Page 1

RPC-320 USER'S MANUAL REV 2

Copyright 1997, 1999 - Remote Processing Corporation.

All rights reserved. However, any part of this document

may be reproduced with Remote Processing cited as the

source.

The contents of this manual and the specifications her ein

may change without notice.

TRADEMARKS

RPBASIC-52™ is a trademark of Remote Processing

Corporation.

PC SmartLINK® is a trademark of Octagon Systems

Corporation.

BASIC-52© is a trademark of Intel Corporation.

NOTICE TO USER

The information contained in this manual is believed

correct. However, Remote Processing assumes no

responsibility for any of the circuits described herein,

conveys no license under any patent or other right, and

make no representations that the circuits are free from

patent infringement. Remote Processing makes no

representation or warr anty that such applications will be

suitable for the use specified without further testing or

modification. The user must make the final

determination as to fitness for a particular use.

Remote Processing Corporation' s general policy does not

recommend the use of its products in life support

applications where the failure or malfunction of a

component may directly threaten life or injury. It is a

Condition of Sale that the user of Remote Processing

products in life support applications assum es all the risk

of such use and indemnifies Remote Pr ocessing against

all damages.

Remote Processing Corporation

79 75 E. Harvard Ave.

Denver, Co 802 31 USA

Tel: (303) 690 - 1588

Fax: (303) 690 - 1875

w w w.rp3.com

P/N 1366

Revision: 2.8

Page i RPC-320

Page 2

TABLE OF CONTENTS

SECTION 1 OVERVIEW

DESCRIPTION ................... 1-1

MANUAL ORGANIZATION .......... 1-1

MANUAL CONVENTIONS ........... 1-1

Symbols and Terminology ......... 1-2

TECHNICAL SUPPORT ............. 1-2

SECTION 2 SETUP AND OPERATION

INTRODUCTION ................. 2-1

OPERATING PRECAUTIONS ......... 2-1

EQUIPMENT .................... 2-1

FIRST TIME OPERATION ........... 2-2

Using a PC ................... 2-2

Using a Terminal ............... 2-2

UPLOADING AND DOWNLOADING

PROGRAMS ................. 2-2

Editing program s and pro gram ming hints 2-3

WHERE TO GO FROM HERE ......... 2-4

TROUBLESHOOTING .............. 2-4

SECTION 3 SAVING PROGRAMS

INTRODUCTION ................. 3-1

SAVING A PROGRAM ............. 3-1

AUTORUNNING .................. 3-2

PREVENTING AUTORUN ........... 3-2

LOADING A PROGRAM ............ 3-2

CHANGING EPROM SIZE ........... 3-2

ALTERNATE EPROMS ............. 3-3

COMMANDS .................... 3-3

SECTION 6 DIGITAL AND OPTO PORTS

INTRODUCTION ................. 6-1

DIGITAL I/O PORTS ............... 6-1

Digital Port J3 ................. 6-1

Digital Port P6 ................. 6-2

High Current Port L8 ............ 6-2

Optically Isolated Input ........... 6-2

Digital I/O Commands ............ 6-2

High Curr ent Output ............. 6-3

Interfacing Digital I/ O to an opto- module

rack ..................... 6-4

Interfacing to switches and other devices 6-4

Digital I/O program ming exa mple .... 6-4

Pulse Width Modulation (PWM) ...... 6-5

COMMANDS .................... 6-6

SECTION 7 CALENDAR/CLOCK

DESCRIPTION ................... 7-1

SETTING DATE AND TIME .......... 7-1

COMMANDS .................... 7-1

SECTION 8 DISPLAY PORT

INTRODUCTION ................. 8-1

CONNECTING DISPLAYS ........... 8-1

WRITING TO THE DISPLAY ......... 8-1

PROGRAMMING EXAMPLE ......... 8-1

DISPLAY TYPES ................. 8-2

DISPLAY CONNECTOR PIN OUT ..... 8-2

COMMANDS .................... 8-2

SECTION 4 SERIAL PORTS

DESCRIPTION ................... 4-1

COM0 SERIAL PORT .............. 4-1

COM1 SERIAL PORT .............. 4-1

RS-422/485 OPERATING INFORMATION . 4-2

RS-422/485 Termination network ..... 4-2

Two wire RS-485 ............... 4-3

Multidrop Network .............. 4-3

ACCESSING SERIAL BUFFERS ....... 4-3

ACCESSING COM0 AND COM1 ....... 4-4

DISABLING CON TROL -C ........... 4-4

SERIAL PORT PIN OUT ............ 4-4

SECTION 5 RAM MEMORY

INTRODUCTION ................. 5-1

CHANGING M EMORY ............. 5-1

BATTERY BACKUP ............... 5-1

Checking the battery ............. 5-1

RESERVED MEMORY ............. 5-2

STORING VARIABLES IN RAM ....... 5-2

BLOCK DATA TRANSFER ........... 5-3

ASSEMBLY LANGUAGE INTERFACE .. 5-3

COMMANDS .................... 5-3

SECTION 9 KEYPAD PORT

INTRODUCTION ................. 9-1

PROGRAMMING EXAMPLE ......... 9-1

KEYPAD P ORT P IN OU T - J5 ......... 9-2

SECTION 10 ANALOG INPUT

DESCRIPTION ................... 10-1

CONNECTING ANALOG INPUTS ...... 10-1

Overvoltage conditions ............ 10-1

Grounding .................... 10-1

INITIALIZATION ................. 10-1

Differential Mode ............... 10-2

Examples using CON FIG AIN ....... 10-2

Acquiring Analog Data .............. 10-2

Noise Notes ................... 10-3

Temperature Measurement ......... 10-3

Data logging on a timer tick ........ 10-4

MEASURING HIGHER VOLTAGES .... 10-4

CONVERTING ANALOG MEASUREMENTS 10-4

Measuring 4-20 mA current loops ..... 10-4

AMPLIFIERS .................... 10-5

CALIBRATION .................. 10-5

COMMANDS .................... 10-5

Page ii RPC-320

Page 3

TABLE OF CONTENTS

SECTION 11 WATCHDOG TIMER

DESCRIPTION ................... 11-1

EXTERNAL RESET ................ 11-1

DESCRIPTION ................... 11-1

OPTICALLY ISOLATED INTERRUPT ... 11-1

INTERRUPT CHARACTERISTICS ...... 11-1

SECTION 12 EXTERNAL INTERRUPT

DESCRIPTION ................... 12-1

PROGRAMMING ................. 12-1

Program examples .............. 12-1

COMMANDS .................... 12-2

SECTION 13 MULTI-MODE COUNTER

DESCRIPTION ................... 13-1

SECTION 14 POWER REDUCTION

FURTHER POWER REDUCTION ...... 14-1

Program Exam ple ............... 14-2

SECTION 15 TECHNICAL INFORMATION

ELECTRICAL SPECIFICATIONS ...... 15-1

MEMORY AND I/O BANK MAP ....... 15-2

MECHANICAL SPECIFICATIONS ..... 15-2

JUMPER DESCRIPTIONS ........... 15-2

Page iii RPC-320

Page 4

SOFTWARE REVISION HISTORY

V1.04 Release for RPC320

V1.05 BSAVE returned a hardware er ror when ver ify

was bad. In fact, save was OK.

V1.06 LCD graphics hardware CS and reset are

reversed. Compensated in software.

V1.07 MTOP was useless in any system, especially a

32K RAM.

V1.08 Variables E and F would get dropped if

followed by a space.

Added delays between data strob e writes to

LCD display.

V1.09 STR(7, . . .) did not put in a CR into the put

string, causing longer strings to be printed.

V1.10 Initial release for RPC-330.

Added AOT command (330 only)

Added COUNT, ON COM, ON COUNT, ON

LINE, and ON KEYPAD

V1.11 11/29/95

Added day of week to DAT E comm and and

function.

V1.12 12/01/95

Added code to use Atmel 29C040A flash.

V1.13 01/12/96

Added code to support IEE centry series

display (3602-100-05420)

Includes PRINT #port

V1.14 03/28/96

Fixed bug in ON COUNT. Returns error for

lines > 100.

V1.15 06/26/96

PEEK$ could cause BASIC to lock up under

right conditions.

V1.16 02/18/97

ON LIN E OF F could cause program to lock up

if running ON COM.

Syntax error when DISPLAY used with IFTHEN-ELSE.

Added PE EKF a nd POKE F com mands.

Page iv RPC-320

Page 5

OVERVIEW SECTION 1

DESCRIPTION

The RP C-320 is a n embed ded contr oller with a built in

Basic language. Several features make it suitable as a

stand alone unit:

Built in RPBASIC-52 programm ing language

supports hardware using single commands. On card

flash EPROM programm er can save up to 8

programs to 62K , or about 500K tota l.

High speed multimode counter accepts quadrature or

single inputs. Programmable for up/dow n, binary,

divide-by-N, X1, X2 or X4 quadr ature counting.

LCD charac ter and gr aphic display and keypad ports

for operator interface.

Two R S-232 ser ial ports, one of whic h is

configurable for RS-422/485.

Watchdog timer resets card if a program "crashes".

34 digital I/O lines, 9 of which are high current

outputs. 24 of these lines can connect to an opto

rack or other TTL devices.

Eight channel, 12 bit resolution analog to digital

converter. Configurable operational amplifiers

allow you to signal condition inputs or measure

temperature.

from your PC are downloaded using a serial

communication program.

MANUAL ORGANIZATION

This manual provides all the infor mation r equired to

install, configure, and operate the RPC-320. Using this

manual you will be able to:

Interface the RPC-320 to your IBM compatible PC

or terminal.

Understand the operation of the RPC-320 hardware

using RPBASIC-52 programming software.

This manual assumes you are familiar with some type of

BASIC programming software. The syntax used by

RPBASIC-52 is similar to BASIC-52. If you are not

experienced with any BASIC softwar e, y ou may w ant to

refer to books and training programs available through

your local book store. The BASIC-52 Programming

Manual has information and examples for the original

commands. Comm ands unique or modified by

RPBASIC-52 are in the Software Supplement in this

manual.

Each chapter or section is written to first provide an

overview. Then, m ore specific information is provided.

Each chapter has some examples using Basic. A

summary of related hardware commands is at the end of

most chapters.

32K, 128K, or 512K RAM battery backable to save

process variables and other data when power is off.

32K or 512K flash EPROM to save program s and

data.

The RPC -320 uses an 80C320 CPU operating at 22.1184

Mhz. It can operate stand alone or on a network using

the RS-485 port. Its 4.7" x 7.0" size with 4 mounting

holes makes it easy to mount in a NEMA box.

Compactness is enhanced by on-board analog and digital

terminal strips.

RPBASIC-52 programming language is standard. T his

language is a version of the original Intel BASIC-52. It

was modified for the RPC -320 for c ontrol, data

acquisition applications, and on board hardware features.

Program development can take place on your PC, using

your word processor, or on the RPC-320. Programs

Page 1-1 RPC-320

MANUAL CONVENTIONS

Information appearing on your screen is shown in a

different type.

Example:

RPBASIC-52 V1.0

Copyright Intel (1985) and Remote Processing

Bytes free: 27434

Page 6

OVERVIEW SECTION 1

TECHNICAL SUPPORT

Symbols and Term inology

If you have a question about the RPC-320 or RPBASIC-

NOTE: Text under this heading is helpful information.

It is intended to act as a reminder of some

operation or interaction with another device that

may not be obvious.

WARNING:

Information under this heading warns you of

situations which might cause catastrophic or

irreversible damage.

52 and can' t find it in this manual, call us and ask for

technical support. Technic al support hours ar e 9 AM to

4 PM mountain time.

When you call, please have your RPC-320 and BASIC-

52 PROGRAMMING MANUAL ready. Many times it is

helpful to know what the RPC-320 is used for, so please

be ready to describe its application as well as the

problem.

W[-] Denotes jumper block pins.

< xxx> Paired angle brackets are used to indicate a

specific key on your keyboard. F or exam ple

< esc> means the escape key.

BASIC uses the decimal convention for designating

addresses and data. There are times when hexadecimal

notation is more convenient to use. Notation use d in this

manual and BASIC-52 is the ' H' character after the

number. 8CH stands for 8C hexadecimal.

Phone: 303-690-1588

FAX: 303-690-1875

The RPC -320 uses a Dallas Semiconductor DS80C320

processor. Additional information can be obtained from

Dallas Semiconductor (214-450-0448, F AX 214-450

0470), or your distributor.

Page 1-2 RPC-320

Page 7

OVERVIEW SECTION 1

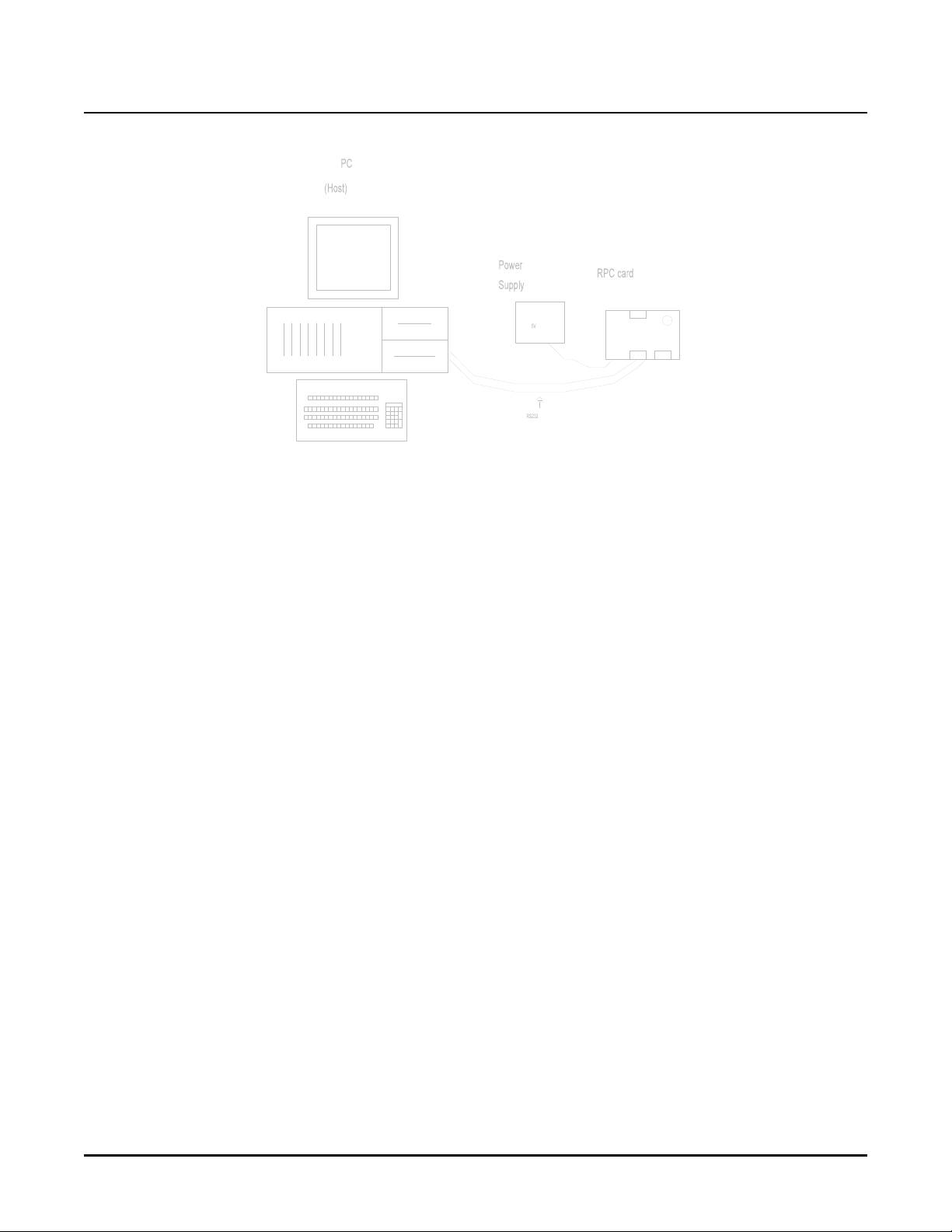

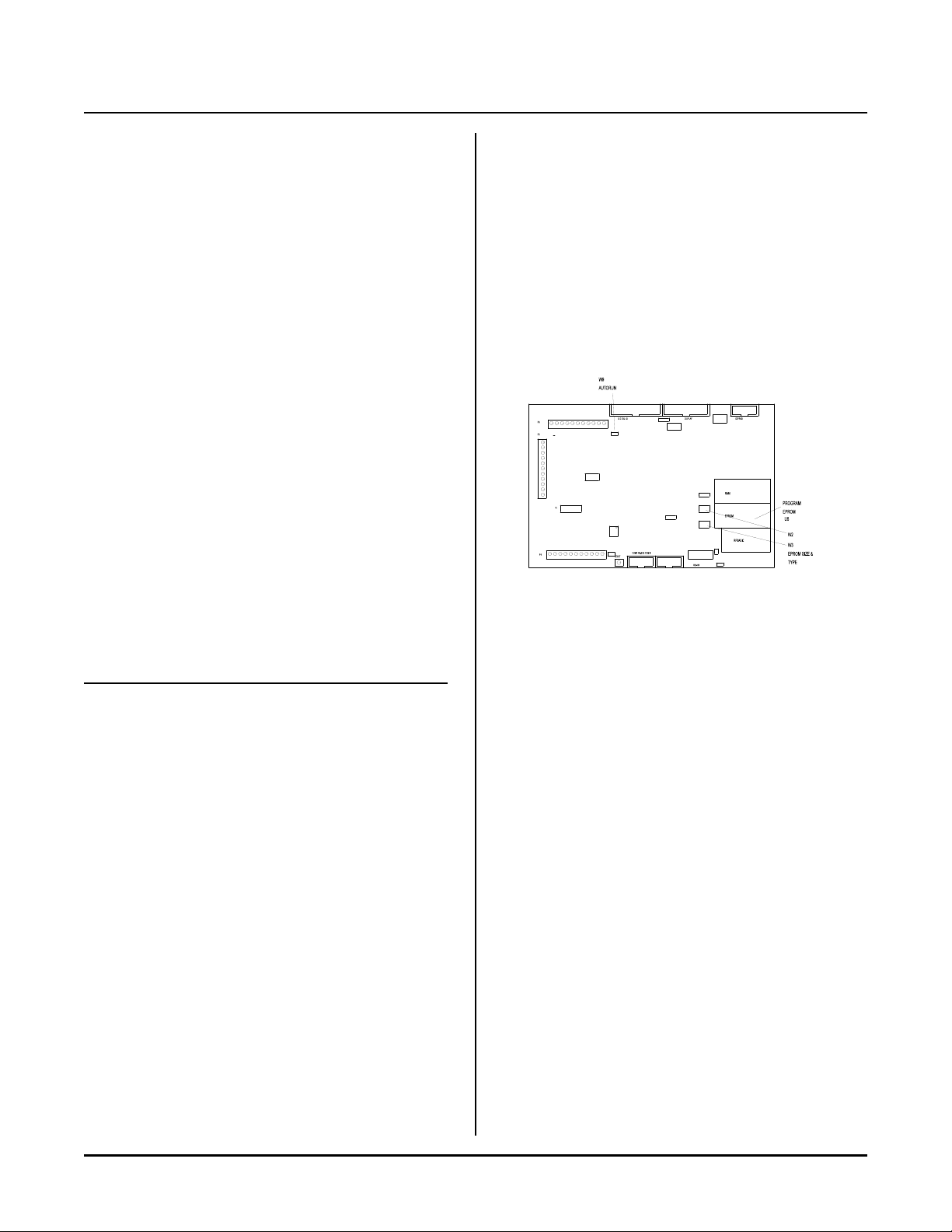

Figure 1-1 System layout

Page 1-3 RPC-320

Page 8

SETUP AND OPERATION SECTION 2

INTRODUCTION

The RPC -320 is ready to program as soon as you

connect it to a ter minal or PC a nd apply pow er. This

chapter describes what is needed to get a sign- on

message and begin programming.

Requirements for uploading and downloading programs

are discussed. A "W here to go from here" section tells

you what chapters to refer to in order to use the various

capabilities of the RPC-320. Finally, a troubleshooting

section helps out on the most common problems.

OPERATING PRECAUTIONS

The RPC -320 is designed to handle a wide variety of

temperature ranges at low power. These characteristics

require using CM OS components. CM OS is static

sensitive. To avoid damaging these components,

observe the following precautions before handling the

RPC-320.

1. Ground yourself before handling the RPC -320

or plugging in cables. Static electricity

can easily arc through cables and to the card.

Simply touching your PC before you touch the

card can greatly reduce the amount of static.

2. Do not insert or remove components when

power is applied. While the ca rd is a + 5 volt

only system, other voltages generated on the

card which affect other components.

EQUIPMENT

You will need the following equipment to begin using the

RPC-320:

RPC-320 embedded controller

PC with a serial port and com munications

program

or a

Terminal

VTC -9F ser ial cable

+ 5, 2 00 ma po wer su pply

Refer to Chapter 4, SERIAL PORTS, for wiring

information to make your own serial cable.

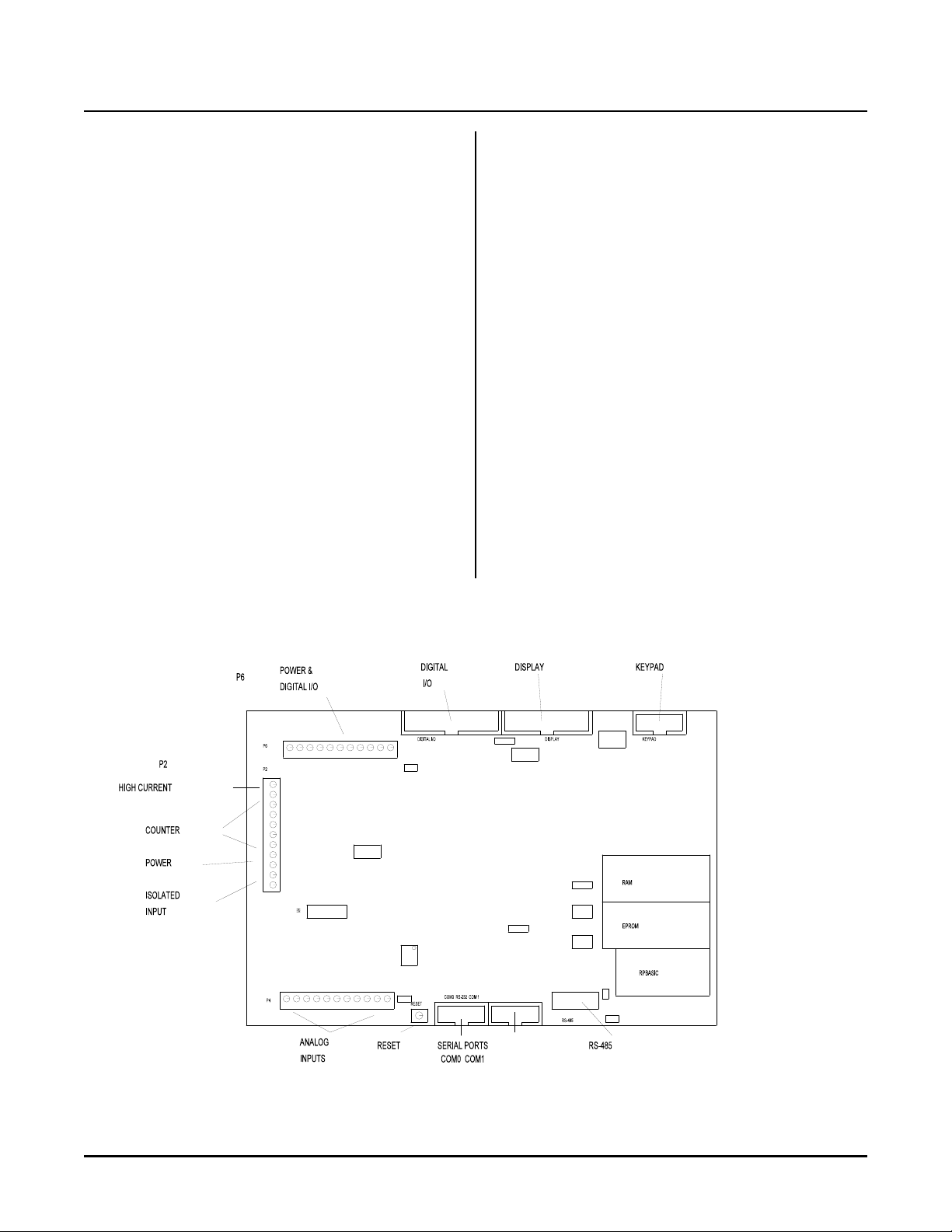

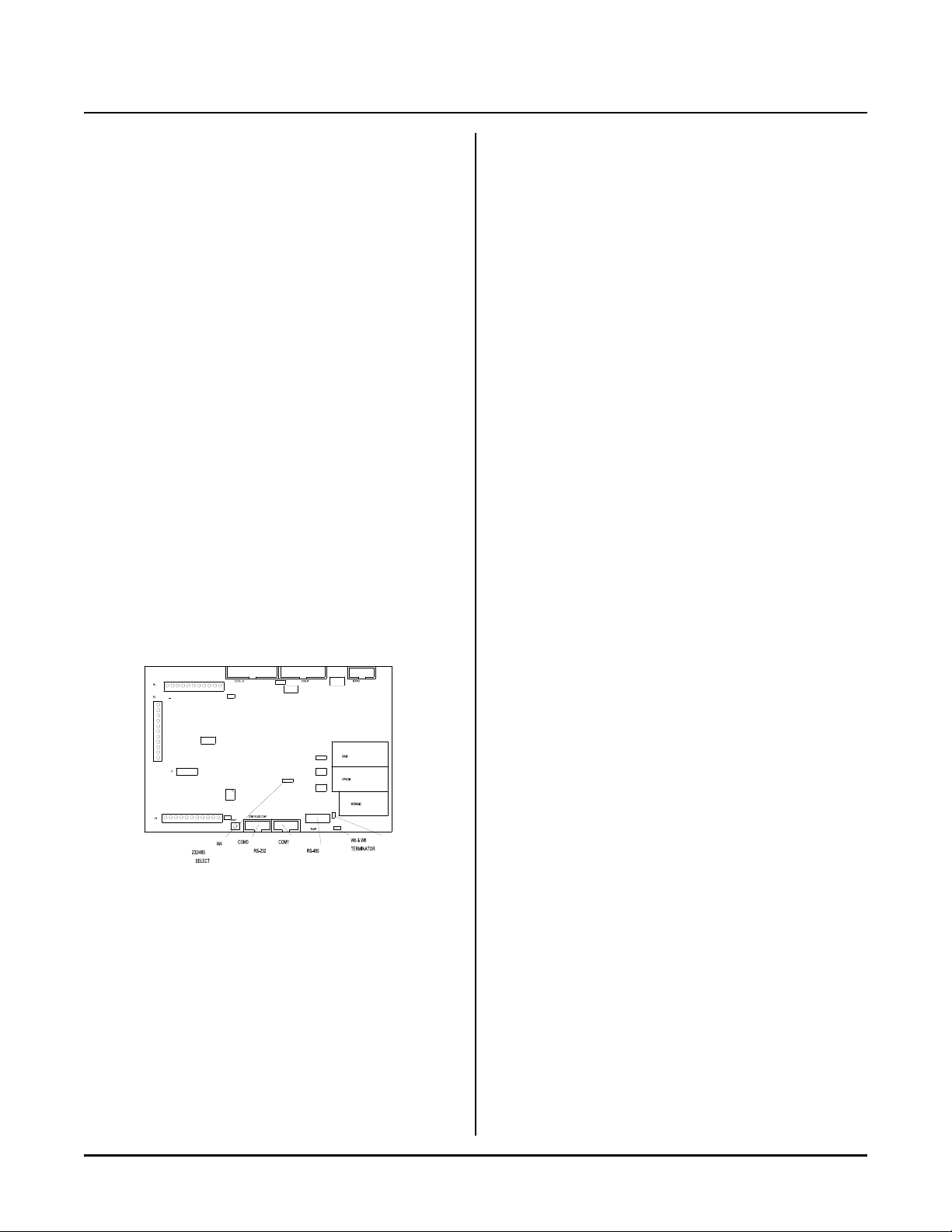

Figure 2-1 Connector location and function

Page 2-1 RPC-320

Page 9

SETUP AND OPERATION SECTION 2

FIRST TIME OPERATION

Become familiar with the locations of connectors before

getting started. See Figure 2-1.

RPC -320 jump ers have been set at the fa ctory to op erate

the system immediately. For first time operation, do not

install any connectors or parts unless specified below.

Jumpers should be kept in default positions.

1. Connect power.

The RPC-320 needs + 5 ±0.25 volts at 100 ma.

Any well regulated supply that supplies this will

work. Be careful when using "switching" power

supplies. Some of the se supplies do no t regulate

properly unless they are adequately loaded. Don' t

forget that power requirements increase w hen opto

modules are used. G4 opto modules require up to

20 ma each.

Make sure pow er is off. Connect the power supply

to one of the appropriately marked terminals on the

RPC-320. There two power connectors: P2 and P6.

Either one may be used to connect power.

2. Hook up to a PC or terminal.

Turn on your power supply. On power up a

copyright message is printed.

RPBASIC-52 V1.09

RPC-320

Copyright Remote Processing (1994)

Bytes free: 63740

65,536 bytes of additional expanded memory detected

512K byte EPROM installed

If a nonsense message appears, your terminal or PC

may not be set to the appropriate communication

parameters. If the system still does not respond,

refer to TROUBLESHOOTING later in this chapter.

The sign on message may differ based on the RAM

and flash EPROM installed.

4. Testing.

The system is now in the " imme diate mode" and is

ready for you to start programming. T ype the

following program:

10 FOR X=0 TO 2

20 PRINT "Hello ",

30 NEXT

40 PRINT

You can use either a PC or CRT term inal to

program the RPC-320. Connect one end of the

VTC-9F connector to the 10 pin COM0 port on the

RPC-320. Refer to Figure 2-1 for connector

location.

Using a PC

Connect the VTC-9F serial cable to the PC's COM1

or COM 2 port. Y ou may need a 9 pin male to 25

pin female adapter. The VTC-9F is designed to

plug directly into the 9 pin serial port connector on a

PC.

Start up your serial communication program. Set

comm unication par ameter s to 9600 baud, 8 data

bits, no parity, 1 stop.

Using a Terminal

Follow your terminal instructions to set the baud

rate to 9600 baud, 8 data bits, no parity, and 1 stop.

You may need a 9 pin male to 25 pin male adapter

to connect the VTC-9F.

3. Power up.

Now type RUN. The system will display:

Hello Hello Hello

READY

>

Terminate a program by typing a < Ctrl> -C.

UPLOADING AND DOWNLOADING

PROGRAMS

Downloading program s means transferring them fr om

your PC (or terminal) to the RPC-320. Uploading

means transferring them from the RPC -320 back to the

PC. This section explains how to do both of these

procedures using generalized instructions for terminal

programs (Procomm , Windows Ter minal, etc.)

When uploading or downloading files, select ASCII text

format. XMODEM, YMODEM, or other formats are

not used.

RPBASIC-52 does not know when you are typing in a

program or if something else (laptop or mainfr ame) is

Page 2-2 RPC-320

Page 10

SETUP AND OPERATION SECTION 2

sending it char acters. The upload and download file

does not contain any special codes; they are sim ply

ASCII characters.

Uploading programs is simply a process of receiving an

ASCII file. You or your program simply need to send

"LIST" to receive the entire program . The default baud

rate (9600) is rather high. The RP C-320' s baud rate is

changed using the CONFIG BAUD command.

Downloading a program requires transmitting an ASCII

file. As you type in (or download) a line, RPBASIC-52

tokenizes, or com piles, that line. The time to do this

depends upon its complexity and how many lines of code

have been entered.

RPBASIC-52 m ust finish compiling a line before starting

the next one. When a line is compiled, a "> " character

is sent. This should be your terminal programs pacing

character for downloading.

If your communications program cannot look for a

pacing prompt, set it to delay transmission after each line

is sent. A 100 ms delay is usually adequate, but your

program may be long and complex and require more

time. A r esult of a short transmission time is missing or

incomplete program lines.

increased download time.

Notice that you can write a program in lower case

characters. RPBASIC-52 translates them to upper case.

Some program mers put "N EW" as the first line in the

file. During debugging, it is common to insert

"temporary" lines. This ensures that these lines are

gone. Down loading time is increase d when the old

program is still pre sent. If you like to wr ite progr ams in

separate modules, you can download them separately.

Modules are assigned blocks of line numbers. Start up

code might be from 1 to 999. Interrupt handling

(keypad, serial ports) might be from lines 1000 to 1499.

Display output might be from 1500 to 2500. The

programmer must determine the number of lines

required for each section.

RPBASIC-52 automatically formats a line for minimum

code space. For example, you could download the

following line of code:

10 fora= 0to5

When you listed this line, it would appear as:

10 FOR A=0 TO 5

Editing programs and program ming hints

Files uploaded or downloaded are simply ASCII DOS

text files. No special characters or control codes are

used. You may create and edit programs using your

favorite word processor or editor. Just be sure to save

files in DOS text form at.

A technique used to further program documentation and

reduce code space is the use of comments in a

downloaded file. For example, you could have the

following in a file written on your editor:

REM Check position

REM Read output from the pot and

REM calculate the position

2200 a = ain(0) :REM Get position

The first 3 comments downloaded to the RPC -320

are ignored. Similarly, the empty lines between

comm ents are a lso ignored . L ine 2200, with its

comment, is a part of the program and could be listed.

The major pena lty by wr iting a progr am this w ay is

Spaces are displayed but not stored. The following line:

10 for a = 0 to 5

would be compressed and displayed as in the second

example above. Spaces are removed. However, spaces

as part of a remark or PRINT are not removed.

Instead of uploading and downloading programs, you can

save them to the on card EPROM. This is useful if you

are using a terminal to write program s. Simply type

SAVE. To retrieve a program, type LOAD.

Page 2-3 RPC-320

Page 11

SETUP AND OPERATION SECTION 2

WHERE TO GO FROM HERE

If you want to do this: Turn to

Chapter

Save a program 3

Run a program at power up or

reset (autorun) 3

Know m ore abo ut serial por ts 4

Install a different RAM mem ory chip 5

Using RAM to save variables 5

Run an assembly language program 5

Configure digital I/O lines 6

Detect on/off switch status 6

Use high current outputs 6

Connect an external opto rack 6

Calendar/clock option 7

Connect Displays 8

Use a keypad 9

Measure voltages 10

Using inter rupts 12

Multi-mode counter 13

Use low power operation 14

attached, you should see a burst of activity. With a

volt meter, you should see a change in voltage.

Using a Fluke 8060A set to measure AC, you

should see a momentary reading above 2 volts.

3. Install the serial cable and make sure the voltages

and output activity are still there. Output is from

pin 3 on the VTC-9F. If not, check to make sure

something is not shorting the output.

4. Check the serial pa ram eters on y our P C or termin al.

They should be set to:

9600 baud, no parity, 8 data bits, 1 stop

5. If you are receiving a sign on me ssage but not ab le

to enter characters, check U8, pin 4 for at least -6

volts. When it is near 0 volts, the terminal or PC's

Tx line is not connected. When you pr ess a

character on the terminal or PC, you should see the

voltage go positive. Check the serial cable.

Transmitted signals from the PC or terminal are

from pin 5 on the 10 pin IDC connector.

Refer to the table of contents for a more detailed listing.

TROUBLESHOOTING

You would probably turn to this section because you

could not get the sign on message. If you are getting a

sign on message but can't enter characters, then read

section 5 below . T he following are tr oubleshooting hints

when you can' t get anything.

1. Check the power source. If it is below 4.65 volts at

the input power terminal, the RPC -320 will reset.

Power is 5 ±0.25 volts. Make sure it is a clean 5

volt source. If it dips intermittently to 4.65 volts

(due to switching noise or ripple), the card will reset

for about 100 ms. If the noise is frequent enough,

the card will be in permanent reset. Check U7, pin

8. If it is high (about 5 volts), then the car d is in

reset. This line should be low (about 0 volts).

2. Check the COM 0 port (J3). Rem ove the connector

from COM 0. R efer to the outline drawing earlier in

this chapter. Connect an oscilloscope (preferred) or

a voltmeter to pin 3 (Txd) and gr ound. Pin 3 should

be -6 volts or more negative. (Pin 1 is designated

by the v symbol on the connecto r. Pin 3 is next to

it, nearer the key opening.) If you have -6 volts or

more, press the reset switch. If you have a scope

If all of this fails, call technical support listed in chapter

1.

Page 2-4 RPC-320

Page 12

SAVING PROGRAMS SECTION 3

INTRODUCTION

Program s are stored in an EPRO M in socket U6. You

can store one or more programs, depending upon

EPROM size. A BASIC program can call another when

a 512K byte EPROM is used.

Maximum program size that can be run at any one time

is about 62K, not including space for variables. 32K

bytes is the maximum program size when a 29C256 IC

type is used to save a program.

A conservative rule to determine program memory

requirements is one line requires 40 bytes. 32K bytes

would stor e 800 lines of code. Your application could

be significantly more or less, depending upon the

number of comm ands/line, com ments, and pr int

statements.

Despite the fact you may have a 128K or 512K RAM

installed, the maximum program size RPBASIC-52 can

run at one time is about 60K (including room for some

variable storage). The table below shows the maximum

capacity, maximum number of program lines, program

size at one time, and number of programs for an

EPROM type.

A flash EPROM is non-volatile (retaining data even

when power is disconnected), having an unlimited

number of read cycles and a limited number of write

cycles (about 1,000). A program is not run from

EPROM . It is transferred to RAM and run from there.

Programs in RAM can be m odified. They are saved to

EPROM for execution later.

The RPC -320 can autorun on power up or r eset by

removing jumper (W9). W hen autorun is on, the

program in EPROM segment 0 is loaded into RAM and

begins to execute immediately.

Figure 3-1 W3 autorun jumper

EPROM Max Prog Max No.

type Cap. lines Bytes Progs

29C256 30K 400 32K 1

29C040 509K 12400 62K 8

One program can call another using the EXECUTE n

command. n is from 0 to 7, depending upon the

EPROM type.

NOTE: When a program calls another, the old program

is completely replaced. All variables and

arrays are cleared (set to 0).

To keep variables, you m ust save them before calling the

new progr am. When the new program is running, these

variables are restored. Use PEEK and POKE to read

and save numbers and strings. See Chapter 5, STORING

VARIABLES IN RAM for more information.

Binary data is saved and read from the EPROM using

BSAVE and BLOAD commands. The EP ROM has a

limited number of write cycles (about 1000), so writing

information should be kept to a minimum.

This chapter discusses saving programs to EPROM (U6)

and program autoexecution.

SAVING A PROGRAM

For this example, assume you wanted to save the

following program:

20 FOR N= 0 TO 2

30 PRINT "Hello ",

40 NEXT

50 PRINT

If this progr am is not alr eady in, type it in now (or , if

you prefer, use your own program).

Type in the following command:

SAVE

RPBASIC-52 responds with:

Saving 35 bytes

Verifying --- OK

Page 3-1 RPC-320

Page 13

SAVING PROGRAMS SECTION 3

The time it takes save a program depends upon the

length and complexity of the program and flash EPROM

type. Programming rate is roughly 600 bytes/second. If

the program is not successfully saved to EPROM, an

error message will appear.

Saving a program overw rites the pr evious one. Ther e is

no way to recover the old one since both occupy the

same space.

Using SAVE without any parameters is the same as

typing SAVE 0.

When a 128K (29C 010) or 5 12K (29C 040) EP ROM is

installed in U6, the SAVE segment parameter is 0 or 1

(128K) or 0 - 7 (512K). EXECU TE loads and runs the

program in the segment specified by SAVE. A 32K

(29C256) EPROM can run just one program.

Make the following modifications to the above program

as instructed to see how one program can call another.

There must be a 128K or 512K EPROM installed to run

this code.

Add the following lines:

10 PRINT "Program segment 0"

60 EXECUTE 1

AUTORUNNING

To autorun a program:

1. Make sure there is a program in EP ROM (from

above). When using a 128K or 512K size EPROM,

make sure the start up progr am w as saved to

segment 0.

2. Remove jumper W9.

Push the reset button. The program will run. If there

are any error s, the program will stop (assuming you

have not trapped them with ON ERROR) and display the

error m essage. EX ECU TE n is used within any

program to load and run another program. The EPROM

size must be a 128K or 512K.

PREVENTING AUTORUN

When troubleshooting a program, it' s not always

convenient for an autoexecute file to r un. This is

especially true if the program has been configured to

ignore the < ESC> or < Ctl-C> keys.

To prevent autorun, install jumper W9 before power up

or reset.

Now type:

SAVE 0

Now m odify lines 10 and 60 as follows:

10 PRINT "Program segment 1"

60 EXECUTE 0

Now type:

SAVE 1

To see the programs operate, type RUN. To stop program

execution, press < Ctrl-C> .

You may notice there is a slight pause between the

printed hello' s and pro gram segmen t number . This is

the time it takes to clear memory and load the program.

Loading and clearing take appr oximately 0.2 5 seconds in

a very small program up to 1 second in a very large

program.

LOADING A PROGRAM

There are tim es when y ou may w ish to tempor arily

modify or otherwise test out a change to a program.

Since the program is loaded into RAM in autorun,

modifications are m ade withou t affecting the pr ogram in

EPROM. Use the LOAD or LOAD n comm and to

transfer the EPROM program to RAM.

If you find out that modifications are not desirable or did

not work, you can restore the original program to RAM

using the LOAD command.

CHANGING EPROM SIZE

The RPC-320 can com e with a 32K or 512 K flash

EPROM . The size may be changed at any time. Set

W3 according to the type/size.

Type Size W3

Bytes Configuration

29C256 32K [3-5], [4-6]

29C010 128K [3-5], [2-4]

Page 3-2 RPC-320

Page 14

SAVING PROGRAMS SECTION 3

29C040 512K [1-3], [2-4]

To change the EPRO M in U6, remove the IC and

replace it with the new one. When installing a 29C256,

pin 1 on the IC goes into socket pin 3. The top two

rows of pins are empty.

ALTERNATE EPROMS

Flash EPROMs are more expensive than UV er asable or

OTPs as of this writing. Large volume OEM' s may

wish to use lower cost EPRO Ms.

Program development must use flash EPROM s. When a

program is finished, the flash EP ROM is used as a

master. Use an exter nal progra m to duplicate progr ams.

Jumper W2 is normally configured for flash EPROM

(W2[3-5] and W2[4-6]). For non-flash E PRO Ms, W2 is

configured for [1-3] and [2-4]. Large volume OEM's

should contact Remote Processing regarding preconfiguring W2 and W3 for your application.

COMMANDS

The following is a list of RPBASIC-52 commands used

for saving, loading, and executing programs and data.

These commands and functions are explained in the

Software Supplement in this manual.

Command Function

BLOAD Transfers binary data from

EPROM to RAM

BSAVE Transfers binary data from RAM

to flash EPROM

EXECUTE Loads, clears memory, then runs

a program from within a program

LOAD n Loads a program from EPROM

SAVE n Saves a program to flash EPROM

Page 3-3 RPC-320

Page 15

SERIAL PORTS SECTION 4

DESCRIPTION

The RPC -320 has two serial ports that interface to a

printer, terminal, RS-485 network, or other serial

devices. This chapter describes their characteristics and

how to use them. Fre quent ref erence s are m ade to

commands listed in the BASIC-52 Programming Manual

or RPBASIC-52 Software Supplement in this manua l.

Please refer to these manuals for more information about

these commands.

Serial por ts are num bered C OM0 and CO M1. COM 0 is

RS232 only and is used for progr am deve lopment.

During r un time, it can be used for other functions.

COM 1 is a general purpose port and is jumperable for

RS-232 or RS-422/485.

Each port has a 256 character interrupt driven input and

output buffer. This allows sending characters without

slowing down program execution. However, if the

PRIN T buffer fills, pr ogram execution is suspended until

all PRINT characters are in the buffer. Both ports have

a 256 character input buffer. When more than 256

characters are received, excess ones are ignored.

COM0 SERIAL PORT

This port uses a VTC-9F serial cable to connect external

serial devices to the port. The cable con sists of a 10 pin

IDC connector wired one-to-one to a DB-9 connector.

Line 10 is sim ply cut off. The pin ou t is designed so it

plugs directly into the 9 pin serial port connector on a

PC.

CTS is a output and is set to high on power up.

Normally, this tells the other device to send data. The

CTS line is set high or low to hold off communication.

The sending device must have a RTS input. Line 400

sets CTS high and 500 sets it low, or to hold off.

400 LINEB 5,0,(LINEB(5,0) .AND. 247)

500 LINEB 5,0,(LINEB(5,0) .OR. 8)

COM 0 is normally used for program ming. D uring run

time it may be used as a general purpose serial port.

When used for programming or with the INPUT

statement, it will accept ASCII character values from 0

to 127. When used with the GET function, it will return

ASCII values from 0 to 255.

CONFIG BAUD controls baud rate and RS-232/485

mode (COM1 only).

Figure 4-1 Serial port and jumper locations

ON C OM $ is useful whe n data is sent in pac kets. This

multitasking command branches to a BASIC subroutine

when a specific character or number of characters is

received.

Another useful function is STR. Strings can be

formatted, analyzed for length and content. When used

in conjunction with ON COM$, networ king over RS-485

is much easier than with the original BASIC-52.

COM1 SERIAL PORT

COM 1 is either an RS-232 or RS-422/485 port. A

VTC-9F serial cable, described above, is used for RS232 level communications. RS-485 is from screw

terminals. COM 1 has 2 hardware handshaking lines,

CTS and RTS.

RTS is an input to the card. W hen RT S to the car d is

low, it usually indicates the sender does not want any

data sent to it. The status of this port is read by the

LINEB statement. The example below retur ns a status

of the RTS line:

100 B = LINEB(5,1) .AND. 32

If B = 32, the sender is not requesting information and

nothing further should be printed.

The CTS line may be set high or low to hold off

communication from a sending device. The sender must

recognize the CTS line. Line 400 sets CTS high and 500

sets it low, or to hold off.

Page 4-1 RPC-320

Page 16

SERIAL PORTS SECTION 4

Figure 4-2 Network diagram

400 LINEB 5,0,(LINEB(5,0) .AND. 251)

500 LINEB 5,0,(LINEB(5,0) .OR. 4)

Jumper W4 determines if COM 1 receive is RS-232 or

RS-422/485.

W4[1-2] RS-485

W4[2-3] RS-232 (default)

COM1 default is RS-232. Use the CONFIG BAUD

statement to set the software to RS-422 or RS-485.

When set to RS-422, the transmitter is always on. RS485 mode turns on the transmitter only when sending.

Page 4-2 RPC-320

RS-422/485 OPERATING INFORMATION

RS-422/485 Termination network

When the RPC-320 is the last physical unit on a network

(RS-485), or it is the only unit (RS-422), the receiver

must be terminated to prevent ringing. Jumper block

W5, 6 installs or removes this network. Insert a jumper

in W5 and W6 to install the network terminator.

Only one slave device on a RS-485 network should have

a terminator installed. The host transmitter should also

have a 100 ohm resistor in series with a 0.1 mfd

capacitor. T he term inator on the RPC -320 includes pull

up and pull down resistors to prevent lines from floating

and generating er roneous char acters.

Page 17

SERIAL PORTS SECTION 4

Two wire RS-485

The RS-485 port on the RPC-320 is set up for 4 wire

mode. 2- wire mode causes transmitted data to be

received. To use the RPC-320 is this mode, your code

should "flush" the received data or otherwise remove

transmitted information.

Mechanically, to make a 2- wire system, simply connect

T+ to R+ and T- to R -. M ake sure CON FIG BAUD is

set up for RS-485 mode.

Multidrop Network

Figure 4-3 Data packet

You can use the RPC-320 in a multidrop network by

using CO M1' s RS-422/485 port. You can c onnect up to

32 units (including other RPC-320' s) over a 4,000 foot

range.

Figure 4-2 shows an example of a multidrop network.

This network includes a host and one or m ore devices.

The host transmits data packets to all of the devices, or

nodes, in the network. A data packet includes an

address, com mand, data, and a checksum. See figure 4-

3. The packet is received by all devices, and ignored by

all except the one addressed.

The response depends upon the nature of the command.

Suppose the command M means "return a digital I/O

port status". The RPC-320 could read the port and

respond with AA2< cr> . The first A is an

acknowledge, that is no errors were detected in the

message. The data, A2, is a hex number and is broken

down as follows:

Bit/line 7 6 5 4 3 2 1 0

Status 1 0 1 0 0 0 1 0 = A2

The relationship described below between nodes and the

host is a master-slave. The host dir ects all

communication. Nodes "do not speak unless spoken to".

Peer to peer communication, while possible with the

RPC-320, is not discussed here.

There are m any com municatio n protoco ls. F or this

example, a protocol might look som ething like this:

> 22MB1

The protocol starts w ith the < cr> charac ter. This

character synchronizes all units and alerts them that the

next few characters coming down are address and data.

In this case, "> 22" is the units address. "M " is the

comm and and " B1" is the ch ecksum . T he comm and is

terminated with a < cr> character.

Lines 1, 5 and 7 are high while the others are low.

The following program fragment uses ON C OM$ and

STR in a network environment. ON COM$ generates an

interrupt when a < CR> is received. The interr upt

program uses a STR function to deter mine if the da ta

packet was addressed to this card.

10 STRING 200,20

20 ON COM$ 1,0,13,1000

30 $(1) = ">05"

.

.

.

1000 $(0) = COM$(1)

1010 A = STR(8,$(0),$(1))

1020 IF A = 0 THEN RETURN

.

.

Line 20 sets up ON COM$ to interrupt on a < CR> and

branch to line 1000. Line 30 sets up this card' s address.

Line 1010 checks to see if the received message = this

card's address. If not, the subroutine ends. When there

is a match, further processing is performed.

ACCESSING SERIAL BUFFERS

Page 4-3 RPC-320

Page 18

SERIAL PORTS SECTION 4

You can access C OM0 and COM 1 buffers in three ways:

1. INPUT statement. This re moves a ll charac ters in

the buffer up to the term inator cha racter and puts

them into a variable.

When using the INPUT statement, program

execution is suspended until a < cr> (Enter key) is

received. W hether this is a problem depends on

your particular application.

INPUT strips bit 7. This means ASCII characters

from 0 to 127 are received.

2. GET function. Char acters ar e removed one at a

time as an ASCII value. A 0 is returned when the

buffer is empty. Use the C OM function to

determine if the buffer is empty or if a 0 is an

ASCII value. Use UIn to select the serial port for

GET.

If you don' t read the b uffer an d the buffer fills, all

subsequent characters are discarded.

3. COM$(n) retrieves all characters in the buffer,

including other control codes (except CR).

ACCESSING COM0 AND COM1

INPUT and GET functions retrieve data using the UIn

comm and. UI0 r outes inputs to C OM 0 while U I1 inputs

from the COM1 port. PRINT outputs are set by the

UOn command. UO0 prints out COM0 while UO1

outputs COM1 using the PRIN T comm and. PR INT #1,

is an alternative way to print to COM 1.

The following show how UIn and UOn work.

100 UI0 Set to COM0

110 INPUT A Get data from COM0 port

DISABLING CONTROL-C

Program execution is terminated by entering a

< Cntl> < C> . To disable < Cntl> < C> so program

execution is not terminated, execute the following

statement:

DBY(38) = DBY(38) .OR. 1

COMMANDS

The following is a list of RPBASIC-52 commands used

for serial I/O. These commands and functions are

explained in the BASIC-52 Programming Manual and

RPBASIC-52 Software Supplement in this manua l.

Command Function

CLEAR COM$ Clears serial input buffer

COM$ Returns string from buffer

COM Returns number of characters

in buffer

CONFIG BAUD Sets serial port parameters

GET Returns a character from the

serial buffer

INPUT Receives string from port

LIST Outputs program listing

PRINT Outputs data in various

formats

PRINT #, Prints to a specified port

SPC Print out n number of spaces

STR String handling commands

TAB Tabs to predetermined

positions

UI0 Reroute inputs to COM0

UI1 Route inputs to COM1

UO0 Rerou te PRIN T statem ent to

COM0

UO1 Route P RINT statement to

COM1

USING PRINT formatting statement

520 UI1 Switch to COM1 port

530 INPUT B Get data from COM1 port

800 REM Print to COM0

810 PRINT "Temperature:",T

900 REM Print to COM 1

910 PRINT#1, "Set pressure at:",CA

Power up default is set to COM0.

SERIAL PORT PIN OUT

Pin outs for J1 and J2 are shown below. Unused pins

are open.

J1 & Name Direction

J2 from card

3 Tx Out

4 RTS* In

Page 4-4 RPC-320

Page 19

SERIAL PORTS SECTION 4

5 RXD In

6 CTS Out

9 Ground

10 +5

*RTS input not in COM0.

A serial cable is made by simply taking a 10 pin female

IDC connector and crim ping a 9 wir e ribbon cable to it.

Page 4-5 RPC-320

Page 20

RAM MEMORY SECTION 5

INTRODUCTION

32K, 128K, or 512K of RAM may be battery backed on

the RPC-320. RAM size can be changed at any time.

RAM is in socket U5.

RAM is backed up when a DS1216DM is installed.

Battery life depends upon RAM size, its power

consumption, ambient temperature, and amount of time

the board is operating. Generally, a battery life of about

3 to 5 y ea rs is e xpected . Op er ati ng the boar d a t 50 °C

reduces battery life by 1/2.

The DS1216DM is also a real time clock. Thus, DATE

and TIM E function s and com mands a re availa ble when it

is installed. See Chapter 7 for more inform ation.

This chapter discusses changing RAM, saving and

retrieving variables, running assembly language

programs, and battery condition. Figure 5-1 shows the

location of U3 and jumper W1.

Increasing RAM size does not necessarily increase the

program size RPBASIC-52 can handle. Maximum

program and variable size is 60K. Additional RAM does

increase the amount of space available for PEEK and

POKE storage.

To install a new memory chip:

1. Turn off power to the RPC-320.

2. Remove the mem ory chip from U 5.

3. Orient the chip so pin 1 is towards the inside.

If installing a 32K RAM, place the chip at the

bottom

of the socket (m emor y chip pin 1 goe s into

socket pin 3). The top two socket pins in each row

are empty.

If installing a 128K or 512K, install the chip into the

socket.

4. Check and change , as n ecessar y, jum per W1 to

conform to the new mem ory.

RAM size Jumper W1

32K [1-2]

128K [1-2]

512K [2-3]

BATTERY BACKUP

An optional battery backup module may be installed.

Principal is the same as installing a RAM chip.

Figure 5-1 RAM and W1 jumper location

CHANGING MEMORY

Different types of memory can be installed at any time.

RPC-320 models come with either 32K or 128K of RAM

installed. Maximum is 512K.

To change a memory chip, you need to rem ove the

original chip, install the new one, and set jumper W1.

WARNING:

An additional modification must be performed to the

DS1216DM module when a 512K RAM is installed.

Contact Rem ote Processing for details.

To install a module:

1. Remove the RAM IC in U5.

2. Install the DS1216DM in U5.

3. Re-install the RAM chip into the top of the module.

Checking the battery

Battery voltage is approximately 3.0 volts, measured

between pin 16 (ground) and 30 (128K RAM), 14 and 28

(32K RAM), or 16 and 32 (512K R AM ) on the IC itself

(not the circuit side of the board). Be sure to power up

the RPC -320 once to a ctivate the batter y backup circuit

in the module.

Page 5-1 RPC-320

Page 21

RAM MEMORY SECTION 5

RESERVED MEMORY

Many control systems use process variables that are

operator entered. "variables" in this context include

numbers, strings, arrays, recipes, or formulas as applied

to your application. They are not a part of the variables

used by Basic. Process variables are accessed by PEEK

and POKE type statements.

The upper 512 bytes of mem ory ar e set aside for this

purpose in a 32K RAM system. In 128K and 512K

RAM systems, all of the first 64K of RAM is used for

program and variable stora ge. P rocess var iables in these

larger versions are stored starting at segment 1 and

higher.

Figure 5-2 RPBASIC-52 memory map

When the combined program and data size exceed 30K,

a 128K or 512K RA M is nec essary. Additional RAM is

necessary when your program has large arrays and / or

string storage requirements.

MTOP should not be used when variables are battery

backed for power off conditions. Basic clears all of

RAM in segment 0 (except for the last 512 bytes in a

32K system) at power up. Store process variables

starting at segment 1 or higher in a 128K or 512K RAM

system or start at address 7E00H, segment 0 in a 32K

RAM system.

STORING VARIABLES IN RAM

Program s and RPBASIC-52 var iables reside in segment

0. Data is generally stored in segment 1 and higher (a

segment is 64K of memory). See memor y map figure 5-

2. "Data Area" is segment 1 or higher.

PEEK and POKE commands store and retrieve values

from memory. For example:

20 POKEB1,12,A

puts the 8 bit value of A into segment 1, address 12.

100 POKEB0,7E00H,C

120 B = PEEKB(0,7E05H)

The highest address in a 32K RAM system is 7FFFH.

Many times it is desirable to store an array containing a

"mixed" set of variables. Suppose you needed to save an

array m ade up of the following elem ents:

Bytes Type Description

1 Byte Job counter

2 Word Analog output offset

6 Floating Correction factor

20 String Job name

Total number of byes required for each array is 30 (add

1 for a < CR> at the end of the string).

The Job counter is incremented ever y time it is

completed. Analog output offset is an output constant or

other var iable used to initialize the outputs. Job name is

used with the display to identify a job.

For this example, suppose there are 20 of these arrays

that need to be set up. A program fragment is as

follows:

Use the PEEK statement to retrieve the variable:

50 B = PEEKB(1,12)

Accessing reserved mem ory in a 32 K RAM system is

accomplished as follows:

100 STRING 400,20 Initialize 20 string arrays

300 NO = 12 Element to fill

310 CF = 23.432 Correction factor

320 JC = JC + 1 Job counter

330 AC = 25 Analog offset

350 GOSUB 1000

500 NO = 5 Element to retrieve

Page 5-2 RPC-320

Page 22

RAM MEMORY SECTION 5

510 GOSUB 2000 Retrieve variables

This subroutine stores variables CF, JC, and AC into an

array starting in segment 1, address 0.

ASSEMBLY LANGUAGE INTERFACE

1000 POKEB1,30*NO, JC

1010 POKEW1,30*NO+ 1,AC

1020 POKEF1,30*NO+ 3,CF

1030 POKE$1, 30*NO+ 9,$(0)

1040 RETURN

Subroutine 2000 - 2040 retrieves data into variables CF,

JC and AC.

2000 JC = PEEKB(1,30*NO)

2010 AC = PEEKW (1,30*N O+ 1)

2020 $(1) = PEEK$(1, 30*NO+ 9)

2030 CF = PEEKF (1,30*NO+ 3)

2040 RETURN

You can store and retrieve strings and variables in this

way. There are many variations of PEEK and POKE

statements. Refer to the RPBASIC-52 Software

Supplement in this manual for additional information and

examples. A list of comm ands appea rs at the end of this

chapter.

BLOCK DATA TRANSFER

Blocks of data are transferred to and from RAM and

flash EPROM using BLOAD and BSAVE comma nds.

Block transfers are useful for loading and storing data,

look-up tables, text, etc. U p to 65,535 bytes can be

moved from RAM to EPROM or EPROM to RAM at

one time. The absolute number of bytes that are moved

is limited by the RAM and EPR OM sizes.

Transfers from EPRO M to RAM , using BLOA D, take

approximately 23.5 m s/1000 bytes. T ransfers from

RAM to EPROM , using BSAVE , are even longer at 100

ms/1000 bytes using a 512K byte EPROM. T his time is

even longer when smaller EPROM s are used (due to the

programming algorithm).

Serial port, tick timer, and external interrupts are

enabled dur ing these tra nsfers. However, response s to

ONT ICK or ONIT R are delayed by the time it takes to

transfer data. W hen ONTIC K or ONIT R must be

serviced faster, transfer data in smaller blocks.

Refer to BLOAD and BSAVE in Appendix A for more

information.

Assembly language programs must be placed in the

RPBASIC-52 EPROM . W hen using RPBASIC-52,

programs should start at addr ess 6000H or higher up to

7FFFH.

RPBASIC is norm ally in a 32K byte EPROM (27C256).

A 64K byte EPROM (27C512) may be used in socket U4

provided the following modification is made: Cut the

trace between W11 pins 1 and 2 on the circuit side.

(Jumper W11 is under socket U4. Pin 1 is designated by

the square pad.) Solder a jumper between W11 pin 2

and 3.

Docum ented assem bly language interface calls listed in

the Intel MCS BASIC -52 Users Manual will not work

with RPBASIC-52. This is because RPBASIC-52 has

been reassembled and code shifted around.

The RP-10 adapter boar d is used to run and debug

assembly and C code. This board plugs into RAM

socket U5 and RPBASIC socket U4. It does not use the

Basic at all.

COMMANDS

The following is a list of RPBASIC-52 commands used

with RAM.

Command Function

BLOAD Transfers data from EPROM to RAM

BSAVE Transfers data from RAM to EPROM

CALL Calls an assembly language routine

CBY Returns code memory data

DBY Returns or assigns internal memory

MTOP Sets top of RAM memory

PEEK B Returns a byte

PEEK F Returns a floating point number

PEEK W Returns a 16 bit value

PEEK $ Returns a string

POKE B Stores a byte

POKE F Stores a floating point number

POKE W Stores a 16 bit value

POKE $ Stores a string

XBY Returns or assigns external memory

Page 5-3 RPC-320

Page 23

DIGITAL AND OPTO PORTS SECTION 6

INTRODUCTION

Digital I/O lines ar e used to inter face with op to-module

racks, switches, low current LED's, and other TTL

devices. The RPC-320 has 34 of these lines. 8 TTL I/O

lines go to a terminal strip. Additionally, there is one

high curr ent output and a n opto-isolated inp ut. R efer to

the figure below for the location of these lines.

Eight lines at P6 are intended for general purpose TTL

I/O such as switches, level sensors or to drive other

devices.

A 24 line connector, J3, is intended to interface to opto

racks or other TT L devices. 8 of these lines are high

current outputs, capable of sink ing 75 to 200 m a. O pto

modules on an opto rack sense presence of AC or DC

voltages or switch them.

L8 at P2 is a "zero" ohm FE T switch. It is intended for

switching L ED back lighting on an LCD display. This

line may also be used to switch high current, high

voltage power. It can switch up to 2 amps.

ISOA/B is used as an isolated input as well as an

interrupt.

technical support for suggestions appropriate to your

application. Power may be applied to ISOA/B at

any time.

Several softwar e comm ands support the digital I/O ports.

ON LINE br anches to a subroutine w hen a line changes.

ON COUNT counts the number of high to low

transitions at a digital line. Maxim um coun ting rate is

about 95 Hz. These commands simplify design and

greatly speed up execution. See Appendix A for more

information.

DIGITAL I/O PORTS

All ports use an 82C55 for I/O. Lines are accessed

using LINE or LINEB commands. Lines at J3 and P6

are configured for inputs or outputs using the CONFIG

LINE comm and. See Appendix A for information.

WARNING:

When using CONFIG LIN E, output lines go low

momentarily (less than 10 micro-seconds) until they

are set high again as per the data in the command

line. Some other lines are affected when CONF IG

LINE 0 is executed. Refer to CONFIG LINE

command in Appendix A for more inform ation.

In addition to the 24 I/O lines from J3, the display port

can be used as digital I/O. Refer to Chapter 8 for more

information.

Figure 6-1 Digital I/O

WARNING:

Apply power to the RPC -320 before applying a

voltage to the digital I/O lines to prevent current

from flowing in and damaging devices. If you

cannot apply power to the RPC-320 first, contact

Digital Por t J3

This port is used to interface opto modules (using the

MPS series racks), drive small r elays, solenoids,

motors, or lamps, and provide general purpose TTL I/O

to other logic devices or mechanical switches. The

LINE command is used to access and control this port.

The lines on J3 are divided into 3 eight bit groups from

an 82C55. Ports A and B are configured as all inputs or

outputs. Port C is progr amm ed as one group of 8 inputs

or outputs or as two groups of four lines (upper and

lower C). The four lines in upper and lower C can each

be programmed as all inputs or outputs. Refer to Table

6-1 to determine the opto channel or J3 pin number for a

port. Use CONFIG LIN E 100 (Appendix A) to

configure ports A, B, and C for inputs or outputs.

When a line is configured as an output, it can sink a

maximum of 2. 5 ma at 0.4V and can source over 2. 5

ma. Outputs sink 15 ma at 1. 0V. This will dr ive opto

modules. Port B is connected to a high current sink

through U12. See "High current output" later.

Digital I/O lines at J3 m ay be pulled up to + 5 volts or to

Page 6-1 RPC-320

Page 24

DIGITAL AND OPTO PORTS SECTION 6

ground through a 10K/100K resistor packs using jumper

W7. 10K is on digital port A only.

Jumper W7 for pull up or down configuration is as

follows:

W7[1-2] Pull up

W7[2-3] Pull down

Setting W7 for pull up makes interfacing to switches and

"open collector" TTL devices easy. See "Interfacing to

Switches and other devices" below.

Digital Port P6

Connector P6 has 8 digital I/O lines for general pur pose

use. Additionally, 3 ground and a + 5V positions are

provided. + 5V power and gr ound may be brought in or

taken from this connector. Lines are numbered L0-L7.

This port may be used to interface switches, dr ive small

LED' s, and provide general purpose TTL I/O to other

logic devices. Voltage and current param eters are the

same as J3 except there is no high current output. Port

C from an 82C55 is used for this I/O.

Upon power up or reset lines L0 to L3 are inputs while

L4 to L7 are outputs. Lines L4 and L5 are low while L6

and L7 are high at power up. All lines are connected to

a 10K pull up resistor (R21). Lines are reconfigured for

all inputs or outputs using the CONFIG LINE 0

command, found in Appendix A.

to the touch. Consider the maximum ambient

temper ature the b oard w ill operate a t. A t 70°C, warm to

the touch at room temperature m ay be too much.

Consider adding a heat sink.

The PW M com mand m ay be used with this port. Use

the circuit in Figure 6-2 when switching inductive loads.

Use the "GN D" ter minal next to L8 when switching

loads.

Optically Isolated Input

ISOA and ISOB ar e inputs to an optica l isolator. This

input is read as L8. It can also generate an interrupt

provided W8[1-2] is jumpered and ONITR is set. Refer

to Chapter 12 for input voltage and interrupt

requirements. This line can be used to "wake up" the

CPU from low power IDLE 2 mode.

The status is read using the LINE(8) function.

A = LINE(8)

A 1 is returned when there is no input and a 0 when

voltage is sufficiently high enough to turn on the isolator

(about 3.5 volts).

The opto isolator is not polarity sensitive. This input can

be used in conjunction with or independently of the

ONIT R statem ent.

High Current Port L8

L8 will switch 2 amperes to ground through a "zero

ohm" FET switch. Maxim um off vo ltage is + 50 volts

DC. "ON" resistance is about 0.5 ohm.

Use this port to switch LED back lighting for LCD

displays on or off under softwar e control.

This line is always an output. Use the LINE 8 com mand

to turn this line off or on.

LINE 8,ON

LINE 8,1 Both commands turn on L8.

The F ET sw itch is rated fo r mu ch higher curr ent.

However, continuous current is much less without a heat

sink attached. You may draw more than the rated 2

amps on an intermittent basis. How m uch and for how

long depends upon your application. A quick w ay to

check for excessive current is to touch (VERY

CAREFUL LY!) Q2 (next to P2). It can be warm to hot

Page 6-2 RPC-320

Digital I/O Commands

The CONFIG LINE statement is used to configure lines

at J3 and P6 for inputs and outputs. J3 power up default

is all inputs. P6 power up default is L0 to L 3 are inpu ts

and L4 to L7 are outputs. CONFIG LINE 0 refers to P6

while CONFIG LIN E 100 to J3.

The L INE comm and has 3 variations: LIN E, LIN E B,

and LINE #. Each is described below. See Appendix A

for more inform ation.

LINE function and statement is used with M PS-X X opto

rack at J3. It accesses a module according to the

position number printed on the MPS board. Lines are

numbered from 100 to 123. The opto module number

used in this command is computed by adding 100 to the

board position number. LINE also accesses L0-L8 on

P2 and P6.

The LIN E B function and statement is used to acc ess

Page 25

DIGITAL AND OPTO PORTS SECTION 6

digital I/O lines 8 bits at a time. T he addr ess for po rt A

is 0, B is 1, and C is 2. J3 I/O bank number is 3.

Address for lines L0-L7 at P6 is 2 and I/O bank number

is 5.

LINE # function and statement accesses lines according

to the pin number at J3. J3 lines are numbered from 101

to 125. The line number used in this com mand is

computed by adding 100 to the connector pin number.

Line 102 is not allowed as it is the + 5V supply. See

table 6-1 to cor respond a pin numb er to a por t and opto

rack position.

P6 lines are numbered 0 to 7, and correspond to the

terminal number on the board. The LINE function and

command are used to access these lines. L8 at P2 is a

high current output and is accessed using LINE 8. The

status of ISOA/B is returned using LINE 8 function.

LINE, LINE B and LIN E # return a ' true' logic level.

A ' 1' indicates + 5 volts or high and a '0' is low or

ground. LINE B and LINE # output true logic levels.

LINE, however, outputs inverted logic. In order to turn

on an opto m odule, a line must go low. Howe ver, to

turn on a module using LINE, specify ' 1' or ON. High

current output chip U 12 inverts c ontrol signa ls sent to it,

regardless of command.

100 LINE 118,1 :REM Turn opto 118 ON

110 LINE 118,ON :REM Turns opto 118 ON

120 LINE#104,0 :REM also turns 118 ON

ON LIN E is a multitasking command. W hen active, the

RPBASIC oper ating system checks the specified line

every 5 ms. If the line changed state from the previous

scan, a software interr upt is set. Upon completion of the

current BASIC command (and assuming no other

interrupts are active), program execution branches to a

specified subroutine. This command is useful for

monitoring lines, such as limit or door switches, that

may not change often or when the program structure

make it unwieldy to check lines frequently.

Another multitasking command, ON C OUN T, causes the

operating system to check the specified line every 5 m s.

Up to 8 lines are monitored. If the line changed from a

high-to-low state, a counter is incremented. M aximum

counting rate is effectively 95 Hz. This command has

two variations. One causes a software interr upt when a

specified num ber of co unts is reac hed. Another simply

counts pulses at a line. The C OUN T function returns

the number of pulses since ON COUNT was initiated.

See Appendix A for command information.

ON C OUN T and ON LIN E do not ne cessarily h ave to

be input lines. They can be outputs controlled by

another part of the program.

High Current Output

Eight lines at J3 can be used as high current driver s.

These outputs will switch loads to ground. Outputs are

controlled by Port B on the 82C55.

Logic outputs are inverted. That is, when a 1 is written

to the high current port, the output is switched on and

goes low.

The output driver chip, U 12, can be replaced w ith a DIP

shunt jumper so it is like the other lines at J3. To do

this, r emove U12. Install a DIP shunt so pin 1 goes to

pin 18. Pins 9 & 10 are open.

NOTE: Outputs at the high current lines are not

compatible with TTL logic levels and should not

be used to drive other logic devices.

Each of the high current outputs can sink 500 ma at 50V.

However, package diss ipation will be ex ceeded if all

outputs are used at the maximum rating. The following

conservative guidelines assume the number of outputs

are on simultaneously:

# of outputs Maximum current

on per output

1 500 ma

2 400 ma

3 275 ma

4 200 ma

5 160 ma

6 135 ma

7 120 ma

8 100 ma

The ther mal time constant of the p ackage is ve ry shor t,

so the number of outputs that are on at any one time

should include those that overlap even for a few

milliseconds.

Incandescent lamps have a "cold" current of 11 times its

operating current. Lamps requiring more than 50 ma

should not be used unless a series resistor is installed.

Page 6-3 RPC-320

Page 26

DIGITAL AND OPTO PORTS SECTION 6

Protection diodes m ust be used with inductive loads.

Refer to figure 6-2

Figure 6-2 Inductive load protection

Do not parallel outputs for higher drive. This could

result in damage since outputs will not share current

equally.

The outputs at U12 are open collector. An external

device must supply power.

Interfacing Digital I/O to an opto-module rack

I/O lines at J3 can interface to an MPS-8, 16, or 24

position opto module rac k. L ines not going to an opto

module connect to a screw terminal on the MPS-XX

series boards. This feature allows you to connect

switches or other TTL type devices to the digital I/O

lines. The MPS-XX series boards accept G4 series

modules.

A CM A-26-24 connects J3 on the RPC-320 to the MPSXX board. Cable len gth should be less than 2 feet.

Excessive cable lengths cause a voltage drop and

consequently unreliable operation. Make sure + 5 V and

ground is connected to the M PS-XX racks.

Before a line is set, the 82C55 chip must be initialized.

This is done using the CONFIG LINE statement. Group

inputs and outputs together. Refer to Table 6-1 for opto

module position, port number, and connector pin out. If

opto channels 16-23 are used, U12 should be replaced by

a DIP shunt jumper.

130 A = LINE#(103) Function

Program line 100 turns external opto module rack

position 0 off. Program line 110 sets J3, pin 3, to a

logical 0 level. Program line 120 returns the status of

external opto module rack position 0. If the module is

"off", a 1 is returned (assuming it is an output module).

Program line 130 returns the status of J3, pin 3 as a 0 or

1.

Example: To turn on opto module in slot position 8, the

following command is executed:

LINE 108, 1

A ' 1' turns on a module while a 0 turns it off. (In actual

fact, a 0 is written at the port. )

See Digital I/ O program ming exam ple later in this

chapter.

Interfacing to switches and other devices

Switches and other digital I/O devices may be connected

directly to P6 or J3. The STB-26 terminal board

provides a convenient way of interfacing switches or

other digital I/ O device s. L ines at J3 are connected to

the STB-26 with a CMA-26 cable. Digital devices are

then connected to the screw terminals on the STB-26.

The M PS-X X serie s opto rac ks also provide a way to

access digital I/O lines.

Switches may be connected directly to a line. When

jumper W7 configures the resistors as pull ups, a switch

closure to ground at a line is read as a 0 using the LINE

# function at J1. 10K resistors are always pulled up at

lines L0 to L7.

When W7 configures the input resistors as pull downs,

one end of the switch must be tied to + 5 volts. If this is

not possible or convenient, a 1K resistor can be tied

between an input and + 5 volts to force it high when a

switch is open.

The LINE and LINE # com mands are used to control

and access opto modules and lines. These commands are

both functions and statements, depending upon how they

are used.

100 LINE 100, 0 Statement

110 LINE #103, 0 Statement

120 A = LINE(100) Function

Page 6-4 RPC-320

Digital I/ O prog ramm ing exam ple

The follow ing exam ple read s a switch at po rt A, bit 3

(J3-25) (program line 200), reads L1 at P6 (program line

210) and turns on opto module at channel 5 (program

line 220). A LED is controlled through the high current

port at J3-10 (port B, bit 0) (program lines 230 and 240).

For testing, a 100 ohm resistor from J3-10 to + 5 volts

can be substituted.

Page 27

DIGITAL AND OPTO PORTS SECTION 6

100 CONFIG LIN E 100,13, 1,1, 1

200 D = LINE #(125)

210 F = LINE (1)

220 LINE 105, 1

230 LINE #110,1 :REM Turn on LED

240 LINE #110,0 :REM Turn off LED

Line 100 configured the 82C55 so ports A and C are

inputs while B is the output.

Note that the LINE statement is us ed to contr ol both opto

modules and individual lines.

Lines can also be read or controlled in the immediate

mode.

PRINT LINE#(125)

returns the status at J3-25. Notice that even when a line

is configured as an output, its status can be read back.

Execute the following to control L7.

LINE 7,OFF

sets L7 low. Executing

LINE 7,ON

sets the line high.

LINEB is used to read and write a byte at a time.

LINEB 3,1,128

sets port B, bit 7 high and bits 0-6 are low.

Pulse Width Modulation (PWM)

Any line accessible by the LINE com mand m ay be pulse

width modulated. PW M comm and parameters determ ine

high and low time (to 5 ms resolution) and, optionally,

number of pulses.

Use PWM to control the brightness of a display (via line

8), control the speed of a motor, or output a number of

pulses to a stepper controller. Brightness control using

LED' s is best achieved when htime or ltime are less than

5 (25 ms). One of the parameters should be 1.

Noticeable flicker occurs when htime and ltime sum to

more than 6 (30 ms).

See the PWM command in the Software Supplement for

more information. Use Table 6-1 to use an output

directly from J3.

Page 6-5 RPC-320

Page 28

DIGITAL AND OPTO PORTS SECTION 6

Table 6-1 Connector pin ou t - J3

Pin # 82C55 Description Opto

Channel

19 Port A, line 0 8

21 Port A, line 1 9

23 Port A, line 2 10

25 Port A, line 3 11

24 Port A, line 4 12

22 Port A, line 5 13

20 Port A, line 6 14

18 Port A, line 7 15

10 Port B, line 0 High current 16

8 Port B, line 1 High current 17

4 Port B, line 2 High current 18

6 Port B, line 3 High current 19

1 Port B, line 4 High current 20

3 Port B, line 5 High current 21

5 Port B, line 6 High current 22

7 Port B, line 7 High current 23

13 Port C, line 0 Lower C 0

16 Port C, line 1 Lower C 1

15 Port C, line 2 Lower C 2

17 Port C, line 3 Lower C 3

14 Port C, line 4 Upper C 4

11 Port C, line 5 Upper C 5

12 Port C, line 6 Upper C 6

9 Port C, line 7 Upper C 7

26 Ground

2 +5V

Figure 6-3 Digital I/O connector pin out (viewed from top)

Page 6-6 RPC-320

Page 29

DIGITAL AND OPTO PORTS SECTION 6

COMMANDS

The following tables shows the RPBASIC-52 commands

used for digital I/O.

Command Function

CONFIG LINE Configu res I/ O por ts

COUNT Returns number of pulses at a line.

LINE Function returns status of an opto

module as a 0 or 1.

LINE Statement turns on or off an opto

module.

LINE B Function returns 8 data bits from any

I/O type device.

LINE B Statement writes 8 data bits to any I/O

type device.

LINE # Function returns status of line at J3

connector as a 0 or 1.

LINE # Statement writes data to a line at J3

connector as a 0 or 1.

ON COUNT Counts pulses and optional generates an

interrupt.

ON LINE Generates an interrupt when a line

changes.

PWM Sets PWM parameters for any line.

Page 6-7 RPC-320

Page 30

CALENDAR/CLOCK SECTION 7

DESCRIPTION

An optional DS1216DM calendar/clock module may be

installed in U5. The DS1216DM also battery backs

RAM.

The DS1216DM from Remote Processing is a modified

version of the Dallas DS1216D. An internal reset line

has been cut. When a 512K RAM is installed, an

additional line is cut and another soldered. Contact

Remote Processing for details.

Battery life depends greatly upon the ambient

temperature. Battery life degrades up to 50% at 50°C,

using 25°C as a reference. RAM size and type also

affect battery life. Generally, you can expect a battery

life of 3 to 5 years.

Accuracy is about 1 minute/month and is not adjustable.

Hours are expressed in 24-hour fo rma t.

Refer to the RPBASIC-52 Software Supplement for

more command information.

NOTE: The clock module is turned off as shipped from

the factory. DATE and TIME functions return

a HARDW ARE erro r until DA TE is set first.

To retrieve date and time as part of a program:

100 PRINT "Time: ",

110 FOR N=0 TO 2

120 PRINT TIME(N),

130 NEXT

140 PRINT "Date: ",

150 FOR N=0 TO 2

160 PRINT DATE(N),

170 NEXT

180 PRINT CR,

190 GOTO 100

run

Time: 13 24 12 Date: 94 11 14

When the clock module is missing, defective, or the date

has not been set, a HARD WARE er ror (code 50 at

address 101H) is returned by RPBASIC when a DATE

or TIME function is performed. Use ONE RR to trap for

this error and report the problem.

The clock module is installed by first r emoving the IC in

U5. Then, install the DS1216DM into the socket. Install

the RAM chip into the socket. When installing a 32K

RAM chip, the top two pins in the DS1216DM are left

open.

Refer to CHAPTER 5 for information about using battery

backed RAM and jumper setting when installing a 512K

RAM.

WARNING: An additional modification to the

DS1216DM is necessary when

installing a 512K RAM. Contact

Remote Processing for details.

SETTING DATE AND TIME

Set the date to turn on the clock module. Date and time

are set while running a progr am or in the imm ediate

mode. Date and time are treated as number s and not

strings. To set the date and time:

DATE 95,11,28

TIME 13,23,43

COMMANDS

The following is a list of RPBASIC-52 commands for

the calendar/clock.

Command Function

DATE Sets date and tur ns on mod ule

DATE(n) Returns date

TIME Sets time

TIME(n) Returns time

The time is set to 1:23:43 PM.

Page 7-1 RPC-320

Page 31

CALENDAR/CLOCK SECTION 7

Figure 7-1 Calendar/Clock

Page 7-2 RPC-320

Page 32

DISPLAY PORT SECTION 8

INTRODUCTION

RPBASIC-52 and the RPC-320 interface to a variety of

displays:

VF (vacuum florescent) character

LCD (liquid crystal) character

LCD graphics

Character display sizes range from four lines by 20

characters to four lines by 40 characters. The graphics

display supports 160 x 128 pixels. Remote Processing

supplies these displays with appropr iate cables. A

contrast adjustment for LC D char acter disp lays is built

into the card.

If a display is not used, this port may be used for general

purpose digital I/O. Port A and part of port B from an

82C55 are available. See CONNECTOR DISPLAY PIN

OUT below for available lines.

The cable length to a display depends upon the amount

of current it requires. A significant amount of voltage

drop occurs with a long cable. Vacuum florescent and

LCD graphics cables should b e less than 2 fee t. A

character LC D display c able should be less than 5 feet.

Additional power wiring is usually required for LCD

graphic and VF charac ter displays. This information is

included with the display. Information content is display

dependent. Below is general information on both.