Page 1

Remote Automation Solutions

Part D301053X012

September 2019

ROC Protocol Specifications Manual

Page 2

ROC Protocol Specifications Manual

ii Revised September-2019

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to

correctly install, configure, program, calibrate, and trouble-shoot your Emerson equipment provides

your engineers and technicians with the skills and confidence to optimize your investment. Remote

Automation Solutions offers a variety of ways for your personnel to acquire essential system

expertise. Our full-time professional instructors can conduct classroom training at several of our

corporate offices, at your site, or even at your regional Emerson office. You can also receive the same

quality training via our live, interactive Emerson Virtual Classroom and save on travel costs. For our

complete schedule and further information, contact the Remote Automation Solutions Training

Department at 800-338-8158 or email us at education@emerson.com.

Page 3

ROC Protocol Specifications Manual

Revised September-2019 Contents iii

Contents

Chapter 1 – Introduction 1-1

1.1 Manual Organization ..................................................................................................................... 1-1

1.2 General Protocol Message Format ............................................................................................... 1-2

1.3 Calculating Data Offsets ............................................................................................................... 1-3

Chapter 2 – Opcodes 2-1

2.1 Opcode Overview .......................................................................................................................... 2-1

2.2 Opcode 0 – General Update ......................................................................................................... 2-4

2.3 Opcode 2 ....................................................................................................................................... 2-8

2.4 Opcode 6 ....................................................................................................................................... 2-9

2.4.1 Opcode 6: ROC300-Series with ROCPAC ..................................................................... 2-9

2.4.2 Opcode 6: ROC300-Series (w/FlashPAC) and FloBoss 407 ....................................... 2-10

2.4.3 Opcode 6: FloBoss 103/104, FloBoss 500-Series, and RegFlo ................................... 2-12

2.4.4 Opcode 6: FloBoss 107 ................................................................................................ 2-14

2.5 Opcode 7 ..................................................................................................................................... 2-17

2.6 Opcode 8 ..................................................................................................................................... 2-18

2.7 Opcode 10 ................................................................................................................................... 2-19

2.8 Opcode 11 ................................................................................................................................... 2-20

2.9 Opcode 17 ................................................................................................................................... 2-21

2.10 Opcode 18 ................................................................................................................................... 2-22

2.11 Opcode 24 ................................................................................................................................... 2-23

2.12 Opcode 102 ................................................................................................................................. 2-23

2.13 Opcode 103 ................................................................................................................................. 2-24

2.14 Opcode 105 ................................................................................................................................. 2-26

2.15 Opcode 107 ................................................................................................................................. 2-28

2.16 Opcode 120 ................................................................................................................................. 2-28

2.16.1 Opcode 120: ROC300-Series and FloBoss 407 ........................................................... 2-29

2.16.2 Opcode 120: FloBoss 500-Series, FloBoss 100-Series, and RegFlo........................... 2-29

2.17 Opcode 121 ................................................................................................................................. 2-31

2.18 Opcode 122 ................................................................................................................................. 2-33

2.19 Opcode 123 ................................................................................................................................. 2-37

2.20 Opcode 126 ................................................................................................................................. 2-39

2.21 Opcode 128 ................................................................................................................................. 2-40

2.22 Opcode 130 ................................................................................................................................. 2-42

2.22.1 Opcode 130: ROC300-Series, FloBoss 407, and FloBoss 500-Series ........................ 2-43

2.22.2 Opcode 130: FloBoss 100-Series and RegFlo ............................................................. 2-44

2.23 Opcode 131 ................................................................................................................................. 2-44

2.24 Opcode 132 ................................................................................................................................. 2-45

2.25 Opcode 133 ................................................................................................................................. 2-45

2.26 Opcode 136 ................................................................................................................................. 2-46

2.27 Opcode 148 ................................................................................................................................. 2-47

2.28 Opcodes 150 and 151 ................................................................................................................. 2-48

2.29 Opcode 158 ................................................................................................................................. 2-48

2.30 Opcode 160 ................................................................................................................................. 2-49

2.31 Opcode 162 ................................................................................................................................. 2-49

2.32 Opcode 165 ................................................................................................................................. 2-49

2.33 Opcode 166 ................................................................................................................................. 2-51

2.34 Opcode 167 ................................................................................................................................. 2-52

2.35 Opcode 170 ................................................................................................................................. 2-53

2.36 Opcode 171 ................................................................................................................................. 2-54

Page 4

ROC Protocol Specifications Manual

iv Contents Revised September-2019

2.37 Opcode 180 ................................................................................................................................. 2-55

2.38 Opcode 181 ................................................................................................................................. 2-56

2.39 Opcode 200 ................................................................................................................................. 2-56

2.40 Opcodes 224 and 225 ................................................................................................................. 2-57

2.41 Opcode 255 – Error Indicator ...................................................................................................... 2-58

2.42 Communications Drivers ............................................................................................................. 2-63

Chapter 3 – Parameter Lists for Point Types 3-1

3.1 ROC Point Types and Data Types ................................................................................................ 3-1

3.1.1 Type, Location/Logical, and Parameter (TLPs) .............................................................. 3-6

3.1.2 Logical/Point Number Details ......................................................................................... 3-6

3.1.3 User Defined Point Types ............................................................................................... 3-7

3.1.4 Bit Assignments .............................................................................................................. 3-7

3.2 ROC Point Type Parameter Defintions ......................................................................................... 3-8

3.2.1 Point Type 0 .................................................................................................................. 3-10

3.2.2 Point Type 1: Discrete Input Parameters ...................................................................... 3-12

3.2.3 Point Type 2: Discrete Output Parameters ................................................................... 3-14

3.2.4 Point Type 3: Analog Input Parameters ........................................................................ 3-16

3.2.5 Point Type 4: Analog Output Parameters ..................................................................... 3-25

3.2.6 Point Type 5: Pulse Input Parameters .......................................................................... 3-27

3.2.7 Point Type 6: Proportional, Integral & Derivative (PID) Parameters ............................ 3-30

3.2.8 Point Type 7: AGA Flow Parameters ............................................................................ 3-33

3.2.9 Point Type 8: Standard History Parameters ................................................................. 3-38

3.2.10 Point Type 9: Local Display Panel Parameters ............................................................ 3-46

3.2.11 Point Type 10: AGA Flow Calculation Values .............................................................. 3-47

3.2.12 Point Type 11: Tank Parameters .................................................................................. 3-49

3.2.13 Point Type 12: ROC Clock Parameters ........................................................................ 3-50

3.2.14 Point Type 13: System Flags ........................................................................................ 3-52

3.2.15 Point Type 14: Communications Ports ......................................................................... 3-58

3.2.16 Point Type 15: System Variables (ROC Information) ................................................... 3-62

3.2.17 Point Type 16: FST Parameters ................................................................................... 3-65

3.2.18 Point Type 17: Soft Point Parameters .......................................................................... 3-67

3.2.19 Point Type 18: Analog Input Calibration Parameters for ROCPAC .............................. 3-69

3.2.20 Point Type 19: Database Parameters ........................................................................... 3-70

3.2.21 Point Type 20: ROC Tasks (ROC300-Series and FloBoss 407) .................................. 3-72

3.2.22 Point Type 20: Diagnostic Parameters (FloBoss 107) .................................................. 3-73

3.2.23 Point Type 21: Information for User Defined Points ..................................................... 3-94

3.2.24 Point Types 32 & 33: Modem Configuration -COMM 1 (Point Type 32) and LOI

and COMM 2 (Point Type 33) (ROC300-Series and FloBoss 407) ............................. 3-95

3.2.25 Point Types 34 & 37: Modbus Configuration -COMM 1 (Point Type 34) and LOI

and COMM 2 (Point Type 37) ...................................................................................... 3-96

3.2.26 Point Types 35 & 38: Function Configuration -COMM 1 (Point Type 35) and LOI

and COMM 2 (Point Type 38) ...................................................................................... 3-98

3.2.27 Point Types 36 & 39: Host Configuration - COMM 1 (Point Type 36) and LOI

and COMM 2 (Point Type 39) .................................................................................... 3-100

3.2.28 Point Type 40: Multi-variable Sensor Parameters ...................................................... 3-102

3.2.29 Point Type 41: Run Parameters ................................................................................. 3-107

3.2.30 Point Type 42: Extra AGA Run Parameters ............................................................... 3-113

3.2.31 Point Type 43: User List Parameters .......................................................................... 3-116

3.2.32 Point Type 44: Radio Power Control Parameters ....................................................... 3-118

3.2.33 Point Type 45: Meter Calibration and Sampler Parameters ....................................... 3-120

3.2.34 Point Type 46: Meter Configuration Parameters ........................................................ 3-122

3.2.35 Point Type 47: Meter Flow Parameters ...................................................................... 3-135

3.2.36 Point Type 48: PID Control Parameters ..................................................................... 3-141

3.2.37 Point Type 52: Battery Performance ........................................................................... 3-145

3.2.38 Point Type 53: Modbus Configuration Parameters ..................................................... 3-146

3.2.39 Point Type 54: Modbus Function Tables .................................................................... 3-147

Page 5

ROC Protocol Specifications Manual

Revised September-2019 Contents v

3.2.40 Point Type 55: Modbus Special Function Tables ....................................................... 3-149

3.2.41 Point Type 56: Analog Input Calibration Parameters.................................................. 3-154

3.2.42 Point Type 56: Analog Input Calibration Parameters (for RegFlo) ............................. 3-156

3.2.43 Point Type 57: Keypad/Login Securities Parameters ................................................. 3-157

3.2.44 Point Type 58: Revision Information ........................................................................... 3-160

3.2.45 Point Type 59: Program Flash Control Parameters .................................................... 3-161

3.2.46 Point Type 80: Ethernet/USB Configuration Parameters (FloBoss 107) .................... 3-163

3.2.47 Point Type 80: Regulator Parameters (RegFlo Only) ................................................. 3-168

3.2.48 Point Type 81: Logic Alarm Parameters ..................................................................... 3-172

3.2.49 Point Type 83: User Analog Values ............................................................................ 3-174

3.2.50 Point Type 84: User Discrete Values .......................................................................... 3-175

3.2.51 Point Type 85: HART Parameters (FloBoss 107) ....................................................... 3-177

3.2.52 Point Type 86: Extended History Parameters ............................................................. 3-190

3.2.53 Point Type 88: BLM User List Parameters ................................................................. 3-198

3.2.54 Point Type 89: Chart User List Parameters ................................................................ 3-199

3.2.55 Point Type 93: License Key Parameters .................................................................... 3-200

3.2.56 Point Type 94: User C Program Parameters .............................................................. 3-201

3.2.57 Point Type 98: Extended Soft Point Parameters ........................................................ 3-203

3.2.58 Point Type 117: Modbus Configuration Parameters ................................................... 3-205

3.2.59 Point Type 118: Modbus Register Mapping ................................................................ 3-208

3.2.60 Point Type 120: Modbus Master Modem Configuration ............................................. 3-217

3.2.61 Point Type 121: Modbus Master Table ....................................................................... 3-218

3.2.62 Point Type 122: DS800 Control and Diagnostic Parameters ..................................... 3-227

3.2.63 Point Type 172: RTU Network Discovery List Point Type .......................................... 3-229

3.2.64 Point Type 173: Network Commissioned List Point Type ........................................... 3-230

3.2.65 Point Type 174: Network Export Data ........................................................................ 3-232

3.2.66 Point Type 175: Network Import Data ......................................................................... 3-233

3.2.67 Point Type 176: IEC62591 Live List Parameters ........................................................ 3-234

3.2.68 Point Type 177: IEC62591 Commissioned List Parameters ...................................... 3-235

Chapter 4 – CRC-16 Code and Example 4-1

Chapter 5 – IEEE Floating Point Format 5-1

Chapter 6 – Spontaneous Report-By-Exception Example 6-1

Chapter 7 – Device-to-Device Communications 7-1

Index I-1

Page 6

ROC Protocol Specifications Manual

vi Contents Revised September-2019

[This page is intentionally left blank.]

Page 7

ROC Protocol Specifications Manual

Revised September-2019 Introduction 1-1

Chapter 1 – Introduction

This manual provides information required to understand the

specifications for the ROC protocol. The intended use is for developing

communication drivers to interface with a Remote Operations

Controller (ROC), FloBoss, and RegFlo. This manual is intended for

users experienced in the development of communication drivers. The

protocol provides access to database configuration, real-time clock,

event and alarm logs, and historically archived data.

The ROC database is broken into individual parameters. Each database

parameter is uniquely associated by parameter number and point type.

See Chapter 3, Parameter Lists for Point Types, for detailed

information.

Note: For simplicity, this manual uses the terms FloBoss 100-Series to

encompass the FloBoss 103, FloBoss 104, and FloBoss 107 and

FloBoss 500-Series to encompass both the FloBoss 503 and

FloBoss 504. Any differences, if significant, are noted where

they occur. Also, this manual uses ROC generically for both the

Remote Operations Controller and FloBoss products. In most

cases, the products are identical in operation. Unless otherwise

noted, the descriptions and procedures apply to all devices using

the ROC protocol.

1.1 Manual Organization

This manual is organized into the following chapters:

Chapter

Description

Chapter 1

Introduction

Describes this manual and provides a summary of

the general protocol message format, summary of

each opcode, and how to calculate data offsets.

Chapter 2

Opcodes

Lists each opcode the ROC protocol uses.

Chapter 3

Parameter Lists for

Point Types

Describes ROC point types and data types.

Chapter 4

CRC-16 Code and

Examples

Provides information concerning the cyclical

redundancy check the ROC protocol uses.

Chapter 5

IEEE Floating Point

Format

Provides information about the binary representation of

floating-point numbers.

Chapter 6

Spontaneous Reportby-Exception

Example

Provides an example of Spontaneous Report-byException (RBX or RBX).

Page 8

ROC Protocol Specifications Manual

1-2 Introduction Revised September-2019

Chapter

Description

Chapter 7

Device to Device

Communications

Provides information detailing store and forward

options in the ROC.

Index

Provides an alphabetic listing of items and topics

contained in this manual.

1.2 General Protocol Message Format

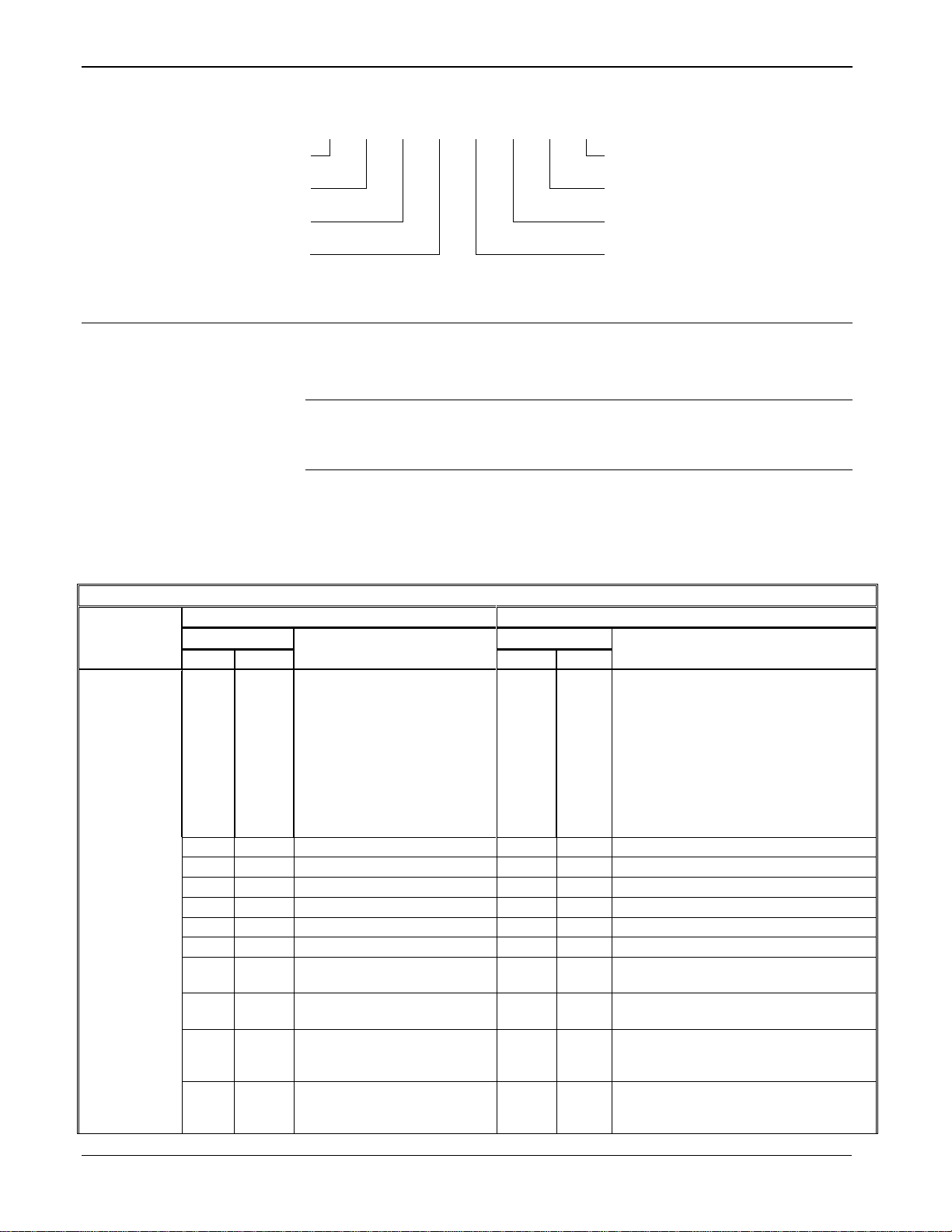

Figure 1-1 shows the various ROC and host protocol message formats.

General Message Format - Station ‘A’ Polling Station ‘B’ for Data/Action:

Destination (B)

Source (A)

Opcode

Data

Length

m Data Bytes

CRC

unit

group

unit

group

# of

bytes

d1

d2

d3 – – – –

dm

lsb

msb

General Message Format - Station ‘B’ Responding to Station ‘A’:

Destination (A)

Source (B)

Opcode

Data

Length

n Data Bytes

CRC

unit

group

unit

group

# of

bytes

d1

d2

d3 – – – –

dn

lsb

msb

Figure 1-1. General Message Format

A message generally contains the following fields, in order from left to

right:

Field

Description

Destination

Specifies the address for the destination device.

Destination has two components:

Unit

One-byte unit code for the station

address. The unit code for a ROC

address is user-configurable. For a host,

this must be a unique number. 0

represents “broadcast within group” and

240 is the “direct connect address.”

Group

Indicates the group code for the station

address. This is user-configurable and

usually set to 2.

Source

Specifies the address for the source device. Source

has two components:

Unit

One-byte unit code for the station

address. The unit code for a ROC

address is user-configurable. For a host,

this must be a unique number. 0

represents “broadcast within group” and

240 is the “direct connect address.”

Group

Indicates the group code for the station

address. This is user-configurable and

usually set to 2.

Opcode

Defines the operation code (opcode) action to

perform.

Page 9

ROC Protocol Specifications Manual

Revised September-2019 Introduction 1-3

Field

Description

# of bytes

Indicates the number of bytes in the data byte field,

consisting of the path, desired opcode, number of

data bytes for the desired message, and the desired

message itself.

Data Bytes

Contains messages of varying lengths, consisting of

the path, desired opcode, number of data bytes for

the desired message, and the message itself.

CRC

Confirms validity of message transmission.

lsb

Least significant byte.

msb

Most significant byte.

Messages are of flexible length. The first six data bytes are used for the

header information including: destination, source, opcode, and data

length (number of bytes). The length of a message equals the number of

data bytes transmitted plus eight overhead bytes (header information

and CRC).

The minimum message length is eight bytes if the number of data bytes

is zero (no data bytes transmitted). The maximum message length is 248

bytes (240 bytes of data). A “nibble” is a four-bit unit or half a byte.

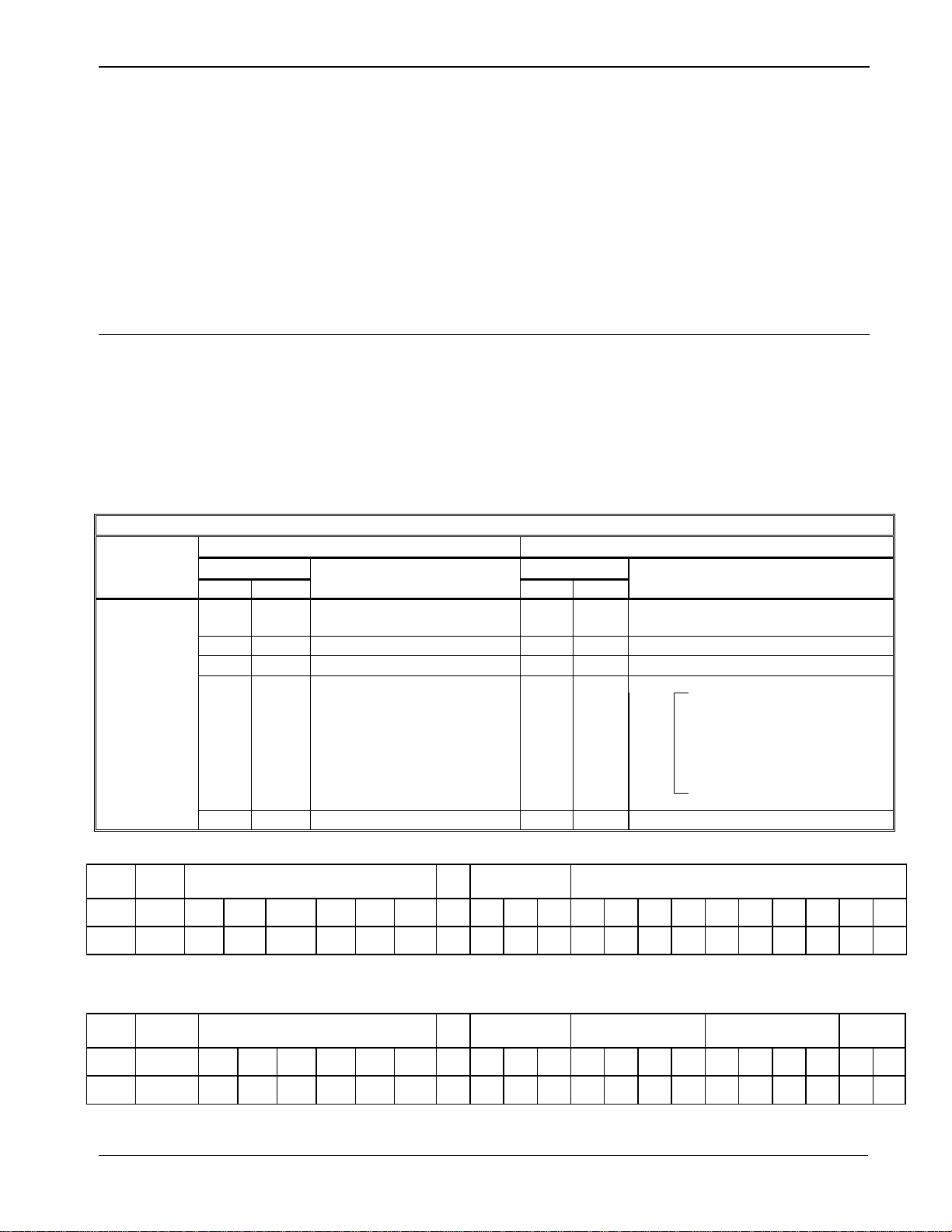

Figure 1-2 provides examples of the messages exchanged if the host

requests the current time and date from ROC 13 of Group 5.

Host Request to ROC:

ROC Address

Host Address

Opcode

Data

Length

CRC

unit

group

unit

group

–

# of

bytes

lsb

msb

13 5 1 0 7 0 l

m

ROC Response to Host:

Host Address

ROC Address

Opcode

Data

Length

8 Data Bytes

CRC

unit

group

unit

group

–

# of

bytes

d1

d2

d3 – – – –-

dn

lsb

msb

1 0 13 5 7

8

sec

min

hr

day

mo

yr

lyr

dwk l m

Figure 1-2. Request/Response Example

Note: Addresses 240,240 and 0,x are reserved and should not be used.

1.3 Calculating Data Offsets

A data byte offset is the offset (zero-based) from the beginning of a

transmit or receive buffer for the data items that comprise the opcode

data. The offset of the first data item is always 6 to allow for the header

information (bytes 0-5).

Page 10

ROC Protocol Specifications Manual

1-4 Introduction Revised September-2019

Certain data offset values are determined based on the ROC

configuration, such as for Opcode 0. The data byte offset for each item

may be calculated. To calculate the next data offset value, add the

previous offset value to the length of the previous data item:

Offset = Previous Offset + Length of Previous Data Item

Page 11

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-1

Chapter 2 – Opcodes

This chapter details each ROC protocol opcode.

2.1 Opcode Overview

Table 2-1 briefly describes each opcode. The tables in this section

provide detailed descriptions of the various opcodes used. For each

opcode, a brief description of the data bytes is provided. In some cases,

the number of data bytes returned for an opcode varies. For example,

Opcode 0, a full update, always returns certain input/output (I/O)

information along with optionally specified data.

Certain opcodes only send data and do not receive data back from the

ROC. For example, Opcode 8 requests the ROC to set the time and date.

The host transmits six to nine data bytes defining the new time and date.

The ROC resets the time and date and sends back an acknowledgment

in which the opcode is repeated, but no data bytes are transmitted back.

All acknowledgments are 8-byte messages that repeat the opcode

received, but do not transmit any data bytes.

Opcode 255 is an error message indicator. This is also an 8-byte

message with no data bytes included. The opcode is set to 255 to

indicate the message received by the ROC had valid Cyclical

Redundancy Check (CRC), but contained invalid parameters. For

example, if a request was made for information on Analog Input #11,

but the ROC was configured for only eight analog inputs (0 to 7), the

ROC would respond back with the 8-byte message with the opcode

equal to 255 (error).

The number of analog inputs varies from ROC to ROC. This variability

is indicated by listing the first analog input and indicating the remaining

analog inputs by a period (“.”). In the following tables, a period in either

the Data byte(s) column or the Description of Data column indicates a

repetition of the proceeding item for the necessary number of instances.

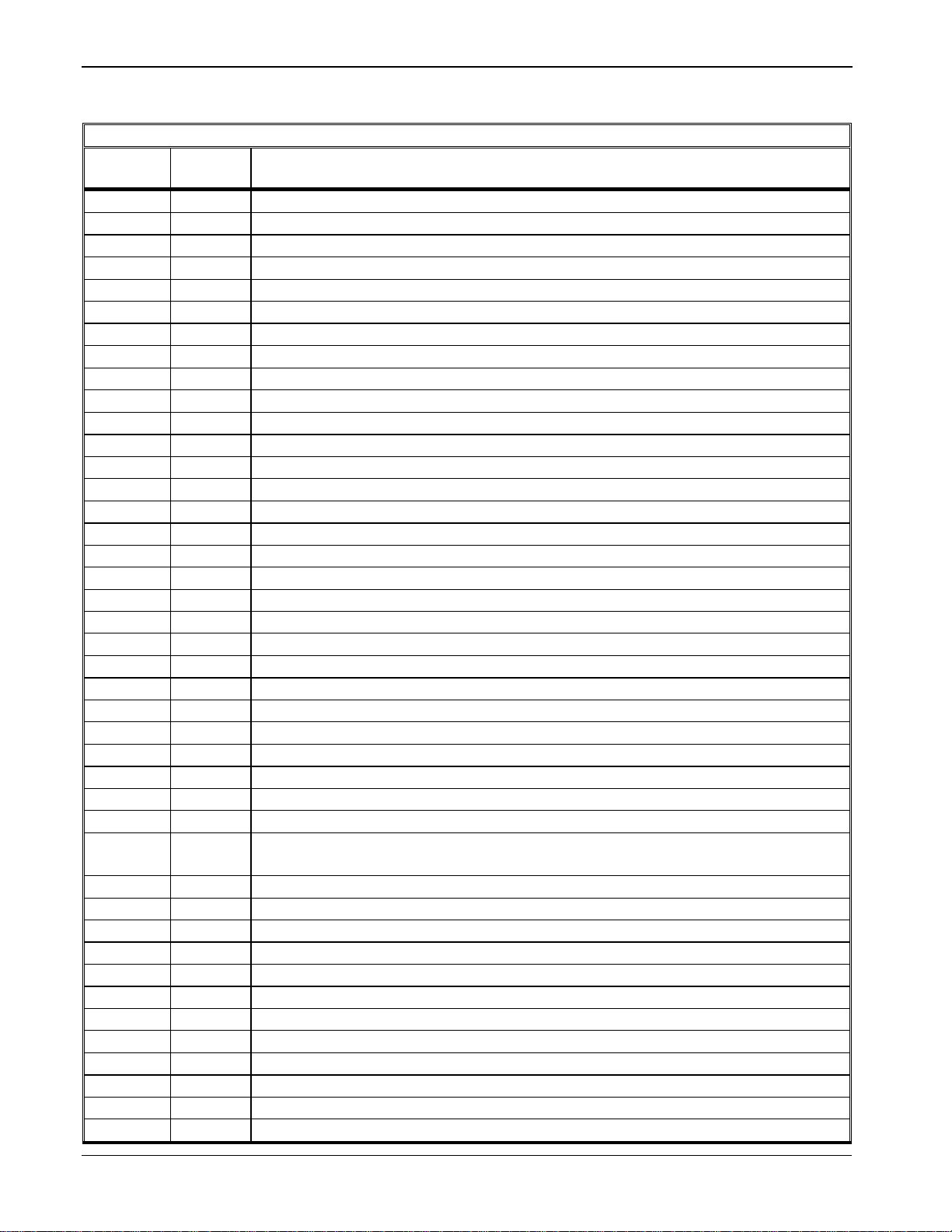

Table 2-1. Summary of Opcodes

Opcode

Description

0

Sends general update such as I/O update, gas flows, and control loop status.

2

Sends 240 characters (starting with 0, ending with 239) of test data.

6

Sends ROC configuration with 20 data bytes defining ROC configuration.

7

Sends current time and date.

8

Sets new time and date.

10

Sends data from configurable opcode tables.

11

Sets data in configurable opcode tables.

17

Sets operator identification.

18

Logs event.

19

RESERVED

24

Stores and forwards.

80

RESERVED

Page 12

ROC Protocol Specifications Manual

2-2 Opcodes Revised September-2019

Opcode

Description

100

Reads user-defined point information (Command 11)

102

Sets system variables.

103

Sends system information such as on/off times, manual/alarm status, firmware version, and current time

and date.

105

Sends history point definition, min/max data, and current values for specified history point.

107

Sends tag and current history period for specified history points.

120

Sends pointers for alarm, event, and history logs.

121

Sends specified number of alarms starting at specified alarm pointer.

122

Sends specified number of events starting at specified event pointer.

123

Reads user template data.

126

Sends last 60 minutes of data for specified history point.

128

Sends archived daily and hourly data for the currently selected day and month.

130

Sends archived hourly and daily data for specified history point starting at specified history pointer.

131

Sends specified number of event sequence numbers starting at specified pointer (Industry Canada).

132

Clears specified number of event sequence numbers starting at specified pointer (Industry Canada).

133

Sends number of writable events (Industry Canada).

136

Requests multiple history points for multiple time periods

148

Reads 240 bytes of data from a specified memory address.

149

RESERVED

150

Sends number of rows for specified display.

151

Sets number of rows for specified display.

158

Sends configuration table.

160

Sends the entire structure for a specified Function Sequence Table (FST).

162

Sets a single parameter.

165

Sets or sends current configurable historical data.

166

Sets specified contiguous block of parameters.

167

Sends specified contiguous block of parameters.

170

Sends current values of specified I/O points.

171

Sets parameters for specified point.

180

Sends specified parameters.

181

Sets specified parameters.

190 & 195

RESERVED

200

Performs HART Pass-thru

224

Sends Spontaneous Report-by-Exception (SRBX or RBX) message to host.

225

Acknowledges Spontaneous Report-by-Exception message from ROC.

255

Transmits error messages by ROC in response to a request with invalid parameters or format.

Page 13

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-3

Table 2-2. Opcode Support by Product

Communication

Opcode

ROC300-Series

with ROCPAC

ROC300-Series

with FlashPAC

FloBoss

407

FloBoss

103/104

FloBoss

107

FloBoss

503/504

RegFlo

0

Yes

Yes

Yes

Yes

Yes

Yes

Yes 2 Yes

Yes

Yes

No

No

No

No 6 Yes

Yes

Yes

Yes

Yes

Yes

Yes 7 Yes

Yes

Yes

Yes

Yes

Yes

Yes 8 Yes

Yes

Yes

Yes

Yes

Yes

Yes

10

Yes

Yes

Yes

Yes

Yes

Yes

Yes

11

Yes

Yes

Yes

Yes

Yes

Yes

Yes

17

Yes

Yes

Yes

Yes

Yes

Yes

Yes

18

Yes

Yes

Yes

Yes

Yes

Yes

No

24

Yes

Yes

Yes

Yes

No

Yes

No

102

Yes

Yes

Yes

No

No

No

No

103

Yes

Yes

Yes

Yes

Yes

Yes

Yes

105

Yes

Yes

Yes

Yes

Yes

Yes

No

107

Yes

Yes

Yes

Yes

Yes

Yes

Yes

120

Yes

Yes

Yes

Yes

Yes

Yes

Yes

121

Yes

Yes

Yes

Yes

Yes

Yes

Yes

122

Yes

Yes

Yes

Yes

Yes

Yes

No

123

Yes

Yes

Yes

Yes

Yes

Yes

No

126

Yes

Yes

Yes

Yes

Yes

Yes

No

128

Yes

Yes

Yes

Yes

Yes

Yes

No

130

Yes

Yes

Yes

Yes

Yes

Yes

Yes

131

Yes

Yes

Yes

No

Yes

No

No

132

Yes

Yes

Yes

No

Yes

No

No

133

Yes

Yes

Yes

No

Yes

No

No

136

No

No

No

No

Yes

No

No

148

Yes

Yes

Yes

Yes

Yes

Yes

Yes

150

Yes

Yes

Yes

No

No

No

No

151

Yes

Yes

Yes

No

No

No

No

158

Yes

Yes

Yes

No

No

No

No

160

Yes

Yes

Yes

No

No

No

No

162

Yes

Yes

Yes

No

No

No

No

165

Yes

Yes

Yes

Yes

Yes

Yes

No

166

Yes

Yes

Yes

Yes

Yes

Yes

Yes

167

Yes

Yes

Yes

Yes

Yes

Yes

Yes

170

Yes

Yes

Yes

No

No

No

No

171

Yes

Yes

Yes

No

No

No

No

180

Yes

Yes

Yes

Yes

Yes

Yes

Yes

181

Yes

Yes

Yes

Yes

Yes

Yes

Yes

200

No

No

No

No

Yes

No

No

224

Yes

Yes

Yes

Yes

Yes

Yes

Yes

225

Yes

Yes

Yes

Yes

Yes

Yes

Yes

255

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Page 14

ROC Protocol Specifications Manual

2-4 Opcodes Revised September-2019

2.2 Opcode 0 – General Update

Opcode 0 obtains a general update of the current state for the physical

input/output (I/O) points and the standard application-oriented points.

Although the opcode can be used to retrieve specific I/O and

application-oriented points, the opcode always sends the diagnostic

(system) analog inputs (AI), the discrete inputs (DI), the timed duration

inputs (TDI), and the analog inputs.

Because the FloBoss 407 has no I/O beyond point 6 of Rack A, the

Multi-Variable Sensor (MVS) data is placed starting at point 17 (first

point of Rack B). This data is treated like additional analog inputs.

Sixteen additional AI points support the four possible Multi-Variable

Sensors in Opcode 0. Refer to Table 2-5 for the point number and

description of each of these AI points.

For example, if you are only interested in flow, only set bit 0 (AGA –

American Gas Association) of the second data byte making up the

requested message. The ROC responds by providing the current state

only for the flows, diagnostic analog inputs, discrete inputs, timed

duration inputs, and the analog inputs.

Notes:

▪ Opcode 0 expresses the point number for the physical I/O differently

from that described in Chapter 3. Chapter 3 designates the physical

I/O as point numbers 0 to 63, but Opcode 0 expresses them as point

numbers 1 to 64.

▪ When an opcode describes a point number, the first byte is the point

number and the additional bytes contain the data.

Table 2-3. Opcode 0 – ROC300-Series, FloBoss 407, FloBoss 100-Series, and FloBoss 500-Series

Opcode 0 – ROC300-Series, FloBoss 407, FloBoss 100-Series, and FloBoss 500-Series

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 0:

General

Update

(ROC300Series,

FloBoss 407,

FloBoss 100Series, and

FloBoss 500Series)

6

1

Block number (start with “0”;

request more blocks if

needed)

6 1 Number of Discrete Inputs configured

7 1 Selection (see below)

7 1 Number of Timed Duration Inputs

configured

Note: When requesting

additional blocks, the selection

remains the same as that

requested with block 0.

8

1

Number of Analog Inputs including

diagnostic Analog Inputs

9 1 Number of Meter Runs configured

10

1

Number of Pulse Inputs configured

Page 15

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-5

Opcode 0 – ROC300-Series, FloBoss 407, FloBoss 100-Series, and FloBoss 500-Series

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

11

1

Number of Proportional, Integral, and

Derivative (PIDs) configured

12

1

Number of Tanks configured (ROC300-

Series with a ROCPAC only)

13

1

Number of Analog Outputs configured

14

1

Number of Timed Duration Outputs

configured

15

1

Number of Discrete Outputs configured

This byte is used to select the types of points to

be sent by setting the corresponding bit. Values

for DI, TDI, AI, and MVS points (FloBoss 407

only) will always be sent. Bytes include:

16

2

Alarm pointer (integer), top bit of msb

set to indicate power reset

bit DOs

TDO

AOs

TNK

PID

PI

AGA

7 6 5 4 3 2 1 0

18

2

Event pointer (integer)

20

2

Hourly history pointer (bit 15 set

indicates ROC300-Series, FloBoss

407, FloBoss 100-Series, or FloBoss

500-Series)

22

4

Diagnostic or system AI, Engineering

Units (EU) value (float) (above

repeated four more times)

42

1

Discrete Input

bit 0 = Status, 1-7 = Point Number

.

(above repeated as necessary)

5

1 Point Number

4 Timed Duration Input, EU (float)

.

(above repeated as necessary)

Offset dependent on ROC configuration

5 1 Point Number

4

Analog Input, EU (float)

80

MVS values (FloBoss 407), sent for four

sensors in Points 16 to 31 as

indicated in Table 2-5.

.

(above repeated as necessary)

Page 16

ROC Protocol Specifications Manual

2-6 Opcodes Revised September-2019

Opcode 0 – ROC300-Series, FloBoss 407, FloBoss 100-Series, and FloBoss 500-Series

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Current gas flow MCF/day

(float)

4

16 4

Mete

r Run

#1

Current energy MMBTU/day

(float)

4

Total MCF since contract hr

(float)

4

Total MMBTU since contract

hour ()

.

(above repeated as necessary)

1

Puls

e#1

Point Number

13 4 Raw accumulator counts

4 Rate, EU / time unit

4 Total today, EU (float)

.

(above repeated as necessary)

1

PID

Status

9 4

Loop

Primary Setpoint (float)

4

#1 Secondary Setpoint (float)

.

(above repeated as necessary)

4

Tank #1: volume since contract hour ()

(ROC300-Series with a ROCPAC

only)

.

(above repeated as necessary)

5 1 Point Number

4 Analog Output, EU (float)

.

(above repeated as necessary)

5 1 Point Number

4 Timed Duration Output, EU (float)

.

(above repeated as necessary)

1

Discrete Output

bit 0 = Status, 1-7 = Point Number

.

(above repeated as necessary)

1

Which contiguous block is being sent1

1. Depending upon I/O count, Opcode 0 responses can exceed the 240-byte maximum. Should this occur, the response is

divided into contiguous blocks consisting of 240 bytes maximum. Bytes 6 to 41 are returned for block 0 only. The block

number is returned as the last byte of every Opcode 0 response.

Page 17

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-7

Table 2-4. Opcode 0 – RegFlo

Opcode 0 – RegFlo

Communi-

cation

Opcode

Host Request to RegFlo

RegFlo Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 0:

General

Update

(RegFlo)

6 1 Always 0

6 1 Number of Discrete Inputs configured

7 1 Always 0

7 1 Not Used

8 1

Number of Analog Inputs

9 2

Not Used

10

2

Not Used

11

1

Number of PIDs configured

12

1

Not Used

13

1

Number of Analog Outputs configured

14

1

Not Used

15

1

Number of Discrete Outputs configured

16

2

Current Alarm Log pointer

18

2

Event pointer (integer)

20

2

0

22

4

Filtered EU of AI point 6 – Accumulated

Flow

26

4

Filtered EU of AI point 7 – Barometric

Pressure

30

4

Filtered EU of AI point 8 – Input Voltage

34

4

Filtered EU of AI point 9 – Board

Temperature

38

4

Filtered EU of AI point 10 – Logic

Voltage

42

1

AI Point Number (=1)

43

4

Filtered EU of AI point 1 – P1 Input

47

1

AI Point Number (=2)

48

4

Filtered EU of AI point 2 – P2 Input

52

1

AI Point Number (=3)

53

4

Filtered EU of AI point 3 – P3 Input

57

1

AI Point Number (=4)

58

4

Filtered EU of AI point 4 – Travel

62

1

AI Point Number (=5)

63

4

Filtered EU of AI point 5 – Inst Flow

Table 2-5 defines the opcode point numbers used for the Multi-Variable

Sensor (MVS) values on the FloBoss 407.

Page 18

ROC Protocol Specifications Manual

2-8 Opcodes Revised September-2019

Table 2-5. Opcode 0 – MVS Values

Opcode 0 – MVS Values (FloBoss 407 only)

Length

Description

20 bytes

MVS Sensor #1

1

4

Point Number – 16

DP EU Value (floating point value)

1

4

Point Number – 17

SP EU Value (floating point value)

1

4

Point Number – 18

PT EU Value (floating point value)

1

4

Point Number – 19

DP Reverse EU Value (floating point value)

20 bytes

MVS Sensor #2

1

4

Point Number – 20

DP EU Value (floating point value)

1

4

Point Number – 21

SP EU Value (floating point value)

1

4

Point Number – 22

PT EU Value (floating point value)

1

4

Point Number – 23

DP Reverse EU Value (floating point value)

.

(above repeated for MVS Sensors #3 and #4

and Point Numbers 24 through 31)

DP = Differential Pressure; SP = Static Pressure; PT = Process Temperature

2.3 Opcode 2

Opcode 2 tests communications along with a data analyzer for simpler

viewing of data.

Note: Opcode 2 is supported only by the ROC300-Series and FloBoss

407 units.

Table 2-6. Opcode 2 - ROC300-Series and FloBoss 407

Opcode 2 – ROC300 Series and FloBoss 407

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 2:

Send 240

Characters of

Test Data

(ROC300Series and

FloBoss 407)

No data bytes.

Returns 240 characters. First character

is 0, followed by 1, then 2, and so on.

Last character is 239.

Page 19

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-9

2.4 Opcode 6

Opcode 6 obtains the current configuration of a ROC or FloBoss.

2.4.1 Opcode 6: ROC300-Series with ROCPAC

Opcode 6 returns the current configuration of a ROC300-Series

containing a ROCPAC. The factory or sales representative sets the

Customer Name value.

Table 2-7. Opcode 6 – ROC300-Series with ROCPAC

Opcode 6 – ROC300-Series with ROCPAC

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 6:

Send ROC

Configuration –

(ROC300Series with

ROCPAC)

No data bytes.

6 1 Number of Discrete Inputs

7 1

Number of Analog Inputs plus five

diagnostic Analog Inputs

8 1

Number of Discrete Outputs

9 1

Number of Analog Outputs

10

1

Number of Active AGA meter runs

11

1

Number of Pulse Inputs

12

1

Number of Active PIDs

13

1

Number of Active Tanks (ROCPAC

only)

14

1

Number of database points for Base

RAM

15

1

Number of database points for RAM1

16

1

Number of database points for RAM2

17

1

Not Used (always 0)

18

1

FST present

19

1

Utilities:

Bit 0 ≥ AGARPT

Bit 1 ≥ LCD

Bit 2 ≥ Com1 User Enable

Bit 3 ≥ Com2 User Enable

Bit 4 ≥ User C Enable

Bit 5-7 ≥ Unused

20

1

ROC Manual Status ≥ point in manual

21

1

ROC Alarm Status ≥ point in alarm

22

1

Number of Soft Points

23

1

Number of Communication Ports

24

1

Indicates Opcode 180 update for User

Defined Points (UDPs) or Type of

ROC

25

1

Number of Configurable Opcode

Tables

26

20

Customer Name

46

18

Number of points defined for User

Defined Points 22 through 39

64

2

Not Used

Page 20

ROC Protocol Specifications Manual

2-10 Opcodes Revised September-2019

2.4.2 Opcode 6: ROC300-Series (w/FlashPAC) and FloBoss 407

Opcode 6 returns the current configuration of a FloBoss 407 or a

ROC300-Series containing FlashPAC. For the FloBoss 407, this opcode

returns 20 more values to cover the additional point types (Point Type

40 and beyond).

Table 2-8. Opcode 6 – ROC300-Series with FlashPAC and FloBoss 407

Opcode 6 – ROC300-Series with FlashPAC and FloBoss 407

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 6:

Send ROC

Configuration

– (ROC300Series with a

FlashPAC and

FloBoss 407)

No data bytes.

6 1 Number of Discrete Inputs

7 1

Number of Analog Inputs

8 1

Number of Discrete Outputs

9 1

Number of Analog Outputs

10

1

Number of Active AGA Meter Runs

11

1

Number of Pulse Inputs

12

1

Number of Active PIDs

13

1

Number of Tanks (always 0)

14

1

History – Base Ram (always 30)

15

1

History – Module 1 (FB407=20,

ROC300=30)

16

1

History – Module 2 (FB407=0,

ROC300=27)

17

1

Not Used (always 0)

18

1

Number of FSTs

19

1

Utilities Bit Map

20

1

Manual Mode Flag – Refer to Note 1.

21

1

Alarm Flag – Refer to Note 2.

22

1

Number of Soft Points

23

1

Number of Communication Ports

24

1

Type of ROC, FloBoss, or RegFlo:

2 = FloBoss 407

3 = ROC300-Series with FlashPAC

4 = FloBoss 100-Series version 1.xx,

FloBoss 503, or RegFlo version 1.xx

5 = FloBoss 504

6 = ROC800

7 = RegFlo version 2.xx or 3.xx

8 = FloBoss 103 version 2.xx

9 = 3095FC

25

1

Number of Configurable Opcodes

26

20

Customer Name

46

1

Number of User Defined Point Type 22

47

1

Number of User Defined Point Type 23

48

1

Number of User Defined Point Type 24

49

1

Number of User Defined Point Type 25

50

1

Number of User Defined Point Type 26

51

1

Number of User Defined Point Type 27

52

1

Number of User Defined Point Type 28

53

1

Number of User Defined Point Type 29

54

1

Number of User Defined Point Type 30

Page 21

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-11

Opcode 6 – ROC300-Series with FlashPAC and FloBoss 407

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

55

1

Number of User Defined Point Type 31

56

1

Number of User Defined Point Type 32

57

1

Number of User Defined Point Type 33

58

1

Number of User Defined Point Type 34

59

1

Number of User Defined Point Type 35

60

1

Number of User Defined Point Type 36

61

1

Number of User Defined Point Type 37

62

1

Number of User Defined Point Type 38

63

1

Number of User Defined Point Type 39

64

1

Number of MVS – Point Type 40

65

1

Number of Run Parameters – Point Type

41

66

1

Number of Extra Run Parameters – Point

Type 42

67

1

Number of User Lists – Point Type 43

(FloBoss 407 only)

68

1

Number of Power Control – Point Type 44

69

11

Point Types 45 to 55 – Not Used

80

1

AI Calibration Values – Point Type 56

81

1

Keypad Logon Security – Point Type 57

82

1

Point Type 58 – Not Used

83

1

Number of Program Flash – Point Type 59

84

1

Point Type 60 – Not Used

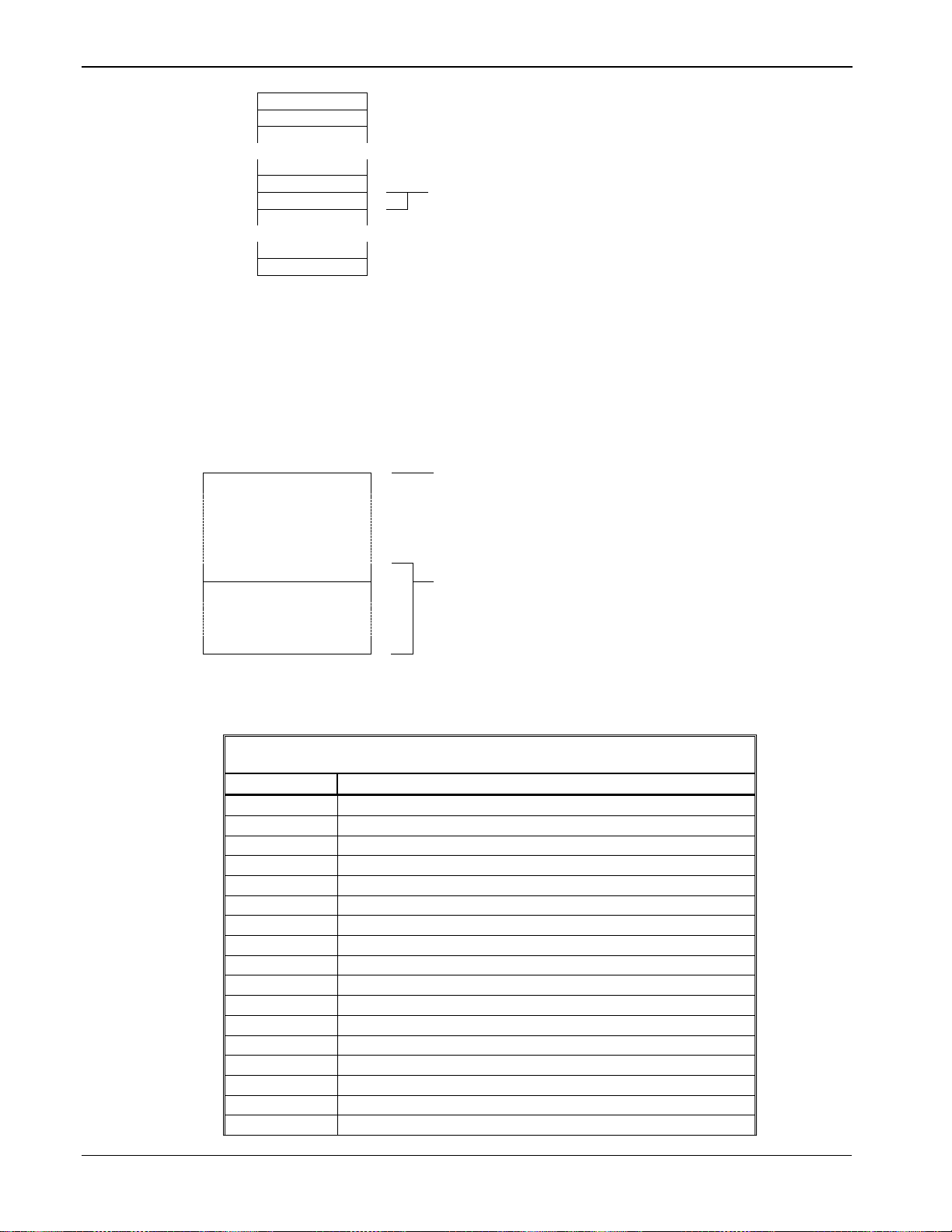

Note: The ROC Manual Status byte returned by Opcode 6 indicates whether the I/O points for a particular I/O point

type are currently in manual mode (1 = manual).

ROC Manual Status byte:

7 6 5 4 3 2 1 0

N/A

Analog Input in Manual

N/A

Analog Output in Manual

N/A

Discrete Input in Manual

Pulse Input in Manual

Discrete Output in Manual

Note: The ROC Alarm Status byte Opcode 6 returns indicates whether the I/O points for a particular point are currently

in a state of alarm (1 = alarm). Possible states of alarm are: low, high, low-low, high-high, rate, A/D failure, and manual.

ROC Alarm Status byte:

7 6 5 4 3 2 1 0

N/A

Analog Input in Alarm

Input Power Alarm

Analog Output in Alarm

Low RAM Battery Alarm

Discrete Input in Alarm

Pulse Input in Alarm

Discrete Output in Alarm

Page 22

ROC Protocol Specifications Manual

2-12 Opcodes Revised September-2019

2.4.3 Opcode 6: FloBoss 103/104, FloBoss 500-Series, and RegFlo

Opcode 6 returns the current configuration of the FloBoss 103/104,

FloBoss 500-Series, and RegFlo. This opcode returns 20 more values to

cover the new point types (Point Type 40 and beyond) added to support

these devices.

Table 2-9. Opcode 6 – FloBoss 103/104, FloBoss 500-Series, and RegFlo

Opcode 6 – FloBoss 103/104, FloBoss 500-Series, and RegFlo

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 6:

Send ROC

Configuration

– (FloBoss

103/104,

FloBoss 500Series, and

RegFlo)

No data bytes.

6

1

Number of Discrete Inputs

7 1

Number of Analog Inputs

8 1

Number of Discrete Outputs

9 1

Number of Analog Outputs

10

1

Number of Active AGA meter runs

Not Used (RegFlo)

11

1

Number of PIs

Not Used (RegFlo)

12

1

Number of Active PIDs

13

1

Number of Tanks – always 0

Not Used (RegFlo)

14

1

History for Base Ram – always 15

Number of History Points – always 20

(RegFlo)

or always 15 (FloBoss 103 version 1.10 or

earlier)

Number of Configured Standard History

Points - 8 to 35 (FloBoss 100-Series

Version 1.20 or greater)

15

1

History for Module 1 – always 0

Number of Extended History Points –

(RegFlo)

Version 1.xx = 0

Version 2.xx or 3.xx = 10

Number of Extended History Points -

(FloBoss 100-Series)

Version 1.10 or earlier = 0

Version 1.20 or greater = 0 to 15

16

1

History for Module 2 – always 0

Not Used (RegFlo)

17

1

Not Used – always 0

Number of Logic Alarms – always 10

(RegFlo)

18

1

Number of FSTs

19

1

Not Used – always 0

20

1

Not Used – always 0

Number of User Analog Values – (RegFlo)

21

1

Not Used – always 0

Number of User Discrete Values – (RegFlo)

22

1

Number of Soft Points

23

1

Number of Comm Ports

Page 23

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-13

Opcode 6 – FloBoss 103/104, FloBoss 500-Series, and RegFlo

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

24

1

Type of ROC, FloBoss, or RegFlo:

2 = FloBoss 407

3 = ROC300-Series with FlashPAC

4 = FloBoss 100-Series, FloBoss 503, or

RegFlo version 1.xx

5 = FloBoss 504

6 = ROC809

7 = RegFlo version 2.xx or 3.xx

8 = Reserved

9 = 3095FC

25

1

Number of Configurable Opcodes

26

20

Customer Name

Offsets 46 through 83 are

the number of points that

exist for Point Types 22

through 59.

Offsets 46-71 are not used –

always 0 (RegFlo).

46

1

Number of User Defined Point Type 22

47

1

Number of User Defined Point Type 23

48

1

Not Used

49

1

Number of User Defined Point Type 25

50

1

Number of User Defined Point Type 26

51

1

Number of User Defined Point Type 27

52

1

Number of User Defined Point Type 28

53

1

Number of User Defined Point Type 29

54

1

Number of User Defined Point Type 30

55

1

Number of User Defined Point Type 31

56

1

Number of User Defined Point Type 32

57

1

Number of User Defined Point Type 33

58

1

Number of User Defined Point Type 34

59

1

Number of User Defined Point Type 35

60

1

Number of User Defined Point Type 36

61

1

Number of User Defined Point Type 37

62

1

Number of User Defined Point Type 38

63

1

Number of User Defined Point Type 39

64

1

Point Type 40 – MVS

65

1

Number of Run Parameter – Point Type 41

66

1

Number of Extra Run Parameters – Point

Type 42

67

1

Number of User Lists – Point Type 43

68

1

Number of Power Control – Point Type 44

69

1

Number of Meter Calibration and Sampler –

Point Type 45

70

1

Number of Meter Configuration Parameters

– Point Type 46

71

1

Number of Meter Flow Values – Point Type

47

72

1

Number of PID Control – Point Type 48

73

1

Point Type 49 – Not Used

74

1

Point Type 50 – Not Used

75

1

Point Type 51 – Not Used

76

1

Number of Battery Parameters – Point

Type 52

77

1

Number of Modbus Configuration – Point

Type 53

Page 24

ROC Protocol Specifications Manual

2-14 Opcodes Revised September-2019

Opcode 6 – FloBoss 103/104, FloBoss 500-Series, and RegFlo

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

78

1

Number of Modbus Function Tables – Point

Type 54

79

1

Number of Modbus Special Function –

Point Type 55

80

1

Number of AI Calculation Values – Point

Type 56

81

1

Number of Logon Parameters – Point Type

57

82

1

Number of Revision Information – Point

Type 58

83

1

Number of Program Flash – Point Type 59

84

1

Not Used – always 0

85

1

Communication Port where Opcode 6

Request Received.

0=LOI

1=COM1

2=COM2 – (FloBoss 100-Series)

Not Used – always 0 (FloBoss 500-Series

and RegFlo)

2.4.4 Opcode 6: FloBoss 107

Opcode 6 returns the current configuration of the FloBoss 107.

Table 2–10. Opcode 6 – FloBoss 107

Opcode 6 – FloBoss 107

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 6:

Send ROC

Configuration

– (FloBoss

107)

No data bytes.

6

1

Number of Discrete Inputs

7 1

Number of Analog Inputs

8 1

Number of Discrete Outputs

9 1

Number of Analog Outputs

10

1

Number of Active meter runs

11

1

Number of PIs

12

1

Number of Active PIDs

13

1

Number of Tanks – always 0

14

1

Number of Standard History Points (0 -

100)

15

1

Number of Extended History Points (0 – 25)

16

1

Not Used – always 0

17

1

Not Used – always 0

18

1

Number of FSTs

19

1

Not Used – always 0

20

1

Not Used – always 0

21

1

Not Used – always 0

22

1

Number of Soft Points

23

1

Number of Comm Ports

Page 25

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-15

Opcode 6 – FloBoss 107

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

24

1

Type of ROC, FloBoss

4 = FB107 (except in boot mode)

10 = FB107 Boot Mode

25

1

Number of Configurable Opcodes

26

20

Customer Name

Offsets 46 through 83 are

the number of points that

exist for Point Types 22

through 59.

46

1

Number of User Defined Point Type 22

47

1

Number of User Defined Point Type 23

48

1

Not Used – always 0

49

1

Number of User Defined Point Type 25

50

1

Number of User Defined Point Type 26

51

1

Number of User Defined Point Type 27

52

1

Number of User Defined Point Type 28

53

1

Number of User Defined Point Type 29

54

1

Number of User Defined Point Type 30

55

1

Number of User Defined Point Type 31

56

1

Number of User Defined Point Type 32

57

1

Number of User Defined Point Type 33

58

1

Number of User Defined Point Type 34

59

1

Number of User Defined Point Type 35

60

1

Number of User Defined Point Type 36

61

1

Number of User Defined Point Type 37

62

1

Number of User Defined Point Type 38

63

1

Number of User Defined Point Type 39

64

1

Number of MVS - Point Type 40

65

1

Number of Run Parameter – Point Type 41

66

1

Number of Extra Run Parameters – Point

Type 42

67

1

Number of User Lists – Point Type 43

68

1

Number of Radio Power Control

Parameters – Point Type 44

69

1

Number of Meter Calibration and Sampler –

Point Type 45

70

1

Number of Meter Configuration Parameters

– Point Type 46

71

1

Number of Meter Flow Values – Point Type

47

72

1

Number of PID Control – Point Type 48

73

1

Point Type 49 – Not Used – always 0

74

1

Point Type 50 – Not Used – always 0

75

1

Point Type 51 – Not Used – always 0

76

1

Not Used – always 0

77

1

Not Used – always 0

78

1

Not Used – always 0

79

1

Number of Modbus Special Function –

Point Type 55

80

1

Not Used – always 0

81

1

Number of Logon Parameters – Point Type

57

82

1

Number of Revision Information – Point

Type 58

Page 26

ROC Protocol Specifications Manual

2-16 Opcodes Revised September-2019

Opcode 6 – FloBoss 107

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

83

1

Number of Program Flash – Point Type 59

84

1

Not Used – always 0

85

1

Communication Port where Opcode 6

Request Received.

0=LOI

1=COM1

2=COM2

3=COM3

4=LCD Port

86

1

Operating Mode

0=Normal

1=Boot

87

1

FB107 Backplane Type

4=Base backplane only - 4 slots

8=Base with expansion backplane – 8

slots

88-91

4

Not Used – always 0

92

1

Maximum number of Standard History

points

93

1

Maximum number of Extended History

points

94

1

Number of Diagnostic Points – Point Type

20

95-112

18

Number of SAM User Points – Point Type

60 - 77

113-114

2

Not Used – always 0

115

1

Number of Ethernet Points – Point Type 80

116-119

4

Not Used – always 0

120

1

Number of HART Points – Point Type 85

121

1

Number of Extended History Information

Points – Point Type 86

122

1

Not Used – always 0

123

1

Number of BLM User List Points – Point

Type 88

124

1

Number of History Chart Points – Point

Type 89

125-127

3

Not Used – always 0

128

1

Number of License Key Information Points

– Point Type 93

129

1

Number of User C Configuration Points –

Point Type 94

130-132

3

Not Used – always 0

133

1

Number of Extended Soft Point Parameters

– Point Type 98

134-151

18

Not Used – always 0

152

1

Number of Modbus Configuration Points –

Point Type 117

153

1

Number Modbus Register to TLP Mapping

Points – Point Type 118

154

1

Not Used – always 0

155

1

Number of Master Modbus Modem

Configuration Points – Point Type 120

Page 27

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-17

Opcode 6 – FloBoss 107

Communi-

cation

Opcode

ROC Response to Host

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

156

1

Number of Master Modbus Polling Table

Points – Point Type 121

157

1

DS800 Configuration – Point Type 122

158-206

49

Not Used (Reserved for Future) – always 0

207

1

RTU Network Discovery List - Point Type

172

208

1

Network Commissioned List - Point Type

173

209

1

Network Export Data – Point Type 174

210

1

Network Import Data – Point Type 175

211

1

IEC62591 Live List Parameters – Point

Type 176

212

1

IEC62591 Commissioned List Parameters

– Point Type 177

213

1

Number of User Defined Point Type 178

214

1

Number of User Defined Point Type 179

215

1

Number of User Defined Point Type 180

216

1

Number of User Defined Point Type 181

217

1

Number of User Defined Point Type 182

218

1

Number of User Defined Point Type 183

219

1

Number of User Defined Point Type 184

220

1

Number of User Defined Point Type 185

221

1

Number of User Defined Point Type 186

222

1

Number of User Defined Point Type 187

223

1

Number of User Defined Point Type 188

224

1

Number of User Defined Point Type 189

225-234

10

Not Used (Reserved for Future) – always 0

2.5 Opcode 7

Opcode 7returns the current time and date, the number of years since the

last leap year, and the day of week.

Note: Read the time/date by using Opcodes 167 and 180 and

specifying Point Type 12.

Page 28

ROC Protocol Specifications Manual

2-18 Opcodes Revised September-2019

Table 2–11. Opcode 7 - All Devices

Opcode 7 – All devices

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 7:

Send Current

Time and Date

No data bytes.

6

1

Current Second

7 1

Current Minute

8 1

Current Hour

9

1

Current Day

10

1

Current Month

11

1

Current Year

12

1

# Years Since Last Leap Year –

(ROC300-Series and FloBoss 407)

Leap Year or Not Leap Year – (FloBoss

100-Series, FloBoss 500-Series, and

RegFlo)

1 = Leap Year

0 = Not Leap Year

13

1

Current day of week

1=Sunday...7=Saturday

2.6 Opcode 8

Opcode 8 is the only way to set the real-time clock. The leap year

counter provides a mechanism to set the leap year. The real-time clock

automatically increments the leap year counter on January 1st. When the

leap year counter is zero (0), the real-time clock enables February 29th.

The “current day of week” for the real-time clock must be initialized to

work properly: the real-time clock does not set “current day of week”

automatically. The Function Sequence Table (FST) command day of

week (DWK) uses the “current day of week” value.

Table 2–12. Opcode 8 – All Devices

Opcode 8 – All devices

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 8: Set

Current Time

and Date

6 1 Current seconds

No data bytes.

7 1 Current minutes

Time and date are set and

acknowledgment sent back.

8 1 Current hour

9 1 Current day

10

1

Current month

11

1

Current year

or

Opcode 8: Set

Current Time

and Date

6 1 Current seconds

No data bytes.

7 1 Current minutes

Time and date are set and

acknowledgment sent back.

8 1 Current hour

9 1

Current day

10

1

Current month

Page 29

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-19

Opcode 8 – All devices

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

11

1

Current year

12

1

Years since last leap year

Ignored by FloBoss 500-Series, but can

be sent.

or

Opcode 8: Set

Current Time

and Date

6 1 Current seconds

No data bytes.

7 1 Current minutes

Time and date are set and

acknowledgment sent back.

8 1 Current hour

9 1 Current day

10

1

Current month

11

1

Current year

12

1

Years since last leap year

Ignored by FloBoss 500-Series, but can

be sent.

13

1

Current day of week

1 = Sunday, 7 = Saturday

Ignored by FloBoss 500-Series, but can

be sent.

or for FloBoss 100-Series, FloBoss 500-Series, and RegFlo only.

Opcode 8: Set

Current Time

and Date –

(FloBoss 100Series,

FloBoss 500Series, and

RegFlo only)

6 1 Current seconds

No data bytes.

7 1 Current minutes

Time and date are set and

acknowledgment sent back.

8 1 Current hour

9 1 Current day

10

1

Current month

11

1

Current year

12

1

Years since last leap year

Ignored by FloBoss 500-Series, but can

be sent.

13

1

Current day of week

1 = Sunday, 7 = Saturday

Ignored by FloBoss 500-Series, but can

be sent.

14

1

Current Century (hundred

years, such as 20 for the

year 2000)

2.7 Opcode 10

Opcode 10 reads data defined by a configurable opcode point. The

Starting Table Location plus the Number of Table Locations must be

less than or equal to 44.

Page 30

ROC Protocol Specifications Manual

2-20 Opcodes Revised September-2019

Table 2–13. Opcode 10 – All Devices

Opcode 10 – All devices

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 10:

Send Data

from

Configurable

Opcode

Tables

6 1 Table Number (0-7) –

(ROC300-Series and

FloBoss 407)

Table Number (0-3) – (FloBoss

100-Series and FloBoss 500Series)

Table Number (0-4) – (RegFlo)

6 1 Table Number (0-7) – (ROC300-Series

and FloBoss 407)

Table Number (0-3) – (FloBoss 100-

Series and FloBoss 500-Series)

Table Number (0-4) – (RegFlo)

7 1 Starting Table Location (0-43)

7 1 Starting Table Location (0-43)

8

1

Number of Table Locations

(1-44)

8 1 Number of Table Locations (1-44)

9 4 Table Version Number

(float)

13

x

Data

2.8 Opcode 11

Opcode 11 writes data defined by a configurable opcode point. The

starting table location plus the number of table locations must be less

than or equal to 44.

Table 2–14. Opcode 11 – All Devices

Opcode 11 – All devices

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 11:

Set Data in

Configurable

Opcode

Tables

6 1 Table Number (0-7) –

(ROC300-Series and

FloBoss 407)

Table Number (0-3) – (FloBoss

100-Series, FloBoss 500Series, and RegFlo)

No data bytes.

7 1 Starting Table Location (0-43)

Acknowledgment sent back.

8 1 Number of Table Locations (1-

44)

9 x Data

Page 31

ROC Protocol Specifications Manual

Revised September-2019 Opcodes 2-21

2.9 Opcode 17

Opcode 17 sets an operator identification code for the communications

port through which communications are occurring. The operator

identification is logged with an event, indicating the operator

responsible for creating the event. The ROC provides a default operator

identification for each communications port.

Once you set the operator identification, it remains set until changed

either by:

▪ Subsequent Opcode 17 requests.

▪ ROC initialized by a cold hard start.

When the following conditions are met:

▪ Using a FloBoss 100-Series, FloBoss 500-Series, or RegFlo with

Security on COM1,

▪ Using a ROC300-Series (version 2.21 or greater) or FloBoss 407

(version 1.10 or greater) with Security on COM1 or COM2,

▪ Enabling Security on LOI,

then the internal security which corresponds to the Operator ID, Access

level, and Password is stored in Point Type 57, Logon Securities, for the

port through which communications is occurring.

Page 32

ROC Protocol Specifications Manual

2-22 Opcodes Revised September-2019

Table 2–15. Opcode 17 – All Devices

Opcode 17 – All devices

Communi-

cation

Opcode

Host Request to ROC

ROC Response to Host

Data

Description of Data

Data

Description of Data

Offset

Length

Offset

Length

Opcode 17:

Set Operator ID –

(ROC300-Series

version 2.20 or less

and FloBoss 407

version 1.08 or less)

6

3

Operator ID

No data bytes.

or

Opcode 17:

Set Operator ID –

(FloBoss 100-Series,

FloBoss 500-Series,

RegFlo, ROC300Series version 2.21 or

greater, and FloBoss

407 version 1.10 or

greater) 6 3

Operator ID

No data bytes.

9

2

Password

Acknowledgment sent back.

or

Opcode 17:

Set Operator ID –

(FloBoss 100-Series

version 1.20 or greater,

FloBoss 500-Series

version 2.40 or greater,

ROC300-Series version

2.21 or greater, and

FloBoss 407 version

1.10 or greater)

6

3

Operator ID

No data bytes.

9

2

Password

Acknowledgment sent back.

11

6

Access Level

6 3

Operator ID

9

2

Password

11

6

“Logout”