Page 1

OB1203SD

Integrated Context Engine for Heart Rate and Bl ood Oxygen Saturation measurement with BLE

X0008647 Rev.1.2

Feb.8.21

Page 1

Copyright © 2021

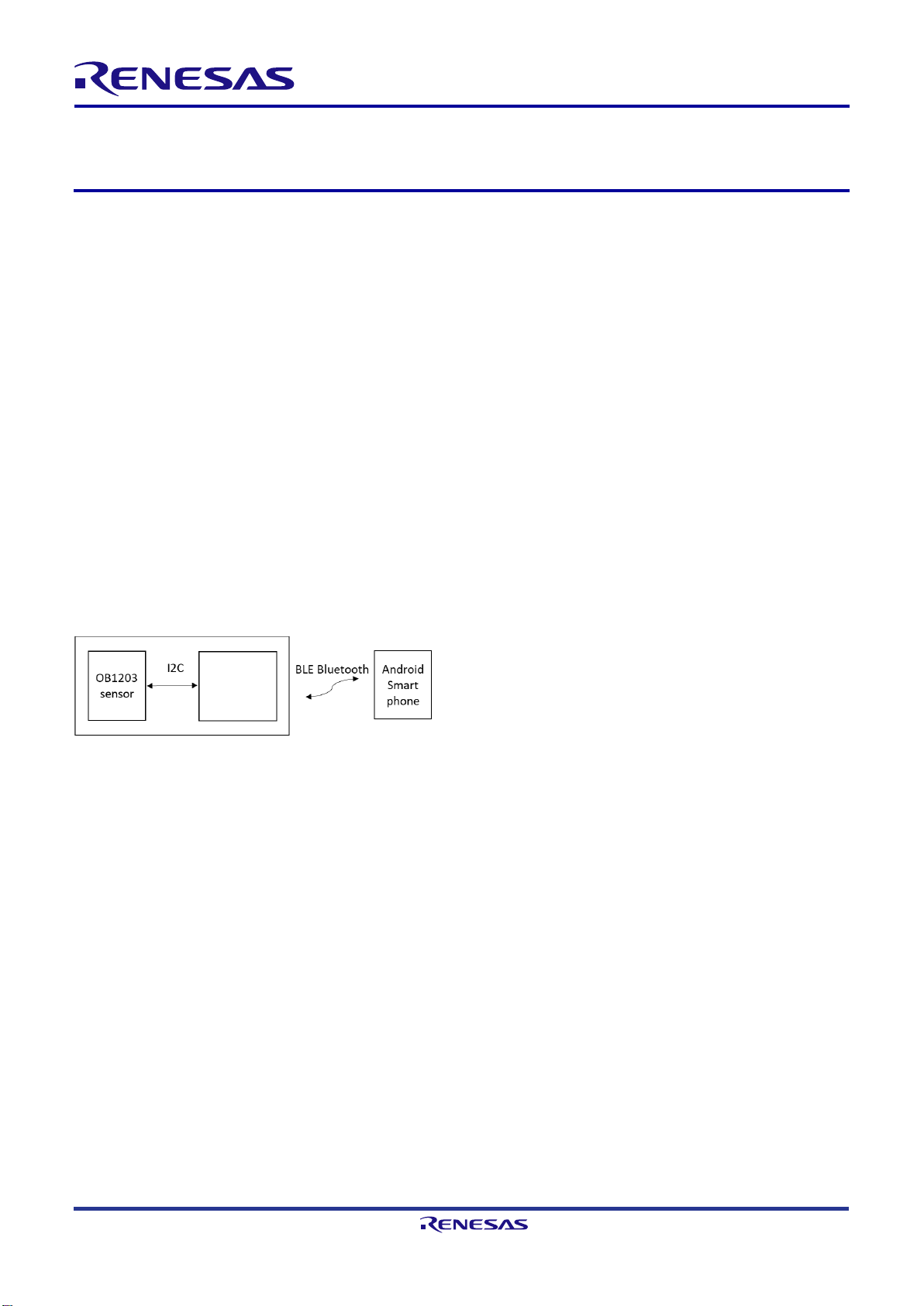

TLSR8258

-BT-EVK

The Integrated Context Engine (ICE) for Biosensing

(see Figure 2) includes:

■

Renesas OB1203 reflective photoplethysmography

(PPG), proximity (PS) and light / color (LS/CS)

sensor

■

Telink’s TLSR8258F512 micro controller with

Bluetooth Low Energy (BLE) radio

■

LiPo’s LP201030 rechargeable Li ion battery , 3.7

V, 40mAh, 10

[1] Light and color sensing function not used in this application.

× 30 × 2 mm

3

.

The ICE hardware performs reflective, non-invasive

measurements (e.g., at the fingertip), transmits the data

via BLE to a smartphone or tablet (see Figure 1), where

the Heart Rate (HR) and blood oxygen saturation

(SpO

) are determined by an Android app. During this

2

process the proximity sensor function keeps the

measurement running as long as there is a finger

present.

Controller

Figure 1. Block Diagram of ICE

OB1203 Sensor Features

■

Highly reliable and industry-proven OSIP package

with integrated cover glass for hypoallergenic

products

■

Integrated and factory trimmed LED source, driver,

and photodetector

■

PPG (Heart Rate and Blood Oxygen Concentration):

●

Aesthetic industrial design options with unique

far-red LED allowing SpO

behind visibly dark, IR-transmissive ink.

●

16 to 18 bits output resolution

●

High speed sampling up to 3200 samples per

second for highest resolution and improved

SNR

●

On-chip averaging and FIFO data storage

enable convenient asynchronous access to data

measurements

2

[1]

Evaluation Kit Manual

■

Proximity Sensor:

●

Up to 16 bits resolution

●

Ambient light suppression

●

Analog and digital crosstalk cancelation

■

Wide operation temperature range: -40°C to +85°C

■

Wide supply voltage range:

●

1.7V to 3.6V for digital / analog

●

3.3 V to 5.0 V for LEDs

■

I2C interface capable of 100kHz or 400kHz

communication

■

Programmable level-based interrupt functions

■

Industry’s smallest package: 4.2 × 2 × 1.2 mm3

14-pin module

Radio Mode Features

■

Telink TLSR8258F512

●

BT 4.2 BLE 2.4GHz radio

●

32-bit MCU at 48MHz, 512 kB flash, 32kB SRAM

●

Wide supply voltage range: 1.9V to 3.6V

■

Compact size: 32-pin, 5.0 × 5.0 × 0.75 mm package

ICE Characteristics

■

PCB (see Figure 2):

●

Operation temperature range: -40°C to +85°C

●

PCB supply voltage range: 3.3 V to 6.5V

●

PCB: 40mm × 11mm (21mm with program pads) ×

5mm with USB charge connector (3.1mm without)

●

Program pad PCB section removable

■

Battery life:

●

150 × 30s measurements

●

Typical PCB quiescence current: 0.5 µA at 4V

●

Battery capacity: 40mAh if charged up to 4.2V

●

Battery operation: 3.3V to 4.2V

●

Rechargeable via USB Micro cable

●

> 70% shelf: 1 year stored (-20°C to 30°C)

■

Battery operating temperature range -20C° to + 60°C

Applications

■

Mobile devices: Wearables, Fitness, and Accessories

■

Industrial: Worker Safety, Driver Assist

Page 2

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 2

Contents

1. ICE Hardware.................................................................................................................................................. 3

2. Sensor Function............................................................................................................................................. 4

3. Getting Started ............................................................................................................................................... 5

4. Resources ....................................................................................................................................................... 7

4.1 PCB Schematics .................................................................................................................................... 7

4.2 PCB Layout ............................................................................................................................................ 9

4.3 PCB Components ................................................................................................................................ 10

4.4 Programming Pins ............................................................................................................................... 10

4.5 Programming Tools ............................................................................................................................. 10

4.6 Bill of Materials .................................................................................................................................... 11

4.7 OB1203 Run Mode .............................................................................................................................. 11

4.8 HR Algorithm ....................................................................................................................................... 12

4.9 SpO2 Algorithm .................................................................................................................................... 12

4.10 Recharging the Battery ........................................................................................................................ 12

4.11 Troubleshoot ........................................................................................................................................ 12

5. Ordering Information ................................................................................................................................... 13

6. Revision History .......................................................................................................................................... 13

Figures

Figure 1. Block Diagram of ICE ................................................................................................................................ 1

Figure 2. ICE Hardware ............................................................................................................................................ 3

Figure 3. Reflective HR and SpO2 Measurement .................................................................................................... 4

Figure 4. PPG Signal Measured at Finger Tip .......................................................................................................... 4

Figure 5. Recommended Height of a Finger Rest .................................................................................................... 4

Figure 6. PCB Activation Switch ............................................................................................................................... 5

Figure 7. Finger Rest Examples ............................................................................................................................... 6

Figure 8. Components for the OB1203 Sensor ........................................................................................................ 7

Figure 9. OB1203 Schematics .................................................................................................................................. 7

Figure 10. MCU Schematics ..................................................................................................................................... 8

Figure 11. Power Schematics ................................................................................................................................... 8

Figure 12. Connector Schematics ............................................................................................................................ 9

Figure 13. PCB Bottom with Telink Chip Left of the Middle ..................................................................................... 9

Figure 14. PCB Top with OB1203 at the Right ......................................................................................................... 9

Figure 15. PCB Functions ....................................................................................................................................... 10

Figure 16. Functions of Programming Pins ............................................................................................................ 10

Tables

Table 1. Bill of Materials ......................................................................................................................................... 11

Page 3

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 3

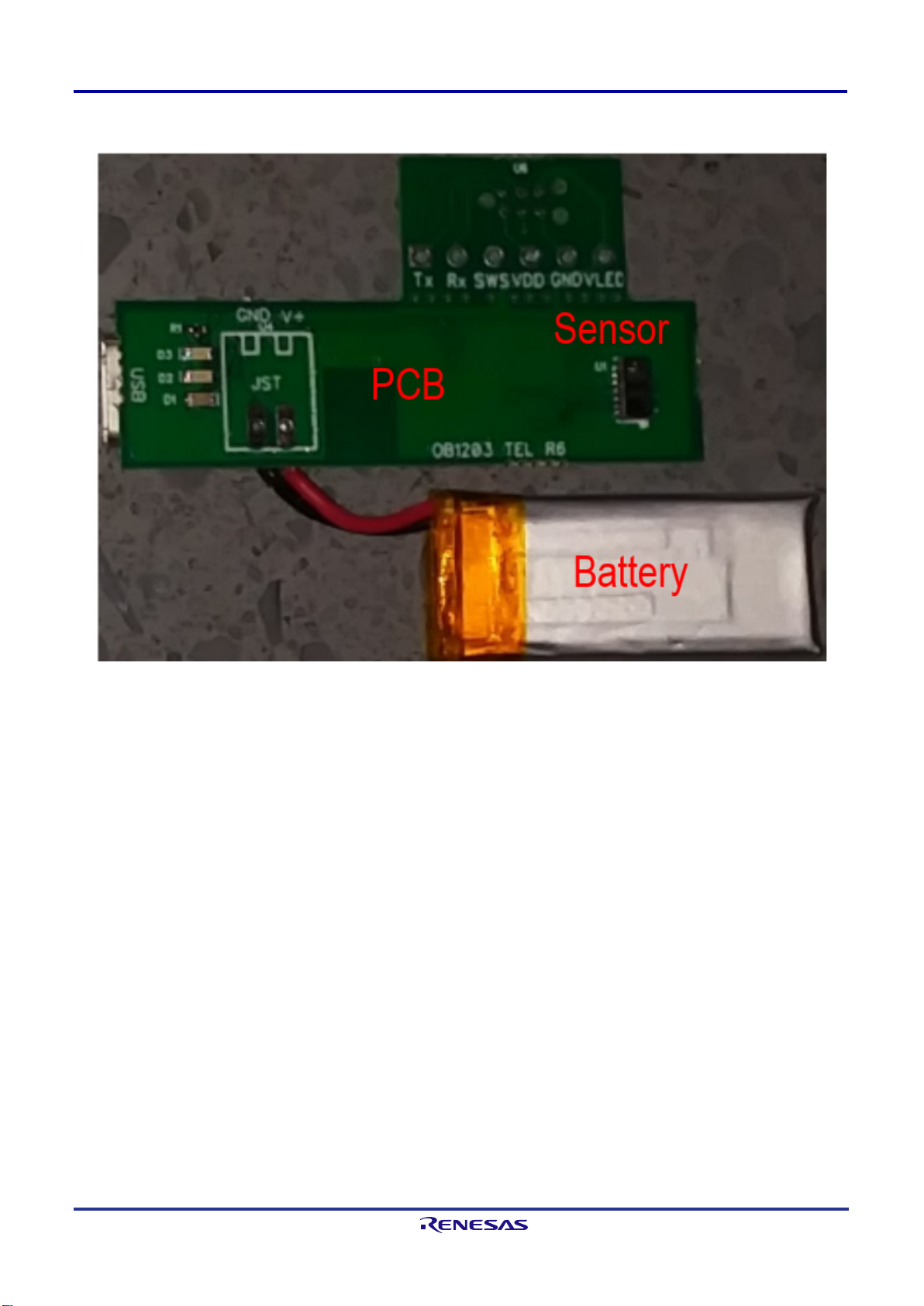

1. ICE Hardware

Figure 2. ICE Hardware

Page 4

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 4

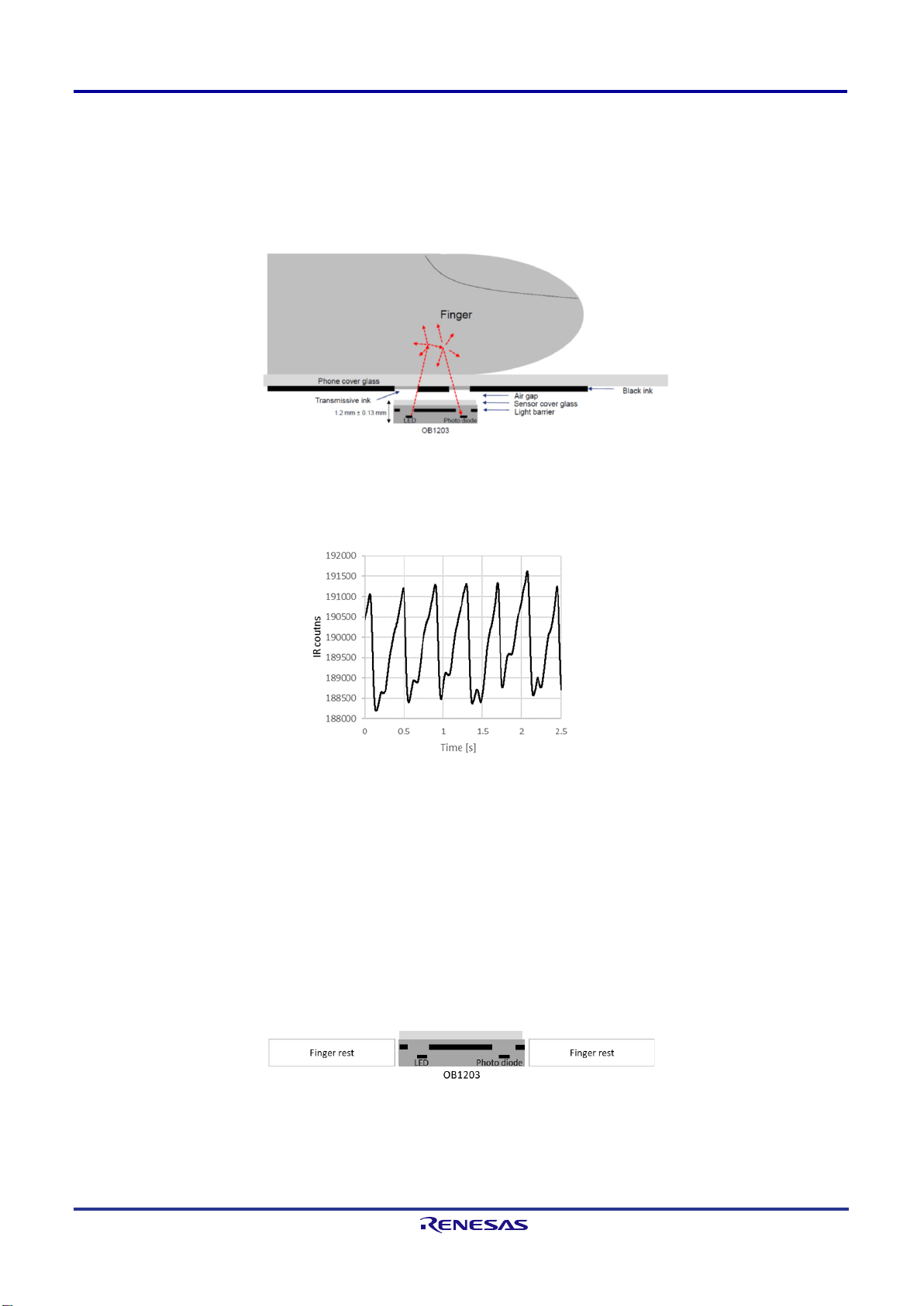

2. Sensor Function

Figure 3 shows the principal of a reflective measu rement. In this case the sensor is located under a cover glass

that uses black and IR transmissive ink to visibly hide the PCB / sensor module. Light from the sensor module’ s

LED is reflected from the finger tissue and detected by the photo diode. As blood absorbs light, changes in bl ood

volume (caused by the heart beat) generate a small change in the intensity of the reflected light.

Figure 3. Reflective HR and SpO2 Measurement

Figure 4 shows this signal change of about 3,000 counts (peak to peak) on top of a DC signal of 190,000 counts

due to direct reflections from the finger tissue.

Figure 4. PPG Signal Measured at Finger Tip

The DC content of the signal as well as light reflections in the sensor set up (like reflections from the cover glass,

etc.) are called optical crosstalk. For a high AC t o DC ratio, a good AC signal and / or a small DC signal are key.

■

In order to get a good blood flow / good AC signal, the finger pressure onto the sensor needs to be light.

■

In order to keep the optical cross talk small, the dist ance from the sensor to the finger should be kept to a

minimum.

For example, without using a cover glass the f inger pressure can be kept low by using a finger rest (like the

cover of the provided sensor house) to spread the finger – sensor force over a larger area.

To recycle some of the diffused light the best col or f or the finger rest is white. To avoid additional optical cros s

talk the finger rest should not be thicker than the package (see Figure 5).

Figure 5. Recommended Height of a Finger Rest

Page 5

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 5

3. Getting Started

1. Install the Android app:

a. Download the app from the USB stick or GitHub

(

https://github.com/hyperdga/Android_OB1203_serial_BLE)

b. Click on the app to install.

c. Go to Settings -> Apps -> IDT HR Sensor -> Permissions -> activate ‘your locati on’ .

d. Turn on Bluetooth.

e. Open app. Activate sensor board by pushing the a ct ivation switch (Figure 6). Keep finger off sensor to

get a low data rate while pairing Android device with sen sor. App asks for Bluetooth pairing. After pairing

close app and reopen it.

f. After sensor re-programming unpair and pair again.

g. If Bluetooth does not connect, turn Bluetooth off / on and / or reboot Android device.

2. Open the app.

3. Put your finger on the heart rate sensor. Apply pressure until the activation switch on the bottom side of the

PCB (see arrow in Figure 6) clicks. Keep pressure until counter starts counting.

The pressure level sufficient to activate the switch is not required during measurement, as the sensor boa rd

stays active for about 30 seconds after the switch i s released. Less pressure on the blood vessels produce

better results.

Figure 6. PCB Activation Switch

4. The proximity function of the sensor deactivates / reactivates the red LED and heart rate measurement if the

finger is out of / back in range. This allows to relax or repositioning the finger without losing Bluetooth

connection.

5. When activated, the sensor measures the reflecte d LED light signals and transmits them to the Android

device which calculates and displays heart rate and S pO2.

6. A Finger Rest around the sensor (examples are shown i n F igure 7) distributes the force between sensor and

finger, improving the blood flow and accuracy of measurement.

Page 6

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 6

Figure 7. Finger Rest Examples

Page 7

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 7

4. Resources

4.1 PCB Schematics

■

The PCB contains the OB1203 and Telink devices a s well as the following components:

●

Voltage stabilization and bypass capacitors for t he OB1203

●

Voltage stabilization and bypass capacitors, ant enna, and quartz for the Telink module

●

Pull-up resistors for the I2C bus and the interrupt

●

A 3.3V voltage regulator

●

A normally open-power switch

●

A re-chargeable battery and a USB 5V to 4.2V Li Ion batt ery charger

Figure 8. Components for the OB1203 Sensor

Figure 9. OB1203 Schematics

Page 8

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 8

Figure 10. MCU Schematics

(Note: The battery voltage sense feature is supported by HW but not programmed yet in FW.)

Figure 11. Power Schematics

(Note: When the switch U2 is pressed (upper left), the U12 becomes conductive and the MCU wakes up. The MCU keeps the wake

line high for about 40 seconds leaving U12 conductive. When releasing the wake line, the system pow er is sw itched off.)

Page 9

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 9

4.2 PCB Layout

Figure 12. Connector Schematics

Figure 13. PCB Bottom with Telink Chip Left of the Middle

Figure 14. PCB Top with OB1203 at the Right

Page 10

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 10

4.3 PCB Components

4.4 Programming Pins

Figure 15. PCB Functions

4.5 Programming Tools

Hardware:

■

Telink Programmer, available from Telink

Software:

■

Telink-Semi IDE

■

Telink BDT

a. Open the .bin file.

b. Select 8258

c. Connect the tool to ICE PCB.

d. Click Erase.

[b]

for C coding and compiling

[b]

(Burn & Debug) for code (.bin file) uploading:

Figure 16. Functions of Programming Pins

(Note: Remove re-chargeable battery for programming)

Page 11

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 11

RefDes Value

Name

Manufacturer

A1 2.4GHz AN T3216A 063R2400A Yageo

C1 18pF CAP 0402 ti ght

C2 1.2pF CAP 0402 ti ght

C3 220pF CAP 0402 ti ght

C4 1.8pF CAP 0402 ti ght

C5 1pF CAP 0402 ti ght

C6, C10, C11, C17 0.1uF CAP 0402 ti ght

C7 4.7uF CAP_0603

C8, C9 10uF CA P_0603

C12, C13 15pF CAP 0402 ti ght

C14, C19, C20, C21 1uF CAP 0402 ti ght

C15 22uF CAP_0603

C16 0.2uF CAP 0402 ti ght

C18

2.2uF CAP 0402 ti ght

C22 DNP

CAP 0402 ti ght

D1 SML-D12U1WT86 LED Red 0603 Rohm

D2, D3 SML-E12M8WT86 Rohm LED Green 0603 Rohm

J2 HDR- 1x 6

L1 1.3nH 0402 IN D

L2 3.3nH 0402 IN D

L4

10uH IN D_0603

R1 200 RES 0402 ti ght

R2

2M RES 0402 tight

R3 10M RES 0402 ti ght

R4, R9 1M RES 0402 ti ght

R5, R10 3.9M

RES 0402 ti ght

R6 15k RES 0402 ti ght

R7, R8 100 RES 0402 ti ght

R11

3.3M RES 0402 tigh t

U1 OB1203

U2 PTS 830GX140 swi tch C&K

U3 ECS-240-12-33Q-JES- TR?

U4 JST+pad 2 pin batt

U5 TLSR8258F512ET32 Telink

U6 Tag_connect_6_ARM

U8 TLV 70033DCKR

U9 TS881I CT

U10 USB m i cro AMP 10118192- 0002LF

U11 500mA Li Po charger MCP 73831T- 2A TI /OT

U12 PMZ950UPEYL l ow l eakage PMOS Nexperia

e. Click Activate.

f. Click Download.

g. Click Start mcu.

[b]

Available with user manual from https://www.telink-semi.com/.

4.6 Bill of Materials

4.7 OB1203 Run Mode

■

1600 samples per second

■

16 times averaging on OB1203 before data gets stored in FIFO

■

Automatic Gain control adjusting the LED currents to keep signal between 70 and 100 % of ADC count range

Table 1. Bill of Materials

Page 12

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 12

4.8 HR Algorithm

■

Partial autocorrelation coarse / fine search method

4.9 SpO2 Algorithm

■

Collect about 2.5s worth of data

■

Measure and remove DC

■

Remove slope

■

Measure RMS

■

R = (Red_rms/Red_dc) / (IR_rm s/IR_dc)

■

SpO2 = f(R), where f is a polynomial fit to hypoxia

■

Calibration data

4.10 Recharging the Battery

■

Use a male micro USB to male USB A cable

■

Charge time around 90min

■

Do not operate the module and keep sensor face clear from objects during charging

4.11 Troubleshoot

Android app starts but shows no data.

1. Tip on the commands in upper window line:

a. Restart Bluetooth device scan.

b. Restart Bluetooth connection.

2. Check phone settings, network, Bluetooth, and pair with OB1203.

a. Bluetooth pairing shows error message ‘Pairing rejected by OB_1203’. OB1203 was already Bluetooth

connected.

b. Un-pair Bluetooth and pair again. Reboot the phone.

Page 13

OB1203SD-BT-EVK Evaluation Kit Manual

X0008647 Rev.1.2

Feb.8.21

Page 13

Orderable Part Number

Description

OB1203SD-BT-EVK

OB1203SD-BT Evaluation Board

Revision

Date

Description

1.2

Feb.8.21

Changed to PCB version R6.

1.1

May.4.20

Reformatted headers and footers within document.

1.0

Jan.10.19

Initial release.

5. Ordering Information

6. Revision History

Updated the document to the latest template.

Redefined document title.

Page 14

IMPORTANT NOTICE AND DISCLAIMER

RENESAS ELECTRONICS CORPORATION AND ITS SUBSIDIARIES (“RENESAS”) PROVIDES TECHNICAL

SPECIFICATIONS AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING

REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND

OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCL AIMS ALL WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for developers skilled in the art designing with Renesas products. You are solely responsible

for (1) selecting the appropriate products for your application, (2) designing, validating, and testing your application, and (3)

ensuring your application meets applicable standards, and any other safety, security, or other requirements. These

resources are subject to change without notice. Renesas grants you permission to use these resources only for

development of an application that uses Renesas products. Other reproduction or use of these resources is strictly

prohibited. No license is granted to any other Renesas intellectual property or to any third party intellectual property.

Renesas disclaims responsibility for, and you will fully indemnify Renesas and its representatives against, any claims,

damages, costs, losses , or liabilities arising out of your use of these resources. Renesas' products are provided only subject

to Renesas' Terms and Conditions of Sale or other applicable terms agreed to in writing. No use of any Renesas resources

expands or otherwise alters any applicable warranties or warranty disclaimers for these products.

Corporate Headquarters

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

www.renesas .com

Trademarks

Renesas and the Renesas logo are trademarks of Renesas

Electronics Corporation. All trad emarks and registered

trademarks are the property of their respective owners.

(Rev.1.0 Mar 2020)

Contact Information

For further information on a product, technology, the most

up-to-date version of a document, or your nearest sales

office, please visit:

www.renesas .com/contact/

© 2020 Renesas Electronics Corporation. All rights reserved.

Loading...

Loading...