Page 1

To our customers,

Old Company Name in Catalogs and Other Documents

On April 1st, 2010, NEC Electronics Corporation merged with Renesas Technology

Corporation, and Renesas Electronics Corporation took over all the business of both

companies. Therefore, although the old company name remains in this document, it is a valid

Renesas Electronics document. We appreciate your understanding.

Renesas Electronics website: http://www.renesas.com

April 1

Renesas Electronics Corporation

Issued by: Renesas Electronics Corporation (http://www.renesas.com)

st

, 2010

Send any inquiries to http://www.renesas.com/inquiry

.

Page 2

Notice

1. All information included in this document is current as of the date this document is issued. Such information, however, is

subject to change without any prior notice. Before purchasing or using any Renesas Electronics products listed herein, please

confirm the latest product information with a Renesas Electronics sales office. Also, please pay regular and careful attention to

additional and different information to be disclosed by Renesas Electronics such as that disclosed through our website.

2. Renesas Electronics does not assume any liability for infringement of patents, copyrights, or other intellectual property rights

of third parties by or arising from the use of Renesas Electronics products or technical information described in this document.

No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights

of Renesas Electronics or others.

3. You should not alter, modify, copy, or otherwise misappropriate any Renesas Electronics product, whether in whole or in part.

4. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of

semiconductor products and application examples. You are fully responsible for the incorporation of these circuits, software,

and information in the design of your equipment. Renesas Electronics assumes no responsibility for any losses incurred by

you or third parties arising from the use of these circuits, software, or information.

5. When exporting the products or technology described in this document, you should comply with the applicable export control

laws and regulations and follow the procedures required by such laws and regulations. You should not use Renesas

Electronics products or the technology described in this document for any purpose relating to military applications or use by

the military, including but not limited to the development of weapons of mass destruction. Renesas Electronics products and

technology may not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited

under any applicable domestic or foreign laws or regulations.

6. Renesas Electronics has used reasonable care in preparing the information included in this document, but Renesas Electronics

does not warrant that such informatio n is error free. Renesas Electronics assumes no liability whatsoever for any damages

incurred by you resulting from errors in or omissions from the information included herein.

7. Renesas Electronics products are classified according to the following three quality grades: “Standard”, “High Quality”, and

“Specific”. The recommended applications for each Renesas Electronics product depends on the product’s quality grade, as

indicated below. You must check the quality grade of each Renesas Electronics product before using it in a particular

application. You may not use any Renesas Electronics product for any application categorized as “Specific” without the prior

written consent of Renesas Electronics. Further, you may not use any Renesas Electronics product for any application for

which it is not intended without the prior written consent of Renesas Electronics. Renesas Electronics shall not be in any way

liable for any damages or losses incurred by you or third parties arising from the use of any Renesas Electronics product for an

application categorized as “Specific” or for which the product is not intended where you have failed to obtain the prior written

consent of Renesas Electronics. The quality grade of each Renesas Electronics product is “Standard” unless otherwise

expressly specified in a Ren esas E lectronics data sheets or dat a books, etc.

“Standard”: Computers; office equipment; communications equipment; test and measurement equipment; audio and visual

equipment; home electron ic appliances; machine tools; personal electronic equipment; and industrial robots.

“High Quality”: Transportation equipment (automobiles, trains, ships, etc.); traffic control systems; anti-disaster systems; anti-

crime systems; safety equipment; and medical equipment not specifically designed for life support.

“Specific”: Aircraft; aerospace equipment; submersible repeaters; nuclear reactor control systems; medical equipment or

systems for life support (e.g. artificial life support devices or systems), surgical implantations, or healthcare

intervention (e.g. excision, etc.), and any other appl i cations or purposes that pose a d irect threat to human life.

8. You should use the Renesas Electronics products described in this document within the range specified by Renesas Electronics,

especially with respect to the maximum rating, operating supply voltage range, movement power voltage range, heat radiation

characteristics, installation and other product characteristics. Renesas Electronics shall have no liability for malfunctions or

damages arising out of the use of Renesas Electronics products beyond such specified ranges.

9. Although Renesas Electronics endeavors to improve the quality and reliability of its products, semiconductor products have

specific characteristics such as t he occu rrence o f failure at a certai n rate an d malfunct io ns under cert ain u se con dition s. Further,

Renesas Electronics prod ucts are not subject to radiation resistance design. Please be sure to implement safety measures to

guard them against the possibility of physical injury, and injury or damage caused by fire in the event of the failure of a

Renesas Electronics product, such as safety design for hardware and software including but not limited to redundancy, fire

control and malfunction prevention, appropriate treatment for aging degradation or any other appropriate measures. Because

the evaluation of microcomputer software alone is very difficult, please evaluate the safety of the final products or system

manufactured by you.

10. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental

compatibility of each Renesas Electronics product. Please use Renesas Electronics products in compliance with all applicable

laws and regulations that regulate the inclusion or use of controlled substances, including without limitation, the EU RoHS

Directive. Renesas Electronics assumes no liability for damages or losses occurring as a result of your noncompliance with

applicable laws and regulations.

11. This document may not be reproduced or duplicated, in any form, in whole or in part, without prior written consent of Renesas

Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this

document or Renesas Electronics products, or if you have any other inquiries.

(Note 1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation an d also includes its majority-

owned subsidiaries.

(Note 2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

Page 3

User’s Manual

M16C PC4701 Emulator Debugger

V.1.03

User’s Manual

Renesas Microcomputer Development

Environment System

Rev.1.00 2007.07

Page 4

Notes regarding these materials

1. This document is provided for reference purposes only so that Renesas customers may select the appropriate

Renesas products for their use. Renesas neither makes warranties or representations with respect to the

accuracy or completeness of the information contained in this document nor grants any license to any

intellectual property rights or any other rights of Renesas or any third party with respect to the information in

this document.

2. Renesas shall have no liability for damages or infringement of any intellectual property or other rights arising

out of the use of any information in this document, including, but not limited to, product data, diagrams, charts,

programs, algorithms, and application circuit examples.

3. You should not use the products or the technology described in this document for the purpose of military

applications such as the development of weapons of mass destruction or for the purpose of any other military

use. When exporting the products or technology described herein, you should follow the applicable export

control laws and regulations, and procedures required by such laws and regulations.

4. All information included in this document such as product data, diagrams, charts, programs, algorithms, and

application circuit examples, is current as of the date this document is issued. Such information, however, is

subject to change without any prior notice. Before purchasing or using any Renesas products listed in this

document, please confirm the latest product information with a Renesas sales office. Also, please pay regular

and careful attention to additional and different information to be disclosed by Renesas such as that disclosed

through our website. (http://www.renesas.com )

5. Renesas has used reasonable care in compiling the information included in this document, but Renesas

assumes no liability whatsoever for any damages incurred as a result of errors or omissions in the information

included in this document.

6. When using or otherwise relying on the information in this document, you should evaluate the information in

light of the total system before deciding about the applicability of such information to the intended application.

Renesas makes no representations, warranties or guaranties regarding the suitability of its products for any

particular application and specifically disclaims any liability arising out of the application and use of the

information in this document or Renesas products.

7. With the exception of products specified by Renesas as suitable for automobile applications, Renesas

products are not designed, manufactured or tested for applications or otherwise in systems the failure or

malfunction of which may cause a direct threat to human life or create a risk of human injury or which require

especially high quality and reliability such as safety systems, or equipment or systems for transportation and

traffic, healthcare, combustion control, aerospace and aeronautics, nuclear power, or undersea communication

transmission. If you are considering the use of our products for such purposes, please contact a Renesas

sales office beforehand. Renesas shall have no liability for damages arising out of the uses set forth above.

8. Notwithstanding the preceding paragraph, you should not use Renesas products for the purposes listed below:

(1) artificial life support devices or systems

(2) surgical implantations

(3) healthcare intervention (e.g., excision, administration of medication, etc.)

(4) any other purposes that pose a direct threat to human life

Renesas shall have no liability for damages arising out of the uses set forth in the above and purchasers who

elect to use Renesas products in any of the foregoing applications shall indemnify and hold harmless Renesas

Technology Corp., its affiliated companies and their officers, directors, and employees against any and all

damages arising out of such applications.

9. You should use the products described herein within the range specified by Renesas, especially with respect

to the maximum rating, operating supply voltage range, movement power voltage range, heat radiation

characteristics, installation and other product characteristics. Renesas shall have no liability for malfunctions or

damages arising out of the use of Renesas products beyond such specified ranges.

10. Although Renesas endeavors to improve the quality and reliability of its products, IC products have specific

characteristics such as the occurrence of failure at a certain rate and malfunctions under certain use

conditions. Please be sure to implement safety measures to guard against the possibility of physical injury, and

injury or damage caused by fire in the event of the failure of a Renesas product, such as safety design for

hardware and software including but not limited to redundancy, fire control and malfunction prevention,

appropriate treatment for aging degradation or any other applicable measures. Among others, since the

evaluation of microcomputer software alone is very difficult, please evaluate the safety of the final products or

system manufactured by you.

11. In case Renesas products listed in this document are detached from the products to which the Renesas

products are attached or affixed, the risk of accident such as swallowing by infants and small children is very

high. You should implement safety measures so that Renesas products may not be easily detached from your

products. Renesas shall have no liability for damages arising out of such detachment.

12. This document may not be reproduced or duplicated, in any form, in whole or in part, without prior written

approval from Renesas.

13. Please contact a Renesas sales office if you have any questions regarding the information contained in this

document, Renesas semiconductor products, or if you have any other inquiries.

Page 5

Overview

The High-performance Embedded Workshop is a Graphical User Interface intended to ease the

development and debugging of applications written in C/C++ programming language and assembly

language for Renesas microcomputers. Its aim is to provide a powerful yet intuitive way of accessing,

observing and modifying the debugging platform in which the application is running.

This help explains the function as a "debugger" of High-performance Embedded Workshop.

Target System

The Debugger operates on the emulator PC4701 system.

Supported CPU

This help explains the debugging function corresponding to the following CPUs.

•

M32C/80, M16C/80 Series

Note: In this help, the information which depends on this CPU is described as "for M32C".

M16C/60, M16C/30, M16C/Tiny, M16C/20, M16C/10 Series

•

Note: In this help, the information which depends on this CPU is described as "for M16C/R8C".

740 Family

•

Note: In this help, the information which depends on this CPU is described as "for 740".

Page 6

Active X, Microsoft, MS-DOS, Visual Basic, Visual C++, Windows and Windows NT are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

IBM and AT are registered trademarks of International Business Machines Corporation.

Intel and Pentium are registered trademarks of Intel Corporation.

Adobe and Acrobat are registered trademarks of Adobe Systems Incorporated.

All other brand and product names are trademarks, registered trademarks or service marks of their respective holders.

For inquiries about the contents of this document or product, fill in the text file the installer generates in the following

directory and email to your local distributor.

¥SUPPORT¥Product-name¥SUPPORT.TXT

Renesas Tools Homepage http://www.renesas.com/en/tools

Page 7

Setup of Debugger 1

1. Features 1

1.1 Real-Time RAM Monitor Function...............................................................................................1

1.1.1 RAM Monitor Area ............................................................................................................1

1.1.2 Sampling Period ................................................................................................................2

1.1.3 Related Windows ...............................................................................................................2

1.2 Break Functions............................................................................................................................3

1.2.1 Software Breaks Function.................................................................................................3

1.2.2 Hardware Break ................................................................................................................4

1.2.3 Protect Break .....................................................................................................................5

1.3 Real-Time Trace Function ............................................................................................................6

1.3.1 Trace Area..........................................................................................................................6

1.3.2 Trace Condition Setting ....................................................................................................7

1.3.3 Trace Data Write Condition..............................................................................................7

1.4 Time Measurement Function .......................................................................................................8

1.4.1 The Measurement Condition ............................................................................................8

1.5 Coverage Function ........................................................................................................................9

1.5.1 Coverage Measurement Area............................................................................................9

1.5.2 Related Windows ...............................................................................................................9

1.6 Real-Time OS Debugging Function............................................................................................10

1.7 GUI Input/Output Function .......................................................................................................10

2. About the Emulator PC4701 11

2.1 Communication methods ............................................................................................................11

2.2 Function table .............................................................................................................................11

3. Before starting the debugger 12

3.1 Communication method by emulator.........................................................................................12

3.1.1 USB Interface ..................................................................................................................12

3.1.2 LAN Interface ..................................................................................................................12

3.1.3 LPT Interface...................................................................................................................12

3.1.4 Proprietary Parallel Interface.........................................................................................13

3.2 Download of Firmware................................................................................................................14

3.3 Setting before emulator starts....................................................................................................15

3.3.1 USB communication........................................................................................................15

3.3.2 LAN communication 1.....................................................................................................16

3.3.3 LAN communication 2.....................................................................................................18

3.3.4 Proprietary parallel communication...............................................................................19

4. Preparation before Use 20

4.1 Workspaces, Projects, and Files .................................................................................................20

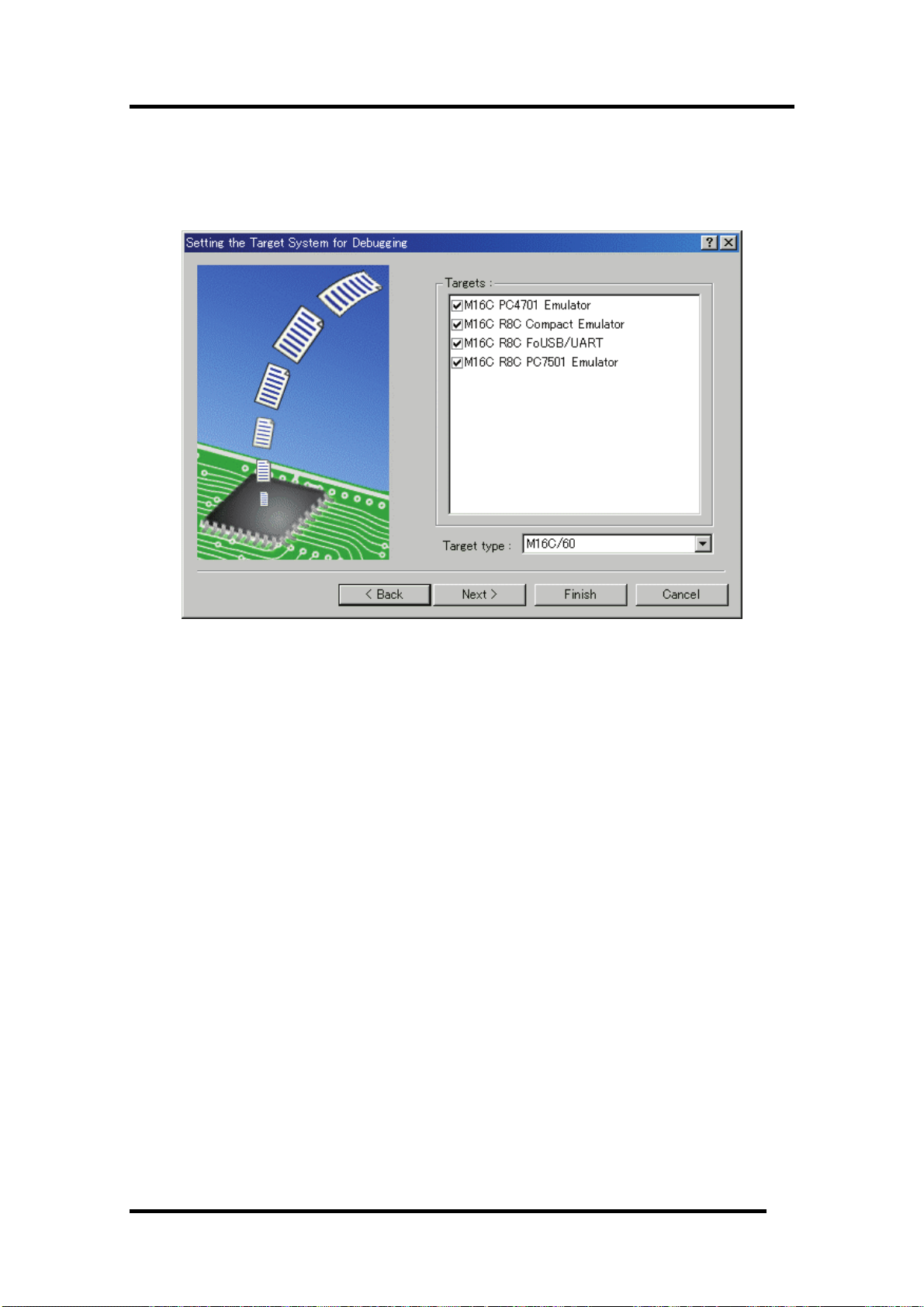

4.2 Starting the High-performance Embedded Workshop..............................................................21

4.2.1 Creating a New Workspace (Toolchain Used)................................................................22

4.2.2 Creating a New Workspace (Toolchain Not Used).........................................................27

4.3 Starting the Debugger ................................................................................................................32

4.3.1 Connecting the Emulator ................................................................................................ 32

4.3.2 Ending the Emulator.......................................................................................................32

5. Setup the Debugger 33

5.1 Init Dialog....................................................................................................................................33

5.1.1 MCU Tab..........................................................................................................................34

5.1.2 Debugging Information Tab............................................................................................37

5.1.3 F/W and Work Area Tab..................................................................................................39

5.1.4 Memory Extension Mode Tab .........................................................................................40

i

Page 8

5.1.5 Clock Tab .........................................................................................................................43

5.1.6 Script Tab.........................................................................................................................44

5.2 Setting of the Communication Interface.................................................................................... 45

5.2.1 Setting of the USB Interface...........................................................................................45

5.2.2 Setting of the LPT Interface ...........................................................................................46

5.2.3 Setting of the LAN Interface........................................................................................... 47

5.2.4 Setting of the Parallel Interface......................................................................................49

5.2.5 Setting of the Serial Interface.........................................................................................49

5.3 Setup the Debugger for M32C....................................................................................................50

5.3.1 Emem Dialog....................................................................................................................50

5.4 Setup the Debugger for M16C/R8C............................................................................................54

5.4.1 Map Command.................................................................................................................54

5.5 Setup the Debugger for 740........................................................................................................55

5.5.1 Map Command.................................................................................................................55

5.6 Method of making MCU file .......................................................................................................56

5.6.1 Method of making MCU file (the M16C/R8C Debugger) ...............................................56

5.6.2 Method of making MCU file (the 740 Debugger) ...........................................................57

Tutorial 59

6. Tutorial 61

6.1 Introduction.................................................................................................................................61

6.2 Usage ...........................................................................................................................................62

6.2.1 Step1 : Starting the Debugger ........................................................................................62

6.2.2 Step2 : Checking the Operation of RAM.........................................................................63

6.2.3 Step3 : Downloading the Tutorial Program ...................................................................64

6.2.4 Step4 : Setting a Breakpoint...........................................................................................66

6.2.5 Step5 : Executing the Program .......................................................................................67

6.2.6 Step6 : Reviewing Breakpoints ....................................................................................... 69

6.2.7 Step7 : Viewing Register .................................................................................................70

6.2.8 Step8 : Viewing Memory .................................................................................................71

6.2.9 Step9 : Watching Variables.............................................................................................72

6.2.10 Step10 : Stepping Through a Program .........................................................................74

6.2.11 Step11 : Forced Breaking of Program Executions........................................................77

6.2.12 Step12 : Displaying Local Variables .............................................................................78

6.2.13 Step13 : Stack Trace Function ......................................................................................79

6.2.14 What Next? ....................................................................................................................80

Reference 81

7. Windows/Dialogs 83

7.1 RAM Monitor Window ................................................................................................................84

7.1.1 Extended Menus ..............................................................................................................86

7.1.2 Setting the RAM monitor area........................................................................................87

7.2 ASM Watch Window ...................................................................................................................88

7.2.1 Extended Menus ..............................................................................................................89

7.3 C Watch Window.........................................................................................................................90

7.3.1 Extended Menus ..............................................................................................................92

7.4 Coverage Window........................................................................................................................93

7.4.1 Extended Menus ..............................................................................................................94

7.4.2 Refer to the Source Line/the Executed Address.............................................................95

7.5 Script Window.............................................................................................................................96

ii

Page 9

7.5.1 Extended Menus ..............................................................................................................97

7.6 S/W Break Point Setting Window ..............................................................................................98

7.6.1 Command Button.............................................................................................................99

7.6.2 Setting and Deleting a Break Points from Editor(Source) Window............................ 100

7.7 H/W Break Point Setting Window............................................................................................101

7.7.2 Specify the Combinatorial Condition............................................................................106

7.7.3 Specify the Process ID...................................................................................................107

7.7.4 Command Button...........................................................................................................107

7.7.5 Specify the Events (Instruction Fetch).........................................................................108

7.7.6 Specify the Events (Memory Access) ............................................................................112

7.7.7 Specify the Events (Bit Access).....................................................................................136

7.7.8 Specify the Events (Interrupt) ......................................................................................138

7.7.9 Specify the Events (External Trigger Signal) ..............................................................140

7.7.10 Specify the Event Combination Condition .................................................................142

7.7.11 Specify the Process ID ................................................................................................. 145

7.8 Protect Window .........................................................................................................................146

7.8.1 Extended Menus ............................................................................................................146

7.9 Trace Point Setting Window.....................................................................................................147

7.9.1 Specify the Trace Event.................................................................................................148

7.9.2 Specify the Combinatorial Condition............................................................................151

7.9.3 Specify the Process ID...................................................................................................152

7.9.4 Specify the Trace Range................................................................................................152

7.9.5 Specify the Trace Write Condition................................................................................153

7.9.6 Command Button...........................................................................................................153

7.9.7 Specify the Events (Instruction Fetch).........................................................................154

7.9.8 Specify the Events (Memory Access) ............................................................................154

7.9.9 Specify the Events (Bit Access).....................................................................................154

7.9.10 Specify the Events (Interrupt) ....................................................................................154

7.9.11 Specify the Events (External Trigger Signal) ............................................................154

7.9.12 Specify the Event Combination Condition .................................................................154

7.9.13 Specify the Process ID ................................................................................................. 154

7.9.14 Specify the write condition..........................................................................................155

7.10 Time Measurement Window...................................................................................................159

7.10.1 Specify the Time Measurement Event........................................................................160

7.10.2 Time Measurement Condition ....................................................................................164

7.10.3 Command Button.........................................................................................................164

7.10.4 Specify the Events (Instruction Fetch).......................................................................165

7.10.5 Specify the Events (Memory Access) ..........................................................................165

7.10.6 Specify the Events (Bit Access)...................................................................................165

7.10.7 Specify the Events (Interrupt) ....................................................................................165

7.10.8 Specify the Events (External Trigger Signal) ............................................................165

7.10.9 Set the Measurement Condition .................................................................................166

7.11 Trace Window..........................................................................................................................170

7.11.1 Configuration of Bus Mode..........................................................................................170

7.11.2 Configuration of Disassemble Mode ...........................................................................172

7.11.3 Configuration of Data Access Mode............................................................................173

7.11.4 Configuration of Source Mode..................................................................................... 174

7.11.5 Extended Menus ..........................................................................................................175

7.11.6 Display of bus information on the M32C Debugger................................................... 176

7.11.7 Display of bus information on the M16C/R8C Debugger...........................................178

7.11.8 Display of bus information on the 740 Debugger....................................................... 180

7.12 Data Trace Window.................................................................................................................181

7.12.1 Extended Menus ..........................................................................................................182

7.13 GUI I/O Window......................................................................................................................183

7.13.1 Extended Menus ..........................................................................................................184

7.14 MR Window .............................................................................................................................185

7.14.2 Display the Task Status..............................................................................................187

iii

Page 10

7.14.3 Display the Ready Queue Status ................................................................................ 191

7.14.4 Display the Timeout Queue Status.............................................................................192

7.14.5 Display the Event Flag Status....................................................................................194

7.14.6 Display the Semaphore Status....................................................................................196

7.14.7 Display the Mailbox Status.........................................................................................198

7.14.8 Display the Data Queue Status ..................................................................................200

7.14.9 Display the Cycle Handler Status ..............................................................................202

7.14.10 Display the Alarm Handler Status ...........................................................................204

7.14.11 Display the Memory Pool Status ..............................................................................205

7.14.12 Display the Task Context.......................................................................................... 207

7.15 MR Trace Window...................................................................................................................209

7.15.1 Extended Menus ..........................................................................................................211

7.15.2 Refer the Execution History of Task(MRxx Window)................................................212

7.16 MR Analyze Window...............................................................................................................218

7.16.1 Configuration of CPU Occupancy Status Display Mode............................................218

7.16.2 Configuration of Ready State Duration Display Mode ..............................................219

7.16.3 Configuration of System Call History Display Mode.................................................219

7.16.4 Extended Menus ..........................................................................................................220

7.16.5 Analyze the Execution History of Task ......................................................................220

7.17 MR Task Pause Window.........................................................................................................223

7.17.1 About Task Pause Function ........................................................................................223

7.17.2 Extended Menus ..........................................................................................................224

7.17.3 Pause the Specified Task.............................................................................................225

7.18 Task Trace Window.................................................................................................................230

7.18.1 Extended Menus ..........................................................................................................231

7.18.2 Refer the Execution History of Task(Taskxx Window).............................................. 232

7.19 Task Analyze Window.............................................................................................................237

7.19.1 Extended Menus ..........................................................................................................237

7.19.2 Analyze the Execution History of Task ......................................................................238

8. Table of Script Commands 239

8.1 Table of Script Commands (classified by function) .................................................................239

8.1.1 Execution Commands....................................................................................................239

8.1.2 File Operation Commands ............................................................................................239

8.1.3 Register Operation Commands.....................................................................................240

8.1.4 Memory Operation Commands .....................................................................................240

8.1.5 Assemble/Disassemble Commands...............................................................................240

8.1.6 Software Break Setting Commands..............................................................................240

8.1.7 Hardware Break Setting Commands............................................................................241

8.1.8 Real-time Trace Commands..........................................................................................241

8.1.9 Coverage Measurement Commands .............................................................................241

8.1.10 Script/Log File Commands..........................................................................................241

8.1.11 Program Display Commands ......................................................................................241

8.1.12 Map Commands ........................................................................................................... 242

8.1.13 Clock Command...........................................................................................................242

8.1.14 WatchDog Timer Commands ......................................................................................242

8.1.15 C Language Debugging Commands............................................................................242

8.1.16 Real-time OS Command..............................................................................................242

8.1.17 Utility Commands .......................................................................................................242

8.2 Table of Script Commands (alphabetical order) ......................................................................243

9. Writing Script Files 245

9.1 Structural Elements of a Script File ........................................................................................245

9.1.1 Script Command ............................................................................................................246

9.1.2 Assign Statement...........................................................................................................246

9.1.3 Conditional Statement ..................................................................................................246

9.1.4 Loop Statement(while,endw) and Break Statement....................................................247

9.1.5 Comment statements ....................................................................................................247

iv

Page 11

9.2 Writing Expressions..................................................................................................................248

9.2.1 Constants .......................................................................................................................248

9.2.2 Symbols and labels ........................................................................................................249

9.2.3 Macro Variables.............................................................................................................250

9.2.4 Register variables ..........................................................................................................251

9.2.5 Memory variables ..........................................................................................................251

9.2.6 Line Nos. ........................................................................................................................251

9.2.7 Character constants ......................................................................................................252

9.2.8 Operators .......................................................................................................................252

10. C/C++ Expressions 253

10.1 Writing C/C++ Expressions ....................................................................................................253

10.1.1 Immediate Values........................................................................................................253

10.1.2 Scope Resolution..........................................................................................................254

10.1.3 Mathematical Operators .............................................................................................254

10.1.4 Pointers ........................................................................................................................254

10.1.5 Reference......................................................................................................................254

10.1.6 Sign Inversion..............................................................................................................255

10.1.7 Member Reference Using Dot Operator .....................................................................255

10.1.8 Member Reference Using Arrow.................................................................................255

10.1.9 Pointers to Members....................................................................................................256

10.1.10 Parentheses................................................................................................................256

10.1.11 Arrays.........................................................................................................................256

10.1.12 Casting to Basic Types ..............................................................................................256

10.1.13 Casting to typedef Types ...........................................................................................257

10.1.14 Variable Name ...........................................................................................................257

10.1.15 Function Name ..........................................................................................................257

10.1.16 Character Constants..................................................................................................257

10.1.17 Character String Literals..........................................................................................257

10.2 Display Format of C/C++ Expressions...................................................................................258

10.2.1 Enumeration Types .....................................................................................................258

10.2.2 Basic Types ..................................................................................................................258

10.2.3 Pointer Types...............................................................................................................259

10.2.4 Array Types..................................................................................................................260

10.2.5 Function Types ............................................................................................................260

10.2.6 Reference Types...........................................................................................................260

10.2.7 Bit Field Types.............................................................................................................260

10.2.8 When No C Symbol is Found ......................................................................................261

10.2.9 Syntax Errors...............................................................................................................261

10.2.10 Structure and Union Types.......................................................................................261

11. Display the Cause of the Program Stoppage 262

12. Attention 263

12.1 Common Attention..................................................................................................................263

12.1.1 File operation on Windows..........................................................................................263

12.1.2 Area where software breakpoint can be set ...............................................................263

12.1.3 Get or set C variables ..................................................................................................264

12.1.4 Function name in C++................................................................................................. 265

12.1.5 Option settings for download modules........................................................................265

12.1.6 Debugging multi modules ...........................................................................................265

12.1.7 Synchronized debugging..............................................................................................265

12.1.8 Down-load of Firmware...............................................................................................265

12.1.9 Restriction of LPT port................................................................................................266

12.1.10 Notes for coverage function.......................................................................................267

12.1.11 Emulator reset switch ...............................................................................................267

12.1.12 Debugging Resource on Emulator ............................................................................267

12.2 Attention of the M32C Debugger ...........................................................................................268

v

Page 12

12.2.1 Stack area used by the emulator ................................................................................268

12.2.2 Interrupt stack pointer when resetting the target program .....................................268

12.2.3 Option of C Compiler/Assembler/Linker ....................................................................268

12.2.4 Target MCU HOLD terminal...................................................................................... 268

12.2.5 Hardware Event ..........................................................................................................269

12.2.6 Time Measurement Resource......................................................................................269

12.2.7 CPU rewrite .................................................................................................................269

12.2.8 MR STK script command ............................................................................................269

12.3 Attention of the M16C/R8C Debugger ...................................................................................270

12.3.1 Map of stack area used by the emulator.....................................................................270

12.3.2 Options for compiler, assembler, and linker ..............................................................270

12.3.3 TASKING C Compiler .................................................................................................270

12.3.4 Target MCU HOLD terminal...................................................................................... 270

12.3.5 Hardware Event ..........................................................................................................271

12.3.6 Operating frequency of MCU ...................................................................................... 271

12.3.7 The correspondence OS version of task pause function.............................................271

12.3.8 Memory Space Expansion ...........................................................................................272

12.3.9 Watch dog timer...........................................................................................................272

12.3.10 CPU rewrite ...............................................................................................................272

12.3.11 MR STK script command ..........................................................................................272

12.4 Attention of the 740 Debugger ...............................................................................................273

12.4.1 Setting of Memory Map...............................................................................................273

12.4.2 Emulation Pod M37515T-RPD....................................................................................273

12.4.3 Stack area used by the emulator ................................................................................273

12.4.4 Specify the Clock..........................................................................................................273

12.4.5 Watch dog timer...........................................................................................................273

12.4.6 Option of C Compiler/Assembler/Linker ....................................................................273

12.4.7 About the single-step execution and the program break function in the internal RAM

area of the mcu .......................................................................................................................274

12.4.8 Debugging in the 16-Timer functions .........................................................................274

12.4.9 Hardware Event ..........................................................................................................274

12.4.10 Operating frequency of MCU ....................................................................................274

12.5 Option of C Compiler/Assembler/Linker................................................................................275

12.5.1 When Using NCxx .......................................................................................................275

12.5.2 When Using the Assembler Package for 740 Family.................................................275

12.5.3 When Using the IAR C Compiler (EW) ......................................................................276

12.5.4 When Using the IAR C Compiler (ICC)......................................................................277

12.5.5 When Using the TASKING C Compiler (EDE)..........................................................278

12.5.6 When Using the TASKING C Compiler (CM)............................................................278

12.5.7 When Using the IAR EC++ Compiler (EW) ...............................................................279

vi

Page 13

Setup of Debugger

1

Page 14

(Blank Page)

2

Page 15

1 Features

1. Features

1.1 Real-Time RAM Monitor Function

This function allows you to inspect changes of memory contents without impairing the realtime

capability of target program execution.

The PC4701 emulator system contains a 1-Kbyte RAM monitor area (which cannot be divided into

smaller areas).

This debugger supports the real time RAM monitor function which allows you to reference the

memory data without sacrificing real time performance during execution of the target program.

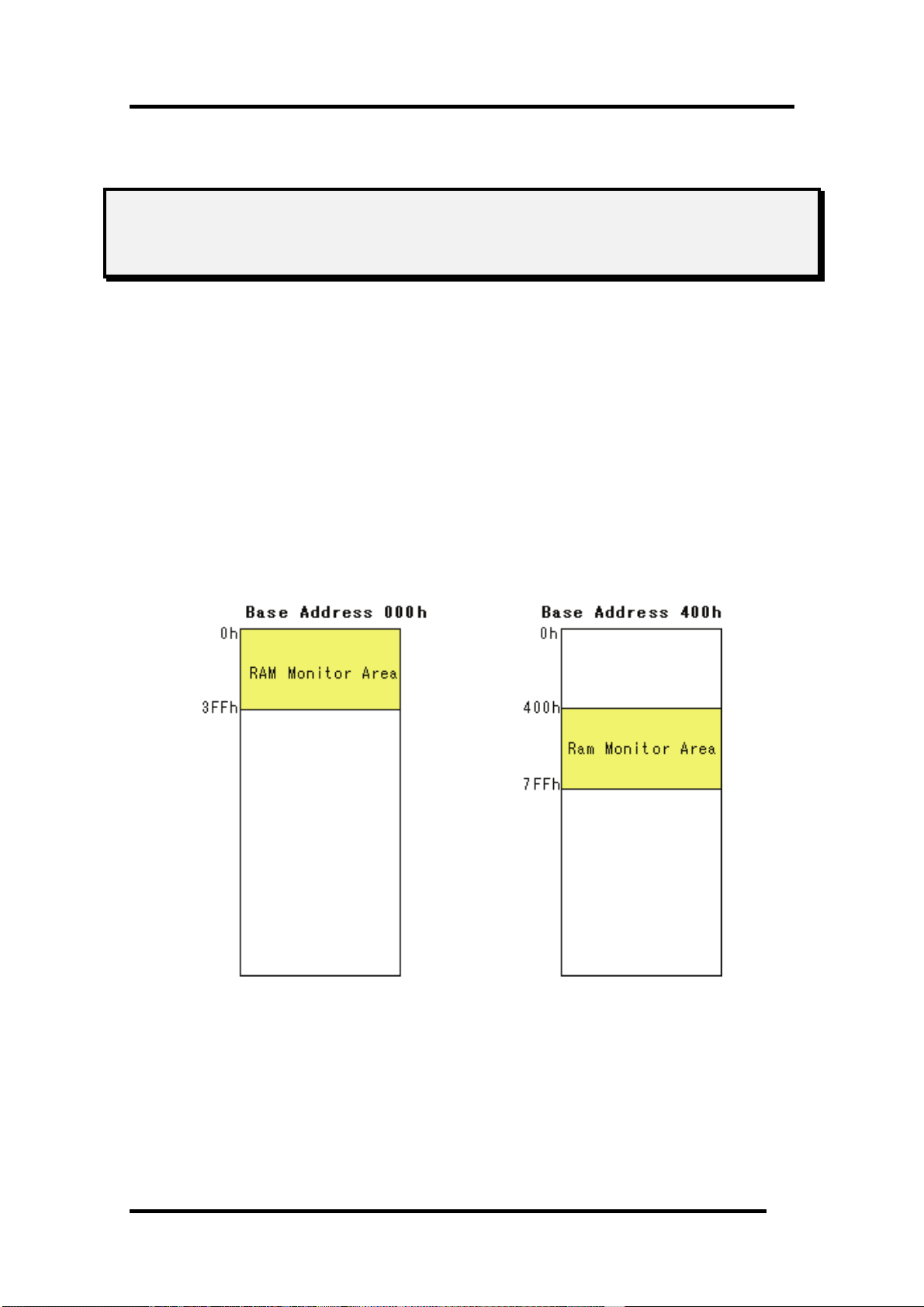

1.1.1 RAM Monitor Area

This debugger provides a 1KB of RAM monitor area, which can be placed at any continuous addresses.

1

Page 16

1.1.2 Sampling Period

Sampling cycle means the display update interval.

You can specify this function in any window which supports the RAM monitor. (The interval of 100

ms is set by default.)

The actual sampling cycle may take longer time than the specified cycle depending on the operating

environment. (Sampling cycle depends on the following environments.)

• Communication interface

• Number of the RAM Monitor windows displayed

• Size of the RAM Monitor window displayed

• Number of ASM watch points within the RAM monitor area of the ASM Watch window

• Number of C watch points within the RAM monitor area of the C Watch window

1.1.3 Related Windows

The window where the function of the real time RAM monitor function can be used is shown below.

• RAM Monitor Window

• ASM Watch Window

• C Watch Window

2

Page 17

1 Features

1.2 Break Functions

1.2.1 Software Breaks Function

Software Break breaks the target program before execution of the command at the specified address.

This break point is called software breakpoint.

The software breakpoint is set/reset in the Editor (Source) window or in the S/W Breakpoint Setting

window. You can also disable/enable a software breakpoint temporarily.

You can specify up to 64 software breakpoints. When specifying two or more software breakpoints, the

breakpoint combination is based on the OR logic. (Arrival to any one of breakpoints breaks the target

program.)

1.2.1.1 Setting of software breakpoint

The software breakpoint can be set by the following windows.

• Editor (Source) Window

• S/W Break Point Setting Window

You can double-click the mouse to set/reset the software breakpoint in the Editor (Source) window.

You can also switch to temporarily disable/enable the software breakpoint in the S/W Breakpoint

Setting window.

1.2.1.2 Area where software breakpoint can be set

The area which can be set for software breakpoint varies depending on the product.

For the areas available for software breakpoint, see the following:

"

12.1.2 Area where software breakpoint can be set"

3

Page 18

1.2.2 Hardware Break

This function causes the target program to stop upon detecting a data read/write to memory,

instruction execution, or the rising/falling edge of the input signal fed from an external trace cable.

The contents of events that can be set vary with each target MCU.

The following designations are available as break events:

• Address designation

- Instruction fetch

- Memory access

- Bit access

• External trigger designation

• Interruption

The number of events that can be specified are six events of all. For the address designation method,

instruction fetch and memory access allow the range designation and logical condition designation, in

addition to the normal one-address designation. Moreover, instruction fetch allows you to specify the

function name.

Memory access allows you to specify the comparison data to read/write data related to the specified

address in the same manner as when setting the H/W breakpoint. It also allows mask designation to

the comparison data.

These break events can be combined as below:

• Trace when all of the valid events are established (AND condition)

• Trace when all of the valid events are established at the same time (simultaneous AND condition)

• Trace when one of the valid events is established (OR condition)

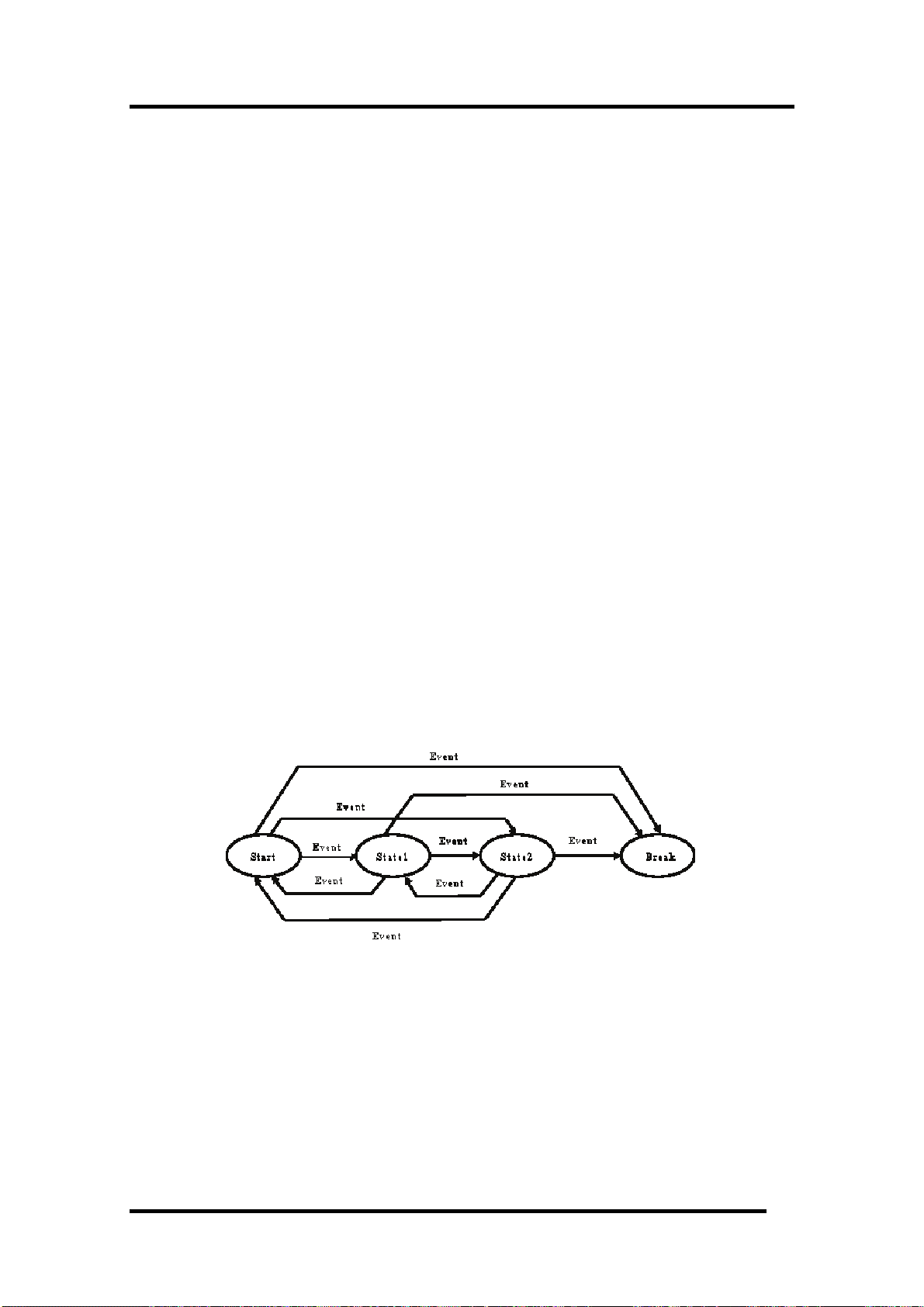

• Trace upon entering a break state during state transition (State Transition condition)

When transitional conditions set in an interstate pass are met, a state transition occurs, in which case

the target program can be made to stop upon entering a break state. The conceptual diagram shown

below depicts the relationship between state and pass.

State transition break allows you to select "specified task only" (or "other than specified task") as the

break condition to meet the real time OS.

4

Page 19

1 Features

1.2.3 Protect Break

This function causes the target program to stop upon detecting a data write to the ROM area or an

access to an unused area (read/write or instruction execution).

Protect Break is a function to detect a write of data to the ROM area and an access (read, write,

command execution) to an unused area and stop the target program.

1.2.3.1 Protect Attribute

You can specify the following attributes in byte.

• Access Disable

• Read Only

• R/W Enable

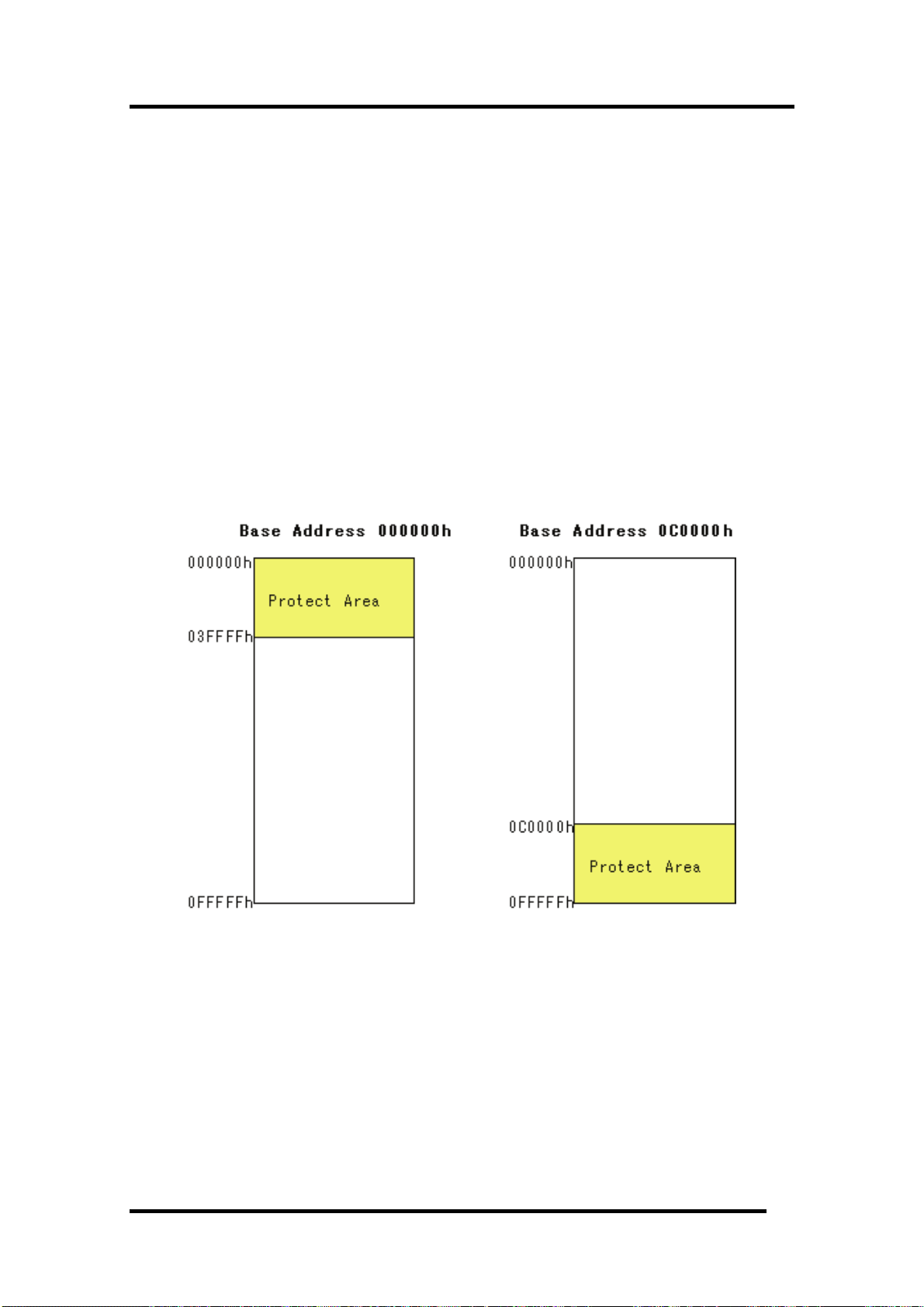

1.2.3.2 Access Protect Area

A protect area is a continuous 256-KB area starting from the 64KB boundary. Its start address is

called protect base address.

The protect base address immediately after starting the emulator is set to 0h.

The entire protect area is set to "R/W Enable" by default at start of the emulator.

1.2.3.3 Set Method of Protect Break

The two types of designation methods are provided:

• To fetch the memory attribute from the target program section information

• To specify the memory attribute of any area

5

Page 20

1.3 Real-Time Trace Function

This function records a target program execution history.

Up to 32K cycles of execution history can be recorded. This record allows inspecting the bus

information, executed instructions, and source program execution path for each cycle.

The real-time trace function records the execution history of the target program.

The execution history is referred to in the tracing window.

The execution history can be referred to in the following mode.

• BUS mode

This mode allows you to inspect cycle-by-cycle bus information. The display content depends on

the MCU and emulator system used. In addition to bus information, this mode allows

disassemble, source line or data access information to be displayed in combination.

• Disassemble mode

This mode allows you to inspect the executed instructions. In addition to disassemble information,

this mode allows source line or data access information to be displayed in combination.

• Data access mode

This mode allows you to inspect the data read/write cycles. In addition to data access information,

this mode allows source line information to be displayed in combination.

• Source mode

This mode allows you to inspect the program execution path in the source program.

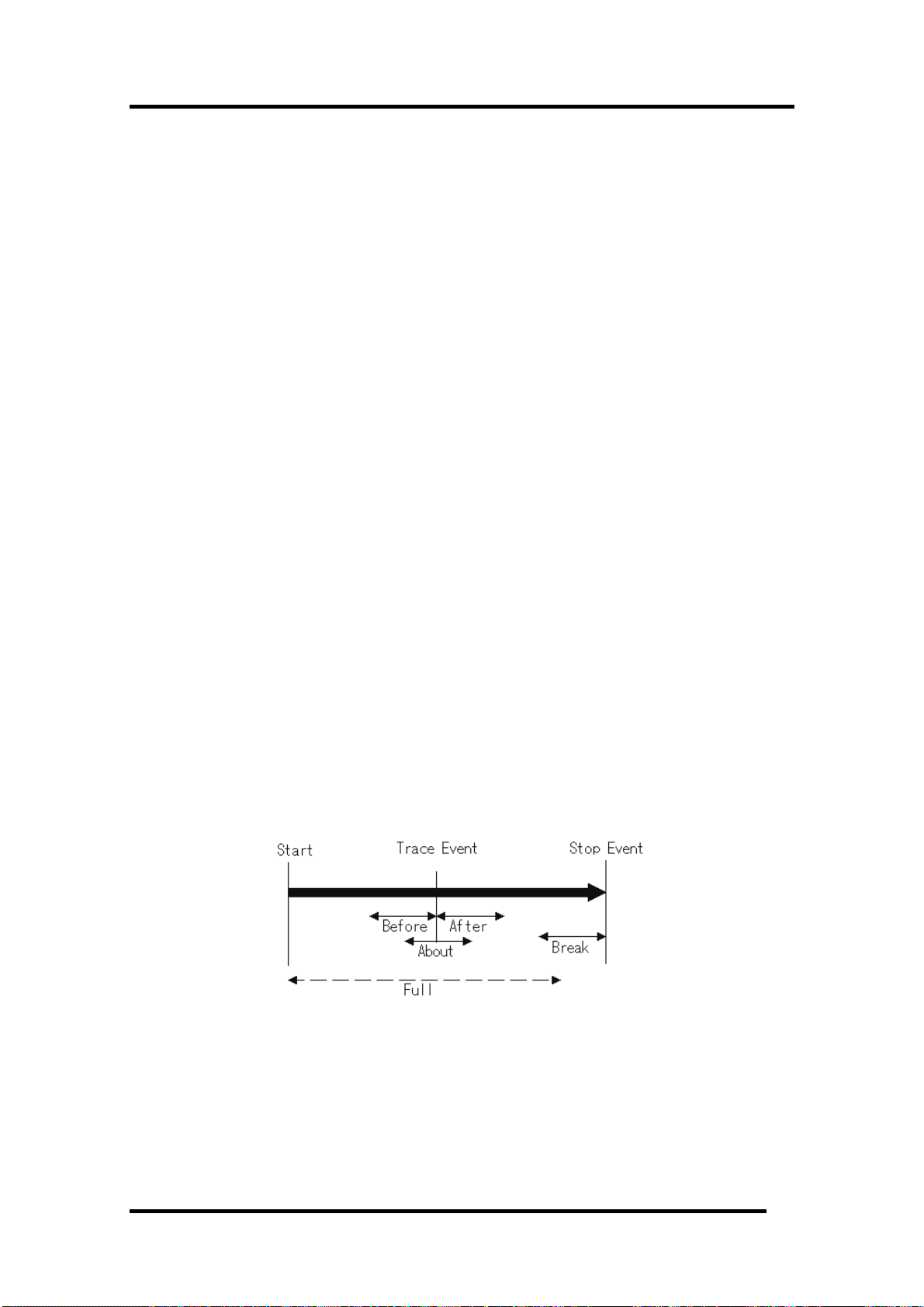

1.3.1 Trace Area

The 32K cycles execution history can be referred to with this debugger.

The trace area of the following 5 mode is being supported.

• Break

32K cycles before target program stops

• Before

32K cycles before trace point

• About

16K cycles either side of trace point

• After

32K cycles after trace point

• Full

Until 32K cycles are written in the trace memory

"Break" is set by default. To refer the execution history before stopping the target program, use

"Break" (designation of trace event is not required).

To refer the execution history at any position, or to continue execution of the target program, specify

the trace event and change the trance range.

6

Page 21

1 Features

1.3.2 Trace Condition Setting

The following designations are available as trace events:

• Address designation

- Instruction fetch

- Memory access

- Bit access

• External trigger designation (eight events)

• Interruption

The number of events that can be specified are six events of all. These break events can be combined

as below:

• Trace when all of the valid events are established (AND condition)

• Trace when all of the valid events are established at the same time (And(same time) comdition)

• Trace when one of the valid events is established (OR condition)

• Trace upon entering a break state during state transition (State Transition condition)

You can select "specified task only" (or "other than specified task") as the trace condition to meet the

real time OS.

1.3.3 Trace Data Write Condition

Trace data write conditions can be specified.

You can specify the following write conditions:

• Write conditions unlimited (default)

• Cycles from the start event established to the end event established

• Only cycles where the start event is established

• Cycles from the start event established to the start event unestablished

• Other than cycles from the start event established to the end event established

• Other than cycles where the start event is established

• Other than cycles from the start event established to the start event unestablished

7

Page 22

1.4 Time Measurement Function

The time measurement function allows you to measure the maximum, minimum, and average

execution times and measurement counts of a specified zone.

With this debugger, time can be measured up to four points simultaneously.

1.4.1 The Measurement Condition

The measurement condition of the zone time can specify the following in each measurement zone.

• Execution time of the specified function

• Time between two events

• Time between event establishments

• Time of event occurrence period

8

Page 23

1 Features

1.5 Coverage Function

Coverage Measurement is a function to record the addresses executed (accessed) by the target

program (C0 coverage).

After stopping execution of the target program, you can understand which addresses are not executed

yet.

By using the coverage measurement function in the test process, you can check for missing test items.

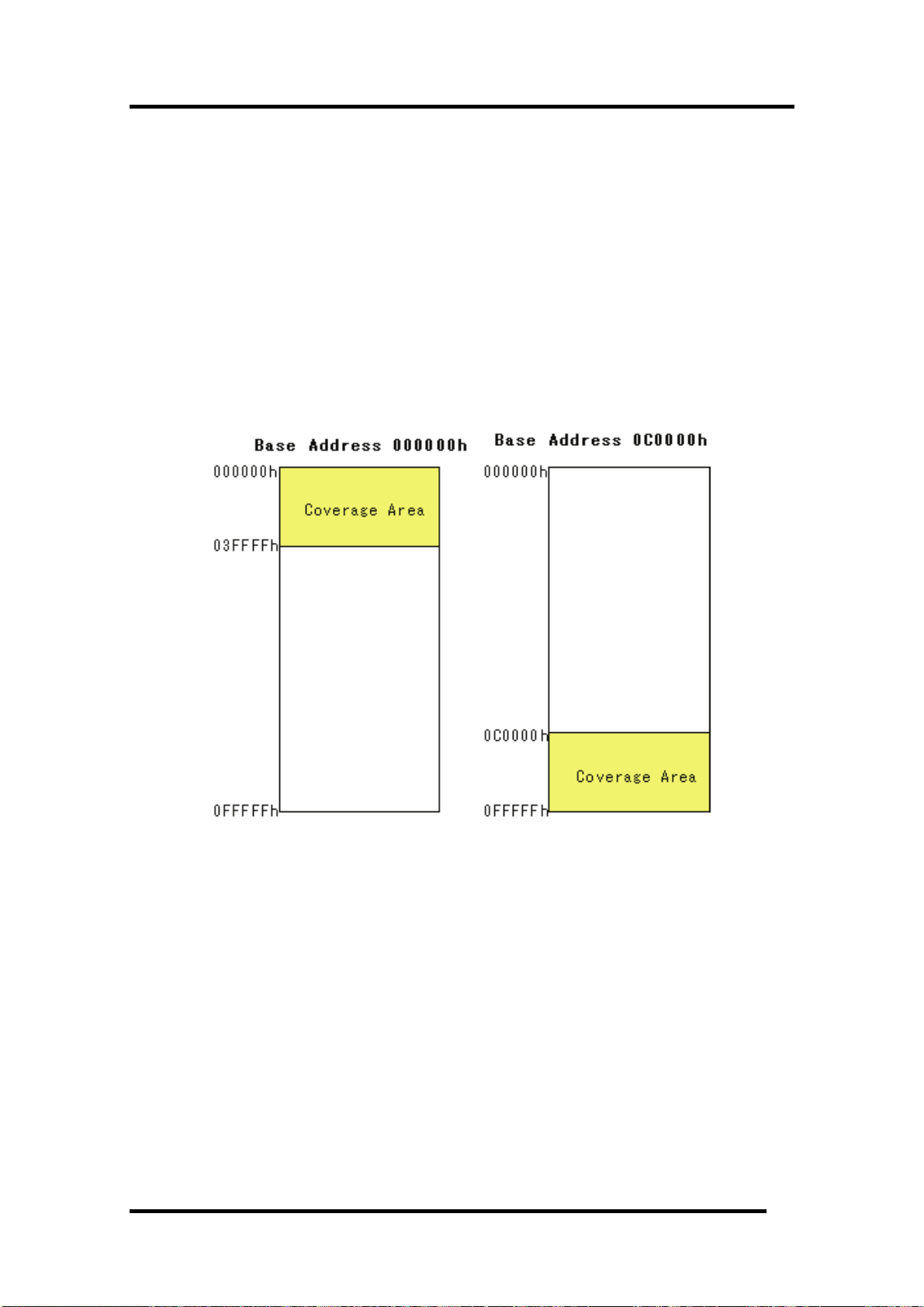

1.5.1 Coverage Measurement Area

The coverage measurement area is any continuous 256 KB area starting from the 64 KB boundary.

The starting address is called coverage base address.

The coverage base address immediately after starting the emulator is set to 0h.

1.5.2 Related Windows

Refer to the coverage measurement result in the following windows.

• Editor (Source) Window

• Memory Window

• Coverage Window

9

Page 24

1.6 Real-Time OS Debugging Function

This function debugs the realtime OS-dependent parts of the target program that uses the realtime

OS.

This function helps to show the status of the realtime OS and inspect a task execution history, etc.

The debugger for 740 can't show the status of the realtime OS.

1.7 GUI Input/Output Function

This function simulates the user target system's key input panel (buttons) and output panel on a

window.

Buttons can be used for the input panel, and labels (strings) and LEDs can be used for the output

panel.

10

Page 25

2 About the Emulator PC4701

2. About the Emulator PC4701

The PC4701 emulator system is a generic term used for the 8/16-bit MCU emulators. It can be used in

combination with the emulation pod for the PC4701 to debug application programs for each MCU.

2.1 Communication methods

The supported communication methods vary with the type of emulator used.

I/F

USB Support - -

LAN Support - Support

LPT Support Support -

Proprietary parallel - Support Support

Serial - Support Support

Depending on communication methods, it is necessary to set up some items before the debugger can

be started. Please see "

3.3 Setting before emulator starts "

Emulator

PC4701U PC4701M PC4701HS

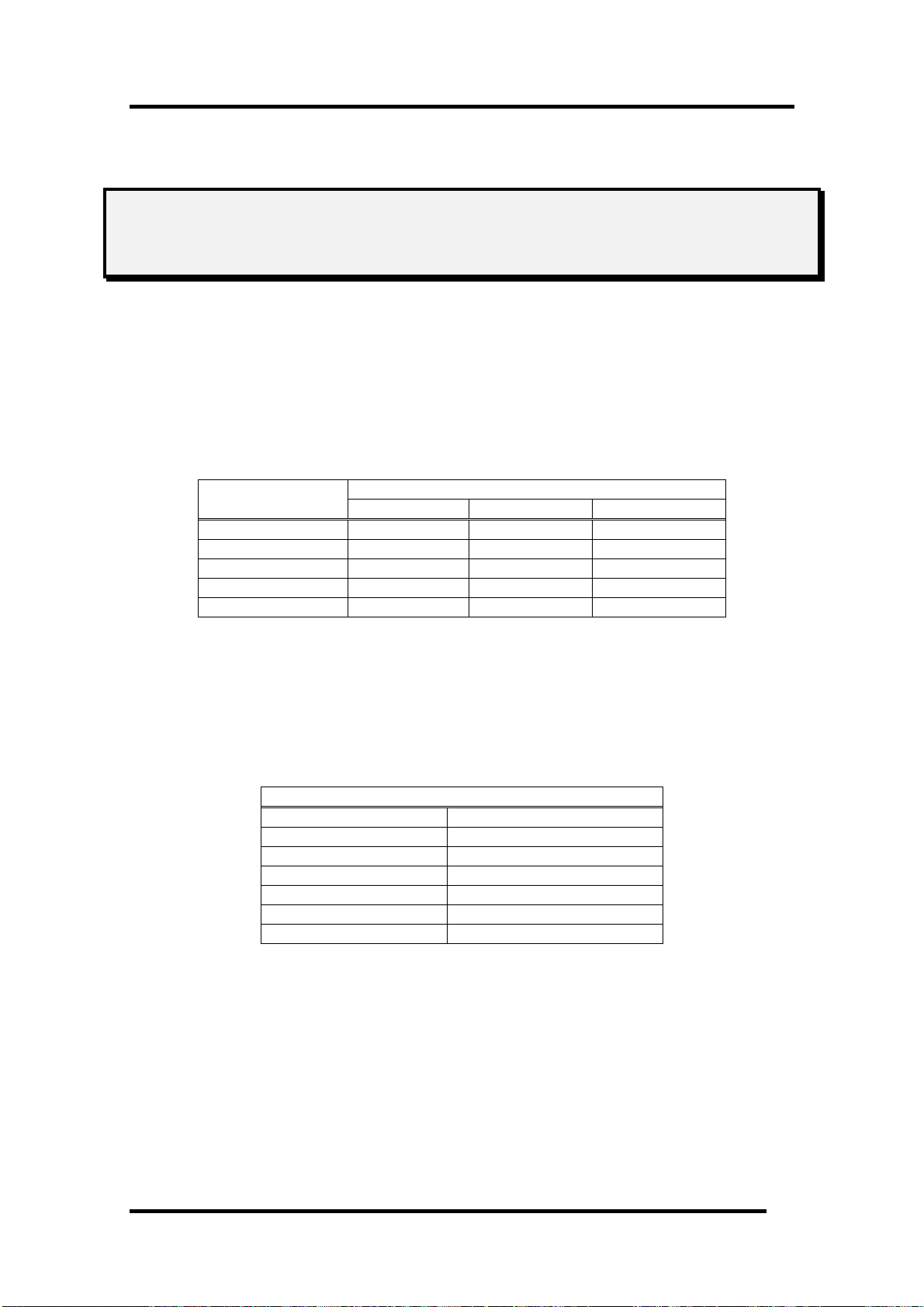

2.2 Function table

The supported functions vary with the type of emulator used.

PC4701U/M/HS

S/W Break 64 point s

H/W Break 6 points

Real-Time Tr e ac 32K Cycles

RAM Monitor 1K bytes area

C0 Coverage 256K bytes area

Time Measurement Go to Stop / 4 points interval

Protect Break Access Protect

11

Page 26

3. Before starting the debugger

3.1 Communication method by emulator

The supported communication methods are as follows. (The supported communication methods vary

with the type of emulator used. )

USB, LAN, LPT, Proprietary parallel, Serial

3.1.1 USB Interface

Supported only when using the PC4701U emulator.

• Compliant with USB Standard 1.1.

• Connections via USB hub are not supported.

• By connecting the host computer and the emulator with USB cable, it is possible to install the

supported device drivers using a wizard.

• The necessary cable is included with the emulator.

3.1.2 LAN Interface

Supported only when using the PC4701U/HS emulator.

• The IP address, etc. must be set in the emulator before it can be connected in a LAN.

• To communicate with the emulator via a LAN on Windows, Windows' registry information must

partly be modified.

• The PC4701U emulator in a LAN can be connected to the PC4701Us on another network

connected to the LAN via a router.

• The emulators PC4701U and PC4701HS use different LAN cables. Specifically, the PC4701U

uses LAN cable (10BASE-T only) generally available on the market, whereas the PC4701HS uses

the LAN cable (10BASE-T/5) included with it.

• The host computer and the emulator can be connected directly.

3.1.3 LPT Interface

Supported only when using the PC4701U/M emulator.

• This communication uses the host computer's parallel (printer) interface.

• The necessary cable is included with the emulator.

• Four communication modes are supported that include ECP, EPP, Byte, and Nibble.

Communication modes that can be supported depend on the host computer's BIOS settings.

(Communication modes may not always be used even when they are supported by BIOS.)

12

Page 27

3 Before starting the debugger

3.1.4 Proprietary Parallel Interface

Supported only when using the PC4701HS emulator.

• The host computer must have a dedicated interface board, the PCA4202G02, incorporated in it

(only the ISA bus is supported). The necessary cable is included with the emulator.

• A device driver must separately be set.

3.1.4.1 Serial Interface

Supported only when using the PC4701M/HS emulator.

• This communication uses the host computer's serial interface.

• The necessary cable is included with the emulator.

13

Page 28

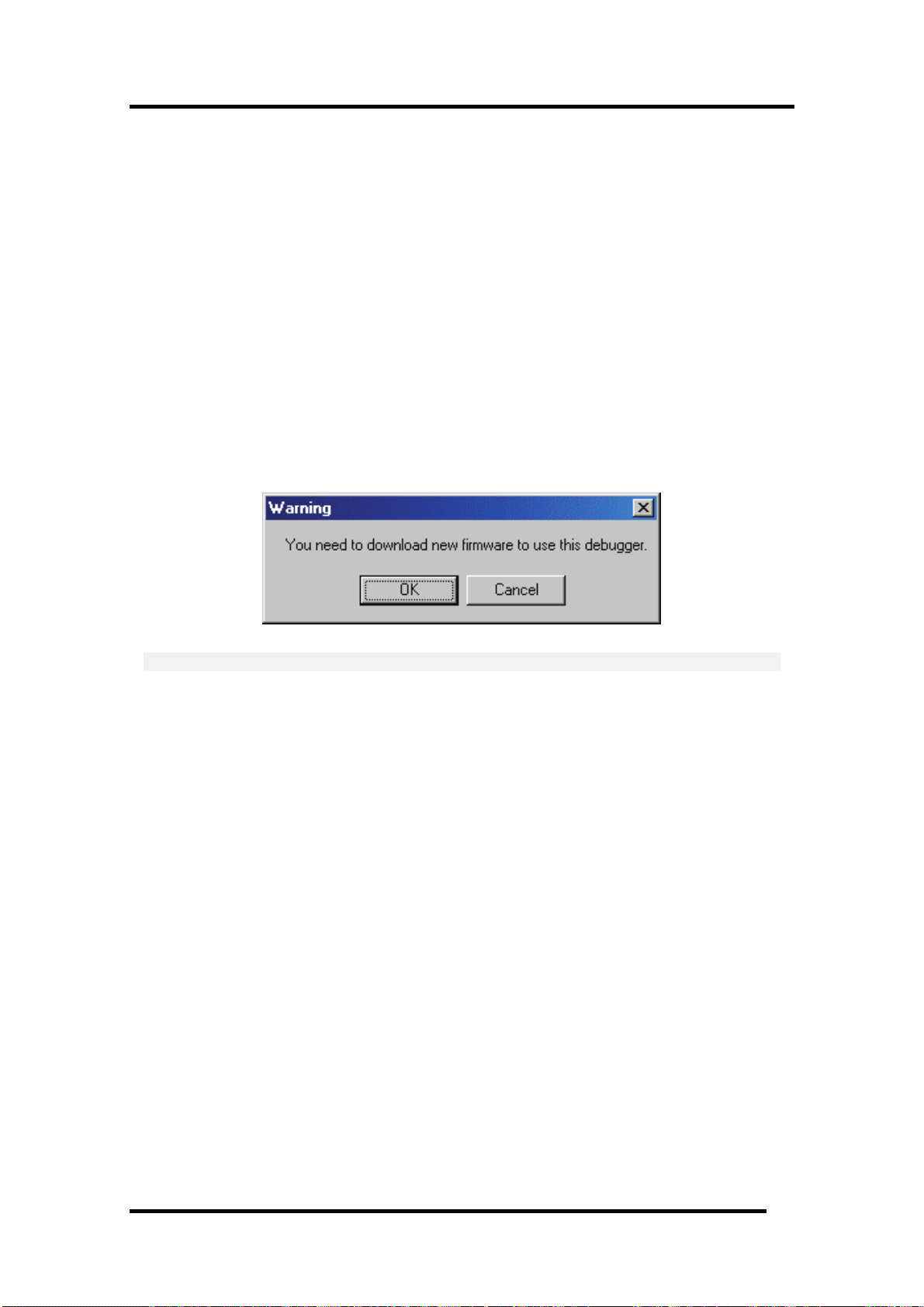

3.2 Download of Firmware

It is necessary to down-load the firmware which corresponds to connected Emulation Pod when the

debugger is started to the emulator.

• You have changed your emulation pod.

• The firmware downloaded to the emulator is unknown one.

• You have setup the debugger for the first time.

• You have upgraded emulator debugger.

Press the system reset switch within two seconds after powering up the PC4701 to establish the

maintenance mode.

This debugger searches the version of the firmware downloaded to the emulator at start. Also when

the firmware downloaded to the emulator is of old version, a mode which drives this debugger to

download firmware is set.

When this debugger gets started while the emulator is set in the mode which drives the debugger to

download firmware forcedly, the following dialog is opened at start.

Click the OK button to download the firmware.

ATTENTION

• If the emulator being used is the PC4701HS, use other communication methods (dedicated

parallel or serial) to download the firmware.

• Before the firmware can be downloaded by the emulator in a LAN connection, the IP address, etc.

must first be registered in the emulator.

14

Page 29

3 Before starting the debugger

3.3 Setting before emulator starts

3.3.1 USB communication

Connection of USB devices is detected by Windows' Plug & Play function. The device driver needed

for the connected USB device is automatically installed.

3.3.1.1 Install of USB device driver

The USB devices connected are detected by Windows' Plug & Play function. The installation wizard

for USB device drivers starts after the device had been detected. The following shows the procedure

for installing the USB device drivers.

1. Connect the host computer and the emulator with USB cable.

2. Set the emulator's communication interface switch to the "USB" position. Then turn on the

power to the emulator.

3. The dialog box shown below appears.

Go on following the wizard, and a dialog box for specifying the setup information file (inf file) is

displayed. Specify the musbdrv.inf file stored in a location below the directory where this debugger is

installed.

ATTENTION

• Before the USB device drivers can be installed, the debugger you use must already be installed.

Install this debugger first.

• A user who install the USB device driver need administrator rights.

• During installation, a message may be output indicating that the device driver proper

musbdrv.sys cannot be found. In this case, specify the musbdrv.sys which is stored in the same

directory as is the musbdrv.inf file.

15

Page 30

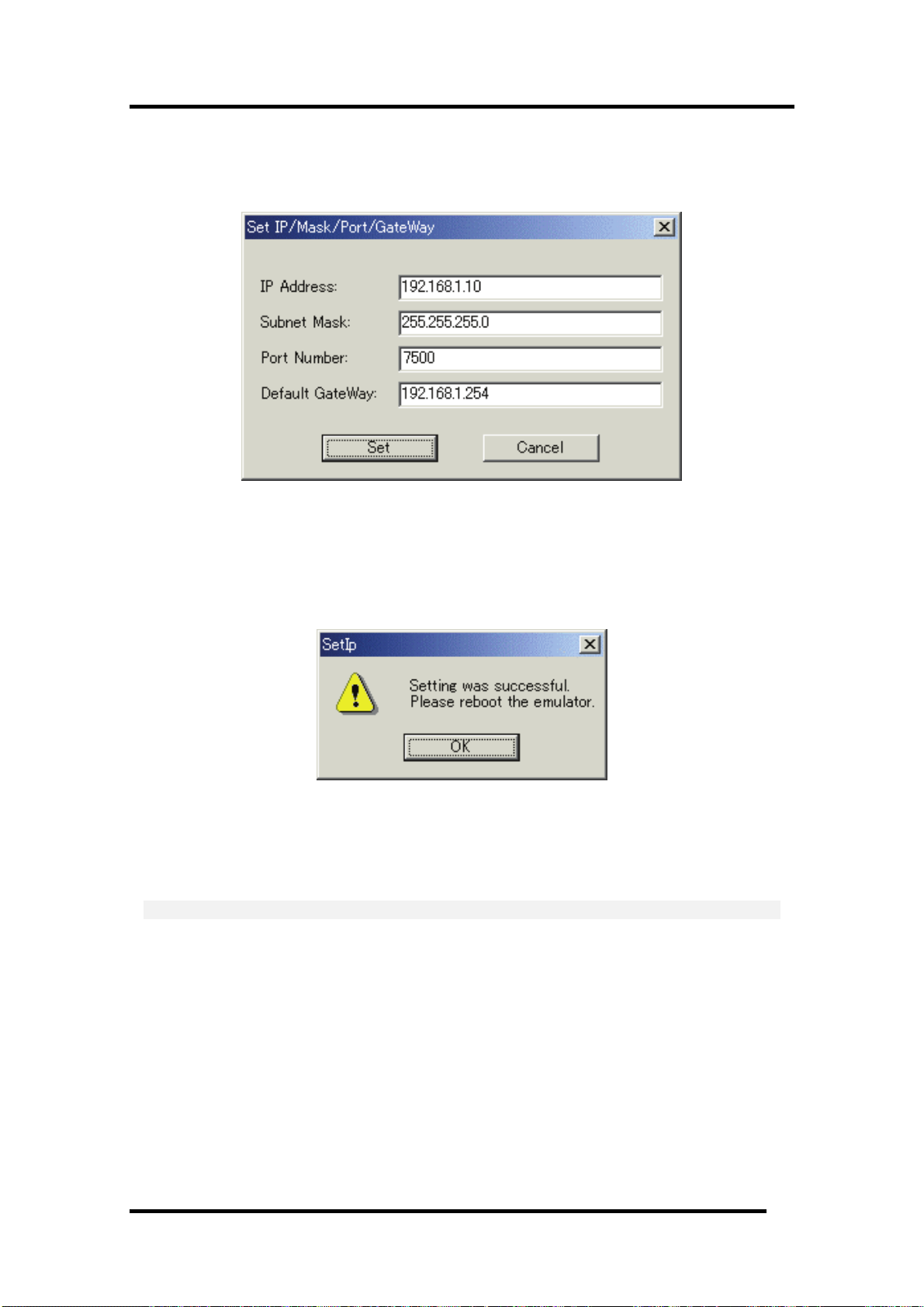

3.3.2 LAN communication 1

Before the emulator can be connected in a LAN, the IP address, etc. must first be registered in the

emulator. For the emulator in default settings, the utility "setip.exe" included with the debugger may

be used to set the IP address, etc. in the emulator.

3.3.2.1 Setting of the LAN Interface using the SETIP.EXE

The utility "SETIP" included with this debugger may be used to set the IP address, etc. in the

emulator while in default settings. SETIP detects the Emulator's in default settings that are

connected to the same network. SETIP is stored in a location below the directory where this debugger

is installed . The file name is "setip.exe".

To register the IP address in the emulator, follow the procedure described below.

1. Connect the emulator with LAN cable to the same network (same subnet) as the host computer

is connected.

2. Set the emulator's communication interface switch to the "LAN" position. Then turn on the

power to the emulator.

3. Start SETIP. When SETIP has started up, the dialog box shown below appears, choose the

emulator of use, click the OK button.

4. Click the OK button, and showing information on the emulator connected to the network. (This

information consists of the MAC address followed by the serial number of the emulator.)

To register the IP address, click the Next button. To cancel registration, click the Close button. If not

displayed, check whether the communication interface switch is set correctly and after temporarily

turning off the power, turn it back on again. Then click the Search button.

16

Page 31

3 Before starting the debugger

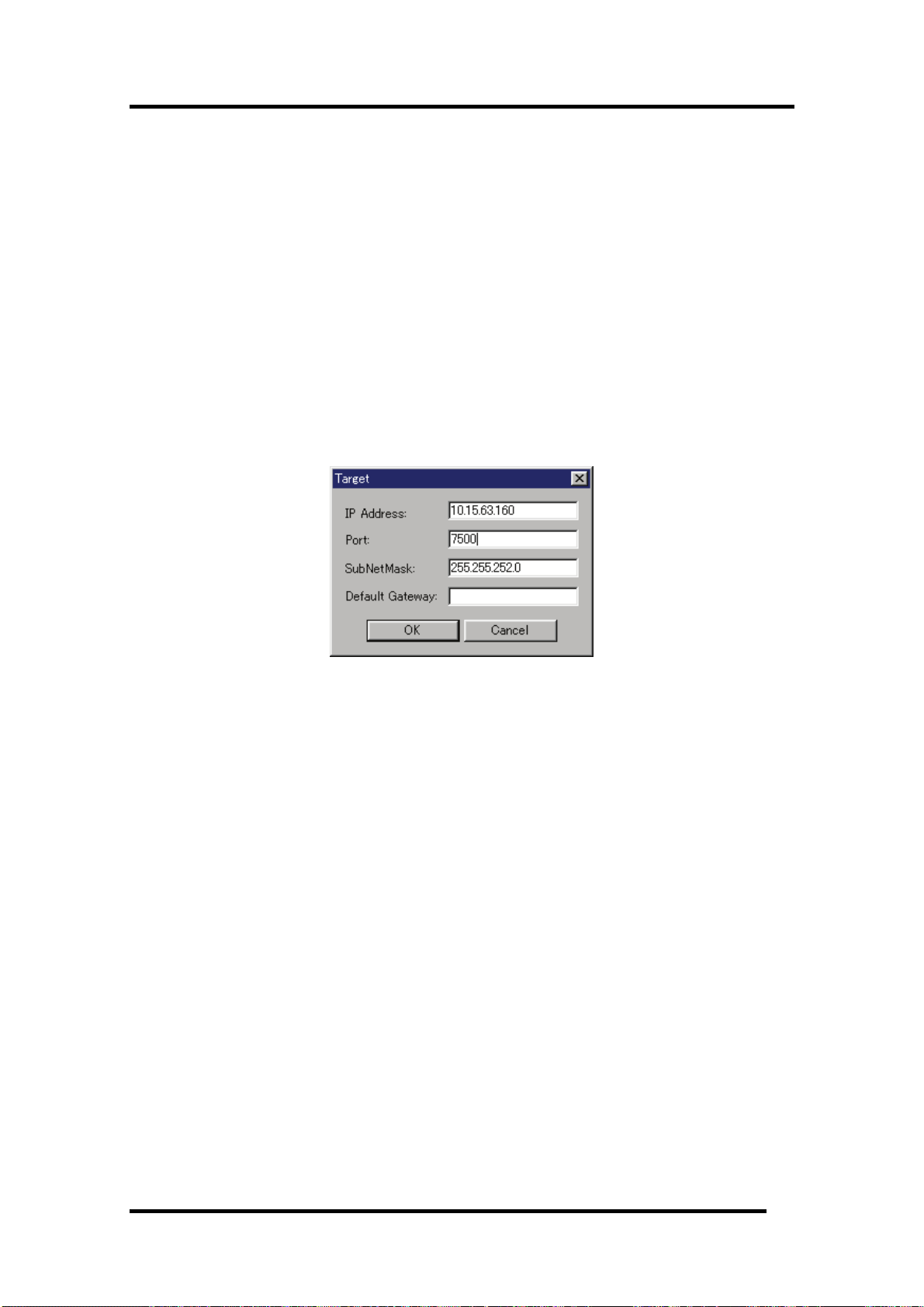

5. Click the Next button, and the dialog box shown below appears. Set the IP address, subnet mask,

port number, and default gateway IP address. When using the emulator on the same network's

same subnet mask, the default gateway IP address may be omitted.

Use any 4-digit number to specify the port number. (Enter that number when starting the debugger.)

For details about the contents of the IP address, subnet mask, and default gateway to be specified,

contact your network administrator.

6. Click the Set button on the dialog box. The IP address, etc. that have been set are registered in

the emulator. When registered correctly, the dialog box shown below appears.

After checking the contents of the dialog box, click the OK button.

7. Temporarily turn off the power to the emulator and turn it back on again. The registered IP

address becomes effective after the emulator is powered up again.

ATTENTION

• If multiple Emulators in default settings are connected on the same network, only the first

emulator detected is displayed.

• The emulators which have had an IP address already set cannot be detected by SETIP. In such a

case, connect to the emulator through another communication interface and re-register the IP

address from the Init dialog box that appears. For details on how to set IP addresses from the Init

dialog box, see "

5.2.3Setting of the LAN Interface."

17

Page 32

3.3.3 LAN communication 2

Please exexute registry setting program (Sack.exe) before starting the debugger. It is necessary for

LAN communication with emulators to set the following registry.

OS

Key Data

Windows XP/2000 HKEY_LOCAL_MACHINE¥S

YSTEM¥CurrentControlSet¥

Services¥Tcpip¥Parameters¥

SackOpts

You can clear the registry with executing the program "UnSack.exe". The above programs are

installed in the directory where this debugger is installed.

ATTENTION

Make sure Sack.exe and UnSack.exe is executed by one who is authorized as an Administrator. No

one but the user who has the authority of an Administrator can install the device driver.

Note

Windows XP/2000 TCP supports "Selective Acknowledgments (SACK)" as documented in RFC 2018.

SACK gives higher performance in the network which have high bandwidth and long round-trip

delays like satellite channels.

SACK support is enabled by default in Windows XP/2000. It is necessary for LAN communication

with emulators by Windows XP/2000 to disable SACK support. Setting the above registry can disable

SACK support.

Note that when you use the network which have high bandwidth and long round-trip delays like

satellite channels, the performance with SACK support disabled is lower than with enabled.

0(REG_DWORD)

18

Page 33

3 Before starting the debugger

3.3.4 Proprietary parallel communication

If you are using this debugger in a combination of the parallel I/F, you need to specify the start

address of I/O addresses (7 bytes) to the device driver for PCA4202G02, (The I/O address for

PCA4202G02 is set to 100h initially.) You can set this setting with setPca4202.exe included with this

debugger. The above programs are installed in the directory where this debugger is installed. At the

first time of using this debugger,or when you want to change the I/O address for PCA4202G02

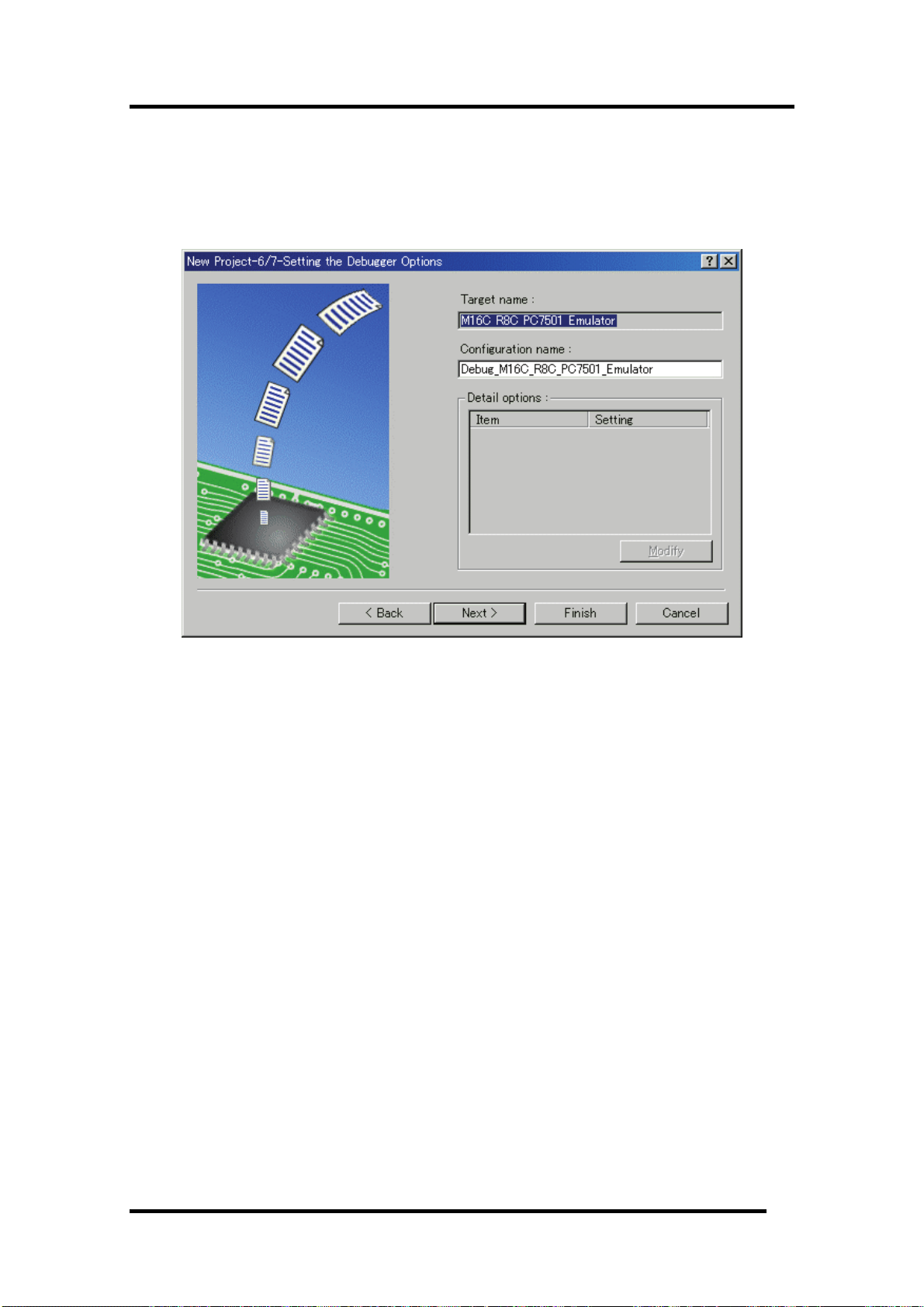

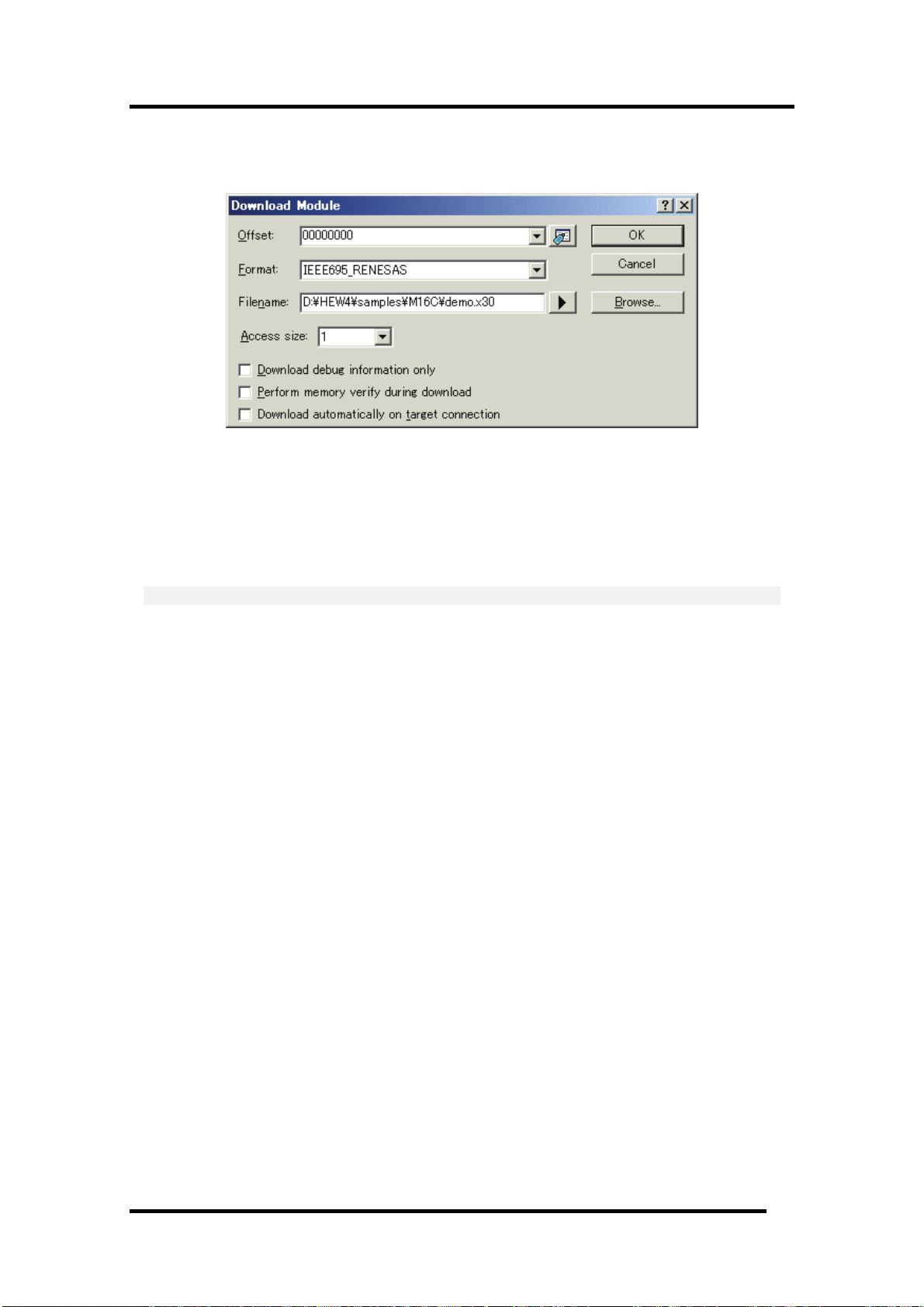

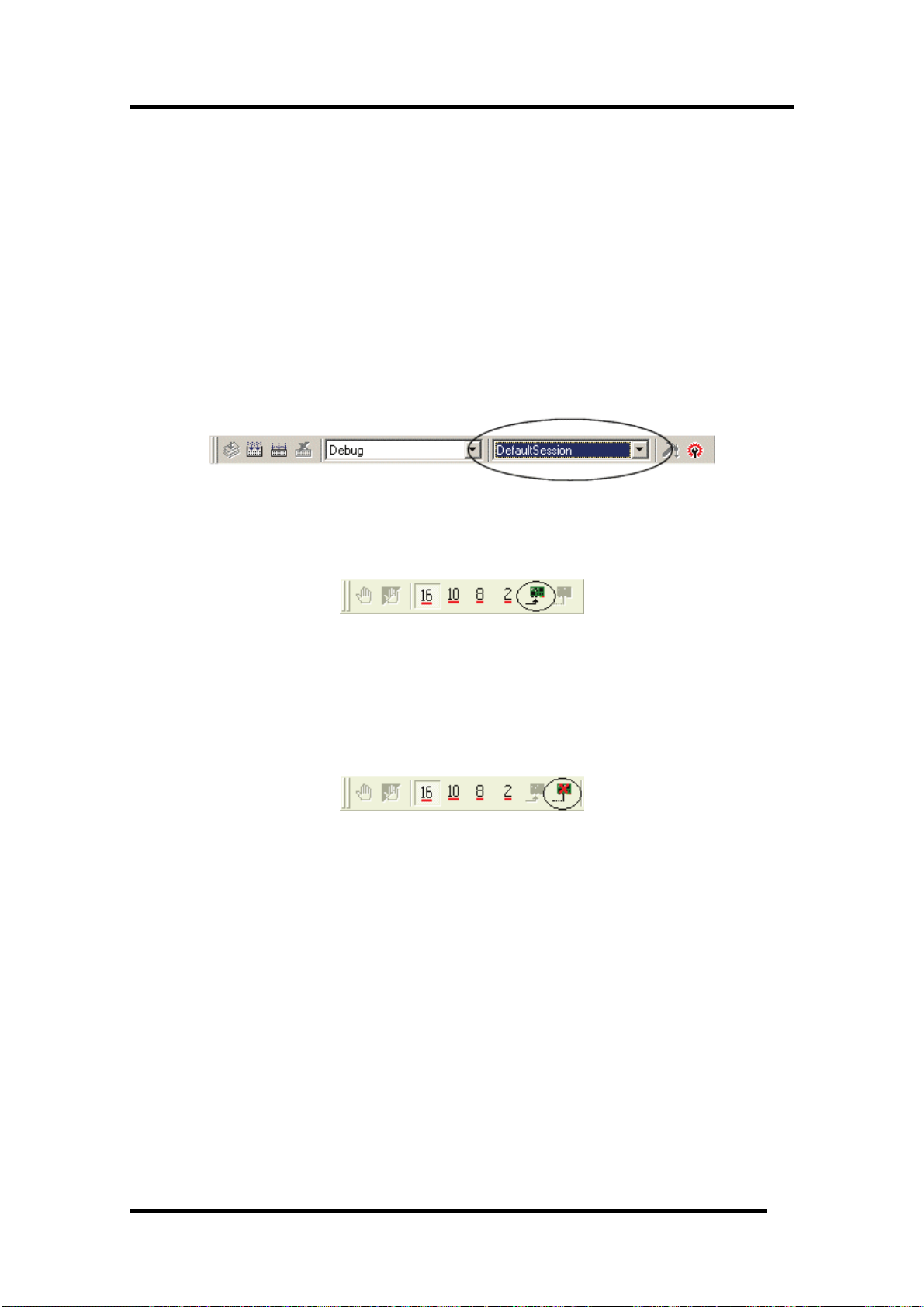

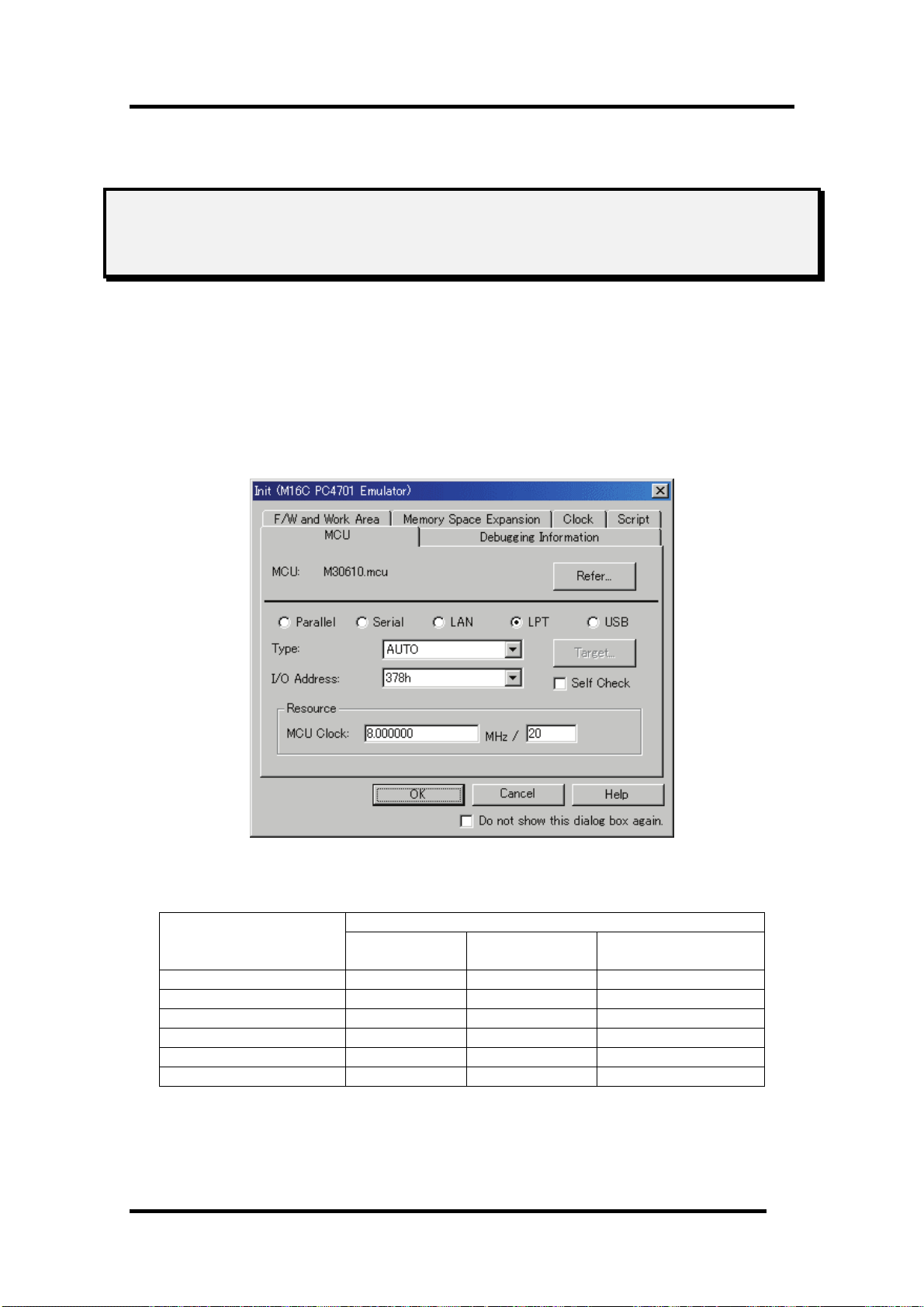

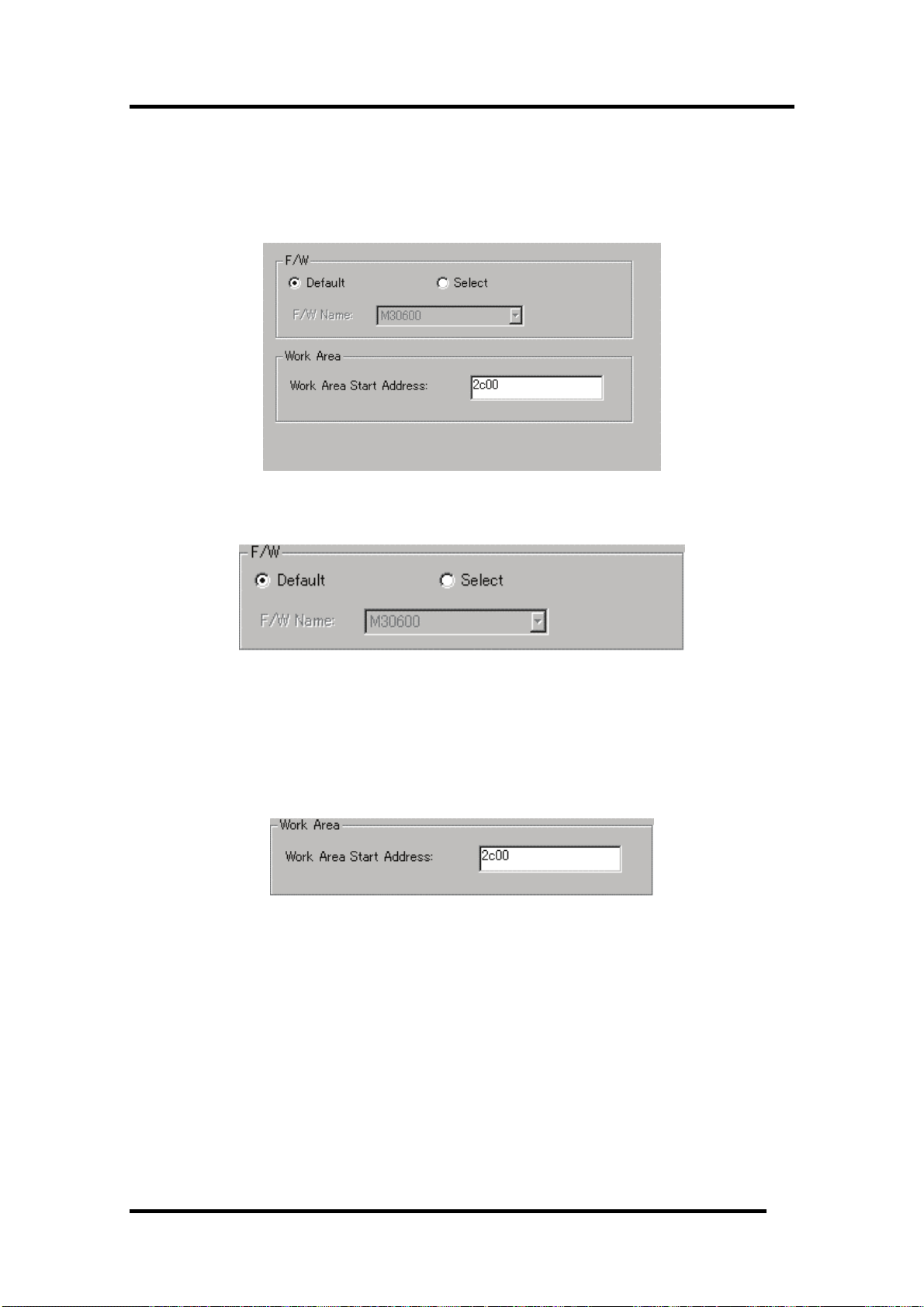

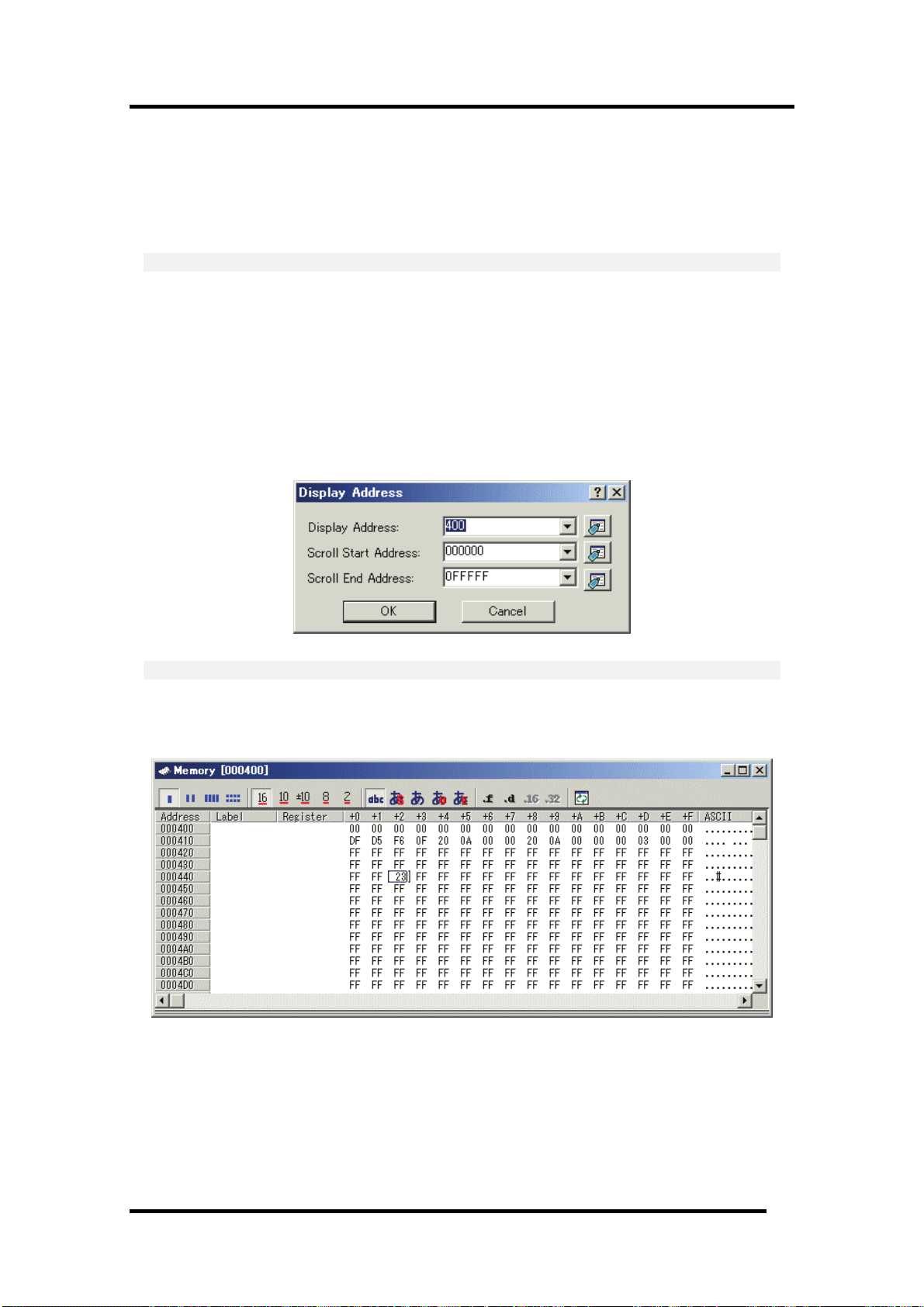

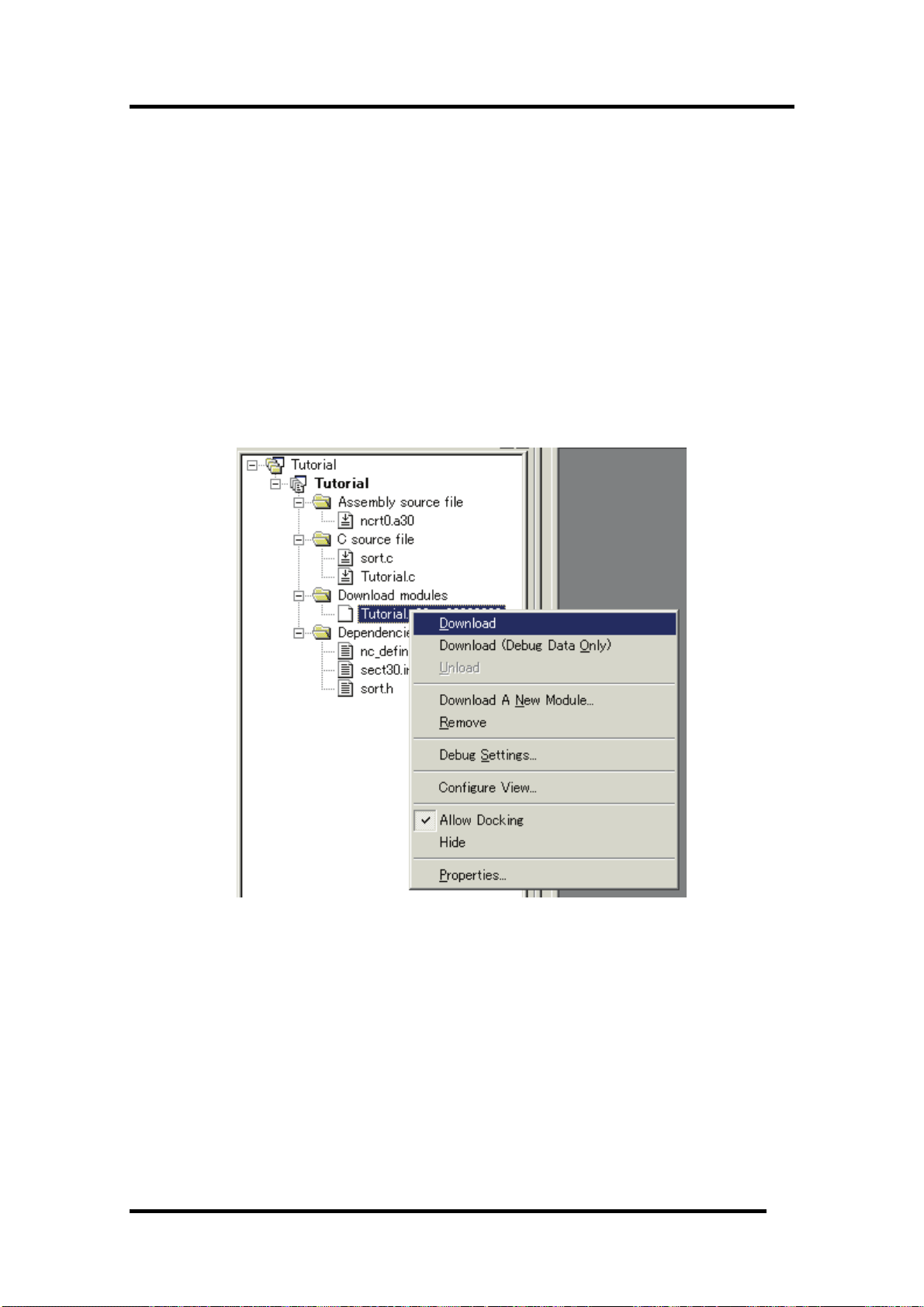

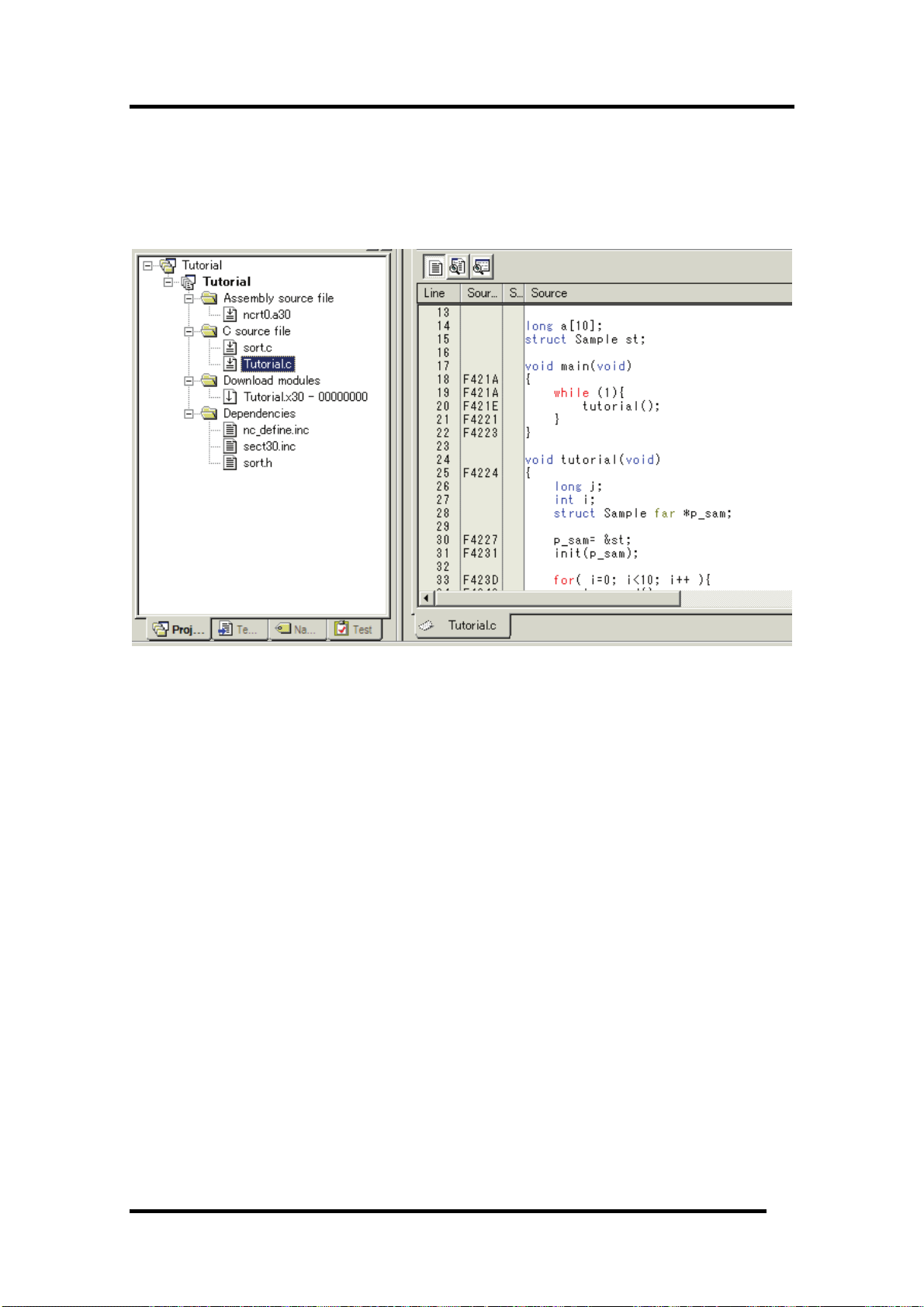

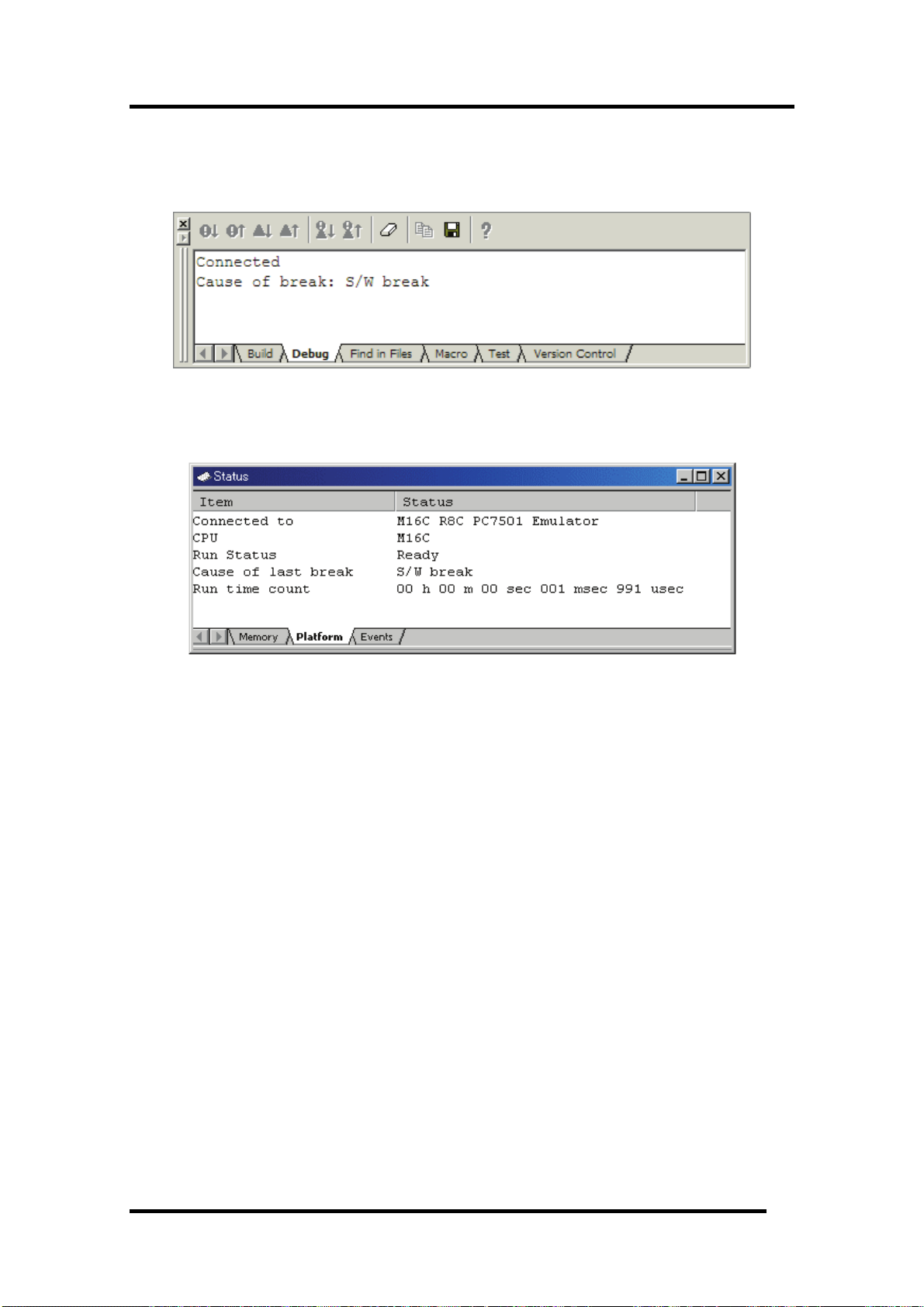

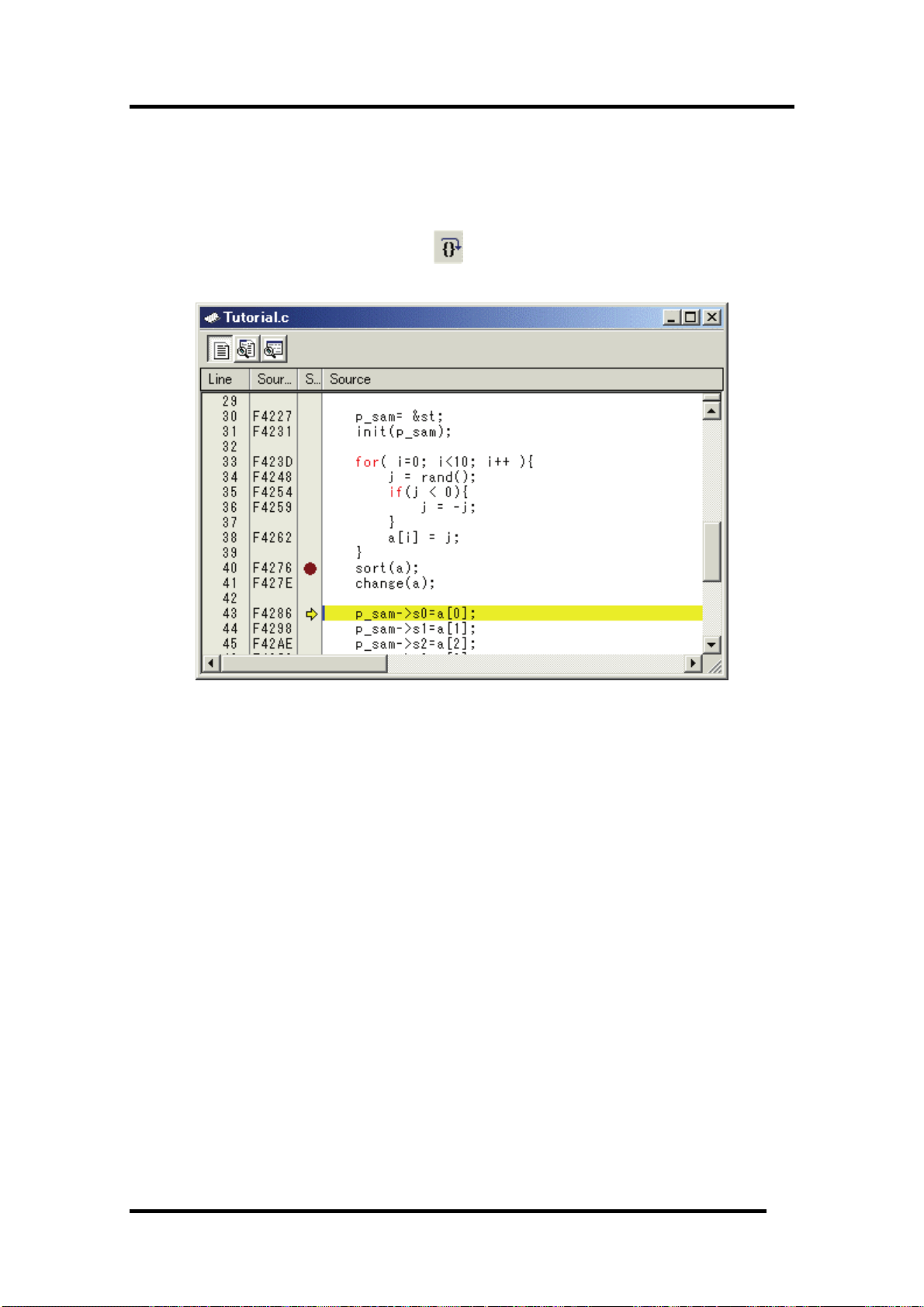

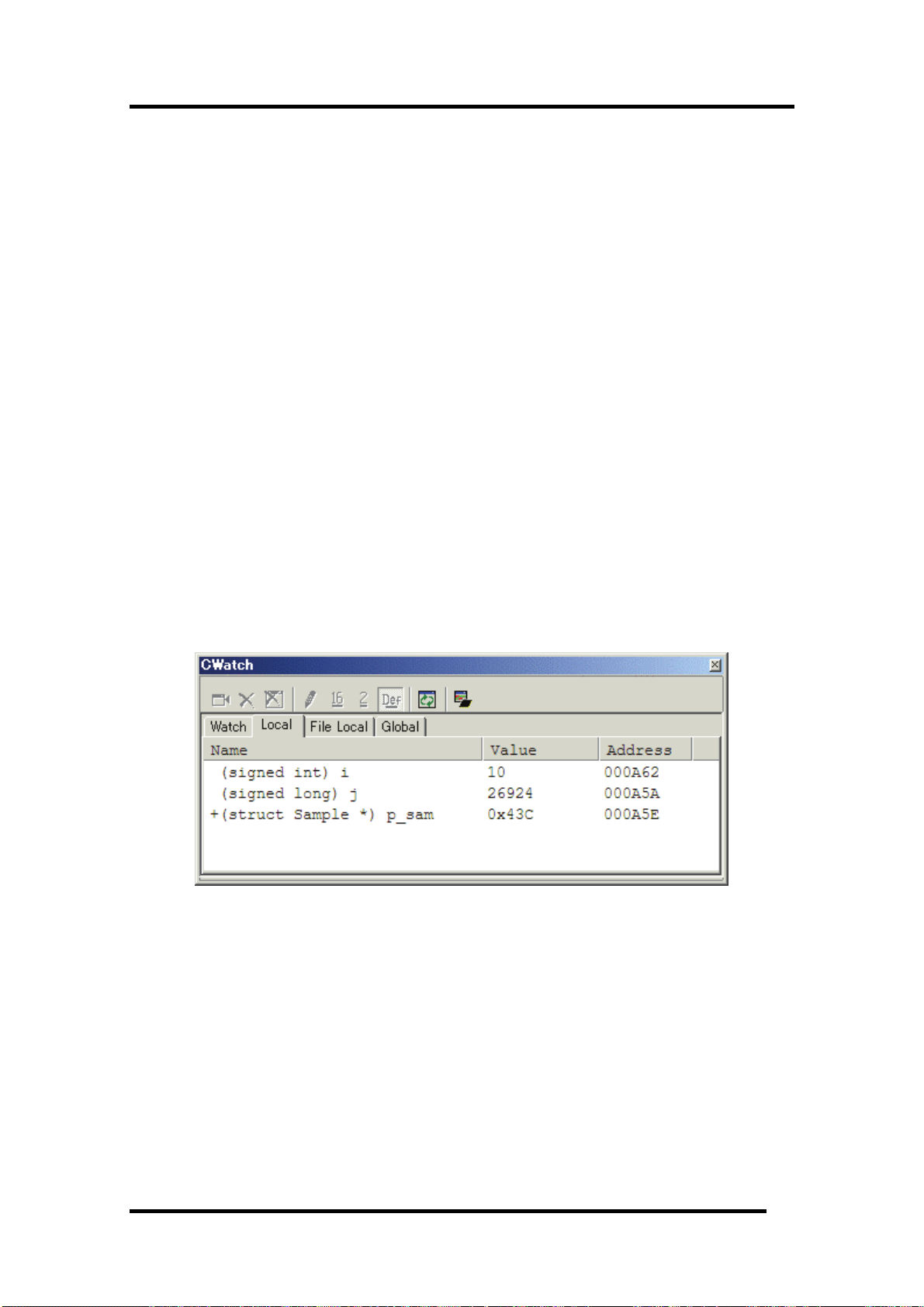

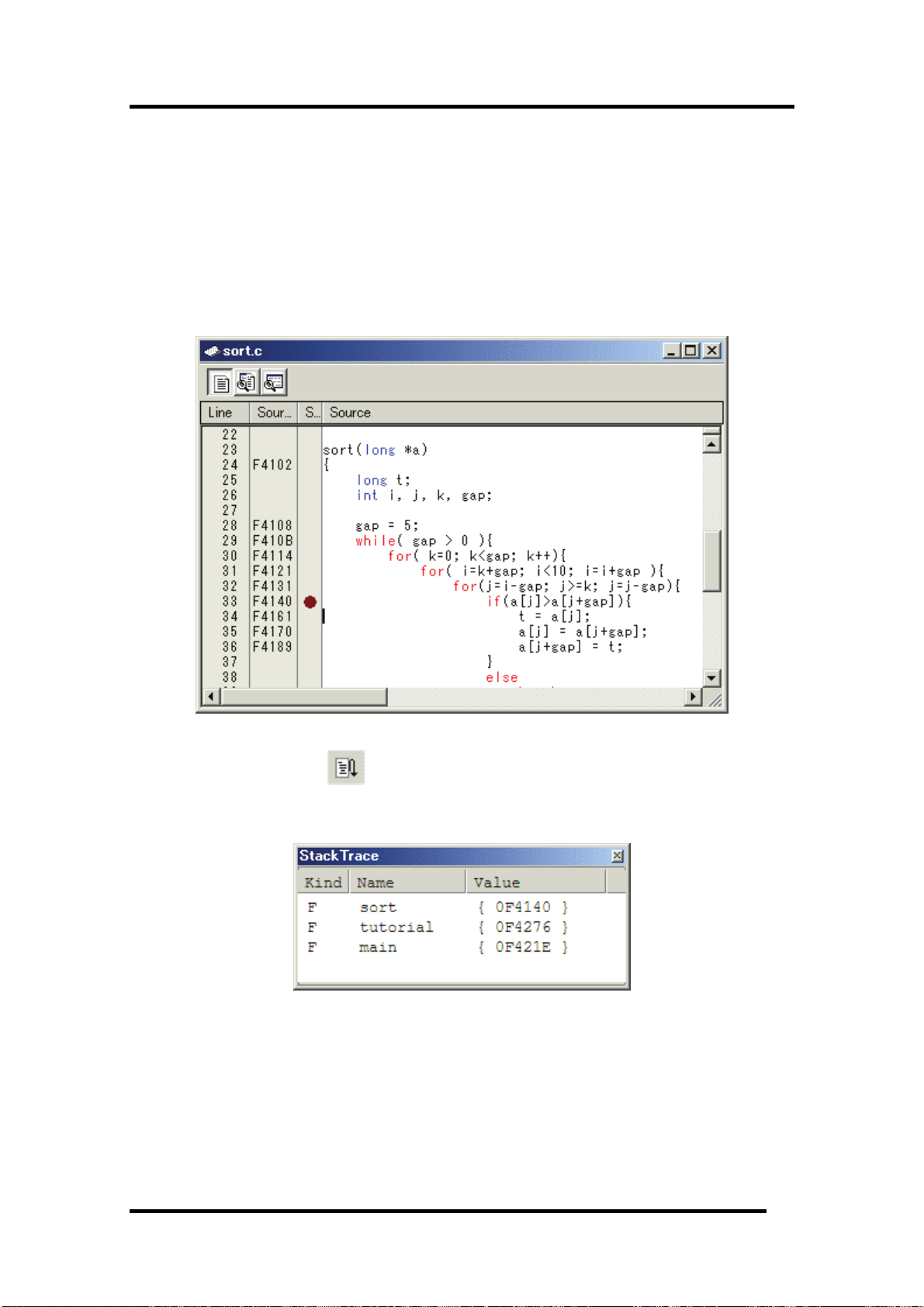

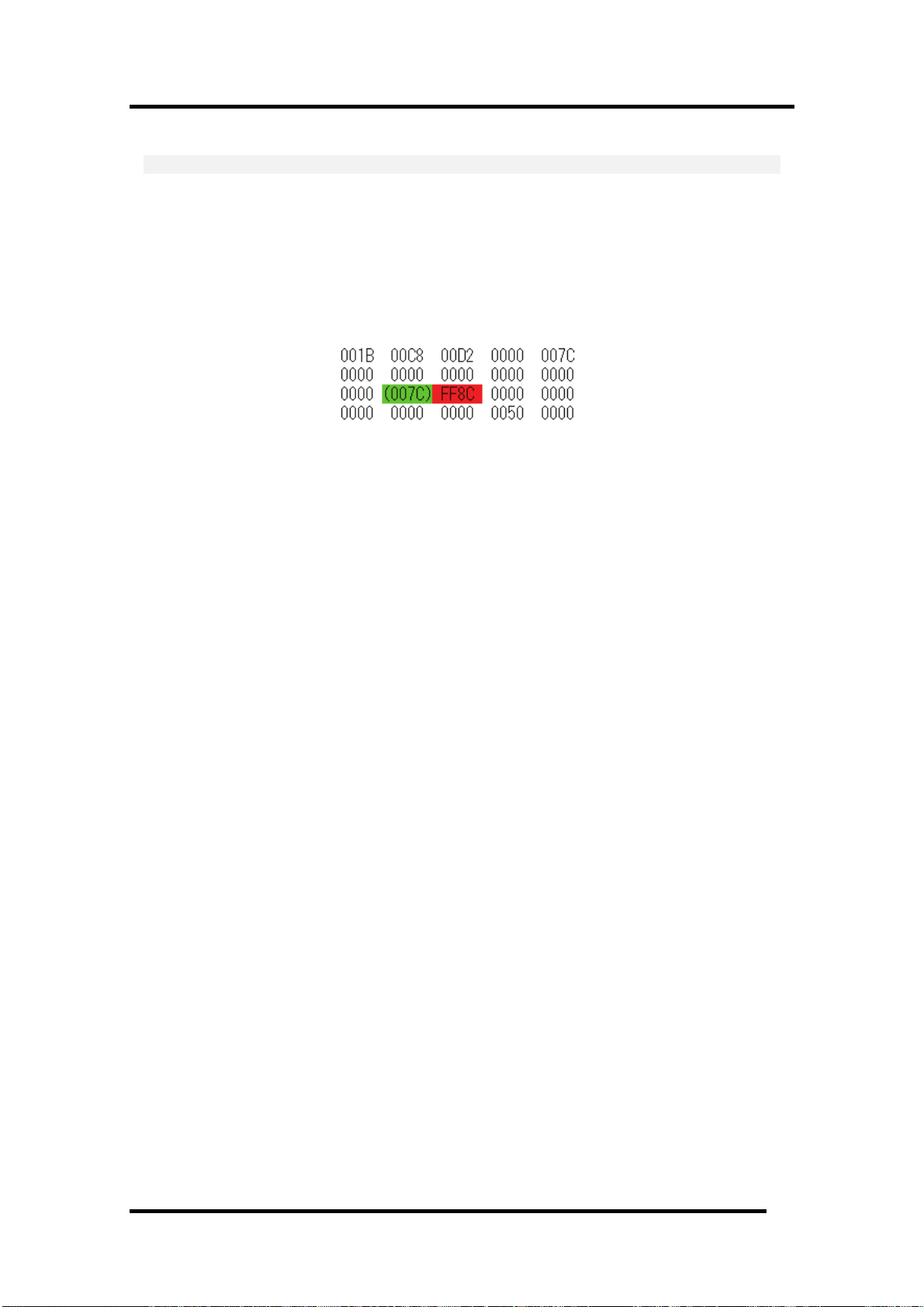

because of conflict with other devices, please follow the procedure of the setting described below.