Remote Automation Solutions Level Sensor Application Module (for FB107) User Manual Manuals & Guides

Page 1

Form A6271

Part Number D301596X012

June 2009

Level Sensor Application Module

™

(for FloBoss

107 Flow Managers)

User Manual

Remote Automation Solutions

Page 2

Level Sensor Application Module User Manual

Revision Tracking Sheet

June 2009

This manual may be revised periodically to incorporate new or updated information. The revision date of each

page appears at the bottom of the page opposite the page number. A change in revision date to any page also

changes the date of the manual that appears on the front cover. Listed below is the revision date of each page

(if applicable):

Page Revision

Initial release Jun-09

NOTICE

Remote Automation Solutions (“RAS”), division of Emerson Process Management shall not be liable for technical or editorial errors in this

manual or omissions from this manual. RAS MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN

NO EVENT SHALL RAS BE LIABLE FOR ANY INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT

NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS INCURRED INCLUDING

WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF THIRD PARTIES.

Bristol, Inc., Bristol Canada, BBI SA de CV and Emerson Process Management Ltd, Remote Automation Solutions division (UK), are wholly

owned subsidiaries of Emerson Electric Co. doing business as Remote Automation Solutions (“RAS”), a division of Emerson Process

Management. FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS, PlantWeb

and the PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the Emerson Electric Co.

All other trademarks are property of their respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational

accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described

herein or their use or applicability. RAS reserves the right to modify or improve the designs or specifications of such products at any time

without notice. All sales are governed by RAS’ terms and conditions which are available upon request.

RAS does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any RAS product remains solely with the purchaser and end-user.

©2009 Remote Automation Solutions, division of Emerson Process Management. All rights reserved

.

ii Issued Jun-09

Page 3

Level Sensor Application Module User Manual

Contents

Page

Chapter 1 – Introduction....................................................................................................................1-1

1.1 Scope and Organization...............................................................................................1-1

1.2 Product Overview .........................................................................................................1-1

1.2.1 Wave Smoothing............................................................................................1-2

1.2.2 Module Wiring................................................................................................1-4

1.3 Program Requirements.................................................................................................1-5

Chapter 2 – Installation......................................................................................................................2-1

2.1 Installing the Application Module..................................................................................2-1

Chapter 3 – Configuration.................................................................................................................3-1

3.1 Level Sensor Configuration Screen..............................................................................3-2

3.2 Level Sensor Data Screen............................................................................................3-4

3.3 Saving the Configuration ..............................................................................................3-8

Chapter 4 – Reference Materials.......................................................................................................4-1

4.1 Point Type 63: Level Sensor Configuration and Status................................................4-3

4.2 Point Type 64: Level Sensor Data................................................................................4-6

Issued Jun-09 Contents iii

Page 4

Level Sensor Application Module User Manual

[This page is intentionally left blank.]

iv Contents Issued Jun-09

Page 5

Chapter 1 – Introduction

This chapter describes the structure of this manual and presents an

overview of the Level Sensor (LS) Application Module for the

FloBoss™ 107 (“FB107”). The LS Application Module provides all the

functions necessary to communicate with a level sensor (such as an

Advanced Telemetrics 1100LD digital tank gauge or any other level

sensor using that protocol), including an onboard communications port

that enables module-to-LS communications without using one of the

communications ports on the FB107.

The standard APP 485 application module (which includes the LS

Application Module) streamlines the installation process by

automatically installing all point types and screens that are part of the

application. APP 485 modules can house a variety of applications; for

further information about additional APP 485 modules, contact your

sales representative.

Level Sensor Application Module User Manual

1.1 Scope and Organization

This document serves as the user manual for the Level Sensor

Application module, which is intended for use in a FloBoss 107

(FB107). This manual describes how to install and configure the Level

Sensor Application module (referred to as the “LS Application module”

or “the module” throughout the rest of this manual). You access and

configure this module using ROCLINK™ 800 Configuration Software

loaded on a personal computer running Windows® 2000 (with Service

Pack 2), Windows XP, or Windows Vista.

The sections in this manual provide information in a sequence

appropriate for first-time users. Once you become familiar with the

procedures and the software, the manual becomes a reference tool.

This manual has the following major sections:

Chapter 1 – Introduction

Chapter 2 – Installation

Chapter 3 – Configuration

Chapter 4 – Reference

This manual assumes that you are familiar with the FB107 and its

configuration. For more information, refer to the FloBoss 107 Flow

Manager Instruction Manual (Form A6206) or the ROCLINK 800

Configuration Software User Manual (for FloBoss 107) (Form A6217).

1.2 Product Overview

The Level Sensor Application module enables the FB107 to

communicate directly with up to ten level sensors (reporting on oil or

Issued Jun-09 Introduction 1-1

Page 6

Level Sensor Application Module User Manual

water or both) on the same EIA-485 (RS-485) communications port.

(The module provides its own communication for this purpose.) The

module serves as an interface between the sensors and the FB107,

supporting the Advanced Telemetrics 1100LD or 1100C digital tank

gauges or any other level sensor using that protocol. The module polls

data from the level sensor, validates that data, and updates the

appropriate production totals using that data.

At a scan interval you specify, the module polls each sensor, requesting

current tank levels and fluid temperatures. As each sensor responds, the

module compares the current tank level value against that sensor’s last

good level value response.

If the sensor reports a difference (representing a drop in level), the

module multiplies that difference by a conversion factor (“strapping

value”) you define, reflects that change in the accumulated runs, and

calculates and updates the closing stock value. For this module, the drop

in level value represents a load. The module also determines production

values, which represent increases in the level values, using the

calculation:

(Closing stock value) + (Accumulated runs) – (Opening stock value)

At the contract hour (which you can either specifically define for the

module or default to the contract hour defined on the FB107), the

module:

Copies the total production values for all tanks to yesterday’s total

production and initializes total production, and

Copies the closing stock values to the opening stock values and

initializes the accumulated runs and production.

1.2.1 Wave Smoothing

The module uses an algorithm to limit the detection of “waves,” or false

changes in fluid level. You use the Level Sensor Data screen (see

Section 3.2) to configure the wave smoothing parameters, which

include:

Maximum wave limit (distance in inches above or below the last

valid reading).

Scan periods (the number of times the module reads the level to

validate the wave height).

Wave timeout (the number of scans to determine if level variations

are due to liquid movement or “sloshing”). This parameter enables

you to validate and count level changes that are smaller than the

maximum wave limit.

To assist in the calculations, the module also tracks the following values

and displays them on the Level Sensor Data screen:

Current level (the actual measured level).

Production accumulation (positive changes in level).

Load accumulation (negative changes in level).

1-2 Introduction Issued Jun-09

Page 7

Level Sensor Application Module User Manual

Change (sensor level minus production or load level).

Once each scan period, the module reads the sensors and performs wave

smoothing calculations. You can configure maximum wave limits

(typically 1 inch) and specify the number of scan periods (typically one

per second) until the module considers a wave a valid reading (where

the wave timeout value = 5) for oil or water.

When the module first reads the sensor, the module stores that value as

the production or load level. When the next sensor reading occurs, the

module compares the stored production level value to the actual reading

and, depending on the amount of change, performs one of three actions:

No change

If the difference between one reading and the next is less than or

equal to the maximum wave limit value, the module retains the

current value for the specified number of scan periods until wave

timeout value expires. At that time the level becomes the production

or load level and the module adjusts the accumulators accordingly.

Positive change

If the difference between one reading and the next is positive and

greater than the maximum wave limit value, the module adds the

change to the production accumulator and the new level becomes

the production or load level. The module continues to add positive

changes to the production accumulator until there are no more

changes outside of the maximum wave limit and the wave timeout

value expires. At that time the level becomes the production or load

level.

Negative change

If the difference between one reading and the next is negative and

greater than the maximum wave limit value, the module adds the

change to the load accumulator and continues adding subsequent

values to the load accumulator as long as the level continues to drop

and the wave timeout value has not expired.

Figure 1 presents a flow chart illustrating this process:

Issued Jun-09 Introduction 1-3

Page 8

Level Sensor Application Module User Manual

Figure 1. Wave Smoothing

1.2.2 Module Wiring

Connect the sensor(s) to the communications port on the module using

between 16 and 24 AWG wiring. Figure 2 shows example wiring

between the module and several sensors.

Note: Level sensors can be either externally powered or obtain power

through the sensor wiring itself.

1-4 Introduction Issued Jun-09

Page 9

Level Sensor Application Module User Manual

120 OHM

TERMINATION RESISTOR

USER SUPPLIED

A

B

FIELD

DEVICE

+

-

A

FIELD

DEVICE

B

++

--

A

FIELD

DEVICE

B

EXTERNAL

Figure 2. Module Wiring

DO Points

To save power, you can specify a DO point the module controls,

which enables you to turn on a level sensor before it is polled and then

turn it off after polling. This is typically a DO status point (2,x,3). To

accomplish this, you need to connect to a DOR module on the FB107

or supply your own relay.

1.3 Program Requirements

The Level Sensor Application module is compatible with version 1.20

(or greater) of the FB107 firmware and with version 1.82 (or greater) of

the ROCLINK 800 software.

EXTERNAL

POWERPOWER

EXTERNAL

POWER

Issued Jun-09 Introduction 1-5

Page 10

Level Sensor Application Module User Manual

[This page is intentionally left blank.]

1-6 Introduction Issued Jun-09

Page 11

Chapter 2 – Installation

This chapter provides instructions for installing the LS Application

module. Read Section 1.3 of this manual for program requirements.

2.1 Installing the Application Module

The application module occupies the standard footprint of a FB107 I/O

or communications module. To install the module, place it in an empty

slot (1 through 7) on the FB107. To ensure that the FB107 recognizes

the module, you must perform a warm start (ROC > Flags > Warm

Start).

Note: Although the label on the physical module is APP 485, the

Description field on the General tab verifies that this module

contains the Level Sensor Application. See Figure 3.

Level Sensor Application Module User Manual

Figure 3. LS Application Module

Once you have verified that the FB107 has recognized the LS

Application module, proceed to Chapter 3 to begin configuring the

module.

Issued Jun-09 Installation 2-1

Page 12

Level Sensor Application Module User Manual

[This page is intentionally left blank.]

2-2 Installation Issued Jun-09

Page 13

Chapter 3 – Configuration

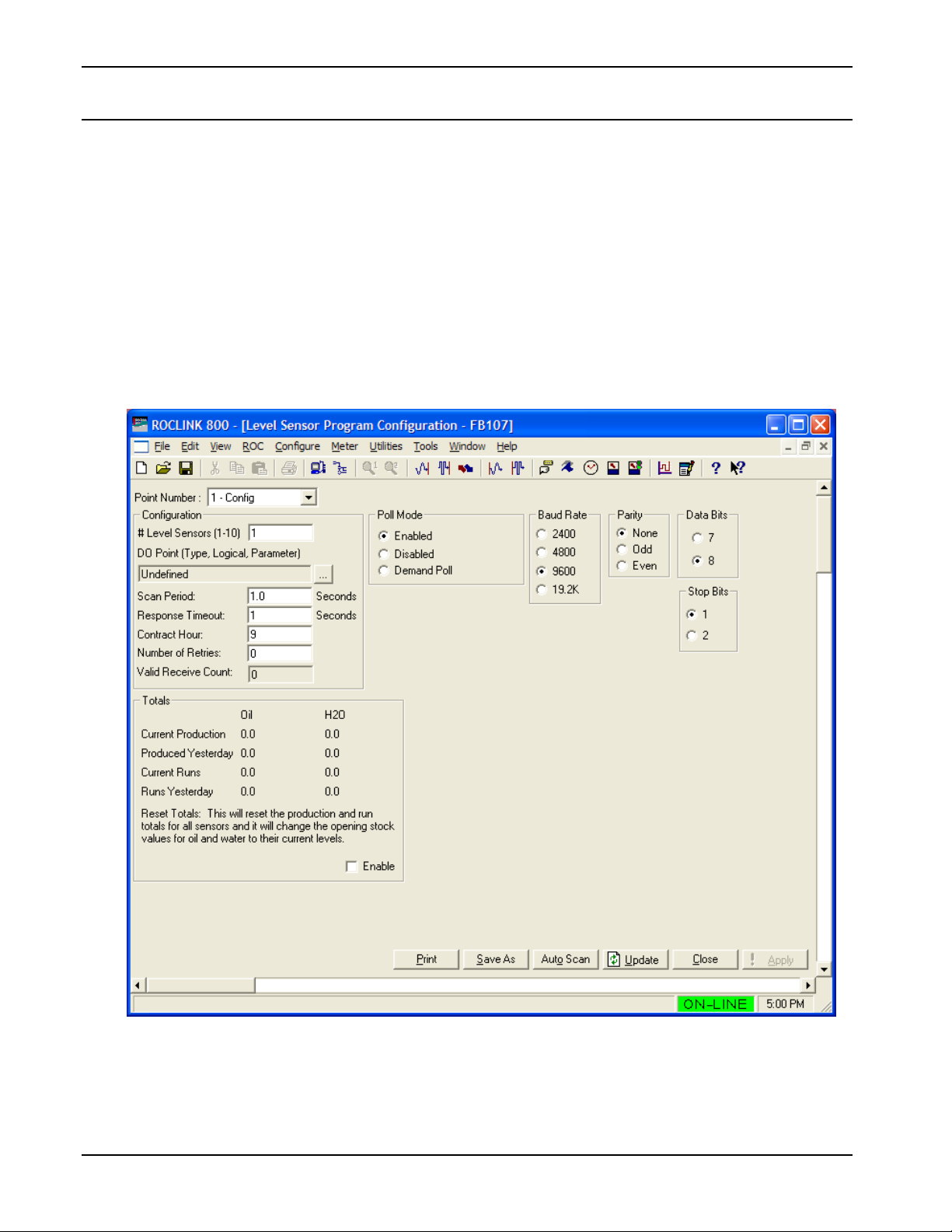

After you have successfully installed the LS Application module in the

FB107, you configure the module using two module-specific screens

(Level Sensor Program Configuration and Level Sensor Data):

Use the Level Sensor Program Configuration screen to define the

number of sensors; assign a DO point to the module, and set scan,

polling, and communication parameters.

Use the Level Sensor Data screen to set sensor-specific parameters

such as labels, alarms, and wave smoothing values. This screen also

displays production information and polling status.

You must configure the module before you can establish

communications with the level sensors. To configure the module (after

logging onto ROCLINK 800 and successfully installing the module),

proceed through the screens as shown in this chapter.

Level Sensor Application Module User Manual

You can access all the module-specific screens from the main

ROCLINK 800 screen:

Figure 4. ROCLINK 800

Issued Jun-09 Configuration 3-1

Page 14

Level Sensor Application Module User Manual

3.1 Level Sensor Configuration Screen

Use this screen to configure communications with one or more level

sensors, associate a digital output point with the module, and enable and

set polling, scan, and communications parameters. To access this

screen:

1. From the Directory Tree, double-click SLOT X - Level Sensor App

Mod (where X is the slot number where the module is installed).

2. Double-click Level Sensor App Mod.

3. Double-click Display #64, Level Sensor Program Configuration.

4. Double-click #1, Config. The Level Sensor Configuration screen

displays:

Figure 5. Level Sensor Configuration

3-2 Configuration Issued Jun-09

Page 15

Level Sensor Application Module User Manual

5. Review the values in the following fields:

Field Description

Point Number

Identifies the point number associated with this

module. 1 – Config is the only valid option.

# Level Sensors

DO Point (Type,

Logical, Parameter)

Scan Period

Response Timeout

Contract Hour

Sets the maximum number of level sensors. Valid

values are 1 to 10. The default is 1.

Sets the digital output TLP associated with the

module for power control. Enter either a specific

TLP or click

and use it to define the TLP.

To save power, you can use this field to specify a

DO point the module controls, turning sensors on

before they are polled and turning them off after

the polling completes.

Sets, in seconds, how often the module scans

the sensors for level information. Valid values are

1 to 9999999. The default is 1.0 second.

Sets, in seconds, how long the module waits for a

response from a level sensor before timing out

the connection. Valid values are 0 to 65535. The

default is 1 second.

Sets the hour (in a 24-hour clock format) at which

the module moves production and load totals

from current to yesterday’s totals. Valid values

are 0 (midnight) to 23 (11PM).

Note: At startup, this value defaults to the

contract hour defined in the FB107. You

can reset this value specifically for this

module.

to display the Select TLP screen

Number of Retries

Valid Receive Count

Totals

Reset Totals

Poll Mode

Issued Jun-09 Configuration 3-3

Sets how many times the module attempts to poll

a level sensor after the initial attempt before

timing out. Valid values are 0 to 255. The default

is 0.

This read-only field shows the number of

validated responses the module has received

from level sensors. This value rolls over after a

maximum of 65535 responses.

These read-only fields show, for oil and water,

production and run totals for yesterday and

today.

Enables you to reset the production and run

totals.

Note: Selecting this option resets the opening

stock values for oil and water to their

current levels.

Controls when the module polls the sensors.

Valid values are Enabled (poll sensors according

to the value in the Scan Period field) or Disabled

(do not poll sensors).

Page 16

Level Sensor Application Module User Manual

Field Description

Initiate Demand Poll

Starts a poll of all sensors, regardless of the

value in the Scan Period field. The module clears

this checkbox after it completes polling and

calculates levels and includes those values in the

current levels.

Note: The module ignores the Wave Limit and

Wave Limit Counts when you issue an ondemand poll.

Baud Rate

Parity

Data Bits

Stop Bits

6. Click Apply to save any changes you have made to this screen.

7. Click Close to return to the ROCLINK 800 screen. Proceed to

Section 3.2 to define sensor data for each sensor.

3.2 Level Sensor Data Screen

Use this screen to review level data the FB107 receives from the

sensors. The module provides one iteration of this screen for up to 10

defined sensors. You can move between sensor data displays using

either the Point Number drop-down box on this screen or from the list

on the Directory Tree.

Sets, in bits per second, the communication baud

rate. 9600 is the default.

Sets the communication parity. None is the

default.

Sets the communication data bits. 8 is the

default.

Sets the communication stop bits. 1 is the

default.

To access this screen:

1. From the Directory Tree, double-click SLOT X - Level Sensor App

Mod (where X is the slot number where the module is installed).

2. Double-click Level Sensor App Mod.

3. Double-click Display #65, Level Sensor Data.

4. Double-click #1, Sensor 1. The Level Sensor Data screen displays:

3-4 Configuration Issued Jun-09

Page 17

Level Sensor Application Module User Manual

Figure 6. Level Sensor Data

5. Review—and change as necessary—the values in the following

fields:

Field Description

Point Number

General

Configuration

Tag Name

Unit Number

Num Levels

Fluid Temperature

Identifies the sensor number (up to 10) for this

screen. Click d to display all defined sensors.

Sets general information for the selected sensor.

Sets a 10-character label for the selected sensor.

The default is Sensor X (where X is a number

between 1 and 10).

Identifies the unit number of the tank associated

with this sensor.

This read-only field shows the number of levels

the sensor reports. Typically, this is two: oil and

water.

This read-only field shows, in degrees

Fahrenheit, the current temperature of the fluid in

the tank.

Strapping Value

Wave Smoothing

Configuration

Issued Jun-09 Configuration 3-5

Sets the conversion factor the module uses to

convert linear measurement to volume. The

module multiplies the level value by this strapping

value to determine the volume of the fluid.

Sets parameters that average (or smooth) wave

variations in fluid (both oil and water) levels.

Page 18

Level Sensor Application Module User Manual

Field Description

Maximum Wave

Sets, in inches, a maximum wave height for

smoothing. The module ignores level changes

less than or equal to this value, attributing them

to sloshing in the tank and ignoring them when

determining production or accumulated values.

Changes in height in excess of this value trigger

an alarm.

Wave Timeout

Wave Timeout Value

Diagnostics –

Communication

Status

Enables the module, if selected, to process the

current oil or water levels after completing the

number of polls specified in the Wave Timeout

Value field, even if the level change has not

exceeded the wave limit for either oil or water.

Sets the number of polls the module must

complete before calculating oil or water levels.

These read-only fields show the status of

communications with the sensors. The module

displays a variety of messages related to the

sensors, which can include:

Polling Disabled

Valid Response Received

Retrying

Invalid Message Format

Response Timeout

Invalid CRC

Invalid Unit Number

No Level Data

No Temperature Data

No Error Data

and No Warning Data.

Messages are color-coded to indicate severity.

Red indicates an alarm condition.

Sensor Error Value

Sensor Warning

Value

Totals

High Level Alarm

Clear

High Level Alarm Set

High Level Alarm EU

3-6 Configuration Issued Jun-09

This read-only field shows the number of errors

read from the sensor.

This read-only field shows the number of

warnings read from the sensor.

These fields, if selected, enable the module to

calculate the total production and run values for

oil and/or water and display those values on the

Level Sensor Configuration screen.

This read-only field indicates that the high level

alarm is currently inactive.

Note: Alarms occur only on oil levels.

This read-only field indicates that the high level

alarm is currently active.

Note: Alarms occur only on oil levels.

Sets the tank level, in engineering units (EUs),

above which the high level alarm occurs. 900 is

the default.

Page 19

Level Sensor Application Module User Manual

Field Description

Alarming Mode

Sets how the program logs alarms with

Spontaneous Report by Exception (SRBX)

notification. Click d to select a mode (described

below).

Note: The system generates one alarm,

regardless of the number of different

errors that may occur in the time before

the alarm clears. SRBX notification occurs

based on the Alarm Logging Mode. For

the system to generate an alarm (such as

for a Poll Sequence Failure error), you

must first enable the Alarm Logging Mode

parameter on the current logical stream.

Production

Information

No Alarm

Logging

Enable

Alarm

Log,

no SRBX

Enable

Log,

SBRX on

Set

Enable

Log,

SRBX on

Clear

Enable

Log,

SRBX on

Both

These read-only fields show the current

production totals for both oil and water.

6. Click Apply to save your changes.

No logging occurs.

Logging occurs, but without

generating SRBX notifications.

Logging occurs, and SRBX

notifications occur on alarm set.

Logging occurs, and SRBX

notifications occur on alarm clear.

Logging occurs, and SRBX

notifications occur on both alarm set

and alarm clear.

7. Click Close to return to the ROCLINK 800 screen. Proceed to

Section 3.3 to save your configuration.

Issued Jun-09 Configuration 3-7

Page 20

Level Sensor Application Module User Manual

3.3 Saving the Configuration

Whenever you modify or change the configuration, it is a good practice

to save the final configuration to memory. To save the configuration:

1. Select ROC > Flags. The Flags screen displays:

Figure 7. Flags screen

2. Click Save Configuration. A verification message displays:

Figure 8. Perform screen

3-8 Configuration Issued Jun-09

Page 21

Level Sensor Application Module User Manual

3. Click Yes to begin the save process. The Status field on the Flags

screen displays In Progress. When the process completes, the

following message displays:

Figure 9. Save Confirmation

4. Click OK. The Status field on the Flags screen displays Completed.

5. Click Update on the Flags screen. This completes the process of

saving your new configuration.

Note: For archive purposes, you should also save this configuration to

your PC’s hard drive or a removable media (such as a diskette or

a flash drive) using the File > Save Configuration option on the

ROCLINK 800 menu bar.

Issued Jun-09 Configuration 3-9

Page 22

Level Sensor Application Module User Manual

[This page is intentionally left blank.]

3-10 Configuration Issued Jun-09

Page 23

Level Sensor Application Module User Manual

Chapter 4 – Reference Materials

This section provides tables of information on the point types the Level

Sensor Application module uses.

Point Type 63 (Level Sensor Configuration and Status)

Point Type 64 (Level Sensor Data)

Issued Jun-09 Reference 4-1

Page 24

Level Sensor Application Module User Manual

[This page is intentionally left blank.]

4-2 Configuration Issued Jun-09

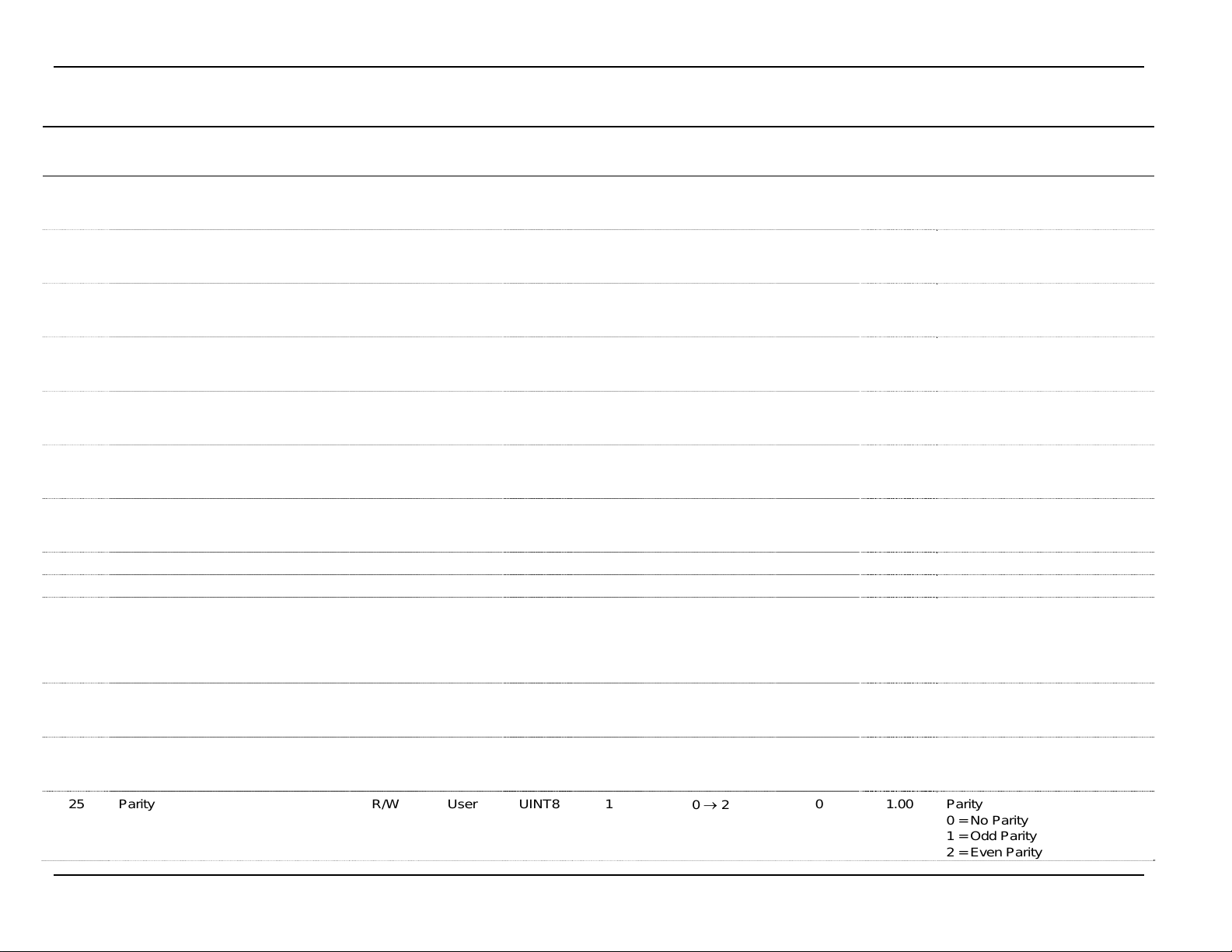

Page 25

Level Sensor Application Module User Manual

4.1 Point Type 63: Level Sensor Configuration and Status

Point type 63 contains the parameters for configuring the Level Sensor Application module and houses the status information from the sensors.

The module maintains one logical point of this point type.

Point Type 63: Level Sensor Application Configuration

Parm

#

0 Point Tag ID R/W User AC 10

1 Not Used

2 Not Used

3 R/W Both UINT8 1

4 Not Used

5 DO Point Type R/W User UINT8 1 DO = 2;

6 DO Logical R/W User UINT8 1 DO = 0-37;

7 DO Parameter R/W User FL 4 DO = 3;

8 Poll Mode R/W User UINT8 1

9 Scan Period R/W User FL 4 Any Positive

10 Response Timeout R/W User UINT16 2

11 Valid Receive Counter R/O System UINT16 1

12 Current Oil Production R/O System FL 4 Any Positive

Name Access

System

or User

Update

Data

Type

Length Range Default Version

0x20 → 0x7E for

each ASCII

character

0 → 10

Softpoint = 17

Disabled = 255

Softpoint = 0 - 31

Disabled = 255

Softpoint = 1 - 21

Disabled = 255

0 → 2

Floating Point

Number

0 → 65535

0 → 65535

Floating Point

Number

“Config“ 1.00 Point Type Description

1 1.00 Number of level sensors polled

255 1.00 Point type for selected DO

255 1.00 Logical for selected DO

255 1.00 Parameter for selected DO

0 1.00 Poll Mode:

1.0 1.00 Scan Period

1 1.00 Response Timeout

0 1.00 Valid Receive Counter

0.0 1.00 Current Oil Production

Description of functionality

0 = Polling Disabled

1 = Normal Poll

2 = Demand Poll

and meaning of values

4-3 Reference Issued Jun-09

Page 26

Level Sensor Application Module User Manual

Point Type 63: Level Sensor Application Configuration

Parm

#

13 Current H2O Production R/O System FL 4 Any Positive

14 Yesterday’s Oil Production R/O System FL 4 Any Positive

15 Yesterday’s H2O Production R/O System FL 4 Any Positive

16 Current Oil Runs R/O System FL 4 Any Positive

17 Current H2O Runs R/O System FL 4 Any Positive

18 Yesterday’s Oil Run R/O System FL 4 Any Positive

19 Yesterday’s H2O Run R/O System FL 4 Any Positive

20 Contract Hour R/W User UINT8 1

21 Cold Start R/W User UINT8 1

22 Baud Rate R/W User UINT8 1

23 Stop Bits R/W User UINT8 1

24 Data Bits R/W User UINT8 1

25 Parity R/W User UINT8 1

Name Access

System

or User

Update

Data

Type

Length Range Default Version

Floating Point

Number

Floating Point

Number

Floating Point

Number

Floating Point

Number

Floating Point

Number

Floating Point

Number

Floating Point

Number

0 → 23

0 → 1

0 → 3

1 → 2

7 → 8

0 → 2

Description of functionality

and meaning of values

0.0 1.00 Current H2O production

0.0 1.00 Yesterday’s Oil Production

0.0 1.00 Yesterday’s H2O Production

0.0 1.00 Current Oil Runs

0.0 1.00 Current H2O Runs

0.0 1.00 Yesterday’s Oil Run

0.0 1.00 Yesterday’s H2O Run

0 1.00 Contract Hour

0 1.00 Cold Start

2 1.00 Baud Rate:

0 = 2400 Baud

1 = 4800 Baud

2 = 9600 Baud

3 = 19200 Baud

1 1.00 Stop Bits:

1 = 1 Stop Bit

2 = 2 Stop Bits

8 1.00 Data Bits

7 = 7 Data Bits

8 = 8 Data Bits

0 1.00 Parity

0 = No Parity

1 = Odd Parity

2 = Even Parity

4-4 Reference Issued Jun-09

Page 27

Point Type 63: Level Sensor Application Configuration

Parm

#

26 Number of Retries R/W User UINT8 1

Name Access

System

or User

Update

Data

Type

Level Sensor Application Module User Manual

Length Range Default Version

1 → 255

0 1.00 Number of Retries

Description of functionality

and meaning of values

Issued Jun-09 Reference 4-5

Page 28

Level Sensor Application Module User Manual

4.2 Point Type 64: Level Sensor Data

Point type 64 contains the parameters for level sensor data. The module maintains 10 logical points of this point type (where logical 0 is sensor 1,

logical 1 is sensor 2, and so on).

Point Type 64: Level Sensor Data

Parm

#

0 Tag R/W User AC 10

1 Not Used

2 Level Sensor Address R/W User UINT8 1

3 Strap Value R/W User FL 4 Any Positive

4 Fluid Temperature R/O System FL 4 Valid Floating

5 System Message R/O System UINT8 1

6 Num Levels R/O System UINT8 1

7 Oil Wave Limit R/W User FL 4 Any Positive

Name Access

System

or User

Update

Data

Type

Length Range Default Version

0x20 → 0x7E for

each ASCII

character

1 → 99

Floating Point

Number

Point Number

0 → 10

0 → 2

Floating Point

Number

Logical 0

= “Sensor

1” to

Logical 9

= “Sensor

10”

0 1.00 Level Sensor Address

1 1.00 Strap Value

0.0 1.00 Dry Heating Value

0 1.00 Error:

0 1.00 Num Levels

0.25 1.00 Oil Wave Limit

1.00 Tag

Description of functionality

0 = Polling Disabled

1 = Valid Response

Received:

2 = Retrying

3 = Invalid Message

Format:

4 = Response Timeout

5 = Invalid CRC

6 = Invalid Unit Number

7 = No Level Data

8 = No Temperature Data

9 = No Error Data

10 = No Warning Data

and meaning of values

4-6 Reference Issued Jun-09

Page 29

Point Type 64: Level Sensor Data

Parm

#

8 H2O Wave Limit R/W User FL 4 Any Positive

9 Oil Wave Limit Count R/W User UINT8 1

10 H2O Wave Limit Count R/W User UINT8 1

11 Current Oil Level R/O System FL 4 Valid Floating

12 Current H2O Level R/O System FL 4 Valid Floating

13 Oil Closing Stock R/O System FL 4 Valid Floating

14 H2O Closing Stock R/O System FL 4 Valid Floating

15 Oil Runs R/O System FL 4 Any Positive

16 H2O Runs R/O System FL 4 Any Positive

17 Opening Stock Oil R/O System FL 4 Valid Floating

18 Opening Stock H2O R/O System FL 4 Valid Floating

19 Oil Production R/O System FL 4 Any Positive

20 H2O Production R/O System FL 4 Any Positive

21 New Oil Level R/O System FL 4 Valid Floating

22 New H2O Level R/O System FL 4 Valid Floating

23 Oil Wave Counter R/O System UINT8 1

24 H2O Wave Counter R/O System UINT8 1

Name Access

System

or User

Update

Data

Type

Length Range Default Version

Floating Point

Number

0 → 255

0 → 255

Point Number

Point Number

Point Number

Point Number

Floating Point

Number

Floating Point

Number

Point Number

Point Number

Floating Point

Number

Floating Point

Number

Point Number

Point Number

0 → 255

0 → 255

Level Sensor Application Module User Manual

Description of functionality

and meaning of values

0.25 1.00 H2O Wave Limit

5 1.00 Oil Wave Limit Count

5 1.00 H2O Wave Limit Count

0.0 1.00 Current Oil Level

0.0 1.00 Current H2O Level

0.0 1.00 Oil Closing Stock

0.0 1.00 H2O Closing Stock

0.0 1.00 Oil Runs

0.0 1.00 H2O Runs

0.0 1.00 Opening Stock Oil

0.0 1.00 Opening Stock H2O

0.0 1.00 Oil Production

0.0 1.00 H2O Production

0.0 1.00 New Oil Level

0.0 1.00 New H2O Level

0 1.00 Tracks scan periods since the

start of the wave.

0 1.00 Tracks scan periods since the

start of the wave.

Issued Jun-09 Reference 4-7

Page 30

Level Sensor Application Module User Manual

Point Type 64: Level Sensor Data

Parm

#

25 Enable Oil Totals R/W User UINT8 1

26 Enable H2O Totals R/W User UINT8 1

27 Cold Start R/W System UINT8 1

28 Yesterday’s Oil Production R/O System FL 1 Any Positive

29 Yesterday’s H2O Production R/O System FL 1 Any Positive

30 Oil Wave Smoothing R/W User UINT8 1

31 H2O Wave Smoothing R/W User UINT8 1

32 Yesterday’s Oil Runs R/O System FL 4 Any Positive

33 Yesterday’s H2O Runs R/O System FL 4 Any Positive

34 Current Oil Volume R/O System FL 4 Valid Floating

35 Current H2O Volume R/W System FL 4 Valid Floating

36 High Level Alarm EU R/W System FL 4 Valid Floating

Name Access

System

or User

Update

Data

Type

Length Range Default Version

0 → 1

0 → 1

0 → 1

Floating Point

Number

Floating Point

Number

0 → 1

0 → 1

Floating Point

Number

Floating Point

Number

Point Number

Point Number

Point Number

Description of functionality

and meaning of values

1 1.00 Enable Oil Totals:

0 = Disable

1 = Enable

1 1.00 Enable H2O Totals:

0 = Disable

1 = Enable

1 1.00 Cold Start:

0 = Disable

1 = Enable

0.0 1.00 Yesterday’s Oil Production

0.0 1.00 Yesterday’s H2O Production

1 1.00 Oil Wave Smoothing:

0 = Disable

1 = Enable

1 1.00 H2O Wave Smoothing:

0 = Disable

1 = Enable

0.0 1.00 Yesterday’s Oil Runs

0.0 1.00 Yesterday’s H2O Runs

0.0 1.00 Current Oil Volume

0.0 1.00 Current H2O Volume

900 1.00 High Level Alarm EU

4-8 Reference Issued Jun-09

Page 31

Point Type 64: Level Sensor Data

Parm

#

37 High Level Alarm Enable R/W User UINT8 1

38 High Level Alarm Indicator R/O System UINT8 1

39 Sensor Error R/O System UINT8 2

40 Sensor Warning R/O System UINT8 2

Name Access

System

or User

Update

Data

Type

Length Range Default Version

0 → 4

0 → 1

0 → 65535

0 → 65535

Level Sensor Application Module User Manual

Description of functionality

and meaning of values

0 1.00 High Level Alarm Enable:b

0 = Disable Logging

1 = Enable Logging, No SRBX

2 = Enable Logging, SRBX on

Set

3 = Enable Logging, SRBX on

Clear

4 = Enable Logging, SRBX on

both Set and Clear

0 1.00 High Level Alarm Indicator:

0 = Disable

1 = Enable

0 1.00 Sensor Error

0 1.00 Sensor Warning

Issued Jun-09 Reference 4-9

Page 32

Level Sensor Application Module User Manual

If you have comments or questions regarding this manual, please direct them to your local sales representative

or contact:

Emerson Process Management

Remote Automation Solutions

Marshalltown, Iowa 50158 USA

Houston, TX 77065 USA

Pickering, North Yorkshire UK Y018 7JA

Website: www.EmersonProcess.com/Remote

4-10 Reference Issued Jun-09

Loading...

Loading...