Page 1

REJ10J1433-0100

SH7125 Series Debugging MCU Board

HS7125EDB01H, HS7125EDB02H, HS7124EDB01H

Renesas Microcomputer Development Environment System

User’s Manual

SuperH™ Family / SH7125 Series

HS7125EDB01HE

Rev.1.00

Revision Date: Jul. 21, 2006

Page 2

Page 3

Keep safety first in your circuit designs!

1. Renesas Technology Corp. puts the maximum effort into making semiconductor products better and

more reliable, but there is always the possibility that trouble may occur with them. Trouble with

semiconductors may lead to personal injury, fire or property damage.

Remember to give due consideration to safety when making your circuit designs, with appropriate

measures such as (i) placement of substitutive, auxiliary circuits, (ii) use of nonflammable material or

(iii) prevention against any malfunction or mishap.

Notes regarding these materials

1. These materials are intended as a reference to assist our customers in the selection of the Renesas

Technology Corp. product best suited to the customer's application; they do not convey any license

under any intellectual property rights, or any other rights, belonging to Renesas Technology Corp. or

a third party.

2. Renesas Technology Corp. assumes no responsibility for any damage, or infringement of any third-

party's rights, originating in the use of any product data, diagrams, charts, programs, algorithms, or

circuit application examples contained in these materials.

3. All information contained in these materials, including product data, diagrams, charts, programs and

algorithms represents information on products at the time of publication of these materials, and are

subject to change by Renesas Technology Corp. without notice due to product improvements or

other reasons. It is therefore recommended that customers contact Renesas Technology Corp. or

an authorized Renesas Technology Corp. product distributor for the latest product information

before purchasing a product listed herein.

The information described here may contain technical inaccuracies or typographical errors.

Renesas Technology Corp. assumes no responsibility for any damage, liability, or other loss rising

from these inaccuracies or errors.

Please also pay attention to information published by Renesas Technology Corp. by various means,

including the Renesas Technology Corp. Semiconductor home page (http://www.renesas.com).

4. When using any or all of the information contained in these materials, including product data,

diagrams, charts, programs, and algorithms, please be sure to evaluate all information as a total

system before making a final decision on the applicability of the information and products. Renesas

Technology Corp. assumes no responsibility for any damage, liability or other loss resulting from the

information contained herein.

5. Renesas Technology Corp. semiconductors are not designed or manufactured for use in a device or

system that is used under circumstances in which human life is potentially at stake. Please contact

Renesas Technology Corp. or an authorized Renesas Technology Corp. product distributor when

considering the use of a product contained herein for any specific purposes, such as apparatus or

systems for transportation, vehicular, medical, aerospace, nuclear, or undersea repeater use.

6. The prior written approval of Renesas Technology Corp. is necessary to reprint or reproduce in

whole or in part these materials.

7. If these products or technologies are subject to the Japanese export control restrictions, they must

be exported under a license from the Japanese government and cannot be imported into a country

other than the approved destination.

Any diversion or reexport contrary to the export control laws and regulations of Japan and/or the

country of destination is prohibited.

8. Please contact Renesas Technology Corp. for further details on these materials or the products

contained therein.

Page 4

Page 5

IMPORTANT INFORMATION

READ FIRST

• READ this user's manual before using this emulator product.

• KEEP the user's manual handy for future reference.

Do not attempt to use the emulator product until you fully understand its mechanism.

Emulator Product:

Throughout this document, the term "emulator product" shall be defined as the following

products produced only by Renesas Technology Corp. and Renesas Solutions Corp. excluding all

subsidiary products.

• E10A-USB emulator main unit

• Debugging MCU board

The user system or a host computer is not included in this definition.

Purpose of the Debugging MCU Board:

This debugging MCU board is used to connect the E10A-USB emulator to the user system.

This debugging MCU board must only be used for the above purpose.

Limited Applications:

This emulator product is not authorized for use in transportation, vehicular, medical (where

human life is potentially at stake), aerospace, nuclear, or undersea repeater applications. Buyers of

this emulator product must notify Renesas Technology Corporation, Renesas Solutions

Corporation or an authorized Renesas Technology product distributor before planning to use the

product in such applications.

Improvement Policy:

Renesas Technology Corp. (including its subsidiaries, hereafter collectively referred to as

Renesas) pursues a policy of continuing improvement in design, performance, and safety of the

emulator product. Renesas reserves the right to change, wholly or partially, the specifications,

design, user's manual, and other documentation at any time without notice.

I

Page 6

Target User of the Emulator Product:

This emulator product should only be used by those who have carefully read and thoroughly

understood the information and restrictions contained in the user's manual. Do not attempt to use

the emulator product until you fully understand its mechanism.

It is highly recommended that first-time users be instructed by users that are well versed in the

operation of the emulator product.

Users are required to be familiar with the basic knowledge for the electric circuits, logic

circuits, and microcomputers.

Precautions to be Taken when Using This Product:

1. This emulator is a development supporting unit for use in your program development and

evaluation stages. In mass-producing your program you have finished developing, be sure to

make a judgment on your own risk that it can be put to practical use by performing integration

test, evaluation, or some experiment else.

2. In no event shall Renesas Solutions Corporation be liable for any consequence arising from the

use of this emulator.

3. Renesas Solutions Corporation strives to renovate or provide a workaround for product

malfunction at some charge or without charge. However, this does not necessarily mean that

Renesas Solutions Corporation guarantees the renovation or the provision under any

circumstances.

4. This emulator has been developed by assuming its use for program development and

evaluation in laboratories. Therefore, it does not fall under the application of Electrical

Appliance and Material Safety Law and protection against electromagnetic interference when

used in Japan.

5. This emulator does not conform to safety standards such as UL or IEC. Be careful when you

take this emulator overseas.

6. Renesas cannot anticipate every possible circumstance that might involve a potential hazard.

The warnings in this user's manual and on the emulator product are therefore not all inclusive.

Therefore, you must use the emulator product safely at your own risk.

II

Page 7

LIMITED WARRANTY

Renesas warrants its emulator products to be manufactured in

accordance with published specifications and free from defects in

material and/or workmanship. Renesas, at its option, will replace any

emulator products returned intact to the factory, transportation charges

prepaid, which Renesas, upon inspection, shall determine to be defective

in material and/or workmanship. The foregoing shall constitute the sole

remedy for any breach of Renesas’ warranty. See the Renesas warranty

booklet for details on the warranty period. This warranty extends only

to you, the original Purchaser. It is not transferable to anyone who

subsequently purchases the emulator product from you. Renesas is not

liable for any claim made by a third party or made by you for a third

party.

DISCLAIMER

RENESAS MAKES NO WARRANTIES, EITHER EXPRESS OR

IMPLIED, ORAL OR WRITTEN, EXCEPT AS PROVIDED

HEREIN, INCLUDING WITHOUT LIMITATION THEREOF,

WARRANTIES AS TO MARKETABILITY, MERCHANTABILITY,

FITNESS FOR ANY PARTICULAR PURPOSE OR USE, OR

AGAINST INFRINGEMENT OF ANY PATENT. IN NO EVENT

SHALL RENESAS BE LIABLE FOR ANY DIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING FROM ANY DEFECTIVE

EMULATOR PRODUCT, THE USE OF ANY EMULATOR

PRODUCT, OR ITS DOCUMENTATION, EVEN IF ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES. EXCEPT AS

EXPRESSLY STATED OTHERWISE IN THIS WARRANTY,

THIS EMULATOR PRODUCT IS SOLD "AS IS ", AND YOU

MUST ASSUME ALL RISK FOR THE USE AND RESULTS

OBTAINED FROM THE EMULATOR PRODUCT.

III

Page 8

State Law:

Some states do not allow the exclusion or limitation of implied warranties or liability for

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may have other rights which may vary from

state to state.

The Warranty is Void in the Following Cases:

Renesas shall have no liability or legal responsibility for any problems caused by misuse,

abuse, misapplication, neglect, improper handling, installation, repair or modifications of the

emulator product without Renesas’ prior written consent or any problems caused by the user

system.

All Rights Reserved:

1. Circuitry and other examples described herein are meant merely to indicate the characteristics

and performance of Renesas’ semiconductor products. Renesas assumes no responsibility for

any intellectual property claims or other problems that may result from applications based on

the examples described herein.

2. No license is granted by implication or otherwise under any patents or other rights of any third

party or Renesas.

3. This user's manual and emulator product are copyrighted and all rights are reserved by

Renesas. No part of this user's manual, all or part, may be reproduced or duplicated in any

form, in hard-copy or machine-readable form, by any means available without Renesas’ prior

written consent.

Figures:

Some figures in this user's manual may show items different from your actual system.

IV

Page 9

SAFETY PAGE

READ FIRST

• READ this user's manual before using this emulator product.

• KEEP the user's manual handy for future reference.

Do not attempt to use the emulator product until you fully understand its mechanism.

DEFINITION OF SIGNAL WORDS

Either in the user's manual or on the product, several icons are used to insure proper

handling of this product and also to prevent injuries to you or other persons, or damage to

your properties. Their graphic images and meanings are given in this safety page. Be sure to

read this chapter before using the product.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

avoided, will result in death or serious injury.

WARNING

avoided, could result in death or serious injury.

CAUTION

avoided, may result in minor or moderate injury.

DANGER indicates an imminently hazardous situation which, if not

WARNING indicates a potentially hazardous situation which, if not

CAUTION indicates a potentially hazardous situation which, if not

CAUTION

potentially hazardous situation which, if not avoided, may result

in property damage.

CAUTION used without the safety alert symbol indicates a

NOTE emphasizes essential information.

In addition to the four above, the following are also used as appropriate.

V

Page 10

WARNING

Observe the precautions listed below. Failure to do so

will result in a FIRE HAZARD and will damage the user

system and the emulator product or will result in

PERSONAL INJURY. The USER PROGRAM will be

LOST.

1. Do not repair or remodel the emulator product by

yourself for electric shock prevention and quality

assurance.

2. Always switch OFF the emulator and user system

before connecting or disconnecting any CABLES or

PARTS.

3. Always before connecting any CABLES, make sure that

pin 1 on both sides are correctly aligned.

4. If cables are connected incorrectly in the case of the

SH7125, the power-supply pins will be shorted as shown

below:

VI

90˚ rotation

4 (Vcc) 52 (AVss)

22 (Vcc) 6 (Vss)

24 (Vss) 8 (VCL)

270˚ rotation

6 (Vss) 22 (Vcc)

8 (VCL) 24 (Vss)

52 (AVss) 4 (Vcc)

Page 11

User Registration

When you have purchased the emulator represented in this user's manual, be sure to register it. As

the H/W Tool Customer Registration Sheet is included with this product, fill it in and send the

same contents to the following address by an email. Your registered information is used for only

after-sale services, and not for any other purposes. Without user registration, you will not be able

to receive maintenance services such as a notification of field changes or trouble information. So

be sure to carry out the user registration.

For more information about user registration, send an email to the following address.

regist_tool@renesas.com

i

Page 12

ii

Page 13

Contents

Section 1 Product Overview ..............................................................................1

1.1 Introduction....................................................................................................................... 1

1.2 Components ......................................................................................................................4

1.3 Components in the Package for the Debugging MCU Board ........................................... 5

1.4 Hardware Configuration ...................................................................................................8

1.5 Environmental Conditions ................................................................................................15

Section 2 Setting Up the Debugging MCU Board.............................................17

2.1 Flow Chart before Using the Debugging MCU Board......................................................17

2.2 Setting Up the Debugging MCU Board ............................................................................18

2.2.1 Connecting the Debugging MCU Board to the E10A-USB Emulator................. 18

2.2.2 Connecting the Debugging MCU Board to the User System............................... 21

2.2.3 Setting the Power-Selection Switch..................................................................... 24

2.2.4 Connecting the Power Cable................................................................................ 25

2.2.5 Setting the Clock-Selection Jumper..................................................................... 26

2.2.6 Installing a Crystal Resonator.............................................................................. 27

2.2.7 Setting the User-System Input Signal Enabling/Disabling Switches................... 28

2.2.8 Connecting the System Ground ........................................................................... 29

2.3 Setting the E10A-USB Emulator ...................................................................................... 30

2.3.1 Setting the DIP Switches of the E10A-USB Emulator ........................................ 30

2.3.2 CD-R.................................................................................................................... 31

2.3.3 Connecting the E10A-USB Emulator to the Host Computer............................... 32

2.3.4 Setting Up the E10A-USB Emulator ................................................................... 33

2.3.5 Activating the High-performance Embedded Workshop..................................... 33

2.4 Setting Up the Debugging MCU Board for Single Operation ..........................................34

2.4.1 Setting Switches on the Debugging MCU Board.................................................34

2.4.2 Inputting Reset Signals to the Debugging MCU Board....................................... 35

Section 3 Hardware Specifications ....................................................................37

3.1 External Dimensions of the Debugging MCU Board ....................................................... 37

3.2 Resulting Dimensions after Connecting User System Interface Board.............................39

3.3 Recommended Dimensions for User System Mount Pad (Footprint)............................... 39

3.3.1 Using the PLQP0064KB-A (FP-64K) Package................................................... 40

3.3.2 Using the PRQP0064GB-A (FP-64A) Package................................................... 41

3.3.3 Using the PLQP0048JA-A (FP-48F) Package..................................................... 42

3.4 Installing the MCU to the User System ............................................................................43

iii

Page 14

3.5 User System Interface Circuits ......................................................................................... 45

3.6 Delay Time for the User System Interface........................................................................ 49

Section 4 Maintenance and Guarantee ..............................................................51

4.1 User Registration .............................................................................................................. 51

4.2 Maintenance...................................................................................................................... 51

4.3 Guarantee .......................................................................................................................... 51

4.4 Repair Provisions.............................................................................................................. 52

4.4.1 Repair with Extra-Charge .................................................................................... 52

4.4.2 Replacement with Extra-Charge.......................................................................... 52

4.4.3 Expiration of the Repair Period ........................................................................... 52

4.4.4 Transportation Fees at Sending Your Product for Repair .................................... 52

4.5 How to Make a Request for Repair................................................................................... 53

Appendix A Repair Request Sheet .................................................................... 55

iv

Page 15

Section 1 Product Overview

1.1 Introduction

The High-performance Embedded Workshop is a graphical user interface intended to ease the

development and debugging of applications written in C/C++ programming language and

assembly language for Renesas microcomputers. Its aim is to provide a powerful yet intuitive way

of accessing, measuring, and modifying the debugging platform in which the application is

running.

This system is a software and hardware development support tool for application systems using

the Renesas original microcomputer.

The debugging MCU board is connected to the user system through the IC socket on the user

system. The user system can be debugged under the conditions similar to the actual application

conditions. The debugging MCU board enables debugging anywhere indoors or out with the

E10A-USB emulator. The host computer for controlling the debugging MCU board must be an

IBM PC compatible machine with USB 1.1/2.0 (Full-Speed).

1

Page 16

Host computer

External power supply

5-V DC

User system

USB 1.1/2.0 (Full-Speed)

Debugging MCU board

High-performance

Embedded Workshop

CD-R

E10A-USB emulator

Figure 1.1 System Configuration with the Debugging MCU Board

2

Page 17

The debugging MCU board provides the following features:

Excellent cost-performance in-circuit emulator

Using the debugging MCU board with the E10A-USB emulator implements low-cost

debugging of the user system without the user pins being occupied by the debugging interface

(H-UDI).

When the AUD function on the debugging MCU board is used, the debugging MCU board

supports the window trace function for trace acquisition of a large-capacity realtime trace or a

memory access (memory access address or memory access data) within the specified ranges.

Realtime emulation

Realtime emulation of the user system is enabled at the maximum operating frequency of the

CPU.

Excellent operability

Using the High-performance Embedded Workshop on the Microsoft

®

Microsoft

Windows® Me, Microsoft® Windows® 2000, and Microsoft® Windows® XP

®

Windows® 98SE,

operating systems enables user program debugging using a pointing device such as a mouse.

The High-performance Embedded Workshop enables high-speed downloading of load module

files.

Debugging of the user system in the final development stage

The user system can be debugged under conditions similar to the actual application conditions.

Compact debugging environment

When the emulator is used, a laptop computer can be used as a host computer, creating a

debugging environment in any place.

3

Page 18

CAUTION

READ the following warnings before using the debugging

MCU board. Incorrect operation will damage the user system

and the debugging MCU board. The USER PROGRAM will be

LOST.

1. Check all components against the component list after unpacking the emulator.

2. Never place heavy objects on the casing.

3. Protect the emulator from excessive impacts and stresses. For details, refer to section 1.5,

Environmental Conditions.

4. Only supply the power of the specified voltages or power-supply frequencies to the debugging

MCU board.

5. When moving the host computer or user system, take care not to vibrate or damage it.

6 After connecting the cable, check that it is connected correctly. For details, refer to section 2,

Setting Up the Debugging MCU Board.

7. Supply power to the connected equipment after connecting all cables. Cables must not be

connected or removed while the power is on.

1.2 Components

After removing the product from its packaging, confirm that you have all of the components. For

details on the components of the debugging MCU board, refer to section 1.3, Components in the

Package for the Debugging MCU Board. If any component is not present, contact your nearest

Renesas sales office.

4

Page 19

1.3 Components in the Package for the Debugging MCU Board

The debugging MCU board supports the SH7125 series (SH7124/SH7125). Table 1.1 lists the

components supplied in the package for the debugging MCU board.

In the product as shipped, the main unit of the debugging MCU board is connected to the user

system interface board with the flexible flat cable (FFC). Do not detach them from each other.

Table 1.1 Components in the Package for the Debugging MCU Board

Classification Component

Hardware

FFC cables 2 Length: 150.0 mm, mass: 1.4 g

User system interface

Power cable 1 Length: 0.5 m

Debugging MCU board

main unit

board

Appearance

Qty Remarks

1 Depth: 80.0 mm, width: 85.0 mm,

height: 22.3 mm, mass: 55.2 g

* The main unit of the debugging

MCU board is connected to the

user system interface board with

the FFC cable. Do not disconnect

these components.

1 Depth: 35.0 mm, width: 40.0 mm,

height: 10.3 mm, mass: 8.5 g

5

Page 20

Table 1.1 Components in the Package for the Debugging MCU Board (cont.)

Classification Component

Hardware

(cont.)

Socket cover 1 For installing the MCU

Screws (M2.0 x 10 mm)

Screws (M2.0 x 6 mm)

Guide pins 2 or 3 *The quantity will differ according

Screwdriver 1

IC socket 1 Connect the IC socket to the user

Appearance

Qty Remarks

system.

*The IC socket provided will differ

according to the supported MCU.

*The socket cover provided will

differ according to the supported

MCU.

4 For fastening the user system

4 For fastening the socket cover

interface board

to the supported device.

Two guide pins are provided for

the SH7125 (PLQP0064KB-A) and

SH7124 (PLQP0048JA-A), and

three are provided for the SH7125

(PRQP0064GB-A).

User’s manual 1 SH7125 Series Debugging MCU

Board User’s Manual (this manual)

6

Page 21

CAUTION

Use the following IC sockets and socket covers on the

user sytem.

For SH7125 (package code: PLQP0064KB-A; former code:

FP-64K):

IC socket: NQPACK064SD-ND (manufactured by Tokyo

Eletech Corporation)

IC socket cover: HQPACK064SD (manufactured by Tokyo

Eletech Corporation)

For SH7125 (package code: PRQP0064GB-A; former code:

FP-64A):

IC socket: NQPACK064SA (manufactured by Tokyo Eletech

Corporation)

IC socket cover: HQPACK064SA (manufactured by Tokyo

Eletech Corporation)

For SH7124 (package code: PLQP0048JA-A; former code:

FP-48F):

IC socket: NQPACK048SB (manufactured by Tokyo Eletech

Corporation)

IC socket cover: HQPACK048SB (manufactured by Tokyo

Eletech Corporation)

7

Page 22

1.4 Hardware Configuration

As shown in figure 1.2, the usable configuration of the debugging MCU board consists of the

main unit, FFC cable, user system interface board, and power cable. The debugging MCU board is

connected, via the E10A-USB emulator, to the host computer over a USB 1.1/2.0 (Full-Speed)

link.

The host computer, E10A-USB emulator, and external power supply must be separately obtained

by the user.

Host computer

E10A-USB emulator

External

power supply

(5-V DC)

User system

interface board

USB1.1/USB2.0

(Full-Speed)

Power cable

FFC cable

(separately available)

Main unit of

the debugging

MCU board

User system

(IC-socket interface)

Figure 1.2 Hardware Configuration of the Debugging MCU Board

8

Page 23

1.4.1 Configuration of the Main Unit of the Debugging MCU Board

The names of each section of the debugging MCU board are explained below.

Top of the Main Unit of the Debugging MCU Board (1)

(a)

(b)(c)

(d)

Figure 1.3 Top of the Main Unit of the Debugging MCU Board (1)

(a) External power LED: Marked ‘BOARD POWER’. This LED is lit while external power is

being supplied from the power cable.

(b) User VCC LED: Marked ‘USER VCC’. This LED is lit while power is being supplied

from the user system to the VCC pin of the MCU.

(c) User AVCC LED: Marked ‘USER AVCC’. This LED is lit while power is being supplied

from the user system to the AVCC pin of the MCU.

(d) Reset LED: Marked ‘RST’. This LED is lit while the reset signal is being input to

the MCU.

9

Page 24

Top of the Main Unit of the Debugging MCU Board (2)

(a)

(e)

(b) (c)

(d)

Figure 1.4 Top of the Main Unit of the Debugging MCU Board (2)

10

Page 25

(a) Power-selection

switch:

This switch is used to select the power source for the debugging MCU

board.

When ‘EXTERNAL’ is selected, an external power supply is the

source for the debugging MCU board.

When ‘USER SYSTEM’ is selected, the VCC power supply on the

user system is the source for the debugging MCU board.

(b) Clock-selection

jumper:

This jumper is used to select the clock signal for input to the MCU on

the debugging MCU board.

When ‘XTAL’ is selected, the input clock signal is from the crystal

resonator on the debugging MCU board. When ‘USER CLK’ is

selected, the input clock signal is from the EXTAL pin on the user

system.

(c) Crystal-resonator

installation sockets:

The crystal resonator for supplying the external clock signal is

mounted here when ‘XTAL’ has been selected on the clock-selection

jumper.

(d) Reset switch: This switch is used to input reset signals manually to the debugging

MCU board.

(e) User-system input

signal enabling/disabling

switches:

These switches are used to enable or disable the input of /RES and

NMI signals from the user system and connect or disconnect the user

system.

11

Page 26

Top of the Main Unit of the Debugging MCU Board (3)

(a)

(d)

(c)

(b)

Figure 1.5 Top of the Main Unit of the Debugging MCU Board (3)

(a) Power-cable connector: This connector is used to connect the debugging MCU board to the

power cable for the external power supply.

(b) H-UDI interface

connector (36 pins):

(c) H-UDI interface

connector (14 pins):

(d) User system interface

connector 1:

This connector is used to connect the debugging MCU board to the

36-pin cable of the E10A-USB emulator.

This connector is used to connect the debugging MCU board to the

14-pin cable of the E10A-USB emulator.

This connector is used to connect the main unit of the debugging

MCU board to the FFC cable.

Note: The FFC cable already occupies this connector in the product as

shipped. Do not remove the cable from the connector.

12

Page 27

Bottom of the Main Unit of the Debugging MCU Board

(a)

Figure 1.6 Bottom of the Main Unit of the Debugging MCU Board

(a) User system interface

connector 2:

This connector is used to connect the main unit of the debugging

MCU board to the FFC cable.

Note: The FFC cable already occupies this connector in the product as

shipped. Do not remove the cable from the connector.

13

Page 28

1.4.2 Configuration of the User System Interface Board

The names of each section of the user system interface board are explained below.

(1) Top of the user system

interface board

(a)

(2) Bottom of the user system

interface board

(b)

(c)

Figure 1.7 User System Interface Board

(a) User system interface

connector 1:

This connector is used to connect the user system interface board to

the FFC cable.

Note: The FFC cable already occupies this connector in the product as

shipped. Do not remove the cable from the connector.

(b) User system interface

connector 2:

This connector is used to connect the user system interface board to

the FFC cable.

Note: The FFC cable already occupies this connector in the product as

shipped. Do not remove the cable from the connector.

(c) User system connector: This connector is for connection to the user system.

14

Page 29

1.5 Environmental Conditions

CAUTION

Observe the conditions listed in tables 1.6 and 1.7 when

using the debugging MCU board. Failure to do so can lead to

abnormal operation of the user system, the debugging MCU

board, and the user program.

Table 1.6 Environmental Conditions

Item Specifications

Temperature

Humidity

Vibration

Ambient gases No corrosive gases may be present

Table 1.7 Operating Environment

Item Description

Host computer IBM PC or compatible machine that satisfies the operating-environment

Emulator Renesas microcomputer development tool:

Power supply DC 5 V ± 10%

Supply current 300 mA (max.)

Operating: +10°C to +35°C

Storage: –10°C to +50°C

Operating: 35% RH to 80% RH, no condensation

Storage: 35% RH to 80% RH, no condensation

Operating: 2.45 m/s

Storage: 4.9 m/s

Transportation: 14.7 m/s

conditions of the E10A-USB emulator

E10A-USB emulator (HS0005KCU01H or HS0005KCU02H)

2

max.

2

max.

2

max.

15

Page 30

16

Page 31

Section 2 Setting Up the Debugging MCU Board

2.1 Flow Chart before Using the Debugging MCU Board

Unpack the debugging MCU board and prepare it for use as follows:

WARNING

READ the reference sections shaded in figure 2.1 before

using the debugging MCU board. Incorrect operation will

damage the user system and the debugging MCU board uct.

The USER PROGRAM will be LOST.

Reference

Unpack the debugging MCU board

Check the components against the component list

Set up the debugging MCU board

- Connect the E10A-USB emulator

- Connect the user system

- Set the switches of the debugging MCU board

Set up the E10A-USB emulator

- Install the emulator's software

(Check the components and register the user information.)

- Insert the emulator

- Set up the main unit of the emulator

Component list

Section 2 in the

Debugging MCU

Board User's

Manual (this

manual)

Section 3 in the

E10A-USB

Emulator User's

Manual

When the debugging MCU

board is used first.

Start the High-performance Embedded Workshop

Turn on the user system

Input the user system reset signal

Figure 2.1 Preparation Flow Chart for the Debugging MCU Board

Section 4 in the

E10A-USB

Emulator User's

Manual

When the debugging MCU

board is used for second

time or later.

17

Page 32

2.2 Setting Up the Debugging MCU Board

To apply the debugging MCU board, you must obtain an E10A-USB emulator. This section

describes how to connect the debugging MCU board, the E10A-USB emulator, and the user

system interface board.

Before making the connections, check that the host computer is turned off, the E10A-USB

emulator is not connected to the host computer via the USB cable, and power is being supplied to

neither the debugging MCU board nor the user system.

2.2.1 Connecting the Debugging MCU Board to the E10A-USB Emulator

Follow the below procedure to connect the debugging MCU board to the E10A-USB emulator.

1. Connect the user system interface cable (14 or 36 pins) provided with the E10A-USB emulator

to the side connector of the E10A-USB emulator as shown in figure 2.2.

Figure 2.2 Connecting the E10A-USB Emulator to the User System Interface Cable

18

Page 33

2. Connect the 14-pin or 36-pin connector of the user system interface cable to the H-UDI

interface connector on the debugging MCU board as shown in figures 2.3 and 2.4.

Connect the 36-pin or 14-pin connector to CN2 or CN3, respectively.

Figure 2.3 Connecting the User System Interface Cable (36 Pins) to the Debugging MCU

Board

19

Page 34

Figure 2.4 Connecting the User System Interface Cable (14 Pins) to the Debugging MCU

Board

20

Page 35

2.2.2 Connecting the Debugging MCU Board to the User System

To connect the debugging MCU board to the user system, follow the instructions below.

WARNING

Always switch OFF the emulator product, the debugging

MCU board, and the user system before any connection or

removal of the USER SYSTEM INTERFACE BOARD.

Furthermore, make sure that the pin 1 positions on both

sides are correctly aligned. Failure to do so will create a

FIRE HAZARD that can damage the emulator product, the

debugging MCU board, the user system interface board, or

the user system, or produce PERSONAL INJURY.

1. Solder the IC socket to the user system.

CAUTION

Before applying solder, use epoxy resin adhesive to affix

the guide points on the IC socket to the user system.

Ensure full wetting of the leads so that the solder flows

over the leads and forms good fillets (use slightly more

solder than you normally would).

21

Page 36

2. Align pin 1 on the IC socket on the user system with pin 1 on the user system interface board,

and plug the user system connector of the interface board into the IC socket on the user system,

as is shown in figure 2.5.

CAUTION

Ensure that the locations of pin 1 on the socket and

connector are aligned before inserting the connector.

If this is not done in the case of the SH7125, power-supply

pins will be shorted as shown below.

90˚ rotation

4 (Vcc) 52 (AVss)

22 (Vcc) 6 (Vss)

24 (Vss) 8 (VCL)

CAUTION

270˚ rotation

6 (Vss) 22 (Vcc)

8 (VCL) 24 (Vss)

52 (AVss) 4 (Vcc)

1. Use a Philips-head screwdriver with a head-size matching

that of the screw.

2. The tightening torque must be no greater than 0.054 N•m.

If the applied torque cannot be accurately measured,

stop tightening the screw when the force required for

further tightening suddenly becomes significantly greater

than was initially required. Excessive tightening may

break the screw head or crack the IC-socket solder,

leading to an IC contact error.

3. If the emulator does not operate correctly, cracks may

have been produced in the solder. Check conduction

with a tester and re-solder the IC socket if necessary.

22

Page 37

3. Fasten the user system interface board to the IC socket on the user system with the four screws

(M2.0

x 10 mm) provided. Tighten each of the screws a little at a time, alternating between

those on opposing corners. Do not concentrate on fully tightening one screw at a time. Take

special care, such as manually securing the IC-socket soldered area, to prevent damage to the

soldered IC socket due to excessive tightening of the screws or twisting of components.

Screws (M2.0 x 10 mm)

User system interface board

Pin 1

User system

IC socket

Figure 2.5 Connecting the User System Interface Board to the User System

23

Page 38

2.2.3 Setting the Power-Selection Switch

The external power supply or the VCC power supply on the user system can be selected as the

source of power for the debugging MCU board. Refer to table 2.1 when selecting the power

supply to be used.

Figure 2.6 Power-Selection Switch

Table 2.1 Correspondence of Power-Selection Switch Settings

Silk-Screened Label Power Supply to be Used

EXTERNAL External power supply connected to the power cable (factory setting)

USER SYSTEM VCC on the user system

24

Page 39

2.2.4 Connecting the Power Cable

When the power-selection switch is set to ‘EXTERNAL’, the power cable must be connected to

the debugging MCU board so that power can be supplied from beyond the board. Connect the

power cable to the power-cable connector on the debugging MCU board as shown in figure 2.7.

Figure 2.7 Connecting the Power Cable to the Debugging MCU Board

25

Page 40

2.2.5 Setting the Clock-Selection Jumper

The EXTAL input from the user system or the crystal resonator installed on the debugging MCU

board can be selected as the source of the clock signal for the MCU. Refer to table 2.2 when

selecting the clock.

Figure 2.8 Clock-Selection Jumper

Table 2.2 Correspondence of Clock-Selection Jumper Settings

Silk-Screened Label Jumper Pin (SW3) Clock to be Used

XTAL Pins 1-2 closed Crystal resonator installed on the debugging MCU board

USER CLK Pins 2-3 closed EXTAL input from the user system (factory setting)

Note: ‘XTAL’ should only be selected if a crystal resonator has been mounted across the crystal-

resonator installation sockets (X1) of the debugging MCU board. Users must provide the

crystal resonator.

26

Page 41

2.2.6 Installing a Crystal Resonator

‘XTAL’ should only be selected if a crystal resonator has been mounted on the debugging MCU

board. Install the crystal resonator across the crystal-resonator installation sockets of the

debugging MCU board.

Figure 2.9 Installing a Crystal Resonator

27

Page 42

2.2.7 Setting the User-System Input Signal Enabling/Disabling Switches

Enabling or disabling of particular input signals from the user system can be set on the debugging

MCU board. In addition, connecting or disconnecting the user system must be set with these

switches. Table 2.3 lists the signals and settings.

Figure 2.10 User-System Input Signal Enabling/Disabling Switches

Table 2.3 Correspondence of User-System Input Signal Enabling/Disabling Switch Settings

Silk-Screened Label Number on SW2 ENABLE DISABLE

UNMI 1 Enables the NMI input.

(factory setting)

URES 2 Enables the /RES input.

(factory setting)

UCON 3 Set this switch when the user

system is connected for

operation. (factory setting)

4 Do not change this switch.

(factory setting)

Disables the NMI input.

Disables the /RES input.

Set this switch for single

operation of the debugging

MCU board.

Do not change this switch.

Note: When ‘UCON’ is set as ‘DISABLE’, the debugging MCU board can be initiated even if

the user system has not been connected. Set the debugging MCU board, referring to

section 2.4, Setting Up the Debugging MCU Board for Single Operation, for the use of

simple evaluation before designing the user system.

28

Page 43

2.2.8 Connecting the System Ground

WARNING

Separate the frame ground and signal ground of the user

system. Failure to do so will create a FIRE HAZARD that can

damage the user system and emulator product, or produce

PERSONAL INJURY.

The signal grounds of the E10A-USB emulator and the debugging MCU board are connected to

the user system's signal ground. In the emulator, the signal ground and frame ground are

connected. In the user system, only connect the frame ground to earth; do not connect the signal

ground to the frame ground (figure 2.11).

If it is difficult to separate the frame ground from the signal ground in the user system, tie the

frame ground of the user system to the same potential as the GND level of the DC power input

(AC adapter) of the host computer. This is because differences in GND potential between the host

computer and target system will lead to excessive flows of current in the low-impedance GND

lines, and thin lines might burn out.

Signal ground

Host

computer

E10A-USB emulator

USB

Logic

Signal

Debugging

MCU board

Signal

User system

Logic

Power

supply

Signal ground

Signal ground

Frame ground

Figure 2.11 Connecting System Ground

29

Page 44

2.3 Setting the E10A-USB Emulator

2.3.1 Setting the DIP Switches of the E10A-USB Emulator

Set the DIP switches of the E10A-USB emulator as follows.

1. Open the sliding switch cover in the lower right portion of the upper side of the E10A-USB

emulator by sliding it to the right as shown in figure 2.12.

2. Turn all of the DIP switches (SW1, SW2, and SW3) on (‘1’ side).

R

ENESAS

USB

I/F

B

S

U

E10A

ACT

1

0

3

2

1

1

0

1

2

3

ON

Figure 2.12 Setting the DIP Switches of the E10A-USB Emulator

OFF

30

Page 45

2.3.2 CD-R

The emulator’s software for the debugging MCU board is included in the CD-R provided with the

E10A-USB emulator.

The root directory of the CD-R contains a setup program for installing the emulator’s software for

the debugging MCU board. The folders contain the files and programs listed below.

Table 2.4 Contents of the CD-R Directories

Directory Name Contents Description

Dlls Microsoft

Drivers E10A-USB emulator driver USB drivers for the E10A-USB emulator.

Help Online help for the E10A-USB

emulator

Manual E10A-USB emulator manuals E10A-USB emulator user’s manuals. They

runtime library A runtime library for the High-performance

Embedded Workshop. The version is checked

at installation and this library is copied to the

hard disk as part of the installation process.

An online help file. This is copied to the hard

disk as part of the installation process.

are provided as PDF files.

Execute Setup.exe from the root directory of the CD-R to start the installation wizard.

Follow the cues given by the installation wizard to install the software.

Note: When a driver is installed in Windows

test may be displayed, but it is not a problem. Select [Continue Anyway] to proceed with

driver installation.

XP, a warning message on the Windows logo

31

Page 46

2.3.3 Connecting the E10A-USB Emulator to the Host Computer

This section describes how to connect the E10A-USB emulator to the host computer. For the

position of each connector of the emulator, refer to the SuperH Family E10A-USB Emulator

User’s Manual.

Notes: 1. When [Add New Hardware Wizard] is displayed, select the [Search for the best driver

for your device. (Recommended)] radio button and then the [Specify a location] check

box to select the path to be searched for drivers. The location must be specified as

<Drive>:\DRIVERS. (<Drive> is the CD drive letter.)

2. When a driver is installed in Windows

test may be displayed, but it is not a problem. Select [Continue Anyway] to proceed

with driver installation.

3. Be sure to install the software for the E10A-USB emulator before putting the emulator

in place.

XP, a warning message on the Windows logo

WARNING

Always switch OFF the emulator product and the user

system before connecting or disconnecting any CABLES

except for the USB interface cable. Failure to do so will result

in a FIRE HAZARD and will damage the user system and the

emulator product or will result in PERSONAL INJURY.

The USER PROGRAM will be LOST.

32

Page 47

The E10A-USB emulator is connected to the host computer via the USB 1.1, and also to the USB

port conforming to USB 2.0. Figure 2.13 shows the system configuration.

Figure 2.13 System Configuration when Connecting the E10A-USB Emulator to the Host

Computer

2.3.4 Setting Up the E10A-USB Emulator

Set up the E10A-USB emulator’s firmware referring to section 3.10, Setting Up the Emulator, and

section 3.11, System Check, in the SuperH Family E10A-USB Emulator User’s Manual.

2.3.5 Activating the High-performance Embedded Workshop

Activate the High-performance Embedded Workshop referring to section 4, Preparations for

Debugging, in the SuperH Family E10A-USB Emulator User’s Manual, which describes the

activation procedure.

33

Page 48

2.4 Setting Up the Debugging MCU Board for Single Operation

Since the debugging MCU board can be initiated even if the user system has not been connected, it

is available for simple evaluation before designing the user system.

WARNING

1. Always disconnect the E10A-USB emulator from the host

computer and switch OFF the debugging MCU board

before setting switches on the debugging MCU board.

Failure to do so will create a FIRE HAZARD that can

damage the E10A-USB emulator product, the debugging

MCU board, or the user system interface board.

2. For the single operation of the debugging MCU board,

connector pins on the bottom of the user system

interface board, which are used for connecting the user

system, are disconnected. To prevent connector pins

from being shorted, be sure to put an insulator under the

user system interface board.

2.4.1 Setting Switches on the Debugging MCU Board

For the single operation of the debugging MCU board, set the switches on the debugging MCU

board as described below and activate the High-performance Embedded Workshop.

1. Only the external power supply is supported. Set the power-selection switch to ‘EXTERNAL’

and supply the external power from the power-cable connector.

2. Only the crystal resonator installed on the debugging MCU board is supported as the source of

the clock signal.

Set the clock-selection jumper to ‘XTAL’ to install the crystal resonator across the crystalresonator installation sockets.

3. The user-system input signal enabling/disabling switches must be set on the debugging MCU

board. Set ‘UCON’ of these switches as ‘DISABLE’.

34

Page 49

2.4.2 Inputting Reset Signals to the Debugging MCU Board

When reset signals must be input, such as the case when activating the High-performance

Embedded Workshop or debugging, they can be manually input from the reset switch on the

debugging MCU board. For details on inputting reset signals, see table 2.5.

Figure 2.14 Reset Switch

Table 2.5 Correspondence of Reset Switch Settings

Setting of SW4 Reset Signal Input to the Debugging MCU Board

Turned to ‘3’ of silkscreened label

Turned to ‘1’ of silkscreened label

Reset signal input from the reset switch is canceled. (factory setting)

Reset signal is input from the reset switch.

Note: This reset switch is used to manually input reset signals to the debugging MCU board.

When the user system is connected, this reset switch is also available for inputting reset

signals to the debugging MCU board, however, note that no reset signal is output to the

user system.

35

Page 50

36

Page 51

Section 3 Hardware Specifications

3.1 External Dimensions of the Debugging MCU Board

Figures 3.1 through 3.3 show the external dimensions of the debugging MCU board.

274.0

149.0

Unit: mm

Tolerance: ±0.5 mm

Figure 3.1 External Dimensions of the Debugging MCU Board

85.0

80.0

80.0

Unit: mm

Tolerance: ±0.5 mm

Figure 3.2 External Dimensions of the Main Unit of the Debugging MCU Board

37

Page 52

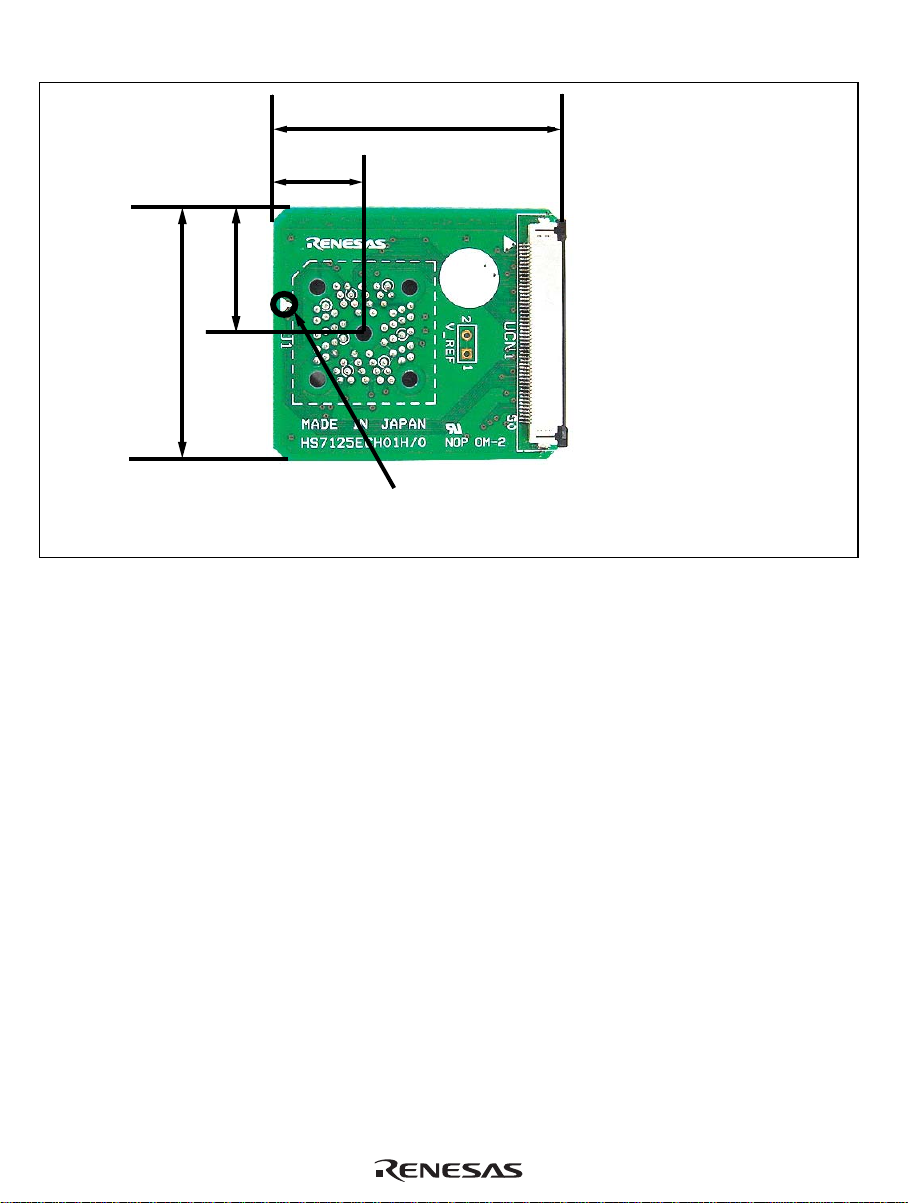

35.0

40.0

12.5

17.5

Pin 1

Unit: mm

Tolerance: ±0.5 mm

Figure 3.3 External Dimensions of the User System Interface Board

38

Page 53

3.2 Resulting Dimensions after Connecting User System Interface Board

Figure 3.4 shows the resulting dimensions, after connecting the user system interface board to the

user system.

User system

interface board

16.7

10.9

User system

IC socket

12.7

Unit: mm

Tolerance: ±1.0 mm

Figure 3.4 Resulting Dimensions after Connecting User System Interface Board

3.3 Recommended Dimensions for User System Mount Pad (Footprint)

Figures 3.5 through 3.7 show the recommended dimensions for the mount pad (footprint) for the

user system with an IC socket. Note that the dimensions in those figures are somewhat different

from those of the actual MCU's mount pad.

39

Page 54

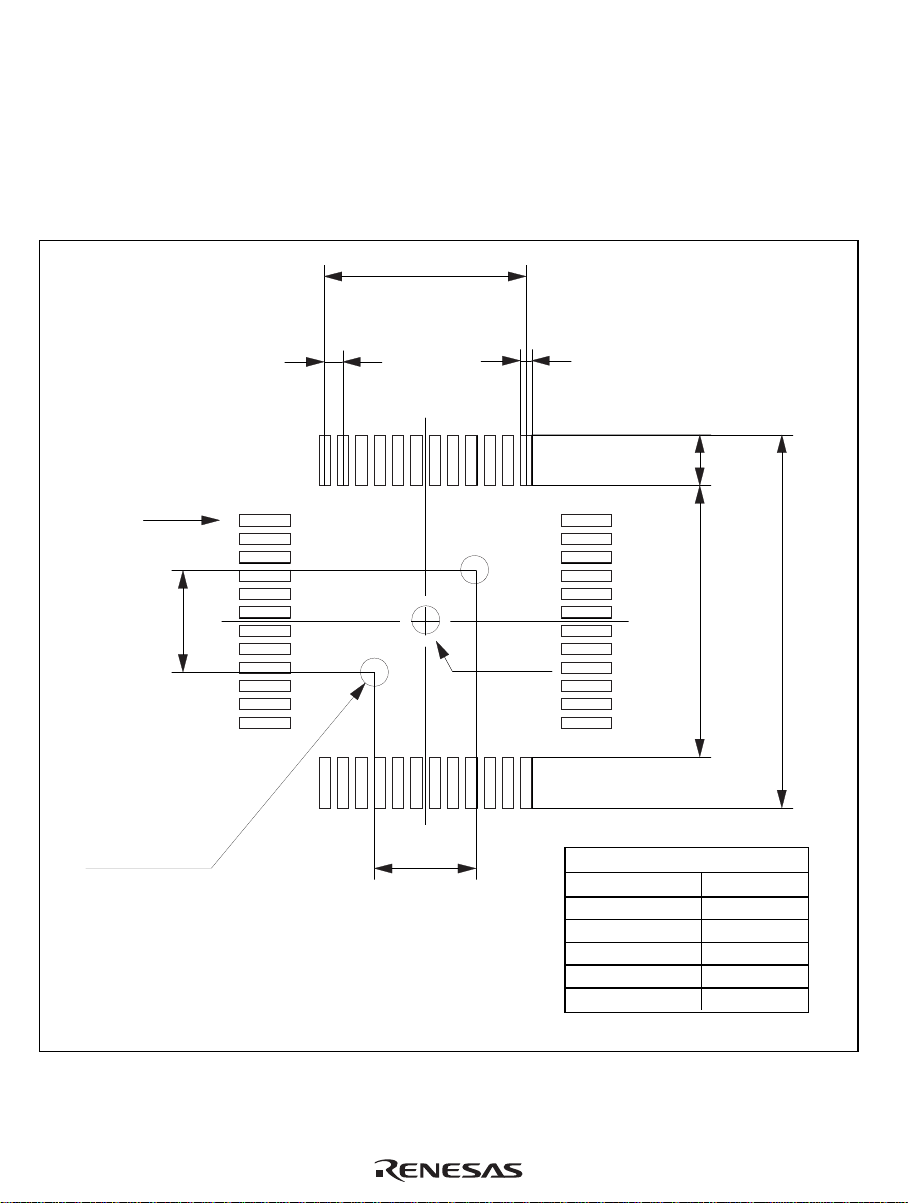

3.3.1 Using the PLQP0064KB-A (FP-64K) Package

Figure 3.5 shows the recommended dimensions for the mount pad (footprint) for the user system

with an IC socket for a PLQP0064KB-A (former code: FP-64K) package (NQPACK064SD-ND:

manufactured by Tokyo Eletech Corporation).

0.5 x 15 = 7.5

0.5 0.25

2

3.4

φ1.6

(SL-type)

10

Dimension and tolerance

Dimension

Up to 1.2

1.3 to 2.0

2.1 to 5.0

5.1 to 10.0

10.1 or above

14

Tolerance

±0.05

±0.10

±0.15

±0.20

±0.30

Unit: mm

Pin 1

3.4

2 - φ1.0

Figure 3.5 Recommended Dimensions for Mount Pad for PLQP0064KB-A (Former Code:

FP-64K)

40

Page 55

3.3.2 Using the PRQP0064GB-A (FP-64A) Package

Figure 3.6 shows the recommended dimensions for the mount pad (footprint) for the user system

with an IC socket for a PRQP0064GB-A (former code: FP-64A) package (NQPACK064SA:

manufactured by Tokyo Eletech Corporation).

0.8 x 15 = 12

Pin 1

0.8

8

3 - φ1.0

8

φ3.2

(SL-type)

0.5

2.3

14

Dimension and tolerance

Dimension

Up to 1.2

1.3 to 2.0

2.1 to 5.0

5.1 to 10.0

10.1 or above

Tolerance

±0.05

±0.10

±0.15

±0.20

±0.30

Unit: mm

18.6

Figure 3.6 Recommended Dimensions for Mount Pad for PRQP0064GB-A (Former Code:

FP-64A)

41

Page 56

3.3.3 Using the PLQP0048JA-A (FP-48F) Package

Figure 3.7 shows the recommended dimensions for the mount pad (footprint) for the user system

with an IC socket for a PLQP0048JA-A (former code: FP-48F) package (NQPACK048SB:

manufactured by Tokyo Eletech Corporation).

0.65 x 11 = 7.15

Pin 1

2 - φ1.0

3.6

0.65

3.6

φ1.6

(SL-type)

0.4

Dimension and tolerance

Dimension

Up to 1.2

1.3 to 2.0

2.1 to 5.0

5.1 to 10.0

10.1 or above

1.8

9.6

Tolerance

±0.05

±0.10

±0.15

±0.20

±0.30

13.2

Unit: mm

Figure 3.7 Recommended Dimensions for Mount Pad for PLQP0048JA-A (Former Code:

FP-48F)

42

Page 57

3.4 Installing the MCU to the User System

CAUTION

1. Check the location of pin 1 before inserting.

2. Use a Philips-type screwdriver whose head matches the

screw head.

3. The tightening torque must be 0.054 N•m or less.

If the applied torque cannot be accurately measured,

stop tightening when the force required to turn the screw

becomes significantly greater than that needed when first

tightening. If a screw is tightened too much, the screw

head may break or an IC socket contact error may be

caused by a crack in the IC socket solder.

4. If the MCU does not operate correctly, cracks might have

occurred in the solder. Check conduction with a tester

and re-solder the IC socket if necessary.

Check the location of pin 1 before inserting the MCU into the IC socket on the user system, as

shown in figure 3.8. After inserting the MCU, fasten the socket cover with the provided four

screws (M2.0

to prevent the IC socket from being damaged by overtightening the screws or twisting the

components.

x 6 mm). Take special care, such as manually securing the IC socket soldered area,

43

Page 58

Screws (M2.0 x 6 mm)

Socket cover

MCU (SH7124/SH7125)

Pin 1

IC socket

44

User system

Figure 3.8 Installing MCU to User System

Page 59

3.5 User System Interface Circuits

Figures 3.9 through 3.14 show user system interface circuits. Use them as a reference to determine

the value of the pull-up resistance.

SH7124/SH7125

MD1

MD0

FWE

SH7124/SH7125

Vcc

47 kΩ

Figure 3.9 User System Interface Circuits

Vcc

47 kΩ

N.C.

N.C.

User system

MD1

MD0

FWE

User system

_WDTOVF _WDTOVF

Figure 3.10 User System Interface Circuits

45

Page 60

SH7124/SH7125

User system

Vcc

AHC14 AHC14

NMI NMI

_RES

HC32

HC08

HC08HC08

HC74

AHC14

47 kΩ

AHC14

Vcc

47 kΩ

Figure 3.11 User System Interface Circuits

_RES

46

Page 61

SH7124/SH7125

User system

PLLVcL

PLLVss

XTAL

EXTAL

VcL

Vcc

PVcc

Vss

AVcc

AVref

AVss

N.C.

0.47 μF

0.47 μF

0.01

μF

0.01

μF

0.1

μF

0.1

μF

SW3

10

μF

10

μF

33

μF

33

μF

HCU04

SW1

SW1

X1

CN1

CN1

N.C.

N.C.

N.C.

N.C.

PLLVss

XTAL

EXTAL

VcL

Vcc

Vss

AVcc

AVss

Figure 3.12 User System Interface Circuits

47

Page 62

SH7124/SH7125

User system

PF(7:0) PF(7:0)

ASEBCK

_ASEBRK

_ASEBRKAK

AVcc

DALC112S1

T2

Vcc

47 kΩ

Vcc

47 kΩ

N.C.

CN2

CN3

Figure 3.13 User System Interface Circuits

_ASEBRK/_ASEBRKAK

SH7124/SH7125

PA(15:0), PB(3:1),

PB5, PB16, PE(15:0)

48

User system

PA(15:0), PB(3:1),

PB5, PB16, PE(15:0)

Figure 3.14 User System Interface Circuits

Page 63

3.6 Delay Time for the User System Interface

Since the _RES and NMI signals are connected to the user system via the logic on the EV-chip

unit, a delay time shown in table 3.1 will be generated until the signal is input from the user

system to the MCU.

Table 3.1 Delay Time for Signals via the EV-chip Unit

No. Signal Name Delay Time (ns)

1 _RES 20

2 NMI 10

49

Page 64

50

Page 65

Section 4 Maintenance and Guarantee

This section describes maintenance, guarantee, repair provisions, and how to request for repair of

the emulator.

4.1 User Registration

When you purchase our product, be sure to register as a user. For user registration, refer to the

section of ‘User Registration’ (p. i) of this user's manual.

4.2 Maintenance

1. If dust or dirt collects on any equipment of this product, wipe the board dry with a soft cloth.

Do not use thinner or other solvents because these chemicals can cause the equipment's surface

coating to separate.

2. When you do not use this product for a long period, for safety purposes, disconnect the power

cable from the power supply.

4.3 Guarantee

If your product becomes faulty within one year after its purchase while being used under good

conditions by observing ‘IMPORTANT INFORMATION’ described in this user's manual, we will

repair or replace your faulty product free of charge. Note, however, that if your product's fault is

raised by any one of the following causes, we will repair it or replace it with new one with extracharge:

Misuse, abuse, or use under extraordinary conditions

Unauthorized repair, remodeling, maintenance, and so on

Inadequate user's system or misuse of it

Fires, earthquakes, and other unexpected disasters

In the above cases, contact your local distributor. If your product is being leased, consult the

leasing company or the owner.

51

Page 66

4.4 Repair Provisions

4.4.1 Repair with Extra-Charge

The products elapsed more than one year after purchase can be repaired with extra-charge.

4.4.2 Replacement with Extra-Charge

If your product's fault falls in any of the following categories, the fault will be corrected by

replacing the entire product instead of repair, or you will be advised to purchase new one,

depending on the severity of the fault.

Faulty or broken mechanical parts

Flaw, separation, or rust in coated or plated parts

Flaw or cracks in plastic parts

Faults or breakage caused by improper use or unauthorized repair or modification

Heavily damaged electric circuits due to overvoltage, overcurrent or shorting of power supply

Cracks in the printed circuit board or burnt-down patterns

Wide range of faults that makes replacement less expensive than repair

Unlocatable or unidentified faults

4.4.3 Expiration of the Repair Period

When a period of one year elapses after the model was dropped from production, repairing

products of the model may become impossible.

4.4.4 Transportation Fees at Sending Your Product for Repair

Send your product to us for repair at your expense.

52

Page 67

4.5 How to Make a Request for Repair

If your product is found faulty, follow the procedure below to send your product for repair.

Fill in the Repair Request Sheet included with this product, then send it along with this product for

repair to your local distributor. Make sure that information in the Repair Request Sheet is written

in as much detail as possible to facilitate repair.

CAUTION

Note on Transporting the Product:

When sending your product for repair, use the packing

box and cushion material supplied with this product when

delivered to you and specify handling caution for it to be

handled as precision equipment. If packing of your product is

not complete, it may be damaged during transportation. When

you pack your product in a bag, make sure to use conductive

polyvinyl supplied with this product (usually a blue bag).

When you use other bags, they may cause a trouble on your

product because of static electricity.

53

Page 68

54

Page 69

Appendix A Repair Request Sheet

Thank you for purchasing the SH7125 series debugging MCU board (HS7125EDB01H,

HS7125EDB02H, or HS7124EDB01H).

In the event of a malfunction, fill in the repair request sheet on the following pages and send it to

your distributor.

55

Page 70

Repair Request Sheet

To Distributor

Your company name:

Person in charge:

Item Symptom

1. Date and time when the malfunction

occurred

2. Frequency of generation of the

malfunction

3. System configuration when the

malfunction occurred

Month/Day/Year {at system initiation, in system operation}

*Circle either of items in the braces { }.

( ) times in ( ) {day(s), week(s), or month(s)}

*Enter the appropriate numbers in the parentheses ( ) and

circle one of the three items in the braces { }.

Enter the system configuration in use when the malfunction

occurred.

• E10A-USB emulator (HS0005KCU01H or

HS0005KCU02H):

Serial No.:

Revision:

The above items are written on the label for product

management at the bottom of the emulator unit; the serial

no. is the five-digit number and the revision is the string of

letters following the number.

• Provided CD-R (HS0005KCU01SR):

Version: V.

Shown as ‘V.x.xx release’ on the CD-R (x: numeral).

• SH7125 series debugging MCU board (HS7125EDB01H,

HS7125EDB02H, or HS7124EDB01H):

Serial No.:

Revision:

These are impressed on the circuit board.

• Host computer in use:

Manufacturer:

Type number:

OS:

Tel.:

56

Page 71

Item Symptom

4. Settings when the malfunction

occurred

5. Failure phenomenon

6. Error in debugging

7. The High-performance Embedded

Workshop does not link-up with the

debugging MCU board.

Enter the operational settings of the debugging MCU board.

(1) Power-selection switch:

EXTERNAL or USER SYSTEM (circle either item).

(2) Clock-selection jumper:

XTAL or USER CLK (circle either item).

Input clock: MHz

(3) User-system input signal enabling/disabling switches:

UNMI: ENABLE or DISABLE (circle either item).

URES: ENABLE or DISABLE (circle either item).

UCON: ENABLE or DISABLE (circle either item).

(4) Operating frequency: MHz

Content of the error message

For errors other than the above, fill in the box below.

57

Page 72

58

Page 73

Renesas Microcomputer Development Environment System

User's Manual

SH7125 Series Debugging MCU Board

HS7125EDB01H, HS7125EDB02H, HS7124EDB01H

Publication Date: Rev.1.00, July 21, 2006

Published by: Sales Strategic Planning Div.

Renesas Technology Corp.

Edited by: Customer Support Department

Global Strategic Communication Div.

Renesas Solutions Corp.

© 2006. Renesas Technology Corp., All rights reserved. Printed in Japan.

Page 74

Sales Strategic Planning Div. Nippon Bldg., 2-6-2, Ohte-machi, Chiyoda-ku, Tokyo 100-0004, Japan

RENESAS SALES OFFICES

Refer to "http://www.renesas.com/en/network" for the latest and detailed information.

Renesas Technology America, Inc.

450 Holger Way, San Jose, CA 95134-1368, U.S.A

Tel: <1> (408) 382-7500, Fax: <1> (408) 382-7501

Renesas Technology Europe Limited

Dukes Meadow, Millboard Road, Bourne End, Buckinghamshire, SL8 5FH, U.K.

Tel: <44> (1628) 585-100, Fax: <44> (1628) 585-900

Renesas Technology (Shanghai) Co., Ltd.

Unit 204, 205, AZIACenter, No.1233 Lujiazui Ring Rd, Pudong District, Shanghai, China 200120

Tel: <86> (21) 5877-1818, Fax: <86> (21) 6887-7898

Renesas Technology Hong Kong Ltd.

7th Floor, North Tower, World Finance Centre, Harbour City, 1 Canton Road, Tsimshatsui, Kowloon, Hong Kong

Tel: <852> 2265-6688, Fax: <852> 2730-6071

Renesas Technology Taiwan Co., Ltd.

10th Floor, No.99, Fushing North Road, Taipei, Taiwan

Tel: <886> (2) 2715-2888, Fax: <886> (2) 2713-2999

Renesas Technology Singapore Pte. Ltd.

1 Harbour Front Avenue, #06-10, Keppel Bay Tower, Singapore 098632

Tel: <65> 6213-0200, Fax: <65> 6278-8001

Renesas Technology Korea Co., Ltd.

Kukje Center Bldg. 18th Fl., 191, 2-ka, Hangang-ro, Yongsan-ku, Seoul 140-702, Korea

Tel: <82> (2) 796-3115, Fax: <82> (2) 796-2145

Renesas Technology Malaysia Sdn. Bhd

Unit 906, Block B, Menara Amcorp, Amcorp Trade Centre, No.18, Jalan Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia

Tel: <603> 7955-9390, Fax: <603> 7955-9510

http://www.renesas.com

Colophon 6.0

Page 75

Page 76

SH7125 Series Debugging MCU Board

HS7125EDB01H, HS7125EDB02H,

HS7124EDB01H User’s Manual

Loading...

Loading...