REJ10J0040-0600(T)

M3062PT3-RPD-E

User’s Manual

Emulation Pod for M16C/62P and M16C/30P Groups

Rev.6.00

Jul. 01, 2006

Keep safety first in your circuit designs!

1. Renesas Technology Corp. puts the maximum effort into making semiconductor products

better and more reliable, but there is always the possibility that trouble may occur with them.

Trouble with semiconductors may lead to personal injury, fire or property damage.

Remember to give due consideration to safety when making your circuit designs, with appropriate measures such as (i) placement of substitutive, auxiliary circuits, (ii) use of nonflammable material or (iii) prevention against any malfunction or mishap.

Notes regarding these materials

1. These materials are intended as a reference to assist our customers in the selection of the

Renesas Technology Corp. product best suited to the customer's application; they do not

convey any license under any intellectual property rights, or any other rights, belonging to

Renesas Technology Corp. or a third party.

2. Renesas Technology Corp. assumes no responsibility for any damage, or infringement of any

third-party's rights, originating in the use of any product data, diagrams, charts, programs,

algorithms, or circuit application examples contained in these materials.

3. All information contained in these materials, including product data, diagrams, charts, programs and algorithms represents information on products at the time of publication of these

materials, and are subject to change by Renesas Technology Corp. without notice due to

product improvements or other reasons. It is therefore recommended that customers contact

Renesas Technology Corp. or an authorized Renesas Technology Corp. product distributor

for the latest product information before purchasing a product listed herein.

The information described here may contain technical inaccuracies or typographical errors.

Renesas Technology Corp. assumes no responsibility for any damage, liability, or other loss

rising from these inaccuracies or errors.

Please also pay attention to information published by Renesas Technology Corp. by various

means, including the Renesas Technology Corp. Semiconductor home page (http://

www.renesas.com).

4. When using any or all of the information contained in these materials, including product data,

diagrams, charts, programs, and algorithms, please be sure to evaluate all information as a

total system before making a final decision on the applicability of the information and

products. Renesas Technology Corp. assumes no responsibility for any damage, liability or

other loss resulting from the information contained herein.

5. Renesas Technology Corp. semiconductors are not designed or manufactured for use in a

device or system that is used under circumstances in which human life is potentially at stake.

Please contact Renesas Technology Corp. or an authorized Renesas Technology Corp.

product distributor when considering the use of a product contained herein for any specific

purposes, such as apparatus or systems for transportation, vehicular, medical, aerospace,

nuclear, or undersea repeater use.

6. The prior written approval of Renesas Technology Corp. is necessary to reprint or reproduce

in whole or in part these materials.

7. If these products or technologies are subject to the Japanese export control restrictions, they

must be exported under a license from the Japanese government and cannot be imported

into a country other than the approved destination.

Any diversion or reexport contrary to the export control laws and regulations of Japan and/ or

the country of destination is prohibited.

8. Please contact Renesas Technology Corp. for further details on these materials or the

products contained therein.

M3062PT3-RPD-E User’s Manual Preface

Preface

The M3062PT3-RPD-E is an emulation pod for the M16C/60 Series M16C/62P Group and M16C/30 Series M16C/30P Group

of 16-bit MCUs. It is used with a PC4701 emulator (excluding the PC4701L and PC4700L).

This user's manual mainly describes specifications of the M3062PT3-RPD-E emulation pod and how to setup it. For details on

the emulator main unit and emulator debugger, which are used with the M3062PT3-RPD-E, refer to each product's user's

manual.

All the components of this product are shown in "1.1 Package components" (page 13). If there is any question or doubt about

this product, contact your local distributor.

The related manuals for using this product are listed below. You can download the latest manuals from the Renesas Tools

homepage (http://www.renesas.com/en/tools).

Related Manuals

Item Manual

Emulator main unit

PC4701M User’s Manual

PC4701HS User’s Manual

Integrated development environment High-performance Embedded Workshop User’s Manual

Emulator debugger

C compiler C compiler package for R8C/Tiny, M16C/60, 30, Tiny, 20, and 10 Series

Assembler C compiler package for R8C/Tiny, M16C/60, 30, Tiny, 20, and 10 Series

PC4701U User’s Manual

M16C PC4701 Emulator Debugger User’s Manual

M3T-PD30 User’s Manual

C Compiler User's Manual

Assembler User's Manual

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 3 of 104

M3062PT3-RPD-E User’s Manual Important

Important

Before using this product, be sure to read this user’s manual carefully.

Keep this user’s manual, and refer to this when you have questions about this product.

Emulator:

The emulator in this document refers to the following products that are manufactured by Renesas Technology Corp.:

(1) PC4701 main unit

(2) Emulation pod

(3) Package converter board for connecting the user system

The emulator herein does not include the customer’s user system and host machine.

Purpose of use of the emulator:

This emulator is a device to support the development of a system that uses the M16C Family M16C/60 Series M16C/62P

Group and M16C/30 Series M16C/30P Group of Renesas 16bit MCUs. It provides support for system development in both

software and hardware.

Be sure to use this emulator correctly according to said purpose of use. Please avoid using this emulator for other than its

intended purpose of use.

For those who use this emulator:

This emulator can only be used by those who have carefully read the user’s manual and know how to use it.

Use of this emulator requires the basic knowledge of electric circuits, logical circuits, and MCUs.

When using the emulator:

(1) This product is a development supporting unit for use in your program development and evaluation stages. In

mass-producing your program you have finished developing, be sure to make a judgment on your own risk that it can be

put to practical use by performing integration test, evaluation, or some experiment else.

(2) In no event shall Renesas Solutions Corp. be liable for any consequence arising from the use of this product.

(3) Renesas Solutions Corp. strives to renovate or provide a workaround for product malfunction at some charge or without

charge. However, this does not necessarily mean that Renesas Solutions Corp. guarantees the renovation or the provision

under any circumstances.

(4) This product has been developed by assuming its use for program development and evaluation in laboratories. Therefore,

it does not fall under the application of Electrical Appliance and Material Safety Law and protection against

electromagnetic interference when used in Japan.

(5) Renesas Solutions Corp. cannot predict all possible situations or possible cases of misuse where a potential danger exists.

Therefore, the warnings written in this user’s manual and the warning labels attached to this emulator do not necessarily

cover all of such possible situations or cases. Please be sure to use this emulator correctly and safely on your own

responsibility.

(6) This product is not qualified under UL or other safety standards and IEC or other industry standards. This fact must be

taken into account when taking this product from Japan to some other country.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 4 of 104

M3062PT3-RPD-E User’s Manual Important

Usage restrictions:

This emulator has been developed as a means of supporting system development by users. Therefore, do not use it as a device

used for equipment-embedded applications. Also, do not use it for developing the systems or equipment used for the following

purposes either:

(1) Transportation and vehicular

(2) Medical (equipment where human life is concerned)

(3) Aerospace

(4) Nuclear power control

(5) Undersea repeater

If you are considering the use of this emulator for one of the above purposes, please be sure to consult your local distributor.

About product changes:

We are constantly making efforts to improve the design and performance of this emulator. Therefore, the specification or

design of this emulator or its user’s manual may be changed without prior notice.

About the rights:

(1) We assume no responsibility for any damage or infringement on patent rights or any other rights arising from the use of

any information, products or circuits presented in this user’s manual.

(2) The information or data in this user’s manual does not implicitly or otherwise grant a license for patent rights or any other

rights belonging to us or third parties.

(3) This user’s manual and this emulator are copyrighted, with all rights reserved by us. This user’s manual may not be

copied, duplicated or reproduced, in whole or part, without prior written consent of us.

About diagrams:

The diagrams in this user’s manual may not all represent exactly the actual object.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 5 of 104

M3062PT3-RPD-E User’s Manual Precautions for Safety

Precautions for Safety

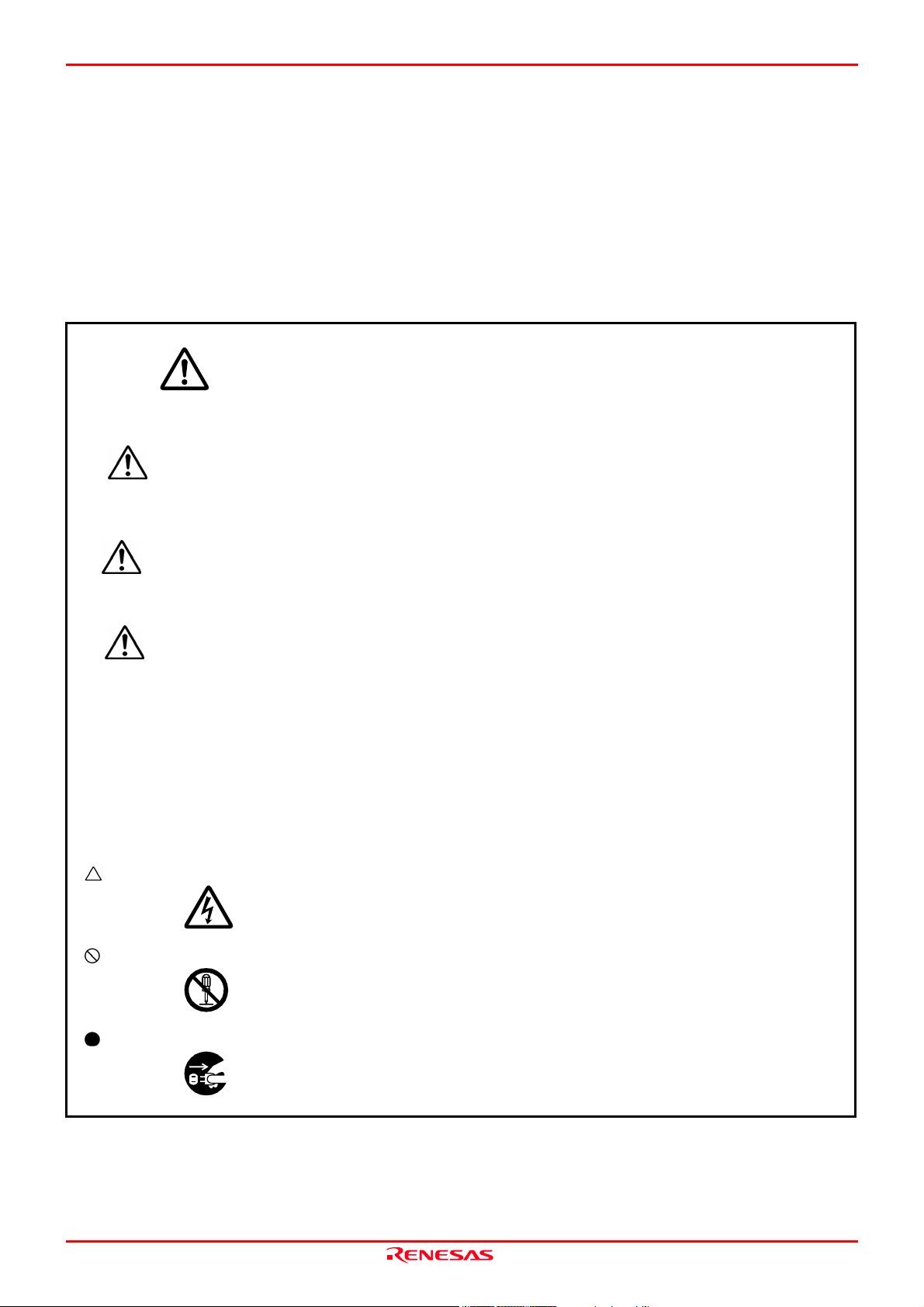

Definitions of Signal Words

In both the user’s manual and on the product itself, several icons are used to insure proper handling of this product and also to

prevent injuries to you or other persons, or damage to your properties.

This chapter describes the precautions which should be taken in order to use this product safely and properly. Be sure to read

this chapter before using this product.

This symbol represents a warning about safety. It is used to arouse caution about a

potential danger that will possibly inflict an injury on persons. To avoid a possible

DANGER

injury or death, please be sure to observe the safety message that follows this symbol.

DANGER indicates an imminently dangerous situation that will cause death or heavy

wound unless it is avoided. However, there are no instances of such danger for the

product presented in this user's manual.

WARNING

CAUTION

CAUTION

IMPORTANT

In addition to the five above, the following are also used as appropriate.

means WARNING or CAUTION.

Example:

WARNING indicates a potentially dangerous situation that will cause death or heavy

wound unless it is avoided.

CAUTION indicates a potentially dangerous situation that will cause a slight injury

or a medium-degree injury unless it is avoided.

CAUTION with no safety warning symbols attached indicates a potentially

dangerous situation that will cause property damage unless it is avoided.

This is used in operation procedures or explanatory descriptions to convey

exceptional conditions or cautions to the user.

CAUTION AGAINST AN ELECTRIC SHOCK

means PROHIBITION.

Example:

DISASSEMBLY PROHIBITED

means A FORCIBLE ACTION.

Example:

UNPLUG THE POWER CABLE FROM THE RECEPTACLE.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 6 of 104

M3062PT3-RPD-E User’s Manual Precautions for Safety

警告警告 WARNING

Warnings for AC Power Supply:

z If the attached AC power cable does not fit the receptacle, do not alter the AC power cable and do not plug it

forcibly. Failure to comply may cause electric shock and/or fire.

z Use an AC power cable which complies with the safety standard of the country.

z Do not touch the plug of the AC power cable when your hands are wet. This may cause electric shock.

z This product is connected signal ground with frame ground. If your developing product is transformless (not

having isolation transformer of AC power), this may cause electric shock. Also, this may give an unrepairable

damage to this product and your developing one.

While developing, connect AC power of the product to commercial power through isolation transformer in

order to avoid these dangers.

z If other equipment is connected to the same branch circuit, care should be taken not to overload the circuit.

z When installing this equipment, insure that a reliable ground connection is maintained.

z If you smell a strange odor, hear an unusual sound, or see smoke coming from this product, then disconnect

power immediately by unplugging the AC power cable from the outlet.

Do not use this as it is because of the danger of electric shock and/or fire. In this case, contact your local

distributor.

z Before setting up this emulator and connecting it to other devices, turn off power or remove a power cable to

prevent injury or product damage.

Warnings to Be Taken for This Product:

z Do not disassemble or modify this product. Personal injury due to electric shock may occur if this product is

disassembled and modified. Disassembling and modifying the product will void your warranty.

z Make sure nothing falls into the cooling fan on the top panel, especially liquids, metal objects, or anything

combustible.

Warning for Installation:

z Do not set this product in water or areas of high humidity. Make sure that the product does not get wet. Spilling

water or some other liquid into the product may cause unrepairable damage.

Warning for Use Environment:

z This equipment is to be used in an environment with a maximum ambient temperature of 35°C. Care should be

taken that this temperature is not exceeded.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 7 of 104

M3062PT3-RPD-E User’s Manual Precautions for Safety

注意注意 CAUTION

Cautions to Be Taken for Turning On the Power:

z Turn ON the power of the emulator and user system as simultaneously as possible. Turn OFF the power of the

emulator and user system as simultaneously as possible.

z Do not leave either the emulator or user system powered on, because of leakage current the internal circuits

may be damaged.

z When turning ON the power again after shutting OFF the power, wait about 10 seconds.

Cautions to Be Taken for Handling This Product:

z Use caution when handling the main unit. Be careful not to apply a mechanical shock.

z Do not touch the connector pins of the emulator main unit and the target MCU connector pins. Static electricity

may damage the internal circuits.

z Do not pull this emulator by the communications interface cable or the flexible cable for connecting the user

system. And, excessive flexing or force may break conductors.

z Do not pull the flexible cable (FLX120-RPD) for connecting to the emulator main unit and the flexible cable

(M3T-FLX160C) for connecting the user system excessively. And, excessive flexing or force may break

conductors.

z Do not use inch-size screws for this equipment. The screws used in this equipment are all ISO (meter-size) type

screws. When replacing screws, use same type screws as equipped before.

Caution to Be Taken for System Malfunctions:

z If the emulator malfunctions because of interference like external noise, do the following to remedy the trouble.

(1) Press the RESET switch on the PC4701’s front panel.

(2) If normal operation is not restored after step (1), shut OFF power to the emulator once and then reactivate

it.

Caution to Be Taken for External Trace Input Voltage:

z Assure that the external trace input voltage of emulator main body does not exceed the TTL level (5.0 V).

Otherwise, internal circuit may be damaged because of overload.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 8 of 104

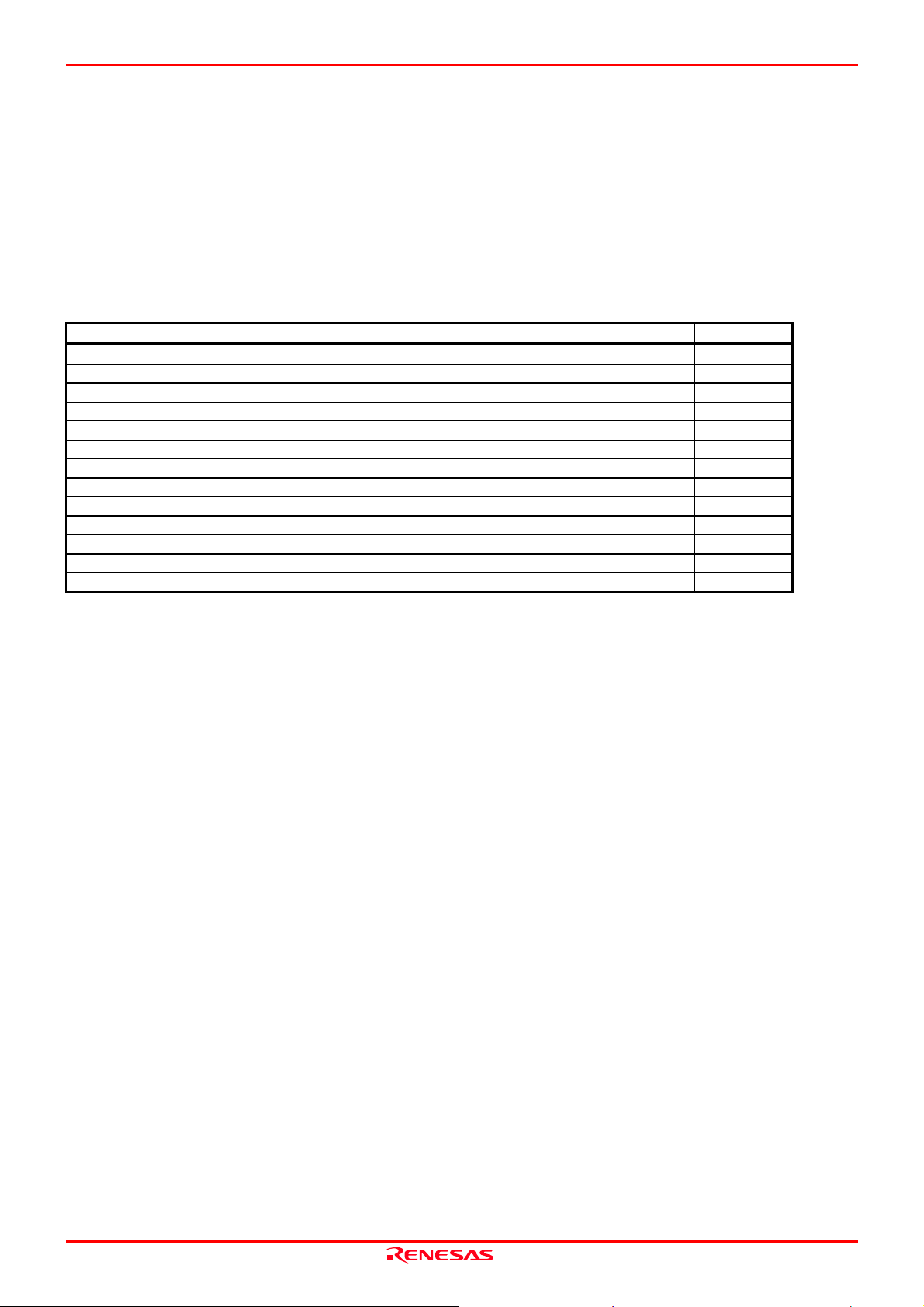

M3062PT3-RPD-E User’s Manual Contents

Contents

Page

Preface.........................................................................................................................................................................

Releated Manuals........................................................................................................................................................ 3

Important......................................................................................................................................................................

Precautions for Safety .................................................................................................................................................

Contents.......................................................................................................................................................................

User Registration .......................................................................................................................................................

Terminology................................................................................................................................................................

1. Outline....................................................................................................................................................................

1.1 Package Components ..................................................................................................................................

1.2 Other Tool Products Required for Development...........................................................................................

1.3 System Configuration ...................................................................................................................................

1.3.1 System Configuration...........................................................................................................................

1.3.2 Names and Functions of the PC4701 Front Panel LEDs ....................................................................

1.4 Specifications................................................................................................................................................

1.5 Operating Environment.................................................................................................................................

2. Setup......................................................................................................................................................................

2.1 Flowchart of Starting Up the Emulator..........................................................................................................

2.2 Installing the Emulator Debugger (M16C PC4701 Emulator Debugger)......................................................

2.2.1 Installing the Emulator Debugger ........................................................................................................

2.3 Connecting the Host Machine ......................................................................................................................

2.4 Connecting the PC4701 ...............................................................................................................................

2.4.1 Connecting the FLX120-RPD to the PC4701 ......................................................................................

2.4.2 Connecting the FLX120-RPD to the Emulation Pod............................................................................

2.5 Turning ON the Power ..................................................................................................................................

2.5.1 Checking the Connections of the Emulator System ............................................................................

2.5.2 Turning ON/OFF the Power .................................................................................................................

2.5.3 LED Display When the Emulator Starts Up Normally ..........................................................................

2.6 Downloading Firmware.................................................................................................................................

2.6.1 When It is Necessary to Download Firmware......................................................................................

2.6.2 Downloading Firmware in Maintenance Mode.....................................................................................

2.7 Self-check .....................................................................................................................................................

2.7.1 Self-check Procedure...........................................................................................................................

2.7.2 If an Error is Detected in the Self-check ..............................................................................................

2.8 Connecting the User System........................................................................................................................

2.8.1 Connecting to a 80-pin 0.65mm Pitch Foot Pattern.............................................................................

2.8.2 Connecting to a 100-pin LCC socket ...................................................................................................

2.8.3 Connecting to a 100-pin 0.65mm Pitch Foot Pattern (Part 1)..............................................................

2.8.4 Connecting to a 100-pin 0.65mm Pitch Foot Pattern (Part 2)..............................................................

2.8.5 Connecting to a 100-pin 0.65mm Pitch Foot Pattern (Part 3)..............................................................

2.8.6 Connecting to a 100-pin 0.5mm Pitch Foot Pattern (Part 1)................................................................

2.8.7 Connecting to a 100-pin 0.5mm Pitch Foot Pattern (Part 2)................................................................

2.8.8 Connecting to a 128-pin 0.5mm Pitch Foot Pattern.............................................................................

2.9 Changing Settings ........................................................................................................................................

2.9.1 Removing/Attaching the Upper Cover .................................................................................................

2.9.2 Each Setting.........................................................................................................................................

2.9.3 Selecting Clock Supply ........................................................................................................................

2.9.4 Switch Settings ....................................................................................................................................

2.9.5 Jumper Switches JP1 and JP2 on the M30620T3-PRT (MCU-dependent board 1)...........................

2.9.6 Installing and Removing Network Resistors for Pullup........................................................................

2.9.7 Bypass Capacitors for A/D Converter ..................................................................................................

3

4

6

9

11

12

13

13

14

15

15

16

18

19

20

20

21

21

22

23

23

24

25

25

25

26

27

27

27

28

28

29

30

31

32

33

34

35

36

37

38

39

39

40

41

45

47

48

49

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 9 of 104

M3062PT3-RPD-E User’s Manual Contents

Page

3. Usage (How to Use the Emulator Debugger) ........................................................................................................ 50

3.1. Making an MCU File ....................................................................................................................................

3.2 Setting the Work Area...................................................................................................................................

3.3 Starting Up the Emulator Debugger .............................................................................................................

3.3.1 Init Dialog Box......................................................................................................................................

3.3.2 Checking Connections of the Emulator System ..................................................................................

3.4 Downloading Program ..................................................................................................................................

3.5 Program execution .......................................................................................................................................

3.6 Hardware Break............................................................................................................................................

3.7 Trace Window...............................................................................................................................................

3.8 RAM Monitor Window...................................................................................................................................

4. Hardware Specifications ........................................................................................................................................

4.1 Target MCU Specifications ...........................................................................................................................

4.2 Access Timing...............................................................................................................................................

4.2.1 Operation Timing of Memory Expansion Mode and Microprocessor Mode (Vcc1=Vcc2=5V).............

4.2.2 Operation Timing of Memory Expansion Mode and Microprocessor Mode (Vcc1=Vcc2=3V).............

4.3 Differences between the Actual MCU and Emulator ....................................................................................

4.4 Connection Diagram.....................................................................................................................................

4.5 External Dimensions.....................................................................................................................................

4.5.1 External Dimensions of the Emulation Pod .........................................................................................

4.5.2 External Dimensions of the M30800T-PTC .........................................................................................

4.5.3 External Dimensions of the Converter Board M3062PT-80FPB..........................................................

4.5.4 External Dimensions of the Converter Board M3T-F160-100NRB......................................................

4.5.5 External Dimensions of the Converter Board M3T-F160-100NSD......................................................

4.5.6 External Dimensions of the Converter Board M3T-F160-128NRD......................................................

4.6 Notes on Using This Product........................................................................................................................

5. Troubleshooting .....................................................................................................................................................

5.1 Flowchart to Remedy the Troubles...............................................................................................................

5.2 When the Emulator Debugger Does Not Start Up Properly .........................................................................

5.3 How to Request for Support .......................................................................................................................

6. Maintenance and Guarantee ...............................................................................................................................

6.1 User Registration........................................................................................................................................

6.2 Maintenance ...............................................................................................................................................

6.3 Guarantee...................................................................................................................................................

6.4 Repair Provisions........................................................................................................................................

6.5 How to Make Request for Repair ...............................................................................................................

50

51

52

52

58

59

60

63

67

71

72

72

73

73

78

83

86

88

88

89

90

90

91

91

92

96

96

97

100

101

101

101

101

101

102

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 10 of 104

M3062PT3-RPD-E User’s Manual User Registration

User Registration

When you have purchased the emulator presented in this user's manual, please be sure to register it. As the H/W Tool Customer

Registration Sheet is included with this manual, fill it in and FAX it to your local distributor or email the same contents to the

following address. If you register it by email, you can use a text format for user registration created when installing the

software in the following folder. Your registered information is used for only after-sale services, and not for any other purposes.

Without user registration, you will not be able to receive maintenance services such as a notification of field changes or trouble

information. So be sure to carry out the user registration.

For more information about user registration, please email to the following address.

Text format for user registration C:\Program Files\Renesas\Hew\Support

For user registration regist_tool@renesas.com

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 11 of 104

M3062PT3-RPD-E User’s Manual Terminology

Terminology

Some specific words used in this user's manual are defined as follows:

Emulator main unit (Hereafter PC4701)

This means a generic name for emulators for M16C, 7700, 740 Families. Take note of the fact that the M3062PT3-RPD-E (this

product) does not support the PC4701L and PC4700L emulators. For details on specific models of PC4701, visit the Renesas

Tools Homepage at http://www.renesas.com/en/tools.

Emulation pod

This means the emulation pod (this product) for the M16C/60 Series M16C/62P Group and M16C/30 Series M16C/30P Group

MCUs.

Emulator system

This means an emulator system built around the PC4701 emulator. The PC4701 emulator system is configured with an

emulator main unit, emulation pod, host machine and integrated development environment High-performance Embedded

Workshop .

Renesas Integrated development environment High-performance Embedded Workshop

This tool provides powerful support for the development of embedded applications for Renesas microcomputers. It has an

emulator debugger function allowing for the emulator PC4701 and emulation pod to be controlled from the host machine via

an interface. Furthermore, it permits a range of operations from editing a project to building and debugging it to be performed

within the same application. What’s more, it supports version management.

Emulator debugger (M16C PC4701 emulator debugger)

This means a software tool starting up from the High-performance Embedded Workshop to control the emulator and this

product and enables debugging.

Firmware

Program that analyzes contents of communication with the emulator debugger and controls the emulator hardware. This

program is installed in the flash memory in the emulator main unit. This program is downloadable from the emulator debugger

to upgrade the firmware or to support other MCUs.

Host machine

This means a personal computer used to control the emulator main unit and emulation pod.

Software break

A software break is a function to break the program before the system executes an instruction at the specified address. The

instruction at the preset address will not be executed.

Hardware break

A hardware break is a function to break the program when the system detects a write/read of data to/from memory or a

leading/trailing edge of the signal entered from the external trace cable. The former break function is called address break; and

the latter break function is called trigger break. While the instruction at the address where the software break is set is not

executed, a hardware break is performed after the specified instruction is executed.

Target MCU

This means the MCU you are going to debug.

User system

This means a user’s application system using the microcomputer to be debugged.

User program

This means the program you are going to debug.

Evaluation MCU

This means the MCU mounted on the emulation pod which is operated in the specific mode for tools.

#

In this user’s manual, this symbol is used to show active Low. (e.g. RESET#: Reset signal)

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 12 of 104

M3062PT3-RPD-E User’s Manual 1. Outline

1. Outline

This chapter describes the package components, the system configuration and the preparation for using this product for the first

time.

1.1 Package Components

The M3062PT3-RPD-E package consists of the following items. When unpacking it, check to see if your M3062PT3-RPD-E

contains all of these items.

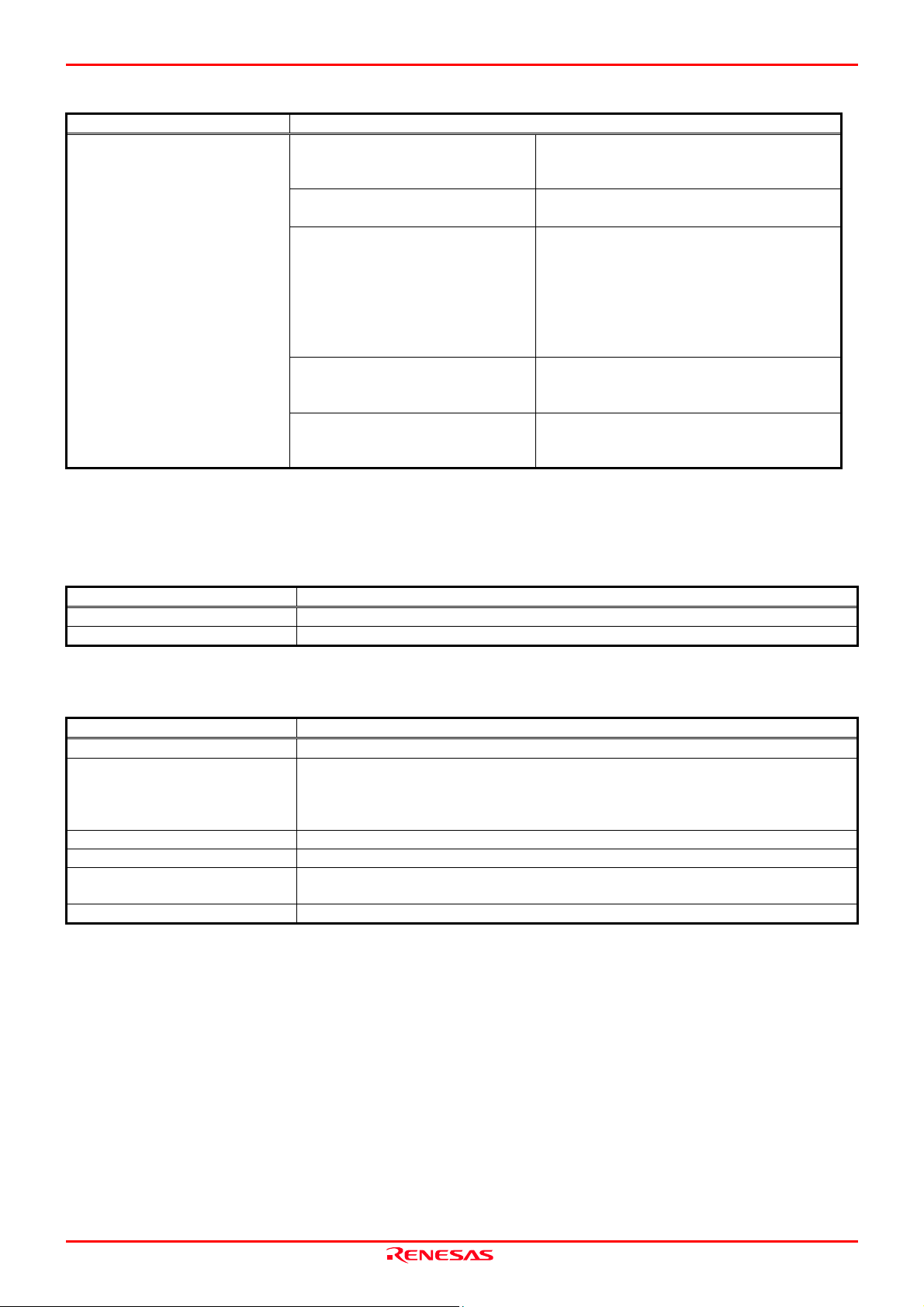

Table 1.1 Package components

Item Quantity

M3062PT3-RPD-E emulation pod 1

FLX120-RPD flexible cable for connecting PC4701 1

M30800T-PTC converter board for 100-pin 0.65mm pitch LCC 1

IC61-1004-051 100-pin 0.65mm pitch LCC socket made by Yamaichi Electronics Co., Ltd. 1

OSC-3 16MHz oscillator circuit board for main clock (preinstalled) 1

OSC-2 oscillator circuit board (bare board)

Network resistors for pulling up ports P0--P5 (51kΩ x 8) 6

H/W Tool Customer Registration Sheet (English) 1

H/W Tool Customer Registration Sheet (Japanese) 1

Repair request sheet (English) 1

Repair request sheet (Japanese) 1

M3062PT3-RPD-E User’s Manual (This manual) 1

M3062PT3-RPD-E User’s Manual (Japanese) 1

* Please keep the M3062PT3-RPD-E's packing box and cushion material in your place for reuse at a later time when sending

your product for repair or other purposes. Always use these packing box and cushion material when transporting this

product.

* If there is any question or doubt about the packaged product, contact your local distributor.

* For purchasing the IC61-1004-051 or for technical information, contact Yamaichi Electronics Co., Ltd.

1

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 13 of 104

M3062PT3-RPD-E User’s Manual 1. Outline

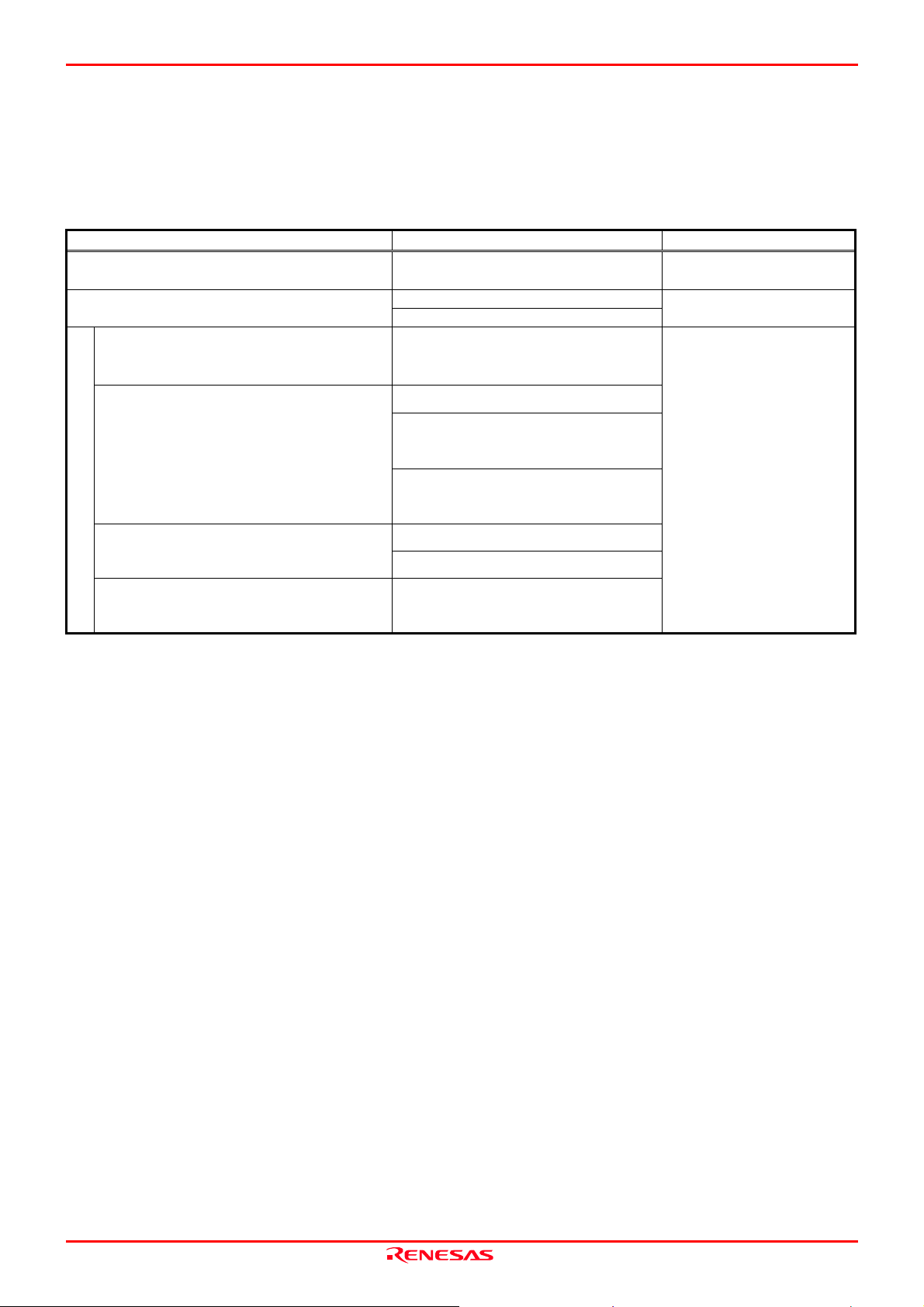

1.2 Other Tool Products Required for Development

To bring forward programs development on the M16C/60 Series M16C/62P Group and M16C/30 Series M16C/30P Group, the

products listed below are necessary in addition to those contained package above. Get them separately.

Table 1.2 Other tool products required for development

Product Product name Notes

Emulator main unit

Emulator debugger

80-pin 0.65mm pitch QFP

(PRQP0080JA-A,

Previous code: 80P6S-A)

100-pin 0.65mm pitch QFP

(PRQP0100JB-A,

Previous code: 100P6S-A)

100-pin 0.5mm pitch LQFP

Pitch converter board

(PLQP0100KB-A,

Previous code: 100P6Q-A)

128-pin 0.5mm pitch LQFP

(PLQP0128KB-A,

Previous code: 128P6Q-A)

* To purchase these products, contact your local distributor.

PC4701

(excluding the PC4700L and PC4701L)

M16C PC4701 Emulator Debugger

M3T-PD30

M3062PT-80FPB

M3T-F160-100NRB

M3T-100LCC-DMS

+

M3T-DIRECT100S

M3T-100LCC-DMS

+

M3T-DUMMY100S

M3T-F160-100NSD

M3T-100LCC-QSD

M3T-F160-128NRD

-

Included with the PC4701

Required according to a foot

pattern of a user system.

Refer to “2.8 Connecting

the User System” (page 30)

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 14 of 104

M3062PT3-RPD-E User’s Manual 1. Outline

1.3 System Configuration

1.3.1 System Configuration

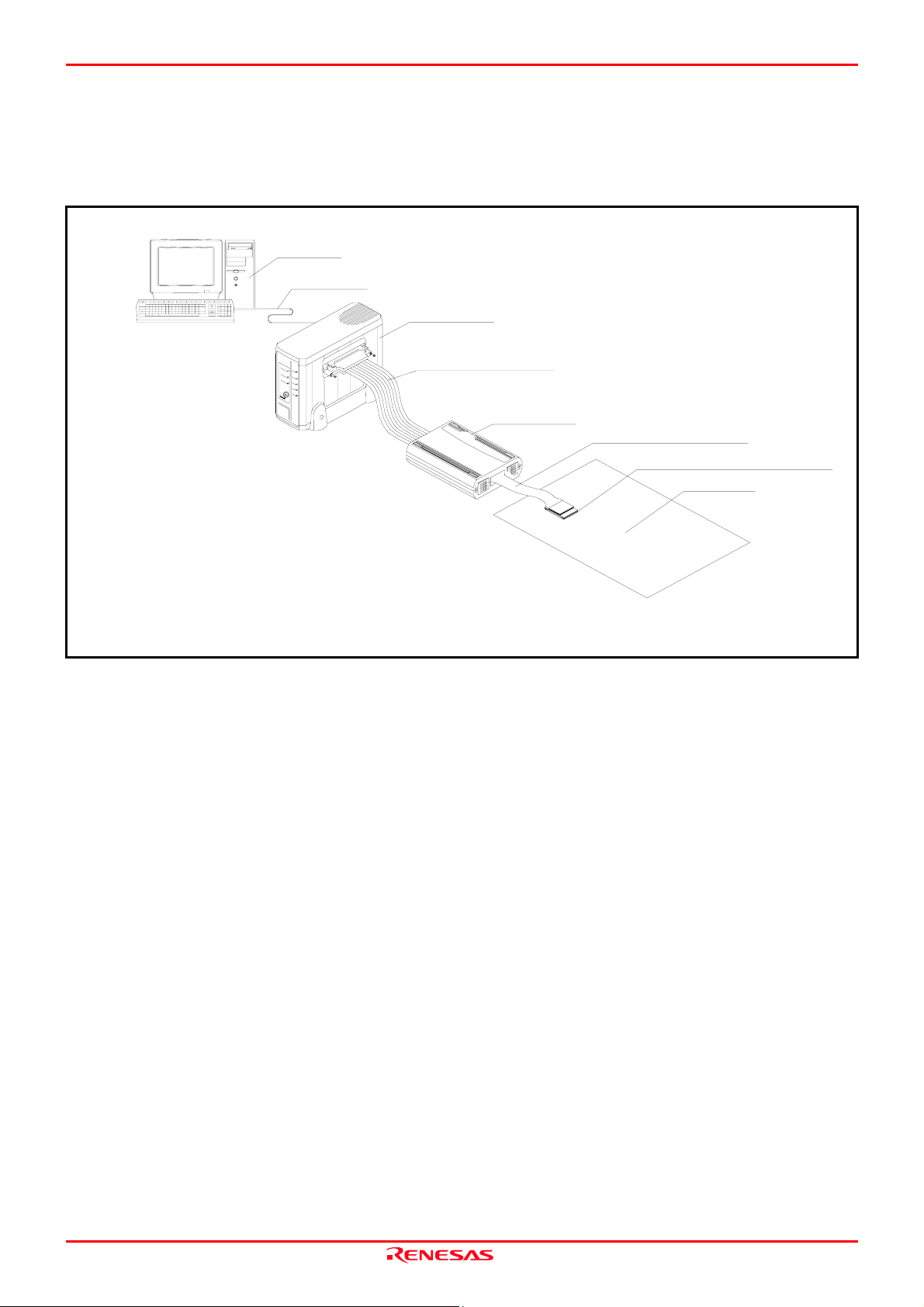

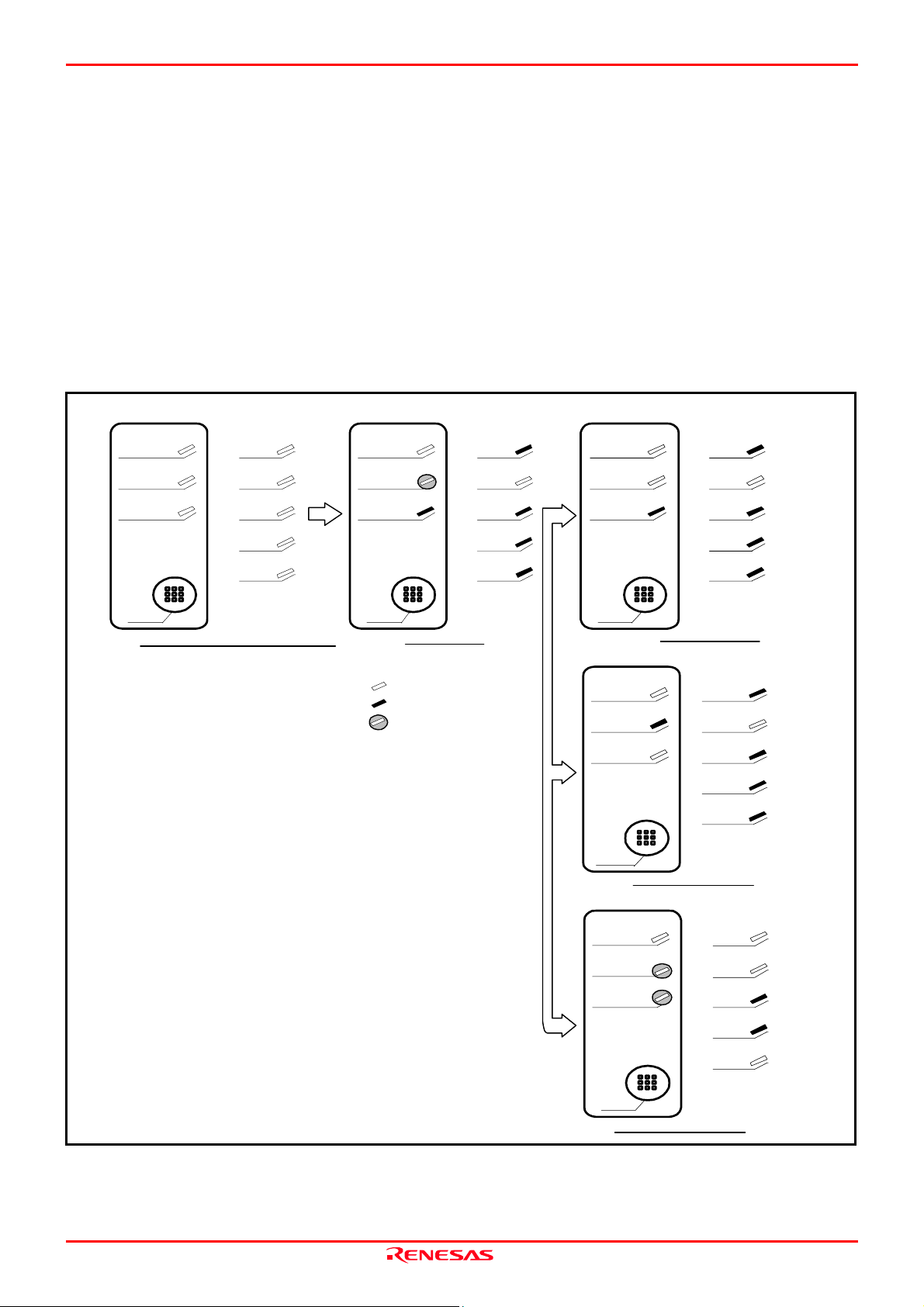

Figure 1.1 shows a configuration of the PC4701 system.

(6) Host machine

Interface cable

Host machine

(5) Emulator main unit

(2)

Flexible cable connecting PC4701

(1) Emulation pod

(3 ) Flexible cable connecting user system

Package converter board for connecting user system

(4)

(7 ) User system

Figure 1.1 System configuration

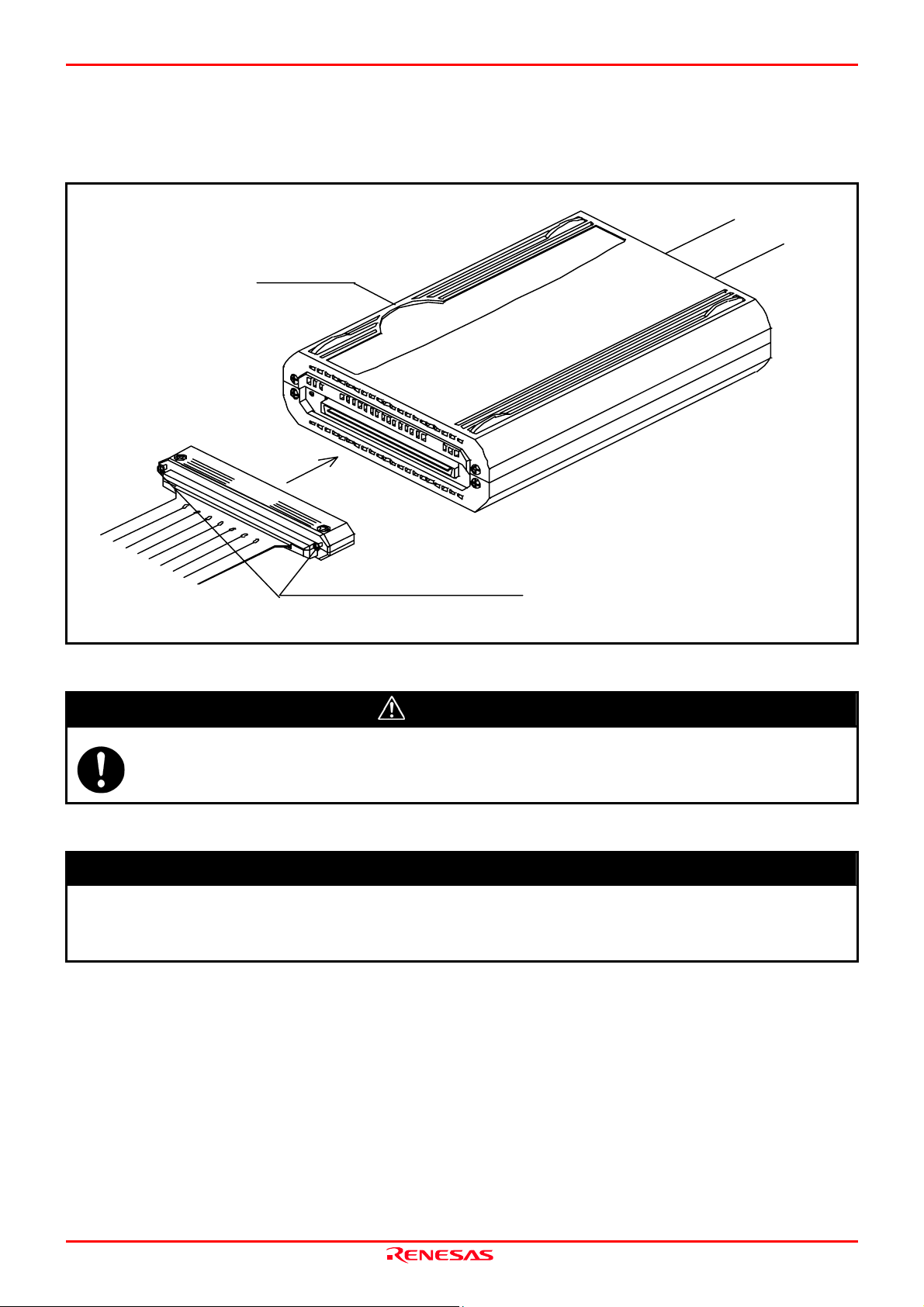

(1) Emulation pod M3062PT3-RPD-E (this product)

Emulation pod for the M16C/60 Series M16C/62P Group and M16C/30 Series M16C/30P Group. This emulation pod

contains an evaluation MCU.

(2) Flexible cable FLX120-RPD (included)

This is a 120-conductor flexible cable for connecting the PC4701 emulator and the emulation pod.

(3) Flexible cable M3T-FLX160C (included)

This is a 160-conductor flexible cable for connecting the emulation pod and the user system.

(4) Converter board M30800T-PTC (included)

This is a converter board for connecting to 100-pin 0.65mm pitch LCC socket IC61-1004-051 on the user system. For

details, refer to "2.8 Connecting the User System" (page 30).

(5) Emulator main unit PC4701

The emulator main unit for the M16C, 7700 and 740 families to be used with this product.

(6) Host machine

A personal computer to control the emulator.

(7) User system

This is your application system.

This emulator cannot supply the power to the user system. Therefore design your system so that the user system is

powered separately.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 15 of 104

M3062PT3-RPD-E User’s Manual 1. Outline

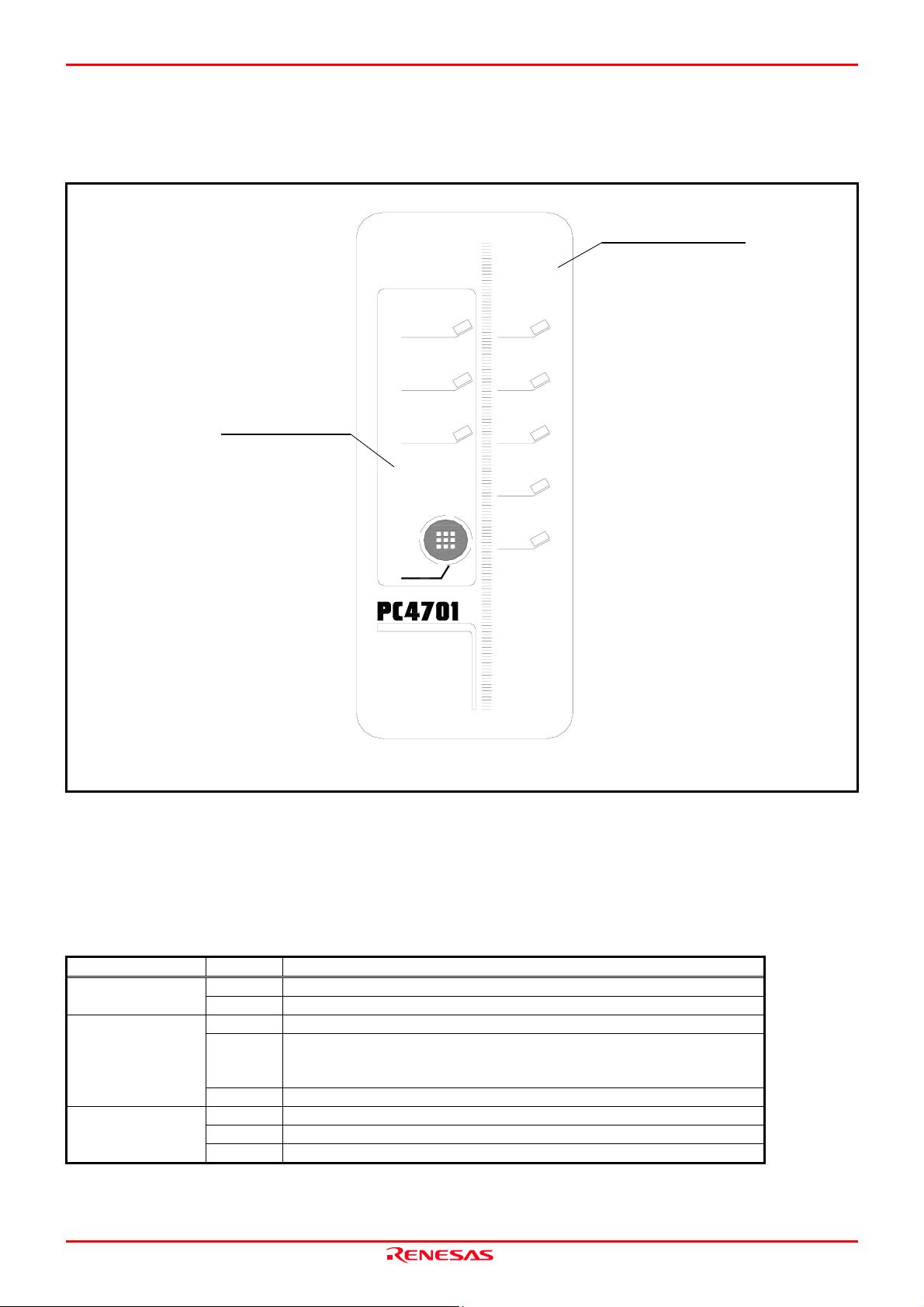

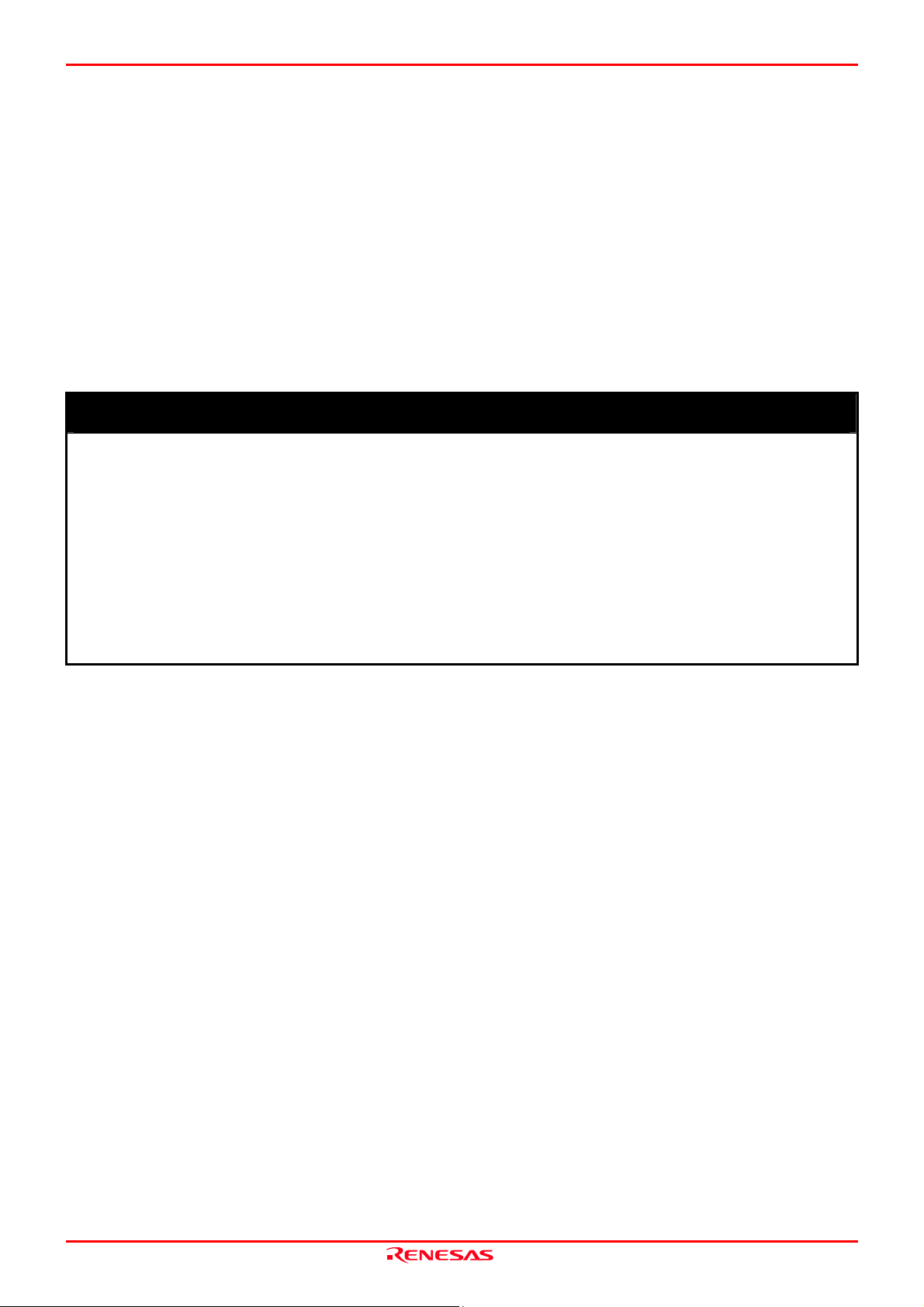

1.3.2 Names and Functions of the PC4701 Front Panel LEDs

Figure 1.2 shows the names of the LEDs on the front panel of the emulator.

Target status LEDs

STATUS OF

TARGET

System status LEDs

POWER

SAFE

ERROR

STATUS OF

SYSTEM

RESET

PERFORMANCE

HIGH

EMULATOR

POWER

CLOCK

RESET

RUN

HALT

Figure 1.2 Names of the LEDs on the front panel of the PC4701

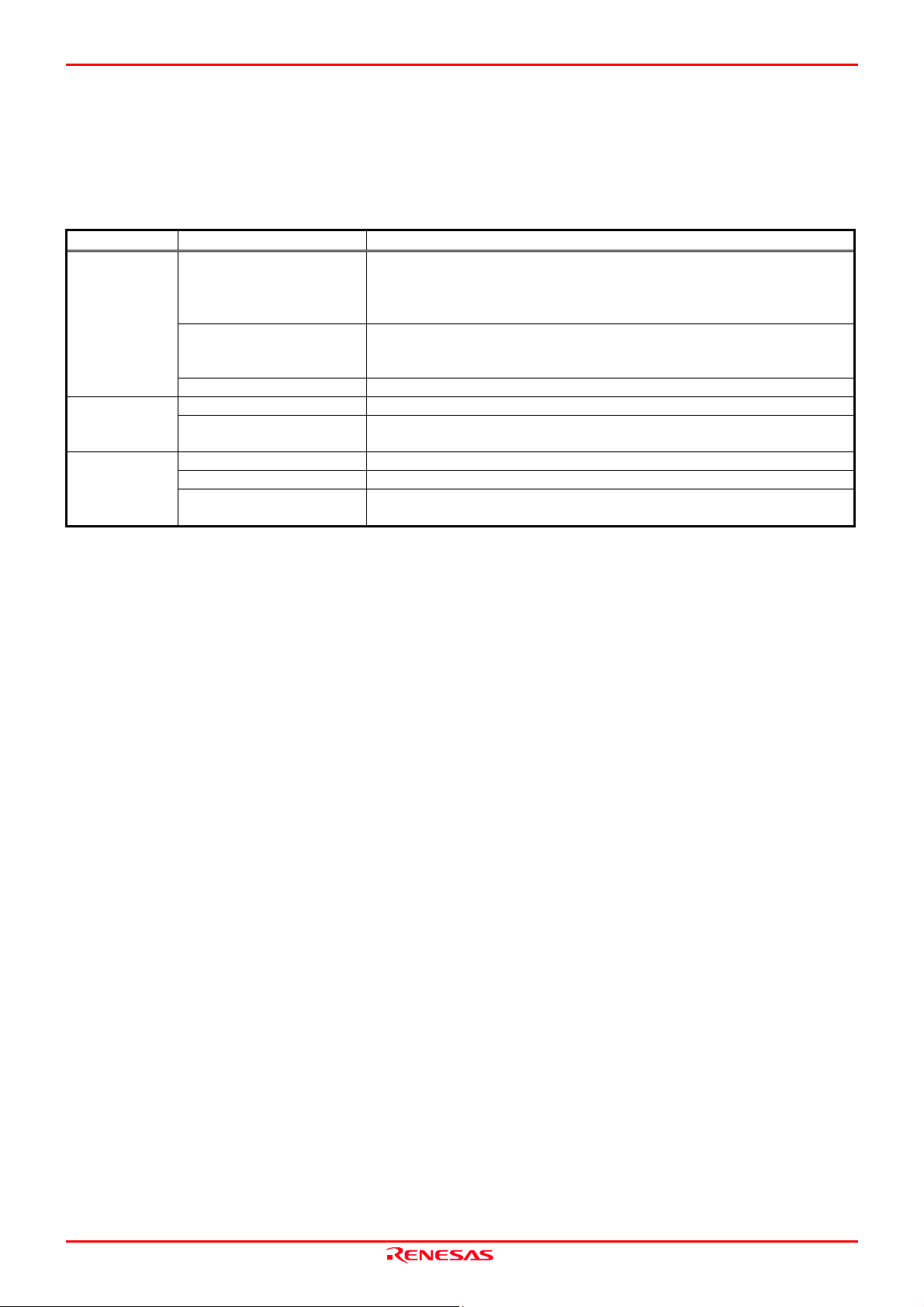

(1) System Status LEDs

The system status LEDs indicate the emulator PC4701's power supply, firmware operating status, etc. Table 1.3 lists the

definition of each system status LED.

Table 1.3 Definitions of the system status LEDs

Name Status Meaning

POWER

ON Emulator system power supply is turned ON.

OFF Emulator system power supply is turned OFF.

ON Emulator system is operating normally.

Special mode (maintenance mode) for downloading firmware. The

SAFE

Flashing

emulator system does not operate except for downloading firmware and

the self-check.

OFF

Emulator system is not operating normally.

ON Emulator system is not operating normally (system status error).

ERROR

Flashing Downloading firmware.

OFF Emulator system is operating normally.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 16 of 104

M3062PT3-RPD-E User’s Manual 1. Outline

(2) Target Status LEDs

The target status LEDs indicate the target MCU's operating status and target board's power supply. Table 1.4 lists the definition

of each target status LED.

Table 1.4 Definitions of the target status LEDs

Name Status Meaning

POWER

CLOCK

RESET

RUN

HALT

ON Power is supplied to the user system.

OFF Power is not supplied to the user system.

ON Target MCU clock is supplied.

OFF Target MCU clock is not supplied.

ON Target MCU is being reset, or reset signal of the user system is held low.

OFF Target MCU is not being reset.

ON User program is being executed.

OFF User program has been halted.

ON CPU clock of target MCU is not oscillating.

OFF CPU clock of target MCU is oscillating.

Note on the Target Status POWER LED:

z If the MCU has two or more Vcc terminals, the LED does not light unless power is supplied to all the

Notes on the Target Status CLOCK LED:

terminals.

z CLOCK LED is turned off when both main and sub clocks are not oscillating. If either clock is oscillating,

the LED is turned on.

z If the LED is not turned on, check the following.

(1) After powering on the PC4701 (before starting up the emulator debugger):

Make sure that the oscillator circuit board in the emulation pod is properly installed and it is oscillating

normally.

(2) After the emulator debugger is started up (after the Init dialog box settings are completed):

Make sure that the oscillator selected in the Init dialog box is oscillating normally.

IMPORTANT

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 17 of 104

M3062PT3-RPD-E User’s Manual 1. Outline

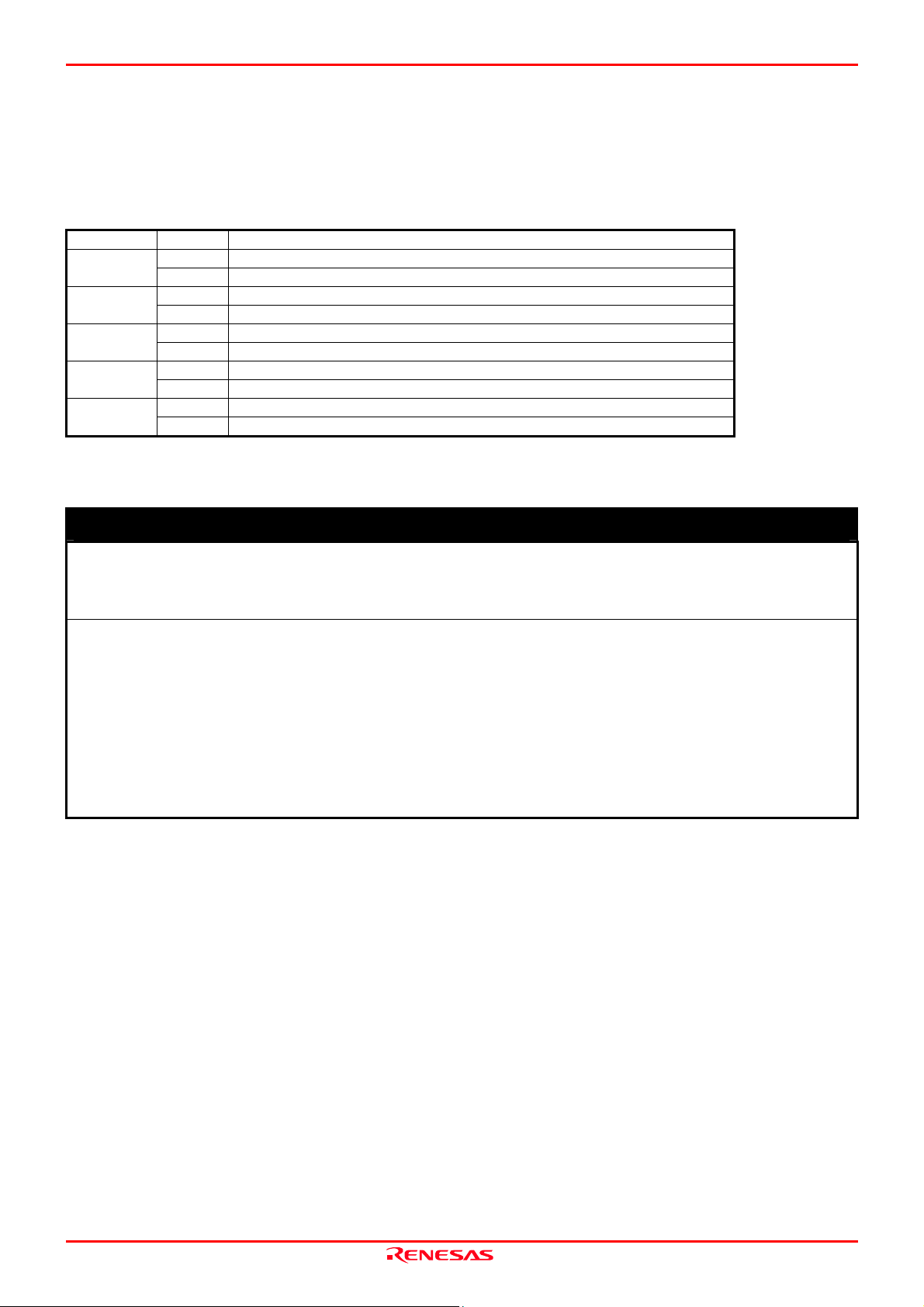

1.4 Specifications

Tables 1.5 and 1.6 list the specifications of the M3062PT3-RPD-E.

Table 1.5 M3062PT3-RPD-E specifications (1/2)

Item Description

Applicable MCU

Usable MCU mode

Maximum operating frequency 16MHz

Applicable power supply 2.7 to 5.5V

Emulation Memory 1MB

Clock supply

Basic debugging functions

Real-time trace function

Real-time RAM monitor function

Hardware break function 6 points (Bus detection, interrupt, external trace signal)

Execution time measurement function

C0 coverage 256KB

Event output Break x1, Event x6

External trigger input TTL level x8

Host machine interface

(see “2.3 Connecting the Host Machine”

on page 22)

Power supply to emulator AC: 100 to 120V, AC: 200 to 240V (50/60Hz)

Power supply to emulation pod Supplied from the PC4701

Overseas standards

*1 Available to connect the host machine that supports USB 2.0. With the USB interface, not all hardware (such as host

machine, USB devices, USB hub) combination will work and guaranteed.

M16C/60 Series M16C/62P Group

M16C/30 Series M16C/30P Group

Single-chip mode

Memory expansion mode

Microprocessor mode

Internal ROM/RAM capacity : 0 wait, 16MHz(max)

External area

Main clock

Sub clock

- Download

- Software break (max. 64 points)

- Program execution/stop (allows free-run execution supporting software

breaks)

- Memory reference/setting (reference/setting C-variables, run-time execution)

- Register reference/setting

- Disassemble display

- C-level debugging, etc.

- 32K-cycle bus information recordable

(Bus, external trigger, time stamp)

- 5 trace modes supported (Break/Before/About/After/Full)

- Can be recorded ON/OFF by events

- 1,024 bytes

- Data/last access result

Time between program start and stop

Maximum/minimum/average execution time and pass count of specified four

zones.

Count clock: Equal to MCU Clock or 16MHz

Dedicated parallel (PC4701HS)

LPT parallel (PC4701M/PC4701U)

Serial (PC4701HS/PC4701M)

USB (USB 1.1, full-speed)*1 (PC4701U)

LAN (PC4701HS/PC4701U)

US EMI Standards [FCC part15 Class A]

CE marking [1998 Class A, EN55024: 1998]

Internal oscillator circuit board (OSC-3)

Switchable to external oscillator input

Internal oscillator circuit (fixed 32.768kHz)

Switchable to external oscillator input

: 0 wait, 8MHz(max)

: 1 wait,16MHz(max)

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 18 of 104

M3062PT3-RPD-E User’s Manual 1. Outline

Table 1.6 M3062PT3-RPD-E specifications (2/2)

Item Description

Connecting the user system

see “2.8 Connecting the User

System” (page 30)

80-pin 0.65mm pitch QFP

(PRQP0080JA-A,

Previous code: 80P6S-A)

100-pin 0.65mm pitch LCC socket

(1) M3062PT-80FPB (not included)

(1) M30800T-PTC (included)

+ IC61-1004-051 (included)

(1) M3T–F160–100NRB (not included)

(2) M30800T-PTC (included)

100-pin 0.65mm pitch QFP

(PRQP0100JB-A,

Previous code: 100P6S-A)

+ M3T-100LCC-DMS (not included)

+ M3T-DIRECT100S (not included)

(3) M30800T-PTC (included)

+ M3T-100LCC-DMS (not included)

+ M3T-DUMMY100S (not included)

100-pin 0.5mm pitch LQFP

(PLQP0100KB-A,

Previous code: 100P6Q-A)

(1) M3T-F160-100NSD (not included)

(2) M30800T-PTC (included)

+ M3T-100LCC-QSD (not included)

128-pin 0.5mm pitch LQFP

(PLQP0128KB-A,

(1) M3T-F160-128NRD (not included)

Previous code: 128P6Q-A)

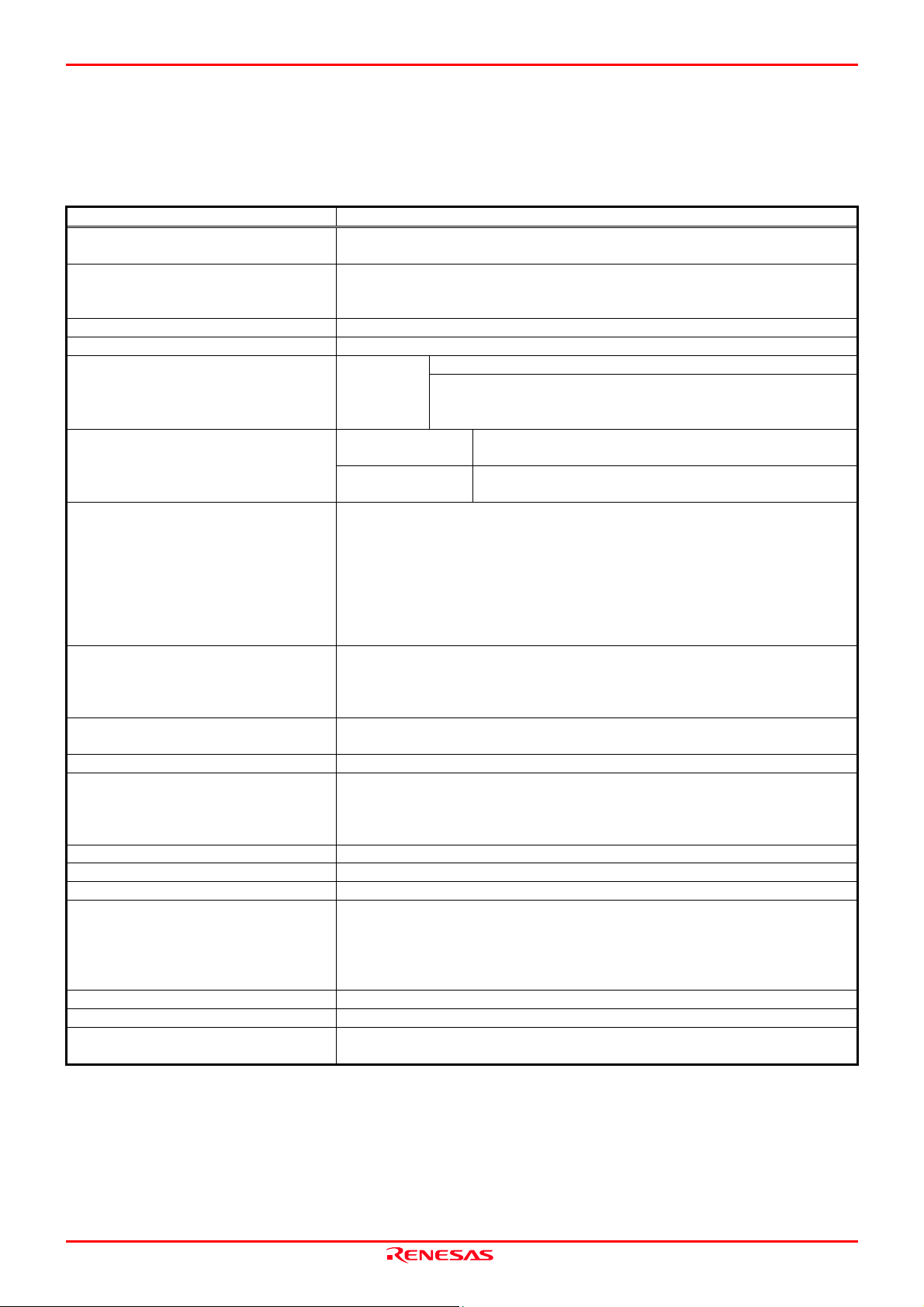

1.5 Operating Environment

Be sure to use this emulator with the operating environmental of the emulator and host machine listed in Tables 1.7 and 1.8.

Table 1.7 Operating environmental conditions

Item Description

Operating temperature 5 to 35°C (no dew)

Storage temperature -10 to 60°C (no dew)

Table 1.8 Operating environment of the host machine

Item Description

Host machine

OS

CPU Pentium III 600 MHz or more recommended

Memory 128 MB or more recommended

Pointing device such as mouse Mouse or any other pointing device usable with the above OS that can be connected to

CD drive Needed to install the emulator debugger or refer to the user’s manual

* Windows is trademarks of Microsoft Corporation in the United States and other countries.

IBM PC/AT compatibles

Windows 98SE

Windows Me

Windows XP

Windows 2000

the main body of the host machine.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 19 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2. Setup

This chapter describes the preparation for using this product, the procedure for starting up the emulator and how to change

settings.

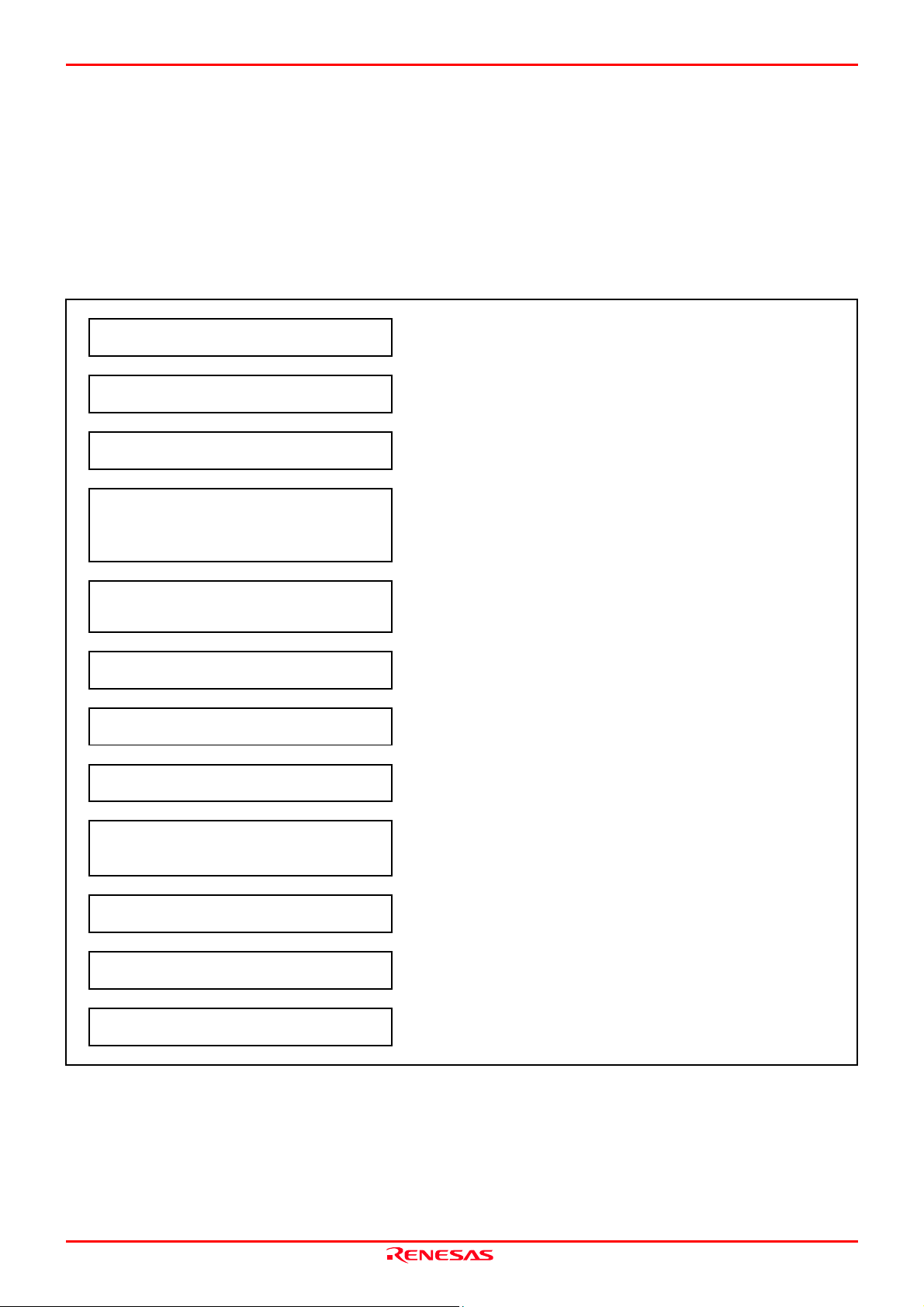

2.1 Flowchart of Starting Up the Emulator

The procedure for starting up the emulator is shown in Figure 2.1. For details, refer to each section hereafter. And, when the

emulator does not start up normally, refer to “5. Troubleshooting” (page 96).

▼

▼

▼

▼

Connect the emulation pod to the emulator.

Check the package components. Refer to “1.1 Package Components” (page 13).

User registration Refer to “User Registration” (page 11).

Install the M16C PC4701 Emulator

Debugger.

Connect the host machine.

Install the M16C PC4701 Emulator Debugger.

Select the interface according to your PC4701 and connect the

PC4701 to the host machine with each interface connector.

Set the interface selection switch on the rear panel of the PC4701 to

the using interface.

Connect the emulation pod M3062PT3-RPD-E to the PC4701 using

the FLX120-RPD.

▼

Connect the power supply for the emulator. Connect a power supply for the emulator.

▼

▼

▼

▼

Start up the emulator debugger from the

High-performance Embedded Workshop.

▼

▼

Debug a program with various functions of

Figure 2.1 Flowchart of starting up the emulator

Connect the user system. Connect the user system as occasion demands.

Turning on the power supply.

Check the LED display of the emulator.

Set the operating environment

of the emulator debugger.

the emulator debugger.

Turn ON the power to the emulator and the user system as

simultaneously as possible.

Check that system status LED, and POWER, CLOCK, RESET and

WARNING of target status LED are lighting. When the user system

is not connected, the POWER LED does not light up.

Start up the High-performance Embedded Workshop, and the

emulator debugger.

Set the INIT dialog box of the emulator debugger.

For how to use the High-performance Embedded Workshop and the

emulator debugger, refer to each online manual.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 20 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.2 Installing the Emulator Debugger (M16C PC4701 Emulator Debugger)

If the OS used in your host machine is Windows XP or 2000, this installation must be executed by a user with administrator

rights. Be aware that users without administrator rights cannot complete the installation.

Install the M16C PC4701 Emulator Debugger following the procedure described below.

2.2.1 Installing the Emulator Debugger

(1) Downloading the M16C PC4701 Emulator Debugger (as occasion demands)

Download the latest M16C PC4701 Emulator Debugger from the URL below (free of charge).

http://download.renesas.com/eng/mpumcu/upgrades/in_circuit_emulators/m16c/index.html

(2) Launching the installer

Start the “setup.exe” program.

(3) Entering the user information

In the “user information” dialog box, enter the user information (contractor, section, contact address, and host machine).

The supplied information will be turned into a format by which user registration will be provided by e-mail.

(4) Completing the installation

A dialog box will be displayed indicating that setup has been completed. It means that the installation you made is

completed.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 21 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.3 Connecting the Host Machine

When connecting the emulator PC4701 to a host machine, interface varies depending on the PC4701 used. Table 2.1 shows the

outline to connect each interface cable. For details on interface, refer to each PC4701 user’s manual used.

Table 2.1 Operating environment of the host machine

PC4701 Interface Remarks

The dedicated parallel interface cable is supplied with the PC4701HS.

For connection with the dedicated parallel interface, the parallel interface

printed circuit board (PCA4202G02: discontinued product) is required on

the host machine side.

The RS232C interface cable, 25-pin female/25-pin female conversion cable

and 25-pin female/9-pin female conversion cable are supplied with the

PC4701HS.

The RS232C interface cable and 25-pin female/9-pin male conversion cable

are supplied with the PC4701M.

No LAN interface cable is supplied with the PC4701U; it is, therefore,

necessary to arrange a LAN interface cable at your end.

PC4701HS

PC4701M

PC4701U

Dedicated parallel

Serial (RS232C)

LAN (10BASE-2/5) The LAN interface cable (10BASE-2/5) is supplied with the PC4701HS.

LPT parallel The LPT parallel interface cable is supplied with the PC4701M.

Serial (RS232C)

LPT parallels The LPT parallel interface cable is supplied with the PC4701U.

USB The USB interface cable is supplied with the PC4701U.

LAN (10BASE-T)

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 22 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

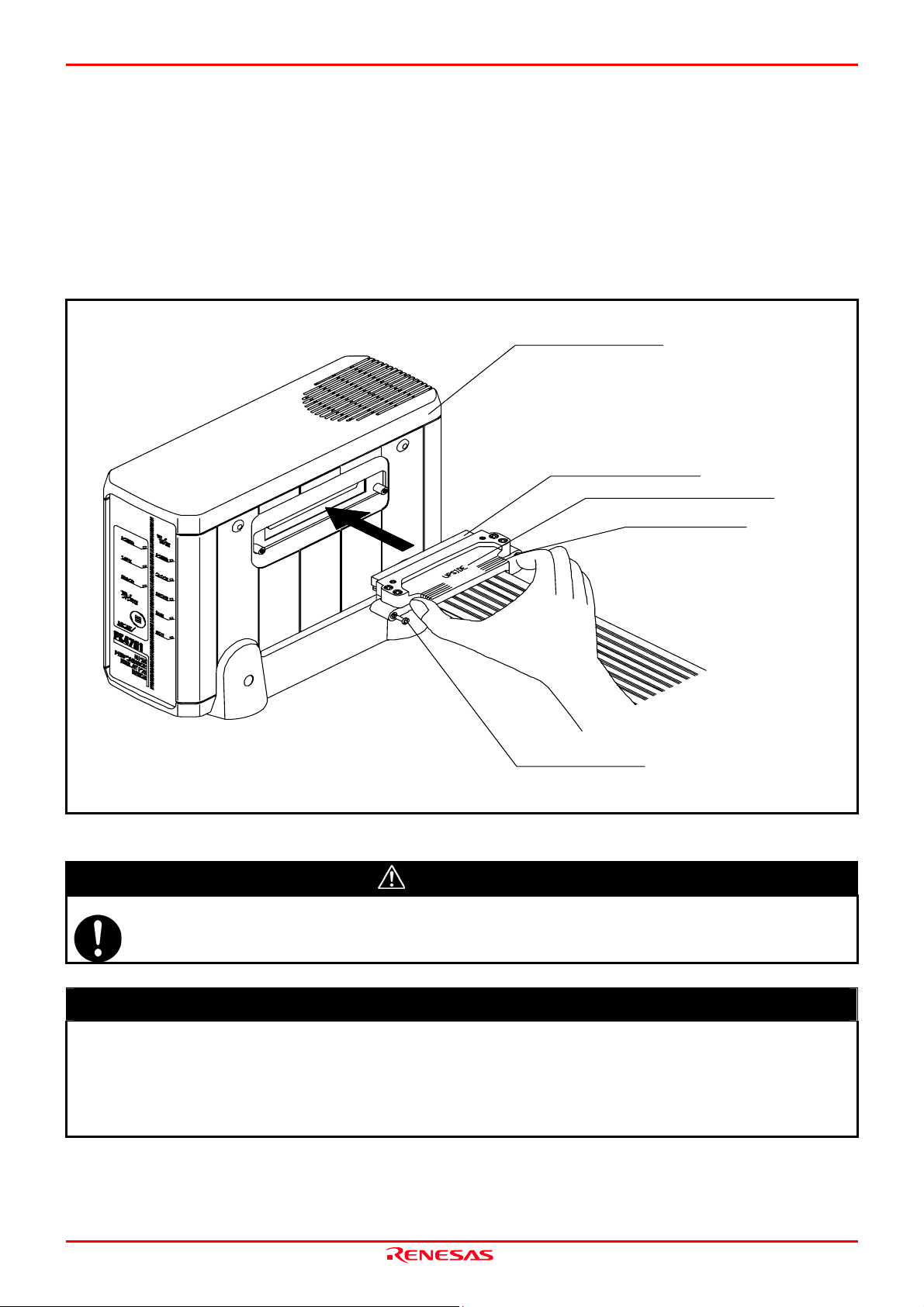

2.4 Connecting the PC4701

To connect the emulation pod to the PC4701, use the FLX120-RPD 120-pin flexible cable included with this product package.

Connect the PC4701 side connector of the FLX120-RPD to the cable connector of the PC4701, then secure with screws the

FLX120-RPD.

2.4.1 Connecting the FLX120-RPD to the PC4701

Figure 2.2 shows how to connect the PC4701 and FLX120-RPD.

Emulator main unit

PC4701 side connector

of FLX120-RPD

UPSIDE should be face up.

Figure 2.2 Connecting the FLX120-RPD to the PC4701

Note on Connecting the PC4701 and FLX120-RPD:

z Always shut OFF power before connecting the cable. Otherwise, the internal circuits may be damaged.

Secure this screw.

CAUTION

Secure this screw.

IMPORTANT

Notes on Connecting the PC4701 and FLX120-RPD, and Securing the Screws:

z To connect the FLX120-RPD, be sure to hold the both sides of the PC4701 side connector horizontally with the

"UPSIDE" facing up.

z After connecting the cable to the emulator main unit PC4701, be sure to secure the screws mounted in both

sides of the connector.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 23 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.4.2 Connecting the FLX120-RPD to the Emulation Pod

Figure 2.3 shows how to connect the FLX120-RPD and the emulation pod.

Emulation pod

FLX120-RPD (Secure with the screws)

Figure 2.3 Connecting the FLX120-RPD to the emulation pod

CAUTION

Note on Connecting the FLX120-RPD and emulation pod:

z Always shut OFF power before connecting the emulation pod and the FLX120-RPD. Otherwise, the internal

circuits may be damaged.

IMPORTANT

Note on Securing the Screws:

z After connecting the emulation pod and the FLX120-RPD, be sure to secure the screws mounted in both sides

of the connector cover.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 24 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.5 Turning ON the Power

2.5.1 Checking the Connections of the Emulator System

Before turning the power ON, check the connection of the interface cable with host machine, PC4701, emulation pod, and user

system.

2.5.2 Turning ON/OFF the Power

Turn ON the power of the emulator and user system as simultaneously as possible. Turn OFF the power of the emulator and

user system as simultaneously as possible.

Do not leave either the emulator or user system powered on, because of leakage current the internal circuits may be damaged.

When turning ON the power again after shutting OFF the power, wait for about 10 seconds.

IMPORTANT

Notes on Power Supply:

z The emulator's pin Vcc is connected to the user system in order to monitor user system voltage. For this reason,

the emulator cannot supply power to the user system. Therefore, provide the user system with a separate power

supply from that of the emulator.

z Keep user system power supply voltage within the following range.

(1) When the JP1 of the M30620T3-PRT is set as Vcc1 = Vcc2

2.7[V] ≤ Vcc1 = Vcc2 ≤ 5.5[V]

(2) When the JP1 of the M30620T3-PRT is set as Vcc1 > Vcc2

4.8[V] ≤ Vcc1≤ 5.2[V]

2.7[V] ≤ Vcc2 < Vcc1

z Do not change user system power supply voltage after power has been activated.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 25 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

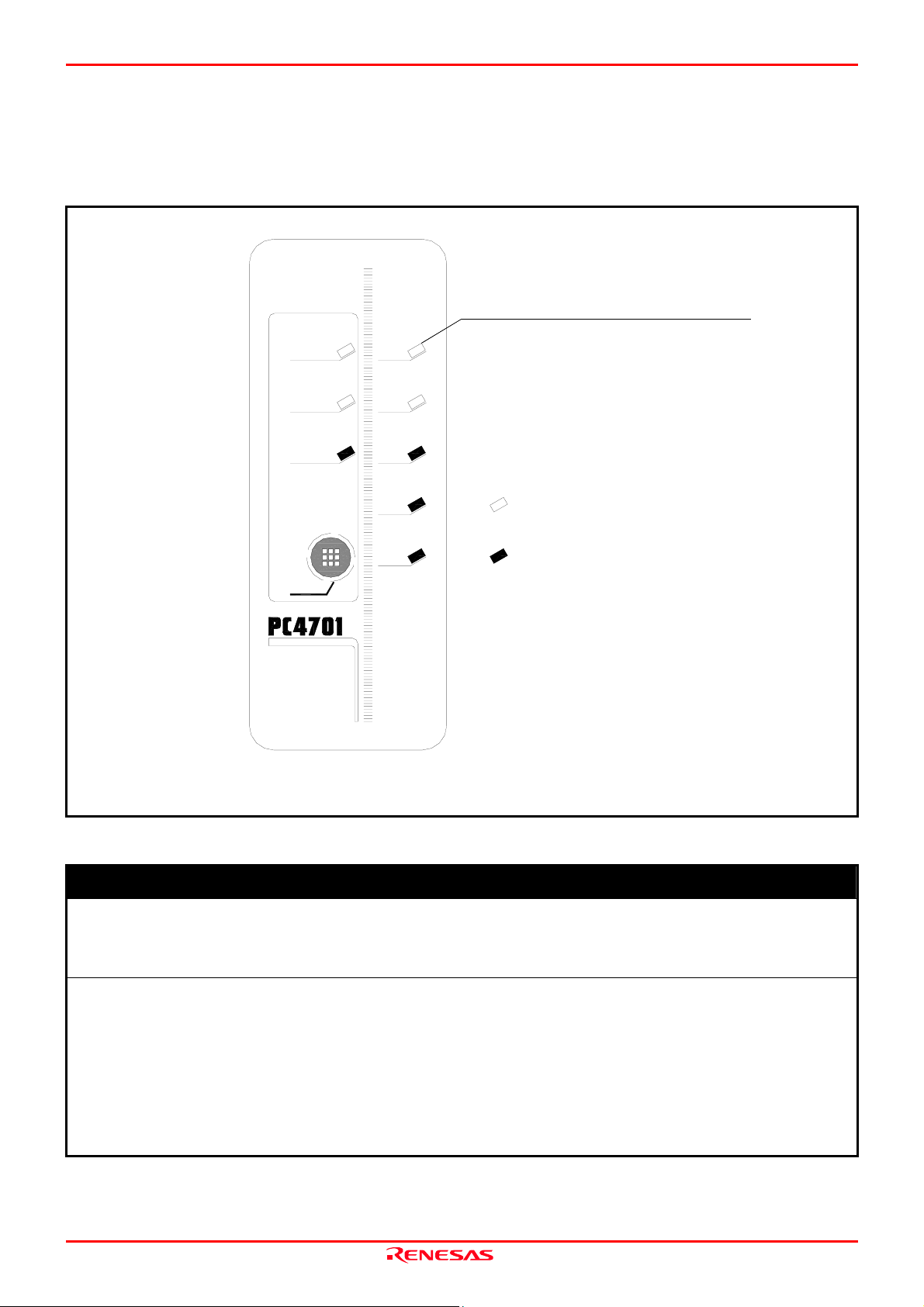

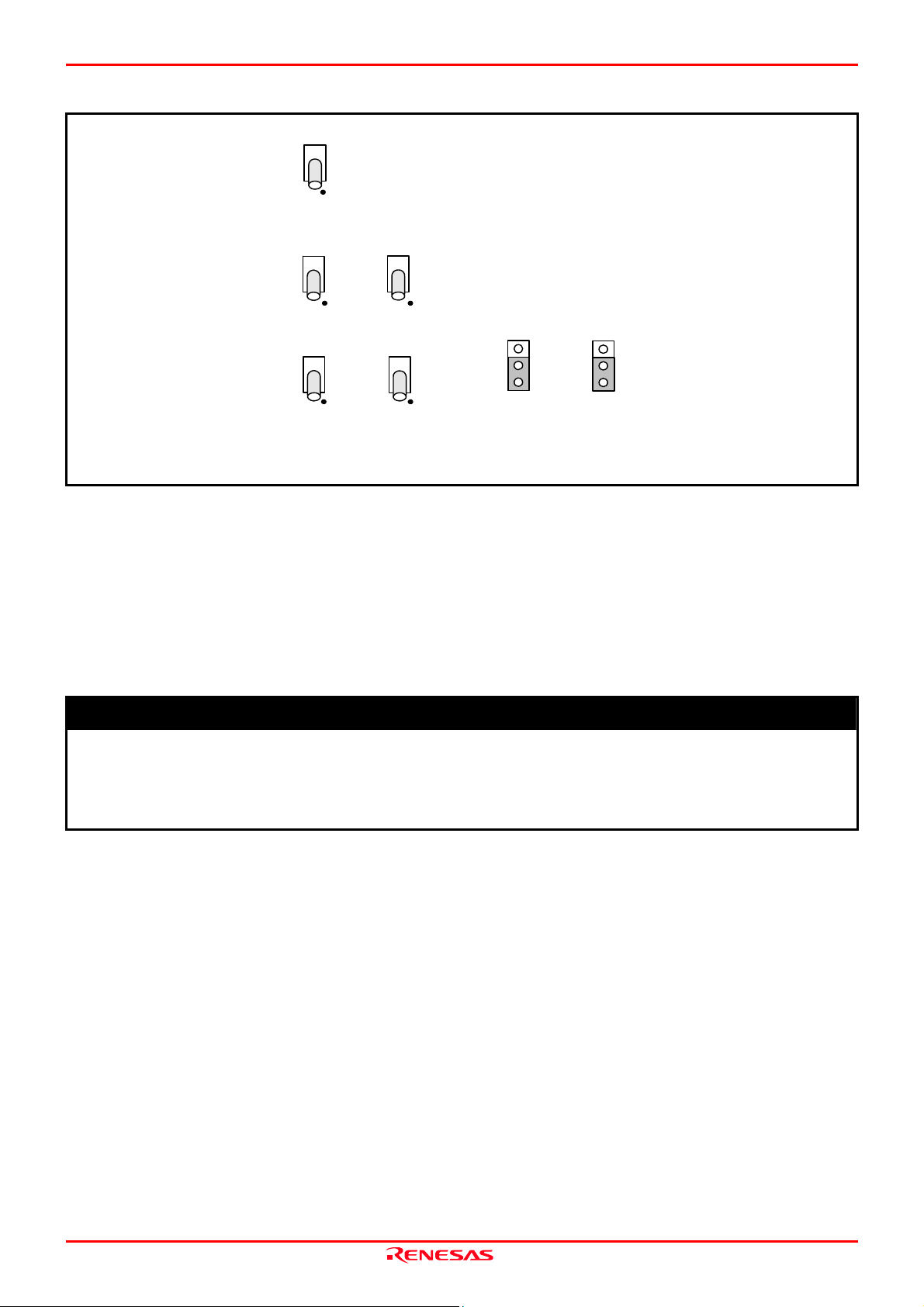

2.5.3 LED Display When the Emulator Starts Up Normally

Figure 2.4 shows front panel LED lighting status when the emulator started up properly. Check it when starting up the

emulator system.

POWER

SAFE

ERROR

STATUS OF

SYSTEM

RESET

PERFORMANCE

HIGH

EMULATOR

STATUS OF

TARGET

POWER

CLOCK

RESET

RUN

HALT

This does not light when the user

system is not connected.

: On

: Off

LED display when the emulator starts up normally

Figure 2.4 LED display when the power turned on

Note on the Target Status POWER LED:

Notes on the Target Status CLOCK LED:

z If the MCU has two or more Vcc terminals, the LED does not light unless power is supplied to all the

terminals.

z CLOCK LED is turned off when both main and sub clocks are not oscillating. If either clock is oscillating, the

LED is turned on.

z If the LED is not turned on, check the following.

(1) After powering on the PC4701 (before starting up the emulator debugger):

Make sure that the oscillator circuit board is properly installed in the PC4701 and it is oscillating normally.

(2) After the emulator debugger is started up (after the Init dialog box settings are complete):

Make sure that the oscillator selected in the Init dialog box is oscillating normally.

IMPORTANT

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 26 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.6 Downloading Firmware

2.6.1 When It is Necessary to Download Firmware

It is necessary to download the firmware in the cases listed below. Normally, the following are automatically detected when the

emulator debugger is started up, and the firmware is downloaded.

(1) When you use this product for the first time

(2) When the firmware has been upgraded

(3) When the emulator debugger has been upgraded

(4) When you use this product with a PC4701 which was used with other emulation pod before

If downloading firmware is not completed in the cases below, redownload the firmware in maintenance mode.

- When the power is unexpectedly shut down during a download from the emulator debugger

- When a communications interface cable is unexpectedly pulled out

2.6.2 Downloading Firmware in Maintenance Mode

Download the firmware in maintenance mode as explained here following. The user system must not be connected when

downloading the firmware.

(1) Set the interface select switch on the rear panel of the PC4701 to the dedicated parallel, LPT or serial interface to connect

the PC4701 and the host machine. Set the interface selection switch on the rear panel of the PC4701 according to the using

interface. The firmware may not be downloaded in maintenance mode correctly with the USB interface.

(2) Within 2 seconds of activating power to the emulator, press the RESET switch on the PC4701 upper panel to switch to

maintenance mode.

Switched to maintenance mode, the SAFE SYSTEM STATUS LED begins to flash.

(3) Start up the emulator debugger. When the Init dialog box setup is complete, the dialog which urges to download the

firmware will appear. Download the firmware following messages. Required time for downloading the firmware is about

60 seconds.

POWER

SAFE

ERROR

STATUS OF

RESET

SYSTEM

POWER

CLOCK

RESET

RUN

HALT

All the LEDs light

Immediately after turning on the power

POWER

SAFE

ERROR

STATUS OF

SYSTEM

RES ET

When maintenance mode sta rted

POWER

CLOCK

RESET

RUN

HALT

SAFE LED lights

POWER

SAF E

ERROR

STATUS OF

RESET

SYST EM

POWER

CLOCK

RES ET

RUN

HAL T

ERROR LED lights

When downloading firmwa re started

POWER

SAFE

ERROR

STATUS OF

SYSTEM

RES ET

POWER

CLOCK

RESET

RUN

HALT

SAFE LED blinks All the LEDs light

POWER

SAFE

ERROR

STATUS OF

RES ET

SYSTEM

POWER

CLOCK

RESET

RUN

HALT

POWER

SAF E

ERROR

STATUS OF

SYSTEM

RESET

POWER

CLOCK

RESET

RUN

HALT

When download complete

: On

: Off

: Blinking

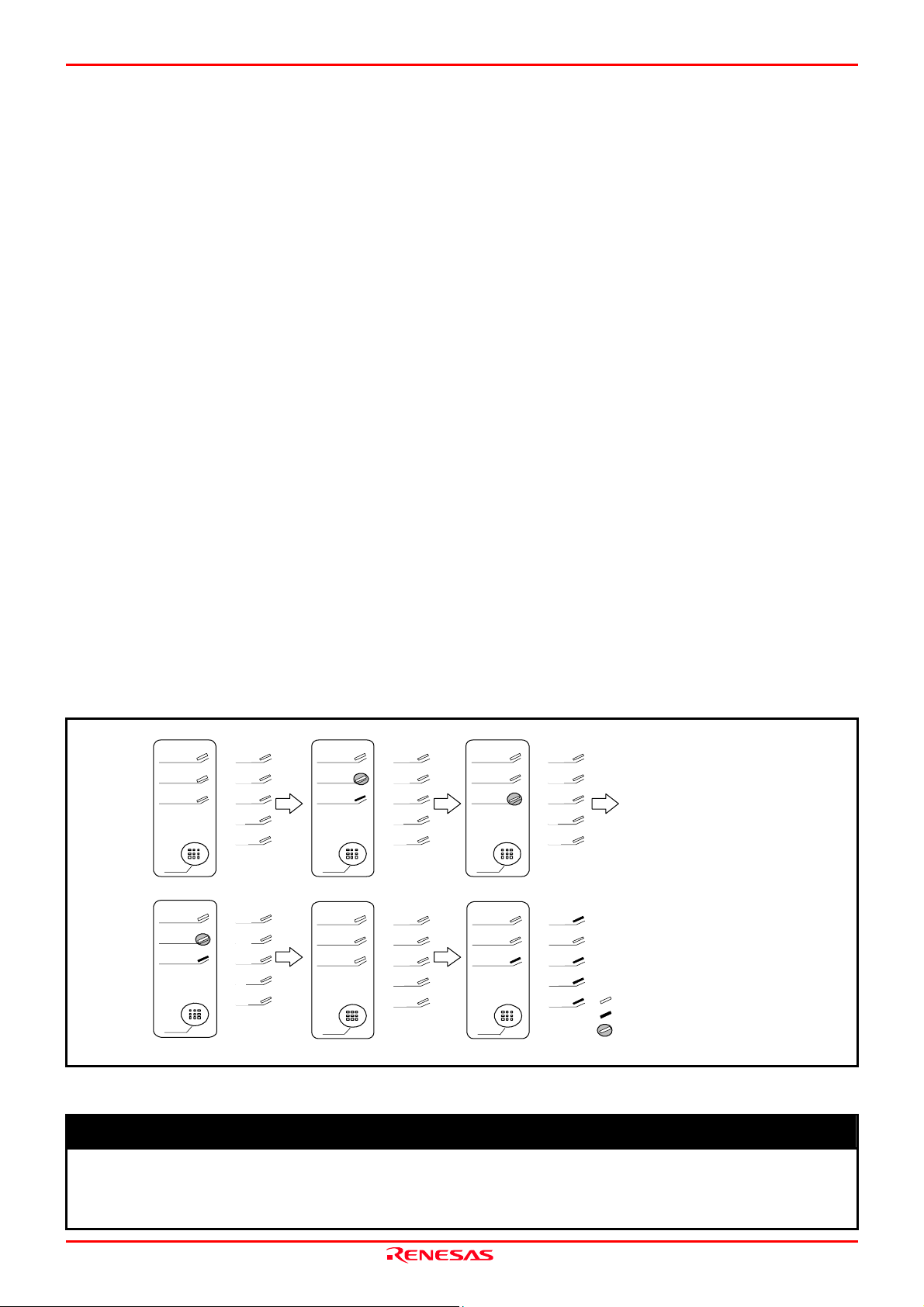

Figure 2.5 Downloading firmware in maintenance mode

IMPORTANT

Note on Downloading Firmware:

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 27 of 104

z Do not shut OFF power while the firmware is being downloaded. Doing so, the emulator will not start up

properly. If power is shut OFF by mistake, redownload the firmware in maintenance mode.

M3062PT3-RPD-E User’s Manual 2. Setup

2.7 Self-check

2.7.1 Self-check Procedure

To run the self-check of the emulator, do so as explained here below. While the self-check is in progress, the LEDs will change

as shown in Figure 2.6.

(1) If the user system is connected, disconnect it.

(2) Set the switches in the emulation pod to the factory settings as shown in Figure 2.7.

(3) Within 2 seconds of activating power to the emulator, press the system reset switch on the emulator front panel to switch

the emulator to maintenance mode.

(4) Check the SAFE LED starts blinking and then press the system reset switch again.

(5) The self-check will start. If the normal result is displayed in about 30 seconds, the self-check has terminated normally.

POWER

SAFE

ERROR

STATUS OF

SYSTEM

RESE T

POWER

CLOCK

RESET

RUN

HALT

(1) All the LEDs light

Immediately after turning on the power

POWER

SAFE

ERROR

STATUS OF

SYSTEM

RESET

Self - check

: On

: Off

: Blinking

POWER

CLOCK

RESET

RUN

HAL T

(2) SAFE LED blinks

POWER

SAF E

ERROR

STATUS OF

SYSTEM

RESET

POWER

SAF E

ERROR

STATUS OF

SYSTEM

RESET

POWER

CLOCK

RESET

RUN

HALT

Completed normally

POWER

CLOCK

RESET

RUN

HALT

ERROR LED lights

System status error

POWER

SAFE

ERROR

STATUS OF

SYSTEM

RESET

Target status error

POWER

CLOCK

RES ET

RUN

HAL T

SAFE and ERROR LED blink

Figure 2.6 LED display in the self-check procedure

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 28 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

BYTE

SW1

(factory-settings)

HOPENL

SW2

CNVss

(factory-settings)

P86/Xcout

SW4

(factory-settings)

L

H

OPEN

P86/XC OP

Xout

SW3

OP Xout

(factory-settings)

P87/Xcin

P87 Xcin

SW5

JP1

(factory-settings)(factory-settings)

M30620T3-PRT board

Figure 2.7 Switch settings for the self-check (factory-settings)

2.7.2 If an Error is Detected in the Self-check

If the self-check does not result normally, check the following.

(1) Whether the emulation pod and PC4701 are connected properly

(2) Whether the proper firmware has been downloaded

(3) Whether the switch settings of this product are the factory-settings

4M

A18_SEL

1M

VCC1>VCC2

VDDIO

=

JP2

VCC1

(factory-settings)

VCC2

Notes on Self-check:

z Perform the self-check while not connecting the user system.

z If the self-check does not result normally (excluding target status error), the emulation pod may be damaged.

Then contact your local distributor.

IMPORTANT

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 29 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

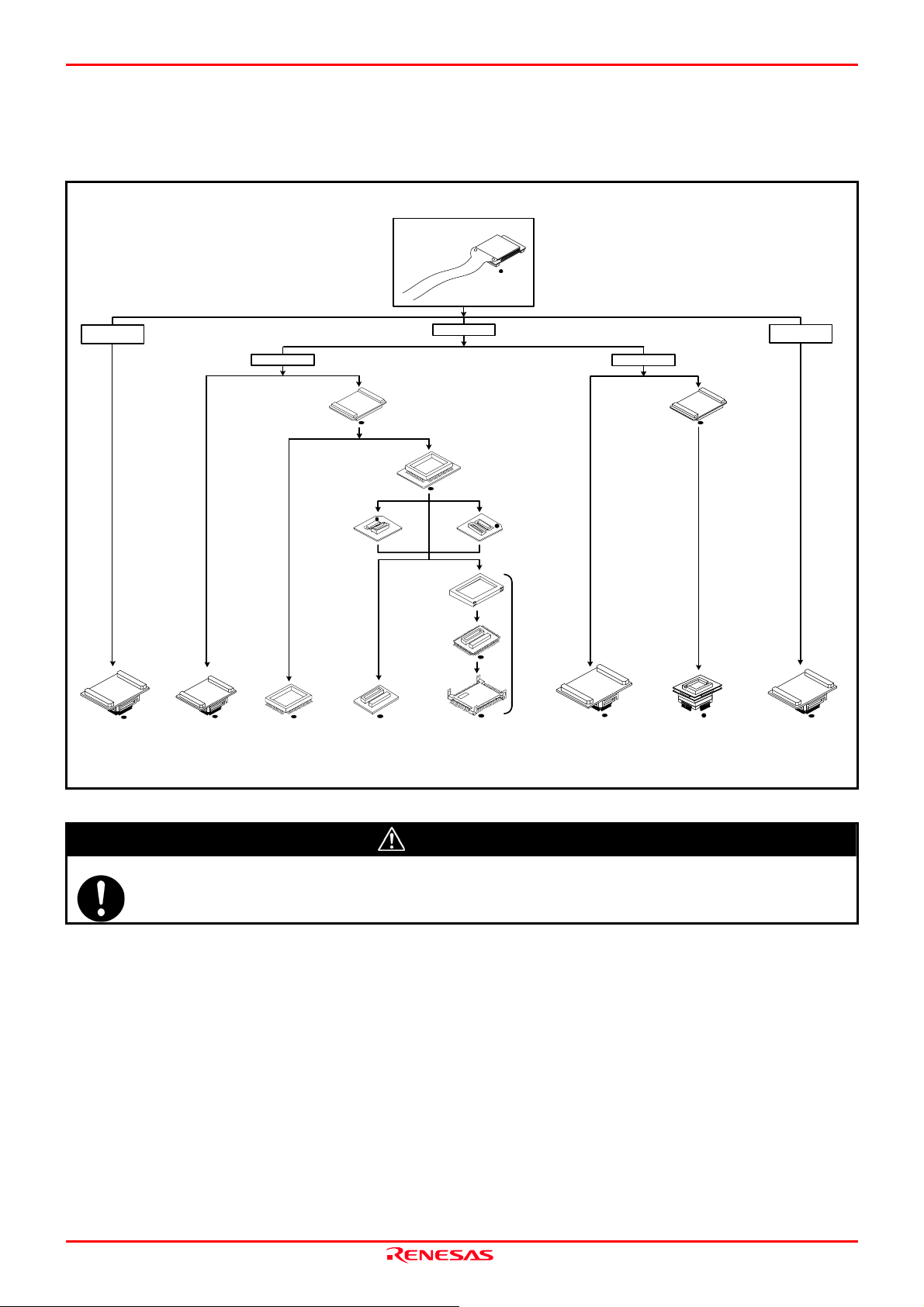

2.8 Connecting the User System

Connect the emulation pod to the user system as shown in Figures 2.8.

Tip of emulation pod probe

80-pin

0.65mm pitch

M 3062PT -80FPB

80-pin

QFP

(not included)

M3T-F160-100NRB

100-pin

QFP

(not included)

100-pin

0.65mm pitch 0.5mm pitch

M30800T-PTC

(included)

M3T -10 0LC C- DMS

(not included)

M3T-FLX100-T M3T- FLX100-R

LCC socket

100-pin LCC

(included)

(not included)

M3T-DIRECT100S

100-pin

QFP

(not included) (not included)

M3T-DUMMY100S

100-pin QFP

●: No.1 pin

*: These three items are included in one package .

(not included)

*1

M3T- F160-100NSD

100-pin LQFP

(not included)

128-pin

0.5mm pitch

M30800T-P TC

(included)

M3T -100 LC C- QSD

100-pin LQFP

(not included) (not included)

M3T-F160-128 NRD

128-pin LQFP

Figure 2.8 Connecting the user system

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulation

pod.

CAUTION

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 30 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.1 Connecting to a 80-pin 0.65mm Pitch Foot Pattern

Figure 2.9 shows how to connect 80-pin 0.65mm pitch foot pattern on the user system to the M3062PT-80FPB (not included),

and here following is its procedure.

For details on the M3062PT-80FPB (not included), refer to its user's manual.

(1) Attach the NQPACK080SB included with the M3062PT-80FPB to the user system.

(2) Attach the YQPACK080SB included with the M3062PT-80FPB to the NQPACK080SB and secure it with the

YQ-GUIDE's.

(3) Attach the CN2 side of the M3062PT-80FPB to the CN2 side of the package converter board connected to the emulation

pod probe.

(4) Attach the M3062PT-80FPB to the YQPACK080SB.

Tip of emulation

pod probe

Package converter board

*

These corners are not round.

*: These four items are included in one package.

Figure 2.9 Connecting to a 80-pin 0.65mm pitch foot pattern

CN2 side

(3)

M3062 PT- 80 FPB (not included)

On-board evaluation

(4)

YQ-GUIDE (x 4)

YQPACK080SB

NQPACK080SB

(2)

80-pin 0.65mm pitch

(PRQP0080JA-A) foot pattern

(1)

No. 1 pin

User system

HQPACK 080SB

(not included)

FLASH MCU, etc.

CAUTION

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulation

pod.

IMPORTANT

Note on Connectors of the Converter board:

z The small connectors of the M3062PT-80FPB are guaranteed for only 50 insertion/removal iterations.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 31 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.2 Connecting to a 100-pin LCC socket

Figure 2.10 shows how to connect a 100-pin LCC socket (IC61-1004-051 of Yamaichi Electronics Co., Ltd.) on the user

system to the M30800T-PTC (included).

(1) Attach the CN2 side of the M30800T-PTC to the CN2 side of the package converter board connected to the emulation pod

probe.

(2) Attach the M30800T-PTC to the 100-pin LCC socket.

Tip of emulation pod probe

Package converter board

CN 2 side

(1)

M 30800T- PTC

Figure 2.10 Connecting to a 100-pin LCC socket

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulation

pod.

Notes on Connectors of the Converter board:

z The connectors of the M30800T-PTC are guaranteed for only 50 insertion/removal iterations.

z The connectors of the IC61-1004-051 are guaranteed for only 20 insertion/removal iterations.

z For purchasing the IC61-1004-051 or for technical information, contact Yamaichi Electronics Co., Ltd.

(2)

CAUTION

IMPORTANT

100- pin LCC socket

No . 1 pin

User system

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 32 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.3 Connecting to a 100-pin 0.65mm Pitch Foot Pattern (Part 1)

Figure 2.11 shows how to connect a 100-pin 0.65mm pitch foot pattern on the user system to the M3T-F160-100NRB (not

included), and here following is its procedure. For details on the M3T-F160-100NRB (not included), refer to its user's manual.

(1) Attach the NQPACK100RB included with the M3T-F160-100NRB to the user system.

(2) Attach the YQPACK100RB included with the M3T-F160-100NRB to the NQPACK100RB and secure it with the

YQ-GUIDE's.

(3) Attach the CN2 side of the M3T-F160-100NRB to the CN2 side of the package converter board connected to the emulation

pod probe.

(4) Attach the M3T-F160-100NRB to the YQPACK100RB.

Tip of emulation pod probe

Package converter board

CN2 side

(3)

M3T-F160-100NRB

(not included))

(4)

*

(2)

These corners are not round.

(1)

*: These four items are available in one package.

Figure 2.11 Connecting to a 100-pin 0.65mm pitch foot pattern (1/3)

On-board evaluation

HQPACK100RB168

YQ-GUIDE (x4)

YQPACK100RB

NQPACK100RB

100-pin 0.65mmpitch

(PRQP0 100JB-A) foot pattern

NO. 1 pin

User system

(not included)

FLASH MCU, etc.

CAUTION

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulator or

user system.

IMPORTANT

Note on Connectors of the Converter board:

z The connectors of the M3T-F160-100NRB are guaranteed for only 50 insertion/removal iterations.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 33 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.4 Connecting to a 100-pin 0.65mm Pitch Foot Pattern (Part 2)

Figure 2.12 shows how to connect a 100-pin 0.65mm pitch foot pattern on the user system to the M3T-DIRECT100S (not

included), and here following is its procedure. For details on the M3T-100LCC-DMS (not included) and M3T-DIRECT100S

(not included), refer to each user's manual.

(1) Attach the M3T-DIRECT100S to the user system.

(2) Attach the M3T-100LCC-DMS to the M3T-DIRECT100S.

(3) Attach the CN2 side of the M30800T-PTC to the CN2 side of the package converter board connected to the emulation pod

probe.

(4) Attach the M30800T-PTC to the M3T-100LCC-DMS.

Tip of emulation pod probe

Package converter board

CN2 side

(3)

M30800T-PTC

(4)

(2)

(1)

Figure 2.12 Connecting to a 100-pin 0.65mm pitch foot pattern (2/3)

CAUTION

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulation

pod.

M3T-100LCC-DMS

(not included)

M3T-DIRECT100S

(not included)

100-pin 0.65mm pitch

(PRQP0100JB-A) foot pattern

No. 1 pin

User system

IMPORTANT

Notes on Connectors of the Converter board:

z The connectors of the M30800T-PTC are guaranteed for only 50 insertion/removal iterations.

z The connectors of the M3T-100LCC-DMS and M3T-DIRECT100S are guaranteed for only 20

insertion/removal iterations.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 34 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.5 Connecting to a 100-pin 0.65mm Pitch Foot Pattern (Part 3)

Figure 2.13 shows how to connect a 100-pin 0.65mm pitch foot pattern on the user system to the M3T-DUMMY100S (not

included), and here following is its procedure. For details on the M3T-100LCC-DMS (not included) and M3T-DUMMY100S

(not included), refer to each user's manual.

(1) Attach the M3T-DUMMY100S to the user system.

(2) Attach the M3T-100LCC-DMS to the M3T-DUMMY100S.

(3) Attach the CN2 side of the M30800T-PTC to the CN2 side of the package converter board connected to the emulation pod

probe.

(4) Attach the M30800T-PTC to the M3T-100LCC-DMS.

Tip of emulation pod probe

Package converter board

CN2 side

(3)

M30800T-PTC

(4)

(2)

100-pin 0.65mm pitch

(PRQP0100JB-A) foot pattern

(1)

No. 1 pin

Figure 2.13 Connecting to a 100-pin 0.65mm pitch foot pattern (3/3)

M3T-100LCC-DMS

(not included)

M3T-DUMMY100S

(not included)

User system

On-board evaluation

FLASH MCU, etc.

CAUTION

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulation

pod.

IMPORTANT

Notes on Connectors of the Converter board:

z The connectors of the M30800T-PTC are guaranteed for only 50 insertion/removal iterations.

z The connectors of the M3T-100LCC-DMS and M3T-DUMMY100S are guaranteed for only 20

insertion/removal iterations.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 35 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.6 Connecting to a 100-pin 0.5mm Pitch Foot Pattern (Part 1)

Figure 2.14 shows how to connect a 100-pin 0.5mm pitch foot pattern on the user system to the M3T-F160-100NSD (not

included), and here following is its procedure. For details on the M3T-F160-100NSD (not included), refer to its user's manual.

(1) Attach the NQPACK100SD-ND included with the M3T-F160-100NSD to the user system.

(2) Attach the YQPACK100SD included with M3T-F160-100NSD to the NQPACK100SD-ND and secure it with the

YQ-GUIDE's.

(3) Attach the CN2 side of th e M3T-F160-100NSD to the CN2 side of the package converter board connected to the emulation

pod probe.

(4) Attach the M3T-F160-100NSD to the YQPACK100SD.

Tip of emulation pod probe

Package converter board

CN2 side

(3)

M3T-F 160- 100 NSD

( not included)

(4)

*

(2)

These corners are not round.

(1)

*: These four items are available in one package .

Figure 2.14 Connecting to a 100-pin 0.5mm pitch foot pattern (1/2)

On- board evaluation

HQPACK 100SD

YQ- GUIDE (x4)

YQPACK 100SD

NQPACK100 SD-ND

100- pin 0.5mm pitch

( PLQP0100KB-A ) foot pattern

No. 1 pin

User system

( not included)

FLASH MCU, etc.

CAUTION

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulation

pod.

IMPORTANT

Note on Connectors of the Converter board:

z The connectors of the M3T-F160-100NSD are guaranteed for only 50 insertion/removal iterations.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 36 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.7 Connecting to a 100-pin 0.5mm Pitch Foot Pattern (Part 2)

Figure 2.15 shows how to connect a 100-pin 0.5mm pitch foot pattern on the user system to the M3T-100LCC-QSD (not

included), and here following is its procedure. For details on the M3T-100LCC-QSD (not included), refer to its user's manual.

(1) Attach the TQPACK100SD to the user system.

(2) Attach the TQSOCKET100SDG to the TQPACK100SD.

(3) Attach the M3T-100LCC-QSD to the TQSOCKET100SDG.

(4) Attach the CN2 side of the M30800T-PTC to the CN2 side of the package converter board connected to the emulation pod

probe.

(5) Attach the M30800T-PTC to the M3T-100LCC-QSD.

Tip of emulation pod probe

Package converter board

CN2 side

(4)

M30800T-PTC

(5)

(3)

(2)

(1)

Figure 2.15 Connecting to a 100-pin 0.5mm pitch foot pattern (2/2)

M3T-100LCC-QSD

(not included)

TQSOCKET100SDG

TQPACK100SD

100-pin 0.5mm pitch

(PLQP0100KB-A) foot pattern

No. 1 pin

User system

CAUTION

Note on Connecting the User System:

z Take care not to attach the converter board in a wrong direction. It may cause a fatal damage to the emulation

pod.

IMPORTANT

Notes on Connectors of the Converter board:

z The connectors of the M30800T-PTC are guaranteed for only 50 insertion/removal iterations.

z The connectors of the M3T-100LCC-QSD are guaranteed for only 20 insertion/removal iterations.

REJ10J0040-0600 Rev.6.00 July 01, 2006 Page 37 of 104

M3062PT3-RPD-E User’s Manual 2. Setup

2.8.8 Connecting to a 128-pin 0.5mm Pitch Foot Pattern

Figure 2.16 shows how to connect a 128-pin 0.5mm pitch foot pattern on the user system to the M3T-F160-128NRD (not

included), and here following is its procedure.

For details on the M3T-F160-128NRD (not included), refer to its user's manual.

(1) Attach the NQPACK128RD included with the M3T-F160-128NRD to the user system.

(2) Attach the YQPACK128RD included with M3T-F160-128NRD to the NQPACK128RD and secure it with the

YQ-GUIDE's.

(3) Attach the CN2 side of the M3T-F160-128NRD to the CN2 side of the package converter board connected to the emulation

pod probe.

(4) Attach the M3T-F160-128NRD to the YQPACK128RD.

Tip of emulation pod probe

Package converter board

CN2 side

(3)

M3T-F160-128NRD

(not included)

*