Page 1

To our customers,

Old Company Name in Catalogs and Other Documents

On April 1st, 2010, NEC Electronics Corporation merged with Renesas Technology

Corporation, and Renesas Electronics Corporation took over all the business of both

companies. Therefore, although the old company name remains in this document, it is a valid

Renesas Electronics document. We appreciate your understanding.

Renesas Electronics website: http://www.renesas.com

April 1

Renesas Electronics Corporation

Issued by: Renesas Electronics Corporation (http://www.renesas.com)

st

, 2010

Send any inquiries to http://www.renesas.com/inquiry

.

Page 2

Notice

1. All information included in this document is current as of the date this document is issued. Such information, however, is

subject to change without any prior notice. Before purchasing or using any Renesas Electronics products listed herein, please

confirm the latest product information with a Renesas Electronics sales office. Also, please pay regular and careful attention to

additional and different information to be disclosed by Renesas Electronics such as that disclosed through our website.

2. Renesas Electronics does not assume any liability for infringement of patents, copyrights, or other intellectual property rights

of third parties by or arising from the use of Renesas Electronics products or technical information described in this document.

No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights

of Renesas Electronics or others.

3. You should not alter, modify, copy, or otherwise misappropriate any Renesas Electronics product, whether in whole or in part.

4. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of

semiconductor products and application examples. You are fully responsible for the incorporation of these circuits, software,

and information in the design of your equipment. Renesas Electronics assumes no responsibility for any losses incurred by

you or third parties arising from the use of these circuits, software, or information.

5. When exporting the products or technology described in this document, you should comply with the applicable export control

laws and regulations and follow the procedures required by such laws and regulations. You should not use Renesas

Electronics products or the technology described in this document for any purpose relating to military applications or use by

the military, including but not limited to the development of weapons of mass destruction. Renesas Electronics products and

technology may not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited

under any applicable domestic or foreign laws or regulations.

6. Renesas Electronics has used reasonable care in preparing the information included in this document, but Renesas Electronics

does not warrant that such informatio n is error free. Renesas Electronics assumes no liability whatsoever for any damages

incurred by you resulting from errors in or omissions from the information included herein.

7. Renesas Electronics products are classified according to the following three quality grades: “Standard”, “High Quality”, and

“Specific”. The recommended applications for each Renesas Electronics product depends on the product’s quality grade, as

indicated below. You must check the quality grade of each Renesas Electronics product before using it in a particular

application. You may not use any Renesas Electronics product for any application categorized as “Specific” without the prior

written consent of Renesas Electronics. Further, you may not use any Renesas Electronics product for any application for

which it is not intended without the prior written consent of Renesas Electronics. Renesas Electronics shall not be in any way

liable for any damages or losses incurred by you or third parties arising from the use of any Renesas Electronics product for an

application categorized as “Specific” or for which the product is not intended where you have failed to obtain the prior written

consent of Renesas Electronics. The quality grade of each Renesas Electronics product is “Standard” unless otherwise

expressly specified in a Ren esas E lectronics data sheets or dat a books, etc.

“Standard”: Computers; office equipment; communications equipment; test and measurement equipment; audio and visual

equipment; home electron ic appliances; machine tools; personal electronic equipment; and industrial robots.

“High Quality”: Transportation equipment (automobiles, trains, ships, etc.); traffic control systems; anti-disaster systems; anti-

crime systems; safety equipment; and medical equipment not specifically designed for life support.

“Specific”: Aircraft; aerospace equipment; submersible repeaters; nuclear reactor control systems; medical equipment or

systems for life support (e.g. artificial life support devices or systems), surgical implantations, or healthcare

intervention (e.g. excision, etc.), and any other appl i cations or purposes that pose a d irect threat to human life.

8. You should use the Renesas Electronics products described in this document within the range specified by Renesas Electronics,

especially with respect to the maximum rating, operating supply voltage range, movement power voltage range, heat radiation

characteristics, installation and other product characteristics. Renesas Electronics shall have no liability for malfunctions or

damages arising out of the use of Renesas Electronics products beyond such specified ranges.

9. Although Renesas Electronics endeavors to improve the quality and reliability of its products, semiconductor products have

specific characteristics such as t he occu rrence o f failure at a certai n rate an d malfunct io ns under cert ain u se con dition s. Further,

Renesas Electronics prod ucts are not subject to radiation resistance design. Please be sure to implement safety measures to

guard them against the possibility of physical injury, and injury or damage caused by fire in the event of the failure of a

Renesas Electronics product, such as safety design for hardware and software including but not limited to redundancy, fire

control and malfunction prevention, appropriate treatment for aging degradation or any other appropriate measures. Because

the evaluation of microcomputer software alone is very difficult, please evaluate the safety of the final products or system

manufactured by you.

10. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental

compatibility of each Renesas Electronics product. Please use Renesas Electronics products in compliance with all applicable

laws and regulations that regulate the inclusion or use of controlled substances, including without limitation, the EU RoHS

Directive. Renesas Electronics assumes no liability for damages or losses occurring as a result of your noncompliance with

applicable laws and regulations.

11. This document may not be reproduced or duplicated, in any form, in whole or in part, without prior written consent of Renesas

Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this

document or Renesas Electronics products, or if you have any other inquiries.

(Note 1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation an d also includes its majority-

owned subsidiaries.

(Note 2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

Page 3

User’s Manual

M306H2T-RPD-E

User’s Manual

Emulation Pod for M16C/6H Group M306H2

Rev.1.00 2003.09

Page 4

* NQPACK, YAPACK, YQSOCKET, YQ-Guide, HQPACK, TQPACK, and TQSOCKET are trademarks of Tokyo Eletech Corporation.

• Renesas Technology Corporation and Renesas Solutions Corporation put the maximum effort into making semiconductor products better

and more reliable, but there is always the possibility that trouble may occur with them. Trouble with semiconductors may lead to personal

injury, fire or property damage. Remember to give due consideration to safety when making your circuit designs, with appropriate

measures such as (i) placement of substitutive, auxiliary circuits, (ii) use of nonflammable material or (iii) prevention against any

malfunction or mishap.

• These materials are intended as a reference to assist our customers in the selection of the Renesas Technology product best suited to

the customer's application; they do not convey any license under any intellectual property rights, or any other rights, belonging to Renesas

Technology Corporation, Renesas Solutions Corporation or a third party.

• Renesas Technology Corporation and Renesas Solutions Corporation assume no responsibility for any damage, or infringement of any

third-party's rights, originating in the use of any product data, diagrams, charts, programs, algorithms, or circuit application examples

contained in these materials.

• All information contained in these materials, including product data, diagrams, charts, programs and algorithms represents information

on products at the time of publication of these materials, and are subject to change by Renesas Technology Corporation and Renesas

Solutions Corporation without notice due to product improvements or other reasons. It is therefore recommended that customers contact

Renesas Technology Corporation, Renesas Solutions Corporation or an authorized Renesas Technology product distributor for the latest

product information before purchasing a product listed herein. The information described here may contain technical inaccuracies or

typographical errors. Renesas Technology Corporation and Renesas Solutions Corporation assume no responsibility for any damage,

liability, or other loss rising from these inaccuracies or errors. Please also pay attention to information published by Renesas Technology

Corporation and Renesas Solutions Corporation by various means, including the Renesas home page (http://www.renesas.com).

• When using any or all of the information contained in these materials, including product data, diagrams, charts, programs, and algorithms,

please be sure to evaluate all information as a total system before making a final decision on the applicability of the information and

products. Renesas Technology Corporation and Renesas Solutions Corporation assume no responsibility for any damage, liability or

other loss resulting from the information contained herein.

• Renesas Technology semiconductors are not designed or manufactured for use in a device or system that is used under circumstances

in which human life is potentially at stake. Please contact Renesas Technology Corporation, Renesas Solutions Corporation or an

authorized Renesas Technology product distributor when considering the use of a product contained herein for any specific purposes,

such as apparatus or systems for transportation, vehicular, medical, aerospace, nuclear, or undersea repeater use.

• The prior written approval of Renesas Technology Corporation and Renesas Solutions Corporation is necessary to reprint or reproduce

in whole or in part these materials.

• If these products or technologies are subject to the Japanese export control restrictions, they must be exported under a license from the

Japanese government and cannot be imported into a country other than the approved destination. Any diversion or reexport contrary to

the export control laws and regulations of Japan and/or the country of destination is prohibited.

• Please contact Renesas Technology Corporation or Renesas Solutions Corporation for further details on these materials or the products

contained therein.

Keep safety first in your circuit designs!

Notes regarding these materials

• This product is a development supporting unit for use in your program development and evaluation stages. In mass-producing your

program you have finished developing, be sure to make a judgment on your own risk that it can be put to practical use by performing

integration test, evaluation, or some experiment else.

• In no event shall Renesas Solutions Corporation be liable for any consequence arising from the use of this product.

• Renesas Solutions Corporation strives to renovate or provide a workaround for product malfunction at some charge or without charge.

However, this does not necessarily mean that Renesas Solutions Corporation guarantees the renovation or the provision under any

circumstances.

• This product has been developed by assuming its use for program development and evaluation in laboratories. Therefore, it does not fall

under the application of Electrical Appliance and Material Safety Law and protection against electromagnetic interference when used in

Japan.

• Do not attempt to modify this equipment. If modified, your authority to operate this equipment might be voided by FCC.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Warning: This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

For inquiries about the contents of this document or product, fill in the text file the installer of the emulator debugger generates in the

following directory and email to your local distributor.

\SUPPORT\Product-name\SUPPORT.TXT

Renesas Tools Homepage http://www.renesas.com/en/tools

Precautions to be taken when using this product

( 2 / 76 )

Page 5

Preface

The M306H2T-RPD-E is an emulation pod for M306H2 of M16C/6H Group of 16-bit MCUs. It is

used with a PC4701 emulator.

This user's manual mainly describes specifications of the M306H2T-RPD-E emulation pod and how

to setup it. For details on the following products, which are used with M306H2T-RPD-E, refer to each

product's user's manual.

• Emulator: PC4701 User's Manual

• Emulator debugger: Emulator debugger for PC4701 series User's Manual

All the components of this product are shown in "2.2 Package Components" (page 23) of this user's

manual. If there is any question or doubt about this product, contact your local distributor.

To use the product properly

Precautions for Safety

• In both this User's Manual and on the product itself, several icons are used to insure

proper handling of this product and also to prevent injuries to you or other persons,

or damage to your properties.

• The icons' graphic images and meanings are given in "Chapter 1. Precautions for

Safety" (page 7). Be sure to read this chapter before using the product.

When using outside Japan

• When using in Europe, the United States, or Canada, be sure to use both the emulator

and the emulation pod which meet overseas standards. EMI standards are not met

when the M306H2T-RPD-E is used with the PC4700H or PC4700L emulator.

( 3 / 76 )

Page 6

Contents

Chapter 1. Precautions for Safety ...........................................................................................7

1.1 Safety Symbols and Meanings ..............................................................................9

Chapter 2. Preparation ..........................................................................................................21

2.1 Terminology ........................................................................................................22

2.2 Package Components ..........................................................................................23

2.3 Other Tool Products Required for Development ................................................23

2.4 Name of Each Part ..............................................................................................24

(1) System Configuration...............................................................................24

(2) Inside of the Emulation Pod .....................................................................25

2.5 When Using the Emulator for the First Time......................................................26

Chapter 3. Setting Up ...........................................................................................................27

3.1 Removing the Upper Cover ................................................................................28

3.2 Setting Switches and Pullup Resistors ................................................................29

3.3 Selecting Clock Supply .......................................................................................35

(1) Using the Oscillator Circuit on the Target System ..................................36

(2) Changing the Internal Oscillator Circuit of the Emulation Pod ...............37

(3) Replacing the Oscillator Circuit Boards ..................................................38

3.4 A-D Conversion Bypass Capacitor .....................................................................39

3.5 Data Slicer I/O Signal and FSC Clock I/O Signal Circuit ..................................40

3.6 Connecting the PC4701.......................................................................................41

(1) Connecting the Cable to the PC4701 .......................................................41

(2) Connecting the Cable to the Emulation Pod ............................................42

3.7 Connecting the Target System ............................................................................43

3.8 Making an MCU File for PD30 ..........................................................................44

Chapter 4. Usage ..................................................................................................................45

4.1 Turning On the Power .........................................................................................46

(1) Checking the Connection of the Emulator System ..................................46

(2) Turning On the Power ..............................................................................46

(3) LED Display When PC4701 Starts Up Normally....................................47

4.2 Downloading Firmware ......................................................................................48

(1) When It is Necessary to Download Firmware .........................................48

(2) Downloading Firmware in the Maintenance Mode .................................48

4.3 Self-checks ..........................................................................................................49

(1) Self-check Procedure ...............................................................................49

(2) If an Error is Detected in Self-checks ......................................................49

( 4 / 76 )

Page 7

Chapter 5. Specifications......................................................................................................51

5.1 Specifications ......................................................................................................52

5.2 Operation Timing in the Memory Expansion and Microprocessor Modes (5 V) ...53

(1) Separate Bus, No-wait..............................................................................53

(2) Separate Bus, With Wait, Accessing External Memory Area .................55

(3) Multiplex Bus, With Wait, Accessing External Memory Area ...............57

(4) Timing Requirements...............................................................................59

5.3 Electrical Characteristics.....................................................................................61

5.4 Connection Diagram ...........................................................................................62

5.5 External Dimensions ...........................................................................................63

(1) External Dimensions of the Emulation Pod .............................................63

(2) External Dimensions of the Pitch Converter Board (FLX160-PRB).......64

(3) External Dimensions of the Pitch Converter Board (M306H2T-PTC)....64

Chapter 6. Troubleshooting ..................................................................................................65

6.1 Flowchart to Remedy the Troubles .....................................................................66

6.2 When the Emulator Debugger Does Not Start Up Properly ...............................67

(1) When the LED Display of the PC4701 is Abnormal ...............................67

(2) Errors Occur When the Emulator Debugger Starts Up

(When the target system is connected)....................................68

(3) Errors Occur When the Emulator Debugger Starts Up

(When the target system is not connected) .............................69

6.3 Operation Differs from That of Actual MCUs....................................................70

(1) Cannot Reset from the Target System......................................................70

(2) Data Values of RAM Area at Power-on are Different .............................70

(3) HOLD* Control .......................................................................................70

(4) A-D Conversion Values are Different from Expected Values ....................70

(5)

Outputs of ALE, Address and Others are Different from Those of Actual MCUs ..

70

Chapter 7. Maintenance and Guarantee................................................................................71

7.1 Maintenance ........................................................................................................72

7.2 Guarantee ............................................................................................................72

7.3 Repair Provisions ................................................................................................72

7.4 How to Request for Repair..................................................................................73

( 5 / 76 )

Page 8

MEMO

( 6 / 76 )

Page 9

Chapter 1. Precautions for Safety

This chapter describes precautions for using this product safely and properly. For precautions for the emulator main unit

and the emulator debugger, refer to each user's manual included with your product.

1.1 Safety Symbols and Meanings ..................................................................................................... 9

WARNING

CAUTION

IMPORTANT

Warning for Installation.............................................................................................10

Warnings for Use Environment .................................................................................10

Caution to Be Taken for Modifying This Product ..................................................... 10

Cautions to Be Taken for Handling This Product......................................................10

Note on Malfunctions in the PC4701 System............................................................10

Notes on Downloading Firmware..............................................................................11

Note on When the Emulator Debugger Ends.............................................................11

Note on Final Evaluation ...........................................................................................11

Notes on Target System ............................................................................................. 11

Notes on Stack Area................................................................................................... 11

Notes on MAP References and Settings ....................................................................12

Note on Setting the Work Area..................................................................................12

Note on RESET* Input ..............................................................................................13

Note on HOLD* Input ...............................................................................................13

Note on RDY* Input..................................................................................................13

Notes on NMI* Input ................................................................................................. 13

Note on Clock Supply to the MCU............................................................................13

Notes on Interruption .................................................................................................14

Note on Address 00000h Access ............................................................................... 14

Note on Stop and Wait Modes ................................................................................... 14

Note on Software Reset .............................................................................................14

Note on BRK Instruction and BRK Instruction Interruption.....................................14

Notes on Address Match Interrupt.............................................................................14

Note on Commands that Access the Single-step Interrupt Vector Area....................15

Note on DMA Transfer..............................................................................................15

Notes on Software Breaks and Hardware Breaks ...................................................... 15

Note on Protect Resistor (PRC2) ...............................................................................15

( 7 / 76 )

Page 10

Notes on Pullup Control Resistor ..............................................................................16

Note on Reading Internal Resources of an MCU ...................................................... 16

Notes on Watchdog Function..................................................................................... 16

Note on Differences between Actual MCUs and the Emulator .................................17

( 8 / 76 )

Page 11

Chapter 1. Precautions for Safety

In both the User's Manual and on the product itself, several icons are used to insure proper handling

of this product and also to prevent injuries to you or other persons, or damage to your properties.

This chapter describes the precautions which should be taken in order to use this product safely and

properly. Be sure to read this chapter before using this product.

1.1 Safety Symbols and Meanings

If the requirements shown in the "WARNING"

WARNING

CAUTION

IMPORTANT

In addition to the three above, the following are also used as appropriate.

sentences are ignored, the equipment may

cause serious personal injury or death.

If the requirements shown in the "CAUTION"

sentences are ignored, the equipment may

malfunction.

It means important information on using this

product.

means WARNING or CAUTION.

Example: CAUTION AGAINST AN ELECTRIC SHOCK

means PROHIBITION.

Example: DISASSEMBLY PROHIBITED

means A FORCIBLE ACTION.

Example:

The following pages describe the symbols "WARNING", "CAUTION", and "IMPORTANT".

UNPLUG THE POWER CABLE FROM THE RECEPTACLE.

( 9 / 76 )

Page 12

WARNING

Warning for Installation:

• Do not set this product in water or areas of high humidity. Spilling water or some other liquid into

the main unit can cause an unrepairable damage.

Warnings for Use Environment:

• The emulation pod is air-cooled with the ventilation slot. Therefore, do not block the ventilation

slot. When heated to high temperatures, the emulation pod may not work properly.

• This equipment is to be used in an environment with a maximum ambient temperature of 35°C. Care

should be taken that this temperature is not exceeded.

CAUTION

Caution to Be Taken for Modifying This Product:

• Do not disassemble or modify this product. Disassembling or modifying this product can cause

damage. Disassembling and modifying the product will void your warranty.

Cautions to Be Taken for Handling This Product:

• Use caution when handling the main unit. Be careful not to apply a mechanical shock.

• Do not touch the connector pins of the emulator main unit and the target MCU connector pins. Static

electricity may damage the internal circuits.

• Do not pull the emulation pod main unit by the flexible cable (FLX120-RPD) for connecting to the

emulator main unit or the flexible cable (FLX64, FLX100 or FLX160) for connecting the target

system. The cable may cause a break.

• Flexible cable (FLX120-RPD) for connecting to the emulator main unit and the flexible cable

(FLX64, FLX100 or FLX160) for connecting the target system are different from earlier models.

The slits make them more flexible. However, excessive flexing or force may break conductors.

•Do not use inch-size screws for this equipment. The screws used in this equipment are all ISO

(meter-size) type screws. When replacing screws, use same type screws as equipped before.

IMPORTANT

Note on Malfunctions in the PC4701 System:

• If the emulator malfunctions because of interference like external noise, do the following to remedy

the trouble.

(1) Press the RESET switch on the emulator front panel.

(2) If normal operation is not restored after step (1), shut OFF power to the emulator once and then

reactivate it.

( 10 / 76 )

Page 13

IMPORTANT

Notes on Downloading Firmware:

• Before using this product for the first time, it is necessary to download the dedicated firmware

(control software for the emulation pod built into the PC4701). Please note that, to do this, it is

necessary to start up the PC4701 in the maintenance mode. For firmware download procedures, see

"4.2 Downloading Firmware" (page 48). Once the firmware has been downloaded, the product can

be used by simply turning on the power.

• Do not shut off the power while downloading the firmware. If this happens, the product will not

start up properly. If power is shut off unexpectedly, redownload the firmware.

• Except when a target status error occurs, if self-checks are not completed successfully, there may

be trouble with the product. In such case, contact your sales representative. However, perform selfchecks in the below setup.

(1) Target system: Not connected

(2) Emulation pod internal switches: At their factory settings

Note on When the Emulator Debugger Ends:

• To restart the emulator debugger after it ends, always shut power to the emulator module off once

and then on again.

Note on Final Evaluation:

• Be sure to evaluate your system with an evaluation MCU. Before starting mask production,

evaluate your system and make final confirmation with a CS (Commercial Sample) version MCU.

Notes on Target System:

• The Vcc pin of emulator is connected to the target system to observe the voltage of the target system.

Therefore design your system so that the emulator MCU is powered by the target system.

• The voltage of the target system should be within the range of the MCU specification.

•Do not change the voltage of the target system after turning on the power.

• Before powering on your emulator system, check that the host machine, the emulator main unit,

the converter board and target system are all connected correctly. Next, turn on the power to each

equipment following the procedure below.

(1) Turn ON/OFF the target system and the PC4701 emulator as simultaneously as possible.

(2) When the PC4701 and emulator debugger start up, check the target status LEDs on the

emulator main unit's front panel to see if this product is ready to operate.

• Is the power supplied? Check target status LED (POWER) is ON.

For details, refer to "Chapter 4. Usage" (page 45).

Notes on Stack Area:

•With this product, a maximum 8 bytes of the user stack is consumed.

• If the user stack does not have enough area, do not use areas which cannot be used as stack (SFR

area, RAM area which stores data, or ROM area) as work area. Using areas like this is a cause of

user program crashes and destabilized emulator control. Therefore, ensure the +8 bytes maximum

capacity used by the user program as the user stack area.

( 11 / 76 )

Page 14

IMPORTANT

Notes on MAP References and Settings:

• For details on referencing and setting MAP information, see user's manual of the emulator

debugger.

• Be sure to set the SFR area to EXTERNAL (an external section).

•When setting 0FFFCh - 0FFFFh to EXTERNAL:

This product uses the 4 bytes area 0FFFCh - 0FFFFh as the stack area. If this 4 bytes memory cannot

be read or written to, reset cannot be properly effected. As a result, you need to alter the map settings

if either of the conditions given below is met.

(1) With the system which shifts from the single-chip mode to the memory expansion (or

microprocessor) mode, using the 4 bytes area of 0FFFCh - 0FFFFh set to EXTERNAL.

(2) With the system which starts up in the microprocessor mode, using the 4 bytes area of 0FFFCh

- 0FFFFh set to EXTERNAL and there is not enough memory to read or write to.

The procedures to alter the MAP settings when the condition (1) or (2) above is met are shown

below.

(1) Set the 4 bytes area of 0FFFCh - 0FFFFh to INTERNAL.

(2) Execute the RESET command of the emulator debugger.

(3) Set the stack pointer.

(Example)

RESET:

FCLR I

○○

LDC #0480H, SP --> Set the stack pointer.

(4) Set the 4 bytes area 0FFFCh - 0FFFFh to EXTERNAL.

Note on Setting the Work Area:

• To use this product, it is necessary to set the work area in the internal reserved area of the MCU.

However, do not set it in the last 10 bytes of the internal reserved area. And be sure to set the internal

reserved area to INTERNAL. (Set the work area by Init dialog of the emulator debugger.)

Example 1: When debugging the program of the MCU whose internal reserved area is 02C00h -

03FFFh, set the work area within the range of 02C00h - 03FF6h.

Example 2: When debugging the program of the MCU whose internal reserved area is 05400h -

05FFFh, set the work area within the range of 05400h - 05FF6h.

For instance, when setting the work area at 05C00h, the emulator uses 10 bytes area of 05C00h -

05C09h.

(Stop the program after executing this instruction.)

( 12 / 76 )

Page 15

Note on RESET* Input:

• The RESET* input from the target system is accepted only while a user program is being executed

(only while the RUN status LED on the PC4701's front panel is lit).

Note on HOLD* Input:

• Be sure to input "L" to the HOLD* pin of the target system during the user program execution (while

the RUN status LED on the PC4701's front panel is lit). Inputting "L" to the HOLD* pin when

stopping the user program may cause a malfunction of the emulator.

Note on RDY* Input:

• Be sure to input "L" to the RDY* pin of the target system during the user program execution (while

the RUN status LED on the PC4701's front panel is lit). Inputting "L" to the RDY* pin when

stopping the user program may cause a malfunction of the emulator.

Notes on NMI* Input:

IMPORTANT

• NMI* input from the target system is accepted only while a user program is being executed (only

while the RUN status LED on the PC4701's front panel is lit).

•NMI* interrupts are generated in the following situations.

(1) Immediately after the NMI* pin changes from "H" to "L" level during the target program

execution

(2) After a reset is released by the target system when the NMI* pin is "L" level during the target

program execution

(3) Immediately after program execution starts with the NMI* pin "L" level, following the reset

input from the emulator debugger or emulator main unit

(4) Immediately after program execution starts when the NMI* pin is "H" level immediately

before the target program stops and changes to "L" level when target program execution starts

Note on Clock Supply to the MCU:

• Clock can be supplied to the evaluation MCU in one of the following two ways. This is determined

by emulator debugger clock selection.

(1) When Internal is selected:

The clock generated by the oscillation circuit in the emulation pod is supplied to the evaluation

MCU. The clock is continually supplied to the evaluation MCU regardless of "target system

clock status" and "user program execution status".

(2) When External is selected:

Clock supply to the evaluation MCU depends on oscillation status (oscillate/off) of the target

system.

( 13 / 76 )

Page 16

IMPORTANT

Notes on Interruption:

• Even when the target program is not being executed (while the target program is stopped or during

runtime debugging), the evaluation MCU keeps running so as to control the emulation pod.

Therefore, note that timers and other components do not stop running even though the target

program is not being executed.

• If a maskable interrupt request is generated when the target program is not being executed (while

the target program is stopped or during runtime debugging), the request is not accepted because the

emulator disables all interrupts. If an interrupt request is generated when the target program is not

being executed, but the target program enables that interrupt, it will be accepted immediately after

program execution starts.

Note on Address 00000h Access:

•With the M16C/6H Group MCUs, when a maskable interrupt is generated, the interrupt data

(interrupt No. and interrupt request level) stored in address 00000h is read out. Also, the interrupt

request bit is cleared when address 00000h is read out. Consequently, when the address 00000h

readout instruction is executed or when address 00000h is read out in the cause of a program

runaway, a malfunction occurs in that the interrupt is not executed despite the interrupt request,

because the request bit of the highest priority interrupt factor enabled is cleared.

For this malfunction, when the reading out to the address 00000h is generated excluding the

interrupt, the yellow LED lights up to alarm. When this LED lights, there is a possibility of wrong

access to address 00000h, therefore check the program. This LED is turned off by the RESET

switch of the emulator main unit.

Note on Stop and Wait Modes:

•Do not perform step execution at addresses in the stop or wait mode. It may cause communication

errors.

Note on Software Reset:

• Do not use a software reset.

Note on BRK Instruction and BRK Instruction Interruption:

• With this emulator system, BRK instructions and BRK instruction interruptions are exclusively

used for software break functions. Therefore, you can not use them for your program.

Notes on Address Match Interrupt:

• Do not set software breaks at the same addresses as address-match interrupts as the program may

run out of control.

• Do not set a hardware break within 4 instructions before an address at which an address-match

interrupt occurs. If you do set a hardware break in this range, the program will run out of control.

•When an address at which an address-match interrupt occurs is executed in one-step mode, the

program stops after executing the first instruction after returning from the address-match interrupt

processing.

( 14 / 76 )

Page 17

IMPORTANT

Note on Commands that Access the Single-step Interrupt Vector Area:

• Do not perform the following debugging operations with the single step interrupt vector area

(addresses FFFECh - FFFEFh).

(1) Step execution of instructions that access the single step interrupt vector area

(2) Program execution using instructions that access the single step interrupt vector area when a

software breakpoint is set in those instructions

Note on DMA Transfer:

•With this product, the program is stopped with a loop program to a specific address. Therefore, if

a DMA request is generated by a timer or other source while the program is stopped, DMA transfer

is executed. However, make note of the fact that DMA transfer while the program is stopped may

not be performed correctly. Also note that the following registers have been changed to generate

DMA transfer as explained here even when the program is stopped.

DMA0 transfer counter register: TCR0

DMA1 transfer counter register: TCR1

Notes on Software Breaks and Hardware Breaks:

• Software breaks generate BRK interrupts by substituting the proper instruction to the BRK

instruction. Therefore, when referencing the result of a trace in bus mode, "00h" is displayed for

the instruction fetch address where a software break is set, and when referencing in reverse

assemble mode, "BRK" instruction is displayed.

• It is not possible to use a software break and a hardware break at the same time. If doing so, it may

not operate normally.

• In the area where the MAP setting is EXTERNAL, software breaks cannot be used.

Note on Protect Resistor (PRC2):

•Make note of the fact that the protect is not canceled when protect register (PRC2), which enables

writing in the port P9 direction registers and the SI/O3, SI/O4 control registers, is changed with the

following procedure.

(1) Step execution of the instruction for setting ("1") PRC2

(2) Setting the break point from the instruction for setting ("1") PRC2 to when the setting the

register for the protect"

(3) Setting ("1") PRC2 from the dump window or script window

( 15 / 76 )

Page 18

IMPORTANT

Notes on Pullup Control Resistor:

• Ports P00 to P57 are not pulled up by the pullup control resistor.

When pulling up the ports P00 to P57, apply a resistance to the inside of the emulator. How to apply

it, refer to "3.2 Setting Switches and Pullup Resistors" (page 29).

Note: Ports P60 to P107 are pulled up by the pullup control resistors.

Note: The pullup control resistors can read and write from P00 to P107 properly.

• When the pullup control resistor 1 (bit 1 of address 3FDh = PU11) of Ports P44 - P47 is set to "1"

(pulled up), ports P15 - P17 are pulled up regardless of the value of the pullup control resistor 0 (bit

3 of address 3FCh = PU03) of Ports P14 - P17.

Note on Reading Internal Resources of an MCU:

• When the registers that are listed in Table 1.1 are read with an emulator, those results will be the

following (the data in the MCU are not effected).

(1) Results of real-time trace

The data values of the cycles read are not displayed correctly.

(2) Real-time RAM monitor

The data values read are not displayed correctly.

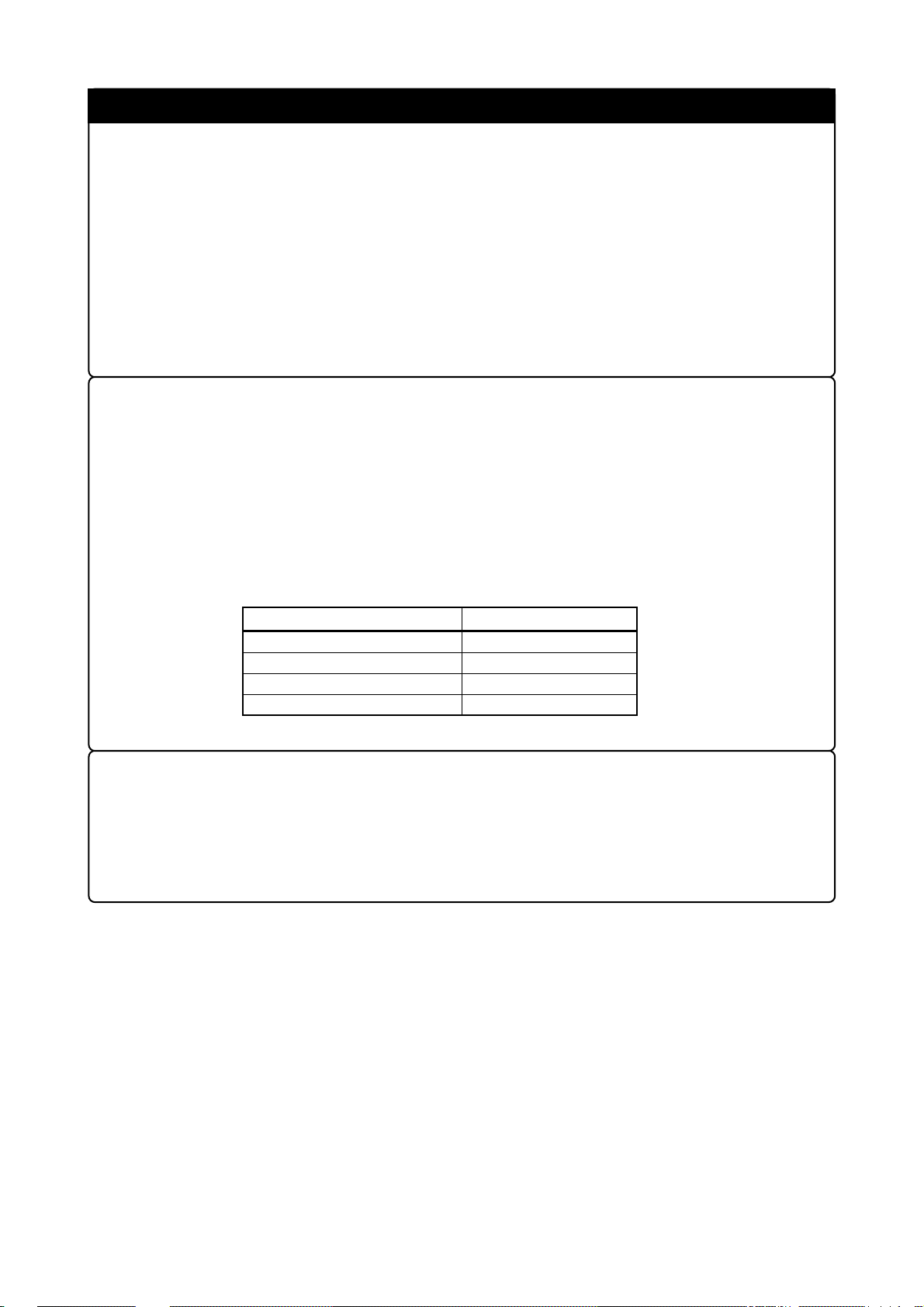

Table 1.1 Resisters and symbols not displayed normally

Resister Symbol

DMA source pointers 0, 1 SAR0, SAR1

DMA destination pointers 0, 1 DAR0, DAR1

DMA transfer counters 0, 1 TCR0, TCR1

DMA control resisters 0, 1 DM0CON, DM1CON

Notes on Watchdog Function:

• The MCU's watchdog timer can be used only while a program is being executed. To use it

otherwise, disable the watchdog timer.

• If the reset circuit of the target system has a watchdog timer, disable it when using the emulator.

( 16 / 76 )

Page 19

IMPORTANT

Note on Differences between Actual MCUs and the Emulator:

• Operations of the emulator system differ from those of actual MCUs as listed below.

(1) Reset condition

Set the rise time (0.2 Vcc to 0.8 Vcc) 1 µs or less.

(2) Initial values of MCU's internal resources

(3) Internal memories (ROM and RAM) capacities etc.

With this emulator system, "INT" (emulation memory ON) is the default for mapping areas

other than the SFR area (addresses 000h - 3FFh). For this reason, the emulation memory can

read and write in areas other than the SFR, internal RAM and internal ROM.

(4) Oscillator circuit

•Make note of the fact that in the oscillator circuit where a resonator is connected between

the XIN and XOUT pins, oscillation does not occur because a flexible cable, buffer IC and other

devices are used between the evaluation MCU and the target system. It is same for sub-clock

oscillator circuits (XCIN and XCOUT).

• For note on when using the oscillator circuit on the target system, refer to "3.3 (1) Using the

Oscillator Circuit on the Target System" (page 36).

(5) Characteristics of ports P00 to P57

With this product, ports P00 to P57 are connected via an emulation circuit. The device used

for the port emulation circuit is as follows.

Device: M60081L-0142FP

(6) HOLD* control

When inputting "L" to the HOLD* pin to run into the HOLD state, P00 to P52 will be in the

HOLD state delaying by 2.5 cycles than the actual MCU (see Figure 5.5 and Table 5.5).

(7) DBC, Single-step and BRK instruction interrupt vector table addresses

You can download data to the DBC, Single-step and BRK instruction interrupt vector table

addresses. However, the data read out from this area is different from expected values, because

the emulator system uses this area (see Table 1.2).

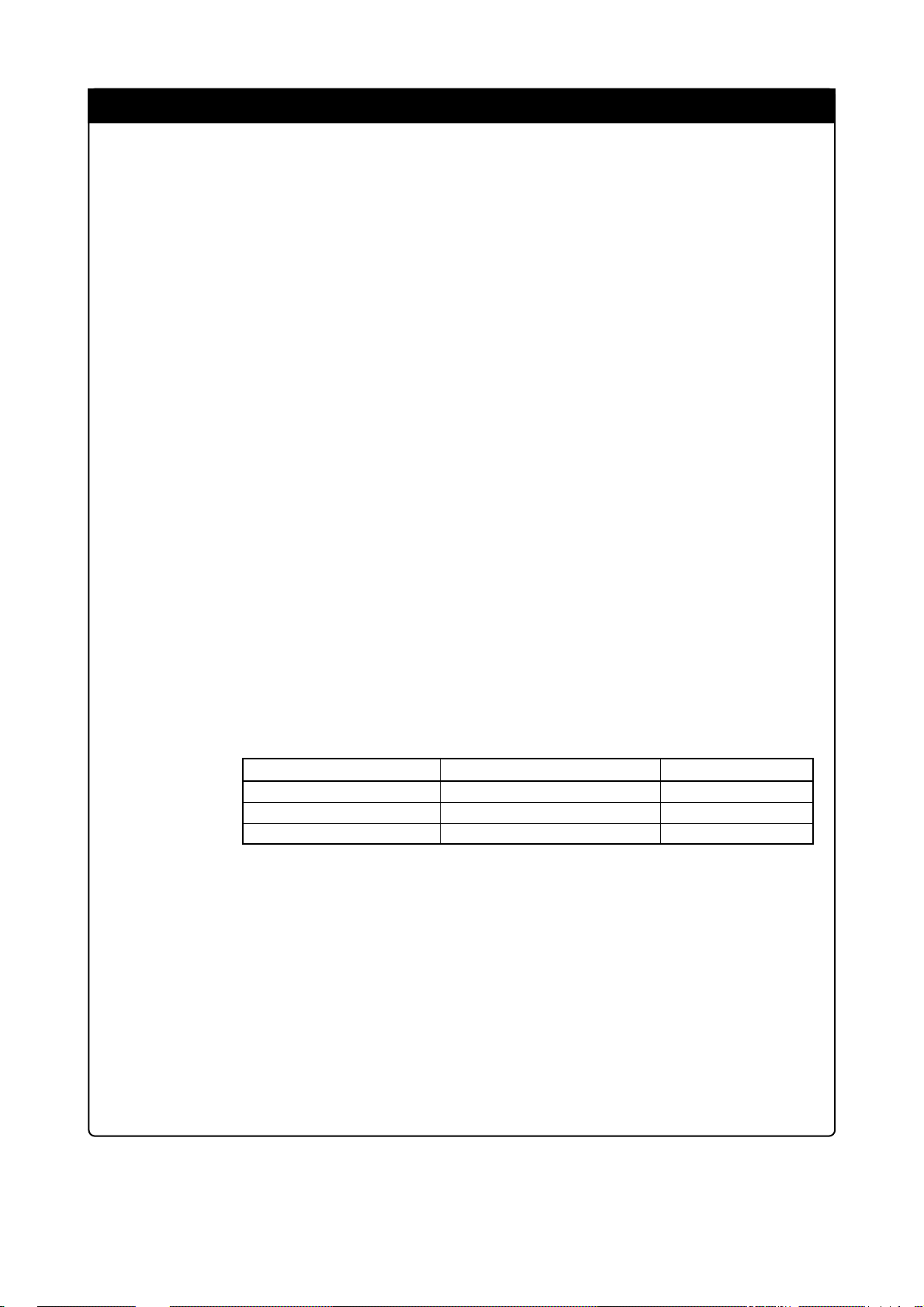

Table 1.2 Vector table addresses for the emulator

Factor of interruption Vector table addresses Data for reading

1

DBC*

Single-step*

BRK instruction FFFE4h

1

FFFF4h - FFFF7h Indefinite

FFFECh - FFFEFh Indefinite

- FFFE7h Indefinite

*1 Interruption for the debugger only

(8) A-D conversion

As a analog switch, flexible cable, pitch converter board and other devices are used between

the evaluation MCU and the target system, some characteristics are slightly different from

those of the actual MCU.

(9) D-A conversion

As a flexible cable, pitch converter board and other devices are used between the evaluation

MCU and the target system, some characteristics are slightly different from those of the actual

MCU.

(10) Outputs of the actual MCU and this product

Outputs of this product are determined according to the user program as listed in Tables 1.3

to 1.6.

( 17 / 76 )

Page 20

IMPORTANT

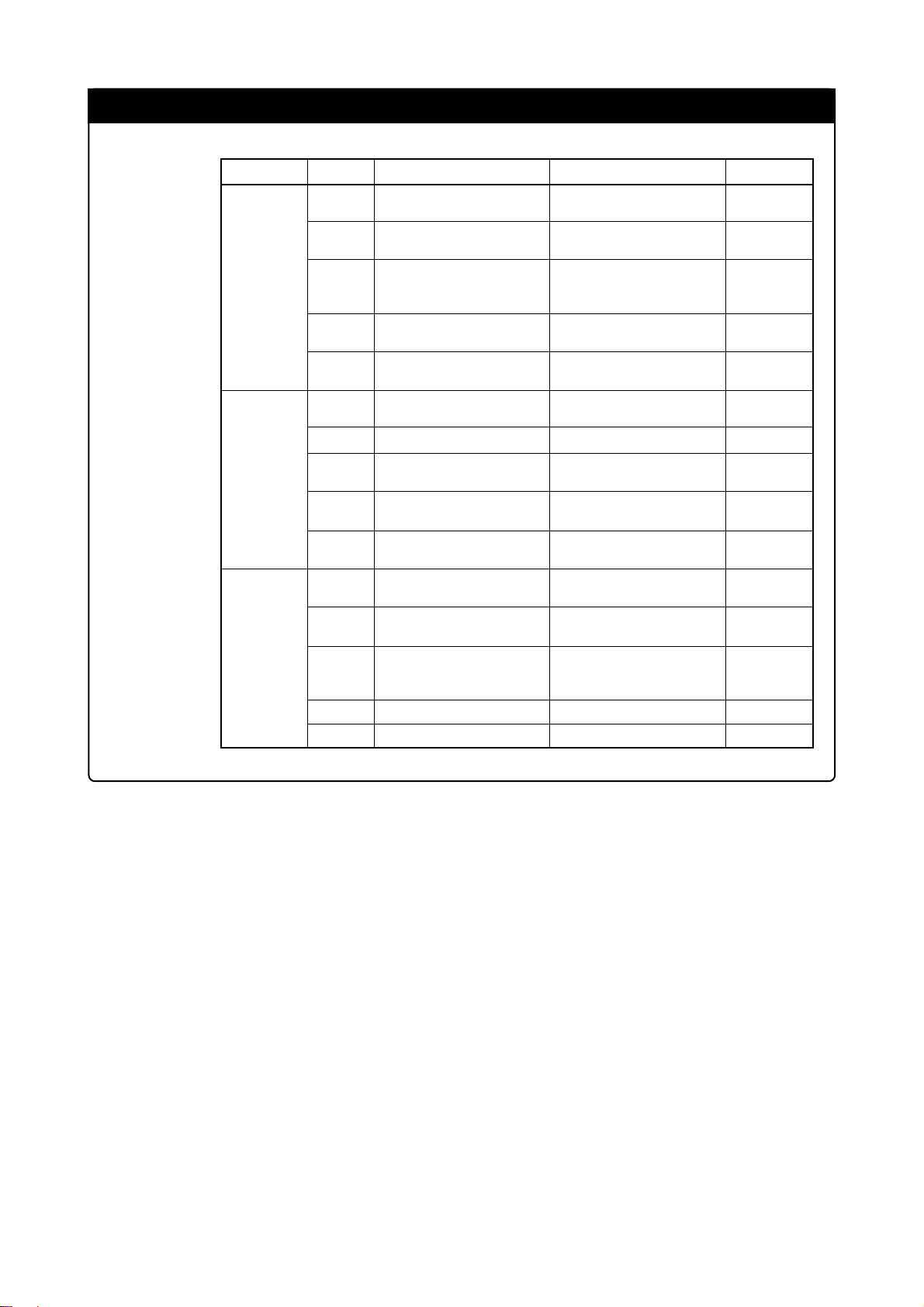

Table 1.3 Differences of outputs between actual MCUs and this product (when executing program)

Access area Signal

Address

BHE*

Data

SFR area

(MAP = EXT)

Internal RAM

Internal ROM

External area

RD*

WR*

CS*

ALE

Address

BHE*

Data

RD*

WR*

CS*

ALE

Address

BHE*

Data

RD*

WR*

CS*

ALE

Actual MCU

Outputs

Outputs

(floating during read cycle)

Outputs

("L" output at write cycle,

"L" output at read cycle)

Does not output

(fixed to "H" output)

Does not output

(fixed to "L" output)

Retains previous status

Floating

Does not output

(fixed to "H" output)

Does not output

(fixed to "H" output)

Does not output

(fixed to "L" output)

Outputs

Outputs

(inputs external data at read cycle)

Outputs

("L" output at write cycle,

"L" output at read cycle)

Outputs

Outputs

This product

Outputs

Floating

Does not output

(fixed to "H" output)

Does not output

(fixed to "H" output)

Outputs

Outputs

Floating

Does not output

(fixed to "H" output)

Does not output

(fixed to "H" output)

Outputs

Outputs

Outputs

(inputs external data at read cycle)

Outputs

("L" output at write cycle,

"L" output at read cycle)

Outputs

Outputs

∗ for difference

∗

∗

∗

∗

∗

( 18 / 76 )

Page 21

IMPORTANT

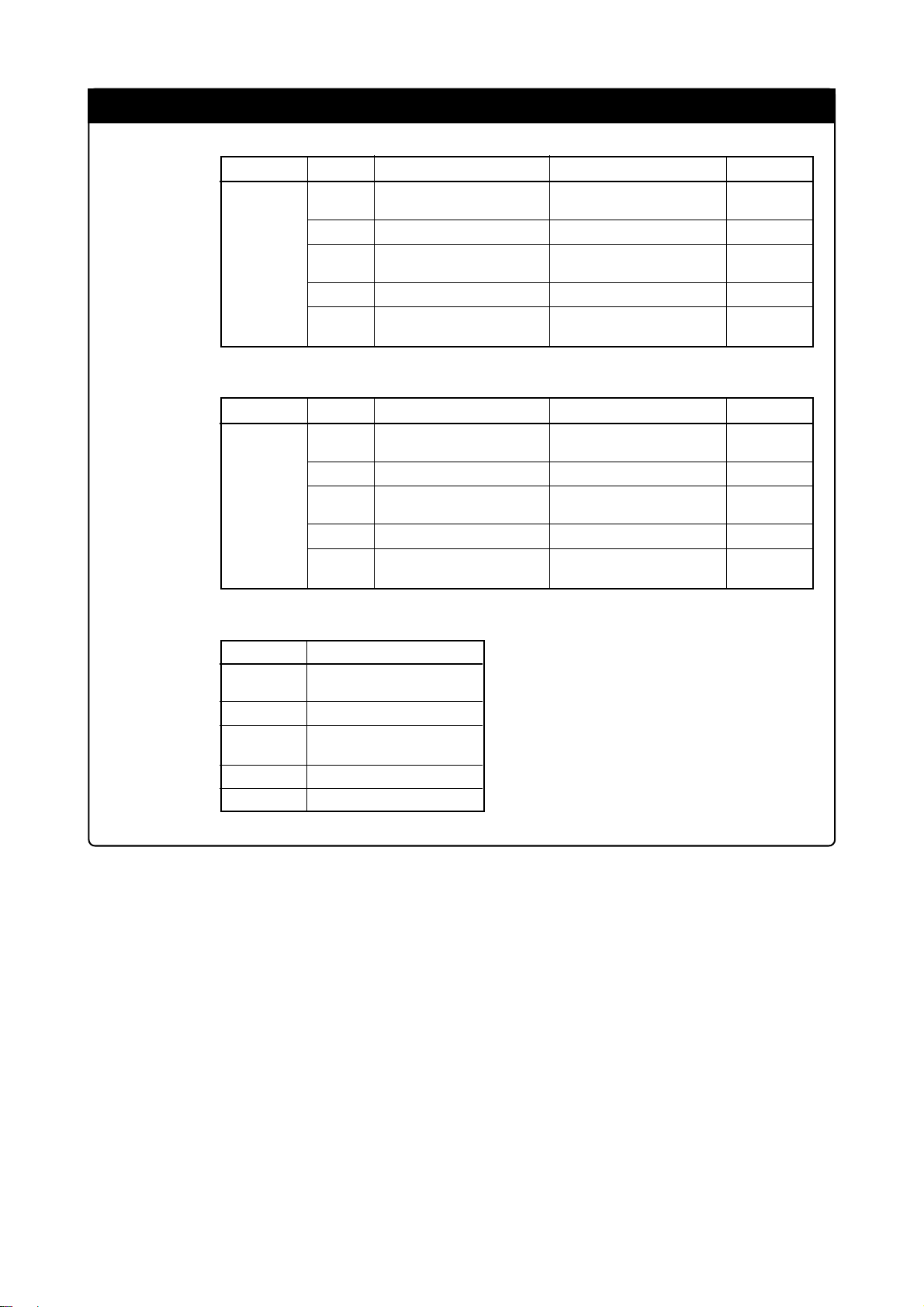

Table 1.4 Differences of outputs between actual MCUs and this product (in stop mode)

Access area-Signal

Address

BHE*

Data Floating

RD*

WR*

CS*

ALE

Actual MCU

Retains previous status

Retains previous status

Does not output

(fixed to "H" output)

Retains previous status

Does not output

(fixed to "H" output)

Table 1.5 Differences of outputs between actual MCUs and this product (in wait mode)

Access area-Signal Actual MCU

Address

BHE*

Data

RD*

WR*

CS*

ALE

Retains previous status

Retains previous status

Does not output

(fixed to "H" output)

Retains previous status

Does not output

(fixed to "H" output)

This product

Retains previous status

Does not output

(fixed to "H" output)

Retains previous status

Does not output

(fixed to "H" output)

This product

Retains previous status

Floating

Does not output

(fixed to "H" output)

Retains previous status

Does not output

(fixed to "H" output)

∗ for difference

∗ for difference

∗

∗

Table 1.6 Outputs of this product when the user program is stopping

Signal

Address

BHE*

Data

RD*

WR*

CS*

ALE

This product

Outputs

Floating

Outputs RD* only

(WR* fixed to "H" output)

Outputs

Outputs

( 19 / 76 )

Page 22

MEMO

( 20 / 76 )

Page 23

Chapter 2. Preparation

This chapter describes the package components, the system configuration and the preparation for using this product for the

first time.

2.1 Terminology ...............................................................................................................................22

2.2 Package Components.................................................................................................................. 23

2.3 Other Tool Products Required for Development........................................................................ 23

2.4 Name of Each Part......................................................................................................................24

(1) System Configuration ...........................................................................................................24

(2) Inside of the Emulation Pod.................................................................................................. 25

2.5 When Using the Emulator for the First Time.............................................................................26

( 21 / 76 )

Page 24

Chapter 2. Preparation

2.1 Terminology

Some specific words used in this user's manual are defined as follows:

Emulator system

This means an emulator system built around the PC4701 emulator. The PC4701 emulator system is

configured with an emulator main unit, emulation pod, host machine and emulator debugger.

Emulator main unit (Hereafter PC4701)

This means a generic name for emulators for 8 and 16-bit MCUs. For details on specific models of

PC4701, visit the Renesas Tools Homepage.

Emulation pod

This means M306H2T-RPD-E (this product). This emulation pod is for M16C/6H Group M306H2.

Host machine

This means a personal computer used to control the emulator and emulation pod.

Emulator debugger

http://www.renesas.com/en/tools

This means a software tool M3T-PD30 to control the emulator from the host machine through an

interface.

Firmware

Program that analyzes contents of communication with the emulator debugger and controls the

emulator hardware. This program is installed in the EEPROM. This program is downloadable from

the emulator debugger to upgrade the firmware or to support other MCUs.

Software break

A software break is a function to break the program before the system executes an instruction at the

specified address. The instruction at the preset address will not be executed.

Hardware break

A hardware break is a function to break the program when the system detects a write/read of data to/

from memory or a leading/trailing edge of the signal entered from the external trace cable. The former

break function is called data break; and the latter break function is called trigger break. While the

instruction at the address where the software break is set is not executed, a hardware break is

performed after the specified instruction is executed.

Evaluation MCU

This means the MCU mounted on the emulation pod which is operated in the specific mode for tools.

Target MCU

This means the MCU you are going to debug.

Target system

This means a user's application system using the microcomputer to be debugged.

*

In this user's manual, this symbol is used to show active LOW. (e.g. RESET*: Reset signal)

( 22 / 76 )

Page 25

2.2 Package Components

The M306H2T-RPD-E package consists of the following items. When unpacking, check to see if

your M306H2T-RPD-E contains all of these items.

Package components

Item

M306H2T-RPD-E emulation pod main unit

FLX120-RPD flexible cable for connecting PC4701

FLX160 flexible cable for connecting pitch converter board (pre-installed in emulation pod)

FLX160-PRB pitch converter board for connecting target system (pre-mounted on FLX160)

M306H2T-PTC pitch converter board for connecting 116-pin 0.65-mm-pitch (116P6A-A)

foot pattern (includes YQPACK116SB×1, NQPACK116SB×1 and YQ-GUIDE×4)

OSC-2 oscillator circuit board

Hardware tool user registration FAX sheet (English)

Hardware tool user registration FAX sheet (Japanese)

M306H2T-RPD-E user's manual (this manual)

M306H2T-RPD-E user's manual (Japanese)

Quantity

1

1

1

1

1

1

1

1

1

1

Please keep the M306H2T-RPD-E's packing box and cushion material in your place for reuse at a later

time when sending your product for repair or other purposes. Always use these packing box and

cushion material when transporting this product.

If any of these items are missing or found faulty, please contact your local distributor. Also, if there

is any question or doubt about the packaged product, contact your local distributor.

2.3 Other Tool Products Required for Development

To bring forward programs development on the M16C/6H Group MCUs, the products listed below

are necessary in addition to those contained package above. Get them separately.

Other tool products required for development

Emulator main unit

Emulator debugger

To purchase these products, contact your nearest distributer.

PC4701

M3T-PD30

( 23 / 76 )

Page 26

2.4 Name of Each Part

(1) System Configuration

Figure 2.1 System configuration

(1) to (4) in Figure 2.1 are included with this product package.

(1) Emulation pod (M306H2T-RPD-E)

This emulation pod contains an evaluation MCU, emulation memory and circuits to feature the

debugging functions.

(2) Flexible cable (FLX120-RPD)

This is a 120-pin flexible cable for connecting the PC4701 emulator and the emulation pod.

(3) Flexible cable (FLX160)

This is a 160-pin flexible cable for connecting the emulation pod and the target system.

(4) Pitch converter board (FLX160-PRB, M306H2T-PTC)

These are pitch converter boards for connecting to the target system. For details, refer to "3.7

Connecting the Target System" (page 43).

( 24 / 76 )

Page 27

(2) Inside of the Emulation Pod

Figure 2.2 Internal view of the emulation pod

(1) MCU-dependent boards 1 and 2

Boards grouping parts (pins and added functions) which vary according to MCU model.

(2) Base board

Board for the M16C/60 and M16C/20 Series MCUs which controls the interface with the PC4701

and the evaluation MCU.

(3) Memory board

Board on which is mounted the emulation memory (1 MB) and the map memory (4 bit×1M) for

the M16C/60 and M16C/20 Series MCUs.

(4) Oscillator circuit board

Oscillator circuit board on which the oscillation module device (10 MHz) and the crystal

oscillator (32.768 kHz) are mounted.

(5) Power circuit board

Power circuit board which determines the power voltage in the pod according to the power voltage

level of the target system.

( 25 / 76 )

Page 28

2.5 When Using the Emulator for the First Time

If you have purchased this emulation pod newly, it is necessary to download the firmware. The

download procedure is given in Figure 2.3.

Before downloading the firmware, check the emulator debugger is installed and the PC4701 is

connected to the host machine. For more information, see each user's manual of the emulator

debugger and the PC4701.

Connect the PC4701 and this product.

Within 2 seconds of turning the power ON, press the

RESET switch of the PC4701 and check the maintenance

mode is accessed.

Download the firmware using the emulator debugger.

End the emulator debugger and shut the power of the

PC4701 OFF.

See "3.6 Connecting the PC4701"

(page 41).

See "4.2 Downloading Firmware"

(page 48).

Figure 2.3 Firmware download procedure when the emulator is used for the first time

To make sure the emulation pod works properly, run the self-checks. For self-check procedures, see

"4.3 Self-checks" (page 49).

( 26 / 76 )

Page 29

Chapter 3. Setting Up

This chapter describes switch settings required for using this product and how to connect this product to the PC4701 and

the target system.

3.1 Removing the Upper Cover........................................................................................................28

3.2 Setting Switches and Pullup Resistors .......................................................................................29

3.3 Selecting Clock Supply .............................................................................................................. 35

(1) Using the Oscillator Circuit on the Target System ............................................................... 36

(2) Changing the Internal Oscillator Circuit of the Emulation Pod............................................ 37

(3) Replacing the Oscillator Circuit Boards ...............................................................................38

3.4 A-D Conversion Bypass Capacitor ............................................................................................39

3.5 Data Slicer I/O Signal and FSC Clock I/O Signal Circuit.......................................................... 40

3.6 Connecting the PC4701..............................................................................................................41

(1) Connecting the Cable to the PC4701....................................................................................41

(2) Connecting the Cable to the Emulation Pod.........................................................................42

3.7 Connecting the Target System.................................................................................................... 43

3.8 Making an MCU File for PD30..................................................................................................44

( 27 / 76 )

Page 30

Chapter 3. Setting Up

To use this emulation pod with your target system, it is necessary to set as follows. Set the following

after removing the upper cover.

• Change the oscillation frequency in the emulation pod.

• Set the switches depending on the target system.

• Install pullup resistors to ports P00 to P57.

• Install the A-D conversion bypass capacitor.

• Change the input frequency for FSC oscillation.

• Change the constant of the circuit for data slicer I/O signal.

3.1 Removing the Upper Cover

The procedure of removing the upper cover is shown below.

(1) Remove the four screws of both sides of this product and lift off the upper cover. (see Figure 3.1)

(2) Set the switches.

(3) Replace the upper cover and secure the four screws.

Figure 3.1 Removing the upper cover

CAUTION

When Removing the Upper Cover:

• Always shut OFF power when removing the upper cover or setting the switches.

•Do not touch the connector pins of the emulator main unit and the target MCU

connector pins. Static electricity may damage the internal circuits.

( 28 / 76 )

Page 31

3.2 Setting Switches and Pullup Resistors

Figure 3.2 shows the positions of switches and a position for installing pullup resistors. Tables 3.1

to 3.4 list how to set each switch and Figure 3.3 shows how to install pullup resistors.

Figure 3.2 Positions of switches and their factory-settings

( 29 / 76 )

Page 32

Table 3.1 Switch settings of the M306H2T-RPD-E (1/4)

Switch Signal Setting Description

16

SW1 BYTE

OPEN

8

SW1

BYTE

16

OPEN

8

SW1

BYTE

16

OPEN

8

SW1

BYTE

(Factory-setting)

H

OPEN

L

SW2

CNVSS

(Factory-setting)

Pulls up the BYTE pin of MCU with a resistance at

33 kΩ.

Does not pull down/up the BYTE pin of MCU.

Pulls down the BYTE pin of MCU with a resistance

at 33 kΩ.

Pulls down the CNVSS pin of MCU with a resistance

at 33 kΩ.

CNVSSSW2

SW3 X

OUT

H

OPEN

L

SW2

CNVSS

H

OPEN

L

SW2

CNVSS

XOUT

OPEN

SW3

XOUT

(Factory-setting)

XOUT

OPEN

SW3

XOUT

Does not pull down/up the CNV

SS pin of MCU.

Pulls up the CNVSS pin of MCU with a resistance

at 33 kΩ.

Does not connect the XOUT pin of MCU to the target

system.

Connects the X

OUT pin of MCU to the target system.

( 30 / 76 )

Page 33

Table 3.2 Switch settings of the M306H2T-RPD-E (2/4)

Switch Signal Setting Description

XCIN

SW4 P8

P86/XCOUTSW5

7/XCIN

P87

SW4

P87/XCIN

(Factory-setting)

XCIN

P87

SW4

P87/CIN

XCOUT

OPEN

P86

SW5

P86/XCOUT

(Factory-setting)

XCOUT

OPEN

P86

SW5

P86/XCOUT

XCOUT

OPEN

P86

SW5

P86/XCOUT

Connects the P8

7/XCIN pin of MCU to the target

system. (Uses P87/XCIN pin as port P87)

Uses P8

Connects the P8

7/XCIN pin as XCIN.

6/XCOUT pin of MCU to the target

system. (Uses P86/XCOUT pin as port P86)

Connects the P86/XCOUT pin of MCU to the target

system. (Uses P86/XCOUT pin as XCOUT and opens

XCOUT)

Connects the P86/XCOUT pin of MCU to the target

system. (Uses P86/XCOUT pin as XCOUT and connect

XCOUT to the target system)

IMPORTANT

Note on Switch Settings:

• Switches SW1 (CNVSS) and SW2 (BYTE) are used for debugging operation without

connecting the target system. When connecting the target system, set both of them

"OPEN".

( 31 / 76 )

Page 34

Table 3.3 Switch settings of the M306H2T-RPD-E (3/4)

Switch Signal Jumper switch setting

SW6 SYNCIN

SW7 Unused

UnusedSW8

CVIN1SW9

SYNC/HOR

JC1

Connects the SYNCIN pin to the

RCA connector JC1 on the M306H0TPRT. (Factory-setting)

JC2

Only this setting is available.

(Factory-setting)

JC3

Only this setting is available.

(Factory-setting)

CVIN1

JC4

Connects the CVIN1 pin to the RCA

connector JC4 on the M306H0TPRT. (Factory-setting)

FLX

FLX

FLX

FLX

SYNC/HOR

JC1

Connects the SYNCIN pin to the

target system via the FLX160.

JC2

Do not use this setting.

JC3

Do not use this setting.

CVIN1

JC4

Connects the CVIN1 pin to the target

system via the FLX160.

FLX

FLX

FLX

FLX

JC5

UnusedSW10

Only this setting is available.

(Factory-setting)

FLX

JC5

Do not use this setting.

FLX

( 32 / 76 )

Page 35

Table 3.4 Switch settings of the M306H2T-RPD-E (4/4)

Switch Signal Jumper switch setting

SW11 SVREF

SW12 Unused

VR4

VREF1

FLX

Connects the SVREF pin to the

changeable resistance VR4 on the

M306H0T-PRT. (Factory-setting)

JC4

FLX

Only this setting is available.

(Factory-setting)

4.43 MHz

FSCIN

VR4

VREF1

FLX

Connects the SVREF pin to the

target system via the FLX160.

JC4

FLX

Do not use this setting.

4.43 MHz

FSCIN

SW13 FSCIN

FLX

Connects the FSCIN pin to the

4.43MHz oscillator circuit on the

M306H0T-PRT. (Factory-setting)

FLX

Connects the FSCIN pin to the target

system via the FLX160.

( 33 / 76 )

Page 36

It is not possible to control the pullup by the pullup control resistors of ports P00 to P57 (possible to

read and write by the pullup control resistors).

However, as this product has sockets for installing the pullup resistors, it is possible to pull up by

mounting the resistor arrays included with this product. For the positions for installing the pullup

resistors, see Figure 3.3.

Figure 3.3 Positions for installing the pullup resistors

( 34 / 76 )

Page 37

3.3 Selecting Clock Supply

There are two ways to supply a clock to the MCU, using the oscillator circuit of the emulation pod

or using the oscillator circuit on the target system. Table 3.5 lists the factory-settings of each clock

supply.

Table 3.5 Clock supply to the MCU

Clock Description Display of emulator debugger Default setting

Internal oscillator circuit of emulation pod

(OSC-3: 10 MHz)

X

IN-XOUT

Target system

Internal oscillator circuit of emulation pod

XCIN-XCOUT

(OSC-2: 32.768 kHz)

Target system

IMPORTANT

Notes on Changing the Clock Supply:

• The clock supply can be set by the Init dialog box when starting up the emulator

debugger or inputting CLK command on the script window.

• For XCIN-XCOUT , it is necessary to set switches in the emulation pod. For details, refer

to "3.2 Setting Switches and Pullup Resistors" (page 29).

Internal

External

Internal

External

Yes

-

Yes

-

( 35 / 76 )

Page 38

(1) Using the Oscillator Circuit on the Target System

When turning on the power supply, the internal clock of emulation pod is selected to supply the clock

to the MCU. To use the external clock on the target system, change the clock by the Init dialog when

starting up the emulator debugger or the CLK command on the script window. (For details, refer to

the user's manual (or online manual) of the emulator debugger)

Figure 3.4 External oscillator circuit

Figure 3.5 Circuit in which oscillation does not occur (same for XCIN-XCOUT)

IMPORTANT

Notes on External Clock:

• To operate the emulation pod with an external clock, construct the oscillator circuit

as shown in Figure 3.4 in the target system and input the oscillator output at 50% duty

(within the operating range of the evaluation MCU) into the XIN pin. And the XOUT

pin should be open.

• Make note of the fact that in the oscillator circuit shown in Figure 3.5 where a

resonator is connected between the XIN and XOUT pins, oscillation does not occur

because a flexible cable, buffer IC and other devices are used between the evaluation

MCU and the target system. It is same for sub-clock oscillator circuits (XCIN and

XCOUT).

( 36 / 76 )

Page 39

(2) Changing the Internal Oscillator Circuit of the Emulation Pod

An oscillator circuit board (OSC-3) for 10 MHz is mounted on this product. To use the emulation pod

at a frequency other than 10 MHz, build the desired oscillator circuit on the included OSC-2 oscillator

circuit board (bare board) and replace the board installed in the emulation pod when shipped from

the factory.

Figure 3.6 shows a view of the OSC-2 oscillator circuit board (bare board) and where connector pins

are located. Figure 3.7 shows the circuitry of the OSC-2 oscillator circuit board (bare board). Use the

number of oscillator circuits recommended by the oscillator manufacturer.

J1-4: GND

J1-3: Oscillator output

J1-2: GND

J1-1: Vcc

Figure 3.6 External view of the oscillator board (OSC-2) and connector pin assignments

IC1

1011 8

9

IC1

CLK

R1

Vcc

14

IC1

7

GND

GND

IC

2

4

C3

6

12

1

**

X1,X 2

R2

3

5

1

C2

X3

* X1: 5.08-mm-pitch 2-pin oscillator IC1: Inverter (Unbuffer)

* X2: 2.54-mm-pitch 2-pin oscillator

* X3: 2.54-mm-pitch 3-pin oscillator

C1

*

13

J1-3

J1-1

J1-2

J1-4

Figure 3.7 Circuit of the oscillator board (OSC-2)

( 37 / 76 )

Page 40

(3) Replacing the Oscillator Circuit Boards

Figure 3.8 shows how to replace the oscillator circuit boards. For the position of the oscillator circuit

board, see Figure 3.2.

(1) Unscrew the screw securing the oscillator circuit board.

(2) Lift off the oscillator circuit board.

(3) Attach the J1 connector of another oscillator circuit board for

replacement to the connector of the MCU-dependent board.

(4) Secure the oscillator circuit board with the screw.

Figure 3.8 Replacing the oscillator circuit boards

( 38 / 76 )

Page 41

3.4 A-D Conversion Bypass Capacitor

With this product, there is a socket (0.1 µF pre-mounted) on the board for changing the bypass

capacitor for the A-D conversion circuit. Remove or replace a suitable bypass capacitor as occasion

demands.

Figure 3.9 shows where the bypass capacitors are mounted, whereas Figure 3.10 shows an

enlargement of the foot patterns.

I/O signal circuit

for data slicer

Figure 3.9 Position for mounting the A-D conversion bypass capacitor (M306H2T-PRT board)

Figure 3.10 Socket for the A-D conversion bypass capacitor

Position to install the bypass capacitor

for A-D converter

AVCC - AVSS bypsass capacitor

REF - AVSS bypsass capacitor

V

IMPORTANT

Note on the A-D Converter:

• Because a flexible board and other devices are used between the evaluation MCU

and the target system, the A-D converter operates differently from the actual MCU.

Make the final evaluation of the A-D converter from the actual MCU.

( 39 / 76 )

Page 42

3.5 Data Slicer I/O Signal and FSC Clock I/O Signal Circuit

With this product, the parts which are used for the data slicer and the FSC clock circuit are connected

by sockets to be changed. Figure 3.11 shows the position of each part which is used for the data slicer

and the FSC clock circuit. Figure 3.2 shows the layout of the parts and Figure 3.12 shows its detailed

layout.

Figure 3.11 Data slicer and FSC clock circuit

Figure 3.12 Detailed layout of the parts

( 40 / 76 )

Page 43

3.6 Connecting the PC4701

To connect the emulation pod to the PC4701, use the FLX120-RPD 120-pin flexible cable included

with this product package. Connect the PC4701 side connector of the FLX120-RPD to the cable

connector of the PC4701, then secure with screws the FLX120-RPD.

(1) Connecting the Cable to the PC4701

Figure 3.13 shows how to connect the PC4701 and FLX120-RPD

Figure 3.13 Connecting PC4701 and FLX120-RPD

CAUTION

Note on Connecting the Cable:

• To connect the FLX120-RPD, be sure to hold the both sides of the PC4701 side

connector horizontally with the "UPSIDE" facing up.

• Always shut OFF power before connecting the FLX120-RPD. The power ON state

could destroy internal circuits.

Note on Securing the Screws:

•After connecting the FLX120-RPD to the emulator main unit PC4701, be sure to

secure the screws mounted in both sides of the connector.

( 41 / 76 )

Page 44

(2) Connecting the Cable to the Emulation Pod

Figure 3.14 shows how to connect the FLX120-RPD and the emulation pod.

Figure 3.14 Connecting FLX120-RPD and emulation pod

CAUTION

Note on Connecting the Cable:

• Always shut OFF power before connecting the cable. The power ON state could

destroy internal circuits.

Note on Securing the Screws:

•After connecting the cable to the emulation pod, be sure to secure the screws.

( 42 / 76 )

Page 45

3.7 Connecting the Target System

Figure 3.15 shows how to connect the M306H2T-RPD-E and the target system.

Figure 3.15 Connecting the emulation pod and the target system

CAUTION

Notes on Connecting the Target System:

• Take care not to attach the converter board in a wrong direction. It may cause a fatal

damage to the emulation pod.

• The small connector of the M306H2T-PTC is guaranteed for only 50 insertion/

removal iterations.

( 43 / 76 )

Page 46

3.8 Making an MCU File for PD30

It is necessary to change the contents of the MCU file according to the MCU to be developed. Make

the MCU file "M306H2.MCU" for M306H2 and store it in the "mcufile" folder in the directory same

as emulator debugger PD30 is stored.

The contents of the MCU file (the SFR area, internal RAM area, internal ROM area, the name of the

firmware file) are shown below. Change the settings according to the MCU to be debugged. Use your

text editor for changing the contents of the MCU file.

The contents of the MCU file when using the M306H2MC are as follows:

0: SFR area Start address

3FF : End address

400 : Internal RAM Start address

17FF : End address

E0000 : Internal ROM Start address

FFFFF : End address

M30620B : Name of firmware (Do not change.)

0: Expansion No. PD30 V.4.00 or later required (Do not change.)

( 44 / 76 )

Page 47

Chapter 4. Usage

This chapter describes from turning on the power of this product to starting up the emulator debugger.

4.1 Turning On the Power ................................................................................................................46

(1) Checking the Connection of the Emulator System...............................................................46

(2) Turning On the Power........................................................................................................... 46

(3) LED Display When PC4701 Starts Up Normally ................................................................47

4.2 Downloading Firmware..............................................................................................................48

(1) When It is Necessary to Download Firmware ...................................................................... 48

(2) Downloading Firmware in the Maintenance Mode ..............................................................48

4.3 Self-checks .................................................................................................................................49