Page 1

16

Rev.1.02 2021.4

R

32

RE01 Group

)

ual

User's Manual

Evaluation Kit RE01 256KB (EK-RE01 256KB

User’s Man

E Family/RE0 Series

All information contained in these materials, including products and product specifications,

represents information on the product at the time of publication and is subject to change by

Renesas Electronics Corporation without notice. Please review the latest information published by

Renesas Electronics Corporation through various means, including the Renesas Electronics

Corporation website (http://www.renesas.com).

Page 2

Notice

Corporate Headquarters

Contact information

Trademarks

1. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of semiconductor products

and application examples. You are fully responsible for the incorporation or any other use of the circuits, software, and information in the design of your

product or system. Renesas Electronics disclaims any and all liability for any losses and damages incurred by you or third parties arising from the use of

these circuits, software, or information.

2. Renesas Electronics hereby expressly disclaims any warranties against and liability for infringement or any other claims involving patents, copyrights, or

other intellectual property rights of third parties, by or arising from the use of Renesas Electronics products or technical information described in this

document, including but not limited to, the product data, drawings, charts, programs, algorithms, and application examples.

3. No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights of Renesas Electronics or

others.

4. You shall be responsible for determining what licenses are required from any third parties, and obtaining such licenses for the lawful import, export,

manufacture, sales, utilization, distribution or other disposal of any products incorporating Renesas Electronics products, if required.

5. You shall not alter, modify, copy, or reverse engineer any Renesas Electronics product, whether in whole or in part. Renesas Electronics disclaims any

and all liability for any losses or dam ages incurred by you or third parties arising from such alteration, modification, copying or reverse engineering.

6. Renesas Electronics products are classified according to the following two quality grades: “Standard” and “High Quality”. The intended applications for

each Renesas Electronics product depends on the product’s quality grade, as indicated below.

"Standard": Computers; office equipment; communications equipment; test and measurement equipment; audio and visual equipment; home

"High Quality": Transportation equipment (automobiles, trains, ships, etc.); traffic control (traffic lights); large-scale communication equipment; key

Unless expressly designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas

Electronics document, Renesas Electronics products are not intended or authorized for use in products or systems that may pose a direct threat to

human life or bodily injury (artificial life support devices or systems; surgical implantations; etc.), or may cause serious property damage (space system;

undersea repeaters; nuclear power control systems; aircraft control systems; key plant systems; military equipment; etc.). Renesas Electronics disclaims

any and all liability for any damages or losses incurred by you or any third parties arising from the use of any Renesas Electronics product that is

inconsistent with any Renesas Electronics data sheet, user’s manual or other Renesas Electronics document.

7. No semiconductor product is absolutely secure. Notwithstanding any security measures or features that may be implemented in Renesas Electronics

hardware or software products, Renesas Electronics shall have absolutely no liability arising out of any vulnerability or security breach, including but not

limited to any unauthorized access to or use of a Renesas Electronics product or a system that uses a Renesas Electronics product. RENESAS

ELECTRONICS DOES NOT WARRANT OR GUARANTEE THAT RENESAS ELECTRONICS PRODUCTS, OR ANY SYSTEMS CREATED USING

RENESAS ELECTRONICS PRODUCTS WILL BE INVULNERABLE OR FREE FROM CORRUPTION, ATTACK, VIRUSES, INTERFERENCE,

HACKING, DATA LOSS OR THEFT, OR OTHER SECURITY INTRUSION (“Vulnerability Issues”). RENESAS ELECTRONICS DISCLAIMS ANY AND

ALL RESPONSIBILITY OR LIABILITY ARISING FROM OR RELATED TO ANY VULNERABILITY ISSUES. FURTHERMORE, TO THE EXTENT

PERMITTED BY APPLICABLE LAW, RENESAS ELECTRONICS DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OR IMPLIED, WITH

RESPECT TO THIS DOCUMENT AND ANY RELATED OR ACCOMPANYING SOFTWARE OR HARDWARE, INCLUDING BUT NOT LIMITED TO THE

IMPLIED WARRANTIES OF MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE.

8. When using Renesas Electronics products, refer to the latest product information (data sheets, user’s manuals, application notes, “General Notes for

Handling and Using Semiconductor Devices” in the reliability handbook, etc.), and ensure that usage conditions are within the ranges specified by

Renesas Electronics with respect to maximum ratings, operating power supply voltage range, heat dissipation characteristics, installation, etc. Renesas

Electronics disclaims any and all liability for any malfunctions, failure or accident arising out of the use of Renesas Electronics products outside of such

specified ranges.

9. Although Renesas Electronics endeavors to improve the quality and reliability of Renesas Electronics products, semiconductor products have specific

characteristics, such as the occurrence of failure at a certain rate and malfunctions under certain use conditions. Unless designated as a high reliability

product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas Electronics document, Renesas Electronics products

are not subject to radiation resistance design. You are responsible for implementing safety measures to guard against the possibility of bodily injury,

injury or damage caused by fire, and/or danger to the public in the event of a failure or malfunction of Renesas Electronics products, such as safety

design for hardware and software, including but not limited to redundancy, fire control and malfunction prevention, appropriate treatment for aging

degradation or any other appropriate measures. Because the evaluation of microcomputer software alone is very difficult and impractical, you are

responsible for evaluating the safety of the final products or systems manufactured by you.

10. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental compatibility of each Renesas

Electronics product. You are responsible for carefully and sufficiently investigating applicable laws and regulations that regulate the inclusion or use of

controlled substances, including without limitation, the EU RoHS Directive, and using Renesas Electronics products in compliance with all these

applicable laws and regulations. Renesas Electronics disclaims any and all liability for damages or losses occurring as a result of your noncompliance

with applicable law s and regulations.

11. Renesas Electronics products and technologies shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is

prohibited under any applicable domestic or foreign laws or regulations. You shall comply with any applicable export control laws and regulations

promulgated and administered by the governments of any countries asserting jurisdiction over the parties or transactions.

12. It is the responsibility of the buyer or distributor of Renesas Electronics products, or any other party who distributes, disposes of, or otherwise sells or

transfers the product to a third party, to notify such third party in advance of the contents and conditions set forth in this document.

13. This document shall not be reprinted, reproduced or duplicated in any form, i n whole or in part, without prior written consent of Renesas Electronics.

14. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this document or Renesas

Electronics products.

(Note1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its directly or indirectly controlled subsidiaries.

(Note2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

electronic appliances; machine tools; personal electronic equipment; industrial robots; etc.

financial terminal systems; safety control equipment; etc.

(Rev.5.0-1 October 2020)

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

www.renesas.com

Renesas and the Renesas logo are trademarks of Renesas

Electronics Corporation. All trademarks and registered trademarks

are the property of their respective owners.

For further information on a product, technology, the most up-to-date

version of a document, or your nearest sales office, please visit:

www.renesas.com/contact/.

Page 3

General Precautions in the Handling of Microprocessing Unit and Microcontroller

Unit Products

The following usage notes are applicable to all Microprocessing unit and Microcontroller unit products from Renesas. For detailed usage notes on the

products covered by this document, refer to the relevant sections of the document as well as any technical updates that have been issued for the products.

1. Precaution against Electrostatic Discharge (ESD)

A strong electrical field, when exposed to a CMOS device, can cause destruction of the gate oxide and ultimately degrade the device operation. Steps

must be taken to stop the generation of static electricity as much as possible, and quickly dissipate it when it occurs. Environmental control must be

adequate. When it is dry, a humidifier should be used. This is recommended to avoid using insulators that can easily build up static electricity.

Semiconductor devi ces must be stored and transported in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work benches and floors must be grounded. The operator must also be grounded using a wrist strap. Semiconductor devices must not be

touched with bare hands. Similar precautions must be taken for printed circuit boards with mounted semiconductor devices.

2. Processing at power-on

The state of the product is undefined at the time when power is supplied. The states of internal circuits in the LSI are indeterminate and the states of

register settings and pins are undefined at the time when power is supplied. In a finished product where the reset signal is applied to the external reset

pin, the states of pins are not guaranteed from the time when power is supplied until the reset process is completed. In a similar way, the states of pins in

a product that is reset by an on-chip power-on reset function are not guaranteed from the time when power is supplied until the power reaches the level

at which resetting is specified.

3. Input of signal during power-off state

Do not input signals or an I/O pull-up power supply while the device is powered off. The current injection that results from input of such a signal or I/O

pull-up power supply may cause malfunction and the abnormal current that passes in the device at this time may cause degradation of internal elements.

Follow the guideline for input signal during power-off state as described in your product documentation.

4. Handling of unused pins

Handle unused pins in accordance with the directions given under handling of unused pins in the manual. The input pins of CMOS products are

generally in the high-impedance state. In operation with an unused pin in the open-circuit state, extra electromagnetic noise is induced in the vicinity of

the LSI, an associated shoot-through current flows internally, and malfunctions occur due to the false recognition of the pin state as an input signal

become possible.

5. Clock signals

After applying a reset, only release the reset line after the operating clock signal becomes stable. When switchi ng the clock signal during program

execution, wait until the target clock signal is stabilized. When the clock signal is generated with an external resonator or from an external oscillator

during a reset, ensure that the reset line is only released after full stabilization of the clock signal. Additionally, when switching to a clock signal produced

with an external resonator or by an external oscillator while program execution is in progress, wait until the target clock signal is stable.

6. Voltage application waveform at input pin

Waveform distortion due to input noise or a reflected wave may cause malfunction. If the input of the CMOS device stays in the area between V

and V

(Min.) due to noise, for example, the device may malfunction. Take care to prevent chattering noise from entering the device when the input level

IH

is fixed, and also in the transition period when the input level passes through the area between V

7. Prohibition of access to reserved addresses

Access to reserved addresses is prohibited. The reserved addresses are provided for possible future expansion of functions. Do not access these

addresses as the correct operation of the LSI is not guaranteed.

8. Differences between products

Before changing from one product to another, for example to a product with a different part number, confirm that the change will not lead to problems.

The characteristics of a microprocessing unit or microcontroller unit products in the same group but having a different part number might differ in terms of

internal memory capacity, layout pattern, and other factors, which can affect the ranges of electrical characteristics, such as characteristic values,

operating margins, immunity to noise, and amount of radiated noise. When changing to a product with a different part number, implement a system-

evaluation test for the given product.

(Max.) and VIH (Min.).

IL

(Max.)

IL

Page 4

Disclaimer

The Evaluation Kit is not guaranteed to be error free, and the entire risk as to the results and performance of the

By using this Evaluation Kit, the user accepts the following terms:

Evaluation Kit is assumed by the User. The Evaluation Kit is provided by Renesas on an “as is” basis without

warranty of any kind whether express or implied, including but not limited to the implied warranties of satisfactory

quality, fitness for a particular purpose, title and non-infringement of intellectual property rights with regard to the

Evaluation Kit. Renesas expressly disclaims all such warranties. Renesas or its affiliates shall in no event be liable

for any loss of profit, loss of data, loss of contract, loss of business, damage to reputation or goodwill, any economic

loss, any reprogramming or recall costs (whether the foregoing losses are direct or indirect) nor shall Renesas or its

affiliates be liable for any other direct or indirect special, incidental or consequential damages arising out of or in

relation to the use of this Evaluation Kit, even if Renesas or its affiliates have been advised of the possibility of such

damages.

Precautions

The following precautions should be observed when operating any Evaluation Kit product:

This Evaluation Kit is only intended for use in a laboratory environment under ambient temperature and humidity

conditions. A safe separation distance should be used between this and any sensitive equipment. Its use outside the

laboratory, classroom, study area or similar such area invalidates conformity with the protection requirements of the

Electromagnetic Compatibility Directive and could lead to prosecution.

The product generates, uses, and can radiate radio frequency energy and may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment causes harmful interference to radio or television reception, which can be determined by turning the

equipment off or on, you are encouraged to try to correct the interference by one or more of the following measures;

• ensure attached cables do not lie across the equipment

• reorient the receiving antenna

• increase the distance between the equipment and the receiver

• connect the equipment into an outlet on a circuit different from that which the receiver is connected

• power down the equipment when not in use

• consult the dealer or an experienced radio/TV technician for help NOTE: It is recommended that wherever

possible shielded interface cables are used.

The product is potentially susceptible to certain EMC phenomena. To mitigate against them it is recommended that

the following measures be undertaken;

• The user is advised that mobile phones should not be used within 10m of the product when in use.

• The user is advised to take ESD precautions when handling the equipment.

The Evaluation Kit does not represent an ideal reference design for an end product and does not fulfil the regulatory

standards for an end product.

Page 5

How to Use This Manual

Document Type

Description

Document Title

Document No.

f the

Evaluation Kit hardware.

User’s Manual

(This manual)

p

and run the first sample.

schematics of the

Evaluation Kit Main Board.

main board schematics

il circuit schematics of the

MIP-LCD Expansion Board.

schematics

User’s Manual: Hardware RE01

1.Objective and Target Users

This manual is designed to provide the user with an understanding of the Evaluation Kit Evaluation Board

hardware functionality, and electrical characteristics. It is intended for users designing sample code on the

Evaluation Kit Evaluation Board platform, using the many different incorporated peripheral devices.

The manual comprises of an overview of the capabilities of the Evaluation Kit product, but does not intend to

be a guide to embedded programming or hardware design.

Particular attention should be paid to the precautionary notes when using the manual. These notes occur within the body

of the text, at the end of each section, and in the Usage Notes section.

The revision history summarizes the locations of revisions and additions. It does not list all revisions. Refer to the text of

the manual for details.

The following documents apply to Evaluation Kit for RE01 256KB. Make sure to refer to the latest versions of

these documents. The newest versions of the documents listed may be obtained from the Renesas

Electronics Web site.

User’s Manual Describes the technical details o

Quick Start Guide Provides simple instructions setu

the Evaluation Kit for RE01 256KB

Schematics Full detail circuit

Schematics Full deta

Hardware Manual Provides technical details of the

RE01 device.

Evaluation Kit RE01 256KB

Evaluation Kit RE01 256KB

Quick Start Guide

Evaluation Kit RE01 256KB

MIP-LCD expansion board

RE01 Group Products with

256-Kbyte Flash Memory

R20UT4801EJ

R20UT4808EJ

R20UT4802EJ

R20UT4564EJ

R01UH0894JJ

Page 6

List of Abbreviations and Acronyms

Abbreviation

Full Form

BLE

Bluetooth Low Energy

DNF

Do Not Fit

E2

Renesas On-chip Debugging Emulator

EH

Energy Harvesting

EHC

Energy Harvesting Control Circuit

EMC

Electromagnetic Compatibility

ESD

Electrostatic Discharge

IRQ

Interrupt Request

LDO

Low Dropout

LED

Light Emitting Diode

MIP-LCD

Memory In Pixel - Liquid Crystal Display

MLCD

Memory In Pixel - Liquid Crystal Display

PC

Personal Computer

RAM

Random Access Memory

RFP

Renesas Flash Programmer

SCI

Serial Communications Interface

SPI

Serial Peripheral Interface

USB

Universal Serial Bus

All trademarks and registered trademarks are the property of their respective owners.

2.

FPC Flexible Printed Circuits

I-jetTM IAR System® JTAG Emulator

J-LinkTM SEGGER debug probe

J-LinkTM OB SEGGER On-board debug probe

n/c (NC) Not Connected

Pmod™

This is a Digilent Pmod™ Compatible connector. Pmod™ is registered to Digilent Inc.

Digilent-Pmod_Interface_Specification

Page 7

Table of Contents

1. Overview ........................................................................................................................................................... 9

1.1 Purpose ...................................................................................................................................................... 9

1.2 Kit Contents ............................................................................................................................................... 9

1.3 Board Specifications ................................................................................................................................ 10

1.4 Board Exterior .......................................................................................................................................... 12

2. Board Layout .................................................................................................................................................. 14

2.1 Component Layout ................................................................................................................................... 14

2.2 Board Dimensions .................................................................................................................................... 15

2.3 Component Placement ............................................................................................................................ 17

2.4 Board Initial Settings ................................................................................................................................ 20

3. Internal Board Connections ............................................................................................................................ 21

4. Power Supply .................................................................................................................................................. 24

4.1 Power Supply System .............................................................................................................................. 24

4.2 Power Supply Source .............................................................................................................................. 25

4.3 External Power Supply ............................................................................................................................. 26

5. Operation/Start-up Mode ................................................................................................................................ 32

5.1 Normal Operation ..................................................................................................................................... 32

5.2 EHC Operation ......................................................................................................................................... 33

5.3 RE01 Start-up Mode ................................................................................................................................ 42

6. Debug ............................................................................................................................................................. 43

6.1 J-LinkTM OB .............................................................................................................................................. 43

6.2 I-jetTM, J-LinkTM ......................................................................................................................................... 46

6.3 E2 ............................................................................................................................................................. 49

6.4 Flash Programmer -Renesas Flash Programmer- .................................................................................. 52

6.5 Flash Programmer -SEGGER J-Flash Lite- ............................................................................................. 57

6.6 Emulator connection in EHC mode .......................................................................................................... 58

7. Current Measurement Circuit ......................................................................................................................... 60

7.1 Current measurement when using the on-board regulator 3.3V ............................................................. 60

7.2 Current measurement when not using on-board regulator 3.3V ............................................................. 62

7.3 Current measurement during EHC operation .......................................................................................... 63

8. User Circuitry .................................................................................................................................................. 66

8.1 Reset Circuit ............................................................................................................................................ 66

8.2 Clock Circuit ............................................................................................................................................. 67

8.3 Switches ................................................................................................................................................... 68

8.4 LED .......................................................................................................................................................... 69

8.5 Pmod™ Interface ..................................................................................................................................... 70

8.6 USB Serial Conversion ............................................................................................................................ 75

8.7 MLCD (Memory In Pixel Liquid Crystal Display) Interface ....................................................................... 77

8.8 Flash Memory .......................................................................................................................................... 78

8.9 Arduino UNO Interface ............................................................................................................................. 79

8.10 External DC/DC Circuit ............................................................................................................................ 82

9. Headers .......................................................................................................................................................... 84

9.1 RE01 Headers ......................................................................................................................................... 84

10. Code Development ....................................................................................................................................... 88

10.1 Overview .................................................................................................................................................. 88

10.2 Mode Support .......................................................................................................................................... 88

10.3 Address Space ......................................................................................................................................... 88

Page 8

11. Additional Information ................................................................................................................................... 89

Page 9

No

Kit Contents

1

Main board

Part No.: RTK70E0118C00001BJ

2

MIP-LCD Expansion board

Part No.: RTK70E015DB00000BJ

3

Solar panel

Part No.: AM-1815CA (Panasonic)

4

USB cable

Type-A male to micro-B male

5

IC clip

Red, Black

Evaluation Kit RE01 256KB R20UT4801EJ0102

Rev.1.02

Apr 16, 2021

1. Overview

1.1 Purpose

This Evaluation Kit is an evaluation tool for Renesas RE01 device. This manual describes the technical

details of the Evaluation Kit hardware.

1.2 Kit Contents

Kit contents included in the Evaluation Kit are shown in Table 1-1.

Table 1-1: Kit Contents

R20UT4801EJ0102 Rev.1.02 Page 9 of 95

Apr 16, 2021

Page 10

Evaluation Kit RE01 256KB 1.Overview

Item

Specifications

Part No.: R7F0E01182CFP

Package: 100-pin LFQFP

On-chip memory: ROM 256KB, RAM 128KB

On-Board Memory

SPI Serial Flash: 64Mbit

RE01 Main: 32MHz

RE01 Sub: 32.768kHz

Debugger: 5V Input

Power Supply IC: 5V Input, 3.3V Output

Power Supply IC: 2.6V Input, 3.3V Output (For peripheral circuit power supply when

using energy harvesting function)

Power Supply IC: 2.6V or 3.3V Input, 1.25V Output (external DC/DC)

Power Supply IC: 2.6V or 3.3V Input, 0.85V Output (external DC/DC)

I-jetTM / J-Link

TM

/ E2 20-pin box header

USB Connector for J-LinkTM OB

Operation Mode Configuration: double-pole, double-throw x 4

Start-up Mode Configuration: single-pole, double-throw x 2

Internal LDO Configuration: double-pole, single-throw x 2

Reset Switch x 1

User Switch x 2

Discharge Switch x 2

Power Indicator: (Green) x 1

For users: (Orange) x 1, (Red) x 1

J-LinkTM OB Power Indicator: (Green) x 1

FPC Connector: 0.3mm pitch,19 pin x 1

MIP-LCD*5: TN0104ANVAANN-GN00(KYOCERA)

Connector: USB-MicroB

Driver: USB Interface IC (Part No. FT230XQ)

MIP-LCD Expansion Board

Interface

Pmod™

PMOD1 *2: Angle type、12-pin connector

External Battery Interface

3.5mm pitch: 2 pin x 1*3

Solar Panel Interface

2.54mm pitch: 2 pin x 1

Arduino UNO Interface

2.54mm pitch: 10 pin x 1 (J6),8 pin x 2 (J10, J18),6 pin x 1 (J19)

RE01 Header*4

2.54mm pitch: 50 pin x 2 (J7, J8, J9, J21)

1.3 Board Specifications

Board specifications are shown in Table 1-2

Table 1-2: Board Specifications

Target Device

Input Clock

Power Supply

、Table 1-3.

Debug Interface*

Slide Switch

Push Switch

1

LED

MLCD

USB Serial Converter Interface

*2

*1

: Use each debugger exclusively. When using J-Link OB, do not connect to other emulators. When using

2.54mm pitch: 12 pin x 1(PMOD1)

another emulator, do not connect to J-Link OB.

*2

: PMOD1 is used both for MIP-LCD Expansion Board and PmodTM.

*3

: The external battery is not included in this product.

*4

: The connector is not included in this product.

*5

: The MIP-LCD is not included in this product.

R20UT4801EJ0102 Rev.1.02 Page 10 of 95

Apr 16, 2021

Page 11

Evaluation Kit RE01 256KB 1.Overview

Item

Specification

Part No.: TN0181ANVNANN-AN00*1 (KYOCERA)

Size: 1.81 inch

Resolution: 200dpi (256(H) x 256(V))

Main Board Interface

2.54mm pitch: 12 pin x 1(PMOD1)

Table 1-3: MIP-LCD Expansion Board Specification

MIP-LCD

*1

: Please contact KYOCERA.

R20UT4801EJ0102 Rev.1.02 Page 11 of 95

Apr 16, 2021

Page 12

Evaluation Kit RE01 256KB 1.Overview

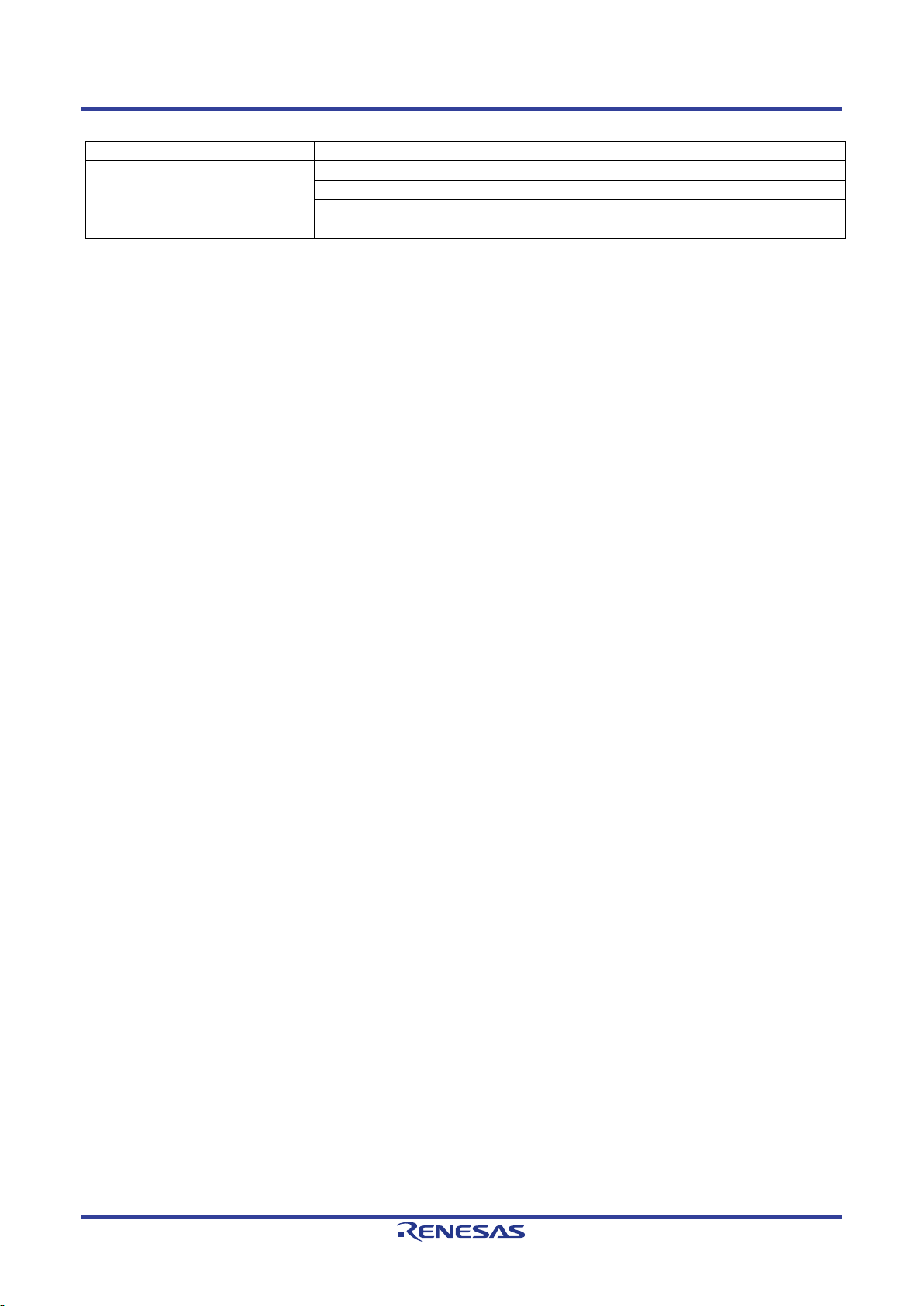

1.4 Board Exterior

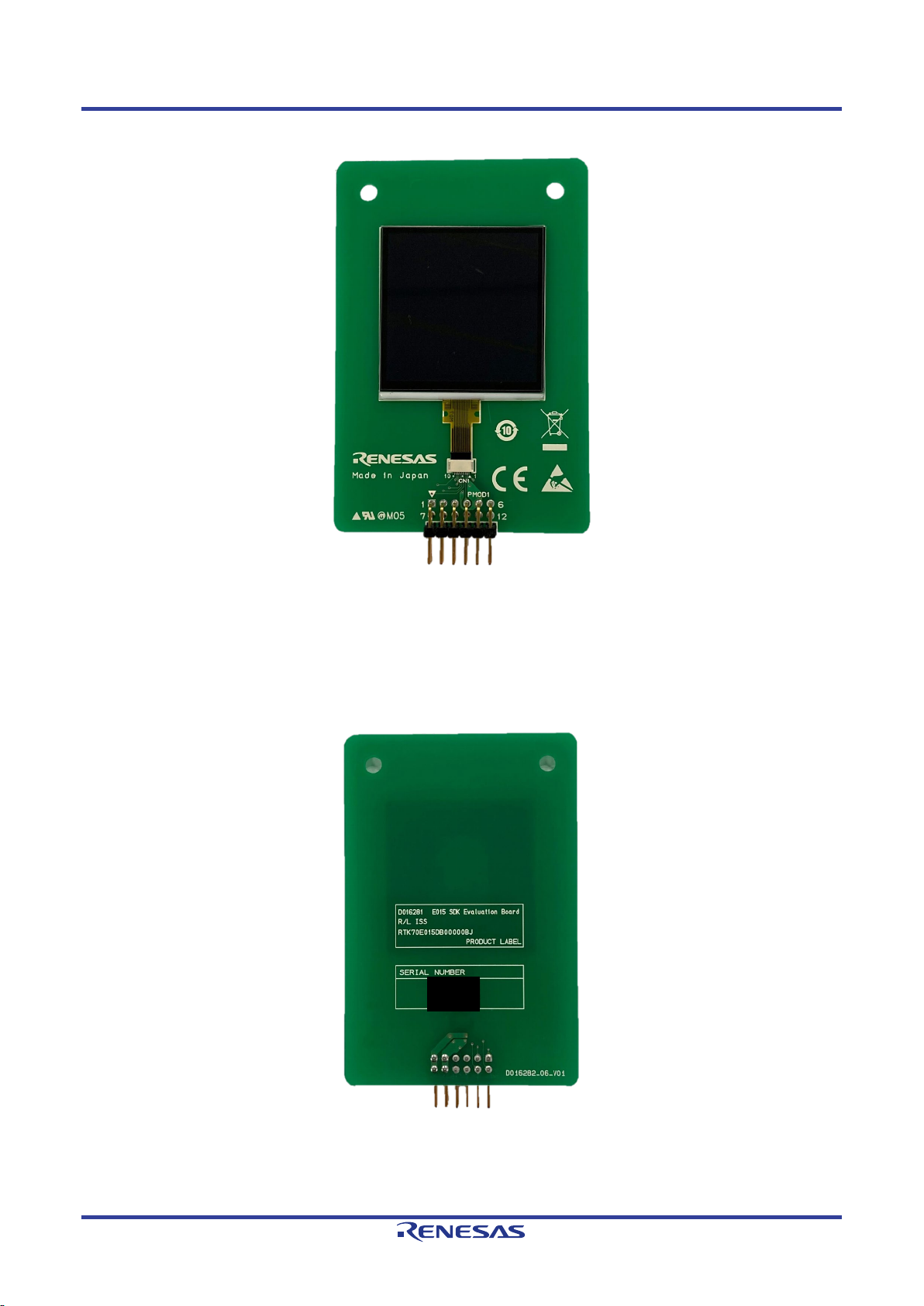

The exterior of Evaluation Kit RE01 256KB is shown in this chapter. Figure 1-1 and Figure 1-2 show the

exterior of the main board. Figure 1-3 and Figure 1-4 show the exterior of MIP-LCD expansion board.

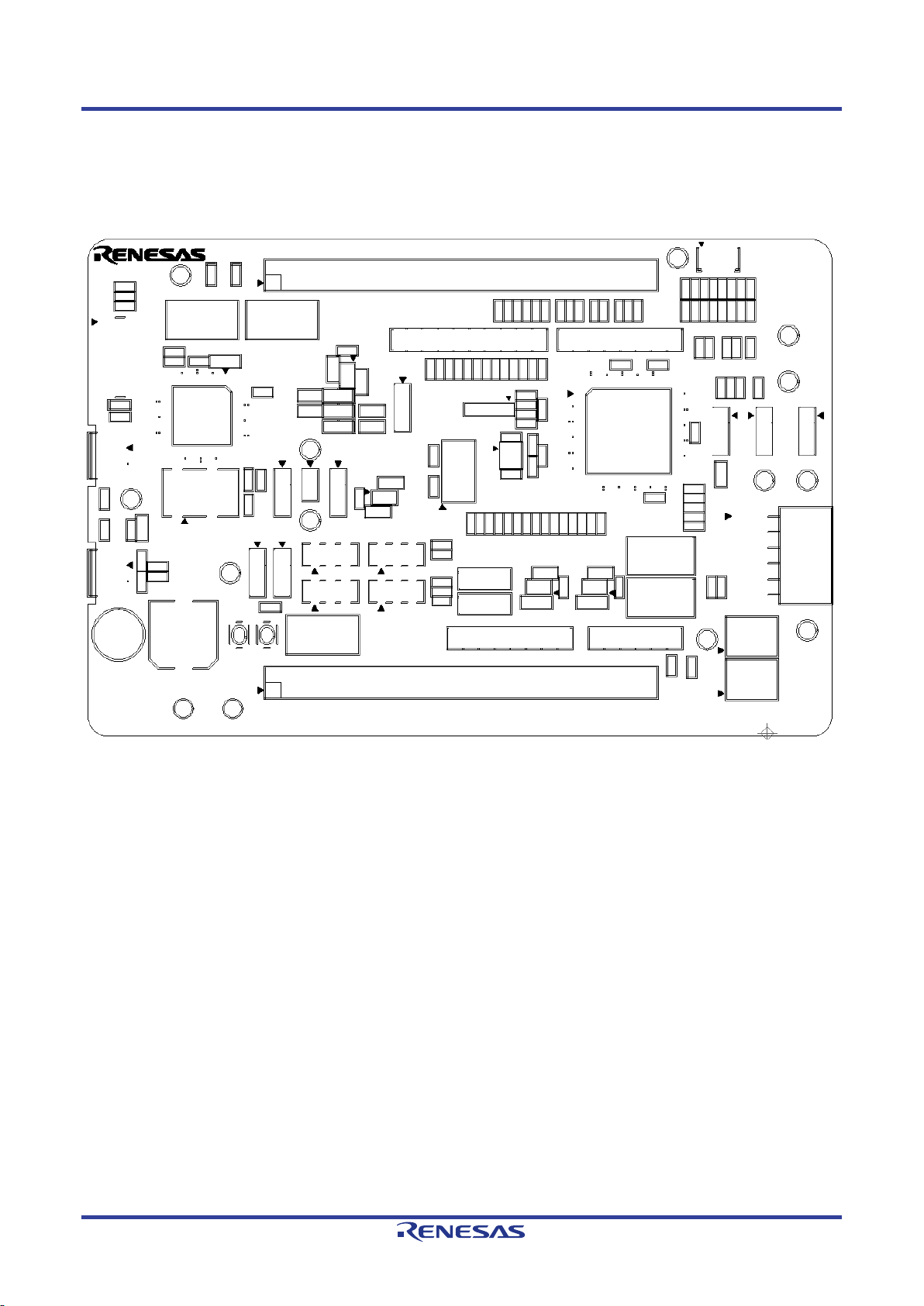

Figure 1-1: Main Board (Top)

Figure 1-2: Main Board (Bottom)

R20UT4801EJ0102 Rev.1.02 Page 12 of 95

Apr 16, 2021

Page 13

Evaluation Kit RE01 256KB 1.Overview

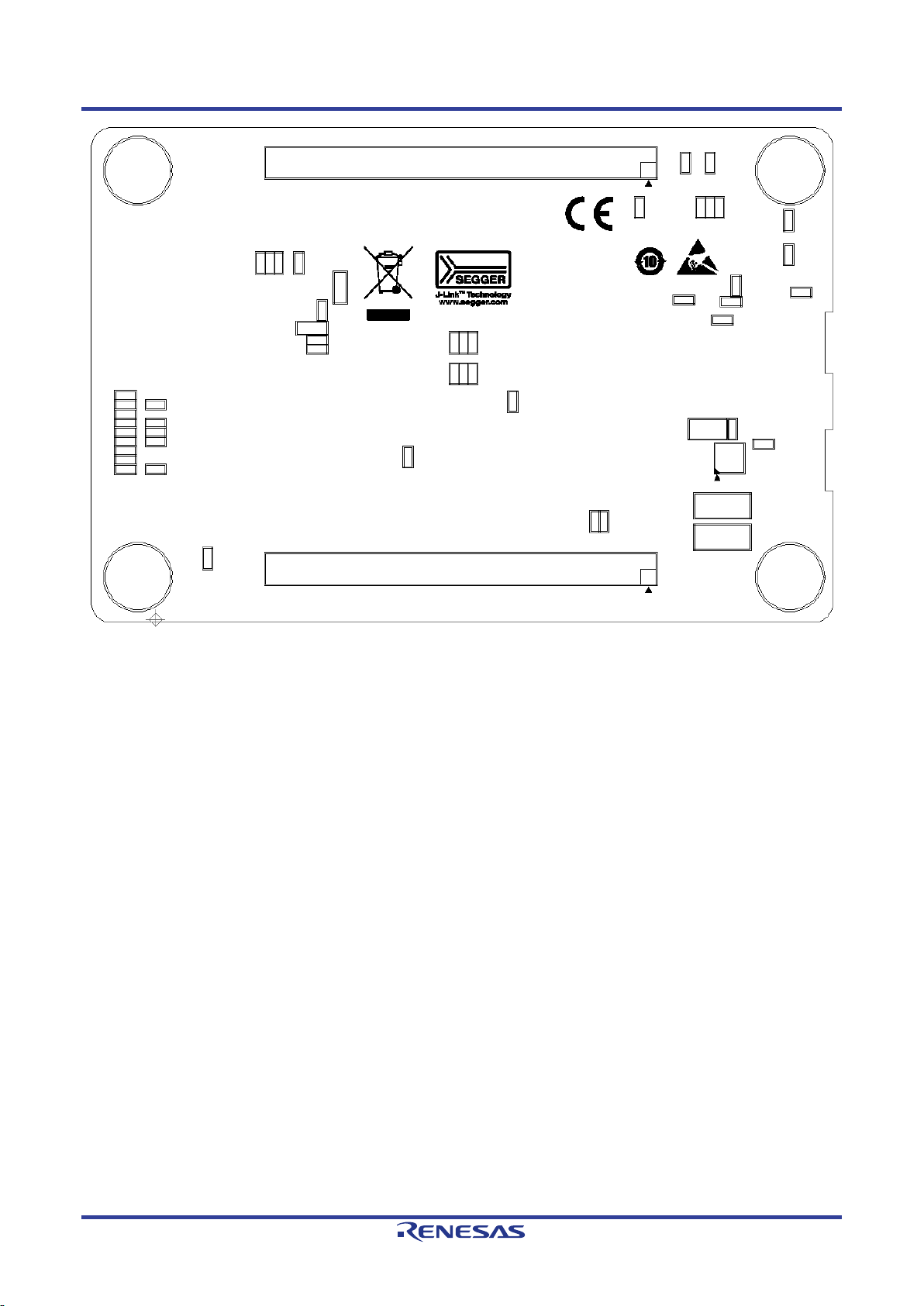

Figure 1-3: MIP-LCD Expansion Board (Top)

Figure 1-4: MIP-LCD Expansion Board (Bottom)

R20UT4801EJ0102 Rev.1.02 Page 13 of 95

Apr 16, 2021

Page 14

Evaluation Kit RE01 256KB 2.Board Layout

MIP-LCD Panel

FPC Connect or

PMOD1

Main Board

Interf ace

2. Board Layout

2.1 Component Layout

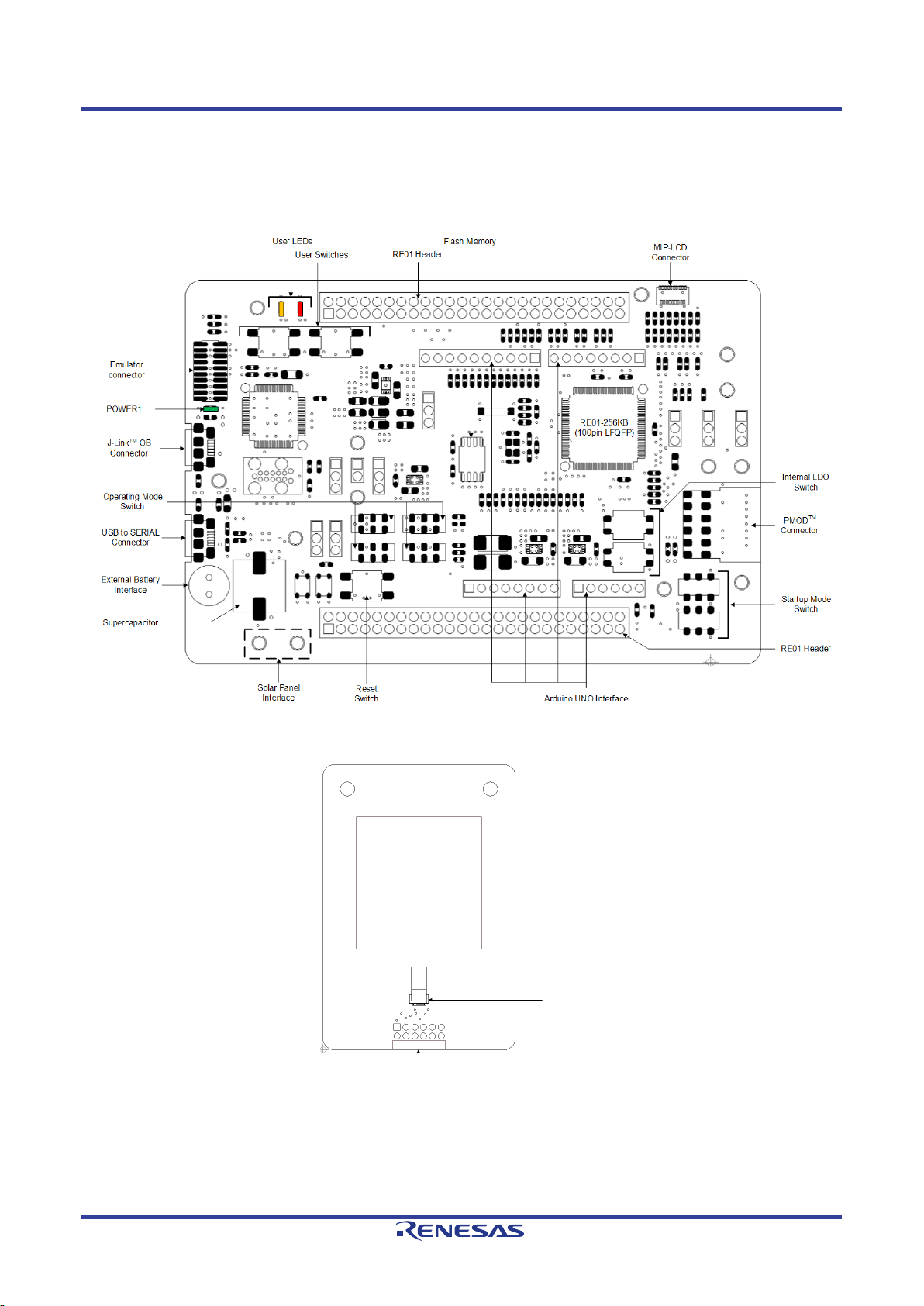

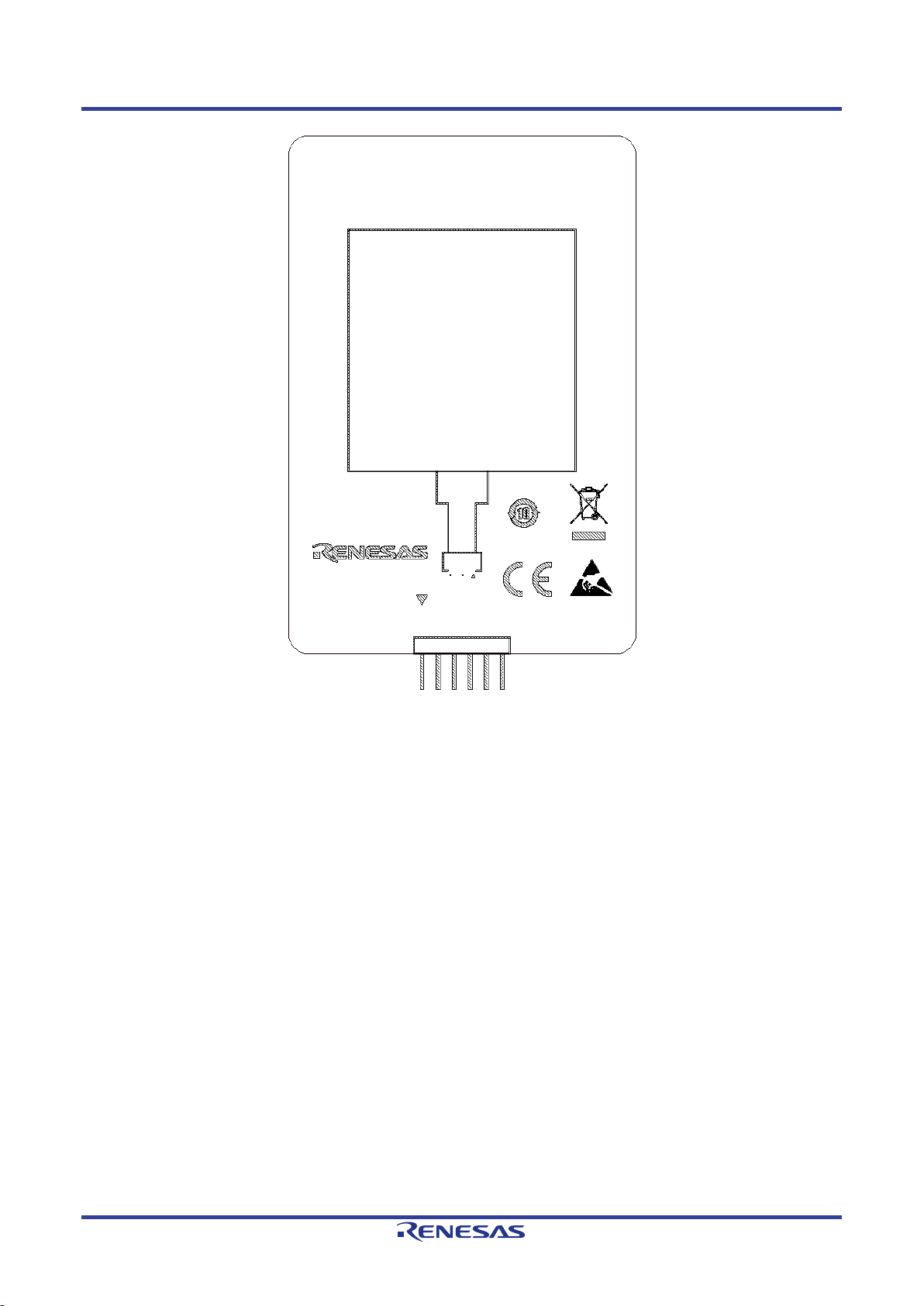

The component layout of Evaluation Kit are shown in Figure 2-1 and Figure 2-2.

Figure 2-1: Main Board Layout

Figure 2-2: MIP-LCD Expansion Board Layout

R20UT4801EJ0102 Rev.1.02 Page 14 of 95

Apr 16, 2021

Page 15

Evaluation Kit RE01 256KB 2.Board Layout

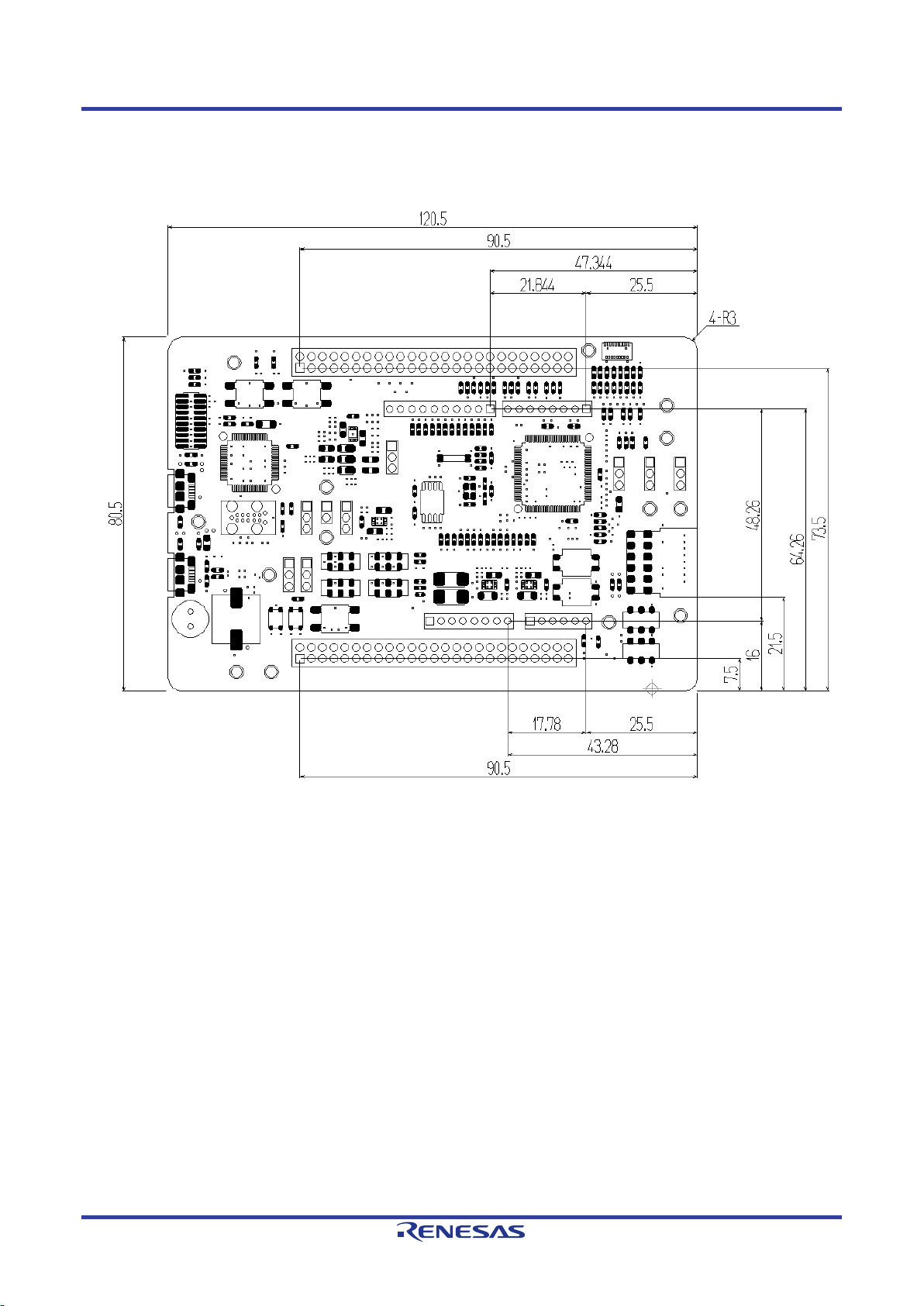

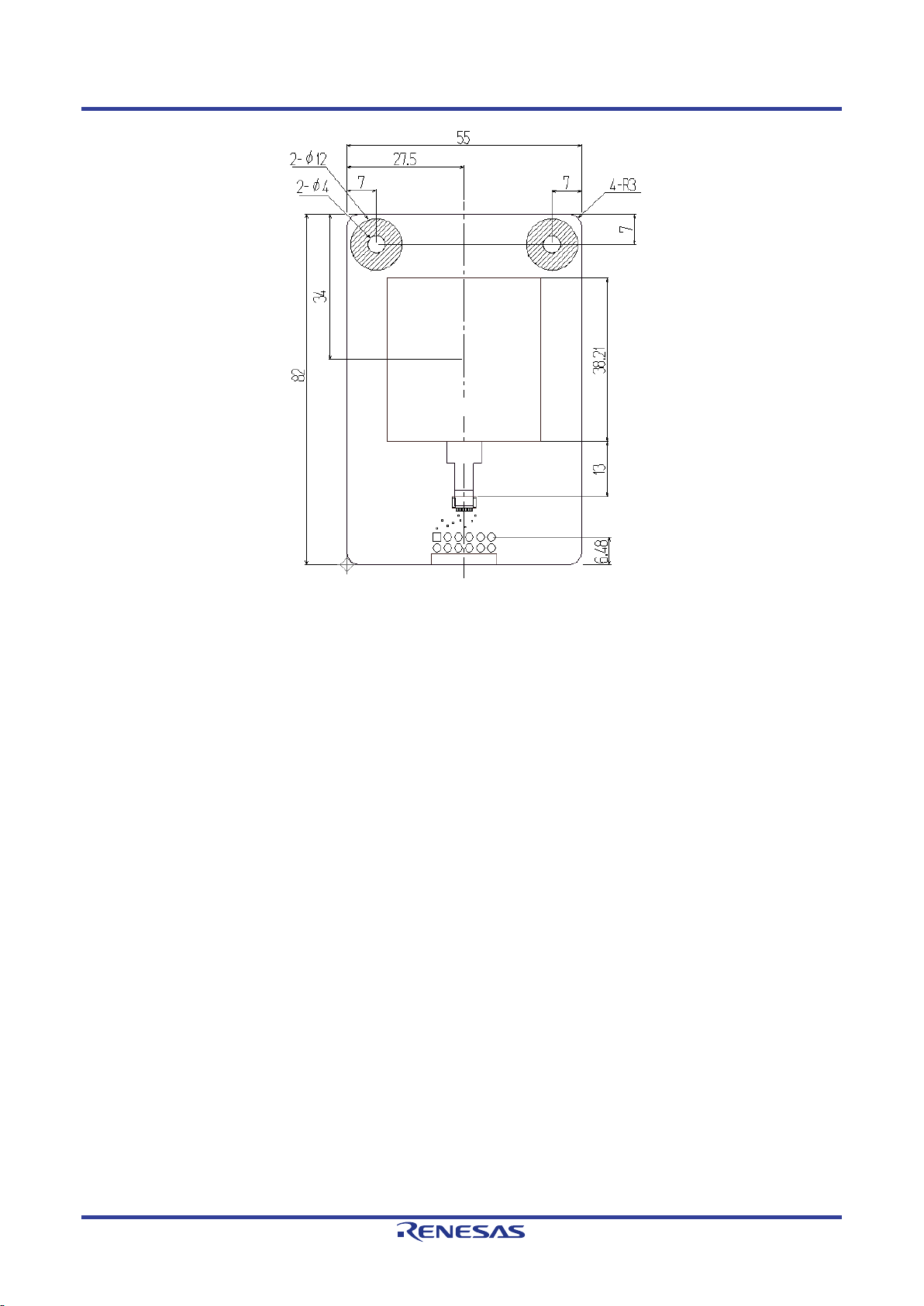

2.2 Board Dimensions

Figure 2-3 and Figure 2-4 below show the board dimensions and connector positions. All the through-hole

connectors are on a common 2.54 mm pitch grid for easy interfacing.

Figure 2-3: Main Board Dimensions (Unit: mm)

R20UT4801EJ0102 Rev.1.02 Page 15 of 95

Apr 16, 2021

Page 16

Evaluation Kit RE01 256KB 2.Board Layout

Figure 2-4: MIP-LCD Expansion Board Dimension (Unit: mm)

R20UT4801EJ0102 Rev.1.02 Page 16 of 95

Apr 16, 2021

Page 17

Evaluation Kit RE01 256KB 2.Board Layout

R1

R10

R11

GND2

LED 0

LED 1

J2

GND1

CN1

R2

R3

R4

R5

R6

R7

R8

R9

SW1 SW2

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

R22

R23

R24

R25

R26

R27

R28

R29

R30

R31

R32

R33

R39

R40 C1

C2

C3

L1

J3

J4

R34

R35

R36

R37

R38

T1

U2

C6

R41

R42

R43

R44

R45

R46

R48

R49

R50

R51

R52

R53

R47

C4 C5

CN2

POW ER1

C9

U6

R57

L2

L3

D1

D2

D3

R59

L4

X1

C8

R58

R61

C10

R60

U1

C7

R54

R55

R56

T2

C12

J5

J6

J7

C15

T4

T5

USB1

J-Link_

10pin_Needle

R68 R86

GND3

C19

L6

LED 2 R69

R66

J8

J9

J10

T3

T6

L5

U3

C16

C18

C13

R67

U7

C11

X2

C14

R62

R63

R64

C17

R71

R72

R73

R74

R75

R76

R77

R78

R79

R80

R81

R82

R83

R84

R85

R70

R87

R88

R89

R90

PMOD1

USB2

C22

C26

R91

R92

T7

J11

J12

SW3 SW4

SW5 SW6

C20

C21

R93

R94

C29

C25

C30

C23

C31

U5

L7

C24

U4

L8

C32

C27

C28

BT1

BT2

R95

SW7 S W8

RES

J13 J14

T8

GND4

J1

T9

T10

R98

R97

SW9

SW10

SW11

SW12

J15

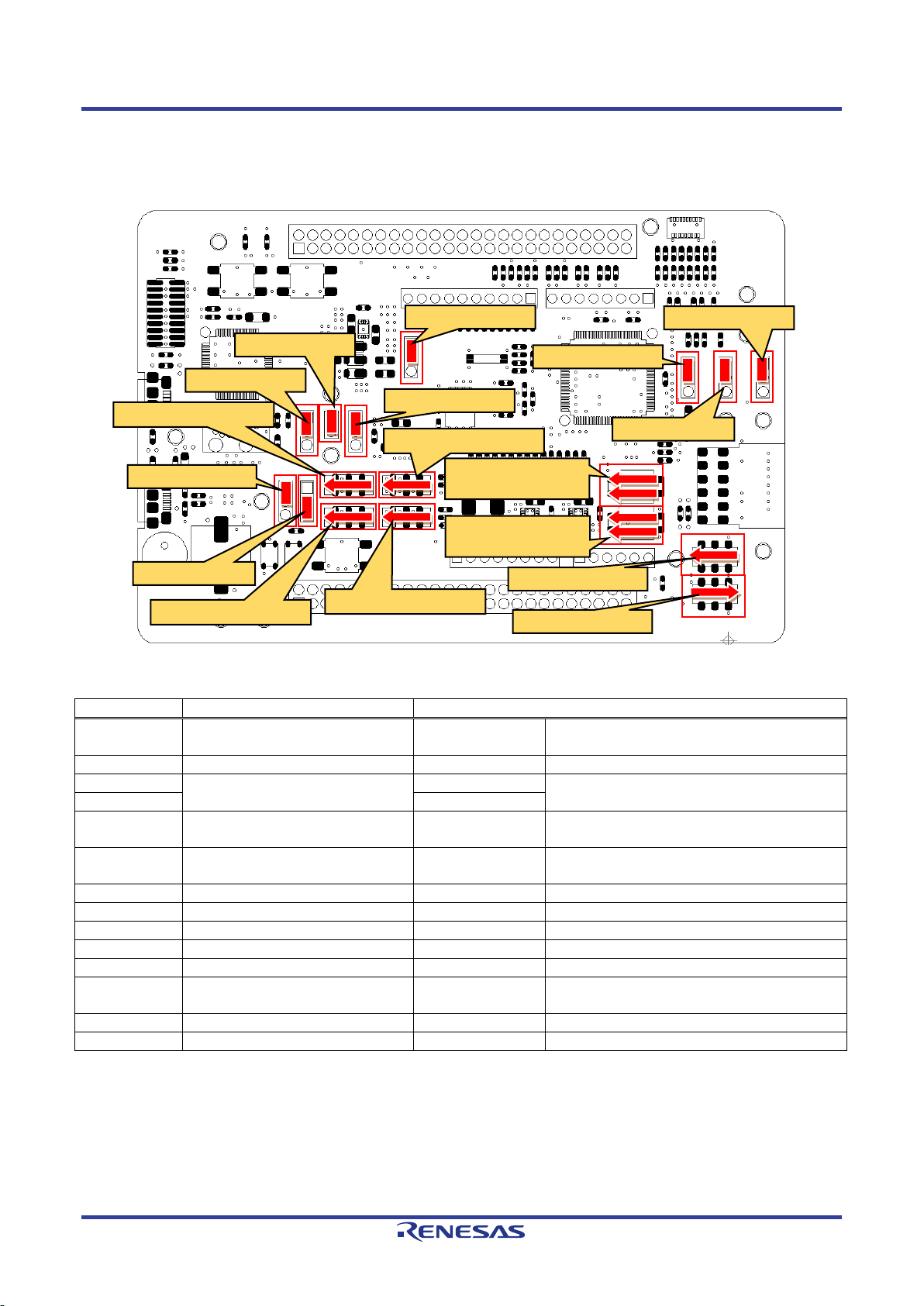

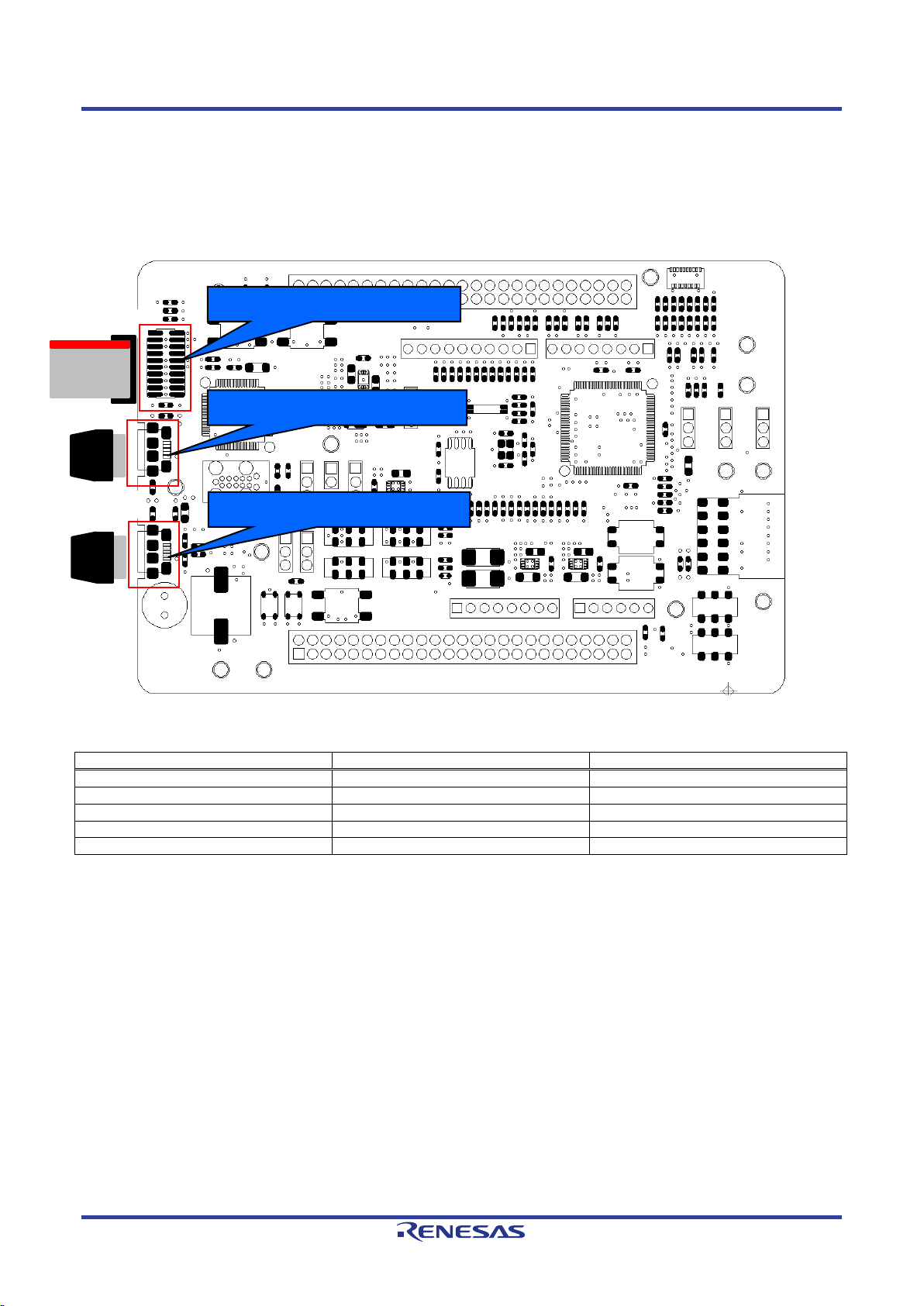

2.3 Component Placement

Figure 2-5, Figure 2-6, and Figure 2-7 show placement of individual components of Evaluation Kit

Component types and values are shown on the board schematics.

.

Figure 2-5: Main Board Component Placement (Top-Side View)

R20UT4801EJ0102 Rev.1.02 Page 17 of 95

Apr 16, 2021

Page 18

Evaluation Kit RE01 256KB 2.Board Layout

J2

R99

R10 0

R10 5 R106

R10 4

R10 3

R10 2

R10 1

C33

R11 0

R10 9

R10 8

R10 7

C35

R11 2

C34

C37

R11 1

C36

C38

C39

C40

R11 3

R11 4

R11 5

R11 6

R11 7

R11 8

R12 2

R11 9

R12 0

R12 3

R12 4

R12 6

R12 8

R13 0

R13 1

R13 3

R13 4

R12 9

R12 7

R12 5

R12 1

R13 2

C41

C42

C43

U8

R135

R138

R13 7

C44

R13 6

J1

Figure 2-6: Main Board Component Placement (Bottom-Side View)

R20UT4801EJ0102 Rev.1.02 Page 18 of 95

Apr 16, 2021

Page 19

Evaluation Kit RE01 256KB 2.Board Layout

CN1

PMOD1

Figure 2-7: MIP-LCD Component Placement (Top-Side View)

R20UT4801EJ0102 Rev.1.02 Page 19 of 95

Apr 16, 2021

Page 20

Evaluation Kit RE01 256KB 2.Board Layout

Item

Function

Setting

SW3, SW5

Operation mode setting

(Emulator setting)

1-2, 5-6: short

Normal mode (using J-LinkTM OB)

SW4, SW6

Operation mode setting

1-2, 5-6: short

Normal mode

SW9

Start-up mode setting

1-2: short

Normal start-up

SW10

2-3: short

SW11,

SW12

Internal LDO setting

1-4: OFF

2-3: OFF

Internal LDO use

J5

Reference voltage generation

circuit setting

1-2: short

Reference voltage generation circuit not

used

J6

IOVCC0 power supply setting

1-2: short

Use output voltage from DCDC converter

J7

IOVCC1 power supply setting

1-2: short

Use output voltage from DCDC converter

J8

Operation mode setting

1-2: short

Normal operation

J9

Current measurement setting

1-2: short

Current measurement not performed

J10

Operation mode setting

1-2: short

Normal start-up

J11

Supercapacitor charging

method selection

1-2: short

Charge from external power supply

J12

Secondary battery selection

2-3: short

Supercapacitor

J15

Operation mode setting

1-2: short

Normal start-up

J8: 1-2 short

J9: 1-2 short

J10: 1-2 short

J11: 1-2 short

J12: 2-3 short

J15: 1-2 short

J7: 1-2 short

J6: 1-2 short

J5: 1-2 short

SW11: 1-4 OFF

2-3 OFF

SW12: 1-4 OFF

2-3 OFF

SW9: 1-2 short

SW10: 2-3 short

SW3: 1-2, 5-6 short

SW5: 1-2, 5-6 short

SW4: 1-2, 5-6 short

SW6: 1-2, 5-6 short

2.4 Board Initial Settings

The switch settings of the default kit configuration are as follows. The component layout is shown in Figure

2-8 and the detailed settings are shown in Table 2-1.

Figure 2-8: Component Layout and Settings

Table 2-1: Board Initial Settings

R20UT4801EJ0102 Rev.1.02 Page 20 of 95

Apr 16, 2021

Page 21

Evaluation Kit RE01 256KB 3.Internal Board Connections

Arduin o UNO Header

(J3,J4,J13,J14)

RE01-25 6KB

IOVCC IOVC C0 IOV CC1 AVCC0 V REFH0

J-LinkTM OB

Emula tor Con nector(CN2 )

Micro -B Connector

(US B2)

USB-UART Circuit

USB-UART IC

(U8)

Flash Memory (U7)

MIP-LCD E xpansi on Boar d Inte rface ( PMOD1)

MIP-LCD(P arallel ) Interf ace (CN 1)

VCC/ IOVCC to VCLH

Voltag e Regulator

VCC/ IOVCC to VCL

Voltag e Regulator

: Signal Line

R

: Resisto r

R

: Resistor(Do no fit)

SSW

: Slide switch

VCC/IOVCC to 3.3V

Voltag e Regulator

SW3, SW5

R

R

R

R

SPI0/1

SWD, RESn

DCDC_Ext_EN

DCDC_EHC_EN

R

QSPI

SC I0

R

User LE DS (LED0, LED 1)

R

IO

Analog IO

IO

MLCD

IIC0/1

IIC0/1

IIC0/1

Analog VREF

R

IO

IO

P000

P001

P002

P003

P004

P005

IO(IOVCC):

Analog IO:

SDA P012

SCL P 013

IIC0/1

(IOVCC0):

CLK P 011

SSL P015

MOSI P 010

MISO P815

SPI0/1:

(IOVCC0):

P409

IO(IOVCC1):

P204

P205

P302

P314

P315

P602

P603

P604

SWCL K P411, SWDIO P207

TXD P7 02, RXD P702, C TS P704, RTS P202

IO: P210,P410

SPCLK P011, SS L P015, MOSI P010, MISO P815

QSPC LK P812, QSS L P807, QIO P80[ 8:11]

IO: P508,P509

SCLK P111, VCOM P113, ENBS P1 09,

XRST P1 12, DATA P10 [0:7],

DEN P110, ENBG P108

P204 P 205 P302 P314 P3 15 P602 P60 3 P604

P000 P 001 P002 P003 P0 04 P005

P409

VR EF

(VREFH0)

VR EFH0

VR EFH0

SDA P012

SCL P 013

P208

P209

User Switches (SW1,SW2)

Contr ol MCU

(U6)

Micro -B Connector

(US B1)

SSW

R

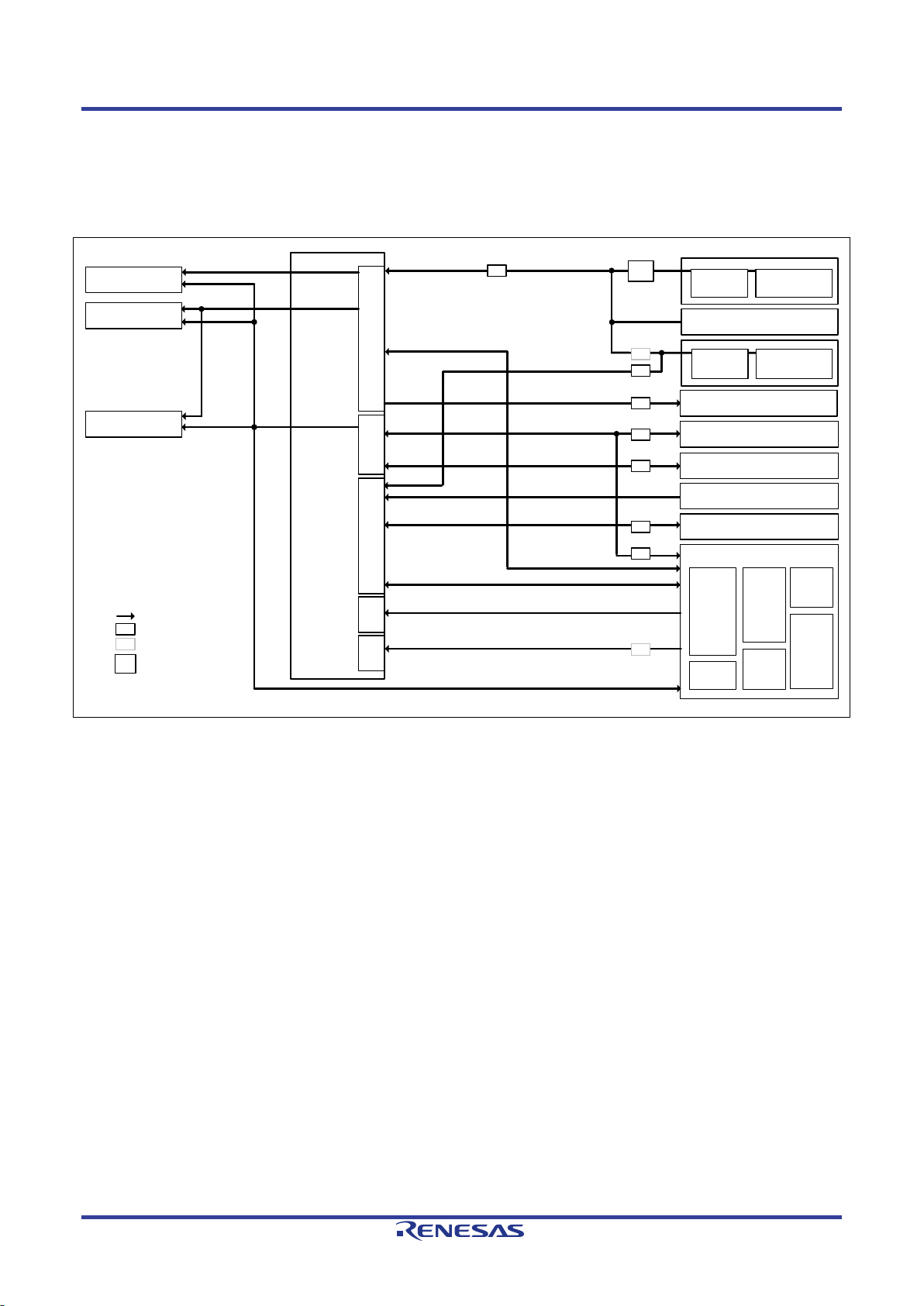

3.Internal Board Connections

Figure 3-1 shows the connectivity between Evaluation Kit and RE01. The pin connections are listed in Table

3-1 and Table 3-2.

Figure 3-1: Internal Board Block Diagram

R20UT4801EJ0102 Rev.1.02 Page 21 of 95

Apr 16, 2021

Page 22

Evaluation Kit RE01 256KB 3.Internal Board Connections

RE01

Main board

XTAL - 12

-

IOVCC

XCOUT - 9

-

IOVCC

SW1

P509

74

J2-24

IOVCC1

LED

LED0

P210

32

J1-32

IOVCC

PMOD*

PMOD_SSLA1_B_P015

P015

92

J2-42

IOVCC0

PMOD_MISOA_B_CTS4_C

P815

98

J2-48

IOVCC0

PMOD_INT_AGTWOA1_B_P814

P814

99

J2-49

IOVCC0

PMOD_IO0_P014

P014

93

J2-43

IOVCC0

USB-Serial

USB_SCI_TXD

P703

40

J1-40

IOVCC

USB_SCI_CTS

P704

39

J1-39

IOVCC1

MIP-LCD

MLCD_VCOM

P113

56

J2-6

IOVCC1

MLCD_XRST

P112

57

J2-7

IOVCC1

MLCD_SI6

P101

70

J2-20

IOVCC1

MLCD_SI4

P103

68

J2-18

IOVCC1

MLCD_SI2

P105

66

J2-16

IOVCC1

MLCD_SI0

P107

64

J2-64

IOVCC1

MLCD_SCLK

P111

58

J2-8

IOVCC1

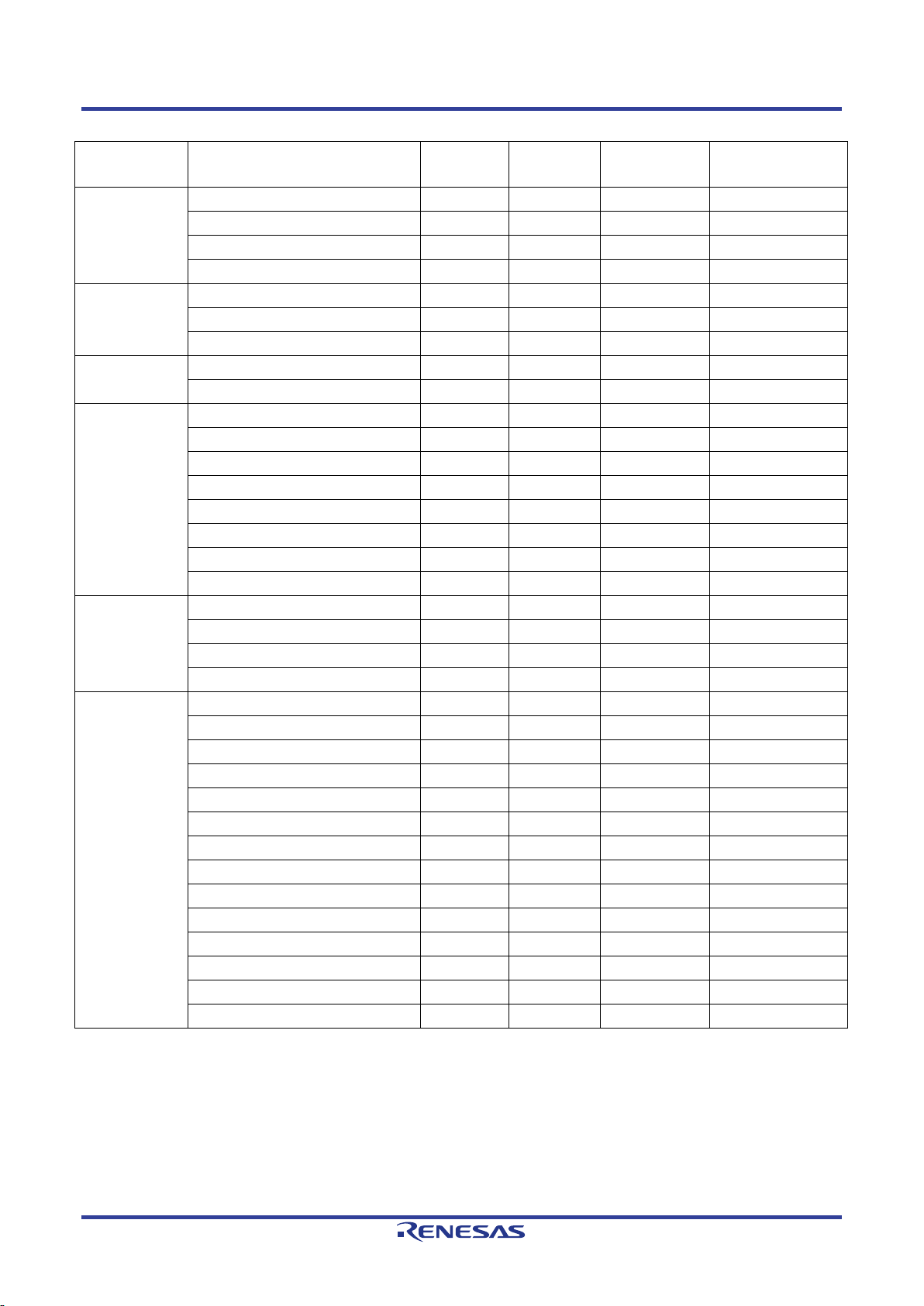

Table 3-1: List of RE01 functions, pin number and header connections(1/2)

Category Function Port

Clock EXTAL - 13 - IOVCC

XCIN - 10 - IOVCC

Switch RES RES# 23 J1-23 IOVCC

SW2 P508 75 J2-25 IOVCC1

LED1 P410 17 J1-17 IOVCC

PMOD_MOSIA_B_P010 P010 97 J2-47 IOVCC0

PMOD_RSPCKA_B_P011 P011 96 J2-46 IOVCC0

PMOD_RESET_RXD4_C P813 100 J2-50 IOVCC0

PMOD_IO1 P806 7 J1-7 IOVCC0

Pin No.

Pin header

Power Domain

USB_SCI_RXD P702 41 J1-41 IOVCC

USB_SCI_RTS P202 38 J1-38 IOVCC1

MLCD_ENBS P109 60 J2-10 IOVCC1

MLCD_SI7 P100 71 J2-21 IOVCC1

MLCD_SI5 P102 69 J2-19 IOVCC1

MLCD_SI3 P104 67 J2-17 IOVCC1

MLCD_SI1 P106 65 J2-15 IOVCC1

MLCD_DEN P110 59 J2-9 IOVCC1

MLCD_ENBG P108 61 J2-11 IOVCC1

*: Please refer to Section 8.5 Pmod™ Interface for the relationship with the pin number of the PMOD connector.

R20UT4801EJ0102 Rev.1.02 Page 22 of 95

Apr 16, 2021

Page 23

Evaluation Kit RE01 256KB 3.Internal Board Connections

RE01

Main board

QSPI_QIO1_A

P810 3 J1-3

IOVCC0

QSPI_QIO0_A

P811 2 J1-2

IOVCC0

QSPI_QIO3_A

P808 5 J1-5

IOVCC0

ARDUINO_IO9_GTIOC2A_B

P302

48

J1-48/J3-2

IOVCC1

ARDUINO_MOSIA_B

P010

97

J2-47/J3-4

IOVCC0

ARDUINO_RSPCKA_B

P011

96

J2-46/J3-6

IOVCC0

ARDUINO_SDA0*

P012

95

J2-45/J3-9

IOVCC0

Arduino

ARDUINO_IO0_RXD5_B

P314

45

J1-45/J4-1

IOVCC1

ARDUINO_IO2_IRQ7_B

P204

36

J1-36/J4-3

IOVCC1

ARDUINO_IO4

P602

53

J2-3/J4-5

IOVCC1

ARDUINO_IO6_GTIOC5B_B

P604

51

J2-1/J4-7

IOVCC1

Arduino

IOVCC0/IOVCC1/

RESn

RES#

23

J1-23/ J13-3

IOVCC

Board_5V

- - J13-5

-

Arduino

ARDUINO_AN000

P000

89

J2-49/J14-1

AVCC0

ARDUINO_AN002

P002

87

J2-37/J14-3

AVCC0

ARDUINO_AN004

P004

85

J2-35/J14-5

AVCC0

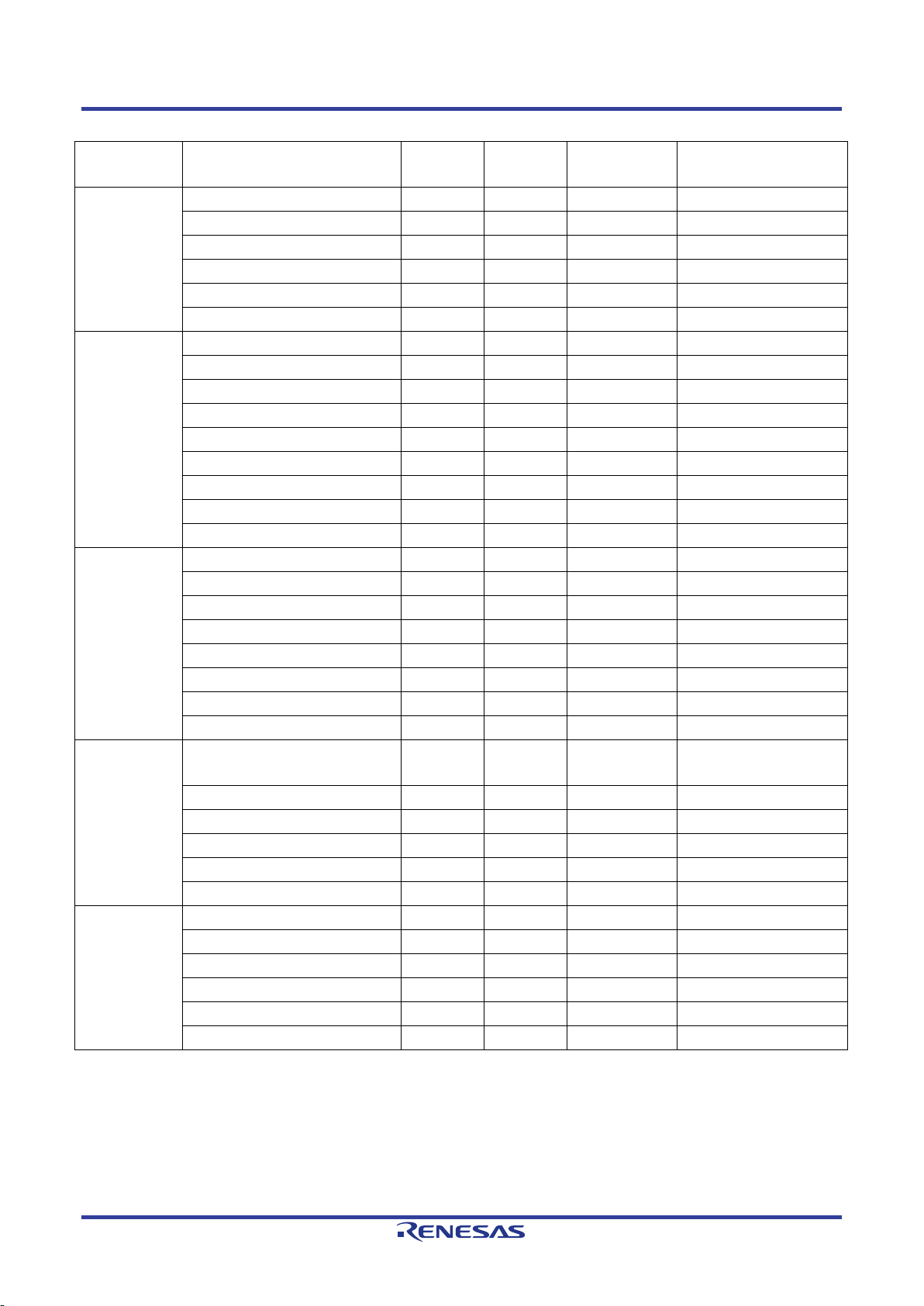

Table 3-2: List of RE01 functions, pin number and header connections (2/2)

Category Function Port

Flash

Memory

Arduino

UNO (J3)

UNO (J4)

QSPI_QSSL_A P807 6 J1-6 IOVCC0

QSPI_QIO2_A P809 4 J1-4 IOVCC0

QSPI_QSPCLK_A P812 1 J1-1 IOVCC0

ARDUINO_IO8 P409 18 J1-18/J3-1 IOVCC

ARDUINO_SSLA1_B P015 92 J2-42/J3-3 IOVCC0

ARDUINO_MISOA_B P815 98 J2-48/J3-5 IOVCC0

ARDUINO_VREF** - 84 J3-8 VREFH0

ARDUINO_SCL0* P013 94 J2-44/J3-10 IOVCC0

ARDUINO_IO1_TXD5_B P315 44 J1-44/J4-2 IOVCC1

Pin No.

Pin header

Power Domain

ARDUINO_IO3_IRQ8_C P205 35 J1-35/J4-4 IOVCC1

ARDUINO_IO5_GTIOC5A_B P603 52 J2-2/J4-6 IOVCC1

ARDUINO_IO7 P300 50 J1-50J4-8 IOVCC1

UNO (J13)

UNO (J14)

*: The default kit configuration uses a transfer rate of 50kbps or less. To increase the transfer rate, change the resistor

values (R21, R22).

**: Not connected by default. Please change the resistor based on your application.

IOVCC0**/IOVCC1/AVCC0** - 91/46/78 J13-1

LP_3V3 - - J13-2 -

LP_3V3 - - J13-4 -

VCC_MCU - 14 J1-14/J13-8 IOVCC

ARDUINO_AN001 P001 88 J2-48/J14-2 AVCC0

ARDUINO_AN003 P003 86 J2-36/J14-4 AVCC0

ARDUINO_AN005 P005 82 J2-32/J14-6 AVCC0

AVCC0

R20UT4801EJ0102 Rev.1.02 Page 23 of 95

Apr 16, 2021

Page 24

Evaluation Kit RE01 256KB 4.Power Supply

RE01-25 6KB

IOVCC

5.0V to 3. 3V

Voltag e Regulator

EHC

VCC/ IOVCC

IOVC C0

IOVC C1 AVCC0 V REF H0

R

R

R

CC

Contr ol MCU

(U6)

Micro -B Connector

(US B1)

J-LinkTM OB

Emula to r Connect or

(CN2 )

Micro -B Connector

(US B2)

USB-UART Circuit

USB-UART IC

(U8)

Flash Memory

(U7)

USER S witches

(SW1, SW2)

MIP-LCD E xpans ion Boar d Inte rface

(PMO D1)

MIP-LCD(P arallel) Int erface

(CN1)

IOVC C0

IOVC C1

Arduin o UNO Header

(J3,J4,J13,J14)

5.0V

R

R

R

R

MCU

VCC/ IOVCC to VCLH

Voltag e Regulator

VCC/ IOVCC to VCL

Voltag e Regulator

R

R

UC_ VCC

VCC_ MCU

VCC_ MCU

UC_ VCC

VR EFH0

5.0V

J8

J10

J6

J7

J5

SSW

SSW

VCC/IOVCC to 3.3V

Voltag e Regulator

J15

SW11

SW12

R

J9

: Power Line

R

: Resisto r

R : Resistor(Do no fit)

C

: Cap acitor

: Jum per sw itch

: T hrough ho le

SSW

: Slide swit ch

LP_P RODUCT_3V3

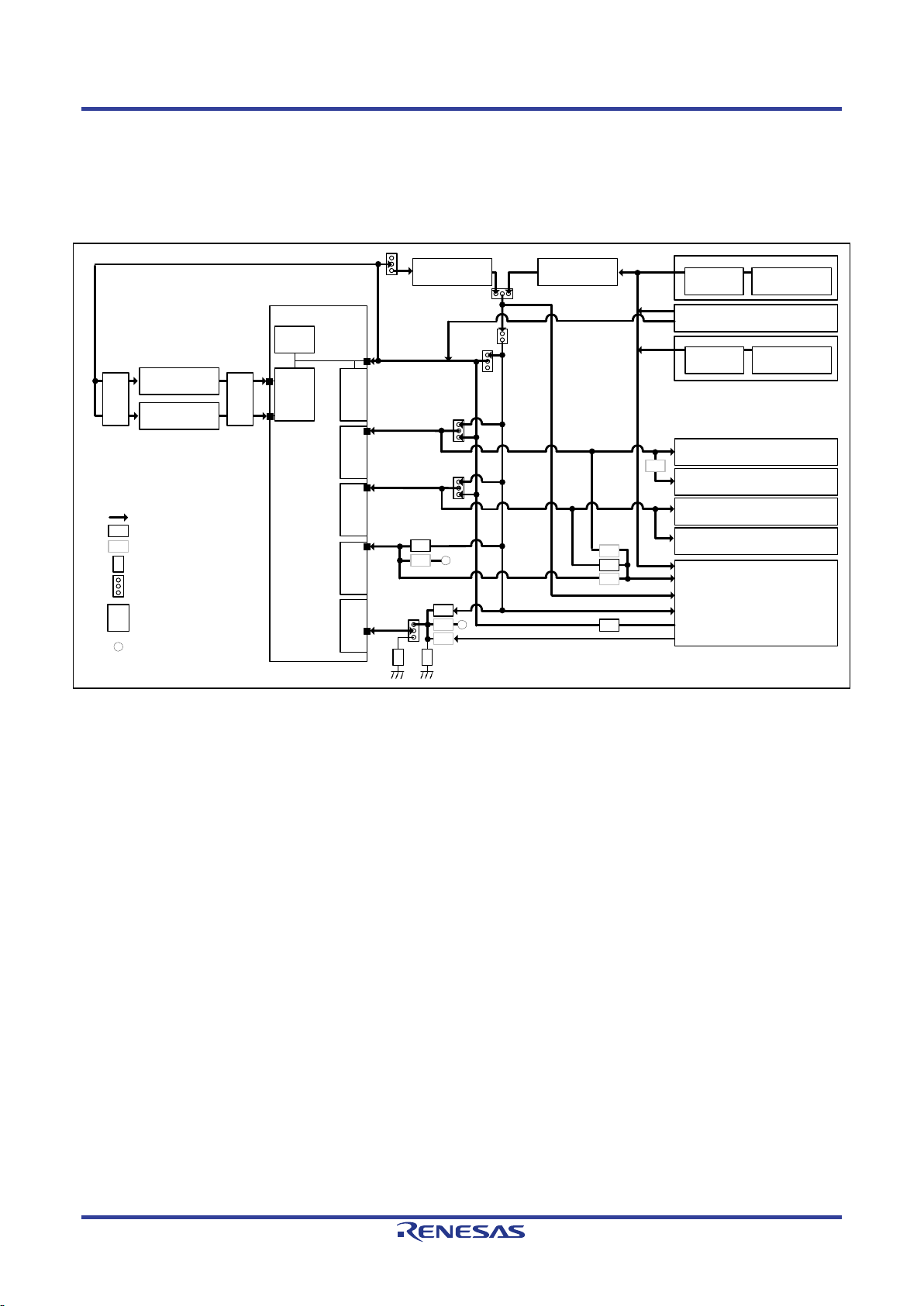

4. Power Supply

4.1 Power Supply System

Figure 4-1 shows power supply system diagram of Evaluation kit.

Figure 4-1: Power Supply System Diagram

R20UT4801EJ0102 Rev.1.02 Page 24 of 95

Apr 16, 2021

Page 25

Evaluation Kit RE01 256KB 4.Power Supply

Source

Supply voltage

Supply current

I-jetTM (CN2)

5V

Maximum 420mA

J-LinkTM OB (USB1)

5V

Maximum 500mA

J-LinkTM (CN2)

5V

Maximum 300mA

E2 (CN2)

3.3V

Maximum 200mA

USB serial (USB2)

5V

Maximum 500mA

Emulator

Emulator connector (CN2)

J-LinkTM OB connector (USB1)

USB cable

USB serial connector (USB2)

USB cable

4.2 Power Supply Source

Evaluation Kit is supplied by emulator through USB cable. The details of power supply components are

shown in Figure 4-2 and Table 4-1. When the Evaluation Kit is connected to another system then that system

should supply power to the Evaluation Kit.

When operating in stand-alone mode, connect a USB cable to USB1 or USB2 and supply the voltage

through VBUS. At that time, do not use J-Link

TM

OB or USB serial function.

Figure 4-2: Components Layout (power supply)

Table 4-1: Power Supply Specifications

R20UT4801EJ0102 Rev.1.02 Page 25 of 95

Apr 16, 2021

Page 26

Evaluation Kit RE01 256KB 4.Power Supply

J8: 1-2 open

Current Measurement Point

SW3: EHC

SW5: EHC

4.3 External Power Supply

It is possible to supply voltage to RE01 power terminal by using external power supply. This allows the entire

or individual power domain to operate at any voltage (1.62 – 3.6V). Normally, the emulator supplies voltage

equivalent to 3.3V, which is the voltage value after reduction by the regulator. (excluding device which can

supply 3.3V)

4.3.1 All power pins

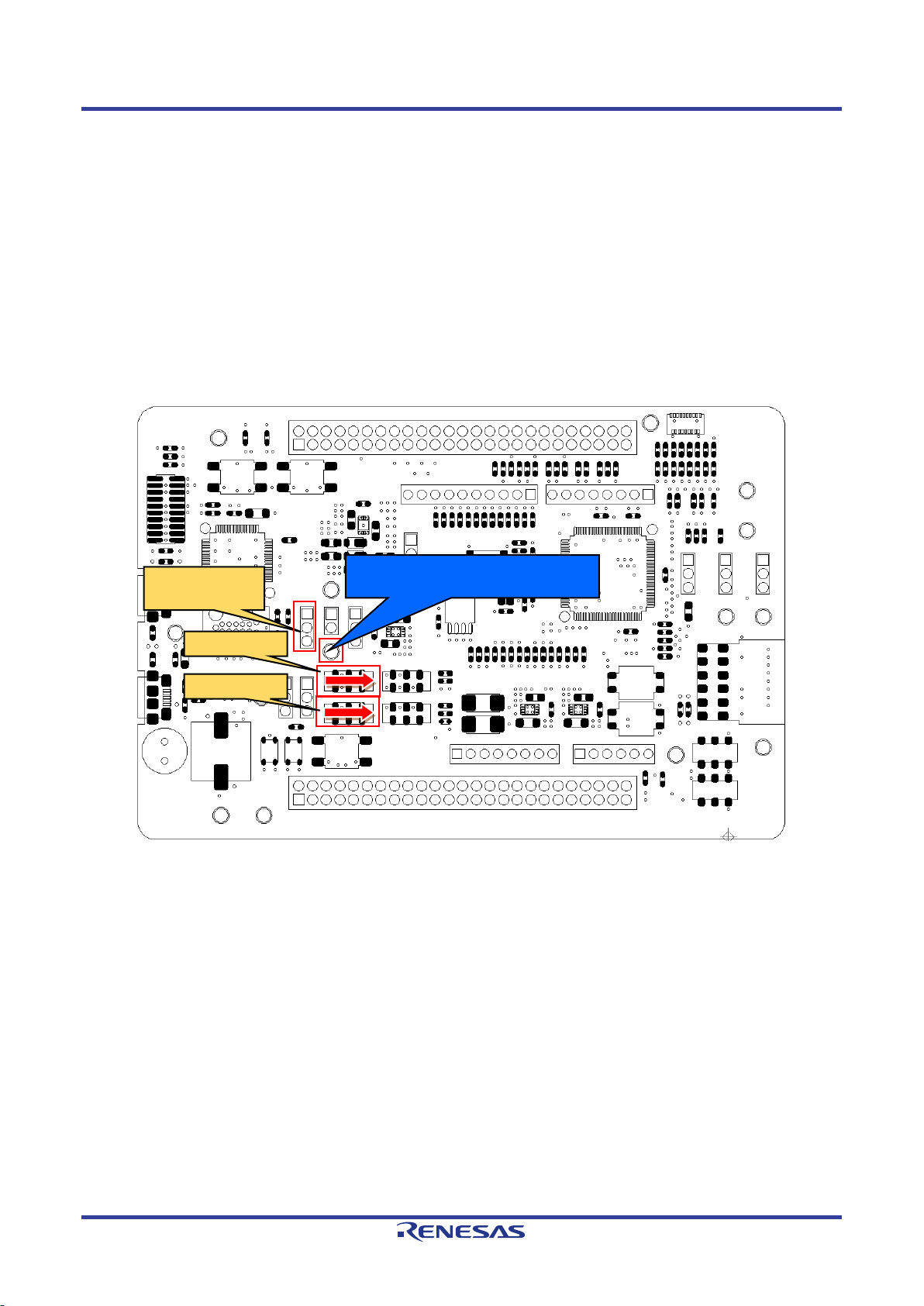

Figure 4-3 shows the component layout. Follow the steps below when supplying voltage from external p

supply to all RE01 power pins:

1. Set SW3 and SW5 to EHC.

2. Open J8 jumper pin 1-2 and 2-3.

3. Supply voltage (1.62V-3.6V) from pin 2 of J8 or T6 using an external power supply.

ower

2-3 open

Figure 4-3: Component Layout and Setting (External Power Supply)

Keep the following in mind when using this feature:

• Debugging using J-Link OB is not possible. Please use another emulator. For details on the other

emulators, refer to chapter 6 Debug.

• When using the E2 emulator, do not supply power from the emulator.

(T6)

R20UT4801EJ0102 Rev.1.02 Page 26 of 95

Apr 16, 2021

Page 27

Evaluation Kit RE01 256KB 4.Power Supply

IOVCC0(T4)

J6: 1-2 open

2-3 open

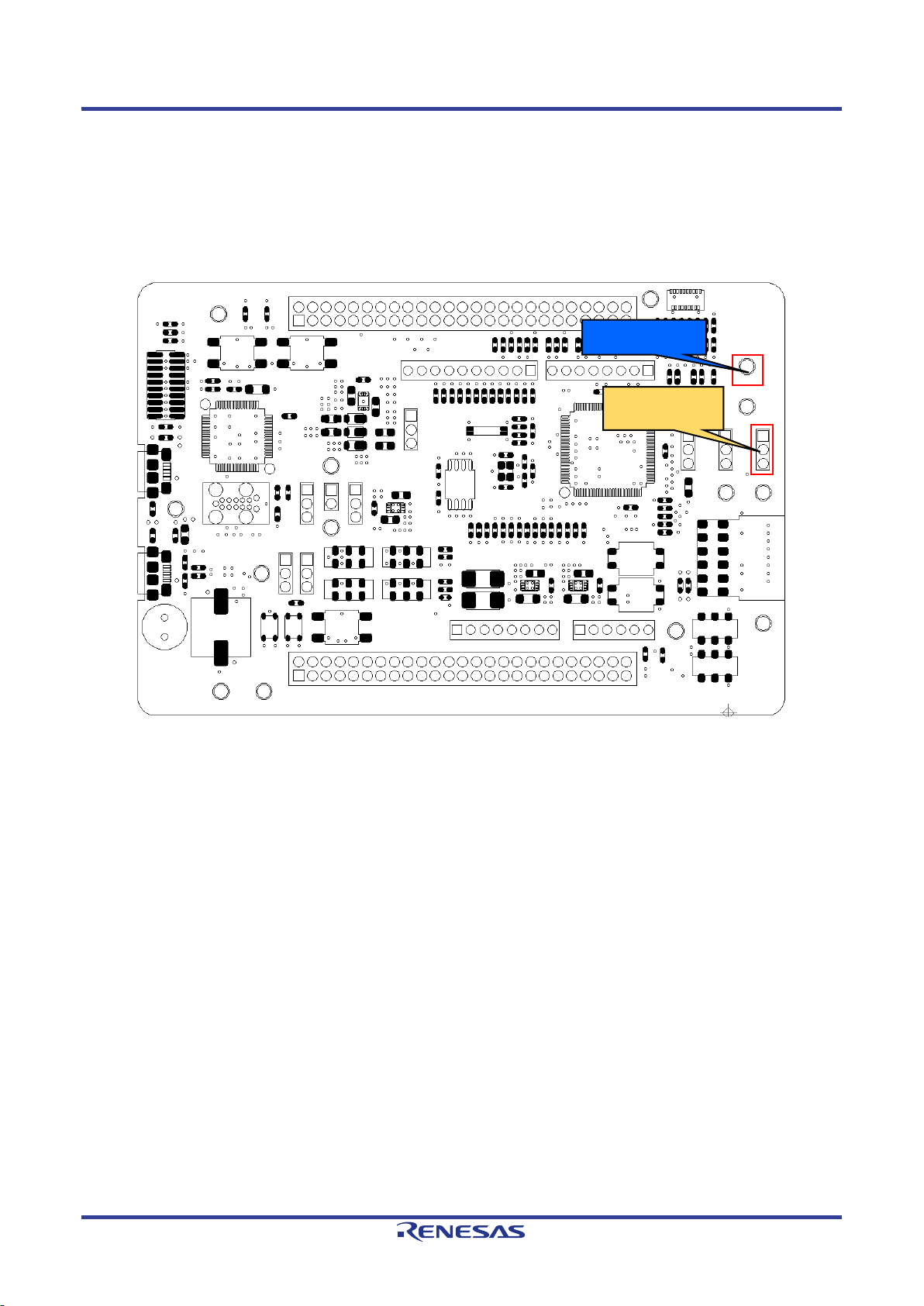

4.3.2 IOVCC0

Figure 4-4 shows the component layout. Follow the steps below when supplying voltage from external power

supply to IOVCC0 pin:

1. Open J6 jumper pin 1-2 and 2-3.

2. Supply voltage (1.62V – 3.6V) to any power supply pins other than IOVCC0 pin.

3. Supply voltage to T4.

Figure 4-4: Component Layout and setting (External Power Supply)

R20UT4801EJ0102 Rev.1.02 Page 27 of 95

Apr 16, 2021

Page 28

Evaluation Kit RE01 256KB 4.Power Supply

IOVCC1(T1)

J7: 1-2 open

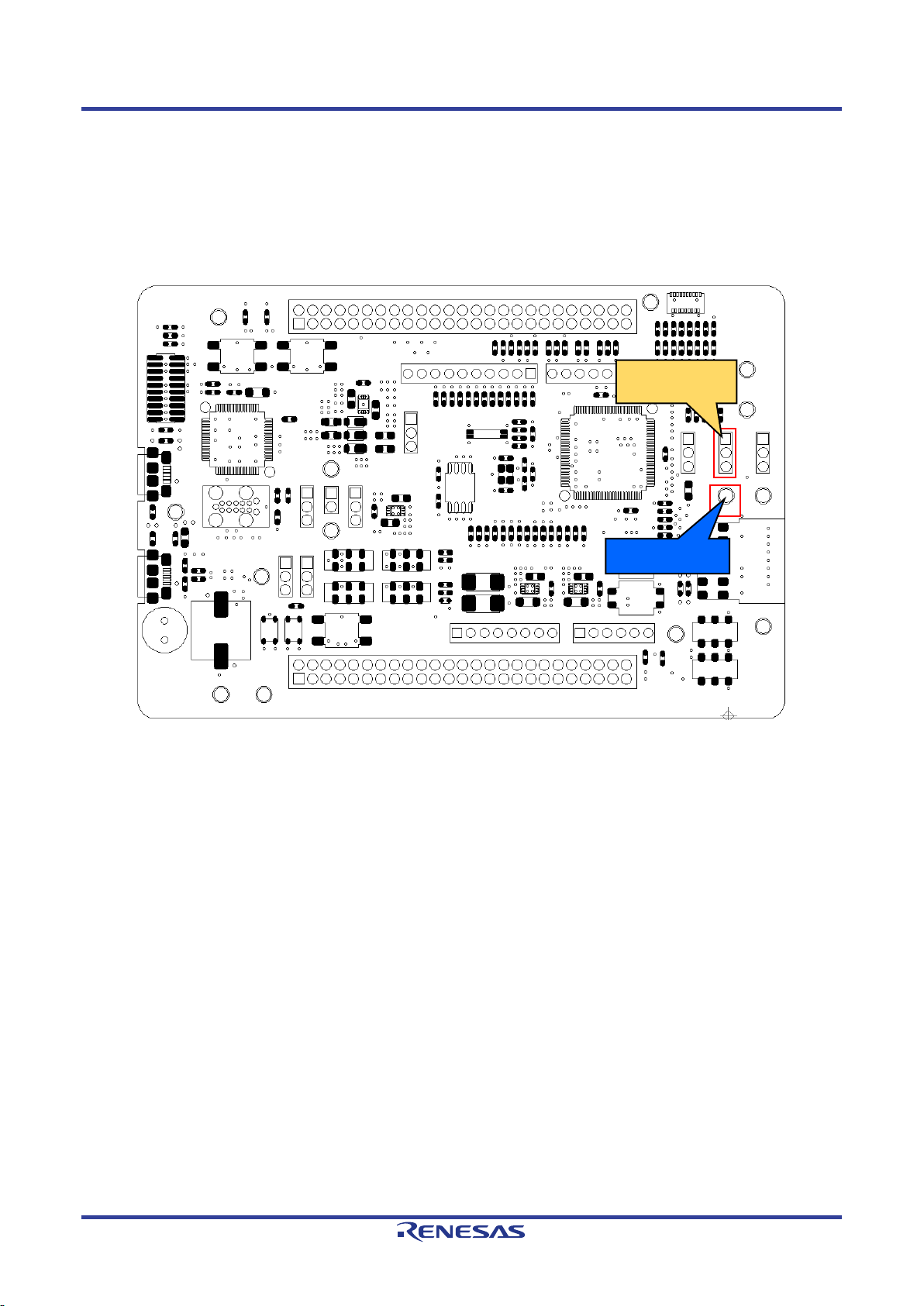

4.3.3 IOVCC1

Figure 4-5 shows the component layout. Follow the steps below when supplying voltage from external power

supply to IOVCC1 pin:

1. Open J7 jumper pin 1-2 and 2-3.

2. Supply voltage (1.62V – 3.6V) to any power supply pins other than IOVCC1 pin.

3. Supply voltage to T1.

2-3 open

Figure 4-5: Component Layout and Setting (External Power Supply)

R20UT4801EJ0102 Rev.1.02 Page 28 of 95

Apr 16, 2021

Page 29

Evaluation Kit RE01 256KB 4.Power Supply

AVCC0(T5)

4.3.4 AVCC0

The component layout are shown in Figure 4-6 and Figure 4-7. Follow the steps below when supplying

voltage from external power supply to AVCC0 pin:

1. Remove R108.

2. Fit R107.

3. Supply voltage (1.62V – 3.6V) to any power supply pins other than AVCC0 pin.

4. Supply voltage to T5.

Figure 4-6: Component Layout (External Power Supply (Top))

R20UT4801EJ0102 Rev.1.02 Page 29 of 95

Apr 16, 2021

Page 30

Evaluation Kit RE01 256KB 4.Power Supply

R108: removed

R107: fitted

Figure 4-7: Component Layout (External Power Supply (Bottom))

R20UT4801EJ0102 Rev.1.02 Page 30 of 95

Apr 16, 2021

Page 31

Evaluation Kit RE01 256KB 4.Power Supply

VREFH0(T2)

J5: 1-2 short

R54: removed

R55: removed

R56: fitted

4.3.5 VREFH0

The component layout and settings are shown in Figure 4-8. Follow the steps below when supplying voltage

from external power supply to VREF0 pin:

1. Remove R54 and R55

2. Fit R56.

3. Short J5 jumper pin 1-2.

4. Supply voltage (1.62V – AVCC0) to any power supply pins other than VREF0 pin.

5. Supply voltage to T2.

Figure 4-8: Component Layout and Settings (External Power Supply)

R20UT4801EJ0102 Rev.1.02 Page 31 of 95

Apr 16, 2021

Page 32

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Component Name

Setting

SW3, SW5*1

1-2, 5-6

Normal Operation

*2

SW4, SW6

1-2, 5-6

Normal Operation

*2

SW3: Normal

SW5: Normal

SW4: Normal

SW6: Normal

5. Operation/Start-up Mode

Evaluation Kit for RE01 supports 2 operation and start-up modes: normal and energy harvesting (hereinafter,

EHC).

5.1 Normal Operation

In normal operation, power is supplied from emulator or external power supply. To use normal operation

mode, several switch settings must be made. The layout and details of the switch setting are shown in Figure

5-1 and Table 5-1.

Other settings will be as per the default kit configuration, as supplied.

Figure 5-1: Component Layout and Settings (Normal Operation)

Table 5-1: Configuration Details (Normal Operation)

*1

: Also depends on debug function used. For more information, refer to Section 6. Debug.

*2

: The settings are supported in default configuration, as supplied.

R20UT4801EJ0102 Rev.1.02 Page 32 of 95

Apr 16, 2021

Page 33

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Component Name

Setting

J8

2-3

short

J10

1-2, 2-3

open

J15

2-3

short

SW3–SW6

2-3, 6-7

EHC

SW9

1-2

Startup*1

SW10

1-2

EHC

Component Name

Settings

J6

1-2

Supply voltage generated by DC/DC converter to IOVCC0 pin of RE01

2-3

Supply voltage generated by VCC/IOVCC pin of RE01 to IOVCC0 pin of

RE01

J7

1-2

Supply voltage generated by DC/DC converter to IOVCC1 pin of RE01

2-3

Supply voltage generated by VCC/IOVCC pin of RE01 to IOVCC1 pin of

RE01

IOVCC0 power selection

J8: 2-3 short

J10: 1-2 open

IOVCC1 power selection

SW3: EHC

SW5: EHC

SW4: EHC

SW6: EHC

SW10: EHC

SW9: Startup

J15: 2-3 short

5.2 EHC Operation

RE01 supports energy harvesting function. In EHC operation, the power is supplied from the included solar

panel. User circuit can start operating when voltage is supplied to VSC_VCC pin of RE01.

Switch settings are required to operate the energy harvesting function. The related component layout and

setting details are shown in Figure 5-2, Table 5-2, and Table 5-3. For more information of energy

control circuit for RE01 specifications, refer to RE01 Group User’s Manual’s Hardware.

switch (J7)

2-3 open

switch (J6)

harvesting

Other settings will be as per the default kit configuration, as supplied.

Figure 5-2: Component Layout and Settings (EHC Operation)

Table 5-2: Configuration Details (EHC Operation)

*1

: The setting is supported in default configuration, as supplied.

Table 5-3: Switch Details (J6, J7)

R20UT4801EJ0102 Rev.1.02 Page 33 of 95

Apr 16, 2021

Page 34

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

RE01-25 6KB

IOVCC IOVC C0 I OVCC1

J-LinkTM OB

Emula tor Con nector(CN2 )

Micro -B Connector

(US B2)

USB-UART Circuit

USB-UART IC

(U8)

: Signal Line

R

: Resisto r

R : Resistor(Do no fit)

SSW

: Slide switch

VCC/IOVCC to 3.3V

Voltag e Regulator

SW3, SW5

EHC

(Ope n)

R

R

SWD, RESn

DCDC_EHC_EN

SC I0

IIC0/1

SWCL K P411, SWDIO P207

SDA P012

SCL P 013

P209

Contr ol MCU

(U6)

Micro -B Connector

(US B1)

R

Boot

Startu p (Single chip)

Norm al

EHC

MD

EHMD

SW9

SW10

RE01-25 6KB

IOVCC

5.0V to 3. 3V

Voltag e Regulator

EHC

VCC/ IOVCC

IOVC C0 IOV CC1 AVCC0 VR EFH0

R

R

R

CC

Flash Memory

(U7)

USER S witches

(SW1, SW2)

MIP-LCD E xpansi on Boar d Inte rface

(PMO D1)

MIP-LCD(P arallel) Int erface

(CN1)

IOVC C0

IOVC C1

Arduin o UNO Header

(J3,J4,J13,J14)

5.0V

R

R

R

R

MCU

R

R

UC_ VCC

VCC_ MCU

VCC_ MCU

UC_ VCC

VR EFH0

J8 2-3 sho rt

J10

Open

J6

1-2 sho rt

VCC/IOVCC to 3.3V

Voltag e Regulator

J15

2-3 sho rt

R

J9

short

: Power Line

R

: Resisto r

R : Resistor(Do no fit)

C

: Cap acitor

: Jum per sw itch

: Thro ugh ho le

SSW

: Slide swit ch

LP_P RODUCT_3V3

Ext_DCDC

Emula tor or

USB

VSC_VCC

VBAT_EHC

SW4 EHC

SW6 EHC

VC C_SU

UC_ VCC

T10

BT1 o r

BT2

J7

1-2 sho rt

J5

1-2 sho rt

Figure 5-3: Block diagram of Signal line (EHC Operation)

Figure 5-4: Block diagram of Power line (EHC Operation)

R20UT4801EJ0102 Rev.1.02 Page 34 of 95

Apr 16, 2021

Page 35

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Solar Panel Interface (T9, T10)

RE01

RE01

Port

Pin

Port

Pin

T9

GROUND

-

-

T10

-

VSC_VCC

29

Solar panel interface

Solar panel interface

Solar panel

5.2.1 Solar Panel

This product is equipped with solar panel interface (T9, T10). The component layout and details are

displayed in Figure 5-5 and Table 5-4. Connect the included solar panel to T9 and T10 using the attached IC

clip.

(T9)

(T10)

Figure 5-5: Component Layout (EHC Operation)

Table 5-4: Solar Panel Interface

Pin

Name

Pin Name

R20UT4801EJ0102 Rev.1.02 Page 35 of 95

Apr 16, 2021

Page 36

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Component Name

Setting

J12

1-2

External battery

2-3

Supercapacitor

Component Name

Setting

J11

1-2

Charging from external power supply

2-3

Charge by using board voltage

Supercapacitor (BT2)

Interface for external

battery(BT1)

Charging method selection switch

Battery selection switch (J12)

Charging Terminal (T7)

5.2.2 Supercapacitor / External Battery

Supercapacitor / external battery can be connected to VBAT_EHC pin in RE01. Switch settings are required

in order to use supercapacitor / external battery. Component layout and configuration details are shown in

Figure 5-6 and Table 5-5.

(J11)

Figure 5-6: Component Layout (EHC Operation)

Table 5-5: Switch Configuration(J12)

When using supercapacitor, the supercapacitor itself may need to be charged because it may have been

discharged. There are 2 charging methods that can be selected through switch setting. The related

component layout and settings are shown in Figure 5-6 and Table 5-6.

When charging, use J12 in the open setting.

• Charging from external power supply

Connect a stabilized power supply to the charging

terminal (T7).

• Charging from the voltage converted on board supplied by an emulator

Connect an emulator to CN2 port or a USB cable to USB1/USB2 port.

Set the charging voltage (2.6V or 3.0V) to the value specified in Secondary Battery (VBAT) Charging Voltage

Select Bit (VBATSEL) in Option Function Select Register 1 (OFS1).

Table 5-6: Switch Configuration(J11)

Set J11 to 1-2 after charging is completed.

R20UT4801EJ0102 Rev.1.02 Page 36 of 95

Apr 16, 2021

Page 37

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

External Battery (BT2)

RE01

RE01

Port

Pin

Port

Pin

1 - VBAT_EHC

28

2

GROUND

-

-

Storage Capacitor (C29)*

Storage Capacitor (C25)

Storage Capacitor (C30)

Make sure that the external battery is already installed before selecting the external battery. The component

layout and setting are described in Figure 5-6 and Table 5-7.

1

The recommended external battery is SLB Series (Nichicon). Because the included solar panel*

generates

42µA, it might take time to charge the recommended external battery, depending on the operation setting of

RE01. Depending on your evaluation

1

: Panasonic AM-1815CA operating voltage 3.0 V, operating current 42.0µA (white fluorescent lamp-

*

200lx(25

o

C))

content, consider charging before mounting.

Table 5-7: External Battery (BT2)

Pin

Signal Name

Pin Signal Name

5.2.3 Storage Capacitor

RE01 has a 200uF capacitor connected to the VCC_SU pin. Depending on your board environment, it may

be necessary to change the capacitor’s capacitance connected to VCC_SU pin. If necessary, mount a

capacitor on C29 (size: 1608). Component layout is shown in Figure 5-7. For more information about storage

capacitor specifications, refer to RE01 Group User’s Manual’s Hardware.

*

: DNF

5.2.4 DC/DC Converter Control

DC/DC converter must be enabled to supply the voltage to the user circuit when using energy harvesting

function. To enable DC/DC converter, output a high level from P209 and make sure that there is enough

charging voltage in external battery/supercapacitor. This voltage equals to the value of VBATSEL setting

(2.6V or 3.

0V).

R20UT4801EJ0102 Rev.1.02 Page 37 of 95

Apr 16, 2021

Figure 5-7: Component Layout (EHC Operation)

Page 38

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Component Name

Setting

J6, J7

1-2

short

J12

2-3

short

J6: 1-2 short

J7: 1-2 short

J12: 2-3 short

Solar Panel Interface

Solar Panel Interface

5.2.5 How to Use

5.2.5.1 When Operating Peripheral Circuits after Steady Operation Period

Follow the steps below to operate peripheral circuits after EHC steady operation period. The settings below

are intended for the case where supercapacitor (charged) is used. The program has to be downloaded to

RE01 internal flash memory in advance.

Sample code is also available on Renesas website, entitled “Maintenance free power management by RE

energy harvesting controller (R01AN4837)”.

1. Follow the setting shown in Figure 5-2 and Table 5-2.

2. Follow the setting shown in Figure 5-8 and Table 5-8.

3. Connect the solar panel to the solar panel interface (T9 and T10).

(T9)

(T10)

Figure 5-8: Component Layout and Settings (EHC Operation)

Table 5-8: Configuration Details (EHC Operation)

The settings in the table above are supported in default configuration, as supplied.

R20UT4801EJ0102 Rev.1.02 Page 38 of 95

Apr 16, 2021

Page 39

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Component Name

Setting

J6

2-3

short

J7

1-2

short*1

J12

2-3

short*1

J6: 2-3 short

J7: 1-2 short

PMOD Connector

(

J12: 2-3 short

Solar Panel Interface

Solar Panel Interface

5.2.5.2 When using the MIP-LCD Expansion Board During Secondary Battery Charging Period

Follow the steps below to operate MIP LCD expansion board during secondary battery charging period. The

setting below are intended for the case where supercapacitor (charged) is used. The program has to be

downloaded to RE01 internal flash memory in advance.

Sample code is also available on Renesas website, entitled “Energy harvesting launch operation and quick

start SMIP display

demo using Evaluation Kit RE01 256KB (R01AN5406)”.

1. Follow the settings shown in Figure 5-2 and Table 5-2.

2. Follow the settings shown in Figure 5-9 and Table 5-9.

3. Connect MIP-LCD expansion board to the PMOD connector (PMOD1). (Refer to Section 8.5.1 MIP-LCD

Expansion Board for more details).

4. Connect the solar panel to solar panel interface (T9, T10).

(T9)

(T10)

Figure 5-9: Component Layout and Settings (EHC Operation)

Table 5-9: Configuration Details (EHC Operation)

*1

: The settings are supported in default configuration, as supplied.

PMOD1)

R20UT4801EJ0102 Rev.1.02 Page 39 of 95

Apr 16, 2021

Page 40

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Component Name

Setting

J6

1-2

short*1

J7

2-3

short

J12

2-3

short*1

J6: 1-2 short

J7: 2-3 short

MIP-LCD Connector(CN1)

J12: 2-3 short

Solar Panel Interface

Solar Panel Interface

5.2.5.3 When using Parallel MIP-LCD during Secondary Battery Charging Period

Follow the steps below to operate parallel MIP LCD during secondary battery charging period. The setting

below are intended for the case where supercapacitor (charged) is used. The program has to be downloaded

to RE01 internal flash memory in advance.

1. Follow the settings shown in Figure 5-2 and Table 5-2.

2. Follow the settin

gs shown in Figure 5-10 and Table 5-10.

3. Connect parallel MIP-LCD to the MIP-LCD connector (CN1). (Refer to Section 8.7 MLCD (Memory In

Pixel Liquid Crystal Display) Interface for more details).

4. Connect the solar panel to solar panel interface (T9, T10).

(T9)

(T10)

Figure 5-10: Component Layout and Settings (EHC Operation)

Table 5-10: Configuration Details (EHC Operation)

*1

: The settings are supported in default configuration, as supplied.

R20UT4801EJ0102 Rev.1.02 Page 40 of 95

Apr 16, 2021

Page 41

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Discharge Switch (SW7)

Discharge Switch (SW8)

5.2.5.4 Discharge Switch (SW7, SW8)

Discharge switches are included in the main board. SW7 is used to discharge RE01 VCC/IOVCC power

supply line. SW8 is used to discharge storage capacitors (C25, C29, and C30). This discharge switches

must be used when the user uses energy harvesting function, operate the main board, then restart the

energy harvesting function again from the beginning. Press the discharge switches before using energy

harvesting function every time the energy harvesting function is started up from the beginning. The

discharge

switches are shown in Figure 5-11.

Figure 5-11: Component Layout (EHC Operation)

R20UT4801EJ0102 Rev.1.02 Page 41 of 95

Apr 16, 2021

Page 42

Evaluation Kit RE01 256KB 5.Operation/Start-up Mode

Switch Setting

Start-up Mode

MD (SW9)

EHMD (SW10)

1-2: short

1-2: short

Energy Harvest Start-up Mode

1-2: short

2-3: short

Normal Start-up Mode

*1

2-3: short

-*2

SCI/USB Boot Mode

Start-up Mode Switch (SW9)

Start-up Mode Switch (SW10)

1-2: short

2-3: short

5.3 RE01 Start-up Mode

RE01 supports 3 start-up modes. Switch settings are necessary to select the start-up mode. Component

layout and settings related to start-up modes are explained in Figure 5-12 and Table 5-11. For more details of

start-up modes for RE01, refer to RE01 Group User’s Manual’s Hardware.

Figure 5-12: Component Layout (RE01 Start-up Mode)

Table 5-11: Configuration Details (RE01 Start-up Mode)

*1

: The setting is supported in default configuration, as supplied.

*2

: Don't care

R20UT4801EJ0102 Rev.1.02 Page 42 of 95

Apr 16, 2021

Page 43

Evaluation Kit RE01 256KB 6.Debug

Supported Emulator

Chapter Reference

J-LinkTM OB

6.1, 6.5

J-LinkTM

6.2, 6.5

I-JetTM

6.2

E2

6.3, 6.4

J-LinkTM OB Connector (USB1)

J8: 1-2 short

J9: short

SW3: Normal

SW5: Normal

USB Cable

R71: Fitted

R72: Removed

R74: Fitted

R76: Removed

J10: 1-2 short

6. Debug

This board supports emulators as listed in Table 6-1.

Table 6-1: Supported Emulators

6.1 J-Link

This main board is equipped with Segger J-Link

included USB cable to this board and host PC.

6.1.1 Component Layout and Settings when using J-Link

When using J-Link

the component layout and detailed settings for using J-Link

configuration, as supplied.

Figure 6-2 and Figure 6-3 show the connection relationship between the power supply and signals in this

setting change.

TM

OB

TM

OB, several switch and resistor settings must be set. Figure 6-1 and Table 6-2 shows

TM

OB. RE01 debugging is possible by connecting the

TM

OB

TM

OB. This function is supported in the default

Other settings will be as per the default kit configuration, as supplied.

R20UT4801EJ0102 Rev.1.02 Page 43 of 95

Apr 16, 2021

Figure 6-1: Component Layout and Settings (J-Link

TM

OB)

Page 44

Evaluation Kit RE01 256KB 6.Debug

Component

Setting

SW3, SW5

1-2, 5-6

Normal

J8

1-2

short

J9 - short

J10

1-2

short

R71, R74

Fitted

R72, R76

Removed

Arduin o UNO Header

(J3,J4,J13,J14)

RE01-25 6KB

IOVCC IOVC C0 IOV CC1 AVCC0 V REFH0

J-LinkTM OB

Emula tor Con nector(CN2 )

Micro -B Connector

(US B2)

USB-UART Circuit

USB-UART IC

(U8)

Flash Memory (U7)

MIP-LCD E xpansi on Boar d Inte rface ( PMOD1)

MIP-LCD(P arallel ) Interf ace (CN 1)

VCC/ IOVCC to VCLH

Voltag e Regulator

VCC/ IOVCC to VCL

Voltag e Regulator

: Signal Line

R

: Resisto r

R : Resistor(Do no fit)

SSW

: Slide switch

VCC/IOVCC to 3.3V

Voltag e Regulator

SW3, SW5

Norm al setting

R

R

R

R

SPI0/1

SWD, RESn

DCDC_Ext_EN

DCDC_EHC_EN

R

QSPI

SC I0

R

User LE DS (LED0, LED 1)R

IO

Analog IO

IO

MLCD

IIC0/1

IIC0/1

IIC0/1

Analog VREF

R

IO

IO

P000

P001

P002

P003

P004

P005

IO(IOVCC):

Analog IO:

SDA P012

SCL P 013

IIC0/1

(IOVCC0):

CLK P 011

SSL P015

MOSI P 010

MISO P815

SPI0/1:

(IOVCC0):

P409

IO(IOVCC1):

P204

P205

P302

P314

P315

P602

P603

P604

SWCL K P411, SWDIO P207

TXD P7 02, RXD P702, C TS P704, RTS P202

IO: P210,P410

SPCLK P011, SS L P015, MOSI P010, MISO P815

QSPC LK P812, QSS L P807, QIO P80[ 8:11]

IO: P508,P509

SCLK P111, VCOM P113, ENBS P1 09,

XRST P1 12, DATA P10 [0:7],

DEN P110, ENBG P108

P204 P 205 P302 P314 P3 15 P602 P60 3 P604

P000 P 001 P002 P003 P0 04 P005

P409

VR EF

(VREFH0)

VR EFH0

VR EFH0

SDA P012

SCL P 013

P208

P209

User Switches (SW1,SW2)

Contr ol MCU

(U6)

Micro -B Connector

(US B1)

SSW

R

R71, R7 4 fitted

R72, R7 6

not fitted

TM

Table 6-2: Configuration Details (J-Link

OB)

The settings in the table above are supported in the default configuration, as supplied.

For details on the connection terminals, please refer to Chapter 3 or Chapter 8 Tables.

R20UT4801EJ0102 Rev.1.02 Page 44 of 95

Apr 16, 2021

Figure 6-2: Block diagram of Signal line (J-LinkTM OB)

Page 45

Evaluation Kit RE01 256KB 6.Debug

RE01-25 6KB

IOVCC

5.0V to 3. 3V

Voltag e Regulator

EHC

VCC/ IOVCC

IOVC C0 I OVCC1

AVCC0

VR EFH0

R

R

R

C

C

Contr ol MCU

(U6)

Micro -B Connector

(US B1)

J-LinkTM OB

Emula to r Connect or

(CN2 )

Micro -B Connector

(US B2)

USB-UART Circuit

USB-UART IC

(U8)

Flash Memory

(U7)

USER S witches

(SW1, SW2)

MIP-LCD E xpans ion Boar d Inte rface

(PMO D1)

MIP-LCD(P arallel) Int erface

(CN1)

IOVC C0

IOVC C1

Arduin o UNO Header

(J3,J4,J13,J14)

5.0V

R

R

R

R

MCU

VCC/ IOVCC to VCLH

Voltag e Regulator

VCC/ IOVCC to VCL

Voltag e Regulator

R

R

UC_ VCC

VCC_ MCU

VCC_ MCU

UC_ VCC

VR EFH0

5.0V

J8 1-2s hort

J10

1-2sho rt

J6

J7

J5

SSWSSW

VCC/IOVCC to 3.3V

Voltag e Regulator

J15

SW11

SW12

R

J9 Sho rt

: Power Line

R

: Resisto r

R : Resistor(Do no fit)

C

: Cap acitor

: Jum per sw itch

: T hrough ho le

SSW

: Slide swit ch

LP_P RODUCT_3V3

HOST PC

USB cable

Main Board

Figure 6-3: Block diagram of Power line (J-LinkTM OB)

6.1.2 Debugger Connections

Figure 6-4 shows the connections between main board (J-Link OB) and host PC. When using J-Link OB, do

not connect to other emulators.

TM

OB)

Figure 6-4: Debugger Connection Diagram (J-Link

R20UT4801EJ0102 Rev.1.02 Page 45 of 95

Apr 16, 2021

Page 46

Evaluation Kit RE01 256KB 6.Debug

Component

Setting

SW3, SW5

2-3, 6-7

EHC (J-Link OB not used)

J8

1-2

short*1

J9 - short*1

J10

1-2

short*1

R71, R74

Fitted*1

R72, R76

Removed*1

Emulator Connector (CN2)

Emulator

J8: 1-2 short

J9: short

SW3: EHC (J-Link OB not used)

SW5: EHC (J-Link OB not used)

R71: Fitted

R72: Removed

R74: Fitted

R76: Removed

J10: 1-2 short

6.2 I-jet

This main board can connect to IAR I-jet emulator or Segger J-Link

TM

, J-LinkTM

TM

emulator. RE01 can be debugged by

using these emulators.

TM

6.2.1 Component Layout and Settings when using I-jet

, J-LinkTM

When using the emulator, several switch and resistor settings must be set. Figure 6-5 and Table 6-3 shows

the component layout and detailed settings. This function is not supported in the default configuration, as

supplied.

Figure 6-6 and Figure 6-7 show the connection relationship between the power supply and signals in this

setting change.

Other settings will be as per the default kit configuration, as supplied.

TM

Figure 6-5: Component Layout and Settings (I-jet

Table 6-3: Configuration Details (I-jet

*1

: The settings are supported in default configuration, as supplied.

TM

, J-LinkTM)

, J-LinkTM)

R20UT4801EJ0102 Rev.1.02 Page 46 of 95

Apr 16, 2021

Page 47

Evaluation Kit RE01 256KB 6.Debug

Arduin o UNO Header

(J3,J4,J13,J14)

RE01-25 6KB

IOVCC IOVC C0 IOV CC1 AVCC0 V REFH0

J-LinkTM OB

Emula tor Con nector(CN2 )

Micro -B Connector

(US B2)

USB-UART Circuit

USB-UART IC

(U8)

Flash Memory (U7)

MIP-LCD E xpansi on Boar d Inte rface ( PMOD1)

MIP-LCD(P arallel ) Interf ace (CN 1)

VCC/ IOVCC to VCLH

Voltag e Regulator

VCC/ IOVCC to VCL

Voltag e Regulator

: Signal Line

R

: Resisto r

R : Resistor(Do no fit)

SSW

: Slide switch

VCC/IOVCC to 3.3V

Voltag e Regulator

SW3, SW5

EHC s etting (J-Link OB not used)

R

R

R

R

SPI0/1

SWD, RESn

DCDC_Ext_EN

DCDC_EHC_EN

R