure 3-6 shows the start-up method in the sample software. In “MTR_MODE_DRIVE”, at first, the rotor is

drawn in. Second, mode is changed to open-loop drive mode. When reference control speed reaches to

change speed, mode is changed to PI control mode.

Voltage

[V]

RUN MODE

0

0

Reference voltage status

Reference speed status

MTR_SPEED_MANUAl

(1)

Speed

[rad/s]

MTR_V_PI_OUTPUT

(2)

g_st_120.st_less.

s2_ol_ref_v

g_st_120.st_less.

s2_ol2less_speed_rad

g_st_120.s2_ref_speed_rad

Open-loop Speed PI control

g_st_120.st_less.

s2_draw_in_ref_v

MTR_V_MANUAL

(1)

MTR_V_ZERO_CONST

(0)

MTR_SPEED_ZERO_CONST

(0)

MTR_MODE_DRIVEMTR_MODE_STOP

Draw-in

Figure 3-6 – Startup Sequence (Sensorless Control Mode)

Page 15

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 15 of 48

2020.08.01

3.1.7 System protection function

This system has the following types of error status and emergency stop functions in case of occurrence of

respective error. Refer to Table 3-5 for settings related to the system protection function.

・Overcurrent error for hardware

When an emergency stop signal (over current detection) from the external hardware is detected, voltage

output is stopped.

・Overvoltage error

The inverter bus voltage is monitored at the overvoltage monitoring cycle. When the inverter bus voltage

exceeds the overvoltage limit, voltage output is stopped. The threshold value of the overvoltage is set in

consideration of the error of resistance value of the detection circuit.

・Low voltage error

The inverter bus voltage is monitored at the low voltage monitoring cycle. When the inverter bus voltage

lowers undervoltage limit, voltage output is stopped. The threshold value of the low voltage is set in

consideration of the error of resistance value of the detection circuit.

・Rotational speed error

The rotational speed is monitored at the rotational speed monitoring cycle. When the rotational speed

exceeds the over speed limit, voltage output is stopped.

・Timeout error

The timeout counter is monitored at the timeout monitoring cycle. When pattern switching by Hall pattern

change in Hall effect sensor control mode or zero-crossing of induced voltage in sensorless control mode

don’t happen for a timeout period, voltage output is stopped.

・Pattern error

The output voltage pattern is monitored at the pattern monitoring cycle. When unexpected pattern is

detected in voltage pattern set from Hall effect sensor in Hall effect sensor control mode or induced

voltage in sensorless control mode, voltage output is stopped.

Table 3-5 – Setting Value of Each System Protection Function

Kinds of error

Threshold

Over current error

Over current limit [A]

2.0

Over voltage error

Overvoltage limit [V]

28

Monitoring cycle [ms]

1

Under voltage error

Low voltage limit [V]

15

Monitoring cycle [ms]

1

Rotational speed error

Speed limit [rpm]

3900

Monitoring cycle [ms]

1

Timeout error

Timeout value [ms]

200

Monitoring cycle [ms]

1

Page 16

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 16 of 48

2020.08.01

3.2 Function specifications of 120-degree conducting control software

Lists of functions used in this control program are shown below. Functions not used in this system are

undescribed.

Table 3-6 – List of Functions “main.c”

file

function

process

main.c

main

argument: none

return: none

Initialization and main loop

・initialization

⇒initialization of hardware

⇒initialization of system variables

⇒initialization of ICS communication

⇒initialization of control system

⇒reset process

⇒waiting for stability of bus voltage

・main loop

⇒system control depending on input from UI

⇒clear watch dog timer

⇒ICS communication process

ics_ui

argument: none

return: none

Process for ICS UI (GUI)

・input values of command variables to ICS variables

・change motor status depending on input event

・initialization of system variables when reset event occurs

board_ui

argument: none

return: none

Process of board UI (H/W)

・change motor status depending on state of switch

・determination of command rotational speed by value of

VR1

software_init

argument: none

return: none

Initialization of system variables

・initialization of variables for main process

・initialization of ICS variables

mtr_ics_process [inline function]

argument: none

return: none

ICS communication process

Page 17

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 17 of 48

2020.08.01

Table 3-7 – List of Functions “r_mtr_ics.c”

file

function

process

r_mtr_ics.c

mtr_set_com_variables

argument: none

return: none

Preprocess to set control variables

・input values of command variables to ICS variables

・input values of ICS variables to ICS buffer variables

mtr_ics_variables_init

argument: none

return: none

Initialization of command variables

R_MTR_Limit

argument: (int16_t) s2_value / target value

(int16_t) s2_max / maximum limit

(int16_t) s2_min / minimum limit

return: (int16_t) s2_temp / limited value

Limit between maximum and minimum values

Table 3-8 – List of Functions “r_mtr_board.c”

file

function

process

r_mtr_board.c

mtr_remove_chattering

argument: (uint8_t) u1_sw / switch signal

(uint8_t) u1_on_off / switch status

return: (uint8_t) u1_flag_chattering / flag for chattering

Remove chattering of switch signal

Page 18

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 18 of 48

2020.08.01

Table 3-9 – List of Functions “r_mtr_ctrl_mrssk.c”

file

function

process

r_mtr_ctrl_mrssk.c

R_MTR_GetSw1

argument: none

return: (uint8_t) MTR_PORT_SW1 / state of SW1

Get state of SW1

Table 3-10 – List of Functions in “r_mtr_ctrl_rl78g1m.h”

file

function

process

r_mtr_ctrl_rl78g1m.h

mtr_input_hall(signal)

argument: none

return: none

Input Hall effect sensor signal

mtr_get_tcr02(cnt)

argument: none

return: none

Get free run timer counts

mtr_set_rtooutc(gate)

argument: none

return: none

Set voltage pattern by RTO

mtr_set_tdr01(duty)

argument: none

return: none

Set PWM duty

mtr_clear_wdt()

argument: none

return: none

Clear watch dog timer (WDT)

mtr_get_adcr(v)

argument: none

return: none

Get A/D result

mtr_clear_rtointpclr()

argument: none

return: none

Clear forced cutoff

mtr_oc_intr_enable()

argument: none

return: none

Enable overcurrent interrupt

mtr_oc_intr_disable()

argument: none

return: none

Disable overcurrent interrupt

mtr_set_tdr03()

argument: none

return: none

[sensorless control mode]

Set delay count

mtr_start_delay_cnt()

argument: none

return: none

[sensorless control mode]

Start delay timer

mtr_stop_delay_cnt()

argument: none

return: none

[sensorless control mode]

Stop delay timer

mtr_clear_inttm03()

argument: none

return: none

[sensorless control mode]

Disable delay interrupt

Page 19

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 19 of 48

2020.08.01

Table 3-11 – List of Functions in “r_mtr_ctrl_rl78g1m.c”

file

function

process

r_mtr_ctrl_rl78g1m.c

R_MTR_InitHardware

argument: none

return: none

Initialization of peripheral functions

mtr_init_unused_pins

argument: none

return: none

Initialization of unused pins

mtr_init_ui

argument: none

return: none

Initialization of ports for board UI

mtr_init_clock

argument: none

return: none

Initialization of clock

mtr_init_it

argument: none

return: none

Initialization of 12-bit interval timer (IT)

mtr_init_rto

argument: none

return: none

Initialization of real-time output control circuit

(RTO)

mtr_init_adc

argument: none

return: none

Initialization of A/D converter

mtr_init_tau

argument: none

return: none

Initialization of timer array unit (TAU)

mtr_init_intp

argument: none

return: none

Initialization of external interrupt (INTP)

mtr_init_hall

argument: none

return: none

[Hall effect sensor control mode]

Initialization of pins for hall effect sensor

R_MTR_get_adc

argument: (uint8_t) u1_ad_ch / channel of A/D

conversion

return: (int16_t) s2_ad_value / result of A/D conversion

Get the result of A/D conversion

R_MTR_get_v_uvw_adc

argument: (int16_t) *s2_v_uvw / UVW voltages

return: none

[sensorless control mode]

Get the results of A/D conversion of UVW

voltage

R_MTR_ctrl_stop

argument: none

return: none

Stop motor control

・Voltage output prohibited

Page 20

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 20 of 48

2020.08.01

Table 3-12 – List of Functions “r_mtr_driver_access.c”

file

function

process

r_mtr_driver_access.c

R_MTR_InitControl

argument: none

return: none

Initialization of control system

・initialization of motor status

・initialization of control variables

R_MTR_IcsInput

argument: (mtr_ctrl_input_t) *st_ics_input / ICS structure

return: none

Input values of ICS variables to ICS

buffer variables

R_MTR_SetVariables [inline function]

argument: none

return: none

Input values of ICS buffer variables to

control variables

R_MTR_InputBuffParamReset

argument: none

return: none

Reset ICS buffer variables

R_MTR_ExecEvent

argument: (uint8_t) u1_event / event

return: none

Change motor status and execute

event process

R_MTR_GetStatus

argument: none

return: (uint8_t) mtr_statemachine_get_status(g_st_120.st_stm)

/ motor status

Get motor status

R_MTR_GetErrorStatus

argument: none

return: (uint16_t) g_st_120.u2_error_status

/ error status

Get error status

R_MTR_Get_Dir

argument: none

return: (uint8_t) g_st_120.u1_dir / direction of rotation

Get direction of rotation

R_MTR_SetSpeed

argument: (int16_t) s2_ref_speed_rpm / command rotational speed

return: (uint8_t) u1_stop_req / flag for requiring flag

Set command speed

R_MTR_ChargeCapacitor

argument: none

return: (uint16_t) u2_charge_cap_error / timeout error

Waiting for stability of bus voltage

R_MTR_UpdatePolling

argument: none

return: none

Set control variables

Page 21

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 21 of 48

2020.08.01

Table 3-13 – List of Functions “r_mtr_statemachine.c”

file

function

process

r_mtr_statemachine.c

mtr_statemachine_init

argument: (st_mtr_statemachine_t) *p_state_machine / structure for motor status

return: none

Initialization of motor

status

mtr_statemacine_reset

argument: (st_mtr_statemachine_t) *p_state_machine / structure for motor status

return: none

Reset motor status

motor status

mtr_state_machine_event

argument: (st_mtr_statemachine_t) *p_state_machine / structure for motor status

(void) *p_object / structure for control variables

(uint8_t) u1_event / event

return: none

Execute event process

mtr_statemachine_get_status

argument: (st_mtr_statemachine_t) *p_state_machine / structure for motor status

return: (uint8_t) p_state_machine->u1_status / motor status

Get motor status

mtr_act_none

argument: (st_mtr_statemachine_t) *st_stm / structure for motor status

(void) *p_param / structure for control variables

return: none

No process is performed

mtr_act_init

argument: (st_mtr_statemachine_t) *st_stm / structure for motor status

(void) *p_param / structure for control variables

return: none

Initialization of

control variables

mtr_act_error

argument: (st_mtr_statemachine_t) *st_stm / structure for motor status

(void) *p_param / structure for control variables

return: none

Stop motor control

mtr_act_drive

argument: (st_mtr_statemachine_t) *st_stm / structure for motor status

(void) *p_param / structure for control variables

return: none

Reset control variables

mtr_act_stop

argument: (st_mtr_statemachine_t) *st_stm / structure for motor status

(void) *p_param / structure for control variables

return: none

Stop motor control

Page 22

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 22 of 48

2020.08.01

Table 3-14 – List of Functions in “r_mtr_120.h”

file

function

process

r_mtr_120.h

mtr_conv_q_voltage(v)

argument: none

return: none

Q value conversion of voltage

mtr_conv_kp_voltage(kp)

argument: none

return: none

Q value conversion of proportional

gain

mtr_conv_kidt_voltage(kidt)

argument: none

return: none

Q value conversion of integral gain

mtr_conv_rpm2rad(v)

argument: none

return: none

Unit converson of rotational speed

from [rpm] to [rad/s]

Table 3-15 – List of Functions in “r_mtr_120.c”

file

function

process

r_mtr_120.c

mtr_120_motor_default_init

argument: (st_mtr_120_control_t) *st_120 / structure for control variables

return: none

Initialization of control

variables

mtr_120_motor_reset

argument: (st_mtr_120_control_t) *st_120 / structure for control variables

return: none

Reset control variables

Page 23

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 23 of 48

2020.08.01

Table 3-16 – List of Functions “r_mtr_interrupt.c” [1/ 3]

file

function

process

r_mtr_interrupt.c

mtr_over_current_interrupt

argument: none

return: none

Overcurrent detection process

・disable over current interrutp

・execute error event

・set error status

mtr_carrier_interrupt

argument: none

return: none

Carrier interrupt

【Hall effect sensor control mode】

・obtain bus voltage

・detect Hall pattern change

・prepare for rotational speed calculation

・set voltage pattern

[sensorless control mode]

・obtain UVW and bus voltages

・draw-in process

・zero-cross detection

・prepare for rotational speed calculation

・open-loop process

・calculate delay counts

・start delay timer

mtr_prepare_speed_calc [inline function]

argument: none

return: none

Prepare for Calculation of rotational speed

mtr_set_chopping_pattern [inline function]

argument: (uint8_t) u1_pattern / conducting pattern

return: none

Set chopping pattern

mtr_set_speed_ref [inline function]

argument: none

return: none

Set reference speed

mtr_set_voltage_ref [inline function]

argument: none

return: none

Set reference voltage

mtr_pi_ctrl [inline function]

argument: (st_mtr_pi_control_t) *pi_ctrl / structure for PI control

return: (int16_t) s2_ref_v_delta / variation of output voltage

PI control calculation (velocity form)

mtr_duty_calc [inline function]

argument: (int16_t) s2_ref_v / reference voltage

(int16_t) s2_vdc_ad / bus voltage

return: (uint16_t) u4_temp / duty

Duty calculation

mtr_abs [inline function]

argument: (int16_t) s2_value / input value

return: (int16_t) s2_temp / conversion value

Conversion to absolute value

mtr_limit_value [inline function]

argument: (int16_t) s2_value / input value

(int16_t) s2_limit_value / limit value

return: (int16_t) s2_temp / conversion value

Limit process

Page 24

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 24 of 48

2020.08.01

Table 3-17 – List of Functions “r_mtr_interrupt.c” [2/3]

file

function

process

r_mtr_interrupt.c

mtr_error_check [inline function]

argument: none

return: none

Error check

mtr_1ms_interrupt_hall

argument: none

return: none

[Hall effect sensor control mode]

IT interrupt (1 [ms))

・set reference speed and voltage states

・calculate reference speed and voltage

・starting-up process

・calculate rotational speed

・check error

mtr_speed_calc [inline function]

argument: none

return: none

[Hall effect sensor control mode]

Calculate rotational speed

mtr_1ms_interrupt_less

argument: none

return: none

[sensorless control mode]

IT interrupt (1 [ms])

・set reference speed and voltage states

・calculate reference speed and voltage

・draw-in process

・calculate rotational speed

・calculate counts for open-loop drive

・check error

mtr_delay_interrupt

argument: none

return: none

[sensorless control mode]

TAU03 interrupt

・set voltage pattern

mtr_draw_in_pattern_set [inline function]

argument: none

return: none

[sensorless control mode]

Set voltage pattern in draw-in state

mtr_detect_zerocross [inline function]

argument: (st_mtr_sensorless_control_t) *st_less

/ structure for control variables

return: (uint16_t) u2_temp_signal / voltage pattern

[sensorless control mode]

Estimate position of rotor from zero-crossing

of induced voltage

mtr_drive_openloop [inline function]

argument: none

return: none

[sensorless control mode]

Open-loop drive process

mtr_set_angle_shift [inline function]

argument: none

return: none

[sensorless control mode]

Calculation of delay count after zero-crossing

Page 25

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 25 of 48

2020.08.01

Table 3-18 – List of Functions “r_mtr_interrupt.c” [3/3]

file

function

process

r_mtr_interrupt.c

mtr_openloop_pattern_set [inline function]

argument: none

return: (uint8_t) u1_pattern / voltage pattern

[sensorless control mode]

Set voltage pattern at open-loop drive

mtr_start_delay_timer [inline function]

argument: none

return: none

[sensorless control mode]

Start delay timer

mtr_stop_delay_timer [inline function]

argument: none

return: none

[sensorless control mode]

Stop delay timer

Page 26

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 26 of 48

2020.08.01

3.3 Lists of variables of sensorless 120-degree conducting control software

Lists of variables used in this control program are shown below. However, note that the local variables are

not mentioned.

In the sample programs, fixed-point number is used for calculation. Therefore, in advance, some control

variables are set in fixed-point number. Bits number in fractional part of fixed-point number is expressed in

the Q format. “Qn” means n bits left shift.

Table 3-19 – List of variables “main.c”

variable

type

Qn

content

Remarks

g_u1_system_mode

static uint8_t

Q0

Mode system management

g_u1_motor_status

static uint8_t

Q0

Motor status management

g_u1_reset_req

static uint8_t

Q0

Reset command flag for SW2

g_u1_stop_req

static uint8_t

Q0

Stop command flag for VR1

g_u2_error_status

static uint16_t

Q0

Error status management

g_u1_flag_ui_change

static uint8_t

Q0

UI changing flag

g_u2_conf_hw

uint16_t

Q0

RMW configuration variables

g_u2_conf_sw

uint16_t

Q0

g_u2_conf_tool

uint16_t

Q0

gui_u1_active_gui

uint8_t

Q0

g_u2_conf_sw_ver

uint16_t

Q0

com_s2_sw_userif

int16_t

Q0

Management variable for UI

0:ICS_UI

1:BOARD_UI

g_s2_sw_userif

int16_t

Q0

com_u1_run_event

uint8_t

Q0

Input event and change run mode

0 : MTR_EVENT_STOP

1 : MTR_EVENT_DRIVE

2 : MTR_EVENT_ERROR

3 : MTR_EVENT_RESET

g_u1_run_event

uint8_t

Q0

g_u2_init_error

uint16_t

Q0

Initialization error management

Table 3-20 – List of variables “r_mtr_board.c”

variable

type

Qn

content

Remarks

u1_sw_cnt

static uint8_t

Q0

Counter for judgement of chattering

Page 27

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 27 of 48

2020.08.01

Table 3-21 – List of variables “r_mtr_ics.c”

variable

type

Qn

content

Remarks

com_u1_direction

uint8_t

Q0

Direction of rotation

0:CW 1:CCW

com_s2_ref_speed_rpm

int16_t

Q0

Command rotational speed [rpm]

Mechanical angle

com_s2_ramp_limit_v

int16_t

Q9

Limit of variation of voltage [V/ms]

com_s2_kp_speed

int16_t

Q18

Proportional gain for speed PI control [V s/rad]

com_s2_kidt_speed

int16_t

Q22

Integral gain for speed PI control

[V s/rad]

com_s2_ramp_speed_rpm

int16_t

Q0

Acceleration [rpm/ms]

Hall effect sensor

control model

com_s2_start_ref_v

int16_t

Q9

Reference voltage at starting [V]

com_s2_ol_ramp_speed_rpm

int16_t

Q0

Acceleration at open-loop drive [rpm/ms]

sensorless control

mode

com_s2_less_ramp_speed_r

pm

int16_t

Q0

Acceleration at sensorless control [rpm/ms]

com_s2_draw_in_ref_v

int16_t

Q9

Reference voltage at draw-in [V]

com_s2_ol_ref_v

int16_t

Q9

Reference voltage at open-loop drive [V]

com_s2_ol2less_speed_rpm

int16_t

Q0

Speed to transition to PI control[rpm]

com_s2_angle_shift_adjust

int16_t

Q0

adjust delay counts

com_s2_enable_write

int16_t

Q0

Variable to allow to input ICS structure

g_s2_enable_write

int16_t

Q0

st_ics_input

mtr_ctrl_input_t

Q0

Variable to allow to input ICS structure

com_u1_direction

uint8_t

Q0

Structure for ICS input

structure

Table 3-22 – List of variables “r_mtr_parameter.h / Structure : st_mtr_ctrl_gain_t”

variable

type

Qn

content

Remarks

s2_speed_pi_kp

int16_t

Q18

Proportional gain for speed PI control

s2_speed_pi_kidt

int16_t

Q22

Integral gain for speed PI control

Page 28

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 28 of 48

2020.08.01

Table 3-23 – List of variables “r_mtr_driver_access.h / Structure : mtr_ctrl_input_t”

variable

type

Qn

content

Remarks

u1_dir

uint8_t

Q0

Direction of rotation

s2_ref_speed_rad

int16_t

Q4

Command rotational speed [rad/s]

electric angle

s2_ramp_limit_v

int16_t

Q9

Limit of variation of voltage [V/ms]

s2_ramp_ speed_rad

int16_t

Q4

Acceleration [krad/s2]

s2_start_ref_v

int16_t

Q9

Reference voltage at starting [V]

Hall effect sensor

control mode

s2_ol_ramp_speed_rad

int16_t

Q4

Acceleration at open-loop drive [krad/s2]

sensorless

control mode

s2_less_ramp_speed_rad

int16_t

Q4

Acceleration at sensorless control [krad/s2]

s2_draw_in_ref_v

int16_t

Q9

Reference voltage at draw-in [V]

s2_ol_ref_v

int16_t

Q9

Reference voltage at open-loop drive [V]

s2_ol2less_speed_rad

int16_t

Q4

Speed to transition to PI control[rad/s]

s2_angle_shift_adjust

int16_t

Q0

adjust delay counts

st_gain

st_mtr_ctrl_gain_t

-

structure for PI control

structure

Table 3-24 – List of variable “r_mtr_driver_access.c”

variable

type

Qn

content

Remarks

g_u1_trig_enable_write

uint8_t

Q0

Flag to allow to input ICS values

st_ics_input_buff

mtr_ctrl_input_t

-

Buffer for ICS input

structure

Table 3-25 – List of variables “r_mtr_statemachine.h / Structure : st_mtr_statemachine_t”

variable

type

Qn

content

Remarks

u1_status

uint8_t

Q0

Motor status

u1_status_next

uint8_t

Q0

Next motor status

u1_current_event

uint8_t

Q0

execution event

Table 3-26 – List of variables “r_mtr_statemachine.c”

variable

type

Qn

content

Remarks

state_transition_table

[MTR_SIZE_EVENT]

[MTR_SIZE_STATE]

static uint8_t

Q0

Macro array for state transition

Array

mtr_action_table

[MTR_SIZE_EVENT]

[MTR_SIZE_STATE]

static mtr_action_t

Q0

Function array for state transition

Array

Page 29

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 29 of 48

2020.08.01

Table 3-27 – List of variables in “r_mtr_120.h / structure: st_mtr_pi_control_t”

variable

type

Qn

content

Remarks

s2_kp

int16_t

Q18

Proportional gain for speed PI control [(V s)/rad]

s2_kidt

int16_t

Q22

Integral gain for speed PI control [(V s)/rad]

s4_pre_refp

int32_t

Q22

Previous proportional term [V]

Table 3-28 – List of variables in “r_mtr_120.h / structure : st_mtr_hall_control_t”

variable

type

Qn

content

Remarks

u1_hall_signal

uint8_t

Q0

Signal from Hall effect sensor

Hall effect sensor

control model

u1_pre_hall_signal

uint8_t

Q0

Previous signal from Hall effect sensor

u1_first_rotation_cnt

uint8_t

Q0

Pattern counter for first rotation

s2_start_ref_v

int16_t

Q9

Reference voltage at open-loop drive [V]

Page 30

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 30 of 48

2020.08.01

Table 3-29 – List of variables in “r_mtr_120.h / structure: st_mtr_sensorless_control_t”

variable

type

Qn

content

Remarks

u1_state_draw_in

uint8_t

Q0

Draw-in state management

sensorless control mode

u1_flag_pattern_change

uint8_t

Q0

Flag for detection of voltage pattern change

u1_flag_set_v_pattern

uint8_t

Q0

Flag for setting voltage pattern

u1_flag_ol2less

uint8_t

Q0

Flag to transition to PI control

u1_flag_zc

uint8_t

Q0

Flag for zero-crossing detection avoiding commutation

u1_flag_vdc_adc

uint8_t

Q0

Flag for measurement bus voltage

u1_bemf_signal

uint8_t

Q0

Estimated Hall pattern

u1_pre_bemf_signal

uint8_t

Q0

Previous estimated Hall pattern

u1_set_v_pattern

uint8_t

Q0

Voltage pattern

u1_ol_v_pattern_num

uint8_t

Q0

Ring buffer for voltage pattern at open-loop drive

u2_cnt_carrier

uint16_t

Q0

Counter every carrier interruption

u2_cnt_delay

uint16_t

Q0

Delay counts

u2_ol_pattern_period

uint16_t

Q0

Period for pattern change at open-loop drive

u2_cnt_draw_in

uint16_t

Q0

Counter for pattern change at draw-in

u2_v_const_period

uint16_t

Q0

Period for pattern change at draw-in

s2_vu_ad

int16_t

Q0

Voltage of U phase

s2_vv_ad

int16_t

Q0

Voltage of V phase

s2_vw_ad

int16_t

Q0

Voltage of W phase

s2_vn_ad

int16_t

Q0

Estimated neutral voltage

s2_ol2less_speed_rad

int16_t

Q4

Speed to transition to PI control [rad/s]

s2_ol_ramp_speed_rad

int16_t

Q4

Acceleration at open-loop drive [krad/s2]

s2_less_ramp_speed_rad

int16_t

Q4

Acceleration at PI control[krad/s2]

s2_draw_in_ref_v

int16_t

Q9

Reference voltage at draw-in [V]

s2_ol_ref_v

int16_t

Q9

Reference voltage at open-loop drive [V]

s2_angle_shift_adjust

int16_t

Q0

Adjust delay counts

Table 3-30 – List of variable “r_mtr_interrupt.c”

variable

type

Qn

content

Remarks

g_st_120

st_mtr_120_control_t

-

Structure for 120 conducting control

structure

g_u1_ol_v_pattern_table[2][7]

Uint8_t

Q0

Array for voltage pattern

Array

Page 31

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 31 of 48

2020.08.01

3.4 Macro definitions of sensorless 120-degree conducting control software

Lists of macro definitions used in this control program are shown below.

Table 3-31 – List of Macro definitions “r_mtr_config.h”

Macro

Definition value

Qn

content

Remarks

RL78_G1M_MRSSK

- - Select CPU board

IP_MRSSK

- - Select inverter board

MP_TG55L

- - Select motor parameters

CP_TG55L

- - Select control parameters

ICS_UI

0 - RMW UI

Default

BOARD_UI

1 - RSSK board UI

MTRCONF_DEFAULT_UI

0/1 - Select UI

BOARD_UI / ICS_UI

HALL

0 - Hall effect sensor

LESS

1 - Sensorless

Default

MTRCONF_SENSOR_MODE

0/1 - Select sensor to detect position of rotor

HALL / LESS

Table 3-32 – List of Macro definitions “r_mtr_motor_parameter.h”

Macro

Definition value

Qn

content

Remarks

MP_POLE_PAIRS

2 - Number of pole pairs

MP_RESISTANCE

9.125f

-

Resistance [Ω]

MP_D_INDUCTANCE

0.003844f

-

D-axis inductance[H]

MP_Q_INDUCTANCE

0.004315f

-

Q-axis inductance[H]

MP_MAGNETIC_FLUX

0.02144f

-

Induced voltage constant [V s/rad]

MP_ROTOR_INERTIA

0.000002050f

-

Rotor inertia [kgm^2]

MP_NOMINAL_CURRENT_RMS

0.42f

-

Nominal current [A]

Page 32

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 32 of 48

2020.08.01

Table 3-33 – List of Macro definitions “r_mtr_control_parameter.h”

Macro

Definition value

Qn

content

Remarks

CP_MAX_SPEED_RPM

3200

-

Maximum limit of command rotational

speed [rpm]

Mechanical

angle

CP_LIMIT_SPEED_RPM

3900

-

Maximum limit of estimated rotational

speed [rpm]

Mechanical

angle

CP_RAMP_LIMIT_V

0.25

-

Limit for variation of voltage [V]

CP_MIN_SPEED_RPM

530 [Hall effect sensor

control mode]/

265 [sensorless

control mode]

-

Minimum limit of command rotational

speed [rpm]

Mechanical

angle

CP_SPEED_PI_KP

0.03015119f [Hall

effect sensor control

mode]/ 0.001041950f

[sensorless control

mode]

-

Proportional gain for speed PI control [V

s/rad]

CP_SPEED_PI_KIDT

0.02192814f [Hall

effect sensor control

mode]/ 0.000551114f

[sensorless control

mode]

-

Integral gain for speed PI control [V s/rad]

CP_HALL2OL_REV_SPEED_RPM

530

-

Speed to transition to open-loop drive

[rpm]

Hall effect

sensor

control mode

CP_RAMP_SPEED_RPM

30

-

Acceleration [rpm/ms]

CP_START_REF_V

3.5f - Initial voltage [V]

CP_OL2LESS_SPEED_RPM

530

-

Speed to transition to open-loop drive

[rpm]

sensorless

control mode

CP_OL_RAMP_SPEED_RPM

2

-

Acceleration at open-loop drive [rpm/ms]

CP_LESS_RAMP_SPEED_RPM

10

-

Acceleration at sensorless control [rpm/ms]

CP_OL_REF_V

4.3f

-

Reference voltage at open loop [V]

CP_DRAW_IN_REF_V

20.0f

-

Reference voltage at draw-in[V]

Table 3-34 – List of Macro definitions “r_mtr_inverter_parameter.h”

Macro

Definition value

Qn

content

Remarks

IP_VDC_RANGE

111.0f

-

Range of bus voltage [V]

IP_INPUT_V

24.0f

-

Input voltage [V]

IP_OVERVOLTAGE_LIMIT

28.0f

-

Upper limit of voltage [V]

IP_UNDERVOLTAGE_LIMIT

15.0f

-

Lower limit of voltage [V]

Page 33

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 33 of 48

2020.08.01

Table 3-35 – List of Macro definitions “main.h”

Macro

Definition value

Qn

content

Remarks

MODE_INACTIVE

0x00

-

Inactive mode

MODE_ACTIVE

0x01

-

Active mode

MODE_ERROR

0x02

-

Error mode

SIZE_STATE

3

-

Number of states

Table 3-36 – List of Macro definitions “ICS_define.h”

Macro

Definition value

Qn

content

Remarks

RL78

-

-

CPU definition

Table 3-37 – List of Macro definitions “r_mtr_ics.h”

Macro

Definition value

Qn

content

Remarks

ICS_ADDR

0xFE00

-

Address of ICS

ICS_INT_LEVEL

2

-

ICS interrupt level setting

ICS_NUM

0x40

-

Data size of ICS communication

ICS_BRR

9

-

ICS bit rate register selection

ICS_MODE

0

-

ICS interrupt mode setting

ADJUST_ICS_PERIOD

150 - Adjust period of ICS communication process

Table 3-38 – List of Macro definitions “r_mtr_board.h”

Macro

Definition value

Qn

content

Remarks

SW_CHATTERING_CNT

10

-

Counts for judgement to remove chattering

VR1_MARGIN

400

-

Margin value for VR1

VR1_SCALING

mtr_conv_rpm2rad(CP_MAX_

SPEED_RPM+VR1_MARGIN)

/0x0200

Q4

Scaling factor for speed calculation

VR1_OFFSET

0x1FF

-

Offset for VR1

Page 34

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 34 of 48

2020.08.01

Table 3-39 – List of Macro definitions in “r_mtr_ctrl_rl78g1m.h” [1/2]

Macro

Definition value

Qn

content

Remarks

MTR_CARRIER_FREQ

20.0f

-

Frequency of carrier interrupt [kHz]

MTR_TAU0_FREQ

20.0f

-

Frequency of TAU0 [MHz]

MTR_1MS_FREQ

1.0f - Frequency of 1ms interrupt [kHz]

MTR_IT_FREQ

15.0f

-

Frequency of 12-bit interval timer [kHz]

MTR_TAU_PWM_CNT

(uint16_t)(MTR_TAU0_FREQ

/ MTR_CARRIER_FREQ *

1000 - 1)

-

Resister counts of carrier interrupt

MTR_IT_1MS_CNT

(uint16_t)(MTR_IT_FREQ /

MTR_1MS_FREQ - 1)

-

Resister counts of 1ms interrupt

MTR_VDC_SCALING

(int16_t)(IP_VDC_RANGE /

1023.0f * (1 <<

MTR_Q_VOLTAGE))

Q9

Scaling factor to convert to voltage

MTR_DUTY_BIT_SHIFT

5 - Bits shift for duty calculation

MTR_DUTY_SCALING

MTR_TAU_PWM_CNT >>

(MTR_Q_VOLTAGE –

MTR_DUTY_BIT_SHIFT)

-

Scaling factor for duty calculation

MTR_TIME_WAIT_CHARGE_CAP

4300

-

Waiting time for capacitor charge

MTR_CNT_WAIT_CHARGE_CAP

20 - Number of loop times for capacitor charge

MTR_PORT_HALL_U

P1_bit.no2

-

U phase Hall effect sensor input port

MTR_PORT_HALL_V

P1_bit.no3

-

V phase Hall effect sensor input port

MTR_PORT_HALL_W

P1_bit.no4

-

W phase Hall effect sensor input port

MTR_PORT_UP

P0_bit.no0

-

U phase (positive phase) output port

MTR_PORT_UN

P0_bit.no1

-

U phase (negative phase) output port

MTR_PORT_VP

P0_bit.no2

-

V phase (positive phase) output port

MTR_PORT_VN

P0_bit.no3

-

V phase (negative phase) output port

MTR_PORT_WP

P0_bit.no4

-

W phase (positive phase) output port

MTR_PORT_WN

P0_bit.no5

-

W phase (negative phase) output port

MTR_PORT_SW1

P12_bit.no5

-

SW1 input port

MTR_PORT_SW2

P13_bit.no7

-

SW2 input port

MTR_PORT_LED1

P4_bit.no0

-

LED1 output port

MTR_TAU1_CNT

TCR01

-

TAU1 count resister

MTR_ADCCH_VR1

7 - A/D converter channel of VR1

MTR_ADCCH_VDC

6 - A/D converter channel of bus voltage

MTR_ADCCH_VU

3 - A/D converter channel of U phase voltage

MTR_ADCCH_VV

4 - A/D converter channel of V phase voltage

MTR_ADCCH_VW

5 - A/D converter channel of W phase voltage

MTR_ADCCH_IU

1 - A/D converter channel of U phase current

MTR_ADCCH_IV

2 - A/D converter channel of V phase current

Page 35

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 35 of 48

2020.08.01

Table 3-40 – List of Macro definitions in “r_mtr_rl78g1m.h” [2/2]

Macro

Definition value

Qn

content

Remarks

MTR_UP_H

0x0010

-

Voltage pattern

MTR_UP_L

0x0000

-

MTR_UP_PWM

0x0001

-

MTR_VP_H

0x0020

-

MTR_VP_L

0x0000

-

MTR_VP_PWM

0x0002

-

MTR_WP_H

0x0040

-

MTR_WP_L

0x0000

-

MTR_WP_PWM

0x0004

- MTR_UN_H

0x0080

- MTR_UN_L

0x0000

-

MTR_UN_PWM

0x0008

-

MTR_VN_H

0x1000

- MTR_VN_L

0x0000

- MTR_VN_PWM

0x0100

-

MTR_WN_H

0x2000

-

MTR_WN_L

0x0000

-

MTR_WN_PWM

0x0200

-

MTR_ALL_OFF

0x0000

-

ERROR_NONE

0x00 - No error

ERROR_CHARGE_CAP_TIMEOUT

0x01 - Timeout error of capacitor charge

Table 3-41 – List of Macro definitions “r_mtr_common.h”

Macro

Definition value

Qn

content

Remarks

MTR_TWOPI

2*3.14159265359f

-

2π

MTR_TWOPI_60

MTR_TWOPI/60

-

2π/60

MTR_CW

0 - CW

MTR_CCW

1 - CCW

MTR_ON

0 - ON

MTR_OFF

1 - OFF

MTR_CLR

0 - Flag clear

MTR_SET

1 - Flag set

Page 36

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 36 of 48

2020.08.01

Table 3-42 – List of Macro definitions “r_mtr_fixed.h”

Macro

Definition value

Qn

content

Remarks

MTR_Q_VOLTAGE

9 - Q-format of voltage

MTR_Q_AFREQ

4 - Q-format of angular frequency

MTR_Q_SPEED_KP

18 - Q-format of proportional gain

MTR_Q_SPEED_KIDT

22 - Q-format of integral gain

RSFT_AFREQ_KP_2VOLTAGE

MTR_Q_SPEED_KP +

MTR_Q_AFREQ –

MTR_Q_VOLTAGE

-

Right shift, (KP * speed) to voltage

RSFT_AFREQ_KIDT_2VOLTAGE

MTR_Q_SPEED_KIDT +

MTR_Q_AFREQ –

MTR_Q_VOLTAGE

-

Right shift, (KIDT * speed) to voltage

Table 3-43 – List of Macro definitions “r_mtr_parameter.h”

Macro

Definition value

Qn

content

Remarks

MTR_SPEED_CALC_BAS

E

(int32_t)(156000 * MTR_TWOPI

* (1 << MTR_Q_AFREQ))

Q9

Calculation parameter to convert the timer

counter to rotational speed

MTR_SPEED_CALC_BAS

E_1ST

MTR_SPEED_CALC_BASE/6

Q9

Calculation parameter to convert the timer

counter to rotational speed at first speed

calculation

MTR_SPEED_CALC_BAS

E_2ND

MTR_PEED_CALC_BASE/3

Q9

Calculation parameter to convert the timer

counter to rotational speed at second speed

calculation

MTR_SPEED_CALC_BAS

E_3RD

MTR_SPEED_CALC_BASE/2

Q9

Calculation parameter to convert the timer

counter to rotational speed at third speed

calculation

MTR_SPEED_CALC_BAS

E_4TH

MTR_SPEED_CALC_BASE*2/3

Q9

Calculation parameter to convert the timer

counter to rotational speed at fourth speed

calculation

MTR_SPEED_CALC_BAS

E_5TH

MTR_SPEED_CALC_BASE*5/6

Q9

Calculation parameter to convert the timer

counter to rotational speed at fifth speed

calculation

MTR_OL_CNT_CALC_BA

SE

MTR_CARRIER_FREQ * 1000

* MTR_TWOPI /

MTR_PATTERN_NUM

-

Calculation parameter to convert rotational

speed to timer counter at open-loop drive

MTR_MAX_SPEED_RAD

mtr_conv_rpm2rad(CP_MAX_S

PEED_RPM)

Q4

Maximum reference rotational speed [rad/s]

MTR_MIN_SPEED_RAD

mtr_conv_rpm2rad(CP_MIN_S

PEED_RPM)

Q4

Minimum reference rotational speed [rad/s]

MTR_MAX_DRIVE_V

mtr_conv_q_voltage(IP_INPUT

_V * 0.90f)

Q9

Maximum output voltage [V]

MTR_MIN_DRIVE_V

mtr_conv_q_voltage(IP_INPUT

_V * 0.0f)

Q9

Minimum output voltage [V]

MTR_MCU_ON_V

mtr_conv_q_voltage(IP_INPUT

_V * 0.8)

Q9

MCU stable supply voltage [V]

Page 37

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 37 of 48

2020.08.01

Table 3-44 – List of Macro definitions “r_mtr_statemachine.h”

Macro

Definition value

Qn

content

Remarks

MTR_MODE_INIT

0x00

Q0

Initialization mode

MTR_MODE_DRIVE

0x01

Q0

Drive mode

MTR_MODE_STOP

0x02

Q0

Stop mode

MTR_SIZE_STATE

3

Q0

Number of states

MTR_EVENT_STOP

0x00

Q0

Stop event

MTR_EVENT_DRIVE

0x01

Q0

Run event

MTR_EVENT_ERROR

0x02

Q0

Error event

MTR_EVENT_RESET

0x03

Q0

Reset event

MTR_SIZE_EVENT

4

Q0

Number of events

Table 3-45 – List of Macro definitions in “r_mtr_120.h” [1/2]

Macro

Definition value

Qn

content

Remarks

MTR_TIMEOUT_CNT

200 - Counts for timeout

MTR_HALL2OL_REV_SPE

ED_RAD

FIX_fromfloat(CP_HALL2OL_REV_

SPEED_RPM *

PU_SF_AFREQ, MTR_Q_AFREQ)

Q4

Speed to transition to PI control

at reverse of direction

Hall effect sensor

control mode

MTR_AVOID_COMMUTAT

ION

4 - Counts for avoiding to detect

zero-crossing after

commutation

Sensorless control

mode

MTR_DRAW_IN_1ST_PAT

TERN

1 - Voltage pattern at first draw-in

MTR_DRAW_IN_2ND_PA

TTERN

2 - Voltage pattern at second drawin

MTR_PATTERN_CW_V_U

2

-

Voltage pattern at CW rotation

MTR_PATTERN_CW_W_

U

3

-

MTR_PATTERN_CW_W_V

1

-

MTR_PATTERN_CW_U_V

5

-

MTR_PATTERN_CW_U_

W

4

-

MTR_PATTERN_CW_V_W

6

-

MTR_PATTERN_CCW_V_

U

5 [Hall effect sensor control mode]/

3 [sensorless control mode]

-

Voltage patten at CCW rotation

MTR_PATTERN_CCW_V_

W

1 [Hall effect sensor control mode]/

2 [sensorless control mode]

-

MTR_PATTERN_CCW_U_

W

3 [Hall effect sensor control mode]/

6 [sensorless control mode]

-

MTR_PATTERN_CCW_U_

V

2 [Hall effect sensor control mode]/

4 [sensorless control mode]

-

MTR_PATTERN_CCW_W

_V

6 [Hall effect sensor control mode]/

5 [sensorless control mode]

-

MTR_PATTERN_CCW_W

_U

4 [Hall effect sensor control mode]/

1 [sensorless control mode]

-

MTR_PATTERN_NUM

6 - Number of voltage patterns

Page 38

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 38 of 48

2020.08.01

Table 3-46 – List of Macro definitions in “r_mtr_120.h” [2/2]

Macro

Definition value

Qn

content

Remarks

MTR_ERROR_NONE

0x00 - No error

MTR_ERROR_OVER_CURRENT

0x01 - Over current error

MTR_ERROR_OVER_VOLTAGE

0x02 - Over voltage error

MTR_ERROR_OVER_SPEED

0x04 - Over speed error

MTR_ERROR_HALL_TIMEOUT

0x08 - Timeout error for Hall effect

sensor control mode

MTR_ERROR_BEMF_TIMEOUT

0x10 - Timeout error for sensorless

control mode

MTR_ERROR_HALL_PATTERN

0x20 - Hall pattern error

MTR_ERROR_BEMF_PATTERN

0x40 - BEMF pattern error

MTR_ERROR_UNDER_VOLTAGE

0x80 - Under voltage error

MTR_ERROR_UNKNOWN

0xff - Undefined error

MTR_DRAW_IN_NONE

0 - No operation

MTR_DRAW_IN_1ST

1 - First draw-in

MTR_DRAW_IN_2ND

2 - Second draw-in

MTR_DRAW_IN_FINISH

3 - Draw-in finished

MTR_SPEED_ZERO_CONST

0 - Reference speed 0 const mode

MTR_SPEED_MANUAL

1 - Reference speed manual input mode

MTR_V_ZERO_CONST

0 - Reference voltage zero const mode

MTR_V_MANUAL

1 - Reference voltage manual input mode

MTR_V_PI_OUTPUT

2 - Reference voltage PI output mode

Page 39

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 39 of 48

2020.08.01

3.5 Control flows (flow charts)

3.5.1 Main process

Main proces s

Initialization of hardware

Initialization of system variable s

Initialization of ICS commu nicat ion

Initialization of con trol system

Reset process

Waiting for stability of bus bo ltage

ICS

Set g_u1_flag_ui_change

UI

Input command varia bles to ICS

structure

Change run mode by input of

u1_run_even t

Initialization for reset event

Clear WDT

ICS communi cation

YES

NO

ICS

BOARD ELSE

Get status

Get status

Set g_u1_syst em_ mode to ACTIVE

Set command speed by VR1

Change run mode by state of switches

com_u1_run_ event changes or

g_u1_flag_ui_change is set

Change UI

Set com_s2_sw_userif to g_s2_sw_userif

NO

YES

YES

NO

g_u2_system_error

Set g_u1_syst em_ mode to ERROR

ERROR_NONE

ELSE

Error process

Figure 3-7 – Main Process Flowchart

Page 40

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 40 of 48

2020.08.01

3.5.2 Carrier cycle interrupt handling

Carrier interruption

Get bus voltage

Prepare speed calculation

End

Set voltage pattern

Hall pattern change ?

YES

NO

Get TAU2 count

u2_run_mode

Motor stop

ELSE

DRIVE

Figure 3-8 – Carrier Cycle Interrupt Handling Flowchart (Hall Effect Sensor Control Mode)

Page 41

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 41 of 48

2020.08.01

Carrier int erruption

Measure bu s voltage

u2_run_mode

u1_state_d raw_in

Zero cross detec tionDraw-in pr ocess

u1_flag_p at te rn_change

Prepare spe ed c alculation

Open-lo op drive process

End

DRIVE

ELSE

NOT FI NISH

FINISH

MANUAL

PI_OUT PUT

SET

SET

CLEAR

CLEAR

u1_state_voltage_ re f

u1_flag_p at te rn_change

Delay counts calc ulation

Set choppi ng pattern

ELSE

u1_flag_s et _v_pattern

SET

CLEAR

Get TAU2 c ount

u1_flag_vdc_adc

Start delay t imer

SET

CLEAR

Measure 3 phase vol tages

Stop mot or

Figure 3-9 – Carrier Cycle Interrupt Handling Flowchart (Sensorless Control Mode)

Page 42

RL78/G1M 120-degree conducting control of permanent magnetic synchronous motor (Implementation)

R01AN5516EJ0100 Rev.1.00 Page 42 of 48

2020.08.01

3.5.3 1 [ms] interrupt handling

1ms interr uption

Get motor status

u2_run_mo de

u1_state_s peed_ref