Page 1

M34519T-MCU

MCU Board for 4500 Series 4518, 4519, 4583 and 4584 Group MCUs

User's Manual

Rev.2.00

July 1, 2004

REJ10J0071-0200Z

Page 2

* IBM and PC/AT are registered trademarks of International Business Machines Corporation.

* NQPACK, YQPACK, YQSOCKET, YQ-Guide, HQPACK, TQPACK and TQSOCKET are trademarks of Tokyo Eletech Corporation.

• Renesas Technology Corporation and Renesas Solutions Corporation put the maximum effort into making semiconductor products better

and more reliable, but there is always the possibility that trouble may occur with them. Trouble with semiconductors may lead to personal

injury, fire or property damage. Remember to give due consideration to safety when making your circuit designs, with appropriate

measures such as (i) placement of substitutive, auxiliary circuits, (ii) use of nonflammable material or (iii) prevention against any

malfunction or mishap.

• These materials are intended as a reference to assist our customers in the selection of the Renesas Technology product best suited to

the customer's application; they do not convey any license under any intellectual property rights, or any other rights, belonging to Renesas

Technology Corporation, Renesas Solutions Corporation or a third party.

• Renesas Technology Corporation and Renesas Solutions Corporation assume no responsibility for any damage, or infringement of any

third-party's rights, originating in the use of any product data, diagrams, charts, programs, algorithms, or circuit application examples

contained in these materials.

• All information contained in these materials, including product data, diagrams, charts, programs and algorithms represents information

on products at the time of publication of these materials, and are subject to change by Renesas Technology Corporation and Renesas

Solutions Corporation without notice due to product improvements or other reasons. It is therefore recommended that customers contact

Renesas Technology Corporation, Renesas Solutions Corporation or an authorized Renesas Technology product distributor for the latest

product information before purchasing a product listed herein. The information described here may contain technical inaccuracies or

typographical errors. Renesas Technology Corporation and Renesas Solutions Corporation assume no responsibility for any damage,

liability, or other loss rising from these inaccuracies or errors. Please also pay attention to information published by Renesas Technology

Corporation and Renesas Solutions Corporation by various means, including the Renesas home page (http://www.renesas.com).

• When using any or all of the information contained in these materials, including product data, diagrams, charts, programs, and algorithms,

please be sure to evaluate all information as a total system before making a final decision on the applicability of the information and

products. Renesas Technology Corporation and Renesas Solutions Corporation assume no responsibility for any damage, liability or

other loss resulting from the information contained herein.

• Renesas Technology semiconductors are not designed or manufactured for use in a device or system that is used under circumstances

in which human life is potentially at stake. Please contact Renesas Technology Corporation, Renesas Solutions Corporation or an

authorized Renesas Technology product distributor when considering the use of a product contained herein for any specific purposes,

such as apparatus or systems for transportation, vehicular, medical, aerospace, nuclear, or undersea repeater use.

• The prior written approval of Renesas Technology Corporation and Renesas Solutions Corporation is necessary to reprint or reproduce

in whole or in part these materials.

• If these products or technologies are subject to the Japanese export control restrictions, they must be exported under a license from the

Japanese government and cannot be imported into a country other than the approved destination. Any diversion or reexport contrary to

the export control laws and regulations of Japan and/or the country of destination is prohibited.

• Please contact Renesas Technology Corporation or Renesas Solutions Corporation for further details on these materials or the products

contained therein.

Keep safety first in your circuit designs!

Notes regarding these materials

• This product is a development supporting unit for use in your program development and evaluation stages. In mass-producing your

program you have finished developing, be sure to make a judgment on your own risk that it can be put to practical use by performing

integration test, evaluation, or some experiment else.

• In no event shall Renesas Solutions Corporation be liable for any consequence arising from the use of this product.

• Renesas Solutions Corporation strives to renovate or provide a workaround for product malfunction at some charge or without charge.

However, this does not necessarily mean that Renesas Solutions Corporation guarantees the renovation or the provision under any

circumstances.

• This product has been developed by assuming its use for program development and evaluation in laboratories. Therefore, it does not fall

under the application of Electrical Appliance and Material Safety Law and protection against electromagnetic interference when used in

Japan.

For inquiries about the contents of this document or product, fill in the text file the installer of the emulator debugger generates in the

following directory and email to your local distributor.

\SUPPORT\Product-name\SUPPORT.TXT

Renesas Tools Homepage http://www.renesas.com/en/tools

Precautions to be taken when using this product

( 2 / 36 )

Page 3

Preface

This user's manual describes the specifications of MCU board M34519T-MCU for the Renesas 4518,

4519, 4583 and 4584 Groups of 4-bit CMOS single-chip MCUs. The M34519T-MCU is an MCU

board for the PC4504 emulator. For emulator main unit PC4504 and emulator debugger M3T-PD45,

refer to each user's manual (online manual).

To use the product properly

Precautions for Safety

• In both this user's manual and on the product itself, several icons are used to insure

proper handling of this product and also to prevent injuries to you or other persons,

or damage to your properties.

• The icons' graphic images and meanings are given in "Chapter 1. Precautions for

Safety". Be sure to read this chapter before using the product.

( 3 / 36 )

Page 4

Contents

Chapter 1. Precautions for Safety ...........................................................................................5

1.1 Safety Symbols and Meanings ..............................................................................5

Chapter 2. Package Contents..................................................................................................9

2.1 Contents of the M34519T-MCU ...........................................................................9

2.2 Other Necessary Products ...................................................................................10

Chapter 3. M34519T-MCU ..................................................................................................11

3.1 Outline.................................................................................................................11

3.2 Specifications ......................................................................................................12

3.3 Switches ..............................................................................................................13

3.4 Check Pins...........................................................................................................14

3.5 Connectors...........................................................................................................14

3.6 Connection to the Target System ........................................................................18

3.7 How to Replace the MCU ...................................................................................22

Chapter 4. Precautions to Be Taken When Debugging a Program ......................................23

4.1 Reset ....................................................................................................................23

4.2 Watchdog Timer..................................................................................................23

4.3 RAM Backup Mode ............................................................................................24

4.4 Port I/O Timings .................................................................................................24

4.5 A-D Converter.....................................................................................................25

4.6 System Clock ......................................................................................................26

4.7 Real-time Capability of the Timer ......................................................................26

4.8 Pullup Transistor Control ....................................................................................26

4.9 Program Execution (G, GB)................................................................................27

4.10 External Trigger Signal .....................................................................................28

4.11 Other Precautions ..............................................................................................28

Chapter 5. Connection Circuit Diagrams .............................................................................29

5.1 Connection Circuit Diagrams..............................................................................29

Chapter 6. Pitch Converter Board External Dimensions......................................................31

6.1 M34513T-PTCA .................................................................................................31

6.2 M34513T-PTCB .................................................................................................31

6.3 M34513T-PTCC .................................................................................................31

Chapter 7. Maintenance and Guarantee................................................................................33

7.1 Maintenance ........................................................................................................33

7.2 Guarantee ............................................................................................................33

7.3 Repair Provisions ................................................................................................33

7.4 How to Request for Repair..................................................................................34

( 4 / 36 )

Page 5

Chapter 1. Precautions for Safety

Both in the M34519T-MCU user's manual and on the product, several icons are used to insure proper

handling of this product and also to prevent injuries to you or other persons, or damage to your

properties.

This chapter describes precautions which should be taken in order to use the M34519T-MCU safely

and properly. Be sure to read this chapter before using this product.

1.1 Safety Symbols and Meanings

If the requirements shown in the "WARNING"

WARNING

CAUTION

IMPORTANT

In addition to the three above, the following are also used as appropriate.

sentences are ignored, the equipment may

cause serious personal injury or death.

If the requirements shown in the "CAUTION"

sentences are ignored, the equipment may

malfunction.

It means important information on using this

product.

means WARNING or CAUTION.

Example: CAUTION AGAINST AN ELECTRIC SHOCK

means PROHIBITION.

Example: DISASSEMBLY PROHIBITED

means A FORCIBLE ACTION.

Example:

The following pages describe the symbols "WARNING", "CAUTION", and "IMPORTANT".

UNPLUG THE POWER CABLE FROM THE RECEPTACLE.

( 5 / 36 )

Page 6

WARNING

Warning for Installation:

• Do not set this product in water or areas of high humidity. Spilling water or some other liquid into

the main unit can cause an unrepairable damage.

Warning for Use Environment:

• This equipment is to be used in an environment with a maximum ambient temperature of 35°C. Care

should be taken that this temperature is not exceeded.

CAUTION

Cautions to Be Taken for This Product:

• Do not disassemble or modify this product. Disassembling or modifying this product can cause

damage. Disassembling and modifying the product will void your warranty.

• Use caution when handling the main unit. Be careful not to apply a mechanical shock.

• Do not pull the emulator probe (100-wire half-pitch cable etc.) to disconnect from the emulator

main unit.

•Do not use inch-size screws for this equipment. The screws used in this equipment are all ISO

(meter-size) type screws. When replacing screws, use same type screws as equipped before.

IMPORTANT

Notes on Differences between Actual MCUs and the Emulator:

• Emulator operation differs from emulation of a mask MCU, as listed below. For details refer to

"Chapter 4. Precautions to Be Taken When Debugging a Program" (page 23).

(1) Reset condition

(2) Operation of the watchdog timer function

(3) Operation in RAM backup mode

(4) Port I/O timings and characteristics

(5) A-D conversion function

• Therefore, always be sure to evaluate your system with an evaluation MCU (OTP version). Also,

be sure to perform onboard evaluation with CS (Commercial Sample) version MCU to make final

confirmation of device operation before starting mask production.

Note on the Target System:

• Make sure that the target's supply voltage is + 3.0 V or + 5.0 V. Therefore the target's supply voltage

should be in the range of + 3.0 V ±10% or + 5.0 V ±10%.

( 6 / 36 )

Page 7

IMPORTANT

Notes on Connecting the Target System:

• When connecting the target system, be sure to shut off the power of the emulator and the target

system.

• Connect the emulator probe carefully.

• When connecting the emulator probe, use care not to twist the cable. An excessive twist may cause

breaking of the wire.

Note on MCU board Installation:

• Before installing and removing the MCU board, always be sure to power off the PC4504 emulator

main unit and unplug its power cord from the outlet.

Note on Registers that Can be Operated from M3T-PD45

•The table below lists the registers that can be operated from M3T-PD45. The "Yes" in the table

means that the register can be operated; the "No" means that the register can not be operated.

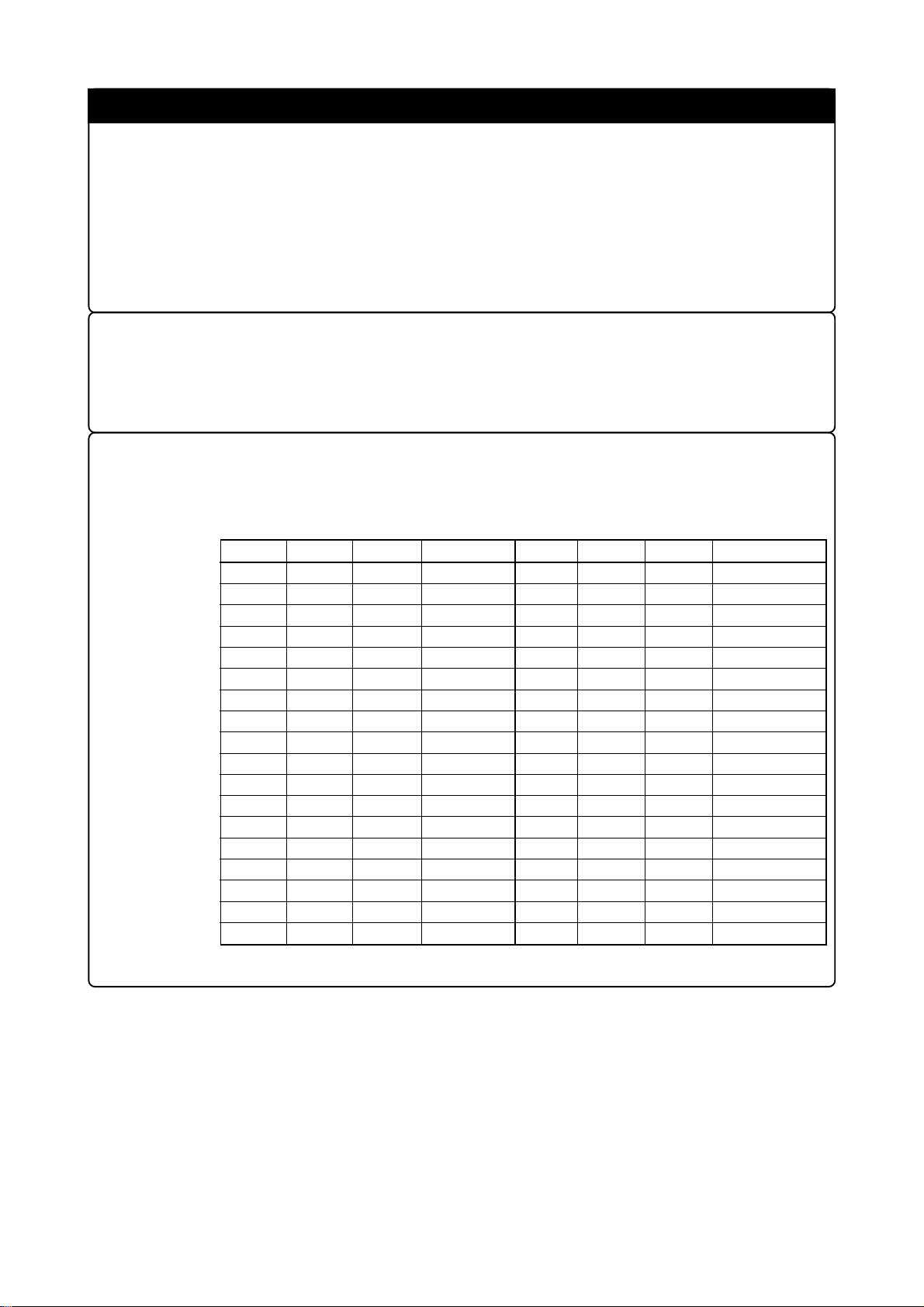

Register Reference Modification Remarks Register Reference Modification Remarks

PC Yes Yes W3 Yes Yes

CY Yes Yes W4 Yes Yes

A Yes Yes W5 Yes Yes

B Yes Yes W6 Yes Yes

D Yes Yes J1 Yes Yes

E Yes Yes Q1 Yes Yes

X Yes Yes Q2 Yes Yes

Y Yes Yes Q3 Yes Yes

Z Yes Yes K0 Yes Yes

V1 Yes Yes K1 Yes Yes

V2 Yes Yes K2 Yes Yes

I1 Yes Yes PU0 Yes Yes

I2 Yes Yes PU1 Yes Yes

MR Yes Yes FR0 No Yes

RG No Yes FR1 No Yes

PA No Yes FR2 No Yes

W1 Yes Yes FR3 No Yes

W2 Yes Yes SI Yes Yes

4518 and 4519 only

4518 and 4519 only

4518 and 4519 only

( 7 / 36 )

Page 8

MEMO

( 8 / 36 )

Page 9

Chapter 2. Package Contents

2.1 Contents of the M34519T-MCU

Table 2.1 shows the contents of the M34519T-MCU package. When unpacking it, check to see that

all of these components are included.

Table 2.1 Contents of the M34519T-MCU package

Item

Product name

Quantity

10

11

12

13

1

2

3

4

5

6

7

8

9

M34519T-MCU

M34584MD-001FP (for replacement)

M4584 monitor ROM for the 4583 and 4584 Groups (for replacement)

100-wire half-pitch cable (40 cm)

50-wire normal-pitch cable (10 cm)

2-wire external trigger cable (50 cm)

Pitch converter board PCA4029

Pitch converter board M34513T-PTCA

Pitch converter board M34513T-PTCB

Pitch converter board M34513T-PTCC

Oscillator circuit board OSC-2 (only J1 mounted)

M34519T-MCU user's manual (this manual)

M34519T-MCU user's manual (Japanese)

1

1

1

1

1

1

1

1

1

1

1

1

1

IMPORTANT

Notes on Components of this Product:

• If you find any item missing or faulty, or any suggestion, contact your local

distributor.

• Keep the packaging carton and cushion material of the M34519T-MCU to transport

it for repair or for other purposes in the future.

• The M34519T-MCU has a preinstalled oscillator circuit board OSC-2 for 6.0 MHz

(main clock) and another oscillator circuit board OSC-2 on which only J1 is

mounted.

( 9 / 36 )

Page 10

2.2 Other Necessary Products

To bring forward your program development with the 4518, 4519, 4583 and 4584 Groups of 4-bit

MCUs, the products listed in Table 2.2 are necessary in addition to those contained in the package.

Get them separately when necessary.

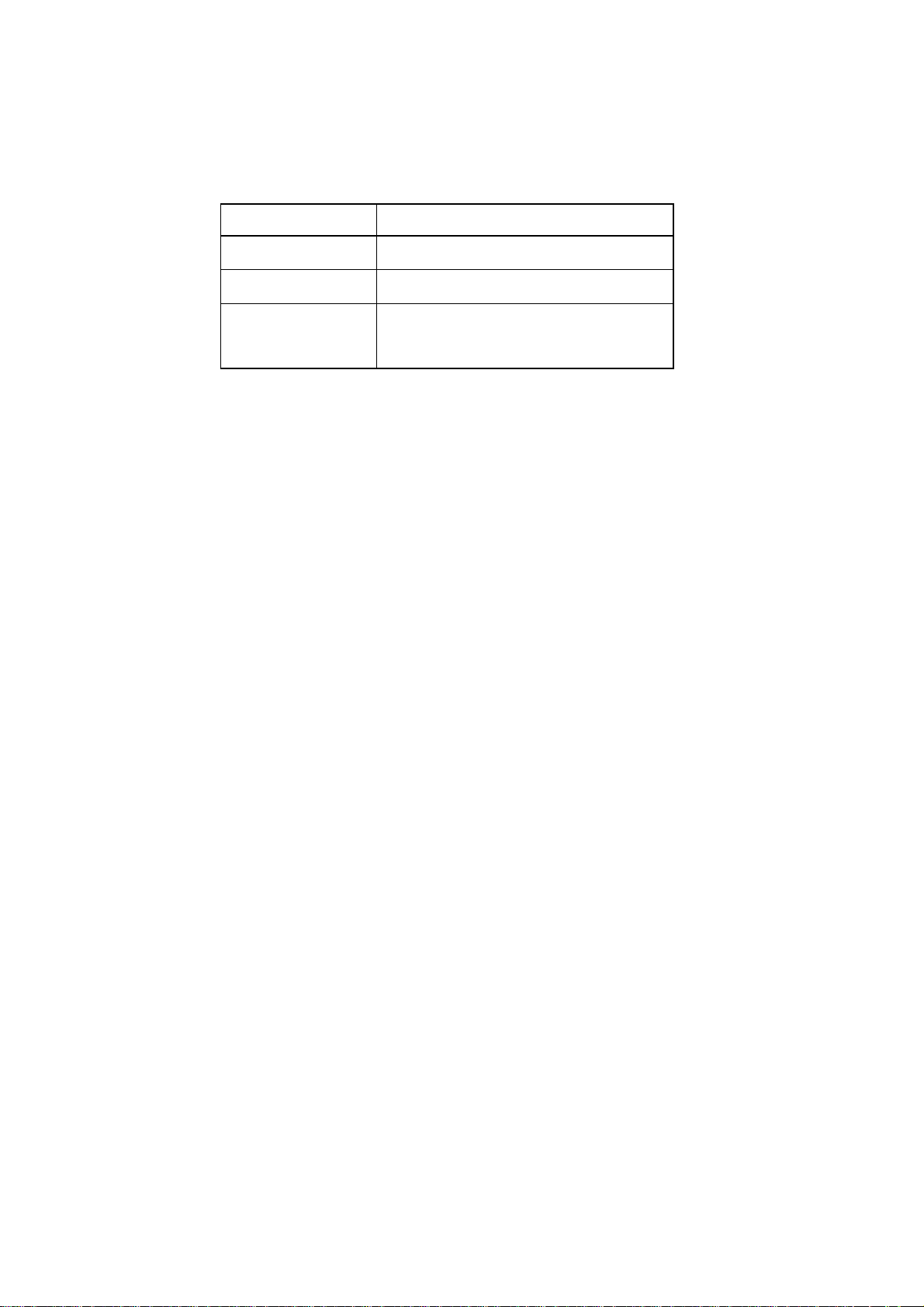

Table 2.2 Other products required for developing the 4518, 4519, 4583 and 4584 Group MCUs

Product

Emulator main unit

Emulator debugger

Programming adapter

Product type name

PC4504

M3T-PD45

PCA7441 (for 4519 and 4584)

PCA7442FPG02 (for 4518 and 4583 LQFP)

PCA7442SP (for 4518 and 4583 SDIP)

( 10 / 36 )

Page 11

Chapter 3. M34519T-MCU

3.1 Outline

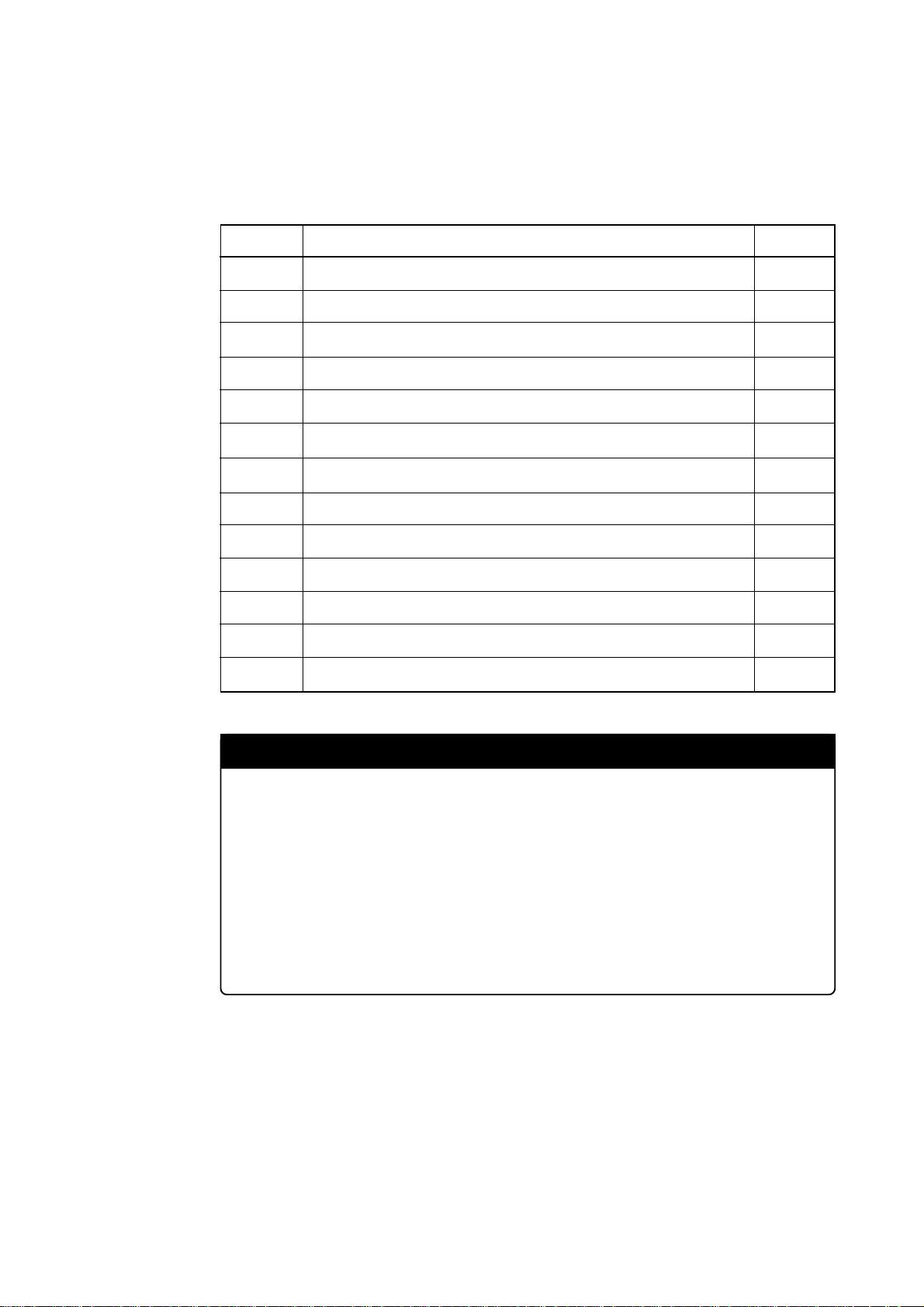

With emulator main unit PC4504, the M34519T-MCU can make up an emulator system which can

be operated by a host machine. Figure 3.1 shows an emulator system configuration. For details on

how to connect the target system, refer to "3.6 Connection to the Target System" (page 18).

Emulator debugger M3T-PD45

CD-ROM

RS-232C

Host machine

CPU board PC4500E

Control board PCA4504A + PCA4504B

Function expansion board PCA4504R + PCA4504B

MCU board M34519T-MCU

M34513T-PTCA

M34513T-PTCB

M34513T-PTCC

For 32-pin LQFP

Emulator main unit PC4504

100-wire half-pitch cable

PCA4029

50-wire normal-pitch cable

Target system

Figure 3.1 Emulator system configuration

Figure 3.2 shows the positions of the switches and connectors.

For 32-pin SDIP

M34513T-PTCA

For 42-pin SSOP

Figure 3.2 Positions of switches and connectors

( 11 / 36 )

Page 12

3.2 Specifications

Table 3.1 lists specifications of the M34519T-MCU.

Table 3.1 M34519T-MCU specifications

Emulator

Applicable MCUs

Evaluation MCU

Monitor program

Clock

Target system voltage

Power supply to MCU

board

Port emulation

Emulated functions

Board dimensions

Operating temperature

Product configuration

Emulator PC4504

4518 Group, 4519 Group, 4583 Group*

1

, 4584 Group*

1

4518, 4519 Groups M34519M8-001FP (preinstalled)

4583, 4584 Groups M34584MD-001FP (included)

4518, 4519 Groups M4519 (preinstalled)

4583, 4584 Groups M4584 (included)

Main clock: 6.0 MHz (OSC-2 [6.0 MHz mounted])

Divide-by-8 mode (f(XIN)/8)

5 V

Divide-by-4 mode (f(XIN)/4)

Divide-by-2 mode (f(XIN)/2)

Through mode (f(XIN))

6.0 MHz

Divide-by-8 mode (f(XIN)/8)

Divide-by-4 mode (f(XIN)/4)

3 V

Divide-by-2 mode (f(XIN)/2)

Through mode (f(XIN))

4.4 MHz

3 V ±10% or 5 V ±10%

Supplied by the PC4504's internal power supply (+5 V, +12 V).

3 V is generated from +12 V.

Port

P00--P03,

P10--P13,

D0--D5

P21, P22

Key-on wakeup input

in RAM backup mode

Pullup resistor control

Port output type control

Direction

Input/output *

Input/output

Input 74HC245

2

Output

Input/Output: 74HC4066

Pin

P00--P03,

INT0, INT1

P10--P13

Pin

P00--P03

P10--P13

Pin

P00--P03,

P10--P13

D0--D5

Device used

74ALS641 (N-ch)

74VHC125 (CMOS)

Factor of return

Edge detection

or level detection

L-level detection

Control register

PU0

PU1

Control register

FR0

FR1, FR2

233.35 x 135.00 x 1.60 mm

5 to 35°C (non-condensing)

• M34519T-MCU

• 100-wire half-pitch cable

• PCA4029

• 50-wire normal-pitch cable

• 2-wire external trigger cable

• M34513T-PTCA

• M34513T-PTCB

• M34513T-PTCC

• OSC-2 (not mounted)

• M34584MD-001FP (MCU for replacement)

• M4584 (ROM for replacement)

*1.Available by changing MCUs

*2.N-ch open drain output and CMOS output are selectable by a control register.

( 12 / 36 )

Page 13

3.3 Switches

Table 3.2 shows the functions of the switches and their factory-settings.

Table 3.2 Functions of the switches

Switch

SW1

Label

OFF

Switch position

ON

Does not output VDD from the

OFF

M34519T-MCU to the target system.

Description

Factory-setting

SW2

SW3

SW4

ON

ROMSIZE

5 V

3 V

519

518

ON

518

518

3 V

3 V

Outputs VDD from the M34519T-MCU

OFF

to the target system.

Set the MCU's ROM size.

• Set "2" for M2

• Set "4" for M4

• Set "6" for M6

• Set "8" for E8, M8

• Set "D" for ED, MD

Operates the evaluation MCU on the

5 V

M34519T-MCU at 5 V.

Operates the evaluation MCU on the

5 V

M34519T-MCU at 3 V.

519

Operates for the 4519 and 4584 Groups.

519

Operates for the 4518 and 4583 Groups.

OFF

8

5 V

519

CAUTION

Caution for Setting the Switches:

• Before changing switch settings, be sure to shut off the power.

( 13 / 36 )

Page 14

3.4 Check Pins

Table 3.3 lists the check pins of the M34519T-MCU, and Figure 3.3 shows their positions.

Table 3.3 Check pins

Function

TP1

TP2

TP3

TP4

TP5

Pin

VDD

XIN

GND

RUN/STOP

WRST

Outputs +3 V or +5 V (MCU voltage) according to the setting of SW3.

Outputs a system clock input to the evaluation MCU.

Ground

Held low when a user program is executed, held high when it is stopped.

Held high when WRST instruction is executed, and you can check the

initialization cycle of the watchdog timer by observing pulse widths.

3.5 Connectors

Figure 3.3 Positions of the check pins

Table 3.4 lists the functions of the connectors of the M34519T-MCU.

Table 3.4 Connectors

Connector

J1

J2

J3

J4

J6

Connects the evaluation MCU bus.

Connects the monitor CPU bus.

Connects the target system. (100-pin)

Connects external trigger signal. (2-pin)

Connects oscillator circuit board OSC-2. (4-pin)

Function

( 14 / 36 )

Page 15

(1) Connector J3

Table 3.5 lists the pin assignments of the 100-wire half-pitch connector J3 for connecting the

PCA4029. And Figure 3.4 shows the pin layout of connector J3.

Table 3.5 Pin assignments of connector J3

Line A Line B Line C Line D

Pin No.

Signal I/O

1 GND 1 GND 1 P13 I/O 1 P12 I/O

2 GND 2 GND 2 D0 I/O 2 P11 I/O

3 GND 3 GND 3 D1 I/O 3 P10 I/O

4 GND 4 GND 4 D2 I/O 4 P03 I/O

5 GND 5 GND 5 D3 I/O 5 P02 I/O

6 GND 6 GND 6 D4 I/O 6 P01 I/O

7 GND 7 GND 7 D5 I/O 7 P00 I/O

8 GND 8 GND 8 D6/CNTR0 I/O 8 P43/AIN7 I/O

9 GND 9 GND 9 D7/CNTR1 I/O 9 P42/AIN6 I/O

10 GND 10 GND 10 P50 I/O 10 P41/AIN5 I/O

11 GND 11 GND 11 P51 I/O 11 P40/AIN4 I/O

12 GND 12 GND 12 P52 I/O 12 P63/AIN3 I/O

13 GND 13 GND 13 P53 I/O 13 P62/AIN2 I/O

14 GND 14 GND 14 P20/SCK I/O 14 P61/AIN1 I/O

15 GND 15 GND 15 P21/SOUT I/O 15 P60/AIN0 I/O

16 GND 16 GND 16 P22/SIN I/O 16 P33 I/O

17 GND 17 GND 17 RESET I 17 P32 I/O

18 GND 18 GND 18 CNVSS - 18 P31/INT1 I/O

19 GND 19 GND 19 XOUT - 19 P30/INT0 I/O

20 GND 20 GND 20 XIN - 20 VDCE I

21 GND 21 GND 21 VSS 21 VDD

22 GND 22 GND 22 NC - 22 NC 23 GND 23 GND 23 NC - 23 NC 24 GND 24 GND 24 NC - 24 NC 25 GND 25 GND 25 NC - 25 NC -

Pin No.

Signal I/O

Pin No.

Signal I/O

Pin No.

Signal I/O

Figure 3.4 Connector J3 pin layout

( 15 / 36 )

Page 16

Some signals which are connected to the target system are emulated by the M34519T-MCU. Table

3.6 lists the connections of the target system and each pin.

Table 3.6 Connection of the target system and each pin

Signal

Item

4519 Group

4584 Group

Pins connected directly to the target system

(12 types 23 pins)

Pins connected to the target system via an

emulation circuit etc. (5 types 16 pins)

Pins not connected to the target system

(3 types 3 pins)

CAUTION

• P20/SCK

• P21/SOUT

• P22/SIN

• P30/INT0, P31/INT1

• P32, P33

• P40/AIN4--P43/AIN7

• P50--P53

• P60/AIN0--P63/AIN3

• D6/CNTR0

• D7/CNTR1

• VDCE

• VSS

• P00--P03

• P10--P13

• D0--D5

• RESET

• VDD

• XIN

• XOUT

• CNVSS

• P20--P23

• P30/INT0, P31/INT1

• P40--P43

• P50--P53

• P60/AIN0, P61/AIN1

• P62, P63

• D6/CNTR0

• C/CNTR1

• VDCE

• VSS

Notes on Connecting the Evaluation MCU and T arget System:

• VDD is not used for inputting power from the target system, but it is used for

outputting power from the power circuit on the M34519T-MCU to the target system.

Output of VDD (ON or OFF) is set by switch SW1, and the voltage (3 V or 5 V) is

set by switch SW3.

• XIN is input from the oscillator board OSC-2 on the M34519T-MCU, and it is not

input from the oscillator on the target system. To change a system clock frequency,

use another oscillator board OSC-2 (included) with other necessary parts.

(2) Connector J4

Connect the 2-wire external trigger cable included with the M34519T-MCU to 2-pin connector

J4 for external trigger signal. Connect the black clip of the 2-wire external trigger cable to GND,

and use the white clip for external trigger signal input.

External trigger signal is used for event input of external trigger breaks or external trace points.

Table 3.7 lists the pin assignments of connector J4.

Table 3.7 Pin assignments of connector J4

Pin No.

1

2

Signal

TRIG

GND

Function

External trigger signal input

GND

( 16 / 36 )

Page 17

(3) Connector J6

Connector J6 is a connector used to connect oscillator circuit board OSC-2. Table 3.8 lists the pin

assignments of connector J6. Figure 3.5 shows the pin layout of connector J6. Figure 3.6 shows

a connection diagram of oscillator circuit board OSC-2 (6.0 MHz).

Table 3.8 Pin assignments of connector J6

Pin No.

1

2

3

4

Signal

VCC

GND

CLK

GND

Figure 3.5 Pin layout of connector J6

Function

Power supply

GND

Clock input

GND

Figure 3.6 Connection diagram of the oscillator circuit

CAUTION

Notes on Changing a Clock Frequency:

• When changing a clock frequency, be sure to shut off the power supply to replace

the oscillator circuit board (OSC-2).

• For details about the oscillation circuit constant, consult your oscillator manufacturer.

( 17 / 36 )

Page 18

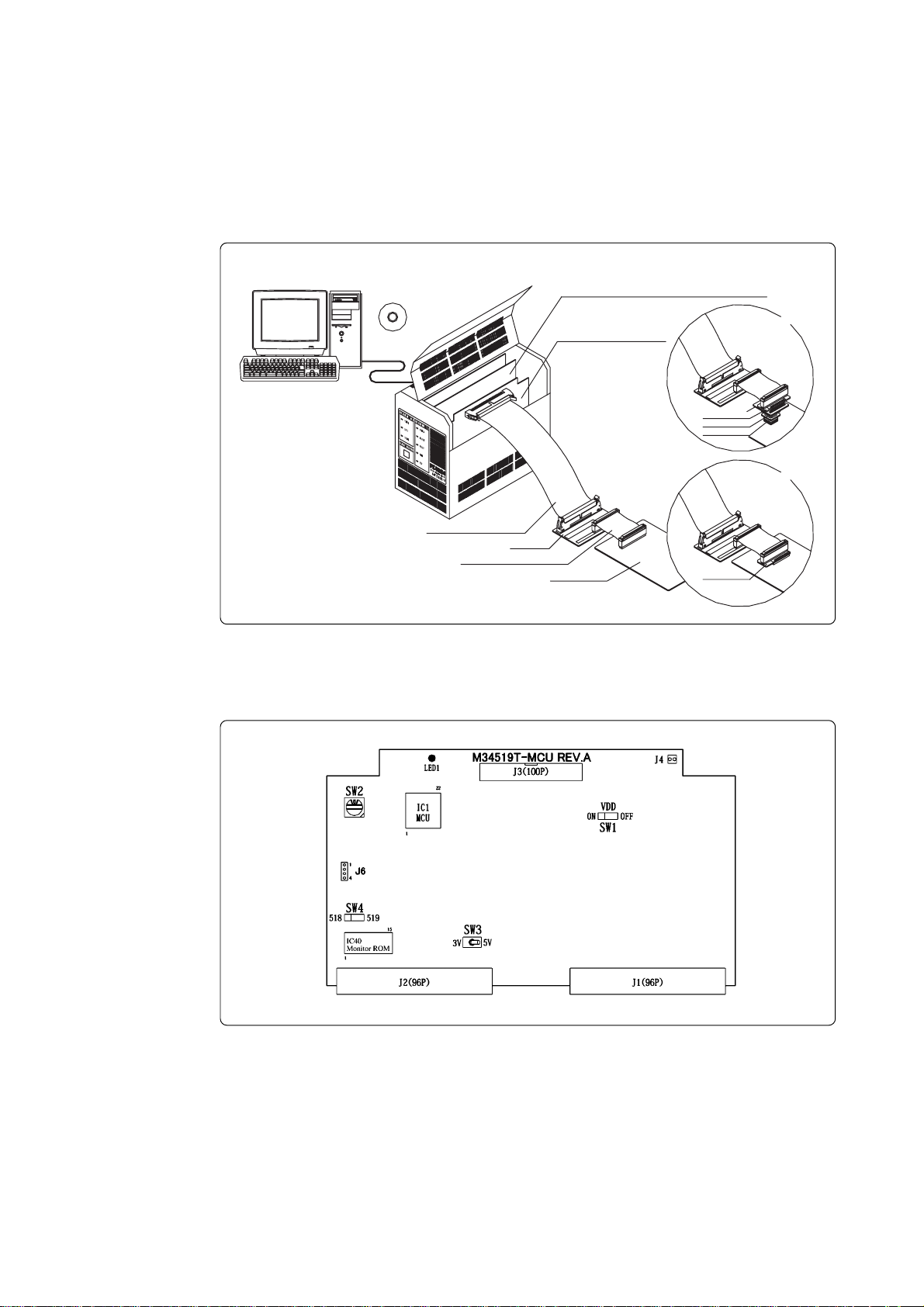

3.6 Connection to the Target System

Connections of the M34519T-MCU and target systems are shown in Figure 3.7 below.

50-wire normal-pitch cable

M34513T-PTCA

M34513T-PTCA

FFC-50BSM1

(1) Connection to 2.54-mm-pitch

50-pole dual-in-line pin

(2) Connection to IC socket

Figure 3.7 Connections to target systems

ME-2-1

for 32-pin SDIP

M34513T-PTCB

M34513T-PTCC

TQPACK032SA

(3) Connection to 32-pin LQFP

foot pattern

( 18 / 36 )

Page 19

(1) Connection to 2.54-mm-pitch 50-pole dual-in-line pins (for 42-pin SSOP)

Connect this product to 50-pole dual-in-line pins using the included 50-wire normal-pitch cable.

Use the following products:

(1) 100-wire half-pitch cable (40 cm)

(2) Pitch converter board PCA4029

(3) 50-wire normal-pitch cable (10 cm)

Table 3.9 lists the connector assignments of the 50-wire normal-pitch cable, and Figure 3.8 shows

the pin layout of the 50-wire normal-pitch cable. Be careful not to connect the cable in a wrong

direction.

Table 3.9 Connector assignments of the 50-wire normal-pitch cable

Connector pin No. MCU pin No. Signal Connector pin No. MCU pin No. Signal

11P13 50 42 P12

22D0 4941 P11

33D1 4840 P10

44D2 4739 P03

55D3 4638 P02

66D4 4537 P01

77D5 4436 P00

88D6/CNTR0 43 35 P43/AIN7

99D7/CNTR1 42 34 P42/AIN6

10 10 P50 41 33 P41/AIN5

11 11 P51 40 32 P40/AIN4

12 12 P52 39 31 P63/AIN3

13 13 P53 38 30 P62/AIN2

14 14 P20/SCK 37 29 P61/AIN1

15 15 P21/SOUT 36 28 P60/AIN0

16 16 P22/SIN 35 27 P33

17 17 RESET 34 26 P32

18 18 NC (CNVSS) 33 25 P31/INT1

19 19 NC (XOUT) 32 24 P30/INT0

20 20 NC (XIN*2)3123VDCE

21 21 VSS 30 22 VDD*

22 - NC 29 - NC

23 - NC 28 - NC

24 - NC 27 - NC

25 - NC 26 - NC

1

*1: VDD is not used for inputting power from the target system, but it is used for outputting power

from the power circuit on the M34519T-MCU to the target system. Output of VDD (on/off) is set by

switch SW1. For details, refer to "3.3 Switches" (page 13).

*2: XIN is input from oscillator board OSC-2 on the M34519T-MCU, and it is not input from the

oscillator circuit on the target system. To change a system clock frequency, change the frequency of

oscillator board OSC-2.

CAUTION

Note on Connecting the Target System:

• Always shut OFF power before connecting the target system. Otherwise internal

circuits of the target system and the emulator may be damaged.

( 19 / 36 )

Page 20

(2) Connection to the IC socket for 32-pin SDIP

Attach pitch converter board M34513T-PTCA to the 50-wire normal-pitch cable, and connect it

to an IC socket for 32-pin SDIP on the target system.

Use the following products:

(1) 100-wire half-pitch cable (40 cm)

(2) Pitch converter board PCA4029

(3) 50-wire normal-pitch cable (10 cm)

(4) Pitch converter board M34513T-PTCA

Table 3.10 lists the connector assignments of pitch converter board M34513T-PTCA. When

attaching the pitch converter board, check the No. 1 pin positions of the cable and the connector.

Be careful not to connect the cable in a wrong direction.

Table 3.10 Connector assignments of pitch converter board M34513T-PTCA

Connector pin No. MCU pin No. Signal Connector pin No. MCU pin No. Signal

11D0 3232 P13

22D1 3131 P12

33D2 3030 P11

44D3 2929 P10

55D4 2828 P03

66D5 2727 P02

77D6/CNTR0 26 26 P01

88D7/CNTR1 25 25 P00

99P20/SCK 24 24 P63/AIN3

10 10 P21/SOUT 23 23 P62/AIN2

11 11 P22/SIN 22 22 P61/AIN1

12 12 RESET 21 21 P60/AIN0

13 13 CNVSS 20 20 P31/INT1

14 14 XOUT 19 19 P30/INT0

15 15 XIN*

16 16 VSS 17 17 VDD*

2

18 18 VDCE

1

*1: VDD is not used for inputting power from the target system, but it is used for outputting power

from the power circuit on the M34519T-MCU to the target system. Output of VDD (on/off) is set by

switch SW1. For details, refer to "3.3 Switches" (page 13).

*2: XIN is input from oscillator board OSC-2 on the M34519T-MCU, and it is not input from the

oscillator circuit on the target system. To change a system clock frequency, change the frequency of

oscillator board OSC-2.

PCA4029

50-wire normal-pitch cable

50-pole dual-in-line socket

Unit: mm

Figure 3.8 Pin layout of the 50-wire normal-pitch cable

( 20 / 36 )

Page 21

(3) Connection to a 32-pin LQFP foot pattern

Attach pitch converter boards M34513T-PTCA and M34513T-PTCB to the included 50-wire

normal-pitch cable, and connect them to the TQPACK032SA soldered on a 32-pin LQFP foot

pattern of the target system via the M34513T-PTCC.

Use the following products:

(1) 100-wire half-pitch cable (40 cm)

(2) Pitch converter board PCA4029

(3) 50-wire normal-pitch cable (10 cm)

(4) Pitch converter board M34513T-PTCA

(5) Pitch converter board M34513T-PTCB

(6) Pitch converter board M34513T-PTCC (including TQPACK032SA)

Table 3.11 lists the pin assignments of the TQPACK032SA. Solder the TQPACK032SA on a 32pin LQFP foot pattern of the target system. Attach the M34513T-PTCC to the TQPACK032SA

matching the No. 1 pin positions (see Figure 3.9). Be careful not to connect them improperly.

Table 3.11 Pin assignments of the TQPACK032SA

Connector pin No. MCU pin No. Signal Connector pin No. MCU pin No. Signal

11D3 3232 D2

22D4 3131 D1

33D5 3030 D0

44D6/CNTR0 29 29 P13

55D7/CNTR1 28 28 P12

66P20/SCK 27 27 P11

77P21/SOUT 26 26 P10

88P22/SIN 25 25 P03

99RESET 24 24 P02

10 10 CNVSS 23 23 P01

11 11 XOUT 22 22 P00

12 12 XIN*

13 13 VSS 20 20 P62/AIN2

14 14 VDD*

15 15 VDCE 18 18 P60/AIN0

16 16 P30/INT0 17 17 P31/INT1

2

1

21 21 P63/AIN3

19 19 P61/AIN1

*1: VDD is not used for inputting power from the target system, but it is used for outputting power

from the power circuit on the M34519T-MCU to the target system. Output of VDD (on/off) is set by

switch SW1. For details, refer to "3.3 Switches" (page 13).

*2: XIN is input from oscillator board OSC-2 on the M34519T-MCU, and it is not input from the

oscillator circuit on the target system. To change a system clock frequency, change the frequency of

oscillator board OSC-2.

No. 1 pin

No. 1 pin

(Bevel edge)

TQPACK032SA

M34513T-PTCC

Figure 3.9 Pin layouts of the TQPACK032SA and M34513T-PTCC

( 21 / 36 )

Page 22

3.7 How to Replace the MCU

For debugging the 4583 and 4584 Group MCUs, it is necessary to replace the evaluation MCU to the

included M34584MD-001FP. When replacing the MCU, match the No. 1 pin of the IC socket and

that of the MCU as shown in Figure 3.10. Incorrect insertion may cause a fatal damage to the MCU.

The M34519M8-001FP is mounted when shipped from the factory.

Top view

42 22

M34584MD-001FP

121

Figure 3.10 Replacing the MCU

CAUTION

Cautions for Replacing the MCU:

• Before replacing the MCU, be sure to shut off the power supply.

• When mounting the evaluation MCU, be sure to match the No. 1 pin. Incorrect

insertion may cause a fatal damage to the MCU.

• When opening and closing the IC socket, hold the adapter horizontally. Otherwise

the inside of the IC socket may become damaged and cause an electrical insulation

failure.

• When debugging a 4583 or 4584 Group MCU, it is necessary to replace the MCU

to the included M34584MD-001FP and change the setting of switch SW4. For

switch setting, see "3.3 Switches" (page 13).

( 22 / 36 )

Page 23

Chapter 4. Precautions to Be Taken for Debugging a Program

4.1 Reset

The M34519T-MCU uses a 74HC14 for its RESET signal input buffer, so that its electrical

characteristics differ from those of an actual MCU. Table 4.1 lists the RESET signal input

characteristics of the M34519T-MCU.

Table 4.1 RESET signal input characteristics

H-level threshold voltage

L-level threshold voltage

Hysteresis voltage

4.2 Watchdog Timer

The M34519T-MCU does not have an operational watchdog timer. Therefore, use an evaluation

MCU (OTP version) to verify the operation associated with a watchdog timer.

The M34519T-MCU outputs a signal whose waveform is shown below from check pin TP5 during

WRST instruction execution cycles. This signal allows you to check the initialization cycle of a

watchdog timer.

Item Symbol

VP

VN

VH

Voltage

VCC = 2.0 V

VCC = 4.5 V

VCC = 6.0 V

VCC = 2.0 V

VCC = 4.5 V

VCC = 6.0 V

VCC = 2.0 V

VCC = 4.5 V

VCC = 6.0 V

Min.

1.0 V

2.3 V

3.0 V

0.3 V

1.13 V

1.5 V

0.3 V

0.6 V

0.8 V

Max.

1.5 V

3.15 V

4.2 V

0.9 V

2.0 V

2.6 V

1.0 V

1.4 V

1.7 V

System clock

XIN

CNVSS

WRST

Figure 4.1 Waveform output from check pin TP5

( 23 / 36 )

Page 24

4.3 RAM Backup Mode

In RAM backup mode, the M34519T-MCU operates differently from the actual MCUs. Although the

actual MCU enters RAM backup mode depending on a combination of instructions EPOF and POF,

the M34519T-MCU is placed in RAM backup mode by executing instruction POF only. Instruction

EPOF has no effect on the M34519T-MCU.

4.4 Port I/O Timings

(1) Port input timings

Port input timings are the same as with actual the MCUs.

(2) Port output timings

Program example 4.1

RC

INY

EPOF

POF

•

•

Program example 4.2

RC

INY

POF

•

•

[Actual MCU]

Placed in RAM backup mode

[M34519T-MCU]

Placed in RAM backup mode

[Actual MCU]

Not placed in RAM backup mode

[M34519T-MCU]

Placed in RAM backup mode

When using the M34519T-MCU, output timings are different from those of the actual MCUs,

because the following ports that are configured with the port emulation circuits.

• Ports D0--D5

• Ports P00--P03

• Ports P10--P13

With the actual MCUs, changes occur at the beginning of the T3 state of an output instruction.

With the M34519T-MCU, changes occur at the beginning of the T2 state of the next output

instruction. Figure 4.2 shows the port output timings of the actual MCUs and M34519T-MCU.

For the other ports, the output timings are the same as with the actual MCUs.

Next output instructionOutput instruction

System clock

XIN

Ports D, P0, P1

output timings

on actual MCUs

Ports D, P0, P1

output timings of

M34519T-MCU

Figure 4.2 Ports D, P0 and P1 output timings

( 24 / 36 )

Page 25

(3) Port I/O Characteristics

With the M34519T-MCU, port I/O characteristics are different from actual MCUs because there

are emulation circuits in ports P00--P03, P10--P13 and D0--D5. Table 4.2 lists port I/O

characteristics of the M34519T-MCU.

Table 4.2 Emulation port I/O characteristics

P0, P1,

D0--D5

P21, P22

Port

Input 74HC245

Output*

Input/

Output

Device Item Condition

VIH

VIL

74ALS641

1

74VHC125

74HC4066

VOL

IOL

VOH

VOL

RON

RON

IOFF

IZ

VCC = 2.0 V

VCC = 4.5 V

VCC = 2.0 V

VCC = 4.5 V

VCC = 4.5 V

VCC = 5.0 V

VCC = 3.0 V

VCC = 4.5 V

VCC = 3.0 V

VCC = 4.5 V

VCC = 2.0 V

VCC = 4.5 V

VCC = 4.5 V

VCC = 12 V

VCC = 12 V

Min.

1.50 V

3.15 V

-

-

-

-

2.48 V

3.94 V

-

-

-

-

-

-

-

Standard

-

-

-

-

0.35 V

-

-

-

-

-

160 Ω

96 Ω

10 Ω

-

-

Max.

-

-

0.50 V

1.35 V

0.5 V

48 mA

-

-

0.44 V

0.44 V

-

200 Ω

-

±1 µA

±1 µA

Remarks

IOH = -4 mA

IOH = -8 mA

IOL = 4 mA

IOL = 8 mA

*1 According to the setting of the output method control register FRx, change its device for output

4.5 A-D Converter

For the M34519T-MCU, its voltage is fixed at 3 V or 5 V. Therefore, because of the difference of

voltage, the results of its A/D conversions are slightly different from the theoretical values. And, some

characteristics are different from those of actual MCUs, because a flat cable and pitch converter board

and other devices are used between the evaluation MCU and target system.

in the emulation circuit.

• When N-ch open drain output chosen: 74ALS641

• When CMOS output chosen: 74VHC125

( 25 / 36 )

Page 26

4.6 System Clock

Depending on the supply voltage and operation mode, use one of the following frequencies listed in

Table 4.3.

Table 4.3 M34519T-MCU operating frequencies

Voltage

Divide-by-8

Divide-by-4

5 V

Divide-by-2

Through

Divide-by-8

Divide-by-4

3 V

Divide-by-2

Through

To change a clock frequency, attach the necessary parts to the included oscillator circuit board OSC-2.

For details about the oscillation circuit constant, consult your oscillator manufacturer.

4.7 Real-time Capability of the Timer

The M34519T-MCU has its internal clock operating even during emulation, so that the timer values

keep changing.

Mode

Frequency

6.0 MHz or less

6.0 MHz or less

4.4 MHz or less

Examples: (1) When single-stepping the program

(2) When registers or internal RAM are referenced or modified

4.8 Pullup Transistor Control

Because the M34519T-MCU has an emulation circuit present in ports P0 and P1, you cannot use the

MCU's internal pullup transistors. Therefore, the M34519T-MCU controls on/off of external pullup

resistors by decoding the pullup control register transfer instructions (TPU0A and TPU1A).

The M34519T-MCU contains 150kΩ pullup resistors for use with the 4518, 4519, 4583 and 4584

Groups. If these pullup resistors need to be changed, replace the RA5 resistor array.

( 26 / 36 )

Page 27

4.9 Program Execution (G, GB)

The PC4504 and M34519T-MCU's hardware is subject to the following restrictions with respect to

the operation of the program execution commands (G and GB).

(1) Continuous description of instructions

Hardware breakpoints set in a continuous description of instructions following one after another

do not cause a break to occur in the continuous description of instructions. A break occurs only

after fetching the address where the continuous description of instructions is discontinued. (See

Program example 4.3.)

However, a break does occur even in a continuous description of instructions when an external

trigger break or forced break is encountered. For execution to be resumed in this case, you need

to make sure that the execution start address is next to the continuous description of instructions.

(See Program example 4.4.)

Program example 4.3

LA 0

POINT: LA 1 ; Continuous description of instructions

LA 2

POINT+2: XAM 3

If a break is set at POINT, execution is halted immediately before the XAM instruction at address

POINT+2.

Program example 4.4

LA 0

POINT: LA 1 ; Continuous description of instructions

POINT+1: LA 2

POINT+2: XAM 3

If a forced or external trigger break is applied at POINT, execution is halted at POINT +1. When

resuming program execution after the break, make sure that the start address is at POINT+2,

an address immediately after the continuous description of instructions is discontinued.

(2) Skip instructions (e.g. SNZP, INY, DEY, SZB, SEAM, SZC and RTS)

In cases when a skip instruction skips the next instruction, a breakpoint set in the skipped

instruction does not cause execution to halt. (See Program examples 4.5 and 4.6.)

Program example 4.5

LXY 0,0

SZD

POINT: B jmp_adr ; Skips when D(0)=0

POINTA: TAM 0

•

•

If a breakpoint is set at address POINT, the program stops before executing the instruction at

POINT when D(0)=1, but does not stop running when D(0)=0 because the instruction at POINT

is skipped. To stop the program immediately after executing a skip instruction, be sure to set

a breakpoint at both POINT and POINT_A.

Program example 4.6

RC 0,0

INY

POINT: TABP ; Skips when D(0)=0

LA 0

•

•

If a break with pass count is set at address POINT, the count is taken and execution is halted

only when the instruction at address POINT is executed.

( 27 / 36 )

Page 28

4.10 External Trigger Signal

(1) External trigger signal input timing

The latch timing of the external trigger signal is shown in Figure 4.3.

System clock

XIN

External trigger

signal TRIG

Figure 4.3 Latch timing of the external trigger signal

(2) External trigger signal input characteristics

Trigger breaks work according to the conditions (leading edge/trailing edge) of signals input from

the external trigger cable. External trigger signals of trace points and break points use the same

signals. The input characteristics of external trigger signals are shown in Table 4.4 below. See the

table before using external trigger signals.

Instruction Next Instruction

Table 4.4 External trigger signal input characteristics

H-level voltage

L-level voltage

4.11 Other Precautions

With the M34519T-MCU, you cannot evaluate systems that use some functions as described below.

In such a case, therefore, the system needs to be evaluated using an evaluation-purpose MCU (OTP

version).

(1) Because an emulation circuit exists in the RESET pin, systems that use RESET output cannot be

evaluated.

(2) Because the M34519T-MCU has its power supply voltage fixed at 3 V or 5 V, systems that use

a power-down detect function cannot be evaluated. Therefore, results of A-D conversions may

be different from expected values.

(3) Power-on reset operation cannot be verified.

(4) Because the M34519T-MCU is clocked by the system clock on the board, its clock source cannot

be changed to an on-chip oscillator, CR or crystal oscillator. When using an emulator, do not use

the CMCK, CRCK and CYCK instructions in a program.

Item

Symbol

VIH

VIL

Voltage

VCC = 2.0 V

VCC = 4.5 V

VCC = 2.0 V

VCC = 4.5 V

Min.

1.5 V

3.15 V

-

-

Max.

-

-

0.5 V

1.35 V

(5) With the M34519T-MCU, you cannot use the SRST instruction. When it is used, it will be

executed as a NOP instruction.

( 28 / 36 )

Page 29

Chapter 5. Connection Circuit Diagrams

5.1 Connection Circuit Diagrams

Figures 5.1 and 5.2 show the connection circuit diagrams of the M34519T-MCU. These circuit

diagrams depict the M34519T-MCU connection centering on circuits connected to the target system.

Emulator control blocks and other similar circuits that are not connected to the target system are

omitted in this diagram.

Figure 5.1 Connection circuit diagram (1/2)

: denotes control signal

( 29 / 36 )

Page 30

Figure 5.2 Connection circuit diagram (2/2)

: denotes control signal

( 30 / 36 )

Page 31

Chapter 6. Pitch Converter Board External Dimensions

6.1 M34513T-PTCA

Figure 6.1 shows external dimensions of the M34513T-PTCA.

Unit: mm

Figure 6.1 External dimensions of the M34513T-PTCA

6.2 M34513T-PTCB

Figure 6.2 shows external dimensions of the M34513T-PTCB.

Figure 6.2 External dimensions of the M34513T-PTCB

6.3 M34513T-PTCC

Figure 6.3 shows external dimensions of the M34513T-PTCC.

Figure 6.3 External dimensions of the M34513T-PTCC

Unit: mm

Unit: mm

( 31 / 36 )

Page 32

MEMO

( 32 / 36 )

Page 33

Chapter 7. Maintenance and Guarantee

7.1 Maintenance

If dust or dirt collects on any equipment of your emulation system, wipe it off with a dry soft cloth.

Do not use thinner or other solvents because these chemicals can cause the equipment's surface

coating to separate.

7.2 Guarantee

If your product becomes faulty within twelve months after its purchase while being used under good

conditions by observing "Precautions for Safety" described in Chapter 1 of this user's manual, we will

repair or replace your faulty product free of charge. Note, however, that if your product's fault is raised

by any one of the following causes, we will repair it or replace it with new one with extra-charge:

• Misuse, abuse, or use under extraordinary conditions

• Unauthorized repair, remodeling, maintenance, and so on

• Inadequate user's system or misuse of it

• Fires, earthquakes, and other unexpected disasters

In the above cases, contact your local distributor. If your product is being leased, consult the leasing

company or the owner.

7.3 Repair Provisions

(1) Repair with extra-charge

The products elapsed more than twelve months after purchase can be repaired with extra-charge.

(2) Replacement with extra-charge

If your product's fault falls in any of the following categories, the fault will be corrected by

replacing the entire product instead of repair, or you will be advised to purchase new one,

depending on the severity of the fault.

• Faulty or broken mechanical portions

• Flaw, separation, or rust in coated or plated portions

• Flaw or cracks in plastic portions

• Faults or breakage caused by improper use or unauthorized repair or modification

• Heavily damaged electric circuits due to overvoltage, overcurrent or shorting of power supply

• Cracks in the printed circuit board or burnt-down patterns

• Wide range of faults that makes replacement less expensive than repair

• Unlocatable or unidentified faults

(3) Expiration of the repair period

When a period of twelve months elapses after the model was dropped from production, repairing

products of the model may become impossible.

(4) Transportation fees at sending your product for repair

Please send your product to us for repair at your expense.

( 33 / 36 )

Page 34

7.4 How to Request for Repair

If your M34519T-MCU is found faulty, follow the procedure below to send your product for repair.

Customer Fill in the Repair Request Sheet included with this product, then send it

along with this product for repair to your local distributor. Make sure

that information in the Repair Request Sheet is written in as much detail

as possible to facilitate repair.

Distributor After checking the contents of fault, the distributor should please send

the faulty product along with the Repair Request Sheet to Renesas

Solutions Corp.

Renesas Solutions When the faulty product is repaired, it will be returned to the customer

at the earliest convenience.

CAUTION

Note on Transporting the Product:

• When sending your product for repair, use the packing box and cushion material supplied with the

product when delivered to you and specify handling caution for it to be handled as precision

equipment. If packing of your product is not complete, it may be damaged during transportation.

When you pack your product in a bag, make sure to use conductive polyvinyl supplied with the

product (usually a blue bag). When you use other bags, they may cause a trouble on your product

because of static electricity.

( 34 / 36 )

Page 35

M34519T-MCU User's Manual

Rev.2.00

July 1, 2004

REJ10J0071-0200Z

COPYRIGHT ©2004 RENESAS TECHNOLOGY CORPORATION

AND RENESAS SOLUTIONS CORPORATION ALL RIGHTS RESERVED

Page 36

Loading...

Loading...