Page 1

Remote Automation Solutions

Part Number D301743X012

June 2019

Tank Manager User Manual

(for ROC800-Series and FloBoss™ 107

Controllers)

Page 2

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

ii Revised June-2019

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install,

configure, program, calibrate, and trouble-shoot your Emerson equipment provides your engineers

and technicians with the skills and confidence to optimize your investment. Remote Automation

Solutions offers a variety of ways for your personnel to acquire essential system expertise. Our fulltime professional instructors can conduct classroom training at several of our corporate offices, at

your site, or even at your regional Emerson office. You can also receive the same quality training via

our live, interactive Emerson Virtual Classroom and save on travel costs. For our complete schedule

and further information, contact the Remote Automation Solutions Training Department at 800-3388158 or email us at education@emerson.com.

Page 3

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Contents iii

Contents

Chapter 1 – Introduction 1

1.1 Scope and Organization ..................................................................................................................... 1

1.2 Product Overview ............................................................................................................................... 2

1.2.1 Definition of Terms ............................................................................................................... 2

1.3 Program Features .............................................................................................................................. 5

1.3.1 License Key.......................................................................................................................... 7

Chapter 2 – Installation 9

2.1 Installing the License Key .................................................................................................................. 9

2.1.1 Installing the License Key for the ROC800 .......................................................................... 9

2.1.2 Installing a License Key for the FB107 .............................................................................. 10

2.1.3 Verifying the License Key Installation (for ROC800) ......................................................... 11

2.2 Installing the Program ...................................................................................................................... 12

2.3 Installing the Optional User Displays (for FB107) ............................................................................ 17

2.3.1 Installing the Haul Log Viewer Display .............................................................................. 17

2.3.2 Installing the Hauler Database Display .............................................................................. 21

2.3.3 Installing the Enumerated Lists Display ............................................................................. 24

2.4 MPU Loading Threshold (for ROC800) ............................................................................................ 27

Chapter 3 – Configuration 29

3.1 PMTM Units ...................................................................................................................................... 31

3.1.1 PMTM Units – Units Tab .................................................................................................... 32

3.1.2 PMTM Units – Advance Settings Tab ................................................................................ 34

3.2 PMTM Tank Manager ...................................................................................................................... 37

3.2.1 PMTM Tank Manager – Liquids Data Tab ......................................................................... 38

3.2.2 PMTM Tank Manager – Liquids Configuration Tab ........................................................... 42

3.2.3 PMTM Tank Manager – Tank Strapping Tab .................................................................... 52

3.2.4 PMTM Tank Manager – Alarms and Rollovers Tab........................................................... 55

3.3 PMTM Allocated Well Values ........................................................................................................... 59

3.3.1 PMTM Allocated Well Values – Allocation/Production Values Tab ................................... 60

3.3.2 PMTM Allocated Well Values – Allocation/Production Config Tab .................................... 64

3.4 PMTM Haul Log Viewer ................................................................................................................... 68

3.4.1 PMTM Haul Log Viewer – Haul Log Overview Tab ........................................................... 69

3.4.2 PMTM Haul Log Viewer – Detailed Viewer and SCADA Pickup Tab ................................ 69

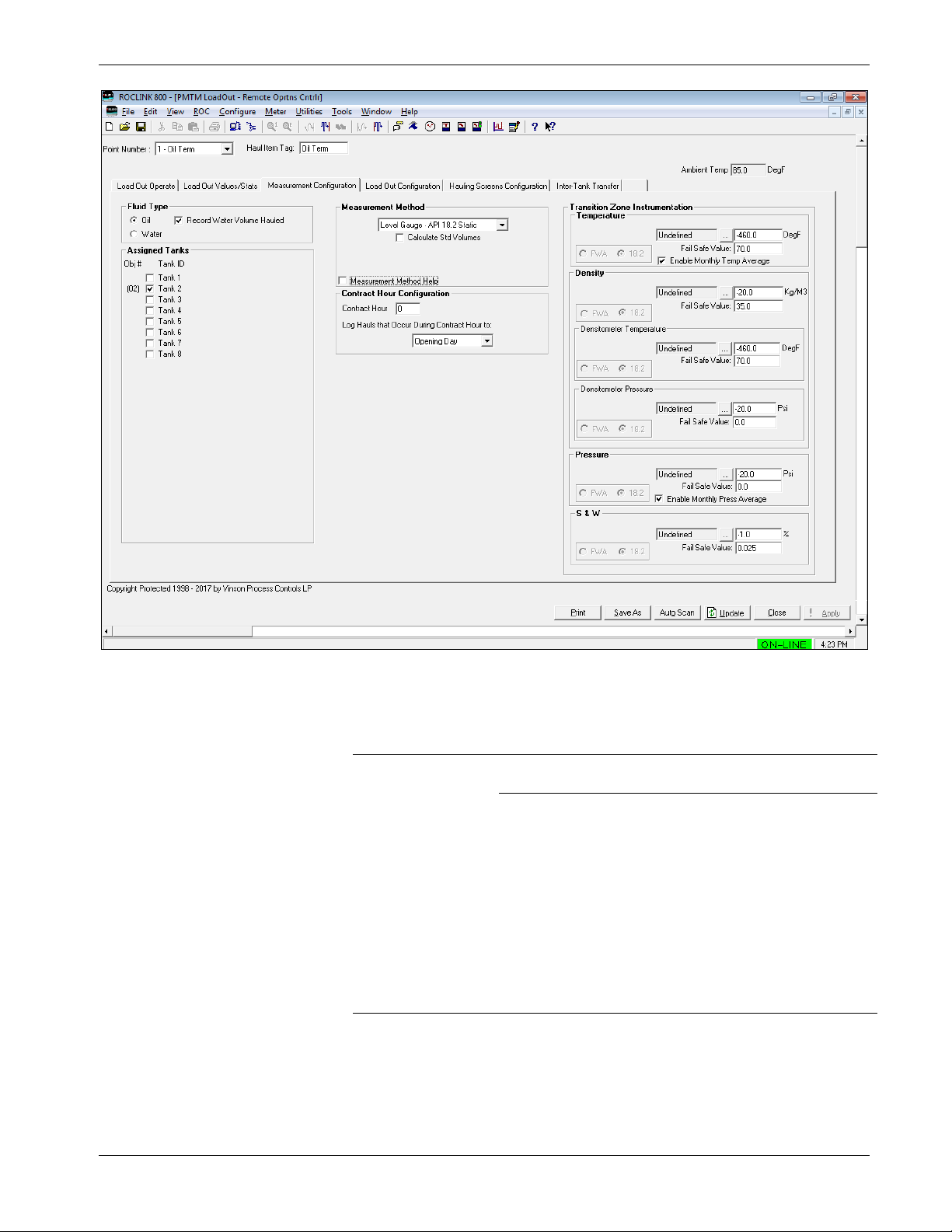

3.5 PMTM Load Out ............................................................................................................................... 71

3.5.1 PMTM Load Out – Load Out Operate Tab ........................................................................ 72

3.5.2 PMTM Load Out – Load Out Values/Stats Tab ................................................................. 79

3.5.3 PMTM Load Out – Measurement Configuration Tab ......................................................... 82

3.5.4 PMTM Load Out – Load Out Configuration Tab ................................................................ 89

3.5.5 PMTM Load Out – Hauling Screens Configuration Tab .................................................... 92

3.5.6 PMTM Load Out – Inter-Tank Transfer Tab ...................................................................... 99

3.6 PMTM Hauler Data Base ............................................................................................................... 100

3.7 PMTM Enumerated Lists ................................................................................................................ 102

3.8 Saving the Configuration ................................................................................................................ 105

Page 4

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

iv Contents Revised June-2019

Chapter 4 – Reference 107

4.1 Point Type 60/187: PMTM Units ................................................................................................... 108

4.2 Point Type 196/178: PMTM Tanks and Aggregates ..................................................................... 113

4.3 Point Type 197/179: PMTM Wells ................................................................................................ 128

4.4 Point Type 198/180: PMTM Haul Logs ......................................................................................... 137

4.5 Point Type 199/181: PMTM Haul Ticketing .................................................................................. 149

4.6 Point Type 230/182: PMTM Fluid Properties ................................................................................ 158

4.7 Point Type 231/183: PMTM Load Outs ......................................................................................... 165

4.8 Point Type 232/184: PMTM Hauler Database .............................................................................. 185

4.9 Point Type 233/185: PMTM Haul Current Values ......................................................................... 186

4.10 Point Type 234: PMTM Simulator ................................................................................................. 202

Appendix A – Log Viewer Utility 207

Appendix B – Retrieving the Haul Logs via SCADA 211

Page 5

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Introduction 1

Chapter 1 – Introduction

Caution

When implementing control using this product, observe best industry

practices as suggested by applicable and appropriate environmental,

health, and safety organizations. While this product can be used as a

safety component in a system, it is NOT intended or designed to be the

ONLY safety mechanism in that system.

This chapter describes the structure of this manual and presents an

overview of the Tank Manager program for the ROC800-Series

(ROC800) and FloBoss™ 107 (FB107) devices.

1.1 Scope and Organization

This document serves as the user manual for the Tank Manager

program, which is intended for use in either a ROC800 or FB107.

This manual describes how to install and configure the Tank Manager

program (referred to as the “program” throughout the rest of this

manual). You access and configure the program using ROCLINK™ 800

Configuration Software (version 2.41 or greater) loaded on a personal

computer (PC) running Microsoft® Windows® 7 (32-bit or 64-bit).

The chapters in this manual provide information in a sequence

appropriate for first-time users. Once you become familiar with the

procedures and the software running in a ROC800 or FB107, the

manual becomes a reference tool.

This manual has the following major sections:

▪ Chapter 1 – Introduction

▪ Chapter 2 – Installation

▪ Chapter 3 – Configuration

▪ Chapter 4 – Reference

▪ Appendix A – Log Viewer Utility

▪ Appendix B – Retrieving the Haul Logs via SCADA

This manual assumes that you are familiar with the ROC800 or FB107

and its configuration. For more information, refer to the following

manuals:

▪ FloBoss™ 107 Flow Manager Instruction Manual (Part

D301232X012)

▪ ROC800 Remote Operations Controller Instruction Manual (Part

D301217X012)

▪ ROCLINK 800 Configuration Software User Manual (for FloBoss™

107) (Part D301249X012)

▪ ROCLINK 800

™

Configuration Software User Manual (for

ROC800-Series) (Part D301250X012)

Page 6

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

2 Introduction Revised June-2019

1.2 Product Overview

The Production Manager Tank Manager (PMTM) program or simply

Tank Manager is designed to function either as a stand-alone product or

as part of Remote Automation Solutions’ SmartProcess

™

Oil and Gas

Application suite. Tank Manager uses a level-based measurement to

manage volumetric inventory, calculate well head production, and

measure truck-hauled volumes. It calculates net standard volume (NSV)

for the hauled hydrocarbon fluid using API Chapter 11, 2004

Calculations (11.1.6.1 and 11.1.6.2) for crude oil. The Production

Manager Tank Manager also includes options for API Chapter 18.2

(2016) compliant custody transfer methodology and calculations.

The program provides SCADA-friendly reporting to document hauling

events, and hosts an HMI interface for truck drivers. The program

supports both metered and level-based hauling measurement, applying

NSV correction to the primary measurement. It provides safety/control

interlocks to automate loading valves or pumps.

The program can calculate inferred production during hauling, provide

“seal on” and “seal off” tracking, and display a variety of tank

production statistics in user-friendly displays.

A version of the Tank Manager program is available with a built-in

simulator for manipulating tank levels, meter rates, and conducting a

haul. This version is intended only for labs or testing, and is not

applicable in a field installation.

Caution

All the versions of Tank Manager include a watchdog counter that

can be used to validate the execution of the program logic. This is a

parameter which continuously increments (1 count per second) while

the program is running. If the value of the parameter does not

change, then the program is not executing logic.

You can monitor this parameter using an external system, such as a

SCADA host system, or an FST within the device, to validate

operation. For the ROC800, this is Point Type 197, Parameter 125. For

the FB107, this is Point Type 179, Parameter 125. For more

information, see the definition for this parameter in Chapter 4.

1.2.1 Definition of Terms

The business of tank management and hauling has its own vocabulary.

Following are terms frequently used in hauling, which appear in the

Tank Manager application.

Term

Definition

API Chapter 11.1.6.1 and 2

The standard for calculating crude oil

measurement. Both the Tank Manager

application and the 800L programs use the

2004 version of these calculations.

Page 7

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Introduction 3

Term

Definition

API Chapter 18.2

The standard used to in part to determine the

program behavior for hauls from the load-out

terminals. The full title of the standard is

Custody Transfer of Crude Oil from Lease

Tanks using Alternative Measurement

Methods.

Average CTL of Base ALT

Correction factor of density recorded at time of

“Grind” to standard temperature.

Average CTL of Observed

Base

Correction factor of fluid temperature

compared to standard temperature.

Base Conditions

The standard temperature and pressure

values defined in the contract, which are

typically 60 degrees Fahrenheit and 14.73

PSIA (also as defined by API).

Basic Sediment and

Water (BS&W)

The non-oil components in a tank, which tends

to be a residual, typically defined as a

percentage (%) of volume.

Closeout

The process of final verification by the truck

driver of the information entered and/or

recorded during the truck haul, which becomes

the recorded haul log audit trail.

Correction for the effect

of Temperature on Liquid

(CTL)

The average of the temperature measured,

compared to the standard temperature.

Correction for the effect

of Temperature on Steel

(CTS)

A correction routine used to compensate for

the expansion of the tank shell material (and

therefore the tank volume), due to the effect of

temperature.

Divert Valve

A 3-way valve with 1 inlet, and 2 outlets. Used

commonly in LACT measurement, if the

sediment and water percentage for a fluid

being transferred exceeds the required

tolerance, the divert valve is activated, and

transfers oil back to a tank.

Equalized Tanks

A group of identically sized tanks for a single

phase liquid application with a common level

measurement used to handle larger capacities.

Flow/Tank Volume

Reconciliation

Specific to the Tank Manager application, this

is the ability to provide and report dual,

independent measurements (flow and tank

volume) of haul events. This process provides

a basis for verification when self-proving of

flow custody transfer is not available.

Gas/Liquids Ratio (GLR)

A method to estimate liquid production rate,

based on measured gas production rate.

Gauging; Gauging the

Tank

The manual or automated process to measure

the current level in the tank.

Grind; Grinding the Tank

The manual measurement technique for

determining the percentage (%) of BS&W in a

tank, as well as the density measurement. This

process requires a recorded temperature of

sample.

Page 8

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

4 Introduction Revised June-2019

Term

Definition

Gross Volume

The total volume of the liquid in the tank at

current ambient and fluid temperature.

Inferred Production

A method for estimating production flow into a

tank during a hauling event when a direct

measurement (such as using GLR) is not

available.

Interface

The intermediate level measurement at the

separation point between oil and water in the

tank.

Leased Automatic

Custody Transfer (LACT)

An automated system for measuring,

sampling, and transferring oil from a lease

location into a pipeline.

Merchantable

Refers to the suitability of oil for purchase or

sale. Oil which has unsuitable characteristics

(such as high sediment and water content or

high amounts of H2S) is said to be nonmerchantable.

Net Standard Volume

(NSV)

The corrected volume of oil at Base

Conditions, less BS&W volume, using the API

Chapter 11 standard.

Preset

A predefined volume of liquid for the truck

haul.

Seal Off/Seal On Tags

A single-use, metal, pre-stamped, numerical

tag connected to the block valve to retain an

audit trail of hauling events. The tag number is

recorded and removed as a Seal-Off Tag at

the beginning of the haul, and a new tag

number is recorded and installed as a Seal-On

Tag at closeout.

Shrinkage

The difference between the maximum volume

(recorded prior to a haul event) and the

volume at the start of the haul process

(recorded on per-haul event basis). Causes of

shrinkage can include gas vaporing or tank

waves.

Strapping

Also known as tank calibration, tank strapping

is the ability to convert a tank level value (fluid

height) to an associated volume.

Tank Aggregate

A group of tanks managing the production of

water and/or oil produced from one or several

wells.

Tank Instance

Specific to the Tank Manager application, this

term defines the number of physical tanks

and/or groups of tanks. For example, three

equalized tanks count as a single Tank

Instance, while an aggregate of three tanks

being managed independently as well as a

collective group, count as four Tank Instances.

Page 9

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Introduction 5

Term

Definition

Tank Strapping

Volumetric equivalent of measured level,

based on the cross-sectional dimensions of a

tank at different levels. Used for non-cylindrical

tanks or where the weight of the liquid causes

deflection of the tank sides.

Tank Transfer

A reportable movement of liquid between

tanks.

Truck Haul

The custody transfer event where the liquids

are loaded onto a truck.

Turndown

When a haul from a tank is started, but is

unable to complete for reasons such as

equipment failure or non-merchantable oil.

The rejected haul is said to be “turned down”.

Unitized Tanks

A predefined/pre-assigned tank piped from the

well(s) and separation train.

1.3 Program Features

Program Variants

The Tank Manager program is distributed on one CD, which

contains all programs for both the ROC800 and FB107 platforms.

The program version you install depends on the functionality you

require, the number of licenses you have purchased, and the number

of tanks and wells you need to support.

ROC800

The following table shows the number of tanks and wells each

program supports:

Program Name

Supported Features

PMTM_V409_xx_8t_SIM.tar

Supports up to 8 tanks and a simulation program.

Note: The simulation program is not intended for

installation on an operating tank farm.

PMTM_V409_xx_8t4w.tar

Supports up to 8 tanks and 4 wells.

PMTM_V409_xx_16t_SIM.tar

Supports up to 16 tanks and a simulation program.

Note: The simulation program is not intended for

installation on an operating tank farm.

PMTM_V409_xx_16t8w.tar

Supports up to 16 tanks and 8 wells.

PMTM_V409_xx_24t_SIM.tar

Supports up to 24 tanks and a simulation program.

Note: The simulation program is not intended for

installation on an operating tank farm.

PMTM_V409_xx_24t12w.tar

Supports up to 24 tanks and 12 wells.

PMTM_V409_xx_32t_SIM.tar

Supports up to 32 tanks and a simulation program.

Note: The simulation program is not intended for

installation on an operating tank farm.

PMTM_V409_xx_32t12w.tar

Supports up to 32 tanks and 12 wells.

PMTM_V409_xx_40t_SIM.tar

Supports up to 40 tanks and a simulation program.

Note: The simulation program is not intended for

installation on an operating tank farm.

PMTM_V409_xx_40t12w.tar

Supports up to 40 tanks and 12 wells.

Page 10

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

6 Introduction Revised June-2019

FloBoss 107

The following table shows the number of tanks and wells the FB107

program supports:

Program Name

Supported Features

PMTM_v409_xx_7.bin

Supports up to 8 tanks and 4 wells.

Version 4.09 of the Tank Manager program is compatible with firmware

version 3.61 of the ROC800, firmware version 1.41 of the ROC800L,

firmware version 1.70 of the FB107, and with version 2.41 (or greater)

of ROCLINK 800 Configuration software and requires firmware

version 1.20 of the keypad display.

Program specifics include:

File Name

Target Unit/

Version

User Defined

Point (UDP)

Flash Used

(in bytes)

DRAM Used

(in bytes)

ROCLINK 800

Version

Display

Number

PMTM_V409_xx_

8t4w.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233

496,248

503,808

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_V409_xx_

8t_SIM.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233,

234

508,376

557,056

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_V409_xx_

16t8w.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233

495,477

548,864

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_V409_xx_

16t_SIM.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233,

234

507,819

565,248

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_v409_xx_

24t12w.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233

495,550

602,112

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_V409_xx_

24t_SIM.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233,

234

508,152

618,496

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_v409_xx_

32t12w.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233

495,594

643,072

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_V409_xx_

32t_SIM.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233,

234

508,095

663,552

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_v409_xx_

40t12w.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233

495,540

688,128

2.41

60, 196, 197,

198, 231, 232,

233

Page 11

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Introduction 7

File Name

Target Unit/

Version

User Defined

Point (UDP)

Flash Used

(in bytes)

DRAM Used

(in bytes)

ROCLINK 800

Version

Display

Number

PMTM_V409_xx_

40t_SIM.tar

ROC800 v3.61

60, 196, 197,

198, 199, 230,

231, 232, 233,

234

508,325

704,512

2.41

60, 196, 197,

198, 231, 232,

233

PMTM_v409

_xx_7.bin

FB107 v1.70

178, 179, 180,

181, 182, 183,

184, 185, 187

490,236

32,768

2.41

79, 80, 81, 83

Note: Depending on the version you install, the flash memory and

DRAM usages may be less.

For information on viewing the memory allocation of user programs,

refer either to the ROCLINK 800 Configuration Software User Manual

(for ROC800-Series) (Part D301250X012) or the ROCLINK 800

Configuration Software User Manual (for FloBoss 107) (Part

D301249X012).

1.3.1 License Key

License keys, when matched with valid license codes, grant access to

applications such as the Tank Manager program.

For ROC800, the term “license key” refers to the physical piece of

hardware that can contain up to seven different licenses (refer to

Figure 1-1). Each ROC800 can have none, one, or two license keys

installed. If you remove a license key after enabling an application, the

firmware disables the task from running. This prevents unauthorized

execution of protected applications in a ROC800.

DOC0422A

J1

U1

Figure 1-1. License Key

Note: Each PMTM license supports up to 8 tanks and 4 wells.

Licenses are delivered on a standard ROC800 license key.

Consult with your Remote Automation Solutions sales

representative to obtain the appropriate number of licenses for

your application.

Page 12

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

8 Introduction Revised June-2019

For FB107, the software licenses are distributed via a secure SafeNet®

Sentinel™ USB drive (“license key”). You must install one license key,

PMTM, to use the Tank Manager program.

Page 13

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 9

Chapter 2 – Installation

This section provides instructions for installing the Tank Manager

program. Read Section 1.3 of this manual for program requirements.

2.1 Installing the License Key

The Tank Manager application requires a license to function. This

section provides instructions for installing the license into the flash

memory on the ROC800 or the FB107.

2.1.1 Installing the License Key for the ROC800

Caution

Failure to exercise proper electrostatic discharge precautions, such as

wearing a grounded wrist strap may reset the processor or damage

electronic components, resulting in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing these procedures. Performing these procedures in a

hazardous area could result in personal injury or property damage.

To install a license key:

1. Remove power from the ROC800.

2. If necessary, remove the wire channel cover.

3. Unscrew the screws from the Central Processing Unit (CPU)

faceplate.

4. Remove the CPU faceplate.

5. Place the license key in the appropriate terminal slot (P4 or P6) in

the CPU (refer to Figure 2-1).

Figure 2-1. License Key Installation

6. Press the license key into the terminal until it is firmly seated (refer

to Figure 2-1).

7. Re-attach the CPU faceplate.

8. Re-attach the screws on the CPU faceplate.

9. If necessary, re-attach the wire channel cover.

10. Restore power to the ROC800.

11. Proceed to Section 2.1.3 to verify your license keys.

Page 14

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

10 Installation Revised June-2019

2.1.2 Installing a License Key for the FB107

Program licenses for the FB107 are stored on a secure SafeNet®

Sentinel™ USB license key. To install a license on the FB107:

1. Insert the USB license key in a USB port on your PC.

2. Select Utilities > License Key Administrator > Transfer Between

DEVICE and KEY from the ROCLINK 800 menu bar. The

Transfer Licenses Between a Device and a Key screen displays.

Figure 2-2. Transfer Licenses Between a Device and a Key

Note: This screen has three sections. The upper portion (Licenses on

Device) shows any software licenses installed on the FB107.

The middle portion (Licenses on Key) shows software licenses

on the license key. The lower portion of the screen (License Key

Event Log) provides a rolling log of the last eight events related

to this license key.

3. Select the key-based license you want to transfer to the FB107

(PMTM, as shown in Figure 2-2).

4. Click Move to Device. ROCLINK moves the license from the key

to the FB107 and updates the screen.

Page 15

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 11

Figure 2-3. License Installed (FB107)

Note: An FB107 can hold up to six different licenses, although you can

install only one instance of each license on the FB107. When

you click Move to Device, ROCLINK 800 moves only one

instance of the license onto the FB107 and automatically

decreases the total number of licenses on the USB drive by one

(if it contains more than one).

5. Verify that the license name now displays in the Licenses on Device

section of the screen. Proceed to Section 2.2 to download the user

program.

2.1.3 Verifying the License Key Installation (for ROC800)

After you install the license key, you can verify whether the ROC800

recognizes the key. From the ROCLINK 800 screen, select Utilities >

License Key Administrator. The License Key Administrator screen

displays:

Page 16

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

12 Installation Revised June-2019

Figure 2-4. Transfer Licenses Between a Device and a Key

2.2 Installing the Program

This section provides instructions for installing the program into the

Flash memory on the ROC800 or FB107.

To download the user program using ROCLINK 800 software:

1. Connect the ROC800 to your computer.

2. Start and logon to the ROCLINK 800.

3. Select ROC > Direct Connect to connect to the ROC800.

4. Select Utilities > User Program Administrator from the

ROCLINK menu bar. The User Program Administrator screen

displays (see Figure 2-5):

Page 17

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 13

Figure 2-5. User Program Administrator

5. Click Browse in the Download User Program File frame. The Select

User Program File screen displays (see Figure 2-5).

Note: If you install the program in the ROC800, choose any

available user program slot. If you use FB107, the program

installs automatically in user program slot 7.

6. Select the path and user program file to download from the CD-

ROM. (Program files are typically located in the Program Files

folder on the CD-ROM). As Figure 2-6 shows, the screen lists all

valid user program files with the .bin (for FB107) or .tar (for

ROC800) extension:

Page 18

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

14 Installation Revised June-2019

Figure 2-6. Select User Program File

7. Click Open to select the program file. The User Program

Administrator screen displays. As shown in Figure 2-7, note that the

Download User Program File frame identifies the selected program

and that the Download & Start button is active:

Figure 2-7. User Program Administrator

8. Click Download & Start to begin loading the selected program.

The following message displays:

Page 19

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 15

Figure 2-8. Confirm Download

9. Click Yes to begin the download. When the download completes the

following message displays:

Figure 2-9. ROCLINK 800 Download Confirmation

10. Click OK. The User Program Administrator screen displays [see

Figure 2-10 (for ROC800) / Figure 2-10a (for FB107)]. Note that:

▪ The Device User Program Environment frame reflects the use of

system memory.

▪ The User Programs Installed in Device frame identifies the

installed program(s).

▪ The Status field indicates that the program is running.

Page 20

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

16 Installation Revised June-2019

Figure 2-10. User Program Administrator (for ROC800)

Figure 2-10a. User Program Administrator (for FB107)

11. Click Close and proceed to Chapter 3, Configuration to configure

the program.

Page 21

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 17

Note: Installing a user program without a license key allows you

only to view the program screens (that is, the program

outputs no data). Installing the license key enables the

program to read from the meter and output data.

2.3 Installing the Optional User Displays (for FB107)

The Tank Manager user program for the FB107 is distributed with three

(3) optional user displays:

▪ Enumerated Lists

▪ Haul Log Viewer

▪ Hauler Database

These optional user displays are not installed with the program by

default. Although these three (3) displays are needed for configuration

of load out functionality, they are not required for operation, and it may

not be necessary to install them in some use cases.

These user displays can either be stored on your computer and opened

manually “from file” as needed, or they can be installed in the FB107

via the ROCLINK 800 Display Administrator. This manual assumes the

displays have been installed in the device using the Display Administer

as shown in the following section.

Note that 196,608 bytes are reserved for user displays in the device’s

flash. The three optional displays included with Tank Manager for the

FB107 consume approximately 63,594 bytes. If that amount of space is

not available, the three displays cannot be installed until space has been

made by removing other user displays.

2.3.1 Installing the Haul Log Viewer Display

To install the Haul Log Viewer Display:

1. Select View > Display > From Device > Administrator. The

Display Administrator screen displays, showing all displays

currently loaded in the FB107.

2. Click slot 1 to highlight it. If slot 1 is not available in your FB107,

you can choose any slot that is available.

Page 22

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

18 Installation Revised June-2019

Figure 2-11. Display Administrator, Slot 1

3. Click Browse to open the Select User Display File dialog.

4. Double-click PMTM 4_9_2 Haul Log Viewer.dsp.

Note: This file is in the CD of the Tank Manager program.

Page 23

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 19

Figure 2-12. Select User Display, PMTM 4_9_2 Haul Log Viewer.dsp

5. The Display Administrator screen re-displays with the Download

button now active. Click Download to add the user display to the

FB107.

6. ROCLINK 800 displays a verification dialog.

Figure 2-13. Verification – Download Display Number 1

7. Click Yes. ROCLINK 800 loads the display in the designated

location and displays a completion dialog.

Page 24

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

20 Installation Revised June-2019

Figure 2-14. Download User Display Number 1 COMPLETED

8. Click OK to close the dialog. The Display Administrator screen

displays, showing the display you have just added.

Note: Use the Flash File System frame on this screen to monitor

the number of bytes you have used and the number of bytes

remaining.

Figure 2-15. Display Administrator, PMTM Haul Log Viewer (Display)

Loaded

9. Click Close.

Page 25

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 21

Proceed to Section 3.4 – PMTM Haul Log Viewer for details.

2.3.2 Installing the Hauler Database Display

To install the Hauler Database Display:

1. Select View > Display > From Device > Administrator. The

Display Administrator screen displays, showing all displays

currently loaded in the FB107.

2. Click slot 2 to highlight it. If slot 2 is not available in your FB107,

you can choose any slot that is available.

Figure 2-16. Display Administrator, Slot 2

3. Click Browse to open the Select User Display File dialog.

4. Double-click PMTM 4_9_2 Hauler Database.dsp.

Note: This file is in the CD of the Tank Manager program.

Page 26

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

22 Installation Revised June-2019

Figure 2-17. Select User Display, PMTM 4_9_2 Hauler Database.dsp

5. The Display Administrator screen re-displays with the Download

button now active. Click Download to add the user display to the

FB107.

6. ROCLINK 800 displays a verification dialog.

Figure 2-18. Verification – Download Display Number 2

7. Click Yes. ROCLINK 800 loads the display in the designated

location and displays a completion dialog.

Page 27

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 23

Figure 2-19. Download User Display Number 2 COMPLETED

8. Click OK to close the dialog. The Display Administrator screen

displays, showing the display you have just added.

Note: Use the Flash File System frame on this screen to monitor

the number of bytes you have used and the number of bytes

remaining.

Figure 2-20. Display Administrator, PMTM Hauler Database (Display)

Loaded

9. Click Close.

Page 28

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

24 Installation Revised June-2019

Proceed to Section 3.6 – PMTM Hauler Data Base for details.

2.3.3 Installing the Enumerated Lists Display

To install the Enumerated Lists Display:

1. Select View > Display > From Device > Administrator. The

Display Administrator screen displays, showing all displays

currently loaded in the FB107.

2. Click slot 3 to highlight it. If slot 3 is not available in your FB107,

you can choose any slot that is available.

Figure 2-21. Display Administrator, Slot 3

3. Click Browse to open the Select User Display File dialog.

4. Double-click PMTM 4_9_2 Enumerated Lists.dsp.

Note: This file is in the CD of the Tank Manager program.

Page 29

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 25

Figure 2-22. Select User Display, PMTM 4_9_2 Enumerated Lists.dsp

5. The Display Administrator screen re-displays with the Download

button now active. Click Download to add the user display to the

FB107.

6. ROCLINK 800 displays a verification dialog.

Figure 2-23. Verification – Download Display Number 3

7. Click Yes. ROCLINK 800 loads the display in the designated

location and displays a completion dialog.

Page 30

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

26 Installation Revised June-2019

Figure 2-24. Download User Display Number 3 COMPLETED

8. Click OK to close the dialog. The Display Administrator screen

displays, showing the display you have just added.

Note: Use the Flash File System frame on this screen to monitor

the number of bytes you have used and the number of bytes

remaining.

Figure 2-25. Display Administrator, PMTM Enumerated Lists (Display)

Loaded

9. Click Close.

Page 31

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Installation 27

Proceed to Section 3.7 – PMTM Enumerated Lists for details.

2.4 MPU Loading Threshold (for ROC800)

To maximize the performance of your ROC800 device, always verify

the performance of specific application combinations before using them

in the field to ensure the MPU load typically remains below 85% with

peak MPU loading levels below 95%.

To check the current MPU load at any time, select ROC > Information

> Other Information and review the value in the MPU loading field.

Figure 2-26. MPU Loading

Page 32

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

28 Installation Revised June-2019

[This page is intentionally left blank.]

Page 33

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 29

Chapter 3 – Configuration

After you install the Tank Manager program, you configure it using

ROCLINK 800 software. The program uses seven (7) screens:

▪ Use the Units screen to configure the units of measure used

throughout the program, as well as other global options.

▪ Use the Tank Manager screen and its tabs to view liquids data,

configure fluid properties, view haul details, and run simulations.

▪ Use the Allocated Well Values screen and its tabs to view and

configure allocation and production details.

▪ Use the Haul Log Viewer to retrieve detailed information about

previous hauls from the tanks.

Note: For the FB107, this screen is an optional user display. Refer

to Section 2.3.1 – Installing the Haul Log Viewer Display for

installation.

▪ Use the LoadOut screen and its tabs to configure haul details, view

specific haul values, and run system diagnostics.

▪ Use the Hauler Data Base screen to manage the database of

credentials required to perform a haul.

Note: For the FB107, this screen is an optional user display. Refer

to Section 2.3.2 – Installing the Hauler Database Display for

installation.

▪ Use the Enumerated Lists screen to manage any combination of

Turndown Reject Reasons, Destination and/or Disposition entries up

to sixty (60) entries are allowed.

Note: For the FB107, this screen is an optional user display. Refer

to Section 2.3.3 – Installing the Enumerated Lists Display for

installation.

Page 34

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

30 Configuration Revised June-2019

Figure 3-1. ROCLINK 800 (for ROC800)

Note: The program number and name depends on which program you

have installed on which platform. This manual uses

PMTM_v409_00_8t4w program.

Page 35

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 31

Figure 3-1a. ROCLINK 800 (for FB107)

3.1 PMTM Units

Use this screen to configure units for the tanks, allocation wells, clear

haul logs and load outs provided by the program.

When Tank Manager is installed in a ROC800L, the application will

align with the unit selections made on the Liquid Calculations – Liquid

Preferences screen. When this is true, a note will be displayed on the top

of the screen, and options defined in the Liquid Calculations user

program will be grayed out.

This screen also includes options for managing the system haul log audit

trail.

To access this screen:

1. From the Directory Tree, double-click User Program.

2. Double-click the following:

▪ For the ROC800: Program #1, PM_Tanks_v409_00_8t4w.

▪ For the FB107: PM Tank Manager.

3. Double-click the following:

Page 36

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

32 Configuration Revised June-2019

▪ For the ROC800: Display #60, PMTM Units.

▪ For the FB107: Display #79, PMTM Units.

4. The Units screen displays:

Figure 3-2. Unit Screen

Follow Section 3.1.1 through Section 3.1.2 to configure the component

tabs of the PMTM Units screen.

3.1.1 PMTM Units – Units Tab

Use this screen to configure units for the tanks.

Page 37

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 33

Figure 3-3. PMTM Units – Units tab

1. Review the values in the following fields:

Field

Description

Time General

Sets the unit of measurement the program

use for general time. Click to display all valid

unit selections.

Short Linear

Sets the unit of measurement the program

use for short lengths. Click to display all

valid unit selections.

Long Linear

Sets the unit of measurement the program

use for long lengths. Click to display all valid

unit selections.

Meter Diff

Pressure

Sets the unit of measurement the program

use for differential pressure. Click to display

all valid unit selections.

Pressure

Sets the unit of measurement the program

use for pressure. Click to display all valid

unit selections.

Temperature

Sets the unit of measurement the program

use for temperature. Click to display all valid

unit selections.

Page 38

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

34 Configuration Revised June-2019

Field

Description

Gas Volume &

Rate Time

Sets the unit of measurement the program

use for both the gas volume accumulation and

gas volume flowrate values. Click to display

all valid options.

Liquid Volume &

Rate Time

Sets the unit of measurement the program

use for both the liquid volume accumulation

and liquid volume flowrate values. Click to

display all valid options.

Mass & Rate

Time

Sets the unit of measurement the program

use for both the mass accumulation and mass

flowrate values. Click to display all valid

options.

Density

Sets the unit of measurement the program

use for density values. Click to display all

valid unit selections.

Velocity

Sets the units of measurement the program

use for velocity values. Click to display all

valid unit selections.

2. Click Apply to save any changes you have made to this screen.

3. Proceed to Section 3.1.2 to configure the Advance Settings tab

3.1.2 PMTM Units – Advance Settings Tab

Use this screen to configure miscellaneous settings applicable to the

entire Tank Manager program. This screen also allows for management

of the Tank Manager haul log, and the optional startup delay settings.

Page 39

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 35

Figure 3-4. PMTM Units – Advance Settings tab

1. Review the values in the following fields:

Field

Description

Tank Location

and Legal

Description

Provides a text description of the location

where you install the device and the

associated tanks. You use this for

informational purposes only.

Tank Manager Flags

Clear Haul Logs

Deletes up to 512 records for previous haul

transactions the program keeps on the flash

file system of the ROC800 or FB107. This

also resets the Next Haul/Transaction Serial

Number back to 1.

Note: This is not visible when the haul log is

empty.

Contact SCADA

for Value: Last

Logged Hard SN

Sets the Hard Haul Serial Number to be used

for the next haul transaction. This allows the

system to resume operation at the next

sequential haul number (as tracked via

SCADA) after the haul log has been cleared.

Note: This field is only visible when the haul

log is empty.

Page 40

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

36 Configuration Revised June-2019

Field

Description

Next Haul /

Transaction

Serial Number

Sets the unique serial number for the next

haul. This value automatically increments as

the hauls occur. This field also allows you to

reset the haul serial numbers back to a

starting point, or other previous value.

Retrieve this

Hard Serial

Number

Sets the hard serial number for the haul log

record that will be populated in the Detailed

Haul Log Viewer (see Section 3.5). This field

can also be used by a SCADA system to load

a previous haul log record for retrieval

Haul Log RBX

This option prompts the program to create an

SRBX (Spontaneous Respond By Exception)

event when a haul occurs. You use this to

inform a host system of the haul event.

Note: This requires you to configure the

SRBX feature on the communications

port of your ROC800.

Site Ambient

Temperature

Click and select the TLP that the program

will use to read the live ambient temperature

of the site. If defined, the current value of the

ambient temperature is shown in the field next

to the input definition. The ambient

temperature is displayed on other screens,

and recorded for each entry in the haul log.

PMTM Startup Delay Settings

The Tank Manager user program is a large application. In the

event of a power cycle or warmstart, the program’s initialization

routine can take a large number of seconds to complete, depending

on other user programs or functionality configured in the device.

This feature allows for the Tank Manager to delay its startup, to

ease the overall system startup MPU loading. The default settings

assure the program will startup as soon as it’s able

(recommended).

MPU Load is %

Sets the percentage that the system MPU

load is required to drop down to (or below) on

an initialization event before Tank Manager

will begin its own initialization routine.

Seconds

Sets the number of seconds that the system

MPU load must remain below the configured

threshold percentage, before Tank Manager

will begin its own initialization routine.

2. Click Apply to save any changes you have made to this screen.

3. Proceed to Section 3.2 to configure the Tank Manager.

Page 41

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 37

Caution

The SCADA System gathers the Haul Log Audit Trail and stays in

synchronization with the ROC800 using the Hard Haul Serial Number.

If this value is reset in the ROC800, the SCADA stops the

synchronization. The Hard Haul Serial Number resets in several

method such as, but not limited to:

▪ Loading point type 198 from a configuration file

▪ Cold starting the haul log through Tank Manager

▪ Replacement of the CPU

▪ Enable (check) the Clear Haul Logs field and enter the Hard Haul

Serial Number into the Contact SCADA for Value: Last Logged

Hard SN box.

To reset the Hard Haul Serial Number, go to ROC > Flags from the

ROCLINK 800 menu and click Cold Start. Go to PMTM Units screen

and enter the last known Hard Haul Serial Number in the Next

Haul/Transaction Serial Number field. The program starts

incrementing the Haul Log with this number.

3.2 PMTM Tank Manager

Use this screen to view liquids data, configure fluid properties, view

haul details, and run simulations.

To access this screen:

1. From the Directory Tree, double-click User Program.

2. Double-click one of the following:

▪ For the ROC800: Program #1, PM_Tanks_v409_00_8t4w.

▪ For the FB107: PM Tank Manager.

3. Double-click one of the following:

▪ For the ROC800: Display #196, PMTM Tank Manager.

▪ For the FB107: Display #80, PMTM Tank Manager.

4. Double-click #1, Tank 1 for either the ROC800 or FB107.

Note: The ROC800 can support up to 40 tanks, depending on the

program version you install. The FB107 supports up to 8

tanks.

5. The Tank Manager screen displays, showing the Liquids Data tab:

Page 42

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

38 Configuration Revised June-2019

Figure 3-6. Tank Manager Screen

Follow Section 3.2.1 through Section 3.2.5 to configure the component

tabs of the PMTM Tank Manager screen.

3.2.1 PMTM Tank Manager – Liquids Data Tab

This screen (which displays first when you open the Tank Manager

screen) provides an operational overview of the selected tank or

aggregate. Use the Point Number field to select up to 8 (for the FB107)

or 40 (for the ROC800) defined tanks.

Page 43

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 39

Figure 3-7. Tank Manager Screen – Liquids Data tab

1. Review the values in the following fields:

Field

Description

Point Number

Selects a tank to view. Click to view

all defined tanks.

Note: This field displays on all tabs

for the Tank Manager screen.

Statistics

There is an alphanumeric (20

characters) additional description field

located beside this field. See below:

Ambient

Temperature

Indicates the current value of the

ambient temperature for the site.

Tank

Displays the total current values for the

defined tank. These values are:

Page 44

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

40 Configuration Revised June-2019

Field

Description

Current Level

This read-only field

displays the current

tank level as a whole

number in the primary

linear units (i.e. feet

or meters) as well as

the fraction of the

short linear units (i.e.

inches or millimeters)

Current Level

This read-only field

displays the current

tank level as a

floating point in the

primary linear units

(i.e. feet or meters).

Load Line

Elevation

This read-only field

displays the height

from the bottom of the

tank, where the

product outlet line

used for loading is

located.

Tank Fill Rate

This read-only field

displays the volume

rate at which the tank

is being filled.

Beginning

Day Level

This read-only field

displays the Current

Level in feet. This is

the sum of water and

oil at the start of the

current day.

Tank

Capacity

This read-only field

displays the Current

Stock Bbls divided by

the Tank Capacity

Bbls configured in the

Liquids Configuration

tab.

Current

Stock

This read-only field

displays the Current

Level in feet

multiplied by 12 to

convert into inches.

Multiplied again by

the Strapping Bbl per

inch field in the

Liquids Configuration

tab.

Oil/Water

Displays the values for the defined

tank. If the defined tank contains no oil,

all values will be zero. This values are:

Note: The border of this frame turns

red when an error occurs.

Page 45

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 41

Field

Description

Current Level

This read-only field

displays the current

tank oil or water level

as a whole number in

the primary linear

units (i.e. feet or

meters) as well as the

fraction of the short

linear units (i.e.

inches or millimeters).

Current Level

This read-only field

displays the current

tank oil or water level

as a floating point in

the primary linear

units (i.e. feet or

meters).

Production

Rate

This read-only field

displays the

production rate.

Beginning

Day Level

This read-only field

displays the Current

Level value at the

start of the current

day.

Begin Day

Stock

This read-only field

displays the Current

Level at the start of

the current day.

Current

Stock

This read-only field

displays the Current

Level in feet

multiplied by 12 to

convert into inches.

Multiplied again by

the Strapping Bbl per

inch field in the

Liquids Configuration

tab.

Current

Haul

This read-only field

displays the amount

of barrels of oil in the

current haul when a

haul is in progress.

Shortage

Indicates the current

calculated shortage of

oil based on the

difference between

the current measured

volume and the

highest measured

volume since the last

haul.

Page 46

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

42 Configuration Revised June-2019

Field

Description

Auto-Haul in

Progress

This field provides an

indication as to if an

auto-haul is currently

in progress for the

tank.

Loadout Haul

in Progress

This field provides an

indication as to if a

haul is currently in

progress for the tank

using one of the Tank

Manager loadout

terminals.

Oil/Water

Accumulators

Displays the Number of Hauls

(instigated by the HMI or an Auto

Haul), the amount of Oil Produced (as

the tank rises), Hauled (as the tank

lowers), Disposal/Transfer Metered,

and produced via Inferred Production.

For each quantity, there is an on-going

accumulator, as well as time based

accumulators relating to Today,

Yesterday, This Month, and for the

Previous Month. If configured, the Oil

Accumulators will include values for the

tank loss due to stabilization, which is

detected by the drop in tank level when

hauls are not occurring, due to

stabilization (or settling) of oil.

2. Click Apply to save any changes you have made to this screen.

3. Proceed to Section 3.2.2 to configure the Liquids Configuration

tab.

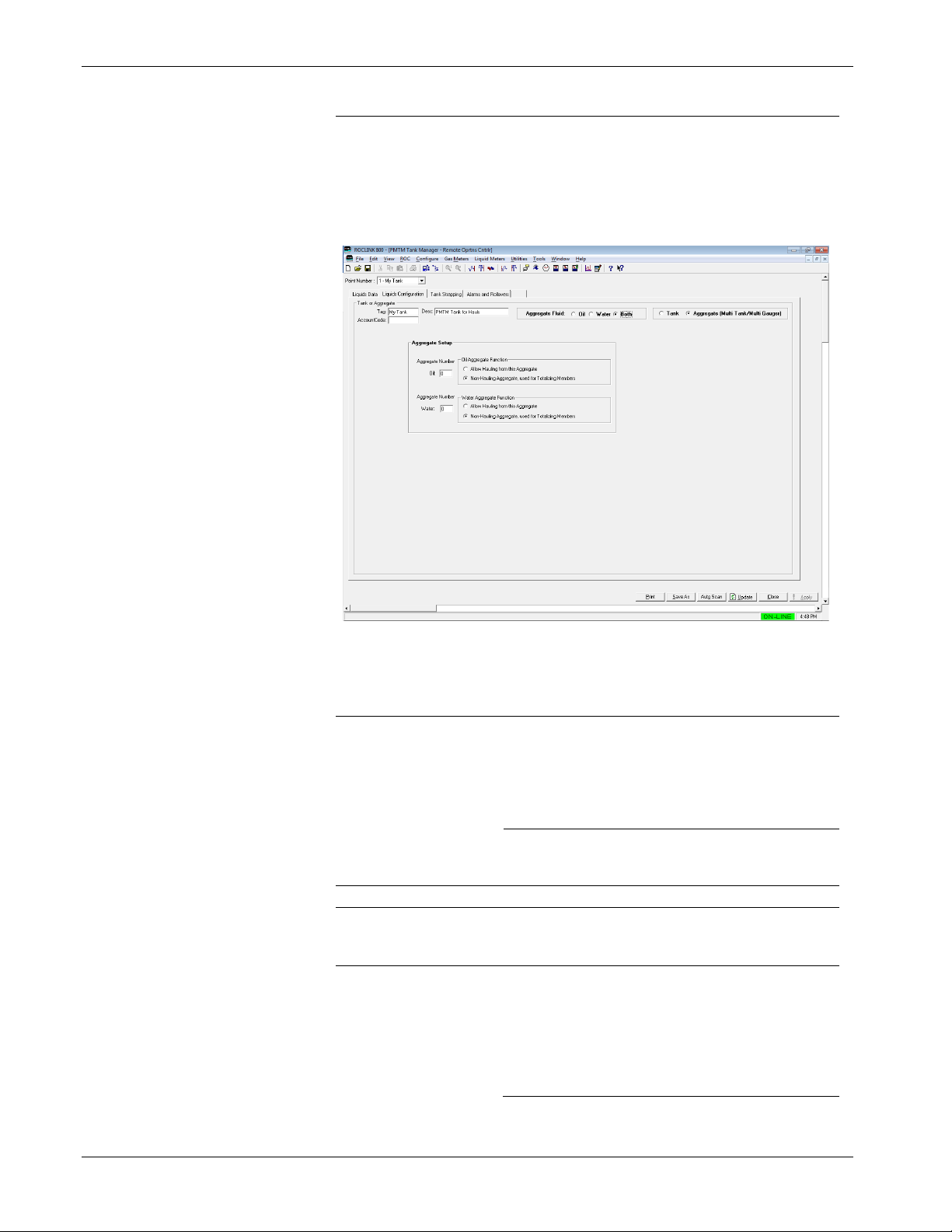

3.2.2 PMTM Tank Manager – Liquids Configuration Tab

Use this screen to configure tanks or aggregates.

To access this screen:

1. Select the Liquids Configuration tab on the Tank Manager screen.

The Liquids Configuration screen displays:

Page 47

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 43

Figure 3-8. Tank Manager Screen – Liquids Configuration tab, Oil

Page 48

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

44 Configuration Revised June-2019

Figure 3-8a. Tank Manager Screen – Liquids Configuration tab, Water

2. Review the values in the following fields:

Field

Description

Tank or Aggregate

Tag

Provides a 10-character alphanumeric

identifier for the tank.

Account Code

Provides an accounting code (if applicable) to

identify this tank.

Desc

Provides a 20-character alphanumeric

identifier for the tank, which can be used if the

facility measurement point (FMP) identifier

exceeds the 10 characters allowed for the tag.

Page 49

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 45

Field

Description

Primary Fluid

Indicates the liquid to haul from this tank or

aggregate. Valid options are Oil or Water.

Note: The Hauling and Production Options

pane of this screen changes

depending on the Primary Fluid

option you choose. When you

choose the Aggregate (Multi

Tank/Multi Gauger) option, this

displays Aggregate Fluid and the

valid options become Oil, Water, or

Both.

Tank

You select this option if the object you define

represents a single liquid tank.

Aggregate (Multi

Tank/Multi Gauger)

You select this option if the object you define

represents a combination of multiple tanks.

Tank Setup

Note: This frame displays only if you select Tank from the Tank or

Aggragate frame.

Max Volume per

Tank

This read-only field specifies the maximum

capacity of the tank.

Load Line Elevation

Specifies the height from the bottom of the

tank where the loading flow line out of the

tank is located. This value is used when

determining the free water clearance for a

haul. During a haul, the free water clearance

is calculated by subtracting the oil/water

interface level from this value. If the free water

clearance is less than the required 4 inches

(or equivalent), a warning indication is

provided.

Aggregate

Membership

Specifies the aggregate to which this tank

belongs.

Page 50

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

46 Configuration Revised June-2019

Field

Description

Aggregate Setup

Note: This frame displays only if you select Aggregate from the

Tank or Aggregate frame. An aggregate is the combination

of multiple tank instances. On the ROC800, if this tank

instance is to be used as an aggregate, the majority of the

tank configuration is hidden from the screen, and only the

aggregate setup frame is shown.

Aggregate Number:

Oil

Assigns an aggregate number. All tanks you

tag with this number roll up into this

aggregate.

Note: This field displays only if you select

Oil or Both as the Aggregate Fluid.

Aggregate Number:

Water

Assigns an aggregate number. All tanks you

tag with this number roll up into this

aggregate.

Note: This field displays only if you select

Water or Both as the Aggregate

Fluid.

Oil/Water Aggregate

Function

Specifies whether the aggregate is hauled

directly or if this aggregate totalizes the

production of the member tanks and hauls.

Tank Zone Instrumentation

Gauger Setup

Note: This frame displays only if you select Tank as the

configuration option.

Interfaced

Select to indicate that the tank has gauges for

both oil and water.

Note: Selecting this value removes the Qty

of Equalized Tanks w/Single Gauge

field from the Tank Setup pane (and

sets this value to 1) and displays the

Water Gauge field.

Page 51

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 47

Field

Description

Top Gauge

Click to display the Select TLP screen and

define a TLP to hold the Top gauge input

value.

Water Gauge

Click to display the Select TLP screen and

define a TLP to hold the water gauge input

value.

Note: This field displays only if you enable

the Interfaced option.

Samples used in

Filtering

Indicates the number of four-second scan

samplings the program uses for filtering. The

default is 10.

Gauge Units

Defines the gauge units. Click to display all

valid units.

Gauger Value Validity

Max Valid EUs

Specifies the maximum number of valid

engineering units the program uses when

validating gauger value.

Max Change

Indicates the maximum change, in volume per

minute, the program accepts when validating

gauger value.

Max 1-Scan Volume

Change

Indicates the maximum change in level the

program accepts during a single scan when

validating gauger value.

Scan-to-Scan Change: The program scans

the top level gauge every 4 seconds. This

setting specifies the maximum value (in units

of liquid volume) that the level gauge is

allowed to change without being considered

invalid. Should a level gauge transmitter

malfunction, this will keep the invalid reading

from being interpreted as true production.

Max Time Invalid (Reset): If the level gauge

malfunction, it provides an unrealistic reading.

This setting determines how long to wait

before re-baselining the understood true level

of the tank. After a guage validity error occurs,

if it is cleared before this configurable time

expires, the large sudden change in level from

the gauge will not be interpreted as true

production.

Oil Density

Selects the TLPs that determine the specific

gravity, temperatures, and pressure. The

program uses these values to calculate the oil

density. You can also manually enter specific

gravity, temperature, and pressure values in

the space provided.

Note: This section displays only when you

select Oil as the Primary Fluid.

Oil Temperature

Sets the TLP of the parameter the program

use to determine the oil temperature. You can

manually enter the temperature value in the

space provided

Note: This section displays only when you

select Oil as the Primary Fluid.

Page 52

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

48 Configuration Revised June-2019

Field

Description

Oil Pressure

Sets the TLP of the parameter the program

use to determine the oil pressure. You can

manually enter the temperature value in the

space provided

Note: This section displays only when you

select Oil as the Primary Fluid.

S and W

Set the TLP of the parameter the program will

use to determine the amount of sediment and

water in the oil. If a live input is not defined,

you can manually enter a fixed S&W value for

the tank in the space provided.

Note: This section displays only when you

select Oil as the Primary Fluid.

Water Density

Sets the TLP of the parameter the program

use to determine the water specific gravity.

You can manually enter the temperature

value in the space provided

Note: This section displays only when you

select Water as the Primary Fluid.

Water Temperature

Sets the TLP of the parameter the program

use to determine the water. If a live input is

not defined, you can manually enter a fixed

water temperature for the tank in the space

provided

Note: This section displays only when you

select Water as the Primary Fluid.

Hauling and Production Options

Oil

Enable Production

Measurement via

Level

Enables configuration of production and

hauling options.

Infer Prod while

Hauling

Enables the program to calculate inferred

production during the haul and adjust hauled

volume accordingly. This situation occurs

when your setup injects the production into

the tank while the haul is currently in

progress.

Page 53

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 49

Field

Description

Stabilization

Parameters

This feature can be used to track the volume

changes in an oil tank which are attributed to

stabilization and settling of the product.

Drops in level which are not large enough to

trigger an auto haul can be measured and

tracked as stabilization loss. Click to select

from the list:

▪ Do Not Accumulate Loss due to

Stabilization – Small in level due to

stabilization are ignored.

▪ Accumulate Stabilization Loss – Drops in

level due to stabilization are recorded as

separate volume accumulators (as seen on

the Liquid Data tab).

▪ Accumulate Loss and Add To Production –

Drops in level due to stabilization are

recoded as separate volume accumulators

(as seen on the Liquid Data tab) and the

accumulation is also added to the Oil

Produced accumulators.

Stabilizer Timer

Indicates the amount

of time that must

pass, before a small

drop in level is

determined to be oil

stabilization, and the

volume quantity is

added to the

stabilization loss

accumulators. When

the timer is in use,

the Remaining field

will count down from

the Preset value, to

zero. Once it reaches

zero, it will

automatically reset to

the Preset time.

Auto Hauling Configuration

Auto Haul Using

Level

Enables the program

to auto-detect a haul

based on a drop in

level even without

input from the HMI to

automatically trigger

a haul.

Page 54

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

50 Configuration Revised June-2019

Field

Description

Apply Density

Correction to Auto

Hauls

Enables corrections

of the volume of the

haul to to base

conditions (NSV),

when performing

auto-hauls. When

you enable this

option, you must

configure the

appropriate tank

instrumentation

(density,

temperature, S&W,

etc) or you must

enter manual values.

Record Water

Volume Hauled

When enabled and

an interfaced (oil and

water) gauge is used,

a drop in the water

level during an auto

haul for oil will result

in that water quantity

being recorded. This

is only true when the

interface level is

above the unsafe

zone for the tank, as

defined by the Load

Line Elevation.

Note: This field

displays only when

you enable Auto

Haul Using Level.

Record Oil

Volume Hauled

When enabled and

an interfaced (oil and

water) gauge is used,

a drop in the oil level

during an auto haul

for water will result in

that oil quantity being

recorded. This is

only true when the

interface level is

above the unsafe

zone for the tank, as

defined by the Load

Line Elevation.

Note: This field

displays only when

you enable Auto

Haul Using Level.

Page 55

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 51

Field

Description

Minimum Oil Haul

Indicates the

minimum amount of

oil level decrease that

automatically triggers

a haul. The default

value is 15.0.

Note: This field

displays only when

you enable Auto

Haul Using Level.

Maximum Oil Haul

Indicates the

maximum volume of

oil on a single haul

(ticket). Exceeding

this value triggers the

creation of additional

logs. The default

value is 200.0.

Note: This field

displays only when

you enable Auto

Haul Using Level.

Close-Out Auto-

Detect Haul after [ ]

Minutes of No-Flow

Sets the amount of

no-flow time, in

minutes, to

automatically trigger a

close-out. The default

value is 15.0.

Note: This field

displays only when

you enable Auto

Haul Using Level.

Water

Enable Production

Measurement via

Level

Enables configuration of production and

hauling options.

Infer Prod while

Hauling

Enables the program to calculate inferred

production during the haul and adjust hauled

volume accordingly. This situation occurs

when your setup injects the production into

the tank while the haul is currently in progress.

Auto Hauling

Configuration

Auto Haul Using

Level

Enables the program

to auto-detect a haul

based on a drop in

level even without

input from the HMI to

automatically trigger a

haul.

Page 56

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

52 Configuration Revised June-2019

Field

Description

Minimum Water

Haul

Indicates the

minimum amount of

water level decrease

that automatically

triggers a haul. The

default value is 15.0.

Note: This field

displays only when

you enable Auto

Haul Using Level.

Maximum Water

Haul

Indicates the

maximum volume of

water on a single

haul (ticket).

Exceeding this value

triggers the creation

of additional logs.

The default value is

180.0.

Note: This field

displays only when

you enable Auto

Haul Using Level.

Close-Out Auto-

Detect Haul after [ ]

Minutes of No-Flow

Sets the amount of

no-flow time, in

minutes, to

automatically trigger

a close-out. The

default value is 15.0.

Note: This field

displays only when

you enable Auto

Haul Using Level.

3. Click Apply to save any changes you have made to this screen.

4. Proceed to Section 3.2.3 to configure the Tank Strapping tab.

3.2.3 PMTM Tank Manager – Tank Strapping Tab

Use this screen to configure the calibration to allow for the conversion

of a level (in feet or inches or meters, etc) to an equivalent volume of

product in the tank.

Note: This tab does not display anything when you select Aggregate

(Multi Tank/Multi Gauger) from the Tank or Aggrate frame.

To access this screen:

1. Select the Tank Strapping tab on the Tank Manager screen. The

Tank Strapping screen displays:

Page 57

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

Revised June-2019 Configuration 53

Figure 3-9. Tank Manager Screen – Tank Strapping tab

2. Review the values in the following fields:

Field

Description

Strapping Table

for Tank #

Displays the unique tank description (tag) you

enter on the previous screen.

Ambient

Temperature

Sets the TLP of the parameter the program

use to determine the ambient temperature of

the site. If a live input is not defined, you can

manually enter a fixed ambient temperature in

the space provided. Click to define a TLP

for the ambient temperature.

Lease Tank ID

Sets a numeric identifier for the tank within the

lease. This optional field is provided for

informational purposes only.

Effective Date

Sets the date of the last calibration of the tank

in the form of YYYYMMDD, where YYYY is

the 4 digit year, MM is the 2 digit month, and

DD is the 2 digit day. For example, 20151201

would be December 1st, 2015. This optional

field is provided for informational purposes

only.

Page 58

Tank Manager User Manual (for ROC800-Series and FloBoss 107)

54 Configuration Revised June-2019

Field

Description

Tank Shell

Material

Selects material of construction of your tank.

The program uses this selection to calculate

the CTS value of the tank. Click to display

all valid material types.

Tank Shell Ref

Temp:

Sets the reference temperature of the tank

during calibration. The program uses this

temperature value to calculate the CTS value

of the tank. This value is typically 60 deg F or

15 deg C.

Tank Insulated?

Indicates whether the tank includes insulation.

The program uses this selection to calculate

the CTS value of the tank.

Incremental

Height:

Selects the units of the smallest linear

increment for the strapping table. Click to

display all valid incremental height options.

Volume Unit per

Increment:

Selects the volume units of the strapping

value increments. Click to display all valid

volume unit options.

Current Strap In

Use

Shows the calculated strapping value in-use

for the current level of the tank.

Table Entry Control

Note: These options determine which values the program requires

to enter and which values the program automatically

calculates for the strapping table.

Level

Determines the primary data entry type for the

strapping table. Click to display all valid

level entry options. If the strapping table data

includes tank height levels, select Enter