Remote Automation Solutions Guide: OpenEnterprise OPC Client RDI Reference Guide Manuals & Guides

Page 1

Reference Guide

D5092

12-Dec-2007

OPC Client RDI

Bristol OpenEnterprise Reference Guide

OPC Client RDI

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 2

Reference Guide

D5092

12-Dec-2007 - Page 2

OPC Client RDI

Contents

1 OPC Client RDI......................................................................................................................... 5

2 The OPC Client RDI Interface ................................................................................................. 6

2.1 Accessing the OPC Client RDI Interface ............................................................................ 6

3 The OPC Server Page.............................................................................................................. 7

3.1 File Menu ............................................................................................................................ 7

3.2 Help Menu ........................................................................................................................... 7

3.3 Database Address............................................................................................................... 7

3.4 Driver Version ..................................................................................................................... 8

3.5 Time Zone ........................................................................................................................... 8

3.6 Timestamp Conversion ....................................................................................................... 8

3.7 OPC Client RDI Driver Status ............................................................................................. 8

3.8 OPC Server Name .............................................................................................................. 8

3.9 OPC Server Prog ID............................................................................................................ 8

3.10 OPC Server Network Address ......................................................................................... 8

3.11 OPC Server OPC Version ............................................................................................... 8

3.12 OPC Server Status ..........................................................................................................9

3.13 Sub Status ....................................................................................................................... 9

3.14 Group Details Button ....................................................................................................... 9

4 The OPC Group Details Page ...............................................................................................10

4.1 Number of Groups............................................................................................................. 10

4.2 OPC Group Name............................................................................................................. 10

4.3 OPC Group Active............................................................................................................. 10

4.4 OPC Group Status ............................................................................................................ 10

4.5 Sub Status......................................................................................................................... 10

4.6 OPC Group Requested Rate ............................................................................................ 10

4.7 OPC Group Revised Rate................................................................................................. 11

4.8 Deadband.......................................................................................................................... 11

4.9 Locale................................................................................................................................ 11

4.10 Time Bias .......................................................................................................................11

4.11 Item Details Button ........................................................................................................ 11

5 The OPC Item Details Page................................................................................................... 12

5.1 Number of Items................................................................................................................ 12

5.2 Item Name......................................................................................................................... 12

5.3 Tag Id ................................................................................................................................ 12

5.4 Item Active ........................................................................................................................ 12

5.5 Item Status ........................................................................................................................ 12

5.6 Sub Status......................................................................................................................... 13

5.7 Requested Type................................................................................................................ 13

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 3

Reference Guide

D5092

12-Dec-2007 - Page 3

Canonical Type ................................................................................................................. 13

5.8

5.9 Access Path ...................................................................................................................... 13

5.10 Access Rights ................................................................................................................ 14

6 Status Codes.......................................................................................................................... 15

6.1 OPC Group Status Codes................................................................................................. 15

6.2 OPC Item Status Codes.................................................................................................... 16

6.3 Sub Status Codes ............................................................................................................. 17

7 OPC Quality Flags ................................................................................................................. 19

7.1 Bad Quality Flags.............................................................................................................. 19

7.2 Uncertain Quality Flags..................................................................................................... 19

7.3 Good Quality Flags ........................................................................................................... 20

8 OPC Client Configuration .....................................................................................................21

8.1 Session Manager Configuration........................................................................................ 21

8.1.1 The Session Manager Task Page .............................................................................. 21

8.1.1.1 The Program ........................................................................................................ 21

8.1.1.2 Run Program in the following folder ..................................................................... 21

8.1.1.3 Program Arguments ............................................................................................. 21

8.1.2 The Task Shutdown Page .......................................................................................... 21

8.2 Polyhedra Config File........................................................................................................ 21

8.2.1.1 Dvi_register_datum_with_values ......................................................................... 21

8.2.1.2 Dvi_triggers_on .................................................................................................... 21

OPC Client RDI

9 Database Configuration ........................................................................................................ 23

9.1 Database DVI Architecture ............................................................................................... 23

9.1.1 Driver ..........................................................................................................................23

9.1.2 Network....................................................................................................................... 23

9.1.3 Device......................................................................................................................... 23

9.1.4 Schedule..................................................................................................................... 24

9.1.5 Datum ......................................................................................................................... 24

9.1.6 Region ........................................................................................................................ 24

9.2 OPC Data Access Interface .............................................................................................. 24

9.2.1 Server ......................................................................................................................... 24

9.2.2 Group.......................................................................................................................... 24

9.2.2.1 Name.................................................................................................................... 24

9.2.2.2 Active ................................................................................................................... 25

9.2.2.3 Percent Deadband ............................................................................................... 25

9.2.2.4 Locale................................................................................................................... 25

9.2.2.5 Time Bias ............................................................................................................. 25

9.2.2.6 Requested Update Rate ...................................................................................... 25

9.2.2.7 Revised Update Rate ........................................................................................... 25

9.2.3 Item............................................................................................................................. 25

9.2.3.1 Item ID (Tag) ........................................................................................................ 25

9.2.3.2 Access Path ......................................................................................................... 25

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 4

Reference Guide

D5092

12-Dec-2007 - Page 4

OPC Client RDI

9.2.3.3

9.2.3.4 Requested Data Type .......................................................................................... 25

9.2.3.5 Canonical Data Type............................................................................................ 26

9.2.3.6 Value .................................................................................................................... 26

9.2.3.7 Quality ..................................................................................................................26

9.2.3.8 Timestamp ........................................................................................................... 26

9.2.3.9 Error Status .......................................................................................................... 26

9.3 Mapped Tables for OPC Client RDI .................................................................................. 26

9.3.1 Dvi_region References ............................................................................................... 27

9.3.2 Dvi_schedule ..............................................................................................................27

9.3.3 OPC Driver ................................................................................................................. 27

9.3.4 OPC Server ................................................................................................................ 27

9.3.5 OPC Device ................................................................................................................ 27

9.3.6 OPC Group ................................................................................................................. 27

9.3.7 OPC Item .................................................................................................................... 28

10 Index ....................................................................................................................................... 29

Active ................................................................................................................... 25

9.3.7.1.1 OPCItemRealAnalog ...................................................................................... 28

9.3.7.1.2 OPCItemIntegerAnalog .................................................................................. 28

9.3.7.1.3 OPCItemDigital ............................................................................................... 28

9.3.7.1.4 OPCItemString................................................................................................ 28

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 5

Reference Guide

D5092

12-Dec-2007 - Page 5

OPC Client RDI

1 OPC Client RDI

OPC (Object Linking and Embedding for Process Control) is a client/server model intended to provide

greater interoperability between automation/control applications, field devices and business/office

applications in the process control industry.

OPC Server applications communicate directly with field devices, whilst OPC Clients are able to

retrieve that information from the OPC Server. In terms of OpenEnterprise this architecture is best

illustrated in the diagram below.

The OPC Client RDI provides a means of collecting data from OPC Servers and inserting the data

into an OpenEnterprise database. The OpenEnterprise OPC Client RDI is capable of communicating

with several OPC Servers concurrently, but only connects to one OpenEnterprise database at a time.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 6

Reference Guide

D5092

12-Dec-2007 - Page 6

OPC Client RDI

2 The OPC Client RDI Interface

The OPC Client RDI interface provides the user with three pages of information which display general

and status information for configured OPC Servers, Groups and Items.

2.1 Accessing the OPC Client RDI Interface

The OPC Client RDI interface can be set to be invisible if the 'Visible on the Desktop' box is left

unchecked on the Settings page for the task. However, if this field is checked, then the interface will

appear as a minimized icon on the Windows® Start bar when the OpenEnterprise session is run.

To edit the OPC Client RDI task within the Session Manager, select the task from the Session

Manager's Task List, select Stop from the context menu to stop the task. Then select the Properties

item from the same context menu. See the Session Manager Help for more information.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 7

Reference Guide

D5092

12-Dec-2007 - Page 7

OPC Client RDI

3 The OPC Server Page

This page displays information about the OPC Servers that the OPC Client RDI is currently set up to

connect to.

3.1 File Menu

The File menu provides only one option, which is to Exit the OPC Client RDI.

3.2 Help Menu

The Help menu provides an option to open this help file, and also to view the About box, which

provides information on the application version and build and also Bristol contact details.

3.3 Database Address

This is the TCP address of the OPC Client RDI driver as defined in the Services file, by default found

in the 'C:\Winnt\System32\Drivers\etc' directory.

An example entry in this file for the OPC Client RDI would be:-

opcclientrdi 11006/tcp OPCCLIENTRDI

The format being <service name> <port number>/<protocol> [aliases...] [#<comment>].

The OPC Client RDI's service name is stored in the address attribute of the applicable driver in the

OPCDriver table entry of the OpenEnterprise database.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 8

Reference Guide

D5092

12-Dec-2007 - Page 8

OPC Client RDI

3.4 Driver Version

This is the OPC Client version number. It does not represent the OPC Data Access standard.

3.5 Time Zone

The Time Zone setting of the OPC Client RDI, as sourced from the OPC Driver table. Because the

OPC standard is vague about how individual OPC Servers should format timestamps, special

consideration should be given as to whether the OPCDriver should convert timestamps to UTC.

3.6 Timestamp Conversion

The OpenEnterprise database requires that all timestamp values are stored in UTC. However the

OPC standard is vague about how individual OPC Servers should format timestamps, and from

experience on site it has been seen that some OPC Servers report timestamps in local time, while

others report timestamps in UTC. The OPC Client RDI can handle both of these situations, as

detailed below.

If the OPC Server is communicating with an OPC Server that does report timestamps in local time,

then the OPC Client RDI must be configured to convert those timestamps into UTC before they are

inserted into the database. This is achieved by setting the OPCDriver attribute ConvertTimeStamps to

TRUE. (which is the default value for this attribute) and ensuring that the timezone attribute of this

table is set to the same timezone as that with which the OPC Server is reporting timestamps. These

values can then be used in conjunction with any time bias that may be defined to correctly convert the

timestamps into UTC before they are inserted into the database.

If the OPC Server returns timestamps in UTC then no time conversion is required, and in this case the

ConvertTimestamps attribute value must be set to FALSE.

3.7 OPC Client RDI Driver Status

A zero means the driver is working properly. Non-zero means there are problems.

3.8 OPC Server Name

The name of the OPC Server. It is sourced from the networkame attribute of the opcserver table.

3.9 OPC Server Prog ID

The program id of the OPC Server as sourced from the OPCServer attribute of the OPCServer table.

3.10 OPC Server Network Address

This displays the computer on which the OPC Server is running. If the Server is running on the local

machine, this field will say 'Local'.

3.11 OPC Server OPC Version

This value indicates the Data Access standard to be used when communicating with the OPC Server.

This will be listed on the dialog as either 1.0 (corresponding to a value of 0 in the opcversion attribute

of the OPCServer table), or 2.04 (corresponding to a value of 1 in the opcversion attribute of the

OPCServer table).

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 9

Reference Guide

D5092

12-Dec-2007 - Page 9

OPC Client RDI

3.12 OPC Server Status

A zero value means there are no errors. Anything else is an error. The possible status codes and their

meaning are described in the OPC Server Status Codes topic. Click the link below to go to this topic

now.

3.13 Sub Status

The SubStatus attribute can hold any error returned either by COM or by a specific OPC Server.

3.14 Group Details Button

When an OPC Server is selected from the list, this button becomes enabled. Clicking the button then

opens the OPC Group Details Page, which displays OPC Groups that have been configured for the

selected OPC Server. Click on the link below to view help for this page.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 10

Reference Guide

D5092

12-Dec-2007 - Page 10

OPC Client RDI

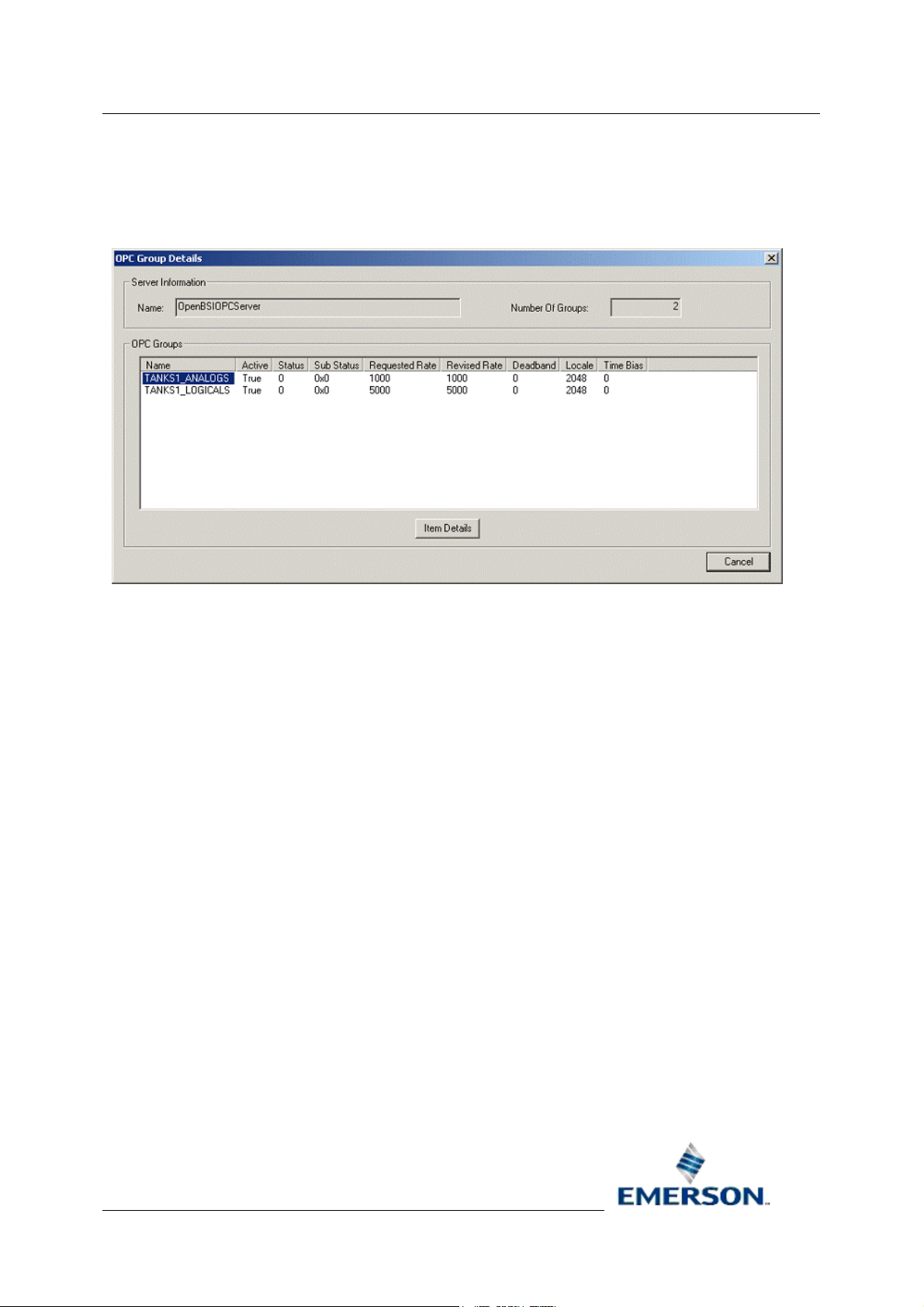

4 The OPC Group Details Page

This page displays details about the OPC Groups which have been configured for the selected OPC

Server.

4.1 Number of Groups

The number of Groups configured for the selected OPC Server

4.2 OPC Group Name

The name of each configured OPC group sourced from the name attribute of the opcgroup table.

4.3 OPC Group Active

This value displays True if the Group is currently active, False if not. If a Group is marked as inactive,

then the OPC item values associated with it will not be reported to the OPC Client RDI.

4.4 OPC Group Status

A zero value means there are no errors. Anything else is an error. The possible status codes and their

meaning are described in the OPC Group Status Codes topic. Click the link below to go to this topic

now.

4.5 Sub Status

The SubStatus attribute can hold any error returned either by COM or by a specific OPC Server.

4.6 OPC Group Requested Rate

The period, in milliseconds, at which the OPC Client RDI requires any changes in data or quality, for

OPC Items within the group, to be reported. This value is sourced from the requestedupdaterate

attribute of the opcgroup table.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 11

Reference Guide

D5092

12-Dec-2007 - Page 11

OPC Client RDI

4.7 OPC Group Revised Rate

The period, in milliseconds, at which the OPC Server is able to supply changes in data or quality for

the OPC Items within the group. The value is sourced from the revisedupdaterate attribute of the

opcgroup table.

4.8 Deadband

Applicable only to real analogue OPC Items within the Group and specifies the percentage change in

value within the update period which is required for a data value change to be reported to the OPC

Client RDI. The value is sourced from the percentdeadband attribute of the opcgroup table.

4.9 Locale

Indicates the locale in which data for this group should be returned. The default value of 2048

indicates that data should be retuned using the default system locale.

The formatting of numbers, dates, language or currency depend on the Locale. It is sourced from the

locale attribute of the opcgroup table.

4.10 Time Bias

Used to indicate a difference in time zone between the device(s) from which the data for this group

was collected, and that in which the OPC Client and OPC Server are located.

This is ignored by the OPC Server but is used by the OPC Client RDI to provide correct time stamp

conversion to UTC for all OPC Items within the group.

This is on top of any time zone and DST conversion defined by the setting of the time zone attributes in the OPCDriver table. The value is sourced from the timebias attribute of the opcgroup table.

4.11 Item Details Button

When an OPC Group is selected from the list, this button becomes enabled. Clicking the button then

opens the OPC Item Details Page, which displays OPC Items that have been configured for the

selected OPC Group. Click on the link below to view help for this page.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 12

Reference Guide

D5092

12-Dec-2007 - Page 12

OPC Client RDI

5 The OPC Item Details Page

This page displays details about the OPC Items that have been configured for the selected OPC

Group. for help on each feature of the page.

5.1 Number of Items

The number of items in the selected Group.

5.2 Item Name

This is the unique name of the signal as it appears in the Signal table. The value is sourced from the

name attribute of the relevant OPCItem table.

5.3 Tag Id

The Tag Id uniquely identifies the OPC Item to the OPC Server. It is sourced from the datumaddress

attribute of the relevant OPCItem table.

5.4 Item Active

This value displays True if the Item is currently active, False if not. If the item is inactive, then changes

in value will not be reported to the OPC Client RDI.

5.5 Item Status

A zero value means there are no errors. Anything else is an error. The possible status codes and their

meaning are described in the OPC Item Status Codes topic. Click the link below to go to this topic

now.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 13

Reference Guide

D5092

12-Dec-2007 - Page 13

OPC Client RDI

5.6 Sub Status

The SubStatus attribute can hold any error returned either by COM or by a specific OPC Server.

5.7 Requested Type

This is the data format with which the OPC Client RDI will request the value for the item from the OPC

Server. It is sourced from the opcrequesteddatatype attribute of the relevant OPCItem table. Code

numbers for the Data Types are given below.

Code

0 Native format - i.e. the data type of the OPC Item as

defined by the OPC Server

1 Single Byte Integer Value

2 Two Byte Integer Value

3 Four Byte Integer Value

4 Four Byte Floating-Point Value

5 Eight Byte Floating-Point Value

8 A String Value.

11 A Boolean Value

If the user is unsure as to the data type of an OPC Item, the requested data type should be set to 0.

Data Type

5.8 Canonical Type

This is the data format with which the OPC Server will actually return the data to the OPC Client. It is

sourced from the opccanonicaldatatype attribute of the relevant OPCItem table. Code numbers for the

Data Types are given below.

Code

Data Type

1 Single Byte Integer Value

2 Two Byte Integer Value

3 Four Byte Integer Value

4 Four Byte Floating-Point Value

5 Eight Byte Floating-Point Value

8 A String Value.

11 A Boolean Value

5.9 Access Path

An optional attribute, which is used to specify to the OPC Server a preferred access path by which the

value for the OPC Item should be obtained.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 14

Reference Guide

D5092

12-Dec-2007 - Page 14

OPC Client RDI

5.10 Access Rights

This displays the access rights applicable to this item, as returned by the OPC Server, taken from the

opcaccessrights attribute of the relevant OPCItem table.

Code

RW

W

RW

Value as seen in database Meaning

1 Readable

2 Writable

3 Read and Writeable

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 15

Reference Guide

eturned

adding group to serve

D5092

12-Dec-2007 - Page 15

OPC Client RDI

6 Status Codes

OPC Server status and sub status codes are displayed on the OPC Server Page of the OPC Client

RDI. The following values apply to the Status attribute of the OPCServer table.

Code Number

-1 Failed to initialise COM. A fatal error that would prevent the OPC Client RDI

from functioning.

-2 The Program Id of the OPC Server could not be resolved.

-3 Unable to start the OPC Server. The value of the SubStatus attribute should

provide additional information as to the cause. This problem is most likely to

happen when the OPC Client RDI and target OPC Server(s) are located

remotely to each other.

-4 OPC Server does not support the IOPCCommon Interface. The most common

reason for this would be that the OPC Server doesn't the support the Data

Access 2.04 standard, but that the associated OPCServer table entry indicates

that the Data Access 2.04 interfaces should be used for communication. This

will generally indicate that no data can be obtained from the OPC Server.

-5 Failed to update Locale. This is a non-fatal error status.

-6 Attempting to restart OPC Server. Informational error indicating that the OPC

Server is not available, but that periodic reconnection attempts are being

made, as per the configuration of the OPCServer table entry.

-7 Unable to start the restart thread. An internal error, which should only happen if

system resources were exhausted.

-8 Unable to start status timeout thread. An Internal error, which should only

happen if system resources were exhausted.

-9 Unable to start status check thread. An Internal error, which should only

happen if system resources where exhausted.

-10 Indicates that the OPC Client RDI is still awaiting an activate message from the

database. The most likely reason for this is that the OPC Client RDI has

connected to the standby.

Explanation

6.1 OPC Group Status Codes

The Group Details page displays status and sub status codes for OPC Groups. The following values

apply to the Status attribute of the OPCGroup table.

Code Number

-1 Group Initialisation failed. There are various reasons for this, not least that the

OPC Server is not available, or that the wrong OPC standard is being used to

communicate with that server, which would result in an E_NO_INTERFACE

value for the SubStatus.

-2 Unable to Add the OPC Group to the Server. The SubStatus will generally

provide an indication of the reason, e.g. a duplicate group name has been

defined, or the OPC Server hasn't initialised.

-3 IUnknown Pointer not r

Explanation

when

r. This would

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 16

Reference Guide

D5092

12-Dec-2007 - Page 16

indicate a problem in the configuration of the OPC Server and/or the definition

of the OPCGroup entry. The SubStatus attribute should be consulted for

further information.

-4 Unable to set up a callback sink with the OPC Server, meaning that

unsolicited data cannot be received.

-5 Unable to obtain a requested interface. Most likely to occur if the associated

OPC Server doesn't support the configured OPC Data Access standard.

-6 Unable to create an OPC Group instance. This would be as a result of an

internal COM error, and is unlikely to occur.

-7 Failed to update one of the following OPC Group

properties.RequestedUpdateRate, Active, PercentDeadBand, Locale, or

TimeBias.

-8 Failed to update OPC Group name. This would occur if the group name is

already defined within the OPC Server generally as a result of another OPC

Client connection to that server.

-9 An attempt to refresh the items within the group failed. A common reason for

this would be that the Group is inactive or that no items within the Group are

currently active.

-10 Indicates that the OPC Client RDI is still awaiting an activate message from

the database. The most likely reason for this is that the OPC Client RDI has

connected to the standby.

-11 Unable to start the Add Items thread. An Internal error, which should only

happen if system resources where exhausted.

OPC Client RDI

6.2 OPC Item Status Codes

The Item Details page displays status and sub status codes for OPC Items. The following values

apply to the Status attribute of the OPC Item table.

Code

Number

-1 OPC Server reported an error related to the OPC Item. The SubStatus attribute

should be consulted for further information.

-2 Unable to add OPC Item to the designated OPC Group. The Substatus attribute

value will indicate the cause of this error, but common causes are that the OPC

Tag is invalid and or that the requested data type is invalid for the tag.

-3 Parent Group does not exist - (an internal error that is unlikely to occur).

-4 This will occur if an attempt is made to change the requested data type for the

OPC Item to an unsupported type for the associated tag. The SubStatus attribute

will generally show the value OPC_E_BADTYPE to reflect this, although other

errors are possible.

-5 Unable to remove the Item from the Group - (only generated in conjunction with

an attempt to move an OPC Item to another Group).

-6 Target Group does not exist. Unlikely to occur due to referential integrity checks

in the database, i.e. an item can't be assigned to a group that doesn't exist!

-7 Failed to update Active property of the OPC Item. The SubStatus attribute

should be consulted for the reason for the failure.

Explanation

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 17

Reference Guide

cates that the OPC Server doesn't

D5092

12-Dec-2007 - Page 17

-8 An attempt to update an OPC Item value failed. See the SubStatus attribute for

further information as to the cause. The most common cause would be that the

OPC Item is not writable, in which case the SubStatus value would be

OPC_E_BADRIGHTS.

-9 A requested refresh for the OPC Item failed. See the SubStatus attribute value

for further details.

-10 Indicates that the OPC Client RDI is still awaiting an activate message from the

database. The most likely reason for this is that the OPC Client RDI has

connected to the standby.

OPC Client RDI

6.3 Sub Status Codes

Because the SubStatus attribute can hold any error returned either by COM or by a specific OPC

Server it is not possible to provide a full listing of all values. The following table highlights the most

common errors that might be encountered. All sub status values are given in hexadecimal format, as

displayed on the OPC Client dialogue.

Code Number

S_FALSE(0x1) Indicates that although the action

completed, there were errors when

dealing with that action. For instance if 10

items are added to an OPC Group in the

same call, and one of those items were

invalid, the OPC Group SubStatus

attribute would show S_FALSE

E_FAIL(0x80004005) Unspecified error. Generally something

catastrophic within the associated OPC

Server.

E_OUTOFMEMORY(0x8007000E) The OPC Client RDI or the OPC Server

was unable to complete the action due to

a lack of available memory.

E_INVALIDARG(0x80070057) An argument used in a call to the OPC

Server is invalid.

DISP_E_TYPEMISMATCH(0x80020005) Generally occurs because an OPC Item

has been configured with an invalid

requested data type, e.g. VT_BOOL for

an OPCItemString.

OPC_E_DUPLICATE_NAME(0xC004000B) This error should never occur, but would

indicate that a group of the same name is

already registered with the applicable

OPC Server.

OPC_S_UNSUPPORTEDRATE(0x4000D) This is a non-fatal status code indicating

that the OPC Server is unable to supply

data at the rate specified by the

RequestedDataRate. The

RevisedUpdateRate attribute can be

consulted for the update rate that the

OPC Server can support.

E_NOINTERFACE(0x80004002) Indi

Explanation

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 18

Reference Guide

D5092

12-Dec-2007 - Page 18

support the requested method. This is

most likely to occur if the OPC Server

doesn't support the data access standard

defined by within the OPCVersion

attribute of the associated OPCServer

table entry.

CONNECT_E_NOCONNECTION(0x80004200) Indicates that an asynchronous request

has been made, but that no callback sink

is available to report the results of that

request back to the client.

OPC_E_UNKNOWNITEMID(0xC0040007) Indicates that the associated OPC Server

has been unable to resolve the OPC

Item, and that no data is therefore

available. E.g. a tag may be defined that

is syntactically correct, but which can't be

obtained by the OPC Server.

OPC_E_INVALIDITEMID(0xC0040008) Indicates that the associated OPC Server

deems the tag format of the OPC Item to

be invalid.

OPC_E_UNKNOWNPATH(0xC004000A) The access path defined for the OPC

Item, is not known to the OPC Server.

OPC_E_BADTYPE(0xC0040004) The data type requested for the OPC

Item (i.e. the value of the

requesteddataatype attribute), is invalid.

OPC_S_CLAMP(0x4000E) Associated with a write request and

indicates that the value was updated, but

was clamped.

OPC_E_RANGE(0xC004000B) Associated with a write request and

indicates that the value was out of range.

OPC_E_BADRIGHTS(0xC0040006) Indicates either that an attempt was made

to write to a non writable item, or that a

read request was made on a non

readable item.

OPC Client RDI

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 19

Reference Guide

D5092

12-Dec-2007 - Page 19

OPC Client RDI

7 OPC Quality Flags

The opcquality attribute of each OPC Item indicates the quality state for an item's data value. This

value can provide very useful diagnostic information. The values that can be returned for the

opcquality attribute belong to one of three OPC quality states: -

1. Bad Quality

2. Uncertain Quality

3. Good Quality

7.1 Bad Quality Flags

The opcquality attribute of each OPC Item indicates the quality state for an item's data value. This

value can provide very useful diagnostic information. The following table lists all values which could

be returned for this field when the OPC quality is bad.

OPCQuality Value

0 The value is bad but no specific reason is known

4 There is some server specific problem with the configuration. For

example the item is question has been deleted from the

configuration.

8 The input is required to be logically connected to something but is

not. This quality may reflect that no value is available at this time, for

reasons like the value may have not been provided by the data

source.

12 A device failure has been detected

16 A sensor failure had been detected (the ’Limits’ field can provide

additional diagnostic information in some situations.)

20 Communications have failed. However, the last known value is

available. Note that the ‘age’ of the value may be determined from

the TIMESTAMP in the OPCITEMSTATE.

24 Communications have failed. There is no last known value is

available.

28 The block is off scan or otherwise locked This quality is also used

when the active state of the item or the group containing the item is

InActive.

Description

7.2 Uncertain Quality Flags

The opcquality attribute of each OPC Item indicates the quality state for an item's data value. This

value can provide very useful diagnostic information. The following table lists all values which could

be returned for this field when the OPC quality is uncertain.

OPCQuality Value

64 There is no specific reason why the value is uncertain.

68 Whatever was writing this value has stopped doing so. The returned

Description

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 20

Reference Guide

D5092

12-Dec-2007 - Page 20

value should be regarded as ‘stale’. Note that this differs from a BAD

value with Substatus 5 (Last Known Value). That status is associated

specifically with a detectable communications error on a ‘fetched’

value. This error is associated with the failure of some external

source to ‘put’ something into the value within an acceptable period

of time. Note that the ‘age’ of the value can be determined from the

TIMESTAMP in OPCITEMSTATE.

90 Either the value has ‘pegged’ at one of the sensor limits (in which

case the limit field should be set to 1 or 2) or the sensor is otherwise

known to be out of calibration via some form of internal diagnostics

(in which case the limit field should be 0).

94 The returned value is outside the limits defined for this parameter.

Note that in this case (per the Fieldbus Specification) the ‘Limits’ field

indicates which limit has been exceeded but does NOT necessarily

imply that the value cannot move farther out of range.

98 The value is derived from multiple sources and has less than the

required number of Good sources.

OPC Client RDI

7.3 Good Quality Flags

The opcquality attribute of each OPC Item indicates the quality state for an item's data value. This

value can provide very useful diagnostic information. The following table lists all values which could

be returned for this field when the OPC quality is good.

OPCQuality Value

192 The value is good. There are no special conditions

204 The value has been Overridden. Typically this is means the input has

been disconnected and a manually entered value has been ‘forced’.

Description

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 21

Reference Guide

D5092

12-Dec-2007 - Page 21

OPC Client RDI

8 OPC Client Configuration

There are three aspects to configuration of the OPC Client RDI: -

1. Start up configuration - Session Manager configuration

2. Start up configuration - Poly.cfg file

3. Database configuration

8.1 Session Manager Configuration

To edit the OPC Client RDI task within the Session Manager, select the task from the Session

Manager's Task List, select Stop from the context menu to stop the task. Then select the Properties

item from the same context menu. See the Session Manager Help for more information.

8.1.1 The Session Manager Task Page

On the Task page of the wizard fill in the following fields.

8.1.1.1 The Program

The full path and filename of the OpenEnterprise OPC Client RDI application is C:\Program

Files\Bristol\OpenEnterprise\bin\OEOPCClientRDI.exe. Use the browse button if you are uncertain.

8.1.1.2 Run Program in the following folder

This will be the Data directory of the OpenEnterprise project.

8.1.1.3 Program Arguments

This should be the switch /r followed by a space, followed by the TCP/IP service name of the OPC

Client RDI - e.g. /r opcclientrdi. No quotes are necessary. This is the most important value for the

OPC Client RDI, because it gives the OpenEnterprise Database a connection to the OPC Client RDI .

8.1.2 The Task Shutdown Page

This value should be set to _NULL, which is the default.

The other values for Session Tasks can also be entered on this key, however the ones above are the

most important. See the Session Manager help file for further information on the other key values, and

more information on configuring the Session Manager.

8.2 Polyhedra Config File

There are two resources within the Poly.cfg file that should be checked before running the

OpenEnterprise OPC Client RDI.

8.2.1.1 Dvi_register_datum_with_values

This resource should be set to TRUE.

8.2.1.2 Dvi_triggers_on

This should be set to FALSE.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 22

Reference Guide

D5092

12-Dec-2007 - Page 22

Refer to the Session Manager help file for more information on the Poly.cfg file resources used by the

database.

OPC Client RDI

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 23

Reference Guide

D5092

12-Dec-2007 - Page 23

OPC Client RDI

9 Database Configuration

The elements of the OpenEnterprise database DeVice Interface (DVI) table architecture and the OPC

Data Access Interface were mapped with each to provide complete compatibility. The following topics

explain how this was done.

9.1 Database DVI Architecture

These tables are structured to model the relations between the RDI drivers and devices (RTU/PLCs)

in the field. An entity diagram for these relations would look like this: -

The base tables to which these entities are mapped are generally derived from to provide information

and management functionality specific to the RDI.

9.1.1 Driver

A Driver is the root node of the hierarchy and generally relates to a specific RDI. This entity is mapped

to the following tables of the OpenEnterprise database:-

• dvi_driver

• dvi_remote_driver

9.1.2 Network

A Network describes a collection of PLC/RTU's. It might be mapped to a particular dedicated

communications path for instance. This entity is mapped to the following table of the OpenEnterprise

database:-

• dvi_network

9.1.3 Device

A Device, as the name implies generally maps to an individual PLC or RTU. This entity is mapped to

the following table of the OpenEnterprise database:-

• dvi_device

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 24

Reference Guide

D5092

12-Dec-2007 - Page 24

OPC Client RDI

9.1.4 Schedule

A Schedule provides a mechanism for grouping datum's into collection groups. This entity is mapped

to the following table of the OpenEnterprise database:-

• dvi_schedule

9.1.5 Datum

A Datum generally represents a physical I/O point within a PLC or RTU. This entity is mapped to the

following table of the OpenEnterprise database:-

• dvi_datum

9.1.6 Region

A Region provides a mechanism for defining collections of datum's. For instance, analogue and digital

datum's might be associated with different regions. This entity is mapped to the following table of the

OpenEnterprise database:-

• dvi_region

9.2 OPC Data Access Interface

This is a three-tiered architecture, constituting OPC Server, OPC Group and OPC Item levels. The

following relationship diagram illustrates the architecture.

9.2.1 Server

An OPC Server object is created for each OPC Client that requires information, and is used to

manage the OPC Client's data requirements. Each OPC Server is generally only able to connect to a

certain type of RTU or PLC and collect data.

9.2.2 Group

An OPC Group is used to define a collection of OPC Items, and how the value and quality of those

items should be reported to the OPC Client. The properties of an OPC Group are as follows.

9.2.2.1 Name

This is the name of the OPC Group. It must be unique to the OPC Server to which the group has

been added.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 25

Reference Guide

D5092

12-Dec-2007 - Page 25

9.2.2.2 Active

Indicates whether the OPC Group is currently active, and therefore whether data is required from that

Group.

9.2.2.3 Percent Deadband

Provides a percentage deadband to be applied to any analogue items defined within the Group when

evaluating changes of value.

9.2.2.4 Locale

This value specifies the language to be used by the OPC Server when returning values as text for

operations on this OPC Group.

9.2.2.5 Time Bias

This allows a time bias to be applied to the timestamps reported by the OPC Server. It is generally

used to provide support for physical devices in different time zones. It does NOT support DST

weighting.

9.2.2.6 Requested Update Rate

OPC Client RDI

This is the maximum rate at which the group expects changes in value or quality of OPC Items within

the group to be reported.

9.2.2.7 Revised Update Rate

This is the rate at which the OPC Server is able to provide changes in value or quality for OPC Items

within the group.

9.2.3 Item

An OPC Item defines a specific point for which value and quality data is required. The following

properties can be defined for an OPC Item.

9.2.3.1 Item ID (Tag)

Provides the OPC Tag that identifies to the appropriate OPC Server the physical I/O point to which

the OPC Item relates.

9.2.3.2 Access Path

Provides an access path that the OPC Server should use to obtain the value associated with the OPC

Item.

9.2.3.3 Active

Indicates whether the OPC Item is currently active, and therefore whether changes in value or quality

for the item are to be reported by the OPC Server.

9.2.3.4 Requested Data Type

This is the data format with which the OPC Client RDI will request the value for the item from the OPC

Server.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 26

Reference Guide

D5092

12-Dec-2007 - Page 26

9.2.3.5 Canonical Data Type

The data type with which the OPC Server stores and manages the value for the OPC Item

9.2.3.6 Value

This is simply the value of the OPC Item.

9.2.3.7 Quality

This is the OPC Quality of the OPC Item. See the OPC Quality Flags sectionpage for help on the

diagnostic information this field could provide.

9.2.3.8 Timestamp

The timestamp indicating the last change of value or quality for the OPC Item

9.2.3.9 Error Status

An error status used to provide additional information about any problems with the OPC Item. For

instance that the Item ID is invalid, or the requested data type is not suitable.

OPC Client RDI

9.3 Mapped Tables for OPC Client RDI

In order for the OPC Client RDI to connect to and obtain data from an OPC Server it needs to know: -

• The OPC Server object that is to connect to and retrieve data from.

• The OPC Group objects that it is interested in.

• The OPC Item objects that are in these groups.

These OPC objects need to be mapped onto the current OpenEnterprise Database DVI objects to

maintain the integrity of the database. In doing this, the concept of an OPC Device has been added to

the OPC Data Access model. The resultant OPC Client Schema definition is shown as an entity

relation chart below.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 27

Reference Guide

D5092

12-Dec-2007 - Page 27

OPC Client RDI

9.3.1 Dvi_region References

The dvi_region table contains entries relating to each of the OPCItem tables, as well as the

OPCGroup table. These references are used to register the OPC Client RDI with the columns of

interest within those tables.

9.3.2 Dvi_schedule

This table is not used within the OPC Client RDI Schema definition.

9.3.3 OPC Driver

The OPCDriver table is derived from the standard dvi_remote_driver table. For every separate OPC

Client RDI to be used on a system, an entry will exist within this table.

The main purpose of this table is to indicate the TCP/IP socket through which the OPC Client RDI will

communicate with the OpenEnterprise database.

9.3.4 OPC Server

The OPCServer table is derived from the standard dvi_network table. Each entry within this table will

define a specific OPC Server with which the OPC Client RDI will communicate.

The definition and relationship between the OPCDriver and OPCServer tables allows scalability in

how the OPC Client RDI is used.

For instance, a single OPCDriver instance might have several OPCServer instances associated with

it. This would indicate that the single OPC Client RDI was expected to communicate with several

distinct OPC Servers.

Alternatively by providing a one to one relationship between OPCDriver and OPCServer table entries

this would indicate that multiple OPC Client RDI's are to be invoked, each communicating with a

single OPC Server.

TheOPCServer table provides the ability for the OPC Client RDI to determine the physical location of

a named OPC Server.

9.3.5 OPC Device

The OPCDevice table is derived from the dvi_device table. Each entry within this table will map to a

specific field device from which data is being requested via an OPC Server.

Signals sourced from the same device can be grouped into separate OPC Groups.

9.3.6 OPC Group

An OPC Group defines how the value and quality of a collection of OPC Items are to be supplied to

the OPC Client. It does NOT imply anything about how the OPC Server actually obtains the data from

the field devices.

The OPCGroup Table is derived from dvi_datum, and will provide similar functionality to that used by

the Network3000 RDI to provide template collection.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 28

Reference Guide

D5092

12-Dec-2007 - Page 28

The main difference is that the OPCGroup instance will not itself maintain lists of those OPC Items

within the group. Instead it is OPC Items themselves that dictate the OPC Group to which they

belong.

As dvi_datum entries reference specific dvi_device entries, it is not possible to associate signals from

different physical devices in the same OPC Group.

OPC Client RDI

9.3.7 OPC Item

The OPC Item part of the OPC entity relationship is split into four tables. These are derived from the

specific signal tables which they relate to (which are derived from dvi_datum). There are four OPC

Item tables, one for each of the major data types supported by OpenEnterprise Databases.

9.3.7.1.1 OPCItemRealAnalog

This table is derived from RealAnalog, and used to store OPC Items whose value is any of the

supported floating point formats.

9.3.7.1.2 OPCItemIntegerAnalog

This table is derived from IntegerAnalog and used to store OPC Items whose value is any of the

supported Integer formats.

9.3.7.1.3 OPCItemDigital

This table is derived from Digital and is used to store OPC Items that request the value in boolean

format.

9.3.7.1.4 OPCItemString

This table is derived from StringSignal and is used to store OPC Items that request the value as a

string.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 29

Reference Guide

D5092

12-Dec-2007 - Page 29

OPC Client RDI

10 Index

A

Access Path .............................................. 15

Access Rights ........................................... 15

Active......................................................... 13

C

Canonical Type ......................................... 14

Configuration Overview ............................. 27

D

Database Address....................................... 5

Database Configuration ............................ 29

Database DVI Architecture........................ 29

Datum........................................................ 30

Deadband.................................................. 10

Design Issues............................................ 29

Details Button ............................................ 11

Device ....................................................... 30

Driver......................................................... 29

Driver Version ............................................. 6

G

Group ........................................................ 31

Group Details Button ................................... 7

Groups

Number .................................................... 9

Groups......................................................... 9

H

Help Menu ................................................... 5

I

Items

Number .................................................. 13

Items.......................................................... 13

L

Locale........................................................ 10

M

Mapped Tables

OPC Client RDI ..................................... 33

Mapped Tables ......................................... 33

Mapping..................................................... 29

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

N

Name .........................................................13

Network......................................................30

Number

Groups .....................................................9

Items ......................................................13

Number ..................................................9, 13

O

OPC Client RDI

Mapped Tables ......................................33

OPC Client RDI..........................................33

OPC Client RDI Driver Status......................6

OPC Client RDI Interface ............................3

OPC Data Access Interface.......................30

OPC Device ...............................................35

OPC Driver ................................................34

OPC Group ................................................35

OPC Group Active .......................................9

OPC Group Details Page ............................9

OPC Group Name .......................................9

OPC Group Requested Rate .....................10

OPC Group Revised Rate .........................10

OPC Group Status.......................................9

OPC Group Status Codes .........................17

OPC Item ...................................................35

OPC Item Details Page .............................13

OPC Item Status Codes ............................18

OPC Server ...............................................34

OPC Server Name.......................................6

OPC Server Network Address .....................7

OPC Server OPC Version ...........................7

OPC Server Prog ID ....................................7

OPC Server Status ......................................7

OPC Server Status Codes.........................17

OPC Servers Page ......................................5

Overview......................................................1

P

Polyhedra Config File ................................28

R

Region .......................................................30

Page 30

Reference Guide

D5092

12-Dec-2007 - Page 30

Requested Type ........................................ 14

S

Schedule ................................................... 30

Server........................................................ 31

Session Manager Configuration................ 27

Status ........................................................ 14

Sub Status....................................... 7, 10, 14

Sub Status Codes ..................................... 19

T

Tag Id ........................................................ 13

Time Bias .................................................. 10

Time Zone ................................................... 6

OPC Client RDI

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 31

Reference Guide

D5092

12-Dec-2007

NOTICE

Remote Automation Solutions (“RAS”), division of Emerson Process Management shall not be liable for technical or editorial errors in this manual or omissions from this

manual. RAS MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING TH E IMPLIED WARRANTIES OF MERCHANTABILITY AND F ITNESS FOR A

PARTICULAR PURPOSE W ITH RESPECT TO THIS MANUAL AND, I N NO EVENT SHALL RAS BE LIABLE FOR ANY INCID ENTAL, PUNITIVE, SPECIAL OR

CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS

INCURRED INLCUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POW ER, AND CLAIMS OF THIRD PARTIES.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow Computer Division are wholly owned subsidiaries of Emerson Electric Co. doing business as

Remote Automation Solutions (“RAS”), a division of Emerson Process Management. ROC, FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and

Helicoid are trademarks of RAS. AMS, PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the

Emerson Electric Co. All other trademarks are property of their respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. RAS reserves the right to

modify or improve the designs or specifications of such products at any time without notice. All sales are governed by RAS’ terms and conditions which are available

upon request.

RAS does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any RAS product

remains solely with the purchaser and end-user.

Engineered and supported by:

Remote Automation Solutions,

Bristol Babcock Ltd. Blackpole Road, Worcester, WR3 8YB, UK

Reg office: 2nd Floor, Accurist House, 44 Baker Street, London, W1U 7AL

Registered in England and Wales, Reg No. 2580226

VAT Reg No. GB 880 9839 67

OPC Client RDI

Emerson Process Management

Remote Automation Solutions

1100 Buckingham St

Watertown, CT 06795

T 1 (860) 945 2200

F 1 (860) 945 2278

www.EmersonProcess.com/Remote

binfo@EmersonProcess.com

© 2007 Remote Automation Solutions, division of Emerson Process Management. All rights reserved.

Emerson Process Management

Remote Automation Solutions

Blackpole Road

Worcester, WR3 8YB

T 44 (0) 1905 856848

F 44 (0) 1905 856930

www.EmersonProcess.com/Remote

oedsupport@EmersonProcess.com

Loading...

Loading...