Page 1

REG10J0020-0200

Renesas Starter Kit LCD Application Board

User's Manual

RENESAS STARTER KIT

Rev.2.00 Renesas Technology Europe Ltd.

Revision date:29.11.2007 www.renesas.com

Page 2

Table of Contents

Chapter 1. Preface..................................................................................................................................................3

Chapter 2. Purpose.................................................................................................................................................4

Chapter 3. Board Layout.........................................................................................................................................5

3.1. Component References ...............................................................................................................................5

3.2. Board Component functions.........................................................................................................................6

3.3. Board Dimensions........................................................................................................................................7

Chapter 4. User Circuitry.........................................................................................................................................8

4.1. Fitting the Target RSK to the RSK LCD application board...........................................................................8

4.2. LCD Module..................................................................................................................................................8

4.3. Coin Cell and switch...................................................................................................................................10

4.4. Capacitors ..................................................................................................................................................10

Chapter 5. Headers...............................................................................................................................................11

5.1. Application Headers ...................................................................................................................................11

Chapter 6. Code Development .............................................................................................................................15

Chapter 7. Additional Information..........................................................................................................................16

ii

Page 3

Chapter 1. Preface

Cautions

This document may be, wholly or partially, subject to change without notice.

All rights reserved. Duplication of this document, either in whole or part is prohibited without the written permission of Renesas

Technology Europe Limited.

Trademarks

All brand or product names used in this manual are trademarks or registered trademarks of their respective companies or

organisations.

Copyright

© Renesas Technology Europe Ltd. 2007. All rights reserved.

Website:

Glossary

CPU Central Processing Unit RTE Renesas Technology Europe Ltd.

HEW High-performance Embedded Workshop RSO Renesas Solutions Organisation.

LCD Liquid Crystal Display RSK Renesas Starter Kit

PC Program Counter E8A E8a On-chip debugger module

http://www.eu.renesas.com/

3

Page 4

Chapter 2.Purpose

This RSK Application Board is an evaluation tool for Renesas microcontrollers with an LCD driver interface. It is used in conjunction with

the RSK for the microcontroller to be evaluated.

Features include:

• Mounting connections to allow RSK to be added to top of board.

• Interface to standard RSK LCD expansion connector and RSK expansion connections.

• 8 character 14 segment “starburst” LCD.

• Coin cell holder to power mounted RSK for low power operation.

4

Page 5

Chapter 3.Board Layout

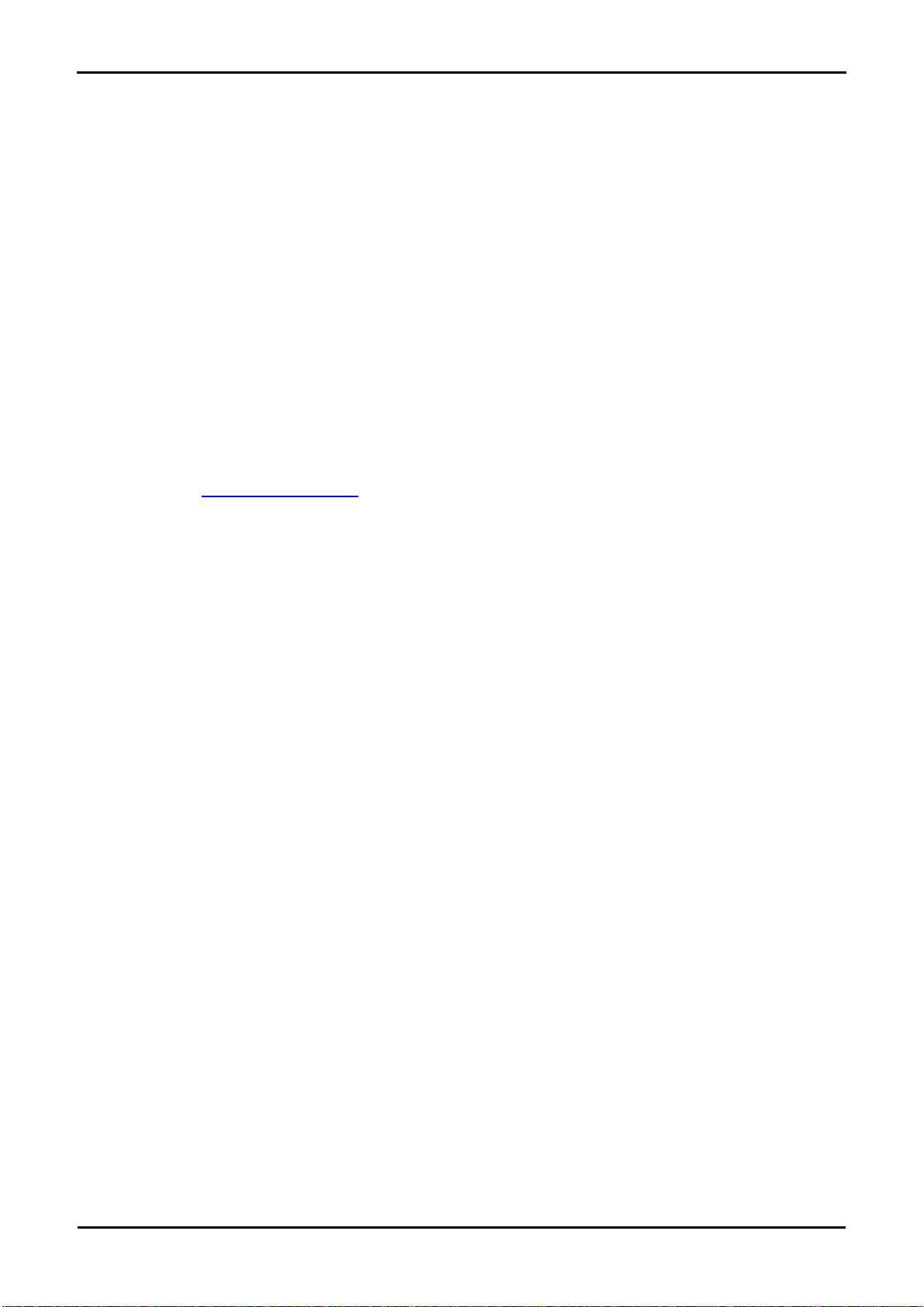

3.1.Component References

The following diagram shows the component references for the board.

Figure 3-1: Component References

5

Page 6

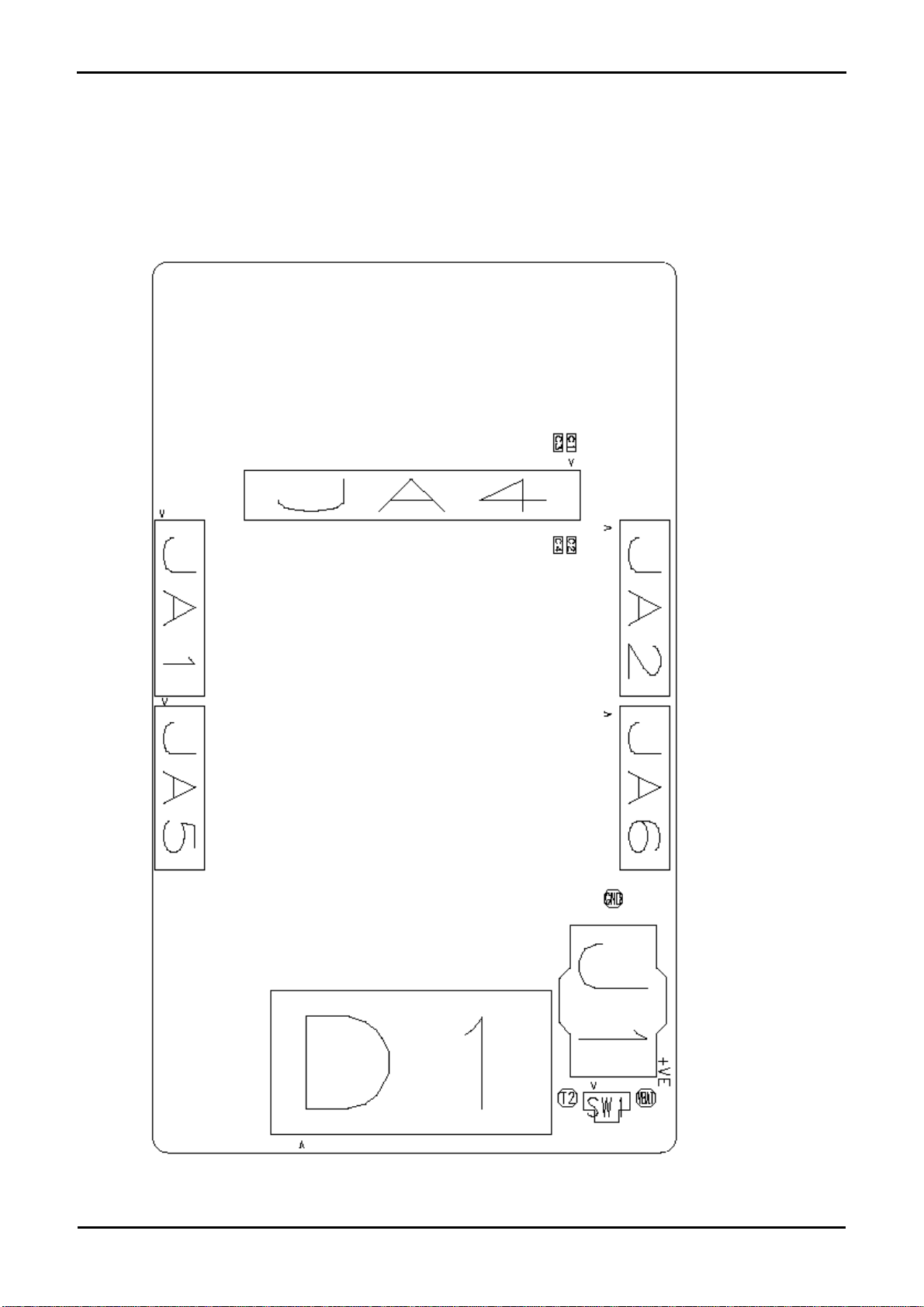

3.2.Board Component functions

The following diagram the shows the functions of the components on the board.

Application Board Interface

JA5 JA1

LCD

JA4

Switch

Coin Cell Holder

Caution: If processor is not in low power mode at start up the battery life will be significantly reduced.

JA6 JA2

Application Board Interface

Figure 3-2: Board Layout

LCD Application Interfac e

6

Page 7

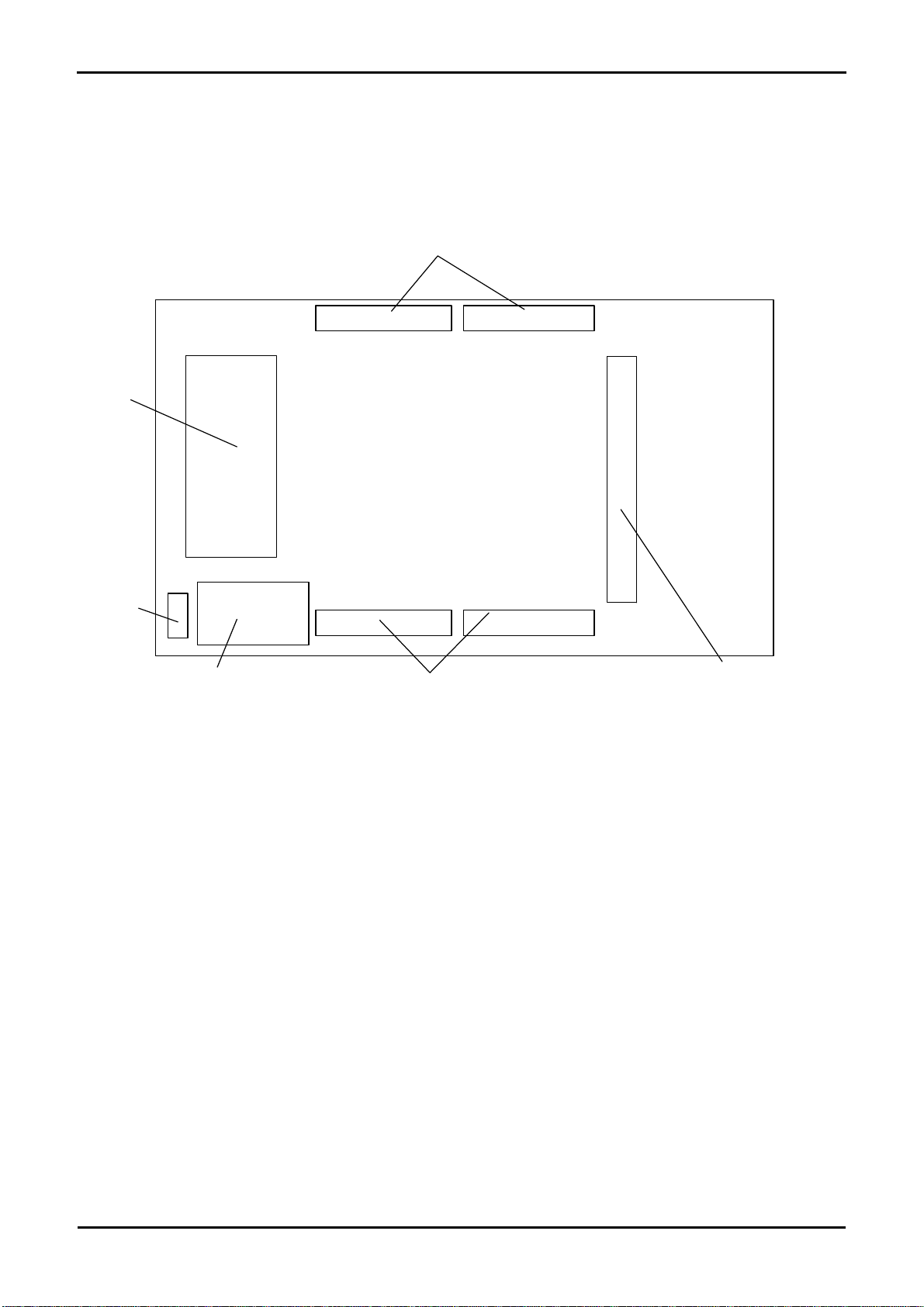

3.3.Board Dimensions

The following diagram gives the board dimensions and connector positions. All through hole connectors are on a common 0.1” grid for easy

interfacing.

170.00mm

115.00mm

86.36mm

50.80 mm

27.00mm

Corners x4

3mm

radius

ONOFF

JA2

JA6

Coin Cell

Holder

LCD

LCD connector

80.01mm

45.00mm

JA4

JA1

JA5

3.81mm

85.00mm

14.00mm

5.00mm

100.00mm

Figure 3-3 : Board Dimensions

7

Page 8

Chapter 4.User Circuitry

4.1.Fitting the Target RSK to the RSK LCD application board

The board is supplied with 2x 24 way sockets, 2x 26 way sockets and 1 x 50 way socket.

These should be soldered on the underside of the host RSK in JA1, JA2, JA5, JA6 and JA4 positions.

The RSK should be plugged into the equivalent connectors on the RSK LCD application board.

4.2.LCD Module

The LCD module on the board is connected to the RSK LCD connector JA4.

It uses ¼ duty cycle and has 4 common lines. There are 8x14 segment starburst characters. Refer to

Each character uses 4 SEG lines. Each SEG line controls 4 segments on the LCD as it uses ¼ duty cycle.

The LCD controller must be programmed for ¼ duty cycle.

In the case of the H838347, a RAM in the LCD controller has 1 bit per segment. Thus each character is a 16 bit number.

The following

The lowest address (H’F740 in the case of the H838347) represents the rightmost character of the display.

The next word address (H’F742 in the case of the H838347) represents the next character, etc.

Table 4-1: LCD character maps gives the bit mappings for common characters for this controller.

Figure 4-1: LCD Segment Names.

X

A

HI

F

B

G

N

E

M

D

Figure 4-1: LCD Segment Names

8

J

K

L

C

DP

Page 9

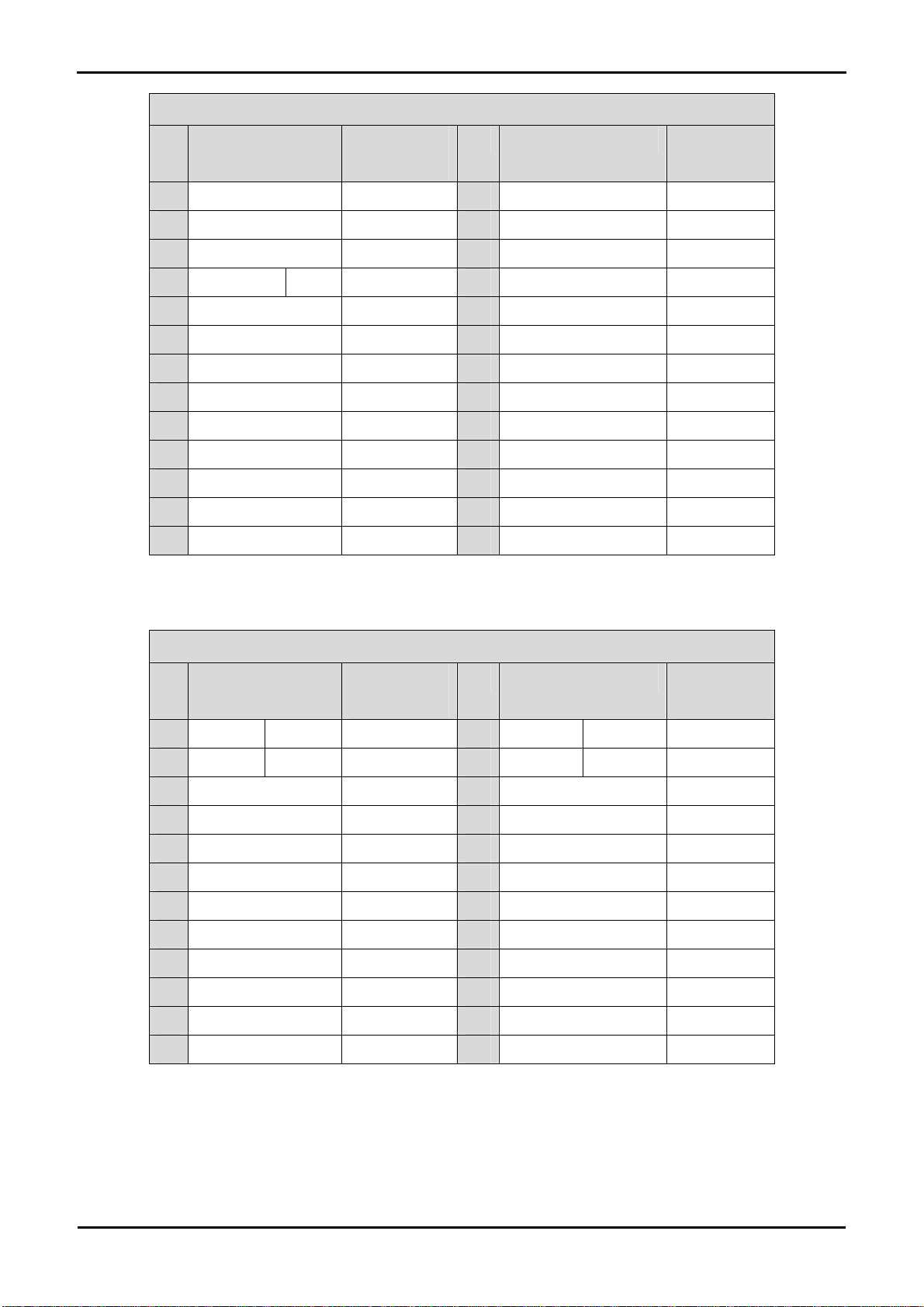

g

A

A

A

A

A

Se

ment L K J I DP C B

DEFXMNGH

Bit number 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 Hex value for RAM

0 1 0 0 0 1 1 1 0 1 1 0 0 0 1 0 4762

B 1 0 1 0 0 0 0 1 1 1 1 0 0 0 1 0

1E2

C 0 0 0 0 0 0 0 1 1 1 1 0 0 0 0 0 01E0

D 0 0 0 0 0 0 0 0 0 1 1 0 0 1 0 1 0065

E 0 1 0 0 0 0 0 1 1 1 1 0 0 0 1 0 41E2

F 0 1 0 0 0 0 0 1 0 1 1 0 0 0 1 0 4162

G 1 0 0 0 0 0 0 1 1 1 1 0 0 0 0 0 81E0

H 0 1 0 0 0 1 1 0 0 1 1 0 0 0 1 0 4662

I 0 0 0 1 0 0 0 1 1 0 0 0 1 0 0 0 1188

J 0 0 0 0 0 1 1 0 1 0 0 0 0 0 0 0 0680

K 1 0 1 0 0 0 0 0 0 1 1 0 0 0 1 0

062

L 0 0 0 0 0 0 0 0 1 1 1 0 0 0 0 0 00E0

M 0 0 1 0 0 1 1 0 0 1 1 0 0 0 0 1 2661

N 1 0 0 0 0 1 1 0 0 1 1 0 0 0 0 1 8661

O 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 07E0

P 0 1 0 0 0 0 1 1 0 1 1 0 0 0 1 0 4362

Q 1 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 87E0

R 1 1 0 0 0 0 1 1 0 1 1 0 0 0 1 0 C362

T 0 0 0 1 0 0 0 1 0 0 0 0 1 0 0 0 1108

S 0 1 0 0 0 1 0 1 1 0 1 0 0 0 1 0 45A2

U 0 0 0 0 0 1 1 0 1 1 1 0 0 0 0 0 06E0

V 1 0 0 0 0 1 1 0 0 0 0 0 0 0 0 1 8601

W 1 0 0 0 0 1 1 0 0 1 1 0 0 1 0 0 8664

X 1 0 1 0 0 0 0 0 0 0 0 0 0 1 0 1

005

Y 0 0 1 0 0 0 0 0 0 0 0 0 1 0 0 1 2009

Z 0 0 1 0 0 0 0 1 1 0 0 0 0 1 0 0 2184

0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 07E0

1 0 0 0 1 0 0 0 0 0 0 0 0 1 0 0 0 1008

2 0 1 0 0 0 0 1 1 1 1 0 0 0 0 1 0 43C2

3 0 1 0 0 0 1 1 1 1 0 0 0 0 0 1 0 4782

4 0 1 0 0 0 1 1 0 0 0 1 0 0 0 1 0 4622

5 0 1 0 0 0 1 0 1 1 0 1 0 0 0 1 0 45A2

6 0 1 0 0 0 1 0 1 1 1 1 0 0 0 1 0 45E2

7 0 0 0 0 0 1 1 1 0 0 0 0 0 0 0 0 0700

8 0 1 0 0 0 1 1 1 1 1 1 0 0 0 1 0 47E2

9 0 1 0 0 0 1 1 1 1 0 1 0 0 0 1 0 47A2

? 0 1 0 0 0 0 1 1 0 0 1 0 1 0 0 0 4328

Table 4-1: LCD character maps

9

Page 10

4.3.Coin Cell and switch.

The board includes a coin cell holder to hold a 2032 3.6V coin cell. To power the attached RSK from this cell the switch must be in the

“ON” position.

IT IS IMPORTANT NOT TO POWER THE ATTACHED RSK VIA THE POWER SUPPLY JACK OR VIA THE

E8A IF THIS OPTION IS USED.

Caution: If processor is not in low power mode at start up the battery life will be significantly reduced.

4.4.Capacitors

Pads are supplied to allow 0603 capacitors to be placed on the LCD drive voltages V1 – V4.

10

Page 11

Chapter 5.Headers

5.1.Application Headers

This information is supplied for reference. Only JA1 pin 3 (battery supply voltage to RSK) and the ground pins are connected on this board.

Table 5-1 and belowTable 5-2 show the standard application header connections.

JA1

Pin Generic Header Name CPU board

Signal Name

1 Regulated Supply 1 5V 2 Regulated Supply 1 GROUND

3 Regulated Supply 2 3V3 4 Regulated Supply 2 GROUND

5 Analogue Supply AVcc 6 Analogue Supply AVss

7 Analogue Reference AVref 8 ADTRG ADTRG

ADC0 I0

9

ADC2 I2

11

DAC0

13

IOPort

15

IOPort

17

IOPort

19

IOPort

21

23 Open drain IRQAEC IRQ3 24 I²C Bus - (3rd pin) IIC_EX

I²C Bus

25

AD0 10 ADC1 I1 AD1

AD2 12 ADC3 I3 AD3

DAC0 14 DAC1 DAC1

IO_0 16 IOPort IO_1

IO_2 18 IOPort IO_3

IO_4 20 IOPort IO_5

IO_6 22 IOPort IO_7

IIC_SDA 26 I²C Bus IIC_SCL

Table 5-1: JA1 Standard Generic Header

Pin Header Name CPU board

Signal Name

11

Page 12

JA2

Pin Generic Header Name CPU board

Signal Name

Pin Header Name CPU board

Signal Name

1 Open drain RESn 2 External Clock Input EXTAL

3 Open drain NMIn 4 Regulated Supply 1 Vss1

5 Open drain output WDT_OVF 6 Serial Port SCIaTX

7 Open drain WUP IRQ0 8 Serial Port SCIaRX

9 Open drain IRQ1 10 Serial Port SCIaCK

11 Up/down MO_UD 12 Serial Port Handshake CTS/RTS

13 Motor control MO_Up 14 Motor control MO_Un

15 Motor control MO_Vp 16 Motor control MO_Vn

17 Motor control MO_Wp 18 Motor control MO_Wn

19 Output TMR0 20 Output TMR1

21 Input TRIGa 22 Input TRIGb

23 Open drain IRQ2 24 Tristate Control TRSTn

25 SPARE - 26 SPARE -

Table 5-2: JA2 Standard Generic Header

Table 5-3 and Table 5-4 below show the optional generic header connections

JA5

Pin Generic Header Name CPU board

Signal Name

Pin Header Name CPU board

Signal Name

1 ADC4 I4 AD4 2 ADC5 I5 AD5

3 ADC6 I6 AD6 4 ADC7 I7 AD7

5 CAN CAN1TX 6 CAN CAN1RX

7 CAN CAN2TX 8 CAN CAN2RX

9 Reserved 10 Reserved

11 Reserved 12 Reserved

13 Reserved 14 Reserved

15 Reserved 16 Reserved

17 Reserved 18 Reserved

19 Reserved 20 Reserved

21 Reserved 22 Reserved

23 Reserved 24 Reserved

Table 5-3: JA5 Optional Generic Header

12

Page 13

JA6

Pin Generic Header Name CPU board

Signal

Pin Header Name CPU board

Signal Name

Name

1 DMA DREQ 2 DMA DACK

3 DMA TEND 4 Standby (Open drain) STBYn

5 Host Serial SCIdTX RS232TX 6 Host Serial SCIdRX RS232RX

7 Serial Port SCIbRX 8 Serial Port SCIbTX

9 Serial Port Synchronous SCIcTX 10 Serial Port SCIbCK

11 Serial Port Synchronous SCIcCK 12 Serial Port Synchronous SCIcRX

13 Reserved 14 Reserved

15 Reserved 16 Reserved

17 Reserved 18 Reserved

19 Reserved 20 Reserved

21 Reserved 22 Reserved

23 Reserved 24 Reserved

Table 5-4: JA6 Optional Generic Header

13

Page 14

Table 5-5 below shows the LCD header connections

JA4

Pin Generic Header Name Signal Name Pin Header Name Signal Name

1 V0 V0 2 V1 V1

3 V2 V2 4 V3 V3

5 GROUND GROUND 6 GROUND GROUND

7 COM1 COM1 8 COM2 COM2

9 COM3 COM3 10 COM4 COM4

11 SEG1 SEG1 12 SEG2 SEG2

13 SEG3 SEG3 14 SEG4 SEG4

15 SEG5 SEG5 16 SEG6 SEG6

17 SEG7 SEG7 18 SEG8 SEG8

19 SEG9 SEG9 20 SEG10 SEG10

21 SEG11 SEG11 22 SEG12 SEG12

23 SEG13 SEG13 24 SEG14 SEG14

25 SEG15 SEG15 26 SEG16 SEG16

27 SEG17 SEG17 28 SEG18 SEG18

29 SEG19 SEG19 30 SEG20 SEG20

31 SEG21 SEG21 32 SEG22 SEG22

33 SEG23 SEG23 34 SEG24 SEG24

35 SEG25 SEG25 36 SEG26 SEG26

37 SEG27 SEG27 38 SEG28 SEG28

39 SEG29 SEG29 40 SEG30 SEG30

41 SEG31 SEG31 42 SEG32 SEG32

43 SEG33 SEG33 44 SEG34 SEG34

45 SEG35 SEG35 46 SEG36 SEG36

47 SEG37 SEG37 48 SEG38 SEG38

49 SEG39 SEG39 50 SEG40 SEG40

Table 5-5: JA4 LCD Expansion connector

14

Page 15

Chapter 6.Code Development

RSKs with appropriate LCD connections will include suitable sample software to drive the LCD on this board. Section 4.2 includes details

of bit mapping for the LCD segments.

15

Page 16

Chapter 7.Additional Information

For details on how to use High-performance Embedded Workshop (HEW), refer to the HEW manual available on the CD or from the web

site.

Online technical support and information is available at:

Technical Contact Details

America: techsupport.rta@renesas.com

Europe:

Japan:

General information on Renesas Microcontrollers can be found on the Renesas website at:

tools.support.eu@renesas.com

csc@renesas.com

http://www.renesas.com/renesas_starter_kits

http://www.renesas.com/

16

Page 17

Renesas Starter Kit LCD Application Board

User's Manual

Publication Date Rev.2.00 29.11.2007

Published by:

Renesas Technology Europe Ltd.

Duke’s Meadow, Millboard Road, Bourne End

Buckinghamshire SL8 5FH, United Kingdom

©2007 Renesas T e chnology Europe and Renesas Solutions Corp., All Rights Reserved.

Page 18

Renesas Starter LCD Application Board

User's Manual

Renesas Technology Europe Ltd.

Duke’s Meadow, Millboard Road, Bourne End

Buckinghamshire SL8 5FH, United Kingdom

Loading...

Loading...