Page 1

APPLICATION NOTE

R20AN0536EJ0100

RH850 Smart Configu rat or

Rev.1.00

User’s Guide: IAREW, MUL TI

Introduction

This application note describes the basic usage of the RH850 Smart Configurator (hereafter called the Smart

Configurator), and the procedure for importing its output files to IAR Embedded Workbench / GHS MULTI.

References to the Smart Configurator and Integrated Development Environment (IDE) in this application note app ly to

the followi ng versions.

• RH850 Smart Configurator V1.10

• IAR Embedded Workbench for RH850 V2.10

• GHS MULTI V7.16

Target device and support compiler

Refer to the following U RL for the range of supported devices:

https://www.renesas.com/smart-configurator

Jan 25, 2019

Sample project

The sample project for RH850/F1KM is also included in the installation folder of Smart Configurator.

• Sample Project for IAR and IAR ICC

• Sample Project for MULTI and GHS CCRH850

Refer to the following instructions .

Smart Configurator: Guide on Sample Project for RH850/F1KM Device (R01AN4422)

Contents

1. Overview ......................................................................................................................... 4

1.1 Purpose ........................................................................................................................................ 4

1.2 Features ....................................................................................................................................... 4

2. Installation and uninstallation ....................................................................................... 5

2.1 Installing the Smart Configurator .............................................................................................. 5

2.2 Uninstalling the Smart Configurator ......................................................................................... 5

3. Operating the Smart Configurator ................................................................................. 6

R20AN0536EJ0100 Rev.1.00 Page 1 of 43

Jan 25, 2019

3.1 Procedure for Operations ........................................................................................................... 6

3.2 Starting the Smart Configurator ................................................................................................ 7

3.3 Create and loading a configuration file .................................................................................... 8

3.3.1 Creating a New Configuration File ...................................................................................... 8

3.3.2 Opening an Existing Configuration File ............................................................................. 8

Page 2

RH850 Smart Configurator User’s Guide: IAREW, MULTI

3.4 Window ......................................................................................................................................... 9

3.4.1 Main menu ........................................................................................................................... 10

3.4.2 Toolbar ................................................................................................................................. 10

3.4.3 Smart Configurator view .................................................................................................... 11

3.4.4 MCU Package view ............................................................................................................. 11

3.4.5 Console view ....................................................................................................................... 12

3.4.6 Configuration Problems view ............................................................................................ 12

4. Setting of Peripheral Modules ..................................................................................... 13

4.1 Board setting ............................................................................................................................. 13

4.1.1 Selecting the device ........................................................................................................... 13

4.1.2 Selecting the board ............................................................................................................. 14

4.1.3 Import board configuration ................................................................................................ 15

4.1.4 Export board configuration ................................................................................................ 15

4.2 Clock settings ............................................................................................................................ 16

4.3 Software component settings .................................................................................................. 17

4.3.1 Adding component ............................................................................................................. 17

4.3.2 Switching between the component view and hardware view ........................................ 18

4.3.3 Deleting a software component......................................................................................... 19

4.3.4 Component configuration settings ................................................................................... 20

4.3.5 Component resource change ............................................................................................ 21

4.4 Pin settings ................................................................................................................................ 24

4.4.1 Assign pins to resources ................................................................................................... 25

4.4.2 Pin setting using MCU package ........................................................................................ 26

4.4.3 Export pin settings ............................................................................................................. 27

4.4.4 Import pin settings .............................................................................................................. 27

4.5 Interrupt settings ....................................................................................................................... 28

4.5.1 Changing the interrupt priority level and OS management setting ............................... 28

5. Managing Conflicts ...................................................................................................... 29

5.1 Resource conflicts .................................................................................................................... 29

5.2 Resource pin conflicts .............................................................................................................. 30

6. Generating Source Code ............................................................................................. 31

6.1 Generating Source Code File ................................................................................................... 31

6.2 Configuration of Generated Files and File Names................................................................. 31

6.3 Initializing Clocks ...................................................................................................................... 33

6.4 Initializing Pins .......................................................................................................................... 34

6.5 Initializing Interrupts ................................................................................................................. 35

6.6 Backing up Generated Source Code ....................................................................................... 35

7. Loading generated files in Integrated development environment ............................ 36

7.1 Loading in IAR Embedded Workbench ................................................................................... 36

R20AN0536EJ0100 Rev.1.00 Page 2 of 43

Jan 25, 2019

Page 3

RH850 Smart Configurator User’s Guide: IAREW, MULTI

7.2 Loading in GHS MULTI ............................................................................................................. 36

8. Creating User Programs .............................................................................................. 37

8.1 Adding Custom Code in the Case of Code Generator .......................................................... 37

9. Generating Reports ...................................................................................................... 39

9.1 Report on Configuration ........................................................................................................... 39

9.2 Configuration of Pin Function List and Pin Number List (in csv Format) ........................... 40

9.3 Image of MCU Package (in png Format) ................................................................................. 40

10. Help ............................................................................................................................... 41

10.1 Help ............................................................................................................................................. 41

11. Documents for Reference ............................................................................................ 42

R20AN0536EJ0100 Rev.1.00 Page 3 of 43

Jan 25, 2019

Page 4

RH850 Smart Configurator User’s Guide: IAREW, MULTI

1. Overview

1.1 Purpose

This application note describes the basic usage of the RH850 Smart Configurator (hereafter called the Smart

Configurator), and the procedure for importing its output files to IAR Embedded Workbench / GHS MULTI.

Refer to the User’s Manual of IAR Embedded Workbench / GHS MULTI fo r how to use them.

1.2 Features

The Smart Configurator is a utility for combining software to meet your needs. It handles the following tow functions to

support the embedding of drivers from Renesas in your systems: Generating driver code and making pin settings.

R20AN0536EJ0100 Rev.1.00 Page 4 of 43

Jan 25, 2019

Page 5

RH850 Smart Configurator User’s Guide: IAREW, MULTI

2. Installation and uninstallation

This section describes the insta lla tion and uninstallation.

2.1 Installing the Smart Configurator

Download the Smart Configurator from the URL below.

https://www.renesas.com/smart-configurator

After activating the installer, install the Smart Configurator and the plug-in by following the procedure of the installer.

You will require administrator privileges to do this.

2.2 Uninstalling the Smart Configurator

If you wish to uninstall the Smart Configurator, select “Smart Configurator for RH850” from [Programs and Features]

in the control panel.

R20AN0536EJ0100 Rev.1.00 Page 5 of 43

Jan 25, 2019

Page 6

RH850 Smart Configurator User’s Guide: IAREW, MULTI

Operations in the Smart Configuration

Operations in

Starting the Smart Configurator

Create and loading a configuration file

Setting of peripheral modules

Generating source code

Setting of interr upts

Refer to ‘3.2 Starting the Smart

Configurator’

Refer to ‘4 Setting of Peripheral Modules’

Refer to ‘4.5 Interrupt settings’

Refer to ‘6 Generating Source Code’

Creating the user program

Refer to ‘8 Creating User Programs’

Building

Execution and debugging

Generating reports

Refer to ‘9 Generating Reports’

Setting pins

Refer to ‘4.4 Pin settings’

Refer to ‘3.3 Create and loading a

Loading generated files in IDE

Refer to ‘7 Loading generated files in

3. Operating the Smart Configurator

3.1 Procedure for Operations

Figure 3-1 Operating procedure, shows the procedure for generating a source file using Smart Configurator and loading

it into IAR Embedded Workbench. To use the sample project, refer to " Smart Configurator: Guide on Sample Project

for RH850/F1KM Device (R01AN 4422)". For the operation of IAR Embedded Workbench and GHS MULTI, refer to

relevant document of IAR or GHS.

IAR Embedded Workbench,

GHS MULTI

configuration file’

Integrated developme nt environ ment’

R20AN0536EJ0100 Rev.1.00 Page 6 of 43

Jan 25, 2019

Figure 3-1 Operating Procedure

Page 7

RH850 Smart Configurator User’s Guide: IAREW, MULTI

3.2 Starting the Smart Configurator

Select [Smart Configurator for RH850 Vx.x.x] of [Renesas Electronics Smart Configura tor] from the Windows start

menu. The main window of the Smart Configurator will be starting.

Note: Please replace Vx.x.x with your versio n.

Figure 3-2 Starting of Smart Configurator

R20AN0536EJ0100 Rev.1.00 Page 7 of 43

Jan 25, 2019

Page 8

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(2)

(3)

(4)

(5)

(6)

(6)

3.3 Create and loading a configuration file

Smart Configurator saves and refers to the configuration file (*. scfg) the configuration information of the

microcontroller, build tool, peripheral function, pin function etc. used in the project.

3.3.1 Creating a New Configuration File

On the main windo w, click the [New Configuration File] b utto n to display the [New Smart Configuration File]

dialog box.

(1) In [Platform:], select the device.

(2) In [Toolchain:], select the toolchain.

To use the IAR compiler, select "IAR RH850 Toolchain".

To use the GHS compiler, select "GHS RH850 Toolchain".

(3) In [File name:], enter the file name.

(4) Confirm [Location:]. If you want to change it, click [Bro wse] and sele c t the save destination.

(5) To set the RTOS, click [Next]. When “IAR RH850 Toolchain" is selected, RTOS can’t be set.

(6) Click [Finish] to create the configuration file.

Figure 3-3 Create a Configuration File

If you select [RIV] in the RTOS setting, you can select non-OS management inte rrupts / OS ma na ge me nt int er r upt s fo r

component interrupts. For details, refer to "4.5.1, Interrupt prio rity level and OS management s ettings".

3.3.2 Opening an Existing Configuration File

On the main windo w, click the [Opening an Existing Configuration File] button to display the [Open] dialog box.

Figure 3-4 Opening an Existing Configuration File

R20AN0536EJ0100 Rev.1.00 Page 8 of 43

Jan 25, 2019

Page 9

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(2)

(3)

(4)

(5)

(6)

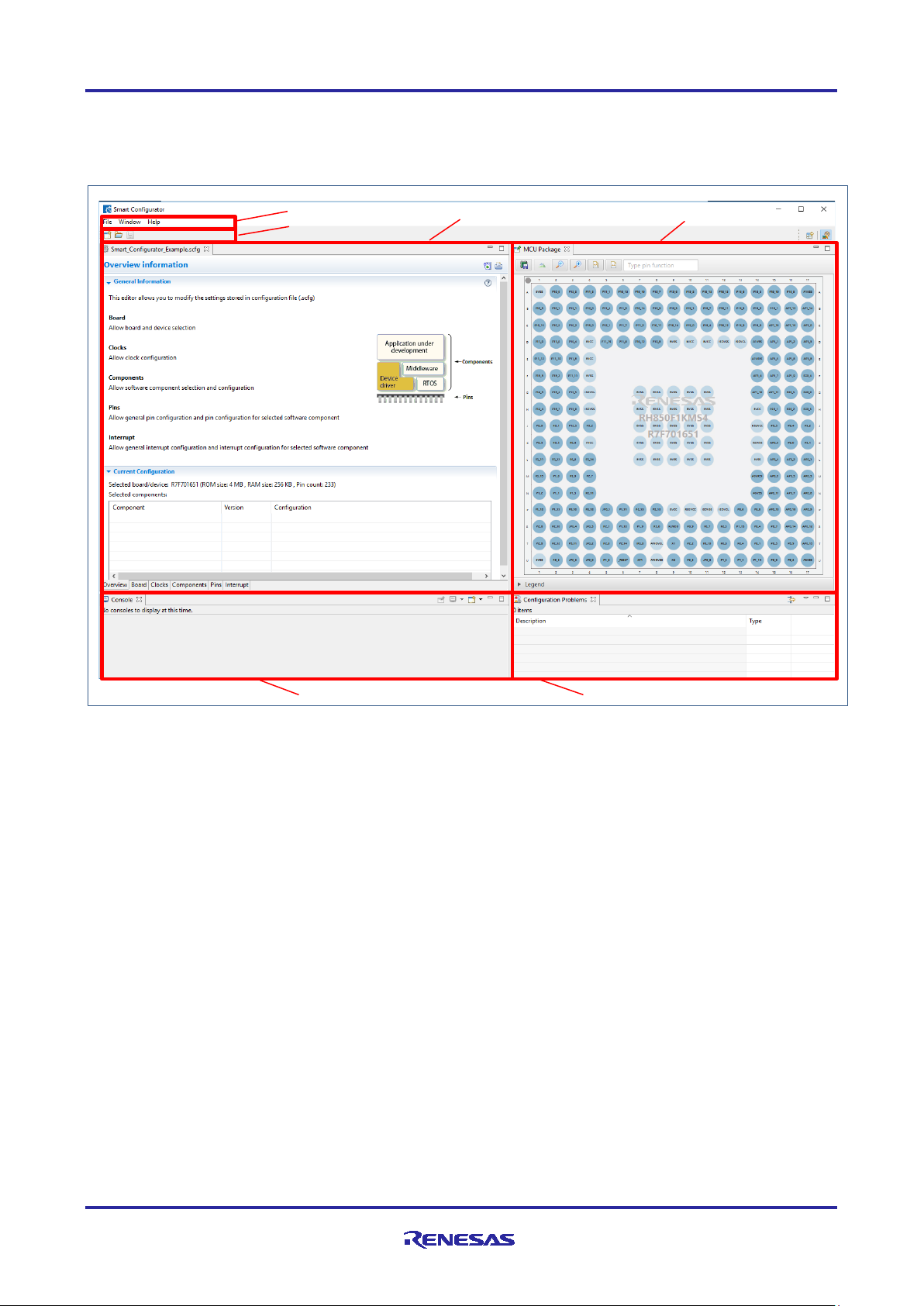

3.4 Window

The main window is displ ayed when the Smart Configurator is started . The configur ation of the window is shown in

Figure 3-5, Ma in Window.

(1) Menu bar

(2) Main tool bar

(3) Smart Configurator view

(4) MCU Package view

(5) Console view

(6) Configuration Problems view

Figure 3-5 Main Window

R20AN0536EJ0100 Rev.1.00 Page 9 of 43

Jan 25, 2019

Page 10

RH850 Smart Configurator User’s Guide: IAREW, MULTI

Menu

Details

File

New

The dialog box [New Smart Configuration File], whic h is used to create a

new configuration file, is displayed.

Open

The dialog box [Open], which opens an existin g configuration file, is

displayed.

Save

Saves a configuration file with the same name.

Restart

Smart Configurator is re-started.

Exit

Execution of the Smart Configurator is terminated.

Window

Preference

The dialog box [Preference], which is used to specify the properties of the

configuration file, is displayed.

Show view

The dialog box [Show view], which is used to set the view of the window,

is displayed.

Help

Help Contents

The help menu is displayed.

About

The version information is displayed.

Toolbar button

Related menu item

[File] → [New Smart Configuration File]

[File] → [Open]

[File] → [Save]

3.4.1 Main menu

Table 3-1, Main Menu Items, lists the items of the mai n me nu.

Table 3-1 Main Menu Items

3.4.2 Toolbar

Some functions of the main menu are allocated to the buttons on the toolbar. Table 3-2, Toolbar Buttons and Related

Menu Items, shows the description of those tool buttons.

Table 3-2 Toolbar Buttons and Related Menu Items

R20AN0536EJ0100 Rev.1.00 Page 10 of 43

Jan 25, 2019

Page 11

RH850 Smart Configurator User’s Guide: IAREW, MULTI

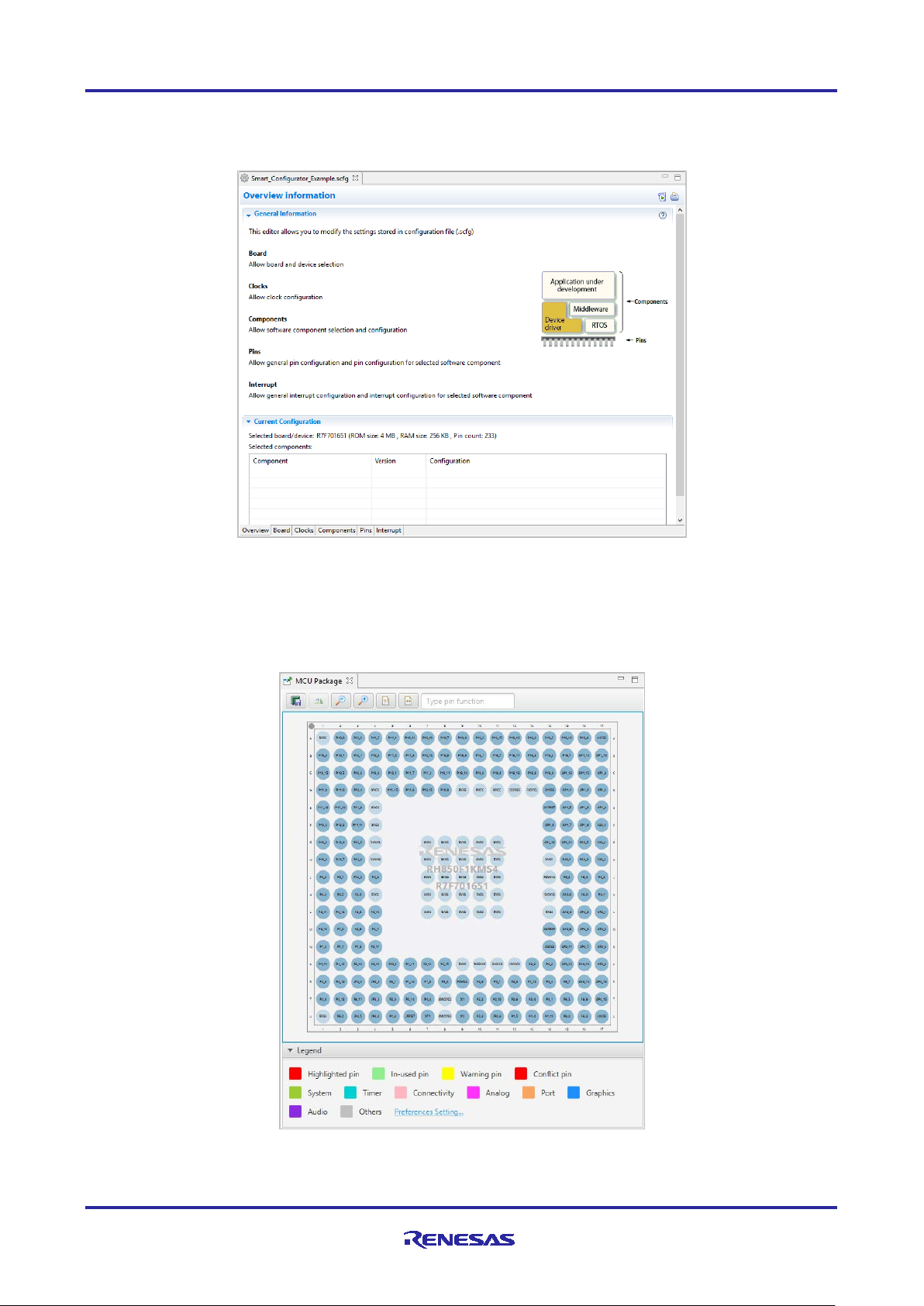

3.4.3 Smart Configurator view

The Smart Configurator view consists of six pages: [Overvie w i nformation], [Board], [Clocks], [Components], [Pins],

and [Interrupts]. Select a page by clicking on a tab; the displayed page will be changed.

Figure 3-6 Smart Configurator View

3.4.4 MCU Package view

Display the MCU package. You can save r otation, enla rgement, r ed uction, and MCU package view of the display to the

image file. You can also confirmation pin assignment and change it.

Figure 3-7 MCU Package View

R20AN0536EJ0100 Rev.1.00 Page 11 of 43

Jan 25, 2019

Page 12

RH850 Smart Configurator User’s Guide: IAREW, MULTI

3.4.5 Console view

The console displays details of changes to the configuration made in the Smart Configurator or MCU Package view.

Figure 3-8 Console View

3.4.6 Configuration Problems view

The Configuration Problems view displays problems with peripheral functions, interrupts, and pin conflicts.

Figure 3-9 Configuration Problems View

R20AN0536EJ0100 Rev.1.00 Page 12 of 43

Jan 25, 2019

Page 13

RH850 Smart Configurator User’s Guide: IAREW, MULTI

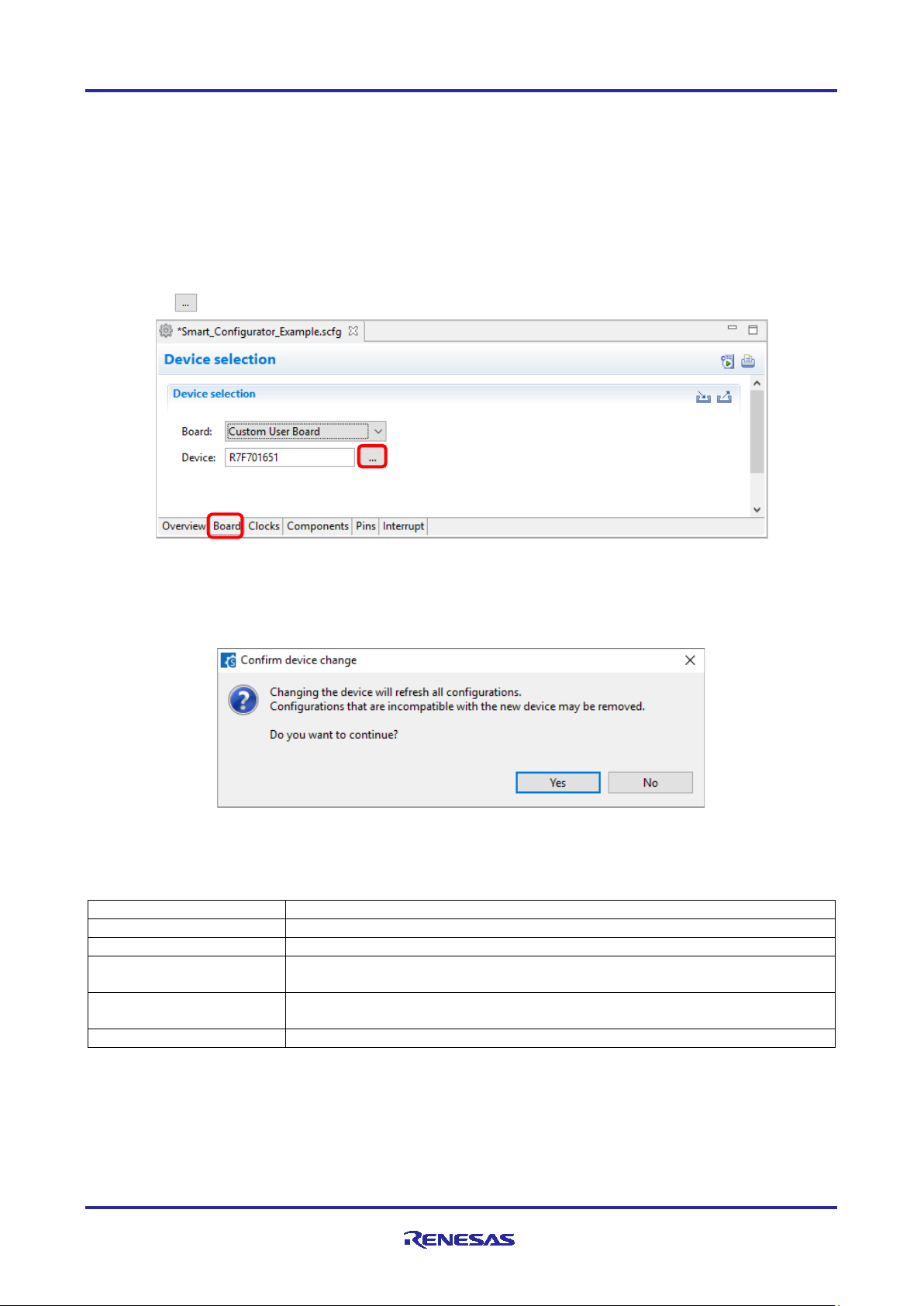

Button

Operation explanation

Yes

Change to the selected device.

No

It does not change the device.

Save and continue

After savi ng the current configurat ion contents to the configuration file, change to the

selected device.

Continue

Changes to the selected device without saving the current configuration contents to

the configuration file .

Cancel

It does not change the device.

4. Setting of Peripheral Modules

You can select peripheral modules from the Smart Configurator view.

4.1 Board setting

On the [Board] page, you can select boards and change devices.

4.1.1 Selecting the device

Click on the [ ] button to select a device.

Figure 4-1 Selecting the Device

The following message i s displayed when changing the device. For each button operation, refer to "Table 4-1, Device

change confirmation operation list".

Figure 4-2 Confirm Device Change

Table 4-1 Device Change Confirmation Operation List

R20AN0536EJ0100 Rev.1.00 Page 13 of 43

Jan 25, 2019

Page 14

RH850 Smart Configurator User’s Guide: IAREW, MULTI

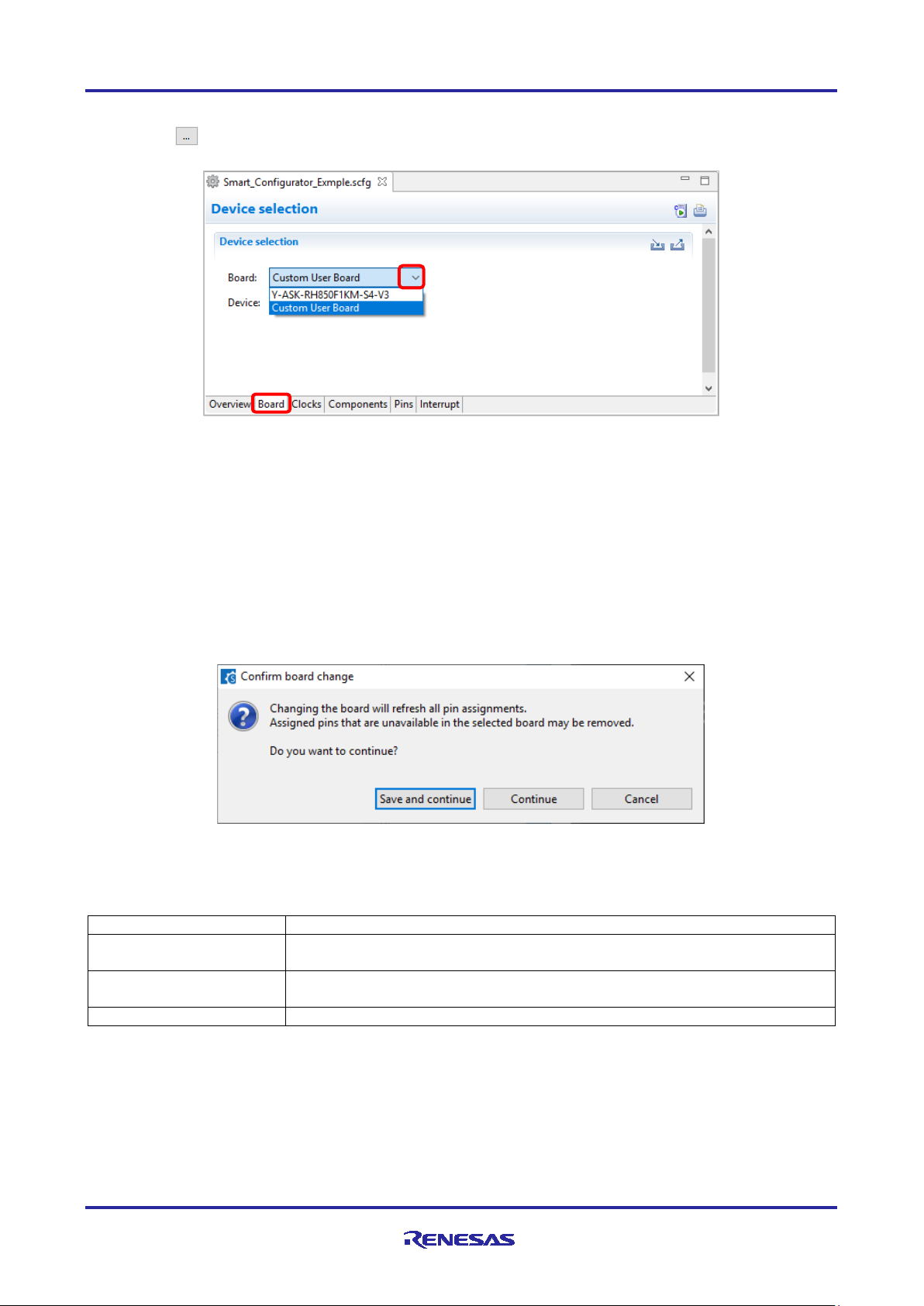

Button

Operation explanation

Save and continue

After savi ng the current configurat ion contents to the configuration file, change to the

selected device.

Continue

Changes to the selected device without saving the current configuration contents to

the configuration file .

Cancel

It does not change the device.

4.1.2 Selecting the board

Click on the [ ] b ut ton to select a device. When peripheral functions are configured by board selection, pins are

automatically set according to board connection.

Figure 4-3 Selecting the Board

The following items are changed according to the configuration of the selected board.

• Pin assignment

• Frequency of the main clock

• Frequency of the sub-clock

• Target device

If you change the board , the message s hown in “Figure 4-2” or the following message will be displayed. For each

button operation, refer to "Table 4-2, Board Change Confirmation Operation List".

Figure 4-4 Confirm Board Change

Table 4-2 Board Change Confirmation Operation List

R20AN0536EJ0100 Rev.1.00 Page 14 of 43

Jan 25, 2019

Page 15

RH850 Smart Configurator User’s Guide: IAREW, MULTI

4.1.3 Import board configuration

The board setting is defined in bdf (Board Description File). Follow the procedure below to import board configuration.

(1) Click on the [ (Import board setting)] button and select a desired bdf file.

(2) The board of the imported settings is added to the board selection menu.

Figure 4-5 Import of Board Configuration (bdf format)

Once a board setting file is imported, the added board is also displayed in the board selection menu of other projects for

the same device group.

4.1.4 Export board configuration

The current main clock frequency, sub clock frequency and pin assignment settings can be exported as board

configuration. Follow the procedure below to export the board configuration.

(1) Click on the [ (Export board setting)] button on the [Board] tabbed page.

(2) Select the output location and specify a name (Display Name) for the file to be exported.

Figure 4-6 Export of Board Configuration (bdf forma t)

R20AN0536EJ0100 Rev.1.00 Page 15 of 43

Jan 25, 2019

Page 16

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(a)

(b)

(2)

(1)

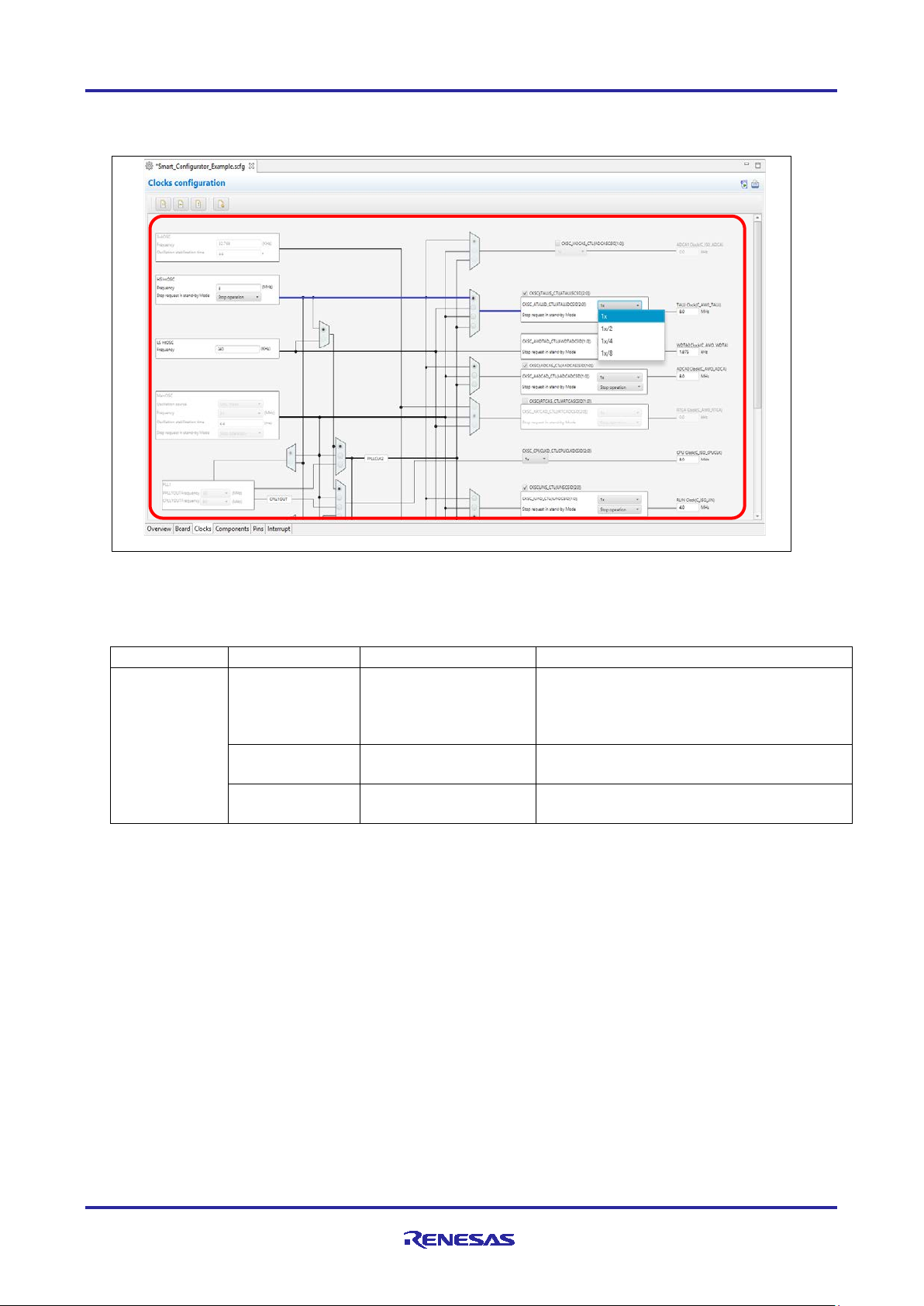

4.2 Clock settings

On the [Clocks] page, set the clock. The [Clocks] page setting is used as the clock source for each component. Set the

clock before configuring the component.

The clocks setting is performed in the following procedure.

(1) Set the clock oscillator circuit.

(2) Sets the clock source to be supplied to the CPU and peripheral functions.

(a) When you move the mouse o n the screen, the clock signal is displayed in blue.

(b) Click on the screen to select the clock selector.

Figure 4-7 Clock Settings

R20AN0536EJ0100 Rev.1.00 Page 16 of 43

Jan 25, 2019

Page 17

RH850 Smart Configurator User’s Guide: IAREW, MULTI

Component tree

(1)

(2)

(3)

4.3 Software component settings

Drivers can be combined as software components on the [Components] page. Added components are displayed in the

component tree at the left of the page.

Figure 4-8 Component Page

4.3.1 Adding component

The following describes the procedure for adding a component.

(1) Click on the [ (Add component)] icon.

Figure 4-9 Adding Components

(2) Select a component from the list in the [Software Component Selection] page of the [New Component] dialo g

box (e.g. PWM Output Fu nction).

(3) Click on [Next].

Figure 4-10 Selection of Software Components

R20AN0536EJ0100 Rev.1.00 Page 17 of 43

Jan 25, 2019

Page 18

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(4)

(6)

(5)

(1)

(2)

(3)

(4)

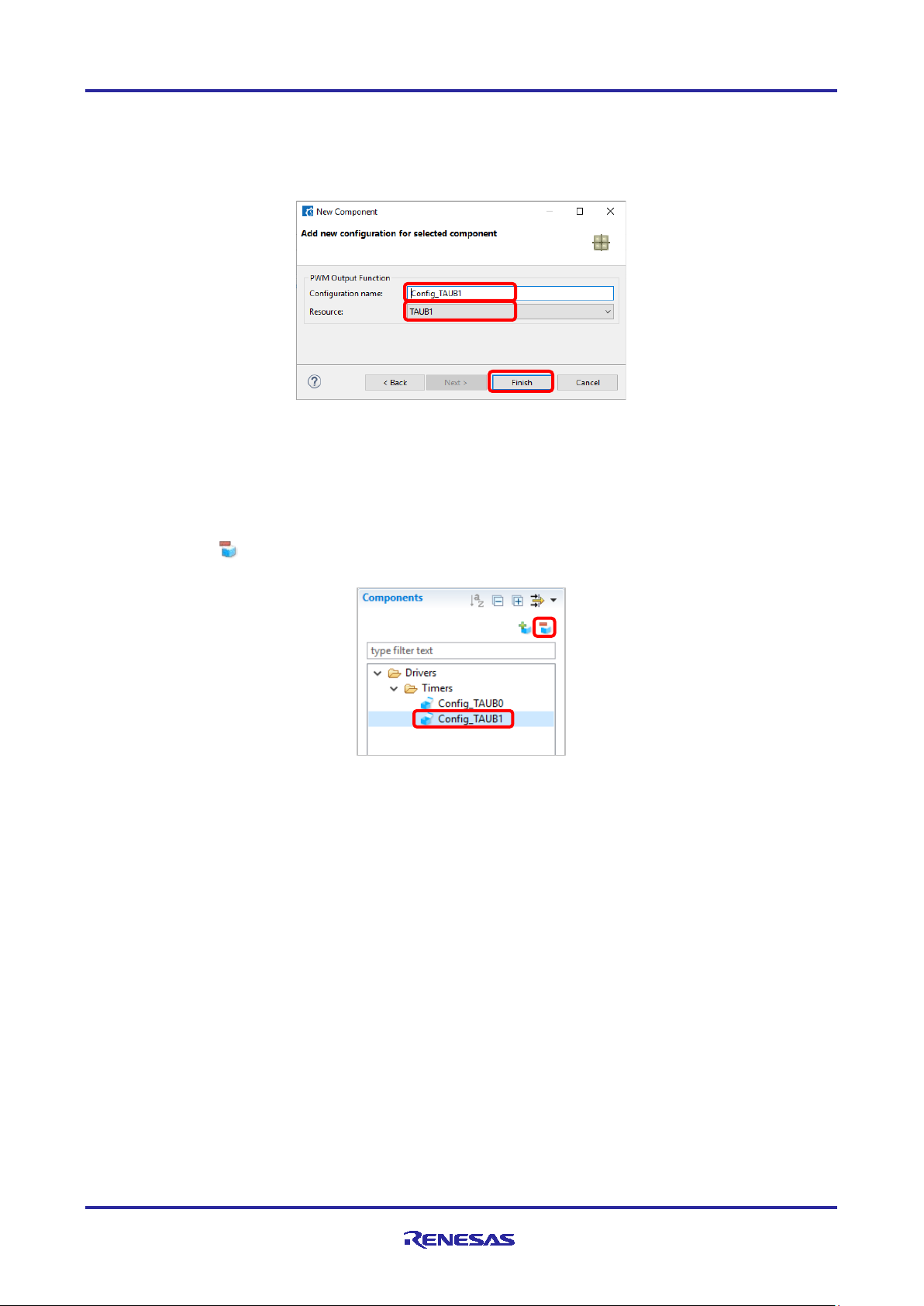

(4) Specify an appropriate configuration name in the [Add new configuration for selected component] page or use

the default name (e.g. Config_TAUB0).

(5) Select a hardware resource or use the default resource (e.g. TAUB0).

(6) Click on [Finish]. The component is added to the component tree.

Figure 4-11 Add New Configuration for Selected Component (e.g. TAUB0)

4.3.2 Switching between the component view and hardware view

The Smart Configurator also provides a function for adding a new c omponent by directly clicking a node in the

Components tree . To use this function, you need to switch the view of the Components tree from the component view to

the hardware view.

(1) Click on the [ (View Menu)] icon and select [Show by Hardware View]. The Components tree will display

the components in a hardware resource hierarchy.

Figure 4-12 Switch to [Show by Hardware View]

(2) Double-click on a hardware resource node (e.g. TAUB10 under Timer Array Unit B1) to open the [New

Component] dialog box.

(3) Select a component from the list (e.g. PWM Output Function) in the [Software Component Selection] page.

(4) Click the [Next].

Figure 4-13 Adding CG Components form the Har dware View

R20AN0536EJ0100 Rev.1.00 Page 18 of 43

Jan 25, 2019

Page 19

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(5)

(7)

(2)

(1)

(6)

(5) Specify an appropriate configuration name in the [Add new configuration for selected component] page or use

the default name (e.g. Config_TAUB1).

(6) Select a hardware resource or use the default resource (e.g. TAUB1).

(7) Click on [Finish]. The component is added to the component tree.

Figure 4-14 Add New Configuration for Selected Component (e.g. TAUB1)

4.3.3 Deleting a software component

Follow the procedure below to removing a software component.

(1) Select a software component from the Components tree.

(2) Click on the [ (Remove component)] icon. The selected software is removed from the component tree. The

selected software component will be removed from the Components tree.

Figure 4-15 Removing a Component

R20AN0536EJ0100 Rev.1.00 Page 19 of 43

Jan 25, 2019

Page 20

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(2) b.

(2) c.

(2) d.

(2) a.

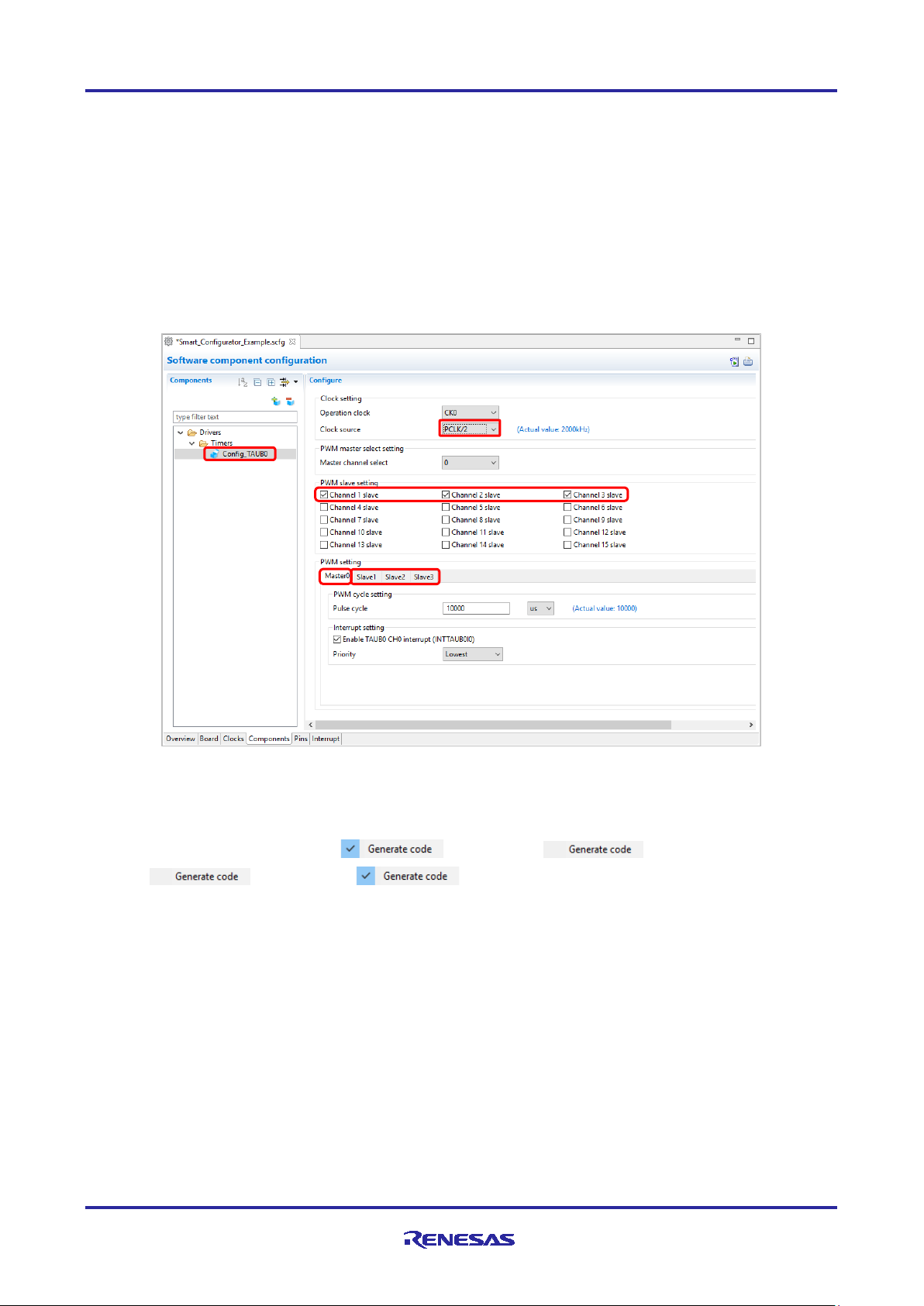

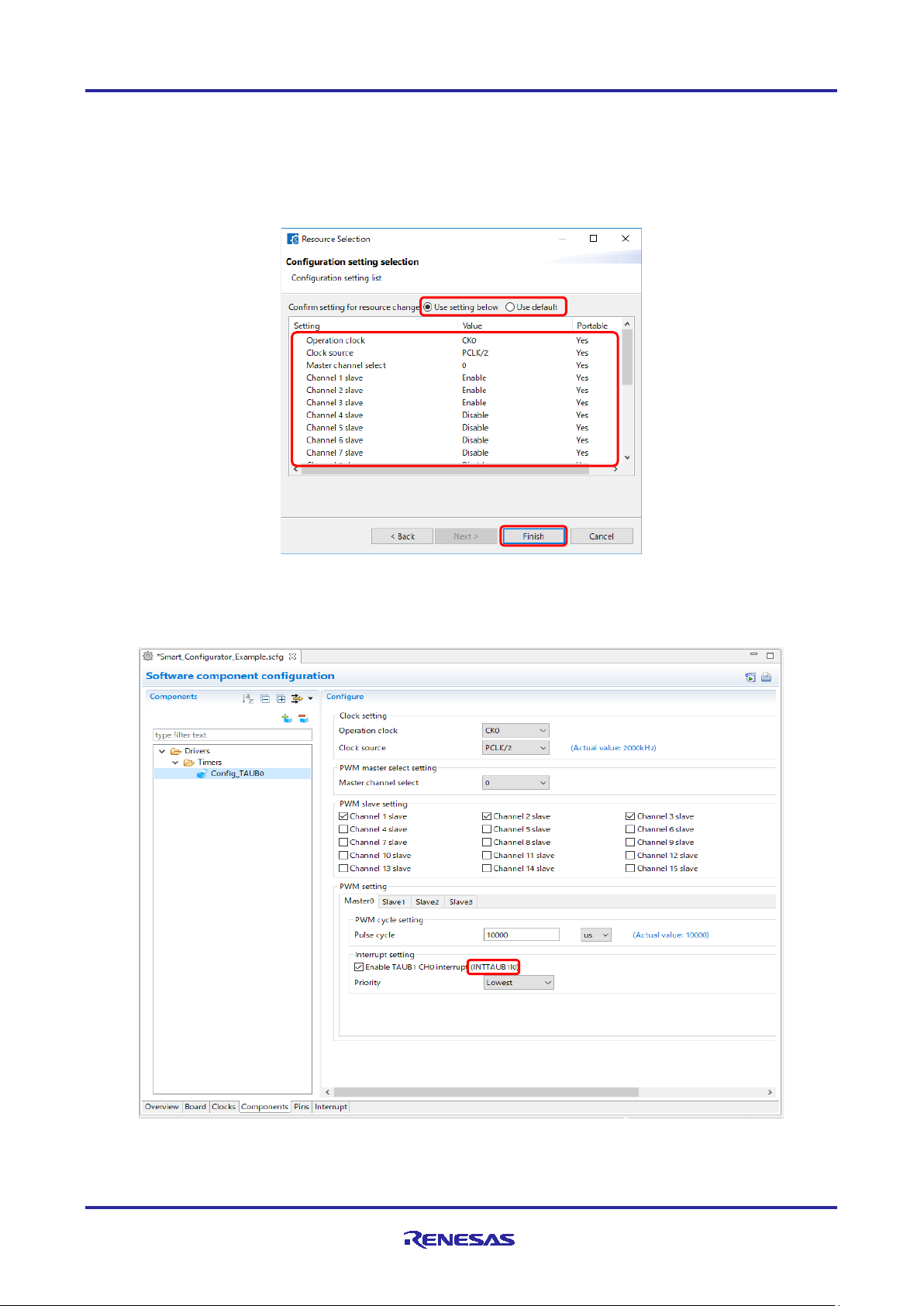

4.3.4 Component configuration settings

Follow the procedure below to setting the component configuration.

(1) Click the component in the component tree. (e.g. Config_TAUB0).

(2) Configure the driver in the [Configure] panel to the right of the Components tree. The Figure 4-16 is an

example.

a. Select [PCLK/2] in the item of [Clock source].

b. Select channel 1 slave, channel 2 s l ave, channel 3 slave.

c. Set the [Pulse cycle] on the [Master0] tab.

d. Set [Duty value] for each of the [Slave 1], [Slave 2], and [Slave 3] tabs.

Figure 4-16 Component Configuration Settings

The code generation of the component is set to enabled by d e fau lt.

Right click on the compo nent and cli ck [ ], it changes t o [ ] and no code is generated.

Clicking [ ] will change to [ ] and generate code.

R20AN0536EJ0100 Rev.1.00 Page 20 of 43

Jan 25, 2019

Page 21

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(2)

(3)

(4)

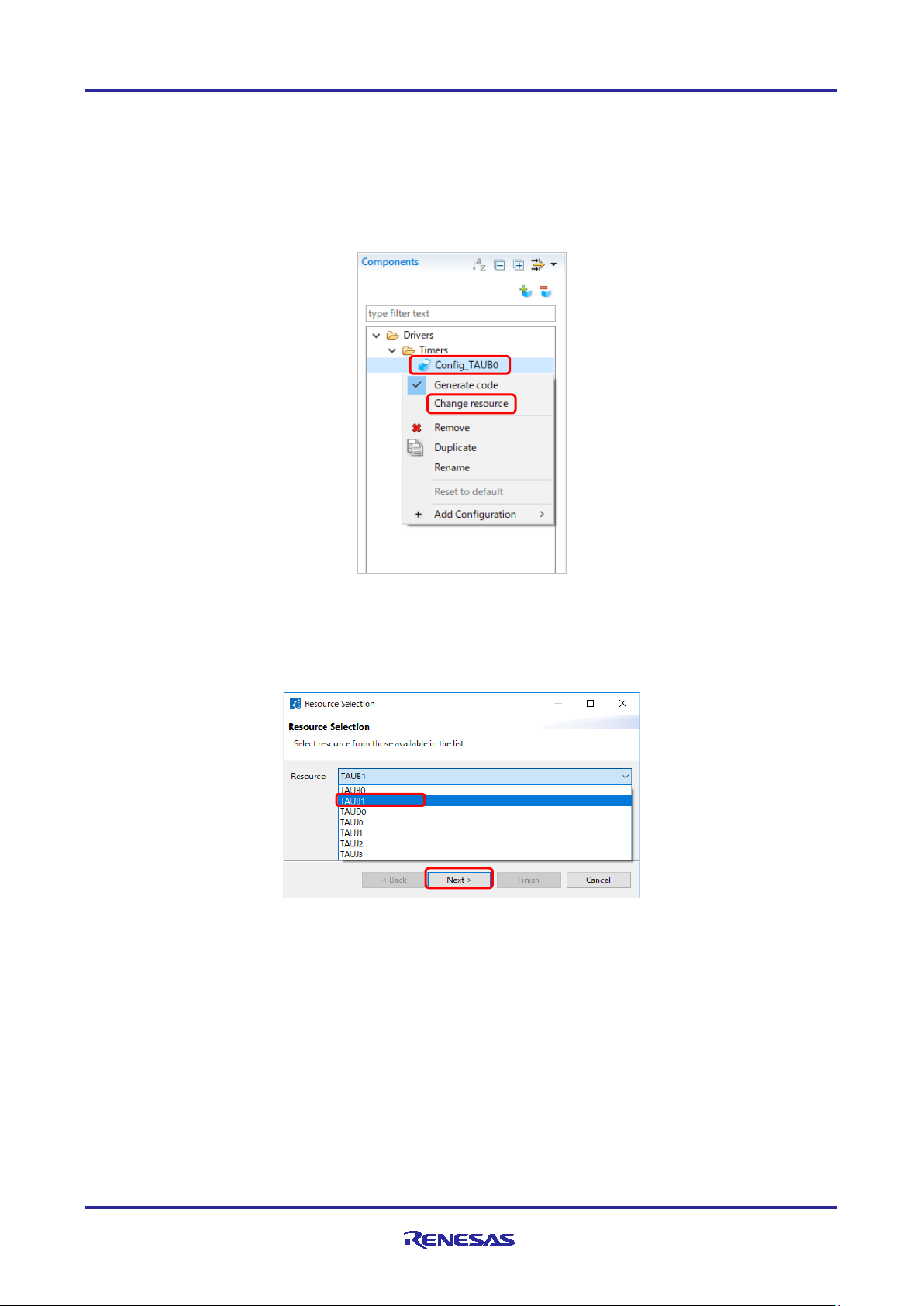

4.3.5 Component resource change

You can change the resource of the component (e.g. change from TAUB0 to TAUB1). Compatible configurations can

be migrated from the current resource to the newly selected resource.

Follow the procedure below to change the resource.

(1) Right-click on a component (e.g. Config_TAUB0).

(2) Select [Change resource] from the context menu.

Figure 4-17 Resource Change

(3) Select a new resource in the [ Resource Selection] dialog box (e.g. TAUB1).

(4) The [Next] button will be active; click on it.

Figure 4-18 Select a New Resource

R20AN0536EJ0100 Rev.1.00 Page 21 of 43

Jan 25, 2019

Page 22

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(6)

(8)

(7)

(5) The configuration information is displayed on the [Configuration setting selection] page of the [Select Resource]

dialog.

(6) Check the portability of the settings.

(7) Select whether to use the lis ted or default settings.

(8) Click on [Finish].

Figure 4-19 Confirm New Resource Settings

The resource is automatically changed (e.g. changed INTTAUB0I0 to INTTAUB1I0).

Figure 4-20 Resource Changed Automatically

R20AN0536EJ0100 Rev.1.00 Page 22 of 43

Jan 25, 2019

Page 23

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(9)

(10)

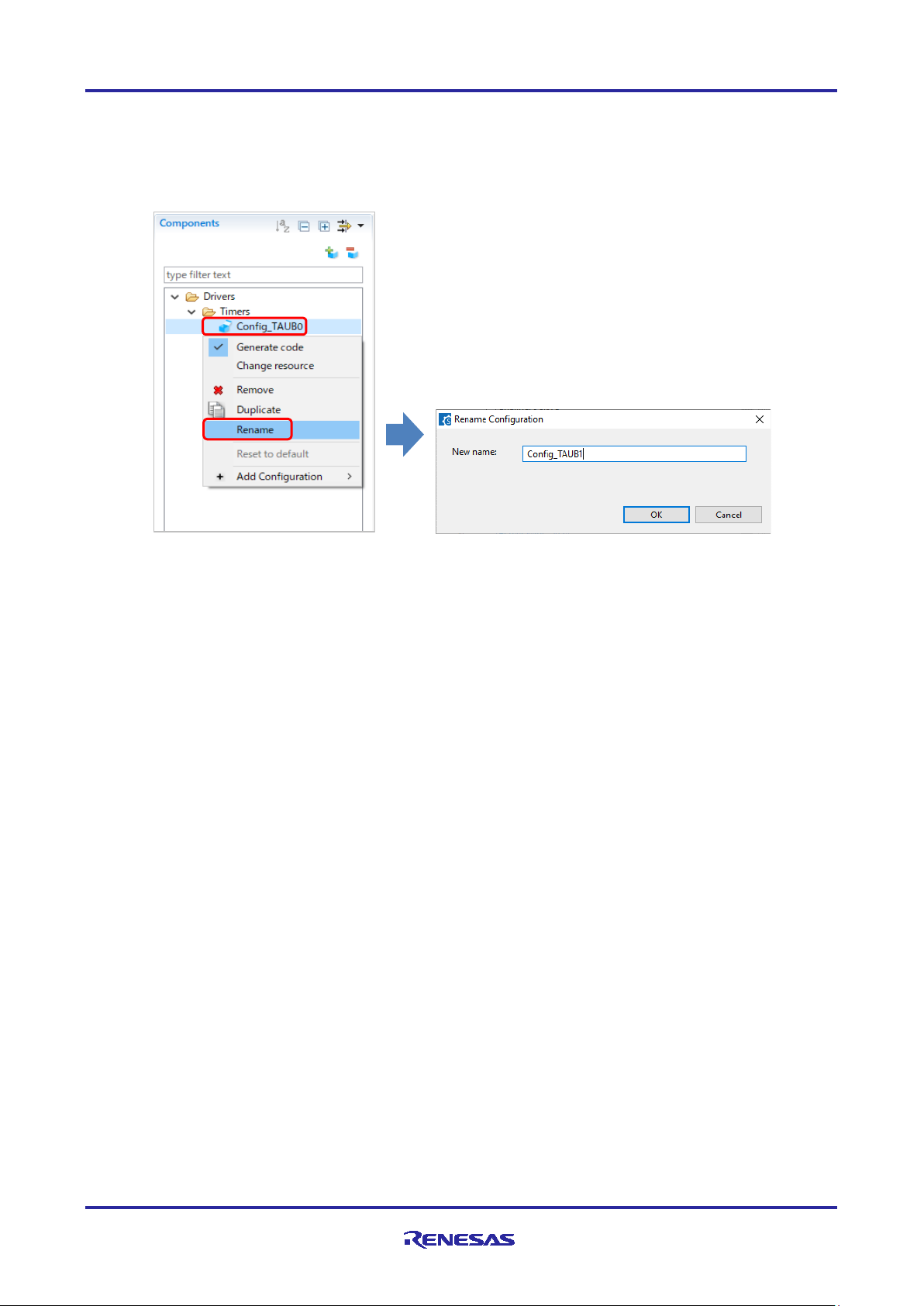

To change the configuration name, follow the procedure below.

(1) Right-click on the component.

(2) Select [Rename] to rename the configuration (e.g. change Config_TAUB0 to Config_TAUB1).

Figure 4-21 Renaming the Configuration

R20AN0536EJ0100 Rev.1.00 Page 23 of 43

Jan 25, 2019

Page 24

RH850 Smart Configurator User’s Guide: IAREW, MULTI

You can sort the display

You can sort the displa y

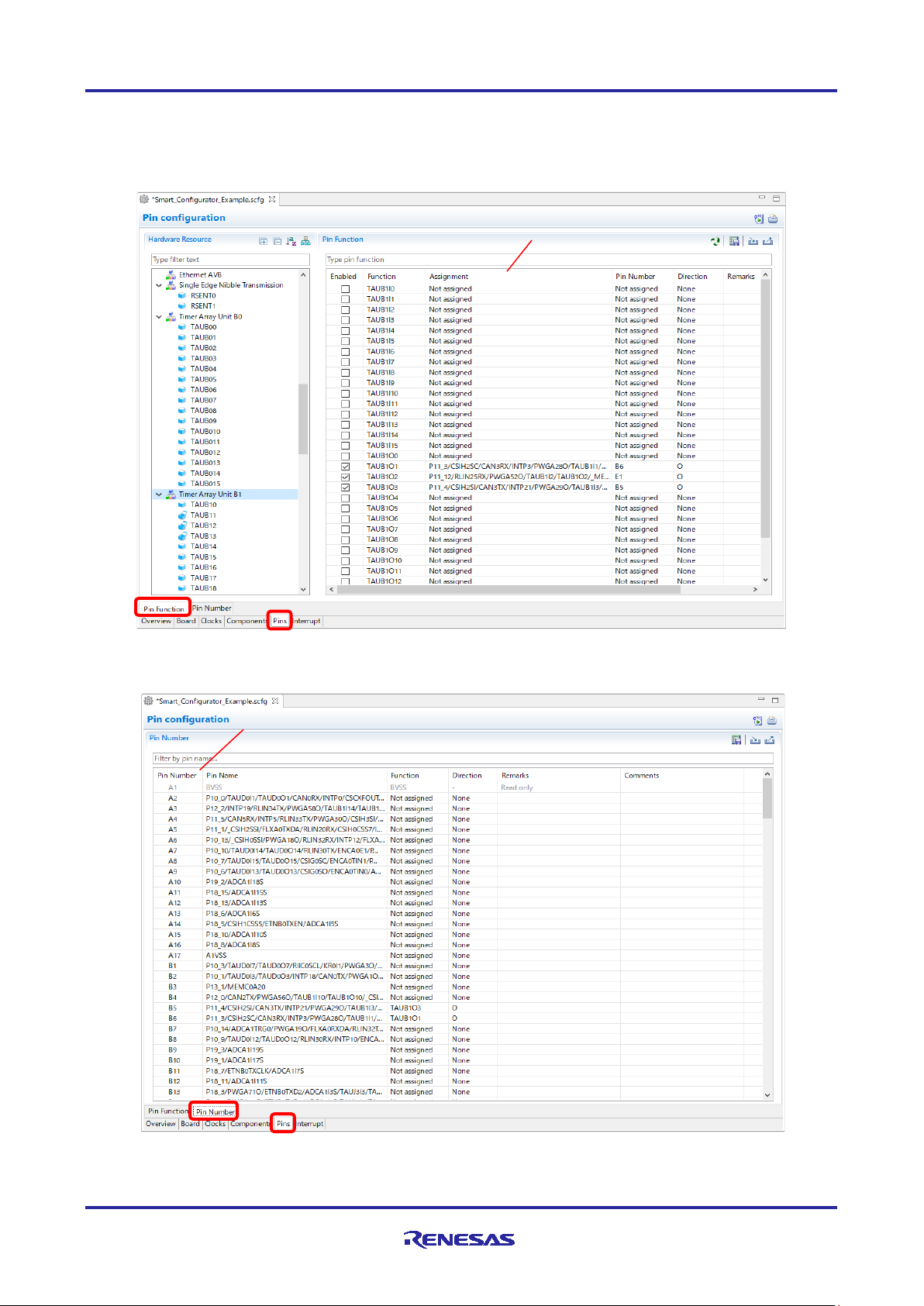

4.4 Pin settings

The [Pins] page is used for allocating pin functions. You can switch the display by clicking on the [Pin Function] and

[Pin Number] tabs. The [Pin Function] list shows the pin functions for each of the peripheral functions, and the [Pin

Number] list shows all pins in order of pin number.

by clicking the title.

Figure 4-22 [Pins] Page ([Pin Function])

by clicking the title.

R20AN0536EJ0100 Rev.1.00 Page 24 of 43

Jan 25, 2019

Figure 4-23 [Pins] Page ([Pin Number])

Page 25

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(2)

(3)

(4)-(a)

(4)-(b)

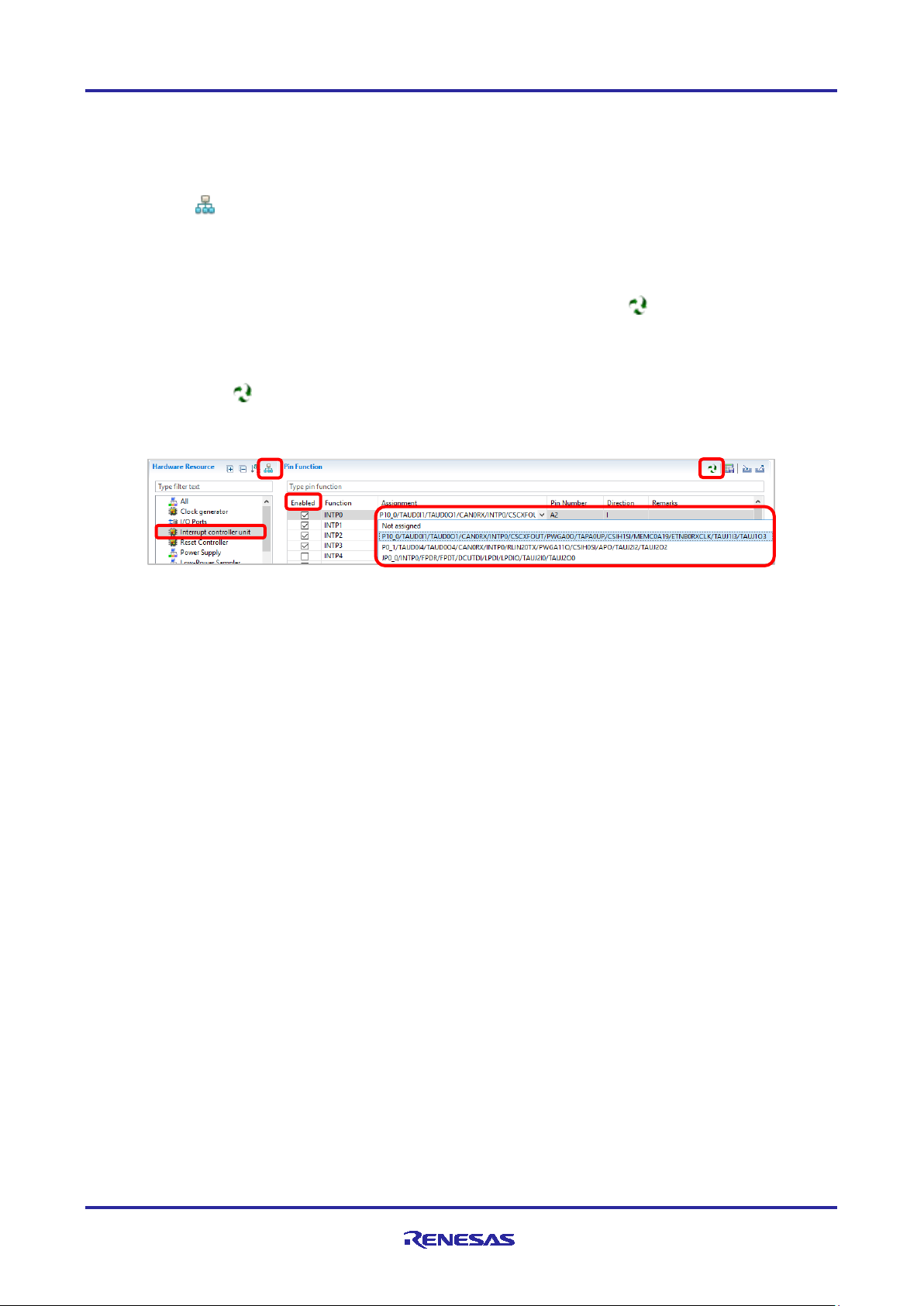

4.4.1 Assign pins to resources

In the Pins page, assign pin to the resource used by the component. Pin assignment can be done in either [Pin Function]

list or [Pin Number] list.

The proce dure for pin as s ignment in t he [Pin Function] list is described below.

(1) Click on [ (Show by Hardware Resource or Software Components)] to switch to the software component

view.

(2) Select the target software component (e.g. Interrupt controller unit).

(3) Click the [Enabled] header to sort by pins used.

(4) Pin assignment is performed with the [Assignment], [Pin Number] column, or [ (Next group of pins for the

selected resource)] button.

(a) Click [Assignment] or [Pin Number] and assign a terminal from the list (e.g. change from P0_1 to P10_0

with [Assi gnment]).

(b) Click the [ (Next group of pins for the selected resource)] button and change the pin assignment. Each

time you click, the pin with the function switches.

Figure 4-24 Pin Assignments in the [Pin function] List

When the component is set, the check box in the [Enabled] column is checked. Pin assignment is possible even when

the component is not set. If pin assignment is done without component being set, we will display "No component is

using this p in" in the [Remarks] column.

Note: The current ve rsion of Sma rt Configurator does not support t he component view for the [ Pins] page.

Use the Hardware Resource view to change the pin assignment.

R20AN0536EJ0100 Rev.1.00 Page 25 of 43

Jan 25, 2019

Page 26

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(2)

(3)

(a)

4.4.2 Pin setting using MCU package

Follow the procedure below to assign pins in the MCU Package view.

(1) Zoom in to the view b y clicking the [ (Zoom in)] butto n o r sc r olling the view with the mous e wheel.

(2) Right-click on the target pin.

(3) Select the signal to be assigned to the pin.

Figure 4-25 Assigning Pins Using the MCU Package View

(a) The color of the pins can be customized through [Preference Setting...].

R20AN0536EJ0100 Rev.1.00 Page 26 of 43

Jan 25, 2019

Page 27

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(1)

4.4.3 Export pin settings

You can expo rt pin assignment settings in XML format. Exported files can be imported into projects of the same device

family. Follow the procedure below to export the pin settings.

(1) Click on the [ (Export board setting)] button on the [Pins] page.

(2) In the [Export] dialog, enter th e file name to export.

Figure 4-26 Export Pin Settings (XML format)

The Smart Configurator can also export the pin settings to a CSV file. Click on the [ (Save the list to .csv file)] button

on the [Pins] page.

4.4.4 Import pin settings

You can import XML format files including pin assignment settings. When you import a file, the terminal assignment is

reflected. Follow the procedure below to import the pin settings.

(1) Click on the [ (Import board setting)] button on the [Pins] page.

(2) In the [Import] dialog, enter the file name to import.

Figure 4-27 Import Pin Settings (XML format)

R20AN0536EJ0100 Rev.1.00 Page 27 of 43

Jan 25, 2019

Page 28

RH850 Smart Configurator User’s Guide: IAREW, MULTI

(1)

(2)

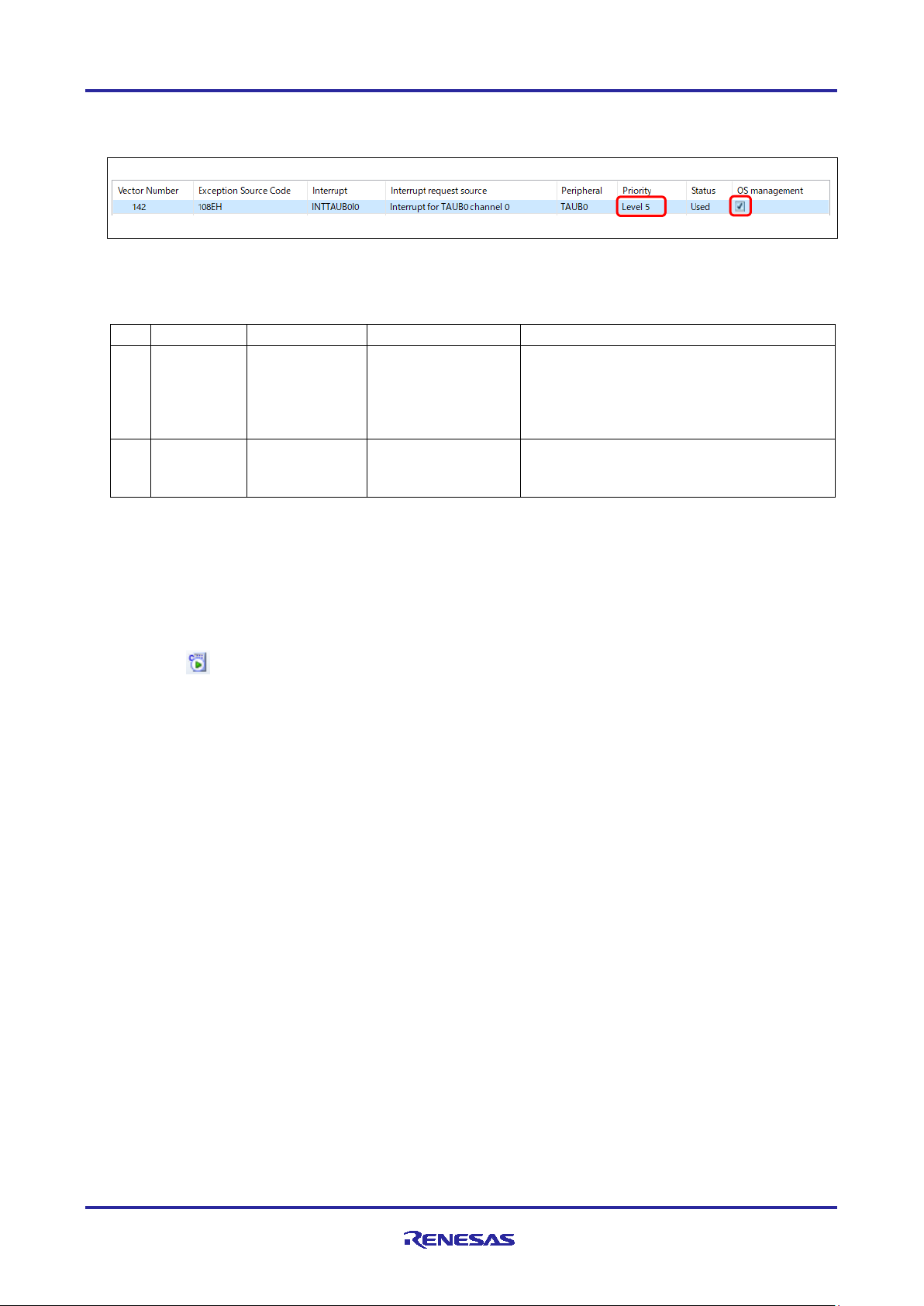

4.5 Interrupt settings

Check and set the interrupts of the peripheral modules that have been selected on the [Components] page.

Figure 4-28 [Interrupts] Page

4.5.1 Changing the interrupt priority level and OS management setting

When an inter rupt is used in a configuration on the [Components] page, the status of t he interrupt will be changed to

"Used". To display the used interrupts only, cl ick on the [ (Show used interrupts)] button.

(1) The interrupt priority level can be c han ged in the [priority] column. Setting the pr iority level is reflected in the

configuration settings of the component.

(2) The [OS management] column becomes active for a project that uses RTOS (RI850V4). Selecting a checkbox in

the column outputs the c orresponding interrup t function in the interr upt format tha t can be managed by the OS.

Figure 4-29 Interrupt Settings

R20AN0536EJ0100 Rev.1.00 Page 28 of 43

Jan 25, 2019

Page 29

RH850 Smart Configurator User’s Guide: IAREW, MULTI

5. Managing Conflicts

Adding co mponents, set t ing pins and interrupts may cause problems related to resource mismatch. This information will

be displayed in the [Configuration Problems view]. User can refer to the information displayed to fix the conflict issues.

5.1 Resource conflicts

When two software components are configured to use the same resource (for e.g. TAUB1), an error mark ( ) will be

displayed in the [Components tree].

The [Configuration Problems view] will display messages on peripheral conflicts to inform the user in which software

configurations peripheral conflicts have been detected.

Figure 5-1 Resource Conflicts

R20AN0536EJ0100 Rev.1.00 Page 29 of 43

Jan 25, 2019

Page 30

RH850 Smart Configurator User’s Guide: IAREW, MULTI

5.2 Resource pin conflicts

When multiple pin functions are assigned to the same pin, an error mark is displayed in the tree and [Pin Function]

list on the [Pins] page.

Figure 5-2 Pin Conflicts

The detailed information regarding conflicts is displayed in the [Configuration Problems view].

Figure 5-3 Pin Conflict Message

To resolve a conflict, right-click on the node with an error mark on the tre e and select [Resolve conflict].

Figure 5-4 Resolving Pin Conflicts

The pins of the selected node will be re-assigned to other pins.

R20AN0536EJ0100 Rev.1.00 Page 30 of 43

Jan 25, 2019

Page 31

RH850 Smart Configurator User’s Guide: IAREW, MULTI

6. Generating Source Code

6.1 Generating Source Code File

Output a source file for the configured details by clicking on the [ (Generate Code)] button i n the Smart Configurator

view.

Figure 6-1 Generating a Source File

The Smart Configurator generates a source file in <ConfigurationFileDir>\src\smc_gen. If your Smart Configurator has

already generated a file, a backup copy of that file is also generated (refer to the section 6.6, Backing up Generated

Source Code).

6.2 Configuration of Generated Files and File Names

Figure 6-2, Configuration of Generated Files and File Names, shows the folders and files output by the Smart

Configurator. "ConfigName" indic ates the configuration name set in the compone nt.

Figure 6-2 Configuration of Generated Files and File Names

R20AN0536EJ0100 Rev.1.00 Page 31 of 43

Jan 25, 2019

Page 32

RH850 Smart Configurator User’s Guide: IAREW, MULTI

Folder

File

Description

This folder is generated for the components that are added to the

ConfigName (configuration name).

{ConfigName}.c

This file contains functions to initial iz e driver

This file contains interrupt service routines and functio ns for user

User can add codes and functions in the dedicated user code areas.

{ConfigName}.h

This is header file for {ConfigName}.c and {ConfigName}_user.c

This file is always generated.

configured in the [Pins] tabbed page (except I/O Ports).

Pin.h

This file is always generated.

This folder is always generated.

of the same peripheral function.

r_cg_xxx.h

(*1)

These files are always generated.

This file is always generated.

settings in the [Clocks] page.

r_cs_cgc.h

This file is always generated.

This header file contains macro definitions to initialize clocks.

This file contains functions to be added to R_CGC_Create.

User can add codes and functions in the dedicated user code areas.

This file is always generated.

This file is always generated.

drivers.

r_cg_main.c

This file is always generated. It d e fine s the main() function.

This file is always generated.

R_Systeminit also calls the functions for initializing clocks.

r_cg_userdefine.h

This file is always generated.

r_smc_interrupt.c

This file is always generated.

r_smc_interrupt.h

This file is always generated.

Table 6-1 Description of Generated File

{ConfigName} -

project. API functions in this folder are named after the

(R_ConfigName_Create) and perform operations that are driver-

specific, e.g. start (R_ConfigName_Start) and stop

(R_ConfigName_Stop).

{ConfigName}_user.c

to add code after the driver initialization (R_ConfigName_Create).

r_pincfg Pin.c

It is a reference of pin function initialization for all peripherals

It contains the function prototypes of pin settings in Pin.c

general -

It contains header files and source files commonly used by dr ive rs

r_cg_cgc.c

r_cs_cgc_user.c

r_cg_intvector.c

r_cg_macrodriver.h

r_cg_ systeminit.c

Note *1: xxx is the name of a component.

The files contain macro definitions for setting SFR registers.

It contains the initialization of clock sources in accordance with the

It contains interrupt vector table definitions.

This header file contains common macro definitions used in

It contains R_Systeminit that ca lls all driver initialization functions

with the name R_ConfigName_Create.

User can add macro definitions in the dedicated user code areas.

R20AN0536EJ0100 Rev.1.00 Page 32 of 43

Jan 25, 2019

Page 33

RH850 Smart Configurator User’s Guide: IAREW, MULTI

Folder

File

Macros/Functions

Description

general

r_cg_cgc.c

R_CGC_Create

This API function initializes clocks.

function.

Macros related to clocks

These macros are for clocks initialization in

R_CGC_Create.

r_cg_cgc_user.c

R_CGC_Create_UserInit

This API function is for user to add code in

R_CGC_Create after the CGC initialization.

6.3 Initializing Clocks

Configurations of clock source in [Clocks] page are generated in \src\smc_gen\r_config folder.

Figure 6-3 Clocks Source Configuration

Table 6-2 Clock Source File Description

r_cg_cgc.h

R_Systeminit in r_cg_systeminit.c will call this

function during execution of the main()

R20AN0536EJ0100 Rev.1.00 Page 33 of 43

Jan 25, 2019

Page 34

RH850 Smart Configurator User’s Guide: IAREW, MULTI

Folder

File

Function

Description

This API function initializes pins used by this

function.

Folder

File

Function

Description

This function contains the initializ a tion codes of

except I/O ports.

6.4 Initializing Pins

Pin configuration settings are generated by the compone nt into source files as shown in (1) and (2) below.

(1) Pins initialization for drivers with { ConfigName}

The pin function is initialized with R_ConfigName_Create of \src\smc_gen\{ConfigName}\{ConfigName}.c.

Table 6-3 File to Initialize Pins

{ConfigName} {ConfigName}.c R_ConfigName_Create

driver. R_Systeminit in r_cg_hardware_setup.c

will call this function before enterin g main()

(1) Reference pins initialization codes

Refer to Pin.c in the \src\smc_gen\r_pincfg folder for the initializatio n code of all pin functi ons set on the [Pins]

page (except I/O ports).

Table 6-4 Reference File for Initialization of All Pins

r_pincfg Pin.c R_Pins_Create

all pins function configured at [Pins] page

Jan 25, 2019

R20AN0536EJ0100 Rev.1.00 Page 34 of 43

Page 35

RH850 Smart Configurator User’s Guide: IAREW, MULTI

No

Item

Folder

File

Description

Interrupt priority level settings are initialized in

function.

OS

{ConfigName}

The interr upt functions defined in t his file are

managed by the OS.

(1)

(2)

6.5 Initializing Interrupts

Configurati ons in [Interrupt] page are generated in few source files.

Figure 6-4 Interrupt Configuration

Table 6-5 Interrupt Generation File Description

(1) Priority {ConfigName} {ConfigName}.c

R_ConfigName_Create in this file.

R_Systeminit in r_cg_

function during execution of the main()

systeminit.c will call this

(2)

management

{ConfigName}_user.c

output in the interrupt format that c an be

6.6 Backing up Generated Source Code

The smart configurator has a source code backup function.

<ConfigurationFileDir>\trash\<Date-and-Time>

The Smart Configurator generates a backup folder for the previously generated source code when new code is generated

by clicking on [ ]. <Date-and-Time> indicates the date and time when the backup folder is created after code

generation.

R20AN0536EJ0100 Rev.1.00 Page 35 of 43

Jan 25, 2019

Page 36

RH850 Smart Configurator User’s Guide: IAREW, MULTI

7. Loading generated files in Integrated development environment

Load source code outputted by Smart Configurator on Integrated Development Environ ment Platform.

7.1 Loading in IAR Embedded Workbench

When IAR environment is selected for the compiler to be used, Smart Configurator also outputs the project connection

file (.ipcf) together with the source file. The project connection file contains source file registration information. It is not

necessary for the user to add or delete source files after configuration c hange in the Smart Configurator.

The usage procedure is as follows.

(1) Select [Add Project Connection..] from the [Project] menu of IAR Embedded Workbench.

(2) The [Add Project Connection] dialog is displayed. Select [IAR Project Connection] and click [OK].

(3) In the [Select IAR Project Connection File] dialog box, browse to the folder where the configuration file is

saved, select the project connection file (.ipcf), and click the [Open] button.

(4) The source file output by the Smart Configurator is added to the workspace.

7.2 Loading in GHS MULTI

When GHS environment is selected for the compiler to be used, Smart Configurator also outputs the project connection

file (.gpj) together with the so urc e file. The project connection file contains source file r egistration information. It is not

necessary for the user to add or delete source files after configuration c hange in the S ma r t Co n figurator.

The usage procedure is as follows.

(1) Select [Open Project Manager ...] from the MULTI [Components] menu.

(2) As the [Select a project to open] dialog box appears, browse to the folder where the configuration file is saved,

select default.gpj, and click the [Open] button.

(3) The source file output by the Smart Configurator is added to the workspace.

R20AN0536EJ0100 Rev.1.00 Page 36 of 43

Jan 25, 2019

Page 37

RH850 Smart Configurator User’s Guide: IAREW, MULTI

/* Start user code for xxxx. Do not edit comment generated here */

8. Creating User Programs

The component type of the Smart Configurator has [code generation]. This section describes how to add custom code of

[code generation].

8.1 Adding Custom Code in the Case of Code Generator

When [Code Generator] is selected as the component type, if files which have the same name already exist, new code

will be merge d only with the existing code that is between the comments below.

/* End user code. Do not edit comment generated here */

In the case of [Code Generator], three files are generated for each of the specified peripheral functions. The file names

are “Config_xxx.h”, “Config_xxx.c”, and “Config_xxx_user.c” as the default, with “xxx” represent ing the name of the

peripheral module. For example, “xxx” will be “TAUB1” for the compare-match timer (resource TAUB1). The

comments to indica te where to add custom code are at the start and end of each of the t hre e files. Comments to i ndic a te

where to add user code are also added to the interrupt function for the peripheral module corresponding to

Config.xxx_user.c. The following examples are for TAUB1 (Config_ TAUB1_user.c).

/*******************************************************************************

Pragma directive

*******************************************************************************/

/* Start user code for pragma. Do not edit comment generated here */

/* End user code. Do not edit comment generated here */

/*******************************************************************************

Includes

*******************************************************************************/

#include "r_cg_macrodriver.h"

#include "r_cg_userdefine.h"

#include "Config_TAUB1.h"

/* Start user code for include. Do not edit comment generated here */

/* End user code. Do not edit comment generated here */

/*******************************************************************************

Global variables and functions

*******************************************************************************/

/* Start user code for global. Do not edit comment generated here */

/* End user code. Do not edit comment generated here */

/*******************************************************************************

* Function Name: R_Config_TAUB1_Create_UserInit

* Description : This function ad ds user code after initializing the TAUB1 channel

* Arguments : None

* Return Val ue : None

*******************************************************************************/

void R_Config_TAUB1_Create_UserInit(void)

{

/* Start user code for user init. Do not edit comment generated here */

/* End user code. Do not edit comment generated here */

}

R20AN0536EJ0100 Rev.1.00 Page 37 of 43

Jan 25, 2019

Page 38

RH850 Smart Configurator User’s Guide: IAREW, MULTI

/*******************************************************************************

* Function Name: r_Config_TAUB1_channel0_interrupt

* Description : This function is TAUB10 interrupt service routine

* Arguments : None

* Return Val ue : None

*******************************************************************************/

#pragma interrupt r_Config_TAUB1_channel0_interrupt(enable=false, channel=256, fpu=true,

callt=false)

void r_Config_TAUB1_channel0_interrupt(void)

{

/* Start user code for r_Config_TAUB1_channel0_interrupt. Do not edit comment generated here

*/

/* End user code. Do not edit comment generated here */

}

/* Start user code for adding. Do not edit comment generated here */

/* End user code. Do n ot edit comment generated here */

R20AN0536EJ0100 Rev.1.00 Page 38 of 43

Jan 25, 2019

Page 39

RH850 Smart Configurator User’s Guide: IAREW, MULTI

9. Gene r ating Reports

The Smart Configurator can output t he configuration information of the project to the report. Follow the procedure

below to generate a report.

9.1 Report on Configuration

A report is output in response to clicking on the [ (Generate Report)] button in the Smart Co nfigurator view.

Figure 9-1 Output of a Report on the Configuration (as a Text File)

Figure 9-2 Dialog Box for Output of a Report

R20AN0536EJ0100 Rev.1.00 Page 39 of 43

Jan 25, 2019

Page 40

RH850 Smart Configurator User’s Guide: IAREW, MULTI

9.2 Configuration of Pin Function List and Pin Number List (in csv Format)

A list of the configuration of pin functions and pin numbers (whichever is selected at the time) is output in response to

clicking on [ (Save the list to .csv file)] on the [Pins] page of the Smart Configurator view.

Figure 9-3 Output of a List of Pin Functions or Numbers (in csv Format)

9.3 Image of MCU Package (in png Format)

An image of the MCU package is output in response to clicking on the [ (Save Package View to external image file)]

button of the [MCU Package] view.

Figure 9-4 Outputting a Figure of MCU Package (in png Format)

R20AN0536EJ0100 Rev.1.00 Page 40 of 43

Jan 25, 2019

Page 41

RH850 Smart Configurator User’s Guide: IAREW, MULTI

10. Help

10.1 Help

Refer to the help system for detailed information on the Smart Configurator.

Figure 10-1 Help Menu

The help system can also be activated from the [Overview] page.

Figure 10-2 Quick Start

R20AN0536EJ0100 Rev.1.00 Page 41 of 43

Jan 25, 2019

Page 42

RH850 Smart Configurator User’s Guide: IAREW, MULTI

11. Documents for Reference

User’s Manual: Hardware

Obtain the latest version of the manual from the web site of Renesas Electronics.

Technical Update/Technical News

Smart Configurator: Guide on Sample Project for RH850/F1KM Device (R01AN4422)

User’s Manua l: Development Enviro nment

Obtain the latest version of the manual from each company web site.

R20AN0536EJ0100 Rev.1.00 Page 42 of 43

Jan 25, 2019

Page 43

RH850 Smart Configurator User’s Guide: IAREW, MULTI

Website and Support

Renesas Electronics Website

http://www.renesas.com/

Inquiries

http://www.renesas.com/contact/

All trademarks and registered trademarks are the property of their respective owners.

R20AN0536EJ0100 Rev.1.00 Page 43 of 43

Jan 25, 2019

Page 44

Rev.

Date

Description

Page

Summary

1.00

Jan 25, 2019

-

First edition issued

Revision History

Page 45

General Precautions in the Handling of Microprocessing Unit and Microcontroller

Unit Products

The following usage notes are applicable to all Microprocessing unit and Microcontroller unit products from Renesas. For detailed usage notes on the

products covered by this document, refer to the relevant sections of the document as well as any technical updates that have been issued for the products.

1. Precaution against Electrostatic Discharge (ESD)

A strong electrical field, when exposed to a CMOS device, can cause destruction of the gate oxide and ultimately degrade the device operation. Steps

must be taken to stop the generation of static electricity as much as possible, and quickly dissipate it when it occurs. Environmental control must be

adequate. When it is dry, a humidifier should be used. This is recommended to avoid using insulators that can easily build up static electricity.

Semiconductor devices must be stored and transported in an anti-static container, static shielding bag or conductive material. All test and

measurement tools including work benches and floors must be grounded. The operator must also be grounded using a wrist strap. Semiconductor

devices must not be touched with bare hands. Similar precautions must be taken for printed circuit boards with mounted semiconductor devices.

2. Processing at power-on

The state of the product is undefined at the time when power is supplied. The states of internal circuits in the LSI are indeterminate and the states of

register settings and pins are undefined at the time when power is supplied. In a finished product where the reset signal is applied to the external reset

pin, the states of pins are not guaranteed from the time when power is supplied until the reset process is completed. In a similar way, the states of pins

in a product that is reset by an on-chip power-on reset function are not guaranteed from the time when power is supplied until the power reaches the

level at which resetting is specified.

3. Input of signal during power-off state

Do not input signals or an I/O pull-up power supply while the device is powered off. The current injection that results from input of such a signal or I/O

pull-up power supply may cause malfunction and the abnormal current that passes in the device at this time may cause degradation of internal

elements. Follow the guideline for input signal during power-off state as described in your product documentation.

4. Handling of unused pins

Handle unused pins in accordance with the directions given under handling of unused pins in the manual. The input pins of CMOS products are

generally in the high-impedance state. In operation with an unused pin in the open-circuit state, extra electromagnetic noise is induced in the vicinity of

the LSI, an associated shoot-through current flows internally, and malfunctions occur due to the false recognition of the pin state as an input signal

become possible.

5. Clock signals

After applying a reset, only release the reset line after the operating clock signal becomes stable. When switching the clock signal during program

execution, wait until the target clock signal is stabilized. When the clock signal is generated with an external resonator or from an external oscillator

during a reset, ensure that the reset line is only released after full stabilization of the clock signal. Additionally, when switching to a clock signal

produced with an external resonator or by an external oscillator while program execution is in progress, wait until the target clock signal is stable.

6. Voltage application waveform at input pin

Waveform distortion due to input noise or a reflected wave may cause malfunction. If the input of the CMOS device stays in the area between V

(Max.) and V

input level is fixed, and also in the transition period when the input level passes through the area between V

7. Prohibition of access to reserved addresses

Access to reserved addresses is prohibited. The reserved addresses are provided for possible future expansion of functions. Do not access these

addresses as the correct operation of the LSI is not guaranteed.

8. Differences between products

Before changing from one product to another, for example to a product with a different part number, confirm that the change will not lead to problems.

The characteristics of a microprocessing unit or microcontroller unit products in the same group but having a different part number might differ in terms

of internal memory capacity, layout pattern, and other factors, which can affect the ranges of electrical characteristics, such as characteristic values,

operating margins, immunity to noise, and amount of radiated noise. When changing to a product with a different part number, implement a systemevaluation test for the given product.

(Min.) due to noise, for example, the device may malfunction. Take care to prevent chattering noise from entering the device when the

IH

(Max.) and VIH (Min.).

IL

IL

Page 46

Notice

1. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of semiconductor products and application examples. You are fully responsible for

the incorporation or any other use of the circuits, software, and information in the design of your product or system. Renesas Electronics disclaims any and all liability for any losses and damages incurred by

you or third parties arising from the use of these circuits, software, or information.

2. Renesas Electronics hereby expressly disclaims any warranties against and liability for infringement or any other claims involving patents, copyrights, or other intellectual property rights of third parties, by or

arising from the use of Renesas Electronics products or technical information described in this document, including but not limited to, the product data, drawings, charts, programs, algorithms, and application

examples.

3. No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights of Renesas Electronics or others.

4. You shall not alter, modify, copy, or reverse engineer any Renesas Electronics product, whether in whole or in part. Renesas Electronics disclaims any and all liability for any losses or damages incurred by

you or third parties arising from such alteration, modification, copying or reverse engineering.

5. Renesas Electronics products are classified according to the following two quality grades: “Standard” and “High Quality”. The intended applications for each Renesas Electronics product depends on the

product’s quality grade, as indicated below.

"Standard": Computers; office equipment; communications equipment; test and measurement equipment; audio and visual equipment; home electronic appliances; machine tools; personal electronic

"High Quality": Transportation equipment (automobiles, trains, ships, etc.); traffic control (traffic lights); large-scale communication equipment; key financial terminal systems; safety control equipment; etc.

Unless expressly designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas Electronics document, Renesas Electronics products are

not intended or authorized for use in products or systems that may pose a direct threat to human life or bodily injury (artificial life support devices or systems; surgical implantations; etc.), or may cause

serious property damage (space system; undersea repeaters; nuclear power control systems; aircraft control systems; key plant systems; military equipment; etc.). Renesas Electronics disclaims any and all

liability for any damages or losses incurred by you or any third parties arising from the use of any Renesas Electronics product that is inconsistent with any Renesas Electronics data sheet, user’s manual or

other Renesas Electronics document.

6. When using Renesas Electronics products, refer to the latest product information (data sheets, user’s manuals, application notes, “General Notes for Handling and Using Semiconductor Devices” in the

reliability handbook, etc.), and ensure that usage conditions are within the ranges specified by Renesas Electronics with respect to maximum ratings, operating power supply voltage range, heat dissipation

characteristics, installation, etc. Renesas Electronics disclaims any and all liability for any malfunctions, failure or accident arising out of the use of Renesas Electronics products outside of such specified

ranges.

7. Although Renesas Electronics endeavors to improve the quality and reliability of Renesas Electronics products, semiconductor products have specific characteristics, such as the occurrence of failure at a

certain rate and malfunctions under certain use conditions. Unless designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas

Electronics document, Renesas Electronics products are not subject to radiation resistance design. You are responsible for implementing safety measures to guard against the possibility of bodily injury, injury

or damage caused by fire, and/or danger to the public in the event of a failure or malfunction of Renesas Electronics products, such as safety design for hardware and software, including but not limited to

redundancy, fire control and malfunction prevention, appropriate treatment for aging degradation or any other appropriate measures. Because the evaluation of microcomputer software alone is very difficult

and impractical, you are responsible for evaluating the safety of the final products or systems manufactured by you.

8. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental compatibility of each Renesas Electronics product. You are responsible for carefully and

sufficiently investigating applicable laws and regulations that regulate the inclusion or use of controlled substances, including without limitation, the EU RoHS Directive, and using Renesas Electronics

products in compliance with all these applicable laws and regulations. Renesas Electronics disclaims any and all liability for damages or losses occurring as a result of your noncompliance with applicable

laws and regulations.

9. Renesas Electronics products and technologies shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited under any applicable domestic or foreign laws

or regulations. You shall comply with any applicable export control laws and regulations promulgated and administered by the governments of any countries asserting jurisdiction over the parties or

transactions.

10. It is the responsibility of the buyer or distributor of Renesas Electronics products, or any other party who distributes, disposes of, or otherwise sells or transfers the product to a third party, to notify such third

party in advance of the contents and conditions set forth in this document.

11. This document shall not be reprinted, reproduced or duplicated in any form, in whole or in part, without prior written consent of Renesas Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this document or Renesas Electronics products.

(Note 1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its directly or indirectly controlled subsidiaries.

(Note 2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

equipment; industrial robots; etc.

(Rev.4.0-1 November 2017)

SALES OFFICES

Refer to "http://www.renesas.com/" for the latest and detailed information.

Renesas Electronics Corporation

TOYOSU FORESIA, 3-2-24 Toyosu, Koto-ku, Tokyo 135-0061, Japan

Renesas Electronics America Inc.

1001 Murphy Ranch Road, Milpitas, CA 95035, U.S.A.

Tel: +1-408-432-8888, Fax: +1-408-434-5351

Renesas Electronics Canada Limited

9251 Yonge Street, Suite 8309 Richmond Hill, Ontario Canada L4C 9T3

Tel: +1-905-237-2004

Renesas Electronics Europe Limited

Dukes Meadow, Millboard Road, Bourne End, Buckinghamshire, SL8 5FH, U.K

Tel: +44-1628-651-700

Renesas Electronics Europe GmbH

Arcadiastrasse 10, 40472 Düsseldorf, Germany

Tel: +49-211-6503-0, Fax: +49-211-6503-1327

Renesas Electronics (China) Co., Ltd.

Room 1709 Quantum Plaza, No.27 ZhichunLu, Haidian District, Beijing, 100191 P. R. China

Tel: +86-10-8235-1155, Fax: +86-10-8235-7679

Renesas Electronics (Shanghai) Co., Ltd.

Unit 301, Tower A, Central Towers, 555 Langao Road, Putuo District, Shanghai, 200333 P. R. China

Tel: +86-21-2226-0888, Fax: +86-21-2226-0999

Renesas Electronics Hong Kong Limited

Unit 1601-1611, 16/F., Tower 2, Grand Century Place, 193 Prince Edward Road West, Mongkok, Kowloon, Hong Kong

Tel: +852-2265-6688, Fax: +852 2886-9022

Renesas Electronics Taiwan Co., Ltd.

13F, No. 363, Fu Shing North Road, Taipei 10543, Taiwan

Tel: +886-2-8175-9600, Fax: +886 2-8175-9670

Renesas Electronics Singapore Pte. Ltd.

80 Bendemeer Road, Unit #06-02 Hyflux Innovation Centre, Singapore 339949

Tel: +65-6213-0200, Fax: +65-6213-0300

Renesas Electronics Malaysia Sdn.Bhd.

Unit 1207, Block B, Menara Amcorp, Amcorp Trade Centre, No. 18, Jln Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia

Tel: +60-3-7955-9390, Fax: +60-3-7955-9510

Renesas Electronics India Pvt. Ltd.

No.777C, 100 Feet Road, HAL 2nd Stage, Indiranagar, Bangalore 560 038, India

Tel: +91-80-67208700, Fax: +91-80-67208777

Renesas Electronics Korea Co., Ltd.

17F, KAMCO Yangjae Tower, 262, Gangnam-daero, Gangnam-gu, Seoul, 06265 Korea

Tel: +82-2-558-3737, Fax: +82-2-558-5338

© 2019 Renesas Electronics Corporation. All rights reserved.

http://www.renesas.com

Colophon 7.2

Loading...

Loading...