Remote Automation Solutions ROCLINK 800 Configuration Software User Manual Manuals & Guides

Page 1

Form A6121

Part Number D301159X012

December 2005

ROCLINK™ 800 Configuration Software

User Manual

Flow Computer Division

Website: www.EmersonProcess.com/flow

Page 2

ROCLINK 800 User Manual

Revision Tracking Sheet

December 2005

This manual is periodically altered to incorporate new or updated information. The date revision level of

each page is indicated at the bottom of the page opposite the page number. A major change in the

content of the manual also changes the date of the manual, which appears on the front cover. Listed

below is the date revision level of each page.

Page Revision

All Pages Dec-05

All Pages Feb-05

All Pages Oct-04

All Pages Apr-04

All Pages Sep-03

All Pages Jul-03

All Pages Sep-02

FloBoss and ROCLINK are marks of one of the Emerson Process Management companies. The Emerson logo is a trademark

and service mark of Emerson Electric Co. All other marks are the property of their respective owners.

This product may be covered unde r pen di n g pat ent a ppl i cat i ons.

© Fisher Controls International, LLC. 2002-2005. All rights reserved.

Printed in the U.S.A.

While this information is presented in good faith and believed to be accurate, Fisher Controls does not guarantee satisfactory

results from reliance upon such information. Nothing contained herein is to be construed as a warranty or guarantee, express

or implied, regarding the performance, merchantability, fitness or any other matter with respect to the pro ducts, nor as a

recommendation to use any product or process in conflict with any patent. Fisher Controls reserves the right, without notice,

to alter or improve the designs or specifications of the products described herein.

Rev. Dec-05 ii

Page 3

ROCLINK 800 User Manual

TABLE OF CONTENTS

Section 1 – ROCLINK 800 Software Basics...............................................................1-1

1.1 ROCLINK 800 SOFTWARE DESCRIPTION ......................................................................................1-1

1.2 C

1.3 C

1.4 SOFTWARE INSTALLATION..............................................................................................................1-2

1.5 STARTING ROCLINK 800 SOFTWARE ...........................................................................................1-4

1.6 USER INTERFACE BASICS................................................................................................................1-6

1.7 CONFIGURATION BASICS ..............................................................................................................1-14

1.8 CREATING A NEW CONFIGURATION FILE......................................................................................1-18

OMPUTER REQUIREMENTS............................................................................................................1-2

ONTACTING THE FLOW COMPUTER DIVISION...............................................................................1-2

1.4.1 Manually Creating a Desktop Shortcut ..................................................................................1-3

1.4.2 Launching ROCLINK 800 During Setup...............................................................................1-4

1.4.3 Un-Installing ROCLINK 800.................................................................................................1-4

1.5.1 Logging On.............................................................................................................................1-5

1.6.1 Menu Bar and Menus.............................................................................................................1-8

1.6.2 Buttons....................................................................................................................................1-8

1.6.3 ToolBar...................................................................................................................................1-9

1.6.4 Keystrokes............................................................................................................................1-10

1.6.5 Help System .........................................................................................................................1-11

1.6.6 About ROCLINK 800 ..........................................................................................................1-12

1.6.7 Basic Navigation ..................................................................................................................1-12

1.6.8 TLP Box Selections..............................................................................................................1-13

1.6.9 AutoScan Update Interval Option........................................................................................1-14

1.7.1 Configuration Checklist (ROC800-Series) ..........................................................................1-15

1.7.2 Configuration Checklist (ROC300-Series) ..........................................................................1-16

1.7.3 Configuration Checklist (FloBoss 100-Series).....................................................................1-16

1.7.4 Configuration Checklist (FloBoss 407)................................................................................1-17

1.7.5 Duplicating a Configuration.................................................................................................1-17

1.8.1 Opening a Configuration File...............................................................................................1-19

1.8.2 Configuration Tree Menu.....................................................................................................1-20

Section 2 – Configuring Communications and Security ........................................... 2-1

2.1 S

2.2 ROCLINK

2.3 DEVICE SECURITY...........................................................................................................................2-6

2.4 L

2.5 D

2.6 ROCLINK 800 COMMUNICATIONS..............................................................................................2-17

Rev. Dec-05 Table of Contents iii

ECURITY ACCESS LEVELS .............................................................................................................2-2

800 SECURITY..............................................................................................................2-5

2.3.1 Device Security – Users (ROC800-Series and FloBoss 100-Series).....................................2-6

2.3.2 Device Security – Users (FloBoss 407) .................................................................................2-8

2.3.3 Device Security – Users (ROC300-Series)............................................................................2-9

2.3.4 Device Security – Groups.....................................................................................................2-10

2.3.5 Device Security – Comm Ports (ROC800-Series and FloBoss 100-Series) ........................2-11

2.3.6 Device Security – Users / Group Summary (ROC800-Series) ............................................2-12

ICENSE KEY ADMINISTRATOR (ROC800-SERIES) ......................................................................2-13

EVICE DIRECTORY......................................................................................................................2-14

2.5.1 Device Root..........................................................................................................................2-15

2.6.1 ROCLINK 800 Communications – General........................................................................2-17

2.6.2 ROCLINK 800 Communications – Advanced.....................................................................2-20

Page 4

ROCLINK 800 User Manual

2.7 COMMUNICATION PORTS ON THE ROC AND FLOBOSS .................................................................2-21

2.7.1 Comm Ports – General.........................................................................................................2-25

2.7.2 Comm Ports – Modbus Host Parameters (FloBoss 407 and ROC300-Series).....................2-27

2.7.3 Comm Ports – Modem .........................................................................................................2-28

2.7.4 Comm Ports – SRBX or RBX..............................................................................................2-30

2.7.5 Comm Ports – Store & Forward (ROC800-Series and FloBoss 407)..................................2-32

2.7.6 Comm Ports – Diagnostics (ROC800-Series)......................................................................2-33

2.7.7 Configuring TCP/IP Communications on the Ethernet Port (ROC800-Series)...................2-34

2.8 CONNECTING TO A ROC OR FLOBOSS ..........................................................................................2-36

2.8.1 Direct Connect......................................................................................................................2-36

2.8.2 Local Operator Interface (LOI – Local Port) .......................................................................2-37

2.8.3 Connect.................................................................................................................................2-37

2.8.4 Successful Login ..................................................................................................................2-37

2.9 TROUBLESHOOTING COMMUNICATIONS .......................................................................................2-38

2.9.1 Troubleshooting Connection Errors.....................................................................................2-38

2.9.2 Troubleshooting ROCLINK 800 Communications .............................................................2-39

2.9.3 Troubleshooting TCP/IP Connections..................................................................................2-39

2.9.4 Communications Monitor.....................................................................................................2-40

2.9.5 Disconnecting from a ROC or FloBoss................................................................................2-40

Section 3 – Configuring System Parameters..............................................................3-1

3.1 SETTING THE CLOCK.......................................................................................................................3-1

3.2 CONFIGURING DEVICE INFORMATION.............................................................................................3-2

3.2.1 Information – General............................................................................................................3-4

3.2.2 Information – Internet (ROC800-Series) ...............................................................................3-6

3.2.3 Information – Points...............................................................................................................3-7

3.2.4 Information – Other Information..........................................................................................3-10

3.2.5 Information – System Configuration (ROC800-Series).......................................................3-12

3.2.6 Information – Revision Info (FloBoss 100-Series)..............................................................3-13

3.2.7 Information – Keypad Display (ROC800-Series)................................................................3-14

3.3 C

ONFIGURING SYSTEM FLAGS ......................................................................................................3-15

3.3.1 Returning the Device to Factory Default Settings................................................................3-18

3.3.2 Flags – Advanced.................................................................................................................3-19

3.3.3 Flags – User Programs (FloBoss 100-Series, ROC300-Series, and FloBoss 407) ..............3-22

Section 4 – Configuring Inputs and Outputs (I/O).................................................... 4-1

4.1 I/O C

4.2 AI – A

4.2.1 AI – General...........................................................................................................................4-2

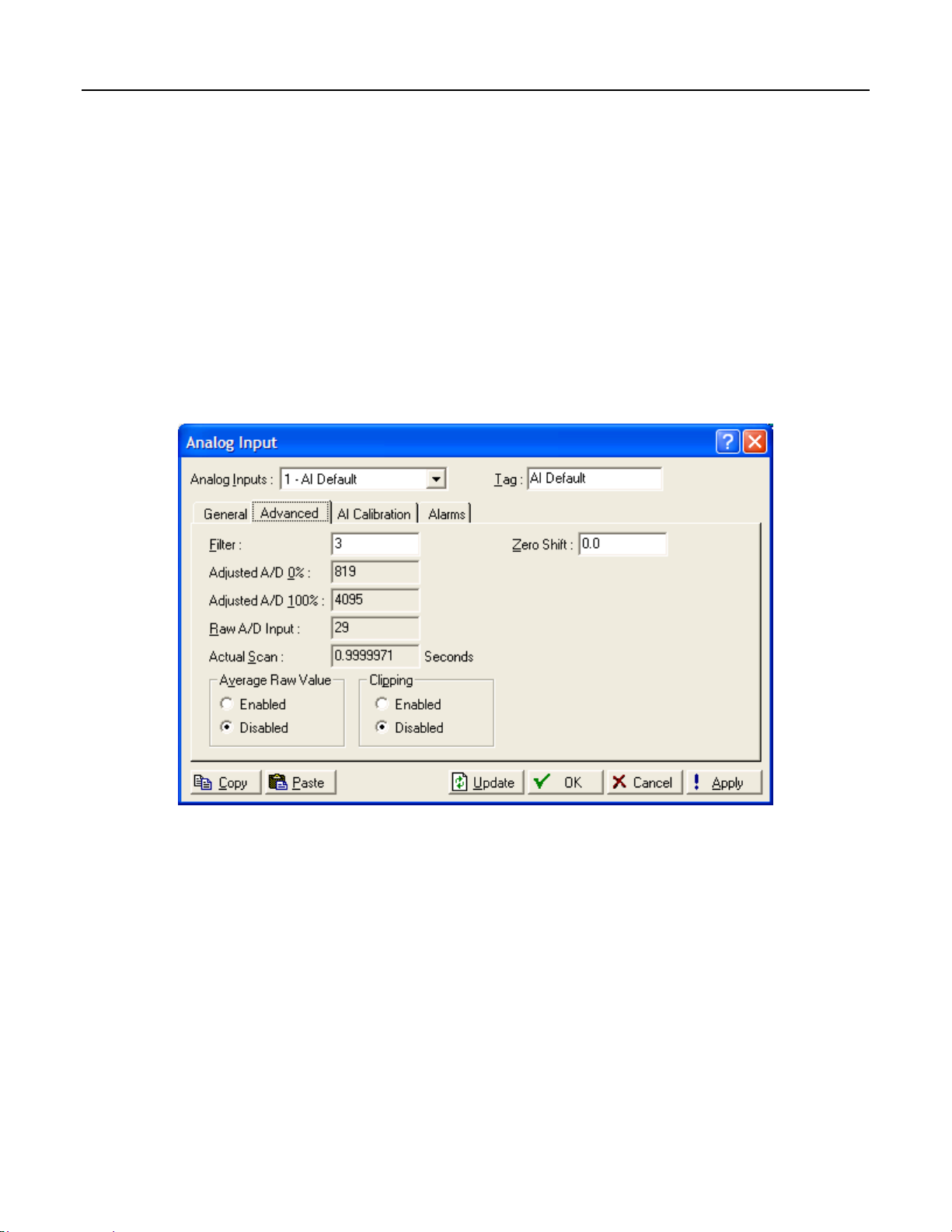

4.2.2 AI – Advanced........................................................................................................................4-4

4.2.3 AI – Alarms............................................................................................................................4-7

4.3 AO – ANALOG OUTPUT CONFIGURATION.......................................................................................4-9

4.3.1 AO – General..........................................................................................................................4-9

4.3.2 AO – Advanced....................................................................................................................4-11

4.3.3 AO – Alarms (ROC800-Series) ...........................................................................................4-13

ONFIGURATION OVERVIEW ....................................................................................................4-1

NALOG INPUT CONFIGURATION............................................................................................4-2

Rev. Dec-05 Table of Contents iv

Page 5

ROCLINK 800 User Manual

4.4 DI – DISCRETE INPUT CONFIGURATION........................................................................................4-14

4.4.1 DI – General.........................................................................................................................4-14

4.4.2 DI – Advanced......................................................................................................................4-16

4.4.3 DI – TDI Parameters (FloBoss 407 and ROC300-Series) ...................................................4-18

4.4.4 DI – Alarms..........................................................................................................................4-19

4.5 DO – DISCRETE OUTPUT CONFIGURATION...................................................................................4-21

4.5.1 DO – General........................................................................................................................4-22

4.5.2 DO – Advanced....................................................................................................................4-24

4.5.3 DO – TDO Parameters.........................................................................................................4-26

4.5.4 DO – Alarms (ROC800-Series) ...........................................................................................4-28

4.6 PI – PULSE INPUT CONFIGURATION..............................................................................................4-29

4.6.1 PI – General..........................................................................................................................4-29

4.6.2 PI – Advanced......................................................................................................................4-32

4.6.3 PI – Alarms...........................................................................................................................4-35

4.7 P

4.8 RTD – RTD I

4.9 TC – THERMOCOUPLE INPUT CONFIGURATION (ROC800-SERIES) ..............................................4-42

4.10 SYSTEM AI – SYSTEM ANALOG INPUT CONFIGURATION (ROC800-SERIES)................................4-46

4.11 HART INPUT CONFIGURATION (ROC800-SERIES).......................................................................4-50

4.12 MVS S

ULSE INTERFACE MODULE DIAGNOSTIC (FLOBOSS 104)............................................................4-37

NPUT CONFIGURATION (ROC800-SERIES) .............................................................4-38

4.8.1 RTD – General .....................................................................................................................4-39

4.8.2 RTD – Advanced..................................................................................................................4-40

4.8.3 RTD – Alarms......................................................................................................................4-41

4.9.1 Thermocouple – General......................................................................................................4-43

4.9.2 Thermocouple – Advanced ..................................................................................................4-44

4.9.3 Thermocouple – Alarms.......................................................................................................4-45

4.10.1 System AI – General (ROC800-Series) ...............................................................................4-47

4.10.2 System AI – Advanced (ROC800-Series)............................................................................4-48

4.10.3 System AI – Alarms (ROC800-Series)................................................................................4-49

4.11.1 HART – General (ROC800-Series) .....................................................................................4-51

4.11.2 HART – Advanced (ROC800-Series)..................................................................................4-53

4.11.3 HART – Device (ROC800-Series).......................................................................................4-54

ENSOR (ROC800-SERIES OR FLOBOSS 407)......................................................................4-57

Section 5 – Configuring the Meter Setup....................................................................5-1

5.1 M

5.2 STATION CONFIGURATION (ROC800-SERIES)................................................................................5-2

5.3 METER SETUP CONFIGURATION....................................................................................................5-11

Rev. Dec-05 Table of Contents v

ETER SETUP BASICS.....................................................................................................................5-1

5.2.1 Station – General (ROC800-Series).......................................................................................5-3

5.2.2 Station – Gas Quality (ROC800-Series) ................................................................................5-5

5.2.3 Station – Advanced (ROC800-Series) ...................................................................................5-7

5.2.4 Station – Alarms (ROC800-Series)........................................................................................5-9

5.3.1 Meter – General....................................................................................................................5-12

5.3.2 Meter – Inputs ......................................................................................................................5-16

5.3.3 Meter – Gas Quality (FloBoss 100-Series, ROC300-Series, and FloBoss 407)..................5-19

5.3.4 Meter – Advanced................................................................................................................5-21

5.3.5 Meter – Sampler (FloBoss 100-Series)................................................................................5-32

5.3.6 Meter – Instrument Calibration (FloBoss 100-Series).........................................................5-33

Page 6

ROCLINK 800 User Manual

5.3.7 Meter – Calibration Factors (ROC800-Series).....................................................................5-34

5.3.8 Meter – Alarms.....................................................................................................................5-35

5.3.9 Meter – Mass Meter Pressure Effect (ROC800-Series).......................................................5-38

Section 6 – Configuring and Viewing History............................................................ 6-1

6.1 H

6.2 HISTORY SETUP (FLOBOSS 100-SERIES).........................................................................................6-3

6.3 HISTORY SETUP (ROC300-SERIES AND FLOBOSS 407)..................................................................6-6

6.4 CONFIGURING HISTORY SEGMENTS (ROC800-SERIES)..................................................................6-8

6.5 CONFIGURING HISTORY POINTS ....................................................................................................6-10

6.6 CONFIGURING HISTORY FOR EFM REPORTING.............................................................................6-13

6.7 EFM R

6.8 H

6.9 DEVICE MEMORY..........................................................................................................................6-35

ISTORY .........................................................................................................................................6-1

6.2.1 Configuring FloBoss 100-Series History...............................................................................6-5

EPORTS..............................................................................................................................6-17

6.7.1 Collecting ROC Data............................................................................................................6-17

6.7.2 Displaying EFM Reports......................................................................................................6-18

6.7.3 Converting EFM Files..........................................................................................................6-19

6.7.4 PGAS Conversions...............................................................................................................6-23

6.7.5 Flow-Cal (.CFX) Conversions .............................................................................................6-31

ISTORY, ALARM, AND EVENT LOG REPORTS..............................................................................6-31

6.8.1 Viewing the History Log......................................................................................................6-31

6.8.2 Viewing the Alarm Log........................................................................................................6-31

6.8.3 Viewing the Event Log.........................................................................................................6-31

6.8.4 Viewing Report Logs From the Device ...............................................................................6-32

6.8.5 Viewing Report Logs From a File........................................................................................6-33

6.8.6 Viewing the History Log Report Graphically (Plot)............................................................6-34

Section 7 – Extended Functions...................................................................................7-1

7.1 SOFT POINTS...................................................................................................................................7-1

7.2 OPCODE TABLE...............................................................................................................................7-3

7.3 SAMPLER/ODORIZER (ROC800-SERIES).........................................................................................7-4

7.4 P

7.5 RADIO POWER CONTROL ..............................................................................................................7-18

7.6 DS800 DEVELOPMENT SUITE SOFTWARE (ROC800-SERIES).......................................................7-21

7.7 U

7.8 USER DATA...................................................................................................................................7-25

ROPORTIONAL, INTEGRAL, AND DERIVATIVE (PID) .....................................................................7-5

7.4.1 PID (ROC800-Series and FloBoss 100-Series)......................................................................7-6

7.4.2 PID (ROC300-Series and FloBoss 407).................................................................................7-8

7.4.3 PID – General.........................................................................................................................7-9

7.4.4 PID – Tuning........................................................................................................................7-13

7.4.5 PID – Status (ROC800-Series).............................................................................................7-16

7.4.6 PID – Example .....................................................................................................................7-17

SER PROGRAM ADMINISTRATOR ................................................................................................7-22

7.7.1 User Program Download Steps ............................................................................................7-24

Rev. Dec-05 Table of Contents vi

Page 7

ROCLINK 800 User Manual

Section 8 – Modbus Communications.........................................................................8-1

8.1 M

8.2 MODBUS CONFIGURATION – HISTORY............................................................................................8-8

8.3 M

8.4 MODBUS REGISTERS (ROC800-SERIES AND FLOBOSS 100-SERIES) ............................................8-18

8.5 MODBUS MASTER TABLE (ROC800-SERIES) ...............................................................................8-29

8.6 MODBUS MASTER MODEM (ROC800-SERIES).............................................................................8-31

8.7 MODBUS HOST PARAMETERS (FLOBOSS 407 AND ROC300-SERIES)...........................................8-32

Section 9 – Saving and Retrieving Configurations....................................................9-1

9.1 SAVING A ROC USER FILE .............................................................................................................9-1

9.2 SAVING A CONFIGURATION.............................................................................................................9-2

9.3 DOWNLOADING A CONFIGURATION ................................................................................................9-3

ODBUS CONFIGURATION (ROC800-SERIES AND FLOBOSS 100-SERIES).....................................8-2

8.1.1 Configuring a ROC800-Series or FloBoss 100-Series as a Modbus Slave............................8-2

8.1.2 Configuring a ROC800-Series as a Modbus Host..................................................................8-2

8.1.3 Modbus Configuration – General...........................................................................................8-3

8.1.4 Modbus Configuration – Scale Values...................................................................................8-5

8.2.1 Modbus Configuration – History Access Registers (FloBoss 100-Series) ..........................8-10

ODBUS EVENTS AND ALARMS FUNCTIONALITY.........................................................................8-13

8.3.1 Modbus Events and Alarms (ROC800-Series) ....................................................................8-14

8.3.2 Reading Modbus Events and Alarms Register.....................................................................8-15

8.3.3 Acknowledging Modbus Events and Alarms.......................................................................8-16

8.4.1 Modbus Conversion (ROC800-Series and FloBoss 100-Series) .........................................8-23

9.3.1 Opening a Configuration........................................................................................................9-4

Section 10 – Calibration..............................................................................................10-1

10.1 CALIBRATION BASICS ...................................................................................................................10-1

10.1.1 Calibration Report................................................................................................................10-2

10.2 STARTING CALIBRATION...............................................................................................................10-3

10.2.1 Verify – Calibration............................................................................................................10-3

10.2.2 Set Zero – Calibration.........................................................................................................10-5

10.2.3 Set Span – Calibration ........................................................................................................10-7

10.2.4 Set Midpoints – Calibration................................................................................................10-8

10.2.5 Zero Shift / Offset / RTD Bias – Calibration....................................................................10-10

10.2.6 Orifice Meter Calibration.................................................................................................. 10-10

10.2.7 Turbine Meter Calibration ................................................................................................10-13

10.2.8 AI and RTD Calibration....................................................................................................10-14

10.2.9 HART Calibration.............................................................................................................10-15

10.3 ANALOG INPUT CALIBRATION VALUES ......................................................................................10-16

10.4 RTD I

10.5 MVS INPUT CALIBRATION VALUES (ROC800-SERIES AND FLOBOSS 407) ...............................10-19

NPUT CALIBRATION VALUES ............................................................................................10-17

Section 11 – Updates and Changes............................................................................11-1

11.1 UPDATE FIRMWARE ......................................................................................................................11-1

11.1.1 Update Firmware – I/O Termination Board........................................................................11-3

11.1.2 Update Firmware – Keypad Display (ROC800-Series)......................................................11-4

11.2 UPGRADE HARDWARE (FLOBOSS 100-SERIES).............................................................................11-5

11.3 P

LATE CHANGE.............................................................................................................................11-6

Rev. Dec-05 Table of Contents vii

Page 8

ROCLINK 800 User Manual

Section 12 – Displays, Diagnostics, and Monitoring................................................12-1

12.1 P

12.2 I/O M

12.3 LCD D

12.4 LCD U

12.5 METER RUN VALUES ....................................................................................................................12-7

12.6 C

12.7 K

RINT CONFIGURATION.................................................................................................................12-2

ONITOR................................................................................................................................12-3

ISPLAY CONFIGURATION (ROC300-SERIES).....................................................................12-5

SER LIST (FLOBOSS 100-SERIES AND FLOBOSS 407)........................................................12-6

USTOM DISPLAYS .......................................................................................................................12-9

12.6.1 Custom Displays – New Display.....................................................................................12-10

12.6.2 Custom Displays – Objects .............................................................................................12-11

12.6.3 Custom Displays – Object Properties..............................................................................12-12

12.6.4 Editing a Custom Display From a File............................................................................12-13

12.6.5 Adding an Expression to a Custom Display Object........................................................12-13

12.6.6 Display Administrator.....................................................................................................12-15

EYPAD DISPLAY EDITOR CONFIGURATION...............................................................................12-16

12.7.1 Creating a New Keypad Display File (ROC800-Series).................................................12-16

12.7.2 Update Keypad Display Firmware (ROC800-Series).....................................................12-17

12.7.3 Editing a Keypad Display File ........................................................................................12-18

12.7.4 Keypad Display Security (ROC800-Series)....................................................................12-19

Appendix A – FST Editor............................................................................................ A-1

A.1 FST EDITOR...................................................................................................................................A-1

A.2 FUNCTION SEQUENCE TABLE INTRODUCTION................................................................................A-1

A.3 FST REGISTERS .............................................................................................................................A-3

A.4 FST EDITOR...................................................................................................................................A-5

A.4.1 FST Function Structure .........................................................................................................A-6

A.4.2 FST Label Field.....................................................................................................................A-7

A.4.3 FST Command Field – CMD................................................................................................A-7

A.4.4 FST Argument Fields – ARG................................................................................................A-7

A.4.5 FST Comment Fields.............................................................................................................A-8

A.4.6 FST Function Examples........................................................................................................A-8

A.4.7 Basic Rules for Creating FSTs..............................................................................................A-8

A.4.8 FST Storage and Restart........................................................................................................A-9

A.5 W

A.6 M

A.7 FST C

ORKING WITH FSTS..................................................................................................................A-10

A.5.1 Creating an FST...................................................................................................................A-10

A.5.2 Altering an FST – Edit Menu..............................................................................................A-13

ONITOR MODE ..........................................................................................................................A-13

A.6.1 FST – Trace Mode...............................................................................................................A-15

OMMAND LIBRARY............................................................................................................A-16

A.7.1 FST Mathematical Commands............................................................................................A-18

A.7.2 FST Logical Commands......................................................................................................A-20

A.7.3 FST Comparison Commands ..............................................................................................A-22

A.7.4 FST Time-Related Commands............................................................................................A-23

A.7.5 FST Control-Related Commands........................................................................................A-24

A.7.6 FST Miscellaneous Commands...........................................................................................A-25

A.7.7 FST Database Commands...................................................................................................A-26

Rev. Dec-05 Table of Contents viii

Page 9

ROCLINK 800 User Manual

Glossary.........................................................................................................................G-1

Index................................................................................................................................I-1

Rev. Dec-05 Table of Contents ix

Page 10

ROCLINK 800 User Manual

SECTION 1 – ROCLINK 800 SOFTWARE BASICS

This section describes how to use the ROCLINK 800 Configuration Software to configure and monitor

ROC800-Series Remote Operations Controllers, ROC300-Series, FloBoss 407 Flow Managers, and

FloBoss 100-Series devices.

The software runs on a personal computer that uses the Windows 98 or higher operating system. This

user manual covers configuration, calibration, monitoring, database archiving, custom displays, and

embedded utilities.

In this Chapter

Section Page

1.1 ROCLINK 800 Software Description............................................................................................. 1-1

1.2 Computer Requirements................................................................................................................. 1-2

1.3 Contacting the Flow Computer Division........................................................................................1-2

1.4 Software Installation.......................................................................................................................1-2

1.5 Starting ROCLINK 800 Software................................................................................................... 1-4

1.6 User Interface Basics ...................................................................................................................... 1-6

1.7 Configuration Basics..................................................................................................................... 1-14

1.8 Creating a New Configuration File...............................................................................................1-18

1.1 ROCLINK 800 Software Description

ROCLINK 800 Configuration Software provides the capability to monitor, configure, and calibrate

ROC800-Series Remote Operations Controllers, ROC300-Series, FloBoss 407 Flow Managers, and

FloBoss 100-Series Flow Managers. The software and user documentation are supplied on a CD-ROM.

ROCLINK 800 software is designed for ease of use. Drop-down menus simplify accessing the functions

provided by the software. Dialog boxes and drop-down list boxes help to direct selections and data

entry. You can perform actions with the keyboard or a pointing device, such as a mouse. Refer to User

Interface Basics for a description of the user interface.

Help screens are accessed either from the Help menu or in a context-sensitive fashion using <F1>. This

feature makes it easy to access on-line information for any ROCLINK 800 software topic.

You can build custom displays for the ROC or FloBoss that combines both graphic and dynamic data

elements. The displays can monitor the operation of the ROC or FloBoss either locally or remotely.

The software also provides multiple levels of security for controlling access to ROCLINK 800 software

functions, as well as the ROC database.

Note: If you are using a serial mouse (typically plugs into serial port COM1), be sure to set up

communications to the ROC or FloBoss through a port that does not share interrupts (typically

COM2), or a conflict occurs.

Rev. Dec-05 ROCLINK 800 Software Basics 1-1

Page 11

ROCLINK 800 User Manual

1.2 Computer Requirements

ROCLINK 800 software runs on most IBM-compatible personal computers (PCs). The PC can be a

desktop or a portable computer. In any case, the PC should meet the following minimum requirements:

♦ Pentium-class processor (233 MHz or greater recommended).

♦ CD-ROM drive.

♦ Windows 98, ME, NT 4.0 (Service Pack 6), 2000 (Service Pack 2), or XP.

♦ 64 MB of RAM (Random Access memory).

♦ SVGA color monitor, 800 by 600 pixels, small fonts.

♦ 15 to 50 MB of available hard disk space depending on Operating System and revision level.

♦ EIA-232 (RS-232) serial connection, a dial-up modem connection, a TCP/IP connection

(ROC800-Series), or a wireless radio (FloBoss 100-Series).

1.3 Contacting the Flow Computer Division

Please contact your local sales representative, or contact the Flow Computer Division directly.

Emerson Process Management

Flow Computer Division

Marshalltown, IA 50158 USA

Houston, TX 77065 USA

Pickering, North Yorkshire UK Y018 7JA

E-mail: fas.tech-support@emersonprocess.com

Website: www.emersonprocess.com/flow/

Technical Support Website: www.emersonprocess.com/flow/Emerson/support/support_index.html

Telephone: (641) 754-3449 (Monday through Friday 7:30 AM to 4:30 PM Central US Time)

1.4 Software Installation

To install ROCLINK 800 software:

1. Start the installation by one of the two methods described below.

♦ Method 1 – If you have a CD-ROM that contains the ROCLINK 800 installation files:

A. Place the ROCLINK Software Installation CD-ROM into your drive.

B. If the CD-ROM runs automatically, click the Install a ROCLINK Product button in the

Main Menu.

C. Click the Install ROCLINK 800 button in the Installation Screen.

Note: If the CD-ROM does not run automatically, click Windows Start > Run.

When the Run dialog box opens, click the Browse button and navigate to the CDROM drive and select Setup.exe. Click the Open button. If the CD-ROM drive is

drive D, the location will be D:\Installs\ROCLINK800_ W68130\Setup.exe. Click

OK in the Run dialog box.

Rev. Dec-05 ROCLINK 800 Software Basics 1-2

Page 12

ROCLINK 800 User Manual

♦ Method 2 – If you have .zip file that contains the ROCLINK 800 installation files:

A. Extract the .zip file to the local hard drive (for example, in the C:\TEMP\ directory).

B. Run setup.exe from extraction location (for example, run C:\TEMP\SETUP.EXE).

The Installation Wizard screen appears.

2. The Installation Wizard determines whether ROCLINK 800 has been installed previously.

♦ If this is an upgrade, a dialog box appears asking whether to continue with the upgrade. Click

Yes. Installation begins. Click Next when prompted.

♦ If this is a new installation, click Next in the ROCLINK 800 Welcome screen. Read the

License Agreement and click Yes to confirm. Enter your Name and Company name, and

click Next.

3. Select a destination folder, if you want to install the software in a folder other than the default,

C:\Program Files\ROCLINK800. The ROCLINK800 default folder is recommended.

4. Click Next.

A confirmation screen appears when you are ready to start copying files.

5. Click Next in the Setup Status screen.

6. Click the Finish button in the Wizard Complete screen.

7. If the installation was performed from the CD-ROM, select View Manual or Exit on the Main

Menu screen. Once you have exited the Main Menu, remove the installation CD-ROM.

Note: A restart may be necessary after installation is complete.

1.4.1 Manually Creating a Desktop Shortcut

ROCLINK 800 software installation should automatically create a Desktop Shortcut on your computer.

If for some reason you need to manually create the Desktop Shortcut, perform the following steps.

1. Double-click the My Computer icon.

2. Navigate to the C:\Program Files\ROCLINK800 folder or the folder where you installed

ROCLINK 800.

3. Select the ROCLINK.exe file.

4. Select Create Shortcut from the File menu.

5. Click and drag the shortcut to your Desktop.

6. Double-click the shortcut on your desktop to launch ROCLINK 800 software.

Rev. Dec-05 ROCLINK 800 Software Basics 1-3

Page 13

ROCLINK 800 User Manual

1.4.2 Launching ROCLINK 800 During Setup

This procedure launches ROCLINK 800 software every time you start this computer.

1. Double-click the My Computer icon.

2. Navigate to the C:\Program Files\ROCLINK800 folder or the folder where you installed

ROCLINK 800 software.

3. Select the ROCLINK.exe file.

4. Select File > Create Shortcut.

5. Depending on the Operating System of your PC, use the required method to place the shortcut

file into the startup folder.

1.4.3 Un-Installing ROCLINK 800

To remove ROCLINK 800 software from a personal computer, perform the following steps.

1. Click the Windows Start button.

2. Select Settings > Control Panel.

3. Double-click the Add/Remove Programs icon.

4. Select ROCLINK 800.

5. Click Add/Remove button.

6. Follow the instructions.

1.5 Starting ROCLINK 800 Software

To use ROCLINK 800 software to configure a hardware device, you must have the ROC or FloBoss

properly connected to power and I/O. Refer to the appropriate hardware instruction manual. Initially, the

ROC should also be connected to a personal computer (PC) running ROCLINK 800 using the Local

Operator Interface (LOI), serial, modem, or Ethernet port.

To run ROCLINK 800 software, perform one of the following steps:

♦ Double-click the Desktop shortcut.

♦ Select Start > Programs > ROCLINK 800 > ROCLINK 800.

♦ Double-click the file ROCLINK.exe located in C:\Program Files\Roclink800 (the default

directory), or wherever you installed ROCLINK 800 software.

The software loads and initializes.

Note: You can only run one version of ROCLINK 800 software at a time.

Rev. Dec-05 ROCLINK 800 Software Basics 1-4

Page 14

ROCLINK 800 User Manual

1.5.1 Logging On

To log on to ROCLINK 800 Software:

1. Connect the ROC or FloBoss to the Local Operator Interface (LOI – Local Port) and launch

ROCLINK 800.

Figure 1-1. Logon

2. Type in your assigned 3-character identifier in the User ID field and press <Enter> or <Tab>.

Note: This User ID is case sensitive.

Your initials are typically your User ID. If User IDs have not yet been assigned, try using the

default User ID. of LOI. User IDs are assigned by using the ROC > Security feature in

ROCLINK 800 software.

3. Type in your assigned 4-digit Password and press <Enter> or click OK. For added security, the

software displays an asterisk for each number that you type. If Passwords have not yet been

assigned, use the default Password of 1000 (valid with default User ID of LOI).

ROCLINK 800 software compares the entered User ID and Password to a list of valid ones.

If the log on is not valid, a dialog box appears. Click OK and re-enter the User ID and Password. You

can repeat the procedure as many times as needed until you successfully enter a valid User ID and

Password.

To exit from the log on screen, press <Esc> or click Cancel. This aborts ROCLINK 800 software and

returns you to the point where you started ROCLINK 800 software.

Rev. Dec-05 ROCLINK 800 Software Basics 1-5

Page 15

ROCLINK 800 User Manual

1.6 User Interface Basics

Users interact with ROCLINK 800 software using various displays on the computer monitor and the

computer keyboard and/or pointing device.

The major components of ROCLINK 800 software user interface are:

♦ Menu bar and menus.

♦ Toolbar.

♦ Function screens.

♦ Dialog boxes.

♦ Help system, including the Status bar and message boxes.

♦ Device Directory or Configuration Tree menu.

ROCLINK 800 software employs a Graphical User Interface (GUI) with a standard Windows menu

structure. After logging on to ROCLINK 800 software, available functions display in a menu bar with

drop-down menus. A Status Line at the bottom left of the display contains pertinent information about

the highlighted item, such as a menu option or a parameter.

Buttons display dialog boxes for further configuration details or perform a desired action, such as the

Update button. To activate the button:

♦ Click the button with a left click of the mouse.

♦ When a button is active, press <Enter> or a function key.

Dialog boxes are areas that “pop up” inside the current screen to allow further selections or values to be

entered. They can also provide messages or information that is more detailed.

The menu structure lists choices from which you can select the desired function. Once a function is

selected, the screen or dialog box for that function displays. This screen or dialog box provides the

requested information and lets you enter the applicable configuration data. Refer to Table 1-1.

Rev. Dec-05 ROCLINK 800 Software Basics 1-6

Page 16

ROCLINK 800 User Manual

Table 1-1. Menu Listing for ROCLINK 800

Menu Menu Options

File

Edit

View

ROC

New, Open…, Download…, Close, Save Configuration, Print Configuration, Print

1, 3, 4

Print Setup

1, 3, 4

Undo

, [List of recent files], Exit

1, 3, 4

, Cut

, Copy

Directory, EFM Report, Calibration Report, History, Alarms, Events, Display, I/O Monitor, Toolbar

Direct Connect, Connect, Collect Data, Clock, Security, Comm Ports, Memory

Flags

Configure

Meter

Utilities

I/O, Control, History Segments

LCD

4

, User Data

2, 3, 4

Setup, Calibration, Values, Plate Change, History

Update Firmware, Update Hardware

Program Administrator, ROCLINK 800 Security, AI Calibration Values, RTD Calibration Values

MVS Calibration Values

Tools

Window

Help

1. This option applies to ROC800-Series units.

2. This option applies to FloBoss 100-Series units.

3. This option applies to FloBoss 407 units.

4. This option applies to ROC300-Series units.

Customize, Options

Cascade, Tile, Device Directory, [List of open windows]

Help Topics, About ROCLINK 800

1, 3, 4

, Paste

1

, History Points, Opcode Table, MODBUS, LCD User List

1, 3

, FST Editor, ROC Keypad Display Editor

1, 3, 4

3, 4

2

, License Key Administrator1, Convert EFM File, User

1

, Communications Monitor

1, 3, 4

2, 3, 4

,

, Information,

2, 3

,

1

,

Rev. Dec-05 ROCLINK 800 Software Basics 1-7

Page 17

ROCLINK 800 User Manual

1.6.1 Menu Bar and Menus

The menu bar appears at the top of the screen.

From the menu bar, you can use either the keyboard or the mouse to activate a menu and then to select a

function in that menu. You can also select functions using ToolBar Buttons or the Configuration Tree

Menu.

Figure 1-2. Menu Bar and ToolBar (ROC800-Series Example)

1.6.2 Buttons

Several buttons appear on the majority of ROCLINK 800 screens.

Minimize and hide windows.

Maximize the size of the windows to fit in the screen area.

Return to Original size of the window.

Close a window.

Expand options listed in the Device Directory or Configuration Tree Menu.

Hide options listed in the Device Directory or Configuration Tree Menu.

Copy contents of window to Clipboard.

Rev. Dec-05 ROCLINK 800 Software Basics 1-8

Page 18

Paste contents of the Clipboard to the active window.

Update contents of the active window from the device.

Apply changes, if any, on the active window to the device and close the active window.

A Confirm Save dialog box appears if there are unsaved changes.

Cancel all unsaved changes and close the active window.

Apply changes on the active window to the device.

Save contents of the active window.

Close the active window. A Confirm Save dialog box appears if there are unsaved

changes.

Delete current selection.

1.6.3 ToolBar

ROCLINK 800 User Manual

The following buttons appear in the ROCLINK 800 toolbar. These buttons will be grayed out if not

applicable to the current screen.

New file creates a New Configuration File. Available configuration parameters can be

specified using menu selections. Configure the file as if you were connected to the device.

Functions requiring a live connection are unavailable in this mode.

Open a disk file opens an existing configuration file. Configuration files are created using the

New Device or Save Configuration functions.

Save file saves the current configuration of the connected Device to a disk file.

Cut deletes currently selected text and places it in the Clipboard.

Copy duplicates currently selected text and places it in the Clipboard.

Paste places text currently in the Clipboard where the cursor is located.

Print prints the configuration file.

AI Points views the Analog Input window.

AO Points views the Analog Output window.

DI Points views the Discrete Input window.

DO Points views the Discrete Output window.

Rev. Dec-05 ROCLINK 800 Software Basics 1-9

Page 19

ROCLINK 800 User Manual

PI Points views the Pulse Input window.

Clock views the Clock window.

Comm Ports views the Comm Ports Setting window.

Direct Connect connects to a Device locally using the (LOI) Local Operator Interface port.

Connect connects to a Device.

Flags views the Flags window.

Meter Setup views the Meter Setup window.

Configure PID Points views the PID Loop window.

Plate Change views the Plate Change window.

FST Editor launches the Function Sequence Table Editor.

Display Program Information displays program information, version, creation date, and

copyright of ROCLINK 800 software.

Help launches ROCLINK 800 on-line help system.

1.6.4 Keystrokes

If you are using the keyboard, you may use the Alt key plus the letter to activate the menus. For

example, press <Alt + F> and press <O> to select the Open file dialog. You may also use the Left Arrow

← and Right Arrow → keys to highlight the menu bar item (the help Status Line at the bottom of the

screen provides a description of the menu) and press the letter.

With a menu displayed, you can highlight the desired item by using the Down Arrow ↓ and Up Arrow ↑

keys or the mouse. With the desired item highlighted, press the <Enter> key to activate the function.

To leave a menu or submenu, press the <Esc> key. You can then select another menu. You can also

access another menu simply by using the Left Arrow and Right Arrow key.

The text scrolling keys are the <Page Up> and <Page Down> keys.

To use the keyboard in configuration screens and dialog boxes, press the <Tab> key to move in a

predetermined sequence from one parameter field or button to the next. The selected field or button

becomes highlighted. Fields unavailable for changes are automatically skipped.

When you <Tab> to the last field or button in the screen or dialog box, pressing the <Tab> key again

jumps back to the first field or button. To go back to a previous field or button, press <Shift + Tab>.

Rev. Dec-05 ROCLINK 800 Software Basics 1-10

Page 20

ROCLINK 800 User Manual

In an option field, the currently selected option is highlighted. To select one of the other options, use the

Up Arrow ↑ and Down Arrow ↓ keys to highlight the desired option, and then press <Enter>.

In a field that requires a text or numerical entry, type in the required characters or numbers from the

keyboard. Use the <Backspace> or <Delete> keys to erase unwanted characters. Use the Left Arrow ←

and Right Arrow → to move the cursor one character at a time and the <Home> and <End> keys to

place the cursor at the beginning and end of the field, respectively.

Other keys or key combinations include:

♦ <F1> – Launches ROCLINK 800 on-line help.

♦ <Esc> – Cancels the current activity, closes the screen, and returns you to the last-used place in

the menu structure, screen, or other place from which the dialog box originated. If a menu is

active, <Esc> closes the last-opened menu, taking you up one level in the menu structure. If the

menu bar is active, <Esc> de-selects all menu options. Press the <Alt> key or click with the

mouse to reactivate the menu bar.

♦ <Ctrl + N> – Creates a new configuration file.

♦ <Ctrl + O> – Opens a configuration file.

♦ <Ctrl + S> – Saves the current configuration file.

1.6.5 Help System

The Help menu provides detailed on-screen information about getting started with ROCLINK 800

software and performing keyboard operations, a list of the Help topics, and the ROCLINK 800 software

version.

To display context sensitive help on a menu item, a parameter, or a button, press <F1> while the item,

parameter, or button is highlighted. A help window appears on the screen.

To view detailed help, select Help > Help Topics.

Contents – The Contents button displays a list of Help Topics that display based on task oriented

situations. Each screen, tab, and field has a help topic associated with it. For example: the Modbus

Scale Values tab is located under Modbus > Modbus Configuration > Scale Values Tab.

Index – Use the Index to locate specific Help Topics. The Index lists each field individually and by the

tab or screen in which the field appears. For example: Modbus Scale Values appears in the Index

under Modbus Configuration > Scale Values Tab and under Scale Values. Each field within the

Scale Values Tab displays under the Index listing Modbus Configuration – Scale Values Tab and

individual based on the name of the field.

Search – Use Search to query on specific word.

Back – Click to return to the last topic that you viewed.

Print – Click to Print the currently displayed topic.

<< and >> – Click the Browse Sequence buttons to navigate forward (>>) and backwards (<<) through

the help system on a per topic basis. The Browse Sequence follows the order of the topics as

displayed in the Contents tab.

See Also – Click to display topics related to the selected topic.

Rev. Dec-05 ROCLINK 800 Software Basics 1-11

Page 21

ROCLINK 800 User Manual

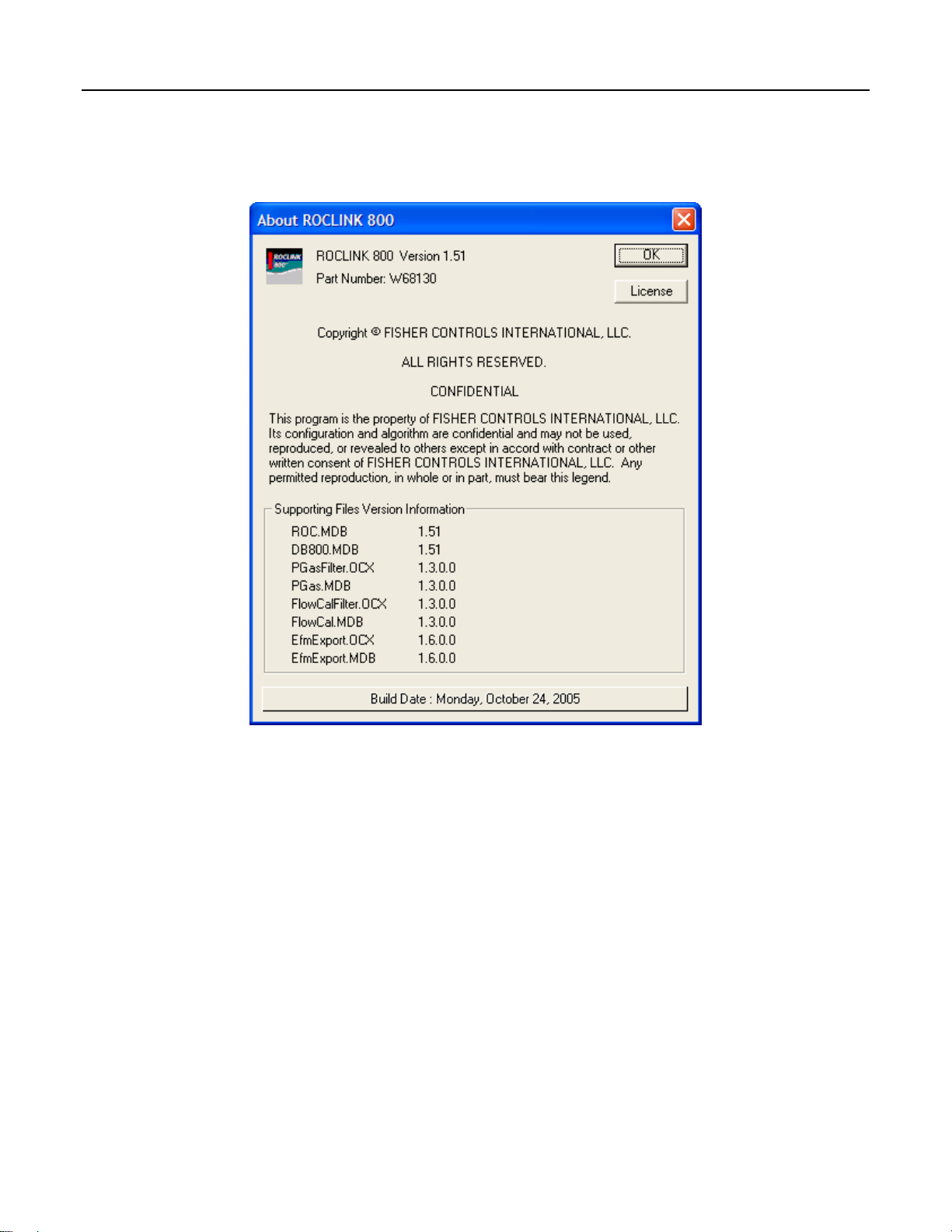

1.6.6 About ROCLINK 800

Select Help > About ROCLINK 800 to view the ROCLINK 800 version number and other information,

such as Supporting Files Version Information.

Figure 1-3. About ROCLINK 800 (ROC800-Series)

1.6.7 Basic Navigation

When you start the ROCLINK 800 software, the Device Directory displays. After you connect to a ROC

or FloBoss, the Configuration Tree View displays. Refer to Figure 1-7.

Use the + and – symbols to display or hide various options. Double-click a point to display the

associated parameter configuration screen. You can also use the menu options and buttons to display the

associated parameter configuration screen.

The Status Line at the bottom of the Device Directory and Configuration Tree View serves two

purposes. First, on the left side of the line, brief information about the device being connected. Second,

on the right side of the line, the device on-line or off-line status and system time display.

Rev. Dec-05 ROCLINK 800 Software Basics 1-12

Page 22

ROCLINK 800 User Manual

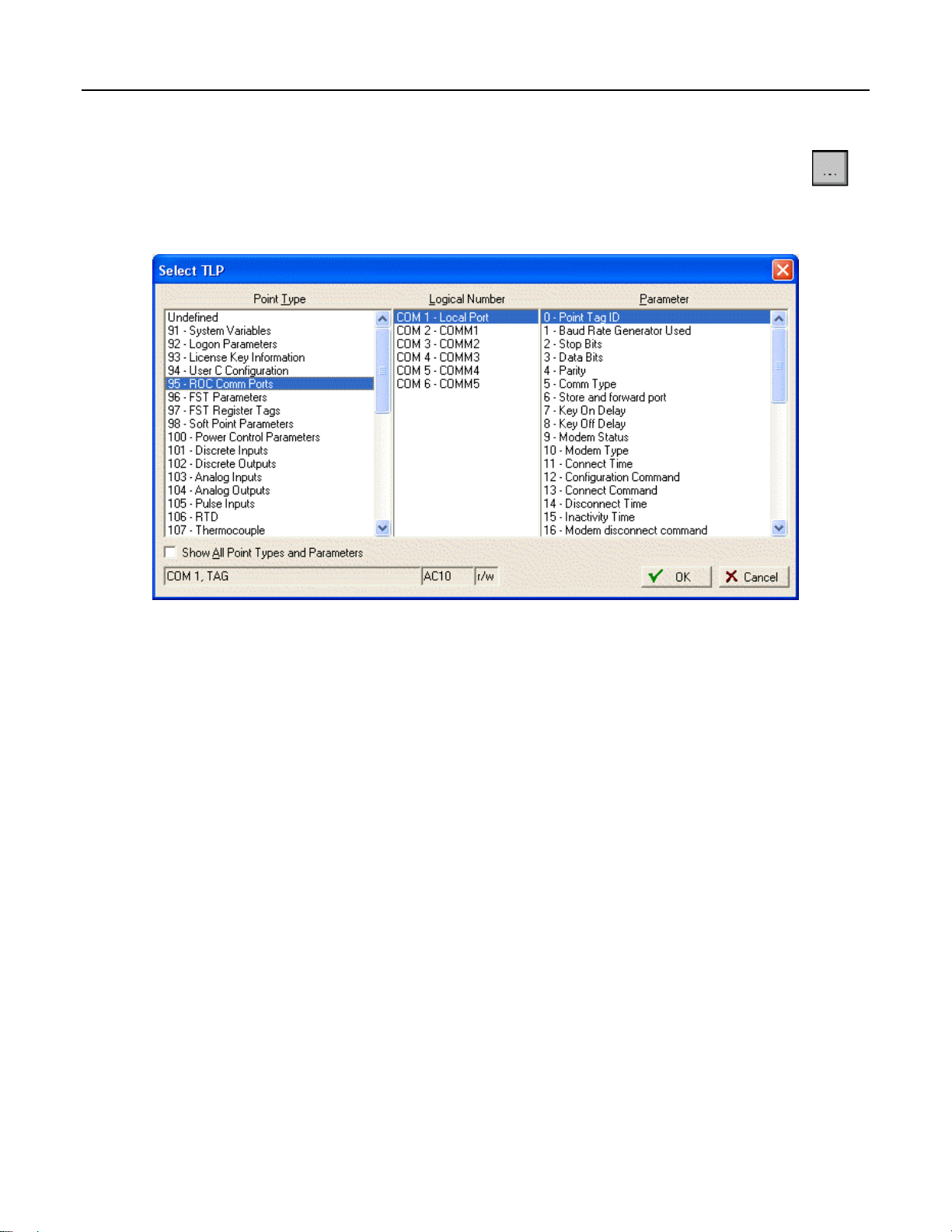

1.6.8 TLP Box Selections

Throughout ROCLINK 800 software, the Select TLP dialog can be accessed by clicking the

browse button with three dots. The Select TLP dialog allows you to assign specific inputs and

outputs to parameters. ROCLINK 800 software uses Point Type (T), Logical Number (L), and

Parameter (P) to define point locations.

Figure 1-4. Select TLP

To use the Select TLP dialog box:

1. Select the Point Type from the list. This opens a list of logical numbers and parameters that

belong to that Point Type.

2. Select the Logical Number. In the configuration screens, the Logical Number is generally

referred to as Point Number or Number.

3. Select the specific Parameter. These are usually called by the same term as the Tag on the

configuration screen. Click OK.

The display field at the bottom of the Select TLP dialog displays the numeric point location of the TLP

point or a text abbreviation, depending on the setting in the Tools > Options window.

Rev. Dec-05 ROCLINK 800 Software Basics 1-13

Page 23

ROCLINK 800 User Manual

1.6.8.1 Display TLP Options

Select Tools > Options to set whether TLPs display as text or numbers in TLP display fields throughout

ROCLINK 800 software, including the FST Editor. For example, the TLP for Register 2 of FST 1 could

display as either “FST 1,R2” or “96, 0, 3”.

Figure 1-5. TLP Options

Select Tools > Options to set the time interval, in seconds, at which the AutoScan feature on various

screens in ROCLINK 800 software will poll the ROC or FloBoss device. Click the AutoScan button to

cause ROCLINK 800 software to poll the device automatically, until the StopScan button is clicked.

1.6.9 AutoScan Update Interval Option

Select Tools > Options to set the time interval, in seconds, at which the AutoScan feature on various

screens in ROCLINK 800 software will poll the ROC or FloBoss device. Pushing the AutoScan button

on any screen will cause ROCLINK 800 software to poll the device automatically, until the StopScan

button is pushed.

1.7 Configuration Basics

Configuration of a ROC or FloBoss unit can be performed by altering an existing configuration file or

by starting a new configuration file.

The full configuration procedure involves using the menu functions or Configuration Tree Menu to

access the configuration screens. Some of the configuration screens may not be required for your

application or may not be available for your type of ROC or FloBoss.

The following checklists present the order of configuration in a typical application. Omit configuration

screens for modules and accessories that do not appear in your hardware configuration and for control

elements (PID, FST, and such) that do not apply to your application.

Rev. Dec-05 ROCLINK 800 Software Basics 1-14

Page 24

ROCLINK 800 User Manual

1.7.1 Configuration Checklist (ROC800-Series)

For a ROC800-Series unit:

♦ ROC menu > ROCLINK 800 Security (logon)

♦ Device Directory > Comm Port > Properties (PC communication configurations)

♦ ROC menu > Security (User List and Comm Port Security)

♦ ROC menu > Clock

♦ ROC menu > Information (system variables)

♦ Utilities menu > License Key Administrator (for user programs, DS800 programs and AGA

Meter Runs)

♦ Meter menu > Setup > Station (for English or Metric Unit selection)

♦ ROC menu > Comm Ports (ROC communication configurations)

♦ Configure menu > I/O menu > AI, AO, DI, DO, PI, HART, MVS, RTD, and T/C

♦ Meter menu > Station Configuration

♦ Meter menu > Orifice or Turbine Meter Setup

♦ Configure menu > History Segments and History Points (history database)

♦ Configure menu > Control menu > PID Loop

♦ Configure menu > Radio Power Control (for communications sleep mode)

♦ Utilities menu > FST Editor

♦ View menu > Display > New or from File (for custom PC displays)

♦ Utilities menu > Keypad Display (for ROC Keypad Display)

♦ ROC menu > Flags (for saving and system variables to Flash memory)

Rev. Dec-05 ROCLINK 800 Software Basics 1-15

Page 25

ROCLINK 800 User Manual

1.7.2 Configuration Checklist (ROC300-Series)

For a ROC300-Series unit:

♦ Utilities menu > ROCLINK 800 Security (logon)

♦ Device Directory > Comm Port > Properties (PC communication configurations)

♦ ROC menu > Security (User List and Comm Port Security)

♦ ROC menu > Clock

♦ ROC menu > Information (system variables)

♦ ROC menu > Comm Ports (ROC communication configurations)

♦ Configure menu > I/O menu > AI, AO, DI, DO, and PI

♦ Meter menu > Setup (Orifice or Turbine meter)

♦ Meter menu > History (Meter run history setup)

♦ Configure menu > Control menu > PID Loop

♦ Configure menu > History Points (history database)

♦ Configure menu > LCD

♦ Configure menu > Radio Power Control (communications sleep mode)

♦ Utilities menu > FST Editor

♦ ROC menu > Flags (for saving and system variables to Flash memory)

1.7.3 Configuration Checklist (FloBoss 100-Series)

For a FloBoss 100-Series unit:

♦ ROC menu > ROCLINK 800 Security (logon)

♦ Device Directory > Comm Port > Properties (PC communication configurations)

♦ ROC menu > Security (User List and Comm Port Security)

♦ ROC menu > Clock

♦ ROC menu > Information (system variables)

♦ ROC menu > Comm Ports (ROC communication configurations)

♦ Configure menu > I/O menu > AI, AO, DI, DO, and PI

♦ Meter menu > Setup (orifice or turbine meter)

♦ Meter menu > History (Meter run history setup)

♦ Configure menu > Control menu > PID Loop

♦ Configure menu > History Points (history database)

♦ Configure menu > LCD User List

♦ Configure menu > Radio Power Control (for communications sleep mode)

♦ Utilities menu > FST Editor

♦ View menu > Display > New or from File (for custom PC displays)

♦ ROC menu > Flags (for saving and system variables to Flash memory)

Rev. Dec-05 ROCLINK 800 Software Basics 1-16

Page 26

ROCLINK 800 User Manual

1.7.4 Configuration Checklist (FloBoss 407)

For a FloBoss 407 unit:

♦ Utilities menu > ROCLINK 800 Security (logon)

♦ Device Directory > Comm Port > Properties (PC communication configurations)

♦ ROC menu > Security (User List and Comm Port Security)

♦ ROC menu > Clock

♦ ROC menu > Information (system variables)

♦ ROC menu > Comm Ports (ROC communication configurations)

♦ Configure menu > I/O menu > AI, AO, DI, DO, PI, and MVS

♦ Meter menu > Setup (Orifice or Turbine meter)

♦ Meter menu > History (Meter run history setup)

♦ Configure menu > Control menu > PID Loop

♦ Configure menu > History Points (history database)

♦ Configure menu > LCD User List

♦ Configure menu > Radio Power Control (communications sleep mode)

♦ Utilities menu > FST Editor

♦ ROC menu > Flags (for saving and system variables to Flash memory)

1.7.5 Duplicating a Configuration

You can duplicate the configuration for another ROC or FloBoss unit by using these menu functions in

the following order:

1. File > Save Configuration to save the configuration to a specified file.

2. ROC > Direct Connect (Local Port) or Connect (modem) to connect physically to the second

unit, and then communicate.

3. File > Download loads the configuration into the unit.

After you have loaded configuration data into the second ROC (Step 3) and changed it as needed, you

can save the configuration to its own disk file by using Step 1.

Rev. Dec-05 ROCLINK 800 Software Basics 1-17

Page 27

ROCLINK 800 User Manual

1.8 Creating a New Configuration File

The new configuration file screen allows you to create a configuration file off-line with the basic

information about the meters and modules that will be installed on the ROC or FloBoss unit for which

the new configuration was created.

1. Select File > New.

Figure 1-6. New File Configuration Example (ROC800-Series)

2. The Type parameter indicates the type of ROC or FloBoss unit.

3. For the ROC800-Series, select the type of I/O or Comm 809 Modules that will reside in each of

the nine module slots of the ROC800-Series unit.

4. For the FloBoss 100-Series, select the type of termination board (I/O Type). Selections are 4

point (old style termination board) or 6 point (new style) with or without I/O points. When 6

point with I/O is selected, External I/O selections appear. Be sure to select the types of I/O for

which the termination board switches and wiring are configured.

5. For the ROC800-Series, enter the number of PID loops, FSTs, Stations, Sampler/Odorizers,

Orifice Meters, and Turbine Meters that will be configured. Only activate the necessary number

of devices.

6. For the FloBoss 100-Series, enter the number of PID Loops.

7. For the FloBoss 100-Series, select the maximum number of History Points in Standard and

Extended History (103 History Sizing). Be sure to select this carefully, as History Points cannot

be added later without clearing current history present in the unit. Standard history affects the

amount of available extended history.

Rev. Dec-05 ROCLINK 800 Software Basics 1-18

Page 28

ROCLINK 800 User Manual

8. Save the configuration file. ROCLINK 800 files have the extension .800.

9. Establish an on-line connection to the ROC or FloBoss unit.

10. Set the parameters and point assignments, as necessary.

The Type parameter indicates the type of ROC or FloBoss unit.

For the FloBoss 100-Series, select the type of termination board (I/O Type). Selections are 4 point (old

style termination board) or 6 point (new style) with or without I/O points. When 6 point with I/O is

selected, External I/O selections appear. Be sure to select the types of I/O for which the termination

board switches and wiring are configured.

For the ROC800-Series, enter the number of PID loops, FSTs, Stations, Sampler/Odorizers, Orifice

Meters, and Turbine Meters that will be configured. Only activate the necessary number of devices. For

the FloBoss 100-Series, enter the number of PID Loops.

For the ROC800-Series, select the type of I/O or Comm 809 Modules that will reside in each of the nine

module slots of the ROC800-Series unit.

For the FloBoss 100-Series, select the maximum number of History Points in Standard and Extended

History (103 History Sizing). Be sure to select this carefully, as History Points cannot be added later.

Optionally, the FloBoss 100-Series units have I/O. When 6 point I/O termination board is selected,

External I/O selections appear. Be sure to select the types of I/O for which the termination board

switches and wiring are configured.

1.8.1 Opening a Configuration File

The Open option allows you to open an existing configuration file either on-line (from a ROC or

FloBoss unit) or off-line (from the PC hard drive or disk). Configuration files are created using the Save

Configuration function. To open a configuration file:

1. Establish an on-line connection to the ROC or FloBoss, if opening a file on-line.

2. Select File > Open.

3. Select the configuration file name. ROCLINK 800 files have the extension .800.

4. Alter the parameters and point assignments as necessary.

Once the configuration file is opened, it automatically becomes active and you may edit the file off-line.

The configuration file may also be loaded into a ROC by using the Download function.

Rev. Dec-05 ROCLINK 800 Software Basics 1-19

Page 29

ROCLINK 800 User Manual

1.8.2 Configuration Tree Menu

When you open a configuration file or go on-line with a ROC or FloBoss unit, the Configuration Tree

appears on the screen. It has a hierarchy tree with the configurable items in the configuration, such as

I/O, Meter Runs, and History.

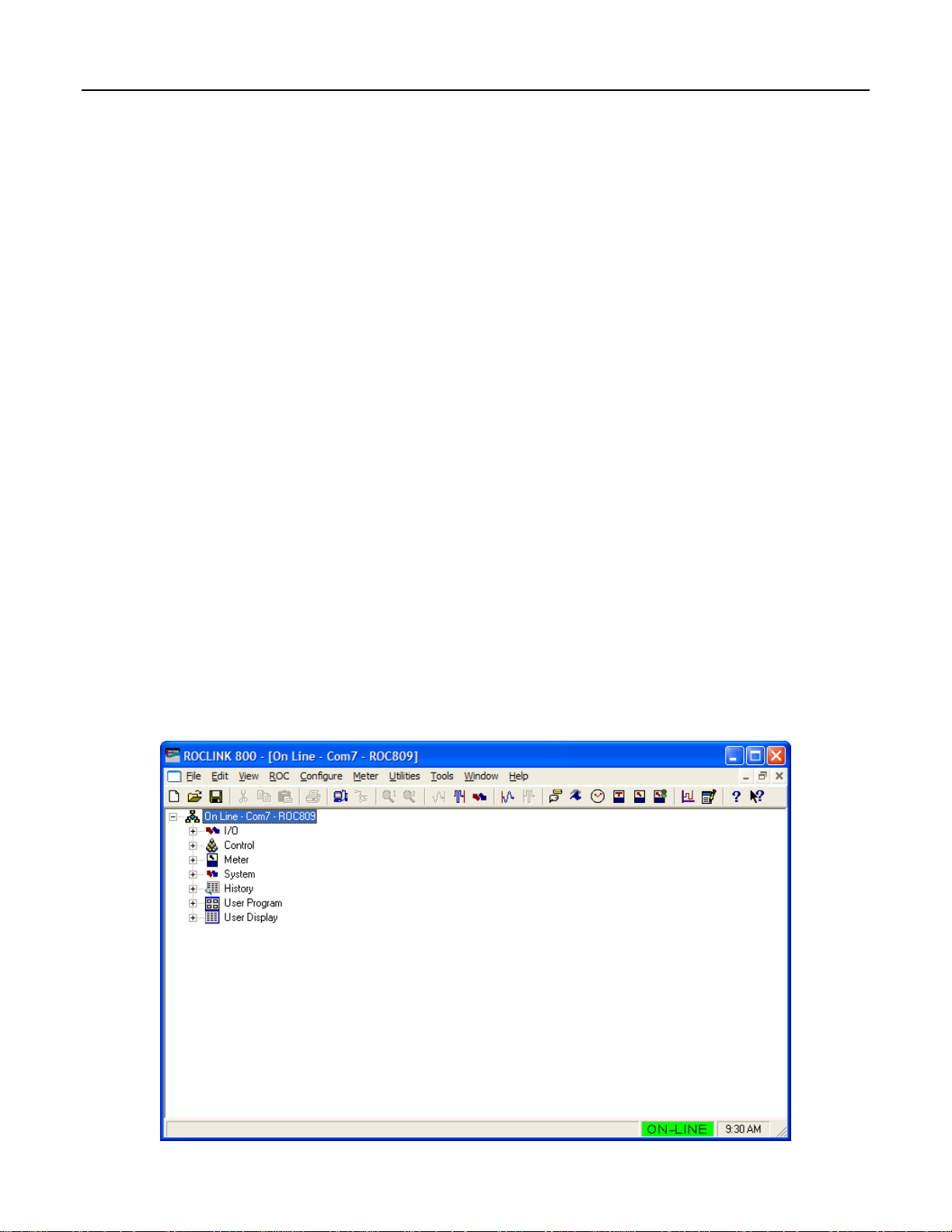

Figure 1-7. Configuration Tree

Rev. Dec-05 ROCLINK 800 Software Basics 1-20

Page 30

ROCLINK 800 User Manual

SECTION 2 – CONFIGURING COMMUNICATIONS AND

SECURITY

This section describes how to configure the communication ports on a PC and on a ROC or FloBoss. It

also describes how to use the Connect and Direct Connect features in ROCLINK 800 software and

security controlling access to the ROC or FloBoss and ROCLINK 800 software.

Security can be controlled in two ways:

♦ ROCLINK 800 Security – The ROCLINK 800 Security screen allows you to control who can

log on to ROCLINK 800 software and which screens they can access. Refer to Section 2.2,

ROCLINK 800 Security, on page 2-5.

♦ Device Security – Device Security screen controls who has access to the Comm Ports on the

ROC or FloBoss device. Refer to Section 2.3, Device Security, on page 2-6.

Note: Security Access Levels enable you to control which users have access to specific

ROCLINK 800 functions. Refer to Section 2.1, Security Access Levels, on page 2-2.

Before attempting to connect to a ROC or FloBoss, configure communication parameters in two places:

♦ ROCLINK 800 Communications – The Device Directory communication configurations allow

ROCLINK 800 software to communicate to an individual ROC or FloBoss unit. Refer to Section

2.6, ROCLINK 800 Communications, on page 2-17.

♦ Communication Ports on the ROC and FloBoss – Use the ROC > Comm Ports to set up

communication ports available for incoming or outgoing communications with the ROC or

FloBoss. Refer to Section 2.7, Communication Ports on the ROC and FloBoss, on page 2-21.

In this Chapter

Section Page

2.1 Security Access Levels...................................................................................................................2-2

2.2 ROCLINK 800 Security .................................................................................................................2-5

2.3 Device Security...............................................................................................................................2-6

2.4 License Key Administrator (ROC800-Series).............................................................................. 2-13

2.5 Device Directory...........................................................................................................................2-14

2.6 ROCLINK 800 Communications .................................................................................................2-17

2.7 Communication Ports on the ROC and FloBoss...........................................................................2-21

2.8 Connecting to a ROC or FloBoss..................................................................................................2-36

2.9 Troubleshooting Communications................................................................................................ 2-38

Rev. Dec-05 Configuring Communications and Security 2-1

Page 31

ROCLINK 800 User Manual

2.1 Security Access Levels

Refer to Table 2-1. The Menu Options focus on the activity while you use the Access Levels to

increase or decrease responsibility levels within the Menu Options.

Note: If security is enabled on any port, at least one user must have the highest level of security

(level 5).

Note: Login requests are rejected when ROCLINK 800 Access Levels are greater than Device

Security.

Table 2-1. Security Access Levels

Menu Menu Option Access Level

ROC Security 5

Utilities License Key Administrator 5

Utilities ROCLINK 800 Security 5

Utilities Update Firmware 4

Utilities Upgrade Hardware 4

Utilities Upgrade to FlashPAC 4

Utilities User Program Administrator 4

Configure Control > DS800 3

Configure Control > FST Registers 3

Configure Control > PID Loop 3

Configure Control > Radio Power Control 3

Configure Control > Sampler Odorizer 3

Configure History Points 3

Configure History Segments 3

Configure I/O > AI Points 3

Configure I/O > AO Points 3

Configure I/O > DI Points 3

Configure I/O > DO Points 3

Configure I/O > MVS Sensor 3

Configure I/O > PI Points 3

Configure I/O > RTD Points 3

Configure I/O > Soft Points 3

Configure I/O > System AI Points 3

Configure I/O > T/C Points 3

Configure LCD User List 3

Configure Modbus > Configuration 3

Configure Modbus > History 3

Configure Modbus > Master Modem 3

Configure Modbus > Master Table 3

Configure Modbus > Registers 3

Configure Opcode Table 3

Configure User Data 3

File Download 3

File New 3

File Save Configuration 3

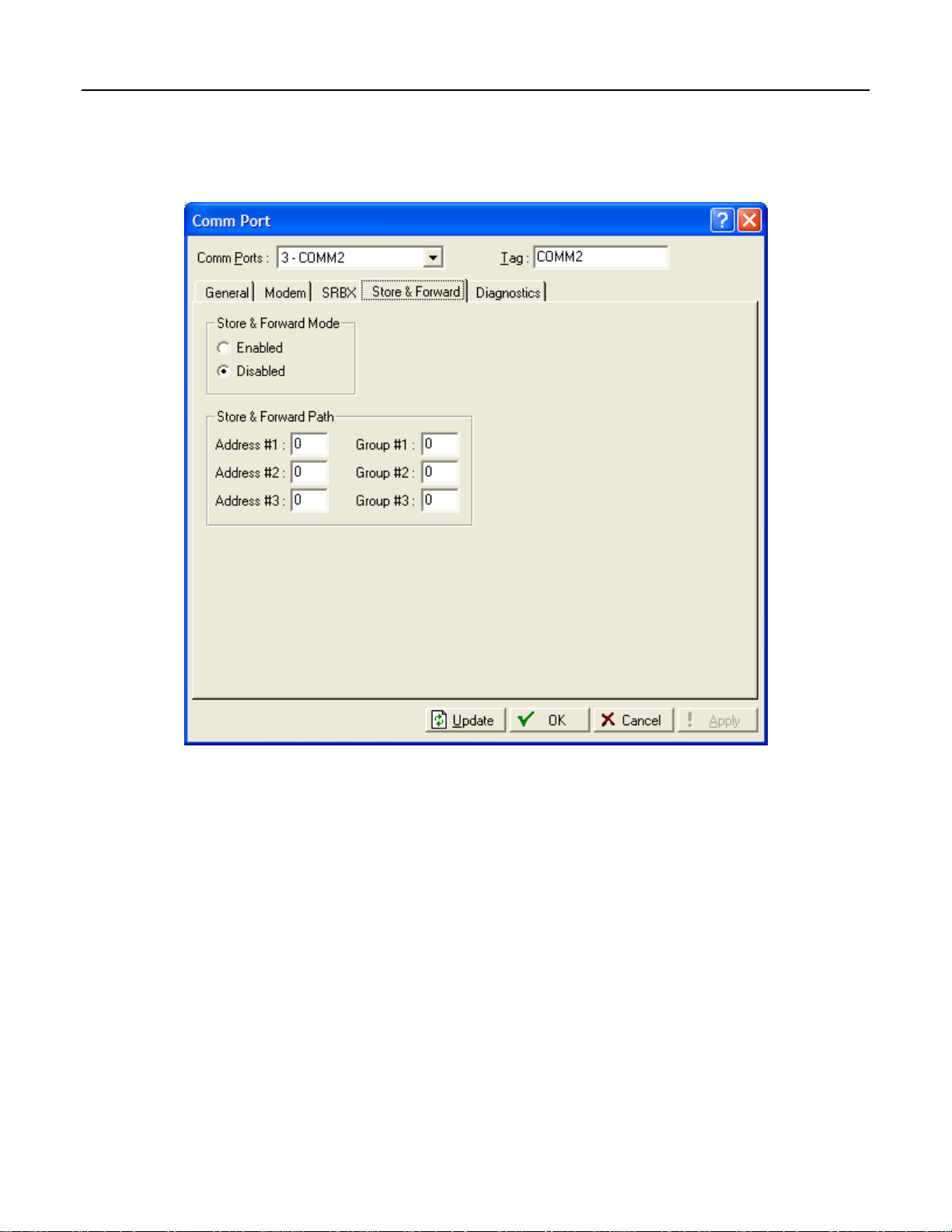

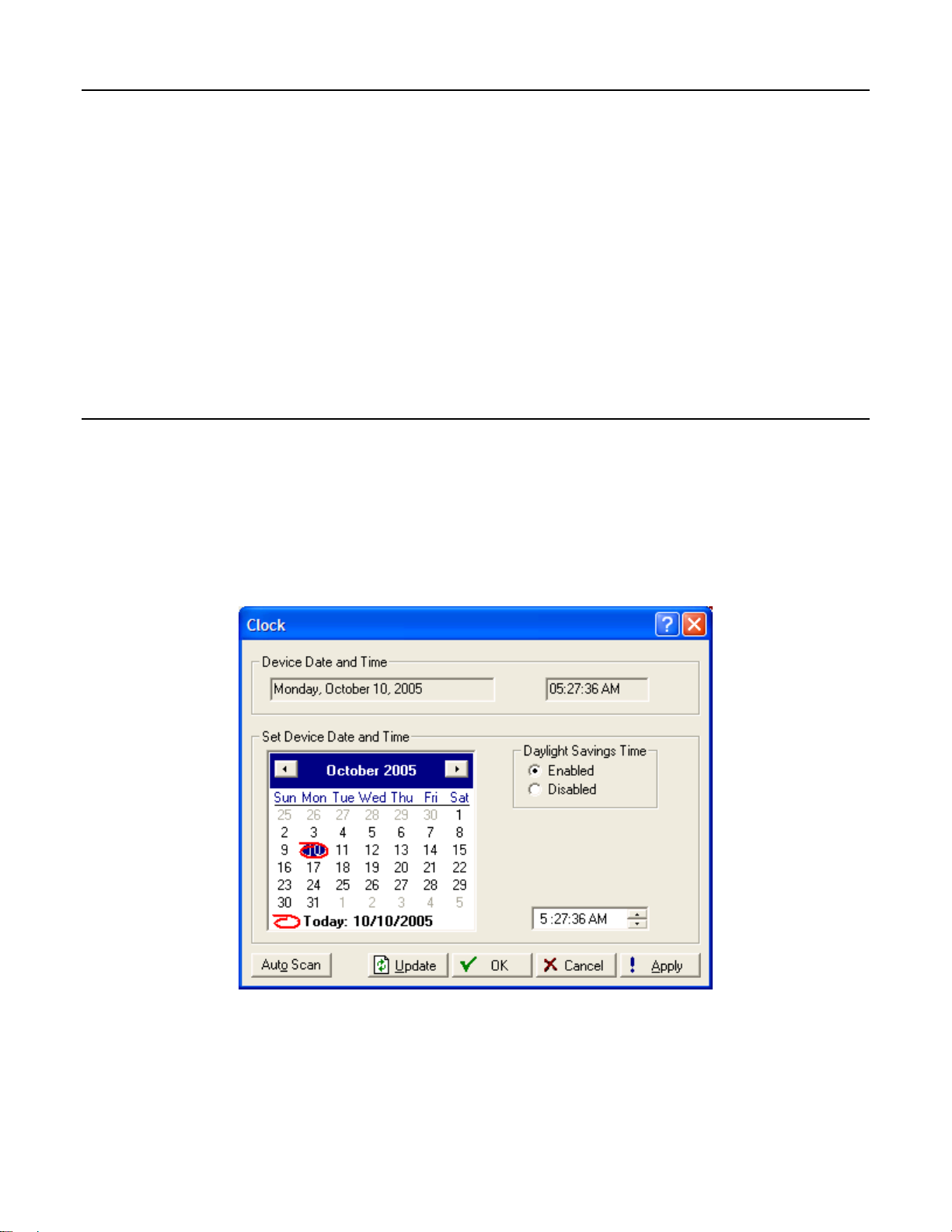

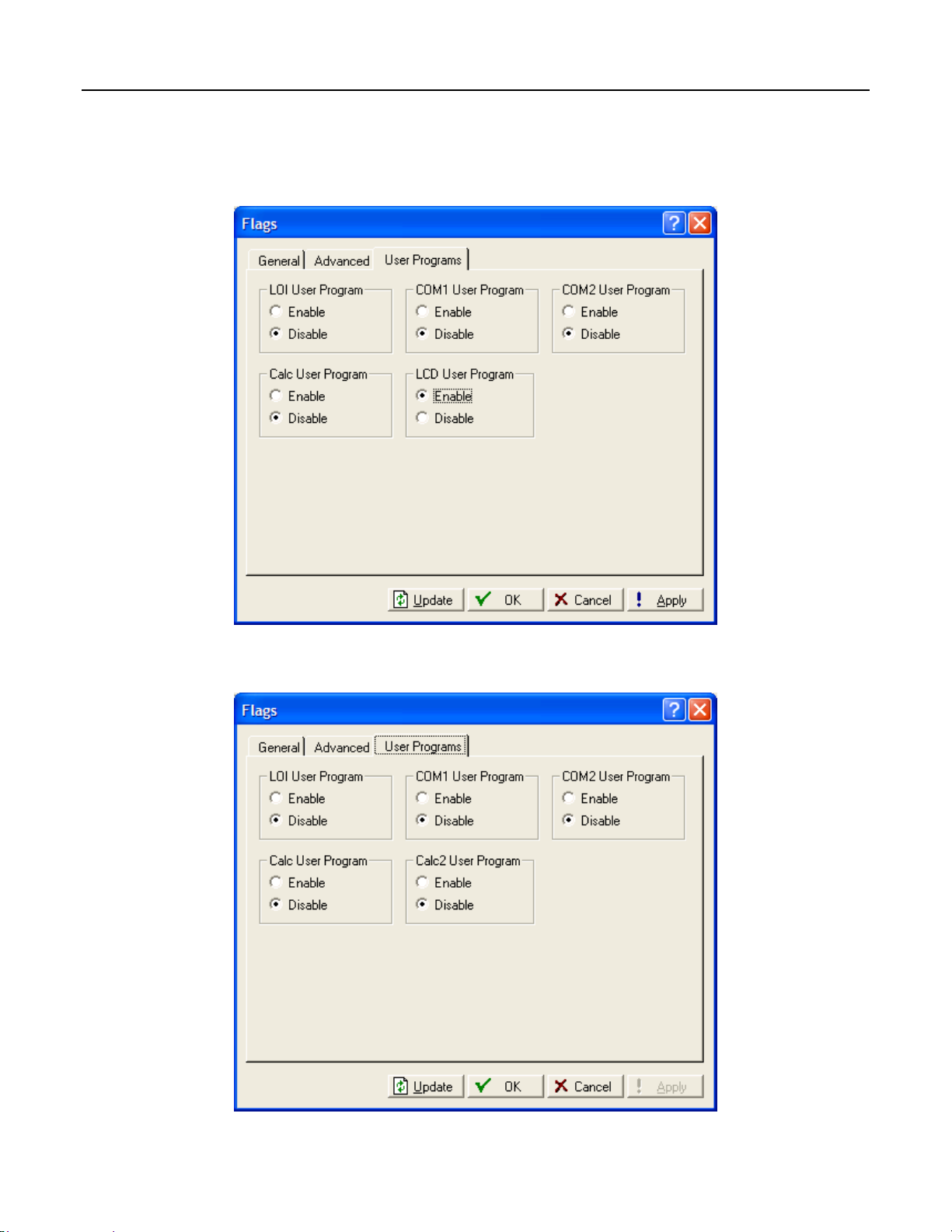

ROC Clock 3