Remote Automation Solutions Surface Control Manager User Manual (FB107+ROC800) Manuals & Guides

Page 1

Remote Automation Solutions

Part D301759X012

January 2017

Surface Control Manager User Manual

(for ROC800-Series and

FloBoss™ 107 Controllers)

Page 2

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

ii Revised January-2017

Revision Tracking Sheet

January 2017

This manual may be revised periodically to incorporate new or updated information. The revision date

of each page appears at the bottom of the page opposite the page number. A change in revision date

to any page also changes the date of the manual that appears on the front cover. Listed below is the

revision date of each page (if applicable):

Page

Revision

All Pages

January-2017

All Pages

August-2016

Initial release

September-2014

Page 3

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Contents iii

Contents

Chapter 1 – Introduction 1

1.1 Scope and Organization ..................................................................................................................... 1

1.2 Product Overview ............................................................................................................................... 2

1.3 Program Requirements ...................................................................................................................... 2

1.3.1 License Key .......................................................................................................................... 3

Chapter 2 – Installation 5

2.1 Installing the License Key .................................................................................................................. 5

2.1.1 Installing the License Key for the ROC800 .......................................................................... 5

2.1.2 Installing the License Key for the FB107 .............................................................................. 6

2.1.3 Verifying the License Key Installation (for ROC800) ............................................................ 7

2.2 Downloading the Program .................................................................................................................. 8

2.2.1 Surface Control Program ...................................................................................................... 8

2.2.2 PMCB Calculation Blocks Program .................................................................................... 12

2.3 MPU Loading Threshold (ROC800) ................................................................................................. 16

Chapter 3 – Configuration 17

3.1 PMSC Action Blocks Screen ............................................................................................................ 18

3.2 PMSC Utilities Screens .................................................................................................................... 25

3.2.1 PMSC Utilities Screen – PMSC Effects Tab ...................................................................... 27

3.2.2 PMSC Utilities Screen – Time Count Tab .......................................................................... 29

3.2.3 PMSC Utilities Screen – Accumulators/Outputs Tab ......................................................... 32

3.2.4 PMSC Utilities Screen – Alarm Blocks Tab ........................................................................ 35

3.2.5 PMSC Utilities Screen – Action Block Domain Statuses Tab ............................................ 38

3.3 PMCB Calculation Blocks ................................................................................................................ 42

3.4 Saving the Configuration .................................................................................................................. 47

3.5 Sample Configurations ..................................................................................................................... 48

3.5.1 Controlling a Pump based on Tank Level .......................................................................... 48

3.5.2 Connecting Two Blocks with an AND Statement ............................................................... 49

3.5.3 Connecting Two Block with an OR Statement ................................................................... 51

3.5.4 Setting Up a Class B Bypass ............................................................................................. 54

3.5.5 Creating a Timed Maintenance Bypass ............................................................................. 56

Chapter 4 – Reference 59

4.1 Point Type 68/28: Action Blocks ...................................................................................................... 60

4.2 Point Type 71/31: Utilities ................................................................................................................ 68

4.3 Point Type 218: Calculation Blocks (for ROC800) ........................................................................... 75

4.4 Point Type 27/39: Calculation Blocks (for FB107) ........................................................................... 78

Appendix A – PMCB Calculation Blocks – Supported Functions 87

A.1 Calculations: Rules and Guidelines ................................................................................................. 87

A.1.1 Execution Order .................................................................................................................. 87

A.1.2 Order of Operators ............................................................................................................. 87

A.1.3 Parentheses ....................................................................................................................... 88

A.1.4 Operands ............................................................................................................................ 88

Page 4

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

iv Contents Revised January-2017

A.2 Operators ......................................................................................................................................... 89

A.2.1 Mathematical Operators ..................................................................................................... 89

A.2.2 Comparison Operators ....................................................................................................... 90

A.2.3 Bitwise Operators ............................................................................................................... 91

A.2.4 Logical Operators ............................................................................................................... 92

A.3 Functions ......................................................................................................................................... 92

A.3.1 AND(): Logical AND ........................................................................................................... 92

A.3.2 OR(): Logical OR ................................................................................................................ 93

A.3.3 Boolean Calculations using AND(), OR() and NOT(!) Operators ....................................... 93

A.3.4 ABS(): Absolute Value ........................................................................................................ 93

A.3.5 INT(): Integer Value ............................................................................................................ 94

A.3.6 MOD(): Modulus ................................................................................................................. 94

A.3.7 POW(): Raise To The Power Of ......................................................................................... 95

A.3.8 SUM(): Summation ............................................................................................................. 95

A.3.9 MIN(): Minimum Value ........................................................................................................ 95

A.3.10 MAX(): Maximum Value ..................................................................................................... 95

A.3.11 IIF(): Inline IF ...................................................................................................................... 96

A.3.12 BFI(): Boolean FAN-IN ....................................................................................................... 96

A.3.13 BFO(): Boolean FAN-OUT ................................................................................................. 96

A.3.14 FOR(): FOR Loop ............................................................................................................... 98

Page 5

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Introduction 1

Chapter 1 – Introduction

Caution

When implementing control using this product, observe best industry

practices as suggested by applicable and appropriate environmental,

health, and safety organizations. While this product can be used as A

safety component in a system, it is NOT intended or designed to be the

ONLY safety mechanism in that system.

This chapter describes the structure of this manual and presents an

overview and installation instructions of the Surface Control Manager

program for the ROC800-Series Remote Operations Controller and the

FloBoss™ 107 Flow Computer.

Note: The Surface Control Manager program (v407_00_XXXblk.tar)

comes with PMCB Calculation Blocks (Display #218) for

ROC800. For FloBoss 107, it is a separate program. For

installation procedures, refer to Section 2.2.2 – PMCB

Calculation Blocks Program for details.

1.1 Scope and Organization

This document serves as the user manual for the Surface Control

Manager program, which is intended for use in a ROC800-Series

(ROC800) and FloBoss 107 (FB107). This manual describes how to

download, install, and configure the Surface Control Manager program

(referred to as the “Surface Control program” or “the program”

throughout the rest of this manual). You access and configure this

program using ROCLINK™ 800 Configuration Software (version 2.30

or greater) loaded on a personal computer (PC) running Microsoft®

Windows® 2000 (with Service Pack 2), Windows XP (with Service

Pack 3), Windows Vista™ (32-bit), or Windows 7 (32-bit and 64-bit).

The sections in this manual provide information in a sequence

appropriate for first-time users. Once you become familiar with the

procedures and the software, the manual becomes a reference tool.

This manual has the following major sections:

Chapter 1 – Introduction

Chapter 2 – Installation

Chapter 3 – Configuration

Chapter 4 – Reference

Appendix A – PMCB Calculation Blocks – Supported Functions

This manual assumes that you are familiar with the ROC800 or FB107

and its configuration. For more information, refer to the following

manuals:

FloBoss

™

107 Flow Manager Instruction Manual (Part

D301232X012)

Page 6

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

2 Introduction Revised January-2017

ROC800-Series Remote Operations Controller Instruction Manual

(Part D301217X012)

ROCLINK

™

800 Configuration Software User Manual (for

FloBoss™ 107) (Part D301249X012)

ROCLINK

™

800 Configuration Software User Manual (for

ROC800-Series) (Part D301250X012)

ROCLINK

™

800 Configuration Software User Manual (for

ROC800L) (Part D301246X012)

1.2 Product Overview

The two main functional areas on a well pad are the well itself

(“downhole”) and the equipment on the surrounding ground (“surface

management”). “Surface control” refers to the ability to manage both

the control logic of that equipment as well as any maintenance bypass

requirements for that equipment and surface shut-in of wells. The

Surface Control Management application enables you to configure the

ROC800 or the FB107 to perform logical control and maintenance

bypass using “action blocks.” Action blocks are configurable program

components that drive effects (such as valves opening or closing). The

FB107 program supports 48 action blocks; the ROC800 programs

support 48, 96, 144 or 192 action blocks. Additionally, a quartet of

utilities accompanies each action block. These utilities provide the

sequential effects for an action block, monitor run times (to calculate

run and down times for air compressors, engines, and other equipment),

accumulate values (for today, yesterday, this month, previous month,

and for a running period), and provide configurable outputs (analog

outputs, pulse outputs, etc.).

The Surface Control Program has an added feature – PMCB Calculation

Blocks. This program enables you to specify complex mathematical or

logical (Boolean) equations for entry in a free-form style. These

equations typically would either not be suited (too complex) for entry in

Action Blocks or Cause & Effect, or possibly you prefer to save Action

Blocks by processing all math and some logic problems in the PMCB

Calculation Blocks program.

1.3 Program Requirements

The Surface Control Manager program is compatible with version 3.52

(or greater) of the ROC800 firmware, version 1.31 (or greater) of the

ROC800L firmware, version 1.61 (or greater) of the FB107 firmware, and

with version 2.30 (or greater) of the ROCLINK 800 software.

Program specifics include:

Note: Load only one version of the program, depending on your action

blocks and utilities requirements:

Page 7

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Introduction 3

The PMSC_v407_00_48blk.tar program file supports 48

action blocks, 4 calc blocks and 16 utilities and installs in a

ROC800 which requires only 1 license.

The PMSC_v407_00_96blk.tar program file supports 96

action blocks, 8 calc block and 32 utilities and installs in a

ROC800 which requires 2 licenses.

The PMSC_v407_00_144blk.tar programs file supports 144

action blocks, 12 calc blocks and 48 utilities and installs in a

ROC800 which requires 3 licenses.

The PMSC_v407_00_192blk.tar programs file supports 192

action blocks, 16 calc blocks and 64 utilities and installs in a

ROC800 which requires 4 licenses.

The PMSC_v407_XX_5.bin supports 48 action blocks and

16 utilities and installs in an FB107 which requires only 1

license.

File Name

Target Unit/

Version

User

Defined

Point (UDP)

Flash Used

(in bytes)

DRAM Used

(in bytes)

ROCKLINK

800 Version

Display

Number

PMSC_v407_00_48blk.tar

ROC800 3.52

ROC800L 1.31

68, 71, 218

130,345

172,032

2.30

68, 71, 218

PMSC_v407_00_96blk.tar

ROC800 3.52

ROC800L 1.31

68, 71, 218

130,345

172,032

2.30

68, 71, 218

PMSC_v407_00_144blk.tar

ROC800 3.52

ROC800L 1.31

68, 71, 218

130,345

172,032

2.30

68, 71, 218

PMSC_v407_00_192blk.tar

ROC800 3.52

ROC800L 1.31

68, 71, 218

130,345

172,032

2.30

68, 71, 218

PMSC_v407_XX_5.bin

FB107 1.61

28, 31

62,808

16,384

2.30

28, 31

PMCB_v400_01_3.bin

FB107 1.61

27

32,651

16,384

2.30

27

PMCB_v400_01_6.bin

FB107 1.61

39

32,651

16,384

2.30

39

For information on viewing the memory allocation of user programs,

refer to the following manuals;

ROCLINK

™

800 Configuration Software User Manual (for

FloBoss™ 107) (Part D301249X012)

ROCLINK

™

800 Configuration Software User Manual (for

ROC800-Series) (Part D301250X012)

ROCLINK

™

800 Configuration Software User Manual (for

ROC800L) (Part D301246X012)

1.3.1 License Key

License keys, when matched with valid license codes, grant access to

applications such as the Surface Control Manager program.

Page 8

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

4 Introduction Revised January-2017

For ROC800, the term “license key” refers to the physical piece of

hardware that can contain up to seven different licenses (refer to Figure

1). Each ROC800 can have none, one, or two license keys installed. If

you remove a license key after enabling an application, the firmware

disables the task from running. This prevents unauthorized execution of

protected applications in a ROC800.

DOC0422A

J1

U1

Figure 1-1. License Key

Note: The Surface Control Manager program for ROC800 requires up

to 3 PMSC license keys depending on your program

requirement. Refer to the Note on Section 1.3 for more

information regarding the program and its corresponding license

key requirements.

For FB107, Remote Automation Solutions delivers software licenses on

secure USB drives. You must install the PMSC license key to use the

Surface Control Manager program.

Page 9

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Installation 5

Chapter 2 – Installation

This section provides instructions for installing the Surface Control

Manager program into the ROC800 or FB107. Read Section 1.3 of this

manual for program requirements.

2.1 Installing the License Key

Section 2.1.1 provides license key installation instructions for ROC800

and Section 2.1.2 provides license key installation instructions for

FB107.

2.1.1 Installing the License Key for the ROC800

If you order the Surface Control Manager program for a new FB107 or

ROC800, your FB107 or ROC800 is delivered with the license key

installed. Go to Section 2.2.

If you order the program for an existing ROC800, you must install the

license key yourself.

Caution

Failure to exercise proper electrostatic discharge precautions, such as

wearing a grounded wrist strap may reset the processor or damage

electronic components, resulting in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing these procedures. Performing these procedures in a

hazardous area could result in personal injury or property damage.

To install a license key:

1. Remove power from the ROC800.

2. Remove the wire channel cover.

3. Unscrew the screws from the Central Processing Unit (CPU)

faceplate.

4. Remove the CPU faceplate.

5. Place the license key in the appropriate terminal slot (P4 or P6) in

the CPU.

Figure 2-1. License Key Installation

6. Press the license key into the terminal unit until it is firmly seated

(refer to Figure 2).

7. Replace the CPU faceplate.

DOC0423A

Page 10

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

6 Installation Revised January-2017

8. Replace the screws on the CPU faceplate.

9. Replace the wire channel cover.

10. Restore power to the ROC800.

11. Proceed to Section 2.1.3 to verify your license keys.

2.1.2 Installing the License Key for the FB107

A license is required to use the Surface Control Manager program. To

install a license on the FB107:

1. Insert the USB license key in a USB port on your PC.

2. Select Utilities > License Key Administrator > Transfer Between

DEVICE and KEY from the ROCLINK 800 menu bar. The

Transfer Licenses Between a Device and a Key screen displays:

Figure 2-2. Transfer Licenses Between a Device and a Key

Note: This screen has three sections. The upper portion (Licenses

on Device) shows any software licenses installed on the

FB107. The middle portion (Licenses on Key) shows

software licenses on the license key. The lower portion of the

screen (License Key Event Log) provides a rolling log of the

last eight events related to this license key.

3. Select the key-based license you want to transfer to the FB107

(PMSC, as shown in Figure 2-2).

4. Click Move to Device. ROCLINK moves the license from the key

to the FB107 and updates the screen.

Page 11

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Installation 7

Figure 2-3. License Installed

Note: An FB107 can hold up to six different licenses, although you

can install only one instance of each license on the FB107.

When you click Move to Device, ROCLINK 800 moves

only one instance of the license onto the FB107 and

automatically decreases the license quantity on the USB key

by one.

5. Verify the license name displays in the Licenses on Device section

of the screen. Proceed to Section 2.2 to download the user program.

2.1.3 Verifying the License Key Installation (for ROC800)

After you install the license key, you can verify whether the ROC800

recognizes the key. From the ROCLINK 800 screen, From the

ROCLINK 800 screen, select Utilities > License Key Administrator.

The License Key Administrator screen displays:

Page 12

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

8 Installation Revised January-2017

Figure 2-4. Transfer Licenses Between a Device and a Key

2.2 Downloading the Program

Section 2.2.1 provides downloading instructions of the Surface Control

Program for ROC800 or FB107 and Section 2.2.2 downloading

instructions of the PMCB Calculation Blocks for FB107.

2.2.1 Surface Control Program

This section provides instructions for installing the program into the

Flash memory on the ROC800 or FB107.

To download the program using ROCLINK 800 software:

1. Connect the ROC800 or the FB107 to your computer using the LOI

port.

2. Start and logon to ROCLINK 800.

3. Select Utilities > User Program Administrator from the

ROCLINK menu bar. The User Program Administrator screen

displays (see Figure 2-5):

Page 13

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Installation 9

Figure 2-5. User Program Administrator

4. Click Browse in the Download User Program File frame. The Select

User Program File screen displays (see Figure 2-6).

Note: If you install the program in the ROC800, choose any

available user program slot. If you use FB107, the program

installs automatically in user program slot 5.

5. Select the path and user program file to download from the CD-

ROM. (Program files are typically located in the Program Files

folder on the CD-ROM). As Figure 2-6 shows, the screen lists all

valid user program files with the .tar (for ROC800) or .bin (for

FB107) extension:

Page 14

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

10 Installation Revised January-2017

Figure 2-6. Select User Program File

6. Click Open to select the program file. The User Program

Administrator screen displays:

Figure 2-7. User Program Administrator

7. Click Download & Start to begin loading the selected programs.

The following message displays:

Page 15

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Installation 11

Figure 2-8. Confirm Download

8. Click Yes to begin the download. When the download completes the

following message displays:

Figure 2-9. ROCLINK 800 Download Confirmation

9. Click OK. The User Program Administrator screen displays (see

Figure 2-10). Note that:

The User Programs Installed in Device frame identifies the

installed program(s).

The Status field indicates that the program is running.

Page 16

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

12 Installation Revised January-2017

Figure 2-10. User Program Administrator

10. Click Close. The ROCLINK 800 screen displays and the download

is complete. Proceed to Chapter 3, Configuration.

2.2.2 PMCB Calculation Blocks Program

This section provides instructions for installing the PMCB Calculation

Blocks program into the Flash memory on the FB107.

Notes:

The PM Calculation Blocks program installs separately into the

FB107.

There are two versions of the PMCB Calculation Blocks program

are included. Installation and operation are identical between

programs, but they use different point type locations, different

display numbers, and are loaded into different program slots on the

FB107. PMCB_v400_01_3.bin loads into user program location 3

and User Defined Point (UDP) 27. PMCB_v400_01_6.bin loads into

user program location 6 and User Defined Point (UDP) 39. Install

the program version that avoids point type conflicts with currently

installed programs.

This document shows the installation of PMCB_v400_01_3.bin. The

installation process and functionality is the same for all version of

the Calculation Blocks program.

To download the program using ROCLINK 800 software:

1. Connect the FB107 to your computer using the LOI port.

Page 17

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Installation 13

2. Start and logon to ROCLINK 800.

3. Select Utilities > User Program Administrator from the

ROCLINK menu bar. The User Program Administrator screen

displays (see Figure 2-11):

Figure 2-11. User Program Administrator

4. Click Browse in the Download User Program File frame. The Select

User Program File screen displays (see Figure 2-12).

5. Select the path and user program file to download from the CD-

ROM. (Program files are typically located in the Program Files

folder on the CD-ROM). As Figure 2-12 shows, the screen lists all

valid user program files with the .BIN extension:

Figure 2-12. Select User Program File

Page 18

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

14 Installation Revised January-2017

6. Click Open to select the program file. The User Program

Administrator screen displays. As shown in Figure 2-13, note that

the Download User Program File frame identifies the selected

program and that the Download & Start button is active:

Figure 2-13. User Program Administrator

7. Click Download & Start to begin loading the selected programs.

The following message displays:

Figure 2-14. Confirm Download

Note: For the FB107, ROCLINK800 assigns program positions

based on memory allocations. For this reason, the

PMCB_v400_01_3.bin program automatically installs as

program 3. For PMCB_v400_01_6.bin program

automatically installs as program 6.

Page 19

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Installation 15

8. Click Yes to begin the download. During the download, the program

performs a warm start, creates an event in the event log, and when

the download completes displays the following message:

Figure 2-15. ROCLINK 800 Download Confirmation

9. Click OK. The User Program Administrator screen displays (see

Figure 2-16). Note that:

The User Programs Installed in Device frame identifies the

loaded program.

The Status field indicates that the program is running.

Figure 2-16. User Program Administrator

10. Click Close and proceed to Section 3.3 – PMCB Calculation Blocks

to configure the program.

Page 20

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

16 Installation Revised January-2017

2.3 MPU Loading Threshold (ROC800)

To maximize the performance of your ROC800 device, always verify

the performance of specific application combinations before using them

in the field to ensure the MPU load typically remains below 85% with

peak MPU loading levels below 95%.

To check the current MPU load at any time, select ROC > Information

> Other Information and review the value in the MPU loading field.

Figure 2-17. MPU Loading

Page 21

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 17

Chapter 3 – Configuration

After you have loaded the Surface Control Manager program on the

FB107 or the ROC800, you configure the program using three programspecific screens:

PMSC Action Blocks

PMSC Utilities

PMCB Calculation Blocks

To configure the program (after logging onto ROCLINK 800 and

successfully installing the program), proceed through the program

screens as shown in the following sections.

You can access all the program-specific screens from the main

ROCLINK 800 screen:

Note: The configuration screens of the Surface Control Manager

program for both the ROC800 and the FB107 platforms are

identical.

Figure 3-1. ROCLINK 800

Page 22

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

18 Configuration Revised January-2017

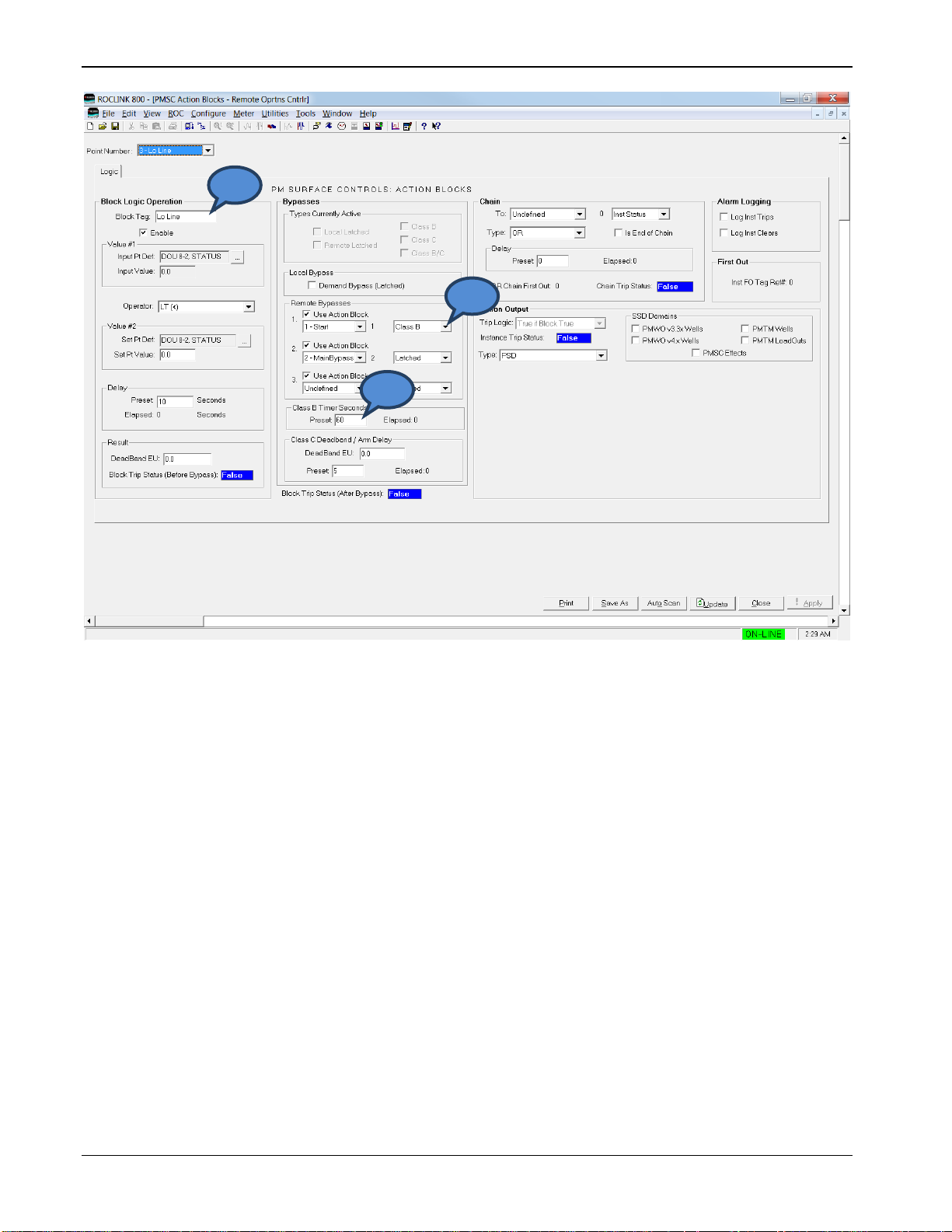

3.1 PMSC Action Blocks Screen

The screen has five main sections:

Block Logic Operation– Use this section to define the logic for each

action block.

Bypasses– Use this section to configure temporary overrides for the

result of the raw action block logic.

Chain– Use this section to logically link one action block to another.

Action Output– Use this section to define any actions to be

performed when the action block is “true”. These actions can

include writing to a defined parameter, moving a value, or shutting

down another aspect of an associated user program, such as Tank

Manager or Well Optimization.

Alarm Logging– Use this section to generate alarms in the device

alarm log, based on the status changes of the action block.

To access this screen:

1. From the Directory Tree, select User Program > Program #1,

PMSC_v407_00_48blk.

2. Double-click Display #68, PMSC Action Blocks.

Note: This section shows how to access the access the Action

Blocks screen for the ROC800. To access the Action Blocks

for FB107, double-click Display #28, PMSC Action Blocks.

3. Double-click #1, Block 1. The PMSC Action Blocks screen

displays:

Note: Depending on the device (ROC800 or FB107) and the

version of the program installed, you may have up to 144 of

these screens, one for each action block.

Page 23

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 19

Figure 3-2. PMSC Action Blocks Screen

4. Review the values in the following fields:

Field

Description

Block Logic Operation

Block Tag

Sets the action block tag name.

Enable

Enables the action block when checked.

Input Pt Def

Sets the TLP source of the input value.

Input Value

Displays the input’s live value.

Operator

Selects a mathematical or logical operator

from the dropdown list. Click to select a

valid operator:

GT (>) – If the Input Value is greater than the

Set Pt Value for the Delay Preset time, the

block is set true.

GE (>=) – If the Input Value is greater than or

equal to the Set Pt Value for the Delay

Preset time, the Block is set true.

LT (<) – If the Input Value is less than the Set

Pt Value for the Delay Preset time, the block

is set true.

LE (<=) – If the Input Value is less than or

equal to the Set Pt Value for the Delay

Preset time, the block is set true.

Page 24

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

20 Configuration Revised January-2017

Field

Description

EQ (==) – If the Input Value is equal to the

Set Pt Value for the Delay Preset time, the

block is set true.

NE (!=) – If the Input Value is not equal to the

Set Pt Value for the Delay Preset time, the

block is set true.

Watchdog – Monitors the Input Value, if it

does not change for the Delay Preset time,

the block is set true.

Trip on Change – If the Input Value is

different than the Set Pt Value, the block is

set true.

pEdge – Monitors the Input Value for a

transition from 0 to 1, block is set true for one

scan.

nEdge - Monitors the Input value for a

transition from 1 to 0, block is set true for one

scan.

Bitwise AND (&) – Compares each bit in the

Input Value to the Set Pt Value. If both bits

are true (1), the block is set true.

Bitwise OR – Compares each bit in the Input

Value to the Set Pt Value. If either bit

matches, the block is set true.

Add (+) – Adds Input Value to Set Pt Value

and displays the results in the Math Result

field.

Subtract (-) – Subtracts the Set Pt Value

from the Input Value and displays the results

in the Math Result field.

Multiply (*) – Multiplies the Input Value by

Set Pt Value and displays the results in the

Math Result field.

Divide (/) – Divides the Input Value by the

Set Pt Value and displays the results in the

Math Result field.

Modulus (%) – Or remainder of the Input

Value divided by the Set Pt Value. Example:

17 modulus 3 = 2, or 17/3 = 5 with a

remainder of 2 displayed in the Math Result

field.

Soft Input Reset Timer – Monitors the Input

Value for a transition from 0 to 1. Once this

transition occurs the block is set true and a

time delay starts for the amount of seconds

specified in the Delay Preset field. When the

timer expires the block is set to false and the

Input Value is forced back to a zero.

Set Pt Def

Selects the TLP source of the Set Pt Value.

Set Pt Value

Shows the value of the point defined in the

Set Pt Def field. If you leave this field

undefined, you can manually enter this value.

Page 25

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 21

Field

Description

Preset

Sets the delay in seconds. This delay is either

for an on delay for logic functions or for soft

input rest timer. (See function description

above.)

Elapsed

Shows the time delay that has elapsed, starts

counting up from zero to the Preset time and

status changes when the Preset time is

reached.

Deadband / Math

Result

Sets the deadband for clearing the

comparator logic or displays the Math Result

for math functions.

Block Trip Status

(Before Bypass)

Displays the logic block trip indicator based

only on the block logic operation, before any

bypasses are applied.

Bypasses

Types Currently

Active

Shows the bypasses that are currently active.

Demand Bypass

(Latched)

Activates the manual latched bypass when

selected. This value could be set or removed

from an FST or from an action block.

Remote

Bypasses

Allows you to browse other action blocks to be

used to define bypass functionality. When the

remote action block is true, the bypass for this

block is true.

Note: If the Use Action Block is un-checked,

click to select a TLP in the system.

Valid bypass types are:

Latched – Bypassed while the Remote

Bypass block is true.

Class B – Bypassed for the amount of time in

the Class B Timer field once the Remote

Bypass block is true.

Class C - Bypassed until the block clears

once the Remote Bypass block is true.

Class B w/C override - Bypassed for the

amount of time in the Class B Timer field or

unless the Block clears before the timer

expires once the Remote Bypass block is

true.

Class B Timer

Seconds – Preset

Sets the timer for Class B bypass.

Class B Timer

Seconds –

Elapsed

Shows the elapsed time for Class B bypass.

Class C

Deadband / Arm

Delay –

Deadband EU

Sets the deadband for Class C bypass.

Class C

Deadband / Arm

Delay – Preset

Sets the timer for Class C bypass.

Page 26

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

22 Configuration Revised January-2017

Field

Description

Class C

Deadband / Arm

Delay – Elapsed

Shows the elapsed time for Class C bypass.

Block Trip Status

(After Bypass)

Shows the combined status of the logic block

and the bypass block. For example, if the

logic block is true and the bypass is not in

effect, then the status is true. If the logic block

is true and the bypass is in effect, then the

status is false.

Chain

To

Allows you to browse a previous action block

to compare results with based on the chain

type.

Type

Sets the logic of chain. Click to select an

available logic type:

AND – If the chained block and current block

are true, the Chain Trip Status is true.

OR – If the chained block or current blocks

are true, the Chain Trip Status is true.

NAND – If the chained block and current block

are false, the Chain Trip Status is true.

XOR Either – If one of the chained block and

current block is true and the other false, the

Chain Trip Status is true.

XOR Local – If the chained block is set to

false and current block is set to true, the

Chain Trip Status is true.

XOR Remote – If current block is set to false

and chained block is set to true, the Chain

Trip Status is true.

Seal-In – If the current block is set to true and

the previous block or the current chain status

are set to true, the Chain Status is true until

the current block status after bypass is false

PWM Lo-Duty – If the current block is set to

true and the previous block is false, the Chain

Status is true for one second then toggles

false for the remaining seconds in the Chain

Delay Preset time. The cycle repeats while

the condition remains the same, the Preset

time must be more than two seconds

PWM-Hi-Duty – If the current block is set to

true and the previous block is false, the Chain

Status is false for one second then toggles

true for the remaining seconds in the Chain

Delay Preset time. The cycle repeats while

the condition remains the same, the Preset

time must be more than two seconds

Is End of Chain

Indicates when this block is the end of a chain

of previous blocks.

Delay

Sets the delay Preset timer and shows the

Elapsed time.

Page 27

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 23

Field

Description

OR Chain First

Out

Shows the number of the action block that is

tripped in a chain of or blocks.

Chain Trip Status

Shows the number of the action block that is

tripped in a chain of OR blocks.

Note: This field displays only when the Chain

Type is OR.

Action Output

Block/Chain Trip

Selects the status that trips the output. Valid

values are:

True if Block True – Output is driven true if

the Block Trip Status (After Bypass) is true on

this action block.

True if Chain True – Output is driven true if

the Chain Status is true on this action block.

True if Either True – Output is driven true if

the Block Trip Status (After Bypass) or the

Chain Status is true on this action block.

True if Both True – Output is driven true if

the Block Trip Status (After Bypass) and the

Chain Status is true on this action block.

Instance Trip

Status

Shows the status of the Output Action.

Type

Selects the type of Output desired from this

action block. Valid values are:

PSD (Permanent Shutdown) – When selected

a submenu of available Applications

(Domains) displays allowing you to select the

instance from the other applications you wish

to permanently shutdown. A manual reset is

required after the shutdown occurs.

TSD (Temporary Shutdown) – When selected

a submenu of available Applications

(Domains) displays allowing you to select the

instance from the other applications you wish

to temporarily shutdown. An automatic reset

occurs after the shutdown clears.

DO (Binary Action) – Allows you to select a

Binary Field to which the signal is sent.

Discrete signals can be sent in the following

format:

Force 1True & 0False

Force 0True & 1False

Poke 1True

Poke 0True

Poke 1True & 0False

Poke 0True & 1False

Force 1True & Poke 0False

Force 0True & Poke 1False

Force 1True

Force 0True

Page 28

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

24 Configuration Revised January-2017

Field

Description

Move Value – Two Functions:

1. When using Math Operators, the Result is

moved to the defined Output TLP.

2. When using Comparator Operators, the

Input Value is moved to the Output TLP

when the block is true.

VAL (to Result Reg) – Pushes the value in

the Output TLP into the internal Result

Register of PMSC.

SAV (from Result Reg) – Pulls the internal

Result Register value from PMSC and pushes

it into the Output TLP.

No Action – No output action will take place

when the block is set true.

SSD Domains

Provides the ability to shutdown aspects of

other associated programs (such as Tank

Manager or Well Optimization), based on the

result of the action block. Once a domain has

been selected, the instances of that domain

for which the block action should apply must

also be selected.

PMTM Wells – Sets either a (Permanent

Shutdown) PSD or a (Temporary Shutdown)

TSD to the associated Well defined in PM

Tank Manager, Allocated Well Values/Trip

Point.

PMTM Loadouts – Sets either a PSD or TSD

to the associated Haul HMI/Station

Permissive. A PSD stops a haul in progress

and a TSD pauses a haul in progress.

PMv 3.3x Wells – Sets either a PSD or TSD to

the associated Production Manager version 3

wells.

PMWO Wells – Sets either a PSD or TSD to

the associated well in PMWO 4.x.

PMSC Effects – Sets a PSD or TSD to the

associated effect in PMSC Utilities.

Note: The SSD Domains are only visible

when the Action Output Type has been

set to PSD or TSD.

Alarm Logging

Alarm Logging

Activates logging in the ROC Alarm Log if the

action block sets (if the Log Inst Trips option is

selected) or clears (if the Log Inst Clears

option is selected).

First Out

Shows the First Out tag of the action block

that was first tripped in a chain for which the

current block is a part.

5. Click Apply to save your changes.

6. Click Close to return to the ROCLINK 800 screen. Proceed to

Section 3.2 to configure the PMSC Utilities Screen.

Page 29

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 25

3.2 PMSC Utilities Screens

The PMSC Utilities screen allows you to configure the following tabs:

PMSC Effects

Time Count

Accumulators/Outputs

Alarm Blocks

Action Block Domain Statuses

To access this screen:

1. From the Directory Tree, select User Program > Program #1,

PMSC_v407_00_48blk.

2. Double-click Display #71, PMSC Utilities.

Note: This section shows how to access the access the Utilities

screen for the ROC800. To access the Action Blocks for

FB107, double-click Display #31, PMSC Utilities.

3. Double-click #1, Inst 1. The PMSC Utilities screen displays:

Page 30

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

26 Configuration Revised January-2017

Figure 3-3. PMSC Utilities Screen

4. Follow Section 3.2.1 through Section 3.2.4 to configure the PMSC

Effects, Time Count, Accumulations/Outputs, and the Action Block

Domain Statuses tabs.

Page 31

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 27

3.2.1 PMSC Utilities Screen – PMSC Effects Tab

Use this screen (which displays when you first access the PMSC

Utilities screen) to configure various aspects of an effect triggered by an

action block. Each effect represents a particular action that is taken

when the action blocks that are linked to it are tripped or cleared. The

action that is taken is the writing of a value out to a user defined

parameter. Different values to be written are defined for when the effect

is tripped vs. when the effect is not tripped. This allows for creating of

custom actions, such as driving a discrete valve or a panel annunciation.

In addition to configuring effects, this tab allows you to configure

outputs separately. You can:

Control the output by multiple action blocks.

Write values to analog type controls (analog outputs, PID setpoints,

and so on).

Page 32

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

28 Configuration Revised January-2017

Figure 3-4. PMSC Utilities Screen – PMSC Effects tab

1. Review and complete the values in the following fields:

Field

Description

Effect Tag

Identifies the specific effect being defined.

Enable

Enables the effect.

PtDef

Sets the output to be driven.

Value When

Tripped

Sets the value to be driven to the PtDef when

the effect is Tripped (true).

Value When Not

Tripped

Sets the value to be driven to the PtDef when

the effect is Not Tripped (false).

Page 33

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 29

Field

Description

Output the Value

When Not

Tripped

Allows the output to be either driven or not

driven when the effect is false. You typically

use this option when the effect needs to be

manually reset. Select this option to enable

the effect to drive the signal each way. If you

do not select this option, the signal is driven

only when the effect is true.

Assert Output

Continuously

During

Selects how to assert effect output to the

parameter defined by the PtDef field. When

the “Neither State” option is selected, then the

output parameter is written to one time on

state change, and not written to again (until

the next state change). When the other

options are selected (“Tripped State Only”,

“UnTripped State Only”, and “Both States”),

the configured value is written to the output

parameter continuously.

Click to select valid options.

Neither State

Tripped State Only

UnTripped State Only

Both States

Cur Outp Value

Shows the current output value.

Effect Trip Status

Indicates the status of the effect trip. Valid

values are 1 (tripped, red box with yellow

letters; active) and 0 (not tripped, blue box

with white letters; inactive).

First-Out Int#

Shows the numerical values of the action

block that first tripped this effect.

First-Out Tag

Shows the tag of the action block that tripped

this effect.

Trips Require

Reset

The user program automatically checks this

box upon a PSD type trip that is connected to

the effect.

The user program automatically unchecks

this box upon a TSD type trip that is

connected to the effect.

A user can override the automatic selection

after the trip has occurred (check or uncheck

it).

When the box is checked, even though action

block that caused the trip is in the cleared

(normal) state, the effect will stay tripped until

a reset action is performed.

When the box is unchecked the effect is

cleared as soon as any tripped action blocks

(connected to the effect) are cleared.

Page 34

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

30 Configuration Revised January-2017

Field

Description

Remote Reset

Command TLP

Click to select a TLP in the ROC800 or FB107

used to reset this effect. For example, a TLP

you might select is a discrete input or soft

point value. When the effect is ready to be

reset, any positive value written to the TLP

performs the reset.

The same remote TLP may be used to reset

several different effects.

The user program automatically resets the

value of the remote TLP back to zero after

processing.

Note: This field shows only if you check or

select the Trips Require Reset option.

Reset Command

Identifies a local reset field which can be

mapped to HMIs, etc. Any positive value

entered will cause a reset action. The value in

this field is reset to zero after processing. This

field is entirely independent from the “Remote

Reset Command TLP” field. The two fields

logically act as an “OR” in resetting the

effect.

2. Click Apply to save any changes you have made to this screen.

3. Proceed to Section 3.2.2 to configure the Utilities Screen – Time

Count tab.

3.2.2 PMSC Utilities Screen – Time Count Tab

Use this screen to configure the time counter of the Surface Control

manager program. Use this utility to set “timers” for equipment on a

well site to remind you to perform preventive maintenance (such as for

a compressor after a certain number of hours).

To access this screen:

1. Select the Time Count tab on the PMSC Utilities screen. The

Time Count screen displays:

Page 35

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 31

Figure 3-5. PMSC Utilities Screen – Time Count tab

Page 36

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

32 Configuration Revised January-2017

2. Review the values in the following fields:

Field

Description

Counter Tag

Identifies the specific counter being defined.

Enable

Select to enable the time counter.

Run-Time Pt Def

Sets the point to be monitored to define if the

On Counter or the Off Counter Advances.

This value is compared using the following

logical functions:

GT (>)

GE (>=)

LT (<)

LE (<=)

EQ (==)

NE (!=).

Value

Defines the value to be compared to the RunTime Pt Def.

Cur Status

Indicates if comparison statement written

above is True (ON) or False (OFF).

Update Interval

Defines how often the accumulating counters

update their associated values in the ROC.

The calculation always runs every second, but

to save MPU load the updating accumulators

are only written out to the ROC points based

on this parameter.

Mins Tdy

This display-only field shows Accumulated

On minutes and Off minutes Today.

Mins Ydy

This display-only field shows Accumulated

On minutes and Off minutes Yesterday.

Hours Tdy

This display-only field shows Accumulated

On hours and Off hours Today.

Hours Ydy

This display-only field shows Accumulated

On hours and Off hours Yesterday.

Pct Tdy

This display-only field shows Percent of time

On and Off Today.

Pct Ydy

This display-only field shows Percent of time

On and Off Yesterday.

Mins TMon

This display-only field shows Accumulated

On minutes and Off minutes This Month.

Mins PMon

This display-only field shows Accumulated

On minutes and Off minutes Previous Month.

Hours TMon

This display-only field shows Accumulated

On hours and Off hours This Month.

Hours PMon

This display-only field shows Accumulated

On hours and Off hours Previous Month.

Pct TMon

This display-only field shows Percent of time

On and Off This Month.

Pct PMon

This display-only field shows Percent of time

On and Off Previous Month.

Contact Hr

Sets the hour, in military hour format, at which

the accumulators roll up the Days On and Off

Times.

Page 37

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 33

Field

Description

Clear Now!

Select this option to clear all accumulators

and reset them to zero. The system

automatically clears this field checkbox is auto

cleared and the accumulation for On and Off

time begin anew.

3. Click Apply to save any changes you have made to this screen.

4. Proceed to Section 3.2.3 to configure the PMSC Utilities Screen –

Accumulators/Output tab.

3.2.3 PMSC Utilities Screen – Accumulators/Outputs Tab

The functionality on this screen changes, depending on the mode you

select. There are 4 possible modes:

Accumulate a Rate – This function provides daily, monthly, and

running total accumulation for a flowrate you specify. The flowrate

comes from a metering device providing a rate in the form of an

analog or HART input, a pulse input EU value rate, or a flow

calculation you implement. The flowrate integrates once per second,

and that incremental amount of accumulation adds to the daily,

monthly, and running totals.

Accumulate a Running Total – This functionally also provides

daily, monthly, and running totals. The totals, however comes from

a smart meter or other device that provides an incremental

accumulator value (commonly provided to the ROC800 or FB107

from a Modbus connection). The program determines the increment

per second based on this accumulator input. The incremental values

are added to the daily, month, and running totals. If applicable, the

rollover of this incremental accumulator input value is automatically

determined.

Output a 4-20mA Signal – This option provide a method to link a

process variable from the internal database of the device to an

Analog Output (AO) point, therefore providing a 4-20 mA signal.

The signal can be of any form, but is commonly used for flowrate

values, valve positions, or other process variables you send to

another device or system.

Output a Pulse at an Interval – Allows you to generate a

reoccurring pulse signal to another devices or system. Typically, this

is used to send a pulse (via a ROC800 or FB107 discrete output) that

represents an accumulated amount of flow. For example, If you have

a daily flowrate in MCF, you can generate a pulse for every unit of

MCF that is measured by the ROC800 or FB107.

To access this screen:

1. Select the Accumulators/Outputs tab on the PMSC Utilities screen.

The Accumulation/Outputs screen displays:

Page 38

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

34 Configuration Revised January-2017

Figure 3-6. PMSC Utilities Screen – Accumulators/Outputs tab

2. Review the values in the following fields:

Field

Description

Accum/Out Tag

Identifies the specific accum/output being

defined.

Enable

Enables this instance of the

Accumulator/Output.

Page 39

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 35

Field

Description

Mode

Selects the type of accumulator or output for

this instance. Click to select a valid option:

Accumulate a Rate – Accumulates the flow

rate defined in the Input Def field.

Accumulate a Running Total – Accumulates

the accumulated value defined in the Input

Def field. This should be an accumulator that

does not reset each day at contract hour. Rollover is handled internally every scan period.

Output a 4-20ma Signal – Sends the value

specified in the Input Def field to the AO

defined in the Output Def and forces the 4-20

mA signal to update.

Generate a Pulse at an Interval – Sends a

Pulse Command to the DO defined in the

Output Def parameter when the flow rate

defined in the Input Def parameter

accumulates a value greater than the value

specified in the DO Out Pulse Interval.

Input Def

Defines the input used in the mode selected.

Time Basis

Defines the frequency of the flow rate in the

Input Definition. Available time periods are

Second, Minute, Hour and Day. For all modes

besides the 4-20 mA output mode.

Output Def

Sets the output to be used. In the 4-20 mA

Output and Pulse Output mode this should

point to an AO or a DO. In the Flow

Accumulation mode it should point to a

softpoint value. The selected softpoint value

defines the first of seven consecutive values

to store the following accumulators:

1 = Today

2 = Yesterday

3 = This Month

4 = Previous Month

5 = Running Accum

6 = This Hour

7 = Previous Hour

Update Interval

Defines how often the accumulators update

their associated values in the ROC. The

calculation always runs every second, but to

save MPU load the program only writes

updated accumulator values to the ROC

points based on this parameter.

Contact Hour

Sets the hour, in military times, at which the

accumulators roll up the Days Accumulated

Flows.

Cur Month

Shows the chronological number of the

current month. Valid values are 1-12.

Cur Day

Shows the chronological number of the

current day. Valid values are 1-31.

Page 40

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

36 Configuration Revised January-2017

Field

Description

Flags

Provides functions for managing and clearing

the accumulator values being stored in an

associated SoftPoint.

Click to select the option:

Normal Operations – Operates as configured

Force End Of Day – Forces all Accumulators

to roll up at that instant and restart their daily

at zero

Force end of Month – Forces all Accumulators

to roll up at that instance, including Monthly

Flush Running Accum – Clears the daily

Accumulator but does not roll up

Cold Start Accumulator Set – Clears all

Accumulators

3. Click Apply to save any changes you have made to this screen.

4. Proceed to Section 3.2.4 to configure the PMSC Utilities Screen –

Alarm Blocks tab.

3.2.4 PMSC Utilities Screen – Alarm Blocks Tab

Use this screen to configure the alarm point of the Surface Control

manager program. Use this utility to set three alarm point mechanisms

per instance.

To access this screen:

1. Select the Alarm Blocks tab on the PMSC Utilities screen. The

Alarm Blocks screen displays:

Page 41

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 37

Figure 3-7. PMSC Utilities Screen – Alarm Blocks tab

2. Review the values in the following fields:

Field

Description

Alarm Tag

Sets a 10-character (for the ROC800) or an 8-

character (for the FB107) alarm identification.

Alarm Point

Definition

Click to designate the TLP for the alarm to

be monitored. This field shows a valid entry

(not Undefined) the value of the specified

point will be displayed in the field on the right

(Alarm Point Current Value) whether alarming

is enabled or not.

Alarm Point

Current Value

Displays the value of the point specified to the

left (Alarm Point Definition). If the Alarm Point

Definition is Undefined or Scanning is set to

“Disable” the current value or any user-

entered value here will remain unchanged.

Page 42

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

38 Configuration Revised January-2017

Field

Description

Alarm Enable

Selects to Enable the Alarm Point Current

Value is monitored for alarm conditions and

the alarm code can be a positive number (an

alarm condition exists).

Selects to Disable the alarm code will always

be zero.

Alarm Type

Selects to Analog, the Alarm Point Current

Value is compared to each of the four

possible alarm type setpoints (Low, Low Low,

High, High High) for setting alarms along with

the Deadband value for clearing alarms.

Selects to Boolean, the Alarm Point Current

Value is compared Boolean Alarm. A Boolean

Alarm is generated when the current value

equals the Boolean Alarm “Set on” value.

Note: Zero and One are the only legal values

for the Boolean Alarm Type. If the

Alarm Point Current value can possibly

be any other value the Alarm Type

should be set to Analog as no Boolean

alarm will be generated for values no

exactly equal to the Boolean Alarm

“Set on” value.

SRBX

RBX on Set

Selects to Enable an RBX attribute is set for

the alarm when any “Alarm Set” is logged.

This causes any Comm Port with SRBX Mode

Enabled to process the alarm setting.

Selects Disable….

RBX on Clear

Selects to Enable an RBX attribute is set for

the alarm when any “Alarm Clear” is logged.

This causes any Comm Port with SRBX Mode

Enabled to process the alarm setting.

Selects Disable….

Scanning

Selects to Enable the Alarm Point Current

Value is the value of the point defined in the

Alarm Point Definition field.

Selects to Disable the program and will not

change the Alarm Point Current Value.

High High

Sets the High High alarm value. The Alarm

Point Current Value is greater than or equal to

the High High value. The alarm remains in

effect until the Alarm Point Current Value

goes less than High High Value minus the

Deadband value.

Note: This field displays only if you select

Analog in the Alarm Type.

High

Sets the High alarm value. The Alarm Point

Current Value is greater than or equal to the

High value. The alarm remains in effect until

the Alarm Point Current Value goes less than

High Value minus the Deadband value.

Note: This field displays only if you select

Analog in the Alarm Type.

Page 43

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 39

Field

Description

Low

Sets the Low alarm value. The Alarm Point

Current Value is less than or equal to the Low

value. The alarm remains in effect until the

Alarm Point Current Value goes greater than

Low Value plus the Deadband value.

Note: This field displays only if you select

Analog in the Alarm Type.

Low Low

Sets the Low Low alarm value. The Alarm

Point Current Value is less than or equal to

the Low Low value. The alarm remains in

effect until the Alarm Point Current Value

goes greater than Low Low Value plus the

Deadband value.

Note: This field displays only if you select

Analog in the Alarm Type.

Boolean Alarm

Sets the boolean value that will determine

when an alarm is triggered. For example, if

the input alarm point definition is a discrete

value where normal operation is a value of

“0”, the option for “Set on 1” should be

selected.

Note: This field displays only if you select

Boolean in the Alarm Type.

Deadband

Sets the Deadband value.

Note: This field displays only if you select

Analog in the Alarm Type.

Alarm Code

This display-only field shows the alarm

values:

1 = Low Alarm

2 = Low Low Alarm

4 = High Alarm

8 = High High Alarm

32 = Boolean Alarm

128 = Manual Alarm

3. Click Apply to save any changes you have made to this screen.

4. Proceed to Section 3.2.5 to configure the PMSC Utilities Screen

– Action Block Domain Statuses tab.

3.2.5 PMSC Utilities Screen – Action Block Domain Statuses Tab

The Action Block Domain Statuses reports the health of other

associated user programs (if installed), such as Tank Manager or Well

Optimization. To access this screen:

To access this screen:

1. Select the Action Block Domain Statuses tab on the PMSC

Utilities screen. The Action Block Domain Statuses screen displays:

Page 44

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

40 Configuration Revised January-2017

Figure 3-8. PMSC Utilities Screen – Action Block Domain Statuses tab

2. Review the values in the following fields:

Field

Description

Point Number

Selects the logical instance you want to

configure.

Page 45

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 41

Field

Description

Tank Mgr Well #

1

Shows the status of any Tank Manager

Allocation Wells. The number beside the field

name refers to the point number of the Tank

Manager allocation well instance you are

viewing. This is not necessarily related to the

PMSC Effect or utilities on this display (of the

same logical instance). If you change the

Point Number, this field can provide the

status of up to 4, 8, or 12 wells, depending on

the version of the Tank Manager program you

install.

Note: The Tank Manager program supports

up to 12 allocation wells, thus the

numbers greater than 12 have no

configuration effect.

SSD Set

This section is checked if the System Shut

Down (SSD) is set for this well.

PSD Set

This section is checked if the Permanent

Shutdown (PSD) is set to this well.

TSD Set

This section is checked if the Temporary

Shutdown (TSD) is set to this well.

Trip Code

Sets the numerical code of First Out action

block that tripped this instance.

Tank Mgr Load

Out # 1

Shows the status of any Tank Manager Truck

Load Out Terminals. The number beside the

field name refers to the point number of the

Tank Manager Load Out Terminal instance

you are viewing. This is not necessarily

related to the PMSC Effect or utilities on this

display (of the same logical instance). If you

change the Point Number, this field can

provide the status of up to 6 loading terminals

in the ROC800 and 2 loading terminals in the

FB107.

Note: The Tank Manager program supports

up to 2 (for FB107) or 6 (for ROC800)

loading terminals, thus the numbers

greater than 2 (for FB107) or 6 (for

ROC800) have no configuration effect.

SSD Set

This section is checked if the System Shut

Down (SSD) is set to this Load Terminal.

PSD Set

This section is checked if the Permanent

Shutdown (PSD) is set to this Load Terminal.

TSD Set

This section is checked if the Temporary

Shutdown (TSD) is set to this Load Terminal.

Trip Code

Sets the numerical code of First Out Action

Block that tripped this instance.

Page 46

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

42 Configuration Revised January-2017

Field

Description

Well Opt Mgr

Well # 1

Shows the status of any Well Optimization

Manager Wells. The number beside the field

name refers to the point number of the well

instance you are viewing. This is not

necessarily related to the PMSC Effect or

utilities on this display (of the same logical

instance). As you change the Point Number,

this field can provide the status of up to 4, 8,

or 12 wells, depending on the version of the

Well Optimization Manager program you

install.

Note: The Well Optimization Manager

program supports up to 12 optimization

wells, thus the numbers greater than

12 have no configuration effect.

SSD Set

This section is checked if the System Shut

Down (SSD) is set to this well.

PSD Set

This section is checked if the Permanent

Shutdown (PSD) is set to this well.

TSD Set

This section is checked if and (Temporary

Shutdown) TSD is set to this well.

Trip Code

Sets the numerical code of First Out Action

Block that tripped this instance.

PM v3.3x Well # 1

Shows the status of any Production Manager

version 3 Wells. The number beside the field

name refers to the point number of the well

instance you are viewing. This is not

necessarily related to the PMSC Effect or

utilities on this display (of the same logical

instance). If you change the Point Number at

the top of this display, this field can provide

the status of up to 4 wells provided by

Production Manager version 3.

Notes:

The Well Optimization Manager program

supports up to 4 optimization wells, thus

the numbers greater than 4 have no

configuration effect.

These domain statuses are provided for

backwards compatibility with previous

versions of Production Manager. If

Production Manager version 3.3x is in

use, then these domain statuses are

applicable. If Well Optimization Manager

is in use (or no Well Optimization

program), then these domain statuses

are NOT applicable. This is not valid if

you install both the PM v3.3x and the

Well Optimization Manager programs in

the same unit.

SSD Set

This section is checked if the System Shut

Down (SSD) is set to this well.

PSD Set

This section is checked if the Permanent

Shutdown (PSD) is set to this well.

Page 47

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 43

Field

Description

TSD Set

This section is checked if and Temporary

Shutdown (TSD) is set to this well.

Trip Code

Sets the numerical code of First Out Action

Block that tripped this instance.

PMSC Effect # 1

Shows the domain status of PMSC Effects.

The number beside the field name refers to

the point number of the instance or utilities

you view. This can be up 12, 24, or 36

depending on your user program version. See

program specifics note in Section 1.3.

SSD Set

This section is checked if the System Shut

Down (SSD) is set to this Effect.

PSD Set

This section is checked if the Permanent

Shutdown (PSD) is set to this Effect.

TSD Set

This section is checked if the Temporary

Shutdown (TSD) is set to this Effect.

Trip Code

Sets the numerical code of First Out action

block that tripped this instance.

3. Click Apply to save any changes you have made to this screen.

4. Proceed to Section 3.3 to configure the PMCB Calculation Blocks.

3.3 PMCB Calculation Blocks

The PMCB Calculation Blocks display allows the configuration of up to

four inputs/input arrays and up to three calculations per instance. A 10-

character tag field is provided for each input and calculation.

To access this screen:

1. From the Directory Tree, select User Program > Program #1,

PMSC_v407_00_48blk.

2. Double-click Display #218, PMCB Calculation Blocks.

Note: This section shows how to access the access the PMCB

Calculation Blocks screen for the ROC800. To access the

PMCB Calculation Blocks for FB107, double-click Display

#27, PMCB Calculation Blocks or Display #39, PMCB

Calculation Blocks.

3. Double-click #1, Calculation Block 1. Select the Calc Blocs tab

and the screen displays:

Page 48

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

44 Configuration Revised January-2017

Figure 3-9. PMCB Calculation Blocks- Calc Blocks tab

Page 49

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

Revised January-2017 Configuration 45

4. Review and complete the values in the following fields:

Field

Description

Enabled

Executes calculations, when selected. Any

defined inputs will be updated (displayed)

whether the “Enabled” checkbox is checked or

not.

Default: Unchecked

Description

Sets a 20-character calculation instance

identification.

Input Variables

Description

Sets the input (defined at Input Definition).

Input Definition

Defines the inputs to be used in the

calculation.

The input selected is either a single data point

or the starting parameter of an array of data

points.

Default: Undefined

Qty in Array

Sets the quantity of data points for the defined

input. Arrays are automatically indexed by

parameter (softpoints and FST registers) or by

instance (all others). If you enter a number

that exceeds the maximum quantity permitted,

the program will change the entry to the

maximum quantity.

Default: 1

Array quantity limits are:

1. Logical (Instance) Indexing:

I/O Card Point Types: Currently limited to

the quantity of channels on the physical

IO card.

Non-I/O Card Point Types: Limited to the

total number of instances and not to

exceed 40 bytes (example 10 floats

maximum).

2. Parameter Indexing:

Soft Point parameters and FST Registers

(all other arrays use logical indexing): All

contiguous parameters must be the same

data type as the defined parameter and not

exceed 40 bytes.

Effectively: 50 doubles, 10 floats, 10

shorts or 10 bytes

Value

Sets the value of the defined data point. If the

array quantity is greater than one, this field

automatically hides itself.

Calculation

Calculation

String

You enter a 40-character free-form text

mathematical equation or logical expression.

If you enter an invalid expression, a carat will

appear under the left most invalid character.

Validated

Validates each calculation string upon

change. If the string is valid the program

checks this box and if “Enabled” is checked,

the calculation is performed.

Page 50

Surface Control Manager Program User Manual (ROC800-Series and FloBoss 107)

46 Configuration Revised January-2017

Field

Description

Error Number

Displays the character position of the first

error (left to right) if the calculation string is

invalid. If the calculation string is valid, the

value is set to zero.

Char

Displays the invalid character reference in the

“Error Number” filed. When the calculation

string is valid, this field is blank.

Results

Results