Page 1

USER’S MANUAL

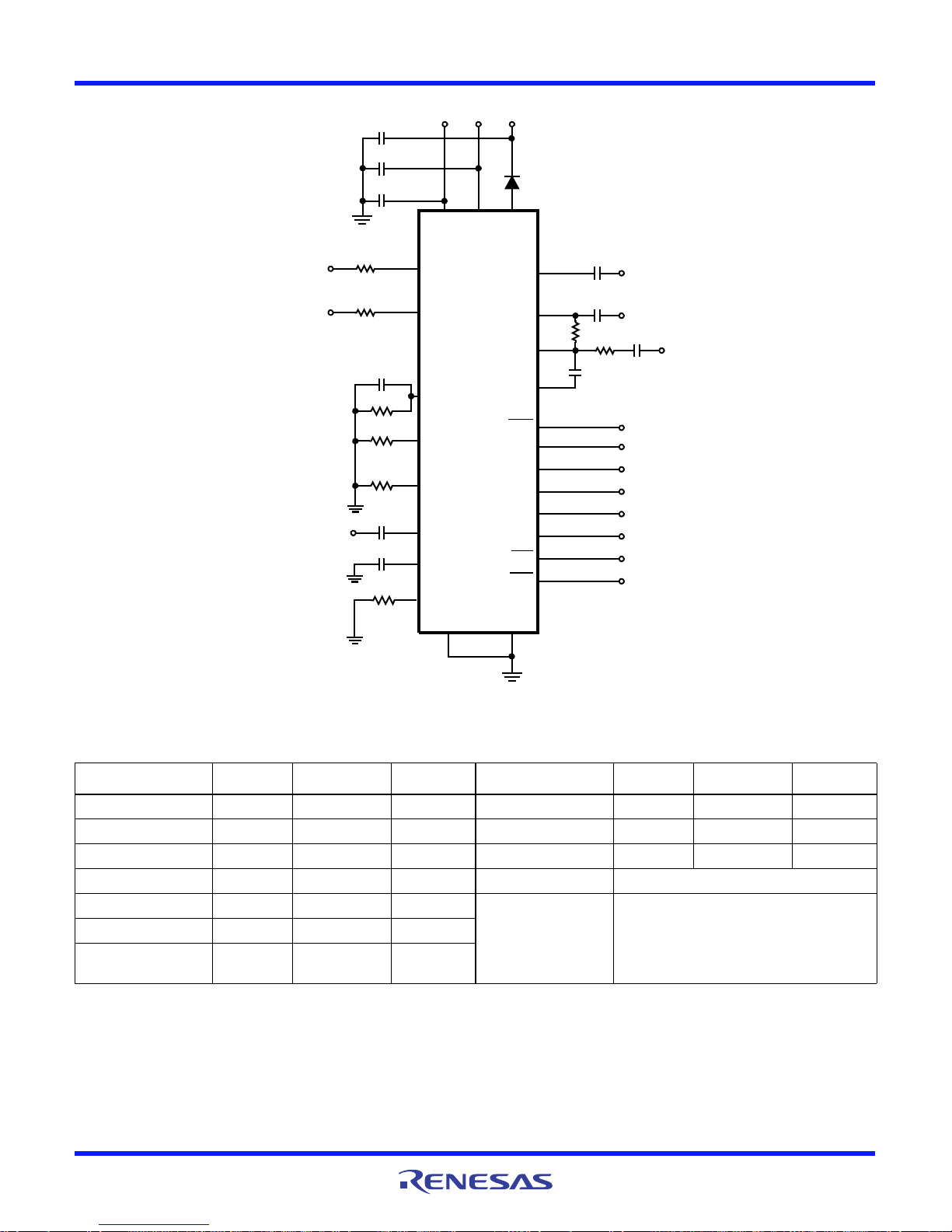

FIGURE 1. EVALUATION BOARD SILK SCREEN

ISL5585XEVAL Evaluation Board User’s Guide

Introduction

The ISL55185XEVAL1 board can be used to evaluate the new

ISL5585 3.3volt SLIC. This platform supports the evaluation of

the performance of the ISL5585 at 3.3 volts with a 5 volt

CODEC. The lab data presented in this application note had

the following supplies voltages: Vcc (ISL5585) = 3.3V,

Vcc (CODEC) = 5V, VBH = -100v and Vbl = -24v.

The ISL5585XEVAL1 evaluation board provides a complete

evaluation system for the ISL5585 family of ringing SLICs.

Included on the evaluation board is a single +5V CODEC for

line circuit evaluations and on board logic for stand alone

operation. The evaluation boards have been designed to

support back to back operation, providing further insight to

the complete signal path and solution.

The transient behavior of the ISL5585 in response to mode

changes has been improved. The benefit to the application

is reduction or more likely elimination of DET

off hook events occur.

Voltage ratings for external components have been selected

based on 100V device operation, therefore compatibility to

lower voltage versions is guaranteed.

glitches when

AN1038

Rev 0.00

Sep 2002

Getting Started

Your evaluation kit should contain application note AN1038

and the following hardware.

1. One

2. One ISL5585X device sample, already in board.

3. One PLCC extraction tool.

4. One cable assembly with multi colored conductors.

5. One cable assembly with solid white conductors.

The evaluation board should have the same appearance as

the silk screen shown in Figure 1.

ISL5585XEVAL1evaluation board.

Applying Power to the Evaluation Board

Here are a few safeguards with power sequencing until you

are accustomed to using the high voltages required by the

devices.

1. Limit the current on all power supplies to 100mA.

2. Turn on the power supplies after the power cables are

attached to the evaluation boards.

AN1038 Rev 0.00 Page 1 of 14

Sep 2002

Page 2

ISL5585

APP CKT

CODEC

APP CKT

CLOCK GENERATION & MUX

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

JP9

JP10

JP11

JP12

J1

J2

J3

J4

J5 J6

J9

J10

J13

J14

J7 J8

J11

J12

J15

S1 S2 S3 S4 S5 S6

FIGURE 2. EVALUATION BOARD FUNCTIONAL DIAGRAM

Evaluation Board Functional Description

Evaluation Board Jumper Definitions

JUMPER DESCRIPTION

JP1 Connects SW- directly to the device Ring terminal of device. Used in conjunction with external load D

JP2 Connects SW+ through test load to the Tip terminal of device. Used in conjunction with external load D

JP3 Not used. Leave open.

JP4 Connects the receive output of the CODEC (U6) to the device receive input -IN. Path is AC coupled with C

JP5 Position1, CODEC: Connects the CODEC receive output to the device ringing input. Path is AC coupled by C

Position 2, EXT: Connects the VRS connector J9 to the device ringing input. Path is AC coupled by C

Position 3 TRAP: Connects the VRS connector J9 thru RC network to the device ringing input. Path is AC coupled.

JP6 Connects the device transmit output VTX to the CODEC amplifier for transhybrid balance. Path is AC coupled by C

JP7 Connects the receive output of CODEC to transhybrid amplifier, AC coupled by C

JP8 Inserting jumper sets the CODEC to A-law coding. Open sets the CODEC to -law coding.

JP9 Inserting jumper powers down the CODEC. Open provides normal CODEC operation.

JP10 Position 1: Sets the CODEC master clock to 2.048MHz.

Position 2: Sets the CODEC master clock to 512kHz

Position 3: Sets the CODEC master clock to 256kHz.

JP11 Enables the on board logic multiplexer. Should be installed for single board or back to back evaluations. Remove when driving

BNCs J10 thru J13.

JP12 Inserting jumper selects on board clock and frame sync generator. Insert to configure board as master for back to back

evaluations or for single board evaluations. Remove to configure board as slave for back to back evaluations.

. Normally inserted for proper operation.

1

and RTA.

TA

and RTA.

TA

.

RS

.

IN

RS

.

.

TX

AN1038 Rev 0.00 Page 2 of 14

Sep 2002

Page 3

Test Points

Each connector interface to the evaluation board has a test

point. All test points are DC coupled and should be guarded

against ground shorts. High impedance test inputs, such as

oscilloscopes or DVMs, should be used to monitor these

points. Unused BNC connections also provide convenient test

point access.

Toggle Switches

The six toggle switches, S1 thru S6, interface directly to the

ISL5585 device. Positioning any switch towards the top of the

board is a logic “1”. Positioning any switch towards the bottom

of the board is a logic “0”. All switches are labeled with the

control signal names.

The switch E0 selects the switch hook (E0 = 1) or the ground

key detector (E0 = 0) to appear at DET

device overrides E0 and sends the ring trip detector to DET

The switched labeled SWC

turns on the uncommitted switch

when set to a logic low. The battery select signal BSEL, selects

the high battery when set to logic high. The operating modes

for the ISL5585 device are provided in Table 1.

. During ringing, the

.

OPERATING MODE F2 F1 F0

Low Power Standby 0 0 0

Forward Active 0 0 1

Unused 0 1 0

Reverse Active 0 1 1

Ringing 1 0 0

Forward Loop Back (Note) 1 0 1

Tip Open 1 1 0

Power Denial 1 1 1

NOTE: The ISL5585 device should always operate from low battery

voltage when using the Forward Loop Back mode.

Refer to the device electrical data sheet for detailed

descriptions regarding each operating mode according to the

device under evaluation.

Evaluation Board Connector Descriptions

CONNECTOR DESCRIPTION

TABLE 1. ISL5585 OPERATING MODES

J1 RJ11 type phone connector.

J2 Ring terminal of board.

J3 Tip terminal of board.

J4 Grounding lug connected to board ground plane.

J5 1: V

J6 Identical pinout as J5. Either connector provides daisy chain connection to second board for back to back evaluation.

J7 Transmit analog output from ISL5585 device, VTX. This path is AC coupled by C

J8 Receive analog input to ISL5585 device, VREC. This path is AC coupled by C

J9 Ringing input to ISL5585 device, VRS. This path is AC coupled by C

J10 Serial transmit data output of CODEC U6.

J11 Serial receive data input to CODEC U6.

J12 Common frame sync input for receive and transmit digital data.

J13 Common clock for CODEC data transfer and conversion.

. Positive 5V supply to CODEC U6, clock generator U5 and logic devices U2 thru U4 (red wire).

CC

2: V

. High negative battery supply to the ISL5585 device (orange wire).

BH

3: V

. Low negative battery supply to the ISL5585 device (yellow wire).

BL

4: +5V. Positive 5V supply to the ISL5585 device and LEDs (green wire).

7 thru 10: GND. Twisted pair returns for external supply connections (black wires).

.

TX

.

IN

.

RS

J14 20 pin, 100 mil spacing header with all digital PCM data interfaces to CODEC U6.

J15 20 pin, 100 mil spacing header with all digital interfaces to ISL5585 device.

AN1038 Rev 0.00 Page 3 of 14

Sep 2002

Page 4

ISL5585

APP CKT

CODEC

APP CKT

CLOCK GENERATION & MUX

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

JP9

JP10

JP11

JP12

J1

J2

J3

J4

J5 J6

J9

J10

J14

J7 J8

J11

J12

J15

S1 S2 S3 S4 S5 S6

FIGURE 3. STAND ALONE CONNECTORS AND JUMPERS

5

FIGURE 4. TEST LOAD SWITCHING

RING

TIP

R

TA

D

TA

SW+

SW-

SWC

JP1

JP2

Stand Alone Configuration

Description

The standalone configuration supports any measurement of

the ISL5585 device. With all the jumper locations open, the

device is totally isolated from all other active circuitry on the

evaluation board. All other circuitry is powered, but does not

interfere with proper SLIC operation.

Power Supply Connections

Power should be applied to the evaluation board using the

primary power cable. Either J5 or J6 may be used. Prior to

applying power, the voltage setting of each supply should be

verified. The power supplies should be turned off while mating

the primary power cable to the evaluation board.

Jumper Settings

All jumper positions should be open for the stand alone

configuration.

Measurement Capability

Nearly all AC and DC parameters of the device can be

measured using this configuration. The device has been

socketed to allow easy measurements of more than a single

device. An extraction tool has been included with the evaluation

kit and should be used to remove the device from the socket.

The typical device measurements are listed below.

Status LEDs

The status LEDs DET and ALM are active for the stand alone

configuration. DET

should only light when a DC current path

exists from Tip to Ring or during forward loop back. ALM

should only light during forward loop back operation. Normal

device evaluations should not cause the ALM

indicator to light.

Uncommitted Switch Jumpers

When the jumpers JP1 and JP2 are installed, the uncommitted

switch is connected across Tip and Ring. The test load of D

and R

the uncommitted switch is turned on. The DC load will result in

DET

below.

will connect across the Tip and Ring terminals when

TA

transitioning to a logic low. The circuit diagram is shown

TA

1. Power supply current per operating mode.

2. Tip and Ring DC voltages per operating mode.

3. On hook AC gains G

4. Off hook AC gains G

5. Other AC parameters such as longitudinal balance.

AN1038 Rev 0.00 Page 4 of 14

Sep 2002

, G24 and G44.

42

, G24 and G44.

42

Socket Removal

The surface mount socket for the ISL5585 device has the

same solder foot print as the PLCC package. Therefore, the

socket may be removed for more extensive characterization.

Page 5

G

4-2

=

V

2W

V

IN

------------ = 2

R

S

R

IN

----------

Z

L

ZLZO+ + 2

RP

---------------------------------------- 2

Z

L

ZLZL+

--------------------

R

S

R

IN

----------==

G

24

Z

O

ZO2RPZ

L

++

---------------------------------------

–=

G

44G42

G

24

R

S

R

IN

----------

–

Z

O

ZL2RPZ

O

++

---------------------------------------

==

Stand Alone Configuration Typical Measurements

Supply Currents (milli amps) - On Hook

OPERATING MODE F2, F1, F0 E0 SWC BSEL

ICC

(Vcc= 3.3v)

IBH

(Vbh= -100v)

(Vbl = -24v)

Low Power Standby 0, 0, 0 x 1 1 2.9 0.6 0.3

Forward Active 0, 0, 1 x 1 0 3.7 0 1.2

Unused 0, 1, 0 n/a n/a n/a n/a n/a n/a

Reverse Active 0, 1, 1 x 1 0 3.7 0 1.2

Ringing 1, 0, 0 x 1 1 5.6 1.5 0.7

Forward Loop Back 1, 0, 1 x 1 0 11.9 0 20

Tip Open 1, 1, 0 x 1 1 2.9 0.6 0.3

Power Denial 1, 1, 1 x 1 x 3.3 0 0.2

Tip and Ring Voltages (Volts) - On Hook

OPERATING MODE F2, F1, F0 E0 SWC BSEL TIP RING

Low Power Standby 0, 0, 0 x 1 1 -0.7 -52

Forward Active 0, 0, 1 x 1 0 -3.9 -17

Unused 0, 1, 0 n/a n/a n/a n/a n/a

Reverse Active 0, 1, 1 x 1 0 -17 -3.9

Ringing 1, 0, 0 x 1 1 -50 -50

IBL

Forward Loop Back 1, 0, 1 x 1 0 -3.9 -17

Tip Open 1, 1, 0 x 1 1 Float -52

Power Denial 1, 1, 1 x 1 x Float Float

AC Gains (dB), Off Hook, 600 Termination - Forward and Reverse Active Only

OPERATING MODE F2, F1, F0 E0 SWC BSEL G

42

Forward Active 0, 0, 1 x 1 0 0.0 -7.3 -7.3

Reverse Active 0, 1, 1 x 1 0 0.0 -7.3 -7.3

AC Gain Equations G

42

G

24

G

44

G

24

G

44

AN1038 Rev 0.00 Page 5 of 14

Sep 2002

Page 6

ISL5585

APP CKT

CODEC

APP CKT

CLOCK GENERATION & MUX

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

JP9

JP10

JP11

JP12

J1

J2

J3

J4

J5 J6

J9

J10

J13

J14

J7 J8

J11

J12

J15

S1 S2 S3 S4 S5 S6

100 x11

FIGURE 5. RINGING CONNECTORS AND JUMPERS

Ringing Configuration

Description

The ringing configuration supports full evaluation of the ringing

capability of the ISL5585 device. The evaluation board design

does not include a 20Hz digital code generator, therefore, all

ringing waveforms will be sourced by external test equipment.

Power Supply Connections

Power should be applied to the evaluation board using the

primary power cable. Either J5 or J6 may be used. Prior to

applying power, the voltage setting of each supply should be

verified. The power supplies should be turned off while mating

the primary power cable to the evaluation board.

Jumper Settings

The jumper JP5 provides three positions for different ringing

techniques.

TABLE 2. JP5 JUMPER POSITIONS

JP5 POSN DESCRIPTION

CODEC Connects the CODEC receive output to the device

ringing input. Signal path is AC coupled.

EXT Connects the VRS connector J9 to the device ringing

input. Signal path is AC coupled.

TRAP Connects the VRS connector J9 thru RC network to

the device ringing input. Signal path is AC coupled.

CODEC Ringing

Most test equipment designed to evaluate the CODEC PCM

interface are capable of output frequencies as low as 20Hz. If

such a piece of equipment is available, then CODEC ringing

can be evaluated. The digital interface to the CODEC would be

AN1038 Rev 0.00 Page 6 of 14

Sep 2002

provided by the BNC connectors J10 thru J13. Verify JP11 is

open prior to driving signals into the BNC connectors. An

output level of 0dBm from the CODEC will provide full scale

ringing when operating from -100V battery.

External Ringing Source

Using an external function generator at J9 provides the most

control of the ringing waveform. The flexibility of the ringing

interface can be fully exercised by the function generator. To

evaluate DC offsets during ringing, the capacitor C

RS

must be

shorted. Most functions generators provide DC offset as part of

the output waveform. Positive DC offsets on VRS move Tip

towards ground and Ring towards battery.

Trapezoidal Ringing

A logic level square wave, at J9, with 50% duty cycle will be

shaped by the components R

jumper position is selected. The components shipped with the

evaluation board will result in a 75V

waveform when operating from a -100V battery.

Ring Trip Control

Three very distinct actions occur when the devices detects a

ring trip. First, the DET

output is latched low. The latching

mechanism eliminates the need for software filtering of the

detector output. The latch is cleared when the operating mode

is changed externally. Second, the VRS input is disabled,

removing the ring signal from the line. Third, the device is

internally forced to the forward active mode. The low battery is

not automatically selected upon ring trip.

TRAP

and C

RMS

when this

TRAP

trapezoidal ringing

Page 7

ISL5585

APP CKT

CODEC

APP CKT

CLOCK GENERATION & MUX

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

JP9

JP10

JP11

JP12

J1

J2

J3

J4

J5 J6

J9

J10

J13

J14

J7 J8

J11

J12

J15

S1 S2 S3 S4 S5 S6

010 x10

FIGURE 6. DIGITAL LOOP BACK CONNECTORS AND JUMPERS

FIGURE 7. DIGITAL LOOP BACK SIGNAL FLOW

JP6

TIP

RING

-IN

VTX -2

PO-

DR

DT

TG

ISL5585 CODEC

J14

VREC (J8)

JP4

600

R

IN

Digital Loop Back Configuration

Description

The digital loop back configuration verifies the interface and

operation of the ISL5585 device and the CODEC. This

configuration provides a self test to verify proper operation of

the board. In addition, it provides a complete digital loop,

allowing analog control of the digital input and output of the

CODEC. Forward active and reverse active or teletax will

support the digital loop back configuration.

Power Supply Connections

Power should be applied to the evaluation board using the

primary power cable. Either J5 or J6 may be used. Prior to

applying power, the voltage setting of each supply should be

verified. The power supplies should be turned off while mating

the primary power cable to the evaluation board.

Jumper Settings

All jumper settings and functions are described below.

TABLE 3. DIGITAL LOOP BACK JUMPER POSITIONS

JUMPER DESCRIPTION

JP6 Connects the device transmit output VTX to the

JP10, POSN 2 Sets the CODEC master clock to 512kHz.

JP11 Enables the on board logic multiplexer.

JP12 Inserting jumper selects on board clock and frame

J14, POSN 1 Connects the CODEC digital output DT to digital

AN1038 Rev 0.00 Page 7 of 14

Sep 2002

CODEC amplifier for transhybrid balance.

sync generator.

input DR.

Signal Flow

Driving a signal at VREC, J8, will result in a signal from the

CODEC receive output when the ISL5585 device is terminated

at Tip and Ring. The following diagram shows the signal path

formed by the jumpers and terminated SLIC.

With VREC input signal level of 0.775V

0.337V

with 600. The signal level at VTX is determined by the 4-wire

to 4-wire gain, G

not connected, therefore, the digitized signal level at the

should result at the VTX output when terminated

RMS

, of the ISL5585. The transhybrid balance is

44

CODEC will be approximately 0.674V

transfer functions are set for unity gain, therefore the signal

level at PO- should be approximately 0.674V

The signal levels for digital loop back are independent of the

clock selected by JP10.

Refer to the device electrical data sheet for the design

equations for the 4-wire to 4-wire gain as a function of

termination and synthesized impedance.

, a signal level of

RMS

. The CODEC

RMS

RMS

.

Page 8

ISL5585

APP CKT

CODEC

APP CKT

CLOCK GENERATION & MUX

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

JP9

JP10

JP11

JP12

J1

J2

J3

J4

J5 J6

J9

J10

J13

J14

J7 J8

J11

J12

J15

S1 S2 S3 S4 S5 S6

010 x10

FIGURE 8. PCM4 CONNECTORS AND JUMPERS

PCM4 Configuration

Description

The PCM4 configuration verifies the AC transmission of the

ISL5585 and CODEC. Any piece of test equipment capable of

PCM testing with digital and analog interfaces can be used in

this configuration.

Power Supply Connections

Clock and Frame Sync

The clock and frame sync signals are driven at connectors J13

and J12 respectively. The clock input is common to the MCLK,

BCLKT and BCLKR of the CODEC. The frame sync input is

common to the receive and transmit frame syncs, FSR and

FST, of the CODEC. These connections define synchronous

mode of operation.

Power should be applied to the evaluation board using the

primary power cable. Either J5 or J6 may be used. Prior to

applying power, the voltage setting of each supply should be

verified. The power supplies should be turned off while mating

the primary power cable to the evaluation board.

Jumper Settings

All jumper settings are described below.

TABLE 4. PCM4 JUMPER POSITIONS

JUMPER DESCRIPTION

JP4 Connects the receive output of the CODEC (U6) to

JP6 Connects the device transmit output VTX to the

JP7 Connects the receive output of CODEC to

JP8 Inserting jumper set the CODEC to A-law coding.

the device receive input -IN through R

path is AC coupled.

CODEC amplifier for transhybrid balance. Signal

path is AC coupled.

transhybrid amplifier, AC coupled by C1.

Open sets the CODEC to -law coding. This must

match PCM test equipment coding scheme for

proper operation.

. Signal

IN

Digital to Analog

The receive signal path is defined from the CODEC PCM input

to the ISL5585 Tip and Ring outputs. The PCM4 tester is

capable of driving digital test signals on the PCM bus and

measuring the resultant signal at Tip and Ring. With this type of

capability, the full receive path can be evaluated. Typical

performance measurements include overall loss, gain variation

versus frequency, gain versus signal level and 2-wire return loss.

In addition fidelity measurements such as idle channel noise and

distortion are also performed.

Analog to Digital

The transmit signal path is defined from ISL5585 Tip and Ring

interface to the CODEC PCM output. The same tests

performed for the receive path also apply to the transmit path.

Digital to Digital

The digital to digital path is from the CODEC PCM input to the

CODEC PCM output. This signal path provides a measure of

the transhybrid balance for the line circuit. Most other AC

performance metrics are base on analog to digital or digital to

analog measurements. For proper transhybrid measurements,

verify jumper JP7 is inserted.

AN1038 Rev 0.00 Page 8 of 14

Sep 2002

Page 9

+1.5

+1.0

+0.0

-1.0

-1.5

200 1000 2000 3000 3600

MODE A 33 VAR. GAIN/FRE. TX:

RX

TS

0

RESULT

dB

TX: TS 0 +0.00 dBm0 201Hz

=100Hz

D-D

A-D

A-A

RX: -0.dBr

FREQ.

SWP/S

D-A

MODE A 33 VAR. GAIN/FRE. TX: +0.0 RX: dBr

+1.5

+1.0

0

RESULT

dB

TX: TS 0

+0.00

dBm0

201Hz

= 100Hz

A-A

D-A

D-D

RX:

TS

+0.0

-1.0

-1.5

200 1000 2000 3000 3600

FREQ.

SWP/S

A-D

MODE A 43 VAR. GAIN/LEV. TX: RX: -0.0dBr

RX:

TS

0

RESULT

dB

TX:

MODIF.

+2.0

+1.0

+0.0

-1.0

-2.0

-55.0 -40.0

1014Hz

+0.0

TS 0 -55.0 = 2.0dB0dBM0

A-A

A-D

D-D

-20.0

LEVEL

SWP/S

D-A

MODE A 43 VAR. GAIN/LEV. TX: +0.0 RX: dBr

MODIF.

RX:

TS

0

RESULT

dB

TX: TS 0 0dBm0 1014Hz = 2.0dB-55.0

A-A

D-A

D-D

+2.0

+1.0

+0.0

-1.0

-2.0

-55.0 -40.0 -20.0 +0.0

LEVEL

SWP/S

A-D

MODE A 55 TOTAL DIST. TX: RX: 0.0dBr

RX:

TS

0

RESULT

dB

TX: TS 0 -55.0 0dBm0 1014Hz = 2.0dB

+44.0

+40.0

+30.0

+20.0

+14.0

A-A

A-D

D-D

-55.0 -40.0 -20.0 +0.0

LEVEL

SWP/S

D-A

MODE A 55 TOTAL DIST. TX: +0.0 RX: dBr

RX:

TS

0

RESULT

dB

TX: TS 0 -55.0 0dBm0 1014Hz = 2.0dB

D-D

D-A

A-A

A-D

SWP/S

LEVEL

+44.0

+40.0

+30.0

+20.0

+14.0

-55.0 -40.0 -20.0 +0.0

PCM4 Configuration Typical Measurements

FIGURE 9. DIGITAL TO ANALOG GAIN vs FREQUENCY FIGURE 10. ANALOG TO DIGITAL GAIN vs FREQUENCY

FIGURE 11. DIGITAL TO ANALOG GAIN vs LEVEL FIGURE 12. ANALOG TO DIGITAL GAIN vs LEVEL

FIGURE 13. DIGITAL TO ANALOG TOTAL DISTORTION FIGURE 14. ANALOG TO DIGITAL TOTAL DISTORTION

AN1038 Rev 0.00 Page 9 of 14

Sep 2002

Page 10

SECONDARY POWER CABLE

MASTER

SLAVE

FIGURE 15. BACK TO BACK CONNECTORS AND JUMPERS

010x11

01x1 00

0

Back to Back Configuration

Description

The back to back configuration connects two evaluation boards

together at the PCM interface. The PCM output data from one

board is the PCM input data to the other board. One board is

configured as a master for clock generation and the other is

configured as a slave. A secondary power cable provides daisy

chain power to the second evaluation board.

Power Supply Connections

Power should be applied to the evaluation board using the

primary power cable. Either J5 or J6 may be used. Prior to

applying power, the voltage setting of each supply should be

verified. The power supplies should be turned off while mating

the power cables to the evaluation boards.

Jumper Settings

All jumper settings are described below.

TABLE 5. MASTER BOARD JUMPER POSITIONS

JUMPER DESCRIPTION

JP4 Connects the receive output of the CODEC (U6) to

the device receive input -IN through R

JP6 Connects the device transmit output VTX to the

CODEC amplifier for transhybrid balance.

JP7 Connects the receive output of CODEC to

JP10, POSN 2 Sets the CODEC master clock to 512kHz.

JP11 Enables the on board logic multiplexer.

JP12 Configures board as master.

transhybrid amplifier, AC coupled by C1.

.

IN

TABLE 6. SLAVE BOARD JUMPER POSITIONS

JUMPER DESCRIPTION

JP4 Connects the receive output of the CODEC (U6) to

the device receive input -IN through R

JP6 Connects the device transmit output VTX to the

CODEC amplifier for transhybrid balance.

JP7 Connects the receive output of CODEC to

transhybrid amplifier, AC coupled by C1.

JP11 Enables the on board logic multiplexer.

.

IN

In this configuration the master board provides the clock and

frame sync to the slave board. The selection of the clock rate is

arbitrary and may be any of the available frequencies.

The ribbon cable used to connect the two boards at J14 also

connects the ground planes of the two evaluation boards.

Having returns adjacent to the high speed clock edges is

critical to reducing board level noise.

If transmission quality is poor verify both master and slave

boards are set up for same coding scheme, JP8. In addition,

verify the transhybrid jumper, JP7, is inserted in both boards. If

signal quality still does not improve, verify JP12 of the slave

board is not populated.

Analog to Analog Verification

The back to back configuration verifies the complete signal

path of two evaluation boards. Full duplex transmission is

provided from one Tip and Ring interface to the other. Both

ISL5585 devices do not have to be in the same transmission

mode (forward, reverse or teletax) for proper back to back

operation.

AN1038 Rev 0.00 Page 10 of 14

Sep 2002

Page 11

AUX

VRS

TIP

VFB

BGNDAGND

VCC

RING

VTX

-IN

VBL

VBH

SW+

SW-

BSEL

SH

RT

CDC

ILIM

E0

F2

F1

F0

DET

ALM

ISL5585

V

CC

POL

SWC

C

IN

C

RS

C

TX

R

IL

C

FB

R

S

R

SH

C

RT

R

RT

D1

C

POL

C

PS1

C

DC

C

PS3

C

PS2

U1

R

P1

R

P2

FIGURE 16. ISL5585 BASIC APPLICATION CIRCUIT

TL

R

TL

R

IN

DC, CFB

, C

PS3

PS1

PS2

1

0.5W,

matched to 0.1.

4.7F 20% 10V

0.1F 20% >100V

0.1F 20% 100V

1N400X type with breakdown > 100V.

Protection resistor values are application

dependent and will be determined by

protection requirements. Standard

applications will use 50 per side.

Basic Application Circuit Component List

COMPONENT VALUE TOLERANCE RATING COMPONENT VALUE TOLERANCE RATING

U1 - Ringing SLIC ISL5585 N/A N/A C

R

RT

R

SH

R

IL

R

S

R

TL

CIN, CRS, CTX, CRT,

C

POL

Design Parameters: Ring Trip Threshold = 90mA

I

SOURCE

and Ring terminals = 603.

= 100mA, I

20k 1% 0.1W C

49.9k 1% 0.1W C

71.5k 1% 0.1W D

66.5k 1% 0.1W RP1, RP2 = 50

17.8k 1% 0.1W

0.47F 20% 10V

= 120mA, Synthesize Device Impedance = 66.5K/133.3 = 500, with 51 protection resistors, impedance across Tip

SINK

. Switch Hook Threshold = 12mA, Loop Current Limit = 24.6mA, Transient current limit:

PEAK

AN1038 Rev 0.00 Page 11 of 14

Sep 2002

Page 12

AN1038 Rev 0.00 Page 12 of 14

Sep 2002

Evaluation Board Schematic

J5

J5

J5

J5

J5

J5

J5

J5

J5

J5

J6

J6

J6

J6

J6

J6

J6

J6

J6

J6

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

V

CC

+5V

+5V VBL VBH

CR3

JP3

CPS5

VREC

VXMIT

JP4

CODEC

CIN

CRS

1

3

5

2

4

6

CODEC

EXT

TRAP

JP7

THB

RTRAP

VRS

CTRAP

C1

CPS3

J5

TIP

J2

RING

J4

TIP

RING

J1

R14

+

-

CR4

CPS4

JP2

DTA

JP1

R15

RTA

1

28

5

6

25

27

26

CRT

RRT

RSH

RIL

+5V

+5V

CDC

+

CPOL

24

17

TIP

RING

SW+

SW-

TD

SH

ILIM

CDC

POL

AGND BGND

ALM

DET

BSEL

AUX

VRS

+5V

VBLVBH

ISL5585

VTX

-IN

VFB

SWC

E0

F0

F1

F2

NC

23 3 4

19

18

20

22

21

7

1

10

9

8

16

15

12

13

CTX

RS

RP CP

CFB

214

R1

CR1

R2

+5V

ALM

CR2

DET

BSEL

2

2

2

2

2

2

3

3

3

3

3

3

1

1

1

1

1

1

S6

S1

S2

S3

S4

S5

F2 F1

F2

E0 SWCF0

15 1 10

11

14

5

4

P

L

CP

U

/D

CE

P0 P1 P2 P3

Q1

Q2

Q3

TC

RC

GND = 8, V

CC

= 16

V

CC

3

2

6

7

12

13

FS_CNT

CE

U/D

CP

PL

P0 P1 P2 P3

Q0

Q1

Q2

Q3

TC

RC

V

CC

4

5

14

11

15 1 10 9

3

2

6

7

12

13

U2

74HC191M

GND = 8, VCC = 16

2.048MHz

512kHz

256kHz

JP10

1

3

5

2

4

6

V

CC

14

X0-43B

V

CC

U5

OUT

GND

8

7

C5 C6

JP12

MASTER

JP11

B2B

115

13

14

10

11

6

5

3

2

FS_IN

CLK_IN

DR_IN

110

111

210

211

310

311

410

411

SOE

4Y

3Y

2Y

1Y

CLK_OUT

FS_OUT

DT_OUT4

7

9

12

U4

74HC257M

R12

R13

VAG

R4

R3

R5

R6

R7

R8

15

JP9

PD

R11

R10

DR

DT

FS

J13

J12

J11

C2

0.1F6

CPS2

CPS1

1

3

5

7

9

11

13

15

17

19

ALM

DET

BSEL

F2

F1

F0

E0

SWC

R0+

R0-

P0-

P1

P0+

TC

TI-

VAC

TI+

V

DD

V

SS

0R

DT

FST

FSR

BCLKR

BCLKT

MCLK

_PCI

/A

1

2

3

4

5

17

18

19

20

JP8

A-LAW

U6

MC145484

8

13

7

14

9

12

11

16

10

9

Q0

2

4

6

8

10

12

14

16

18

20

V

CC

V

CC

V

CC

V

CC

J15

J8

J7

J10

CLK

C4

R9

1

3

5

7

9

11

13

15

17

19

DT_OUT

FS_OUT

CLK_OUT

2

4

6

8

10

12

14

16

18

20

J14

DR_IN

CLK_IN

FS_IN

DR_N

U2

74HC191M

TL

RTL

RIN

Page 13

ISL5585XEVAL1 Electrical Component List

COMPONENT VALUE TOLERANCE RATING COMPONENT VALUE TOLERANCE RATING

U

- Ringing SLIC HC5518x N/A N/A R3, R

1

U2, U

U

4

U

5

U

6

RRT, R

R

SH

R

IL

R

TA

R

S

R

P

R

, R

1

R

IN

3

TRAP

2

74HC191M N/A N/A R5, R6, R8, R9,

74HC257M N/A N/A R14, R15 51 5%, picked to

XO-43B N/A N/A CRT, CIN, CRS,

MC145484DW N/A N/A CDC, CFB 4.7F 20% 20V

20k 1% 0.10W CPS1, CPS2,

49.9k 1% 0.10W C2, C3, C4, C5, C6 0.1F 20% 20V

71.5k 1% 0.10W CR3 DL4003CT-ND N/A N/A

100 1% 0.25W DTA BAS21ZXCT N/A N/A

66.5k 1% 0.10W CR1, CR2 LN1251C N/A N/A

0 1% 0.10W R4 44.2k 1% 0.10W

499 1% 0.10W RTL 17.8k 1% 0.10W

66.5k 1% 0.10W

7

R10, R11, R12,

R13

CTX, C1, CPOL,

CTRAP

CPS3, CPS4,

CPS5

100k 1% 0.10W

10k 1% 0.10W

0.1

0.47F 20% 20V

0.1F 20% 100V

0.50W

ISL5585XEVAL1 Mechanical Component List

COMPONENT VALUE TOLERANCE RATING COMPONENT VALUE TOLERANCE RATING

U

- Socket 822271-1 N/A N/A J14, J15 10 Pin Header N/A N/A

1

U

Socket IC51-0202-347 N/A N/A J2, J3, J4 39F893 N/A N/A

6

J5, J6 43045-1000 N/A N/A JP5, JP10 3 Pin Header N/A N/A

J1 555165-1 N/A N/A JP1, JP2, JP3, JP4,

J7, J8, J9, J10, J11,

J12, J13

JP6, JP7, JP8, JP9,

JP11, JP12

CBJR20 N/A N/A S1, S2, S3, S4, S5,

S6

1 Pin Header

65F1681 N/A N/A

AN1038 Rev 0.00 Page 13 of 14

Sep 2002

Page 14

http://www.renesas.com

Refer to "http://www.renesas.com/" for the latest and detailed information.

Renesas Electronics America Inc.

1001 Murphy Ranch Road, Milpitas, CA 95035, U.S.A.

Tel: +1-408-432-8888, Fax: +1-408-434-5351

Renesas Electronics Canada Limited

9251 Yonge Street, Suite 8309 Richmond Hill, Ontario Canada L4C 9T3

Tel: +1-905-237-2004

Renesas Electronics Europe Limited

Dukes Meadow, Millboard Road, Bourne End, Buckinghamshire, SL8 5FH, U.K

Tel: +44-1628-651-700, Fax: +44-1628-651-804

Renesas Electronics Europe GmbH

Arcadiastrasse 10, 40472 Düsseldorf, Germany

Tel: +49-211-6503-0, Fax: +49-211-6503-1327

Renesas Electronics (China) Co., Ltd.

Room 1709 Quantum Plaza, No.27 ZhichunLu, Haidian District, Beijing, 100191 P. R. China

Tel: +86-10-8235-1155, Fax: +86-10-8235-7679

Renesas Electronics (Shanghai) Co., Ltd.

Unit 301, Tower A, Central Towers, 555 Langao Road, Putuo District, Shanghai, 200333 P. R. China

Tel: +86-21-2226-0888, Fax: +86-21-2226-0999

Renesas Electronics Hong Kong Limited

Unit 1601-1611, 16/F., Tower 2, Grand Century Place, 193 Prince Edward Road West, Mongkok, Kowloon, Hong Kong

Tel: +852-2265-6688, Fax: +852 2886-9022

Renesas Electronics Taiwan Co., Ltd.

13F, No. 363, Fu Shing North Road, Taipei 10543, Taiwan

Tel: +886-2-8175-9600, Fax: +886 2-8175-9670

Renesas Electronics Singapore Pte. Ltd.

80 Bendemeer Road, Unit #06-02 Hyflux Innovation Centre, Singapore 339949

Tel: +65-6213-0200, Fax: +65-6213-0300

Renesas Electronics Malaysia Sdn.Bhd.

Unit 1207, Block B, Menara Amcorp, Amcorp Trade Centre, No. 18, Jln Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia

Tel: +60-3-7955-9390, Fax: +60-3-7955-9510

Renesas Electronics India Pvt. Ltd.

No.777C, 100 Feet Road, HAL 2nd Stage, Indiranagar, Bangalore 560 038, India

Tel: +91-80-67208700, Fax: +91-80-67208777

Renesas Electronics Korea Co., Ltd.

17F, KAMCO Yangjae Tower, 262, Gangnam-daero, Gangnam-gu, Seoul, 06265 Korea

Tel: +82-2-558-3737, Fax: +82-2-558-5338

SALES OFFICES

© 2018 Renesas Electronics Corporation. All rights reserved.

Colophon 7.0

(Rev.4.0-1 November 2017)

Notice

1. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of semiconductor products and application examples. You are fully responsible for

the incorporation or any other use of the circuits, software, and information in the design of your product or system. Renesas Electronics disclaims any and all liability for any losses and damages incurred by

you or third parties arising from the use of these circuits, software, or information.

2. Renesas Electronics hereby expressly disclaims any warranties against and liability for infringement or any other claims involving patents, copyrights, or other intellectual property rights of third parties, by or

arising from the use of Renesas Electronics products or technical information described in this document, including but not limited to, the product data, drawings, charts, programs, algorithms, and application

examples.

3. No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights of Renesas Electronics or others.

4. You shall not alter, modify, copy, or reverse engineer any Renesas Electronics product, whether in whole or in part. Renesas Electronics disclaims any and all liability for any losses or damages incurred by

you or third parties arising from such alteration, modification, copying or reverse engineering.

5. Renesas Electronics products are classified according to the following two quality grades: “Standard” and “High Quality”. The intended applications for each Renesas Electronics product depends on the

product’s quality grade, as indicated below.

"Standard": Computers; office equipment; communications equipment; test and measurement equipment; audio and visual equipment; home electronic appliances; machine tools; personal electronic

equipment; industrial robots; etc.

"High Quality": Transportation equipment (automobiles, trains, ships, etc.); traffic control (traffic lights); large-scale communication equipment; key financial terminal systems; safety control equipment; etc.

Unless expressly designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas Electronics document, Renesas Electronics products are

not intended or authorized for use in products or systems that may pose a direct threat to human life or bodily injury (artificial life support devices or systems; surgical implantations; etc.), or may cause

serious property damage (space system; undersea repeaters; nuclear power control systems; aircraft control systems; key plant systems; military equipment; etc.). Renesas Electronics disclaims any and all

liability for any damages or losses incurred by you or any third parties arising from the use of any Renesas Electronics product that is inconsistent with any Renesas Electronics data sheet, user’s manual or

other Renesas Electronics document.

6. When using Renesas Electronics products, refer to the latest product information (data sheets, user’s manuals, application notes, “General Notes for Handling and Using Semiconductor Devices” in the

reliability handbook, etc.), and ensure that usage conditions are within the ranges specified by Renesas Electronics with respect to maximum ratings, operating power supply voltage range, heat dissipation

characteristics, installation, etc. Renesas Electronics disclaims any and all liability for any malfunctions, failure or accident arising out of the use of Renesas Electronics products outside of such specified

ranges.

7. Although Renesas Electronics endeavors to improve the quality and reliability of Renesas Electronics products, semiconductor products have specific characteristics, such as the occurrence of failure at a

certain rate and malfunctions under certain use conditions. Unless designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas

Electronics document, Renesas Electronics products are not subject to radiation resistance design. You are responsible for implementing safety measures to guard against the possibility of bodily injury, injury

or damage caused by fire, and/or danger to the public in the event of a failure or malfunction of Renesas Electronics products, such as safety design for hardware and software, including but not limited to

redundancy, fire control and malfunction prevention, appropriate treatment for aging degradation or any other appropriate measures. Because the evaluation of microcomputer software alone is very difficult

and impractical, you are responsible for evaluating the safety of the final products or systems manufactured by you.

8. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental compatibility of each Renesas Electronics product. You are responsible for carefully and

sufficiently investigating applicable laws and regulations that regulate the inclusion or use of controlled substances, including without limitation, the EU RoHS Directive, and using Renesas Electronics

products in compliance with all these applicable laws and regulations. Renesas Electronics disclaims any and all liability for damages or losses occurring as a result of your noncompliance with applicable

laws and regulations.

9. Renesas Electronics products and technologies shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited under any applicable domestic or foreign laws

or regulations. You shall comply with any applicable export control laws and regulations promulgated and administered by the governments of any countries asserting jurisdiction over the parties or

transactions.

10. It is the responsibility of the buyer or distributor of Renesas Electronics products, or any other party who distributes, disposes of, or otherwise sells or transfers the product to a third party, to notify such third

party in advance of the contents and conditions set forth in this document.

11. This document shall not be reprinted, reproduced or duplicated in any form, in whole or in part, without prior written consent of Renesas Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this document or Renesas Electronics products.

(Note 1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its directly or indirectly controlled subsidiaries.

(Note 2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

Loading...

Loading...